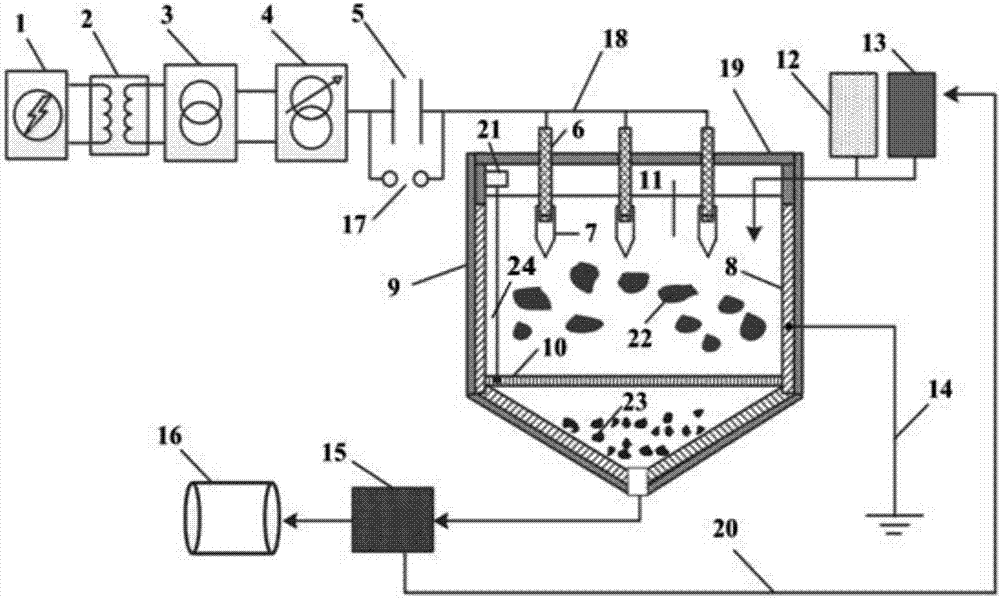

Method for improving ore grinding efficiency through electric pulse ore pretreatment

A pretreatment and electric pulse technology, applied in the field of mineral processing, can solve the problems such as the decline of the recovery ability of the target minerals by the sorting method, and achieve the effects of improving the degree of monomer dissociation, saving enterprise costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

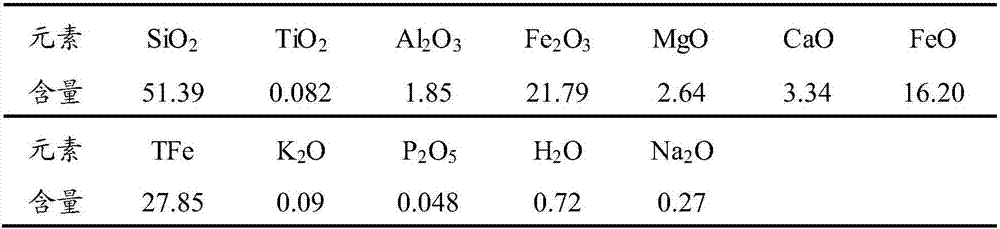

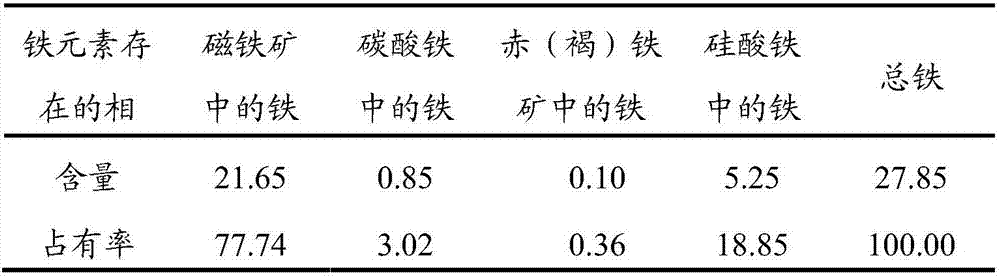

[0024]The ore sample used in this example is the raw ore of an iron ore factory in Liaoning, and its main chemical composition is shown in Table 1. It can be seen from Table 1 that the magnetite-poor ore of this mine has the common characteristics of Anshan-type sedimentary metamorphic iron-poor quartzite, that is, the chemical composition is simple, high in silicon, poor in iron, low in calcium, magnesium, and aluminum, and the harmful impurities sulfur and phosphorus are lower than industrial Allowed acidic ore, ore TFe grade is low. The chemical phase analysis of raw ore Fe element is shown in Table 2. As can be seen from Table 2, the content of magnetite in the ore accounts for 77.94% of the total iron, and the content of iron silicate is higher, followed by red (brown) iron ore and iron carbonate. form exists.

[0025] Table 1 Chemical composition analysis of raw ore / %

[0026]

[0027] Chemical phase analysis results / % of iron element in table 2 ore

[0028]

[...

Embodiment 2

[0034] The ore sample used in this embodiment is taken from the raw ore of a certain copper mine in Yunnan. Its main chemical composition is shown in Table 4, its phase analysis is shown in Table 5, and the chemical phase analysis results of copper in the ore are shown in Table 6. , as can be seen from Table 6, the copper in the ore mainly exists in bornite, chalcopyrite, and copper blue of copper sulfide in the form of independent minerals, accounting for about 44.00% of the total copper; copper exists in the red copper oxide as independent minerals. Copper ore and malachite account for about 41.82% of the total copper. Another part of copper exists in gangue minerals and chrysocolla in the form of isomorphism (that is, combined with copper oxide), accounting for about 14.18% of the total copper.

[0035] Table 4 Raw ore chemical analysis results / %

[0036]

[0037] Table 5 Raw ore copper phase analysis results / %

[0038]

[0039] Chemical phase analysis results / % of ...

Embodiment 3

[0046] The ore sample used in this embodiment is taken from a certain lead-zinc oxide ore dressing plant in Yunnan. The metal minerals in the ore are mainly lead and zinc. The raw ore chemical multi-element analysis is as shown in Table 8, and the raw ore lead phase analysis is as shown in Table 9. The phase analysis of raw ore zinc is shown in Table 10. The chemical multi-element analysis and phase analysis of the raw ore show that the raw ore is lead-zinc oxide ore, and the main elements with recovery value are lead and zinc, and the oxidation rate of lead is 51.39%. Zinc oxidation rate is 39.45%. As far as the current level of mineral processing technology is concerned, the recyclable zinc oxide mineral is only zinc carbonate (ie smithsonite), the grade of raw ore zinc is low and the distribution rate of smithsonite is only 20.18%. The zinc oxide minerals in the mine do not have comprehensive recovery value. Therefore, the target minerals recovered by ore dressing are main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com