Patents

Literature

58results about How to "Increase monomer dissociation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

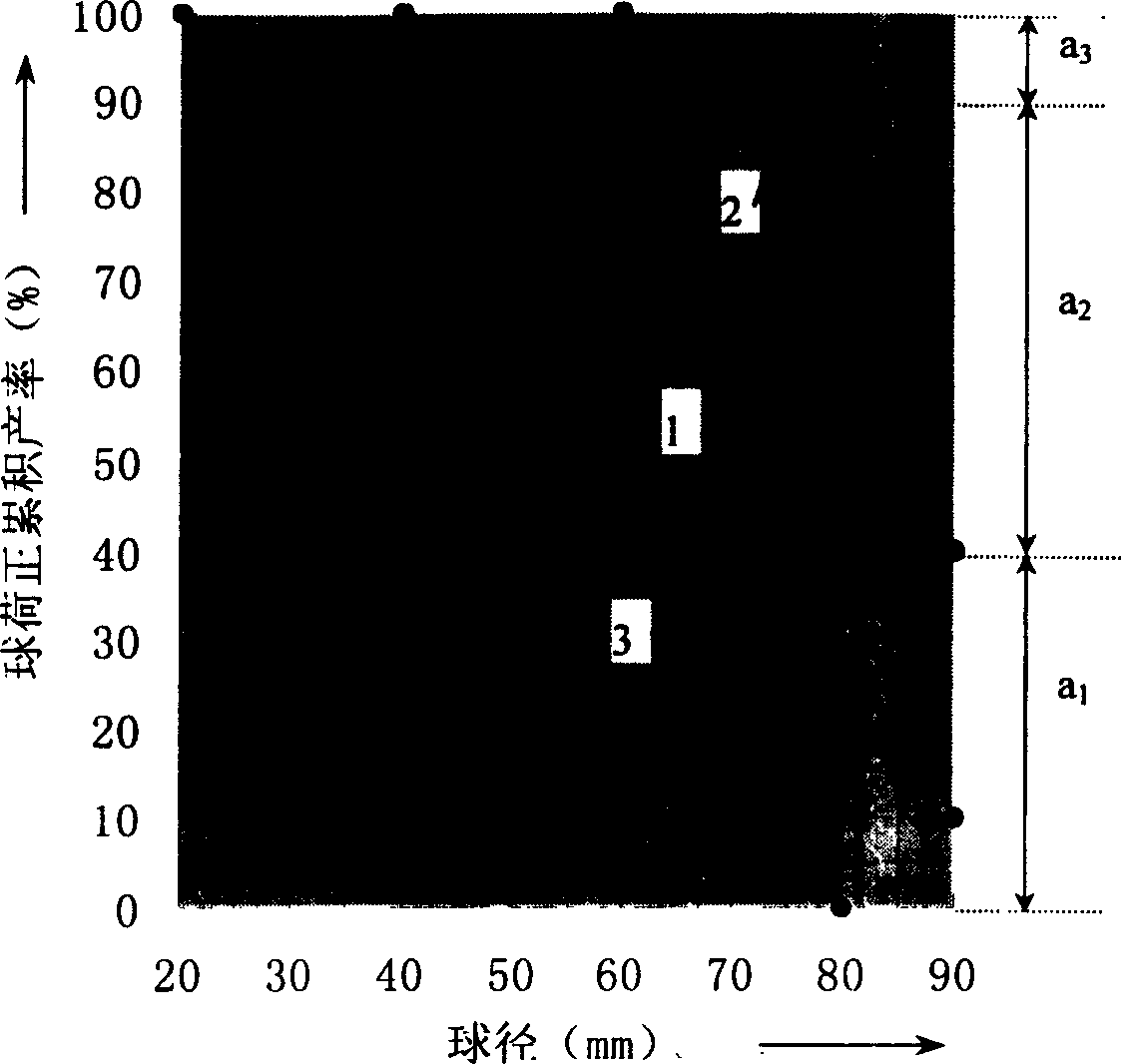

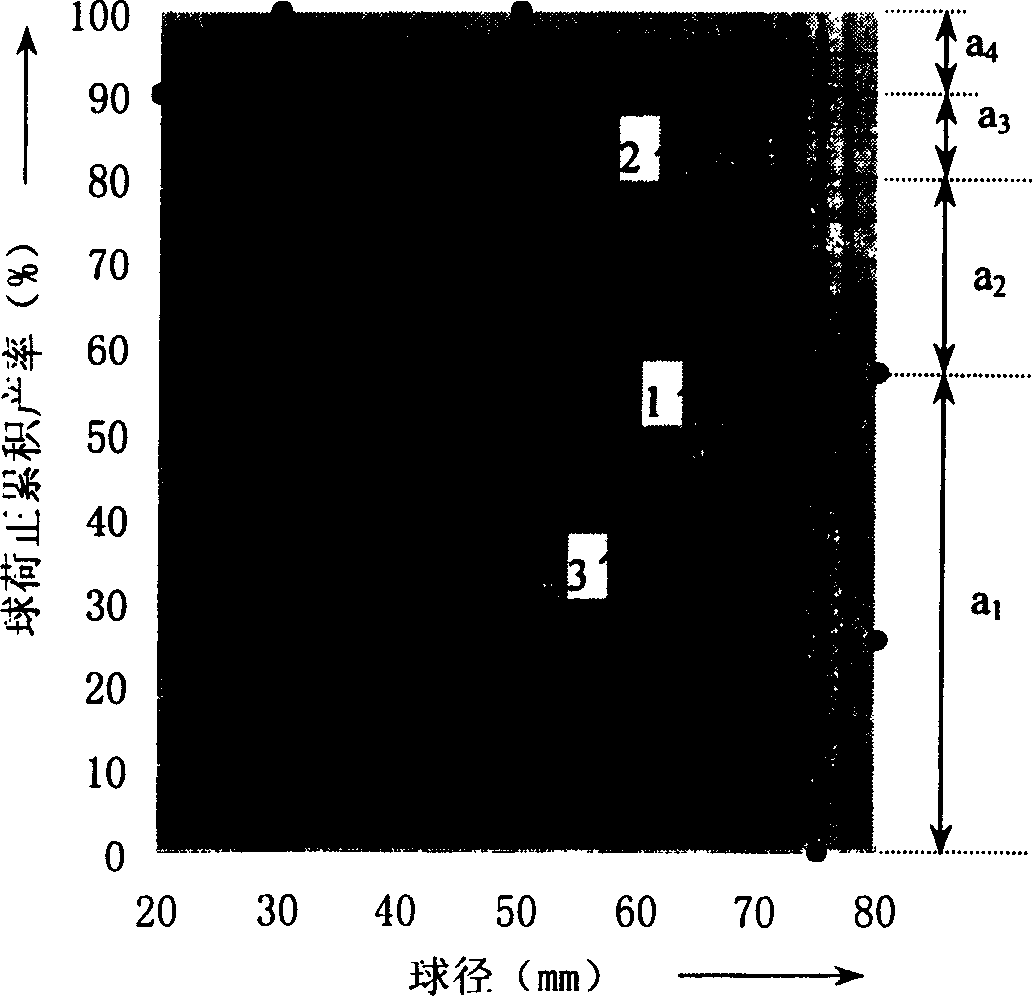

Ball grinder accurate ball loading method

The invention is a method for ball mill to recuperate balls precisely, which belongs to ore pulverizing, grinding technology field. The method includes: measures the mechanical parameter of ore; sifts and analyzes the mill ore and back sands, calculates the ore particle components and groups them; calculates the particle radius value according to ball radius haft theory formula; determines the ball ratio of the mill according to the ore particle and the needed ball radius; paints the ball particle accumulating curve, thus acquires the radius and recuperating ratio precisely. The proportion is reasonable, the method is simple, the productivity is upgraded greatly, and the quality is improved.

Owner:KUNMING UNIV OF SCI & TECH +2

High-voltage electric pulse pretreatment method for intensifying leaching of difficult-to-treat gold ore

ActiveCN106824454AIncrease the content of useful mineralsIncrease monomer dissociationGrain treatmentsPretreatment methodMineral particles

The invention discloses a high-voltage electric pulse pretreatment method for intensifying the leaching of difficult-to-treat gold ore, and belongs to the technical field of the processing of minerals of gold ore. According to the method, the high-voltage electric pulse crushing pretreatment is realized by utilizing the differences of the dielectric properties of different minerals in ore; a high-voltage electric pulse discharge crushing device is used for carrying out selective crushing on gold-containing ore; gold and a gangue mineral in a gold-containing material are prompted to generate a micro crack and a running crack at an interface; a crystal of a gold-containing mineral is completely dissociated into monomer mineral particles; in this way, the exposed surface area of the gold is increased; therefore, the contact probability of cyanide and a gold grain is increased, so that the sufficient improvement of the leaching rate of the gold is facilitated.

Owner:NORTHEASTERN UNIV

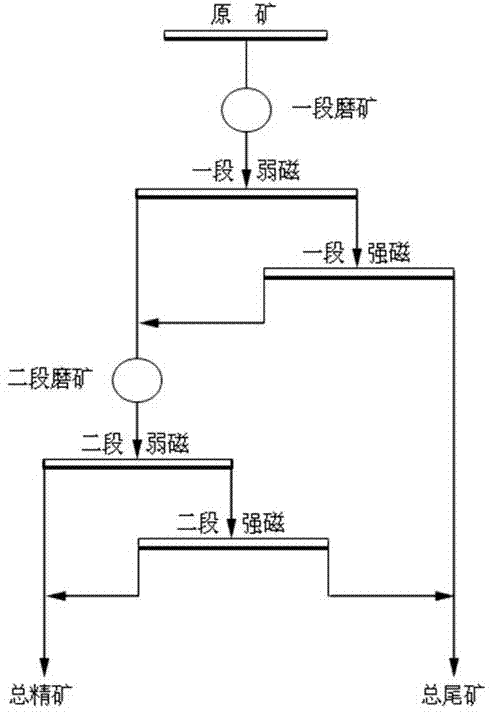

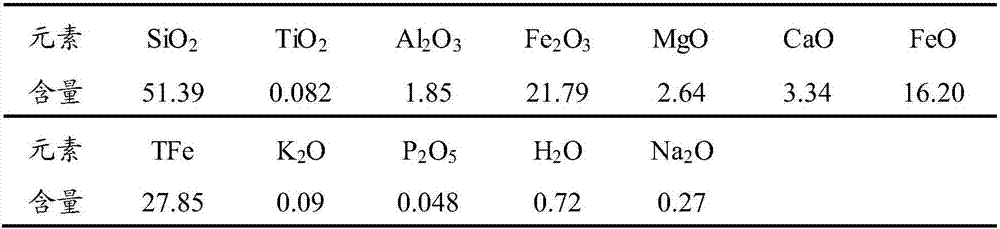

Beneficiation method of efficiently recovering fine-grain low-grade magnetite

The invention discloses a mineral processing method for efficiently recovering fine-grained low-grade magnetite. Iron concentrate I and tailings I can be obtained by weak magnetic separation with a magnetic induction intensity of 1100-1300Oe; iron concentrate II and tailings II can be obtained from tailings I by strong magnetic separation with a magnetic induction intensity of 0.9-1T; iron concentrate I and iron Concentrate II is combined and ground to -0.045mm, accounting for 75-85% to obtain fine-grained ore II; fine-grained ore II is subjected to weak magnetic separation with a magnetic induction intensity of 1000-1200Oe to obtain iron concentrate III and tailings III; Iron concentrate IV and tailings IV are obtained by strong magnetic separation with a magnetic induction intensity of 0.560-0.783T, and iron concentrate III and iron concentrate IV are combined to obtain a total concentrate, and tailings II and tailings IV are combined to throw tailings. The invention has the characteristics of short process flow, less grinding amount, high beneficiation efficiency, iron recovery rate and high concentrate grade.

Owner:YUXI DAHONGSHAN MINING

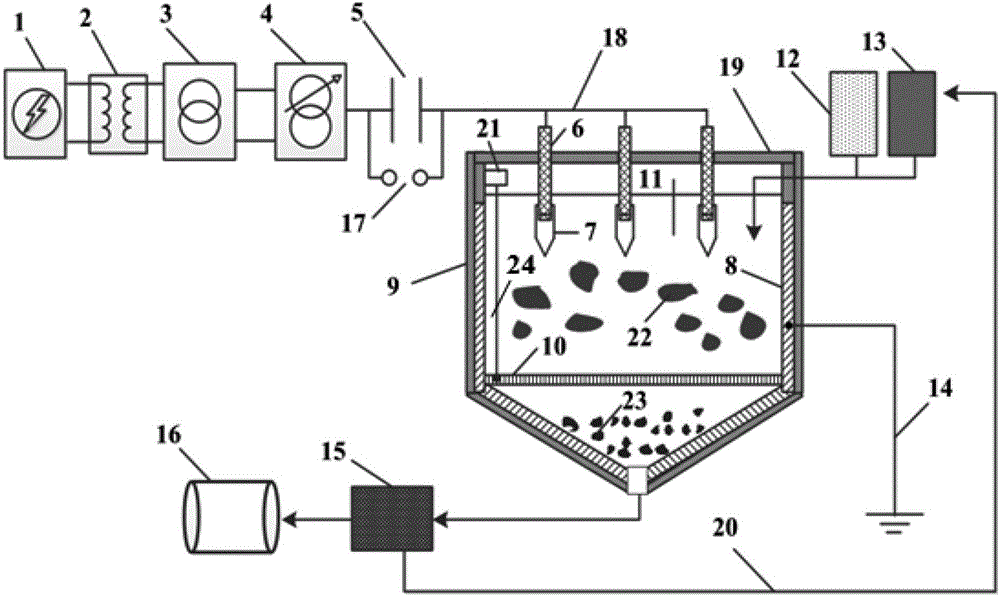

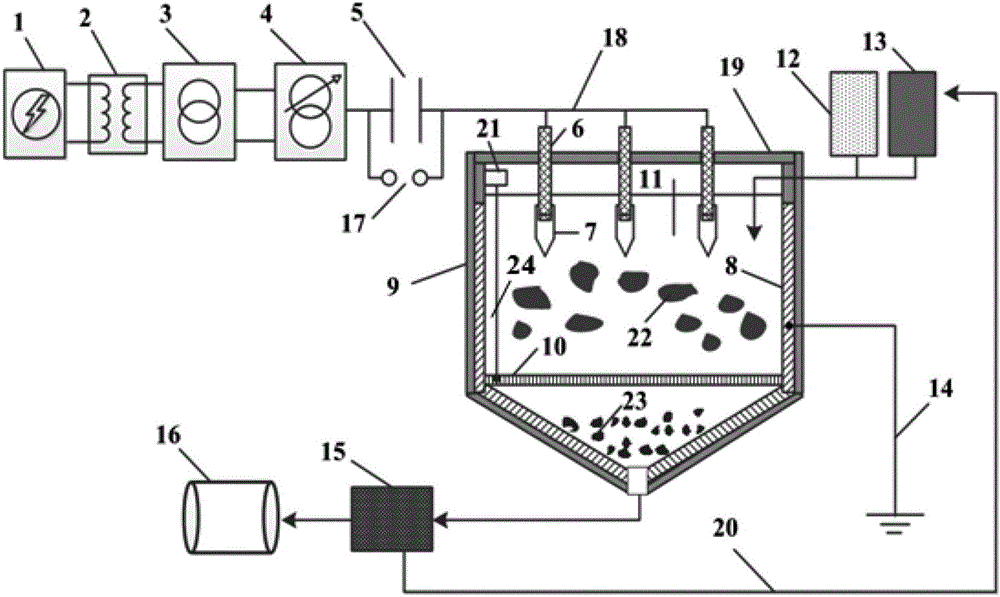

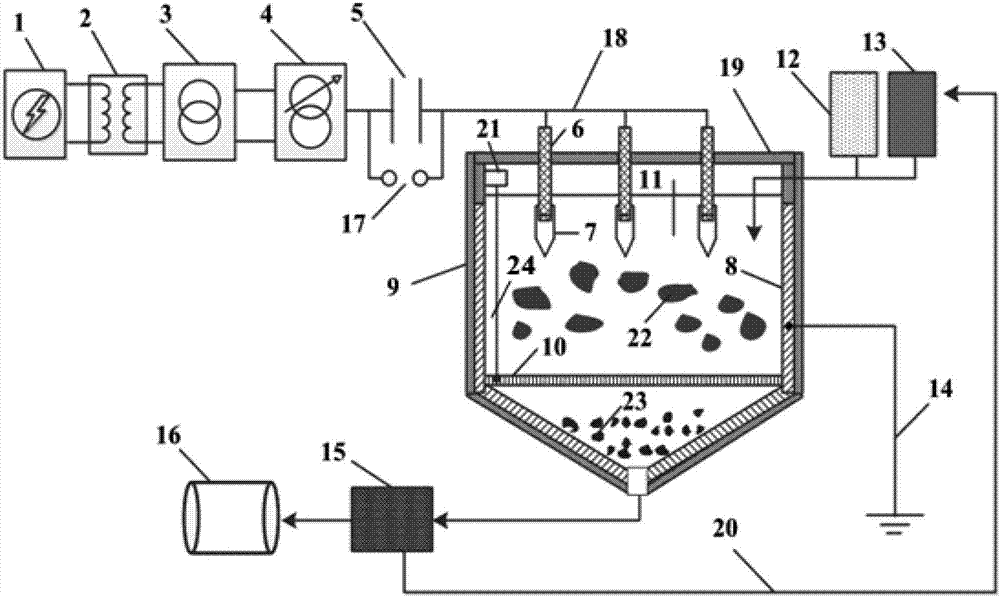

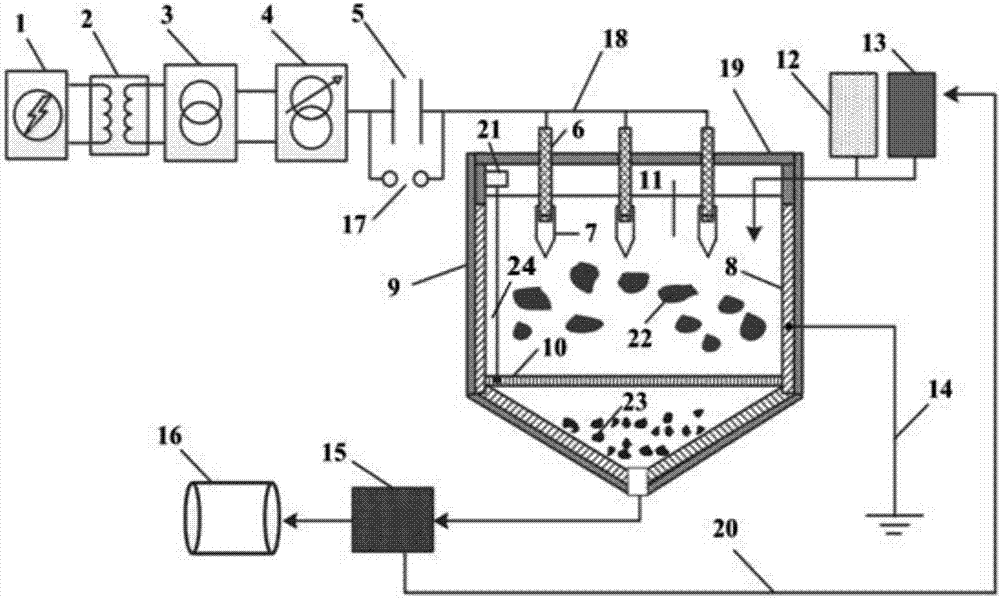

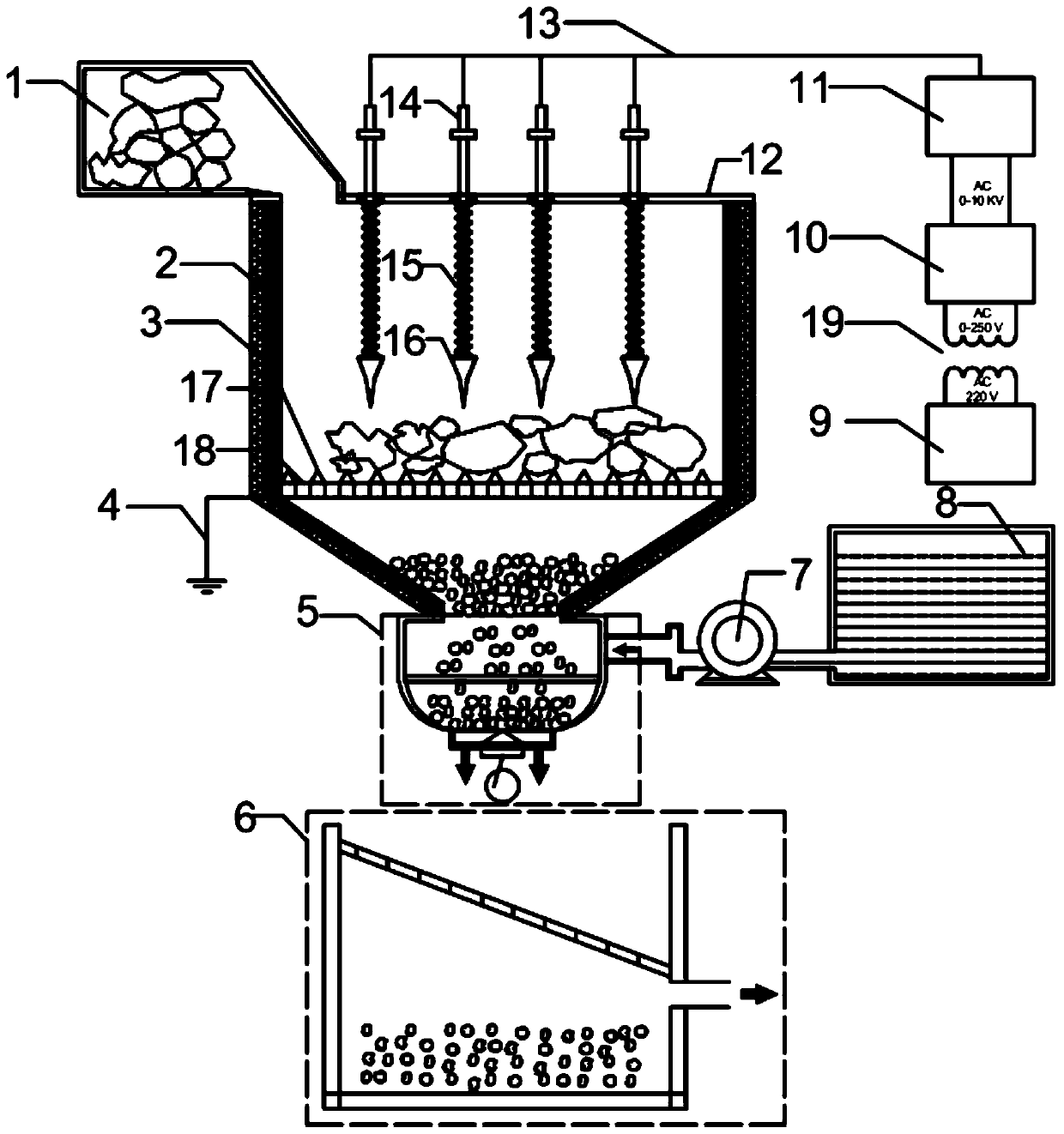

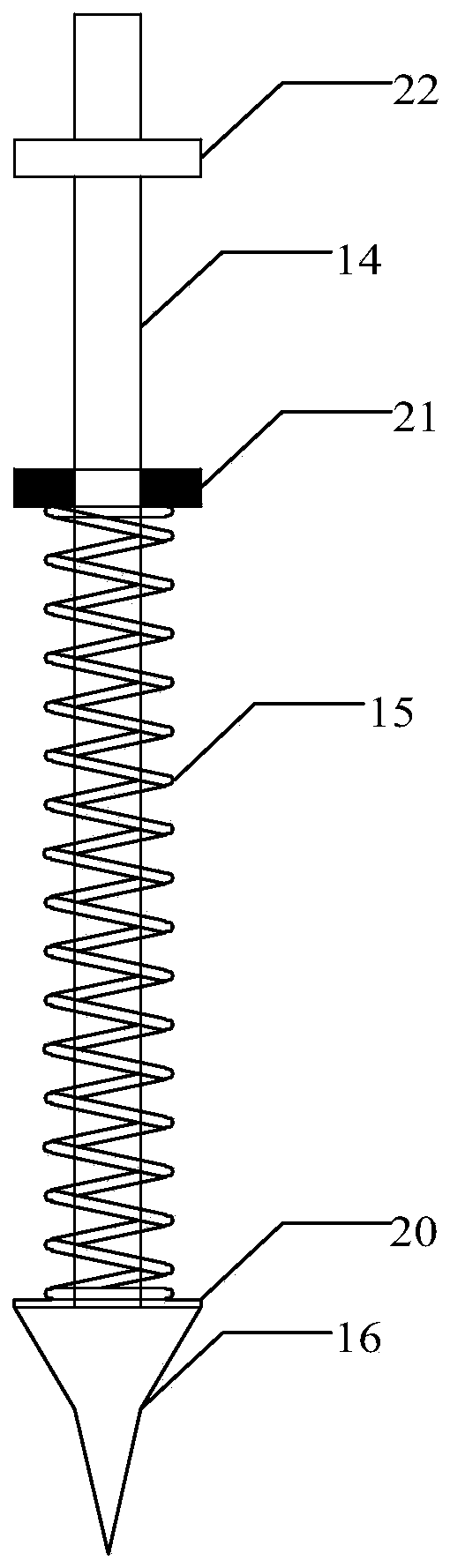

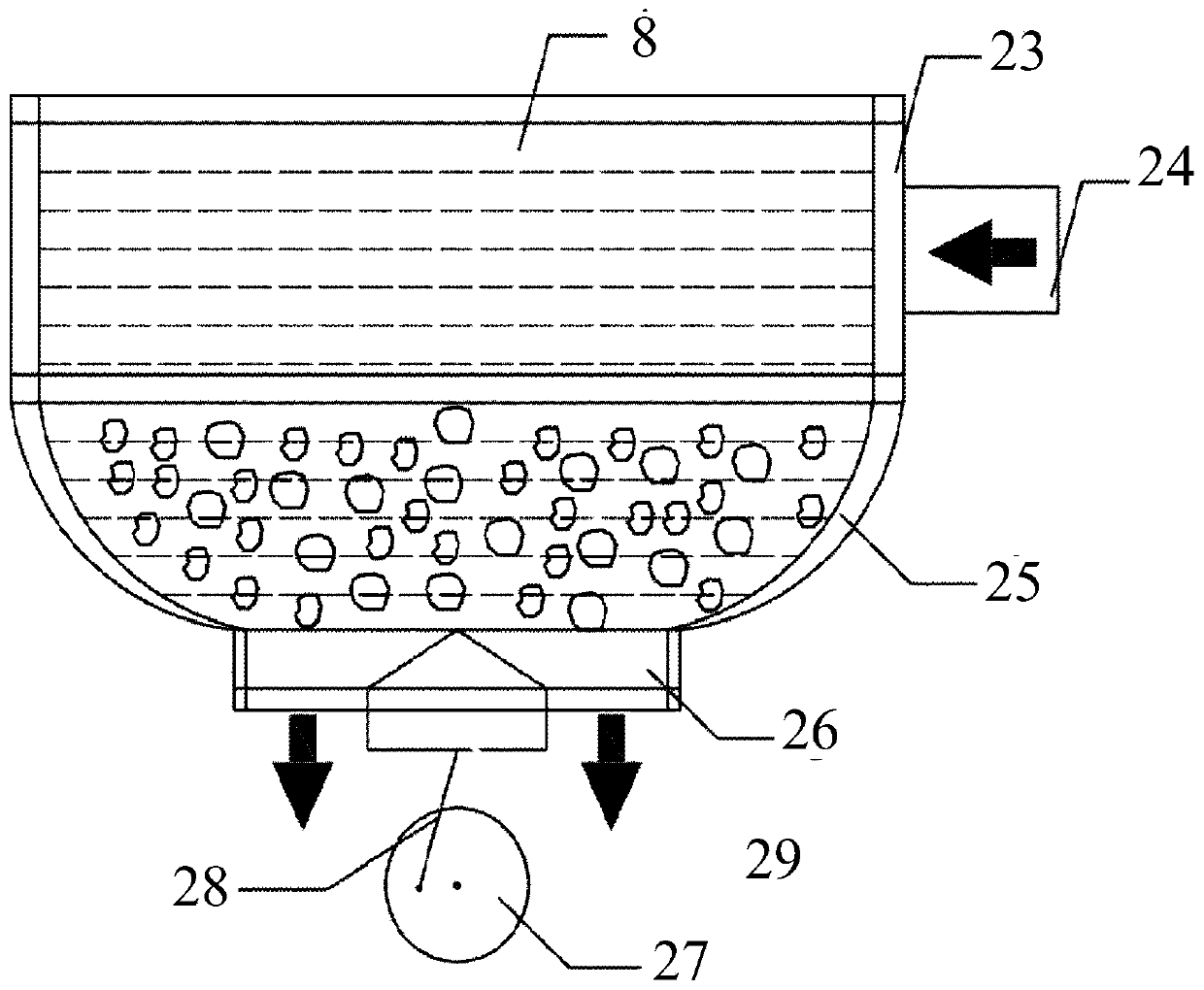

High-voltage electric pulse ore crushing device and method for ore pre-treatment

ActiveCN106824455ADoes not destroy crystal formImproved cleavage propertiesSievingScreeningTransformerCeramic capacitor

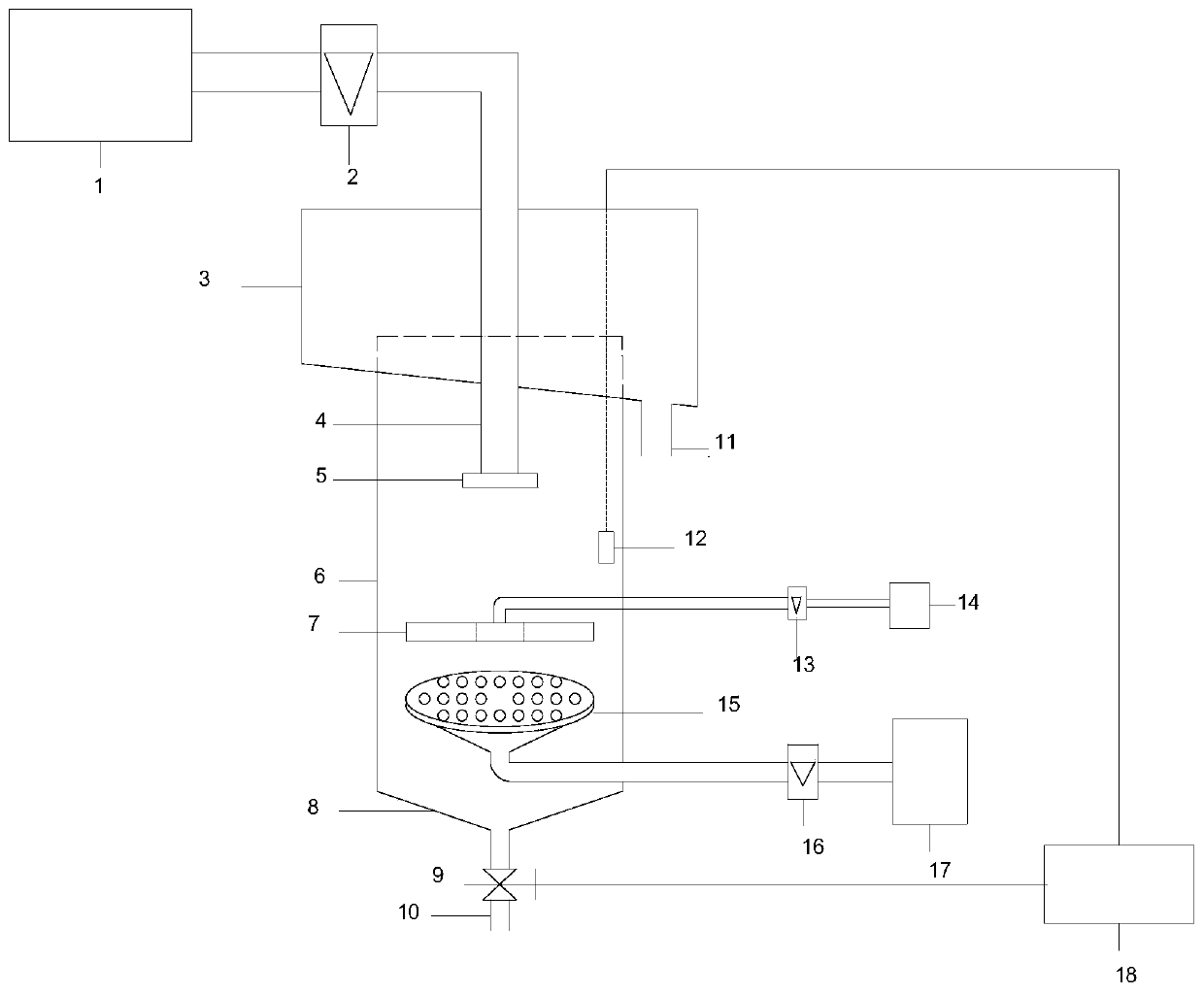

The invention discloses a high-voltage electric pulse ore crushing device and a method for ore pre-treatment and belongs to the technical field of ore crushing pre-treatment in mineral processing. The device mainly comprises a power supply, a single-phase voltage regulator, an alternating-current ignition transformer, a six-time-voltage rectification circuit, an ultrahigh-voltage ceramic capacitor, a gas switch, a high-voltage electrode, a conductive barrel body, a discharging and ore crushing bucket, a vibration screen mesh, insulating liquid, a solid-liquid separator, a product collector and the like; all the units are fixedly connected through a lead wire and other auxiliary devices to form a complete equipment system. The ores are treated and then are selectively dissociated and crushed according to different conductive properties of useful metal minerals and non-metal mineral components of gangues, and extension cracks and fissures are generated on mineral interfaces on the ores, so that physical properties of the minerals are improved and subsequent treatment energy consumption is reduced; meanwhile, useful minerals are prevented from excessive abrasion and separation indexes are improved.

Owner:NORTHEASTERN UNIV

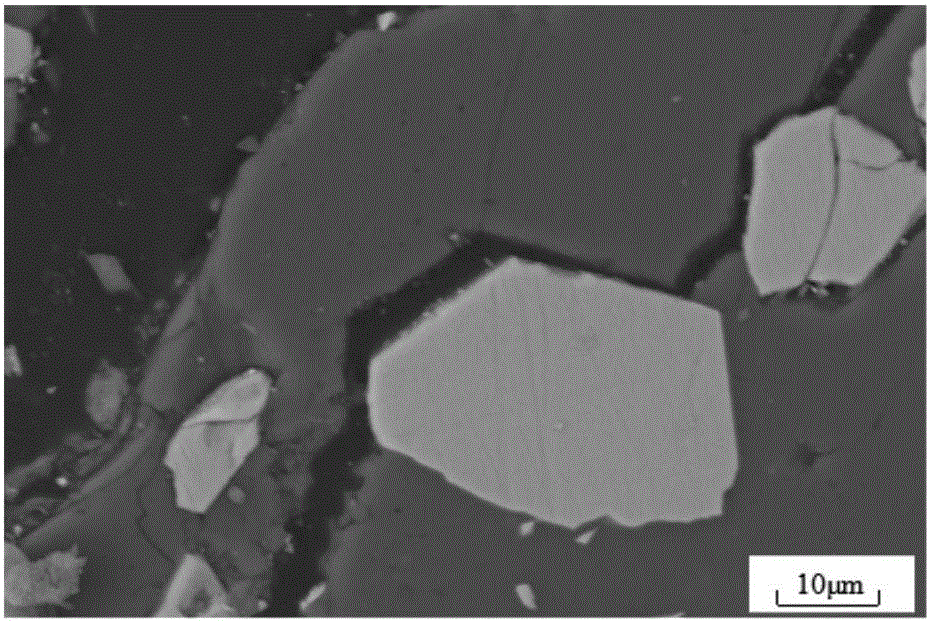

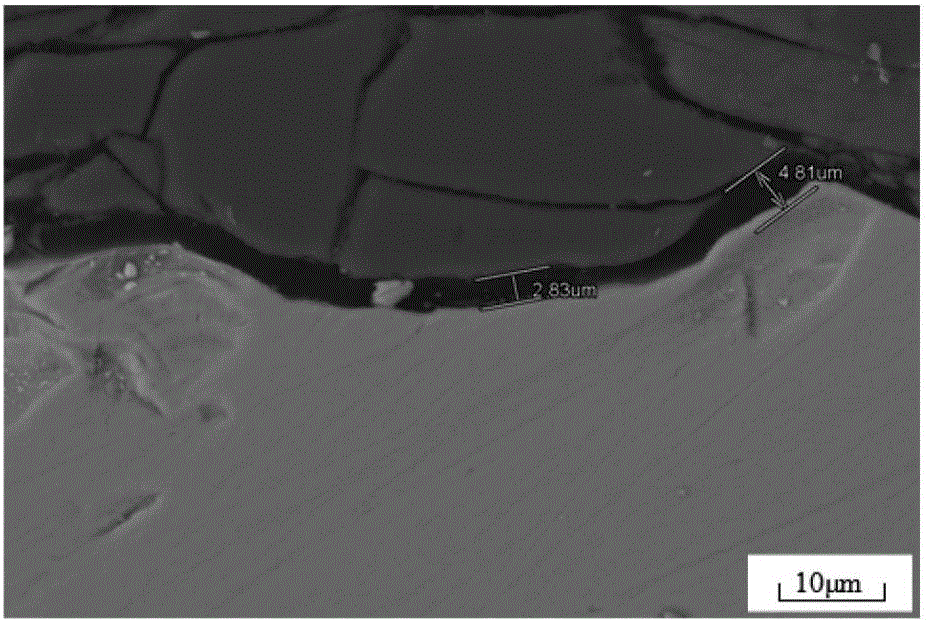

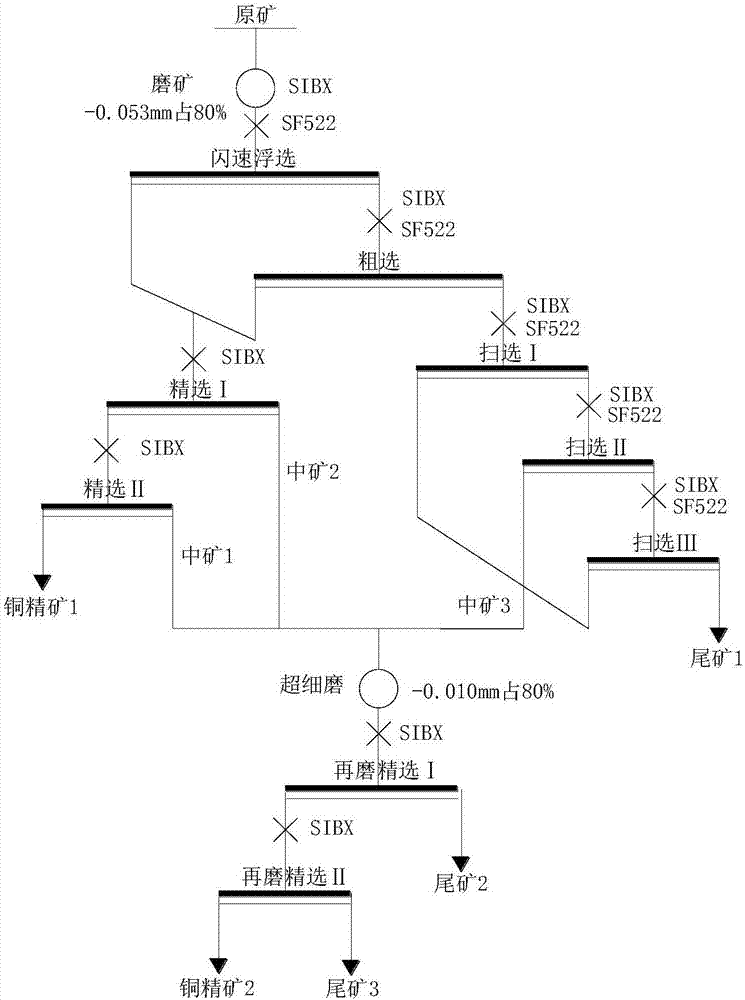

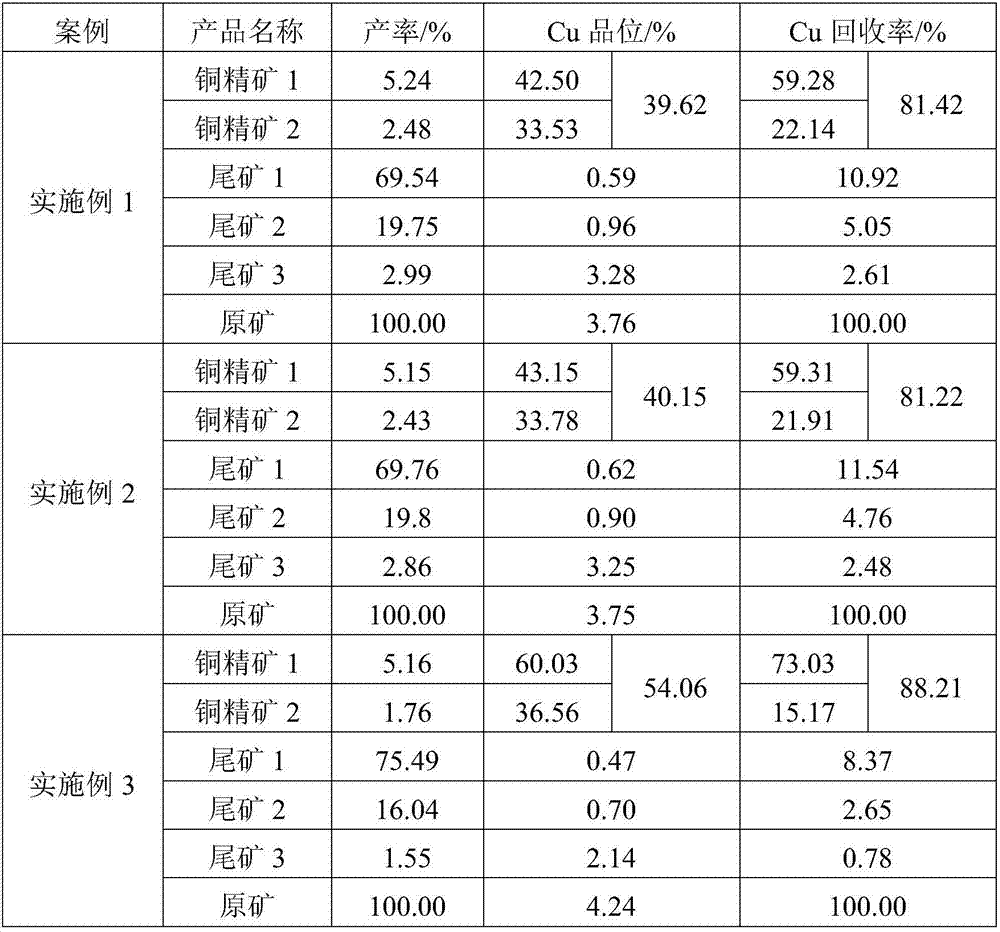

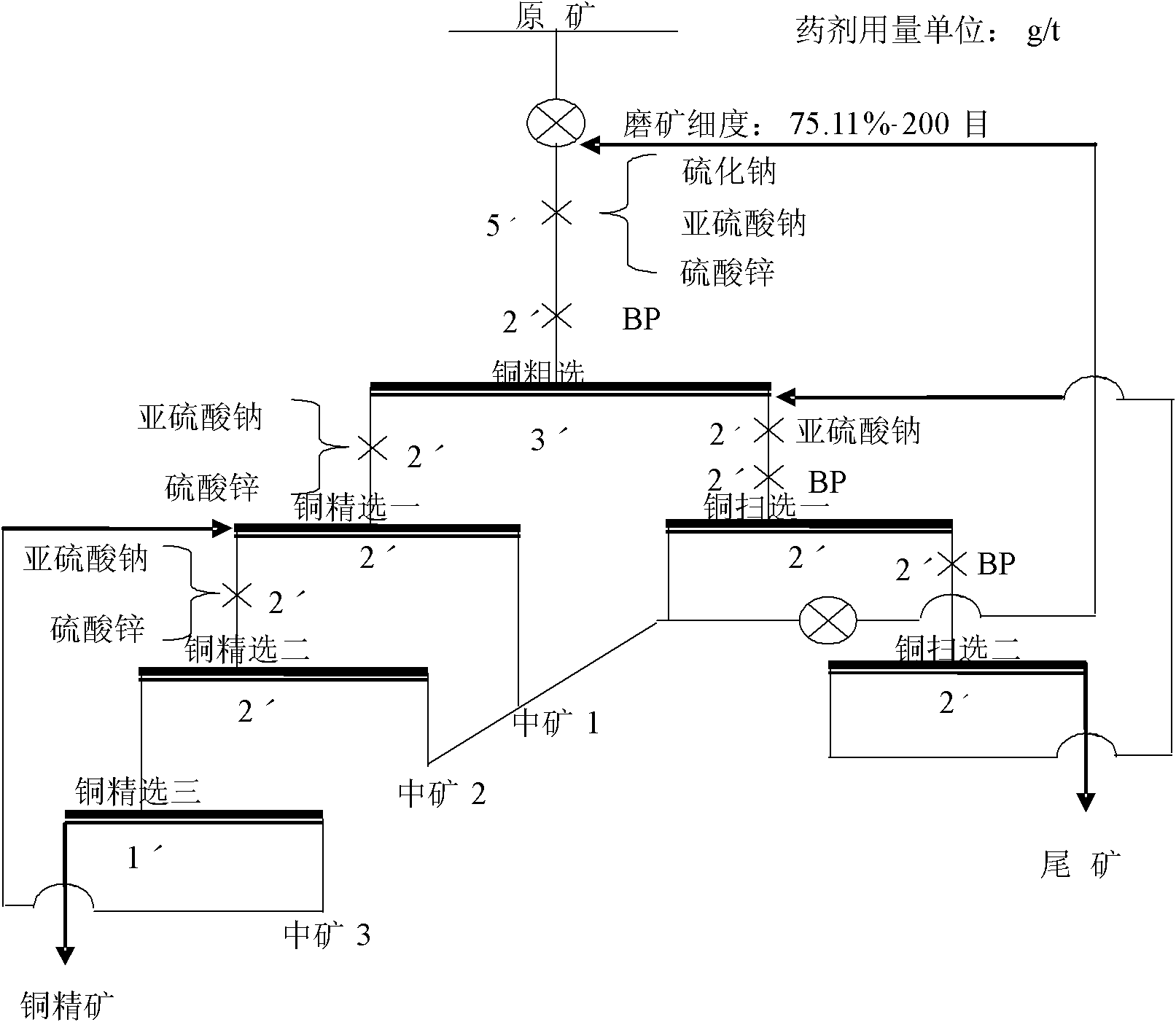

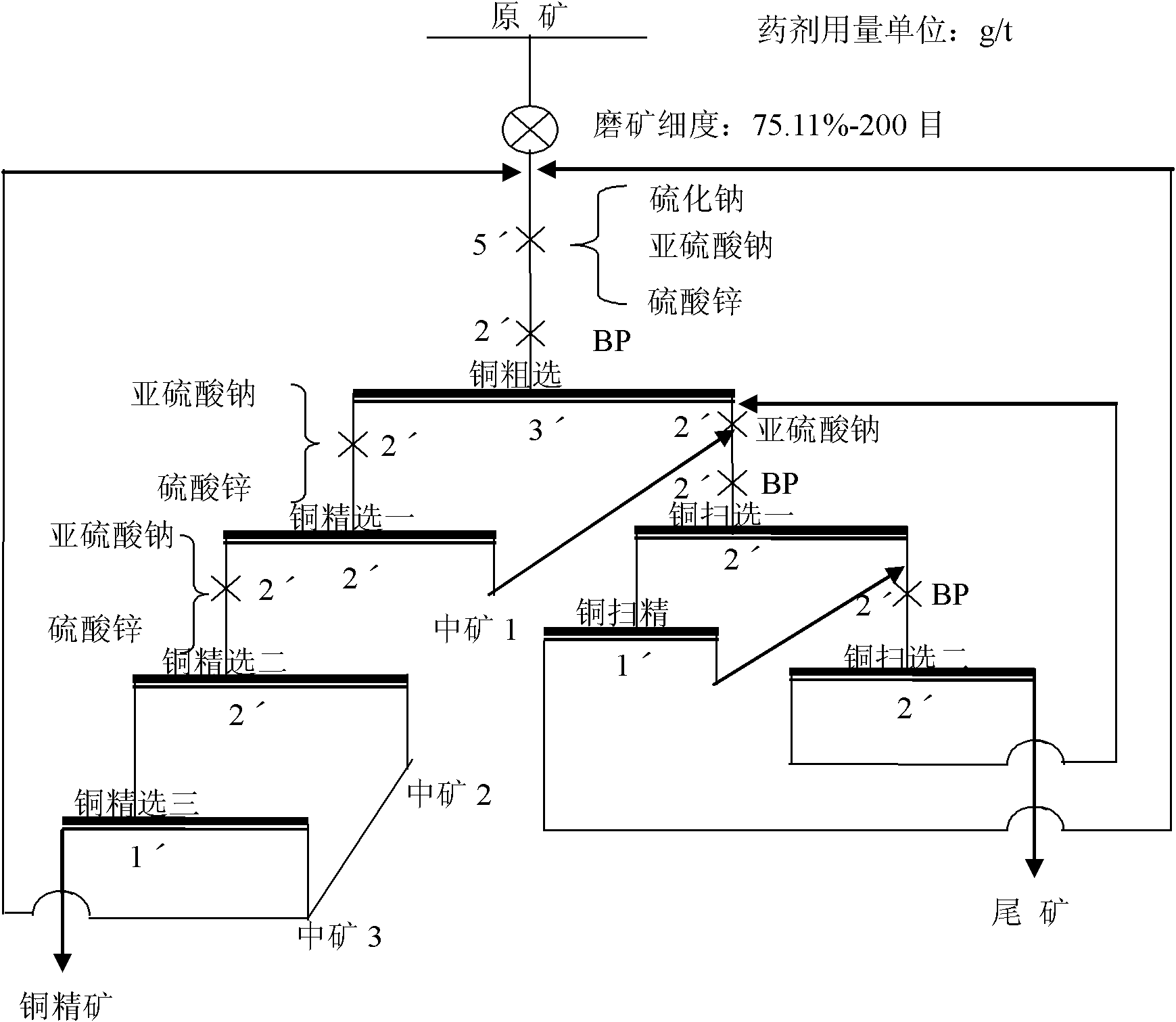

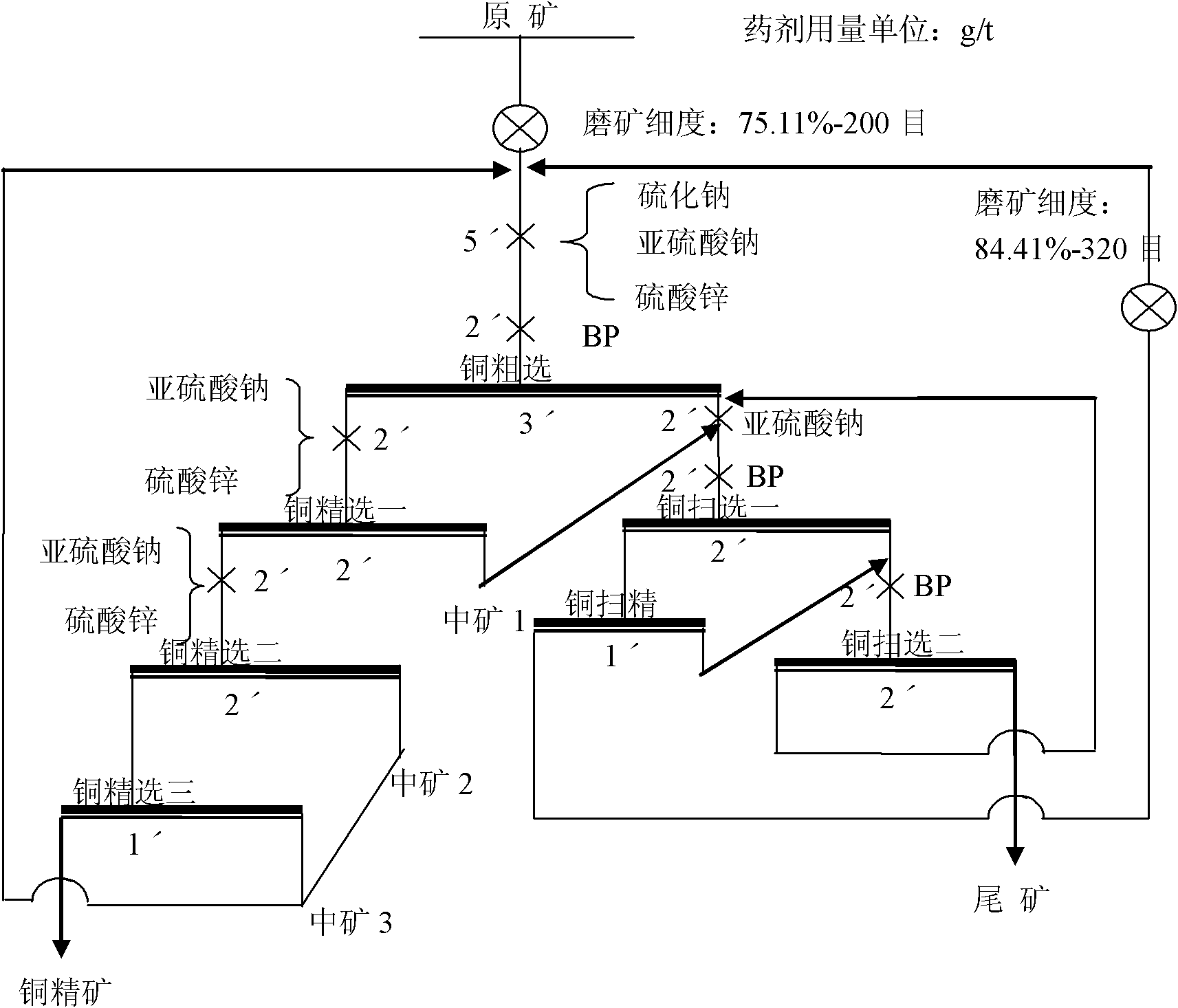

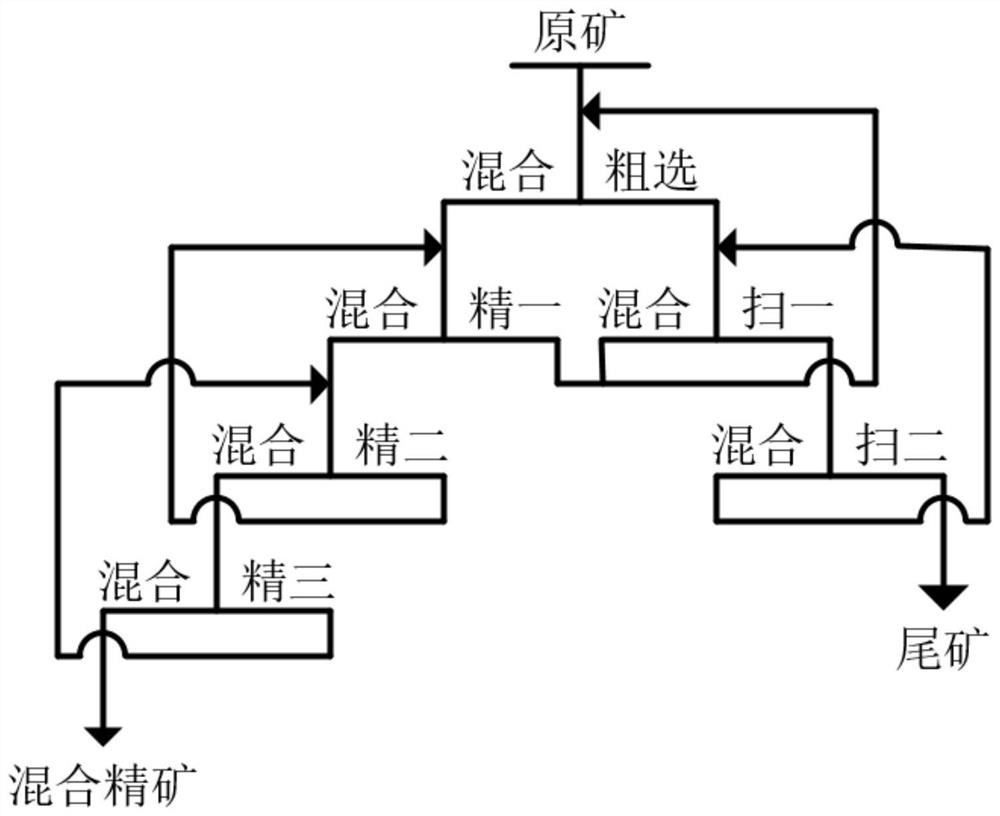

Separation process for copper sulphide ore with superfine disseminated grain sizes

ActiveCN107282312AImproved particle size distributionIncrease monomer dissociationFlotationGrain treatmentsSeparation processMaceral

The invention discloses a separation process for copper sulphide ore with superfine disseminated grain sizes. The separation process comprises the steps that collectors are added in the coarse grinding process and give full play to the fresh surfaces of minerals, the action efficiency of the collectors on the mineral surfaces is improved, a part of copper ore which is subjected to monomer separation is obtained through quick floatation, rough concentrate is then subjected to low concentration and medium rotating speed concentration operation for two times to obtain high-grade copper concentrate 1, middlings 1 and middlings 2, roughing tailings are subjected to three-section scavenging operation to obtain middlings 3, the middlings 1, the middlings 2 and the middlings 3 are combined and enter ultrafine grinding operation, ultrafine grinding products are subjected to regrinding concentration I and regrinding concentration II operation, and copper concentrate 2 is obtained. The effect of treating the copper sulphide ore with the superfine disseminated grain sizes is good, adaptability is high, and high-grade concentrate products can be obtained.

Owner:厦门紫金矿冶技术有限公司

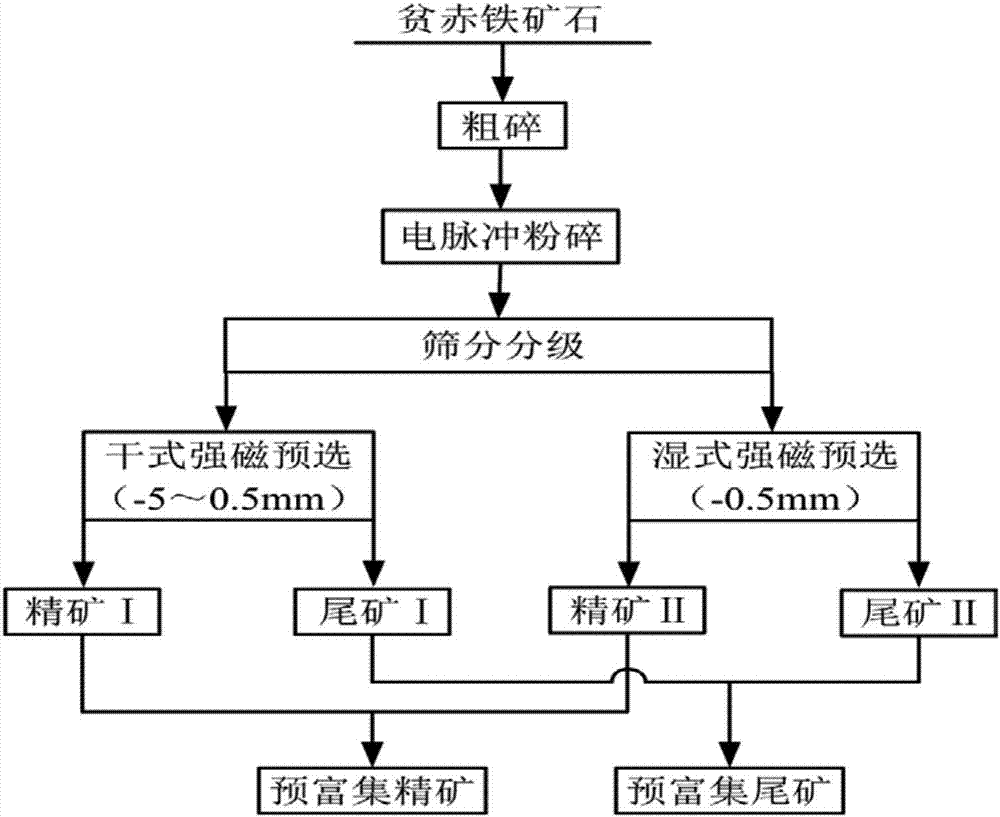

High-voltage electric pulse selective pulverizing and pre-enriching method for lean hematite ores

ActiveCN106984412ADoes not destroy crystal formImproved cleavage propertiesSievingScreeningElectrical impulseHigh pressure

The invention discloses a high-voltage electric pulse selective pulverizing and pre-enriching method for lean hematite ores. The method is characterized in that high-voltage electric pulse pulverizing pretreatment is realized by utilizing dielectric property difference of different minerals in ores, energy with extremely high power density is output by high-voltage pulses, and the energy is discharged onto the lean hematite ores through a high-voltage electrode; valuable mineral hematite, gangue mineral quartz and the like in the ores form a plurality of micro cracks among interfaces, so that selective dissociation for hematite and gangue minerals is realized; and pre-enriched concentrate is obtained through strong magnetic separation. The method improves beneficiation feed grade of the ores, and is beneficial for improving follow-up grading and sorting indexes.

Owner:NORTHEASTERN UNIV

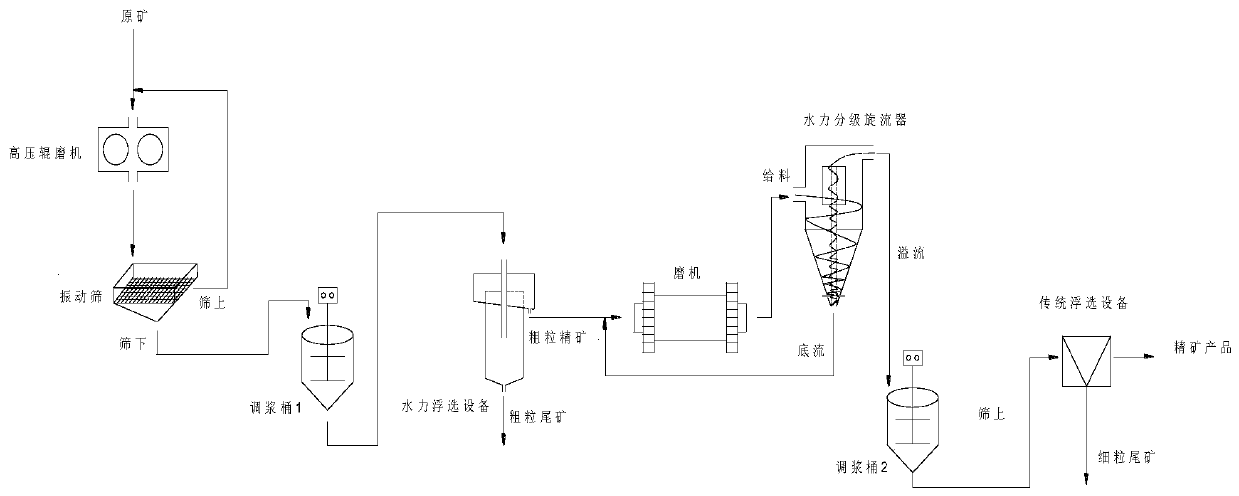

Coarse particle tailing discarding sorting system based on hydraulic flotation technology

InactiveCN110882829AReduce wearIncrease monomer dissociationFlotationGrain treatmentsProcess engineeringCoarse particle

The invention relates to a coarse particle tailing discarding sorting system based on a hydraulic flotation technology, which comprises a high-pressure roller mill, a vibrating screen, a pulp mixing barrel 1, hydraulic flotation equipment, traditional mill equipment, a hydraulic classification cyclone, a pulp mixing barrel 2, traditional flotation equipment and other operation units. The high-efficiency and low-energy consumption high-pressure roller mill is mainly selected, raw minerals are crushed to an appropriate coarse particle size range, then the coarse particle minerals are sorted andgraded in advance through the hydraulic flotation equipment, obtained low-grade coarse particle tailings can be directly discarded and meanwhile high-grade concentrates are enriched for subsequent flotation. All operation units of the sorting system operate in a combined mode, abrasion of the mill is reduced, the total energy consumption of ore grinding is reduced, and the ore dressing treatment capacity can be improved. The total flotation process is expected to be shortened, and the ore grinding-ore dressing operation cost is reduced.

Owner:ZHENGZHOU UNIV

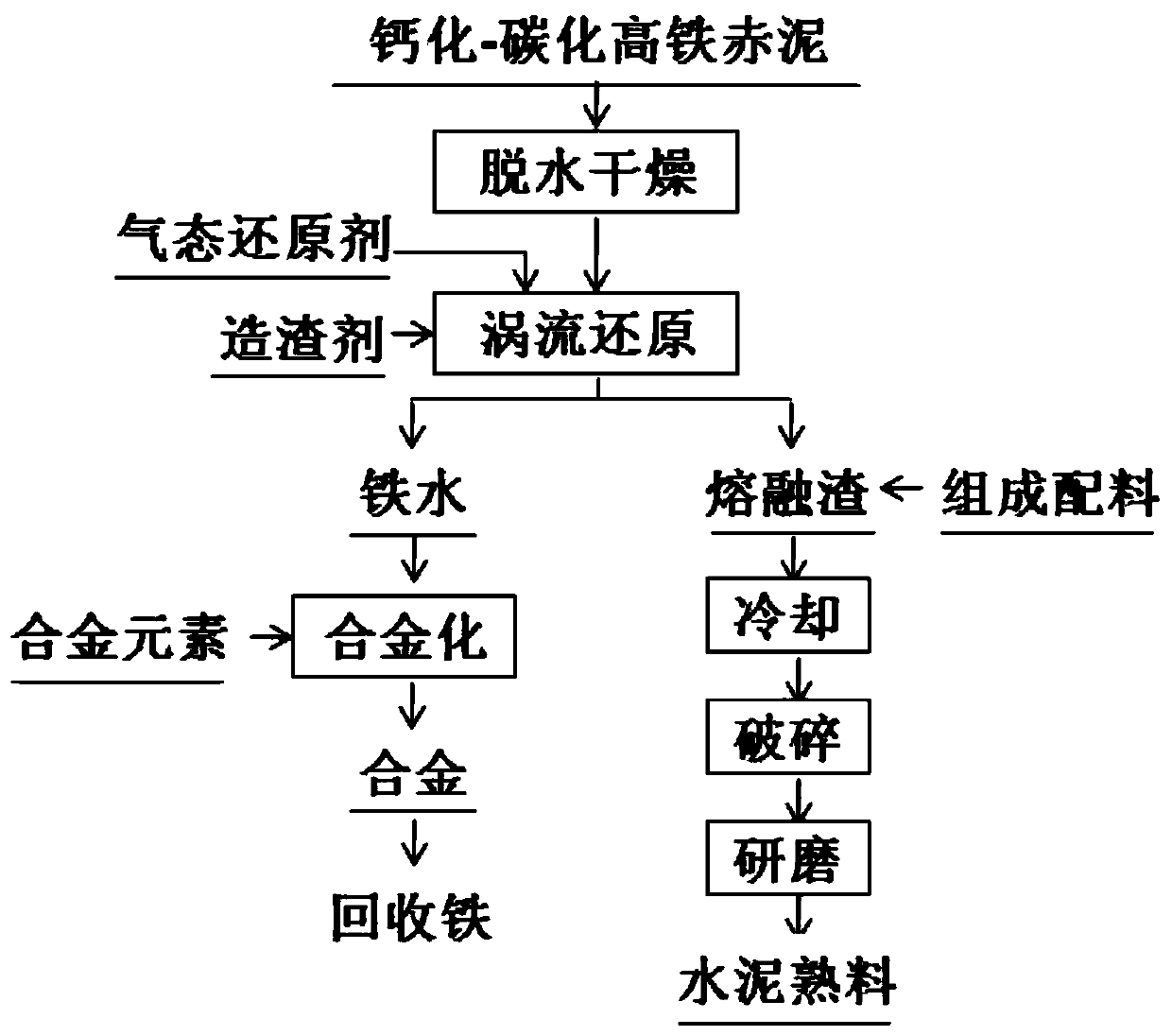

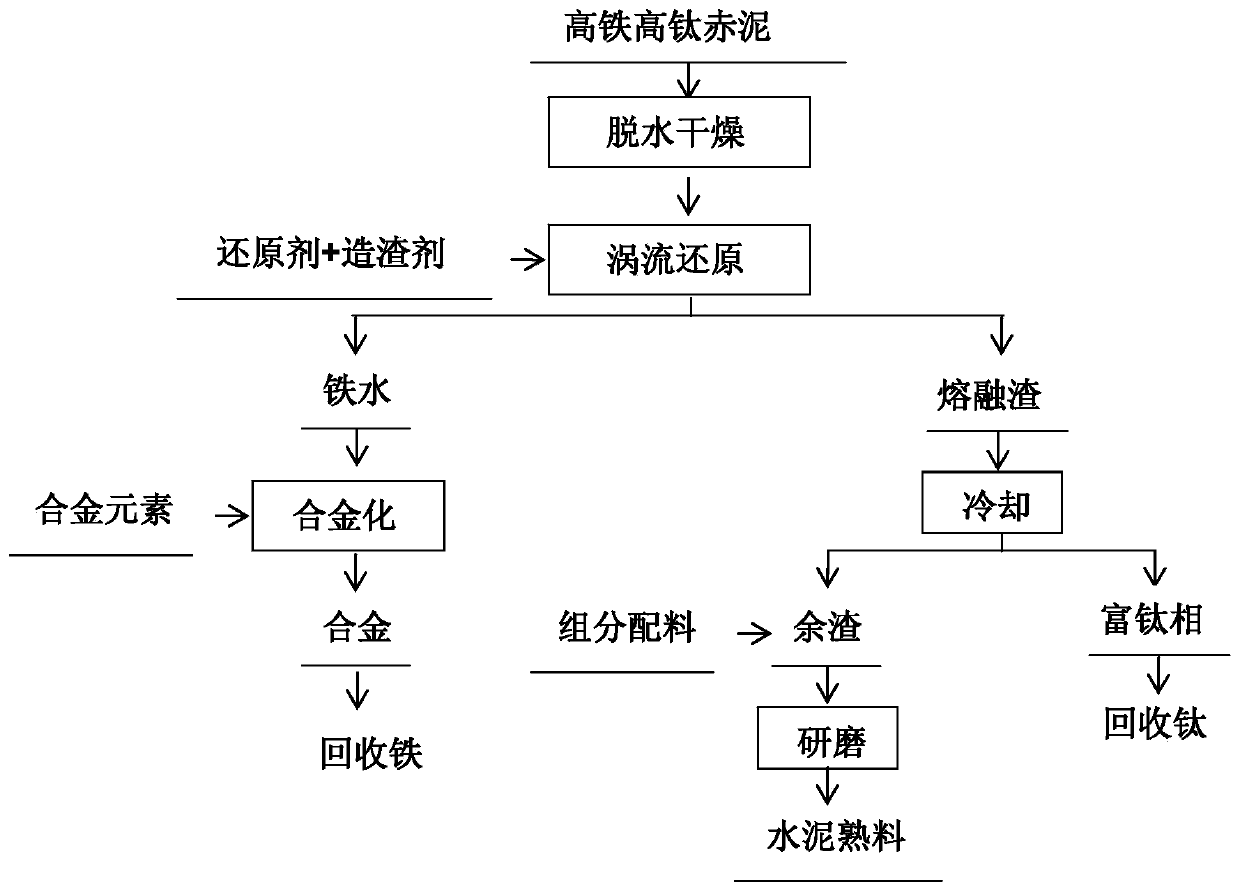

Calcified-carbonized high-iron red mud recycling iron and tailings cementation method

InactiveCN110055365ARemove restrictionsIncrease dosageCement productionGas emission reductionRed mudCarbonization

The invention relates to a calcified-carbonized high-iron red mud recycling iron and tailings cementation method which comprises the process steps of (1) drying and dewatering high-iron red mud treated through a calcification-carbonization method; (2) grinding a slag former and red mud mixture, directly spraying and blowing to a vortex center of a vortex stirring smelting reduction high-temperature furnace without sintering, and rolling into a molten pool; (3) carrying out vortex stirring in the molten pool at 1300 to 1600 DEG C, and meanwhile, feeding a gas-state reducing agent for reducing for 10 to 60min; (4) obtaining reduced molten iron and a melted slag, and carrying out overflow separation; (5) adding ferrochrome and ferromanganese into the molten iron, and smelting into wear-resisting cast iron; (6) adjusting compositions of the melted slag in the vortex stirring high-temperature furnace so as to enable the melted slag to meet the cement requirement; and (7) cooling, crushing and grinding the melted slag so as to directly obtain a cement clinker. According to the calcified-carbonized high-iron red mud recycling iron and tailings cementation method provided by the invention,the utilization rate of the red mud is 100 percent, and the extraction rate of the iron is more than 90 percent.

Owner:NORTHEASTERN UNIV

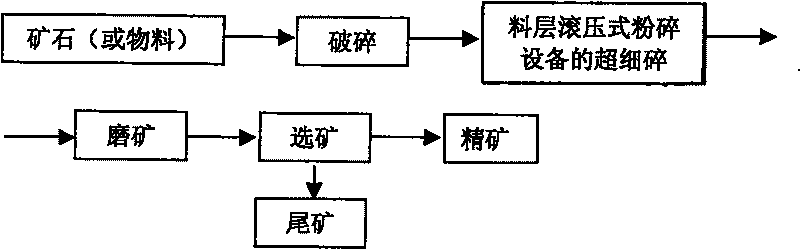

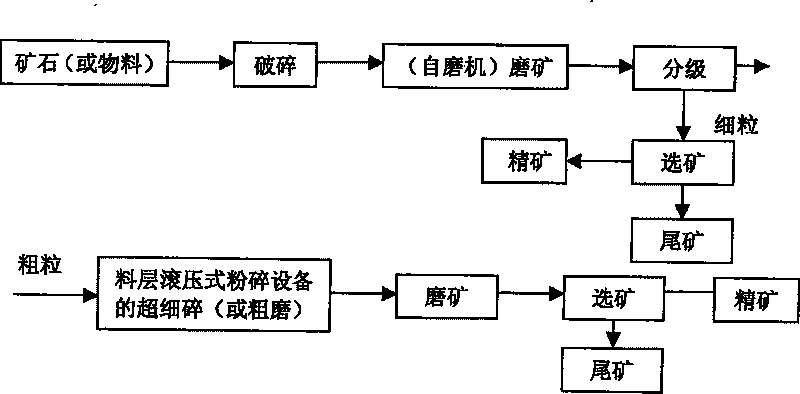

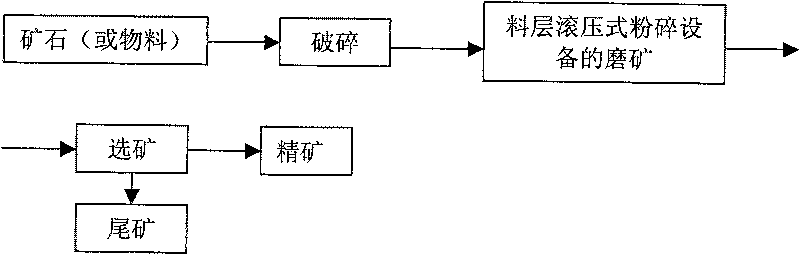

Concentration for qualifying headings and increasing recovery rate

InactiveCN1895788AFacilitate dissociationFast dissociationMagnetic separationGrain treatmentsBall millMaterials science

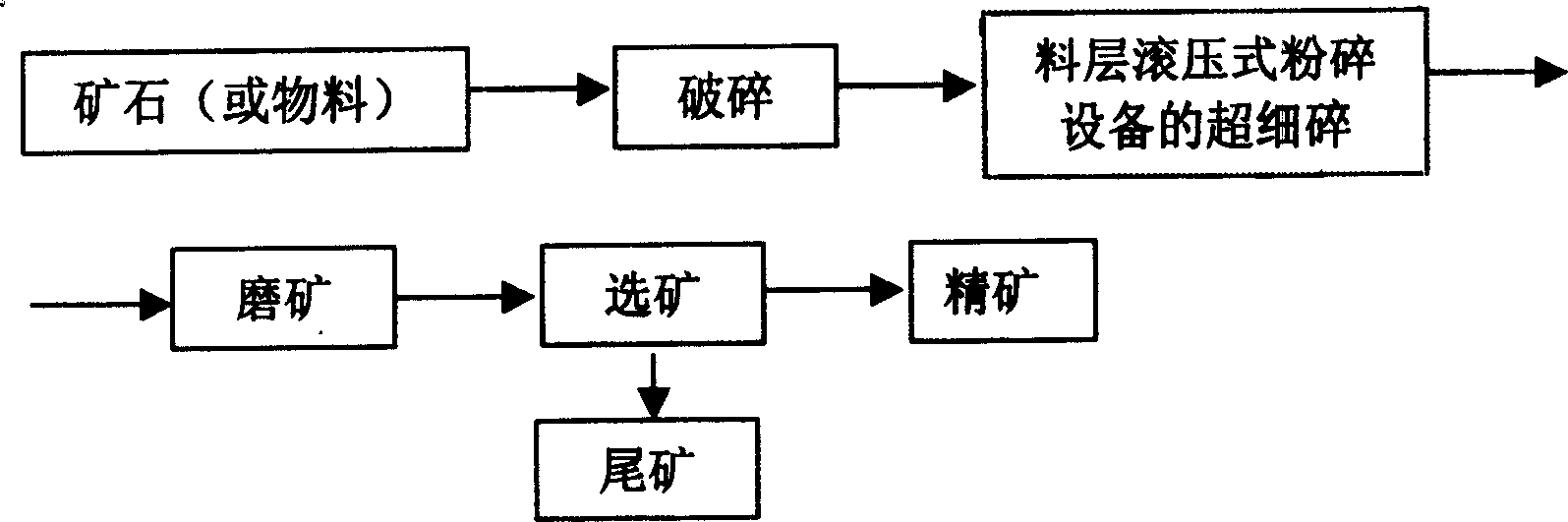

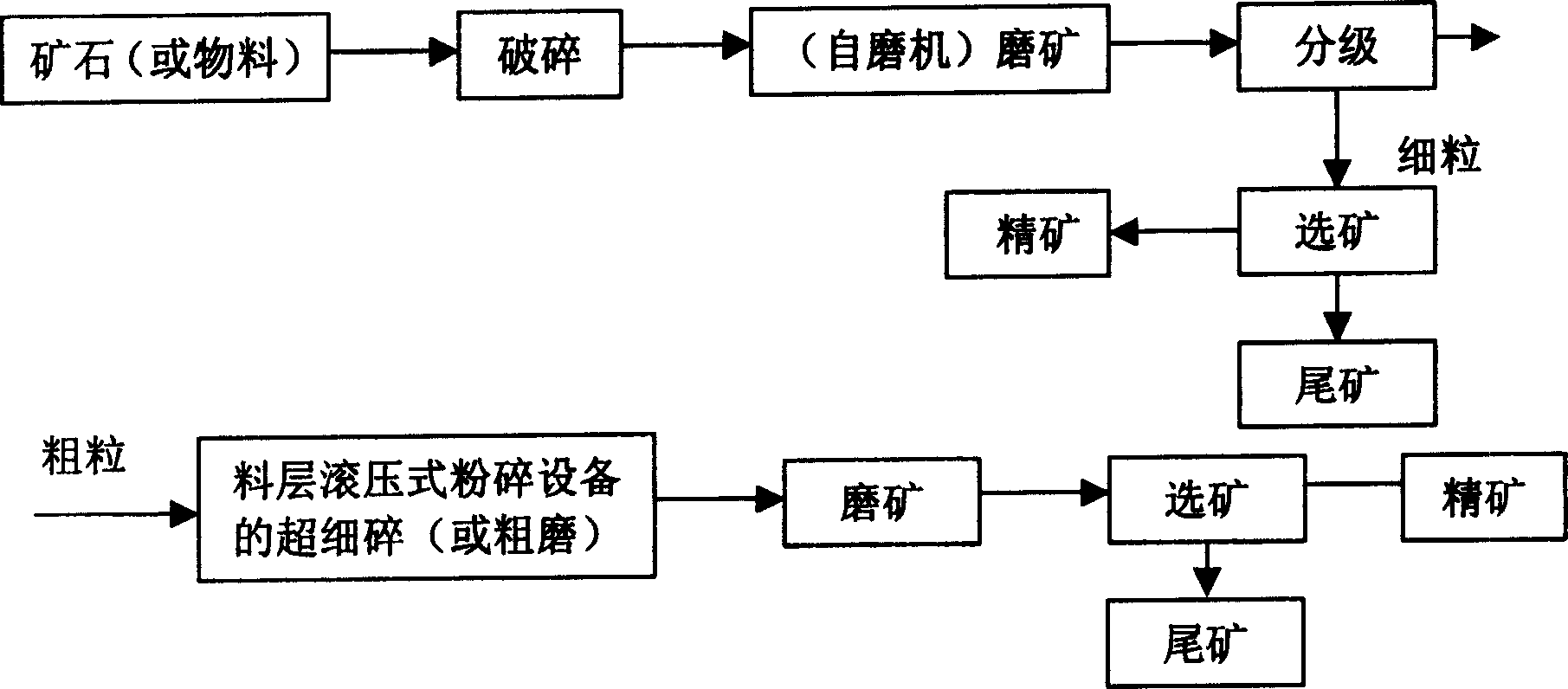

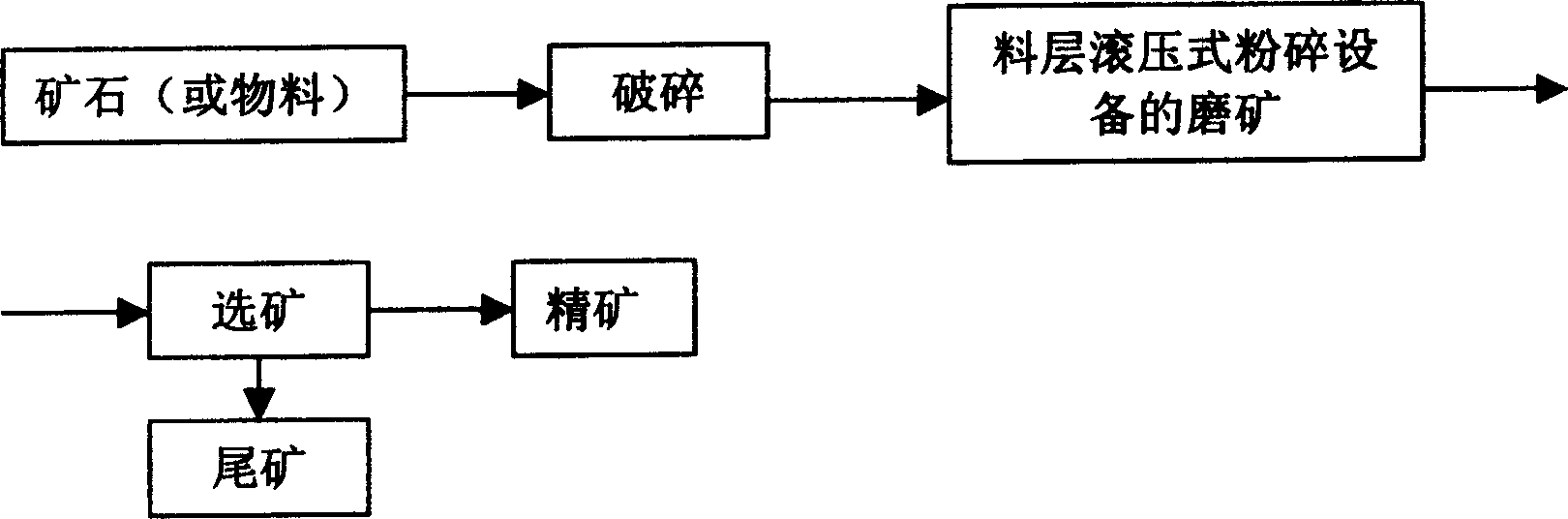

An ore dressing technology for increasing the quality and recovery rate of ore concentrate includes such steps as crushing, rolling, grinding, and separating. Another two approaches are also disclosed.

Owner:郝志刚

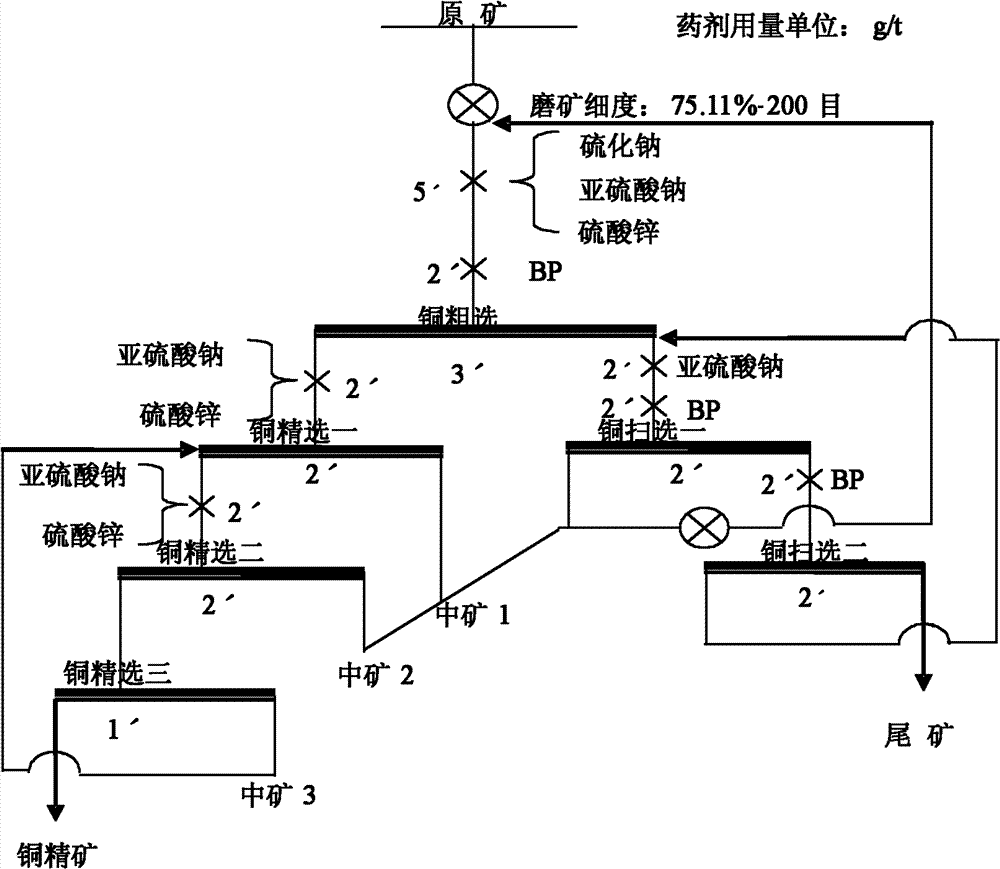

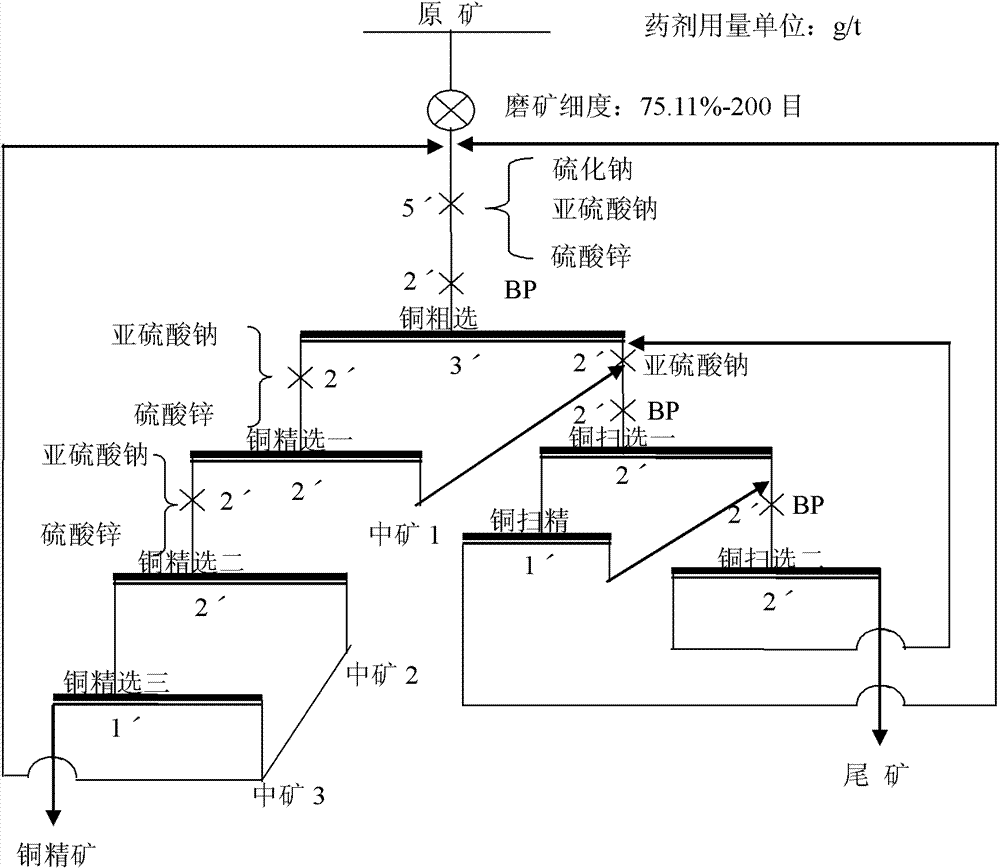

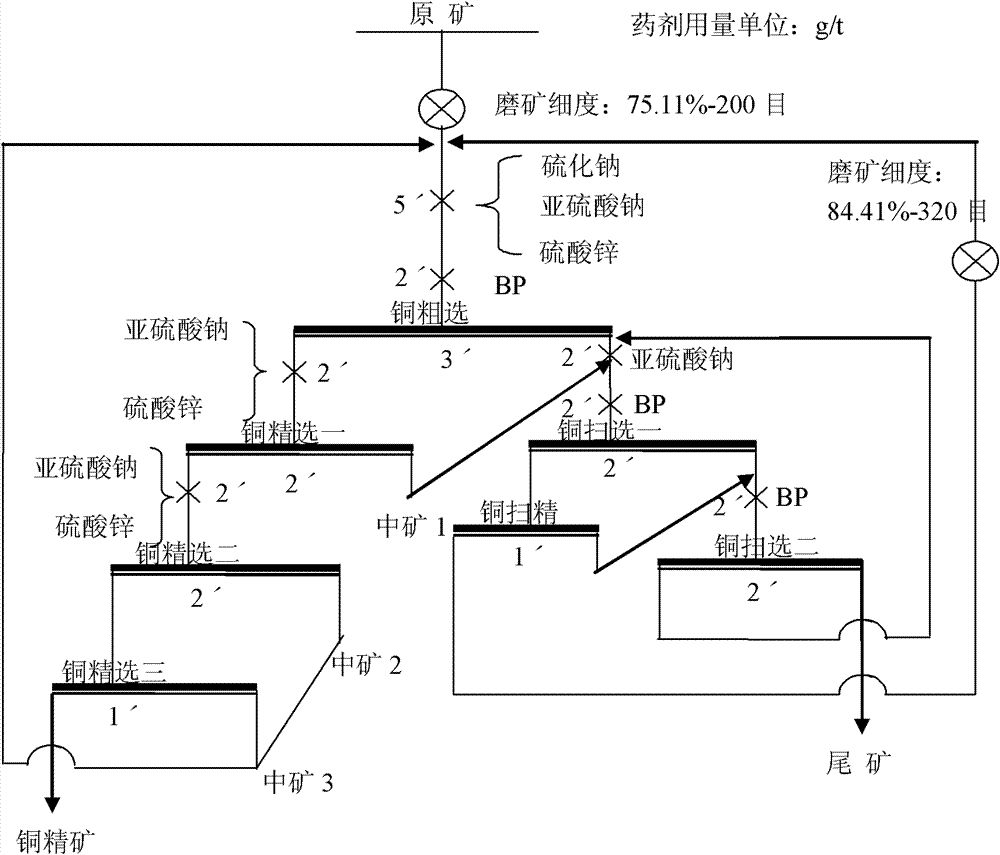

Complex copper-lead ore beneficiation separation method adopting middling returning and regrinding technology

The invention relates to a complex copper-lead ore beneficiation separation method adopting a middling returning and regrinding technology, comprising the following steps of: carrying out ore grinding on raw ores, and then carrying out copper roughing; carrying out copper choiceness by adopting flotation on rough concentrates obtained through the copper roughing; and carrying out copper scavenging on tailings obtained through the copper roughing. The complex copper-lead ore beneficiation separation method is characterized in that in the copper-lead separation process of the copper choiceness, middling chosen in a first copper choiceness process is returned to a first copper scavenging process, and the middling chosen in a second copper choiceness process and the middling chosen in a third copper choiceness process are intensively returned to the copper roughing process, therefore, the influence of impurities on grades is prevented, and the purpose of enhancing the grades of the copper concentrates is achieved; in the copper scavenging process, concentrates subjected to primary choiceness are reground, and ore charges are conveyed to the copper choiceness process to form selective milling after regrinding, thereby not only enhancing the dissociation degree of copper-lead ores but also preventing overgrinding, and enabling the copper concentrates to obtain higher recovery rate.

Owner:BAIYIN NONFERROUS GROUP +1

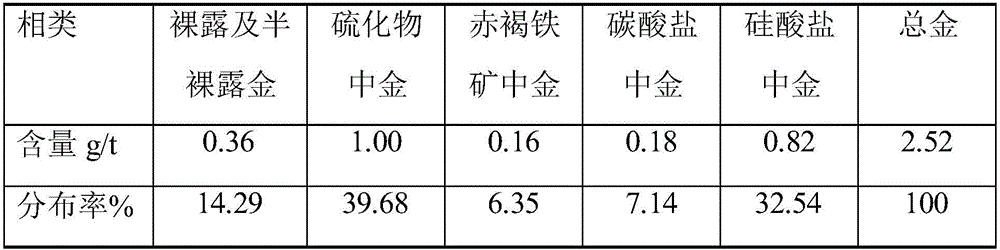

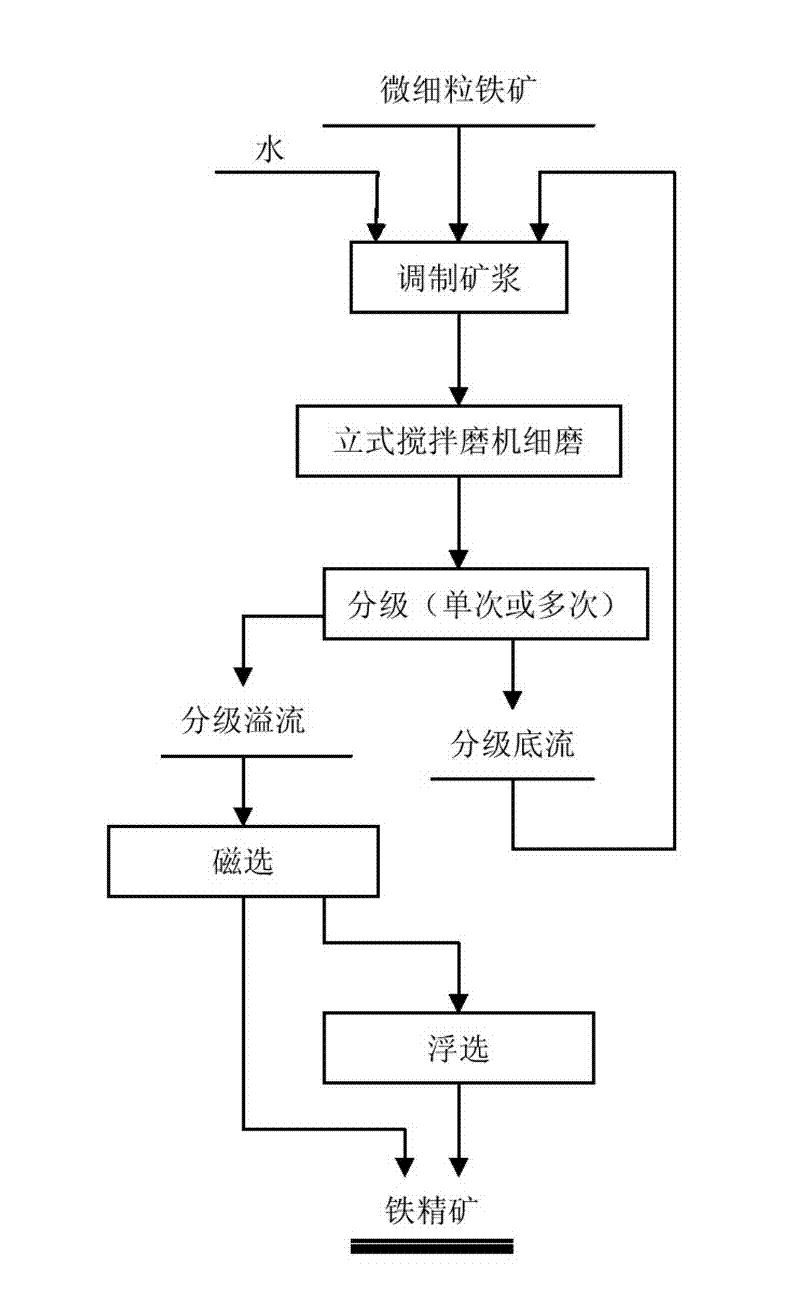

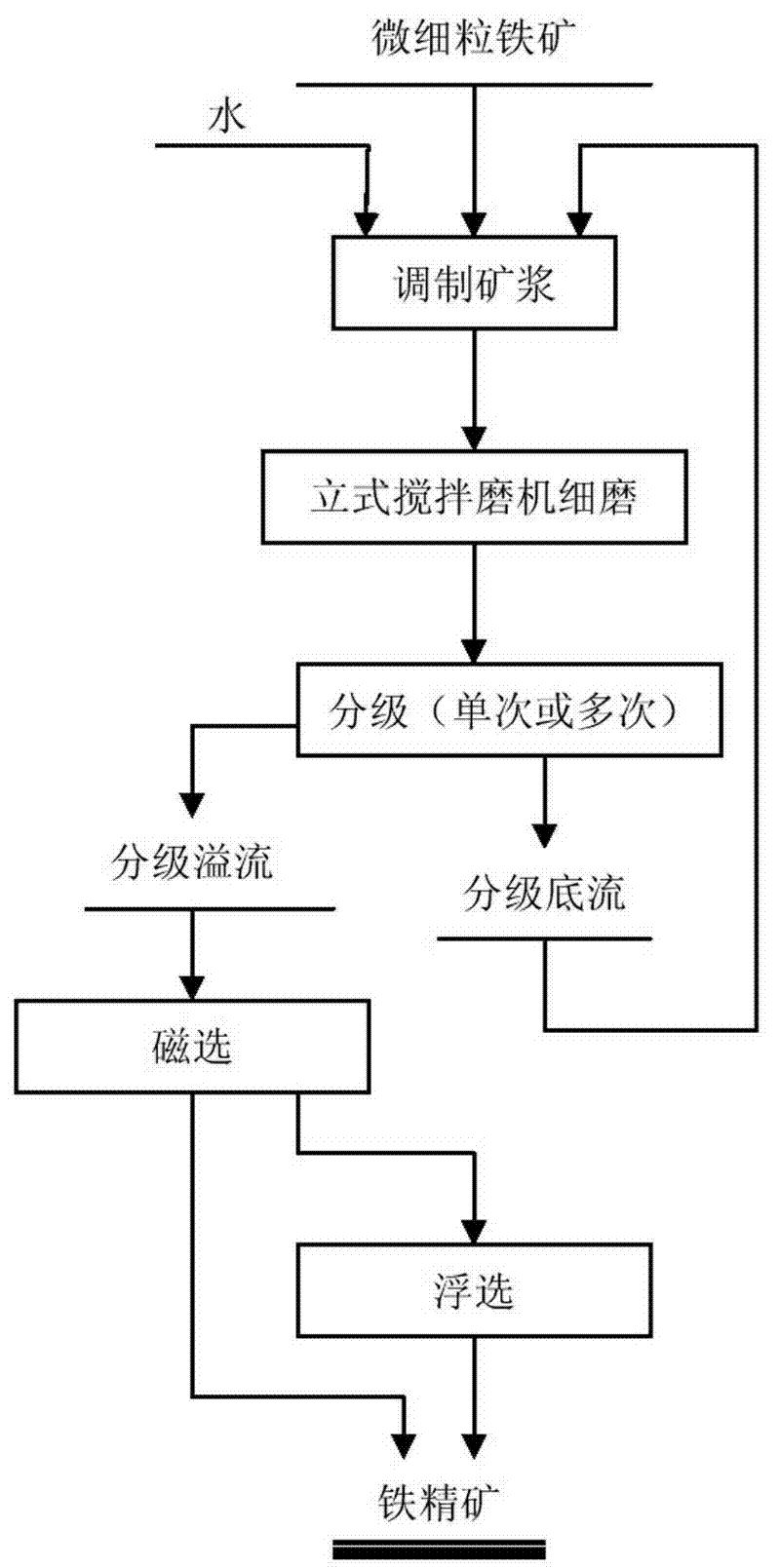

Method for finely grinding and separating fine grain iron ore

InactiveCN102125888AIncrease monomer dissociationImprove utilization efficiencyWet separationMagnetic separationFine grain

The invention relates to a method for separating iron ore, and in particular discloses a method for finely grinding and separating fine grain iron ore. The method comprises the following steps of: preparing 30 to 70 mass percent ore pulp from the fine grain iron ore, feeding into a vertical stirring grinder for fine grinding, discharging a finely-ground material, adding into a fine grain classifier for classifying, returning classified bottom flow to prepare the pulp, adding into the vertical stirring grinder for the fine grinding again, and performing magnetic separation or magnetic suspension united separation on classified overflow so as to obtain iron ore concentrate. By finely grinding and separating the fine grain iron ore by the method, the grade and the recovery rate of the iron ore concentrate can be obviously improved, and ore separating cost can be lowered.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for improving ore grinding efficiency through electric pulse ore pretreatment

The invention discloses a method for improving ore grinding efficiency through electric pulse ore pretreatment, and belongs to the technical field of mineral processing. According to the method, high-voltage electric pulse crushing pretreatment is achieved through dielectric property differences of different minerals in ore, high-voltage pulse outputs energy with the extremely high power density, electricity is discharged to ore through a high-voltage electrode, multiple microcracks are formed on the interfaces between gangue minerals and useful minerals in ore, accordingly, the strength of ore is lowered, the dissociation characteristic is improved, the ore grinding efficiency can be improved, energy consumption can be reduced, and separation indexes can be modified and improved.

Owner:NORTHEASTERN UNIV

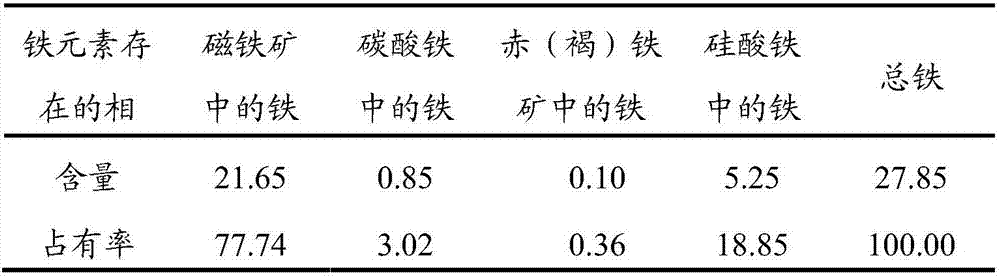

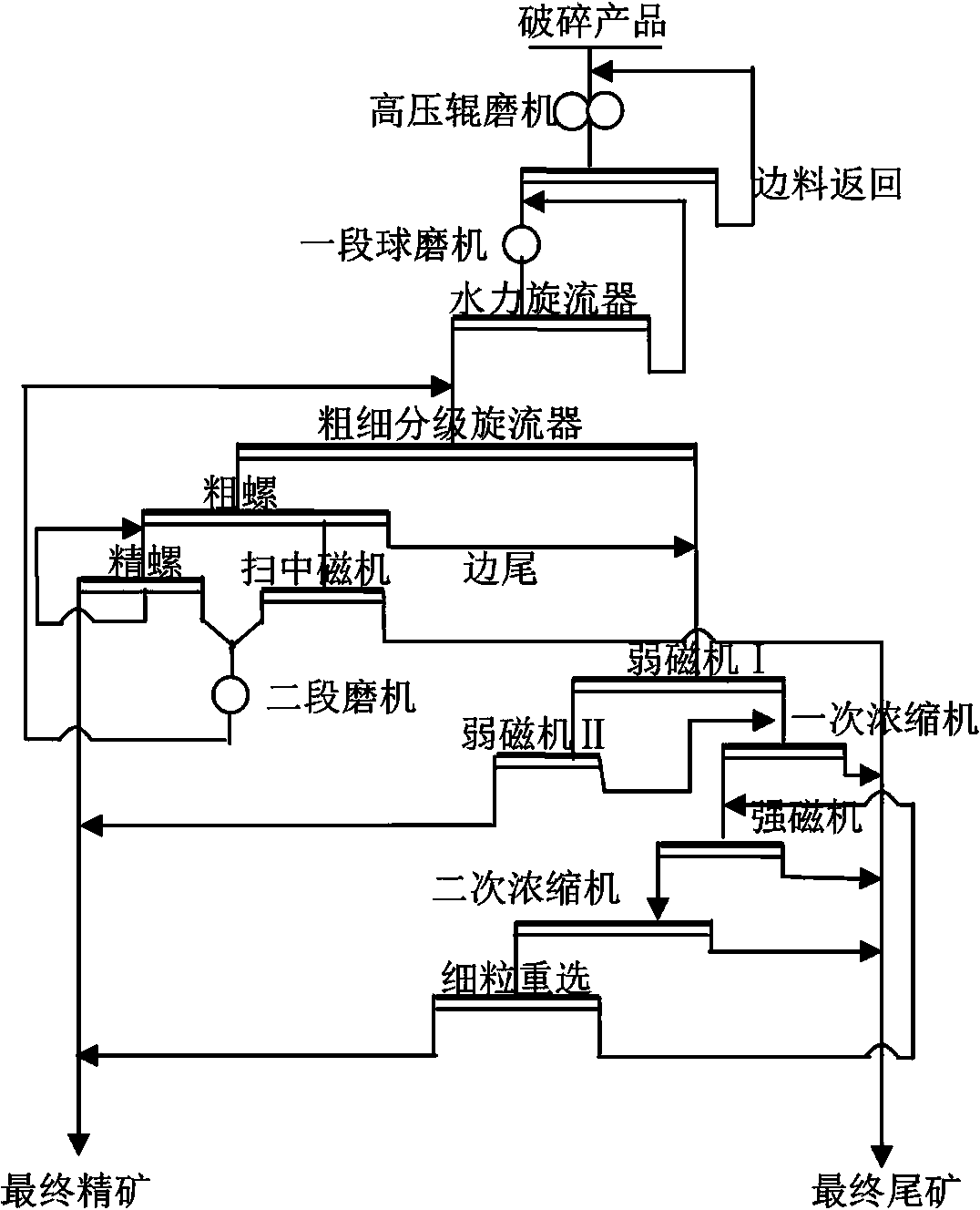

Coarse and fine separation-gravity concentration-magnetic separation combined beneficiation process for processing Anshan type iron ores

InactiveCN111013811AIncrease monomer dissociationReduce grinding costsWet separationIronstoneReverse flotation

The invention relates to a coarse and fine separation-gravity concentration-magnetic separation combined beneficiation process for processing Anshan type iron ores. The process comprises fine crushing, one-stage closed loop ore grinding, coarse and fine grading, gravity concentration and magnetic separation. The process is characterized in that the process is improved such that fine-crushing-ball-milling-grading flows are replaced by roll milling-ball-milling-grading flows; an edge tail product of a coarse screw is added into a fine grain product for selection; pre-grading before a regrind mill is cancelled; and two-stage continuous weak magnetic separation is adopted for the processed fine grain product for taking the concentration, and a reverse flotation operation is replaced by a finegrain gravity concentration operation subsequently. The grade of raw ores is 27-31%, the final concentrate grade is 66.5-67.3%, and the final tailing grade is 7-8.5%. The process has the advantages that 1) the ore grinding efficiency is improved and the machine-hour is increased; 2) the edge of the coarse screw is classified in fine grain product treatment, so that the loss of magnetic fine iron ores in scavenging is reduced; 3) qualified concentrate is yielded by two-stage weak magnetic separation, so that the production cost is lowered; and 4) reverse flotation is replaced by fine grain gravity concentration, so that the agent cost and the ore pulp warming energy consumption are saved.

Owner:ANSTEEL GRP MINING CO LTD

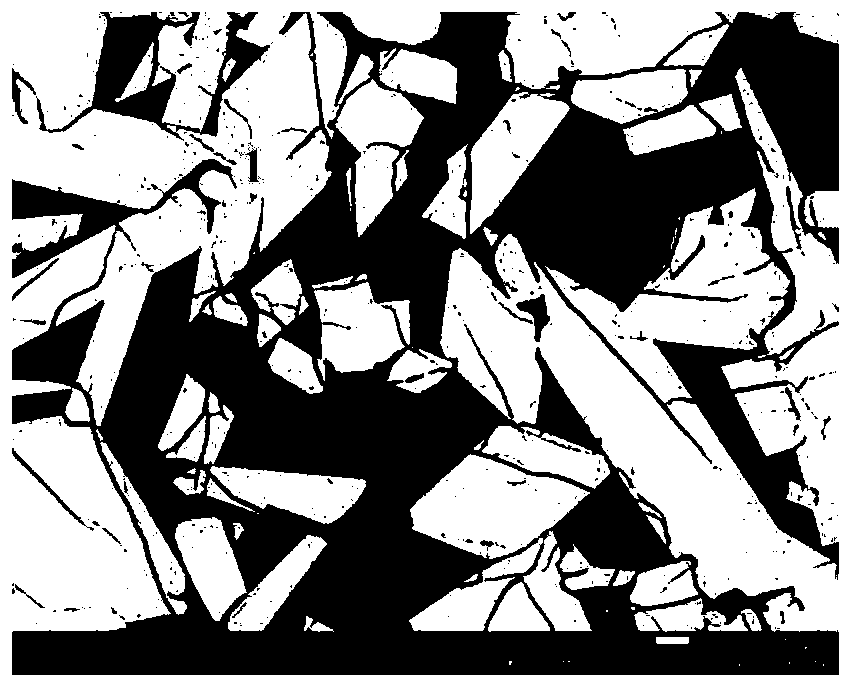

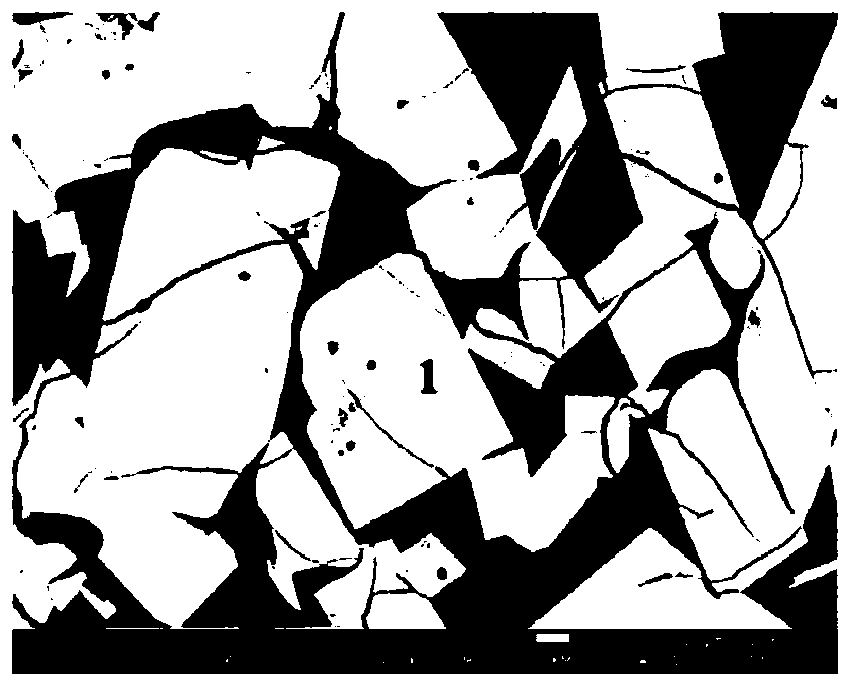

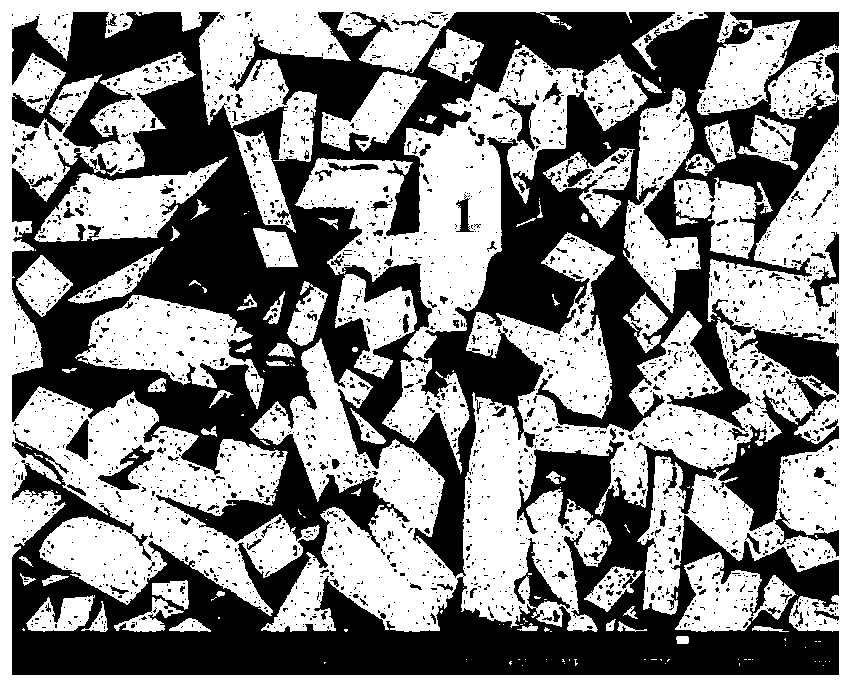

A method for controlling the crystallization phase of molten titanium slag

ActiveCN107653380BPromote crystallizationRaise the gradeProcess efficiency improvementSulfateReducer

The invention relates to a method for adjusting and controlling a melt separation titanium slag crystallization phase. According to the method, the components of titanium slag are adjusted and controlled to comprise, by weight, 40-70% of TiO2, 4-18% of MgO, 4-18% of Al2O3 and a reducer, wherein the weight ratio of the reducer to TiO2 is 0.01-0.15; and the titanium slag is heated to be melted, after complete reacting, the temperature is decreased to be 1300-1500 DEG C at the speed rate of 0.1-20 DEG C / min for quenching treatment so as to obtain the melt separation titanium slag. According to the method for adjusting and controlling the melt separation titanium slag crystallization phase, through adjusting and controlling over the components and controlling over the crystallization process,anosovite becomes a sole precipitated phase of the melt separation titanium slag, the TiO2 grade of an anosovite titanium-rich phase in the melt separation titanium slag is high, the grain size is large, the mineral phase structure is compact, the single separation degree is high, and after subsequent treatment, the high-grade titanium slag with the TiO2 grade being 76% or above can be obtained. According to the method for adjusting and controlling the melt separation titanium slag crystallization phase, the requirement of a sulfate process titanium dioxide technique for the titanium slag grade is met, and the method is suitable for industrialized application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recovering iron and titanium from high-iron high-titanium red mud and carrying out direct cementation

InactiveCN109913656AEasy extractionIngredient requirements metCement productionProcess efficiency improvementWear resistantRed mud

The invention provides a method for recovering iron and titanium from high-iron high-titanium red mud and carrying out direct cementation. The method includes the following steps that (1), the raw material, namely the high-iron high-titanium red mud treated with a carbonization-carbonization method is prepared; (2), a dewatered raw material is obtained after drying; the dewatered raw material, a solid-state carbonaceous reducing agent and a slagging former are mixed into a mixture, the mixture is spray-blown to the vortex center of a vortex stirring high-temperature furnace, and vortex stirring reducing is carried out; (3), molten iron formed after reducing is separated from titanium-containing molten slag; ferrochromium and ferromanganese are added into the molten steel, and a wear-resistant cast iron product is prepared; and (4), titanium-containing components in the titanium-containing molten slag are enriched to form a titanium-containing phase, and the titanium-containing phase isseparated from residual slag; the components of the residual slag are adjusted, so that the residual slag meets the requirements of cement clinker, and breaking and grinding are carried out. By meansof the method, iron and titanium can be comprehensively recovered, the recovery rate of titanium can reach 60% or above, and the utilization rate of the red mud reaches 100%.

Owner:NORTHEASTERN UNIV

Beneficiation method capable of recycling valuable metal from tin magnetic pyrite

InactiveCN107051712AReduce over crushingIncrease monomer dissociationWet separationSpecific gravityPrecondition

The invention discloses a beneficiation method capable of recycling valuable metal from tin magnetic pyrite. The method comprises graded ore grinding work, magnetic separation work, thick flotation work and reselection work. The method has the beneficial effects that a bar grinding machine is adopted to grade ground ore in advance, over pulverizing of tin stone can be reduced, the single separation degree of the tin stone can be increased, and the precondition is provided for effective recycling of the tin stone; secondly, magnetic separation is adopted to remove the magnetic pyrite with the large proportion and the higher iron containing rate, floatation is adopted to remove the magnetic pyrite with the large proportion and the higher sulphur containing rate, disturbance of heavy mineral is reduced, and the advantage is created for subsequent reselection and separation of tin stone; thirdly, the middling re-grinding and reselection flow is adopted, energy consumption of ore grinding can be reduced, over pulverizing of the tin stone is reduced, the single separation degree of tin stone can be improved, the cost is low, and industrial production is easily achieved; fourthly, secondary pollutions in the production process are not needed, and the method is friendly to the environment.

Owner:KUNMING METALLURGY INST

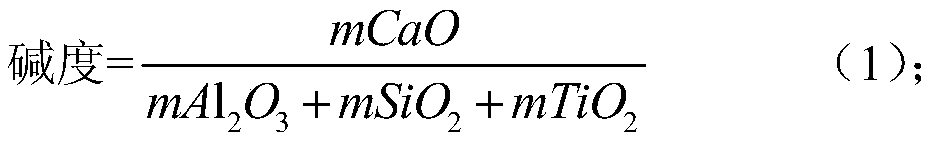

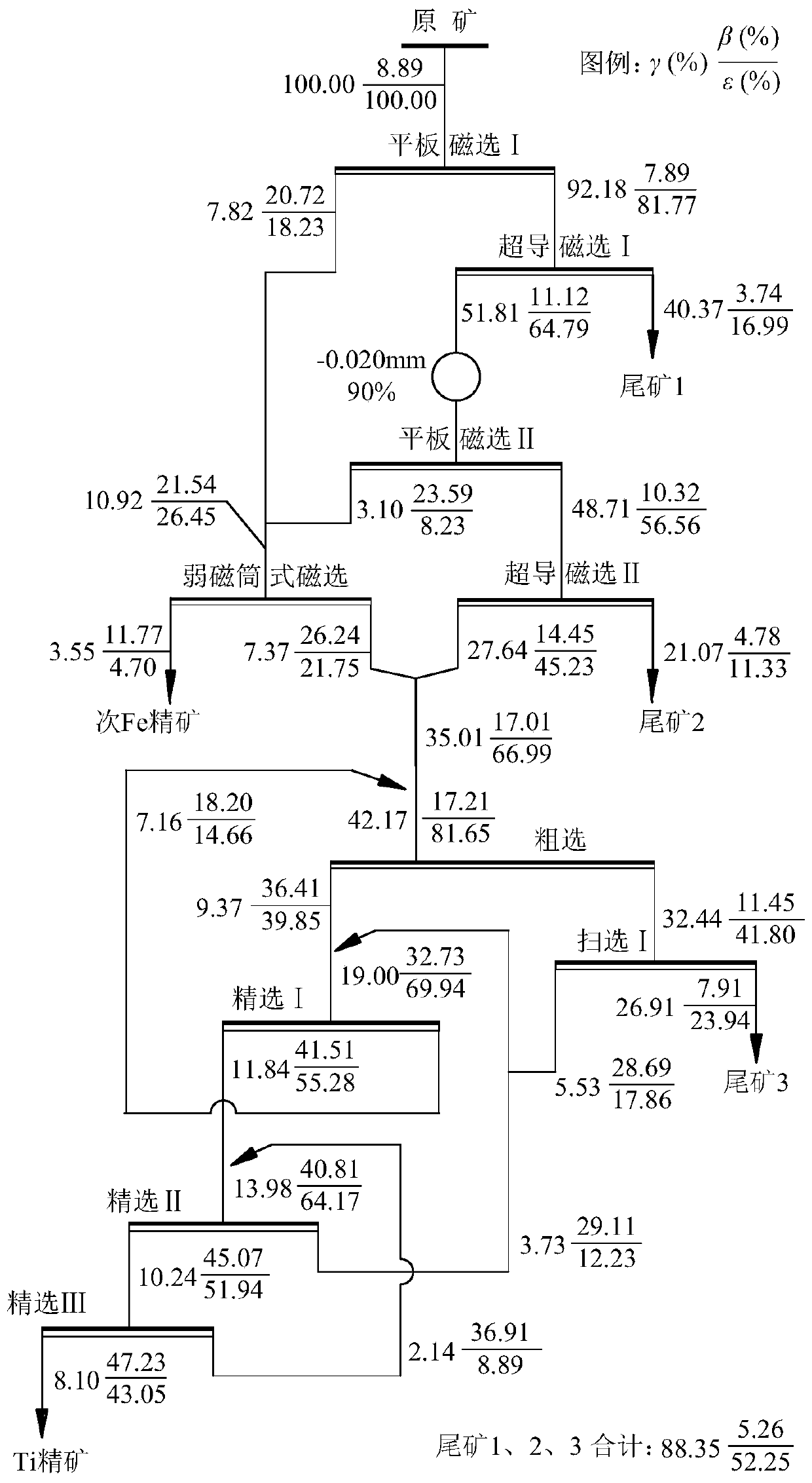

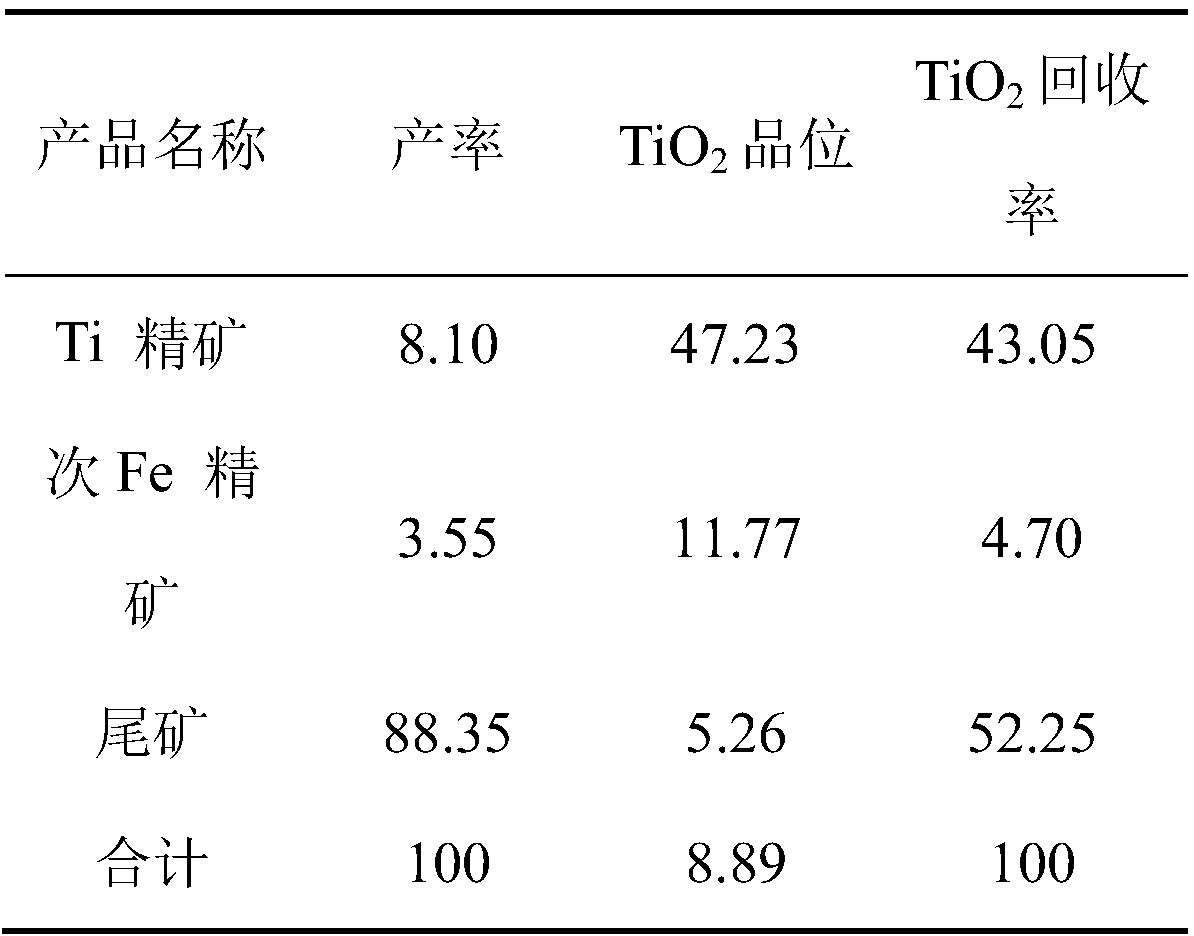

Ultrafine-grained ilmenite material pre-enrichment and selection process

InactiveCN110665640AEfficient removalHigh efficiency pre-enrichmentFlotationMagnetic separationIlmeniteEnergy consumption

The invention discloses an ultrafine-grained ilmenite material pre-enrichment and selection process. The process mainly comprises the following two parts of (1) realizing effective pre-enrichment of ultrafine-grained ilmenite by using a ''medium magnetic pre-selection-superconducting magnetic separation'' process to obtain a flotation raw material; and (2) using a ''flotation machine-flotation column'' combined process to select ilmenite after magnetic separation pre-enrichment, and finally acquiring ilmenite concentrate whose TiO2 grade is greater than 47% and a TiO2 recovery rate is greaterthan 40%. The method of the invention has the characteristics of low energy consumption, high efficiency, easy conversion into production practice and the like, and effective recovery of ultrafine-grained ilmenite is realized under a condition of ensuring quality of concentrate products.

Owner:江苏旌凯中科超导高技术有限公司

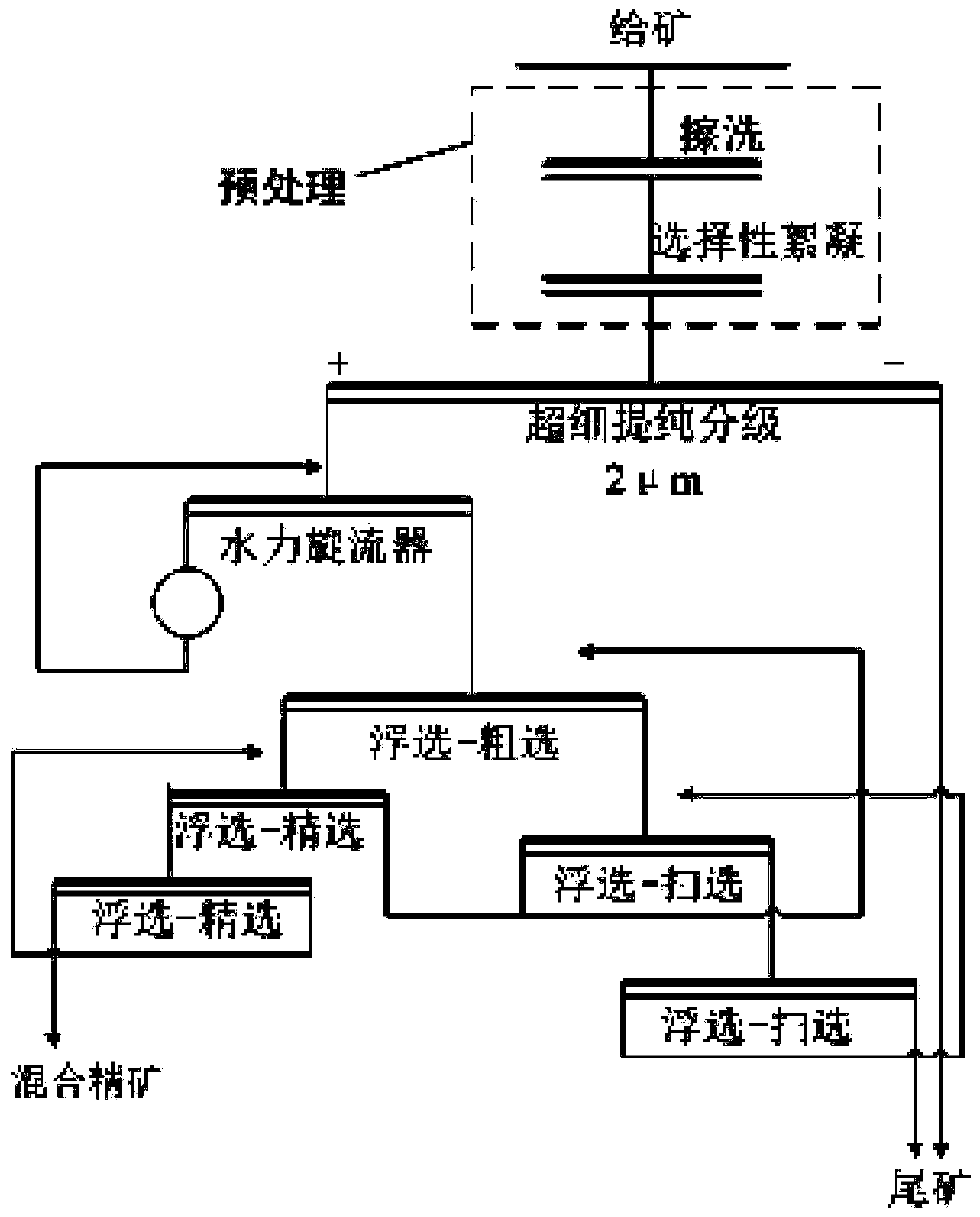

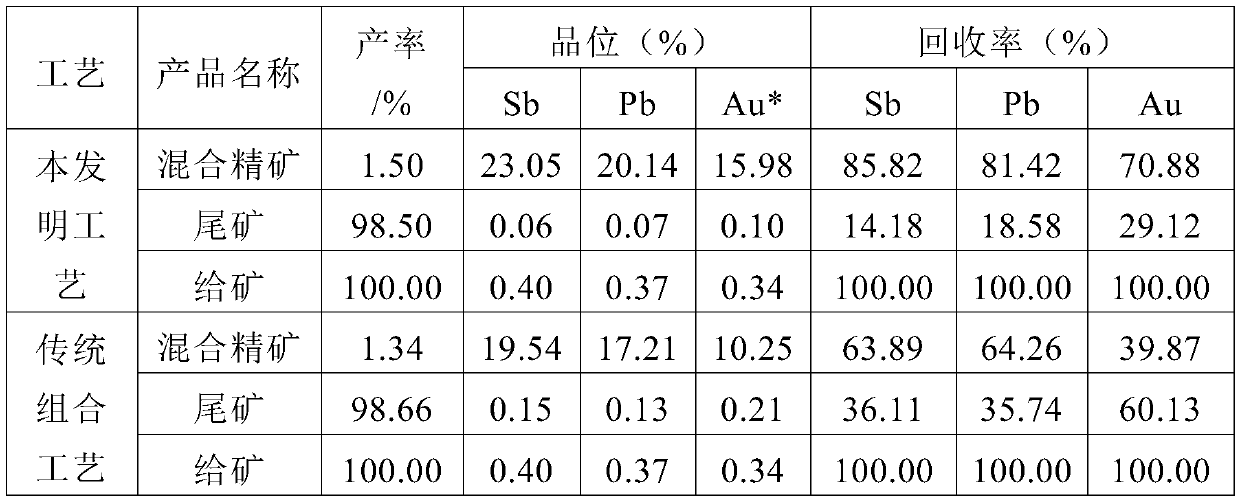

Combined process for recovering antimony, lead and gold from multi-metal tailings

ActiveCN111330751AIncrease flocculation particle sizeEliminate adverse effectsVortex flow apparatusWet separationOre concentratePre treatment

The invention discloses a combined process for recovering antimony, lead and gold from multi-metal tailings. The combined process comprises the following steps: (1) pretreating the tailings, specifically, the tailings are put in a stirring barrel for slurry mixing and scrubbing, and then a flocculating agent is added for selective flocculation; (2) performing superfine purification classificationby using a superfine purification classifier to remove fine mud below 2 microns; and (3) allowing settled sand to enter a hydrocyclone for classification, grinding the classified underflow, returningto the hydrocyclone for classification, and performing classified overflow for flotation to obtain mixed concentrate. According to the process disclosed by the invention, the recovery rate of valuableelements in the tailings is greatly improved and the desliming effect is greatly improved through the measures of pretreatment of the tailings, superfine purification desliming, construction of a selective grinding loop and the like.

Owner:有研资源环境技术研究院(北京)有限公司

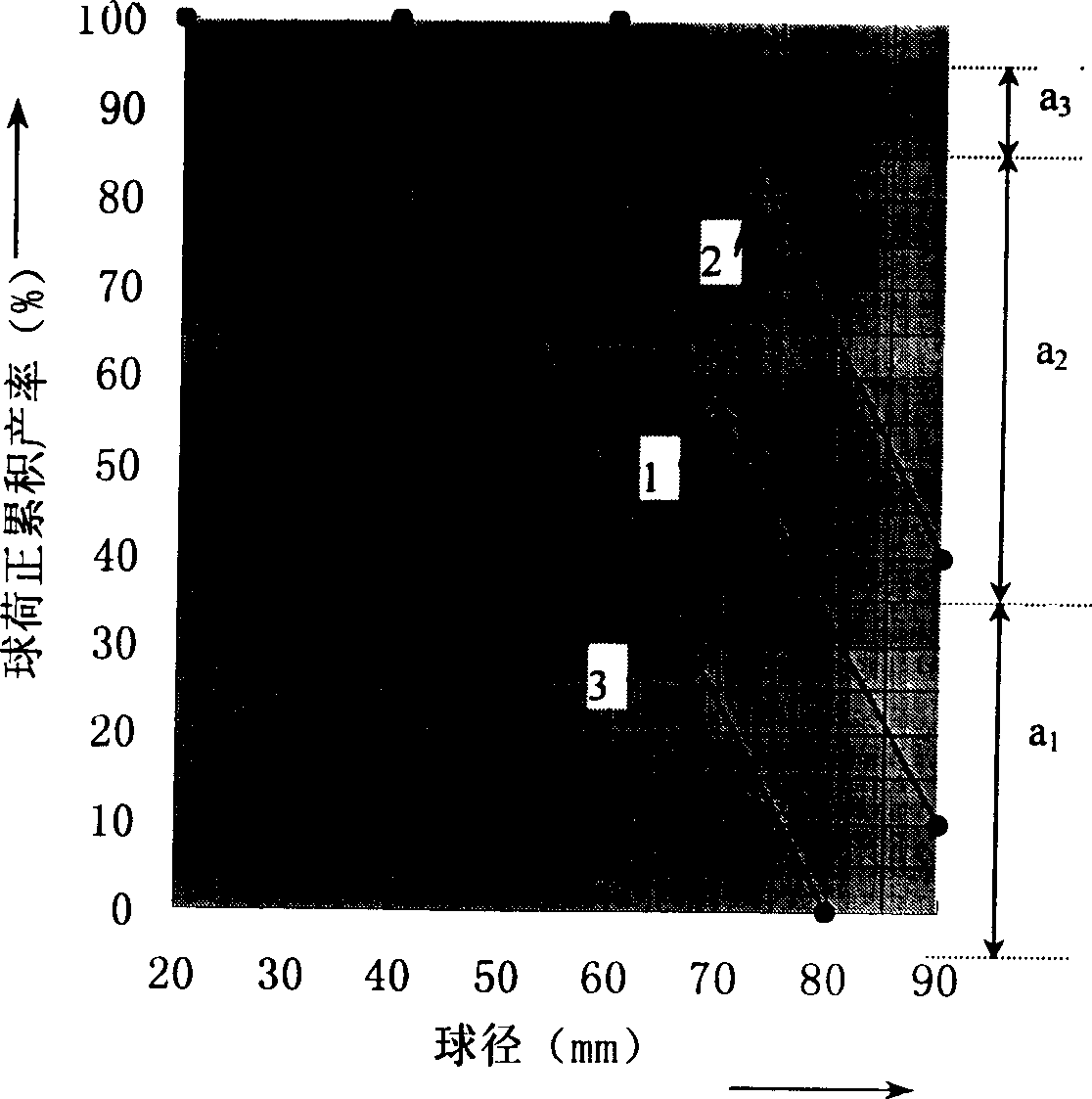

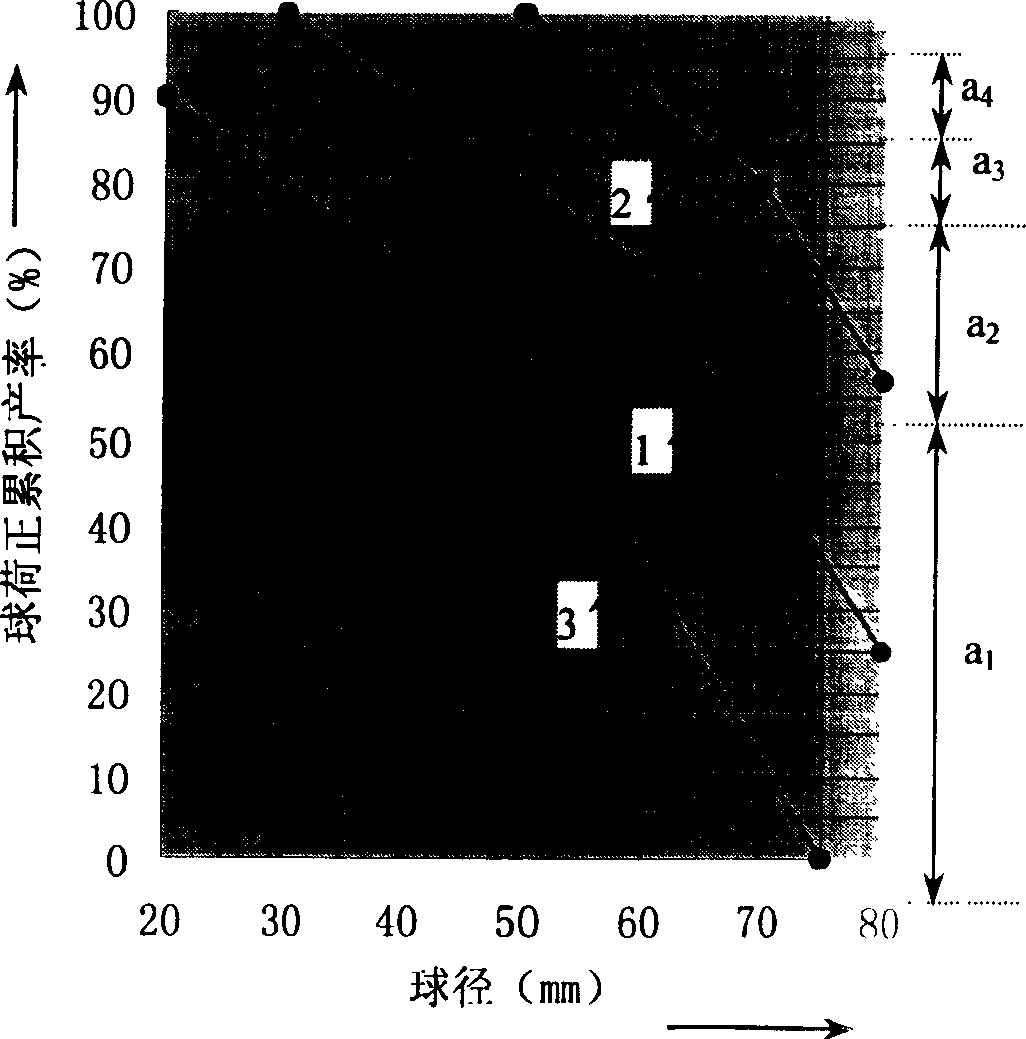

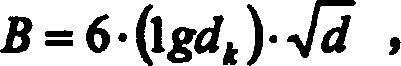

Ball grinder accurate ball loading method

InactiveCN1278775CAccurate ball diameterChoose accuratelyGrain treatmentsBall bearingMineral particles

The invention relates to a method for accurately loading and replenishing balls in a ball mill, which belongs to the technical field of ore crushing and fine grinding. According to the purpose of ore grinding, this accurate and convenient method of filling balls is proposed, including: measuring the mechanical parameters of the ore to be ground; screening and analyzing the new feed ore and sand return of the mill, and calculating the full feed The ore particle size is composed and grouped; the ball diameter value required by each group of ore particles is calculated using the ball diameter semi-theoretical formula; the ball ratio of the balls initially loaded in the mill is determined according to the ore particles of each group and the required ball diameter to be ground; Draw the positive cumulative characteristic curve of the particle size of the ball charge, and then obtain the ball diameter and the proportion of the ball to be added accurately from the graph. Applying this method to replenish balls, due to the precise ball diameter, reasonable proportion and simple method, increases the output per hour of the mill, improves the quality of the grinding product, reduces the power consumption of the ball, and increases the dissociation degree of the grinding product monomer. The beneficiation recovery rate and concentrate grade have also been improved.

Owner:KUNMING UNIV OF SCI & TECH +2

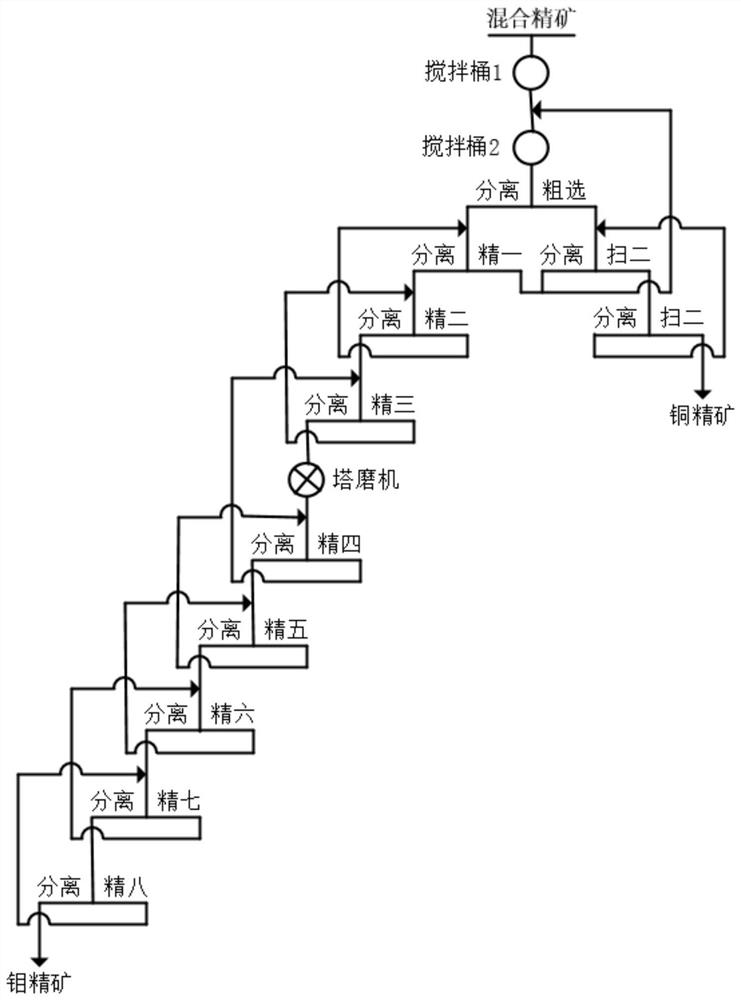

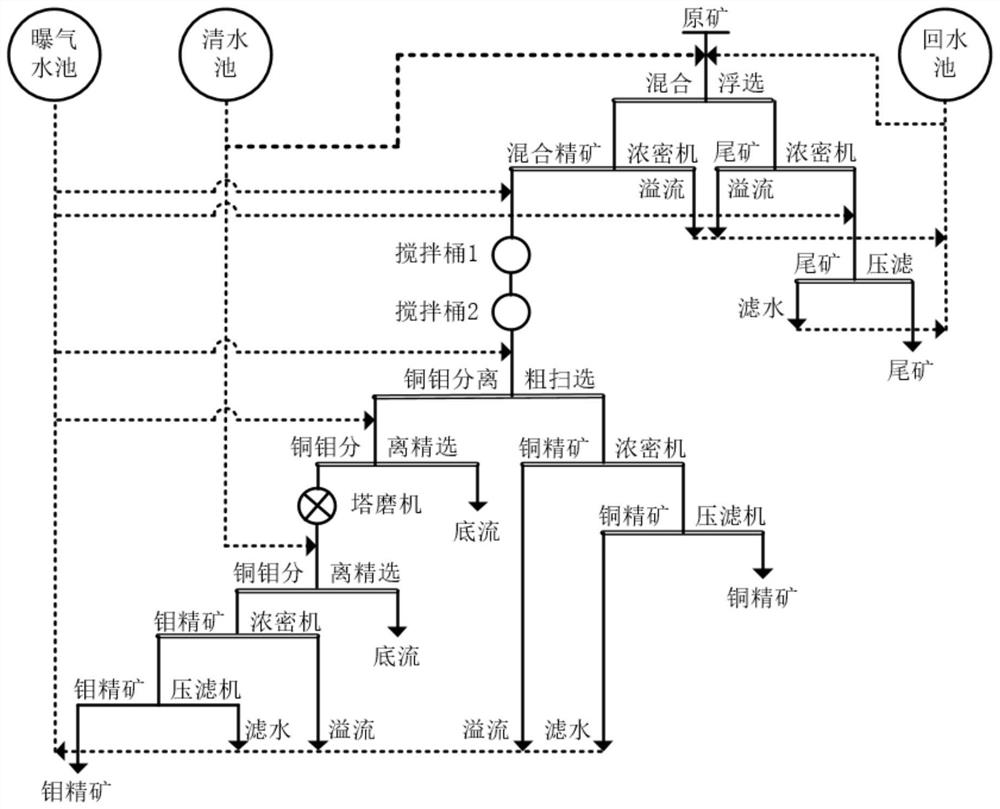

Copper-molybdenum separation method for low-grade copper-molybdenum ore with consideration of backwater utilization

The invention provides a low-grade copper-molybdenum ore copper-molybdenum separation method giving consideration to backwater utilization, which comprises the following steps: carrying out copper-molybdenum bulk flotation on copper-molybdenum ore to obtain copper-molybdenum bulk concentrate and tailings; the tailings are subjected to concentration and filter pressing, and low-water-content tailings are obtained; and the copper-molybdenum bulk concentrate is concentrated, pulp mixing is conducted, then copper-molybdenum separation operation is conducted, and molybdenum concentrate and copper concentrate are obtained. According to the invention, sodium hydrosulfide and sodium thioglycollate are combined for use, so that the use amount of sodium hydrosulfide is greatly reduced; a pulp mixing and stirring barrel is arranged before the copper-molybdenum separation operation, the concentration of floating pulp is stabilized, meanwhile, sodium hydrosulfide is adopted for adjusting the potential of the pulp, and through the modes of sodium hydrosulfide reagent removal, high-concentration concentration reagent removal, aeration reagent removal, stirring friction washing and the like, residual reagents in the copper-molybdenum mixing operation in the pulp are reduced. According to the method provided by the invention, copper and molybdenum can be well separated.

Owner:TIBET HUATAILONG MINING DEV

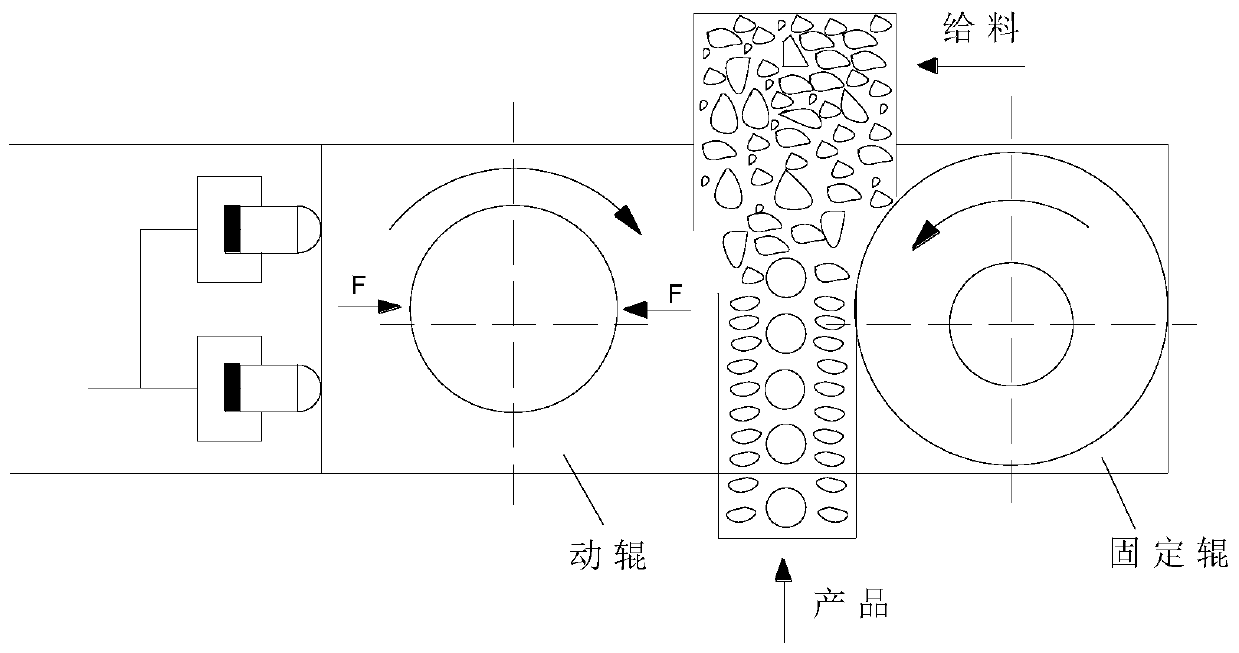

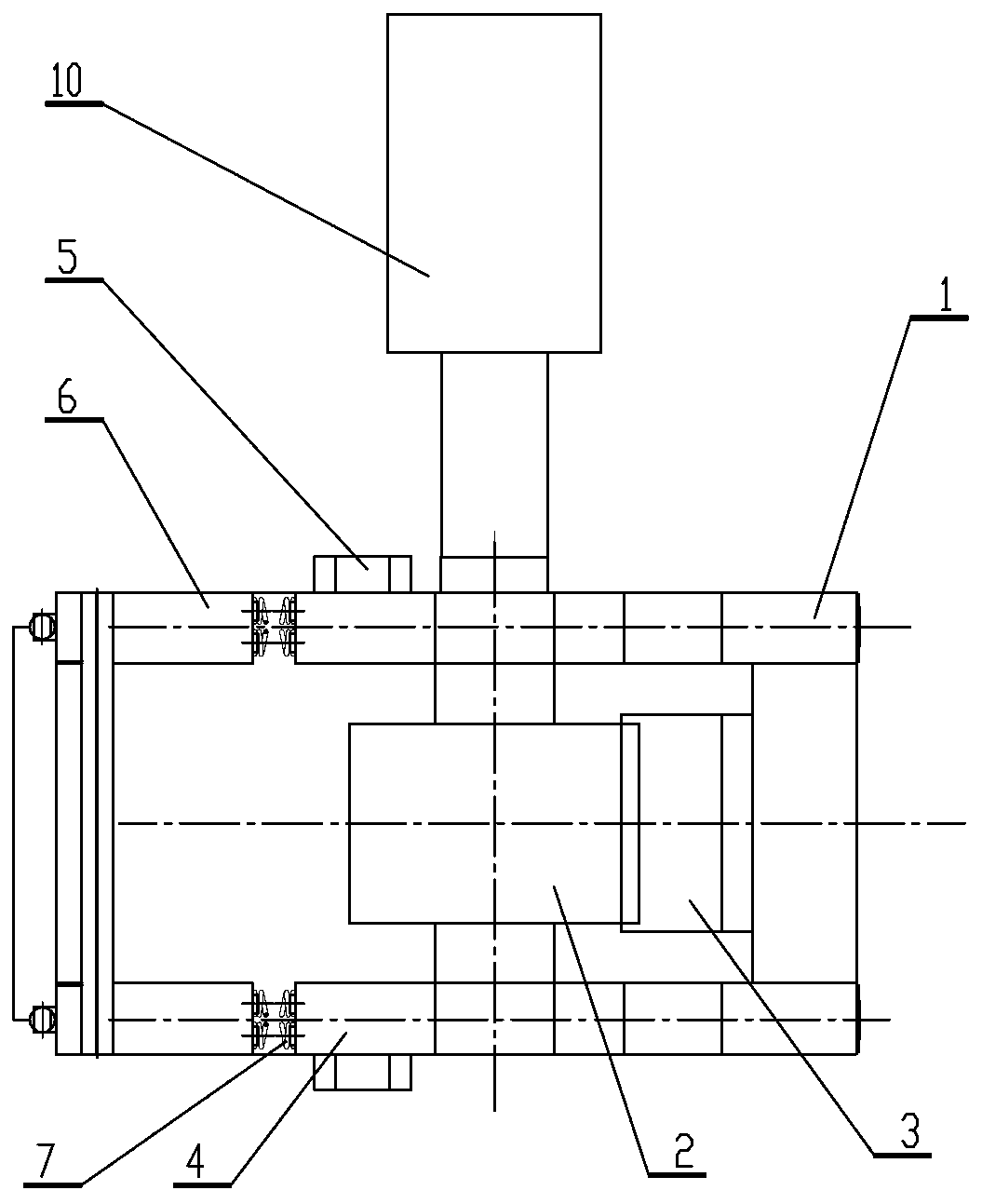

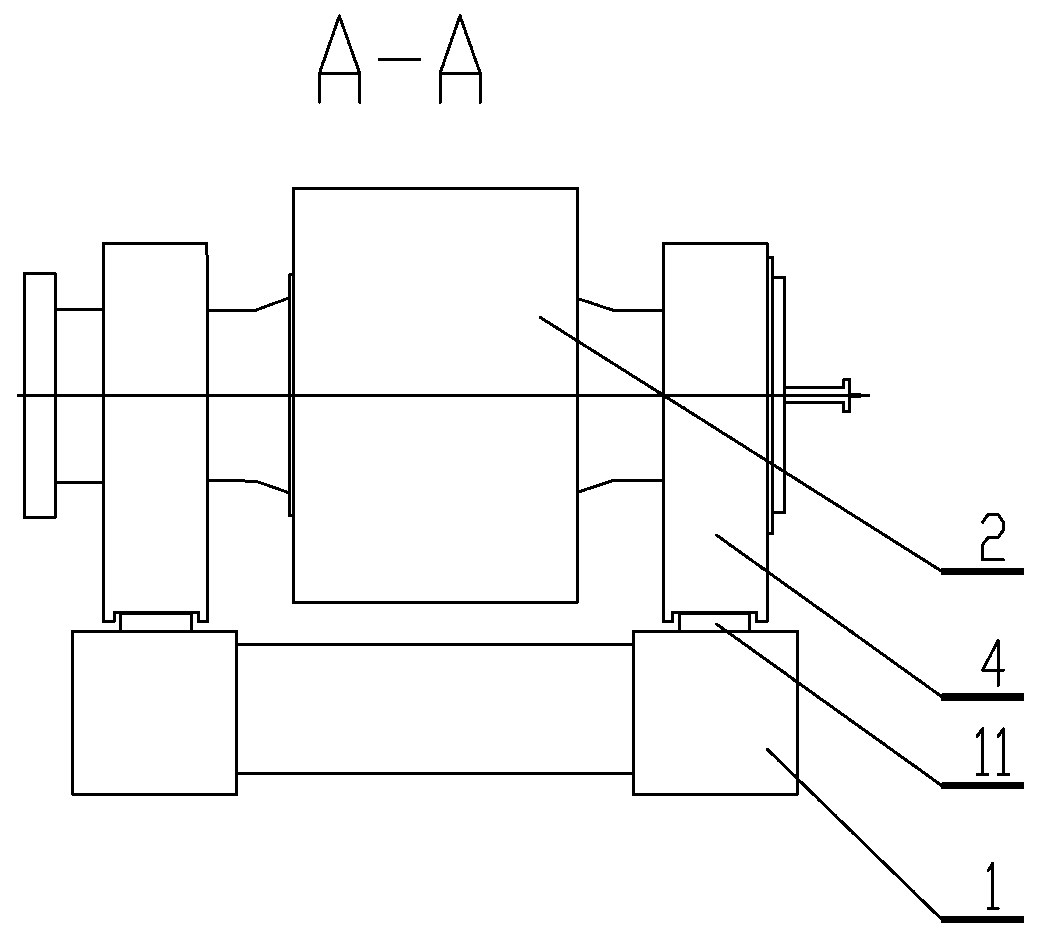

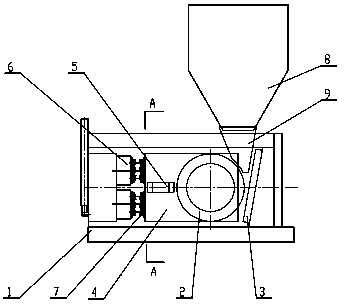

Single-roller high-pressure and high-frequency vibrating roller milling crusher

The invention relates to a single-roller high-pressure and high-frequency vibrating roller milling crusher which comprises a roller milling crusher main piece, a drive device, a stand, a feeding funnel and a guide plate; the roller milling crusher main piece is installed on the stand and is connected with the drive device and hydraulic devices. The single-roller high-pressure and high-frequency vibrating roller milling crusher is characterized in that the roller milling crusher main piece comprises two bearing seats which are arranged on stand rails respectively, an extrusion roller which is installed on the bearing seats, a fixed extrusion plate which is slantingly arranged on the surface of the extrusion roller correspondingly, and high-frequency vibration exciters which are installed onthe two sides of the bearing seats respectively and perform vibration in a horizontal direction; the bearing seats are connected with the hydraulic devices through springs respectively; the extrusionroller is connected with the drive device through a center axis. The single-roller high-pressure and high-frequency vibrating roller milling crusher has the advantages that 1) the fixed extrusion plate replaces a fixed roller of a high-pressure roller mill, and the equipment cost is lowered; 2) the high-frequency vibration exciters on the bearing seats enable the crushing effect to be better; 3)the springs for connecting the bearing seats with the hydraulic devices respectively enable equipment to be strong in adaptability and reliable in performance.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Grinding method for improving quality of copper concentrate and reducing impurities

InactiveCN109465095AIncrease monomer dissociationQuality improvementFlotationGrain treatmentsBall millMineral processing

The invention relates to a grinding method for improving the quality of copper concentrate and reducing impurities, belonging to the technical field of non-ferrous metal mineral processing. In order to solve the problem that the monomer dissociation effect of the existing grinding method is not good, high impurity content in the copper concentrate, the grinding method includes the steps of inputting copper ore into a ball mill to perform rough grinding under the action of a rough grinding medium, inputting the roughly ground product into a hydrocyclone for classification, making settling sandreturn to the ball mill for further rough grinding, enabling the ore particles with certain particle size to enter a pulp stirring tank with the overflow of the hydrocyclone, making the particles enter a roughing flotation machine after stirring for roughing, and obtaining copper rough concentrate after roughing and enabling the copper rough concentrate to enter a horizontal sand mill for fine grinding under the action of fine grinding medium, wherein 80% of the copper concentrate product has particle size less than 25 [mu]m. The invention improves the degree of monomer dissociation, obtains copper concentrate with copper > 25%, silicon < 10% and aluminum < 2%, effectively reduces the content of silicon and aluminum impurities in the copper concentrate, improves the concentrate quality andincreases the product benefit value.

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD

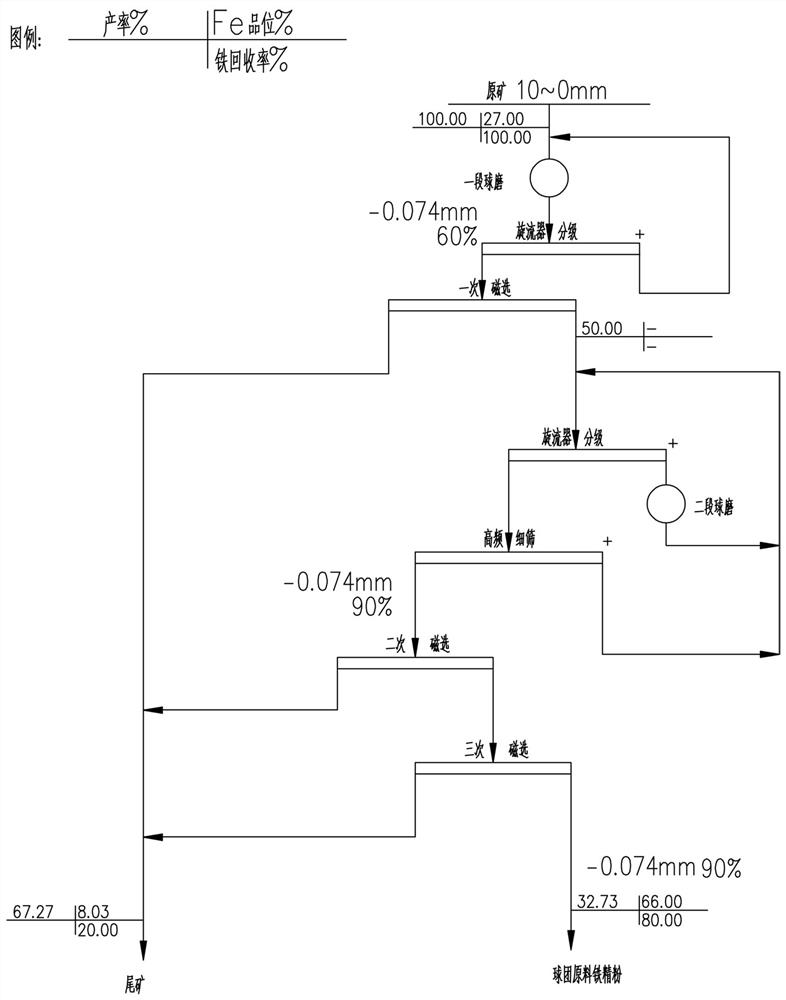

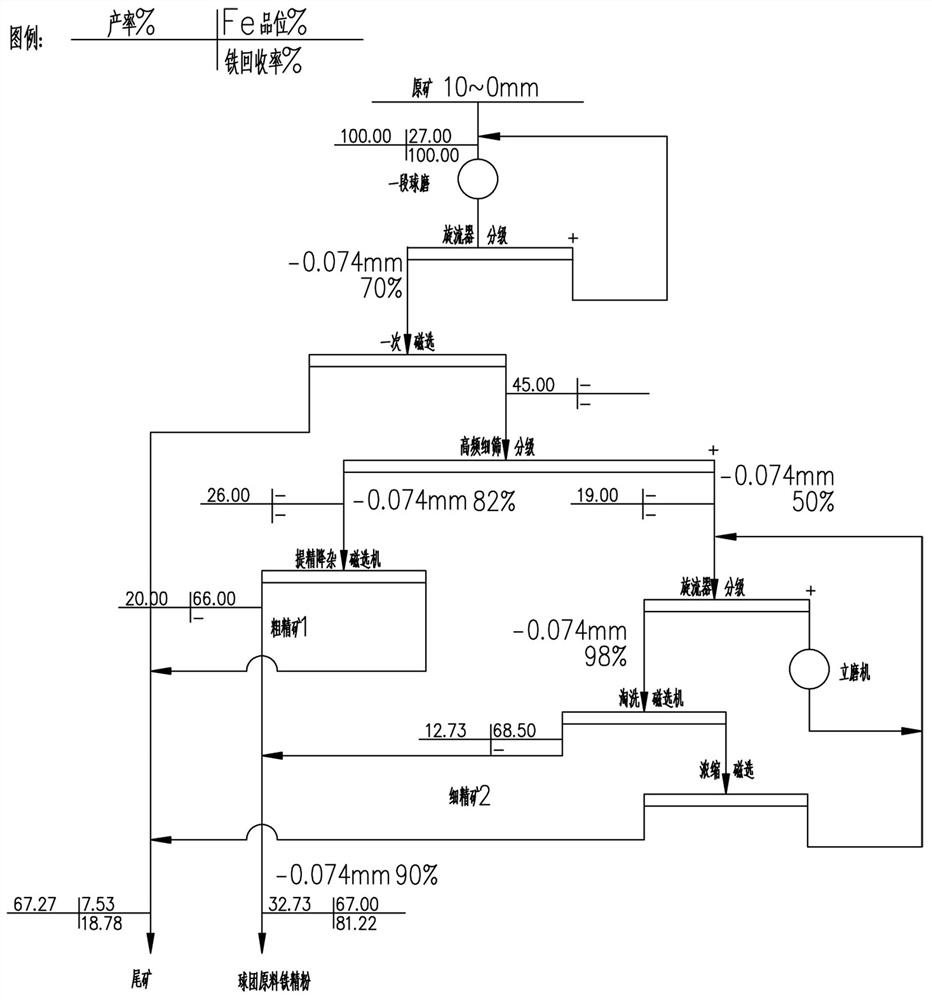

Grinding and separating process for producing pellet ore raw material fine iron powder

InactiveCN113019681AReduce overgrindingHigh recovery rateMagnetic separationWet separationIron powderMagnetic separator

The invention relates to a grinding and separating process for producing pellet ore raw material fine iron powder. The grinding and separating process is characterized by comprising the following steps: the fineness of a first-stage graded overflow product is increased to be more than or equal to 70%; and first-stage magnetic separation concentrate is treated through the following process steps that 1, coarse and fine grading is conducted, specifically, the first-stage magnetic separation concentrate is divided into undersize products and oversize products through a high-frequency fine screen; 2, the undersize products are treated through a JCTN refining and impurity reducing magnetic separator, and second-stage magnetic separation concentrate I is obtained; and 3, the oversize products are treated through second-stage closed circuit grinding and second-stage magnetic separation operation II to obtain second-stage magnetic concentrate II, and second-stage magnetic separation concentrate I and the second-stage magnetic separation concentrate II are combined to obtain fine iron powder. Compared with the prior art, the method has the advantages that: 1) the fine iron powder meets the pellet requirements, the grade TFe is larger than or equal to 67%, the fineness -0.074 mm particle content is larger than or equal to 90%, and 2) excessive grinding is reduced, the metal recovery rate is increased, energy is saved, consumption is reduced, and the production cost is reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Novel ore grinding method used for optimizing copper ore flotation behavior

The invention discloses a novel ore grinding method used for optimizing a copper ore flotation behavior. According to the novel ore grinding method, a vertical stirring grinder is used as ore grinding main equipment, aluminum oxide ceramic balls are adopted as ore grinding media, the ore grinding conditions such as the filling rate, the pulp density, the pulp temperature, the pulp pH, grinding aid types and contents and other factors are strictly controlled, the single separation degree of ore can be improved easily, ore grinding products evener in particle size are obtained, and beneficial conditions are created for subsequent copper ore flotation operation. According to the method, the ore grinding time is shortened by 60%, the ore grinding power consumption is reduced by 40%, medium wear is reduced by 75%, the copper concentrate grade is improved by 2.46%, and the recovery rate is improved by 8.15%.

Owner:NORTHEASTERN UNIV

Concentration method for qualifying headings and increasing recovery rate

InactiveCN1895788BFacilitate dissociationFast dissociationMagnetic separationGrain treatmentsBall millMaterials science

Owner:郝志刚

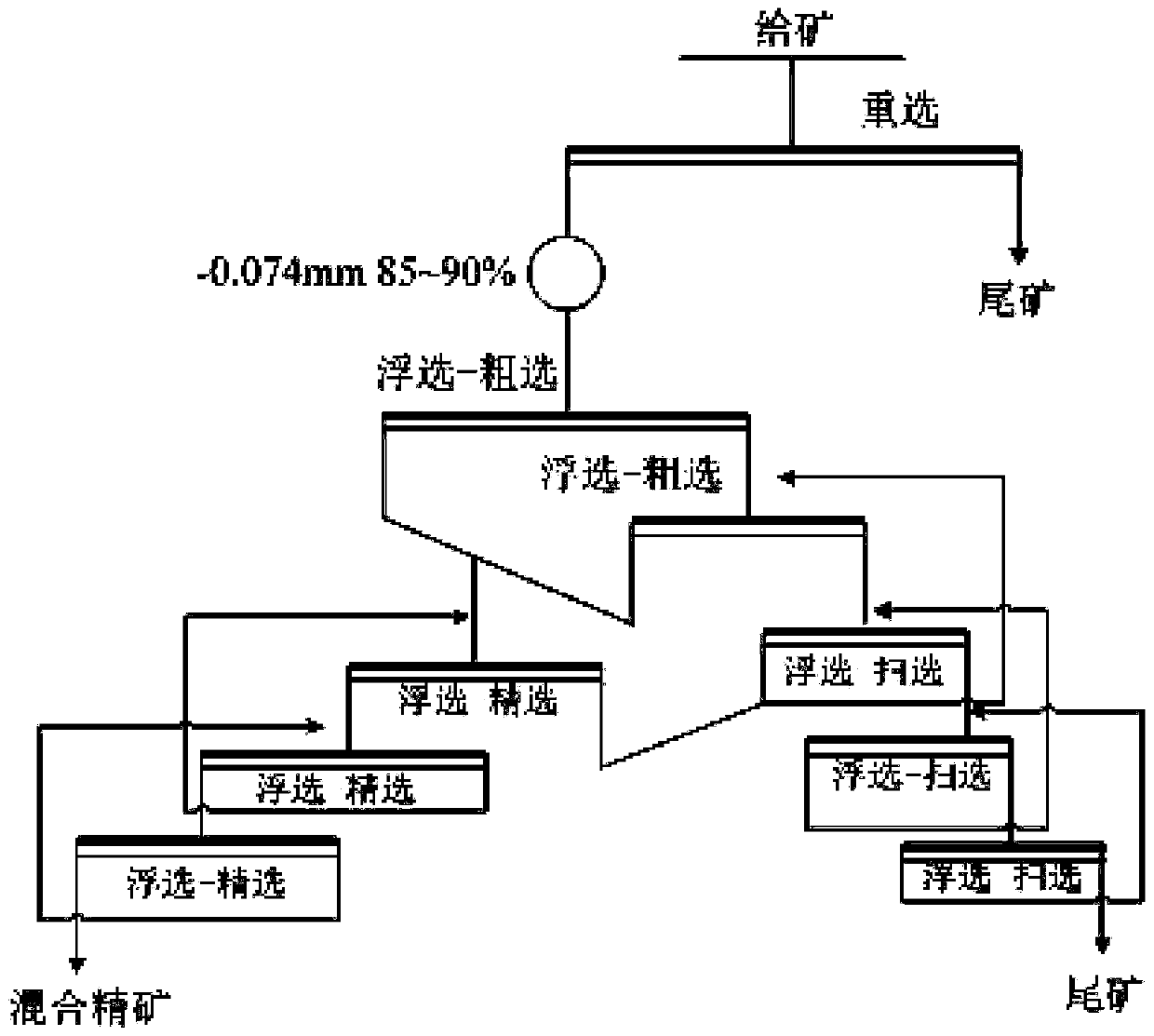

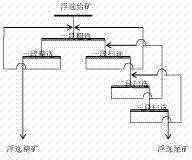

A New Method of Reverse Flotation Separation, Grinding and Separation

InactiveCN102259065AIncrease monomer dissociationIncrease Concentrate ProductionFlotationMineral flotationEngineering

The invention relates to the technical field of beneficiation of lean hematite, in particular to a new method for flotation, regrinding and re-election, which includes one-stage roughing, one-stage beneficiation, and three-stage sweeping operations, and the concentrate of one-stage roughing operation is fed into The tailings of one stage of selection operation and one stage of roughing operation are fed into one stage of sweeping operation, and the fine tailings of one stage of selected middle ore return to one stage of roughing operation, the concentrate of one stage of concentration operation is flotation concentrate, and the tailings are fed The second-stage sweeping operation, the second-stage sweeping concentrate is returned to the first-stage sweeping operation, the tailings are fed into the third-stage sweeping operation, the third-stage sweeping concentrate is returned to the second-stage sweeping operation, and the first-stage sweeping operation The concentrate is re-grinded to greatly increase the monomer dissociation degree of the concentrate in the first stage of scavenging operation, and the re-grinded product returns to the original flotation process for further separation. Minerals are more fully sorted, which reduces the amount of medium ore circulation in each operation of flotation, and makes the flotation circuit form a virtuous circle. The grade of flotation concentrate is improved, the grade of flotation tailings is reduced, and the metal recovery rate is improved.

Owner:ANSTEEL GRP MINING CO LTD

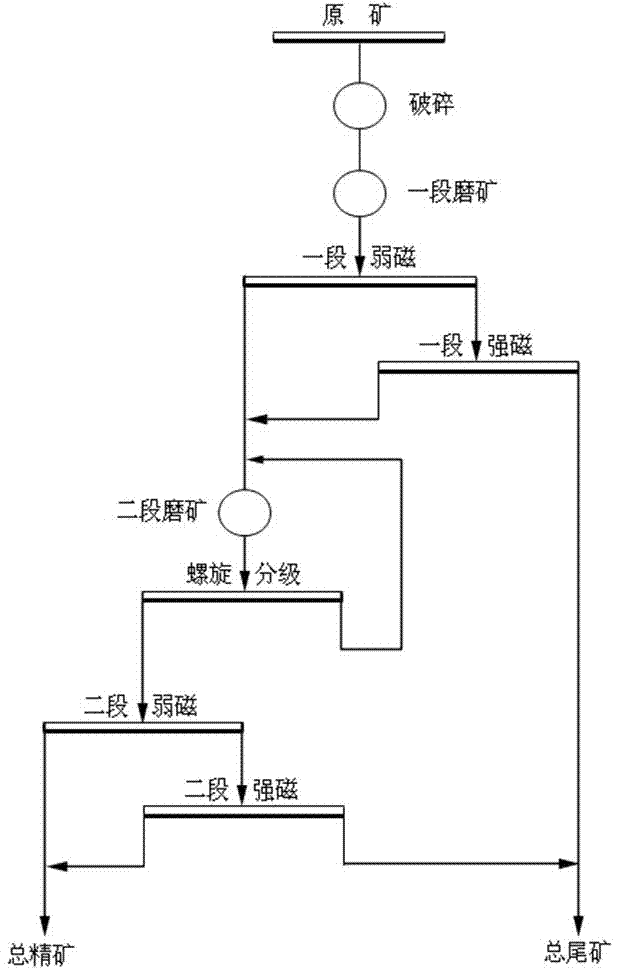

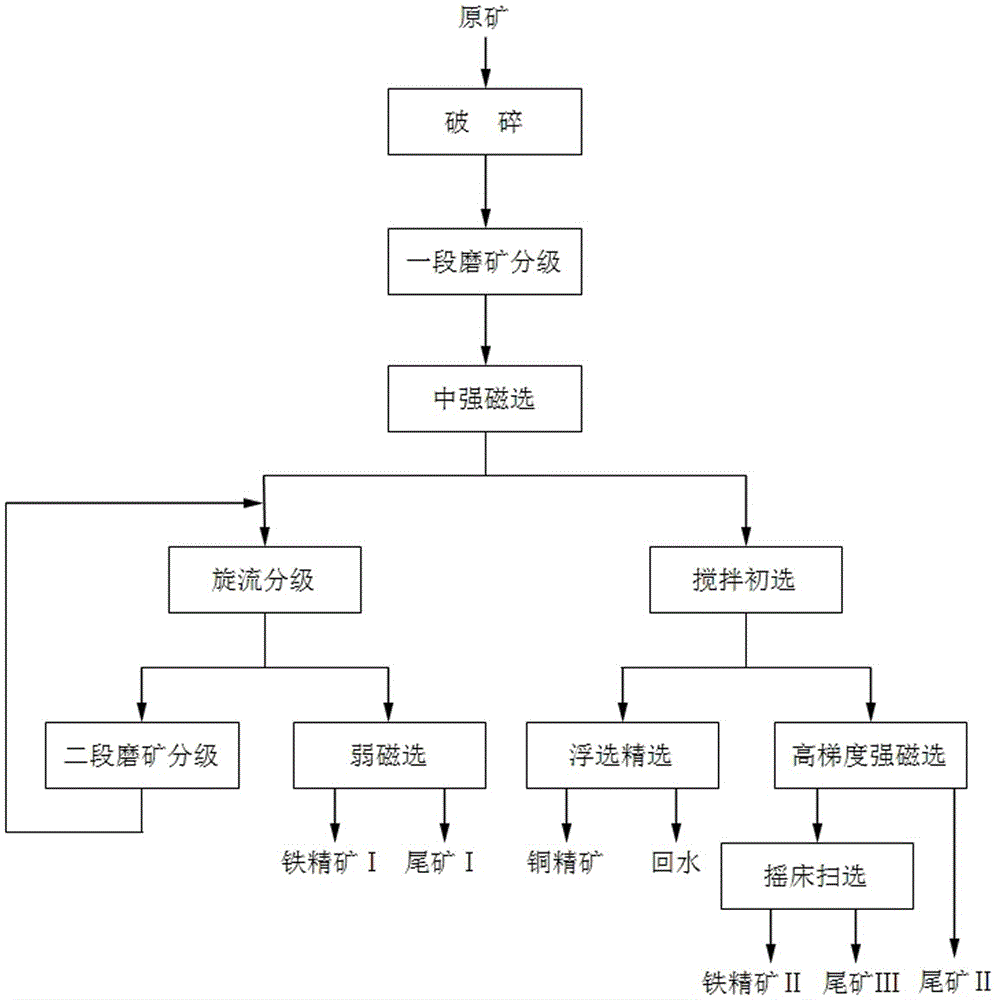

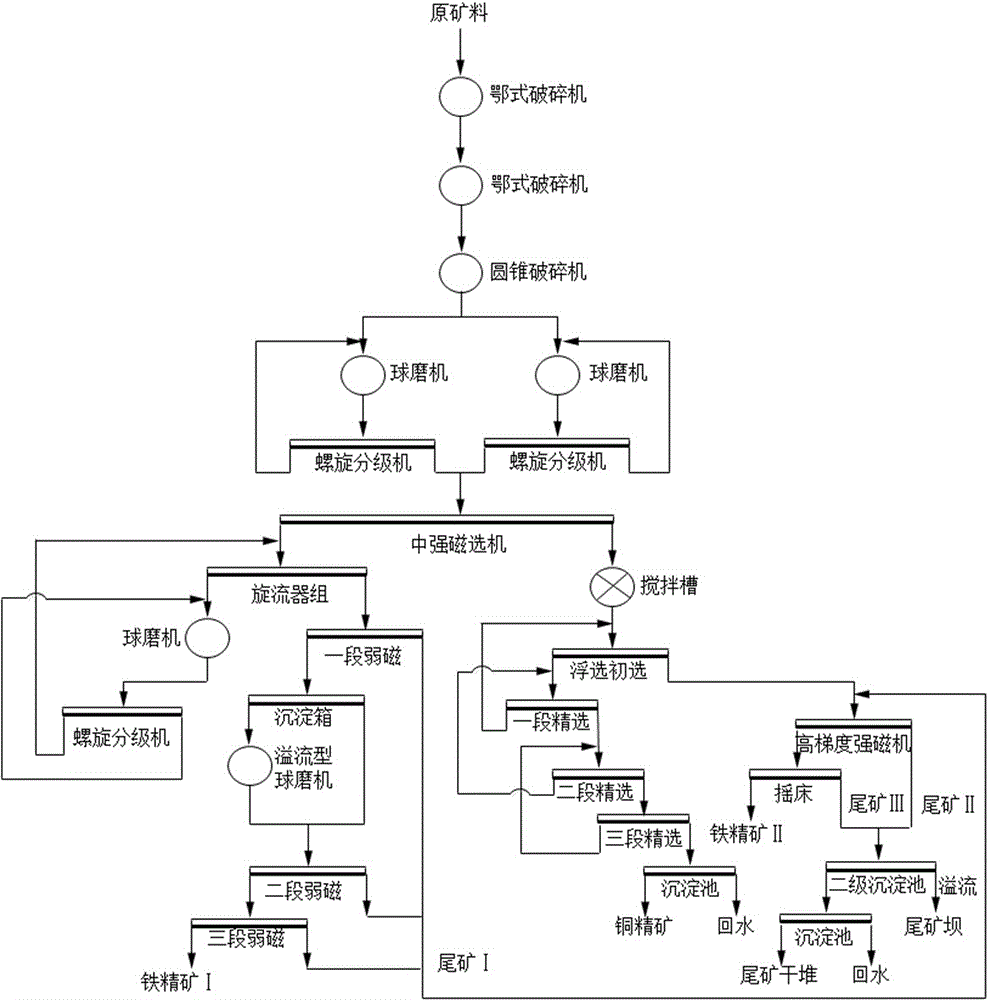

Beneficiation method for efficiently recycling low-grade copper-bearing lava magnetite

The invention discloses a beneficiation method for efficiently recycling low-grade copper-bearing lava magnetite. The beneficiation method comprises the following steps: smashing; grinding and performing spiral grading on smashed ores; enabling graded fine ores to be subjected to medium-strong magnetic separation, so as to obtain crude iron ores and tailings; performing rotational flow grading on the crude iron ores, so as to obtain fine ores and crude ores; enabling the fine ores to be subjected to series-connected 2-3 sections of low intensity magnetic separation, so as to obtain fine iron ores I and tailings I; enabling the crude ores to be subjected to second-stage grinding and spiral grading, enabling the fine ores to be subjected to rotational flow grading, and returning the crude ores to the second-stage grinding; stirring and mixing the tailings with medium-strong magnetic property and a chemical, and performing primary flotation, so as to obtain crude copper ores and tailings; enabling the crude copper ores to be subjected to series-connected 2-3 sections of fine separation and precipitation, so as to finally obtain fine copper ores; performing strong magnetic separation on tailings obtained after primary flotation, so as to obtain crude iron ores and tailings II; performing shaking table scavenging on the crude iron ores, so as to obtain fine iron ores II and tailings III. According to the invention, the ore grinding amount is less, the mineral monomer separation is sufficient, the resource recovery capability is strong, and the ore concentrate grade is high.

Owner:YUXI DAHONGSHAN MINING

High-voltage pulse pretreatment method for reinforcing cassiterite crushing and sorting

ActiveCN110193418AImprove sorting indexPromote productionGrain treatmentsPretreatment methodEngineering

The invention provides a high-voltage pulse pretreatment method for reinforcing cassiterite crushing and sorting, a high-voltage pulse device is adopted, and the high-voltage pulse pretreatment methodcomprises the following steps that (1), a water pump is started, water continuously enters a pulsating insulation cylinder body, and is discharged from a water outlet of a product collector; (2), cassiterite ore is conveyed into a pulse insulating cylinder body through a ore feeding bin and is accumulated on a screen, and the top of the cassiterite ore is in contact with a high-voltage electrode;(3), a power supply is turned on, and discharging is carried out between the high-voltage electrode and a high-voltage negative electrode to enable the cassiterite ore to be broken; (4), through therotation of an eccentric wheel, the lifting of the water flow acts on the ore on the screen, and a small particle part moves downwards; and (5), the crushed cassiterite ore enters the product collector. The method can be used for improving the useful mineral content of crushed products, the monomer dissociation degree of the crushed products is improved, the energy consumption in the subsequent processing process is reduced, and the enterprise cost is reduced.

Owner:NORTHEASTERN UNIV

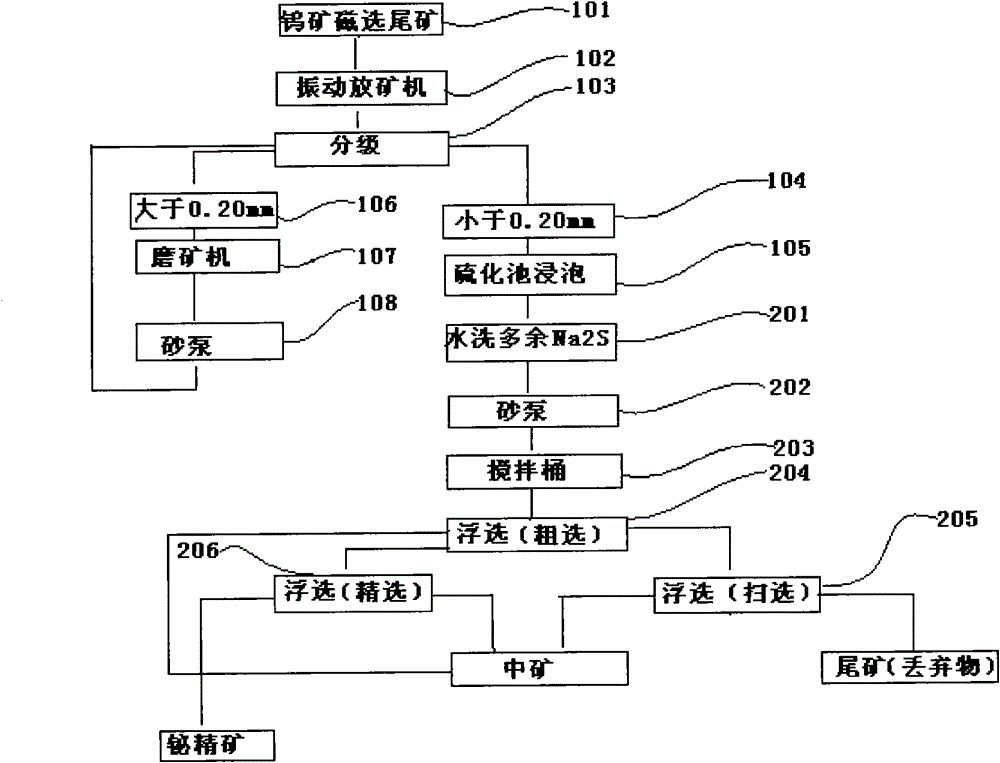

Process for recycling bismuth concentrate from tungsten ore magnetic separation tailings

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

Complex copper-lead ore beneficiation separation method adopting middling returning and regrinding technology

The invention relates to a complex copper-lead ore beneficiation separation method adopting a middling returning and regrinding technology, comprising the following steps of: carrying out ore grinding on raw ores, and then carrying out copper roughing; carrying out copper choiceness by adopting flotation on rough concentrates obtained through the copper roughing; and carrying out copper scavenging on tailings obtained through the copper roughing. The complex copper-lead ore beneficiation separation method is characterized in that in the copper-lead separation process of the copper choiceness,middling chosen in a first copper choiceness process is returned to a first copper scavenging process, and the middling chosen in a second copper choiceness process and the middling chosen in a thirdcopper choiceness process are intensively returned to the copper roughing process, therefore, the influence of impurities on grades is prevented, and the purpose of enhancing the grades of the copperconcentrates is achieved; in the copper scavenging process, concentrates subjected to primary choiceness are reground, and ore charges are conveyed to the copper choiceness process to form selective milling after regrinding, thereby not only enhancing the dissociation degree of copper-lead ores but also preventing overgrinding, and enabling the copper concentrates to obtain higher recovery rate.

Owner:BAIYIN NONFERROUS GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com