A kind of piezoelectric antibacterial nano film air filter membrane and preparation method thereof

A nano-film and air filtration technology, applied in the field of air purification, can solve problems such as affecting the commercial application of nanofiber dust-proof and resisting protection, affecting the filtration efficiency, maintenance cost, and increasing the operating cost of the filter membrane. Toughness, filtration effect Long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be further described in detail below.

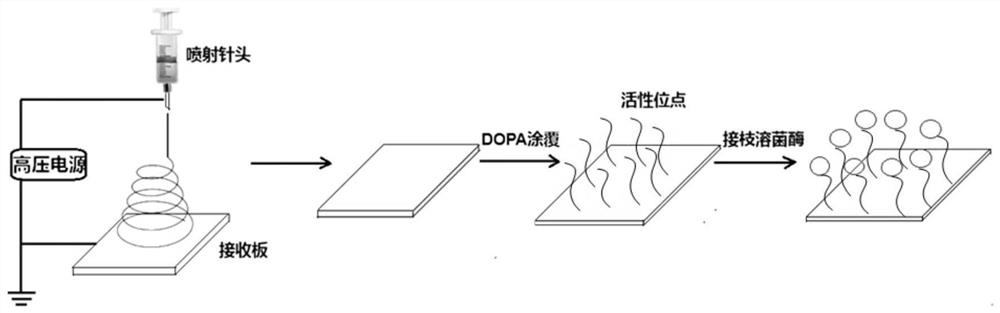

[0039] A piezoelectric antibacterial nano film air filter membrane, such as figure 1 As shown, it is prepared by the following steps:

[0040] In step S1, a certain mass of PVDF particles was first dissolved in a DMF / acetone mixed solvent with a volume ratio of 7 / 3, stirred in an oil bath at 80°C for 2 hours, and then placed in an ultrasonic oscillator until a uniform and transparent solution was formed. The mass percent content of PVDF in the PVDF solution is 15-25%.

[0041] Step S2, placing a layer of filter cloth on the receiving plate as a supporting material. Inject the PVDF solution into the needle, adjust the injection speed to 0.5ml / h, and adjust the voltage until 10kv, and you can see a continuous and stable jet sprayed from the needle and landed on the receiving plate. Take off a PVDF electrospun fiber membrane every 3 hours, and put the product into a vacuum ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com