Patents

Literature

192 results about "Mevalonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mevalonic acid (MVA) is a key organic compound in biochemistry; the name is a contraction of dihydroxymethylvalerolactone. The carboxylate anion of mevalonic acid, which is the predominant form in biological environments, is known as mevalonate and is of major pharmaceutical importance. Drugs like statins (which lower levels of cholesterol) stop the production of mevalonate by inhibiting HMG-CoA reductase.

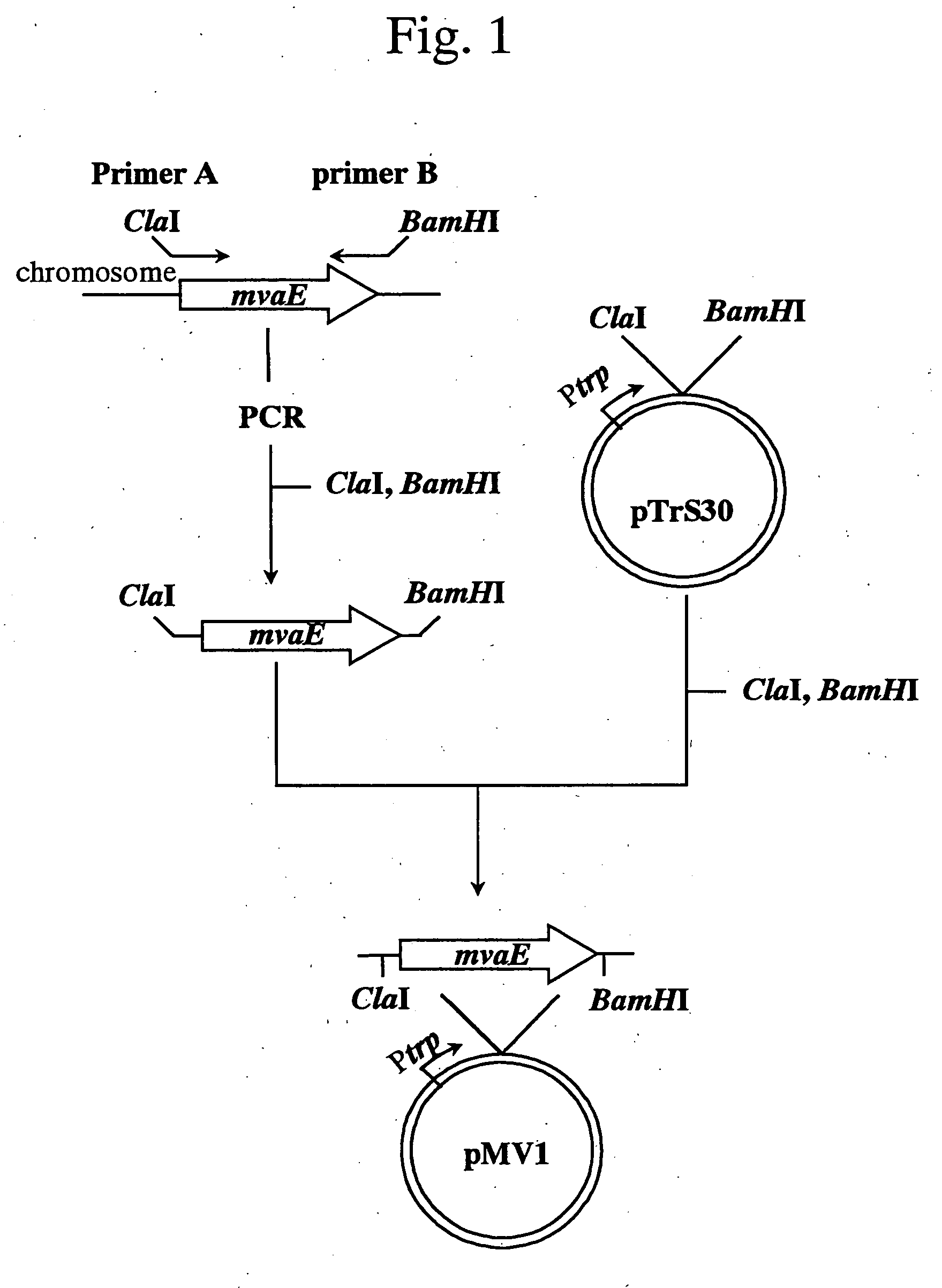

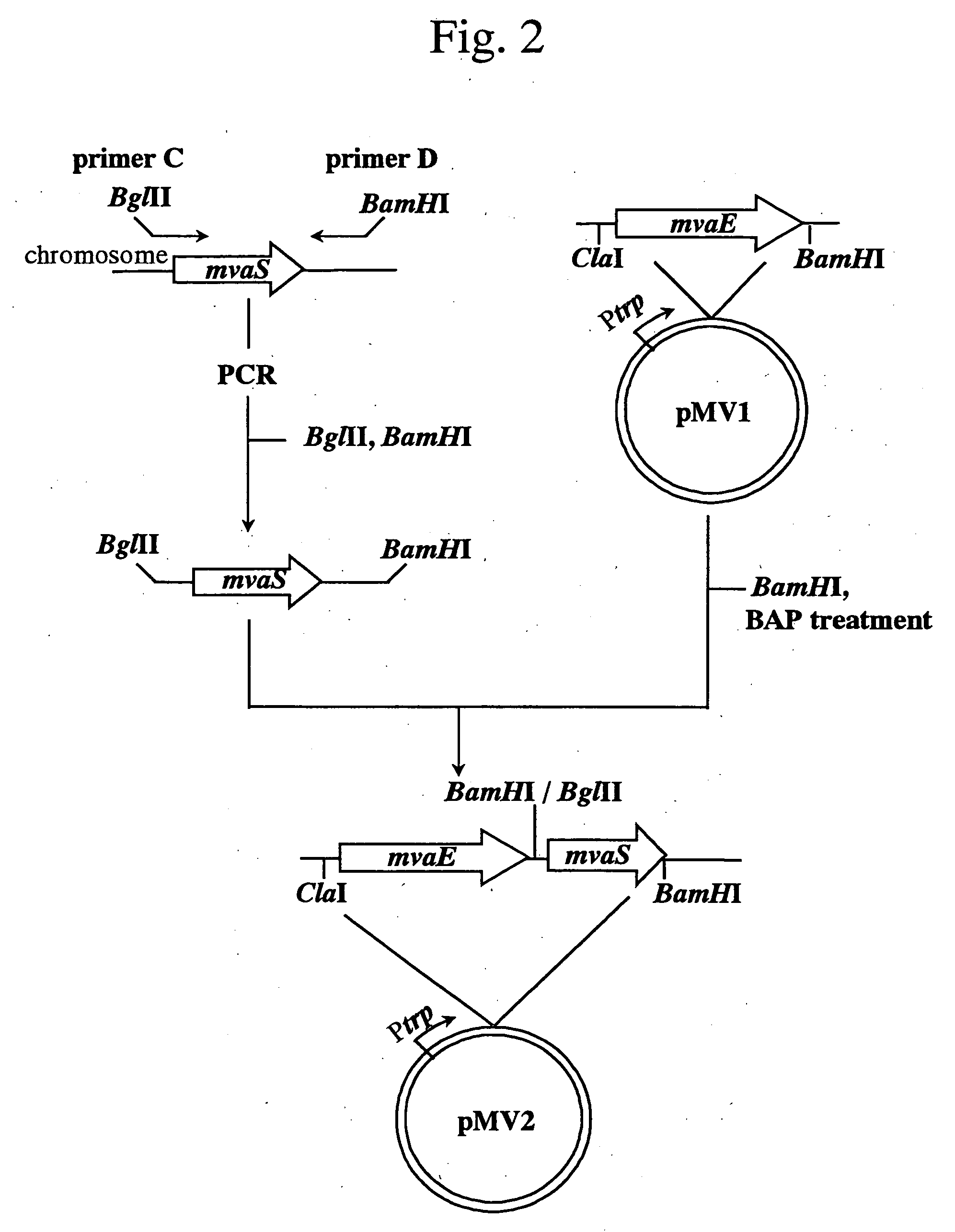

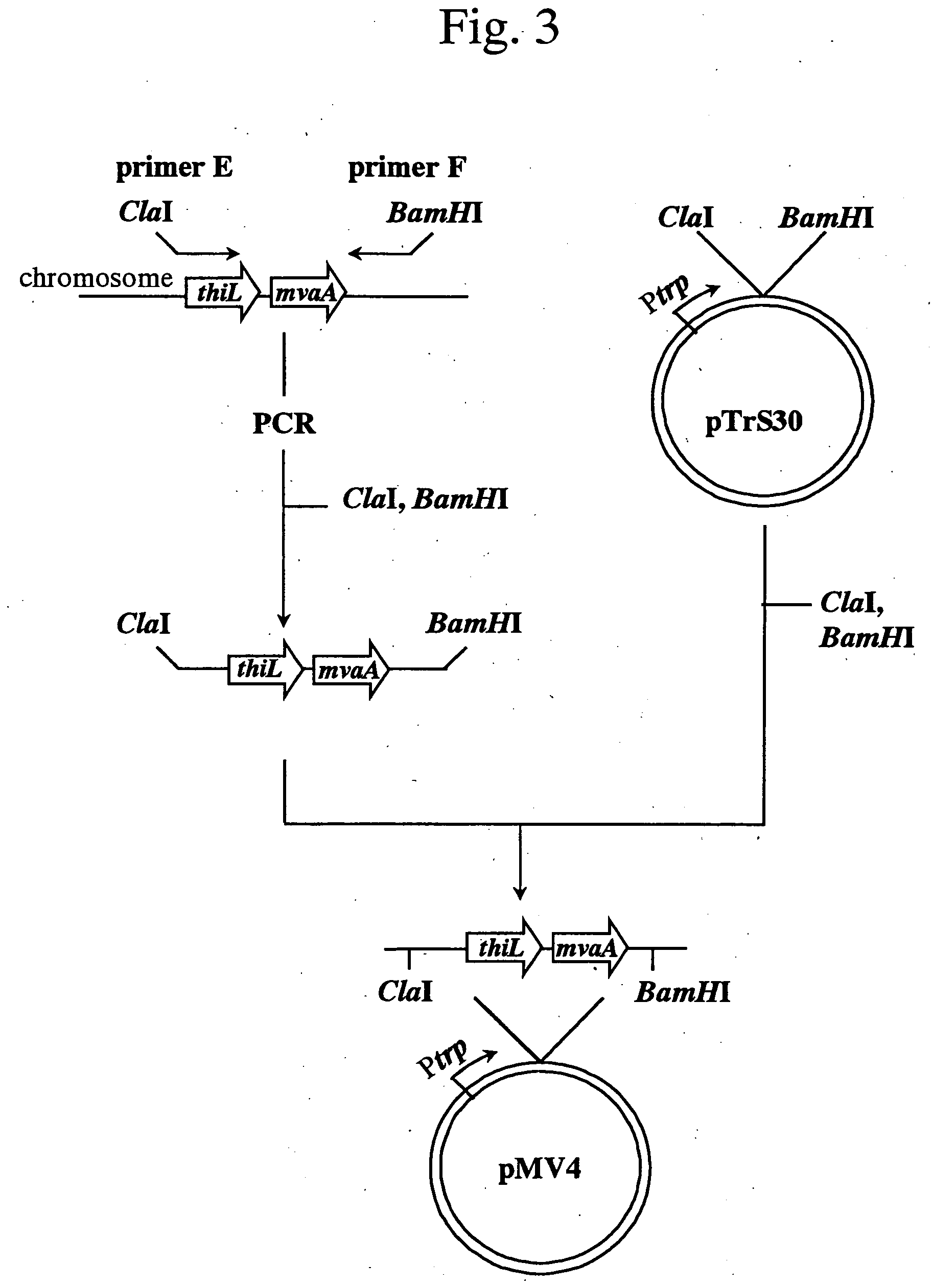

Process for producing mevalonic acid

InactiveUS20050287655A1Avoid difficult choicesHigh activityBacteriaGenetic engineeringMicroorganismMicrobiology

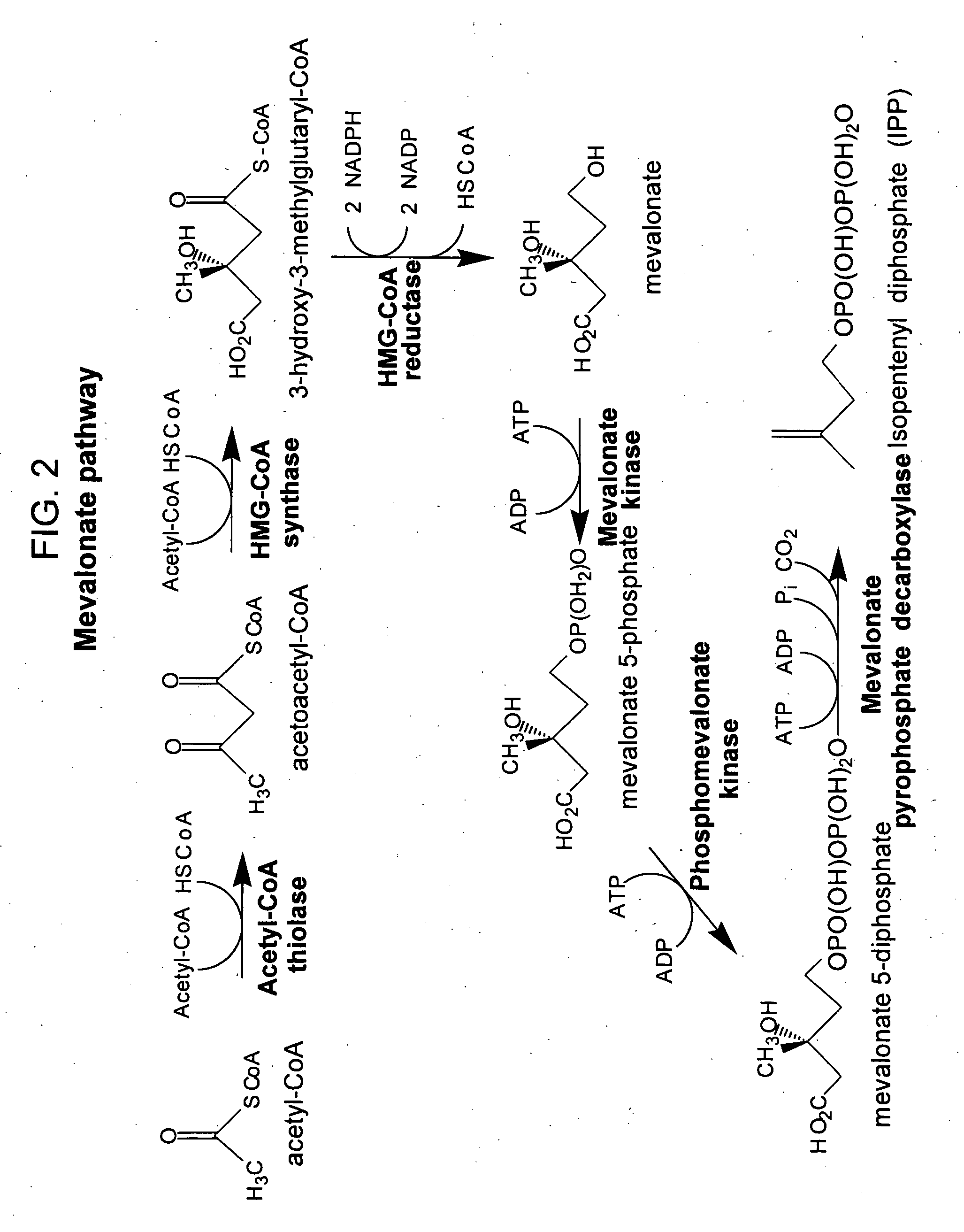

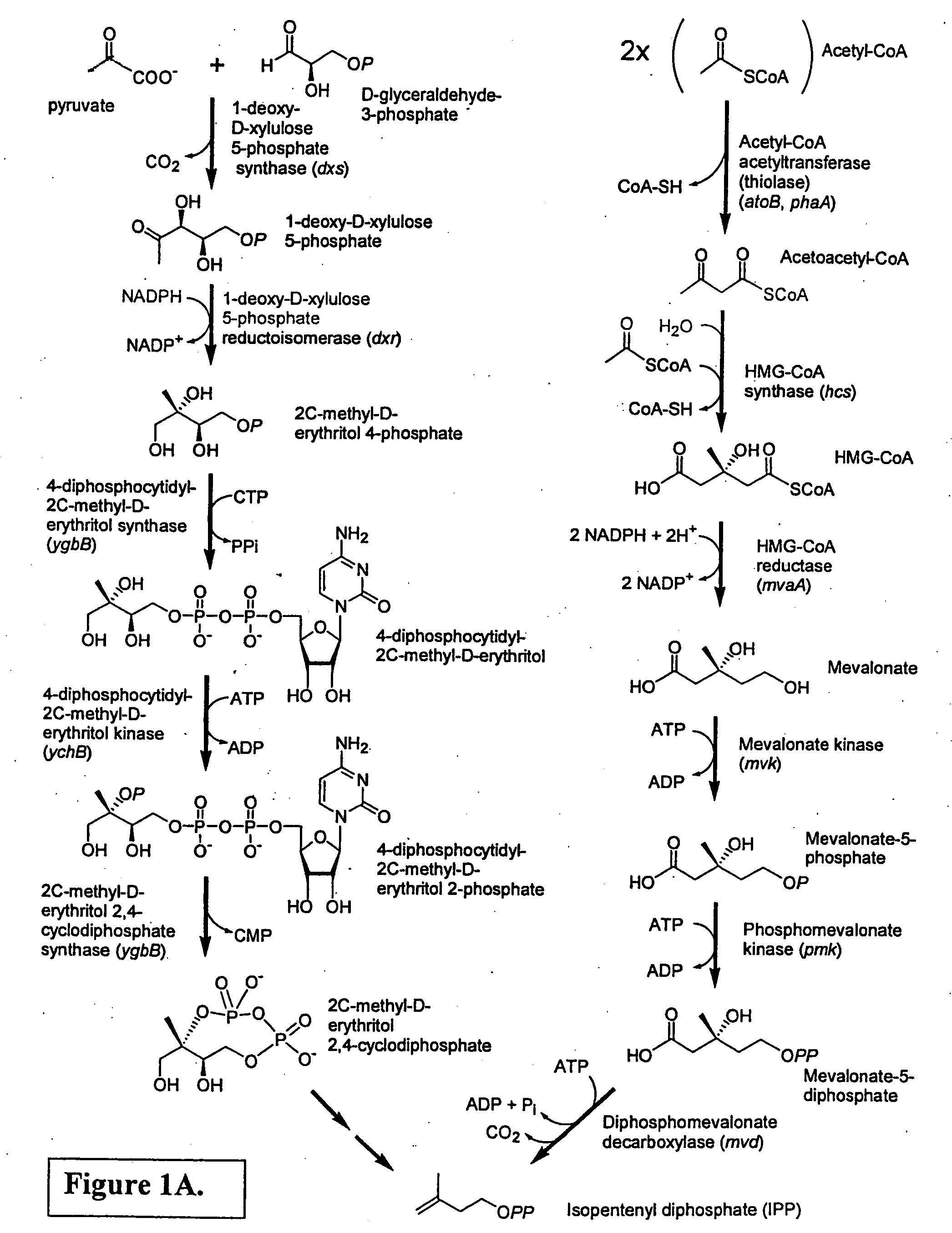

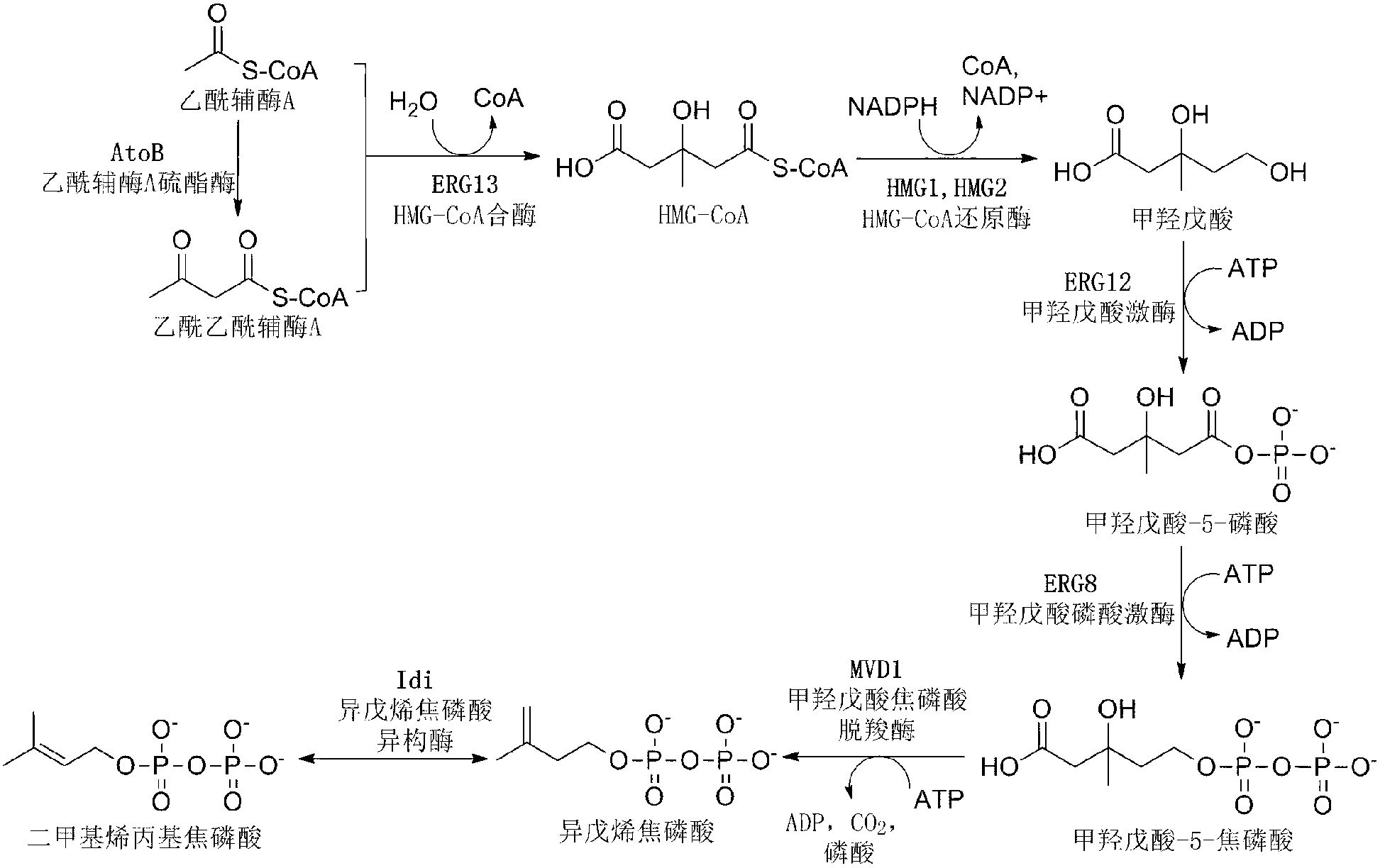

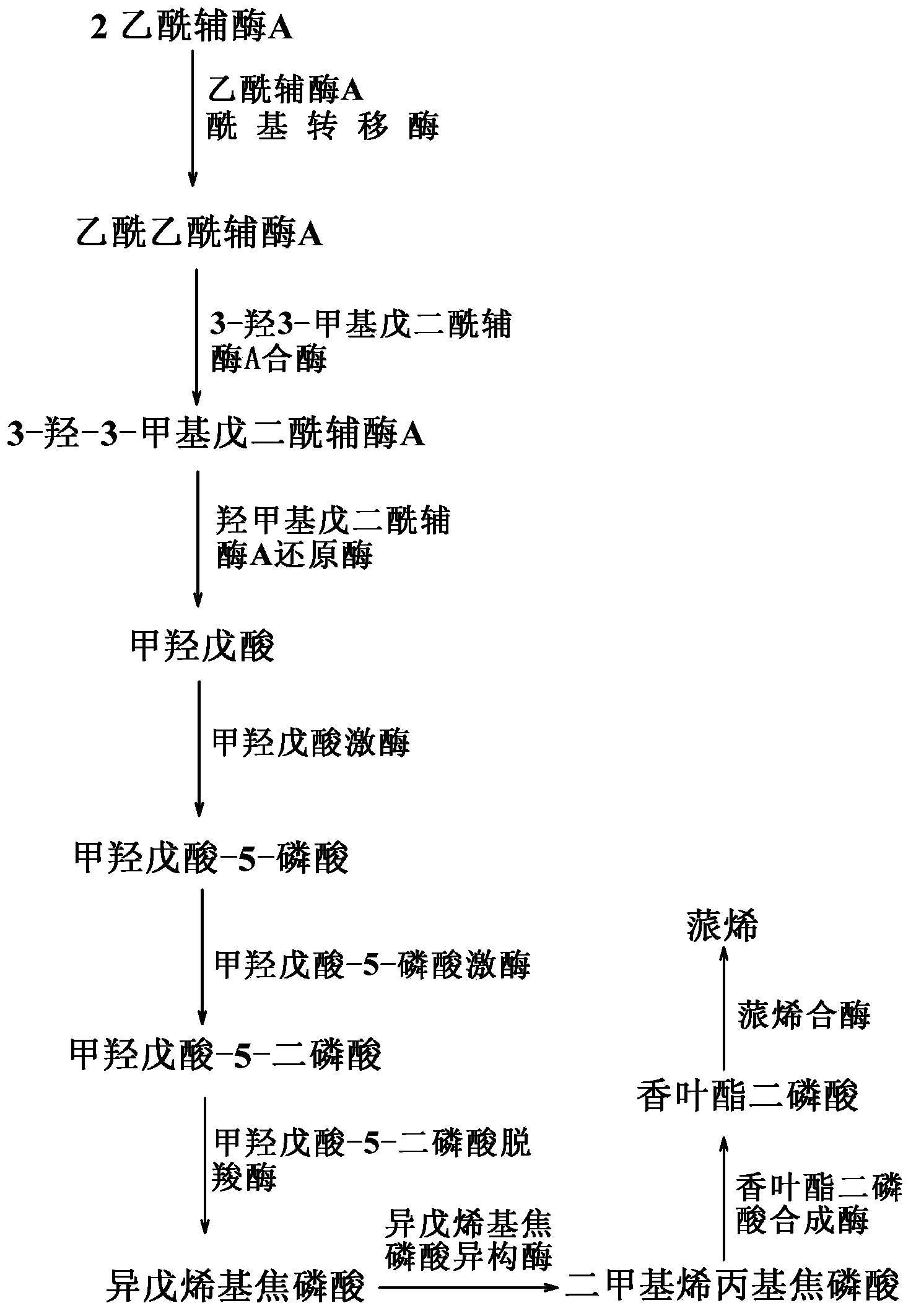

A microorganism having the ability to biosynthesize mevalonic acid from acetyl-CoA is obtained by transfecting a DNA participating in biosynthesis of mevalonic acid from acetyl-CoA into a host microorganism, preferably into a microorganism having only a non-mevalonic acid pathway, to express the DNA therein. Mevalonic acid can be efficiently produced by culturing the microorganism, and recovering mevalonic acid that is produced and accumulated in a large amount in the culture.

Owner:KYOWA HAKKO KOGYO CO LTD

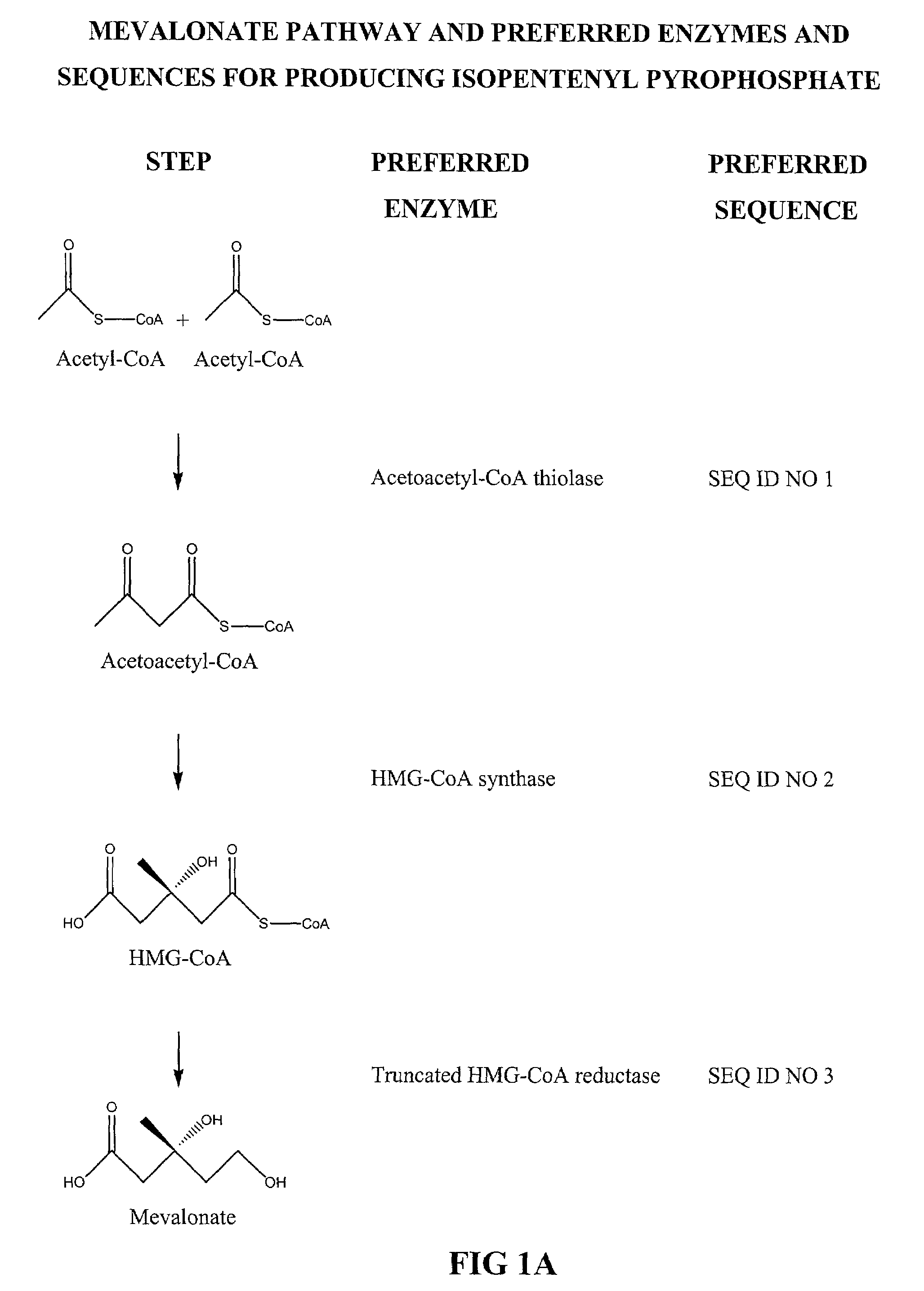

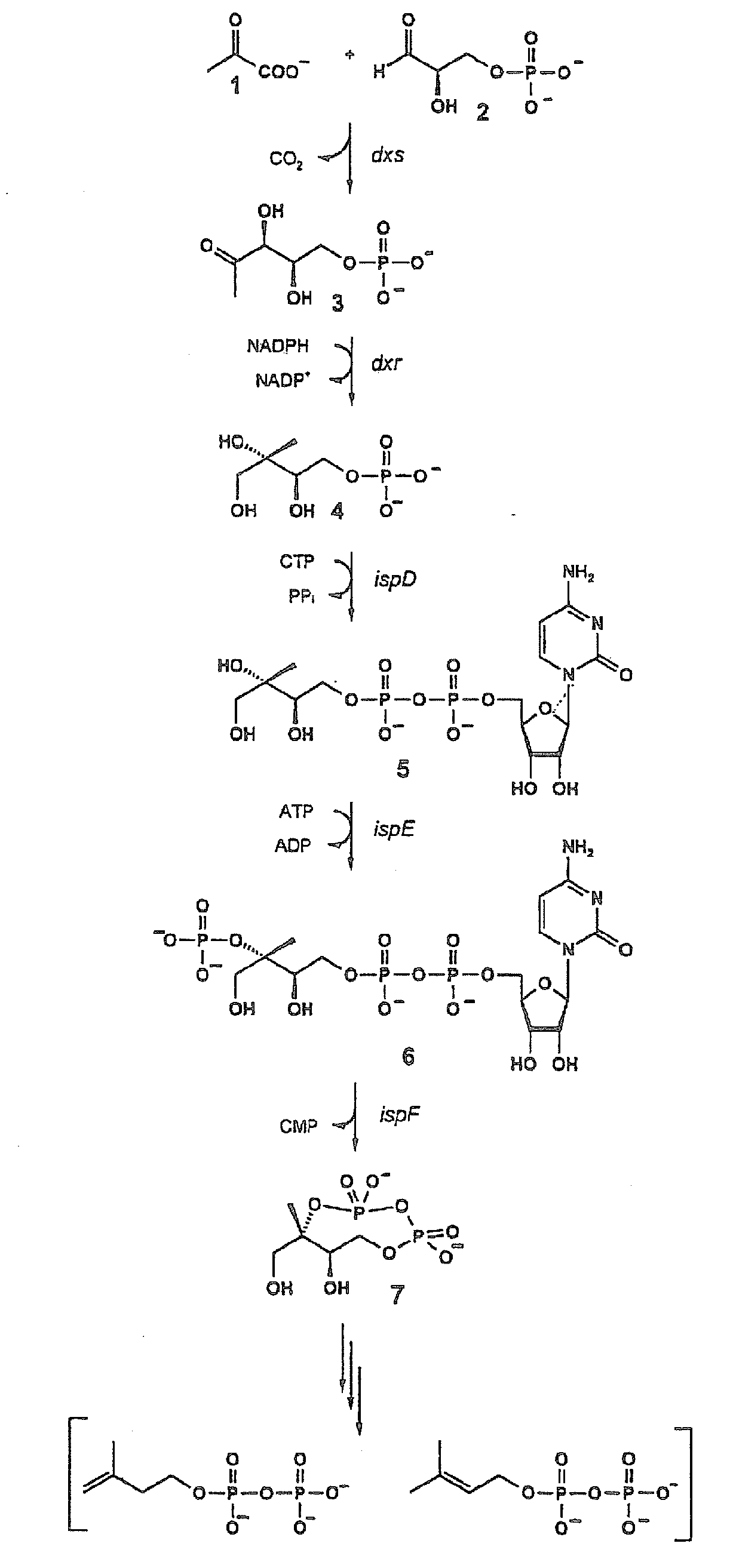

Biosynthesis of isopentenyl pyrophosphate

InactiveUS7172886B2High yieldImprove efficiencySugar derivativesBacteriaMicroorganismIsopentenyl pyrophosphate

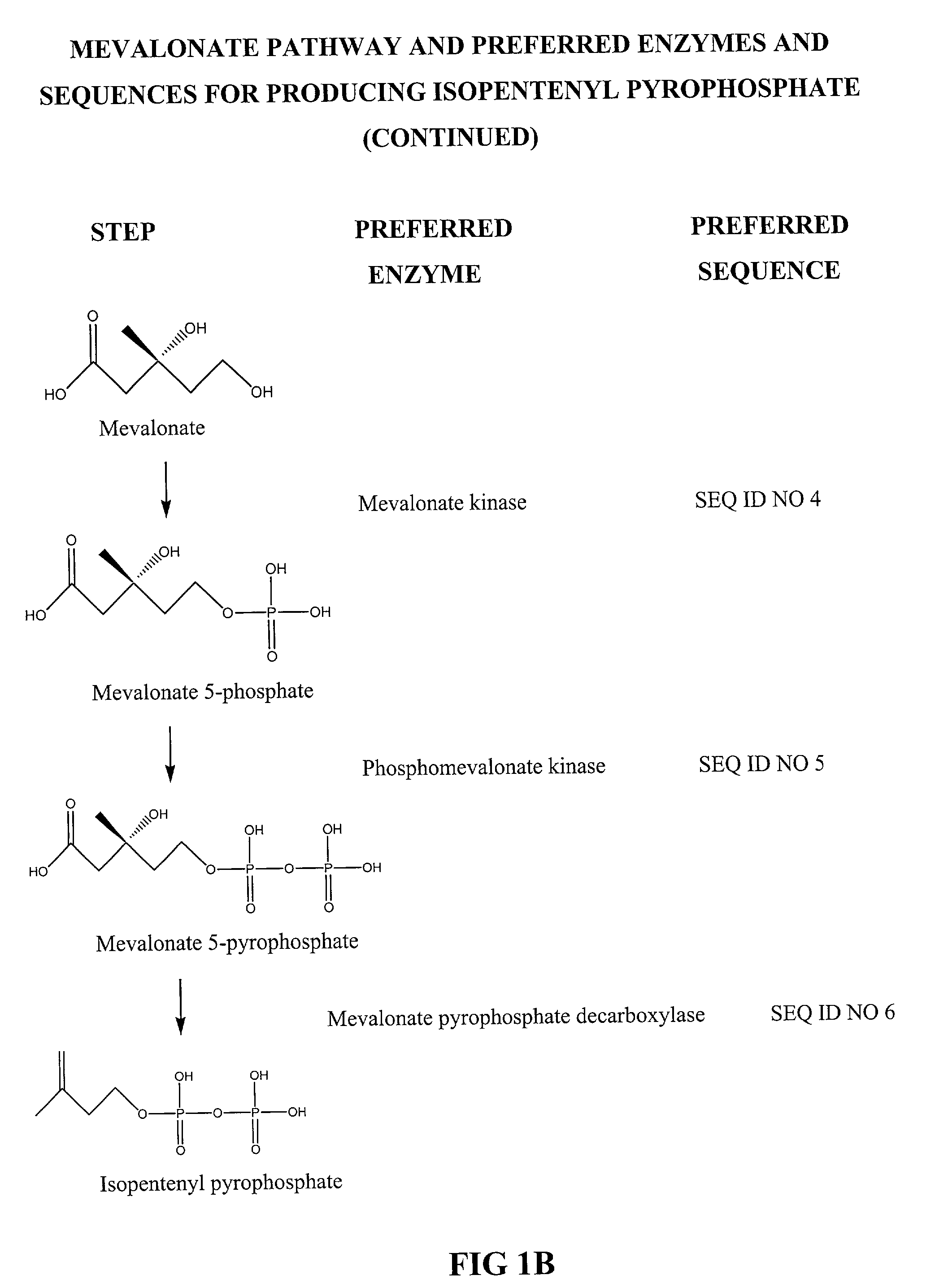

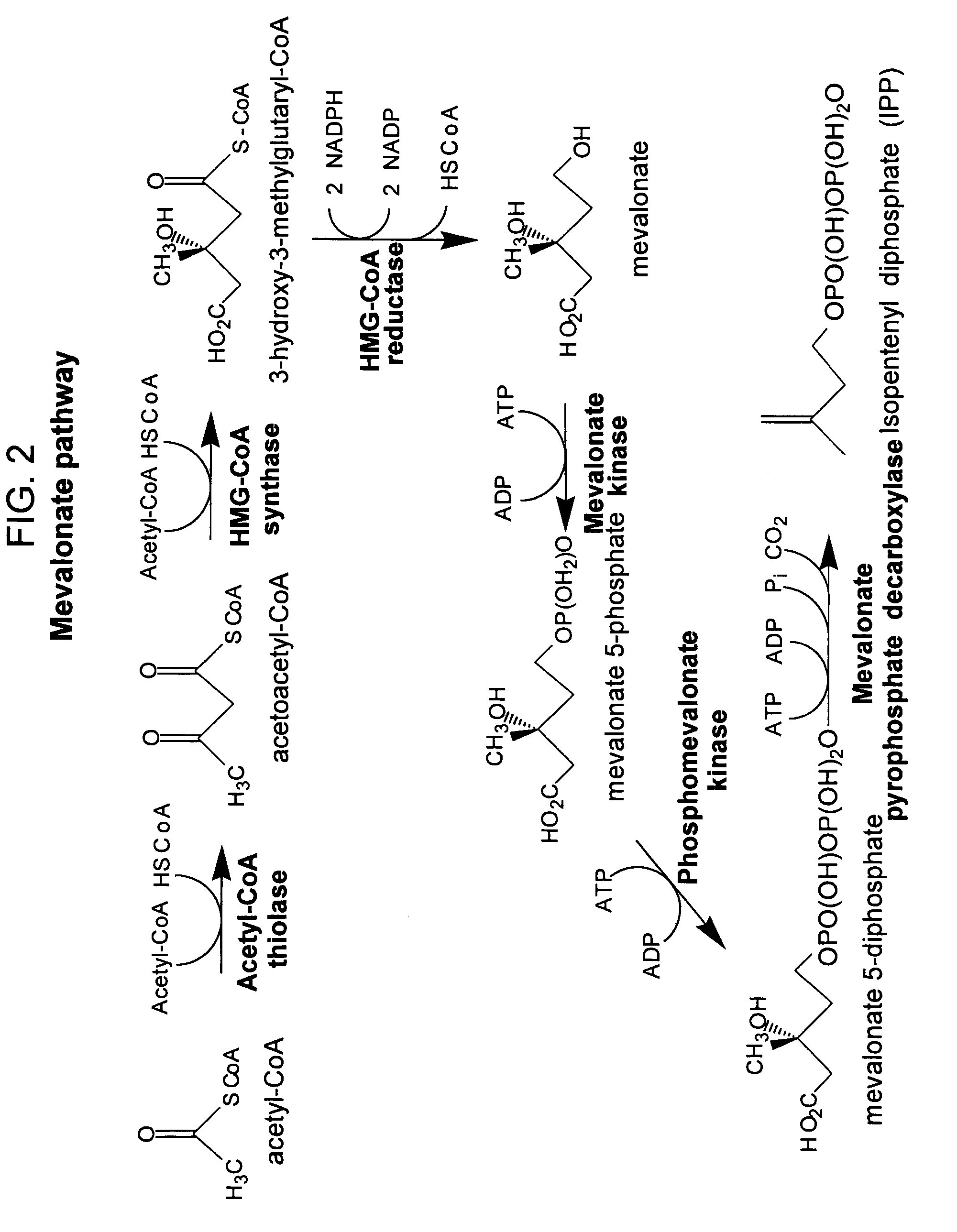

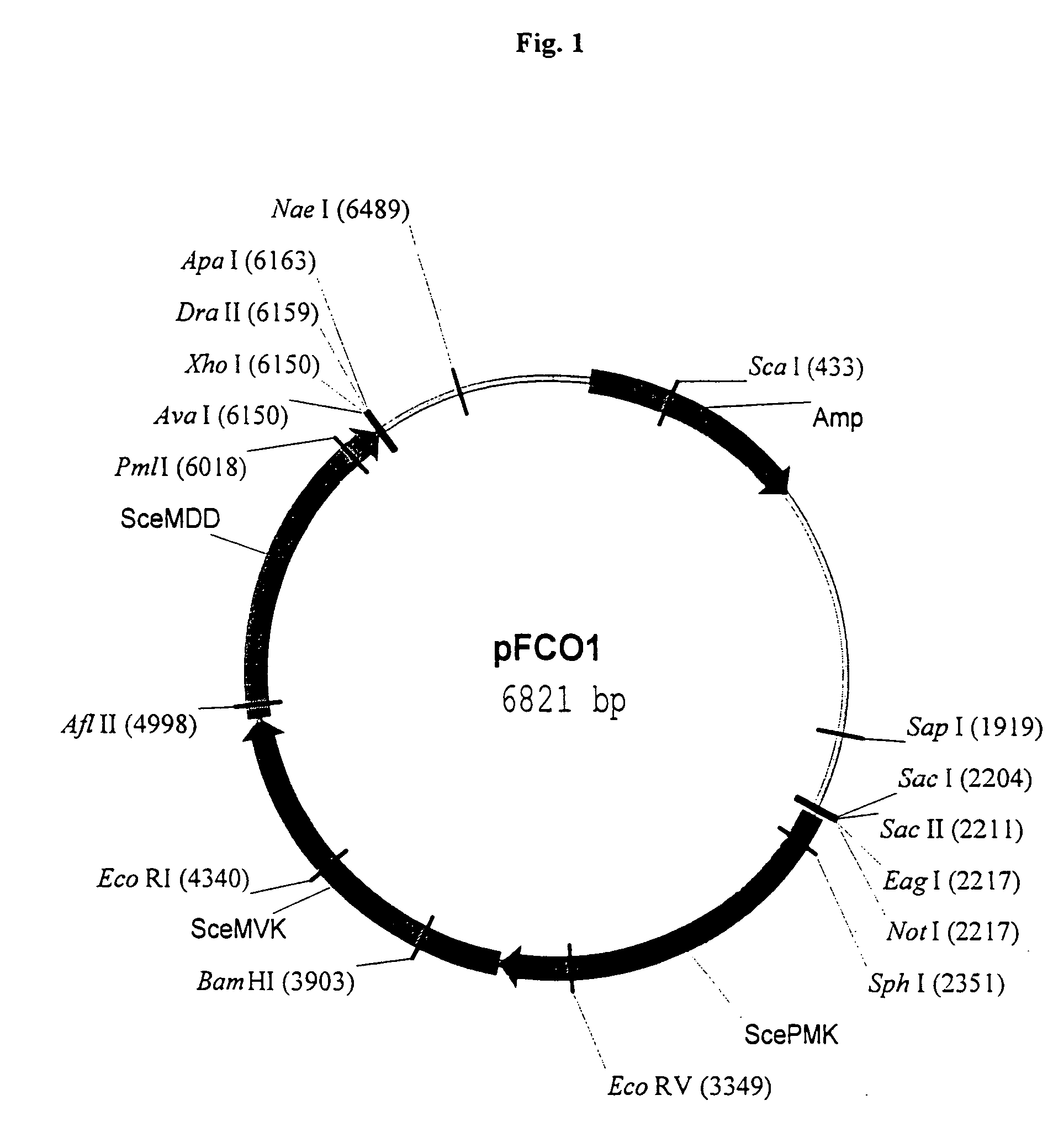

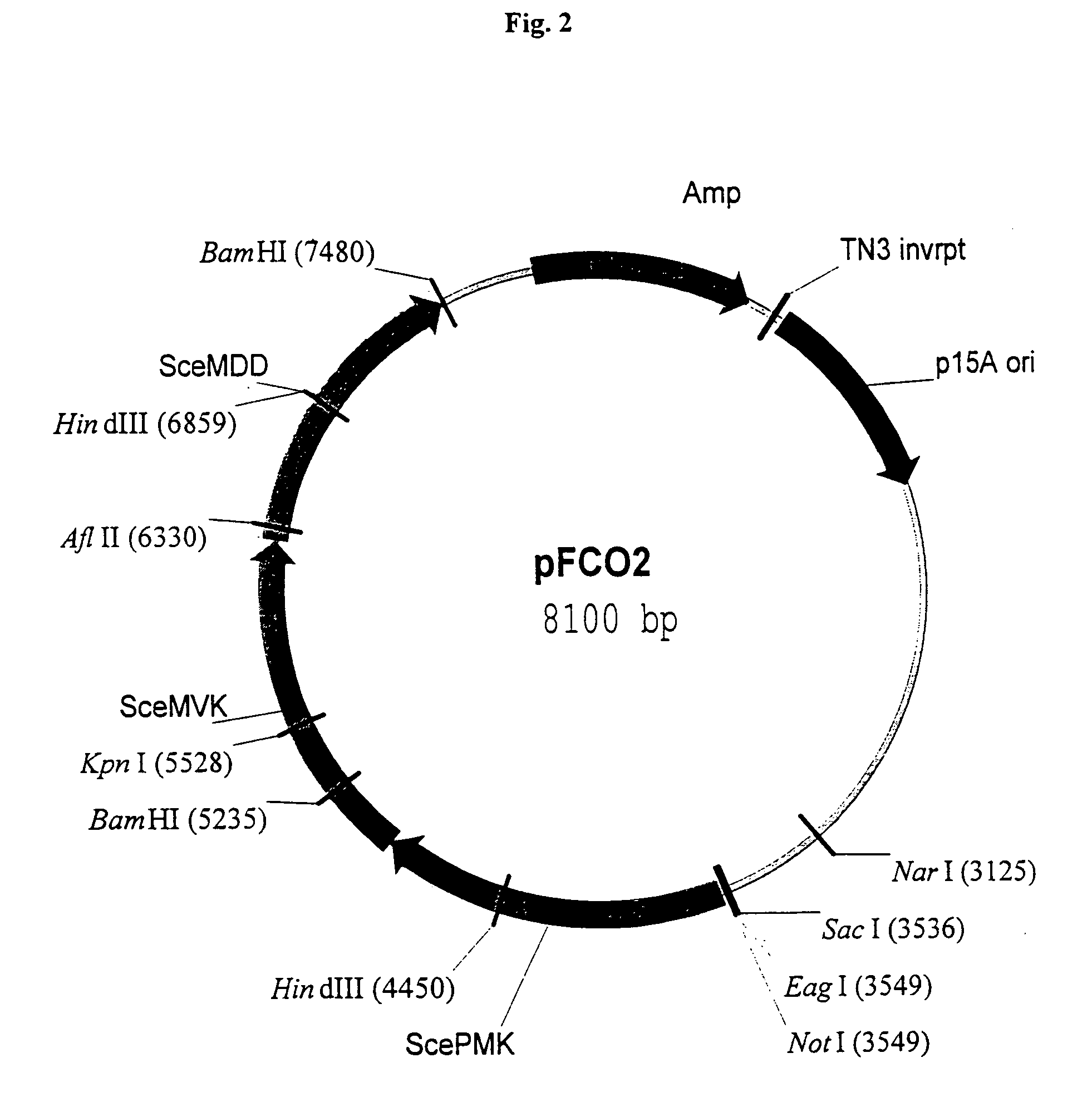

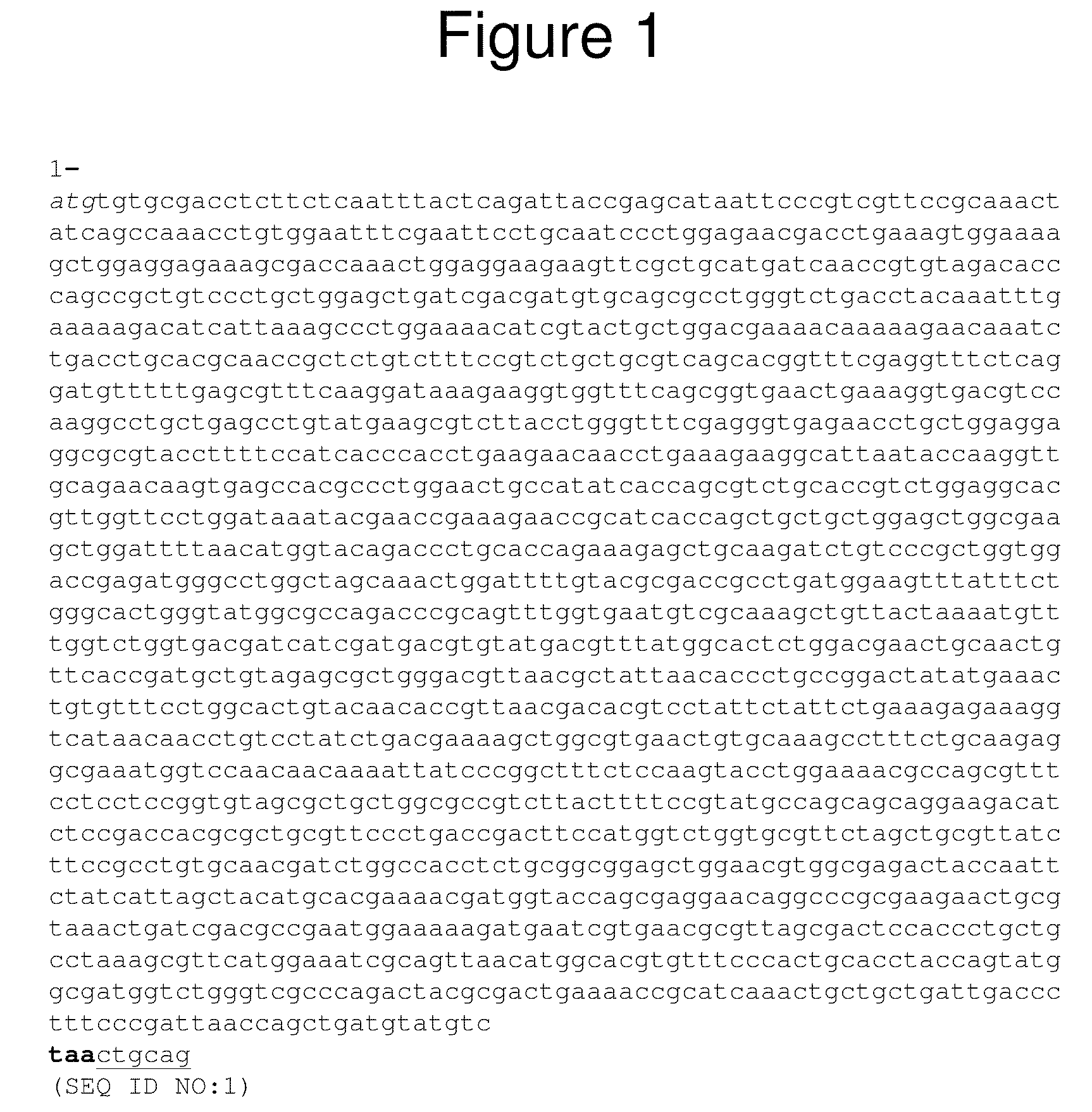

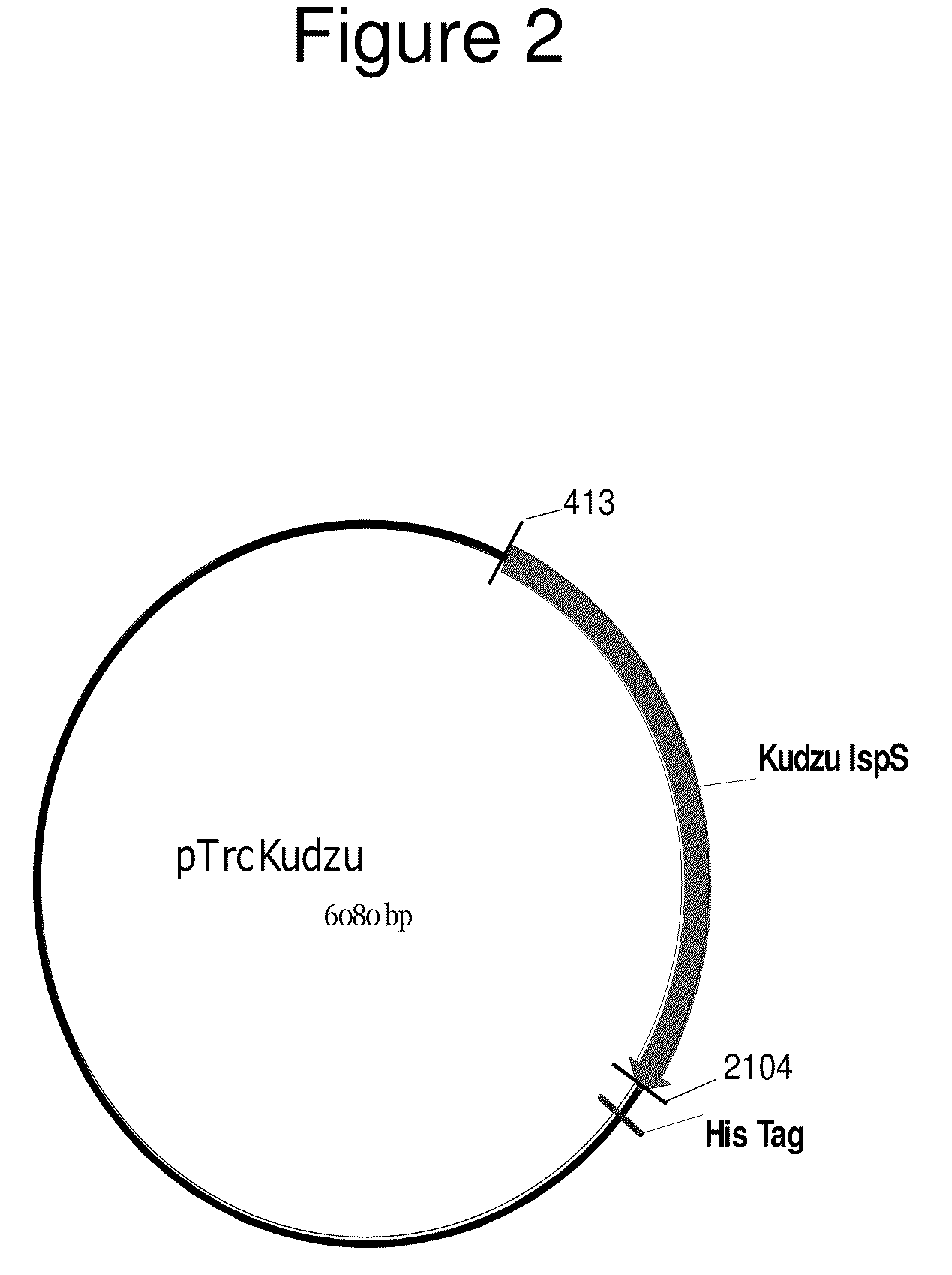

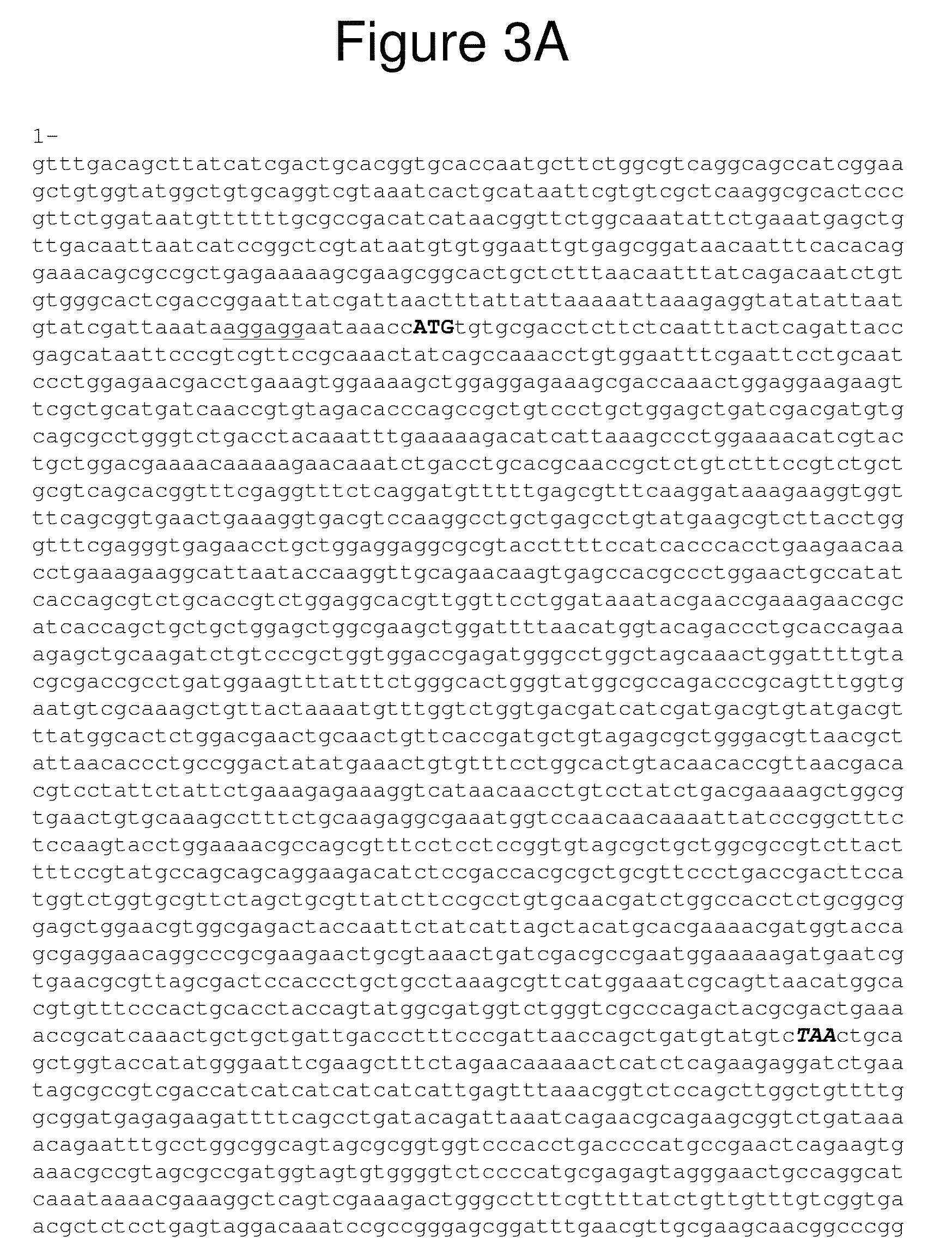

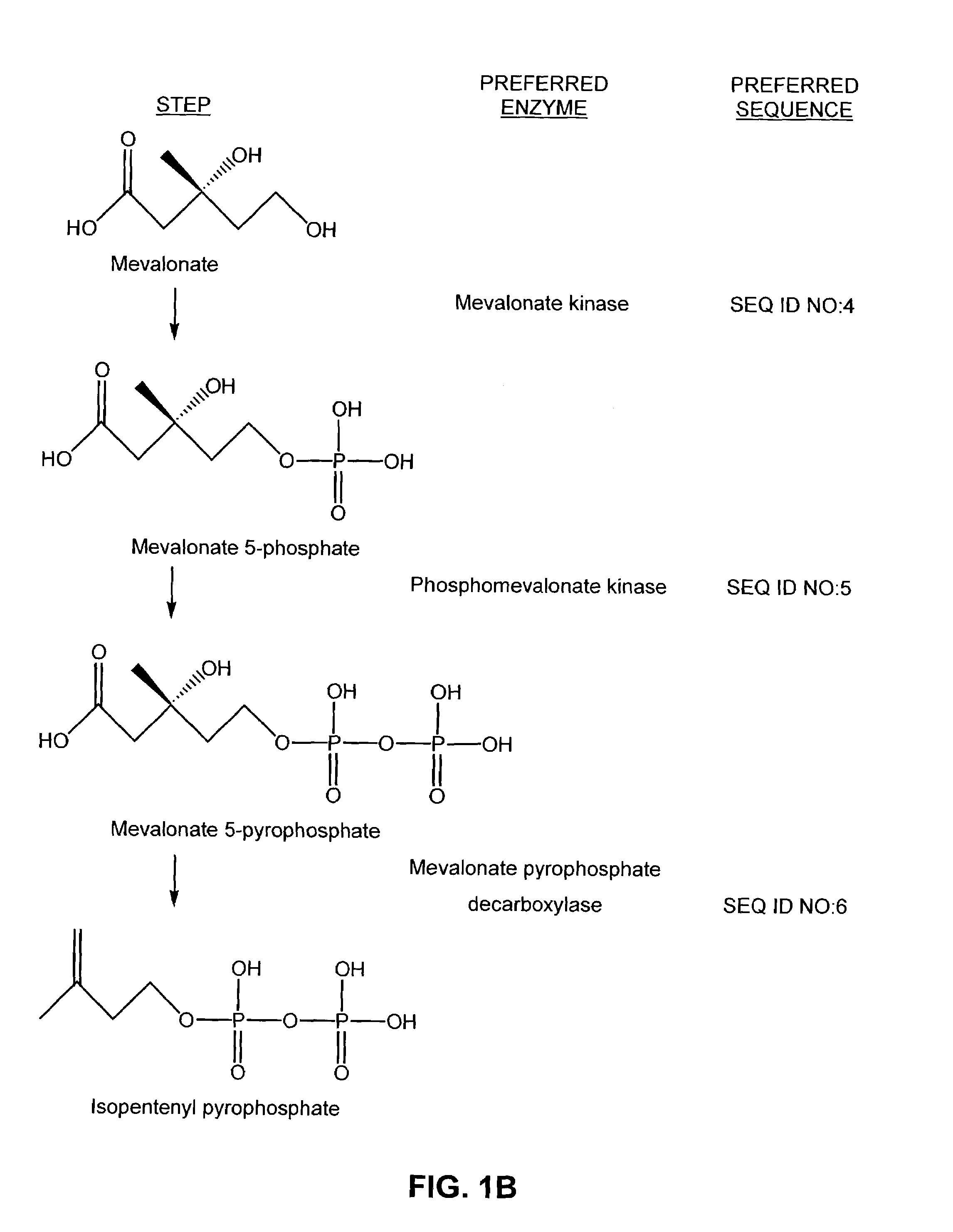

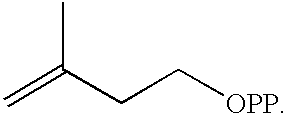

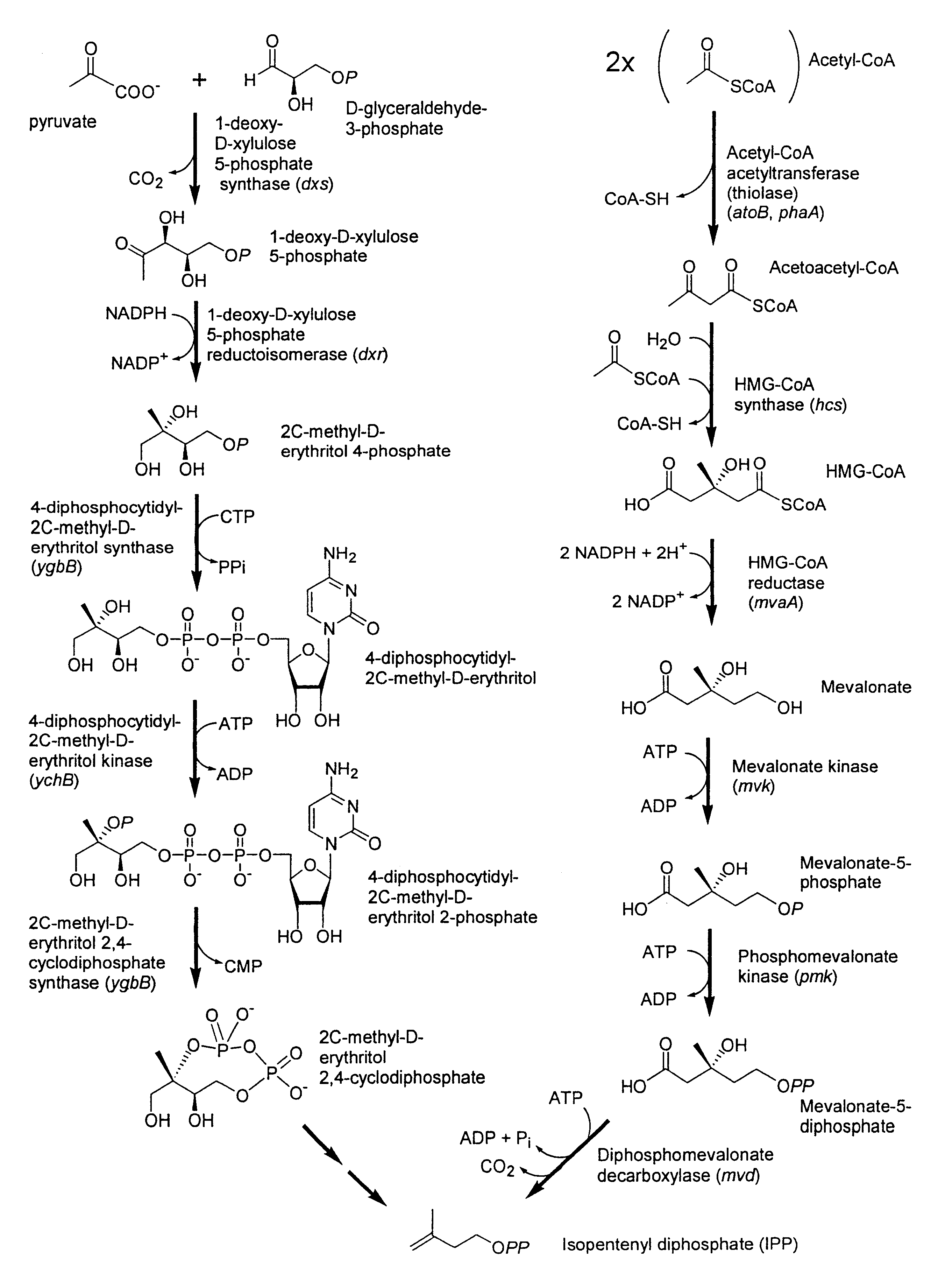

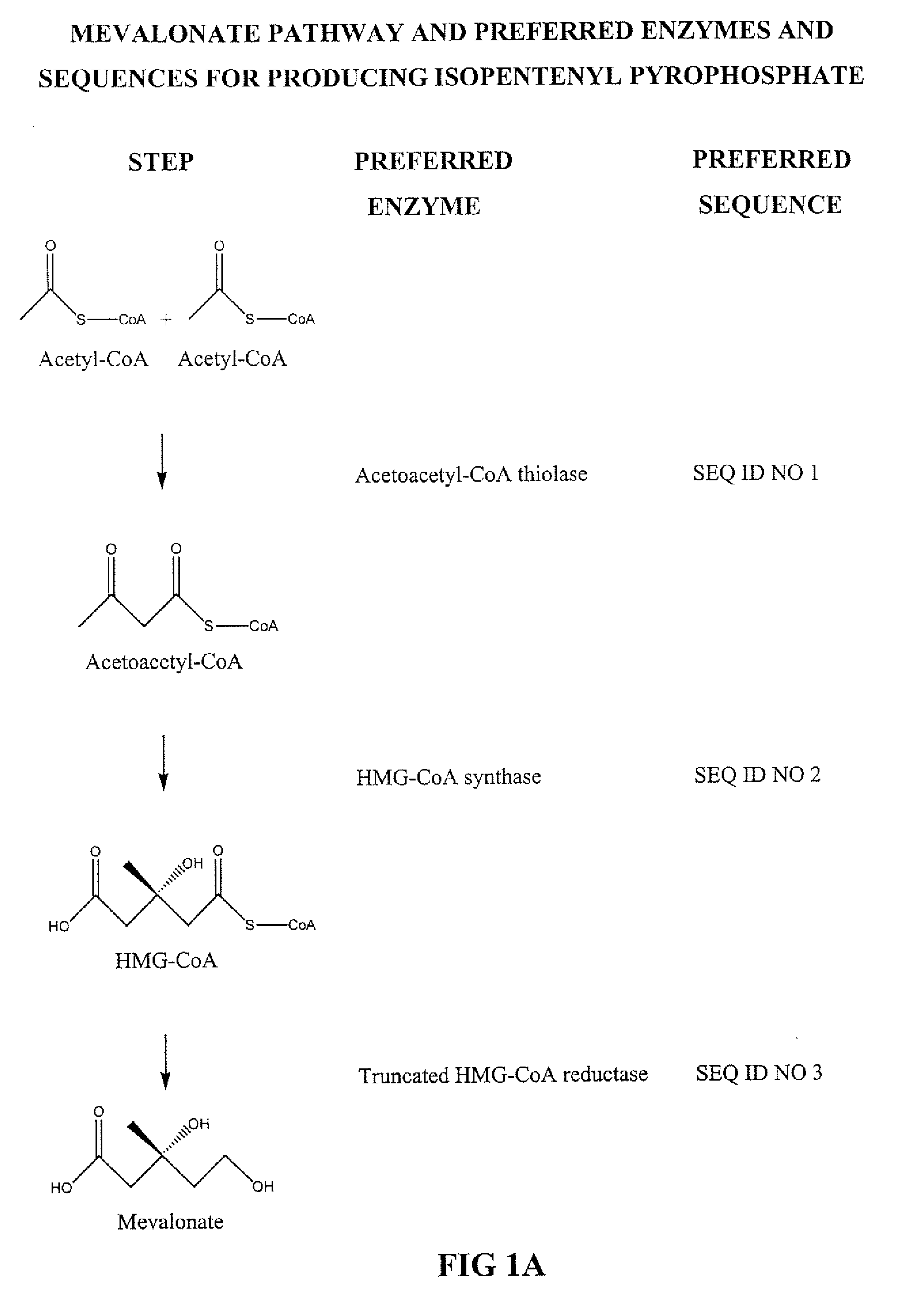

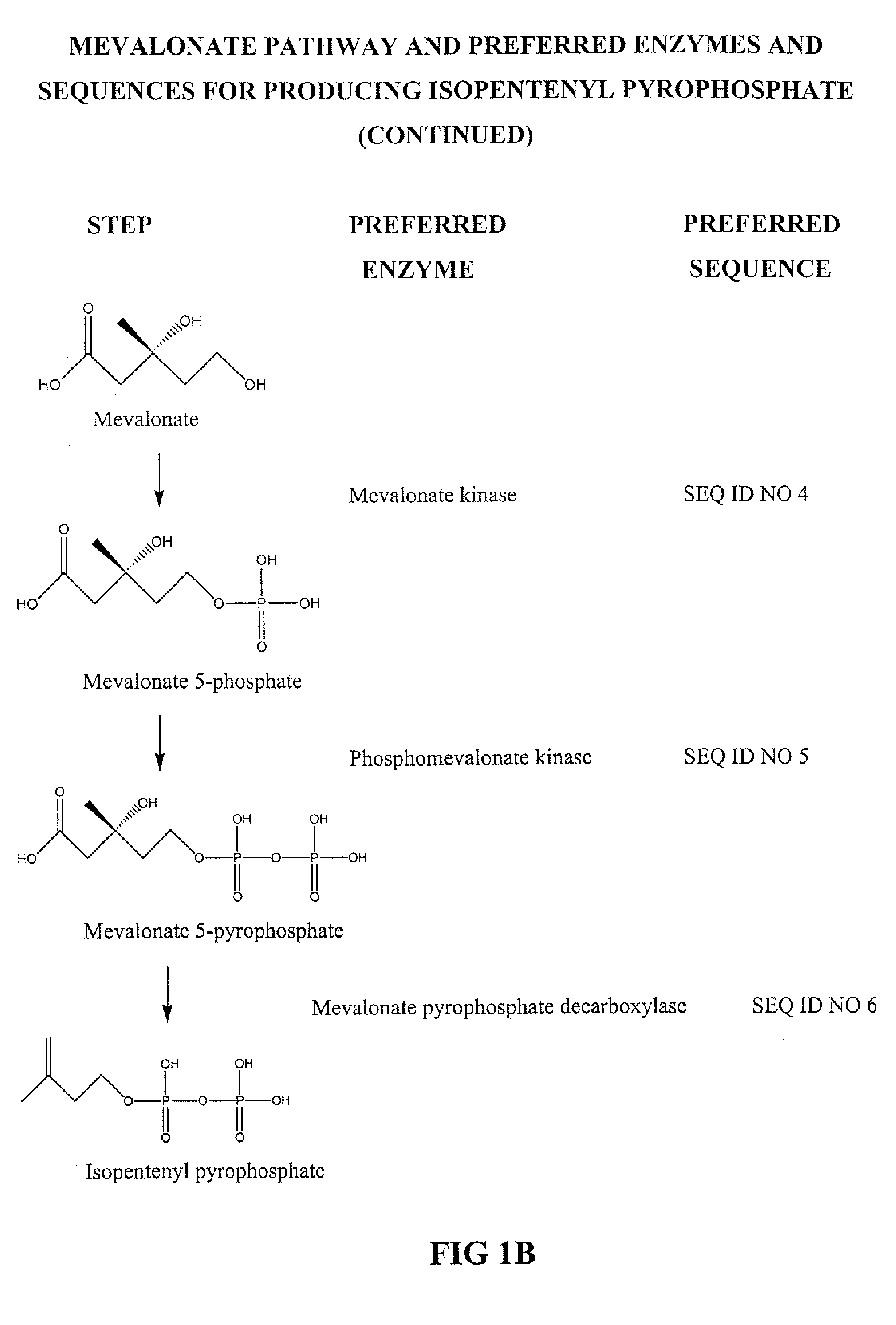

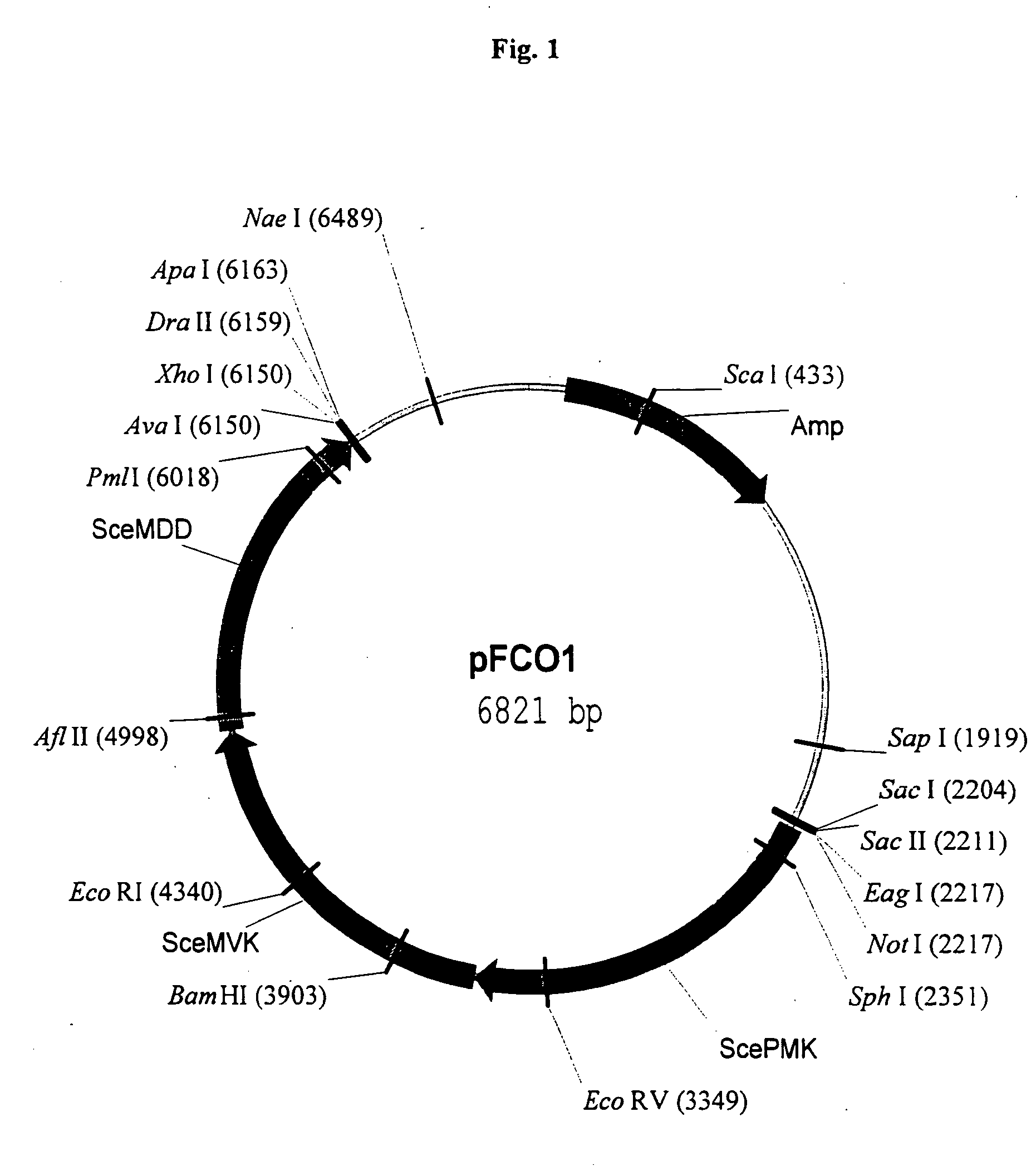

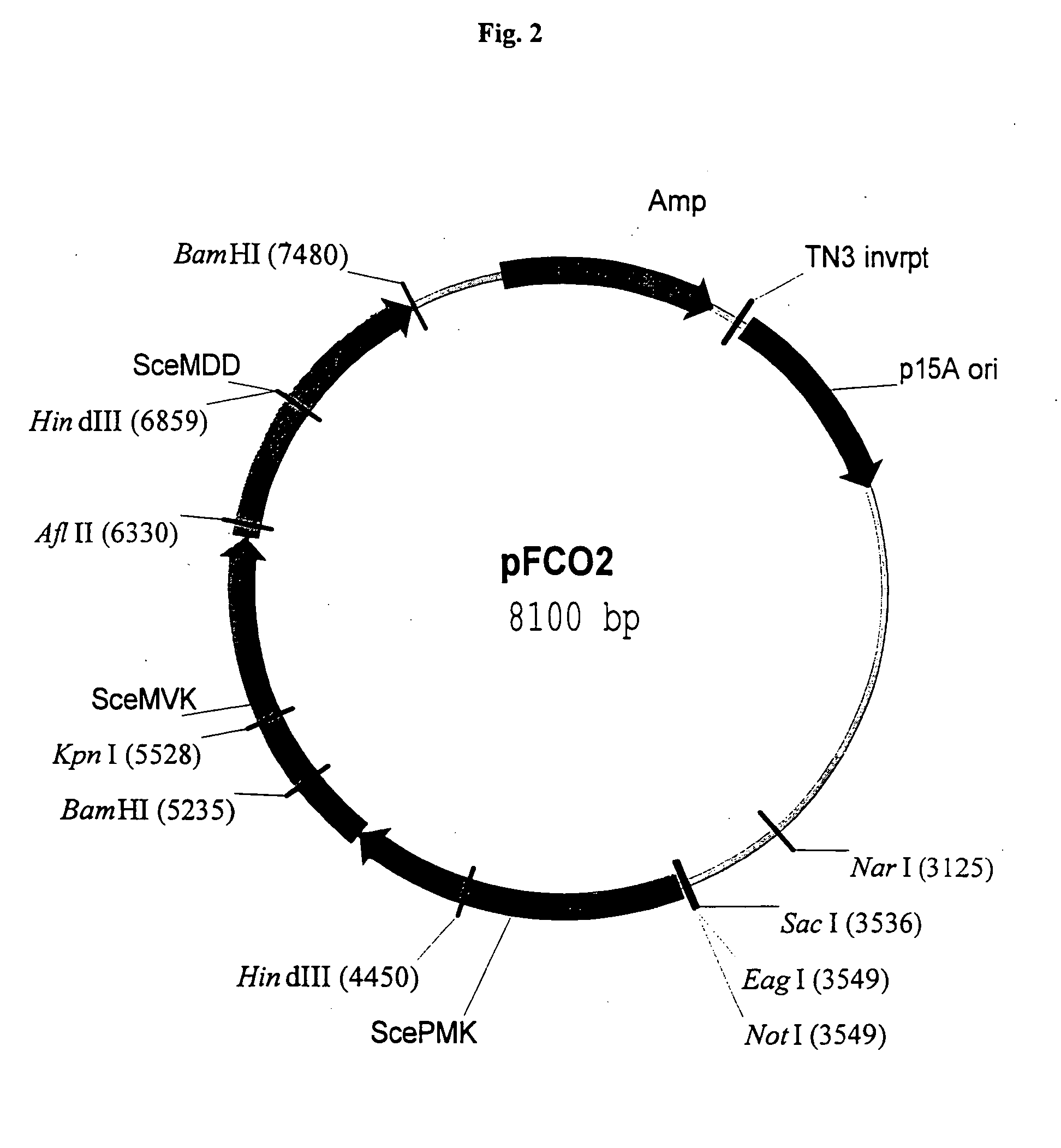

Methods for synthesizing isopentenyl pyrophosphate are provided. A first method comprises introducing into a host microorganism a plurality of heterologous nucleic acid sequences, each coding for a different enzyme in the mevalonate pathway for producing isopentenyl pyrophosphate. A related method comprises introducing into a host microorganism an intermediate in the mevalonate pathway and at least one heterologous nucleic acid sequence, each sequence coding for an enzyme in the mevalonate pathway necessary for converting the intermediate into isopentenyl pyrophosphate. The invention also provides nucleic acid sequences, enzymes, expression vectors, and transformed host cells for carrying out the methods.

Owner:RGT UNIV OF CALIFORNIA

Method for enhancing production of isoprenoid compounds

The present invention provides methods of producing an isoprenoid or an isoprenoid precursor in a genetically modified host cell. The methods generally involve modulating the level of hydroxymethylglutaryl-CoA (HMG-CoA) in the cell, such that the level of HMG-CoA is not toxic to the cell and / or does not substantially inhibit cell growth, but is maintained at a level that provides for high-level production of mevalonate, IPP, and other downstream products of an isoprenoid or isoprenoid pathway, e.g., polyprenyl diphosphates and isoprenoid compounds. The present invention further provides genetically modified host cells that are suitable for use in a subject method. The present invention further provides recombinant nucleic acid constructs for use in generating a subject genetically modified host cell, including recombinant nucleic acid constructs comprising nucleotide sequences encoding one or more mevalonate pathway enzymes, and recombinant vectors (e.g., recombinant expression vectors) comprising same. The present invention further provides methods for identifying nucleic acids that encode HMG-CoA reductase (HMGR) variants that provide for relief of HMG-CoA accumulation-induced toxicity. The present invention further provides methods for identifying agents that reduce intracellular accumulation of HMG-CoA.

Owner:RGT UNIV OF CALIFORNIA

Materials and methods for increasing isoprenoid production in cells

InactiveUS7129392B2Other foreign material introduction processesIsomerasesPhytoene synthesisOpen reading frame

Owner:KUEHNLE AGROSYST COMPANY +1

Increased isoprene production using the archaeal lower mevalonate pathway

Owner:THE GOODYEAR TIRE & RUBBER CO

Biosynthesis of amorpha-4,11-diene

InactiveUS7192751B2High yieldImprove efficiencySugar derivativesBacteriaMicroorganismIsopentenyl pyrophosphate

Methods for synthesizing amorpha-4,11-diene synthase from isopentenyl pyrophosphate are provided. A first method comprises introducing into a host microorganism a plurality of heterologous nucleic acid sequences, each coding for a different enzyme in the mevalonate pathway for producing isopentenyl pyrophosphate. Amorpha-4,11-diene synthase is then produced using an optimized amorpha-4,11-diene synthase gene. The invention also provides nucleic acid sequences, enzymes, expression vectors, and transformed host cells for carrying out the methods.

Owner:RGT UNIV OF CALIFORNIA

Method for enhancing production of isoprenoid compounds

ActiveUS20060079476A1Modulating levelToxic levelGenetic material ingredientsOxidoreductasesENCODEMevalonate pathway

The present invention provides methods of producing an isoprenoid or an isoprenoid precursor in a genetically modified host cell. The methods generally involve modulating the level of hydroxymethylglutaryl-CoA (HMG-CoA) in the cell, such that the level of HMG-CoA is not toxic to the cell and / or does not substantially inhibit cell growth, but is maintained at a level that provides for high-level production of mevalonate, IPP, and other downstream products of an isoprenoid or isoprenoid pathway, e.g., polyprenyl diphosphates and isoprenoid compounds. The present invention further provides genetically modified host cells that are suitable for use in a subject method. The present invention further provides recombinant nucleic acid constructs for use in generating a subject genetically modified host cell, including recombinant nucleic acid constructs comprising nucleotide sequences encoding one or more mevalonate pathway enzymes, and recombinant vectors (e.g., recombinant expression vectors) comprising same. The present invention further provides methods for identifying nucleic acids that encode HMG-CoA reductase (HMGR) variants that provide for relief of HMG-CoA accumulation-induced toxicity. The present invention further provides methods for identifying agents that reduce intracellular accumulation of HMG-CoA.

Owner:RGT UNIV OF CALIFORNIA

Increased isoprene production using mevalonate kinase and isoprene synthase

Owner:THE GOODYEAR TIRE & RUBBER CO

Isoprenoid production

Owner:DSM NUTRITIONAL PROD +1

Isoprenoid production

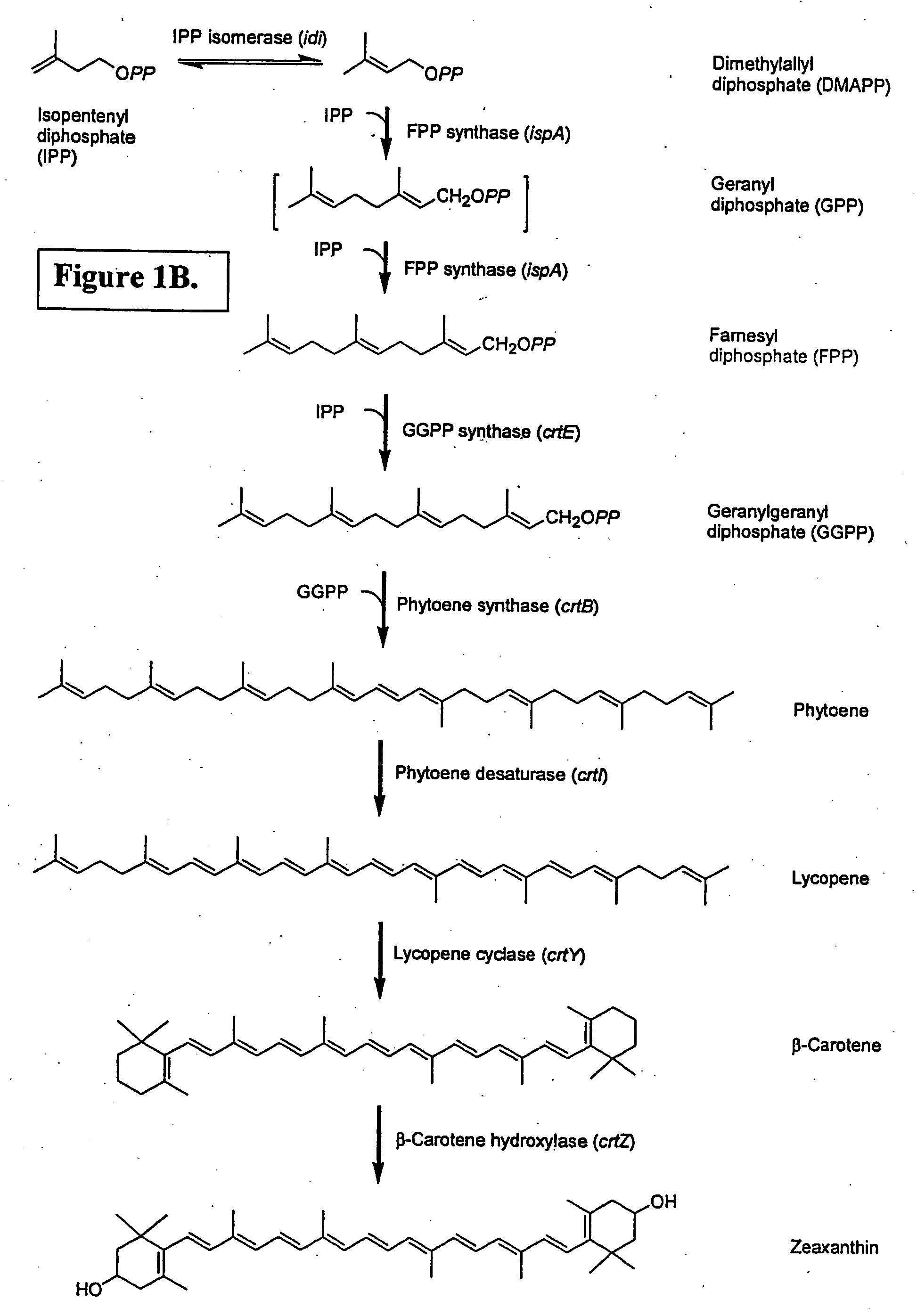

Isolated polynucleotides encoding polypeptides having the activity of enzymes in the mevalonate pathway are provided. These sequences are useful for recombinantly producing isoprenoid compounds, such as carotenoids, in particular zeaxanthin. Expression vectors, cultured cells, and methods of making isoprenoid compounds are also provided.

Owner:DSM IP ASSETS BV

Biosynthesis of isopentenyl pyrophosphate

InactiveUS20070077616A1Enhancing yield and efficiencyReduce side effectsBacteriaSugar derivativesHeterologousMicroorganism

Methods for synthesizing isopentenyl pyrophosphate are provided. A first method comprises introducing into a host microorganism a plurality of heterologous nucleic acid sequences, each coding for a different enzyme in the mevalonate pathway for producing isopentenyl pyrophosphate. A related method comprises introducing into a host microorganism an intermediate in the mevalonate pathway and at least one heterologous nucleic acid sequence, each sequence coding for an enzyme in the mevalonate pathway necessary for converting the intermediate into isopentenyl pyrophosphate. The invention also provides nucleic acid sequences, enzymes, expression vectors, and transformed host cells for carrying out the methods.

Owner:RGT UNIV OF CALIFORNIA

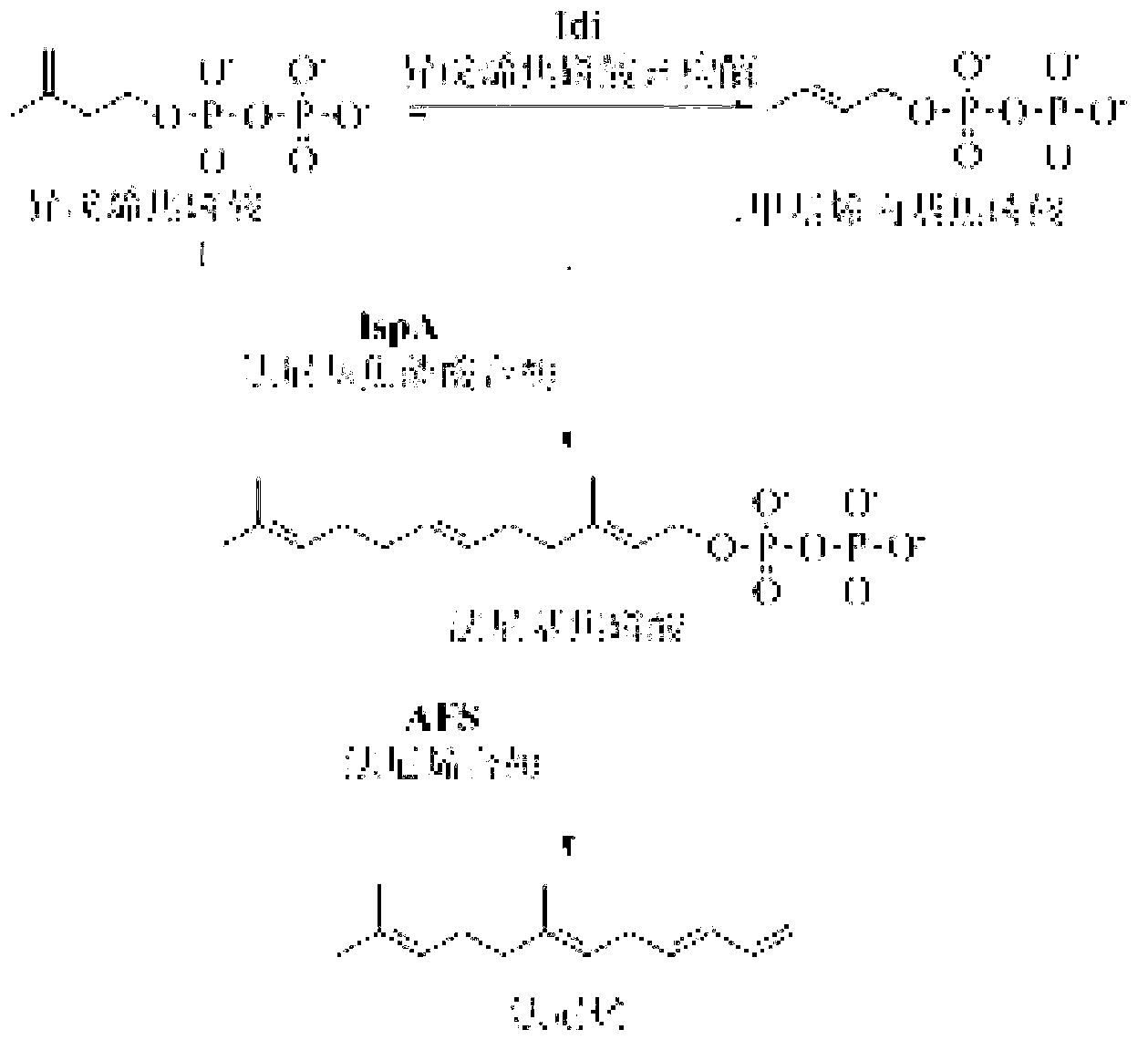

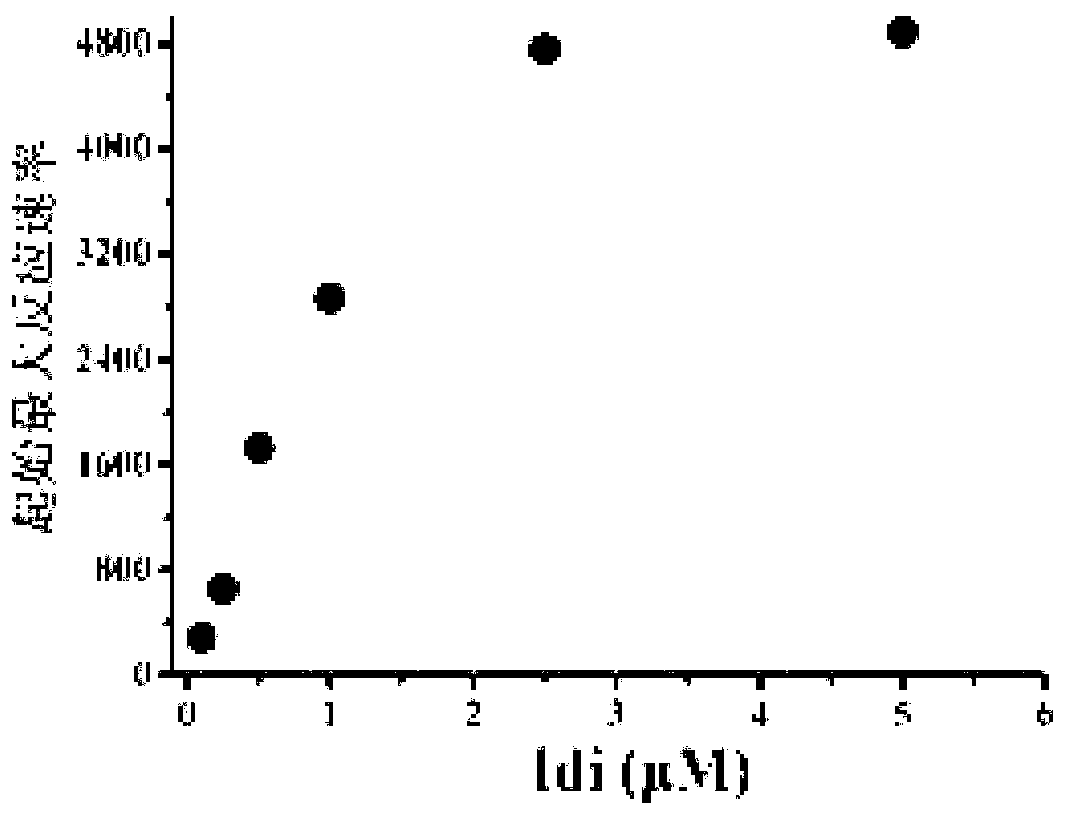

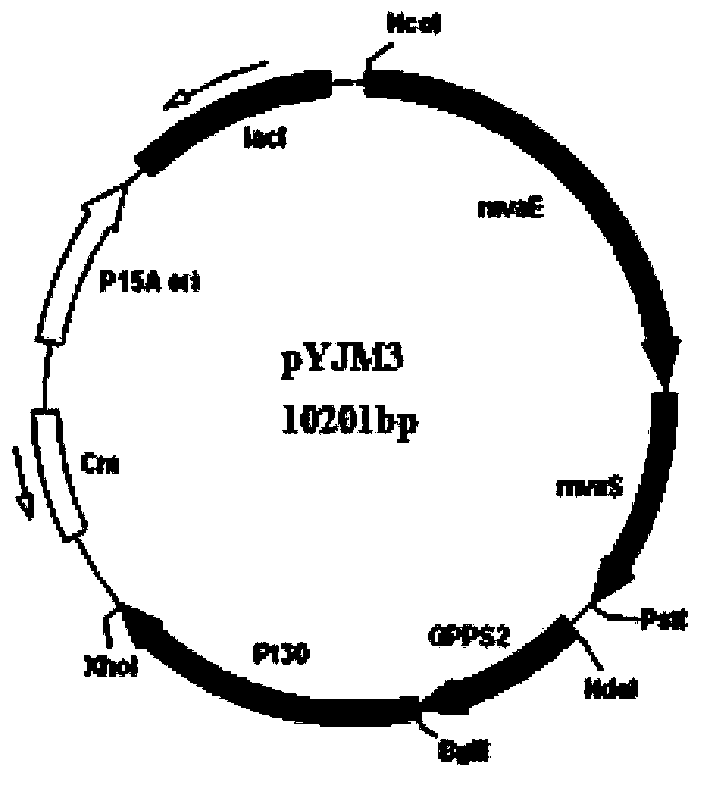

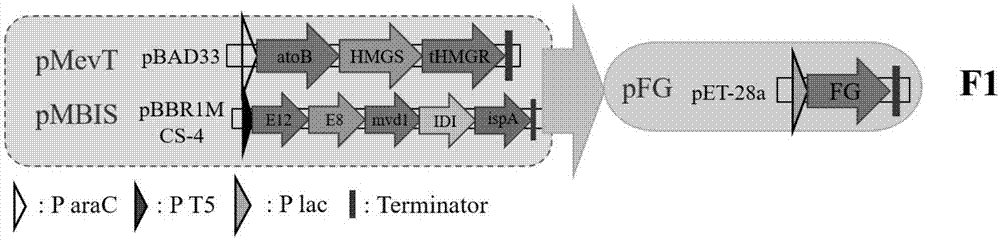

Bacterial strain for producing farnesene and application of bacterial strain

ActiveCN103243065AIncrease productionRational experimentBacteriaMicroorganism based processesBacterial strainCulture mediums

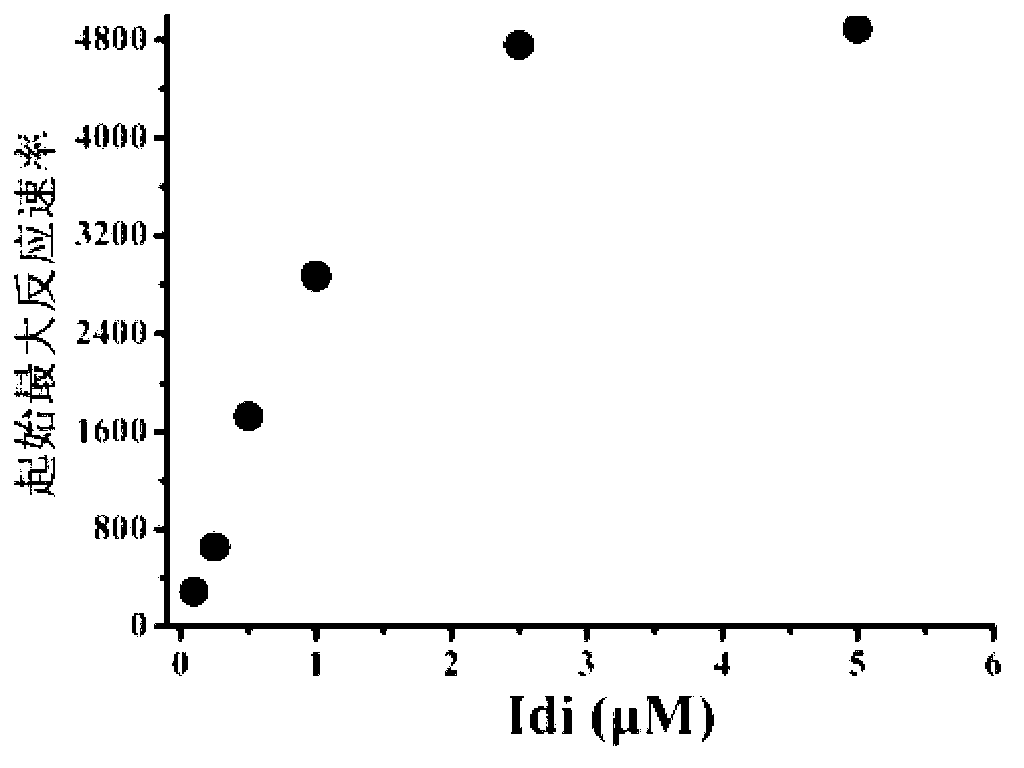

The invention discloses a bacterial strain for producing farnesene and an application of the bacterial strain, belonging to the field of synthetic biology. The bacterial strain for producing the farnesene contains related genes for synthesizing the farnesene through a mevalonic acid pathway and codon optimization; and the sequence of a farnesene synthetic gene afs optimized by codons is as shown by SEQ ID NO.1. The bacterial strain can be used for producing the farnesene, and a seed solution of the bacterial strain is inoculated into a culture medium containing a carbon source to carry out prokaryotic expression to obtain the farnesene. The gene for synthesizing the farnesene is subjected to codon optimization or the farnesene is synthesized by using the mevalonic acid pathway to ensure that each protein is closer to a ratio of AtoB:ERG13:tHMG1:ERG12:ERG8:MVD1:Idi:IspA:AFS=1:10:2:5:5:2:5:2:2, so that the production of the farnesene can be further promoted. By adopting the bacterial strain, the output of the farnesene is greatly improved to be more than 1g / L.

Owner:SHENZHEN ACTION TECH CO LTD

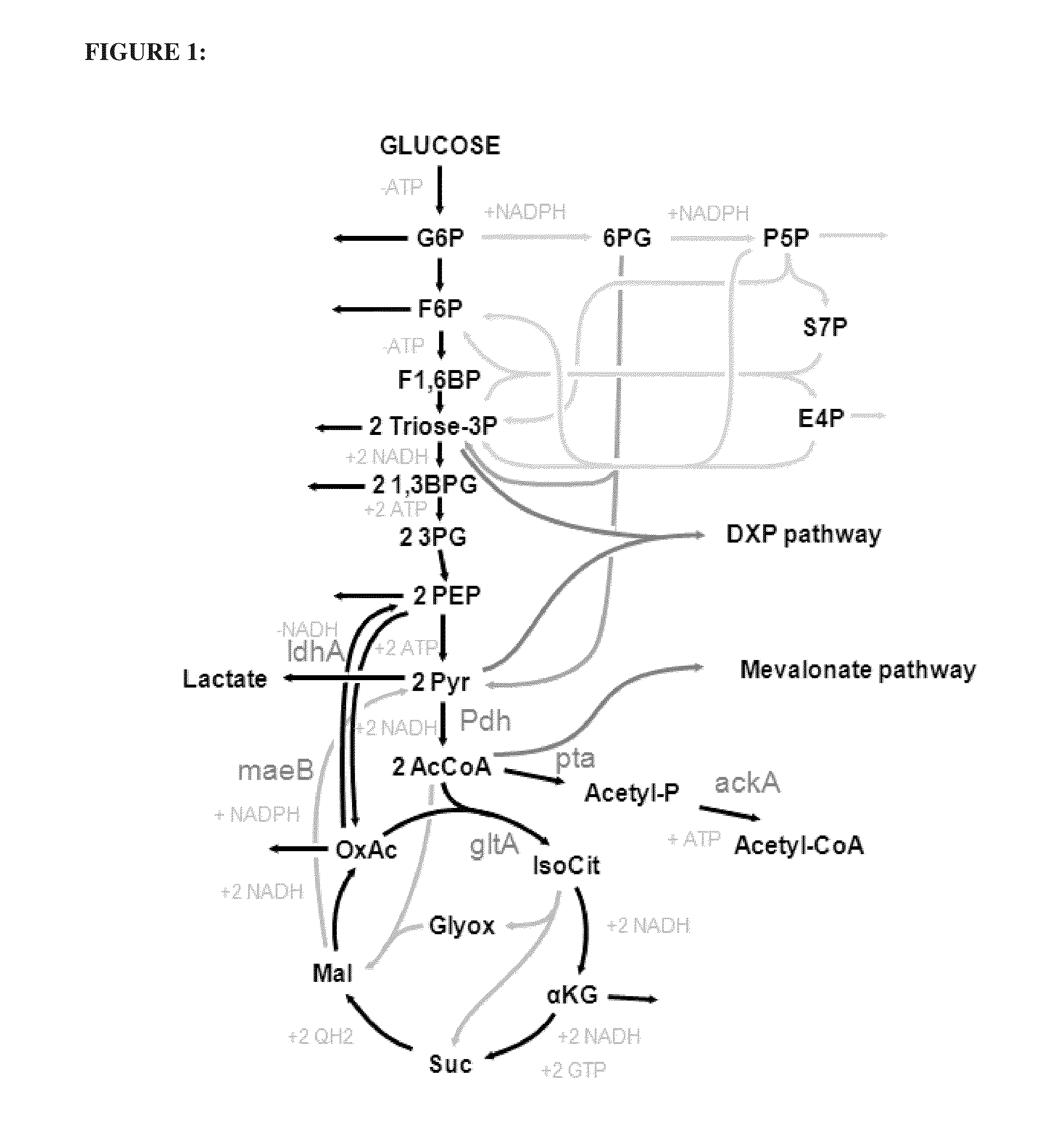

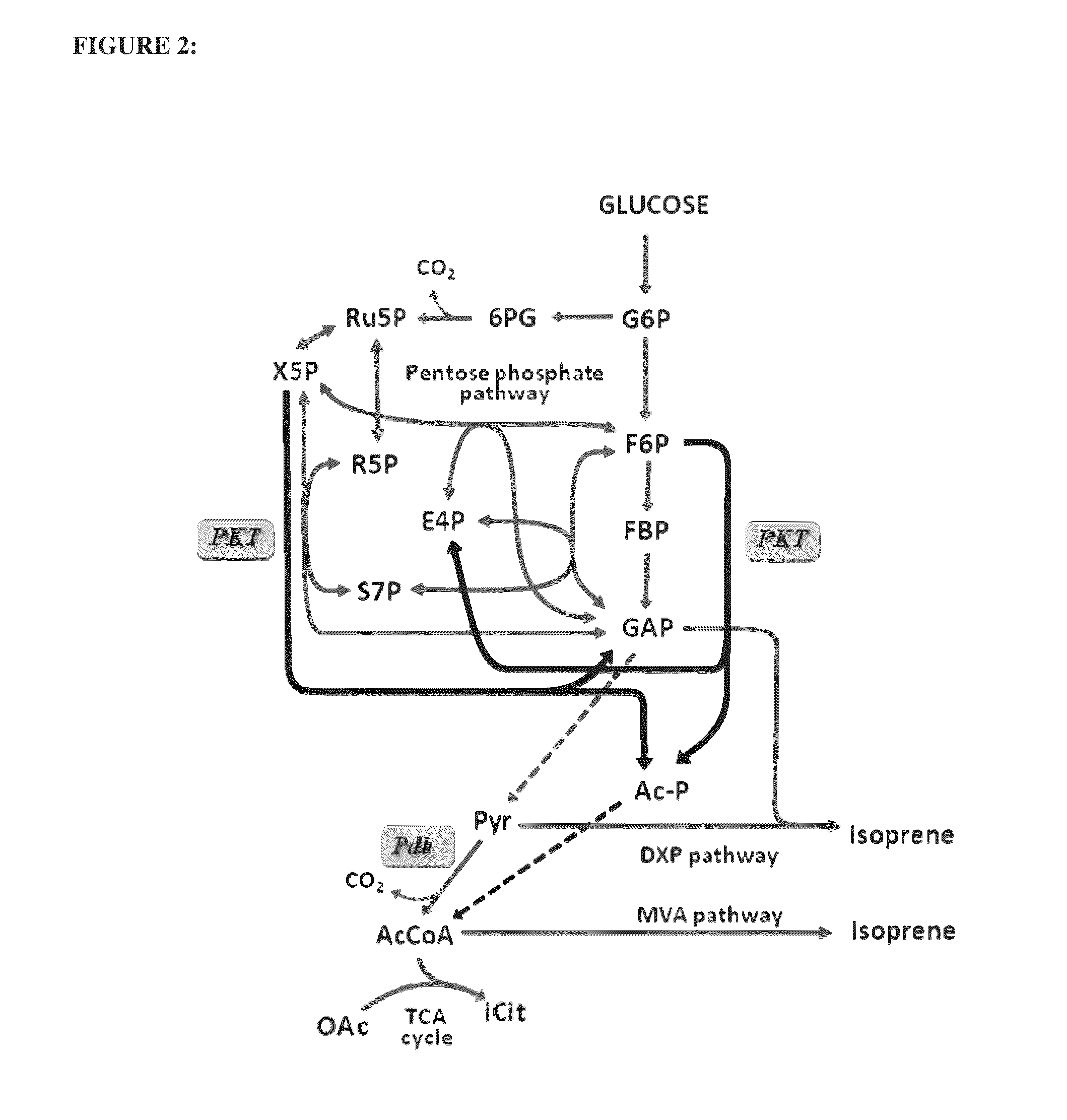

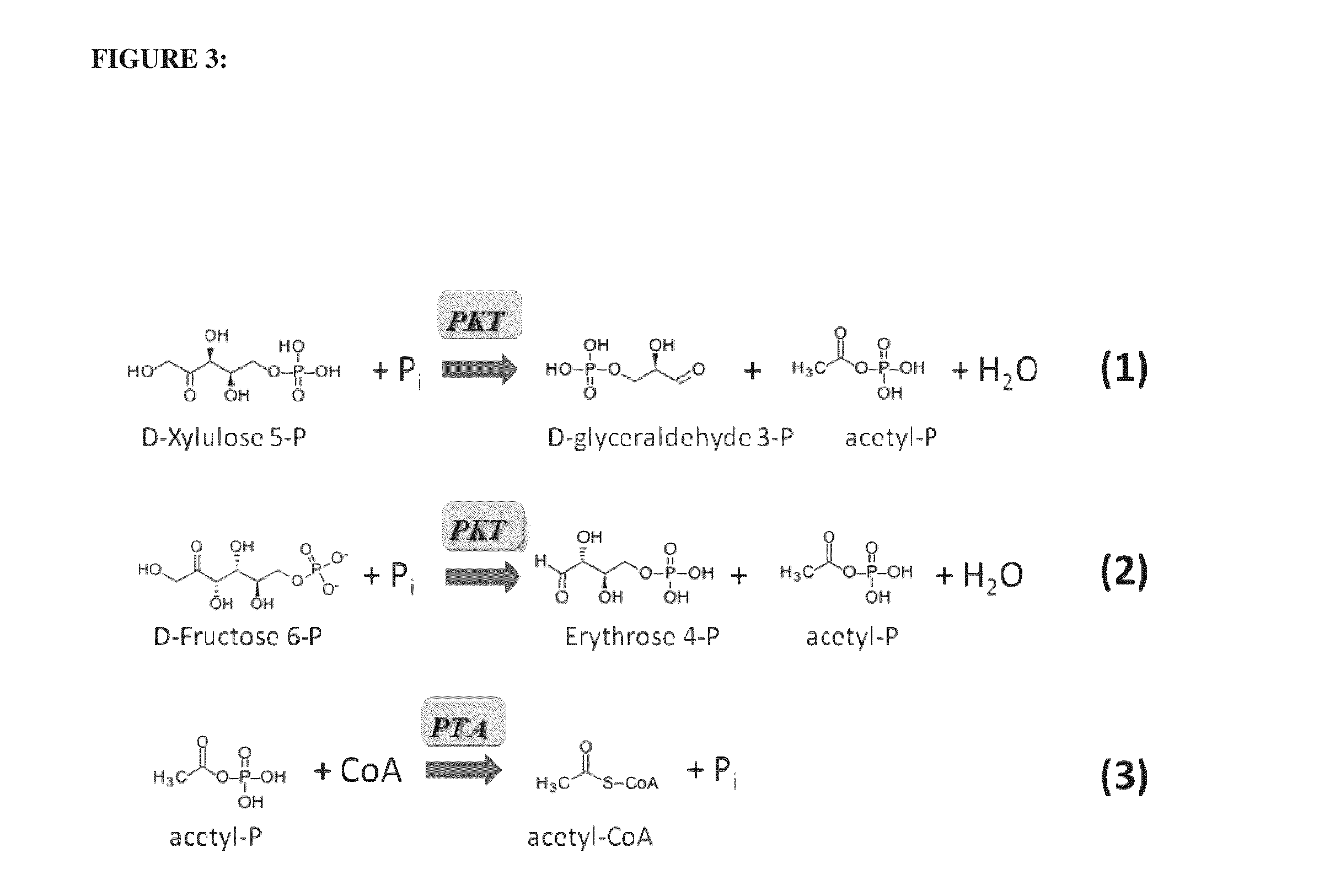

Utilization of phosphoketolase in the production of mevalonate, isoprenoid precursors, and isoprene

The invention provides for methods for the production of mevalonate, isoprene, isoprenoid precursor molecules, and / or isoprenoids in cells via the heterologous expression of phosphoketolase enzymes.

Owner:THE GOODYEAR TIRE & RUBBER CO

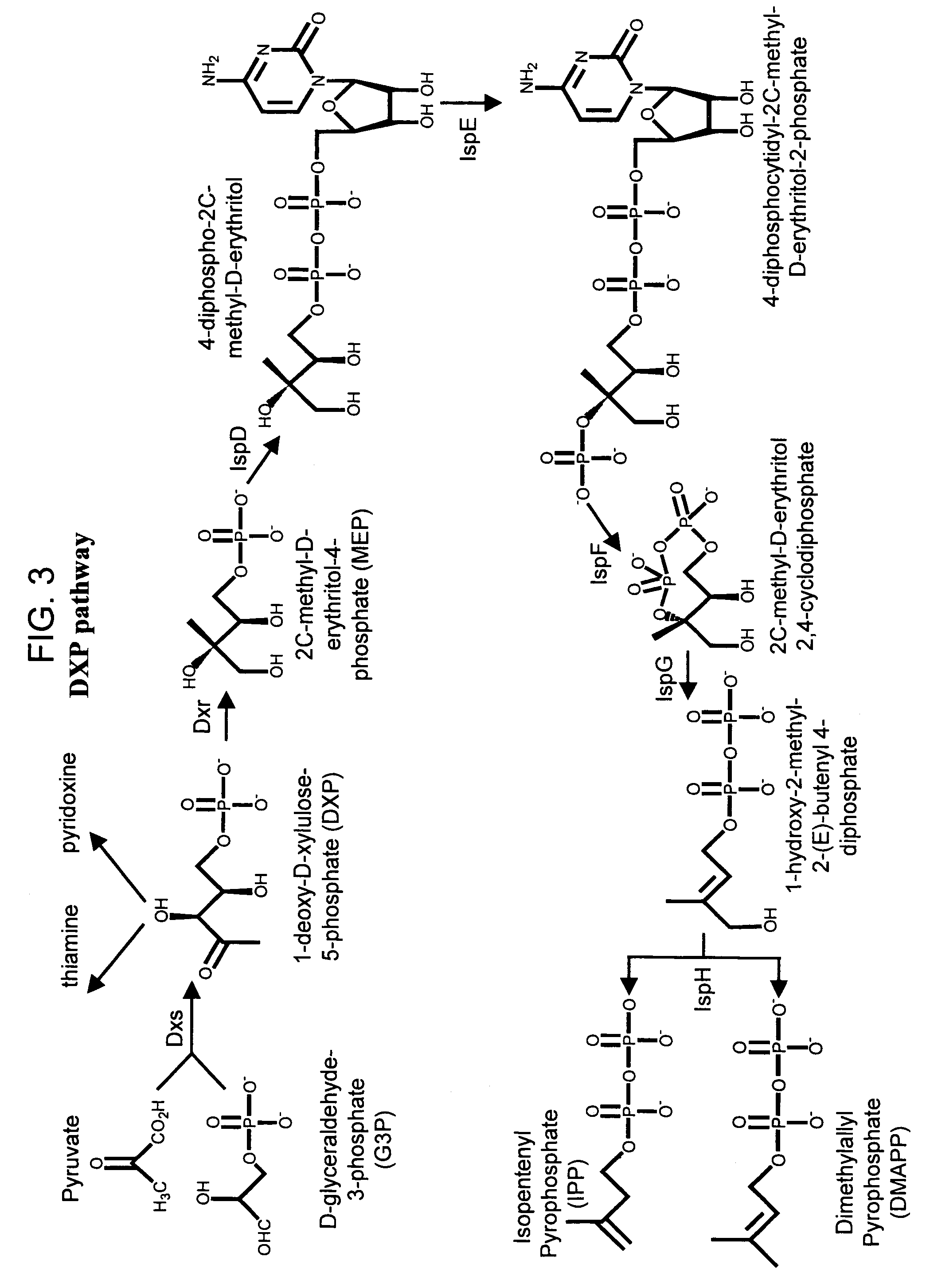

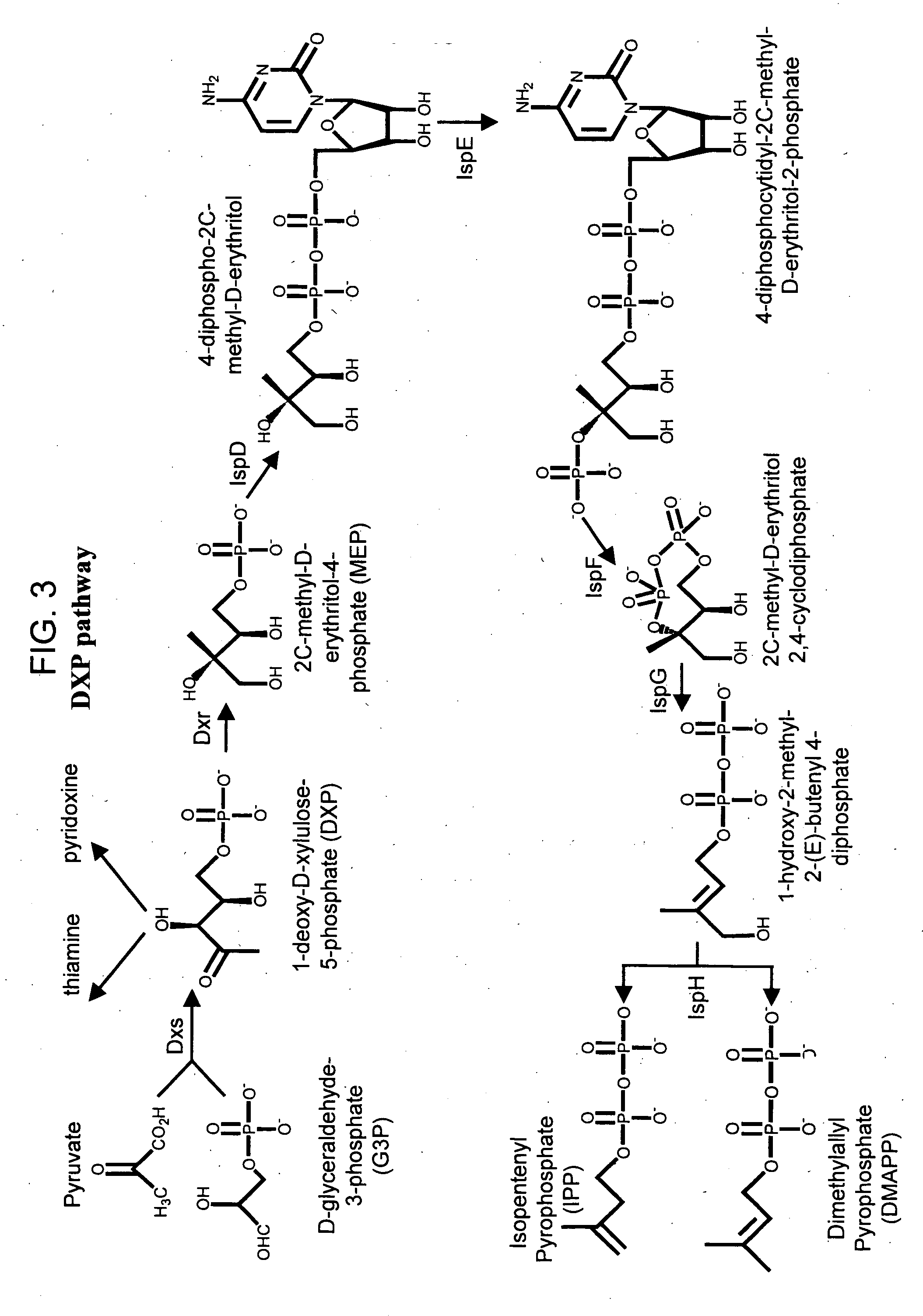

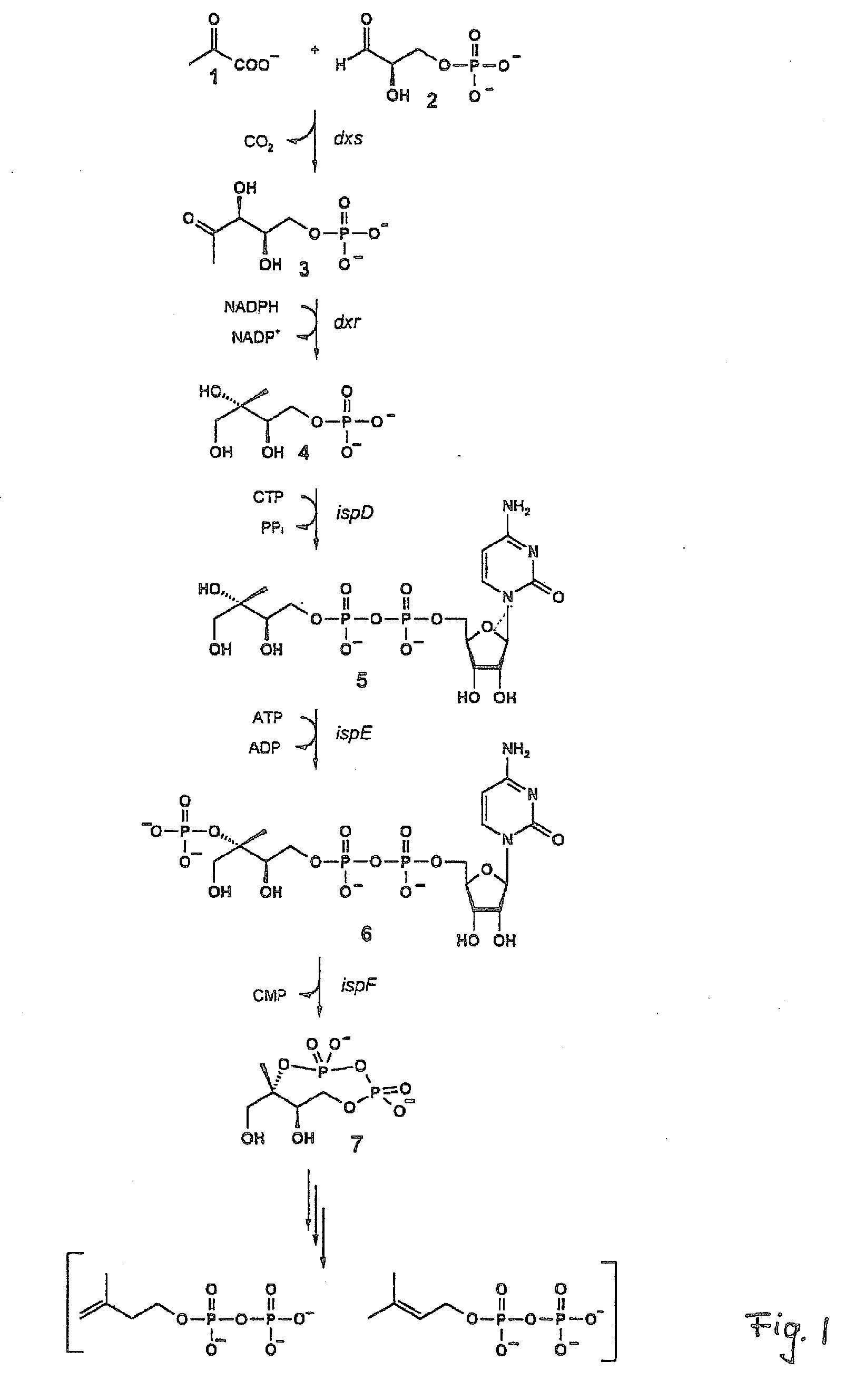

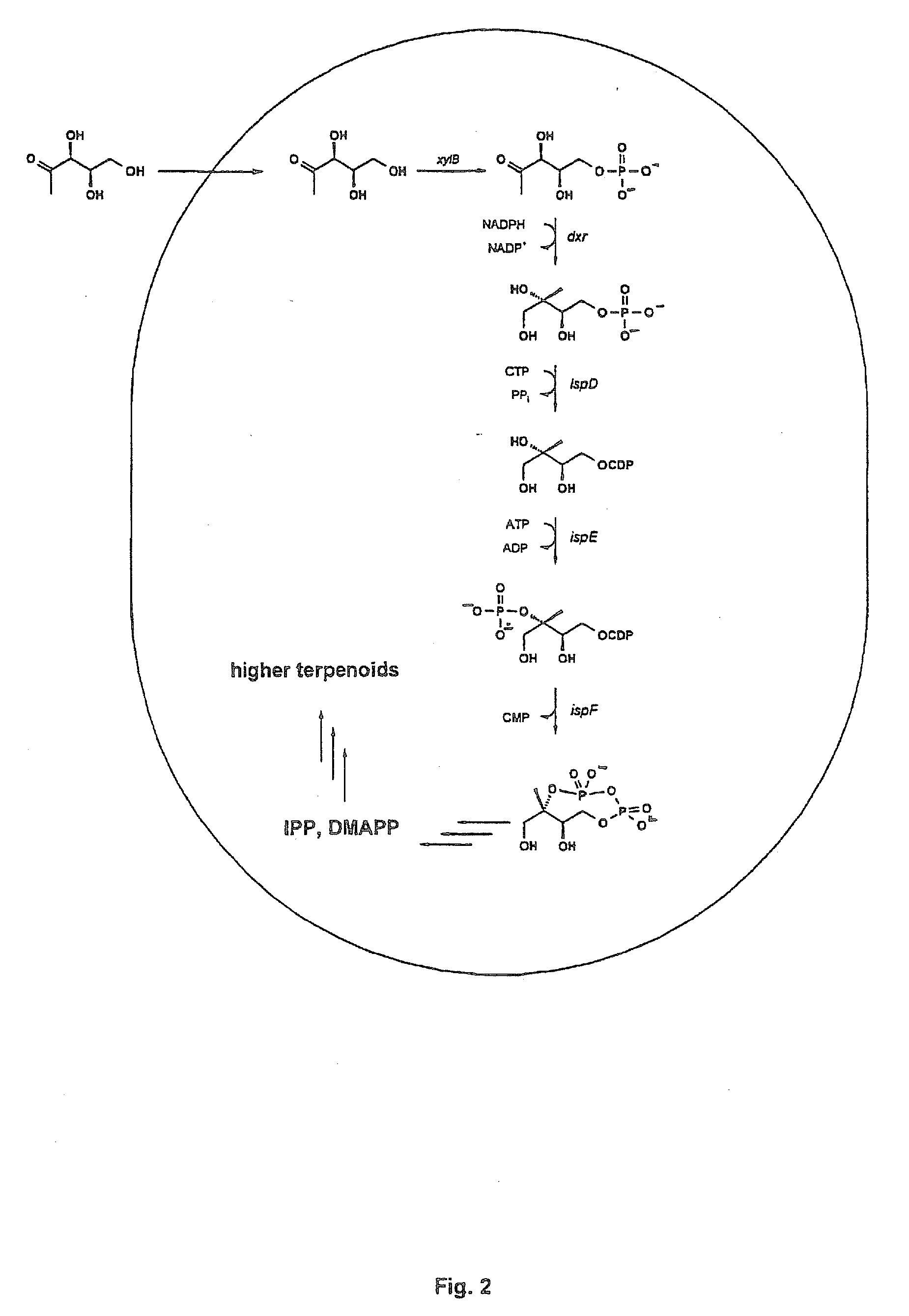

Intermediates and enzymes of the non-mevalonate isoprenoid pathway

The invention provides a protein in a form that is functional for the enzymatic conversion of 2C-methyl-D-erythritol 2,4-cyclodiphosphate to 1-hydroxy-2-methyl-2-butenyl 4-diphosphate notably in its (E)-form of the non-mevalonate biosynthetic pathway to isoprenoids. The invention also provides a protein in a form that is functional for the enzymatic conversion of 1-hydroxy-2-methyl-2-butenyl 4-diphosphate, notably in its (E)-form, to isopentenyl diphosphate and / or dimethylallyl diphosphate. Further, screening methods for inhibitors of these proteins are provided. Further, 1-hydroxy-2-methyl-2-butenyl 4-diphosphate is provided and chemical and enzymatic methods of its preparation.

Owner:BACHER ADELBERT +5

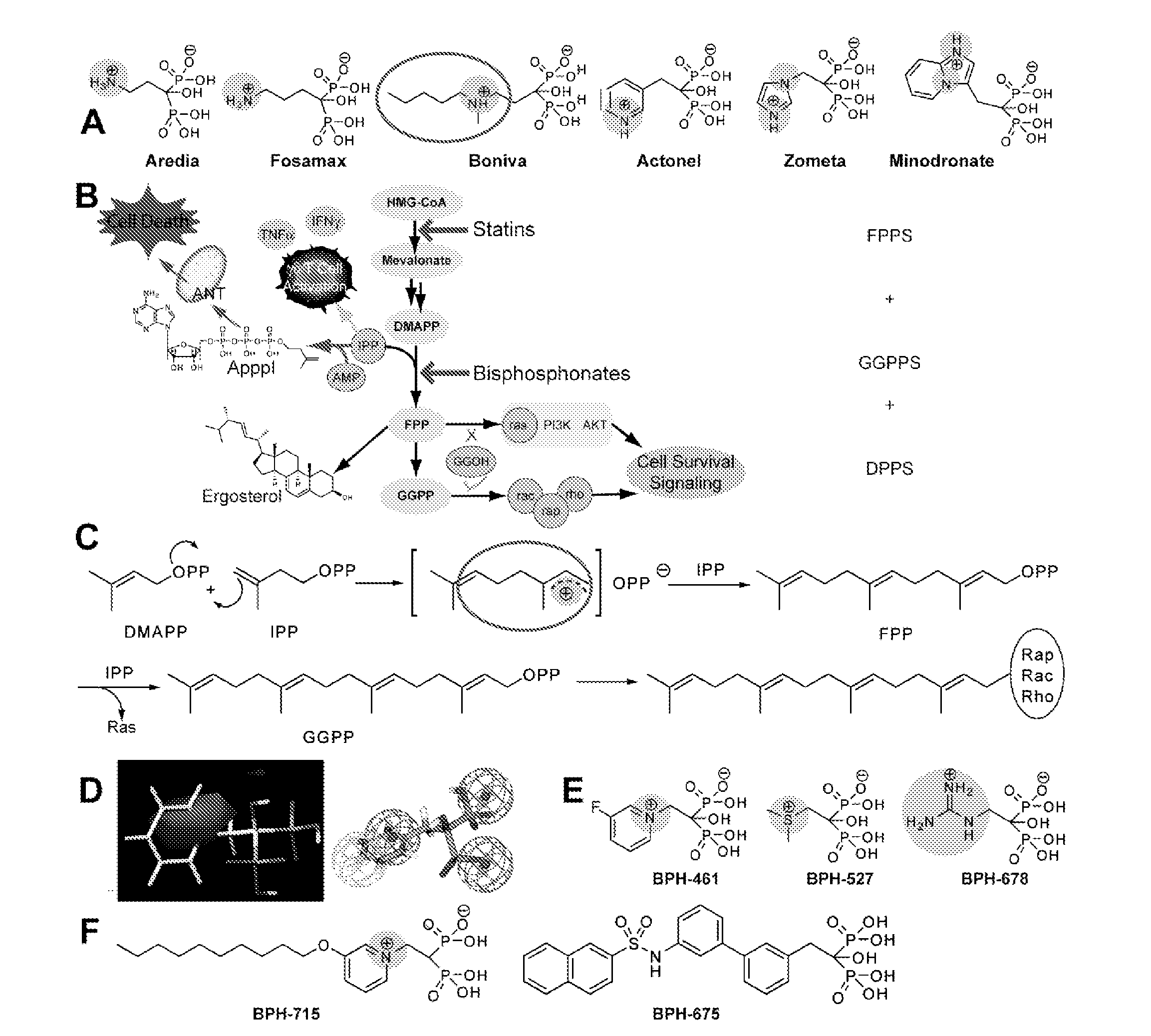

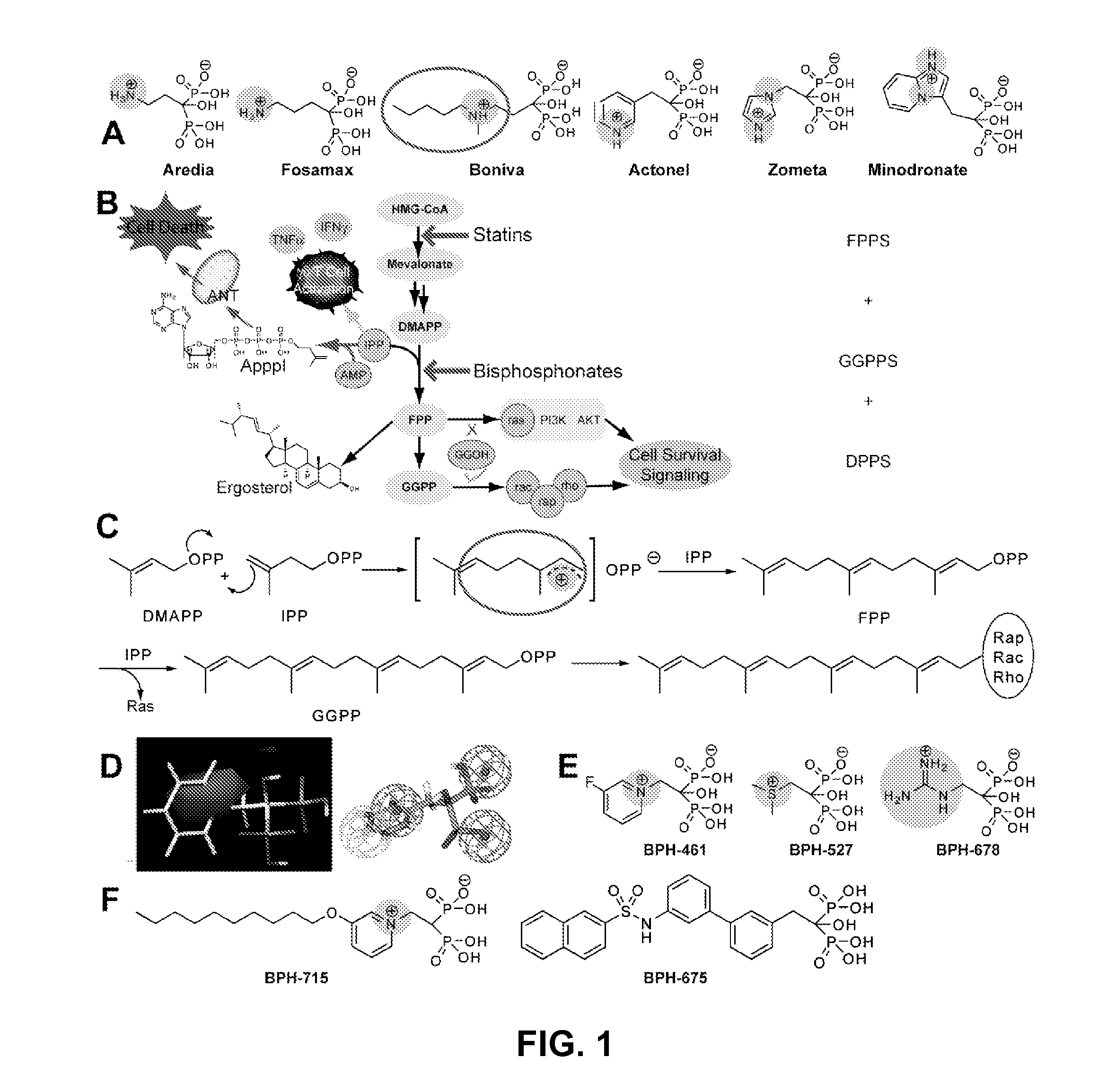

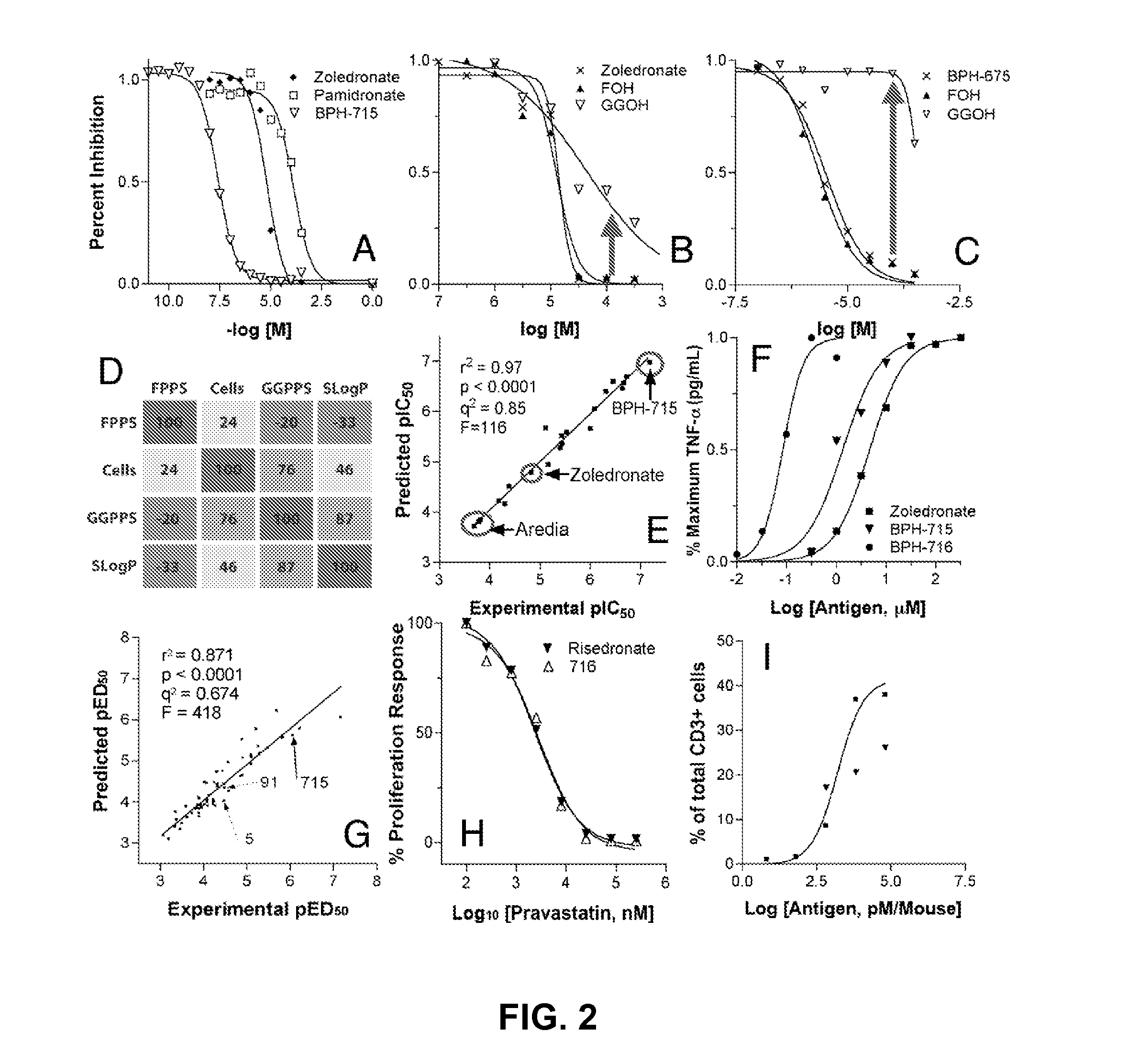

Bisphosphonate Compounds and Methods with Enhanced Potency for Multiple Targets including FPPS, GGPPS, AND DPPS

InactiveUS20080255070A1High activityGood effectBiocideMicrobiological testing/measurementCancer cellDiphosphonates

The disclosure provides, inter alia, novel bisphosphonate compounds and methods of making and using such compounds. In certain embodiments, compounds of the invention include bisphosphonates that are capable of selectively inhibiting one or more of farnesyl diphosphate synthase (FPPS), geranylgeranyl diphosphate synthase (GGPPS), and decaprenyl pyrophosphate synthase (DPPS). In preferred embodiments, compounds of the invention are capable of selectively inhibiting two or more of FPPS, GGPPS, and DPPS. In embodiments, compounds and methods of the invention demonstrate superior activity levels, such as in the anti-cancer context, immunostimulation context, and other contexts, which in several cases exceed the activity levels of previous generation bisphosphonate drugs by orders of magnitude. In embodiments, the invention provides compounds and methods in connection with research and therapeutic applications, e.g., for tumor or cancer cell growth inhibition, activation of gammadelta T cells, inhibition of certain enzymes related to the mevalonate metabolic pathway, bone resorption diseases, cancer, immune disorders, immunotherapy, and infectious diseases.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method for sensitizing cancer cells to cancer therapies with a mevalonate-reducing compound

The present invention provides a pharmaceutical kit useful for treating cancer cells in a mammal. Using this kit, the cancer cells are first sensitized by administering to the mammal an agent which comprises an effective amount of a HMG-CoA reductase inhibitor. The sensitized cancer cells are then treated with an anti-cancer agent which reduces the survival or growth of the cancer cells.

Owner:SHIAO MING SHI

Treatment of hyperproliferative, inflammatory and related mucocutaneous disorders using inhibitors of mevalonate synthesis and metabolism

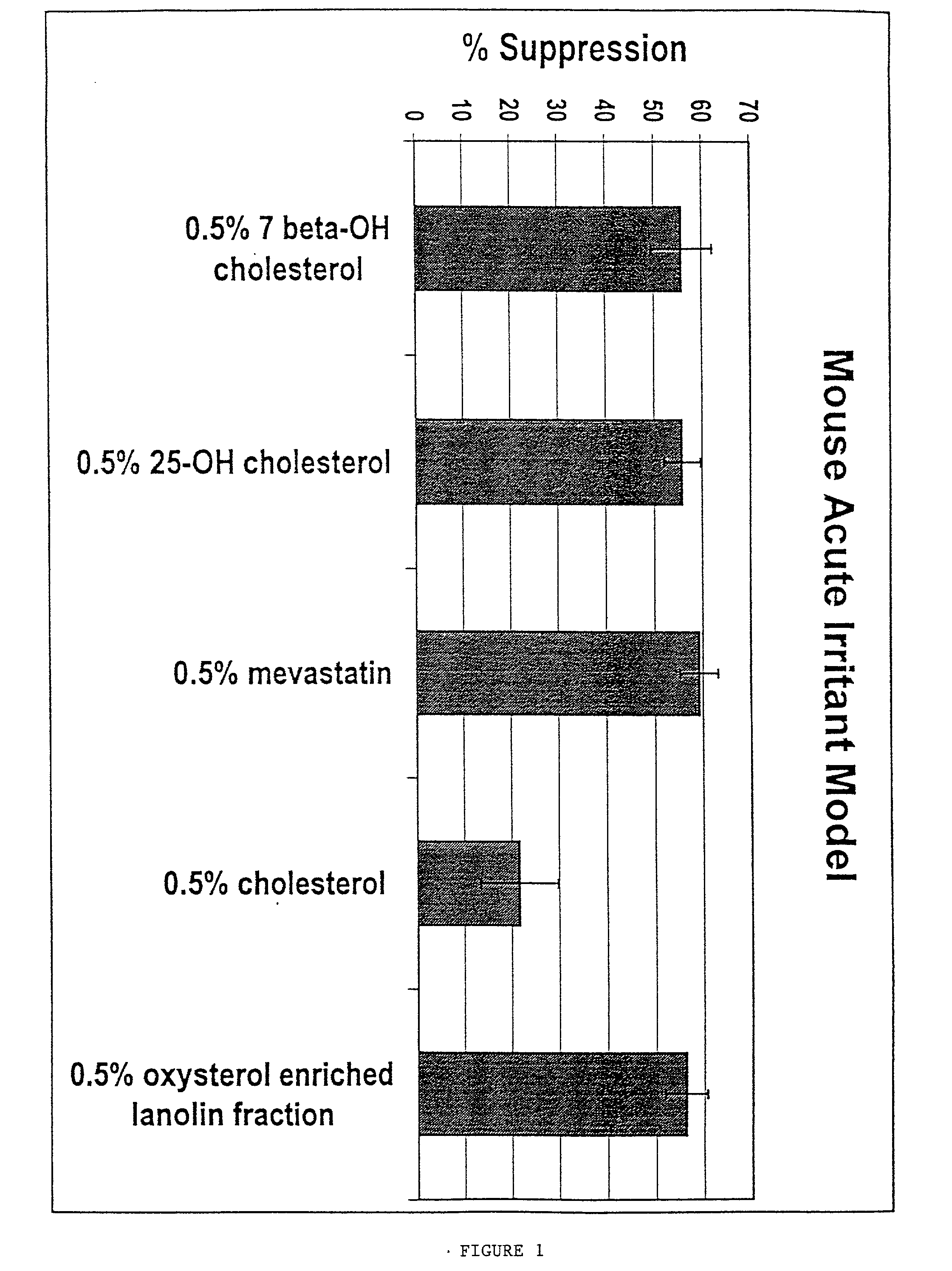

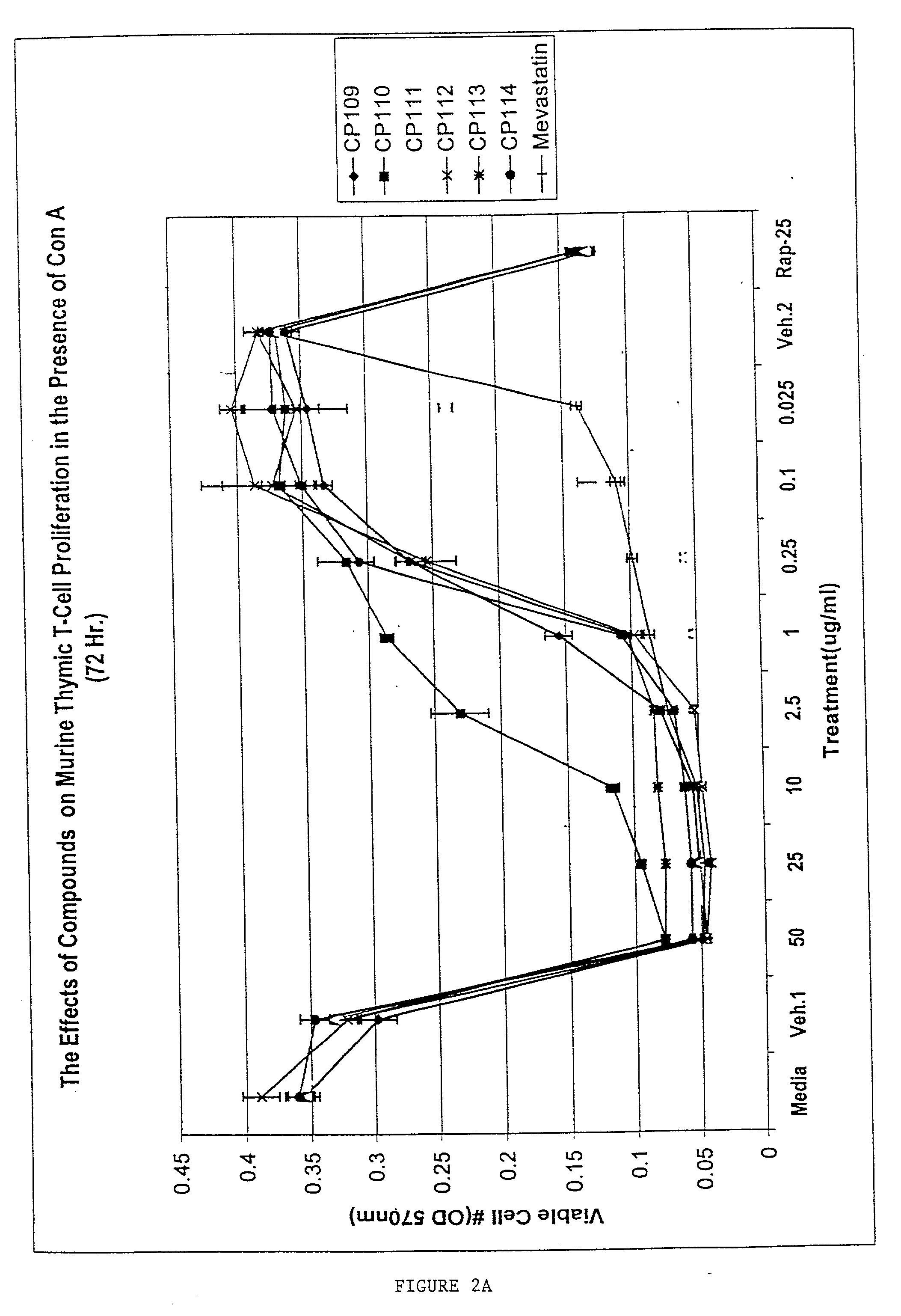

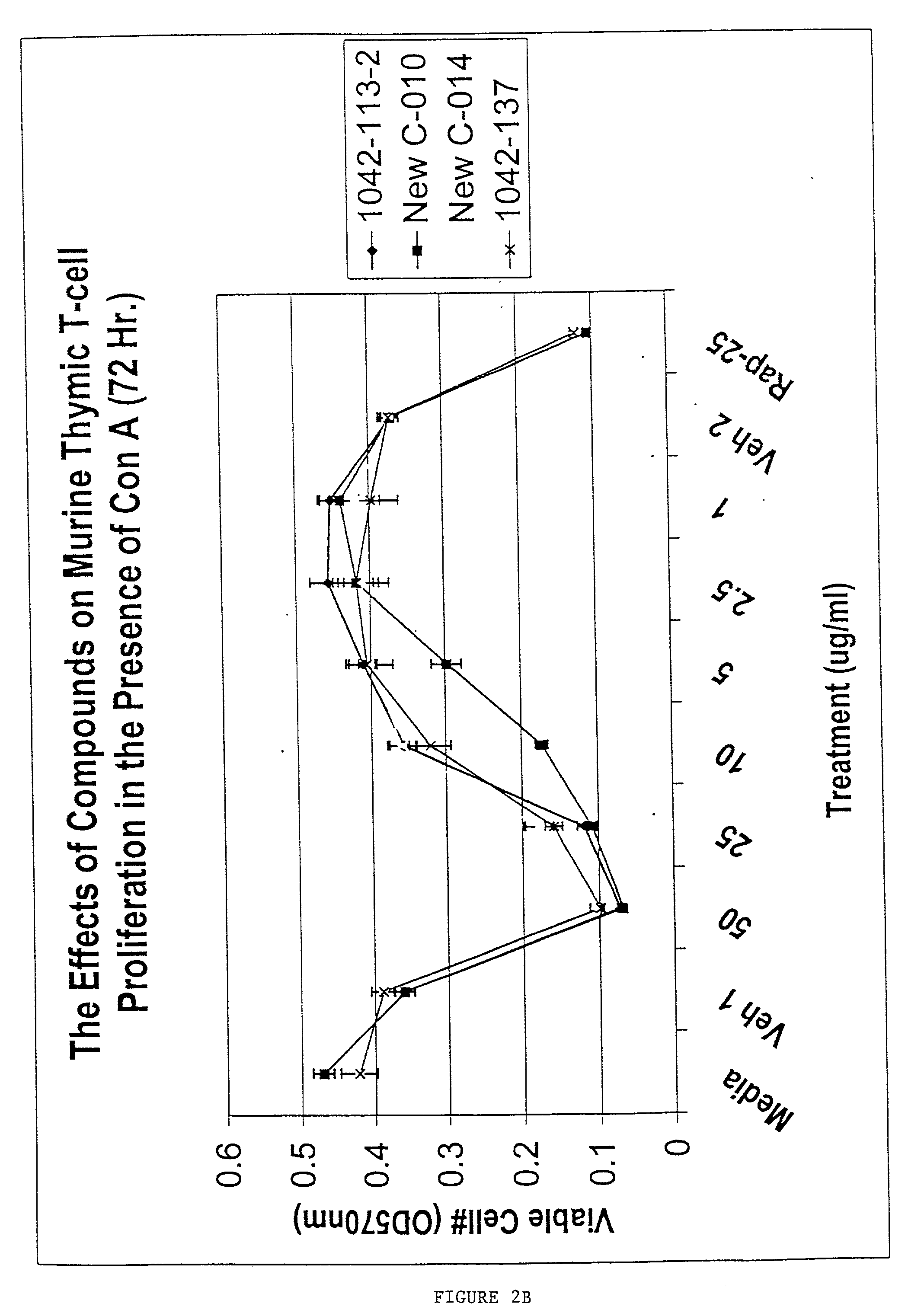

InactiveUS20020010128A1Inhibit cell proliferationInhibit expressionCosmetic preparationsBiocideSquamous CarcinomasAntiinflammatory drug

The present invention provides methods for treating a variety of hyperproliferative and inflammatory mucocutaneous disorders, including, basal cell carcinoma, squamous cell carcinoma, psoriasis and atopic dermatitis, as well as skin irritation and disorders associated with skin aging and skin photodamage using inhibitors of cholesterol metabolism. The present invention further relates to the discovery that the combined use of several inhibitors of cholesterol metabolism produces synergistic effects. Furthermore, the present invention is directed to the use of inhibitors of cholesterol metabolism as excipients to enhance the effects of antiinflammatory drugs.

Owner:CELLEGY PHARMACEUTICALS INC

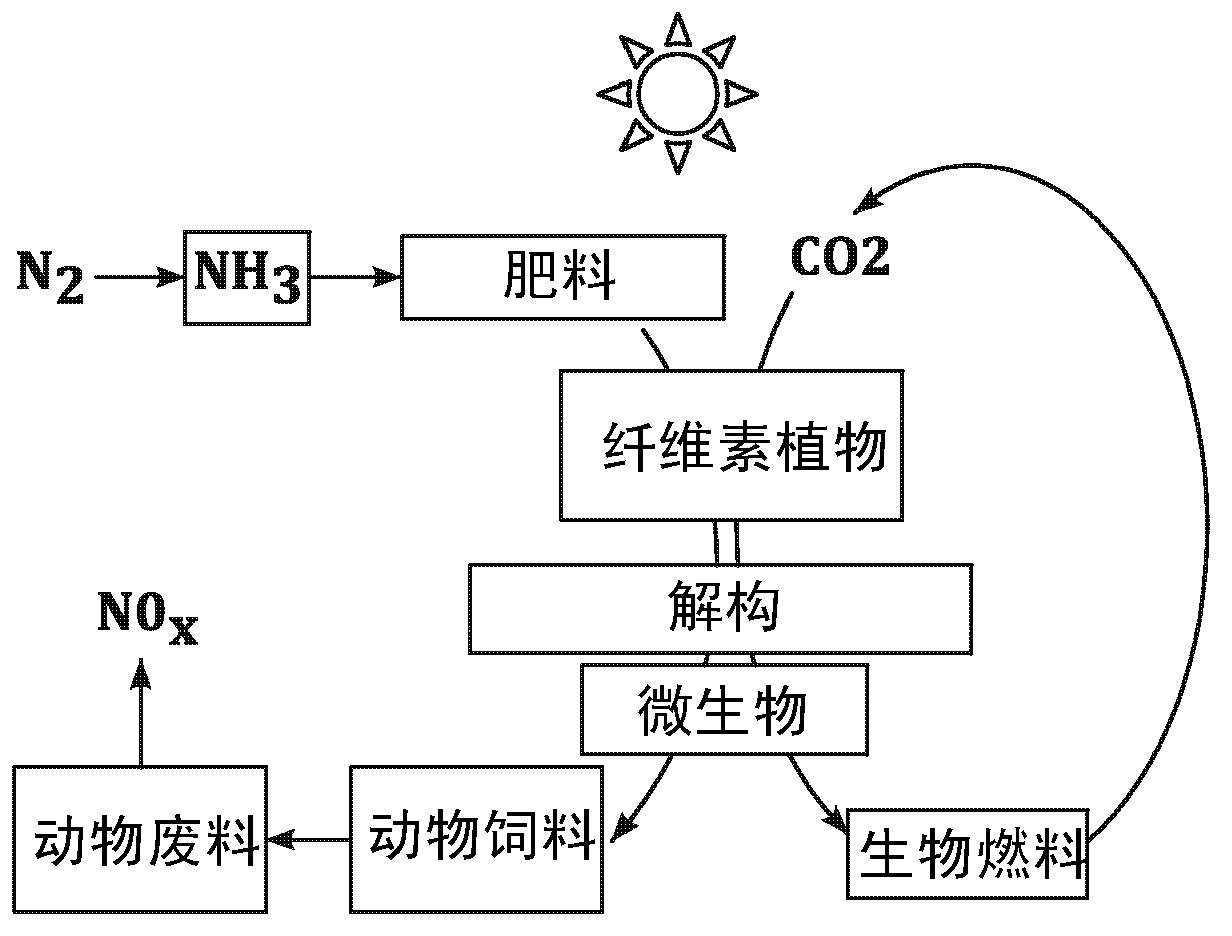

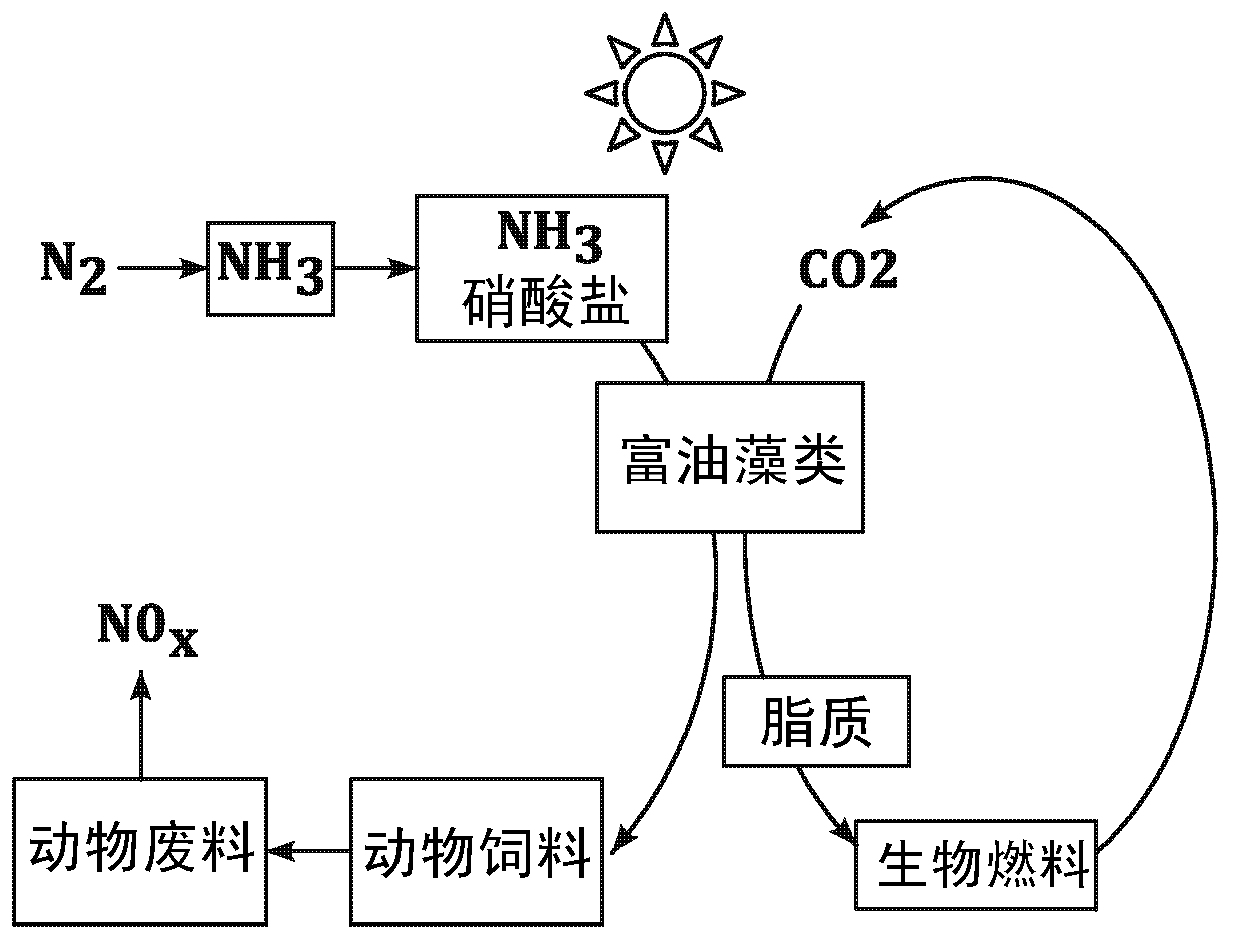

Biofuel and chemical production by recombinant microorganisms via fermentation of proteinacious biomass

Provided herein are metabolically modified microorganisms characterized by having an increased keto-acid flux when compared with the wild-type organism and comprising at least one polynucleotide encoding an enzyme, and causing the production of a greater quantity of a chemical product when compared with the wild-type organism. The recombinant microorganisms are useful for producing a large number of chemical compositions from various nitrogen containing biomass compositions and other carbon sources. More specifically, provided herein are methods of producing alcohols, acetaldehyde, acetate, isobutyraldehyde, isobutyric acid, n- butyraldehyde, n-butyric acid, 2-methyl-l-butyraldehyde, 2-methyl-l -butyric acid, 3- methyl-l-butyraldehyde, 3 -methyl- 1 -butyric acid, ammonia, ammonium, amino acids, 2,3-butanediol, 1,4-butanediol, 2-methyl-l, 4-butanediol, 2-methyl- 1,4-butanediamine, isobutene, itaconate, acetoin, acetone, isobutene, 1,5-diaminopentane, L-lactic acid, D- lactic acid, shikimic acid, mevalonate, polyhydroxybutyrate (PHB), isoprenoids, fatty acids, homoalanine, 4-aminobutyric acid (GABA), succinic acid, malic acid, citric acid, adipic acid, p-hydroxy-cinnamic acid, tetrahydrofuran, 3-methyl-tetrahydrofuran, gamma-butyrolactone, pyrrolidinone, n-methylpyrrolidone, aspartic acid, lysine, cadeverine, 2-ketoadipic acid, and / or S-adenosyl-methionine (SAM), from a suitable nitrogen rich biomass.

Owner:RGT UNIV OF CALIFORNIA

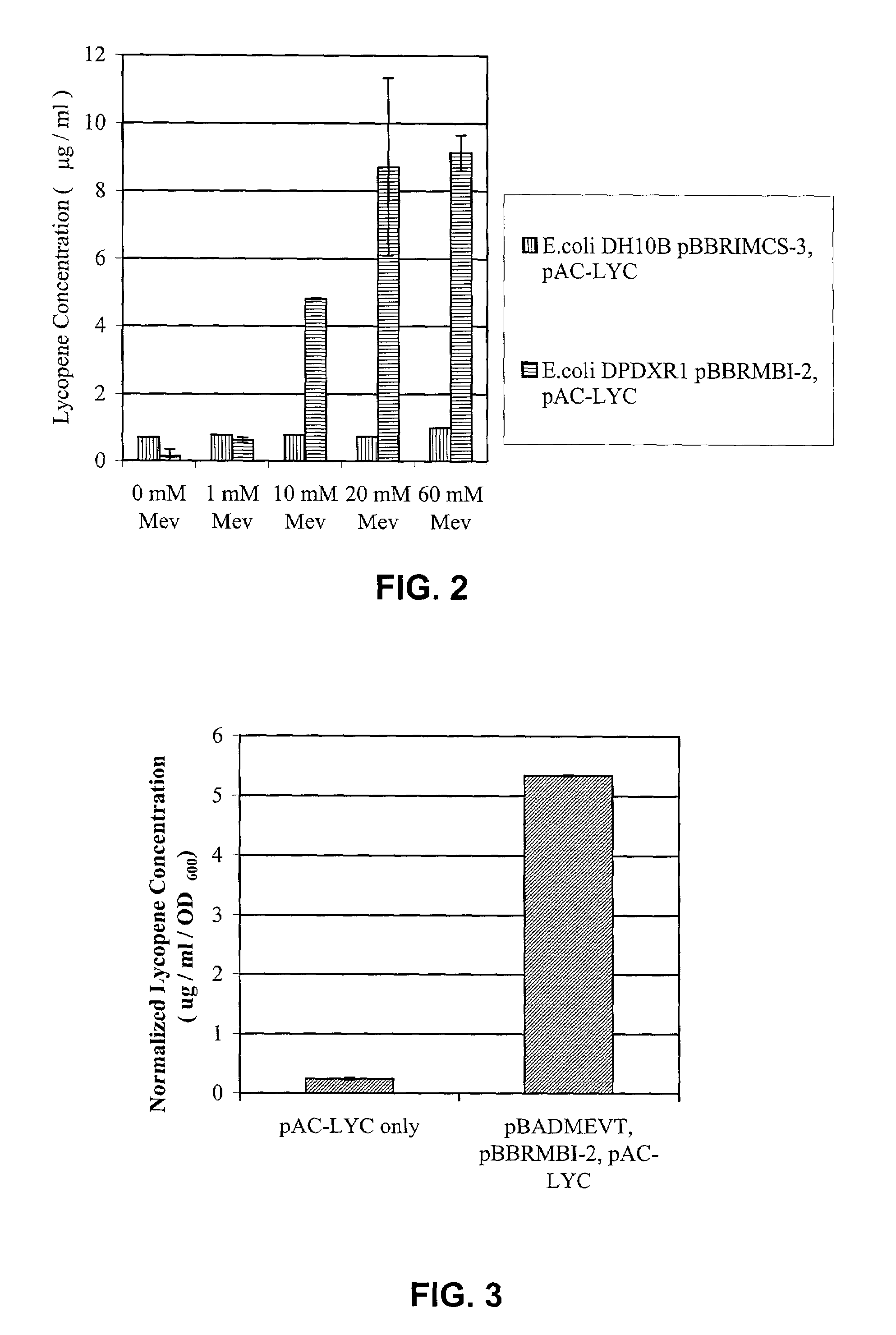

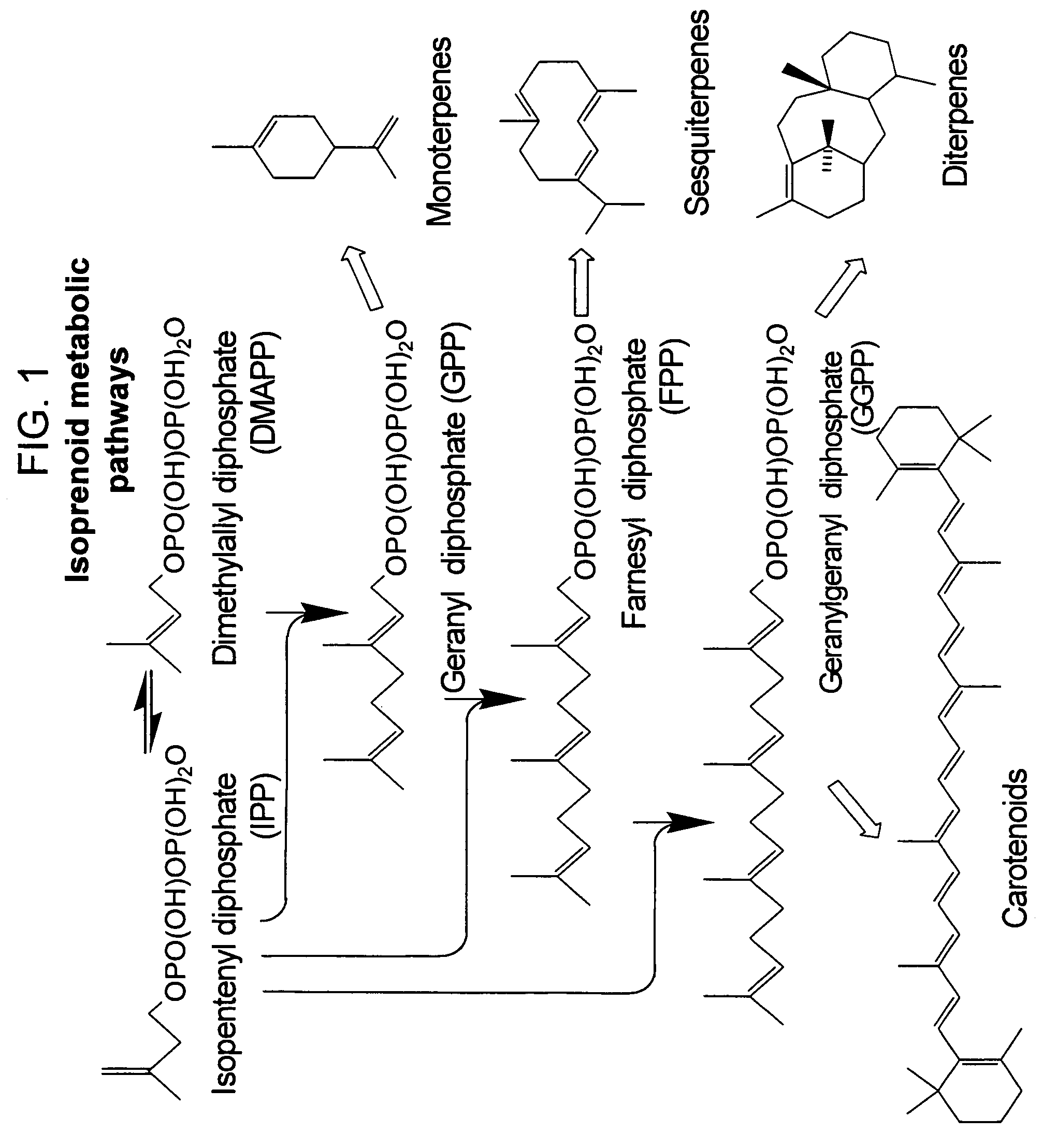

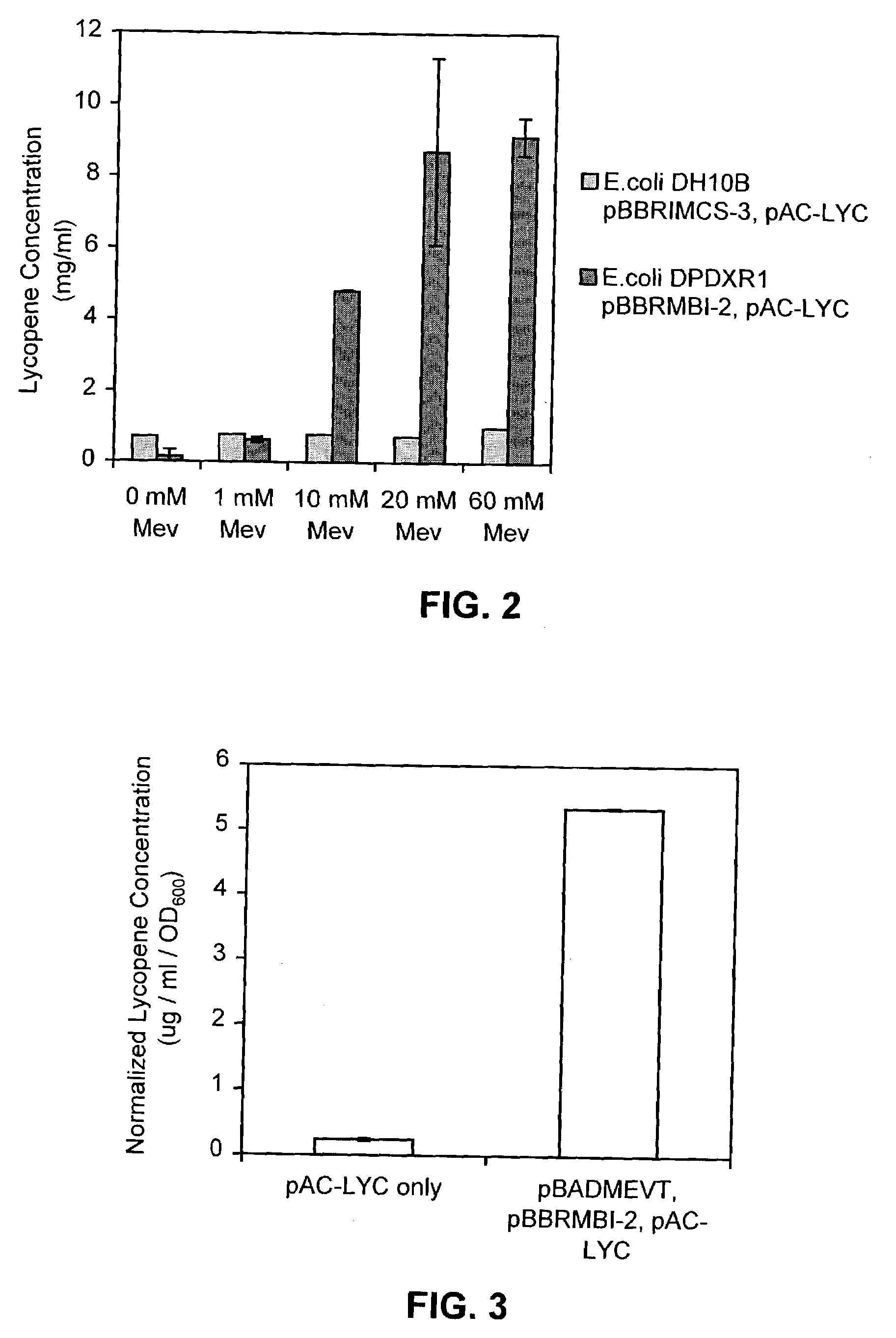

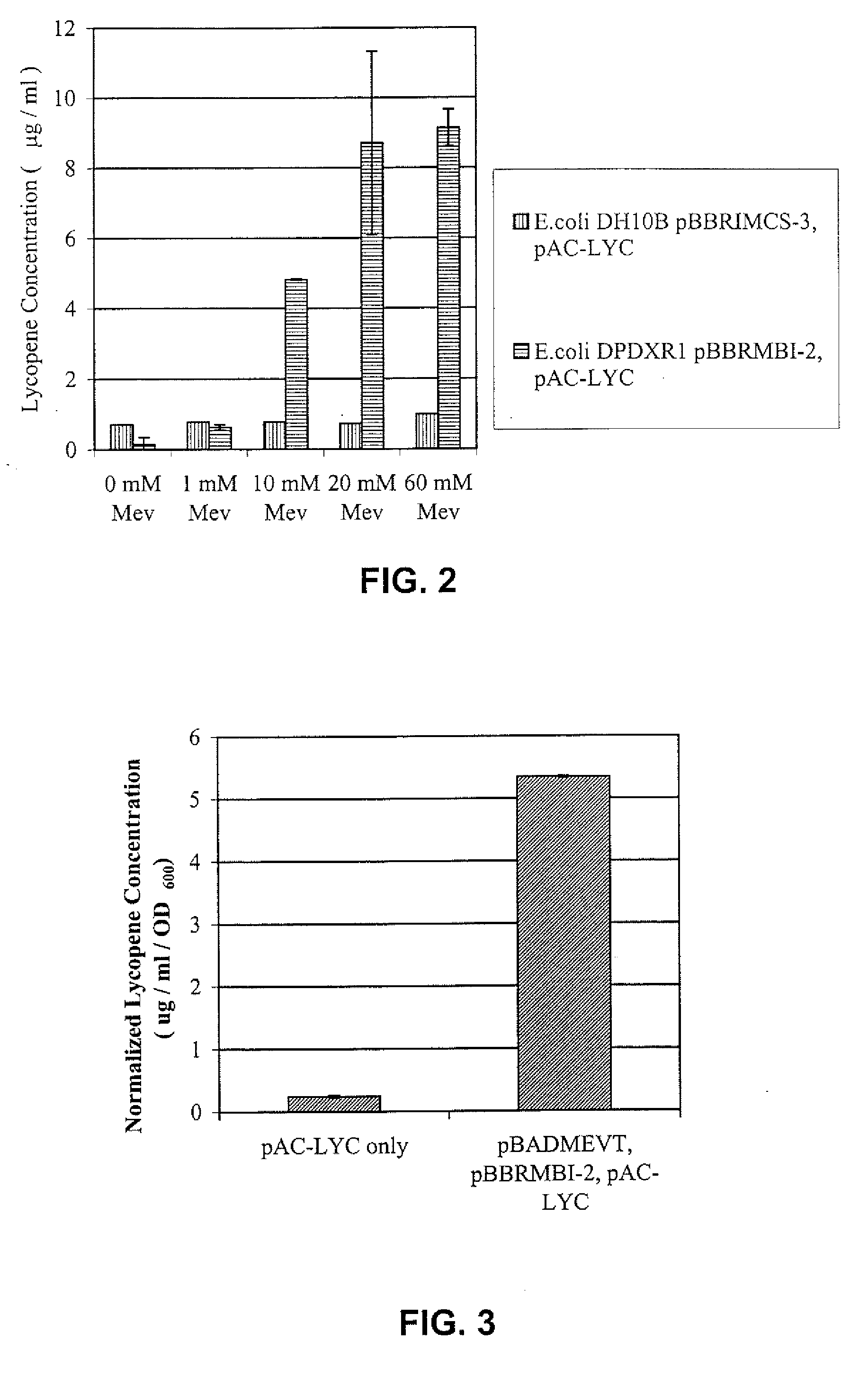

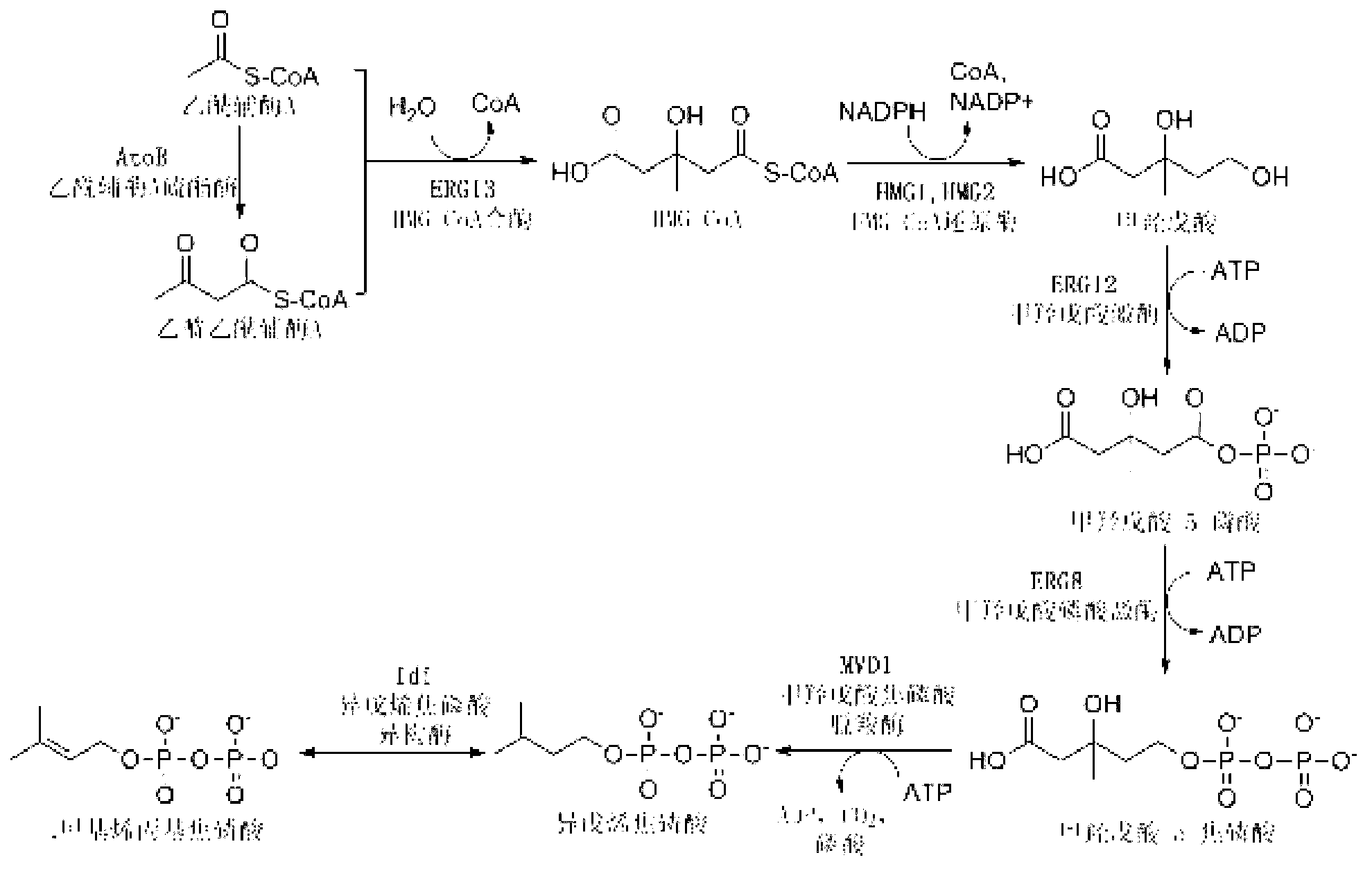

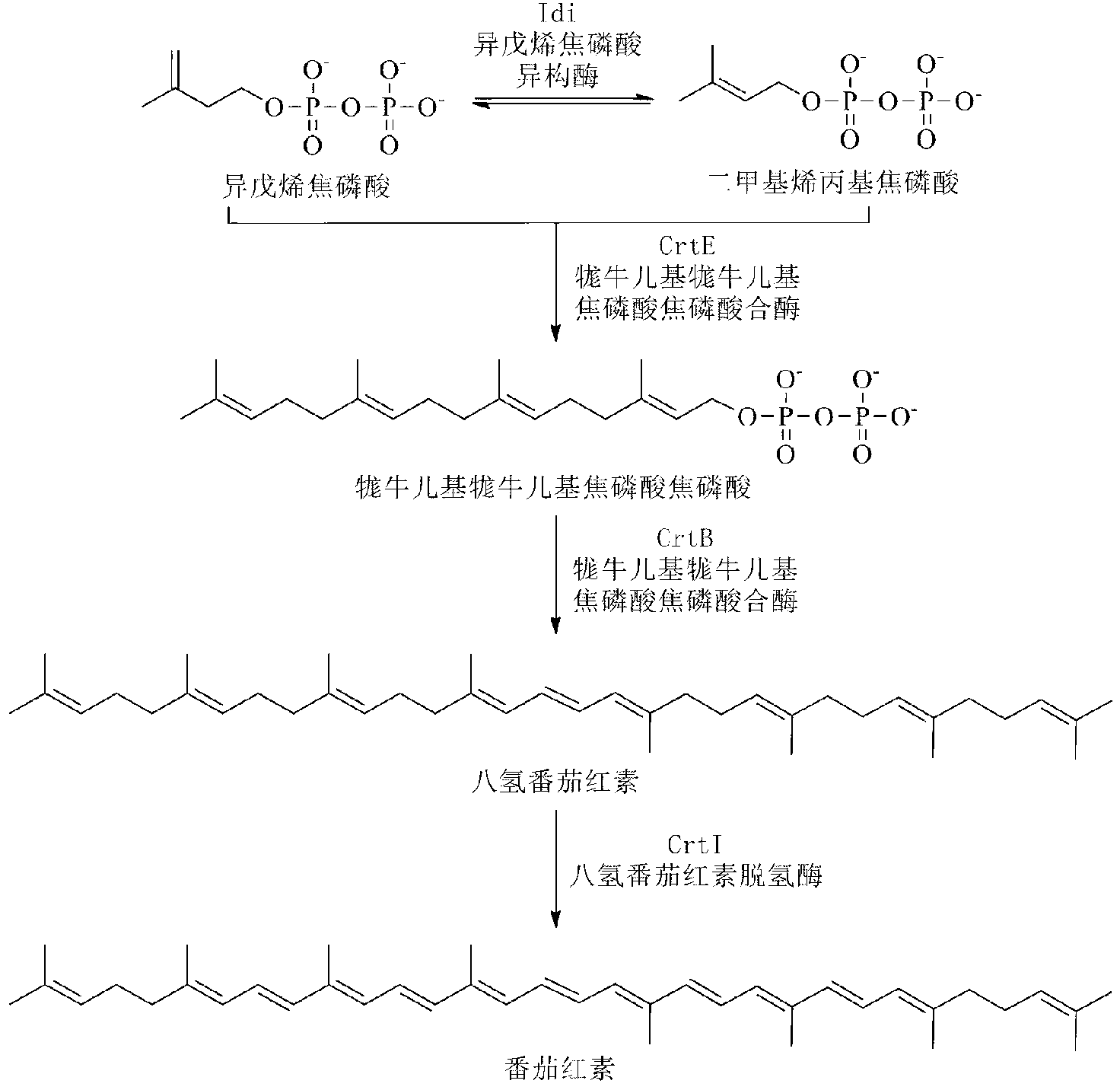

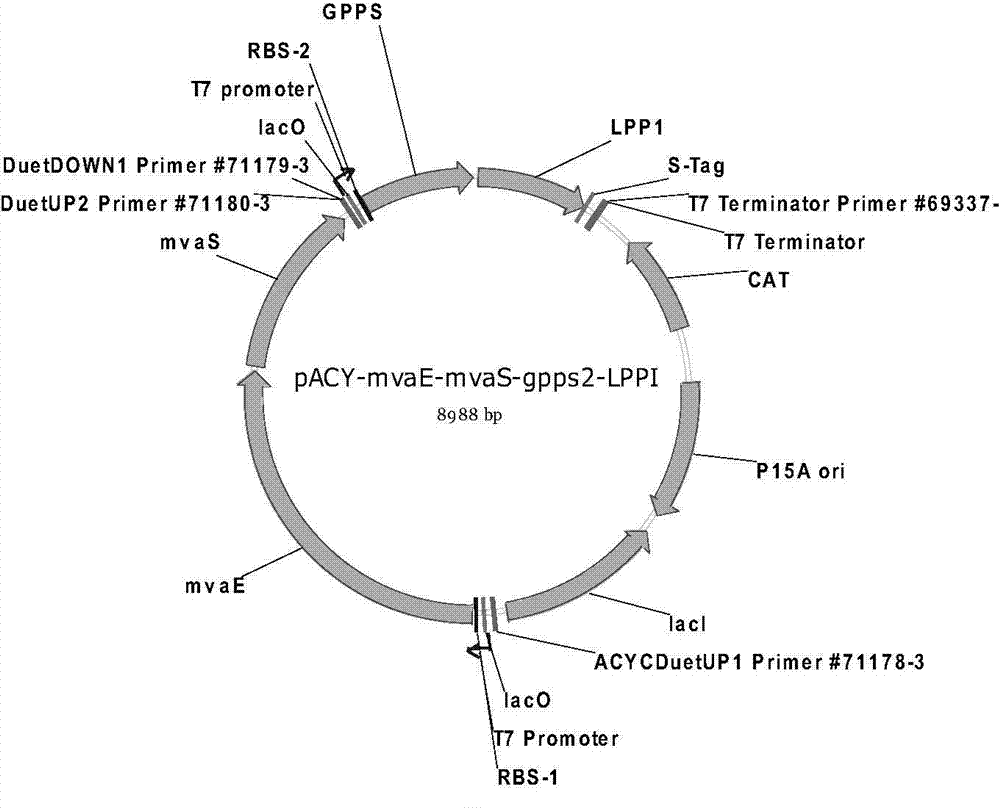

Bacterial strain for producing lycopene and application of bacterial strain

ActiveCN103243066AImprove the ability to produce lycopeneIncrease productionBacteriaMicroorganism based processesLycopene synthesisBacterial strain

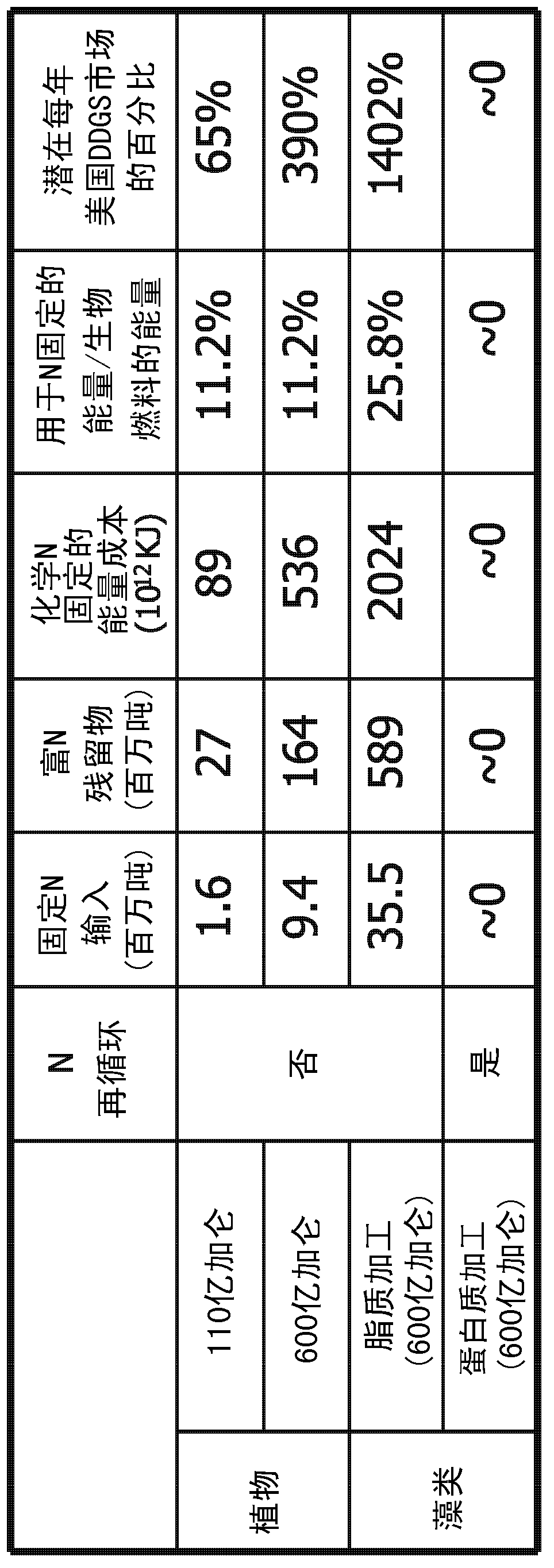

The invention discloses a bacterial strain for producing lycopene and an application of the bacterial strain, and belongs to the field of synthetic biology. The bacterial strain for producing lycopene contains a mevalonate pathway and a related gene which is synthetized by the lycopene optimized by a codon; and the synthetic gene sequence of the lycopene optimized by the codon is shown in SEQ ID NO.1-3. The bacterial strain can be used for producing the lycopene; and a seed solution of the bacterial strain is inoculated into a culture medium containing a carbon source to carry out prokaryotic expression, so as to obtain the lycopene. The gene synthetized by the lycopene is optimized by the codon or each protein of the mevalonate pathway is closer to A to B:ERG13:tHMG1:ERG12:ERG8:MVD1:Idi=1:10:2:5:5:2:5; and production of the lycopene can be further promoted. By adopting the bacterial strain, the yield of the lycopene can be greatly improved to over 1g / L; and the fermentation cycle is shortened by over 50%.

Owner:WUHAN UNIV

Compositions containing HMG Co-A reductase inhibitors and policosanol

InactiveUS6890941B1Lowering of total serum cholesterol levelInhibiting cholesterol synthesisBiocideHydroxy compound active ingredientsLipid storageElevated serum cholesterol

The present invention provides pharmaceutical compositions, methods, combinations, and kits for treating a disorder related to elevated serum cholesterol concentration, for example, hypercholesterolemia, atherosclerosis, elevated LDL plasma levels, low HDL plasma levels, hypertriglyceridemia, hyperlipidemia, hypertension, cholesterol gallstones, and lipid storage diseases. The compositions, methods, combinations, and kits of the present invention are pharmaceutical compositions comprising atherapeutically effective amount of a lipid regulating agent, such as a HMG-CoA reductase inhibitor, and compound that inhibits cholesterol synthesis at a point between the formation of acetate and mevalonate. A typical pharmaceutical composition of the invention contains and effective amount of atorvastatin and an effective amount of policosanol.

Owner:PROCAPS

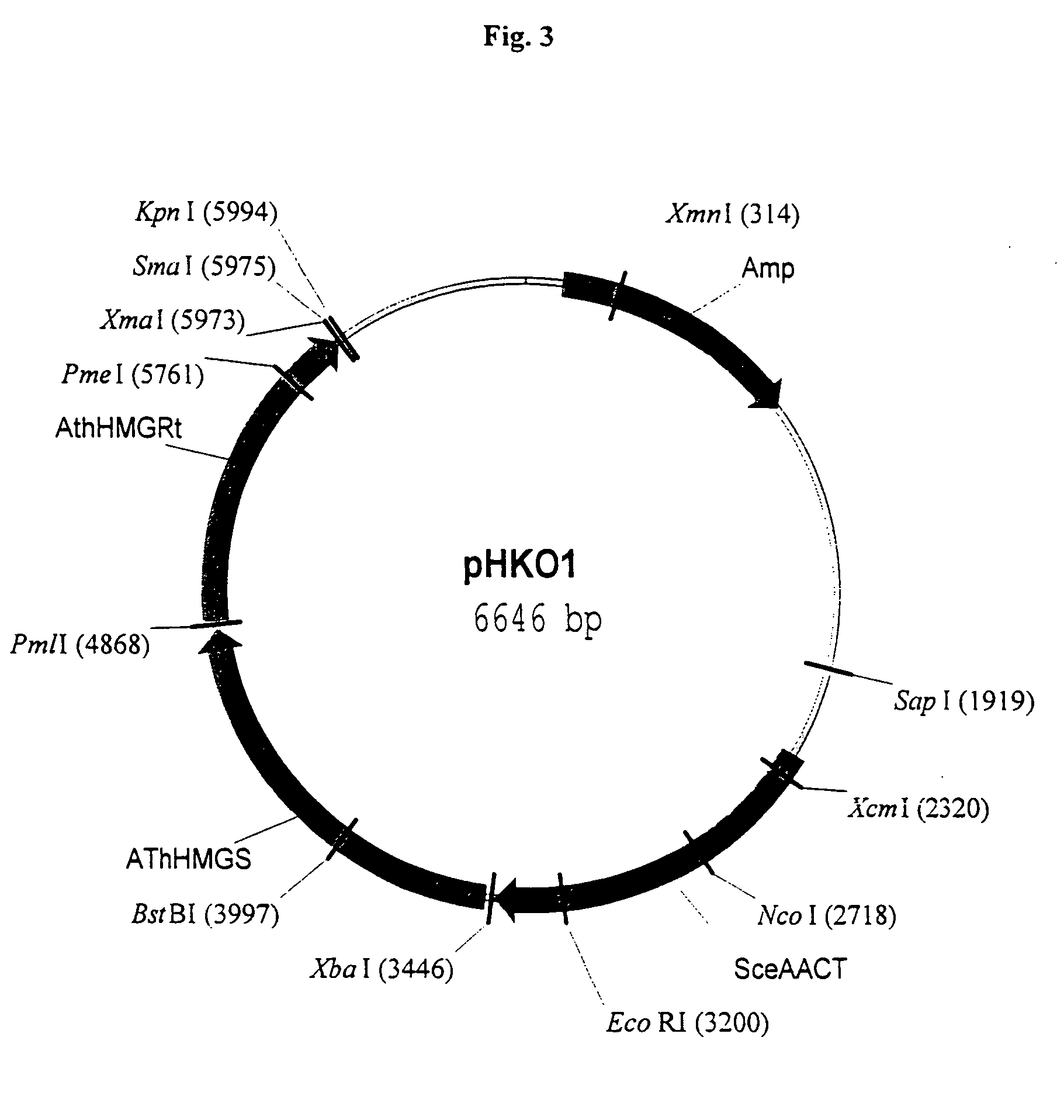

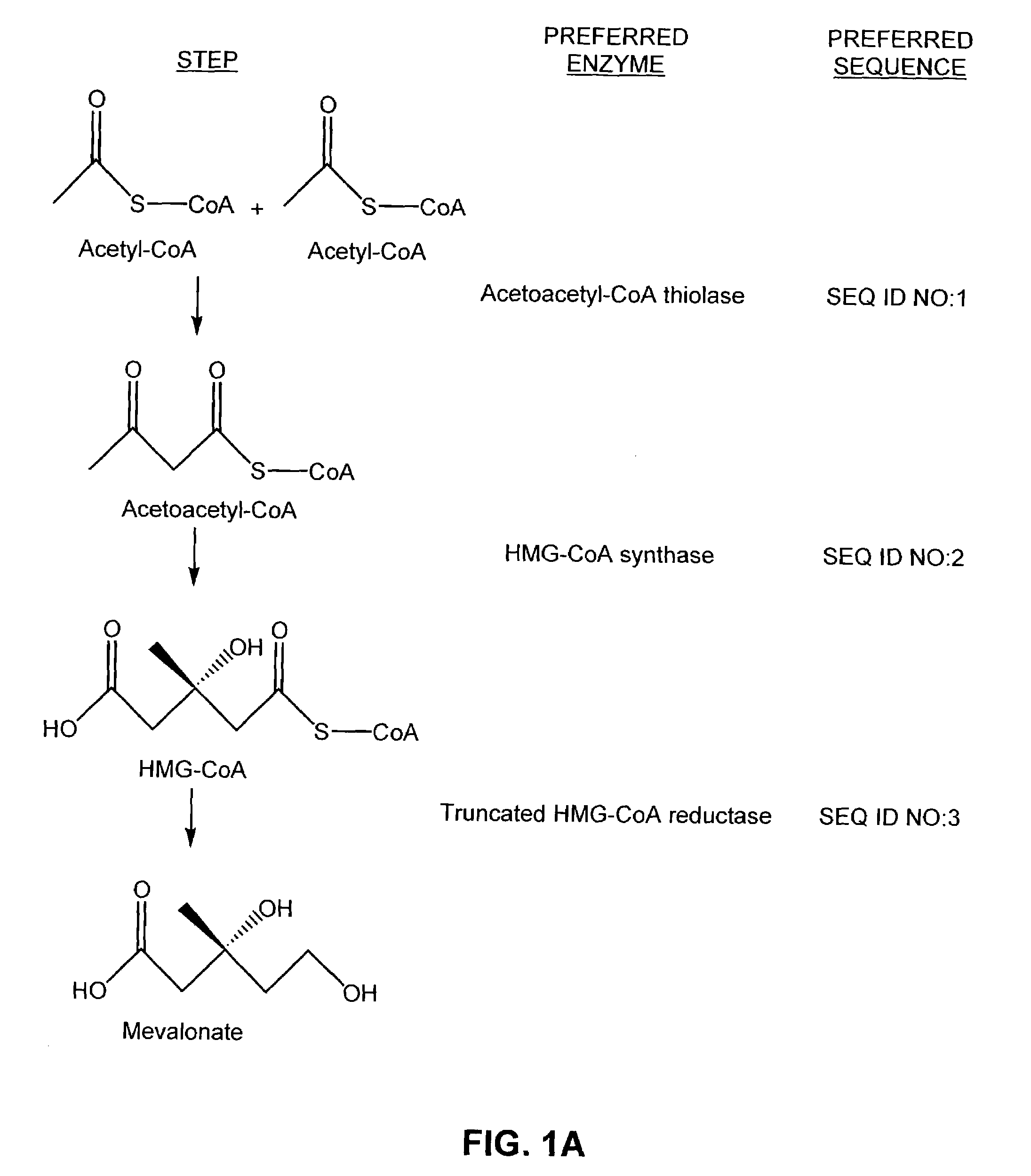

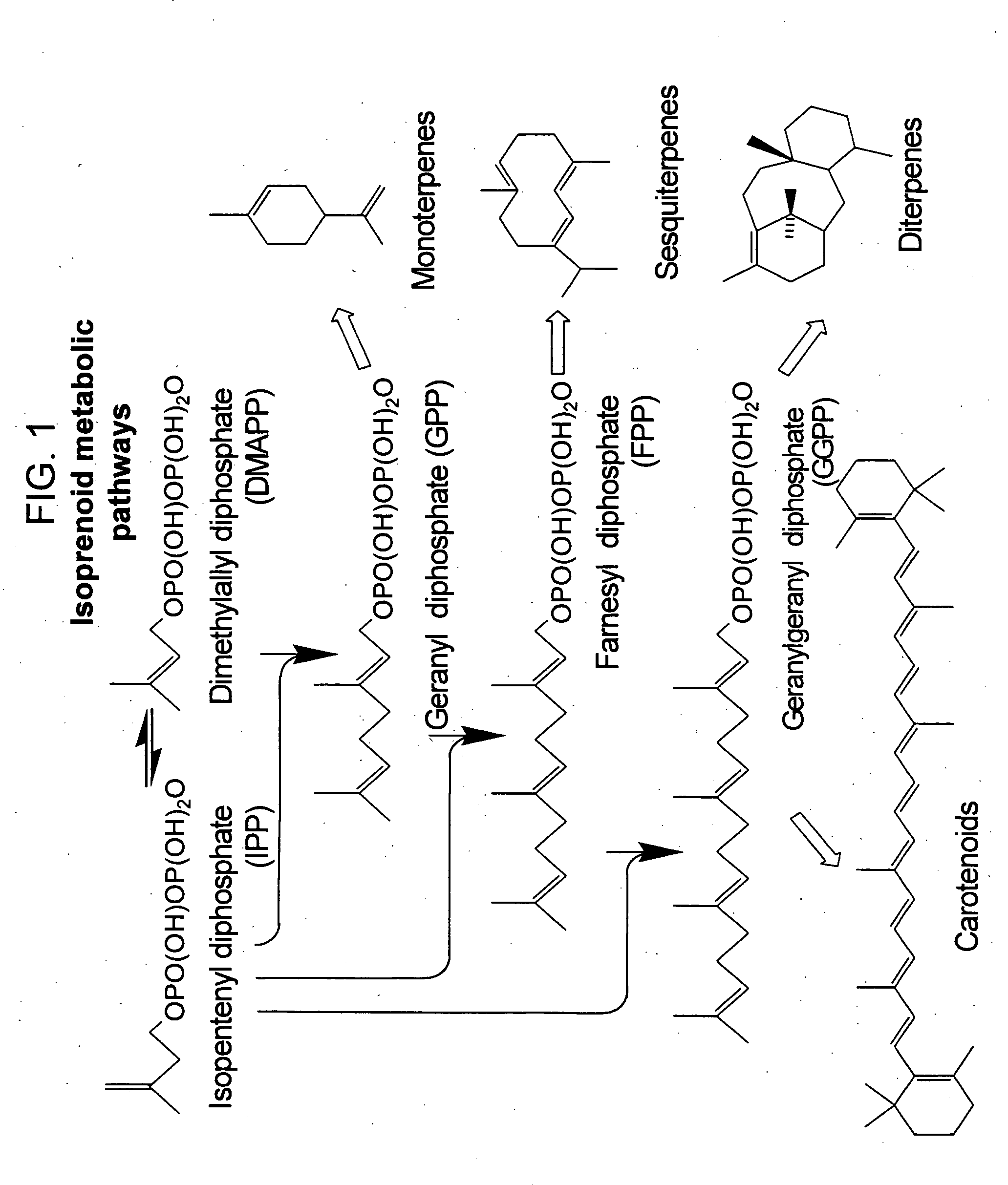

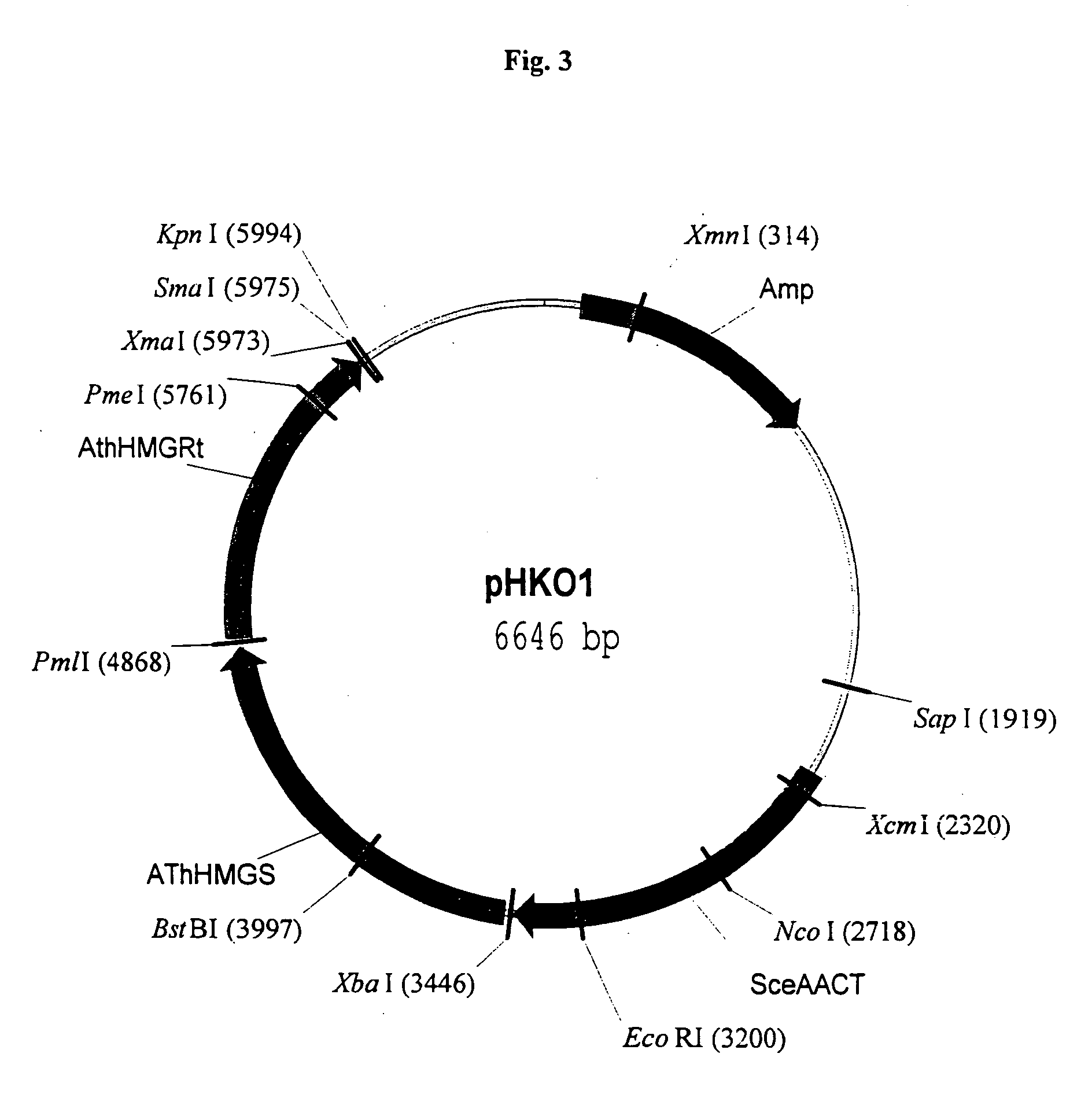

Manipulation of genes of the mevalonate and isoprenoid pathways to create novel traits in transgenic organisms

InactiveUS20050241017A1Other foreign material introduction processesIsomerasesOpen reading frameNucleotide

Disclosed are the uses of specific genes of the mevalonate and isoprenoid biosynthetic pathways, and of inactive gene sites (the pseudogene) to (1) enhance biosynthesis of isopentenyl diphosphate, dimethylallyl diphosphate and isoprenoid pathway derived products in the plastids of transgenic plants and microalgae, (2) create novel antibiotic resistant transgenic plants and microalgae, and (3) create a novel selection system and / or targeting sites for mediating the insertion of genetic material into plant and microalgae plastids. The specific polynucleotides to be used, solely or in any combination thereof, are publicly available from GeneBank and contain open reading frames having sequences that upon expression will produce active proteins with the following enzyme activities: (a) acetoacetyl CoA thiolase (EC 2.3.1.9), (b) 3-hydroxy-3-methylglutaryl-coenzyme A (HMG-CoA) synthase (EC 4.1.3.5), (c) HMG-CoA reductase (EC 1.1.1.34), (d) mevalonate kinase (EC 2.7.1.36), (e) phosphomevalonate kinase (EC 2.7.4.2), (f) mevalonate diphosphate decarboxylase (EC 4.1.1.33), (g) isopentenyl diphosphate (IPP) isomerase (EC 5.3.3.2), and (h) phytoene synthase (EC 2.5.1.32).

Owner:UNIV OF HAWAII +1

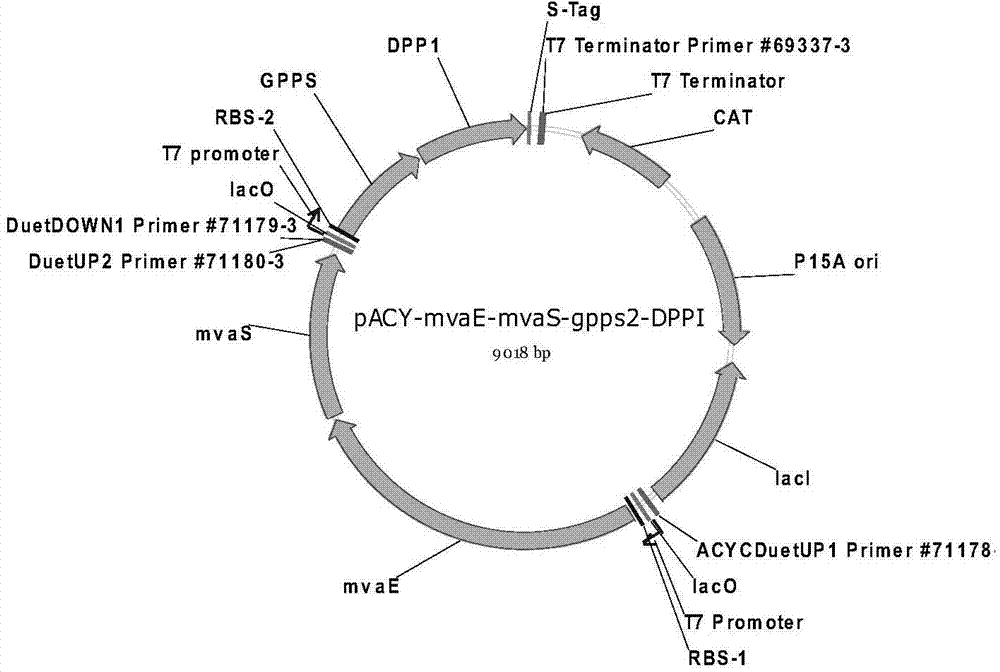

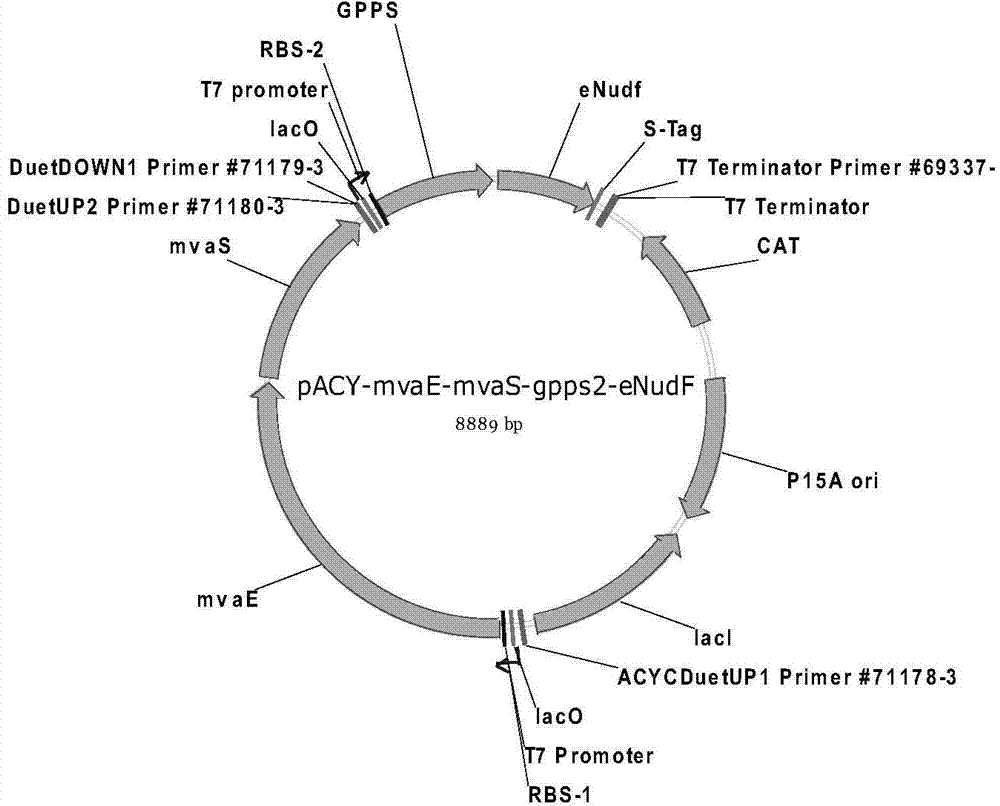

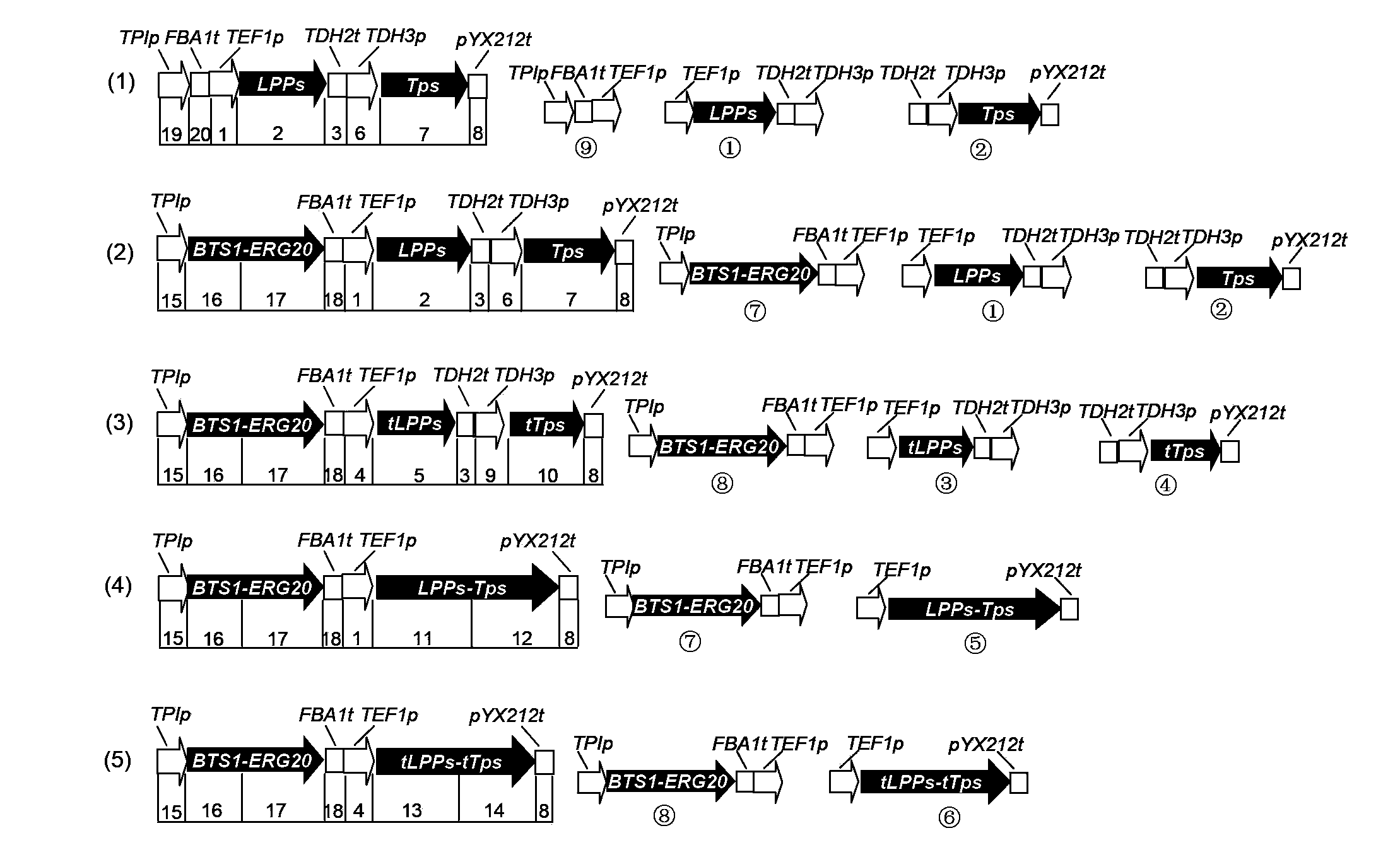

Method for synthesizing alpha-pinene or beta-pinene by adopting biological process

InactiveCN104120148AFast growthShort fermentation cycleBacteriaMicroorganism based processesHydroxy methyl glutarylGlutaryl-coenzyme A

The invention provides a biological method for synthesizing alpha-pinene or beta-pinene from acetyl coenzyme A and a reconstitution cell capable of synthesizing the alpha-pinene or beta-pinene, wherein the acetyl coenzyme A is obtained from a simple starting material like glucose. The method for synthesizing the alpha-pinene or beta-pinene by adopting a biological process comprises the following steps: transferring acetyl coenzyme A acyltransferase, 3-hydroxy-3-methyl glutaryl coenzyme A synthase, hydroxymethyl glutaryl coenzyme A reductase, mevalonic acid kinase, mevalonic acid-5-phosphokinase, mevalonic acid-5-diphosphonic acid decarboxylase, isopentenylpyrophosphate isomerase, geranyldiphosphate synthetase and pinene synthase into an appropriate host cell by adopting metabolic engineering technology, and culturing the obtained reconstitution cell, so that the target product, namely alpha-pinene or beta-pinene can be obtained.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

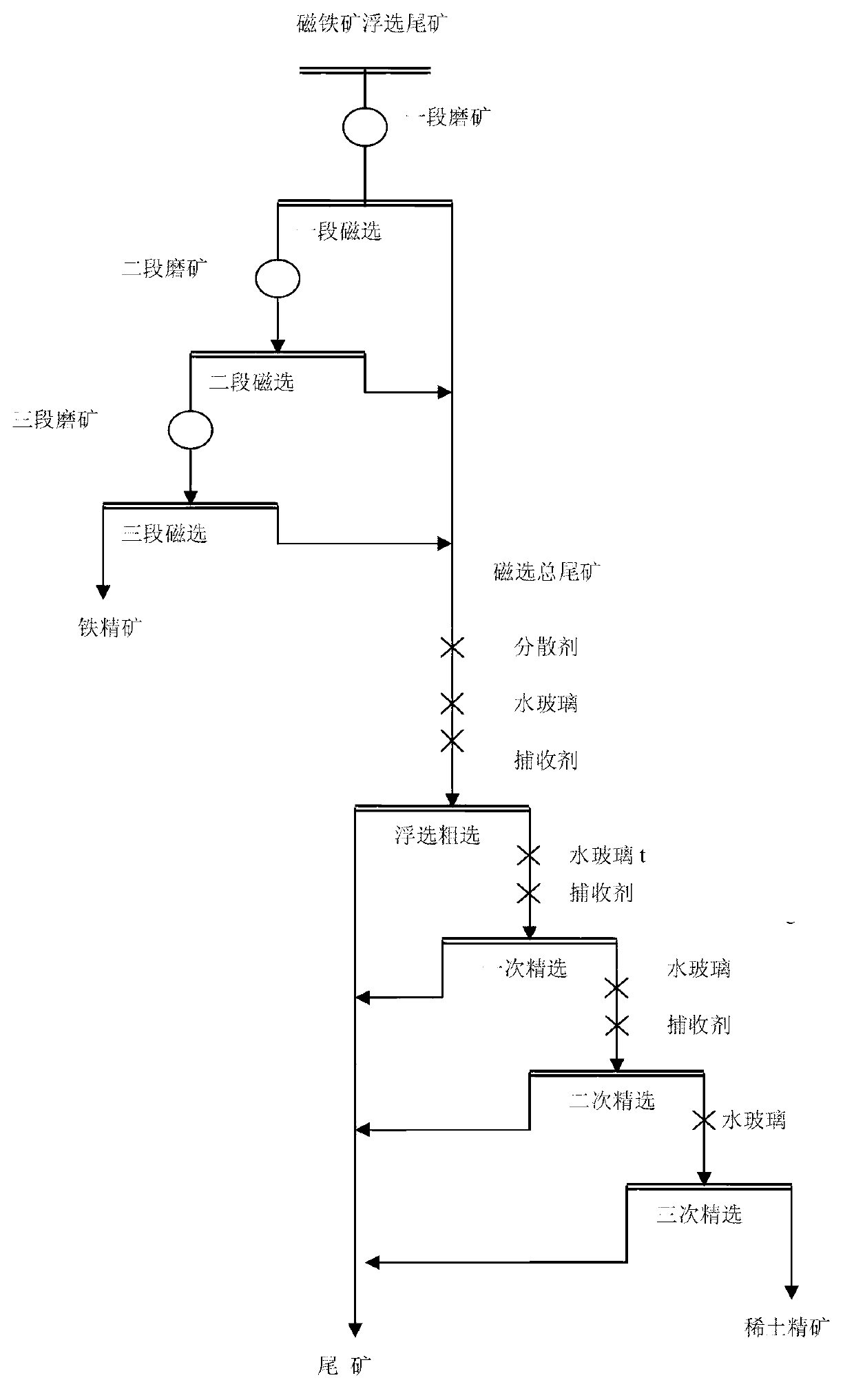

Mineral separation process for recycling iron and rare earth in baotite magnetite flotation tailings

ActiveCN103272698AEffective dissociationRaise the gradeFlotationMagnetic separationMagnetiteMaterials science

The invention belongs to the technical field of mineral engineering, and aims to provide a mineral separation process for recycling iron and rare earth in baotite magnetite flotation tailings. Three sections of ore grinding and three sections of magnetic separation are adopted, and iron ore concentrate which contains more than 63% of iron and has the recycling rate larger than 72% is obtained from the magnetite flotation tailings containing 28%-32% of iron. Then total tailings in an iron recycling process serve as rare earth flotation materials, sodium polyphosphate or sodium hexametaphosphate serves as pulp dispersing agents, 2-hydroxy3-naphthyl mevalonic acid or salicylhydroxami acid and alkyl hydroximic acid in a mass ratio of 6-8:1 serve as rare earth collecting agents, water glass serves as efficient flotation combination reagents of pH regulators and inhibitor, the dispersing state of pulp micro-fine particle minerals is well controlled, the rare earth separation process with once coarse separation and three-time fine separation is adopted, rare earth ore concentrate which contains more than 53% of rare earth and has the recovery rate larger than 47% is obtained from the tailings containing 5-7% of rare earth, and effective separation of rare earth minerals and gangue minerals is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

High-yield s-linalool genetic engineering strain and building method thereof

InactiveCN102071155AReduce feedback inhibitionEasy to buildFungiMicroorganism based processesHeterologousLinalool

The invention discloses a high-yield s-linalool genetic engineering strain and a building method, which belong to the field of genetic engineering. Through the metabolic engineering reformation, linalool synthetase from actinidiaarguta is expressed in saccharomyces cerevisiae CEN.PK2-1 in a heterologous way, the terpene synthesis path-mevalonic acid (MVA) path carbon metabolizing flow is increased, and the high-yield s-linalool genetic engineering strain CEN. PK2 linalool is obtained. Compared with an initial strain CEN. PK2-1C, the modified genetic engineering strain CEN. PK2 linalool can metabolize and produce s-linalool, in addition, the feedback inhibition of the s-linalool is obviously reduced, the yield of the s-linalool can reach 12 mg / L, and the genetic engineering strain has good application prospects.

Owner:JIANGNAN UNIV

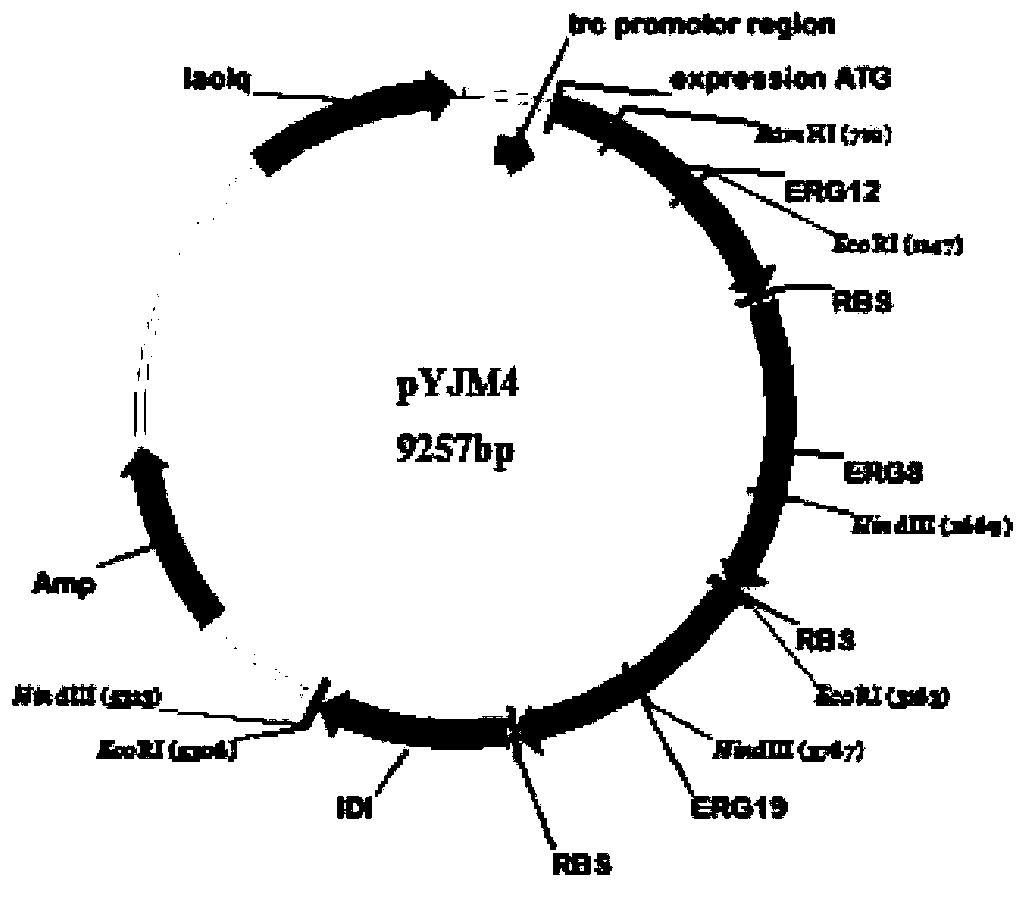

Genetically engineered bacterium co-generating geraniol and nerol and construction method and application thereof

ActiveCN103898037AFast growthShort fermentation cycleBacteriaMicroorganism based processesEscherichia coliGenetically engineered

The invention discloses a genetically engineered bacterium co-generating geraniol and nerol and a construction method and an application thereof, and belongs to the technical field of generic field. According to the genetically engineered bacterium disclosed by the invention, acetyl coenzyme A acyltransferase / hydroxymethyl glutaryl coenzyme A reductase, 3-hydroxyl-3-methyl glutaryl coenzyme A synthase, mevalonic acid kinase, mevalonic acid-5-phosphokinase, mevalonic acid-5-diphosphonic acid decarboxylase, isopentenylpyrophosphate isomerase, geranyl diphosphonic acid synthetase and geraniol synthetase or phosphatase are expressed. The metabolic pathways of geraniol and nerol synthesized in escherichia coli are successfully constructed by genetic engineering means, and glucose is biologically converted into geraniol and nerol.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

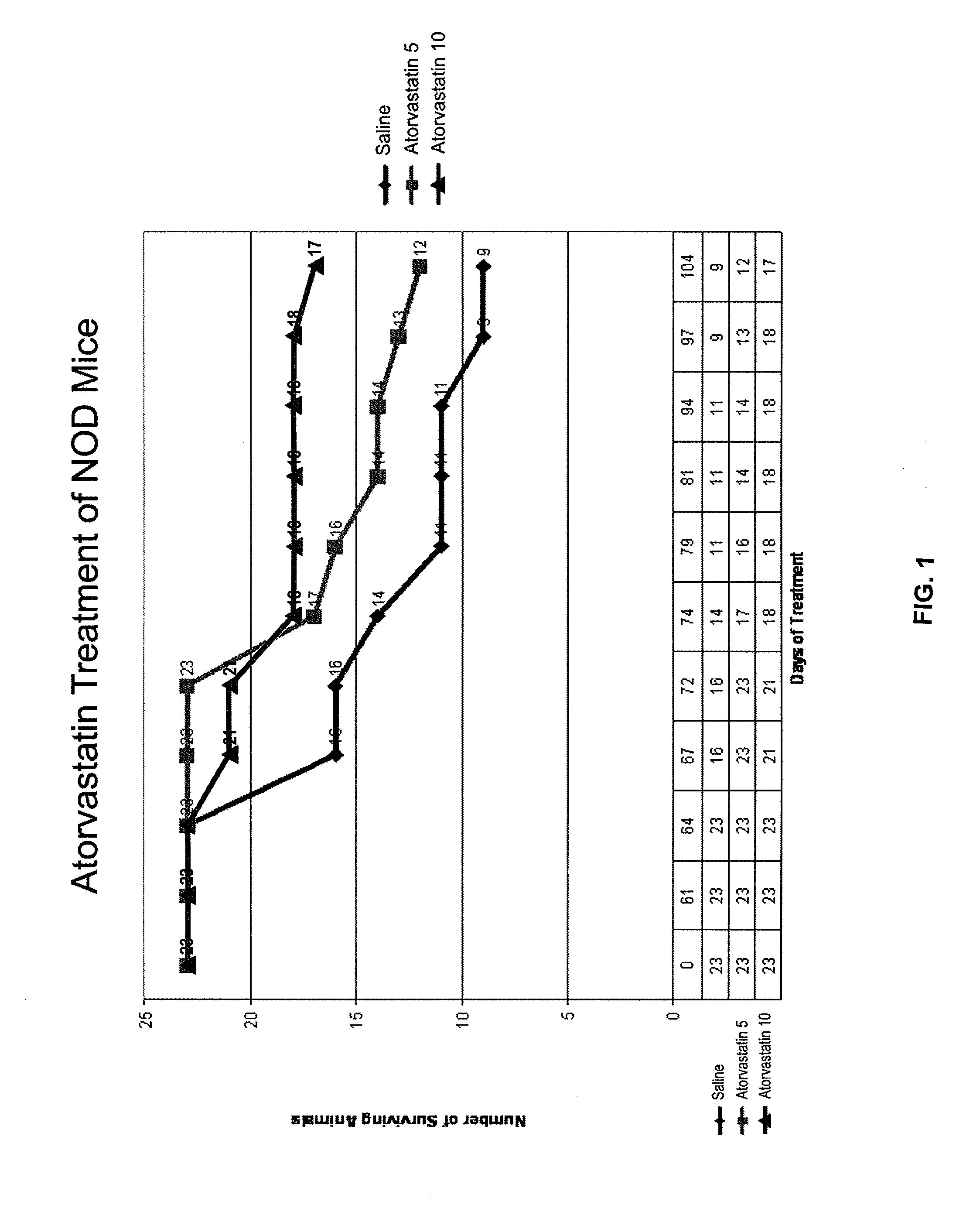

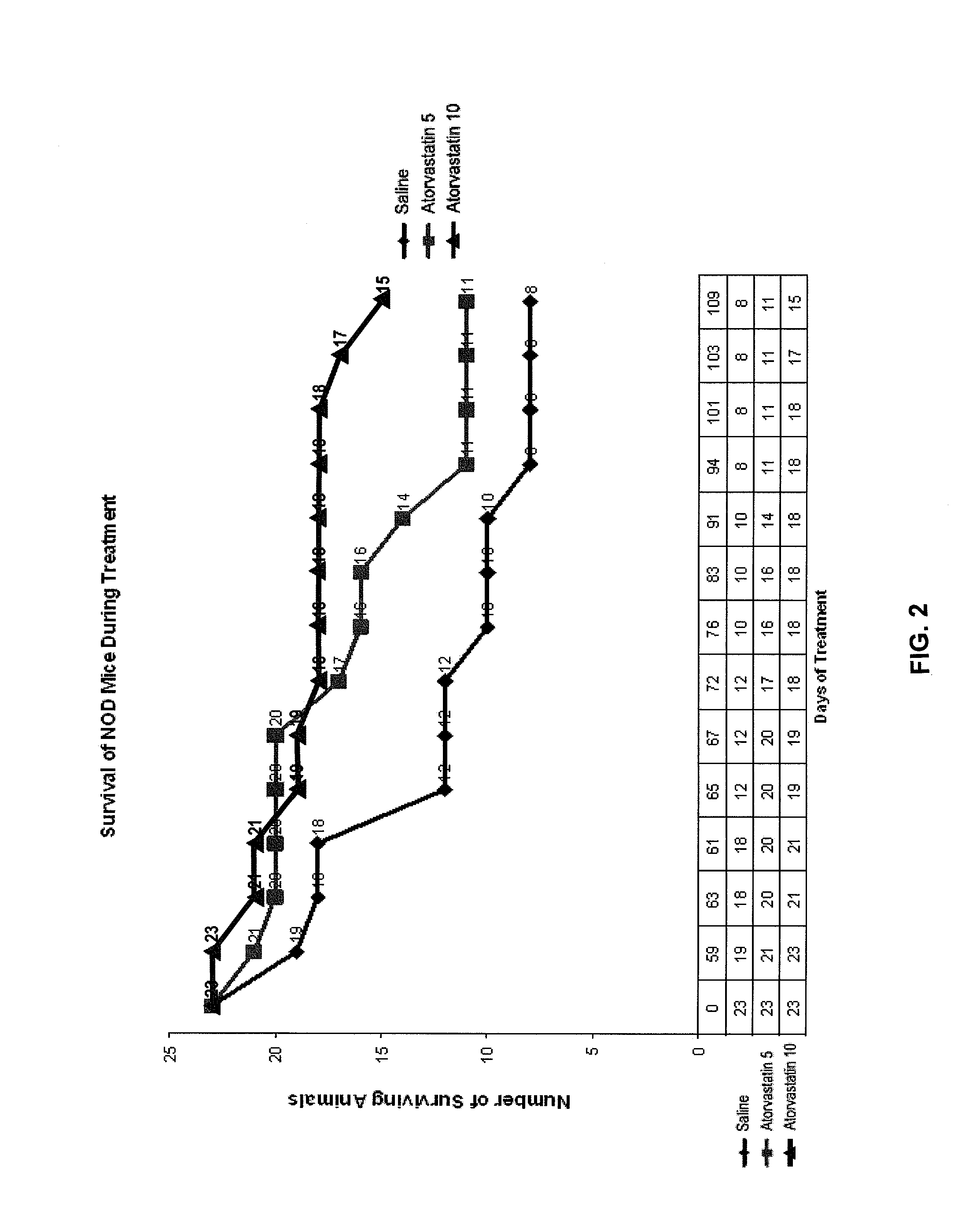

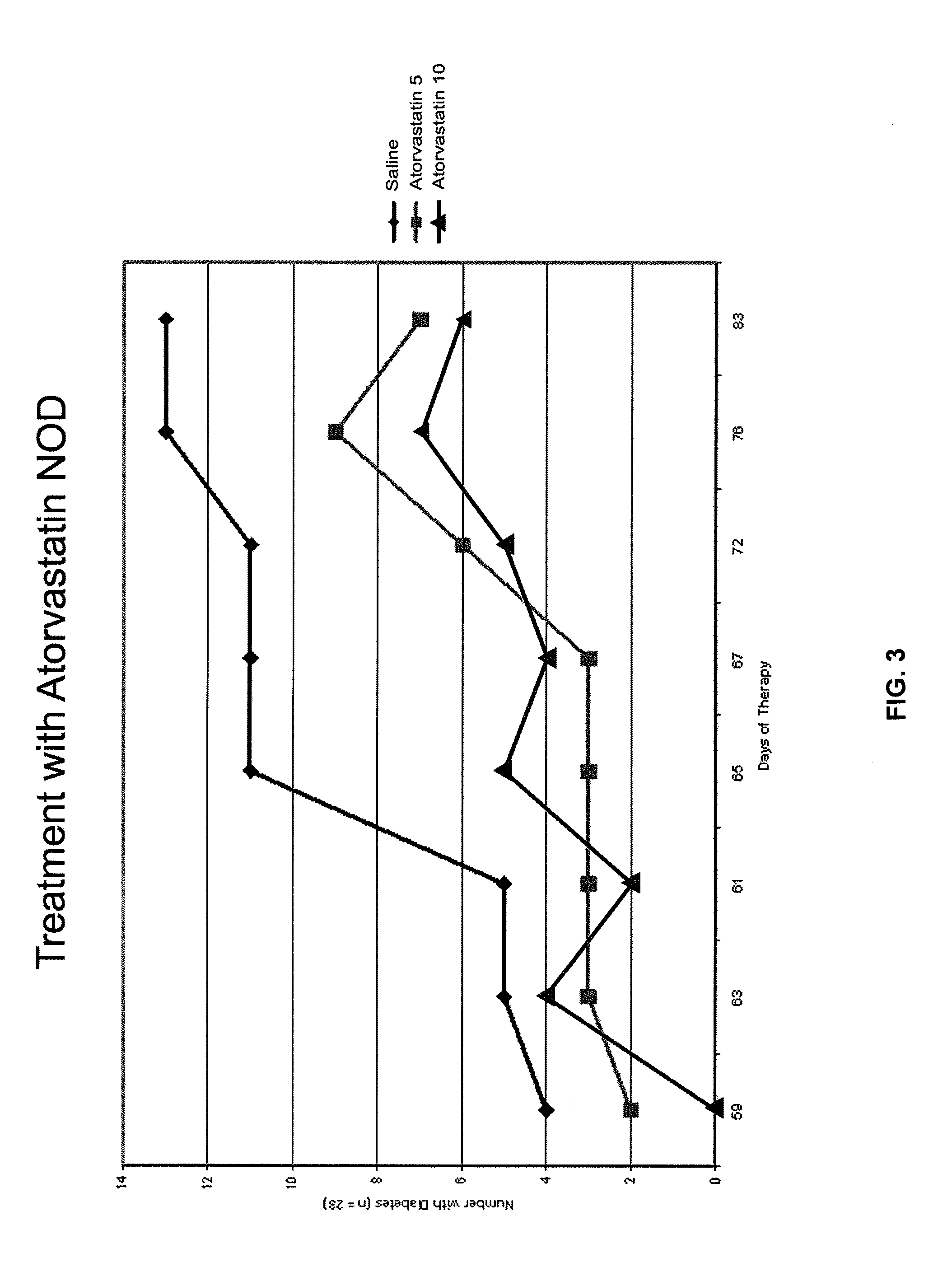

Methods of treating juvenile type 1 diabetes mellitus

InactiveUS20080227846A1Reducing chronic complicationReducing premature deathBiocideMetabolism disorderNewly diagnosedIslet cells

The present disclosure describes methods for treating or preventing Type 1 diabetes mellitus in juveniles, particularly in juveniles newly diagnosed with Type 1 diabetes. This prevention or treatment of Type 1 diabetes is achieved by administering one or more therapeutic agents to a juvenile in need, wherein the therapeutic agent is, for example, a competitive inhibitor of mevalonate synthesis, a competitive inhibitor of 3-hydroxy-3-methylglutaryl coenzyme A (HMG-CoA) reductase, or an inducer of AMP protein kinase (AMPK) activity. In certain embodiments, juveniles with Type 1 diabetes are treated with an HMG-CoA reductase inhibitor such as a statin, thereby decreasing the destruction of islet cells, or maintaining endogenous insulin production, in the juvenile.

Owner:MUSC FOUND FOR RES DEV

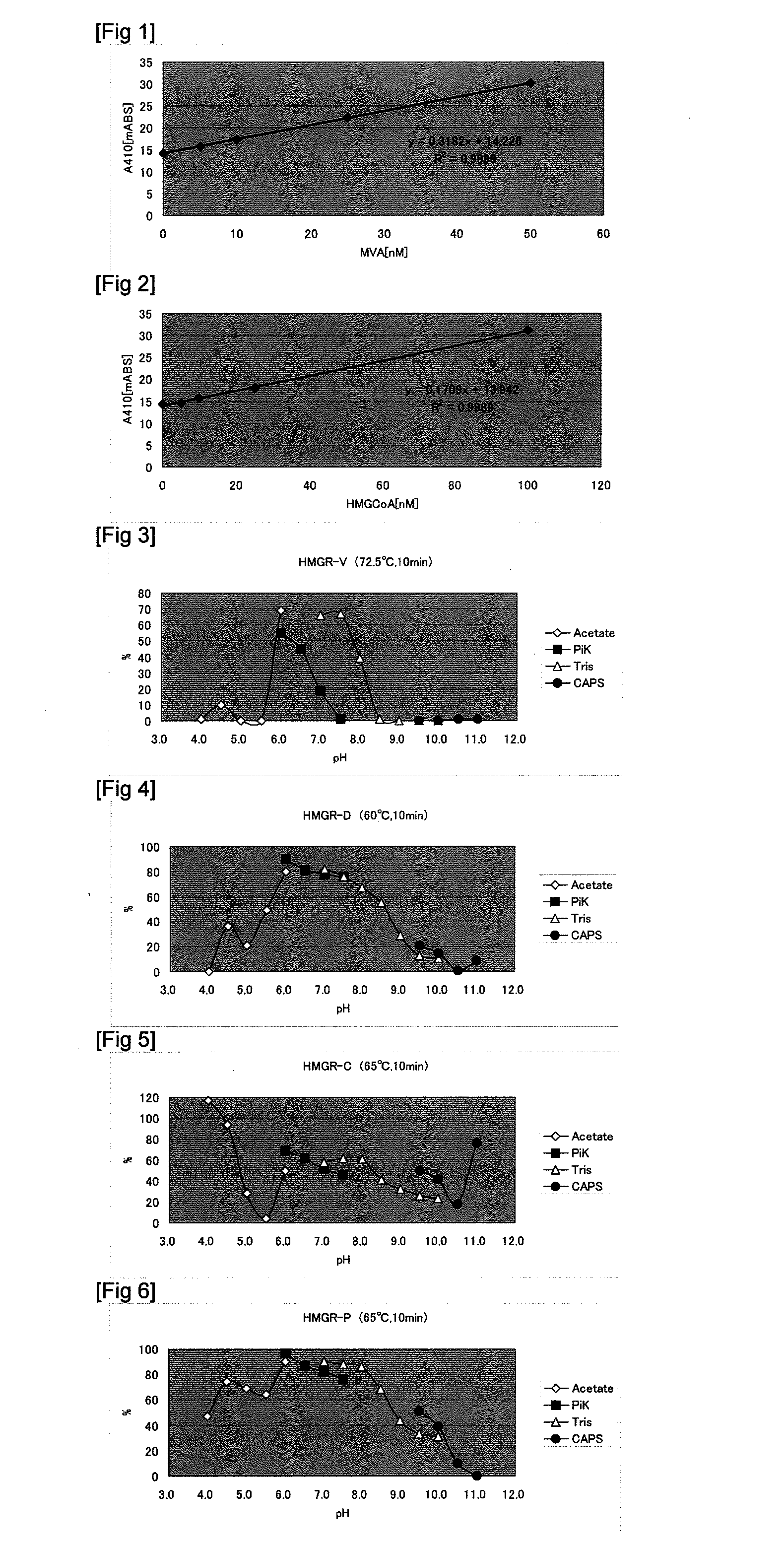

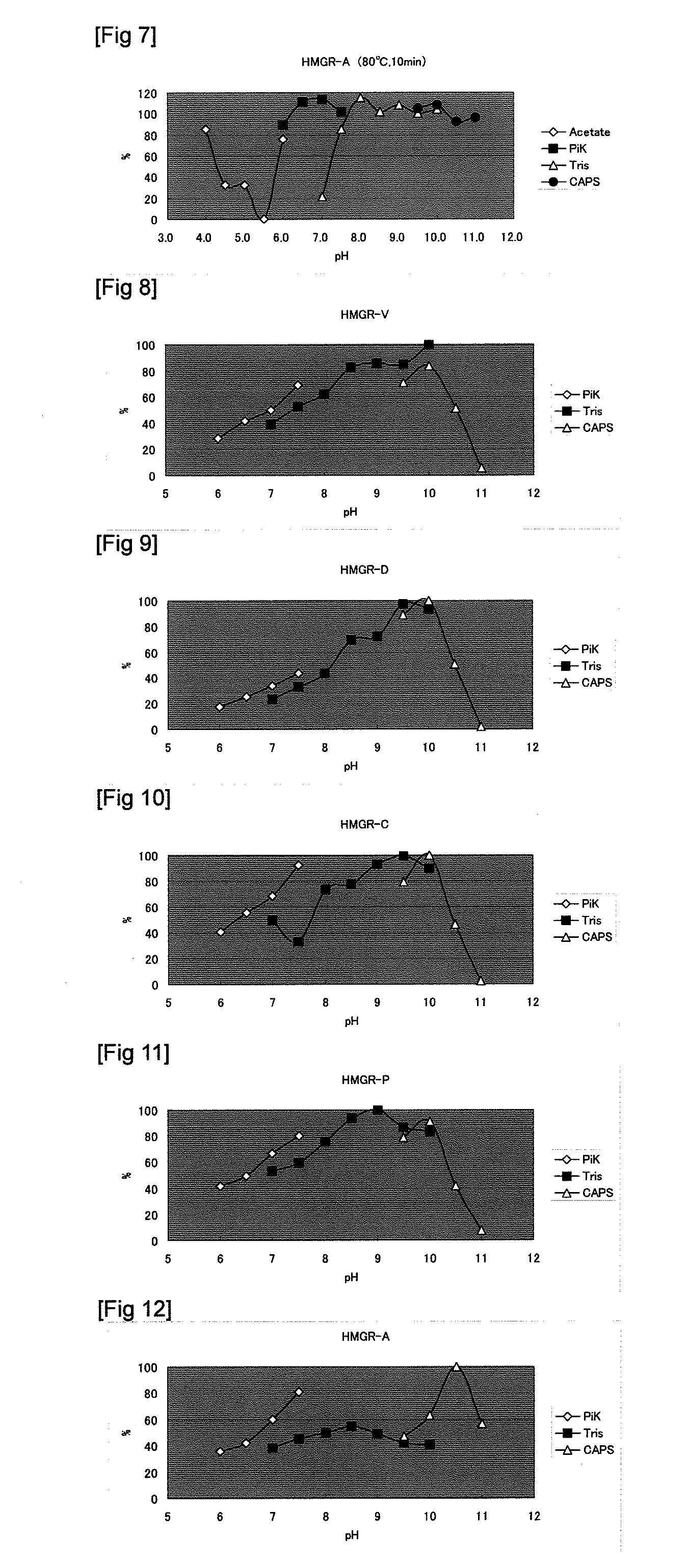

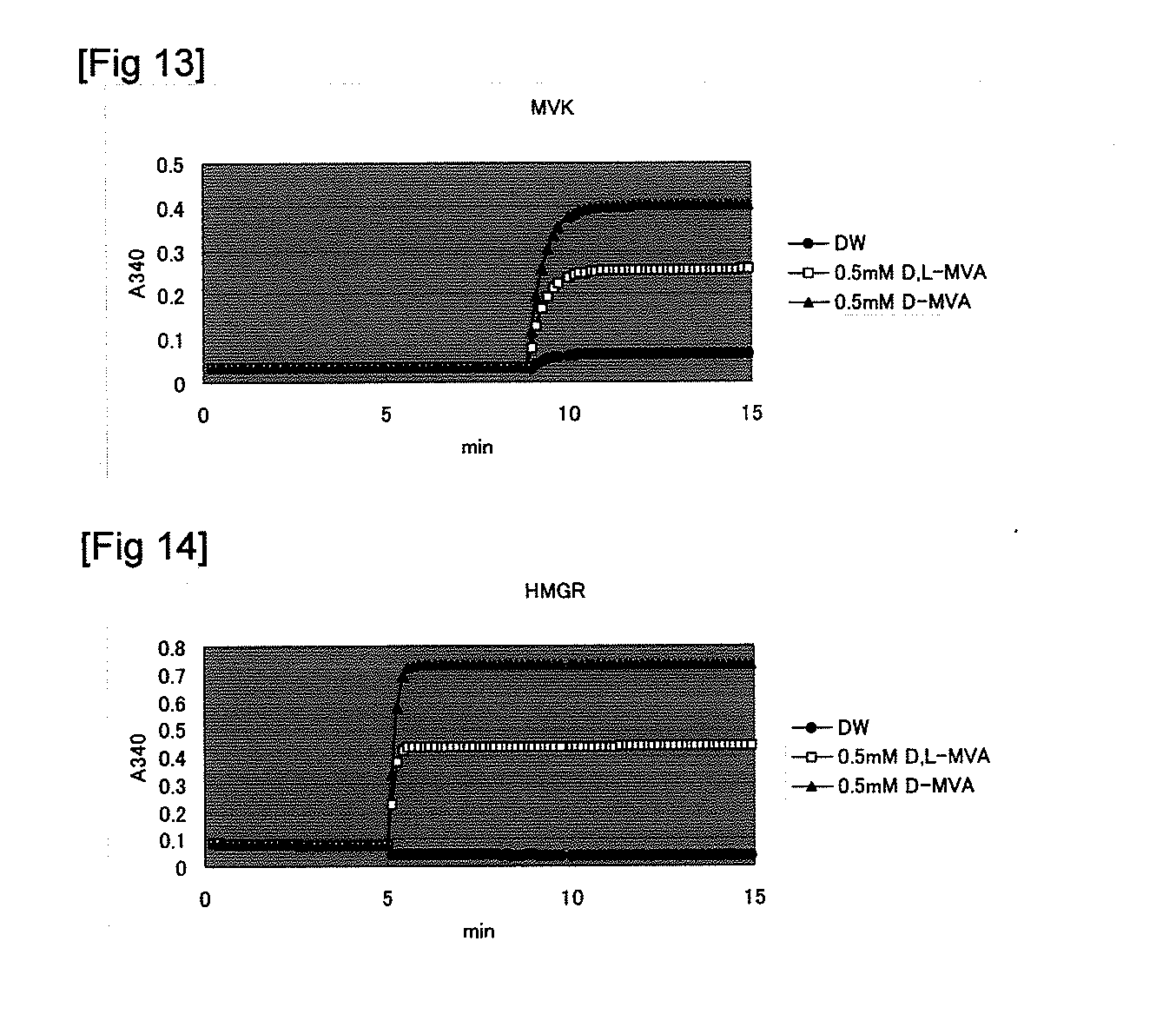

Method and reagent for measuring mevalonic acid, 3-hydroxymethylglutaryl coenzyme a, and coenzyme a

The present invention provides a method for measuring the concentration of an analyte in a test solution wherein the analyte is mevalonic acid and / or 3-hydroxymethylglutaryl coenzyme A, comprising the following steps (p) and (q): (p) a step of allowing an enzyme that catalyzes a reaction represented by Reaction Formula 1 and an enzyme that catalyzes a reaction represented by Reaction Formula 2 to act on a test solution containing mevalonic acid and / or 3-hydroxymethylglutaryl coenzyme A in the presence of a hydrogen acceptor X, a hydrogen donor Y, and coenzyme A; and (q) a step of measuring an amount of: a reduced hydrogen acceptor X that is produced; or an oxidized hydrogen donor Y that is produced; or a hydrogen acceptor X that is decreased; or a hydrogen donor Y that is decreased, wherein the hydrogen donor Y and the reduced hydrogen acceptor X are not the same.

Owner:ASAHI KASEI PHARMA

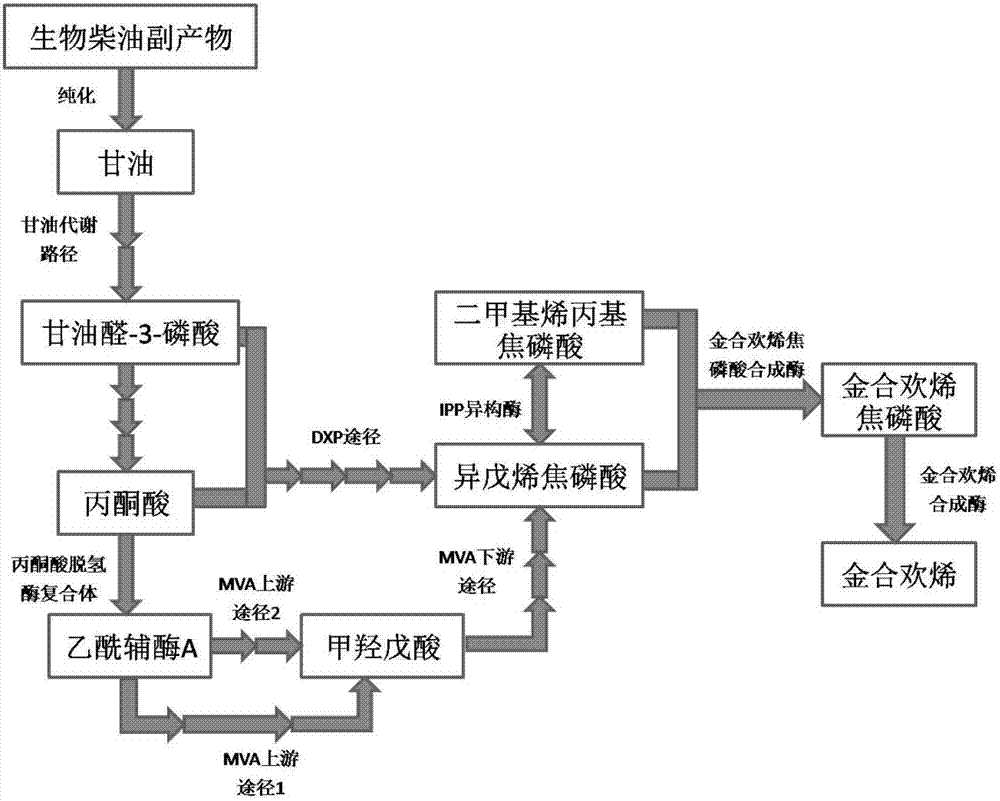

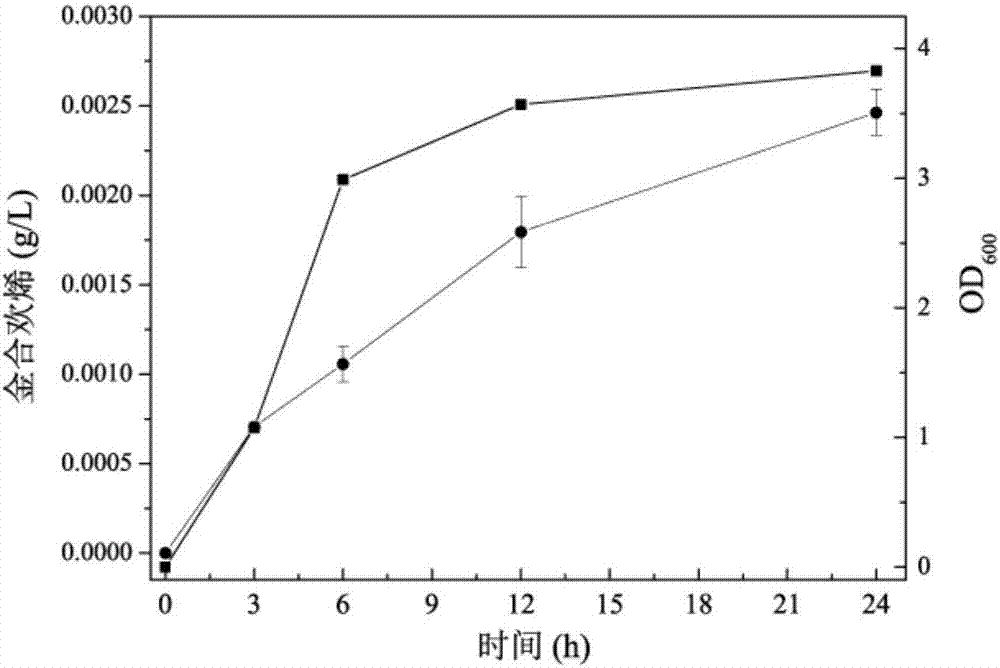

Method for preparing farnesene by using biodiesel by-product

ActiveCN107418978ABroaden raw material selectionConducive to sustainable large-scale productionBacteriaMicroorganism based processesBiodieselIsopentenyl pyrophosphate

The invention discloses a method for preparing farnesene by using a biodiesel by-product. The method comprises the steps of purification of the biodiesel by-product, wherein the purity of the purified glycerin reaches 63.8% (w / w), building of a recombinant host cell for preparing farnesene from the purified glycerin as the raw material, wherein the recombinant host cell comprises related genes in a mevalonate pathway or deoxymutulose-5-hexose monophosphate pathway, an isopentene pyrophosphate isomerase gene, a farnesene isopentenyl pyrophosphate synthetase gene and a farnesene synthetase gene. The method also comprises fermentation of the purified glycerin as the raw material in the recombinant host cell to prepare the farnesene, wherein the concentration of the obtained farnesene is 0.025g / L; and optimum construction of the recombinant host cell capable of improving the yield of the farnesene by employing the purified glycerin as the raw material, wherein the concentration of the obtained farnesene reaches 2.9g / L, and the concentration is improved by 115 times in comparison with that before optimization.

Owner:TIANJIN UNIV

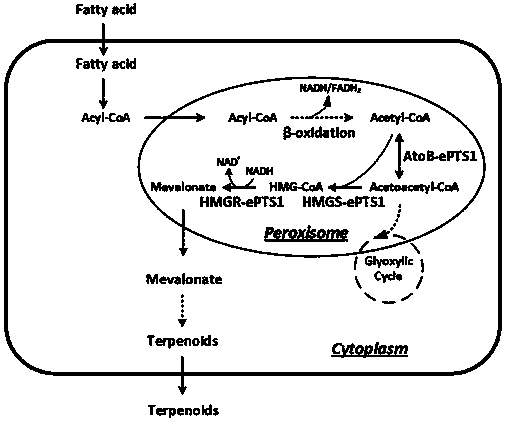

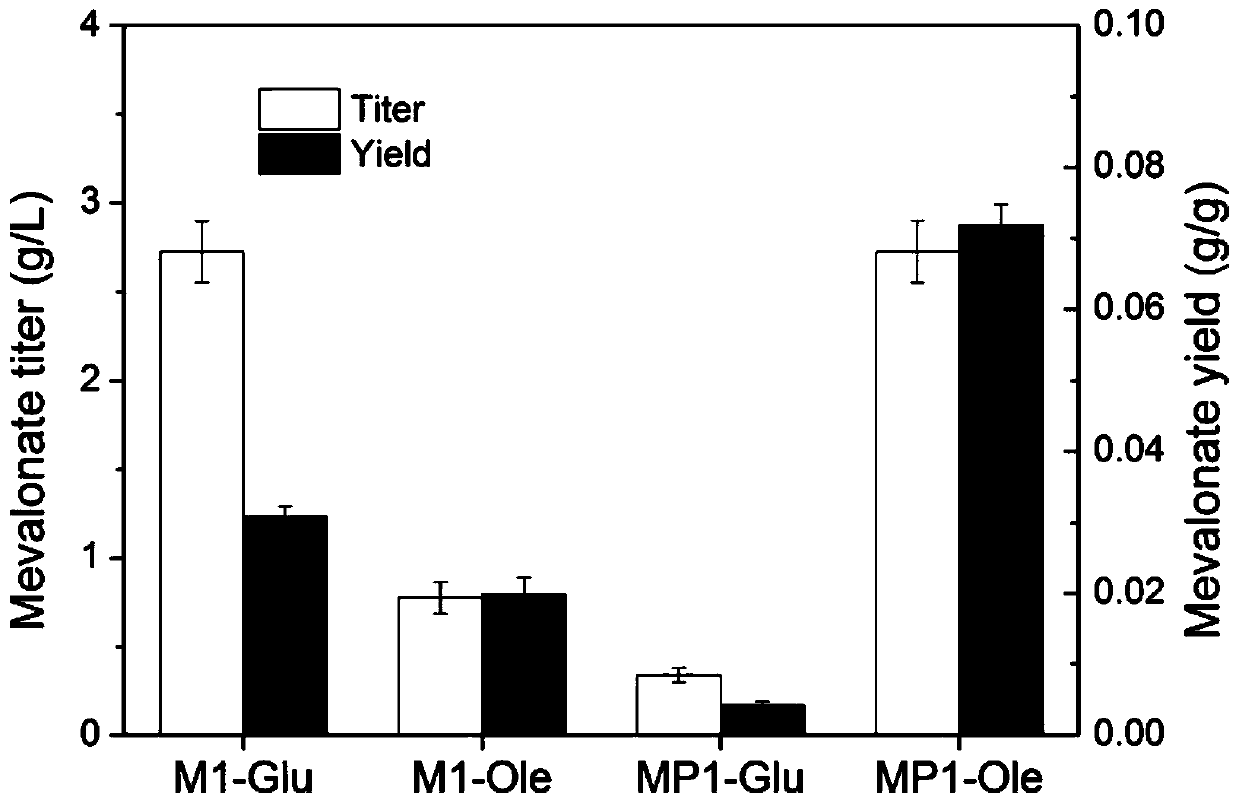

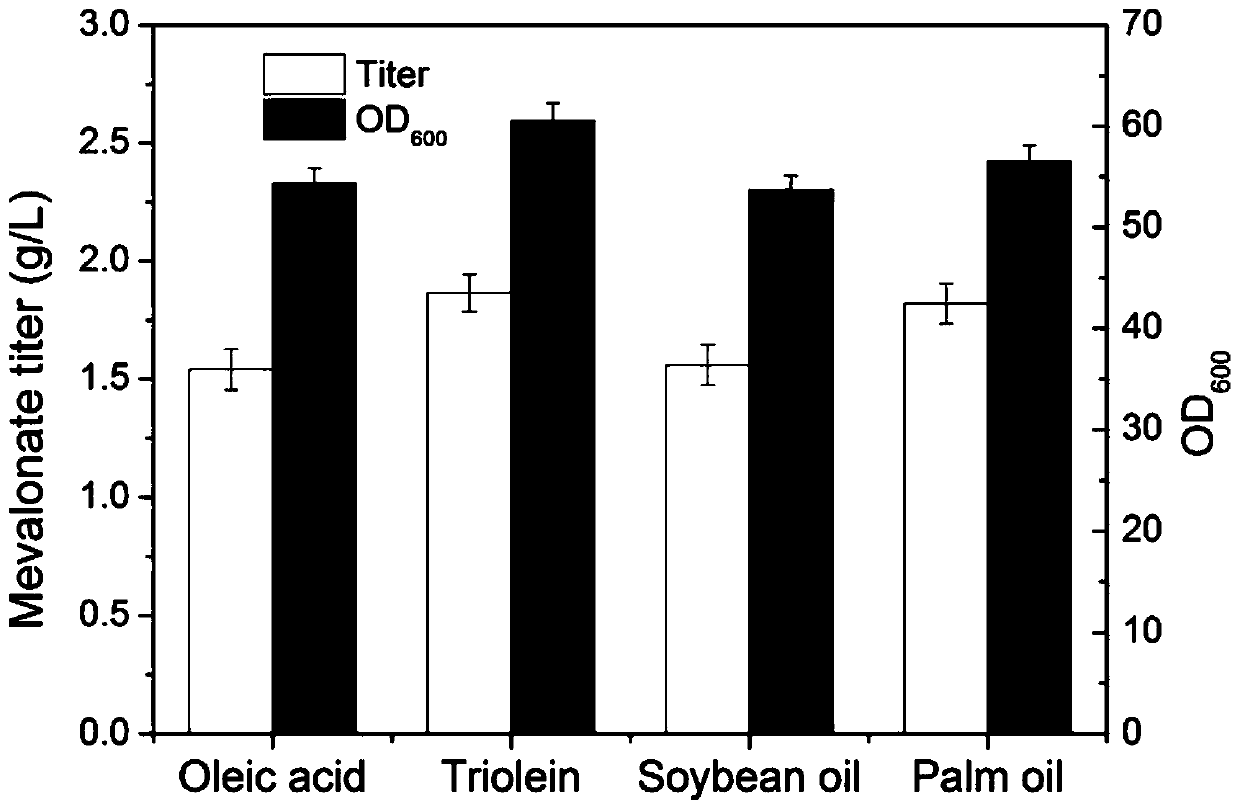

Method for positioning and synthesizing terpenoids by means of Yarrowia lipolytica way

ActiveCN110106209AHigh synthetic yieldImprove the added value of the applicationMicroorganism based processesFermentationHMG-CoA reductaseAlpha-farnesene

The invention discloses a method for positioning and synthesizing terpenoids by means of the Yarrowia lipolytica way. The method comprises the steps that an acetoacetyl coenzyme A thiolase, HMG-CoA synthetase and HMG-CoA reductase in the synthetic route of mevalonic acid in Yarrowia lipolytica are over-expressed and positioned to the peroxisome, and engineering bacteria MP1 are obtained; on the basis of the engineering bacteria MP1, the alpha-farnesene synthesis way is expressed, and engineering bacteria FP1 are obtained; or, the beta-carotene synthesis way is expressed, and engineering bacteria CP1 are obtained; or, the linalool synthesis way is expressed, engineering bacteria LP1 are obtained; the bacteria FP1 or CP1 or LP1 can synthesize the terpenoids under the aerobatic condition by means of a culture medium containing fatty acid or grease, and the yield of the synthesized terpenoids is higher compared with a traditional method. According to the method, fatty acid, grease and cheap food waste oil can be used for generating mevalonic acid downstream terpenoids, and the considerable application prospect and the economic value are achieved.

Owner:SHANDONG UNIV

Construction method for high-yield sclareol strain

InactiveCN103387944AEfficient productionFungiMicroorganism based processesBiotechnologyCoenzyme A biosynthesis

The invention discloses a method for constructing a high-yield sclareol engineering strain by a synthetic biology methdo, and an application thereof. The construction method for the strain relates to express plant sourced key enzymes for synthesizing sclareol, wherein the key enzymes comprise a pyrophosphoric acid ladanum enediol ester synthase and a sclareol synthase; and overexpress a combination of one or more yeast endogenous enzyme-based genes, wherein the enzyme-based genes comprise a key enzyme of a mevalonic acid approach-(hydroxymethyl) coenzyme A reductase, and two enzymes of an isopentenylpyrophosphate approach-a farnesyl pyrophosphate synthase and a geranylgeranyl diphosphate synthase. The method can efficiently produce sclareol, with a shake flask fermentation level reaches 9 mg / l, and has industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com