A sulfur and selenium compound composite array preparation method

A selenium compound and composite array technology, applied in the field of solar cells, can solve problems such as complicated process, unsatisfactory product performance, and harsh conditions, and achieve broad application prospects, good electrochemical characteristics, catalytic performance, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Dissolve 5mmol of cobalt nitrate in 50mL of distilled water, then add 10mmol of ammonium fluoride and 25mmol of urea, stir the solution evenly and transfer it to a reaction kettle with a conductive glass (FTO) sheet in the reaction kettle , then hydrothermally reacted at 120°C for 5h and then cooled to room temperature to obtain a conductive glass (FTO) sheet covered with basic cobalt carbonate;

[0018] (2) Add selenium powder and sulfur powder to solvent water and pass nitrogen gas (the molar ratio of selenium powder and sulfur powder is 1:2, the total molar weight of selenium powder and sulfur powder is 10mmol), and then add sodium borohydride (22mmol) solution, then add the conductive glass (FTO) sheet covered with basic cobalt carbonate obtained in step (1), continue to pass in nitrogen gas, take out the conductive glass sheet after soaking for 10h and clean it to obtain a composite array of sulfur-selenide compounds .

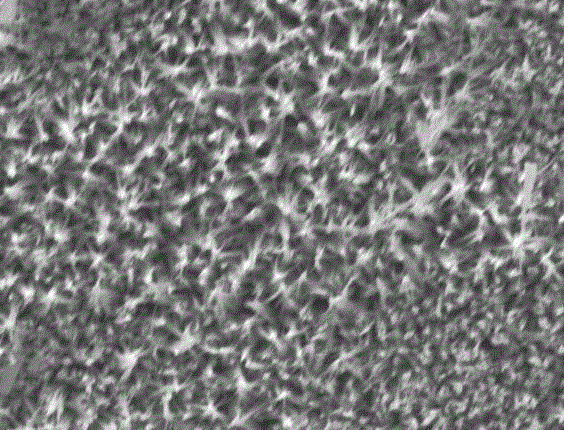

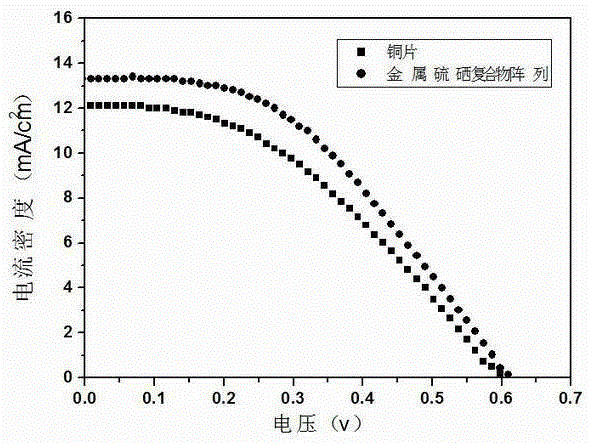

[0019] figure 1 The scanning electron ...

Embodiment 2

[0022] (1) Dissolve 5mmol of cobalt nitrate in 50mL of distilled water, then add 10mmol of ammonium fluoride and 25mmol of urea, stir the solution evenly and transfer it to a reaction kettle with a conductive glass (FTO) sheet in the reaction kettle , then hydrothermally reacted at 120°C for 5h and then cooled to room temperature to obtain a conductive glass (FTO) sheet covered with basic cobalt carbonate;

[0023] (2) Add selenium powder and sulfur powder to solvent ethanol and pass nitrogen gas (the molar ratio of selenium powder to sulfur powder is 1:1, the total molar weight of selenium powder and sulfur powder is 8mmol), and then add hydroboration Sodium (16mmol) solution, then add the conductive glass (FTO) sheet covered with basic cobalt carbonate obtained in step (1), continue to pass in nitrogen gas, take out the conductive glass sheet after soaking for 12 hours and clean it to obtain a sulfur-selenium compound compound array.

Embodiment 3

[0025] (1) Dissolve 5mmol of ferric nitrate in 50mL of distilled water, then add 10mmol of ammonium fluoride and 25mmol of urea, stir the solution evenly and transfer it to a reaction kettle with a conductive glass (FTO) sheet in the reaction kettle , then hydrothermally reacted at 120°C for 5h and then cooled to room temperature to obtain a conductive glass (FTO) sheet covered with basic iron carbonate;

[0026] (2) Add selenium powder and sulfur powder to the mixed solution of solvent water and ethanol and pass through argon gas (the molar ratio of selenium powder and sulfur powder is 1:2, and the total molar weight of selenium powder and sulfur powder is 10mmol ), then add sodium borohydride (20mmol) solution, and then add the conductive glass (FTO) sheet covered with basic iron carbonate obtained in step (1), continue to pass in argon gas, soak for 12h and take out the conductive glass sheet for cleaning After cleaning, a composite array of sulfur-selenium compounds is obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com