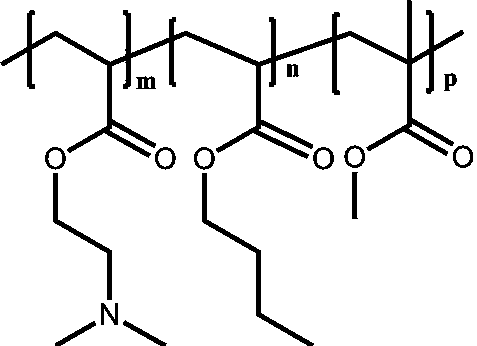

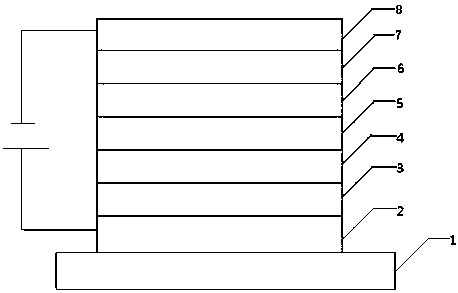

Acrylate copolymer-modified metal oxide, QLED and preparation method

A technology of acrylate and copolymer, which is applied in the field of light-emitting diodes, can solve the problems of structural defects of electron transport materials, low transport and light transmittance of electron transport layers, etc., to improve electron transport capacity, surface potential and dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

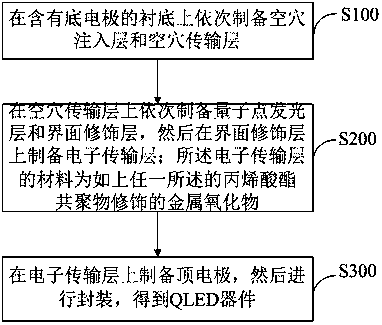

[0059] The preparation steps of the zinc oxide nanoparticle dispersion liquid modified by acrylate copolymer are as follows:

[0060] (1) Use ethylene glycol monomethyl ether as solvent to prepare 10ml of 30mg / ml zinc acetate solution and 2ml of 200mg / ml tetramethylammonium hydroxide solution respectively. Use xylene as a solvent to prepare a 50mg / ml acrylate copolymer solution;

[0061] (2) Heat the zinc acetate solution described in (1) to 80°C, stir it with a magnet at a speed of 1500 rpm to fully dissolve it, and then pour the prepared tetramethylammonium hydroxide solution at a uniform speed Inject into the zinc acetate solution, keep stirring for several minutes, add 10mL of the acrylate copolymer solution described in (1), keep the temperature at 60°C, and stir for 1h to obtain a mixed solution;

[0062] (3) Add methanol solution to the mixture to purify the acrylate copolymer-modified zinc oxide nanoparticles, take the mixture and centrifuge (8000 rpm, 5 min), remove ...

Embodiment 2

[0073] First prepare the zinc oxide nanoparticle precipitation of acrylate copolymer modification according to the same method as in Example 1, then use octadecane solution to redisperse the zinc oxide nanoparticle modification of acrylate copolymer to obtain a final concentration of about 3mg / ml Acrylate Copolymer Modified Zinc Oxide Nanoparticle Dispersion.

[0074] Prepare the QLED device according to the method of Example 1, the difference is that the vacuum-evaporated hole transport layer and the vacuum-evaporated quantum dot light-emitting layer are used: the triphenylamine compound 4,4'-di-(N-naphthyl-N -Phenylamino)biphenyl (NPB) as the hole transport layer, using a vacuum coating machine at 3×10 -4 The NPB film layer was vacuum thermally evaporated at a vacuum degree of Pa with a thickness of 30 nm. Using vacuum coating machine in 3×10 -4 The quantum dot light-emitting layer was vapor-deposited on the hole transport layer at a vacuum degree of Pa.

[0075] In summa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com