Flotation method of aphanitic graphite

A cryptocrystalline graphite and graphite technology, used in flotation, chemical instruments and methods, wet separation, etc., can solve the problems of waste of resources and low grade of concentrate, and achieve improved utilization efficiency, low operating costs, and enhanced mutual effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

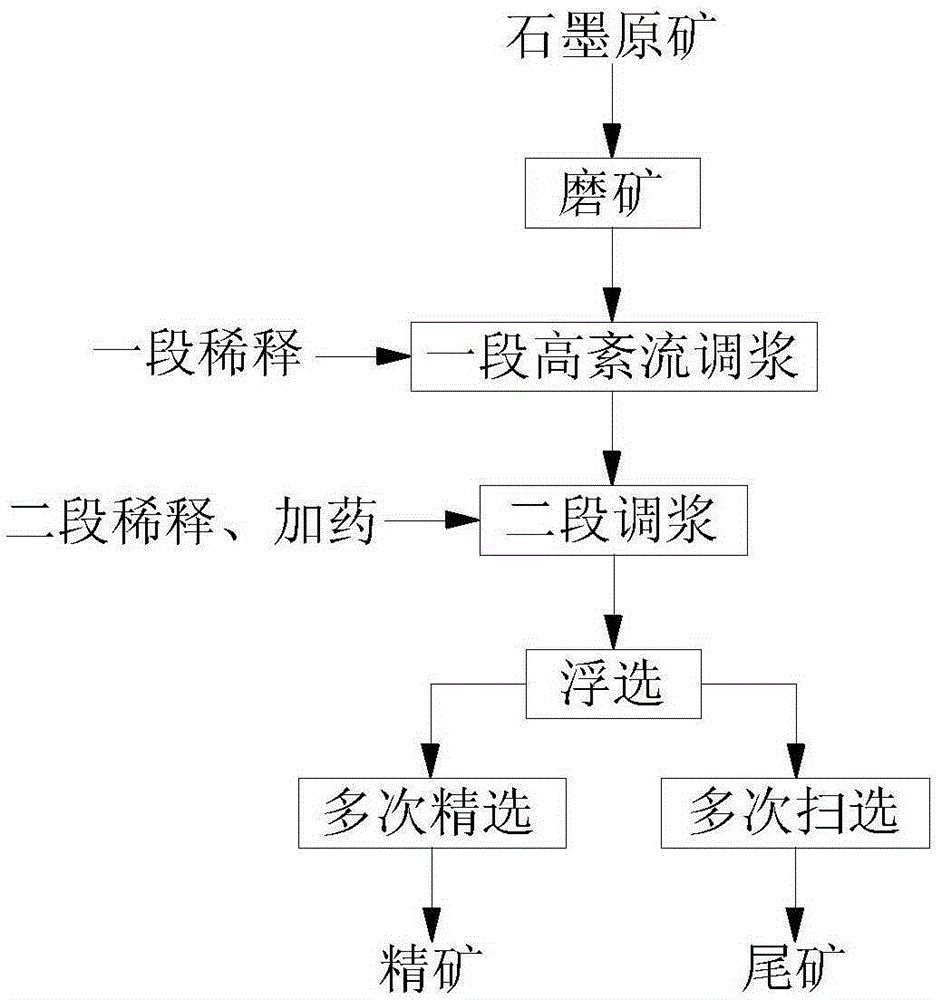

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Aphanitic graphite raw ore with a grinding fineness of 2.32 μm and a grade of 86.20% is used as a flotation feed material, and it is added with water to prepare an ore slurry with a concentration of 10% by mass, and a section of high turbulent slurry adjustment is performed. The pulping time is 10 minutes; after the first stage of pulping is completed, the pulp is mixed in the second stage, and diluted with water to a concentration of 5% by mass, and then sodium bicarbonate is added to the pulp to adjust the pH value of the pulp to 8.5, and the dispersant sodium silicate is 1.5kg / t, collector kerosene 50kg / t, foaming agent 2-octanol 360g / t, mixing time 1min. The ore pulp after the two stages of pulping is sent to the roughing equipment for sorting. The roughed concentrate is then subjected to a beneficiation operation. No chemicals are added during the beneficiation process. The roughed tailings and the selected tailings are used together as the final tailing...

Embodiment 2

[0028] Example 2: Aphanitic graphite raw ore with a grinding fineness of 1.05 μm and a grade of 86.94% is used as a flotation feed material, and it is added with water to prepare an ore slurry with a concentration of 10% by mass, and a section of high turbulent slurry adjustment is performed. The pulping time is 10 minutes; the pulp that has completed the first stage of pulping is carried out to the second stage of pulping, and diluted with water to a concentration of 5% by mass, and then sodium carbonate is added to the pulp to adjust the pH value of the pulp to 9.0, and the dispersant sodium silicate, 2kg / t, collector kerosene 30kg / t, foaming agent 2-octanol 500g / t, mixing time 1min. The ore pulp after the two stages of pulping is sent to the roughing equipment for sorting, and the roughed concentrate is then subjected to two beneficiation operations. No chemicals are added during the beneficiation process. The roughed tailings and the selected tailings are used together as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com