Patents

Literature

88 results about "Iron carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) carbonate, or ferrous carbonate, is a chemical compound with formula FeCO 3, that occurs naturally as the mineral siderite. At ordinary ambient temperatures, it is a white ionic solid consisting or iron(II) cations Fe2+ and carbonate anions CO2− 3.

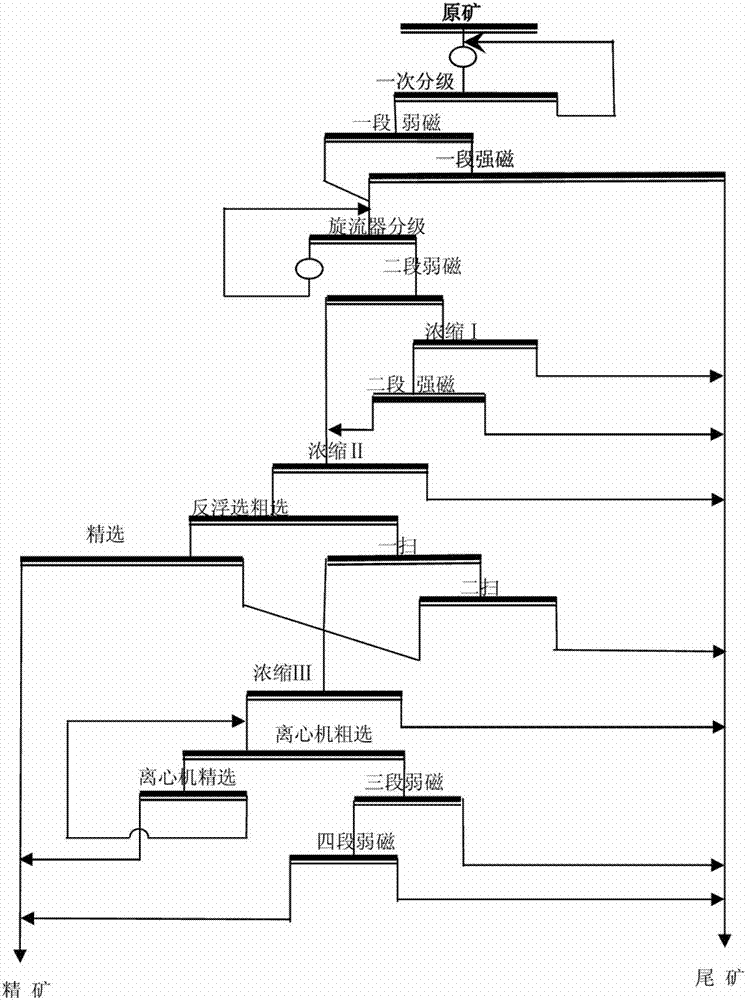

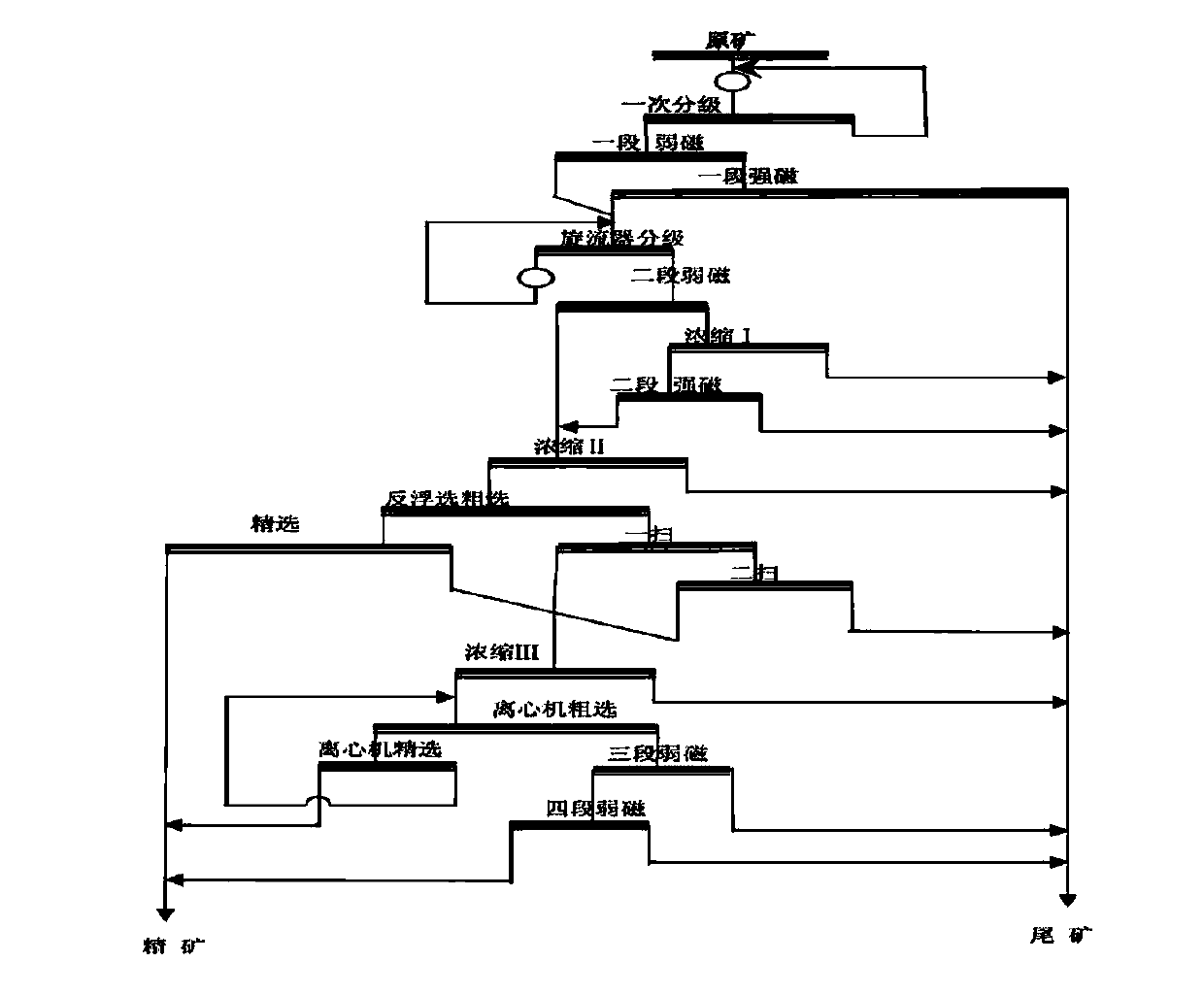

New technology for sorting lean hematite and magnetite orecontaining iron carbonate

The invention relates to a new technology for sorting a lean red magnetite ore containing iron carbonate, which is characterized by comprising the following steps of: enriching and discarding tailings by adopting a 'technology for stage grinding and strong magnetic discarding tailings', thereby obtaining a mixed magnetic concentrate; sorting the mixed magnetic concentrate by adopting an 'open-circuit reverse flotation technology with one-stage roughing, one-stage fining and two-stage scavenging', thereby obtaining a high-grade hematite and magnetite concentrate; adopting a 'close-circuit centrifuge technology with one-stage roughing and one-stage fining' for sorting a high iron carbonate ore enriched in mine obtained by adopting the 'open-circuit reverse flotation technology', thereby obtaining a siderite concentrate; feeding the centrifuge tailings into a weak magnetic machine and sorting; and recycling fine fraction magnetic concentrates. The new technology provided by the inventionhas the advantages that the lean hematite and magnetite ore containing iron carbonate is sorted by adopting a 'combined sorting process flow with stage grinding, strong magnetic discarding tailings, reverse flotation-centrifuge', so that the sorting indexes of the whole iron grade of the obtained comprehensive concentrate being more than 65% and the metal recovery rate being more than 65% are achieved and the maximization of utilization benefit of iron ore resources is realized.

Owner:鞍钢集团矿业设计研究院有限公司

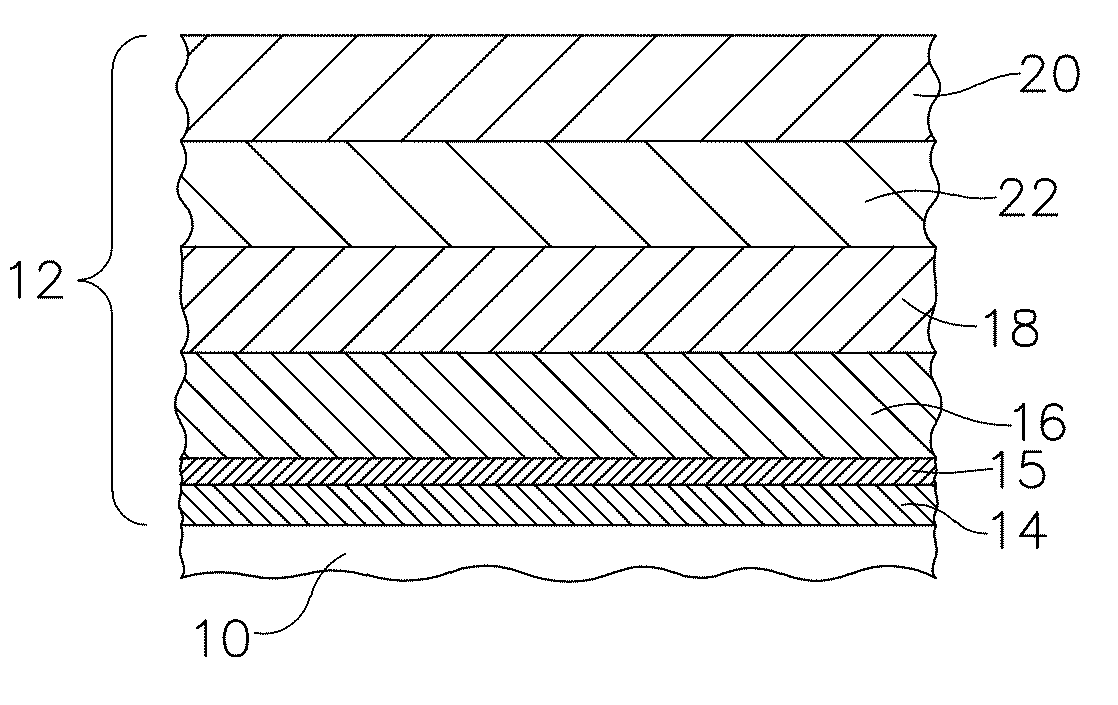

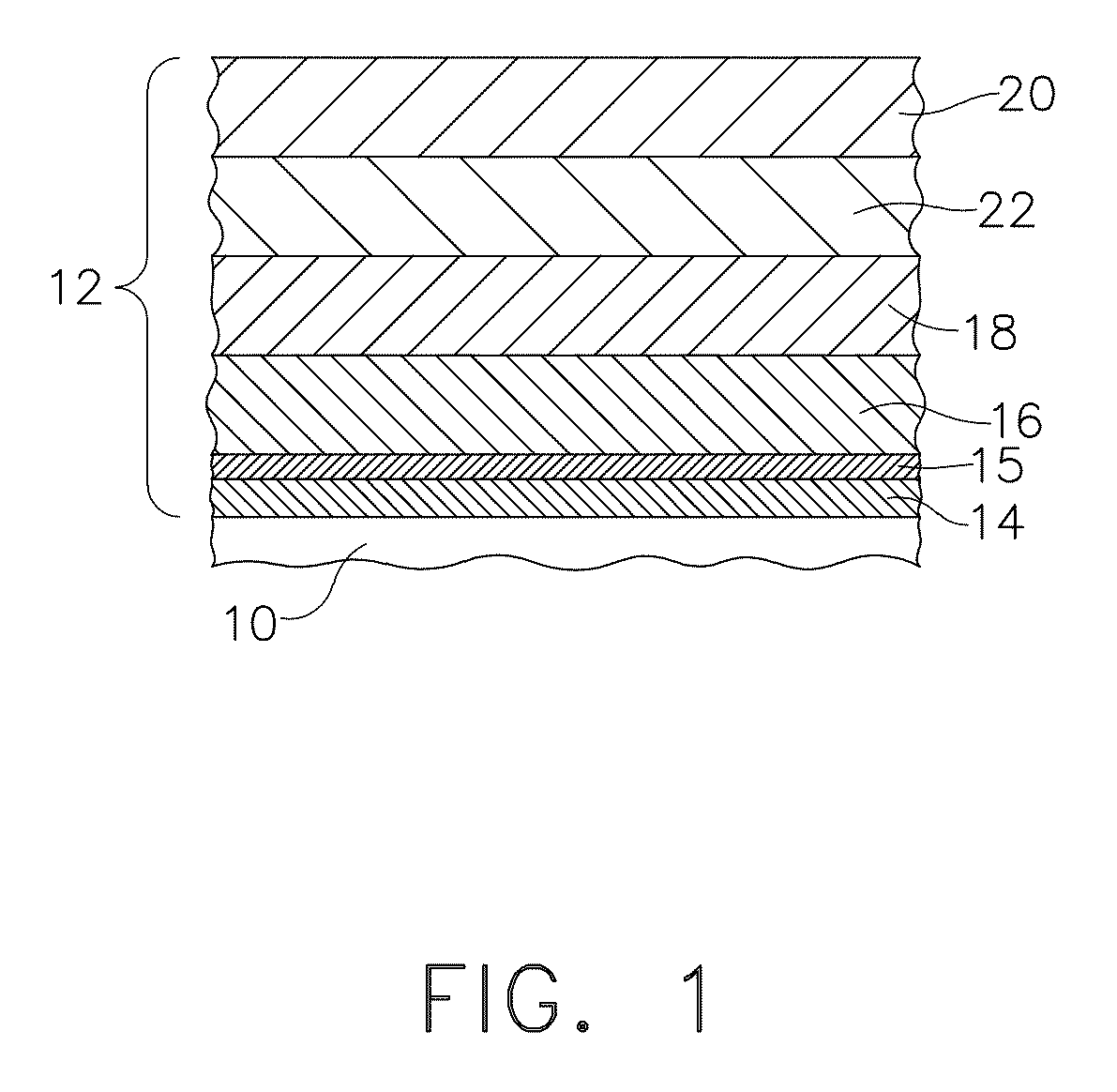

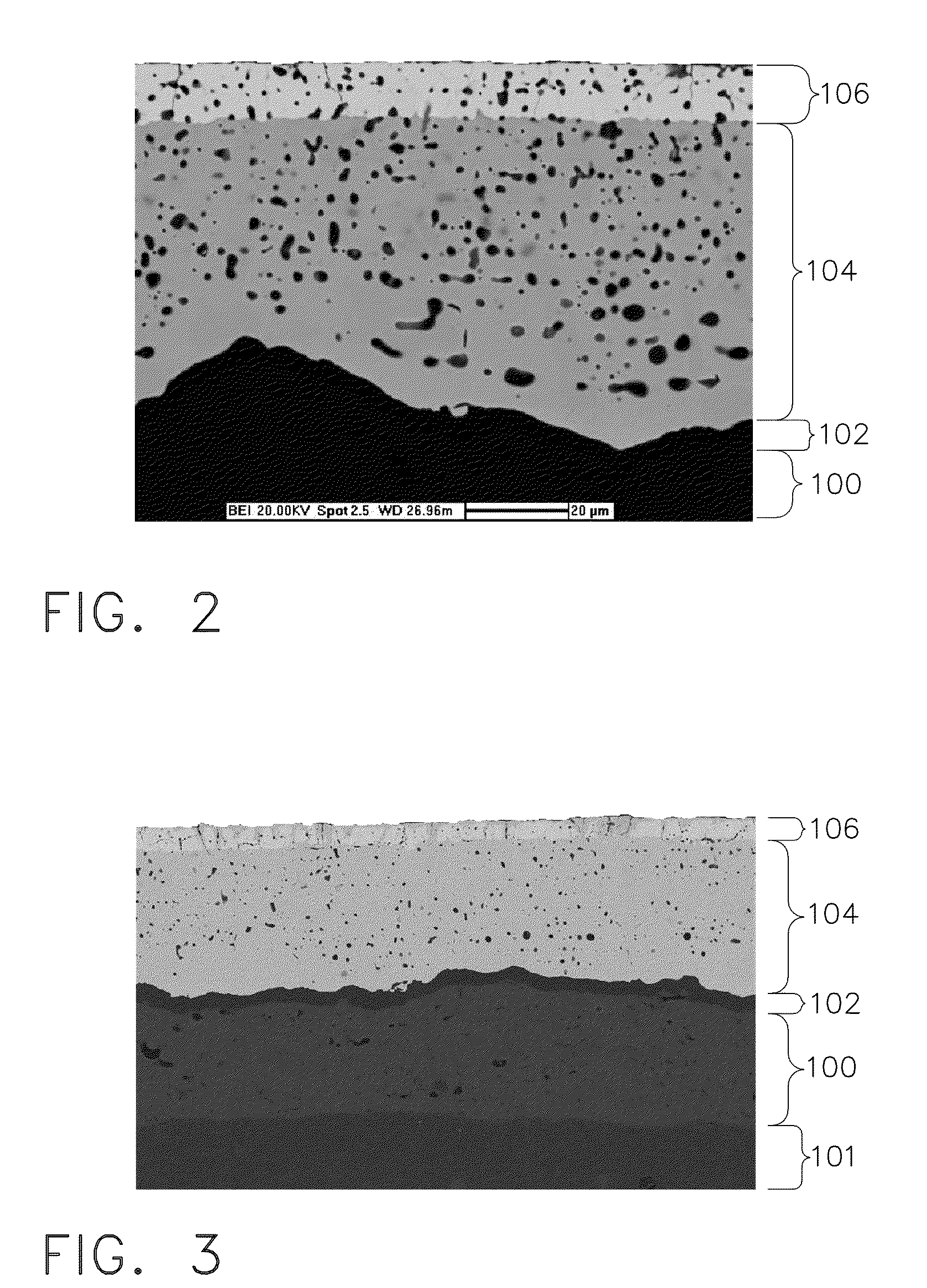

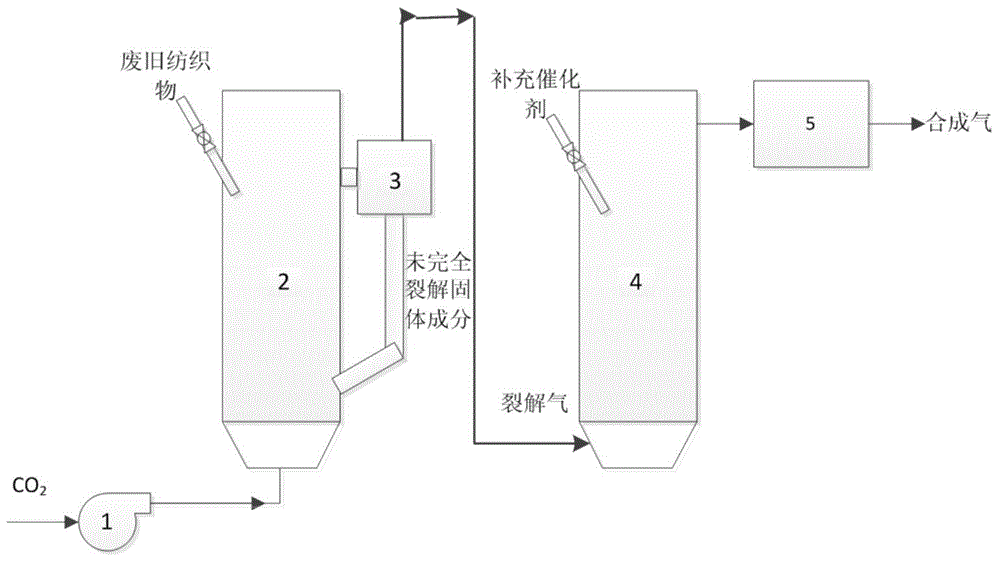

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

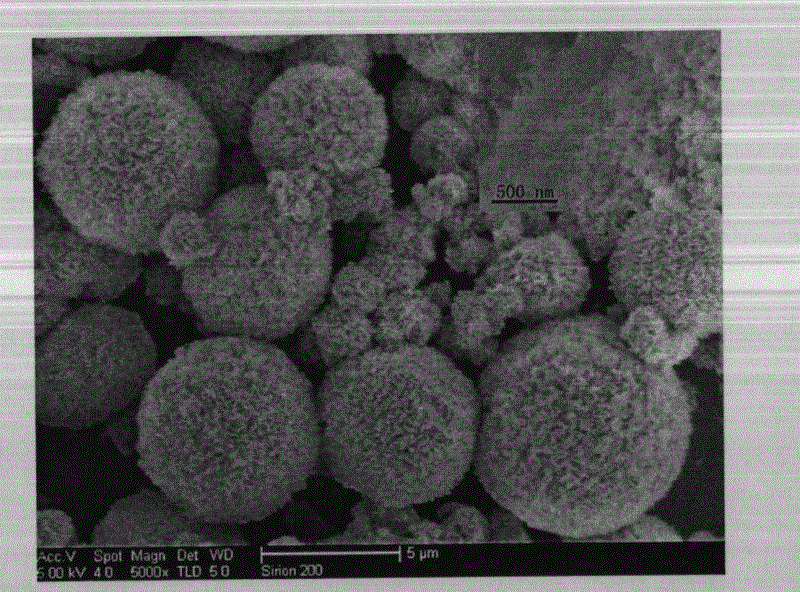

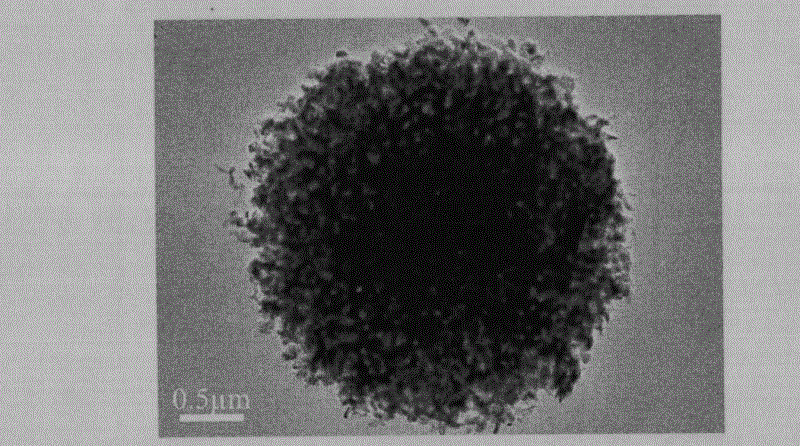

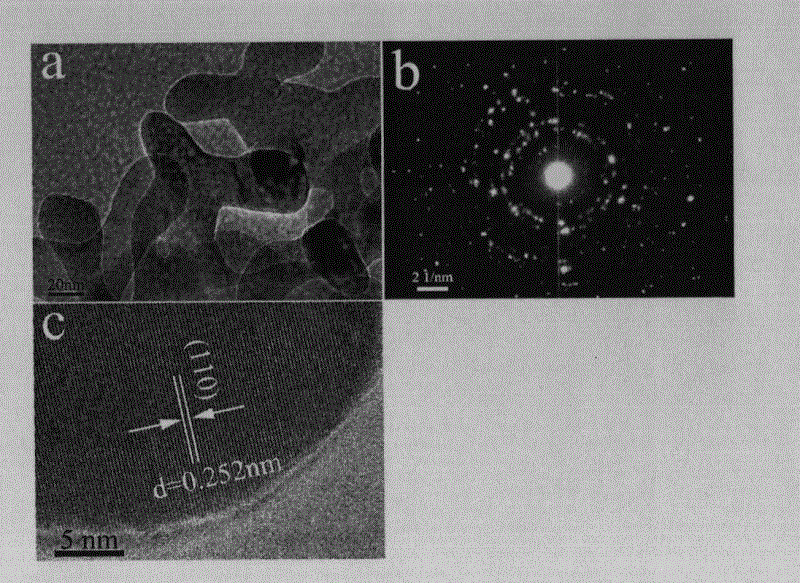

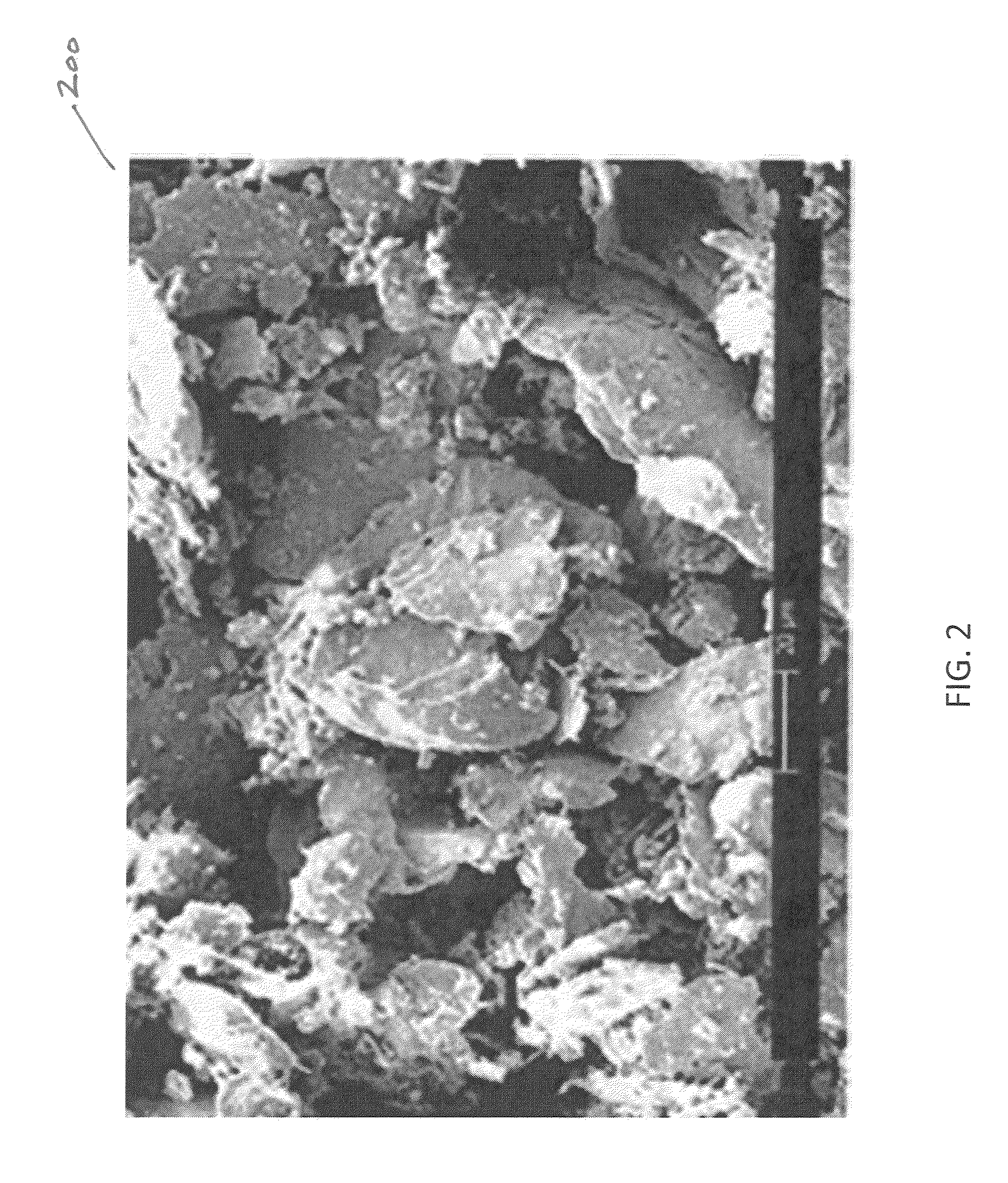

Fe2O3 micro-nano porous sphere, preparation method thereof and uses thereof

InactiveCN102616861ALarge specific surface areaImprove thermal stabilityWater/sewage treatment by irradiationOther chemical processesMicro nanoOrganic dye

The invention discloses a Fe2O3 micro-nano porous sphere, a preparation method thereof and uses thereof. The porous sphere is formed by Fe2O3 nanoparticles having a nanometer mesoporous alpha-Fe2O3 phase structure therebetween, wherein the diameter of the sphere is 500-5000nm, the specific surface area of the sphere is 15-25m<2> / g, particle sizes of the particles are 20-60nm, and pore diameters of mesopores are 2-50nm. The method comprises the following steps: mixing ferric chloride hexahydrate, ascorbic acid, urea and water, and uniformly stirring them to obtain a mixed liquid; reacting the mixed liquid under conditions that the temperature is 140-180DEG C and the pressure is a self-generated pressure for at least 4h to obtain an intermediate product; separating, washing and drying the intermediate product to obtain porous iron carbonate; and annealing the porous iron carbonate at 450-550DEG C for at least 4h, and naturally cooling the porous iron carbonate to room temperature to prepare the Fe2O3 micro-nano porous sphere. The Fe2O3 micro-nano porous sphere can be placed in water polluted by organic dyes to photocatalytically degrade under visible light, or in water polluted by potassium dichromate to adsorb.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

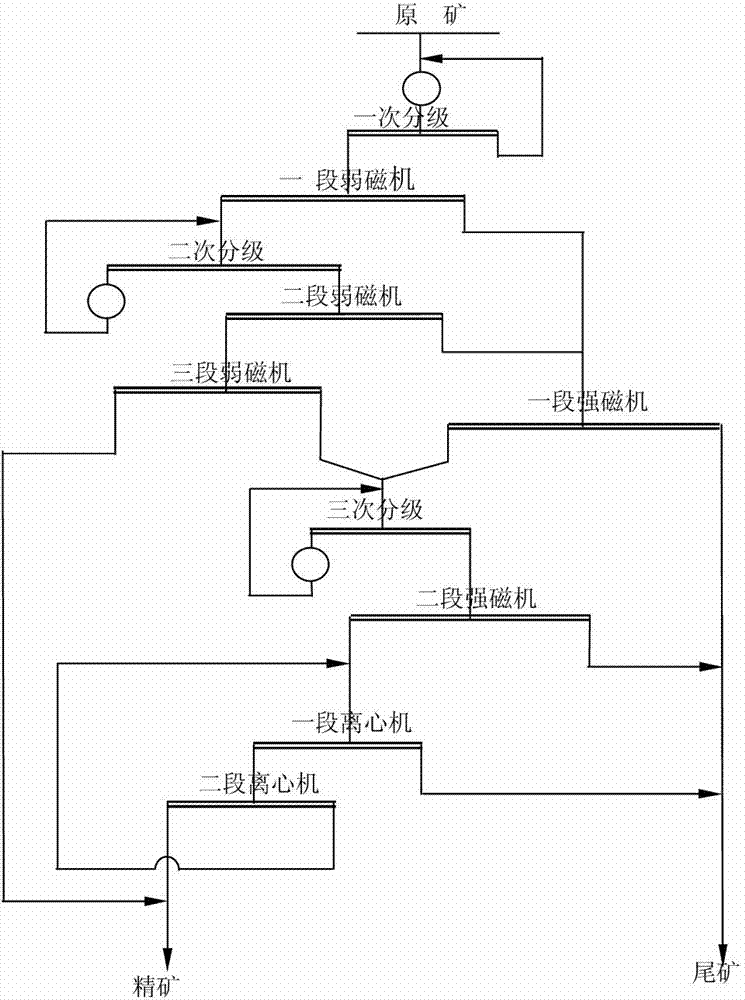

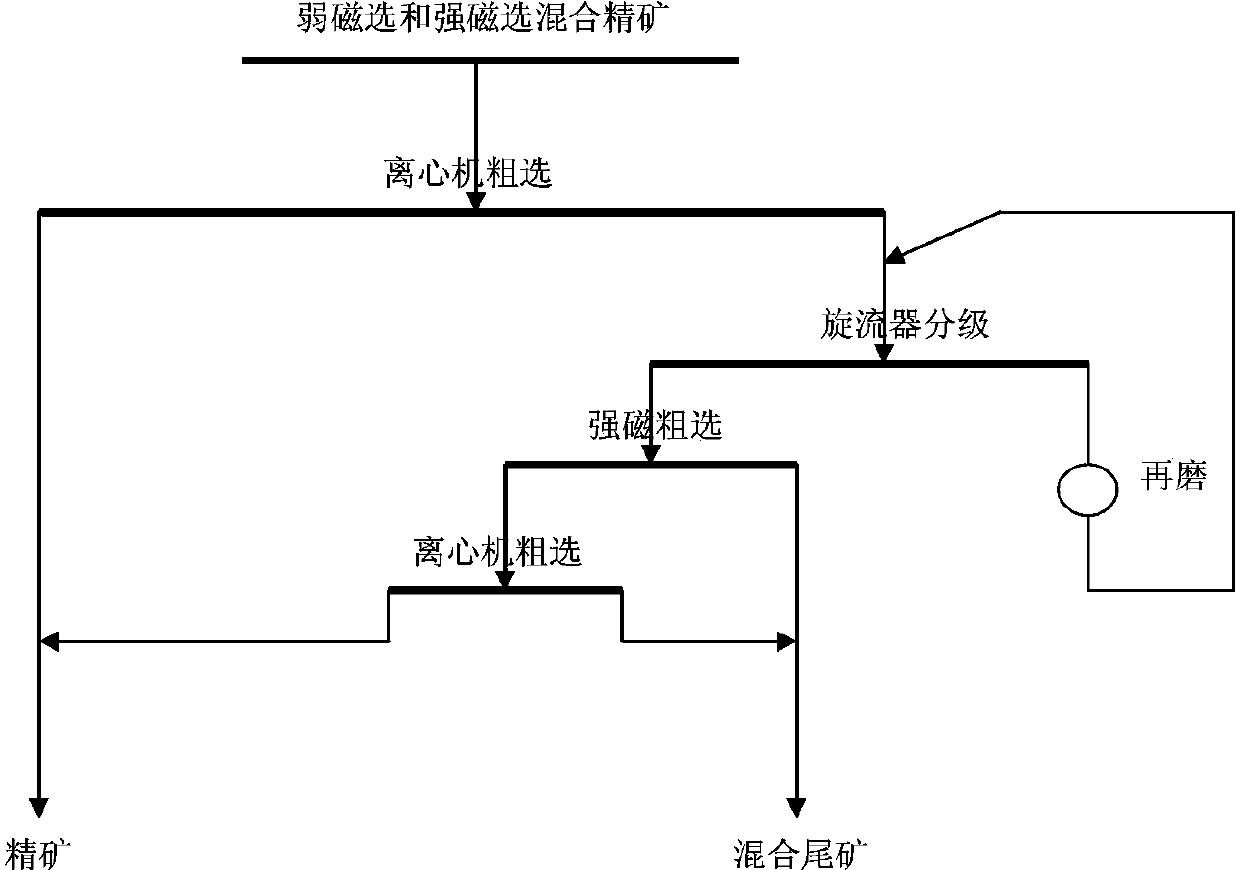

Technique for processing high-iron-carbonate mixed ore

The invention relates to a technique for processing high-iron-carbonate mixed ore. The technique for processing the high-iron-carbonate mixed ore is characterized in that the stage grinding technique and the weak magnetic-strong magnetic-centrifugal machine technique are adopted, and separate grinding and separate screening are carried out on the high-iron-carbonate mixed ore. The technique for processing the high-iron-carbonate mixed ore has the advantages that the weak magnetic technique, the strong magnetic technique and the centrifugal machine technique are allocated flexibly and reasonably according to specific screening indexes of work to recover iron carbonate and hematite in raw ore, environmental pollution is light, the technological process is simple, and qualified iron ore concentrate which has the iron grade of more than 65% after sintering and is capable of meeting smelting requirements can be obtained.

Owner:ANSTEEL GRP MINING CO LTD

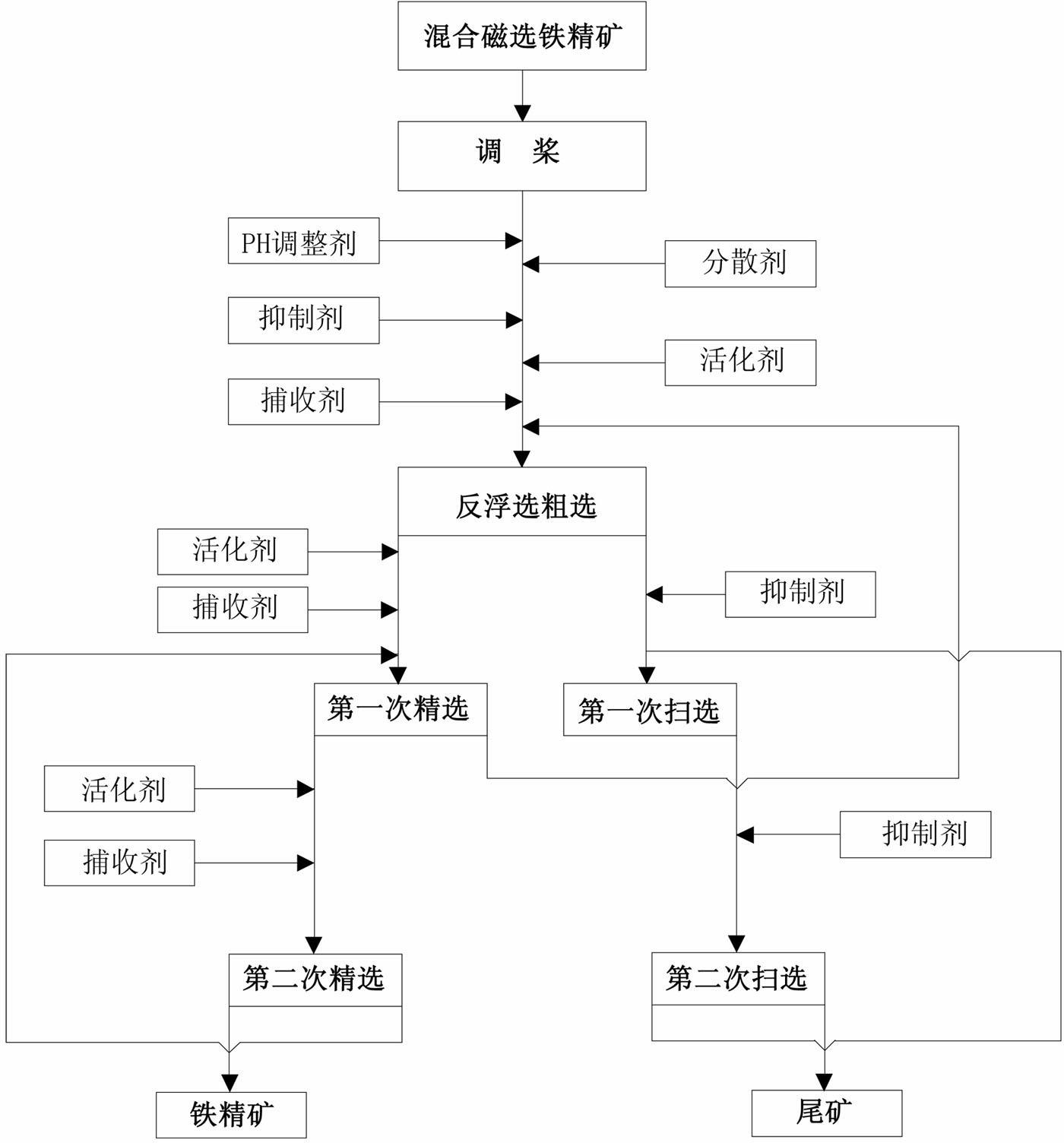

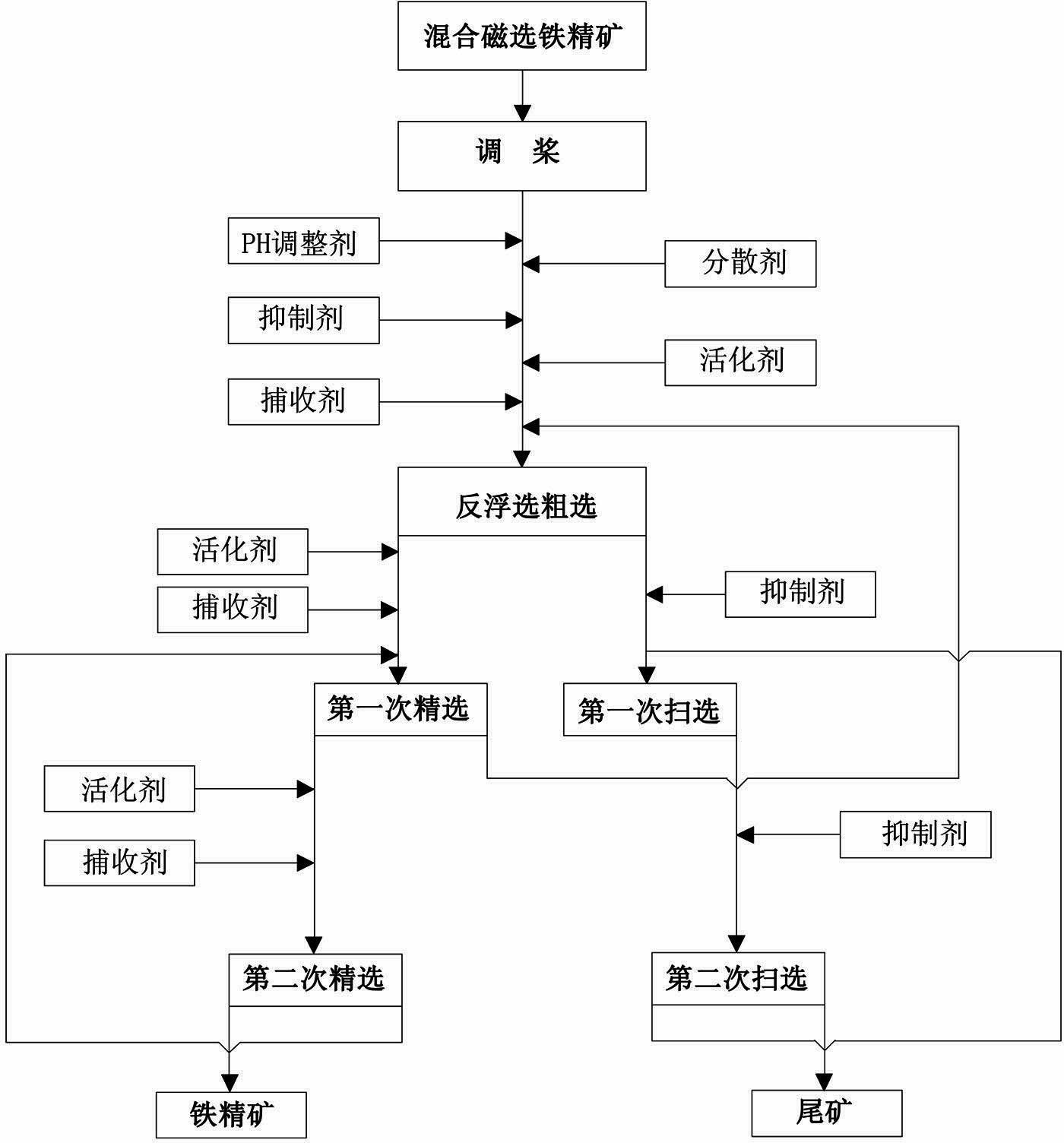

Dispersed flotation separation method for carbonate-containing iron ore

InactiveCN102688806AEliminate or reduce cap phenomenonEliminate or reduce the effects of flotationFlotationIronstoneMining engineering

The invention relates to a dispersed flotation separation method for carbonate-containing iron ore. The reverse flotation is directly carried out on carbonate-containing mixed magnetic separation iron ore concentrate, i.e. the rough concentration, the scavenging and the selection separation. Particularly, a roughing separation method comprises the following steps of: adjusting the mixed magnetic separation iron ore concentrate into ore pulp with the weight concentration of 20-40%, adding 200-1000g / t of dispersing agent-salinized water glass, adding 1200-2400g / t of inhibitor-starch, adding 400-1000g / t of activating agent-lime, and adding 600-1400g / t of collecting agent-KS-III. As the dispersing agent is added, the covering phenomenon among minerals can be eliminated or weakened, so that the ore pulp is under the stable dispersing status, the influence of the iron carbonate to the flotation can be weakened or reduced, and the iron ore concentrate of which the Fe grade is larger than 66% and the recovery rate is 65%-75% can be finally obtained. The method is simple in technological process and lower in cost.

Owner:ANSTEEL GRP MINING CO LTD

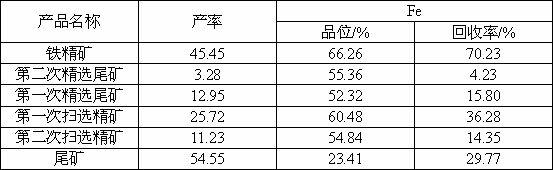

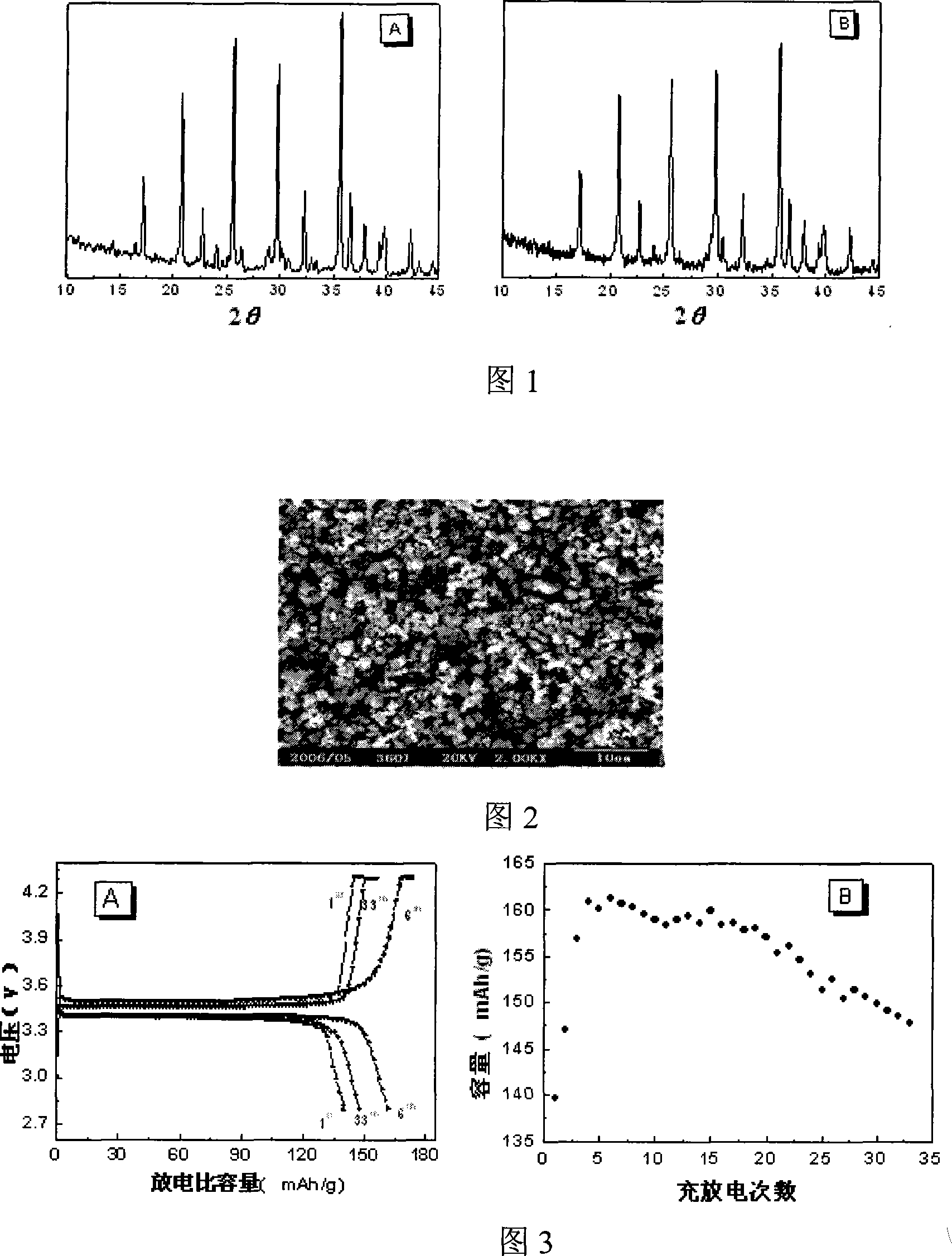

Lithium iron carbonate material prepared by vacuum carbon reduction and method

InactiveCN101070149ALower synthesis costHigh yieldCell electrodesPhosphorus compoundsChemical reactionPhosphate

This invention relates to a kind of anode material and method used for reducing preparation of lithium iron phosphate by vacuum carbon. It uses cheap phosphate, iron compound and lithium compound as raw material, compound of cheap heavy metal as adulteration modifying agent, cheap and abundant activated carbon, acetylene black and graphite as reducing agent. Dealing with it using ball milling techniques and makes solid-phase chemical reaction under the vacuum condition, then get the anode material adulterating lithium iron phosphate which contains carbon. Lithium iron phosphate compounded in this invention has a stable performance, physical chemistry of products has a good homogeneity and consistency and a high productivity; lithium iron phosphate produced in this invention has a high tap density and electric specific votume, good discharging capability of high-current, stable electrochemistry circulation capability, and low local action, besides, it is easy to control content of tantalum adulterated. The tap density of lithium iron phosphate produced by this method is 1.63-2.04g / cu cm, the highest discharging specific votume is 161.3mAh / g.

Owner:HUBEI UEE ENERGY TECH CO LTD

Lean hematite processing technology

InactiveCN102921540ASimple production processShort processWet separationEngineeringReverse flotation

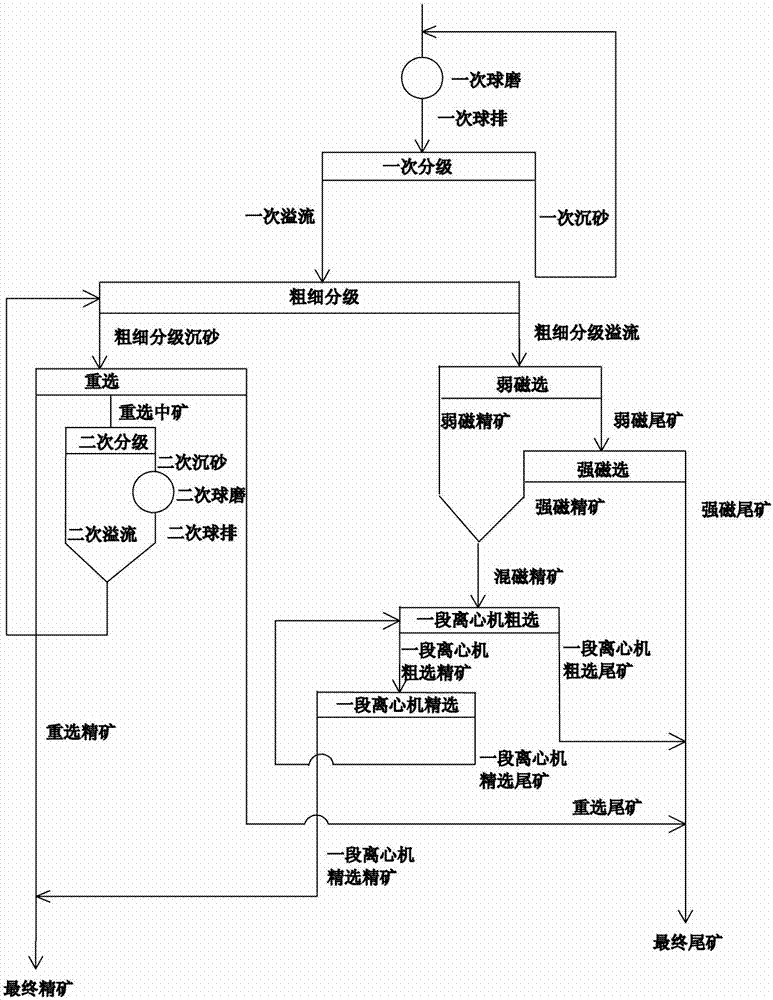

The invention belongs to the technical field of lean hematite processing, in particular to a lean hematite processing technology which comprises the steps of stage grinding, coarse-fine separation, coarse fraction gravity separation, fine-fraction magnetic separation and centrifuge beneficiation. The lean hematite processing technology disclosed by the invention adopts centrifuge beneficiation to replace reverse flotation beneficiation in the original technology, so that the whole production technological flow is optimized and becomes shorter, and the loss of fine fraction high-grade hematite particles in tailings is reduced; besides, the technological course is more adaptive to properties of the hematite, so that the influence of over-high content of iron carbonate over reverse flotation in the original technological course is effectively solved; and furthermore, due to the adoption of centrifuge beneficiation, reagents does not need to be used and hematite pulp does not need to be heated, so that expenses of reagents and coal are effectively saved and the hematite processing cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

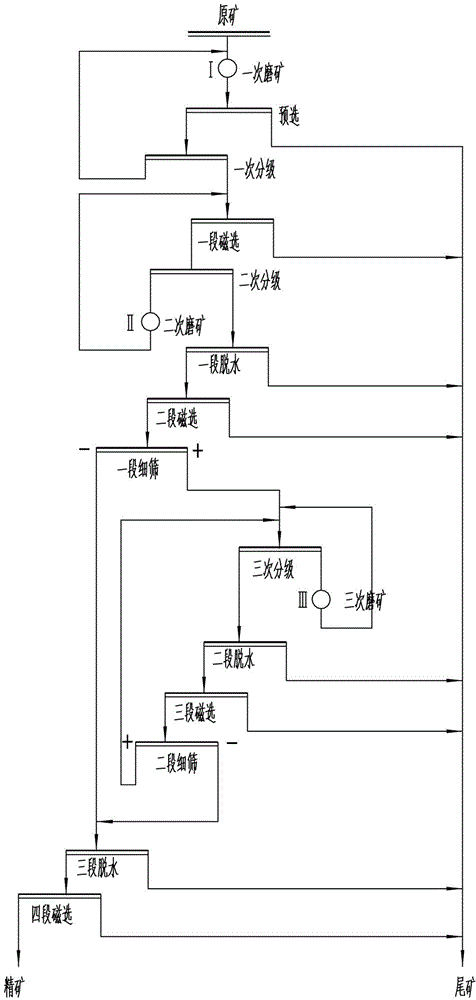

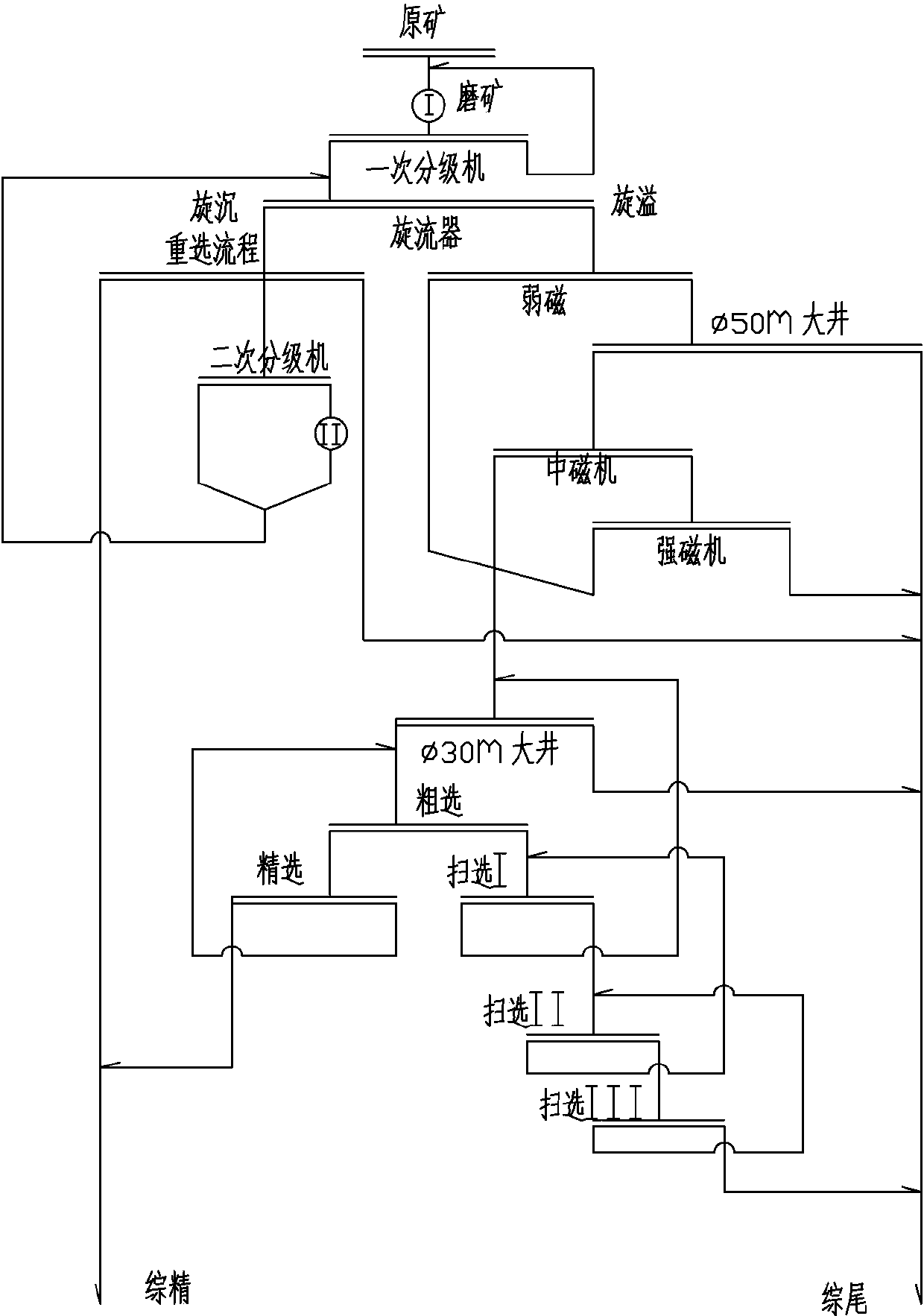

Process for processing hematite ore containing iron carbonate

InactiveCN101632957AImprove technical indicatorsEfficient recyclingFlotationMagnetic separationMonomerMaterials science

The invention relates to a process for processing hematite ore containing iron carbonate. The process comprises the following steps that: ore is subjected to ore grinding to achieve monomer separation; concentrated ore obtained through magnetic separation of a weak magnetic separator, a medium magnetic separator and a strong magnetic separator are converged; the converged concentrated ore is subjected to coarse separation and fine separation sequentially by a floatation medicament with strong selective collection capacity on the iron carbonate to obtain iron carbonate concentrated ore; the obtained iron carbonate concentrated ore enters a thermal decomposition process; the decomposed ore enters a water-addition stirring tank to prepare ore pulp with appropriate concentration; the ore pulp and tailings after being subjected to floatation by the iron carbonate are mixed together for reverse floatation of the hematite; and after the reverse flotation, final concentrated ore and final tailings are obtained. The thermal decomposition process utilizes a rotary kiln to carry out thermal decomposition on the iron carbonate concentrated ore. The weight percentage of the appropriate concentration of the ore pulp is between 42 and 48 percent. The process can effectively reclaim the iron carbonate lost in the tailings, improves the grade of the final concentrated ore, provides referential significance for domestic similar ore separation and has remarkable economic and social benefits.

Owner:ANSTEEL GRP MINING CO LTD

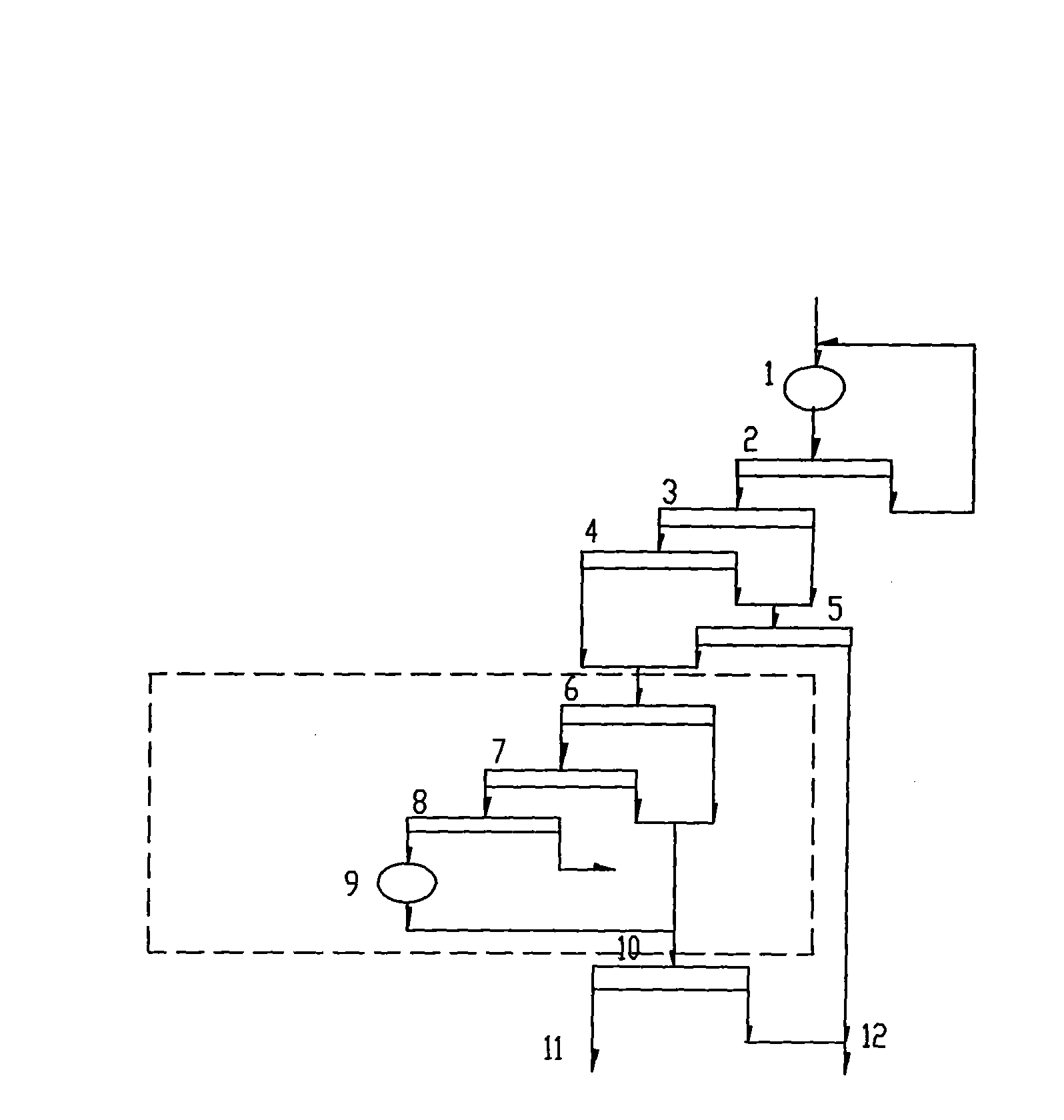

Simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore

ActiveCN104128259AEasy to handleImproved particle size compositionMagnetic separationPhysical chemistryMagnetic separator

The invention relates to a simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore. The process includes ore grinding, grading and magnetic separation and comprises the following concrete steps: ore grinding three times; presorting with a large-wrap angle medium-intensity magnet separator; grading with a cyclone three times; dehydration in three stages; fine sieving in two stages; and magnetic separation with a magnet separator in four stages. The invention provides the energy-saving, low-carbon, environment-friendly and reliable production process for treatment of iron carbonate-containing lean magnetite ore by using a simple magnetic separation method; the process can further improve treating capability, enhance technical and economic indexes, reduce production cost and greatly increase the utilization efficiency of inferior resources while improving ore grinding, grading and sorting efficiency.

Owner:ANSTEEL GRP MINING CO LTD

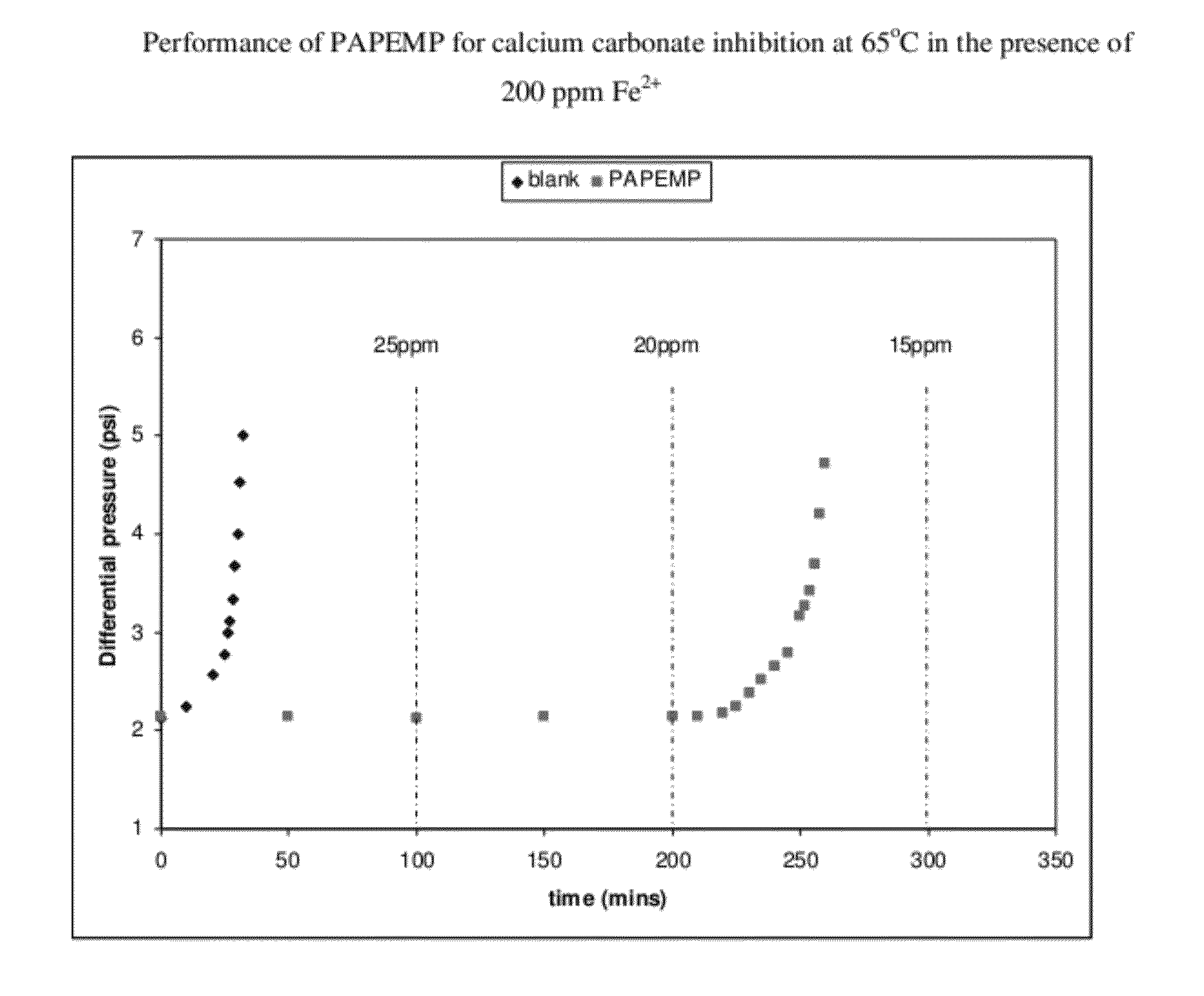

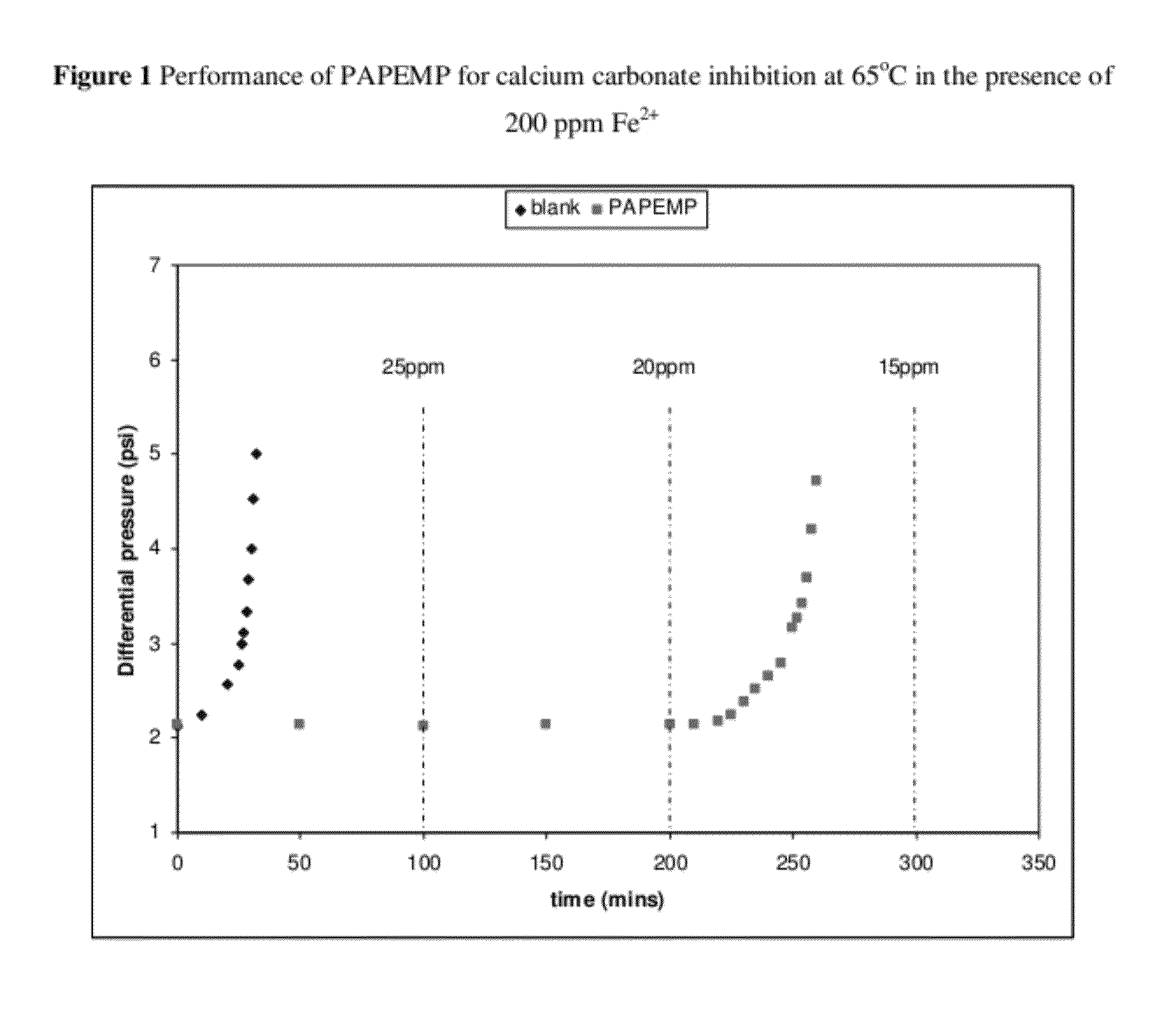

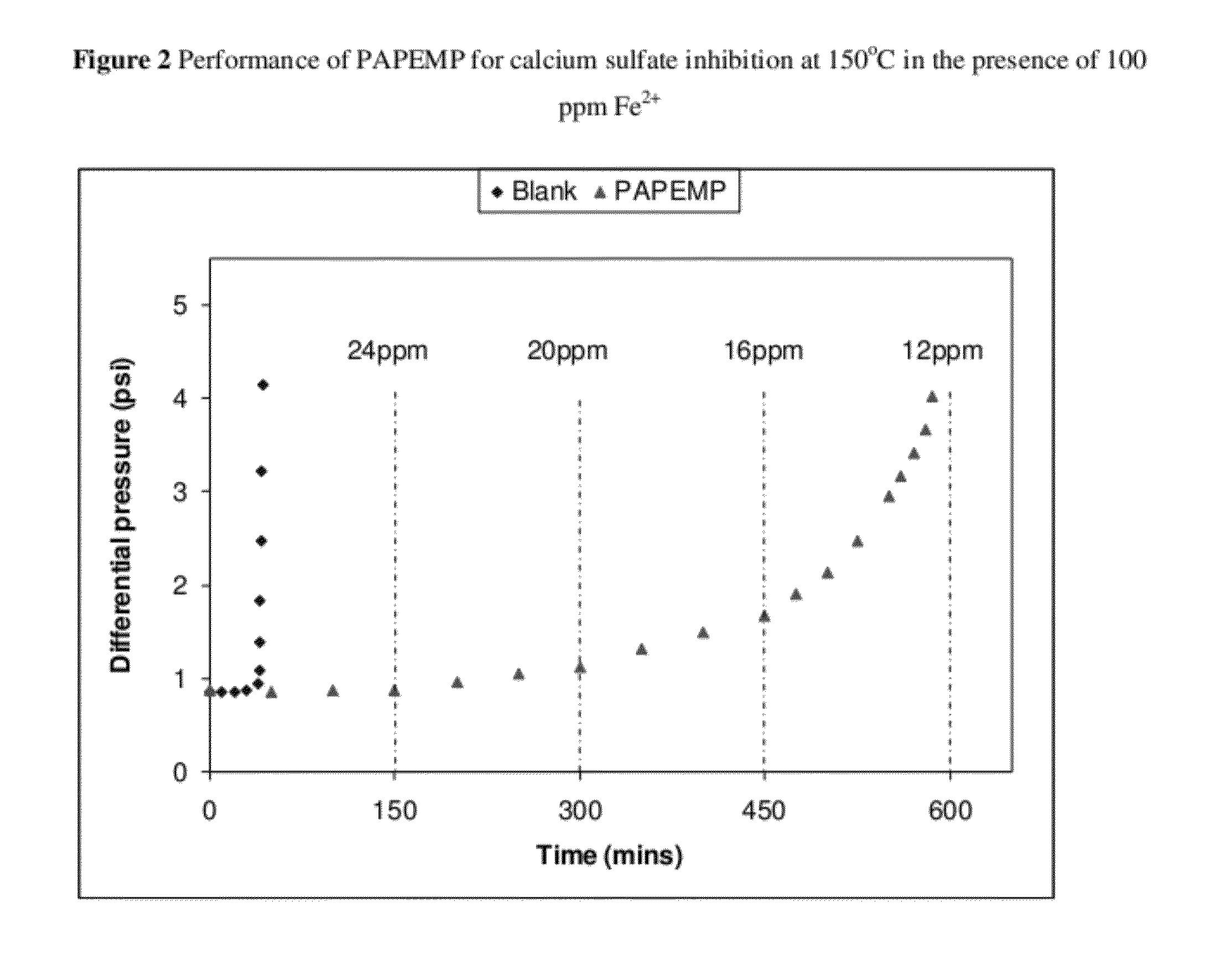

Method for preventing scale formation in the presence of dissolved iron

The present invention relates to a method of using threshold scale inhibitors of the formula:wherein n is 2 or 3 and M is hydrogen or an alkali metal cation, for preventing calcium carbonate, iron carbonate, and calcium sulfate scale formation in oilwell brines containing dissolved iron.

Owner:BAKER HUGHES INC

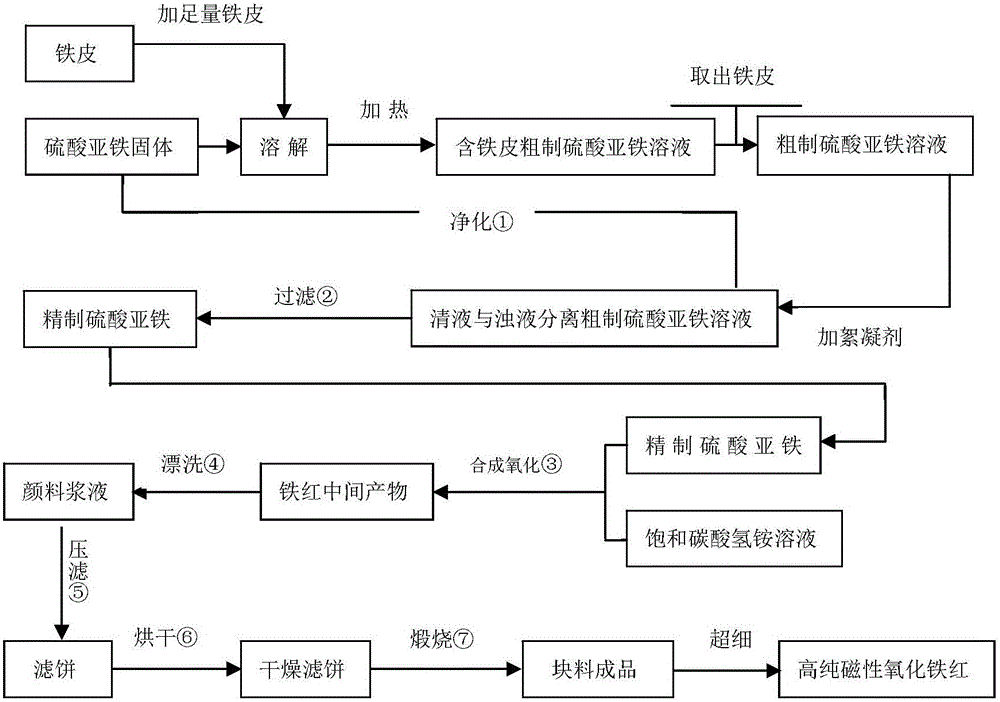

Method for preparing high-purity gamma-Fe2O3 iron oxide red pigment

InactiveCN105110382AEasy to filter washNo crushing requiredFerric oxidesSulfateFerric hydroxide oxide

The invention relates to a method for preparing high-purity gamma-Fe2O3 iron oxide red pigment. The method includes the following steps: firstly, dissolving the ferrous sulfate solid in water, controlling the obtained solution to be at a certain temperature, adding a certain amount of a flocculating agent, and keeping at a certain temperature; after a certain time, filtering to obtain a refined ferrous sulfate solution; adding saturated ammonium bicarbonate solution into the refined ferrous sulfate solution for synthesizing iron carbonate and iron hydroxide precipitate with high magnetic properties under the conditions of a certain temperature and a pH value. According to the invention, the method is low in cost and simple and convenient to operate; the obtained product is high in stability and suitable for industrial production.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Heat-insulation fireproof coating applied to pre-buried pipe of vacuum cast aluminium alloy casting

The invention discloses a heat-insulation fireproof coating applied to a pre-buried pipe of a vacuum cast aluminium alloy casting. The heat-insulation fireproof coating is prepared from the following components in parts by weight: 20-30 parts of sepiolite powder, 4-6 parts of cationic starch, 4-6 parts of expanded graphite, 1.5-3 parts of chloroplatinic acid, 1-3 parts of industrial alkali, 4-6 parts of modified clay, 4-6 parts of aluminium oxide, 4-6 parts of silicon carbide, 4-6 parts of sodium carboxymethylcellulose, 30-50 parts of deionized water, 1-3 parts of mullite, 1-3 parts of shell, 4-6 parts of sea mud, 1-3 parts of potassium titanate whiskers, 1-3 parts of silicon nitride, 1-3 parts of boron nitride, 1-3 parts of iron carbonate, 1-3 parts of titanium dioxide whiskers, 1-3 parts of magnesium carbonate, 1-3 parts of zinc oxide, 4-6 parts of calcined kaolin, 1-3 parts of white alum and 4-6 parts of kyanite powder. By improving the preparation of the conventional fireproof mud, a pre-buried copper pipe or stainless steel pipe is coated with a layer of fireproof coating with specific thickness; and the effects of insulating heat, preventing softening and preventing a liquid aluminum accommodation copper pipe from entering a pipeline can be implemented.

Owner:CHUZHOU JINNUO INDAL

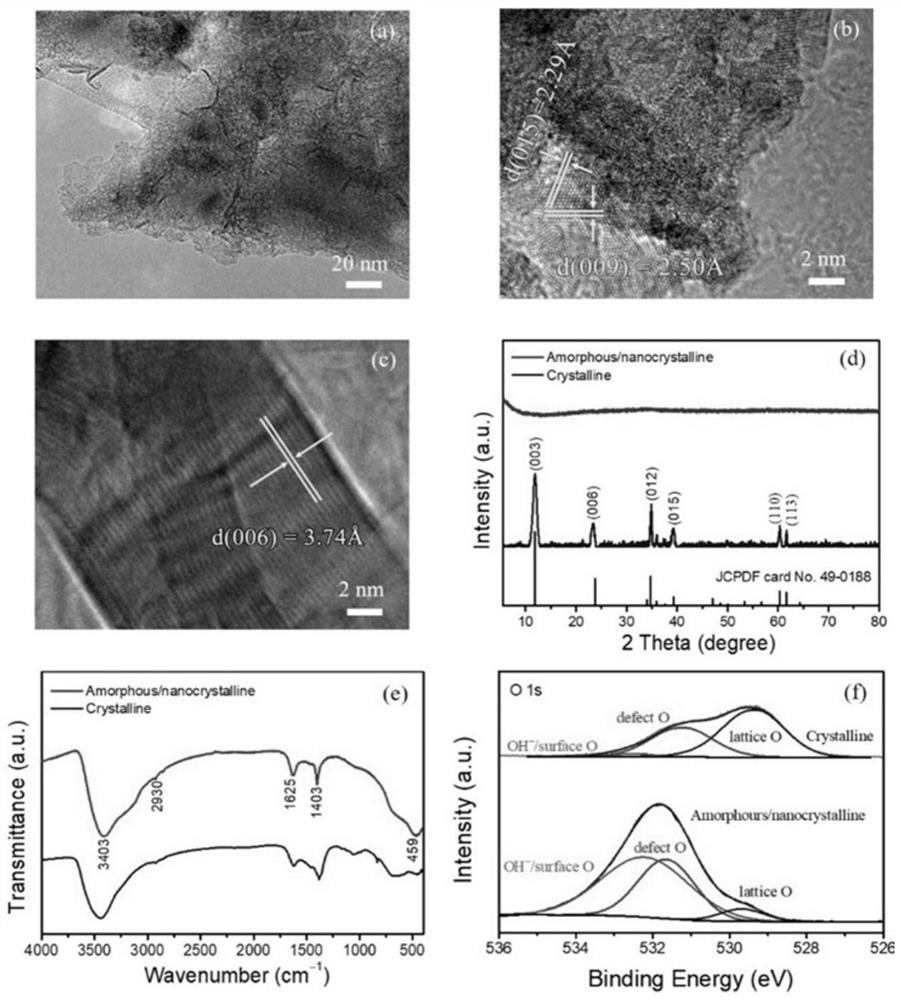

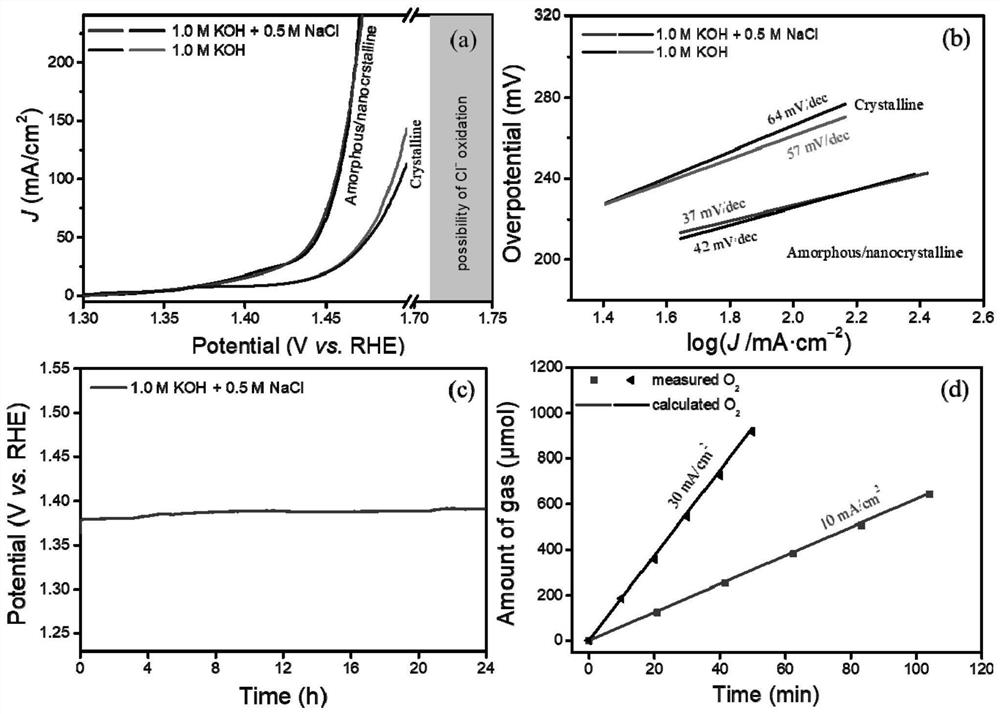

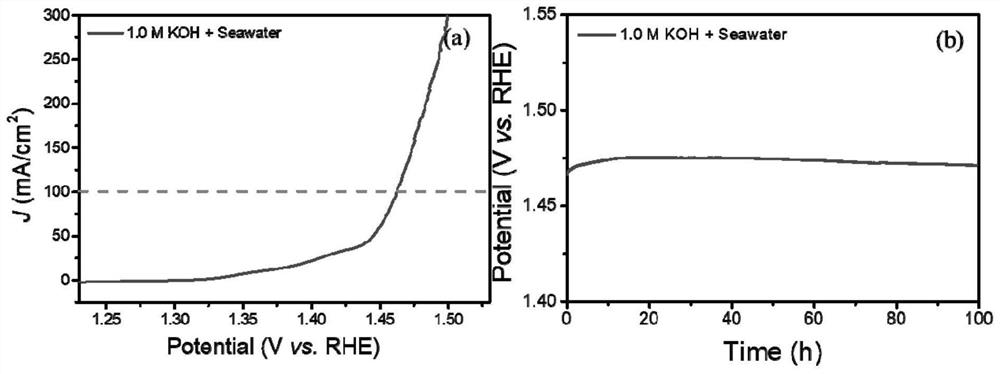

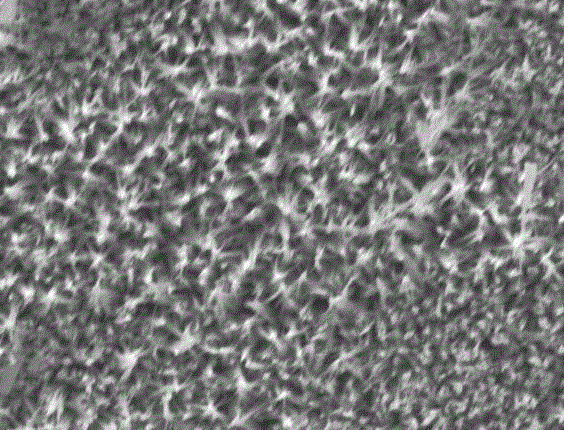

Oxygen evolution reaction catalyst, preparation, application, electrolysis device and seawater cracking method

ActiveCN112501647AImprove adsorption capacityImprove performanceMaterial nanotechnologyCellsPtru catalystEngineering

The embodiment of the invention provides an oxygen evolution reaction catalyst, preparation, an application, an electrolysis device and a seawater cracking method. The oxygen evolution reaction catalyst comprises a foamed nickel substrate and amorphous / nanocrystalline basic iron carbonate loaded on the foamed nickel substrate. The amorphous and nanocrystalline mixed structures of basic nickel ironcarbonate (FeNiCH) contain more surface adsorption oxygen and oxygen defects, which can adjust the electronic structure of Fe (III) / Ni (II) and optimize the adsorption energy of the OER intermediate.The surface adsorption oxygen and defect oxygen may be related to chloride resistance and high corrosion resistance. Therefore, the electro-catalytic OER performance of the oxygen evolution reactioncatalyst is less affected by chloride ions, the high performance of the electrolytic tank can be well maintained for a long time when the oxygen evolution reaction catalyst is applied to the electrolytic tank, and the oxygen evolution reaction catalyst shows excellent OER performance in alkaline offshore seawater electrolysis and can meet the requirements of high current density (greater than or equal to 500mA / cm<2>) and low overpotential (less than or equal to 300mV).

Owner:UNIV OF JINAN

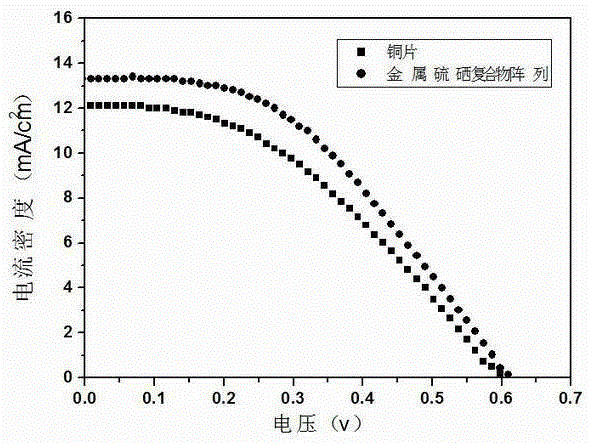

A sulfur and selenium compound composite array preparation method

ActiveCN105280387AGood electron transport propertiesEasy to prepareLight-sensitive devicesElectronic transmissionElectrochemistry

The invention provides a sulfur and selenium compound composite array preparation method and belongs to the technical field of solar cells. The sulfur and selenium compound composite array preparation method comprises the steps of preparing an electric conduction glass sheet with the surface covered with basic iron carbonate or basic cobalt carbonate and preparing a sulfur and selenium compound composite array. The preparation method is simple and the reaction conditions are moderate; obtained sulfur and selenium compound composite arrays have favorable electronic transmission channels and catalytic activity, thereby presenting favorable electrochemical properties and catalytic properties. The sulfur and selenium compound composite arrays can be better applied to counter electrodes of quantum dot sensitized solar cells and have broad application prospects in the field of solar cells.

Owner:HENAN NORMAL UNIV

Method for recycling tailings of magnetic separation by adopting preselection-calcination-magnetic levitation processes

InactiveCN108212504AReduce grinding costsHigh pre-concentrate gradeWet separationEngineeringReverse flotation

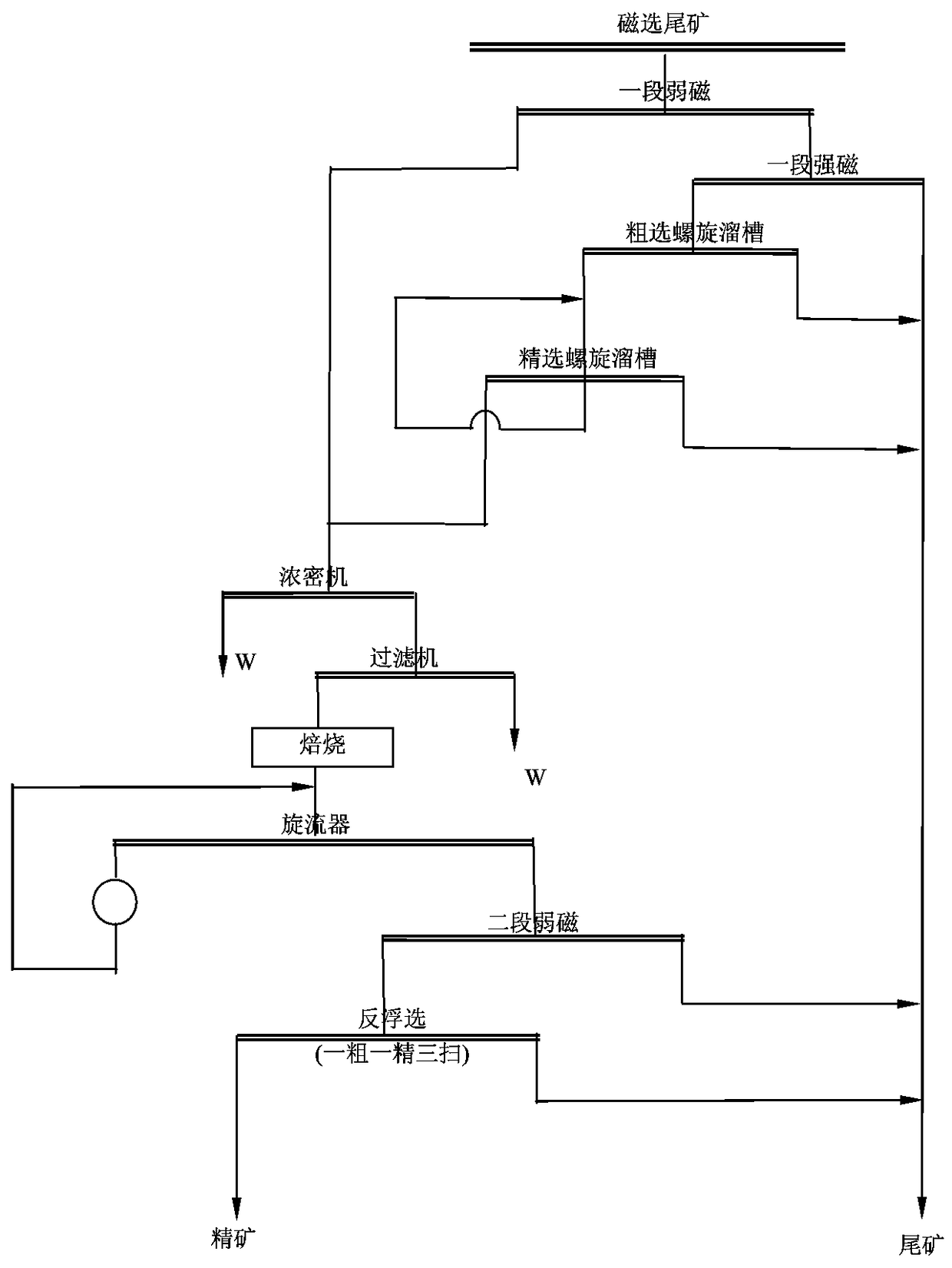

The invention relates to a method for recycling magnetic tailings by adopting preselection-calcination-magnetic levitation processes. The method comprises the following steps of supplying a first period of weak magnetism to the magnetic tailings of which the iron grade is 9 to 13% and the content of iron carbonate is more than 3%, supplying a first period of strong magnetism to the magnetic tail,performing spiral chute reselecting operation of one coarseness and one fineness on one strong concentrate, merging fine spiral tailings and coarse spiral tailings and one strong tailing into primarytailings, and merging fine spiral concentrate and first magnetic concentrate into primary concentrate; condensing, filtering and roasting the primary concentrate so as to obtain roasted ore; performing closed circuit grinding on the roasted ore, supplying a second period of weak magnetism to overflow products of which the -0.046mm content is 83% to 90%, performing reverse flotation of one coarseness and one fineness and three sweep on second magnetic concentrate, wherein the reverse flotation concentrate is final concentrate of which the grade is more than 65%, and merging the tailings of a centrifugal machine and second magnetic tailings and the primary tailings into final tailings of which the grade is 7% to 10%. The method has the advantages that (1) preselection is performed without grinding; (2) magnetic separation is combined with reverse flotation, the regrinding particle size is coarse, and the yield is increased.

Owner:ANSTEEL GRP MINING CO LTD

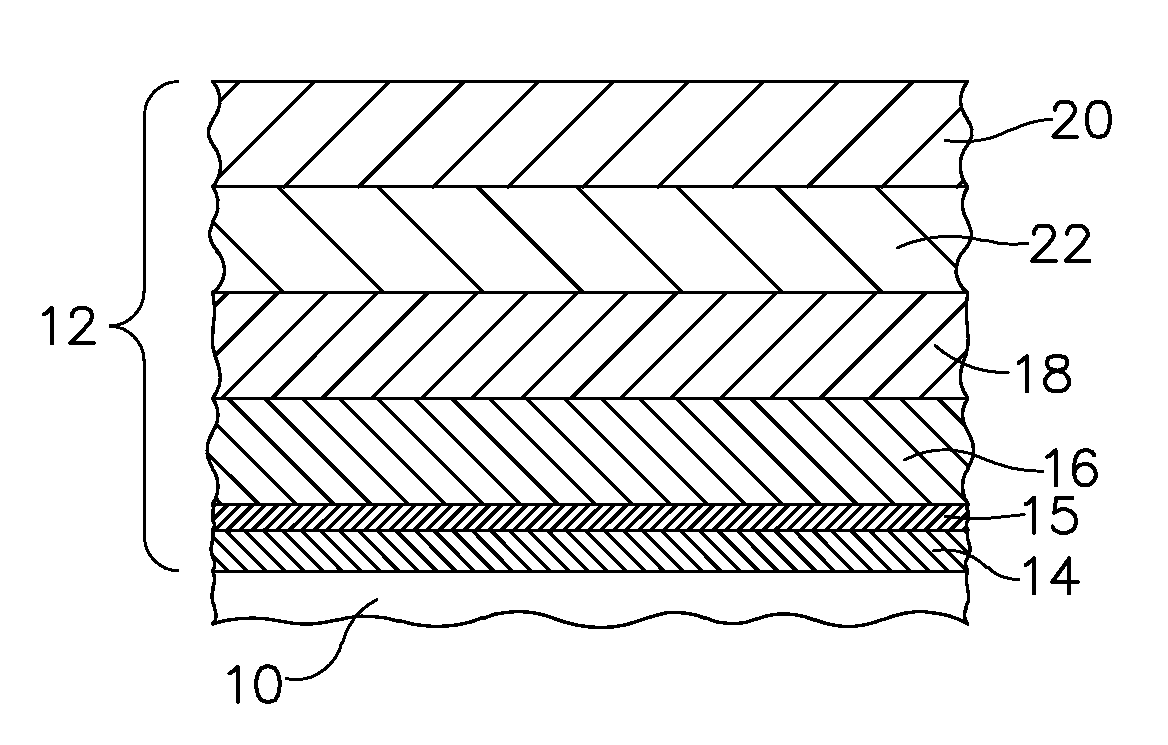

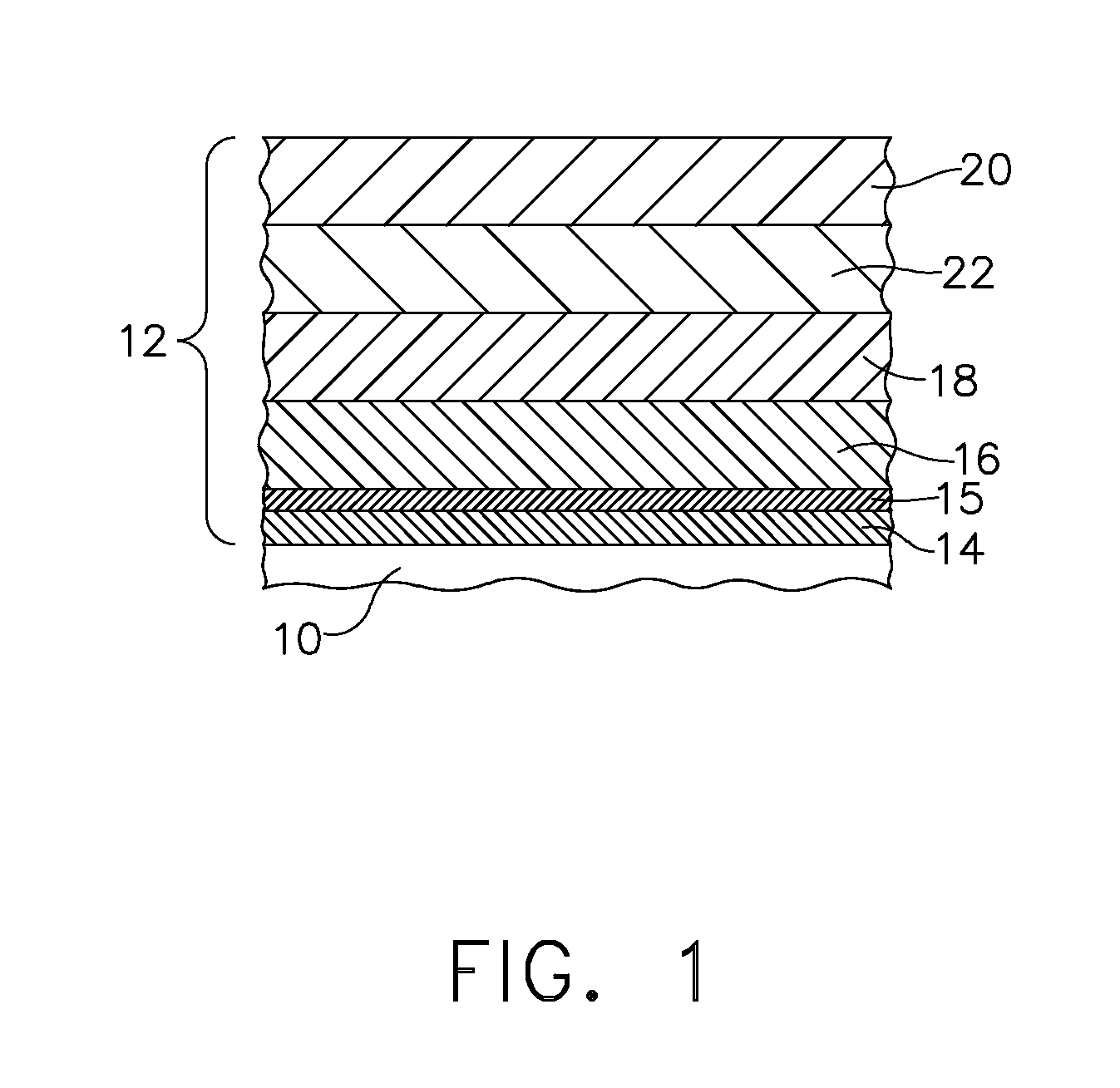

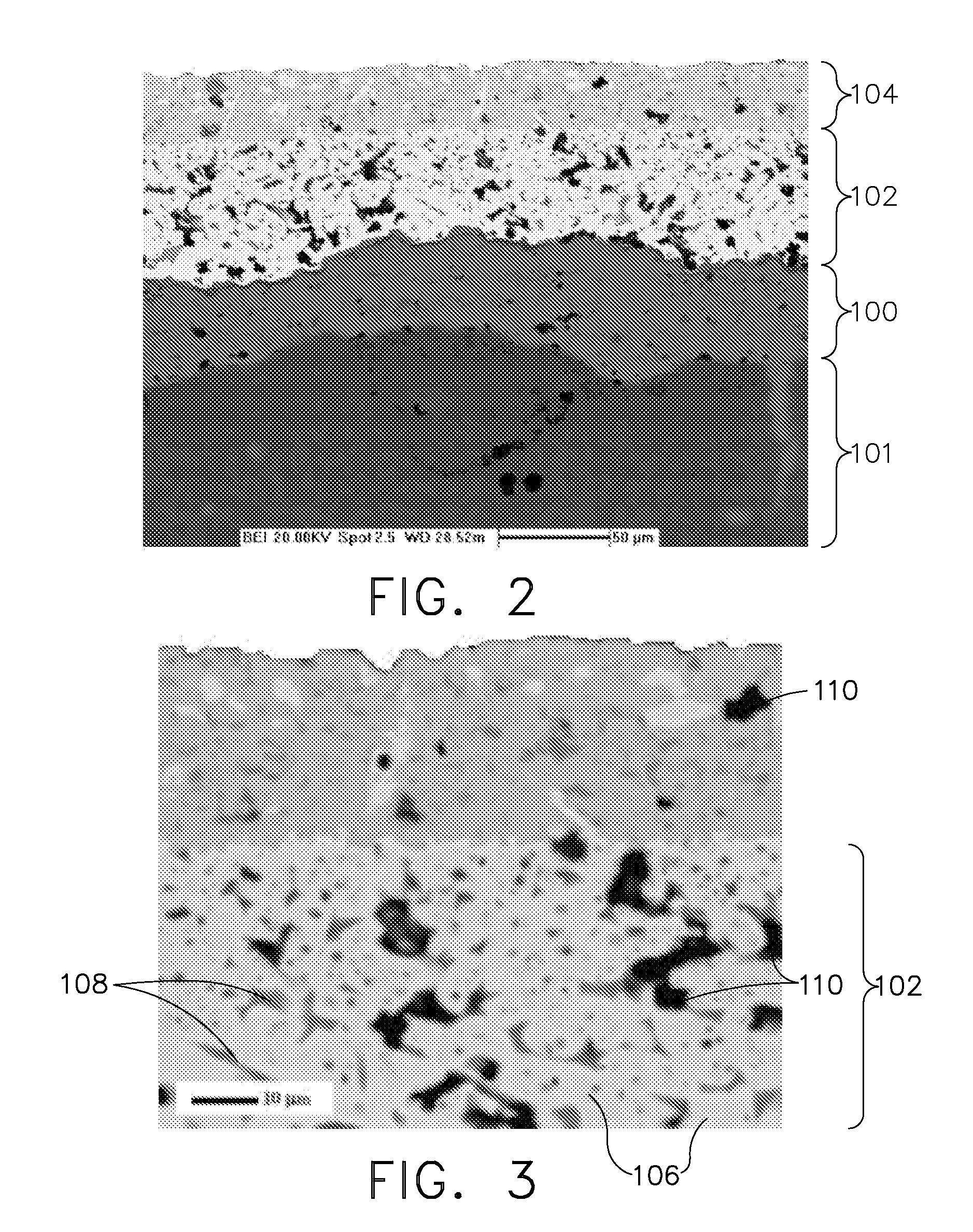

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

ActiveUS20110217511A1Improve surface roughnessPretreated surfacesRecord information storageIron saltsNickel salt

Methods for improving surface roughness of an environmental barrier coating involving providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness wherein the slurry includes water; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, water soluble iron salts, water soluble gallium salts, water soluble aluminum salts, water soluble nickel salts, water titanium salts, water soluble boron salts, and water soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

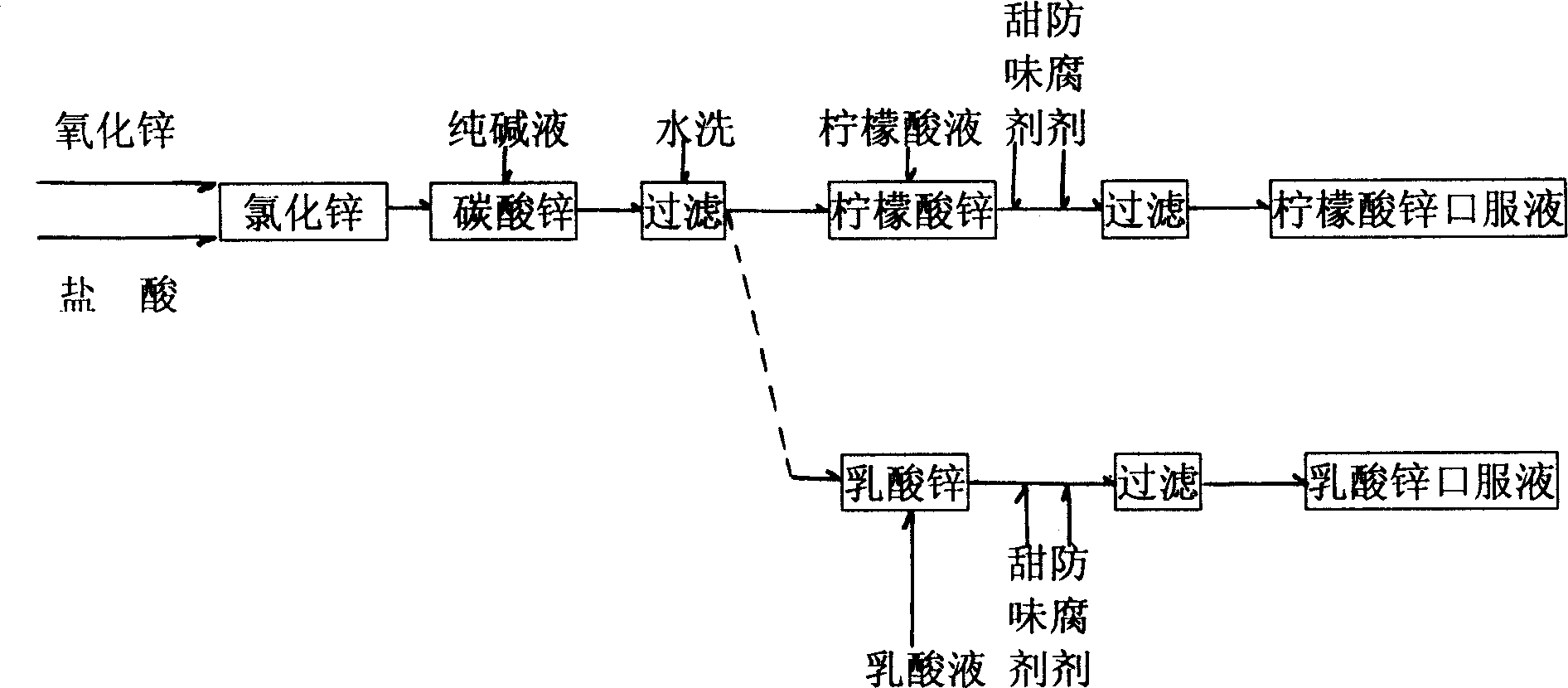

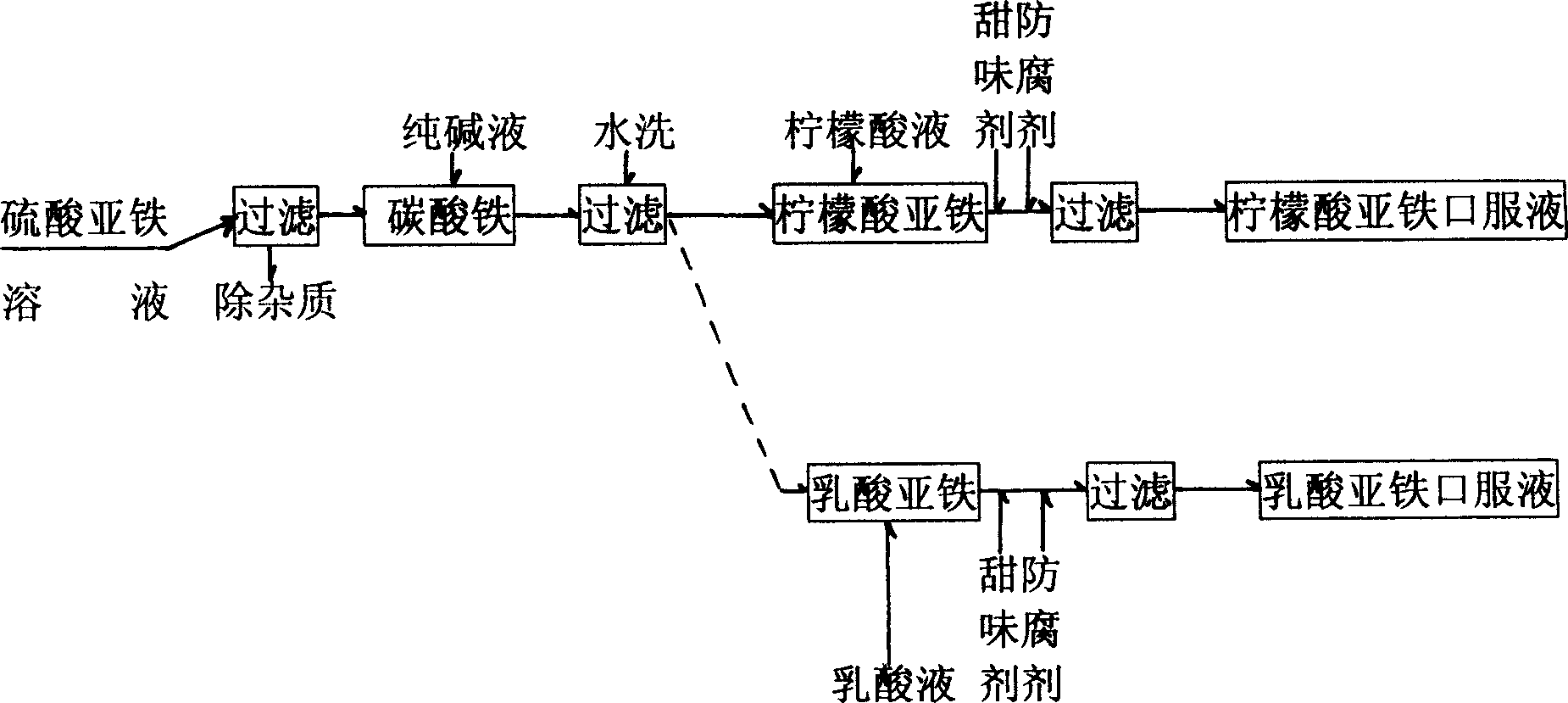

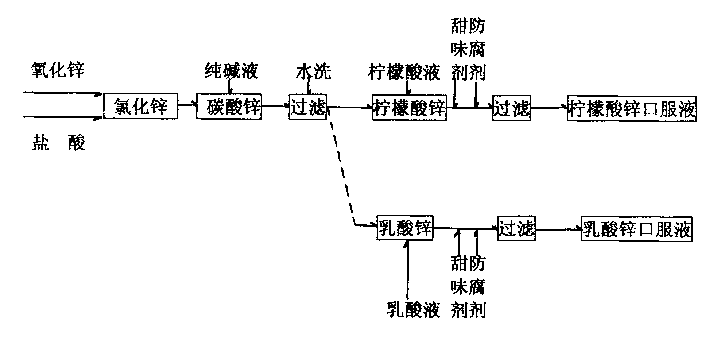

Simple production process for zinc citrate, zinc lactate, ferrous citrate and ferrous lactate

InactiveCN1636557APromote absorptionLow priceOrganic active ingredientsMetabolism disorderZINC LACTATEOrganic acid

The present invention relates to the simple production process of zinc citrate, zinc lactate, ferrous citrate and ferrous lactate oral liquid, and features that the zinc citrate, zinc lactate, ferrous citrate and ferrous lactate oral liquid is produced through the direct chemical reaction between organic acid and zinc carbonate or ferric carbonate while adding protect CO2 gas to prevent ferrous ion from being oxidized. The present invention can produce cheap zinc replenishing and iron replenishing oral liquid easy to be absorbed by human body and with high stability, high purity and no side effect.

Owner:李恕勤

Completion fluid pH value buffer agent and preparation method thereof

InactiveCN109135689AAvoid damageAvoid crackingDrilling compositionFerric hydroxideSodium bicarbonate

The invention discloses a completion fluid pH value buffer agent which is a mixed liquid of a first buffer liquid system and a second buffer liquid system, wherein the pH value of the mixed liquid is9.85-10.45; the first buffer liquid system is a mixed solution of an ammonium chloride solution and ammonia water; the pH value of the first buffer liquid system is 9.15-10.35; the second buffer liquid system is a mixed solution of sodium carbonate and sodium bicarbonate; the pH value of the second buffer liquid system is 9.0-10.5. The completion fluid pH value buffer agent is high in efficiency in removing hydrogen sulfide and the like and inhibiting iron scale and is capable of effectively preventing sleeve damage and cracks caused by hydrogen brittleness and hydrogen induced brittleness; inaddition, due to addition of the completion fluid pH value buffer agent, a completion fluid is constantly maintained under an alkali condition, corrosion products, namely ferric hydroxide and iron carbonate, have very low solubility, a metallic surface is solidly covered by a small amount of generated ferric hydroxide and iron carbonate, further corrosion of a metal can be prevented, and a stablecompletion fluid system can be maintained.

Owner:CNPC BOHAI DRILLING ENG

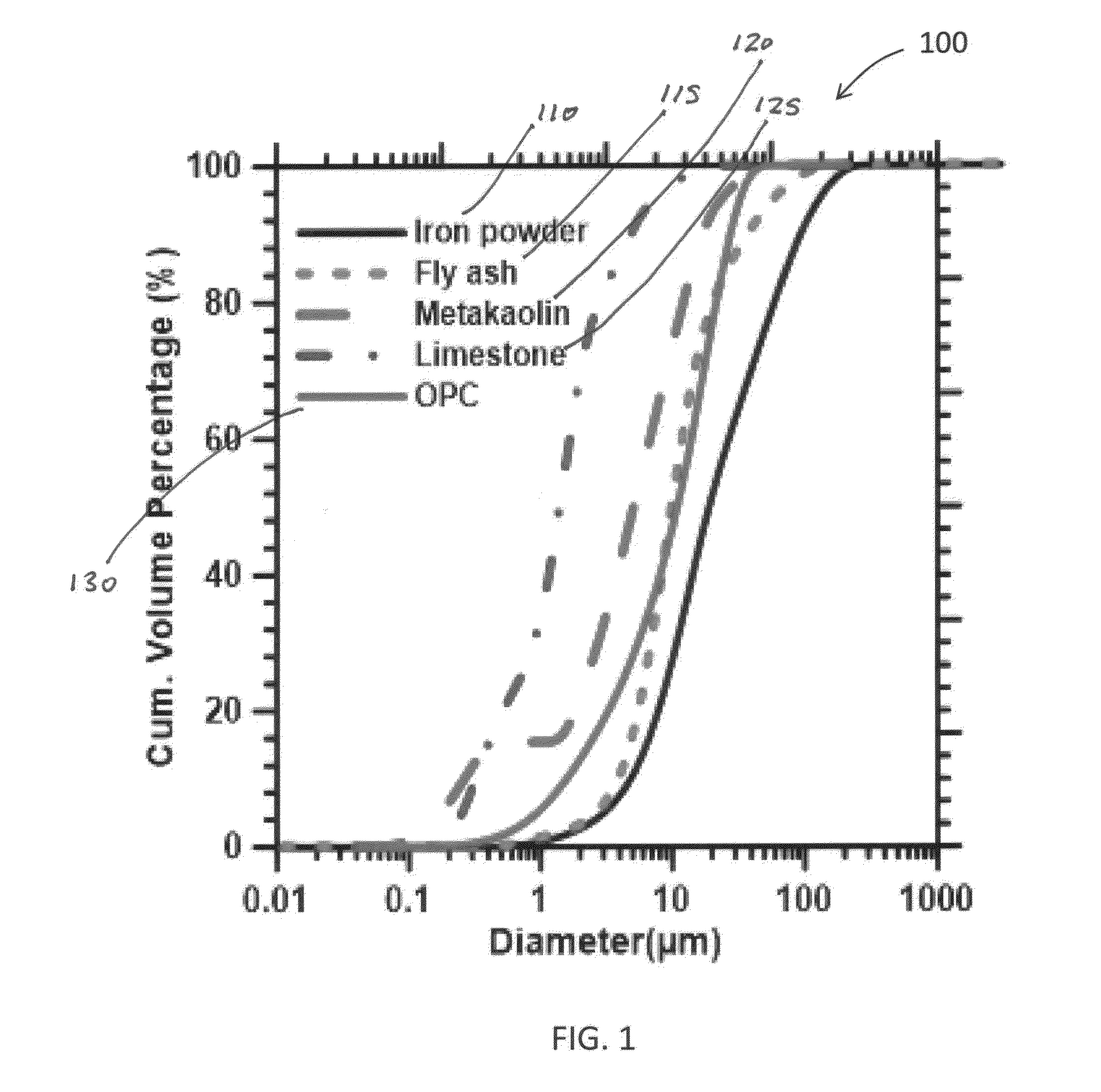

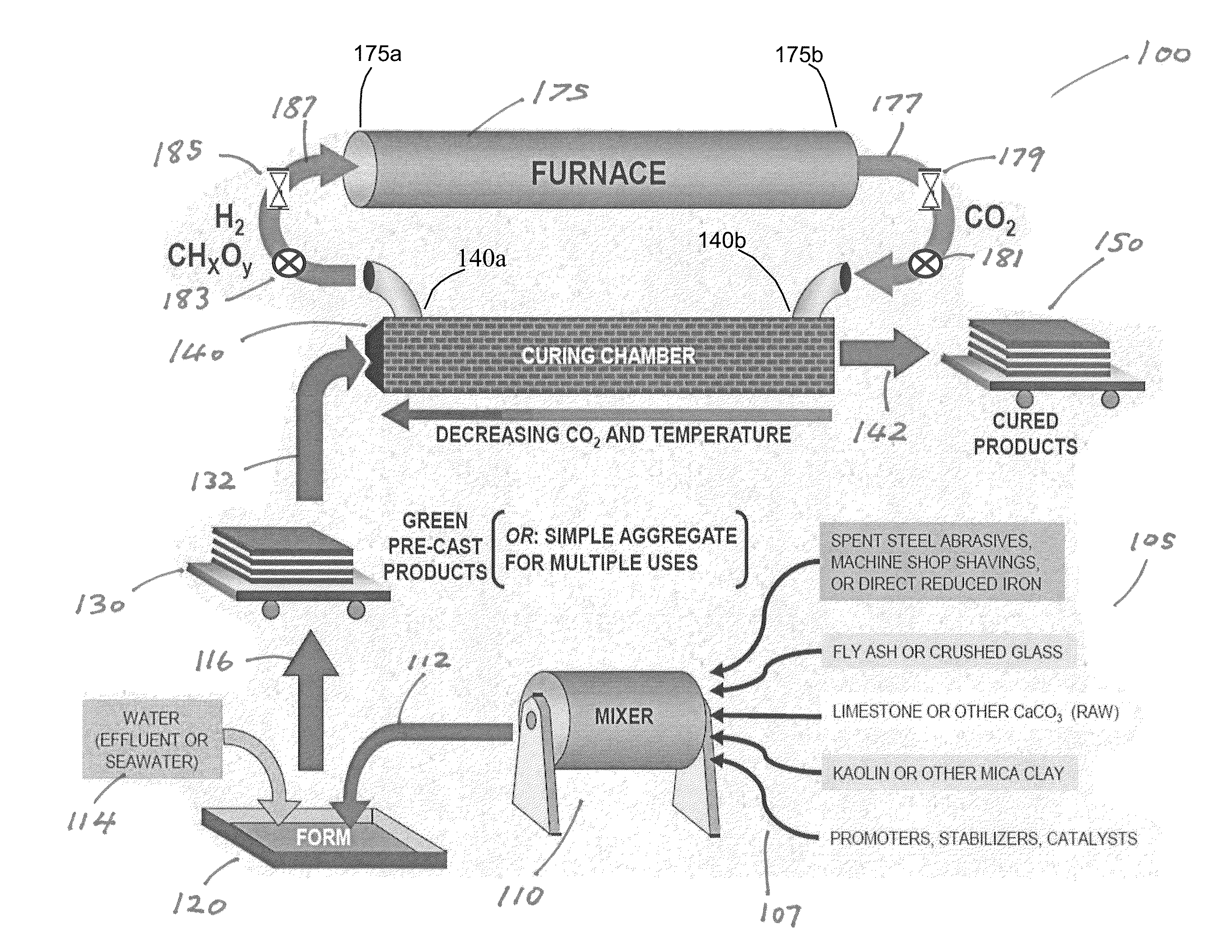

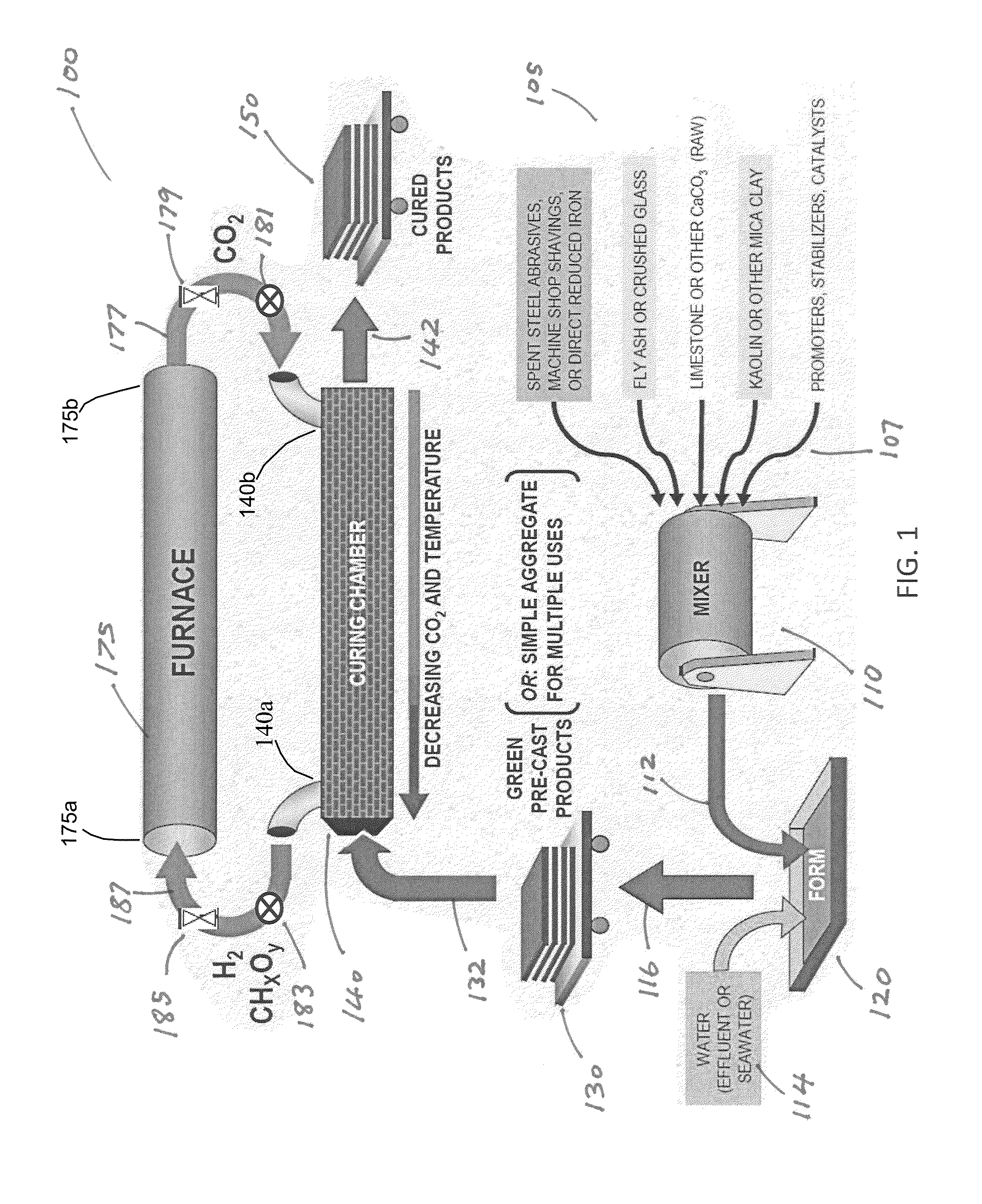

Binder compositions and method of synthesis

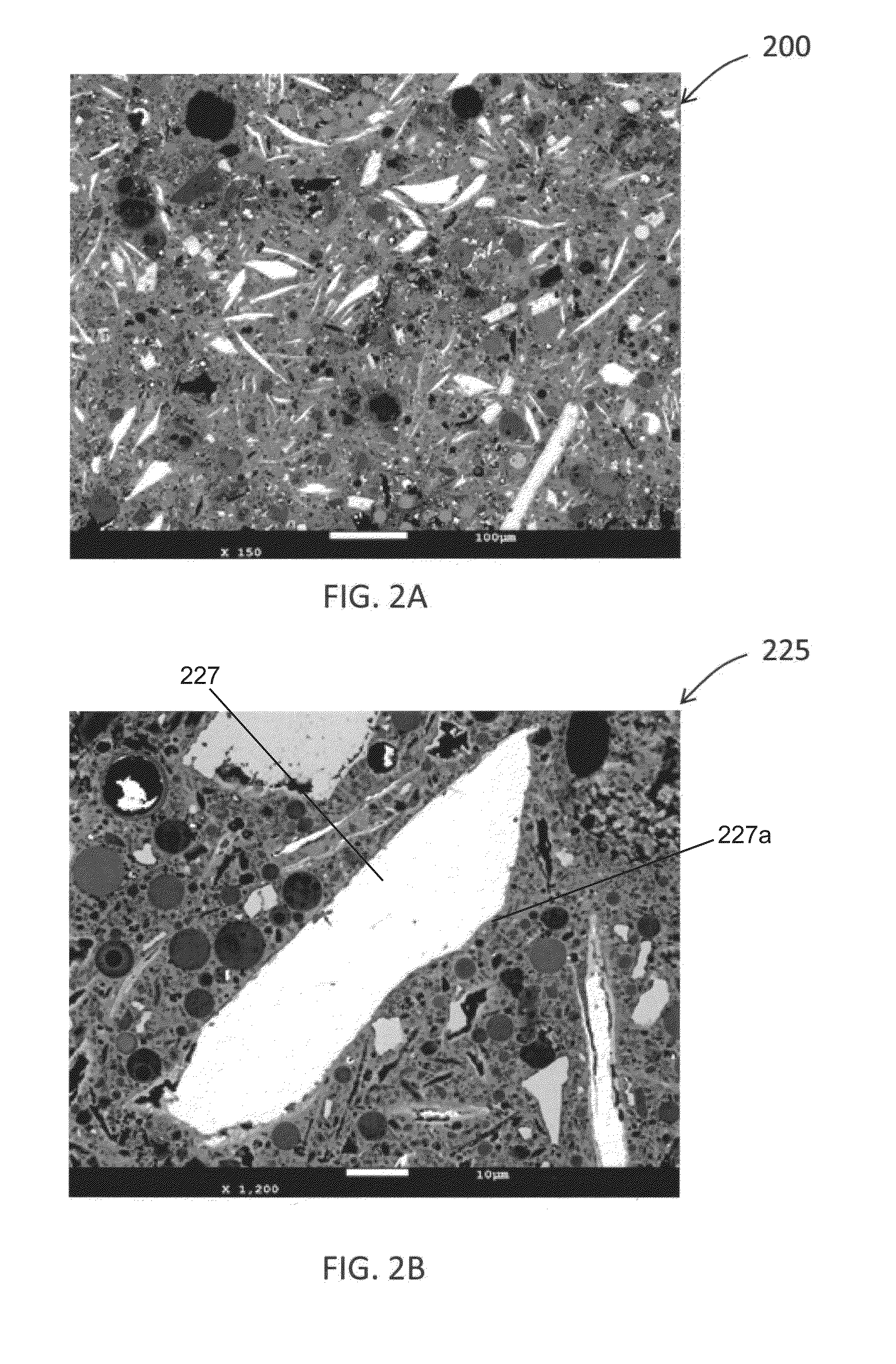

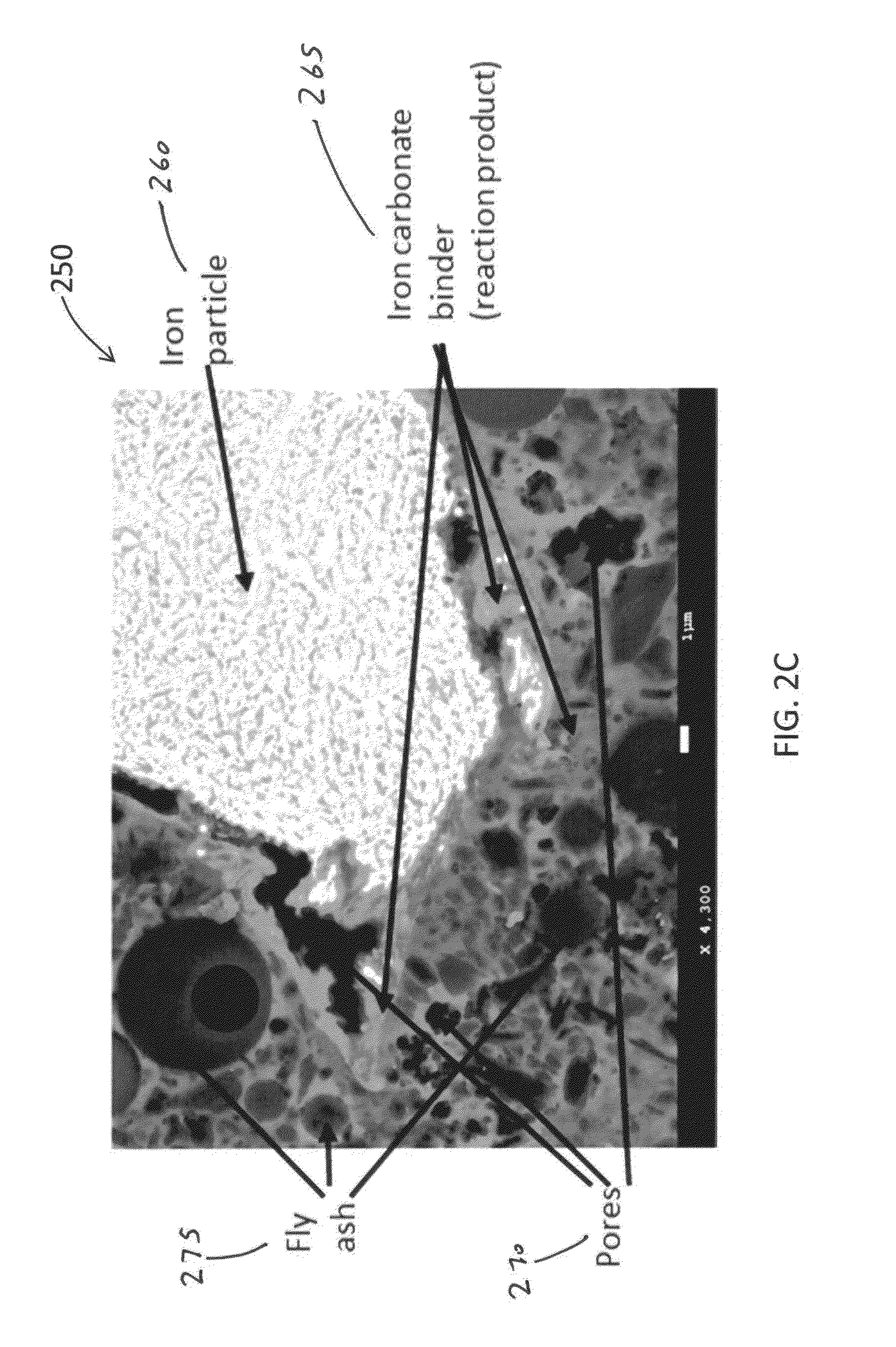

Some embodiments of the invention include cementitious iron carbonate binder precursor compositions that includes powdered iron or steel, a first powdered additive including silica, a second powdered additive including calcium carbonate, at least one powdered clay, and a fibrous and / or woven additive. In some embodiments of the invention, the precursor composition includes an alumina additive. In some further embodiments, the powdered clay includes kaolinite clay and / or metakaolin clay. In some further embodiments, the precursor composition includes an organic reducing agent such as oxalic acid. Some embodiments include up to about 60% by weight of powdered iron or steel, up to about 20% by weight of the first powdered additive, up to about 8% by weight of the second powdered additive, up to about 10% by weight of at least one powdered clay, and up to about 2% by weight of an organic acid.

Owner:ARIZONA STATE UNIVERSITY

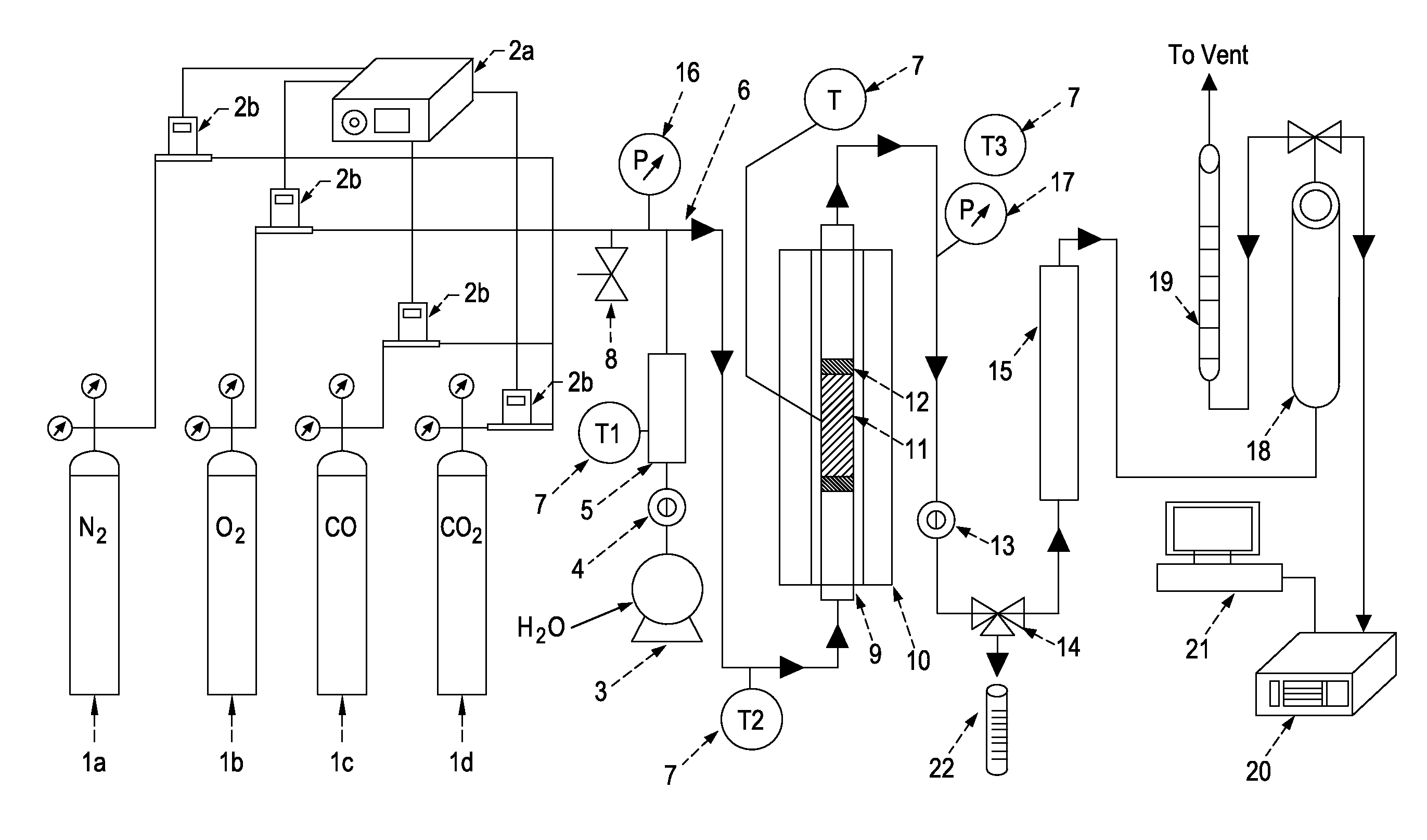

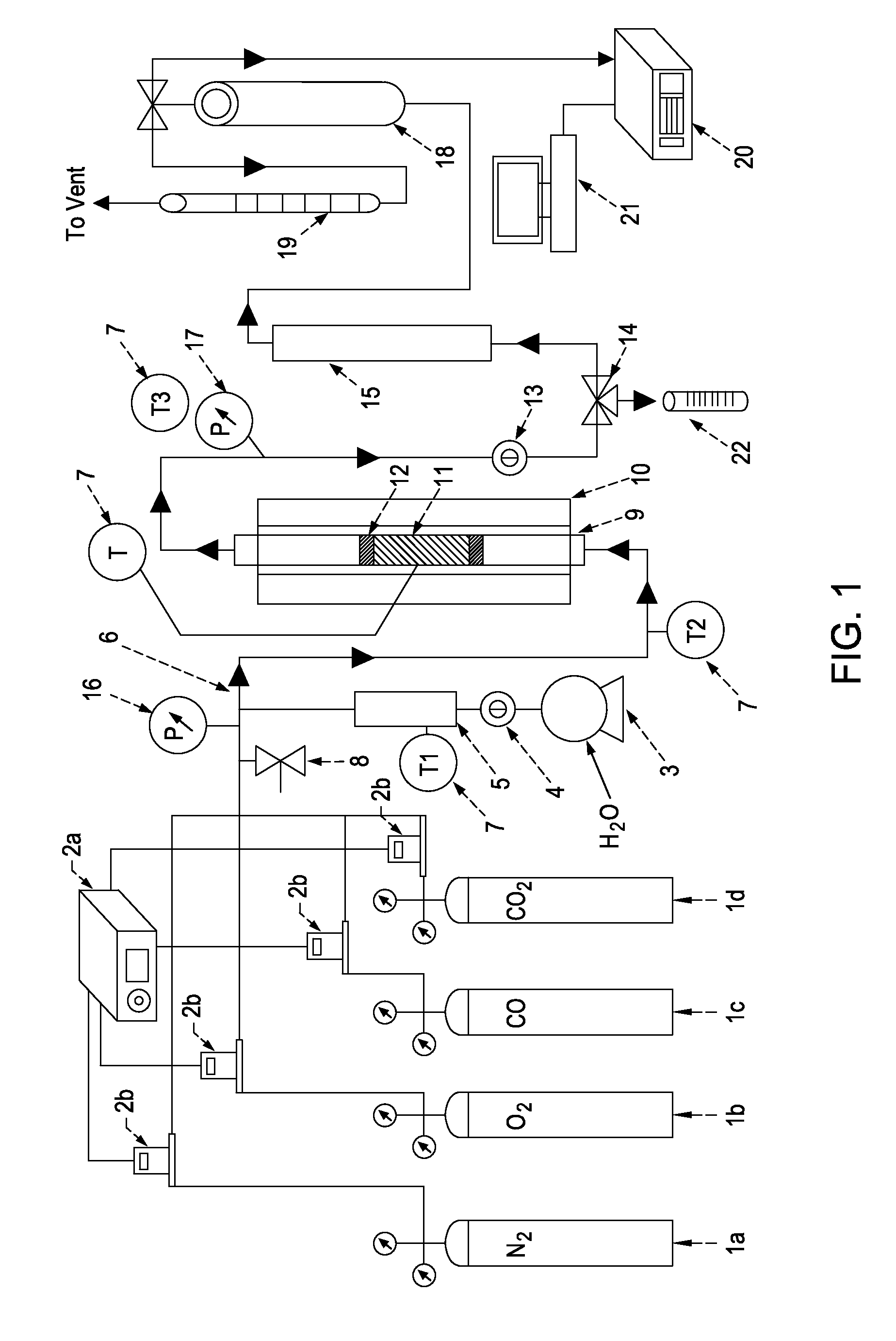

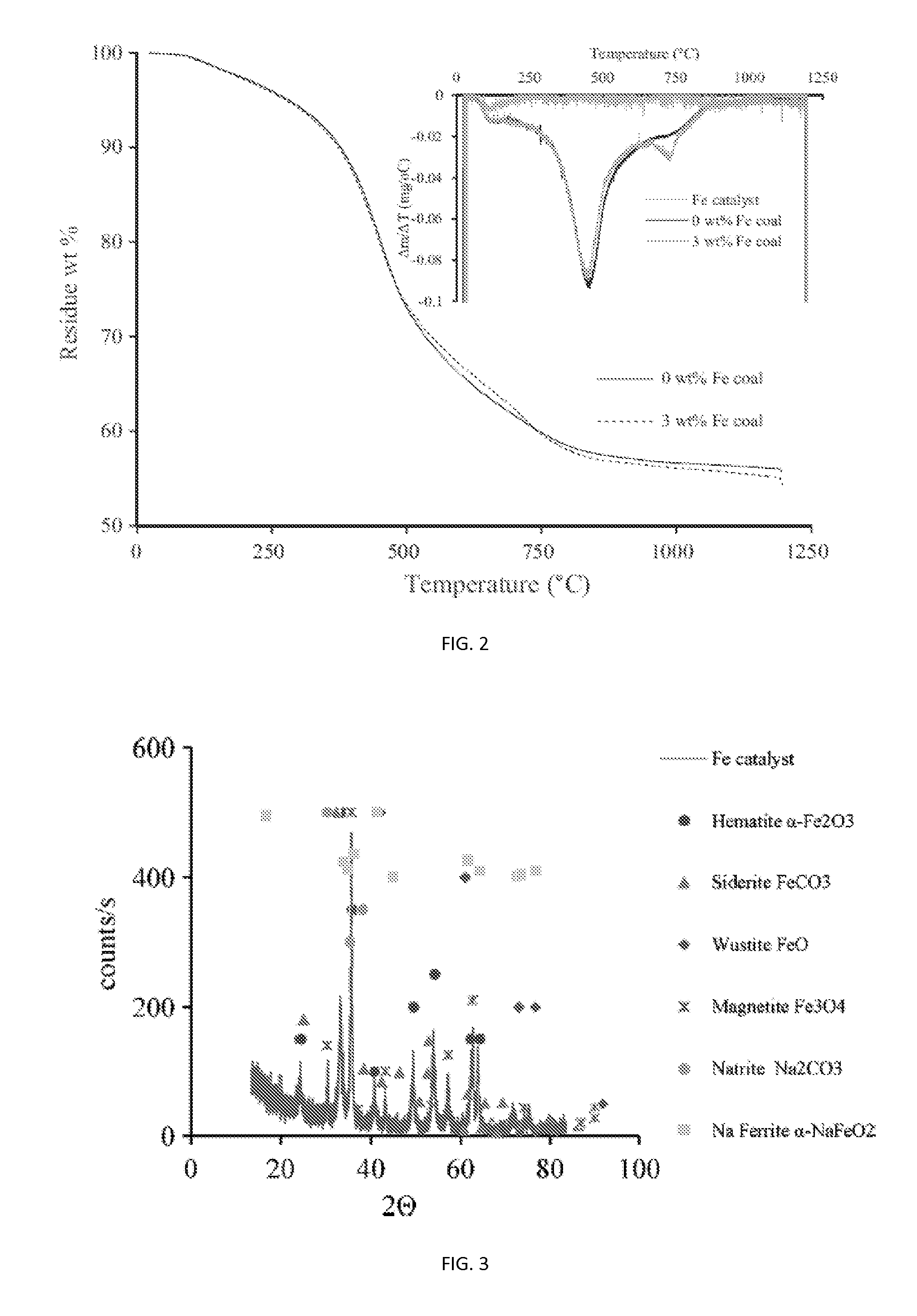

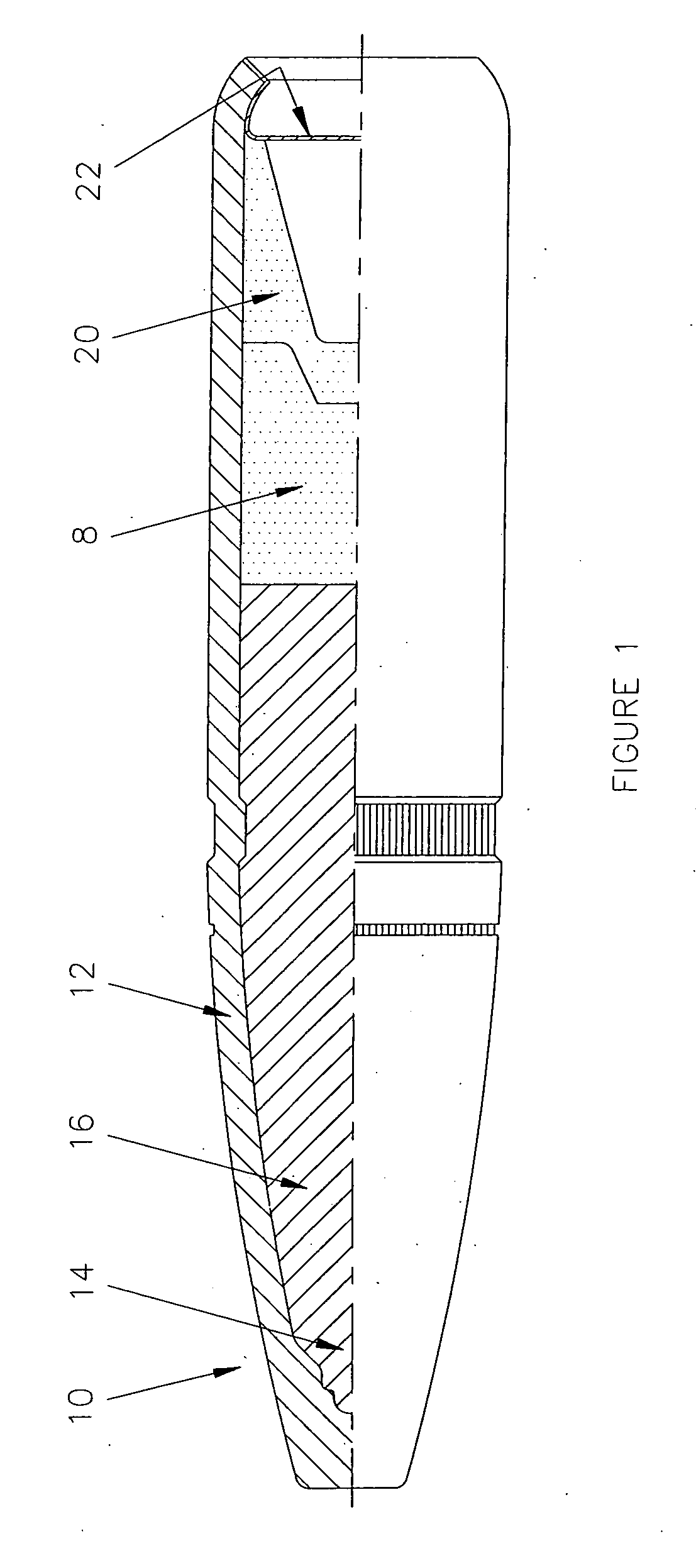

Coal gasification with feco3 catalyst

Embodiments described herein generally relate to iron carbonate utilized as a catalyst in coal gasification processes. An FeCO3 catalyst is active in both pyrolysis and gasification operations, and may increase carbon conversion rate and reduce the activation energy of coal gasification. Methods described herein also include suitable processing conditions for performing coal gasification with the FeCO3 catalyst.

Owner:UNIVERSITY OF WYOMING

Non-toxic, metallic-boron-containing, IR tracer compositions and IR tracer projectiles containing the same for generating a dim visibility IR trace

InactiveUS20060231179A1Improves Structural IntegrityReduce soot formationAmmunition projectilesTraining ammunitionHexafluoropropyleneFire retardant

A novel non-toxic IR tracer composition is provided herein which, when incorporated into an IR tracer projectile which is then fired, generates a dim visibility IR trace. Such IR tracer composition is a non-toxic, metallic-boron-containing, IR tracer composition comprising: from about 20 to about 30% by weight, or from about 45 to about 60% by weight, of at least one of potassium chlorate or sodium nitrate; from about 5 to about 16% by weight of a metallic fuel which consists of metallic boron; optionally, from about 15 to about 25% by weight, or from about 40 to about 50% by weight, of a non-metallic fuel which consists of sodium salicylate; from about 5 to about 20% by weight of a retardant which consists either of iron carbonate, or magnesium carbonate or calcium carbonate; from about 5 to about 15% by weight of a first binder which consists of calcium resinate; and up to about 7.5% by weight of a second synthetic resin binder which consists either of a copolymer of hexafluoropropylene and vinylidene fluoride or cellulose acetate butyrate, wherein the total percentage of such ingredients add up to 100%. A novel IR tracer projectile containing such IR tracer composition for generating a dim visibility IR trace is also provided.

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA

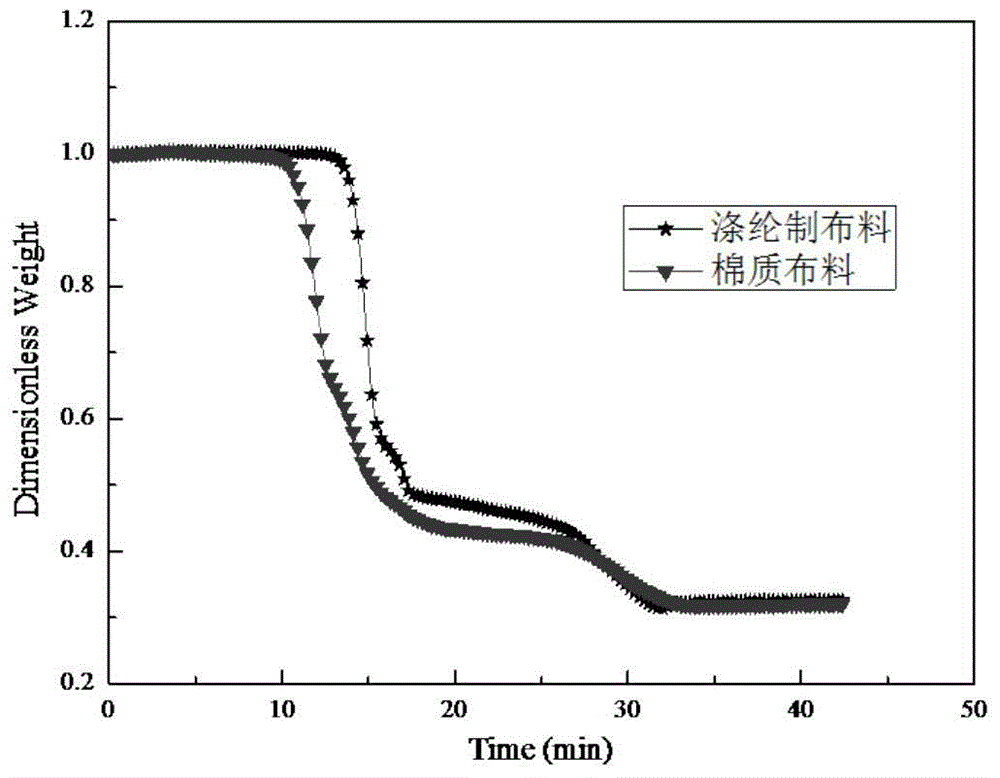

Gasification method of waste textile fabrics

InactiveCN104479758AEasy to getLower reaction conditionsSolid waste disposalGasification processes detailsDecompositionGreenhouse

The invention discloses a CO2 gasification method of waste textile fabrics. The method mainly comprises that with the waste textile fabrics as a gasification object, CO2 as a gasification gas, and iron carbonate, calcium carbonate, potassium carbonate, sodium carbonate or a mixture thereof as a catalyst, and at a certain temperature, a reaction is carried out to generate synthetic gases CO and H2. The splitting decomposition temperature of the waste textile fabrics is 300-400 DEG C, the gasification temperature is 800-1000 DEG C, the reaction conditions are easy to obtain, and the reaction temperature can be further reduced by adding the catalyst; and emissions of the waste textile fabrics and greenhouse gases can be effectively reduced, and a climate deterioration process is alleviated.

Owner:NANJING UNIV OF SCI & TECH

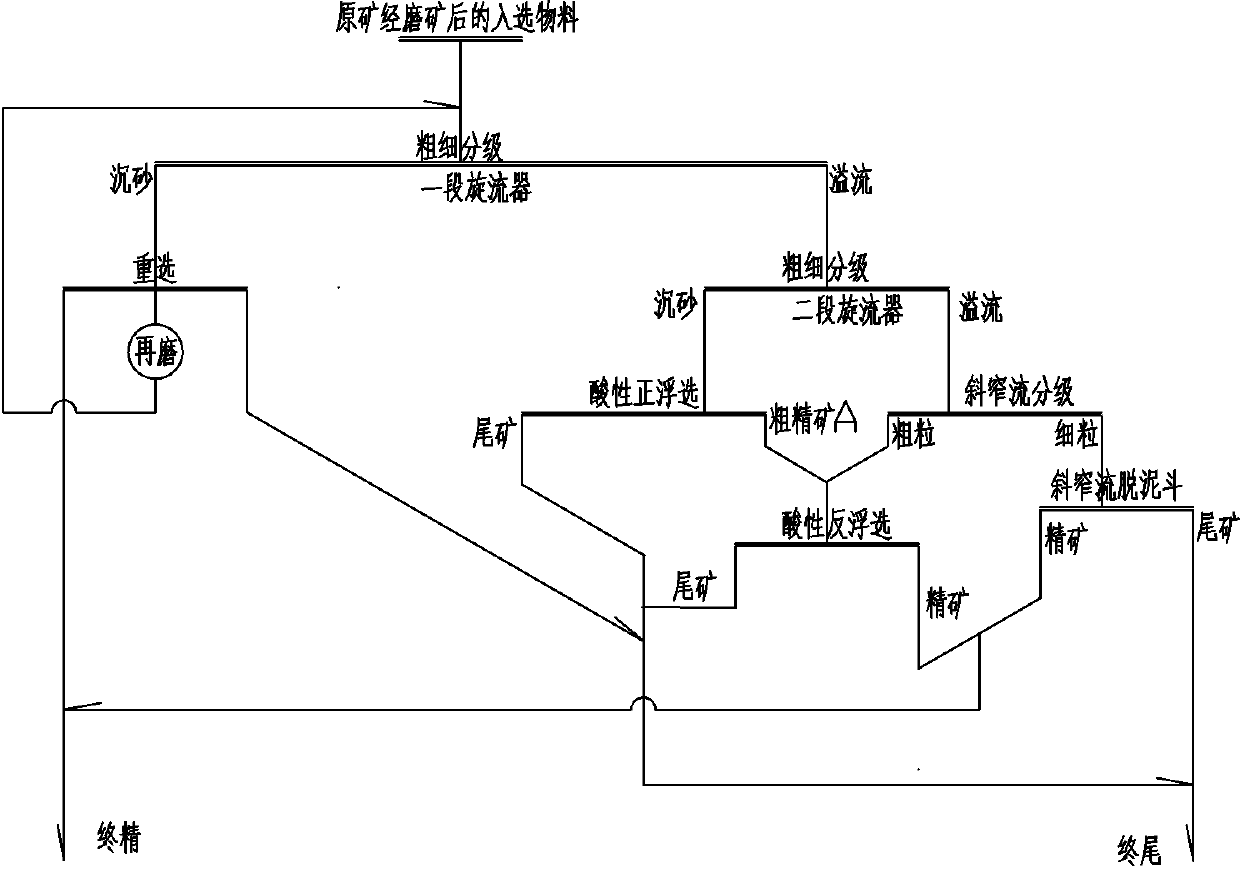

Flocculation desliming and acidic flotation method for iron carbonate ore fine-grained products

ActiveCN103464287AGood particle size composition conditionsIncrease dissociationDifferential sedimentationFlotationCycloneFlocculation

The invention relates to a flocculation desliming and acidic flotation method for iron carbonate ore fine-grained products. The flocculation desliming and acidic flotation method includes feeding selected materials of ground crude ores into a primary fineness classification cyclone to be subjected to classification operation, and is characterized in that settle sand of the primary fineness classification cyclone is graded in a gravity concentration procedure, split flow of the primary fineness classification cyclone is fed into a secondary fineness classification cyclone to be subjected to grading operation, settled sand of the secondary fineness classification cyclone is subjected to acidic direct flotation operation, spilt flow of the secondary fineness classification cyclone is fed into a titling narrow flowing classifier to be subjected to desliming classification operation, coarse-grained products, which have the desliming classification larger than 19 micrometers, of the tilting narrow flowing classifier and rough concentrates A which are obtained by means of acidic direct flotation are combined with one another and then are subjected to acidic reverse flotation grading operation, and concentrates and tailings which are obtained by means of acidic reverse flotation are graded by means of a rougher acidic reverse flotation process, a cleaner acidic reverse flotation process and two scavenging acidic reverse flotation processes. Owing to the processes, the flocculation desliming and acidic flotation method has the advantage that ore dressing technical indexes of the iron carbonate ore ground fine-grained products are greatly improved.

Owner:ANSTEEL GRP MINING CO LTD

A kind of manufacturing method of hematite powder pellet

The invention relates to a method for preparing hematite powder pellets. The method comprises the steps of proportioning, mixing, pelletizing and roasting, and is characterized in that: iron carbonate ore powder in weight ratio of 5-15 percent, which is subjected to damp-mill pretreatment, is added during proportioning of hematite powder and bentonite. The method comprises the following specific steps of: I, performing damp-mill pretreatment on the iron carbonate ore powder: filtering the iron carbonate ore powder with water content of not more than 8.5 percent or drying in a rotary drum dryer to keep the water content of the iron carbonate ore powder not more than 6.5 percent, and feeding the iron carbonate ore powder into a damp mill to perform the damp-mill pretreatment; II, proportioning: proportioning the iron carbonate ore powder, the hematite powder and the bentonite in the following percentage by weight: 5-15 percent of iron carbonate ore powder, 83.5-93 percent of hematite powder and 0.5-2 percent of bentonite; III, pelletizing: uniformly mixing the components, adding the components into a pan pelletizer and replenishing water for pelletizing to produce pellets; and IV, roasting: distributing and roasting on a chain grate machine-rotary kiln to obtain finished product pellets. The hematite powder pellets prepared by using the method disclosed by the invention has the advantages of low preheating combustion temperature and high strength.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for preparing red iron oxide with sludge produced in neodymium-iron-boron waste recovery

InactiveCN105293586AAchieve recyclingHigh puritySolid waste disposalFerric oxidesEcological environmentSludge

The invention discloses a method for preparing red iron oxide with sludge produced in neodymium-iron-boron waste recovery. According to the invention, a raw material which is a sludge waste produced during a neodymium-iron-boron waste recovery process is subjected to acid dissolution, oxidation, precipitation, filtration and firing, such that red iron oxide is obtained. According to the invention, the sludge is soaked for 1-4h with 10-35% hydrochloric acid under stirring and under a temperature of 40-80 DEG C, wherein a final pH value is controlled at 1-7; divalent iron is oxidized into trivalent iron with potassium chlorate, wherein a dose of potassium chlorate is 1-10% of the weight of dry sludge; the temperature is quickly increased to 50-100 DEG C by heating; ammonium bicarbonate is used for precipitation, wherein the addition amount of ammonium bicarbonate satisfies that the pH value of the solution reaches 7-14; and iron carbonate is fired in a firing kiln with a temperature of 200-800 DEG C. with the method provided by the invention, valuable elements can be completely recycled, mineral resources can be saved, ecological environment can be protected, and more importantly red iron oxide with extremely high purity can be recovered from waste sludge.

Owner:郭耀

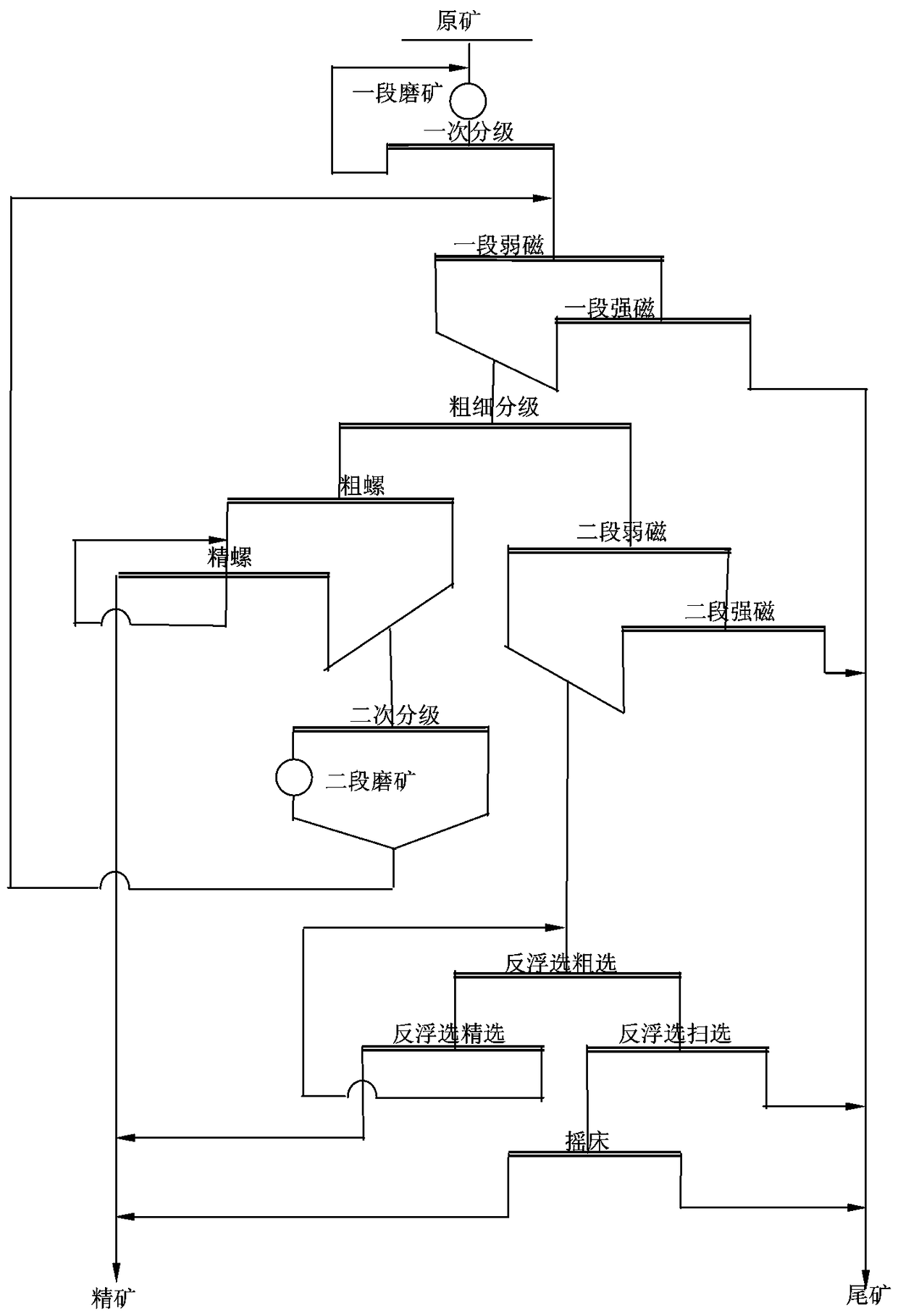

Separation technology for hematite containing iron carbonate

InactiveCN109201322AEnhanced strong magnetic coarse-grained tail throwingEnhanced tail throwGrain treatmentsWet separationSeparation technologyEngineering

The invention relates to a separation technology for hematite containing iron carbonate. The separation technology comprises the step that iron ores with the hematite distribution rate being higher than 40% are fed into first-stage closed circuit grinding operation. The separation technology is characterized by further comprises the steps of first-stage weak-magnetic and strong-magnetic operation,thickness grading operation, gravity separation operation, secondary-grading grinding operation, second-stage weak-magnetic and strong-magnetic operation and reverse flotation operation, wherein primary-grading overflow products and middling regrinding products are treated through first-stage weak-magnetic and strong-magnetic operation, first-stage weak-magnetic and strong-magnetic mixed concentrates are treated through thickness grading operation, coarse grain products subjected to thickness grading operation are treated through gravity separation operation, gravity separation operation tailings are treated through secondary-grading grinding operation, fine grain products subjected to thickness grading operation are treated through second-stage weak-magnetic and strong-magnetic operation, second-stage weak-magnetic and strong-magnetic mixed concentrates are treated through reverse flotation operation, and reverse flotation operation middlings are treated through table separation operation. The separation technology has the advantages that first-stage strong magnetic tailing discarding after rough grinding is enhanced, the middling circulation volume is decreased, the technological process is simplified, and the production cost is saved.

Owner:ANSTEEL GRP MINING CO LTD

Bad-flavor-free multifunctional electric power equipment casing rust-resisting paint preparation method thereof

InactiveCN104513587AImprove adhesionGood film formingAnti-corrosive paintsPolyether coatingsPolymer scienceAluminum silicate

The invention discloses a bad-flavor-free multifunctional electric power equipment casing rust-resisting paint characterized by comprising the following components by weight: 2-3 parts of polycaprolactone, 1-2 parts of sodium benzoate, 2-4 parts of iron carbonate, 0.2-0.3 part of vanillin, 6-9 parts of silicone acrylic emulsion, 4-6 parts of precipitated barium sulfate, 4-6 parts of mica iron oxide, 0.4-0.6 part of polyoxyethylated castor oil, 1-2 parts of zinc stearate, 1-2 parts of dibutyl phthalate, 32-37 parts of epoxy resin, 3-5 parts of aluminium silicate, 1-2 parts of crosslinking agent TAIC (triallyl isocyanurate), 22-26 parts of diphenyl oxide resin, 0.5-1.0 part of dodecencylsuccinic acid, 10-14 parts of xylene, 5-7 parts of butyl acetate and 4-7 parts of an additive; the bad-flavor-free multifunctional electric power equipment casing rust-resisting paint has high adhesion and good film forming effect, the paint film is flexible and hard, the added vanillin and silicone acrylic emulsion can improve paint bad flavor to make the flavor pleasant and easy to accept, the bad-flavor-free multifunctional electric power equipment casing rust-resisting paint has good water, rust and corrosion resistance and high aging resistance, the added additive also has the noise reduction effect to improve impact of noise produced by the work of electric power equipment on the people's physical and mental health.

Owner:BENGBU NANZI INSTR

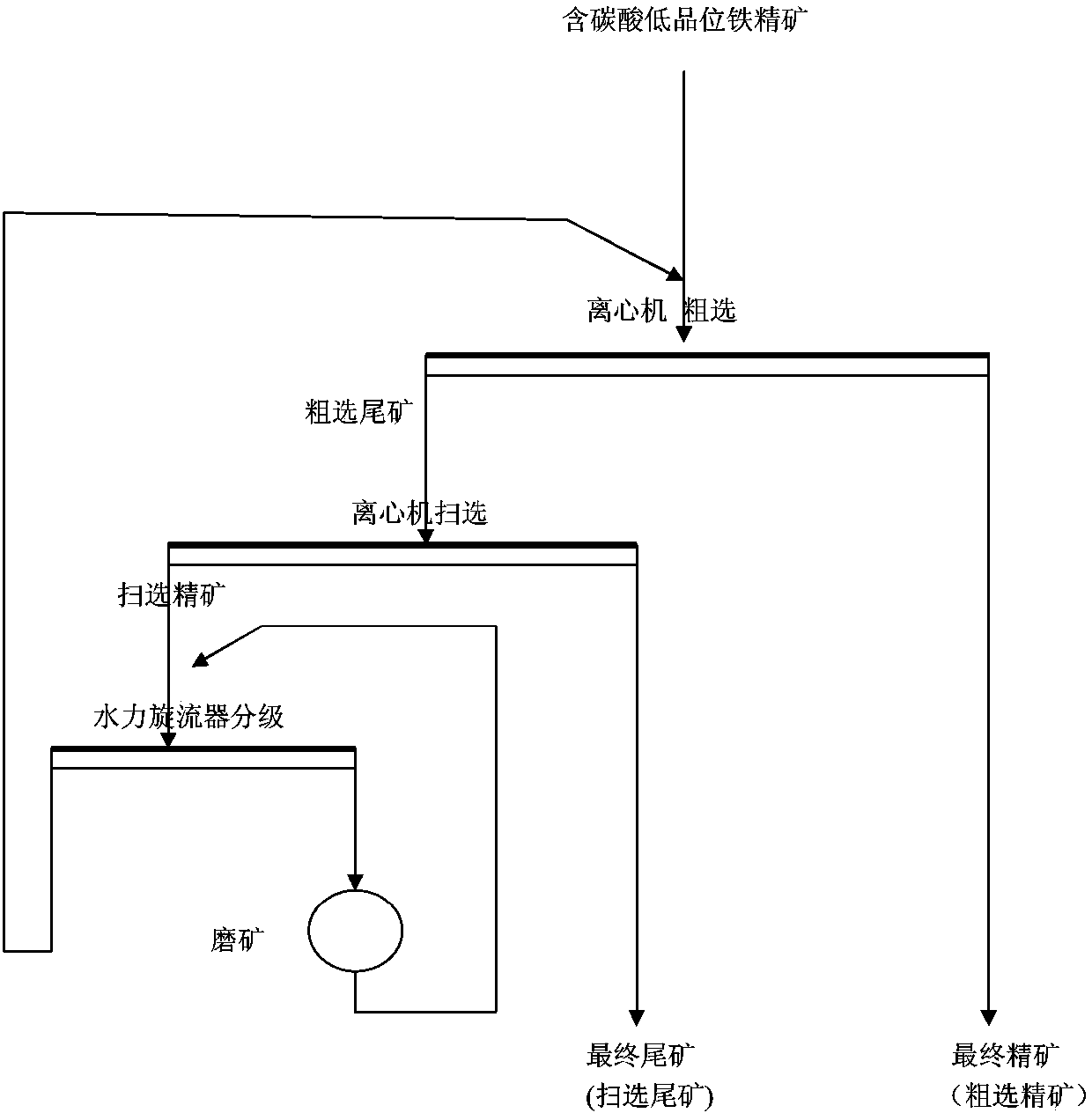

Process for sorting iron-carbonate-containing low-grade iron ore concentrate

The invention discloses a process for sorting iron-carbonate-containing low-grade iron ore concentrate. The process is characterized in that the iron-carbonate-containing low-grade iron ore concentrate is fed into a centrifugal machine for two sections of sorting work including roughing and scavenging and a section of grinding and grading work, so that grade of the iron ore concentrate is effectively increased and can reach above 67%, and the iron-carbonate-containing iron ore concentrate after sorting completely meets requirements of ironmaking production; the process adopting the centrifugal machine is free of environmental pollution and simple and easy to operate. The process has the advantages that the iron-carbonate-containing low-grade iron ore concentrate is fed into the centrifugal machine for the two sections of sorting work including roughing and scavenging and a section of grinding and grading work, so that the grade of the iron ore concentrate is effectively increased and can reach above 67%, a sorting index that metal recovery rate is 70% is realized, the iron-carbonate-containing iron ore concentrate after sorting completely meets the requirements of ironmaking production; the process adopting the centrifugal machine is free of environmental pollution and simple and easy to operate.

Owner:ANSTEEL GRP MINING CO LTD

Binder Compositions and Method of Synthesis

InactiveUS20160075603A1Improve reaction speedSlow kineticsSolid waste managementMixingSynthesis methodsSilicon dioxide

Some embodiments of the invention include a method of producing iron carbonate binder compositions including providing a plurality of binder precursors including a powdered iron or steel, a first powdered additive comprising silica, a second powdered additive including calcium carbonate, and a powdered clay. The method includes mixing the plurality of binder precursors and a water additive to form an uncured product, and feeding at least a portion of the uncured product into a curing chamber. The curing chamber is fluidly coupled to a CO2 source so that some CO2 from the CO2 source reacts with the uncured product to form a cured iron carbonate containing product and at least one reaction byproduct, where at least some byproduct can be fed from the curing chamber to the CO2 source for use as a fuel by the CO2 source.

Owner:ARIZONA STATE UNIVERSITY

Two-step desulfurization technology of coal burning process

InactiveCN105381707AGood for desulfurization purposesLower combustion temperatureGas treatmentDispersed particle separationSlagPotassium

The invention discloses a two-step desulfurization technology of the coal burning process. The technology comprises the following steps that S1, pulverized coal is mixed with a desulfurizing agent A to prepare desulfurized coal A, and the desulfurized coal A is sprayed into a boiler to be burnt, wherein the desulfurized coal A is prepared by mixing coal slags, calcium oxide, calcium hydroxide and aluminum oxide according to proportions; S2, pulverized coal is mixed with a desulfurizing agent B to prepare desulfurized coal B, and then the desulfurized coal B is sprayed into a main burning zone of the boiler through a material spray pipe, wherein the material spray pipe and a secondary air pipe are arranged in a crossed mode, the desulfurizing agent B is prepared by mixing aluminum sulfate, sodium carbonate, potassium chloride, iron carbonate, vanadium pentoxide and zinc borate according to proportions, the desulfurizing agent B is added to water and mixed to be prepared into mixed suspension with the mass percent of 12%-20%, the mixed suspension is mixed with the pulverized coal, standing is conducted till the water content ranges from 3% to 5%, and the desulfurized coal B is prepared. According to the two-step desulfurization technology of the coal burning process, the desulfurizing agents are added in a segmented mode, the effect of calcium-based desulfuration agents is fully exerted, and the desulfurization efficiency is greatly improved.

Owner:GUANGXI KUONENGBA ENERGY TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com