Patents

Literature

63results about How to "Effective dissociation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

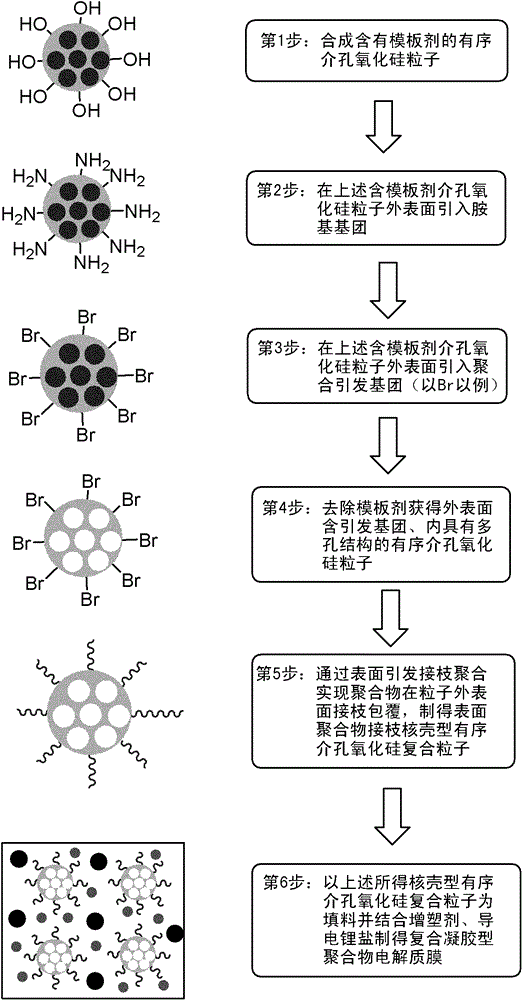

Composite gel polymer electrolyte membrane and application thereof

ActiveCN102005609AGood compatibilityImprove the interface strengthSecondary cellsPolymer electrolytesPolymer science

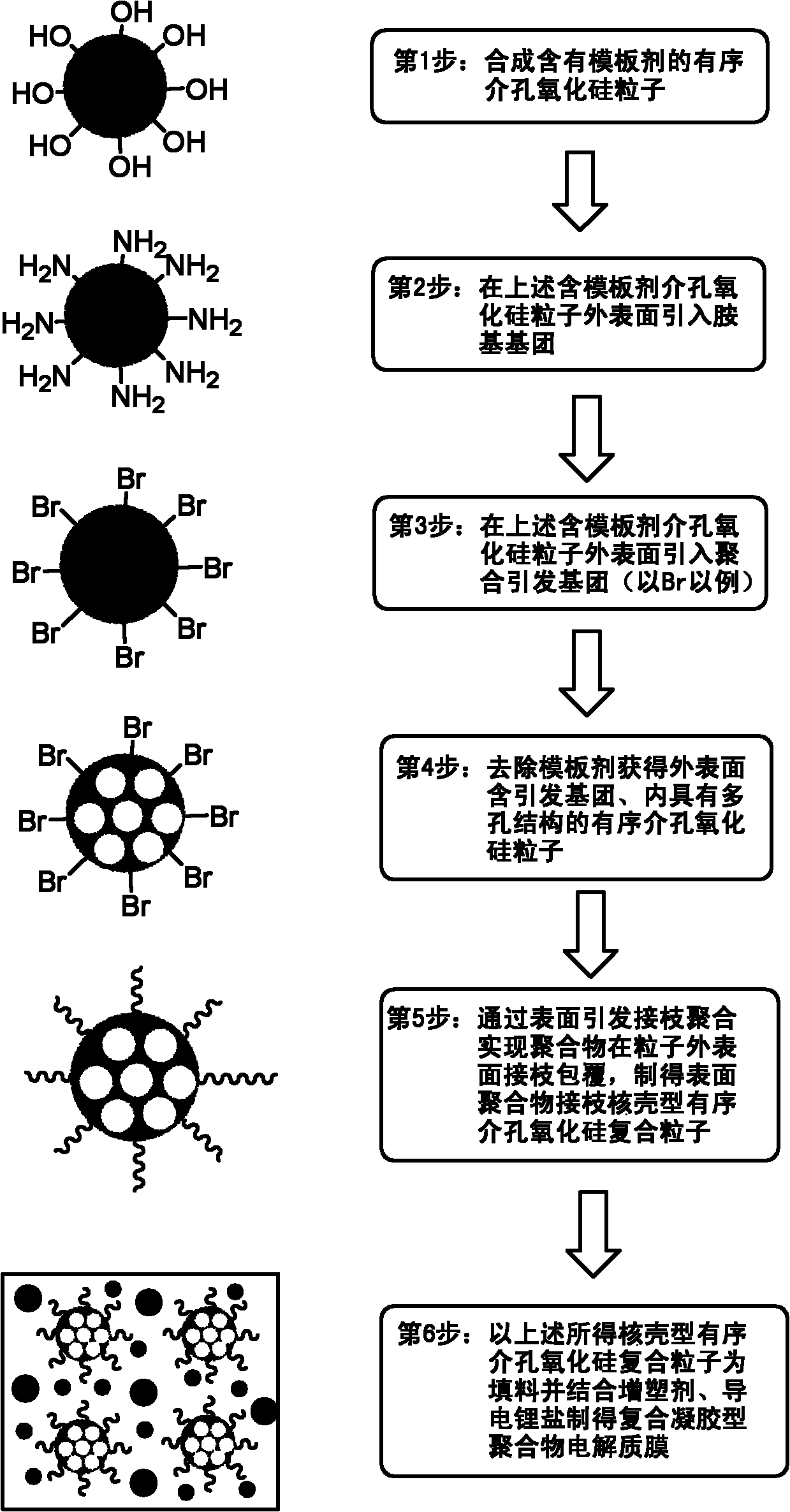

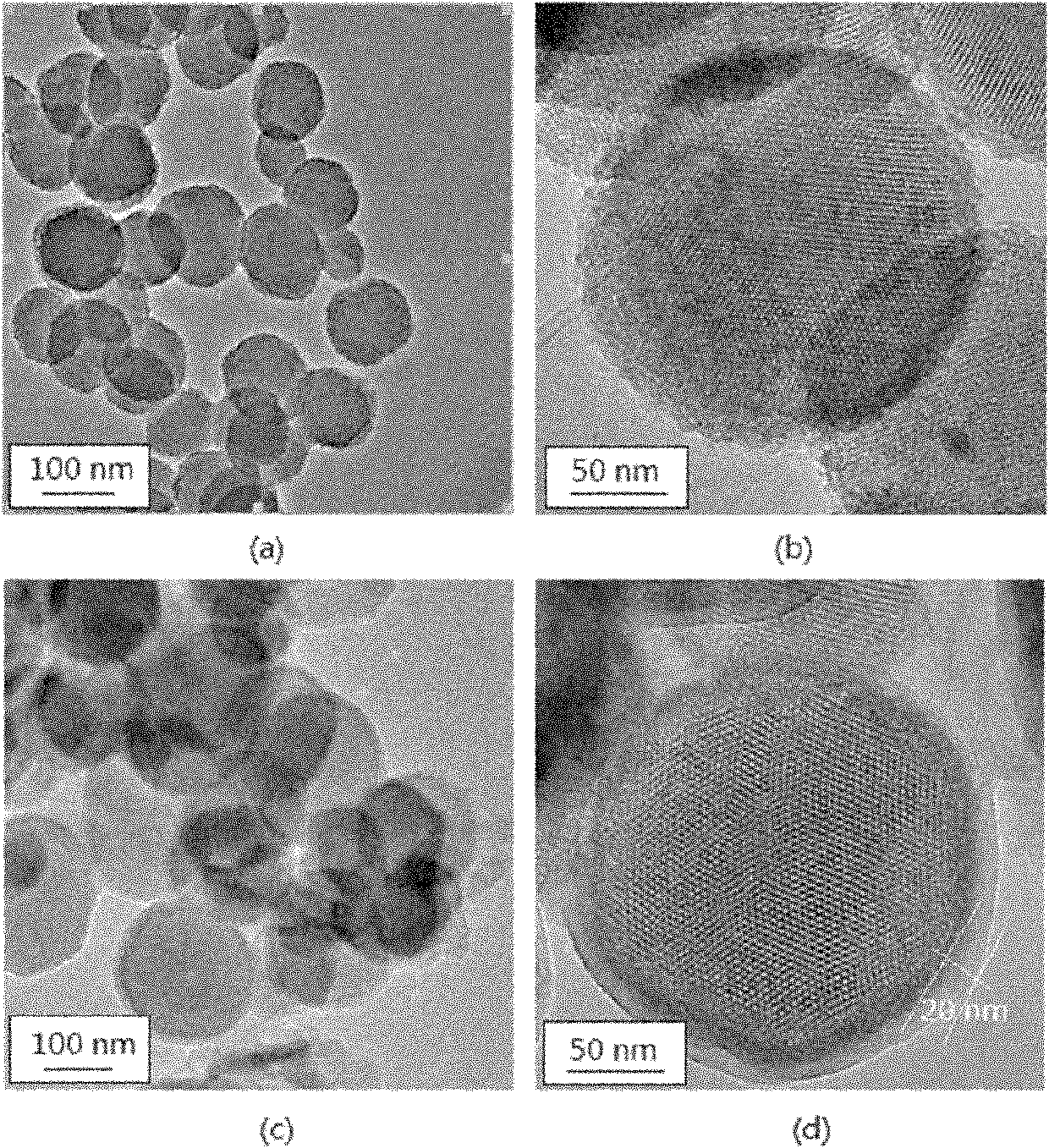

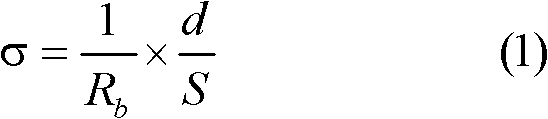

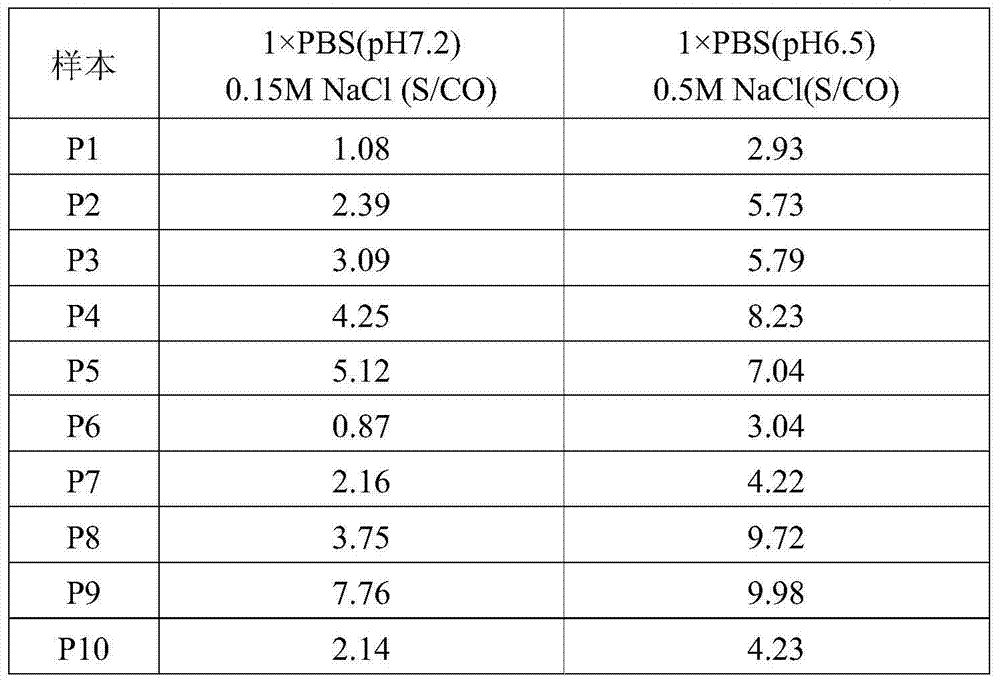

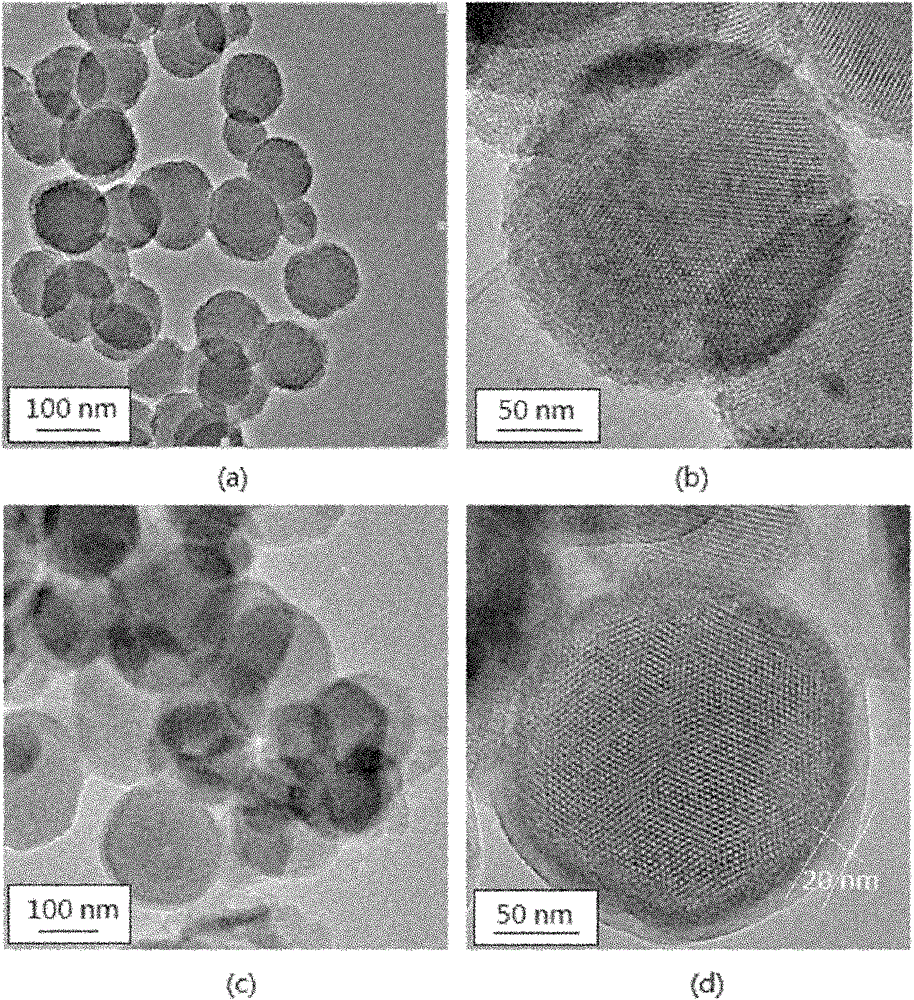

The invention discloses a composite gel polymer electrolyte membrane and application thereof. The composite gel polymer electrolyte membrane is prepared by adding core-shell ordered mesoporous silica composite particles into a conventional gel polymer electrolyte system, wherein the adding mass of the core-shell ordered mesoporous silica composite particles is 5 to 30 percent based on the mass ofa polymer matrix in the conventional gel polymer electrolyte system; the core-shell ordered mesoporous silica composite particles take ordered mesoporous silica particles as cores; a polymer is grafted and coated on the outside surfaces of the ordered mesoporous silica particles to form shells; and the shell polymer has good compatibility with the polymer matrix in the conventional gel polymer electrolyte system. The composite gel polymer electrolyte membrane prepared in the invention has higher room-temperature ionic conduction capacity, simultaneously has better mechanical strength and heatresistance, and is suitable for polymer lithium ion batteries.

Owner:ZHEJIANG UNIV OF TECH

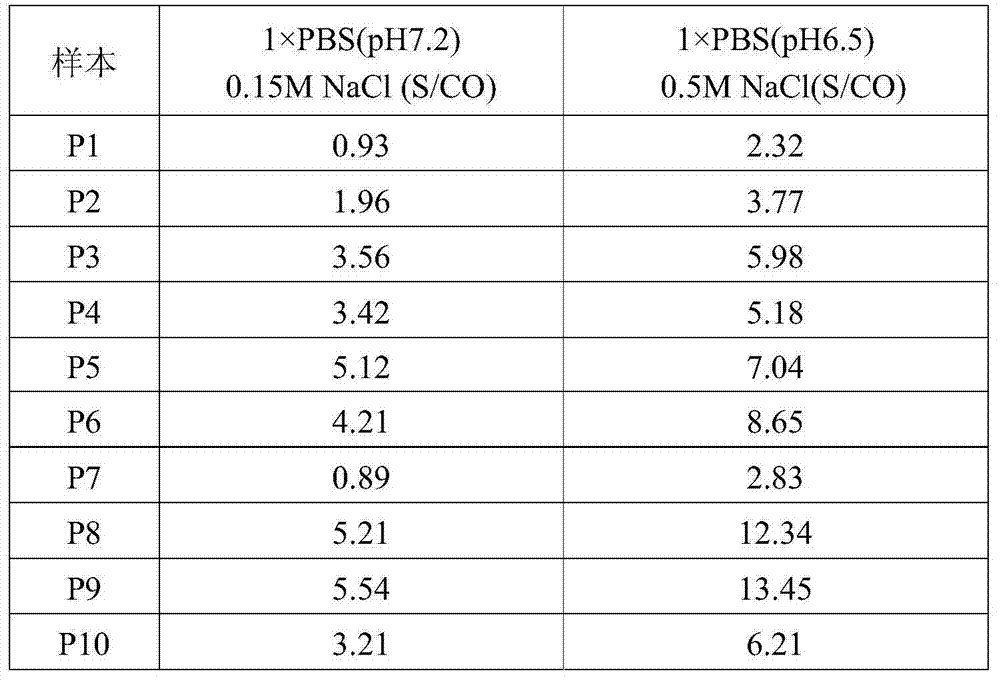

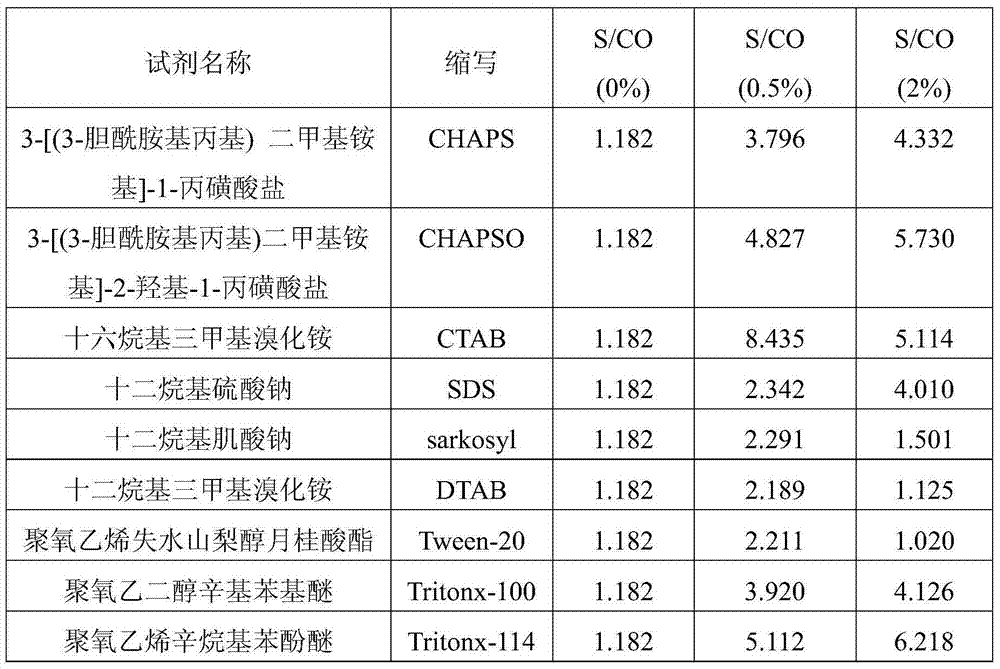

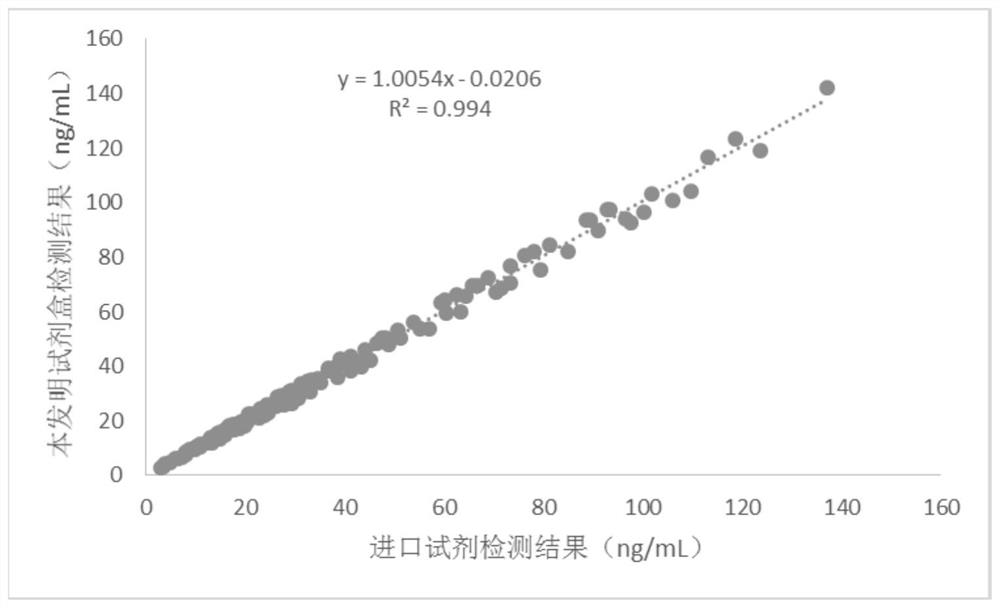

Kit for processing antigen-antibody immune complex in serum or plasma sample and application of kit

ActiveCN103674657AHigh detection sensitivityHigh clinical application valuePreparing sample for investigationSolventIon

The invention discloses a kit for processing an antigen-antibody immune complex in a serum or plasma sample. The kit is prepared from a meta-acid buffer solution serving as a solvent, high-concentration salt ions, an ionic surfactant, a nonionic surfactant, a reducing agent, urea, trehalose and a defoaming agent. The kit is suitable for processing the serum or plasma sample which is suspected to generate the antigen-antibody immune complex to further influence the antigen or antibody detection result, and the processed serum or plasma sample is suitable for the sample detection, such as enzyme-linked immunoassay and chemiluminescence immunoassay, while the sample which does not generate the immune complex does not affect the normal detection result after being processed via the conditioning fluid of the kit. The kit disclosed by the invention can effectively dissociate the formed antigen-antibody immune complex in the sample, greatly improves the detection sensitivity of the sample, and has a very high clinical application value.

Owner:朱之炜

Method for recovering germanium from germanium-containing materials

InactiveCN103952575AEfficient leachingImprove solubilityProcess efficiency improvementStrong acidsHydrometallurgy

The invention relates to a method for recovering germanium from germanium-containing materials, particularly relates to a method for recovering germanium from germanium-containing materials of non-ferrous smelting industry, and belongs to the technical field of hydrometallurgy. The method comprises the steps of leaching germanium-containing materials as raw materials of which the particle sizes are 100 meshes with inorganic strong acid as an leaching agent of which the concentration is 50-120g / L and an aid-leaching agent at 35-95 DEG C and filtering to obtain a germanium-containing leaching solution, adjusting the pH value of the germanium-containing leaching solution to be 6-9, stirring and carrying out liquid-solid separation to obtain germanium residues, and calcining the germanium residues at 350-500 DEG C to obtain a crude germanium dioxide product, wherein the aid-leaching agent is one of tartaric acid, water-soluble tartrate, citric acid, water-soluble citrate, oxalic acid and water-soluble oxalate. The method disclosed by the invention has the advantages of simple process, easiness in operation, high recovery ratio of germanium, large enrichment ratio, and convenience in industrial production and application.

Owner:CENT SOUTH UNIV

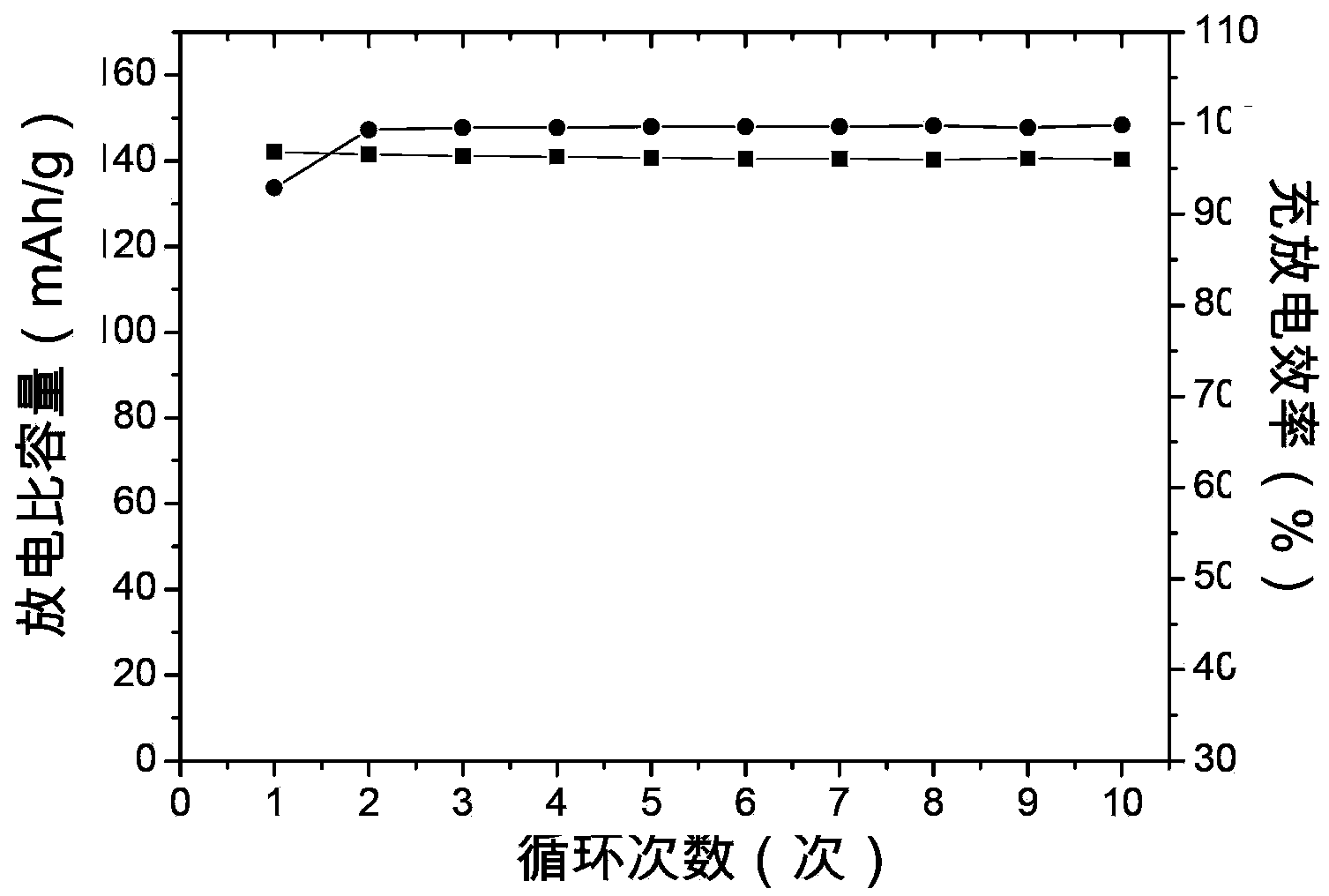

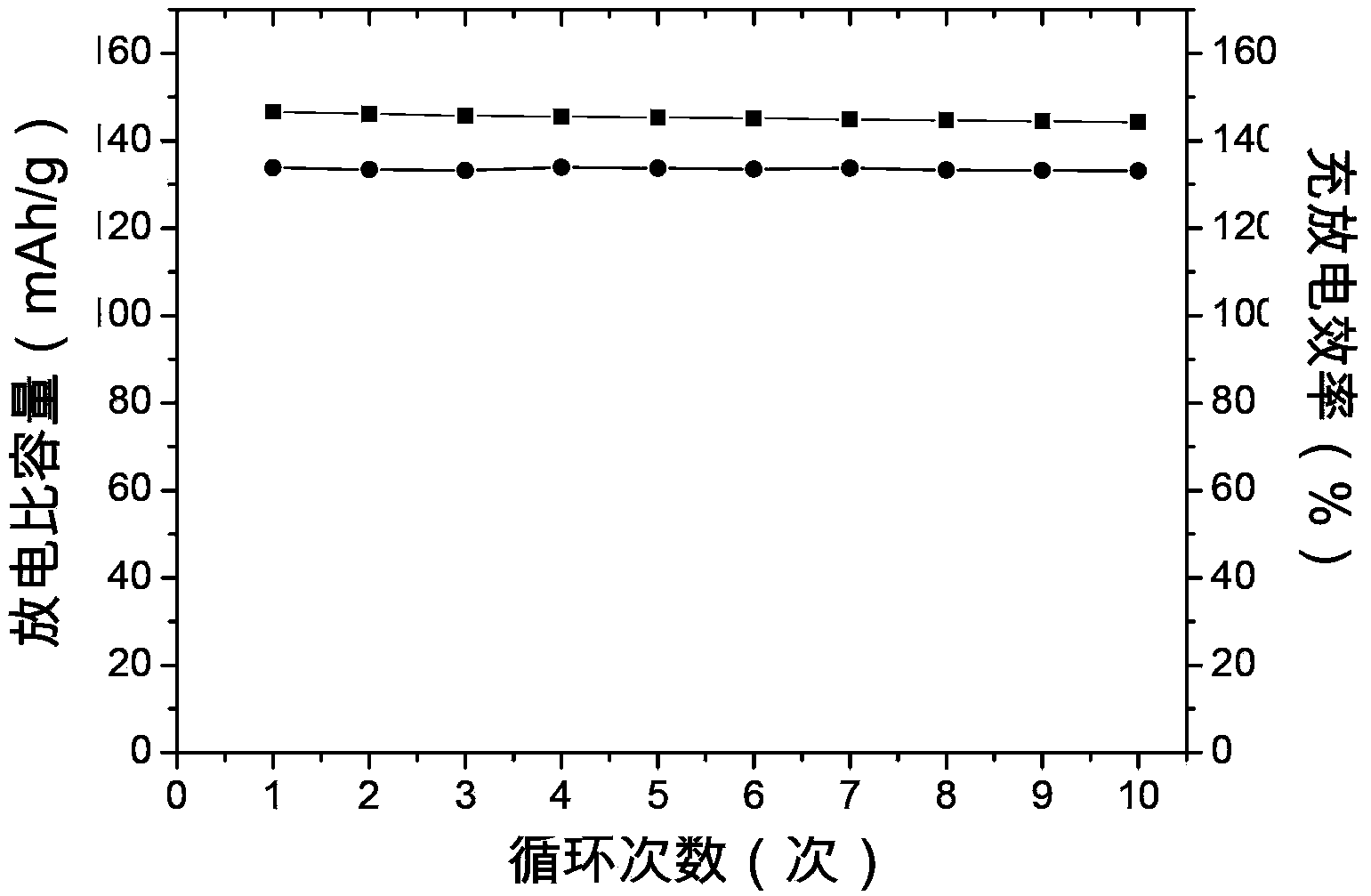

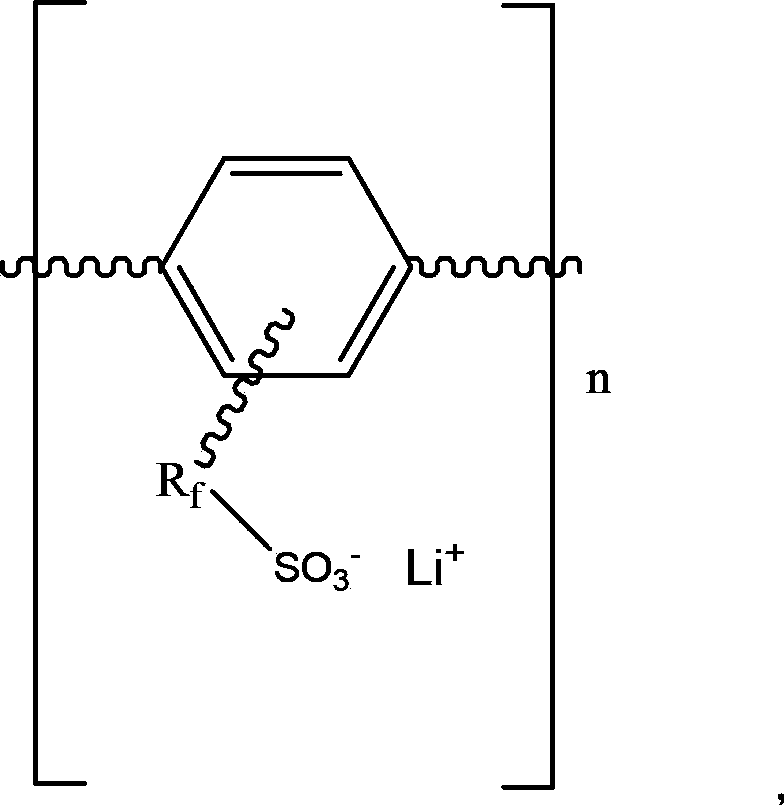

Binder used for lithium ion battery anode, lithium ion battery anode using the same and preparation method thereof

InactiveCN103840163AReduce usageHarm reductionSecondary cellsNon-aqueous electrolyte accumulator electrodesOrganic solventSide chain

The invention provides a binder used for a lithium ion battery anode. The binder is an aromatic polymer containing a lithium fluorosulfonate side group, or an aromatic polymer containing a lithium fluorosulfimide side group, or a mixture of the two. The binder has strong binding power, and powder does not fall off. Ethanol and water are adopted as the solvent, and organic solvent consumption is reduced, thereby reducing harm to the environment. The side chain unit contains the -SO3Li or -SO2N<->Li<+>SO2- structure, so that lithium ions can be effectively dissociated so as to supplement lithium ions to the lithium ion battery anode, thus not only improving the utilization rate of lithium ions, but also indirectly enhancing the battery capacity. Experiments prove that the lithium ion battery taking the binder as the anode binder has stable electrochemical performance, and cannot be degraded along with the charge-discharge cycle of the battery, thereby effectively prolonging the service life of the battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

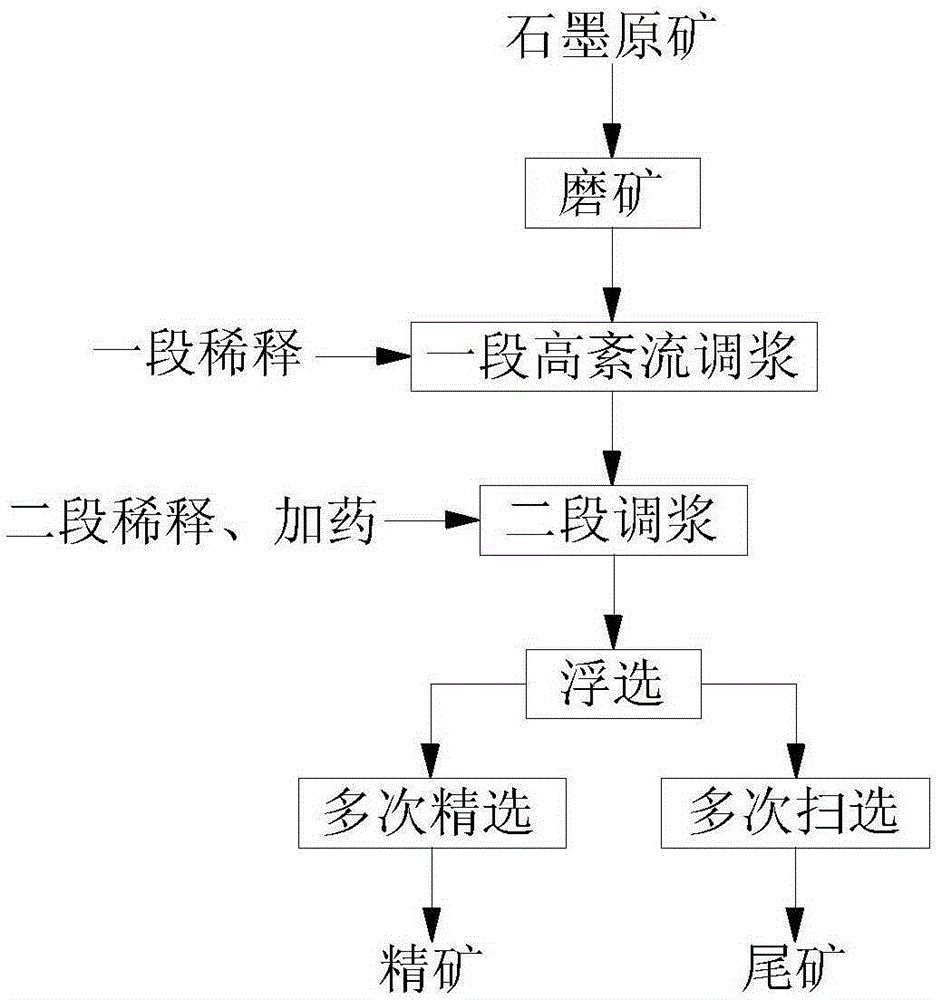

Flotation method of aphanitic graphite

ActiveCN105381867AImprove sorting efficiencyHigh recovery rateFlotationWet separationFoaming agentGraphite

The invention discloses a flotation method of aphanitic graphite. The method comprises an ore grinding process, a two-stage pulp mixing process and a flotation process. The method is characterized in that original graphite ores are fed into an ore grinding machine; water is added to a product subjected to ore grinding to obtain ore pulp with the mass percent concentration of 10 to 50%; then the ore pulp is fed into a first-stage high-turbulence pulp mixing device to stir and mix; the oil pulp subjected to the first-stage mixing is fed into a second-stage pulp mixing device, and water is added to the second-stage pulp mixing device to dilute until the mass percent concentration is 5 to 10%; a PH regulator, a dispersing agent, a collecting agent and a foaming agent are sequentially added to the oil pulp; the oil pulp subjected to the second-stage mixing is fed into a rough selecting device to sort; the roughing concentrate is subjected to multi-stage concentration to obtain the final concentrate; the rougher tailings are subjected to multi-stage scavenging to obtain the final tailings. According to the method, the high-turbulence pulp mixing method and the flotation method are combined to achieve high-precision sorting of the aphanitic graphite, and the problem of efficient sorting of the aphanitic graphite can be solved.

Owner:CHINA UNIV OF MINING & TECH

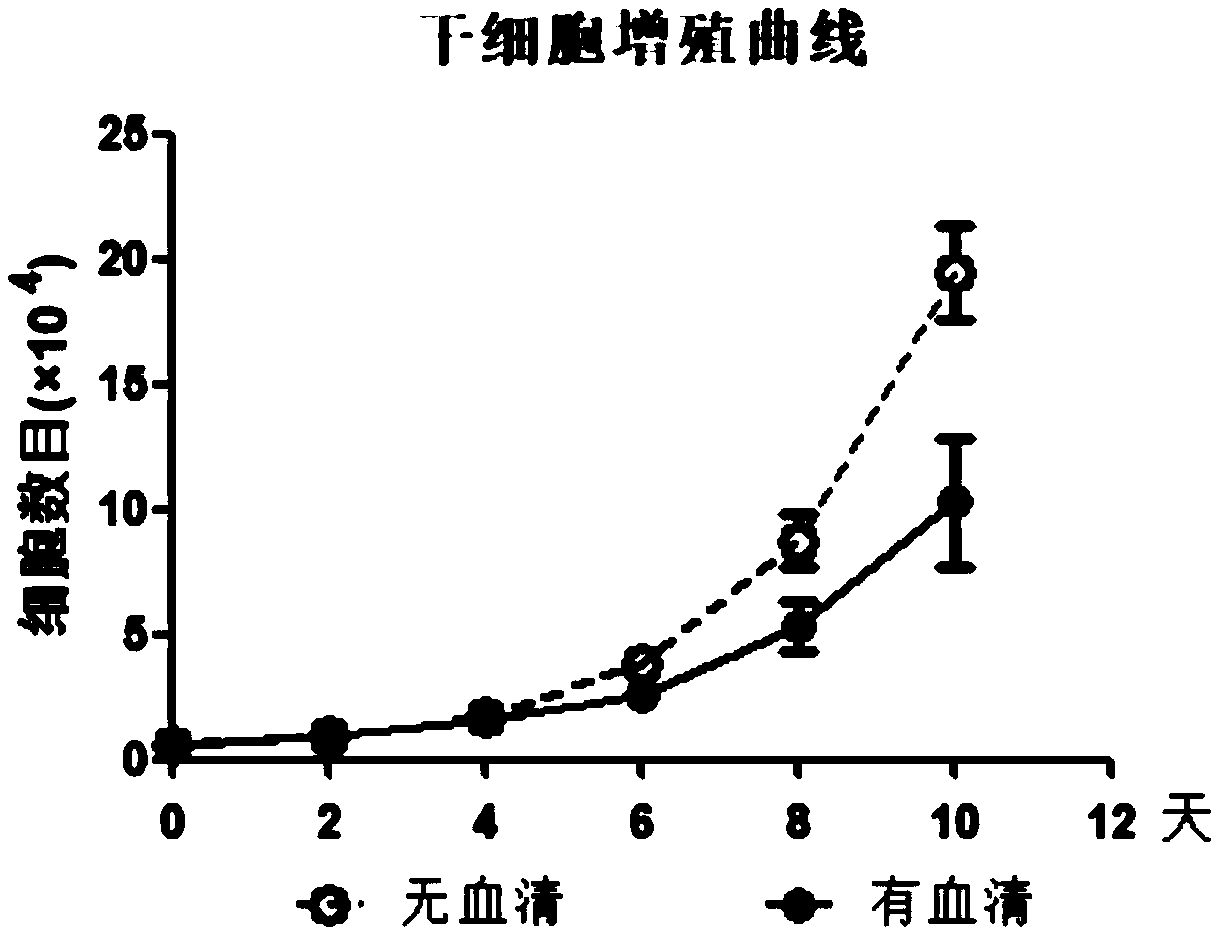

Method for separating and culturing human adipose-derived stem cells

The invention relates to a method for separating and culturing human adipose-derived stem cells. The method comprises the following steps: (1) digesting an adipose suction substance by adopting a mixed digestive enzyme solution which consists of collagenase I, collagenase II and ACCUTASE, neutralizing the digestive enzyme after digesting is ended, centrifuging, filtering, and then further removinghybrid cells by using a lymphocyte separating liquid; (2) culturing adipose-derived stem cells by adopting a serum-free culture medium. According to the method for separating and culturing the humanadipose-derived stem cells, on one hand, cells can be dissociated from an adipose tissue quickly and effectively, the yield of the stem cells is improved, the cell separating time is shortened, and the activity of the cells is kept to the greatest extent; on the other hand, the culture medium is clear in components, does not contain any exogenous serum component, can remarkably improve the wall adhering capacity and the multiplication capacity of the adipose-derived stem cells, is beneficial to in-vitro amplification and stemness maintenance of the adipose-derived stem cells, and has a good application prospect.

Owner:SHANGHAI LIFE SCI & TECH CO LTD

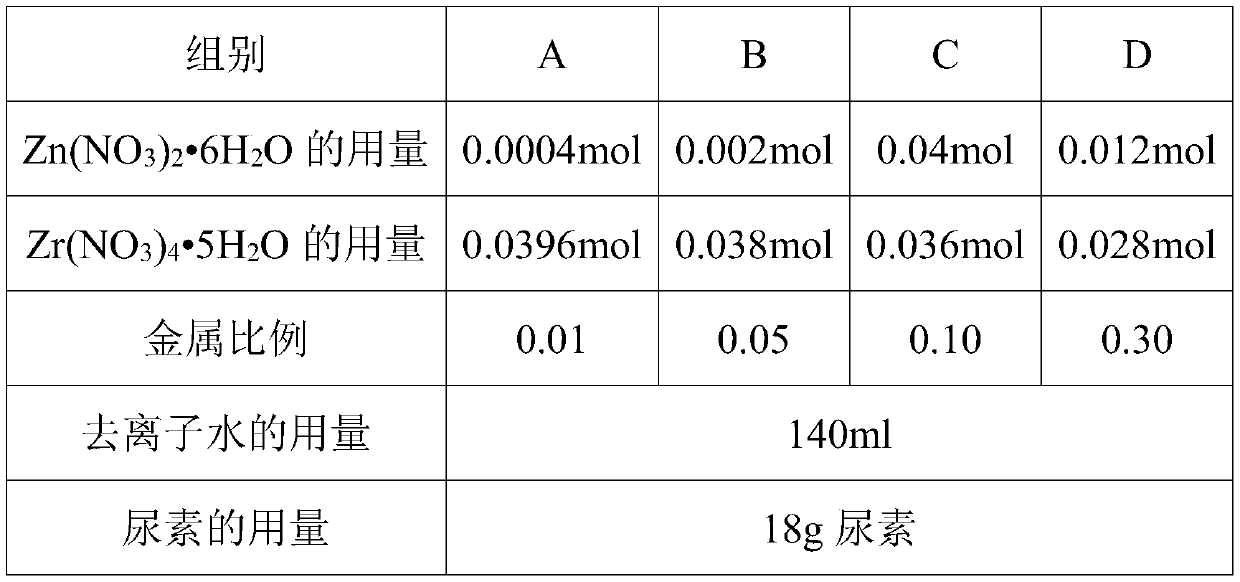

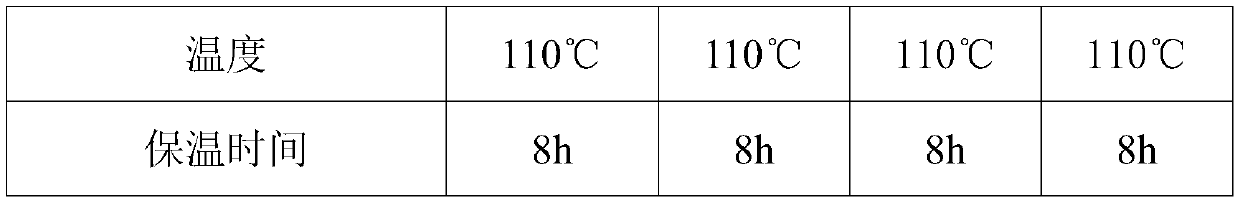

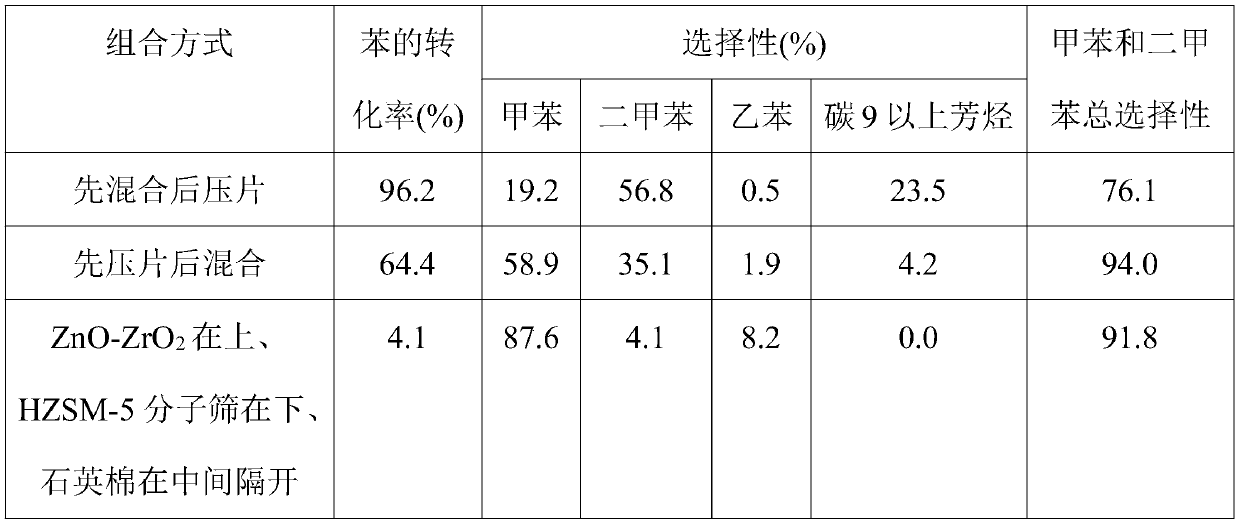

Catalyst for catalyzing synthesis gas and benzene to prepare methylbenzene and xylene and preparation method thereof

ActiveCN111167507AHigh selectivityImprove conversion rateHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveHigh selectivity

The invention discloses a catalyst for catalyzing synthesis gas and benzene to prepare methylbenzene and xylene and a preparation method thereof. The catalyst is composed of a bimetallic oxide and anHZSM-5 molecular sieve with a silica-alumina ratio of 10 to 100, wherein the bimetallic oxide is an AxOy-ZrO2 solid solution, A is Zn, Cd or Ga, the molar ratio of A to (A + Zr) is 0.01-0.4, and the amount of the AxOy-ZrO2 solid solution accounts for 10-60 wt% of the total amount of the catalyst. The catalyst has the beneficial effects that the catalyst is applied to the reaction of preparing methylbenzene and xylene through alkylation reaction of synthesis gas and benzene, and has high activity and high selectivity.

Owner:NORTHWEST UNIV

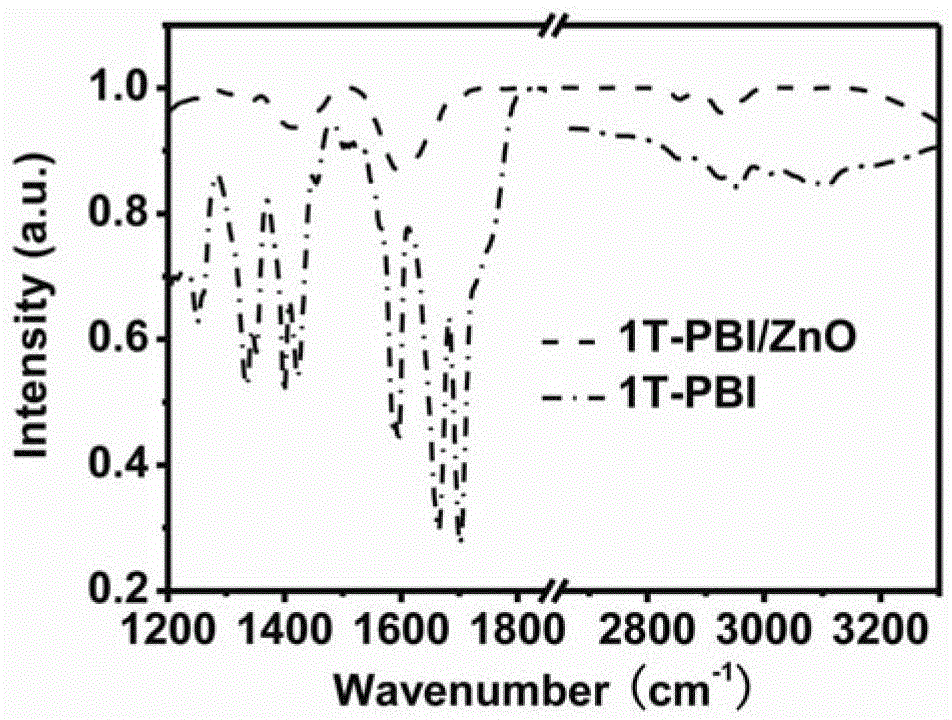

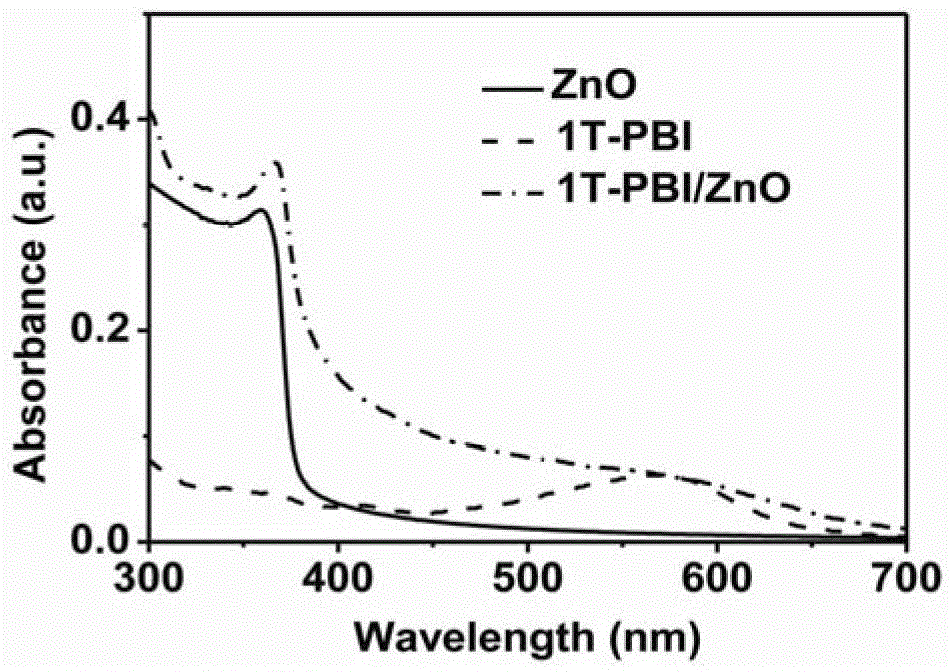

Organic-inorganic hybrid nano material, and preparation method and application thereof

InactiveCN103337591AImprove photoelectric performanceEffective dissociationFinal product manufactureSolid-state devicesSimple Organic CompoundsSemiconductor materials

The invention discloses an organic-inorganic hybrid nano material, and a preparation method and an application thereof. The nano material is composed of a donor-acceptor-type organic compound and an n-type inorganic semiconductor material; the molecular formula of the donor-acceptor-type organic compound is shown in formula I or formula II; the mass ratio of the donor-acceptor-type organic compound to the n-type inorganic semiconductor material is 1: (50-250). The organic-inorganic hybrid nano material has an excellent photoelectric property, and can be used for building a photoconducting device. The preparation method provided by the invention is simple and feasible, can realize bonding of the donor-acceptor-type organic compound on the surface of the n-type inorganic semiconductor material, and can realize effective grading electron transfer so as to promote the effective dissociation of excitons and improve the conversion efficiency of the photoconducting device, so that a photoelectric material with excellent performance is provided. The organic-inorganic hybrid nano material and the preparation method have a wide application prospect in the field of photoconducting devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI

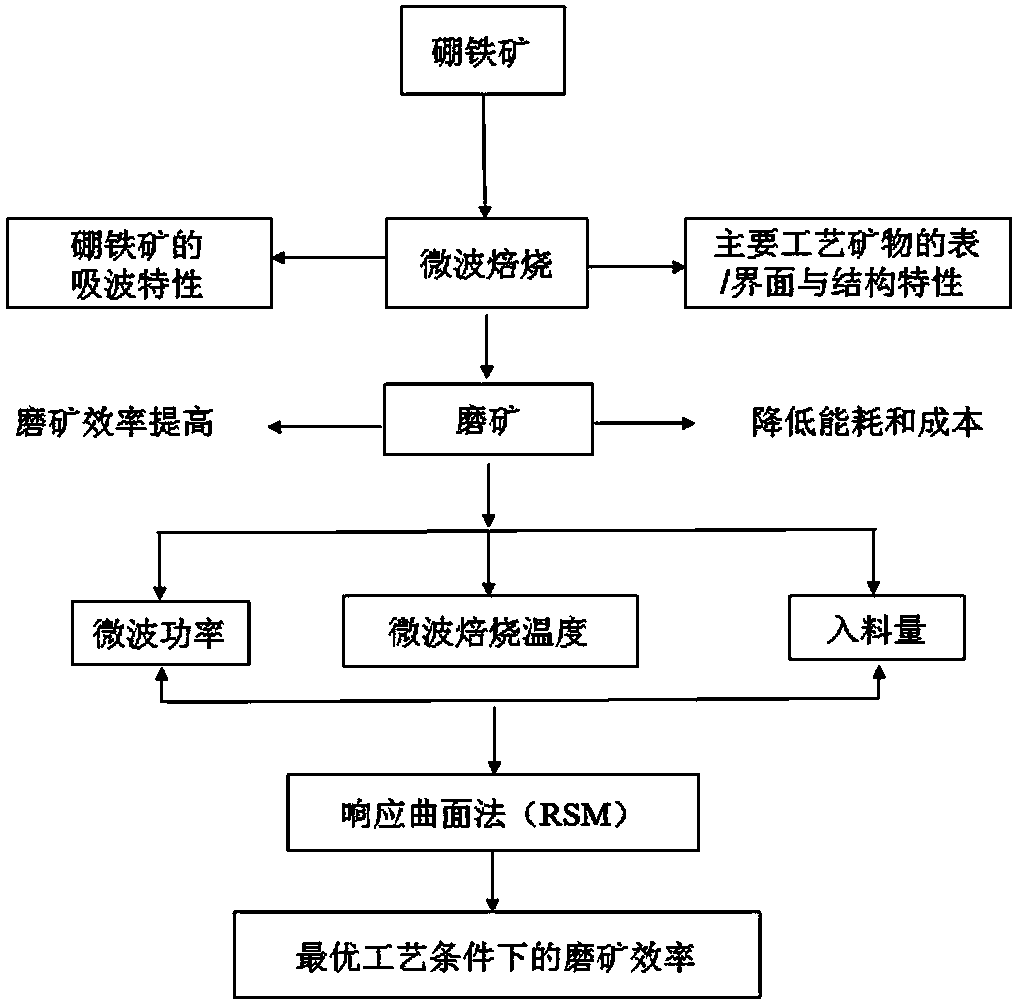

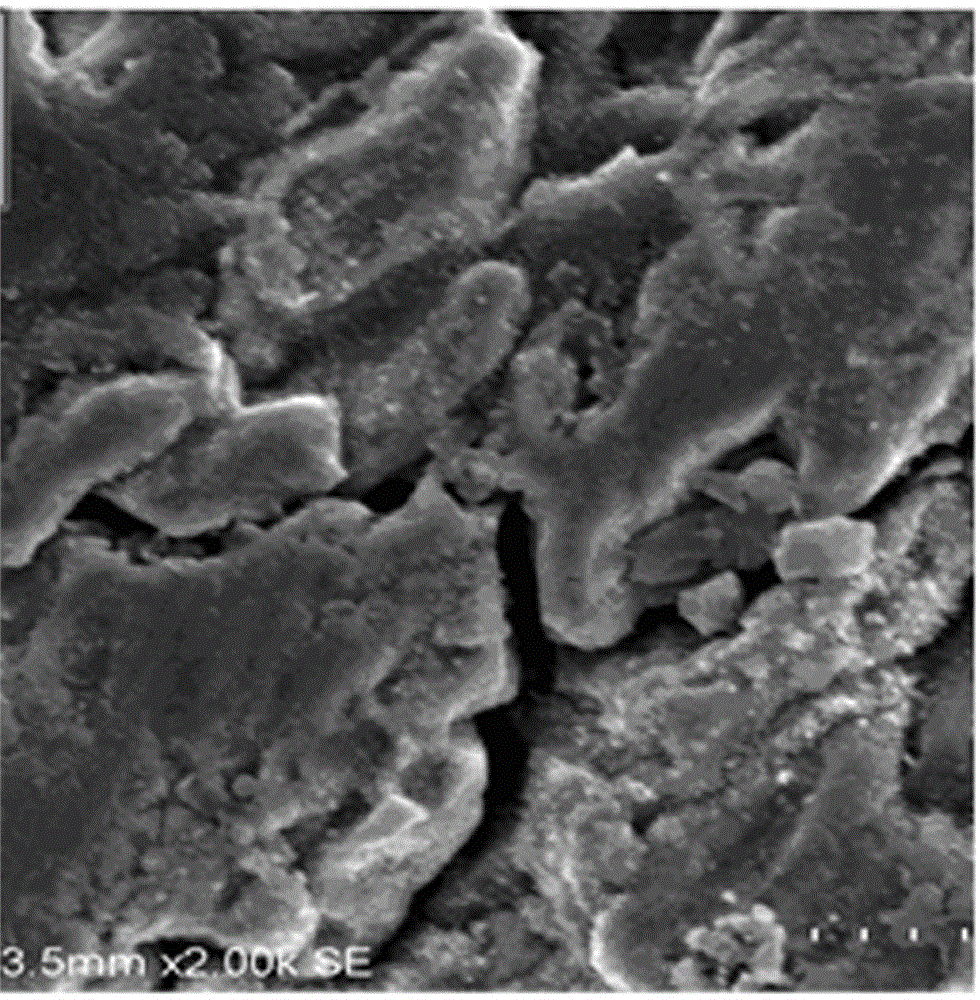

Parameter analysis method of paigeite ground by adopting microwave assisted method

ActiveCN104353534AExpand and change mechanical propertiesChange the mechanical propertiesGrain treatmentsDesign–ExpertMicrowave oven

The invention relates to a parameter analysis method of paigeite ground by adopting a microwave assisted method and belongs to the technical field of mineral processing. The parameter analysis method comprises the following steps: (1) carrying out microwave roasting on paigeite in a microwave oven, ensuring that the microwave power is 1500-2500 W, heating to be 450-650 DEG C and ensuring that the feeding quantity is 50-250 g; (2) grinding the paigeite treated by microwaves for 5-6 minutes and screening parts of which the grain sizes are less than or equal to 75 [mu]m; (3) optimizing the ball-milling process of the paigeite by adopting the central composite design of a response surface method, wherein the selected influence factors are microwave power X1 of which the unit is W, microwave roasting temperature X2 of which the unit is DEG C and feeding quantity X3 of which the unit is g, and a response value Y which is set to be the yield percentage of grains with the grain size of less than or equal to 75 [mu]m; (4) analyzing the influence of the selected experimental factors on the grinding efficiency of the paigeite through Design-Expert experimental design optimization software so as to obtain significant factors and optimal technological conditions capable of influencing the paigeite grinding efficiency.

Owner:NORTHEASTERN UNIV

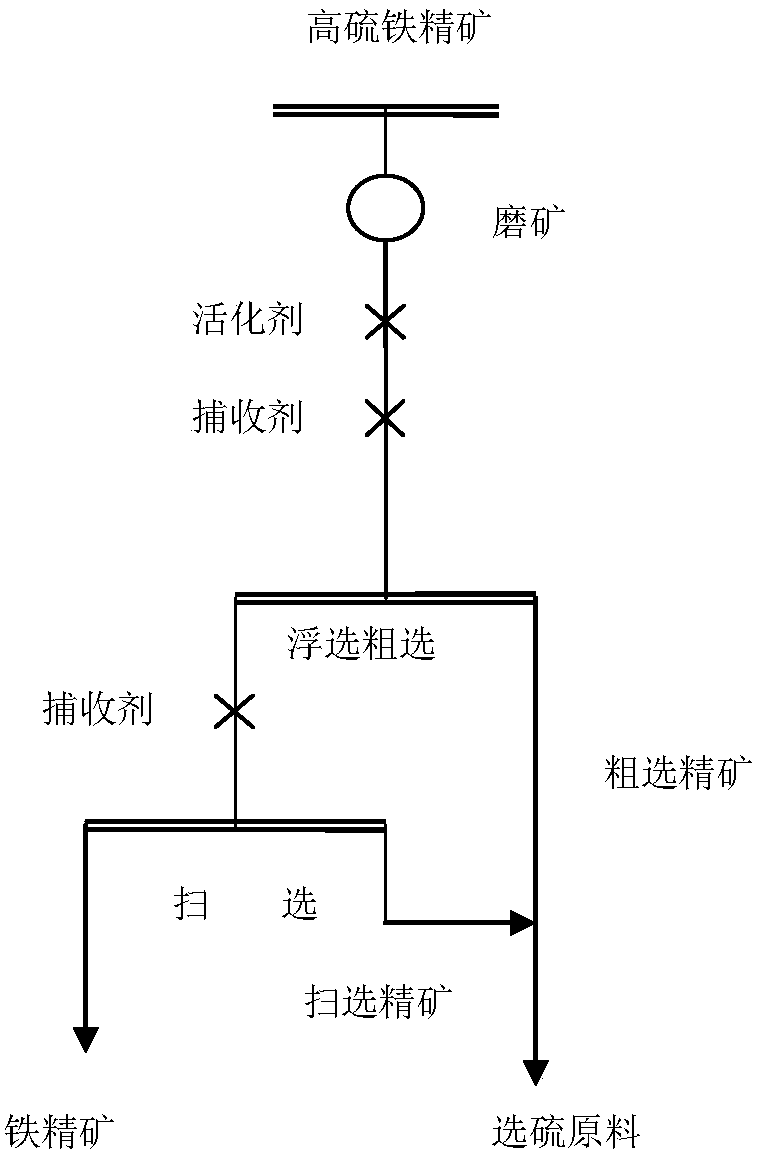

Method for removing pyrrhotite from high-sulfur iron ore concentrate

ActiveCN108097453ARaise the gradeHigh recovery rateFlotationWet separationAluminium sulfateSodium phosphates

The invention relates to a method for removing pyrrhotite from high-sulfur iron ore concentrate and belongs to the technical field of mineral engineering. The sulfur content of high-sulfur iron ore concentrate is higher to seriously affect the quality of the iron ore concentrate. Pyrrhotite is likely to have oxidation and argillization, and the oxidization degrees are different, so that the sulfurcontent in the iron ore concentrate is difficult to be reduced below 0.3%, and the recovery rate loss of the iron ore concentrate is larger. According to the method, through proper ore grinding, mostof monomers of pyrrhotite are separated and are prevented from excessively grinding to avoid argillization. Efficient and feasible aluminum sulfate or the mixture of aluminum sulfate, sodium phosphate and ammonium fluosilicate is adopted as an activator and a pH regulator of pyrrhotite, and a collecting agent with better selectivity and collecting performance is adopted to activate the mineral surface of pyrrhotite, and the electrical charge state of the surface of mineral in ore pulp is better controlled, so that magnetite and pyrrhotite are effectively separated and high-quality iron ore concentrate with high grade and high recovery rate and rough concentrate of pyrrhotite are obtained.

Owner:内蒙古薪宝高科技开发有限公司

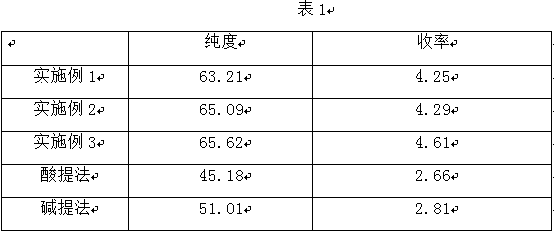

Method for extracting beta-glucan from Sparassis crispa

The invention discloses a method for extracting beta-glucan from Sparassis crispa. The method realizes pretreatment of the Sparassis crispa abd effective destroy of cells through physical grinding andaddition of a wall-breaking enzyme in order to dissolves out contents, so the extraction rate of the glucan is increased; high-pressure microwave treatment makes separation of glucan and cell tissuesfurther realized in order to achieve dissociation, so finally the glucan is obtained by extraction; and starch, proteins and other polysaccharides can be effectively removed by adding an impurity removal enzyme and ammonium sulfate, so that the purity of glucan is greatly improved.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV

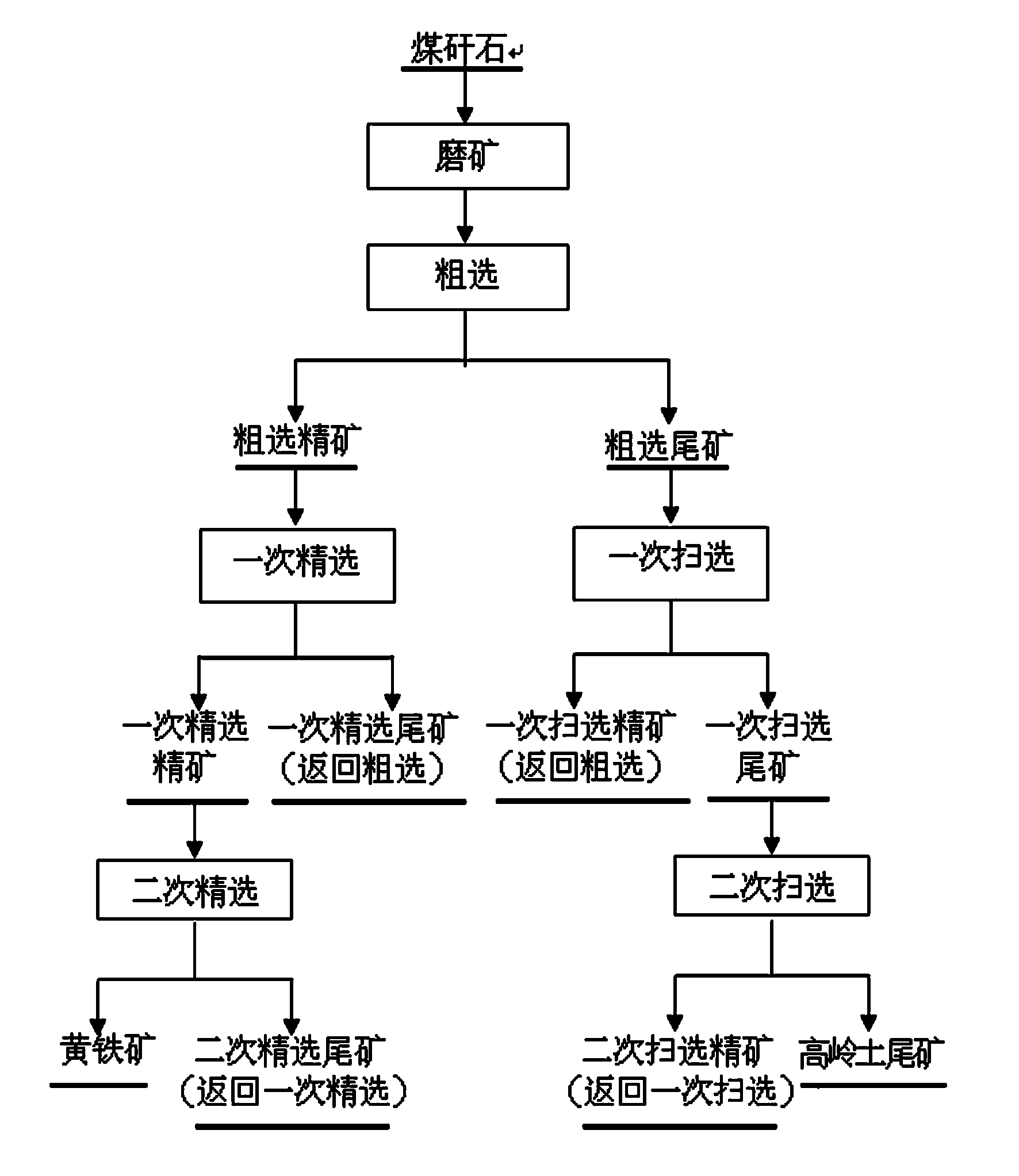

Method for recovering pyrite from coal gangue

InactiveCN103657838AEffective dissociationReduce mudFlotationWet separationOre concentrateCoal gangue

The invention discloses a method for recovering pyrite from coal gangue. The method is characterized by comprising the following steps that the coal gangue is subjected to two-stage closed-circuit crushing, grinding, roughing, primary scavenging, secondary scavenging, primary cleaning and secondary cleaning. In the roughing step, acidified water glass, xanthate and number two oil are sequentially added to fed ore pulp, so that rougher concentrates and rougher tailings are obtained. In the primary scavenging step, acidified water glass, xanthate and number two oil are sequentially added to the rougher tailings, so that primarily scavenged concentrates and primarily scavenged tailings are obtained. In the secondary scavenging step, acidified water glass, xanthate and number two oil are sequentially added to the primarily scavenged tailings, so that secondarily scavenged concentrates and kaolin tailings are obtained. In the primary cleaning step, acidified water glass is added to the rougher concentrates, so that primary cleaner concentrates and primary cleaner tailings are obtained. In the secondary cleaning step, acidified water glass is added to the primary cleaner concentrates, so that the pyrite and secondary cleaner tailings are obtained. The method for recovering the pyrite from the coal gangue is simple; the pyrite recovery rate is high; environmental pollution is reduced; the pyrite can be produced on a large scale.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

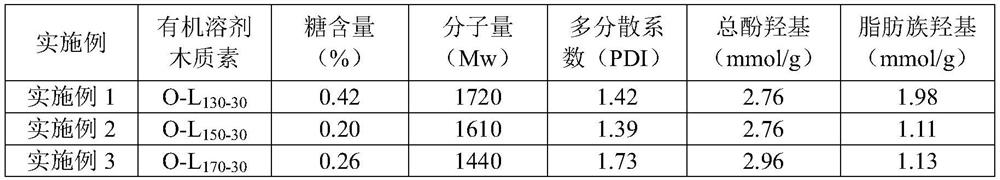

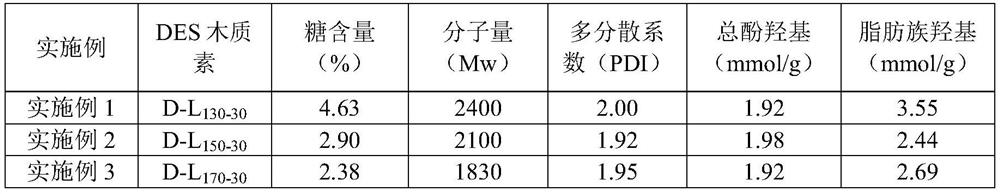

Method for pretreating eucalyptus graded lignin and co-producing furfural based on DES two-phase system

ActiveCN113956299AImprove solubilityEffective dissociationLignin derivativesAqueous acetonePtru catalyst

The invention aims to provide a method for pretreating eucalyptus graded lignin and co-producing furfural based on a DES two-phase system. The method comprises the following steps of: (1) pretreatment of raw materials: crushing, dewaxing and drying; (2) preparation of DES: mixing a hydrogen bond acceptor and a hydrogen bond donor, performing heating and stirring until the mixture is uniform and transparent; and (3) pre-treating graded lignin and co-producing furfural by using the two-phase system: 1) blending the raw material, DES, an organic solvent and a catalyst, and adding the mixture into a reaction kettle for reaction; 2) performing cooling after the reaction is finished, and separating the mixture to obtain a eutectic reaction mixture and an organic extraction phase; and 3) carrying out rotary evaporation on an eluent obtained by washing the eutectic reaction mixture with an acetone / aqueous solution and the organic extraction phase, and then carrying out acid water precipitation, centrifugation and freeze drying to respectively obtain the DES lignin and the organic solvent lignin. According to the method, lignin with different fractions and high purity and good uniformity is obtained through a one-step method, and furfural is co-produced.

Owner:BEIJING FORESTRY UNIVERSITY

Method adopting microwave to assist grinding separation of paigeite

The invention relates to a method adopting microwave to assist grinding separation of paigeite, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, carrying out microwave roasting on paigeite in a microwave oven under a microwave power of 1500-2500W per 100g of paigeite, and heating paigeite to 450-650DEG C; 2, milling the microwave roasted paigeite by adopting a ball mill under a rotating speed of 94-98r / min for 5-6min; 3, screening out obtained particles with the granularity of 75[mu]m or less; and 4, carrying out magnetic separation to obtain iron concentrate. The method starts from grinding, researches the change of the mechanical performances of ore in advance through a certain means, creates favorable conditions for subsequent grinding work, and realizes the increase of the grinding and magnetic separation efficiency.

Owner:NORTHEASTERN UNIV LIAONING

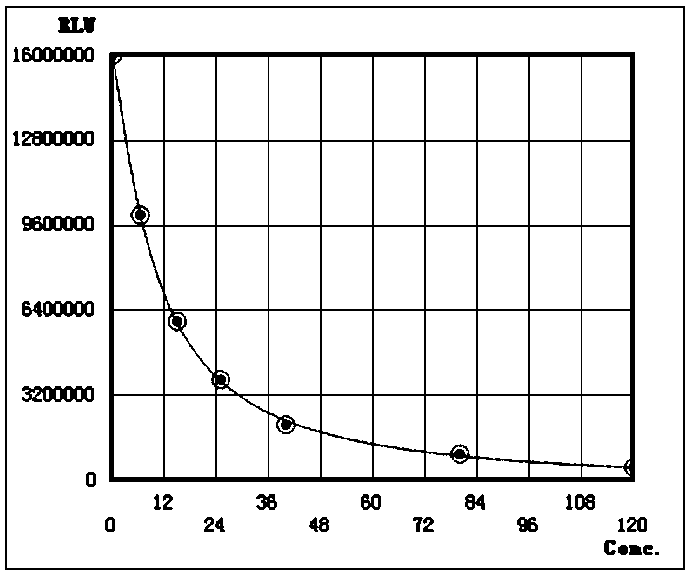

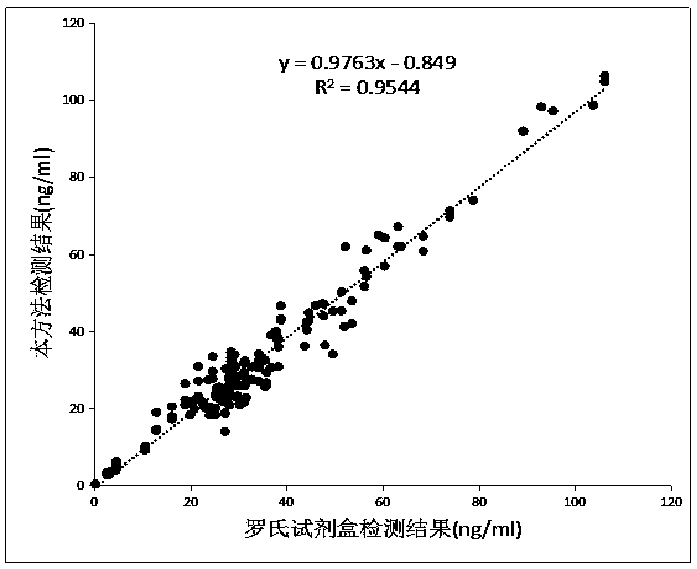

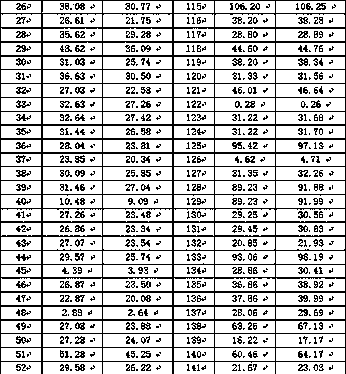

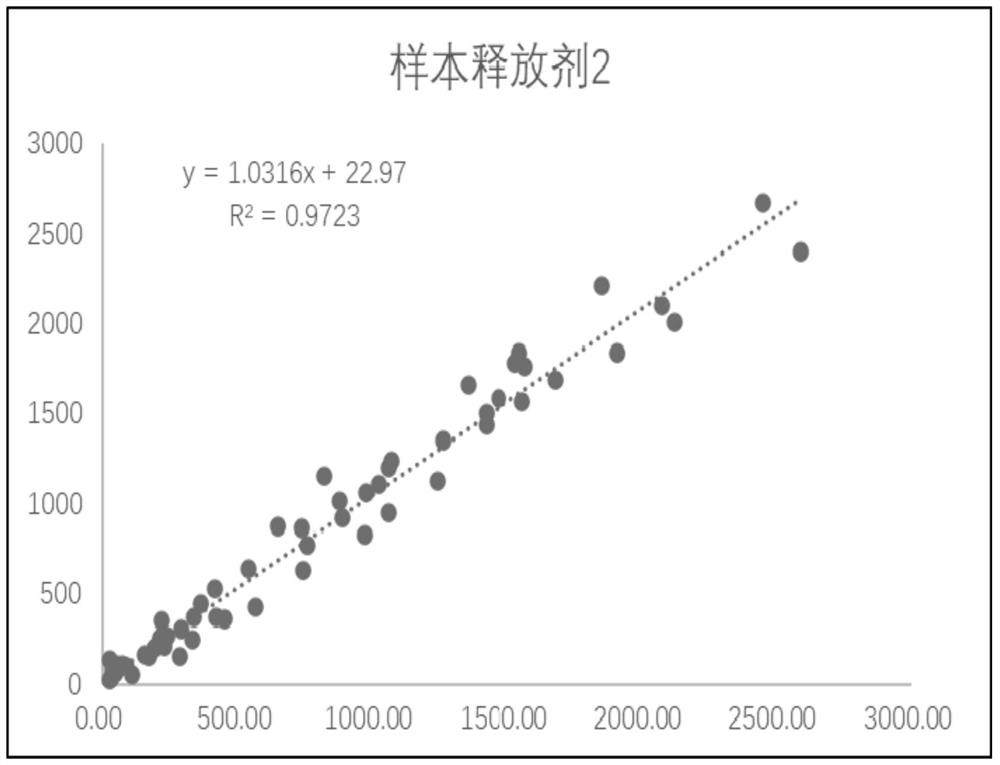

Releasing agent for detecting content of 25-hydroxyvitamin D in human serum sample and detection method thereof

ActiveCN108089015AHarm reductionThe preparation method is simple and easyBiological testingCoatingsMetaboliteDodecylsulfonic acid

The invention discloses a releasing agent for detecting the content of 25-hydroxyvitamin D in a human serum sample. The releasing agent is prepared from, by mass-to-volume ratio, 0.05-0.3% of sodium dodecyl sulfate, 1-20% of dimethyl sulfoxide and 1-10% of ethyl alcohol; during preparation, the sodium dodecyl sulfate is weighed firstly, after the sodium dodecyl sulfate is dissolved in a small quantity of 0.05 M Tris-NaCl buffer solution, the dimethyl sulfoxide and the ethyl alcohol are added, 0.05 M Tris-NaCl buffer solution is used for constant volume, concentrated hydrochloric acid is used for adjusting the pH value to 7.0, and a releasing agent finished product is obtained. The releasing agent has the advantages that the preparation method is simple, and the components used are less harmful to the environment and organisms; when in detection, the 25-hydroxyvitamin D and the metabolite of the same can be effectively released from binding protein, and thus be fully detected; there isno need to pretreat the sample, the sample can be added with other reagents at the same time, and it is convenient to conduct automatic operation.

Owner:AUTOBIO DIAGNOSTICS CO LTD

Method for filling and synthetizing full waterborne polyurethane base leather through nano attapulgite

InactiveCN104727156ARich sourcesImprove mechanical propertiesTextiles and paperWoven fabricPolymer chemistry

The invention discloses a method for filling and synthetizing full waterborne polyurethane base leather through nano attapulgite. The method includes adopting non woven fabrics as the base fabric, and soaking the non woven fabric in NaCl water solution; drying and ironing the soaked base fabric, and calendering the surface; adopting attapulgite as raw material, smashing, soaking in water, extruding through opposite rollers, aging and adding anionic waterborne polyurethane for high speed pre-dispersion; adding foaming agent, foam stabilizing agent and aqueous colorant sequentially, mixing at high speed, and obtaining waterborne polyurethane synthesis leather slurry; soaking the pretreated base fabric in the waterborne polyurethane synthesis leather slurry, scraping the surface, drying, and obtaining the waterborne polyurethane base leather. The attapulgite filler is low in cost and easy to prepare, the synergistic reinforcement effect of fibrillar attapulgite and associated minerals is played completely, the mechanical property of the synthesis base leather is improved effectively, organic solvent is omitted during production, safety and environment protection can be achieved, the process is easy and simple to implement, and large-scale production is easy to implement.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for preparing electronic-grade high-purity quartz sand

PendingCN114378026AReduce intensityEffective dissociationSilicaCleaning using liquidsUltra high voltagePhysical chemistry

The invention discloses a method for preparing electronic-grade high-purity quartz sand, which comprises the following steps: washing quartz raw ore with ultrahigh-pressure water, crushing into 30 mm quartz blocks, finely selecting the quartz blocks, pretreating by adopting high-voltage electric pulse, crushing and screening to prepare-40-mesh quartz sand, carrying out magnetic separation on the quartz sand to remove magnetic minerals, and drying to obtain the electronic-grade high-purity quartz sand. Non-quartz silicate minerals are removed through flotation, residual impurity minerals on the surfaces of quartz sand and quartz particles are removed from flotation fine sand through dynamic acid pickling, the flotation fine sand is dried, calcined, rapidly cooled and acid-pickled, acid-pickled fine sand is graded to obtain quartz sand with a certain specification, and the quartz sand is subjected to vacuum degassing, cooling and packaging. It is ensured that the product meets the quality requirement of high-purity quartz sand for electronic products SJT 3328.1-2016, and the requirement of the domestic electronic industry for high-purity quartz sand is met.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

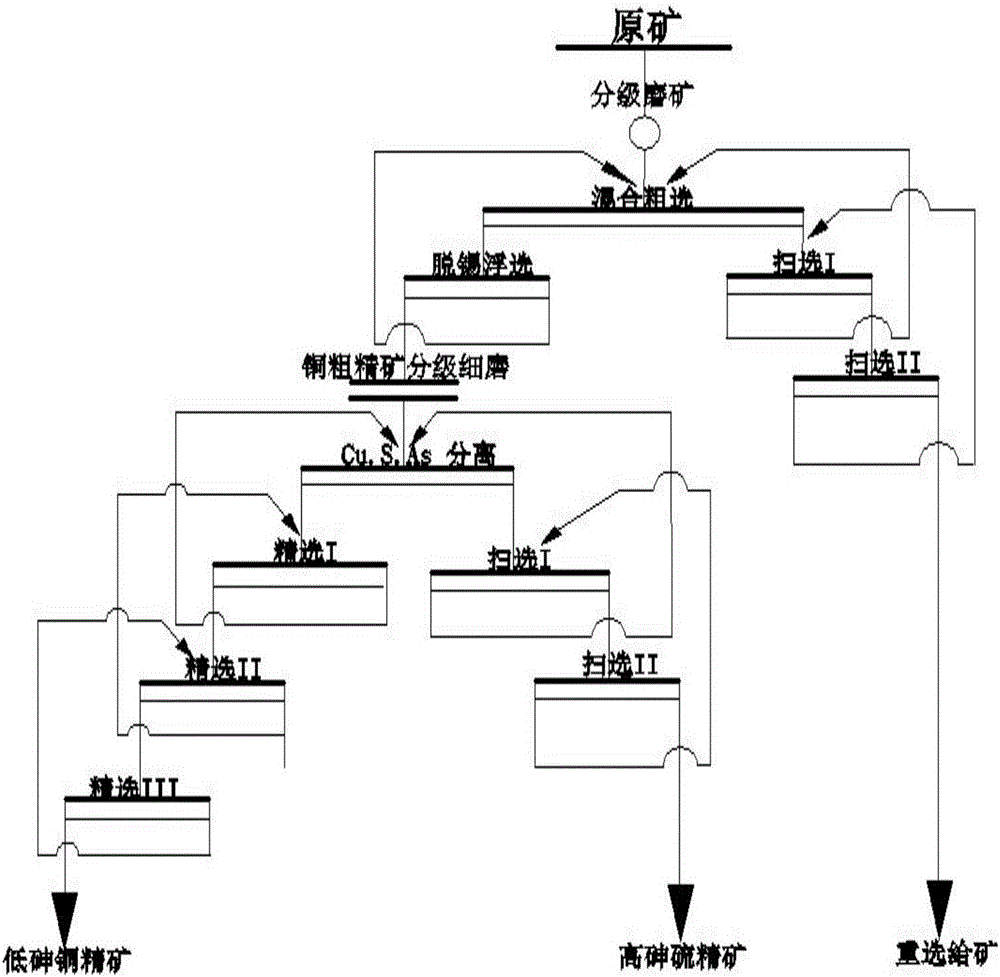

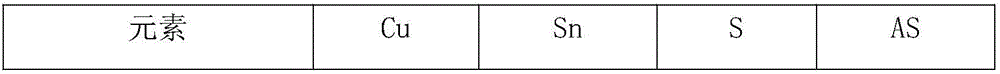

Production online flotation arsine-reduction method for high arsenic-containing copper concentrate

InactiveCN106733142ASimplify the arsenic reduction processSimple and efficient operationSolid separationArsineArsenic

The invention discloses a production online flotation arsine-reduction method for high arsenic-containing copper concentrate. Firstly, bulk flotation high arsenic-containing copper concentrate is produced through a copper-sulfur-arsenic bulk flotation technique, and tailings are treated through a tin re-flotation technique; before copper-sulfur-arsenic separation flotation for arsine reduction, a long-conical hydrocyclone is adopted for slight steel forging and classified fine grinding, inhibitors are added to achieve effective monomer separation, analytic reagent removal and reinhibition; and finally, production online arsine reduction is conducted through the copper-sulfur-arsenic separation flotation arsine-reduction technique, low arsenic-containing copper concentrate and high arsenic-containing copper-sulfur-arsenic separation sulfur concentrate are produced, the propose of production online direct flotation arsine reduction in the production process of tin-copper-sulfur-arsenic symbiotic complex refractory multi-metal sulfide ores is achieved. According to the production online flotation arsine reduction method for the high arsenic-containing copper concentrate, the steps of the copper concentrate arsine reduction technique are simplified, operation is easy, the production online flotation arsine reduction method is practical, operation cost is low, the arsenic content of the copper concentrate is low, copper metal loss in the arsine reduction technological process is greatly reduced, and the recycling rate of copper and tin metal is increased.

Owner:YUNNAN TIN

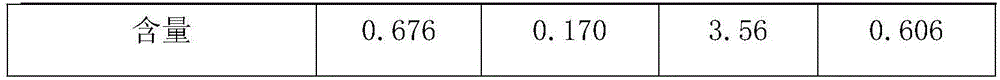

Method for reinforcing copper inhibition molybdenum extraction during copper-molybdenum separation

The invention relates to a method for reinforcing copper inhibition molybdenum extraction during copper-molybdenum separation, and belongs to the field of mineral separation. The method comprises thesteps of a, carrying out beforehand tailing discarding, one-time roughing, three-time scavenging and five-time concentration on copper-molybdenum mixed concentrate, so as to obtain concentrate foam; b, adding a copper inhibitor into the concentrate foam obtained in the step a; c, feeding pulp formed in the step b into a mill to be reground; d, adding a molybdenum collecting agent into an ore grinding product obtained in the step c; and e, carrying out six-time concentration to ten-time concentration flotation on a product obtained in the step d, so as to obtain final copper concentrate and molybdenum concentrate. According to the method, sodium hydrosulfide is added during the regrinding process of five-time concentration foam, the problem that copper minerals are hard to inhibit during the copper-molybdenum separation process is solved, and copper and molybdenum are effectively separated while the argillization phenomenon caused by mass crushing of gangue minerals is avoided through regrinding of five-time concentration foam; and besides, kerosene is added before the reground product enters the next process, so that recovery for molybdenum in follow-up operation is reinforced, andthe recovery rate of molybdenum is increased.

Owner:CHANGCHUN GOLD RES INST

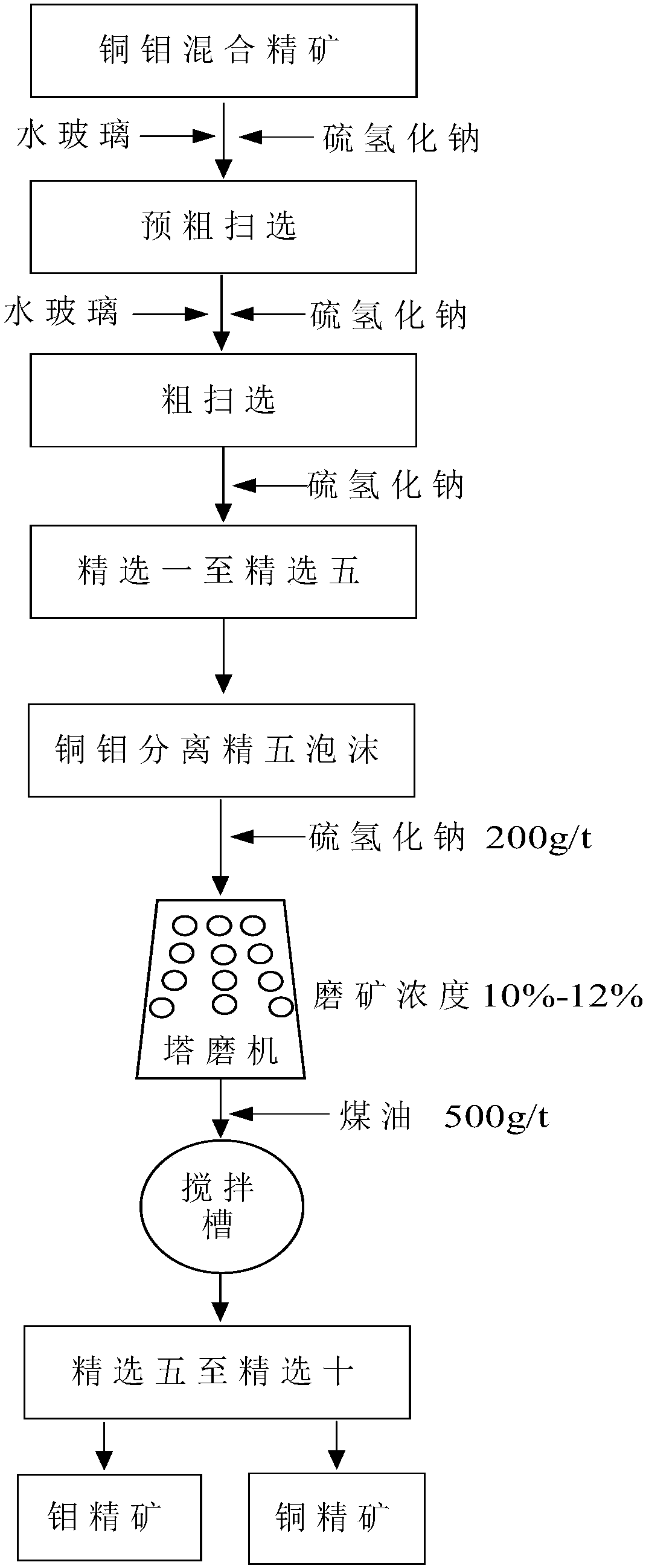

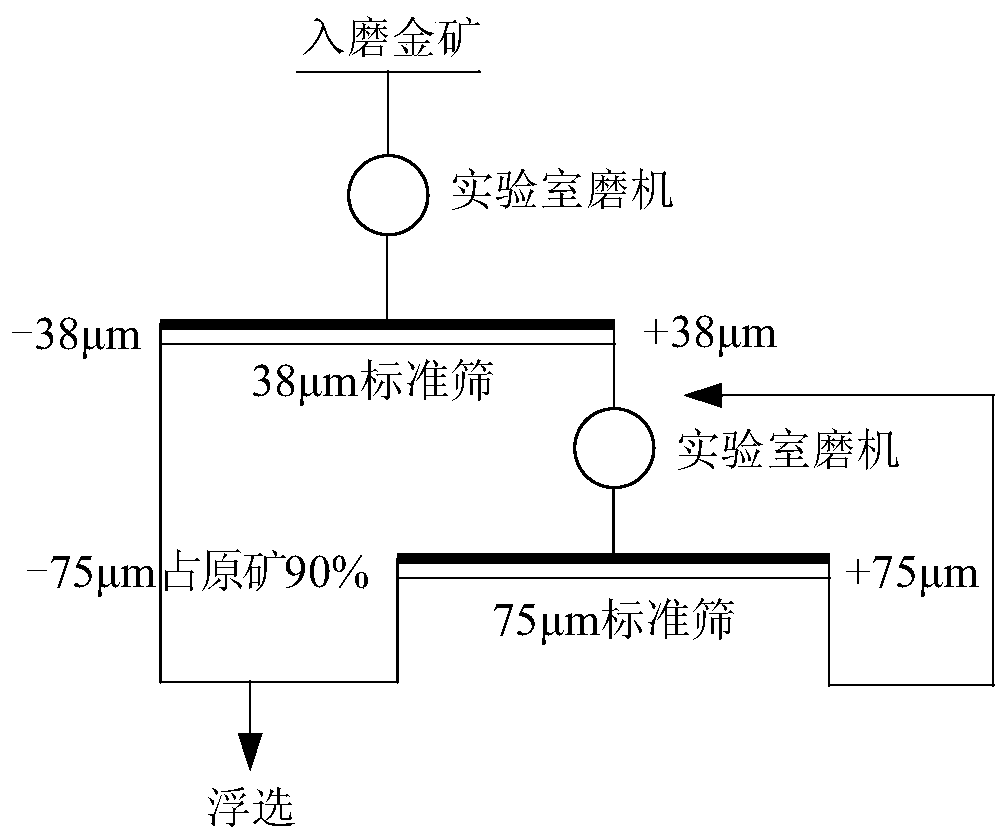

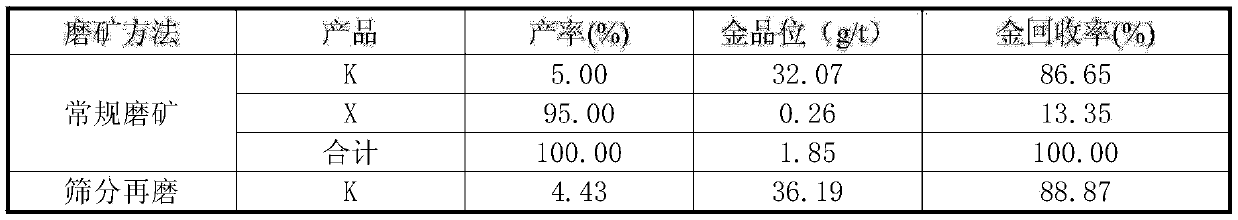

Laboratory ore grinding method for unevenly inlaid gold ore

ActiveCN110624682AImprove grinding effectPrevent over- or under-grindingWet separationNon-ferrous metalGold ore

The invention relates to a laboratory ore grinding method for an unevenly inlaid gold ore. The unevenly inlaid gold ore is ground by adopting a laboratory mill. The laboratory ore grinding method comprises the steps that ore grinding is conducted, ground gold ore is added into a first laboratory mill for conventional ore grinding, and ground to be -75 [mu]m accounting for 80%, and then dischargingis conducted to obtain first ore pulp; screening is conducted, a standard screen of 38 [mu]m is added to screen the first ore slurry, and the first ore slurry is screened into size fractions of +38 [mu]m or above and size fractions of -38 [mu]m or below; regrinding is conducted, the size fractions of +38 [mu]m or above are added into a second laboratory mill for regrinding, and ground until the conventional standard screen of 75 [mu]m is used for screening out size fractions of +75 [mu]m accounting for 10% of raw ore, and then discharging is conducted to obtain second ore pulp; and mixing isconducted, the size fractions of -38 [mu]m or below are mixed with the second ore pulp to obtain third ore pulp, the comprehensive ore grinding fineness of the size fractions of +75 [mu]m of the thirdore slurry accounts for 10%, namely size fractions of -75 [mu]m account for 90%, and finally the third ore slurry enters floatation operation. The laboratory ore grinding method has the advantages ofeffectively dissociating target minerals, preventing the phenomena of over grinding or under grinding, creating good floatation particle size conditions for the subsequent floatation operation and the like, and is suitable for the application to the field of non-ferrous metal beneficiation.

Owner:ZIJIN MINING GROUP

25-hydroxyvitamin D detection kit, preparation method and detection method

InactiveCN111721944AEffective dissociationHigh activityChemiluminescene/bioluminescenceBiological testingAntigenBlood plasma

The invention relates to the technical field of in-vitro diagnosis and detection, and particularly relates to a 25-hydroxyvitamin D detection kit, a preparation method and a detection method. The 25-hydroxyvitamin D detection kit comprises a reagent R1, a reagent R2, a reagent R3 and a sample treatment reagent, wherein the reagent R1 comprises a streptavidin magnetic particle solution; the reagentR2 is prepared from an alkaline phosphatase labeled 25-hydroxyvitamin D monoclonal antibody solution; the R3 reagent is prepared from a biotin labeled 25-hydroxyvitamin D antigen solution; the sampletreatment reagent comprises a weakly acidic buffer solution, a reducing agent and a lower alcohol solvent. The kit provided by the invention has high sensitivity, specificity and a wide detection range, can be used for detection only by using 40 [mu]L of serum or plasma, has good patient experience, can be combined with a full-automatic chemiluminescence analyzer, and realizes automatic monitoring.

Owner:深圳市爱康试剂有限公司

Supercritical extraction method of maca essential oil

InactiveCN106318629AKeep active ingredientsEffective dissolutionEssential-oils/perfumesFatty-oils/fats productionFree stateExtraction methods

The invention provides a supercritical extraction method of maca essential oil. The method comprises the three steps of pulverization, supercritical fluid leaching and separation. Mechanical wall breaking and granulation are performed to provide favorable conditions for extracting effective components in maca; by adopting a CO2 supercritical fluid leaching mode, the effective components in the maca are firstly extracted, and the effective components are converted into a free state in the CO2 supercritical fluid system; and the extraction pressure is lowered to selectively extract the effective components.

Owner:广东玛海娑生物科技有限责任公司 +2

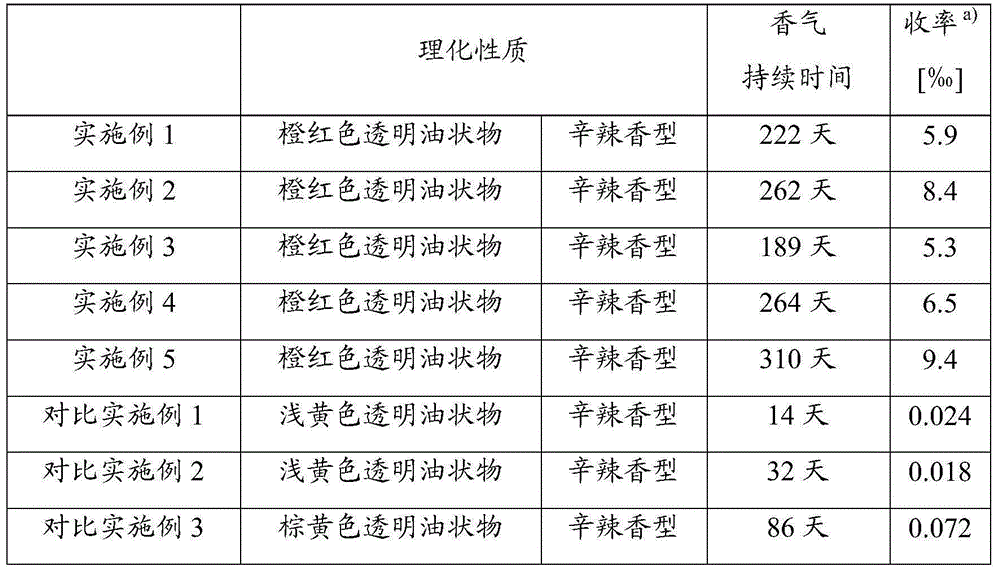

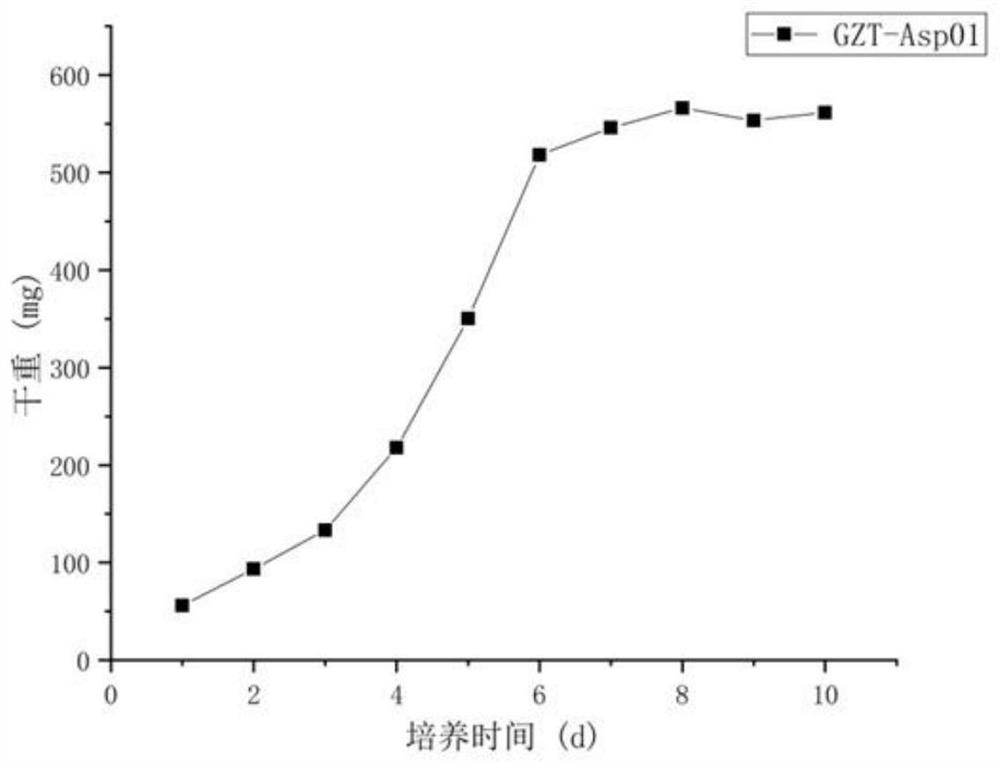

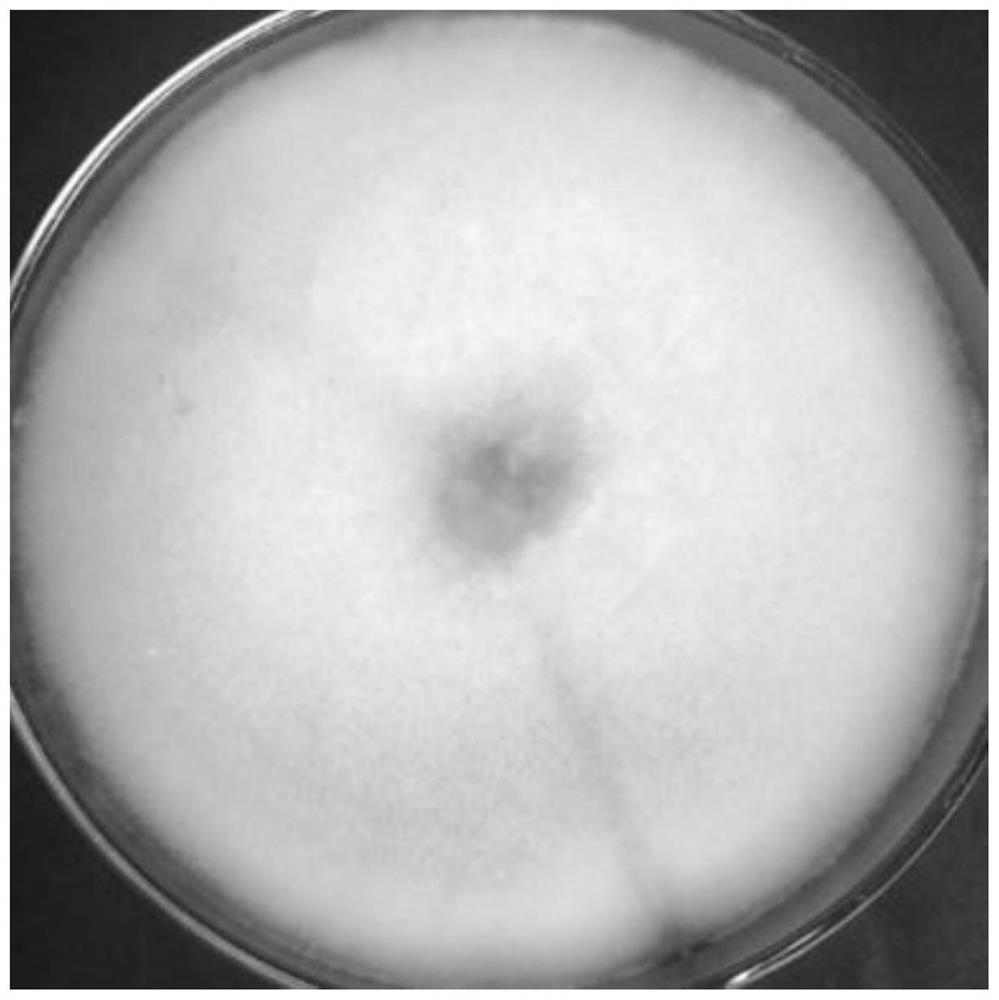

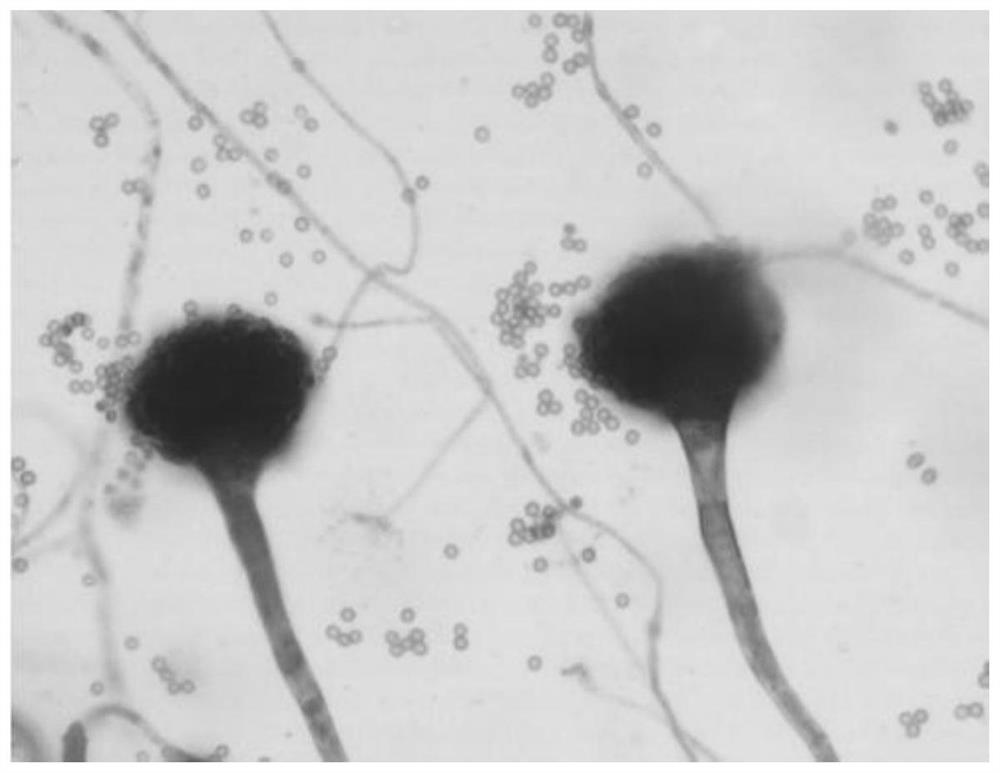

Coal gangue microbial fungal fertilizer and preparation method thereof

ActiveCN113979790ARealize resource reuseEffective dissociationBio-organic fraction processingMicroorganism based treatmentBiotechnologyAspergillus fumigatus

The invention discloses a coal gangue microbial fungal fertilizer and a preparation method thereof. The fertilizer comprises or is a product obtained by treating raw materials with aspergillus fumigatus GZT-Asp01; the main component of the raw materials is coal gangue or coal gangue; the method for treating the raw materials by using the aspergillus fumigatus GZT-Asp01 comprises the following steps: crushing the raw materials, and preparing the aspergillus fumigatus GZT-Asp01 into a bacterial solution; and under continuous stirring, spraying the bacterial liquid on the crushed raw materials, performing uniform stirring, timed overturning, temperature control treatment and airing to obtain a product. According to the coal gangue microbial fungal fertilizer disclosed by the invention, the coal gangue is treated by using the aspergillus fumigatus GZT-Asp01, so that insoluble phosphorus, potassium, calcium, nitrogen and other components in the coal gangue can be effectively converted into available phosphorus, quick-acting potassium, exchangeable calcium, hydrolytic nitrogen and other nutritional components which can be absorbed by plants, and resource reutilization of the coal gangue is realized; in addition, the technological process for dissociating the coal gangue through the aspergillus fumigatus GZT-Asp01 is remarkable in effect, low in cost and environmentally friendly.

Owner:中国烟草总公司贵州省公司

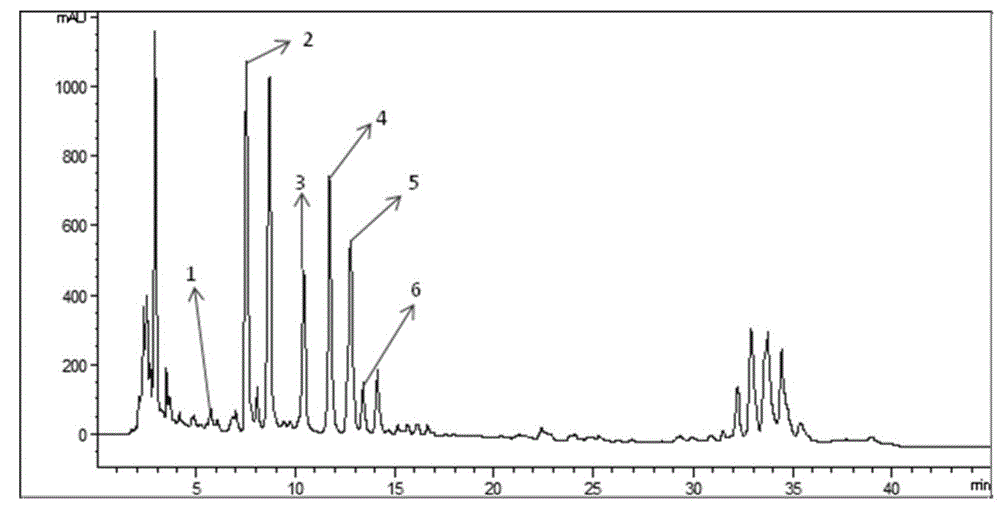

Enrichment method of low abundance protein in bee venom

InactiveCN103204900AHigh specificityReduce loss ratePeptide preparation methodsChemistryEnrichment methods

The invention relates to an enrichment method of low abundance protein in bee venom. The method includes: using hexapeptide ligand microspheres bonded with porous poly(2-hydroxyethyl methacrylate) granules as absorbent base, mixing the absorbent base with bee venom to absorb the protein in the bee venom, washing with PBS (phosphate buffered saline) buffer solution to remove excess high-abundance protein, and eluting the protein absorbed to the absorbent base with eluent to obtain the eluent with the enriched low-abundance protein. The enrichment method of low abundance protein is efficient, stable, well repeatable and highly specific and has great significance to enhancing the study on low-abundance protein, the search on information of more allergens in bee venom, the development of traditional Chinese medicines, the study on disease diagnosis markers and occurrence mechanisms of disease, and the like.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

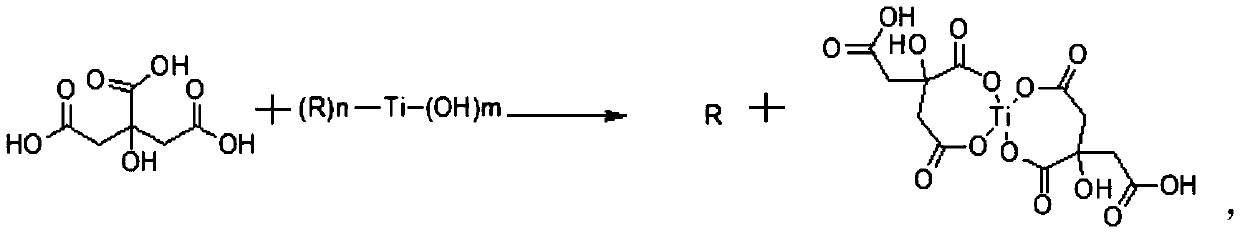

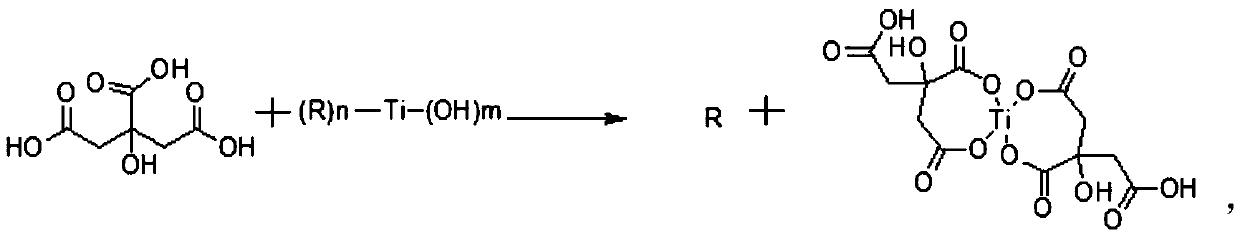

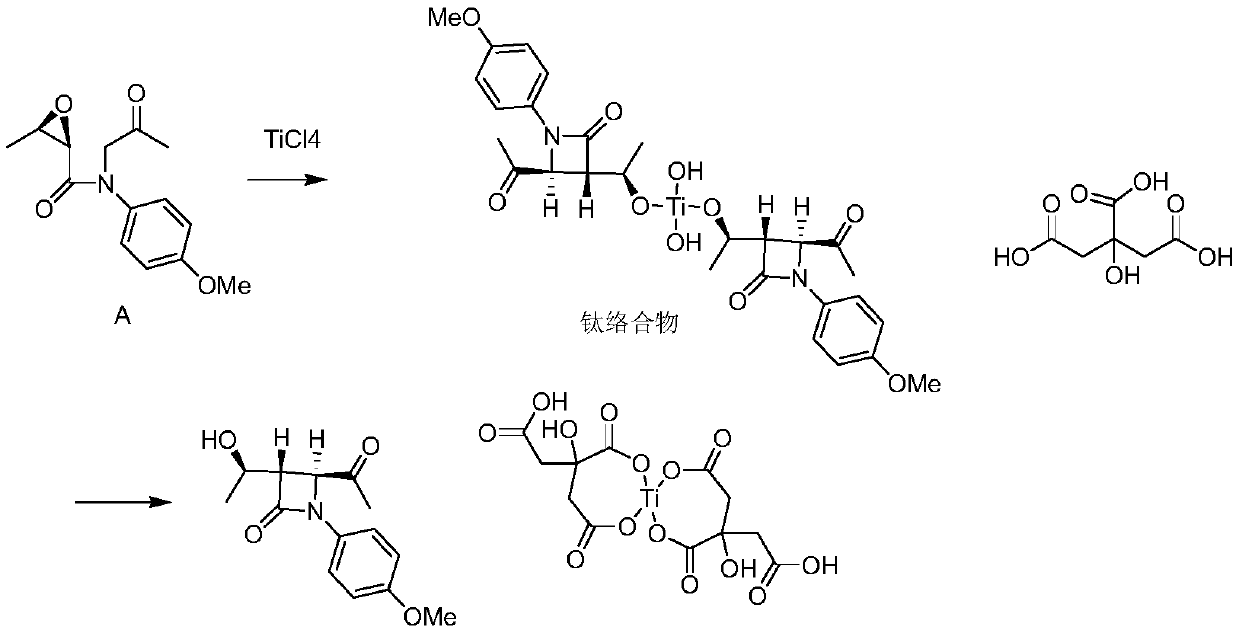

Dissociation method and application of titanium complex drug

The invention discloses a dissociation method and application of a titanium complex drug. According to the dissociation method, the stronger coordination property of citric acid and metal ions is utilized, the citric acid competes with drug molecules for coordination of titanium ions, the drug molecules complexed in the titanium complexation drug are released, and then separation operation is performed to collect the released drug molecules. According to the dissociation method disclosed by the invention, the purity of the drug compound can be obviously improved, because the citric acid can becompletely complexed with the titanium ions, a titanium complex formed by the drug molecules and the titanium ions is disintegrated, and then the dissociated drug compound is directly concentrated and collected through separation operation, so that the drug compound is obtained. The method is simple and efficient, the obtained drug compound has fewer impurities and higher purity, and the qualityof the drug is obviously improved.

Owner:广东省科学院珠海产业技术研究院有限公司

A New Method of Reverse Flotation Separation, Grinding and Separation

InactiveCN102259065AIncrease monomer dissociationIncrease Concentrate ProductionFlotationMineral flotationEngineering

The invention relates to the technical field of beneficiation of lean hematite, in particular to a new method for flotation, regrinding and re-election, which includes one-stage roughing, one-stage beneficiation, and three-stage sweeping operations, and the concentrate of one-stage roughing operation is fed into The tailings of one stage of selection operation and one stage of roughing operation are fed into one stage of sweeping operation, and the fine tailings of one stage of selected middle ore return to one stage of roughing operation, the concentrate of one stage of concentration operation is flotation concentrate, and the tailings are fed The second-stage sweeping operation, the second-stage sweeping concentrate is returned to the first-stage sweeping operation, the tailings are fed into the third-stage sweeping operation, the third-stage sweeping concentrate is returned to the second-stage sweeping operation, and the first-stage sweeping operation The concentrate is re-grinded to greatly increase the monomer dissociation degree of the concentrate in the first stage of scavenging operation, and the re-grinded product returns to the original flotation process for further separation. Minerals are more fully sorted, which reduces the amount of medium ore circulation in each operation of flotation, and makes the flotation circuit form a virtuous circle. The grade of flotation concentrate is improved, the grade of flotation tailings is reduced, and the metal recovery rate is improved.

Owner:ANSTEEL GRP MINING CO LTD

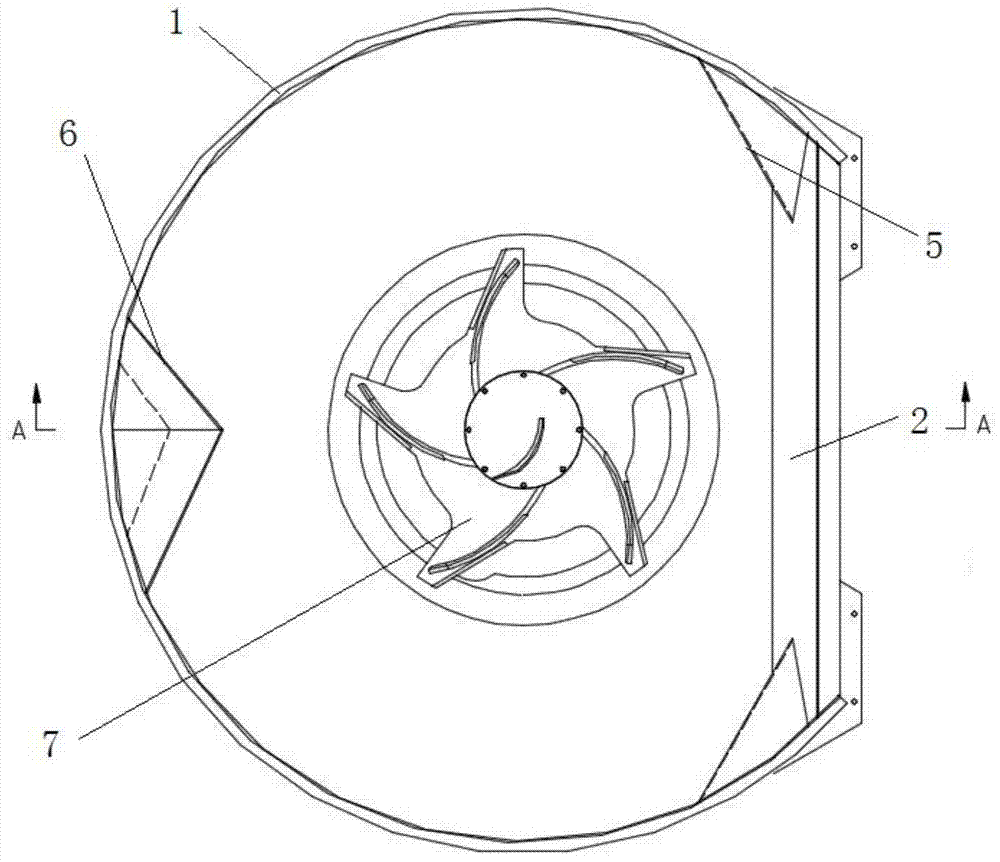

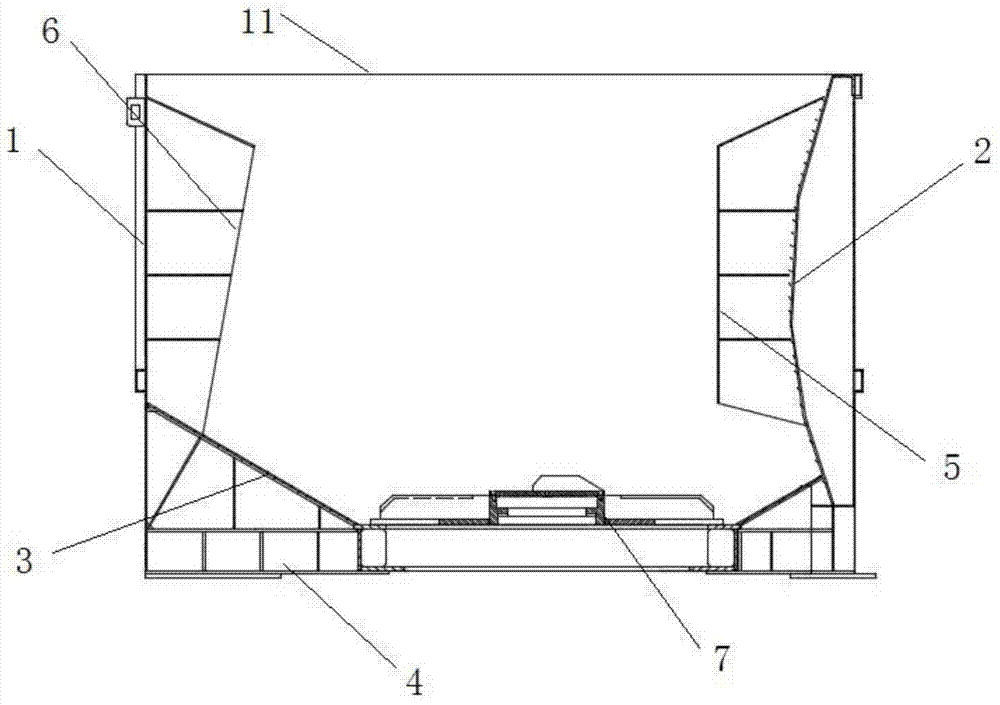

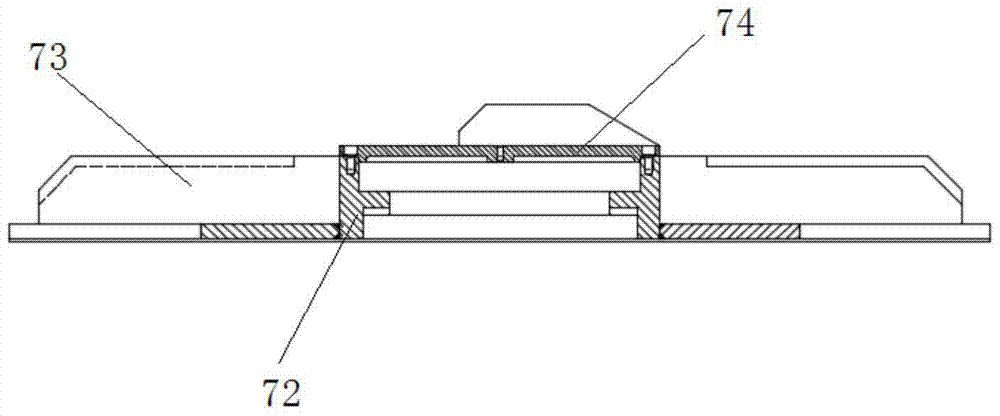

A rotor and a d-type pulper using the same

ActiveCN105178077BEffective dissociationWon't break downPaper recyclingRaw material divisionImpellerFiber

A rotor is used for carrying out waste paper repulping treatment in a waste paper repulping treatment workshop section in the papermaking industrial, and can disassociate waste paper raw material so as to separate out useful fibers from impurity; the rotor comprises a rotor bottom plate and a rotor middle shaft; the periphery of the rotor bottom plate is provided with a plurality of blades extending outwards, and provided with a plurality of pulping impellers used for diverting and disassociating the waste paper raw material; a pulping surface edge of the blade is provided with a blade wearing layer; a pulping surface edge of the pulping impeller is provided with an impeller wearing layer; a rotor top cover is arranged above the rotor middle shaft; the top surface of the rotor top cover is fixedly provided with a spoiler. A D-type pulper applying the rotor is provided with an oblique edge used for reducing waterpower effect; the inner surface of a cylinder body is provided with a baffle plate, thus improving disassociating efficiency, and disassociation can be milder; over disassociation can be prevented, and energy saving effect is obvious.

Owner:烟台大为环保科技有限公司

Composite gel polymer electrolyte membrane and application thereof

ActiveCN102005609BGood compatibilityImprove the interface strengthSecondary cellsPolymer electrolytesPolymer science

The invention discloses a composite gel polymer electrolyte membrane and application thereof. The composite gel polymer electrolyte membrane is prepared by adding core-shell ordered mesoporous silica composite particles into a conventional gel polymer electrolyte system, wherein the adding mass of the core-shell ordered mesoporous silica composite particles is 5 to 30 percent based on the mass ofa polymer matrix in the conventional gel polymer electrolyte system; the core-shell ordered mesoporous silica composite particles take ordered mesoporous silica particles as cores; a polymer is grafted and coated on the outside surfaces of the ordered mesoporous silica particles to form shells; and the shell polymer has good compatibility with the polymer matrix in the conventional gel polymer electrolyte system. The composite gel polymer electrolyte membrane prepared in the invention has higher room-temperature ionic conduction capacity, simultaneously has better mechanical strength and heatresistance, and is suitable for polymer lithium ion batteries.

Owner:ZHEJIANG UNIV OF TECH

Estradiol release reagent and detection kit thereof

PendingCN112394182AImprove detection efficiencyFast dissociationBiological testingEstradiolsCompetitive binding

According to the estradiol release reagent and the detection kit thereof, the estradiol release reagent can influence the combination of estradiol and sex hormone binding protein, so that estradiol isreleased; the estradiol releasing reagent contains at least one of a reagent for competitively binding to the sex hormone binding protein and a reagent for reducing the binding force between estradiol and the sex hormone binding protein. Compared with the prior art, the estradiol releasing agent is used as a component of an estradiol enzymatic chemiluminescence immunoassay reagent, and estradiolcan be rapidly and effectively dissociated from albumin and sex hormone binding protein.

Owner:深圳市辰纳生物科技有限公司

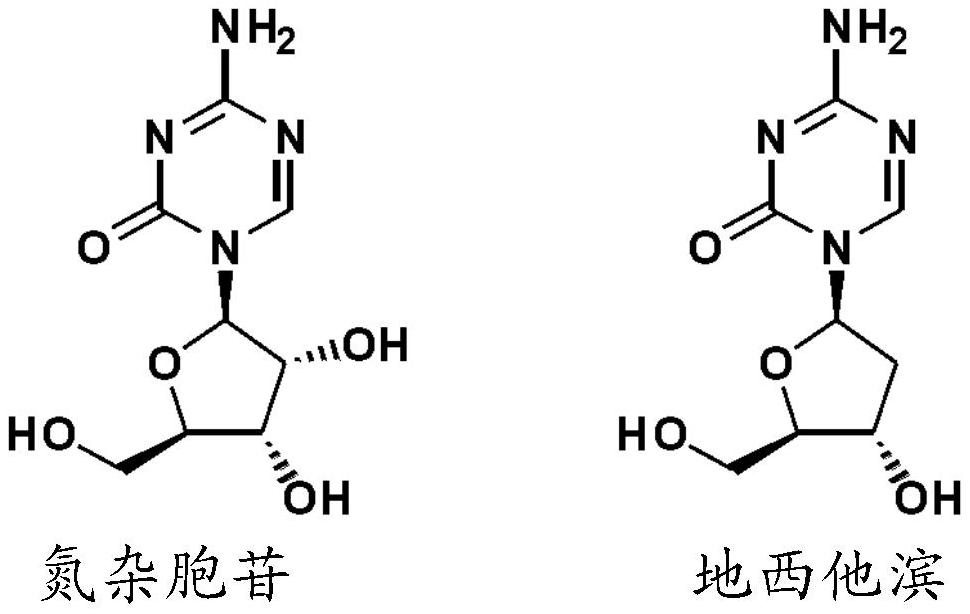

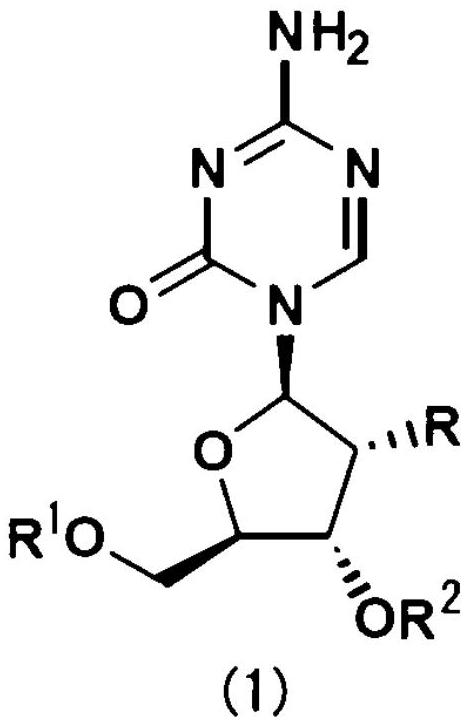

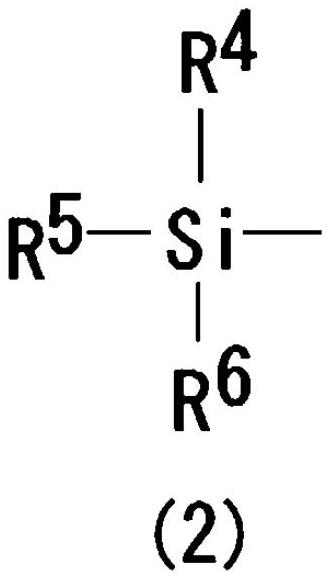

The sugar moiety silyl ether derivatives of 5-azacytidine

ActiveCN108368148BEffective dissociationInhibit synthesisOrganic active ingredientsSugar derivativesMetabolizing enzymesCytidine deaminase

The present invention provides a prodrug of 5-azacytidine or 2'-deoxy-5-azacytidine with high stability to the metabolic enzyme cytidine deaminase, to replace clinically used drugs in patients with myelodysplastic syndromes including myelodysplastic syndromes. Injection (5-azacytidine or 2'-deoxy-5-azacytidine) used for the treatment of various bone marrow tumors in China. Above-mentioned technical problem is solved by the compound or its salt represented by chemical formula (1) (in said chemical formula, R is OR 3 group or hydrogen atom, R 1 , R 2 and R 3 Each is a hydrogen atom or a silyl group represented by the chemical formula (2) (in the chemical formula, R 4 , R 5 and R 6 Each is an optionally substituted alkyl group, an optionally substituted aryl group, or an optionally substituted arylalkyl group). And, R 1 , R 2 and R 3 are not hydrogen atoms at the same time).

Owner:OHARA PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com