Patents

Literature

422 results about "Electrospun fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle filter system incorporating nanofibers

ActiveUS20080110342A1Electric discharge heatingFilament/thread formingElectric field modulationFiber

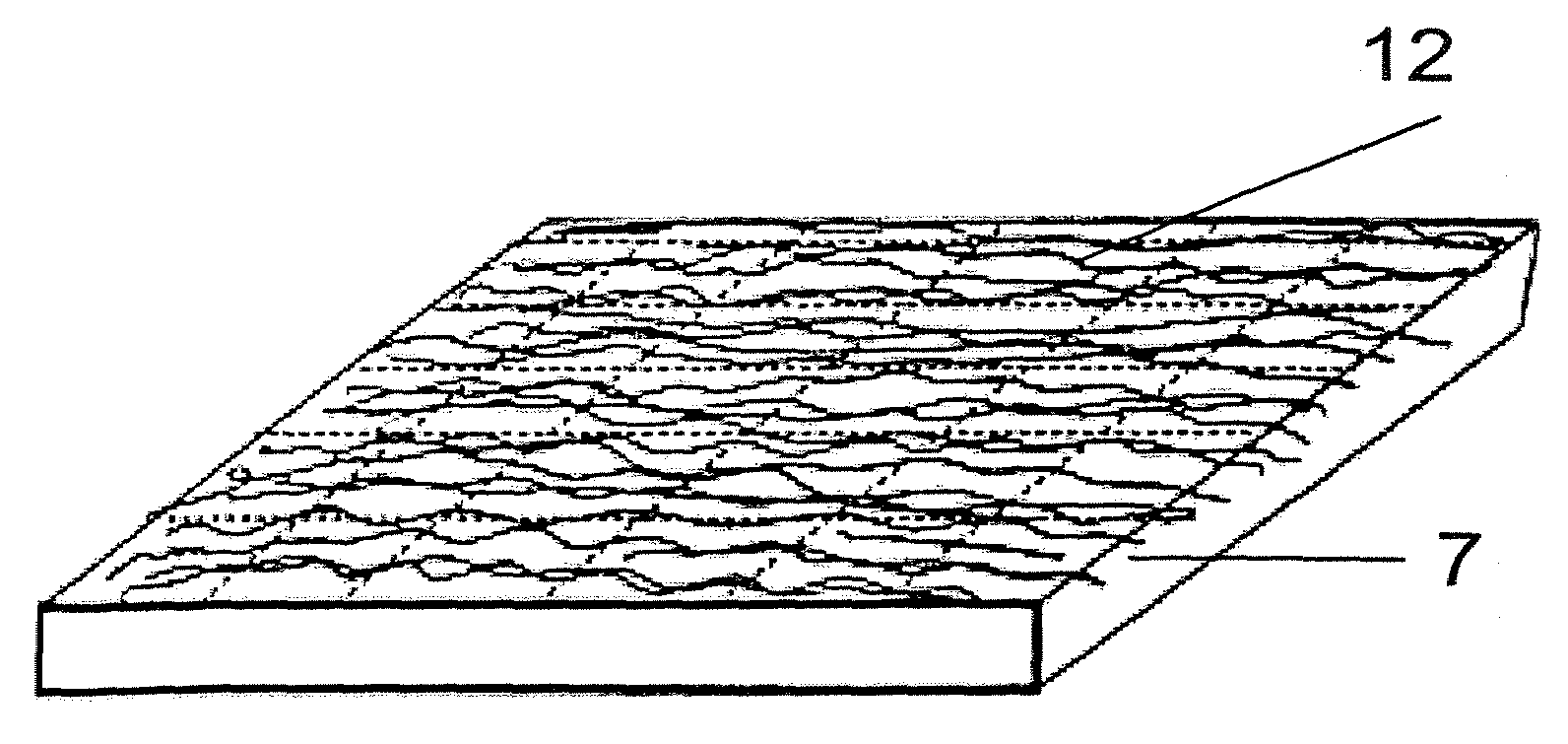

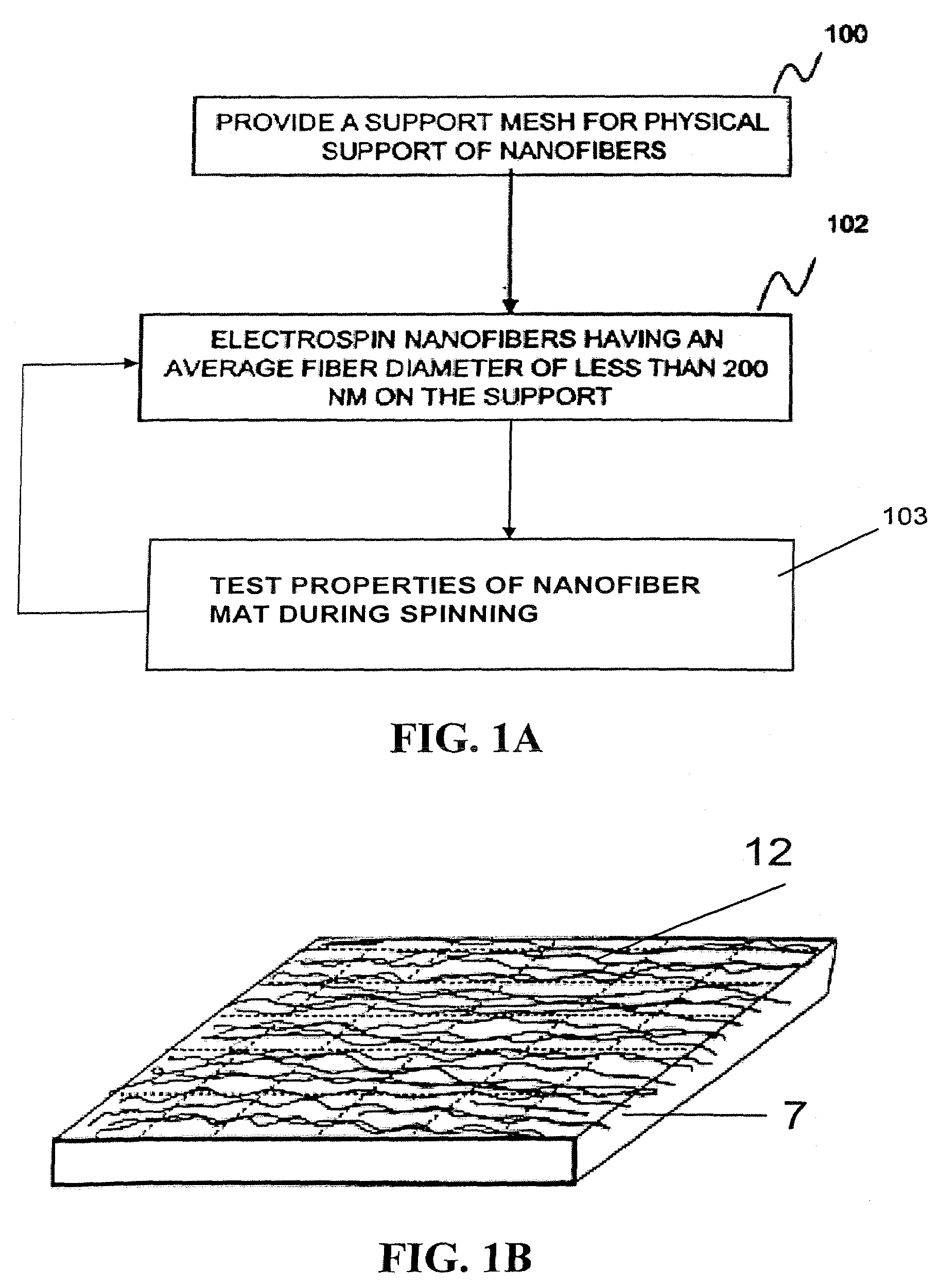

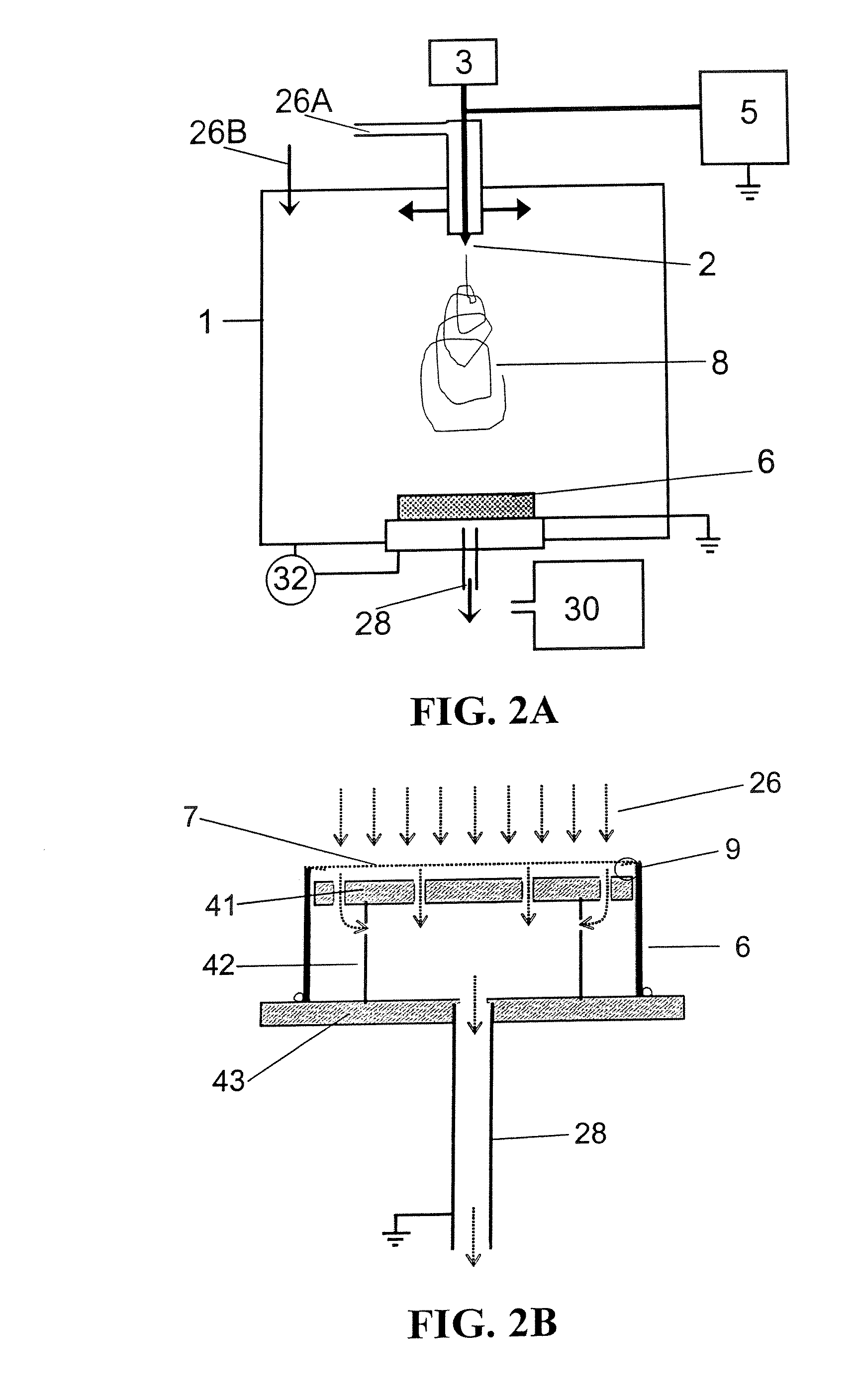

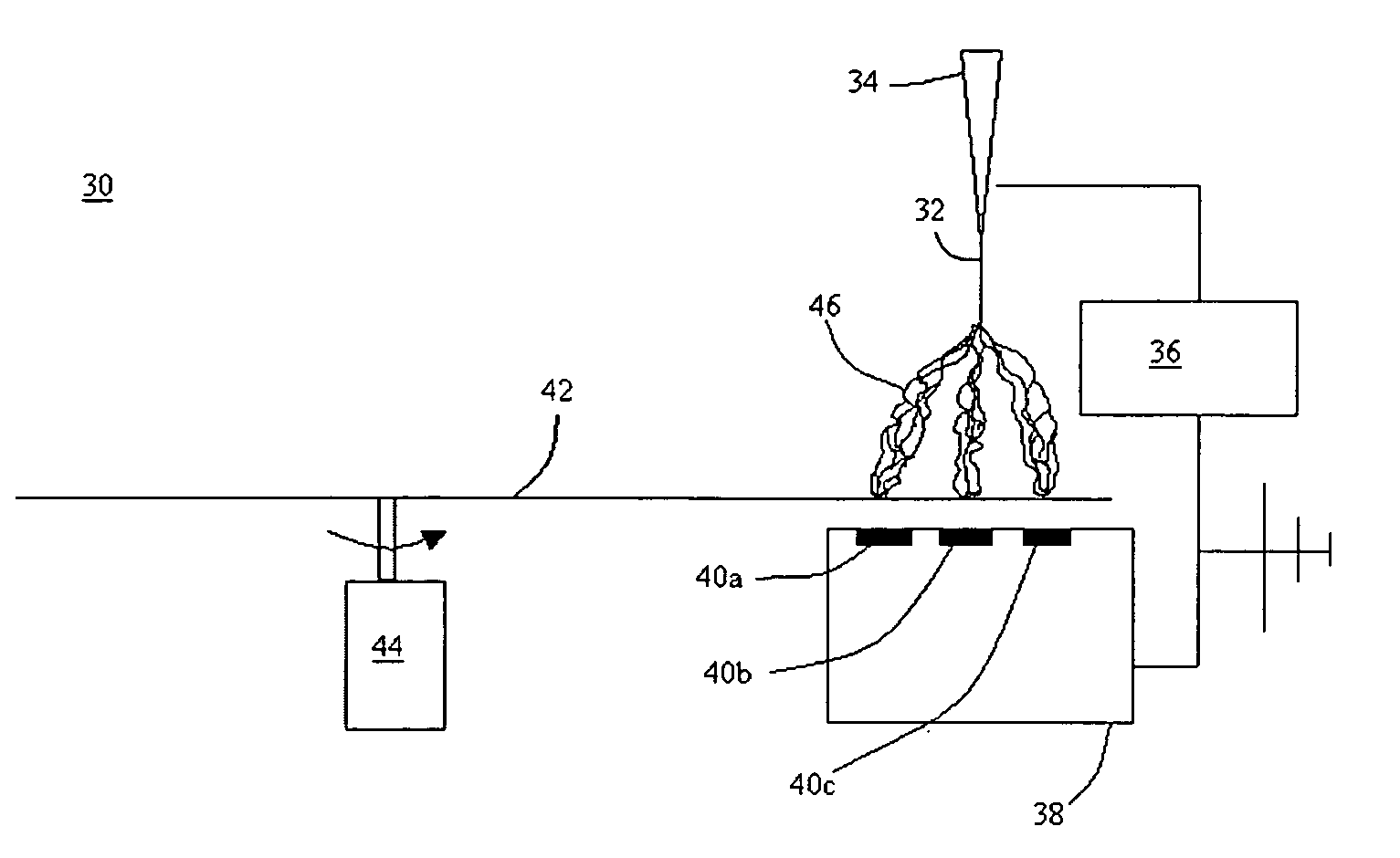

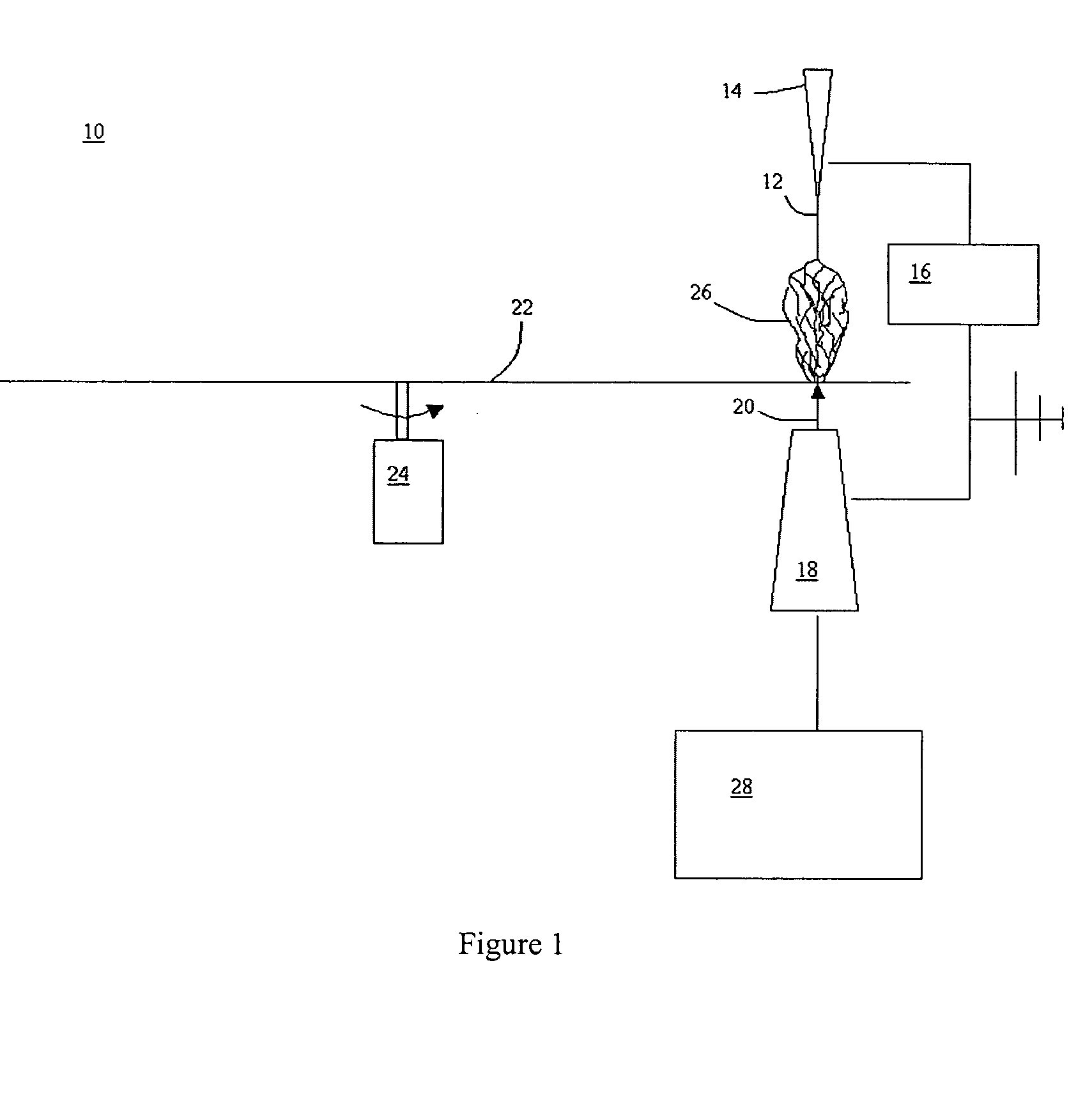

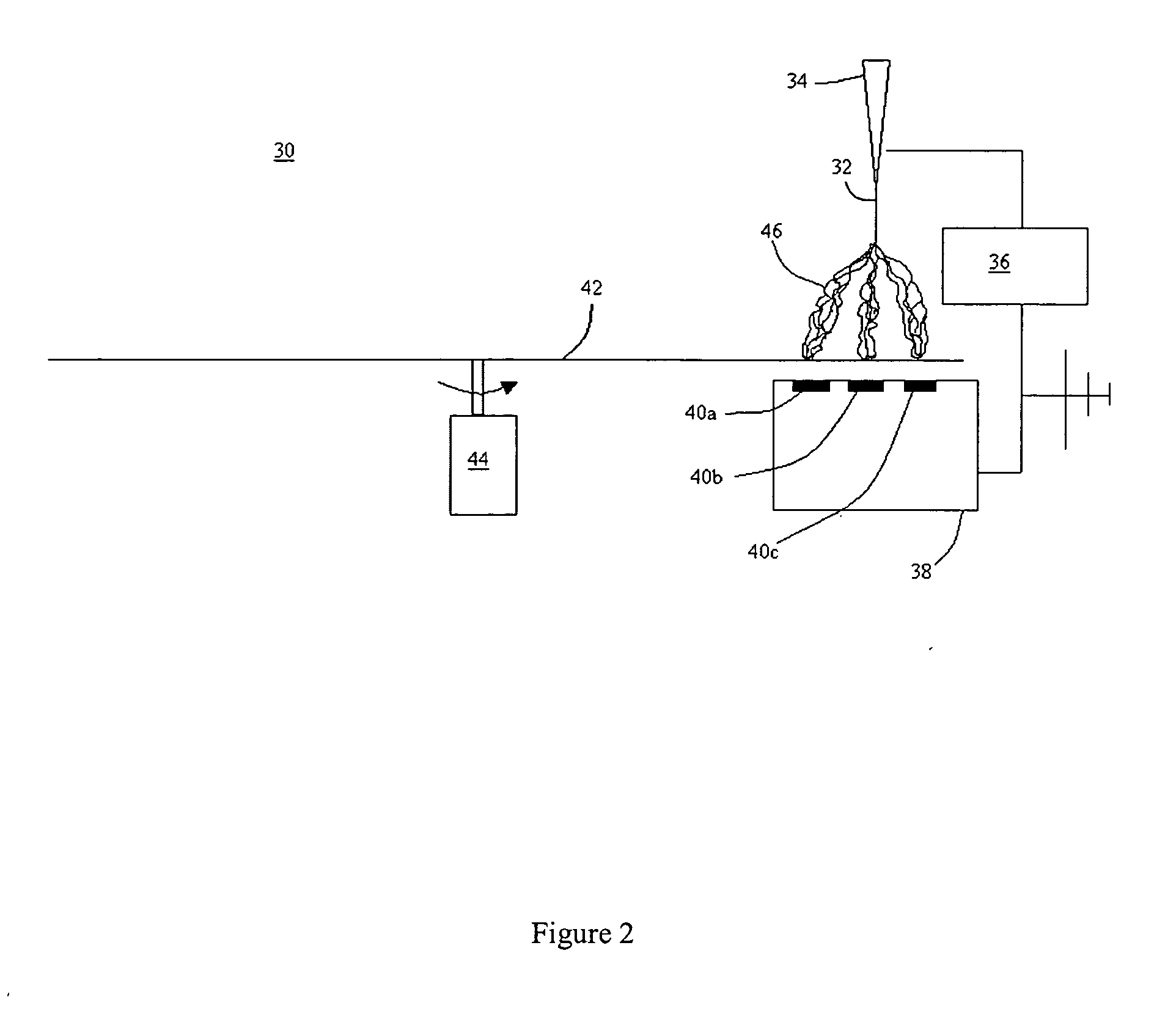

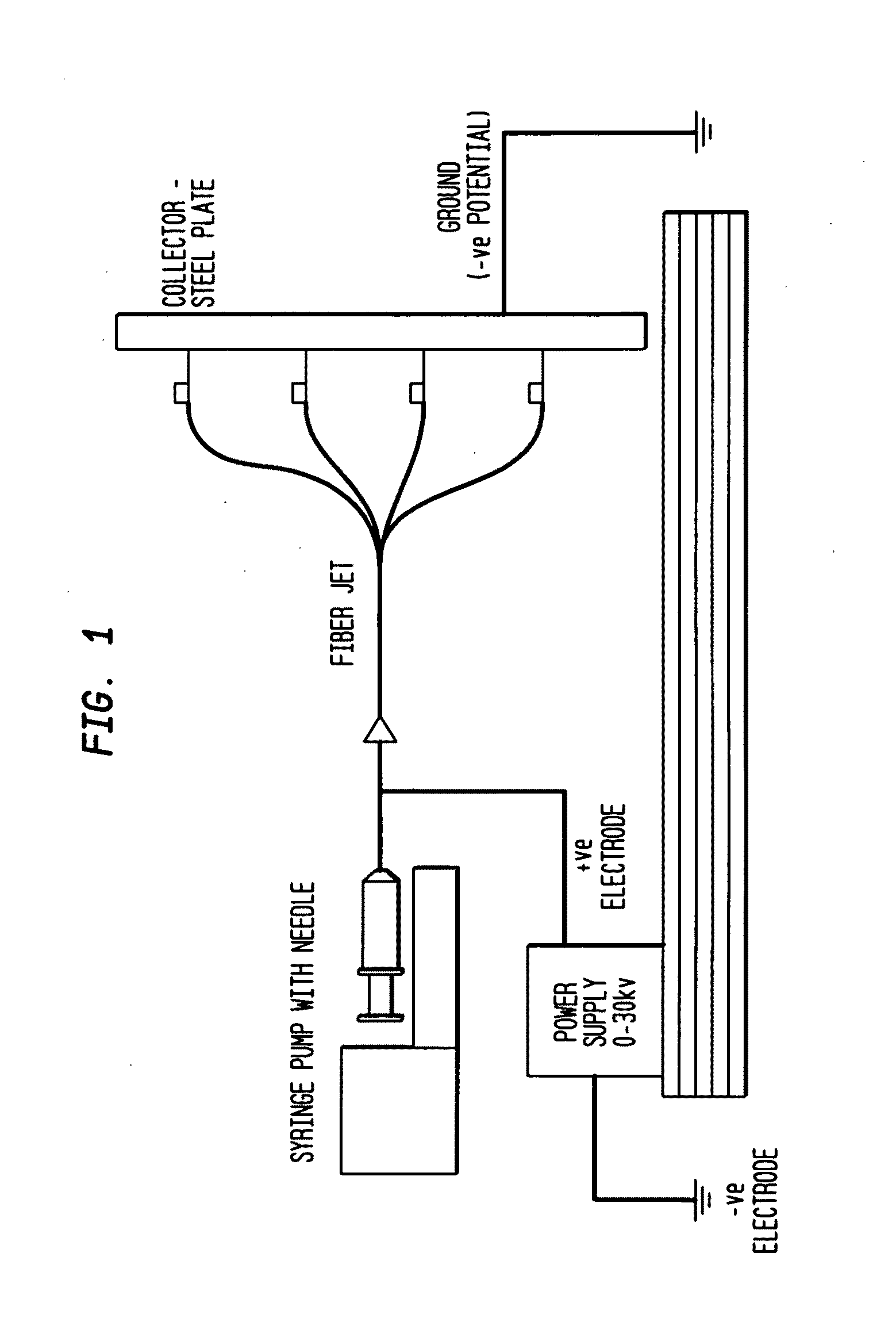

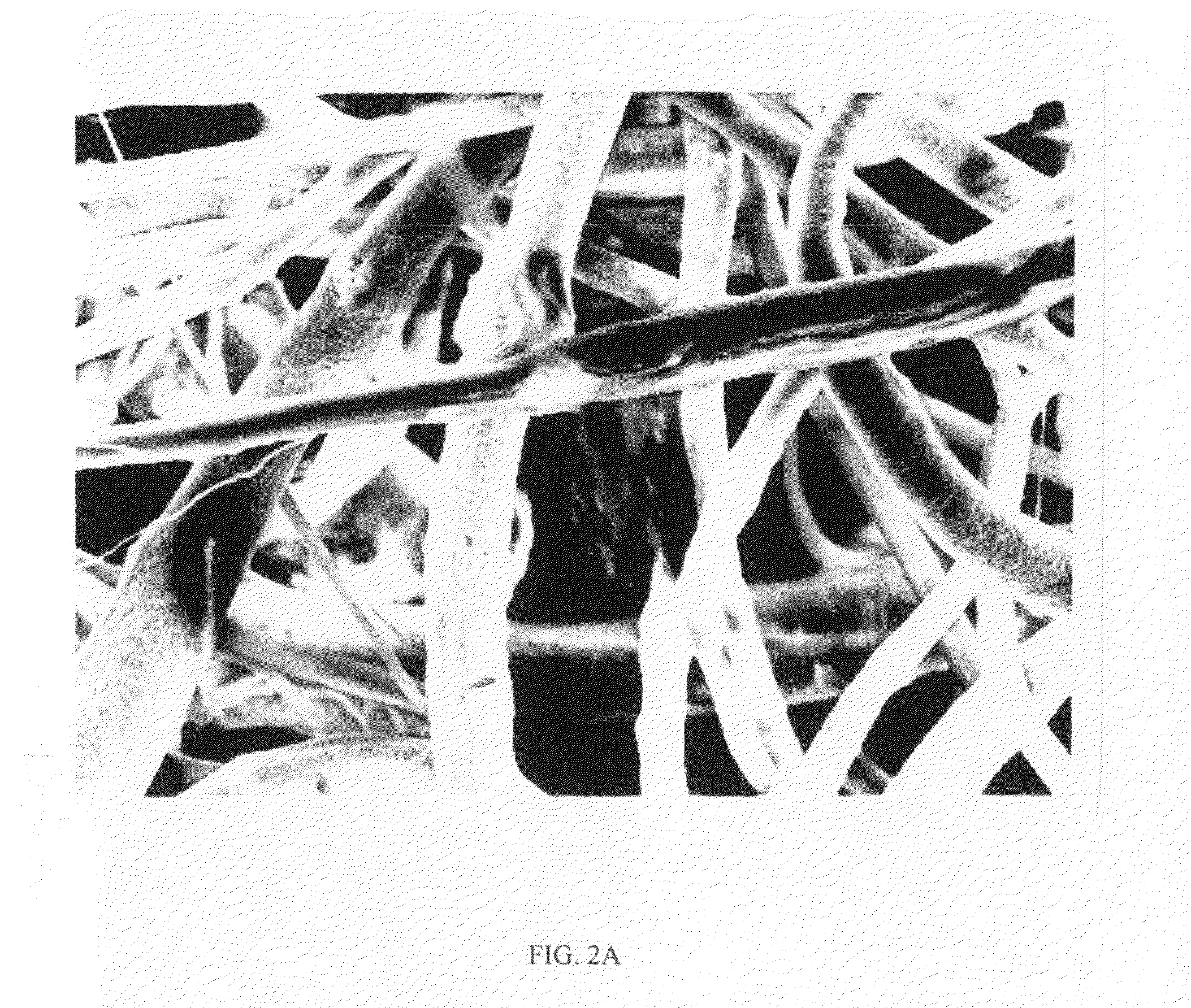

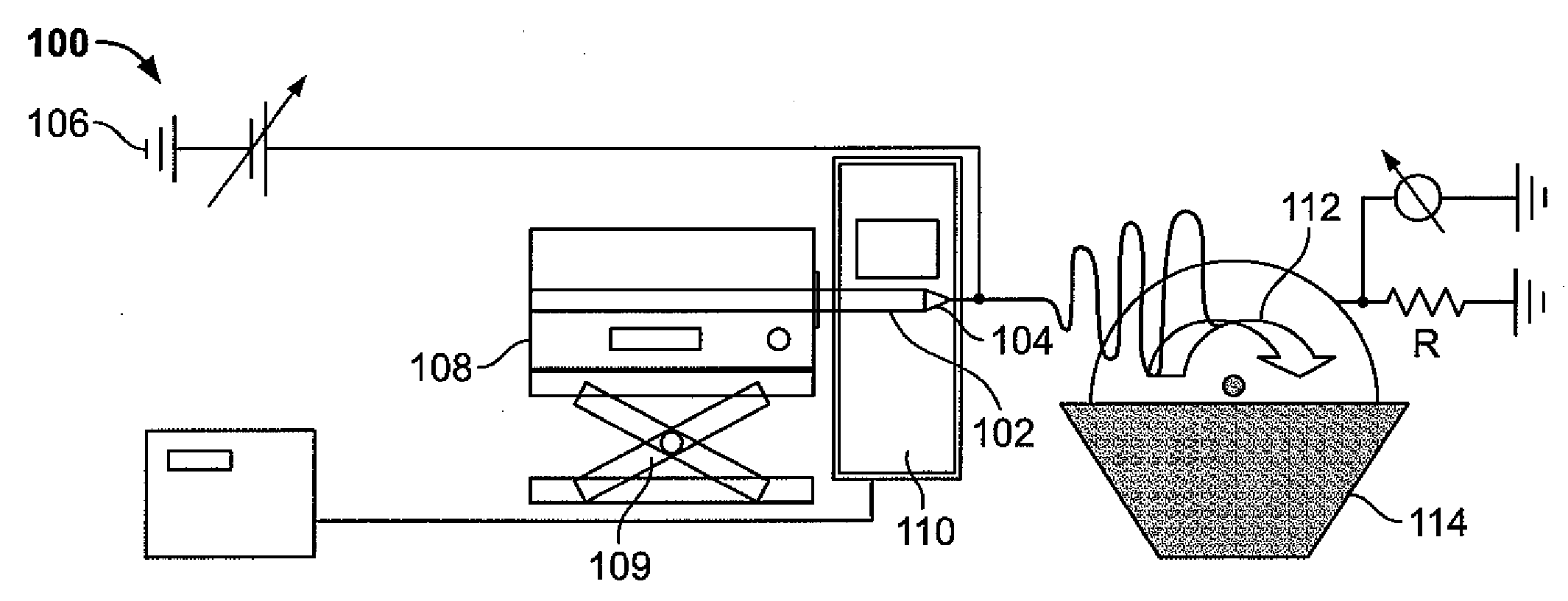

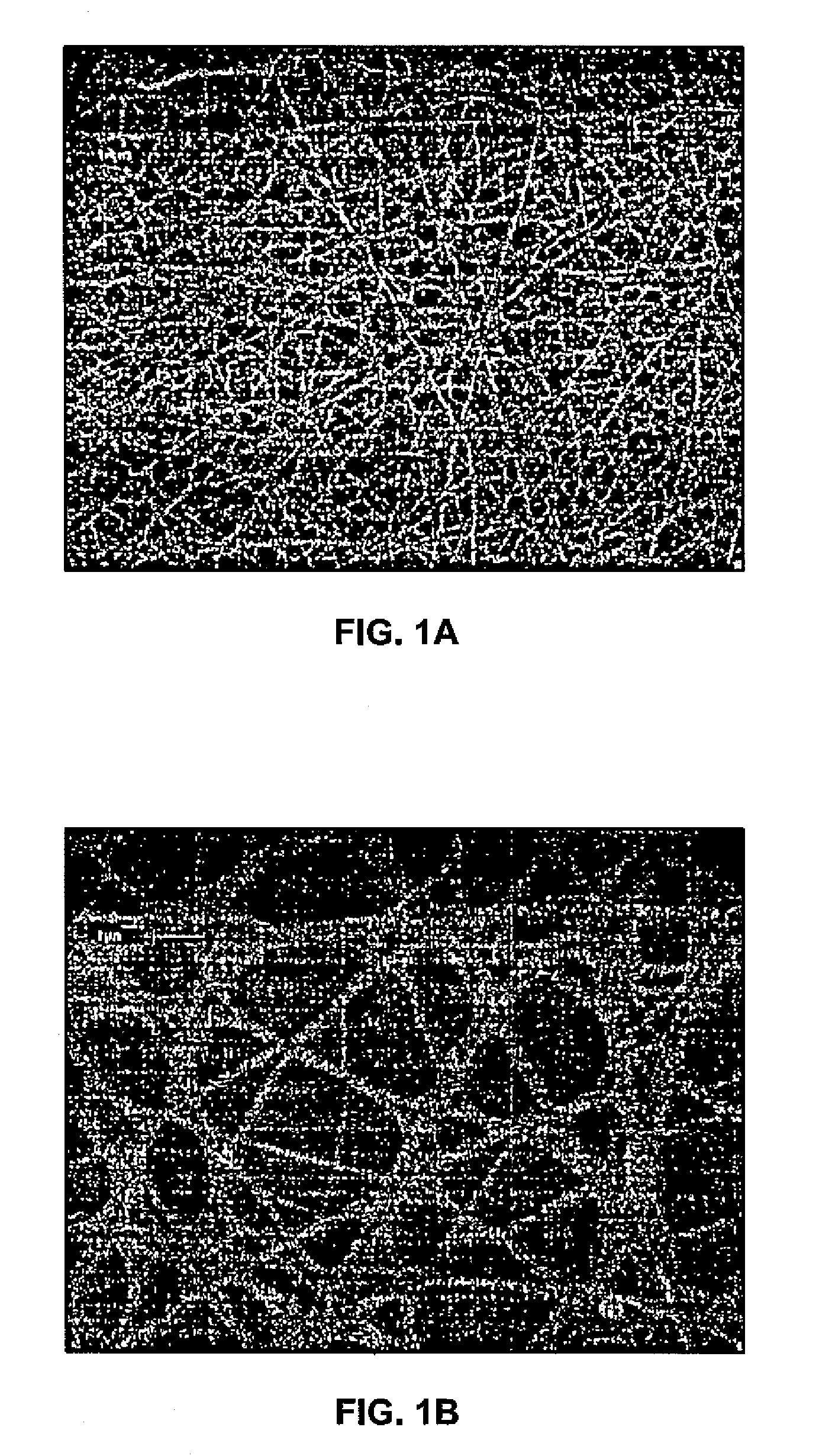

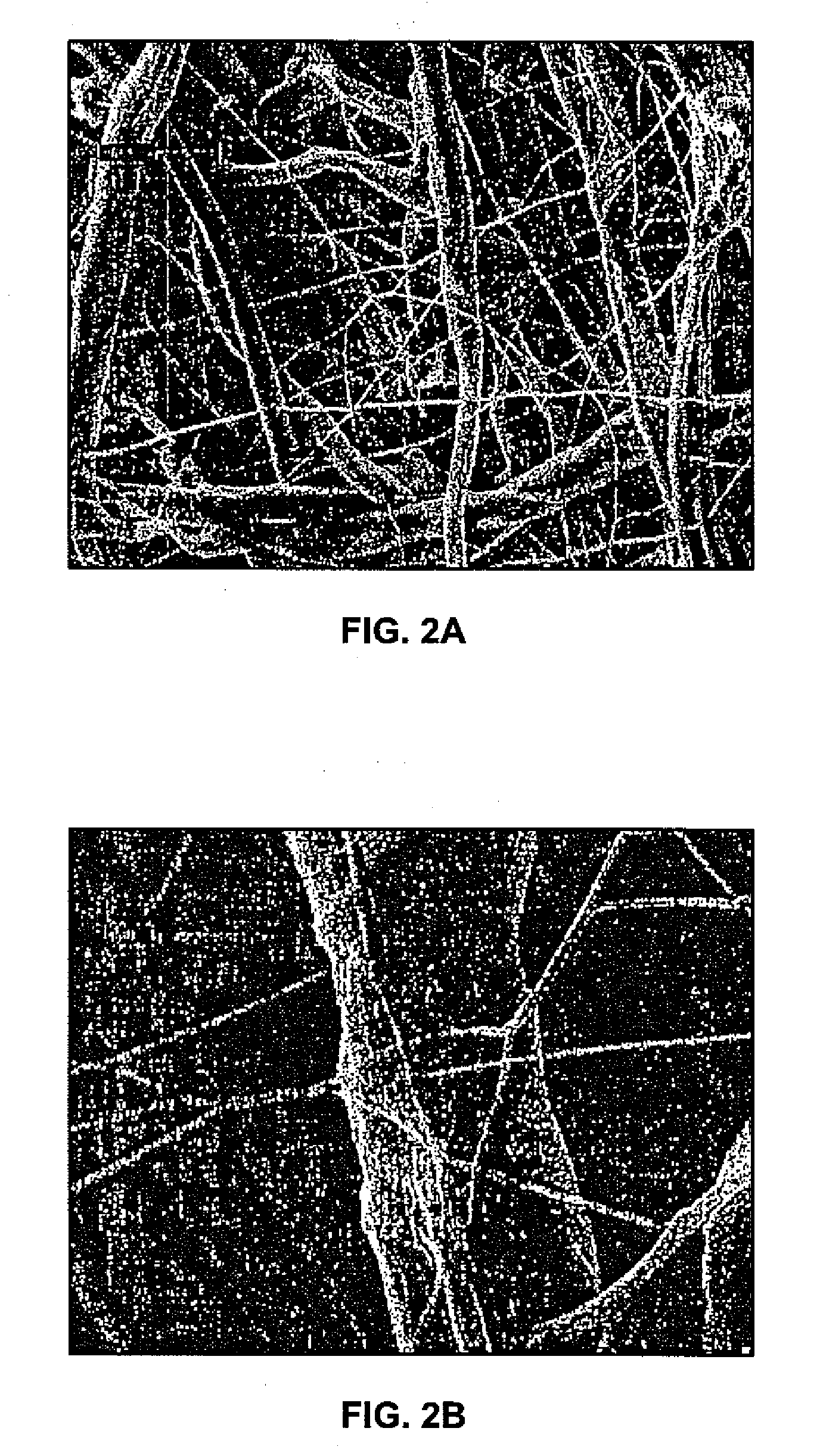

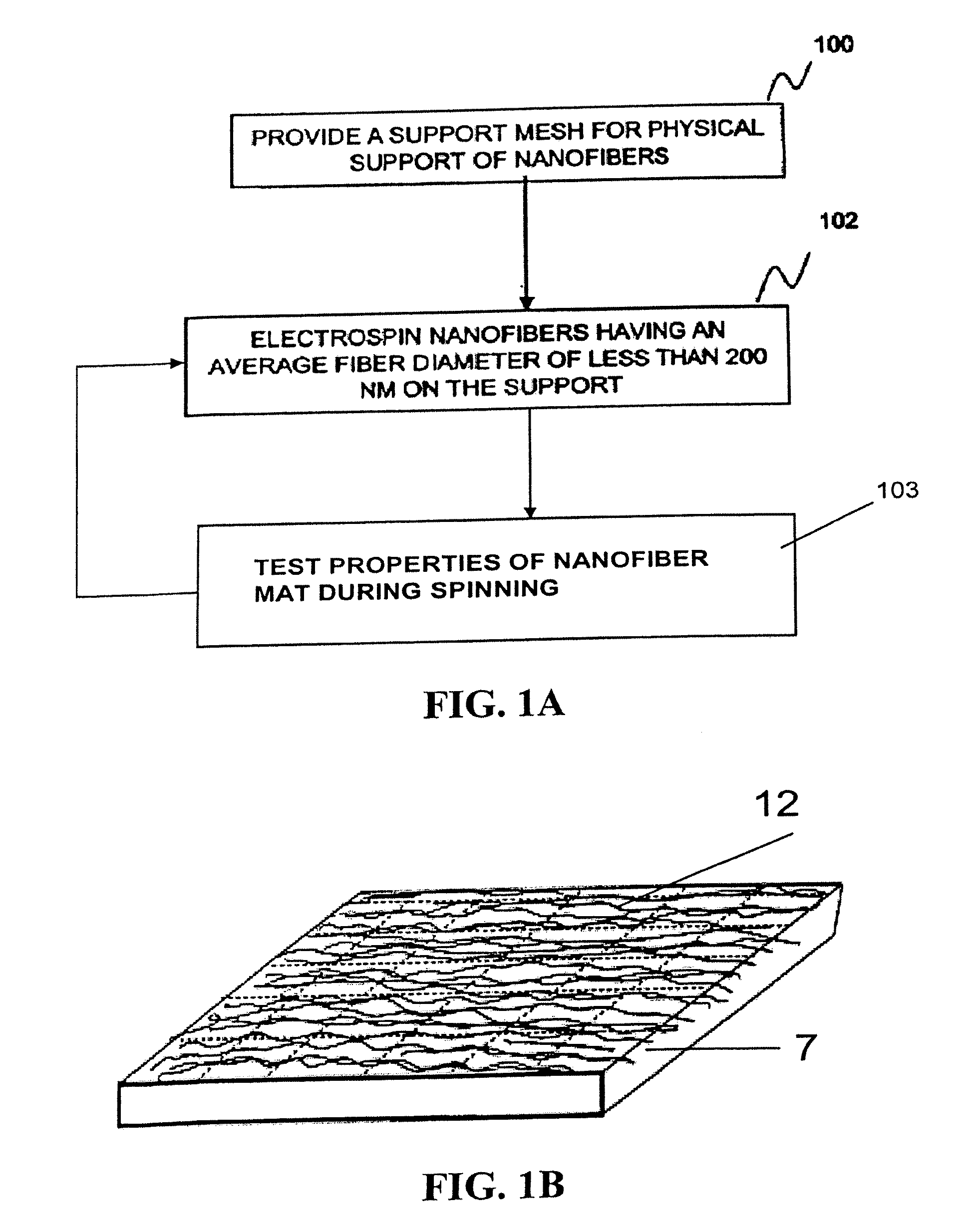

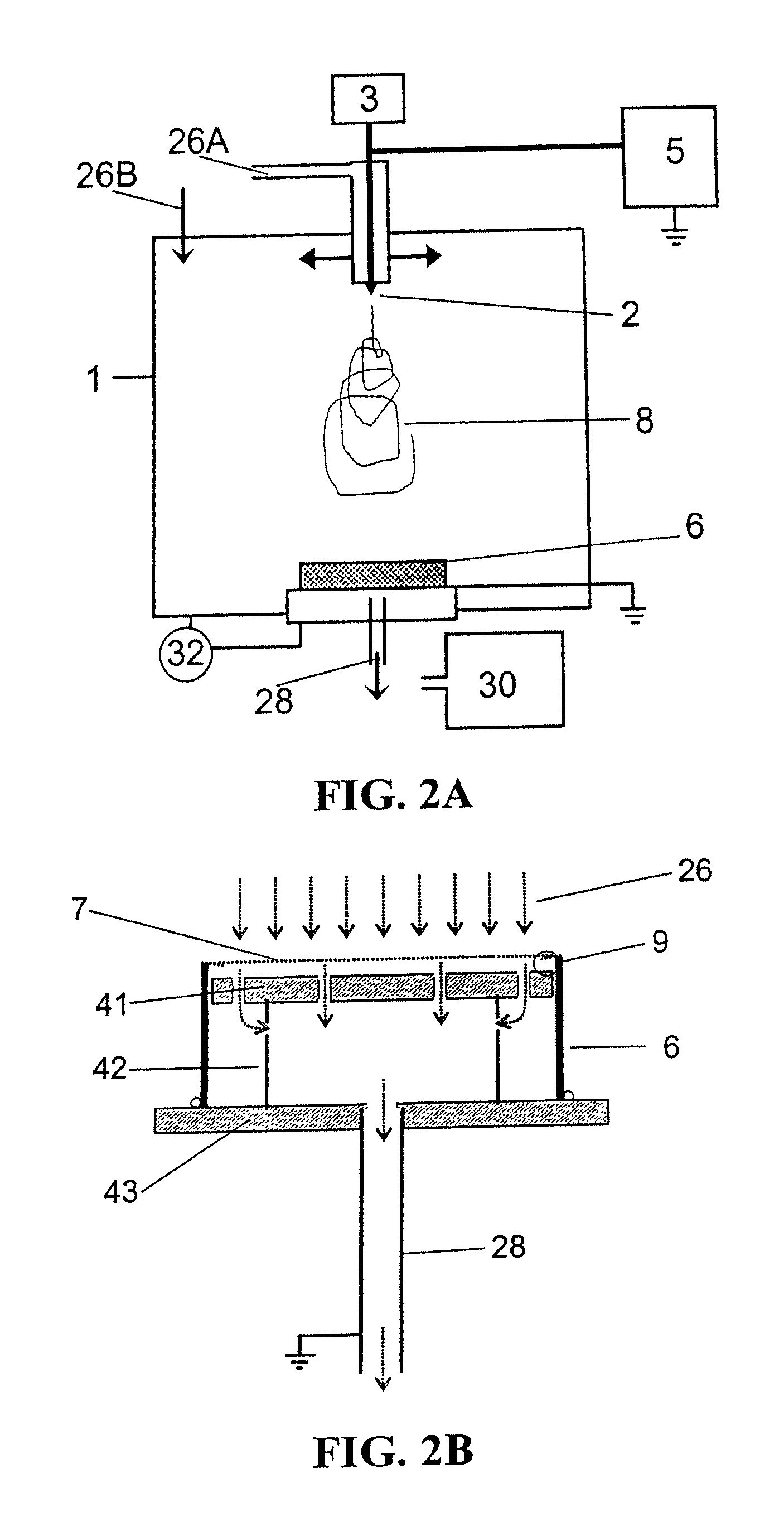

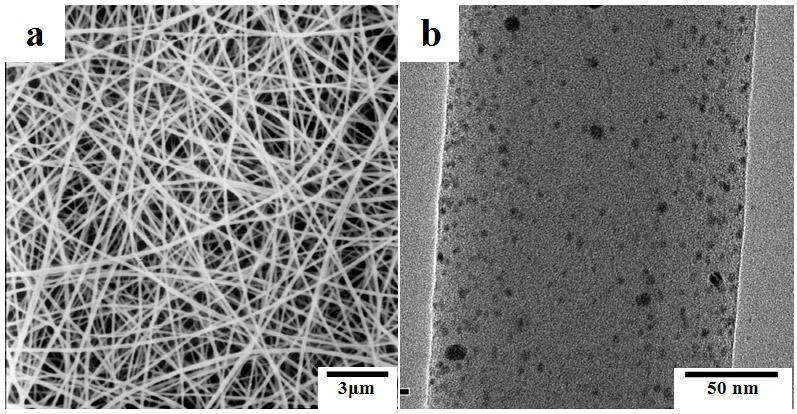

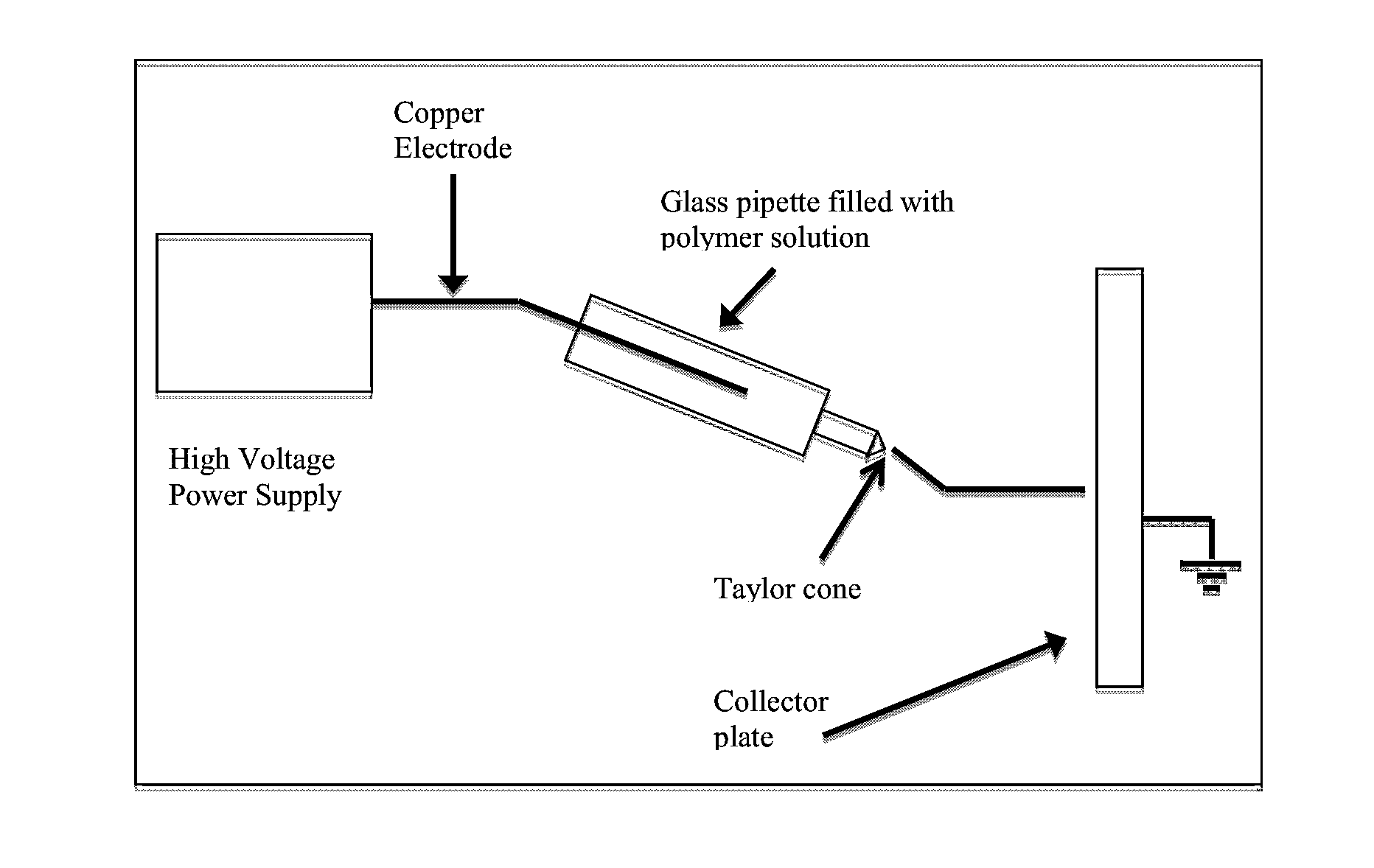

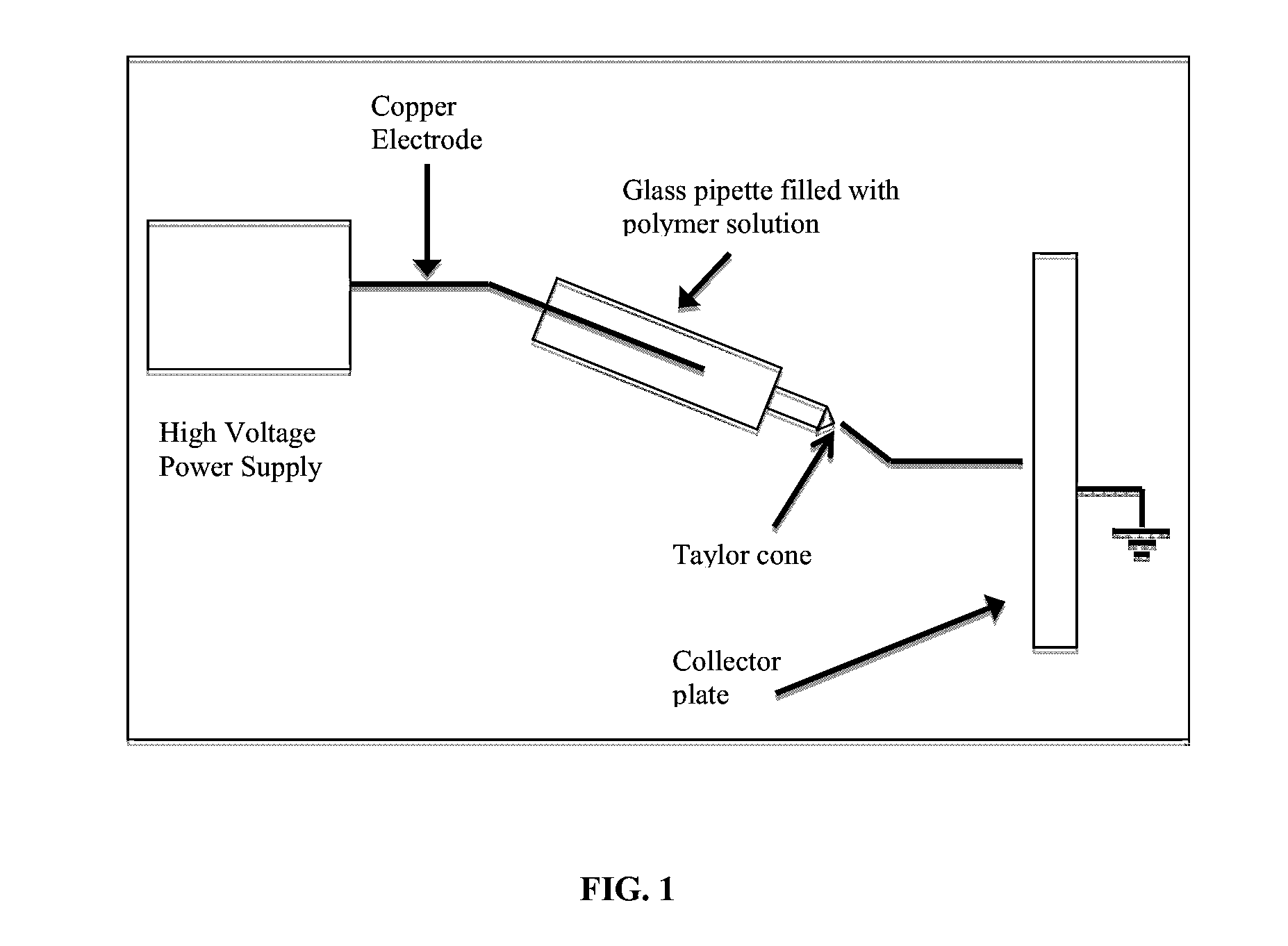

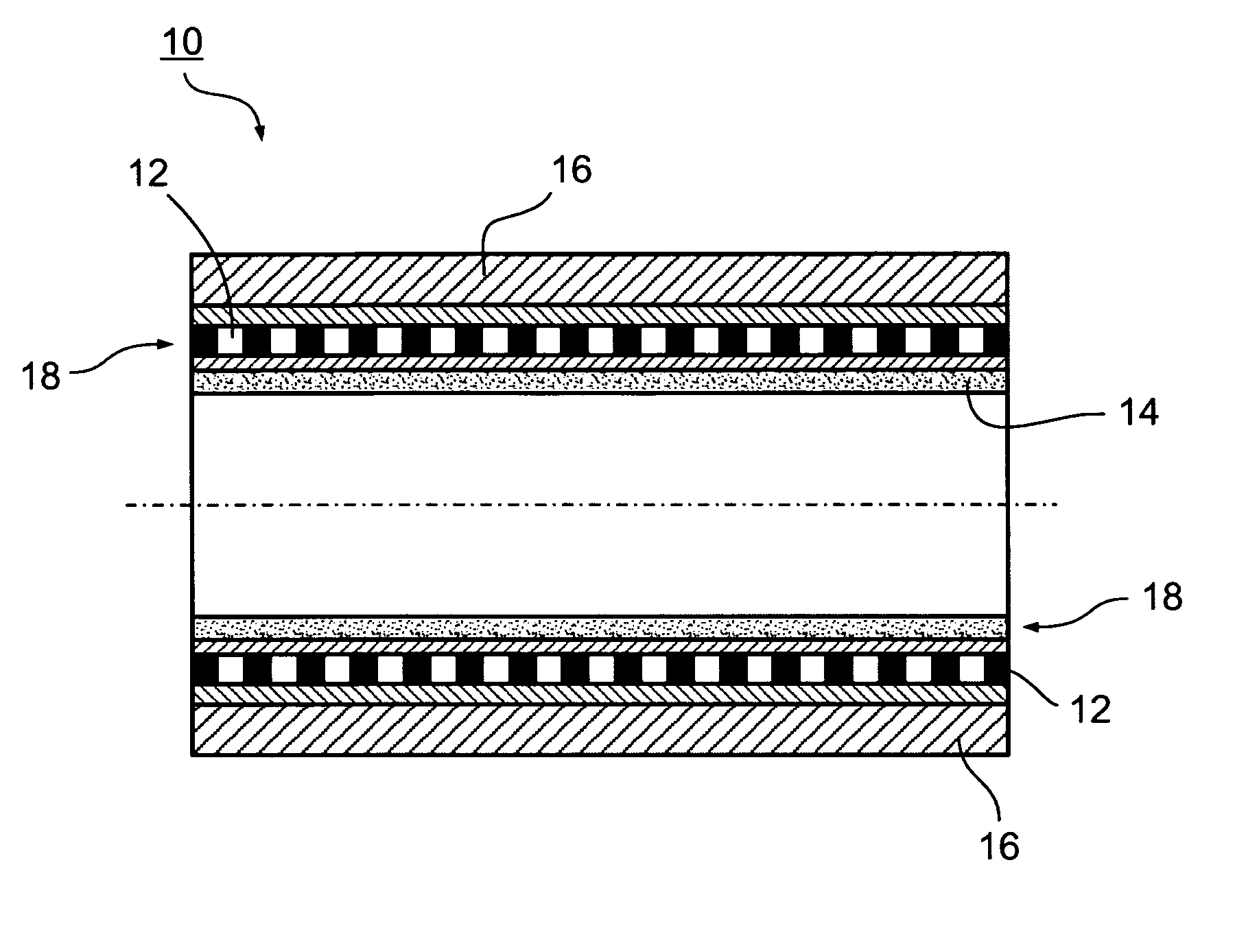

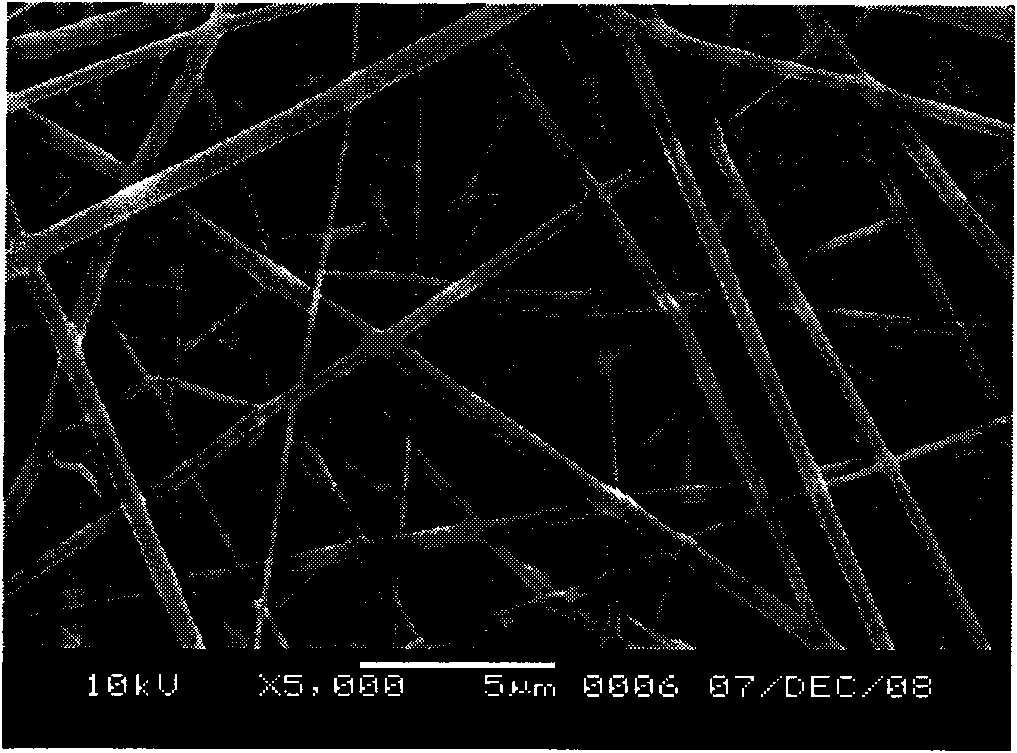

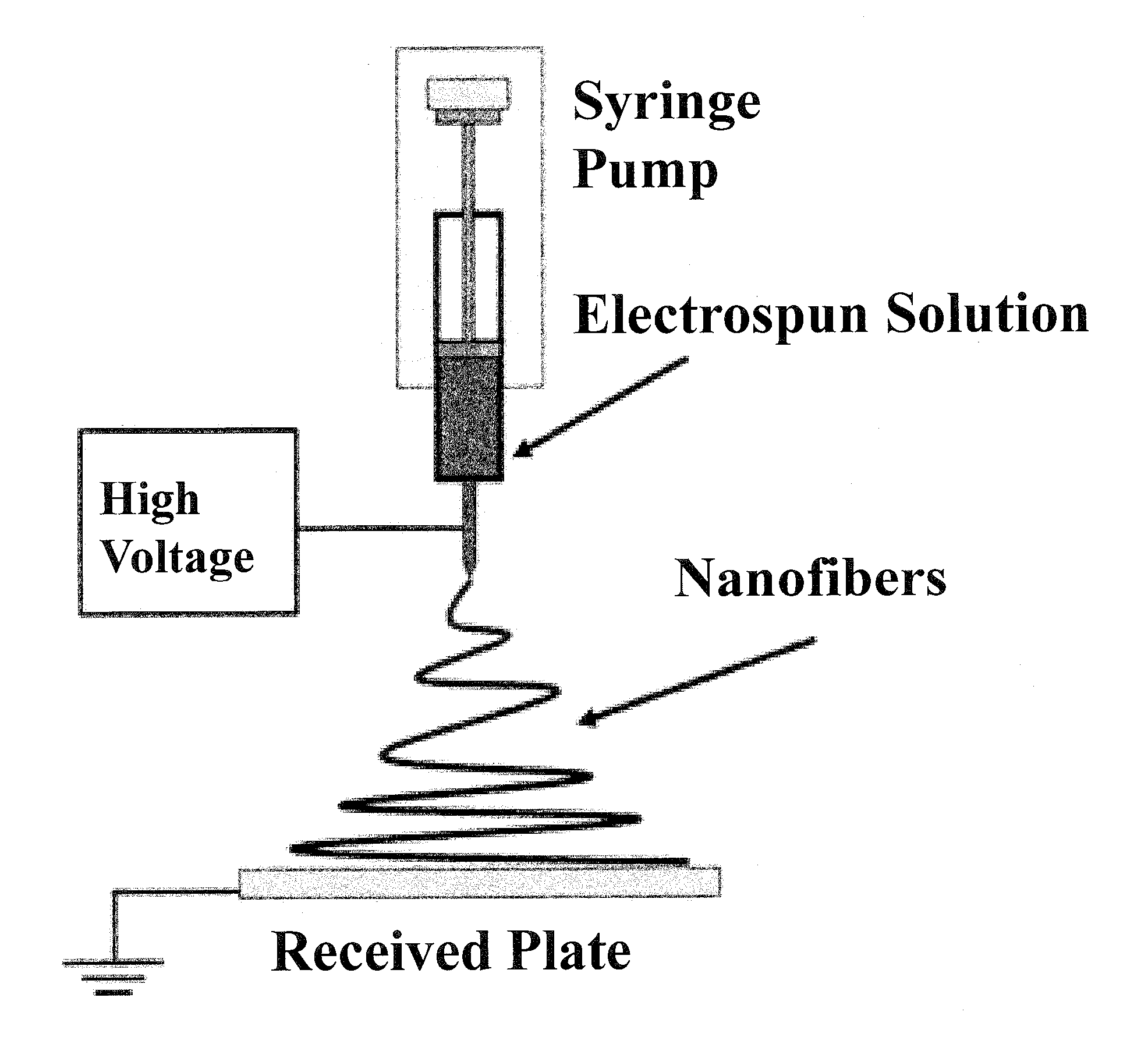

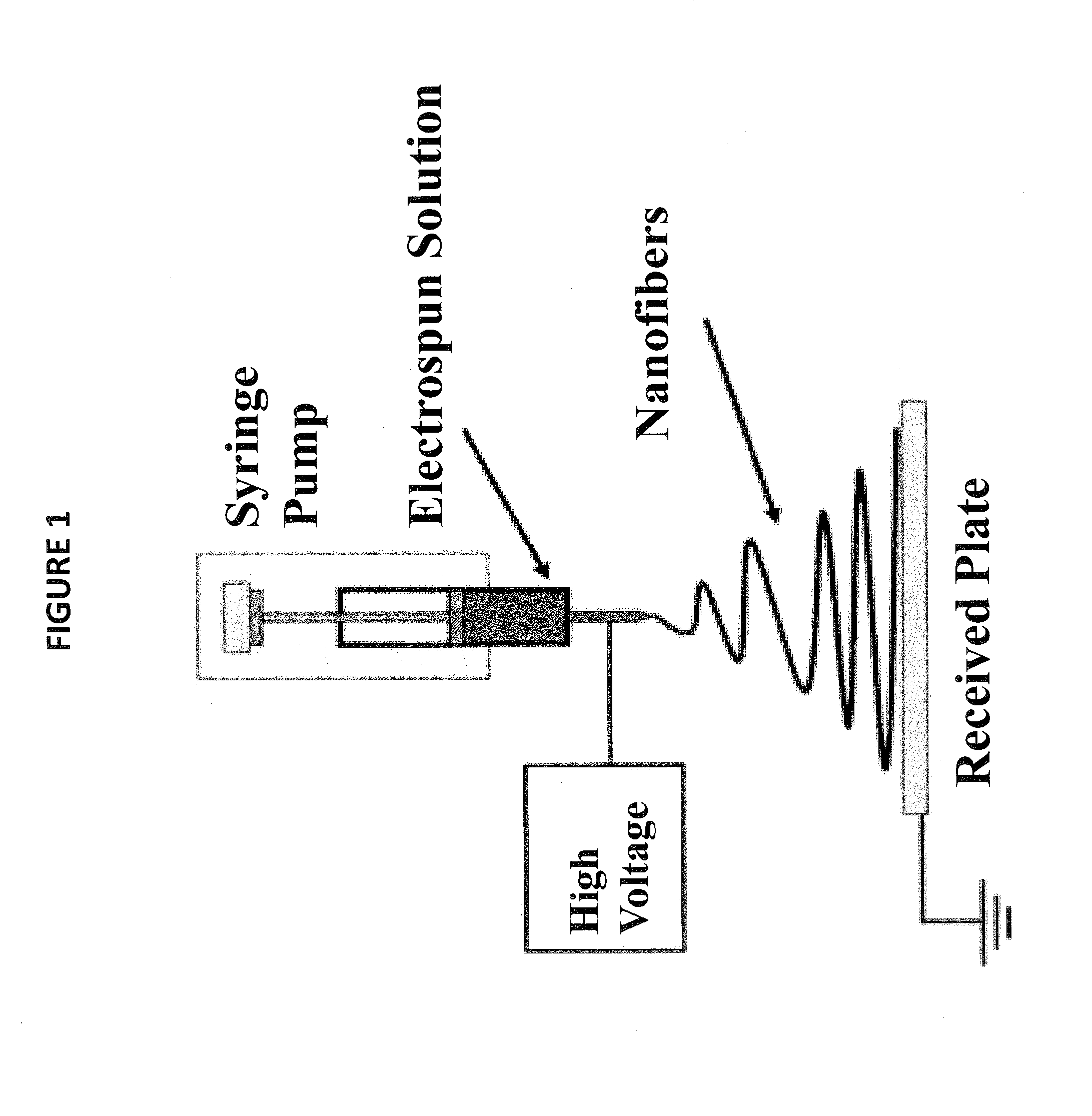

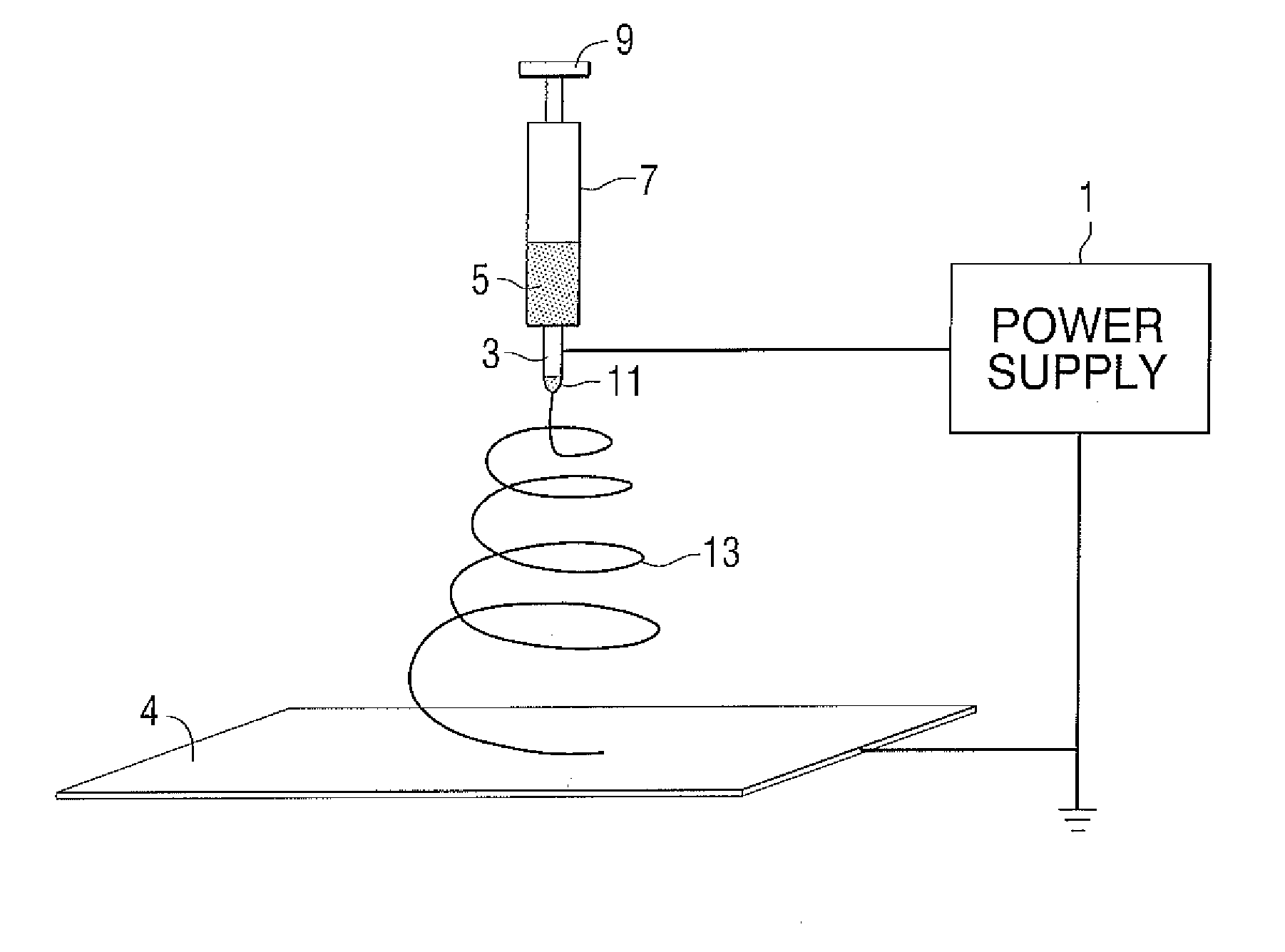

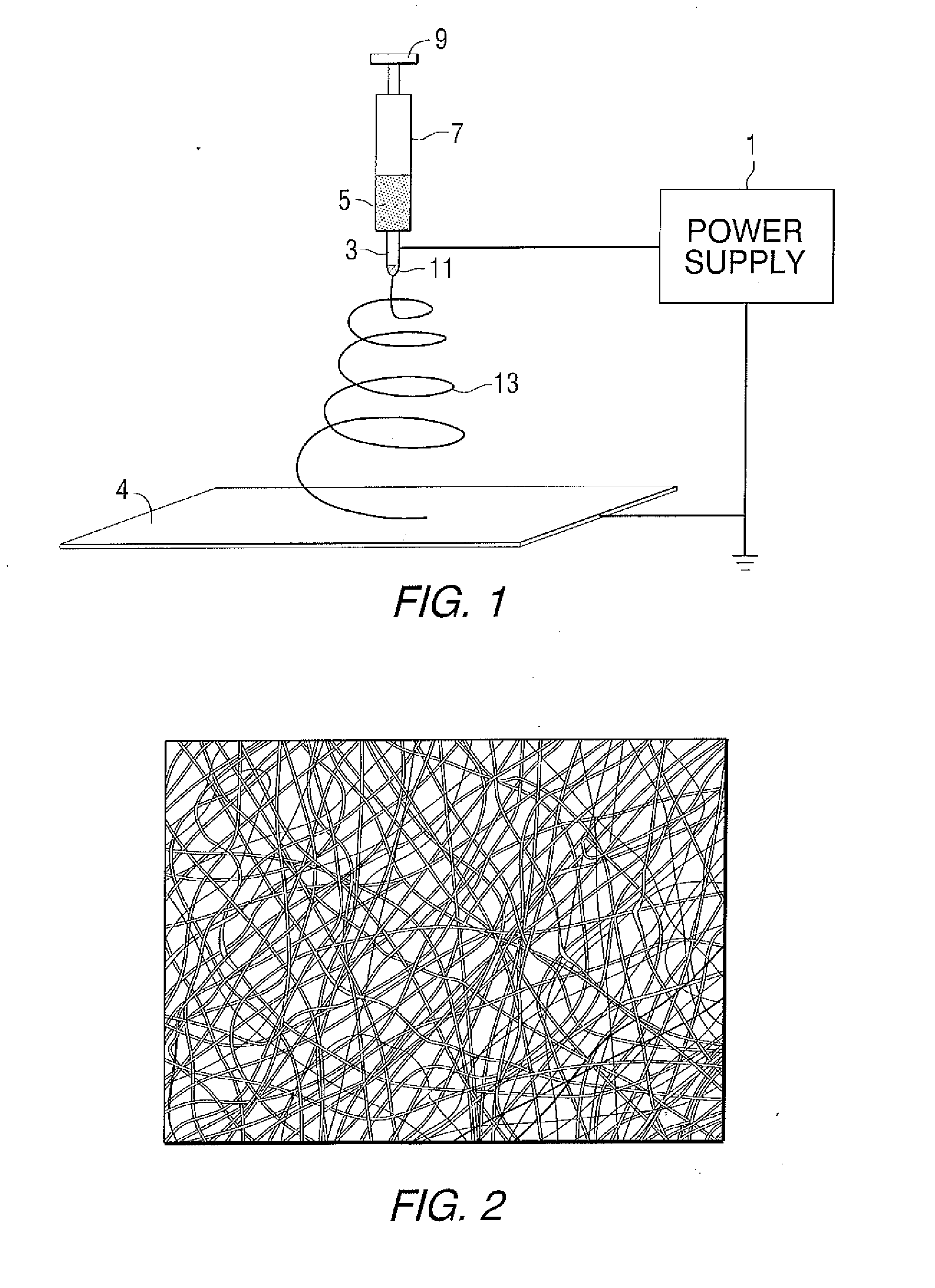

A filtration device including a filtration medium having a plurality of nanofibers of diameters less than 1 micron formed into a fiber mat in the presence of an abruptly varying electric field. The filtration device includes a support attached to the filtration medium and having openings for fluid flow therethrough. A device for making a filter material. The device includes an electrospinning element configured to electrospin a plurality of fibers from a tip of the electrospinning element, a collector opposed to the electrospinning element configured to collect electrospun fibers on a surface of the collector, and an electric field modulation device configured to abruptly vary an electric field at the collector at least once during electrospinning of the fibers. A method for making a filter material. The method provides a support having openings for fluid flow therethrough, electrospins nanofibers across an entirety of the openings, and abruptly varies an electric field at the collector at least once during electrospinning of the fibers.

Owner:RES TRIANGLE INST

Patterned electrospinning

A polymer is directed from a source electrode into an electric field that drives the formation of electrospun fibers that are deposited onto a collecting surface to thereby form a patterned polymer structure. The collecting surface can be a counterelectrode or a collecting surface that is between the source electrode and a counterelectrode. Apparatus employed to conduct the method include an electrospinning source that directs polymer into an electric field formed by source and counterelectrodes. A collecting surface, such as the counterelectrode or a surface interposed between the source and counterelectrodes, collects electrospun fibers. Articles of manufacture formed by the method of apparatus include, for example, a structure of patterned electrospun fibers comprising multiple aggregations of polymeric electrospun fibers.

Owner:PHYSICAL SCI

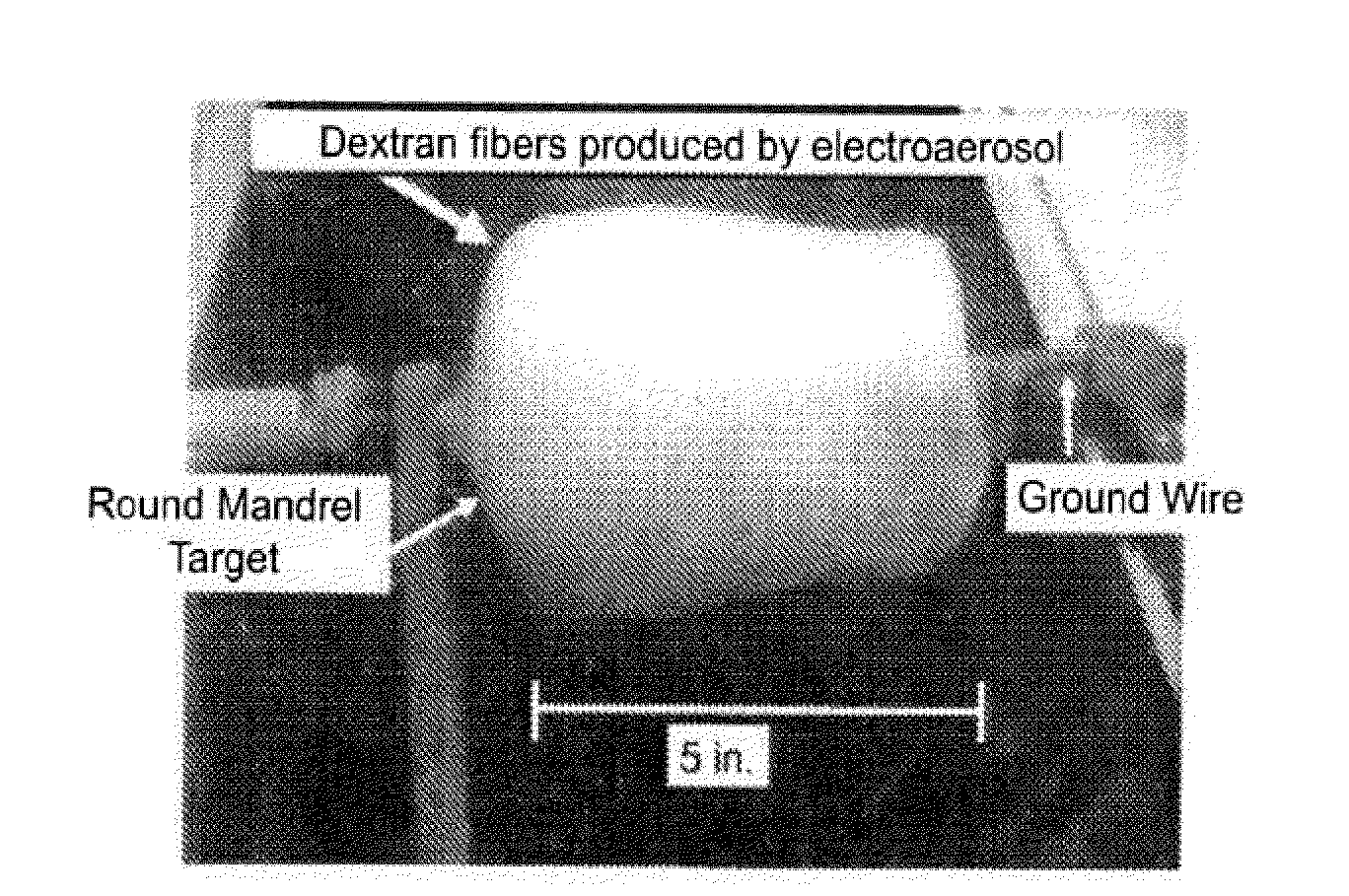

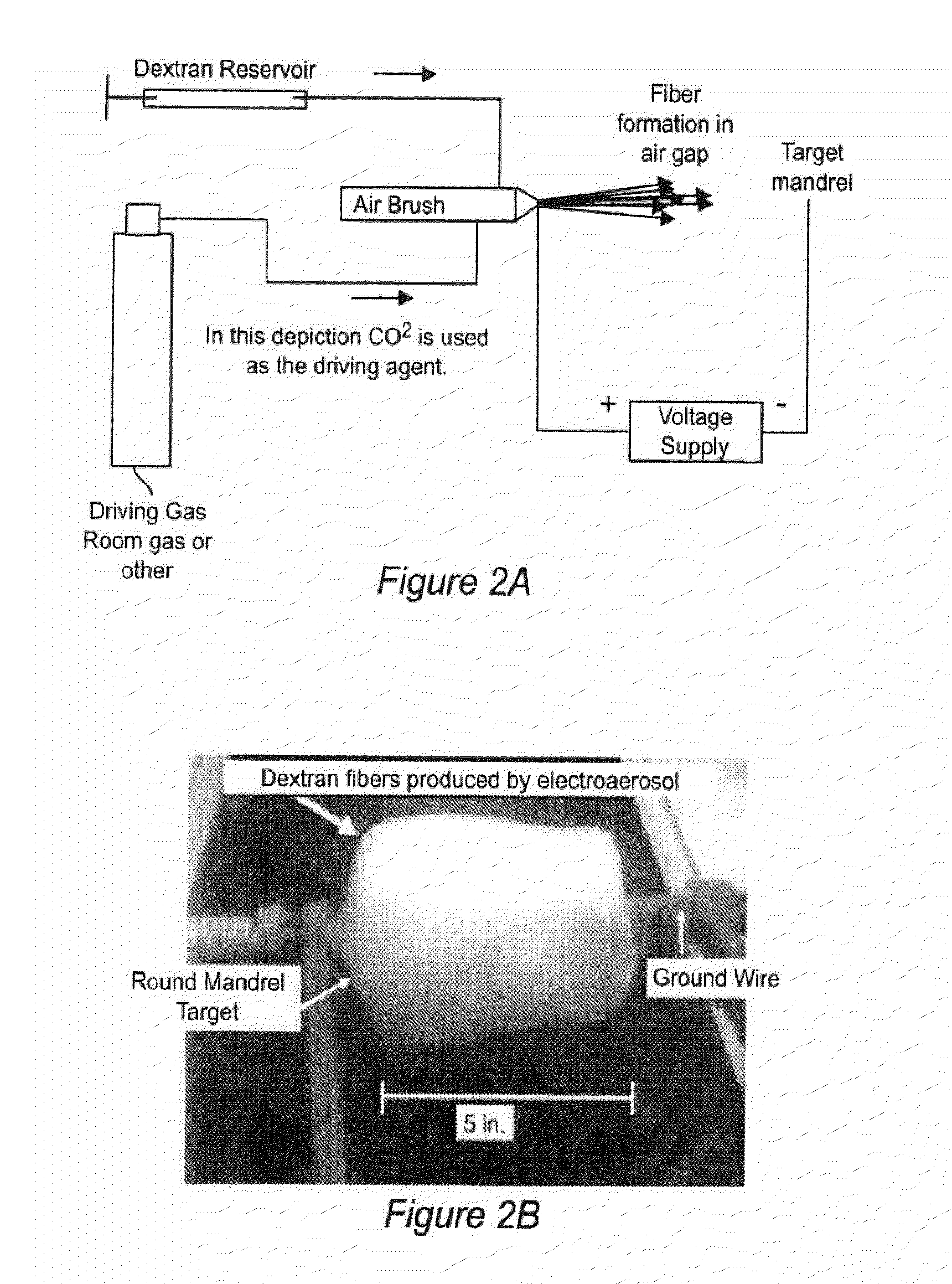

Electrospun dextran fibers and devices formed therefrom

The invention generally relates to dextran fibers which are preferably electrospun and devices formed from such fibers. In particular, such devices may include substances of interest (such as therapeutic substances) associated with the electrospun fibers. Upon exposure to a liquid the electrospun fibers dissolve immediately and the substances of interest are released into the liquid. Exemplary devices include bandages formed from electrospun dextran fibers and associated agents that promote hemostasis, such as thrombin and fibrinogen.

Owner:THE HENRY M JACKSON FOUND FOR THE ADVANCEMENT OF MILITARY MEDICINE INC +1

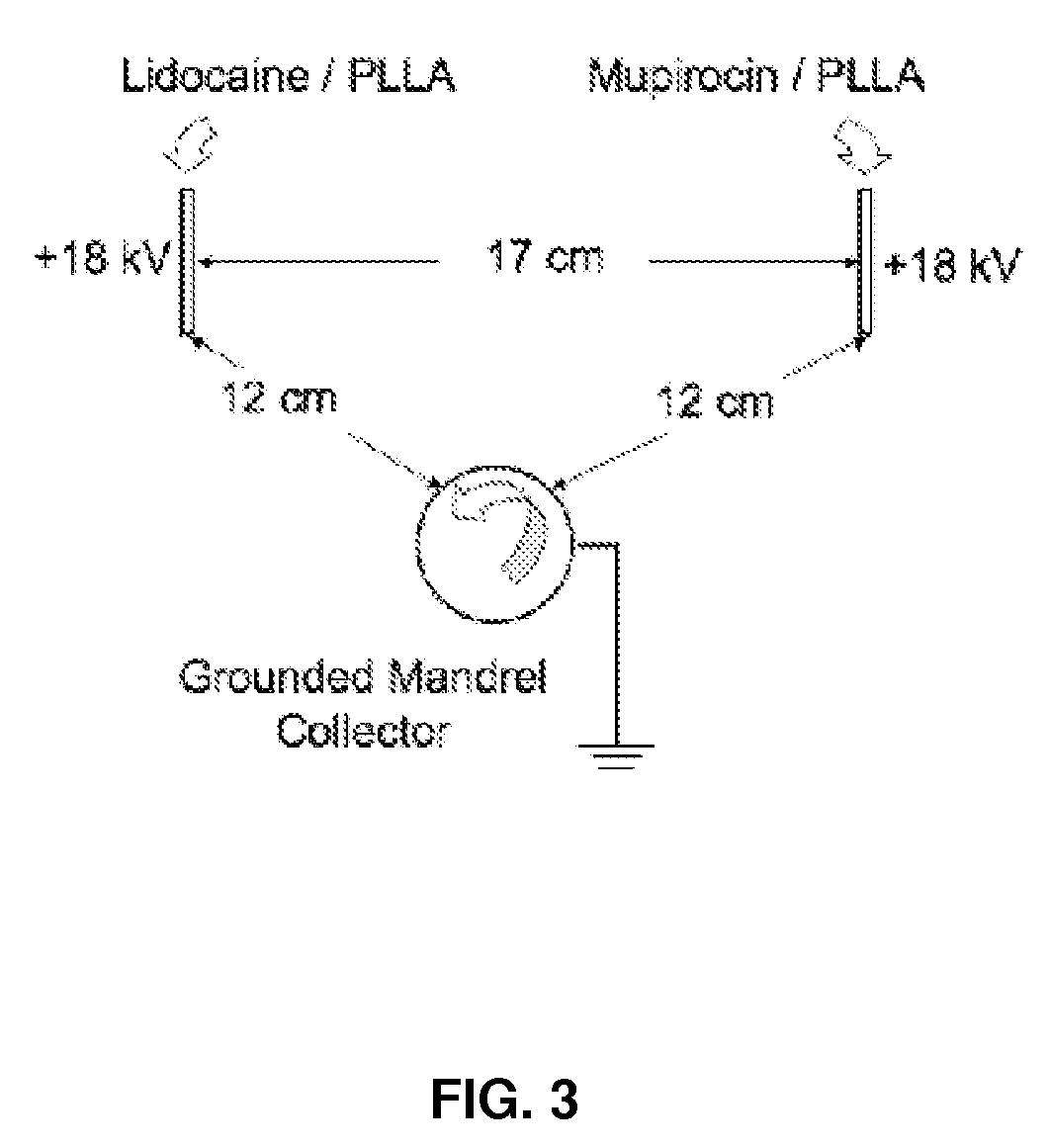

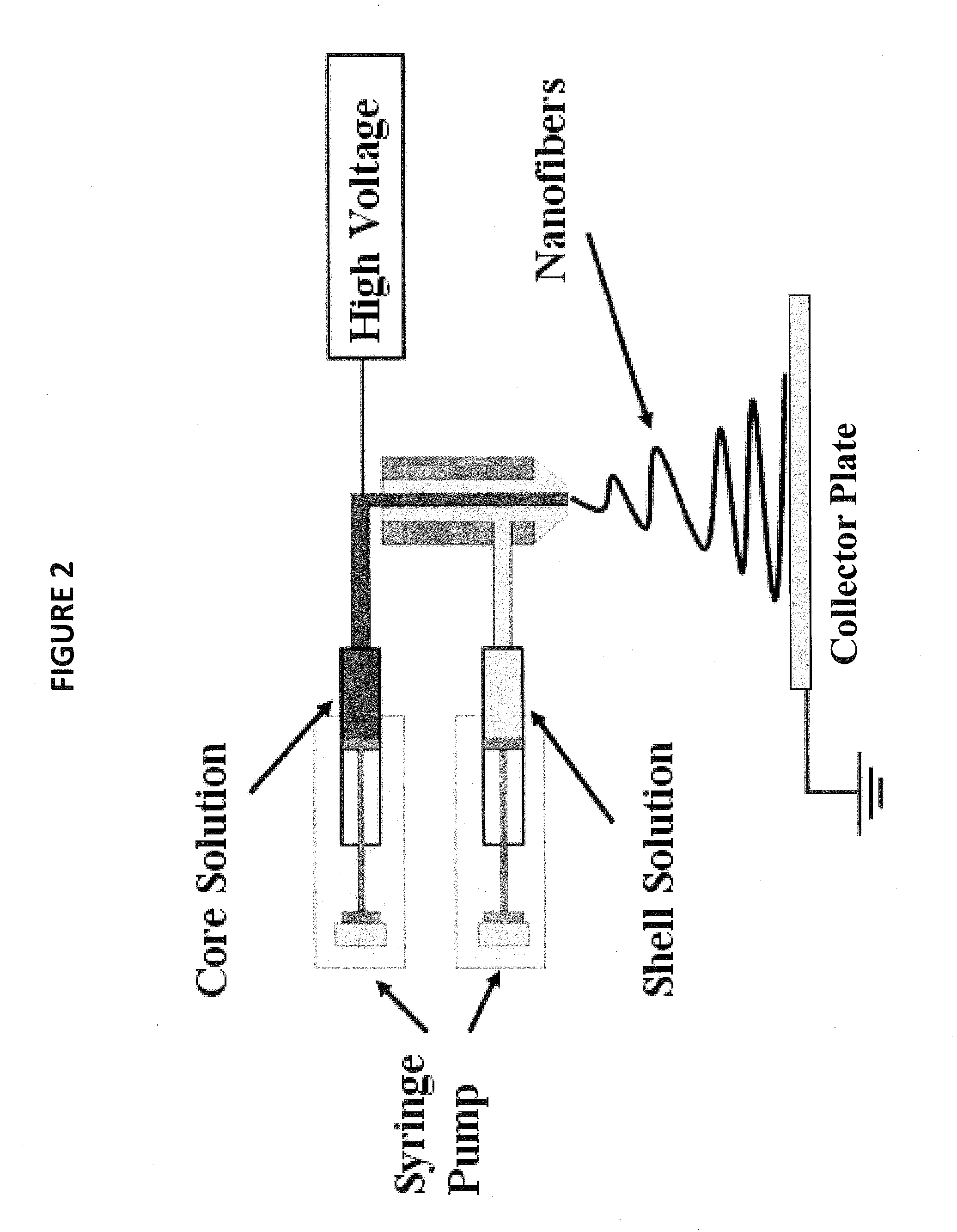

Electrospun matrices for delivery of hydrophilic and lipophilic compounds

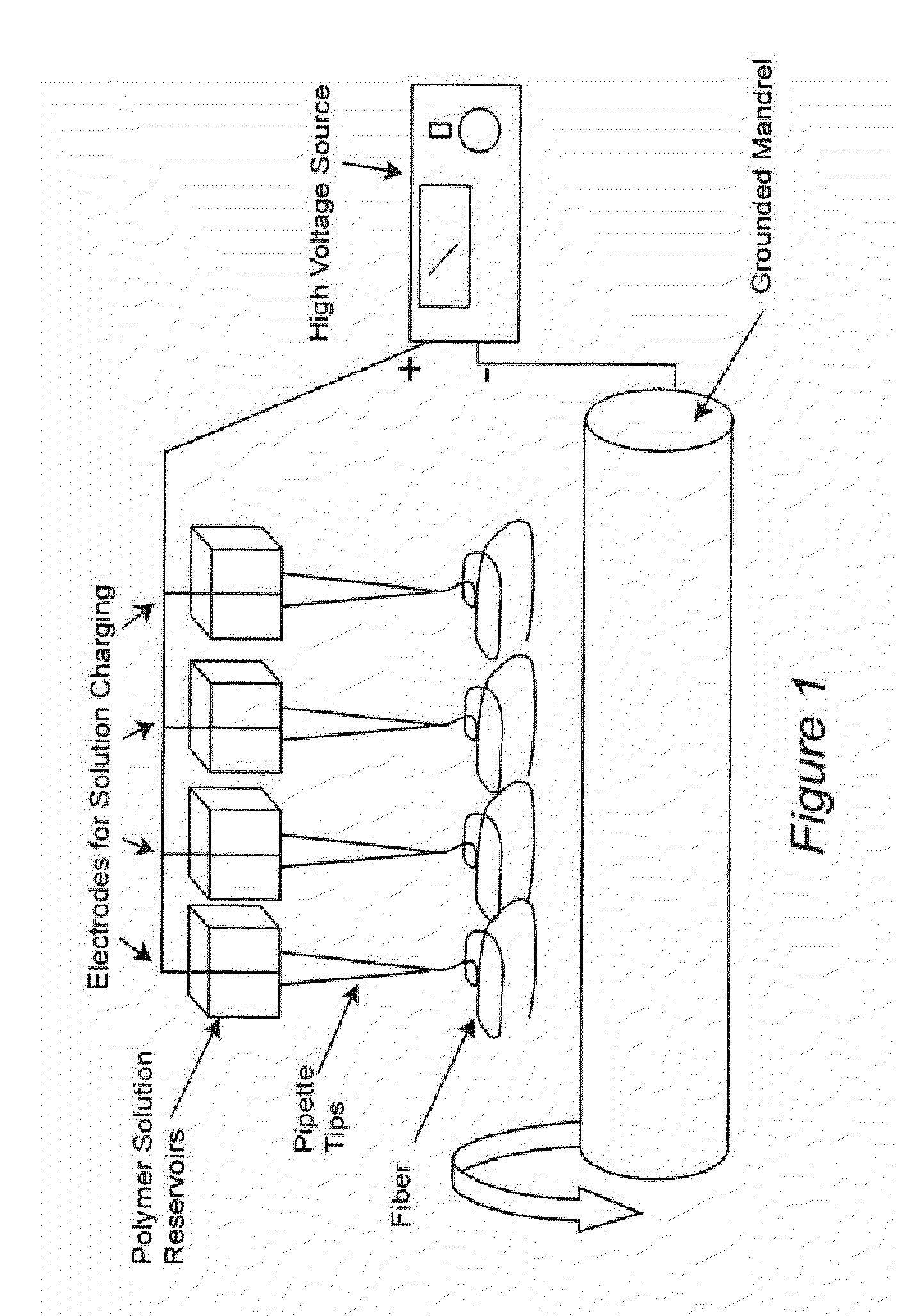

InactiveUS20100166854A1Monocomponent protein artificial filamentElectric discharge heatingFiberCompound a

A method of forming electrospun fiber mats from a plurality of different biodegradable polymeric fibers is provided, in which a plurality of up to six different biodegradable polymer solutions are electrospun together by a method comprising the steps of providing a plurality of up to six different biodegradable polymer solutions each containing at least one biologically or pharmaceutically active material and each in communication with a needle for electrospinning a biodegradable polymer fiber from the solution, and pumping each solution through its respective needle into an electric field under conditions effective to produce uncontrolled charged jet streams of the polymer solutions directed at a grounded rotating mandrel, thereby forming fiber threads of the biologically or pharmaceutically active compounds and polymers in the solutions that are deposited on the mandrel to form an electrospun non-woven fiber mat, wherein the needles are positioned for co-deposition of the fiber threads from the polymer solution streams together on the mandrel to form a fiber mat.

Owner:RUTGERS THE STATE UNIV

Therapeutic Electrospun Fiber Compositions

InactiveUS20100303881A1Promote nerve growthEfficient releaseBiocideNervous disorderFiberActive agent

The instant invention provides electrospun fiber compositions comprising one or more polymers and one or more biologically active agents. In specific embodiments, the biologically active agents are nerve growth factors. In certain embodiments, the electrospun fiber compositions comprising one or more biologically active agents are on the surface of a film, or a tube. The tubes comprising the electrospun fiber compositions of the invention can be used, for example, as nerve guide conduits.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Electrospun Ceramic-Polymer Composite As A Scaffold For Tissue Repair

The present invention relates to compositions and methods of preparing a three-dimensional matrix of micron sized electrospun fibers, wherein the electrospun fibers are formed from a electrospun composite comprising a bioactive ceramic component and a polymer component. The matrix provides an osteoconductive and osteoinductive scaffold supporting osteogenesis and thereby facilitates bone repair.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

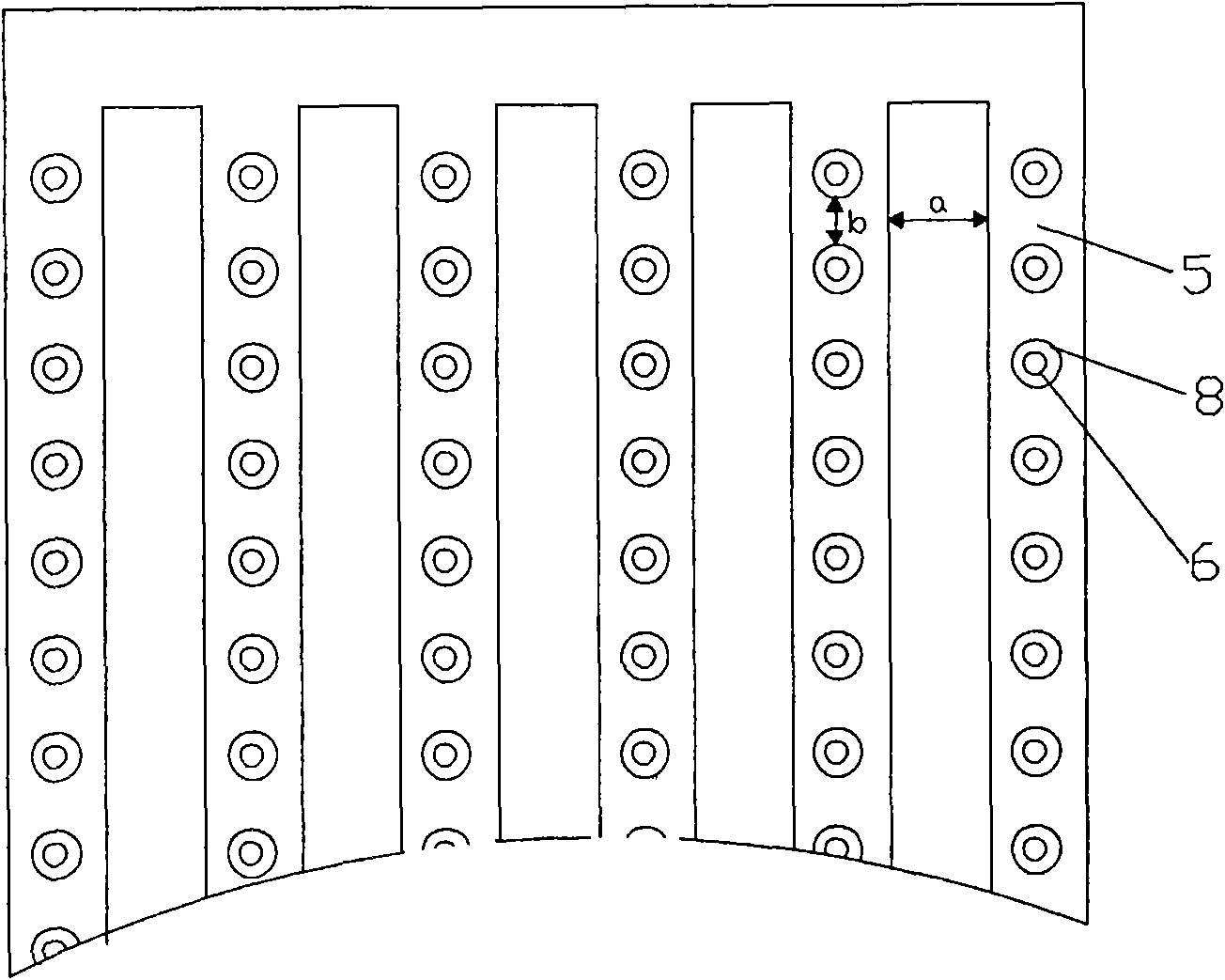

Array multi-nozzle electrospinning device

InactiveCN101586288ARealize mass productionEasy to disassembleArtificial thread manufacturing machinesFilament/thread formingFiberEngineering

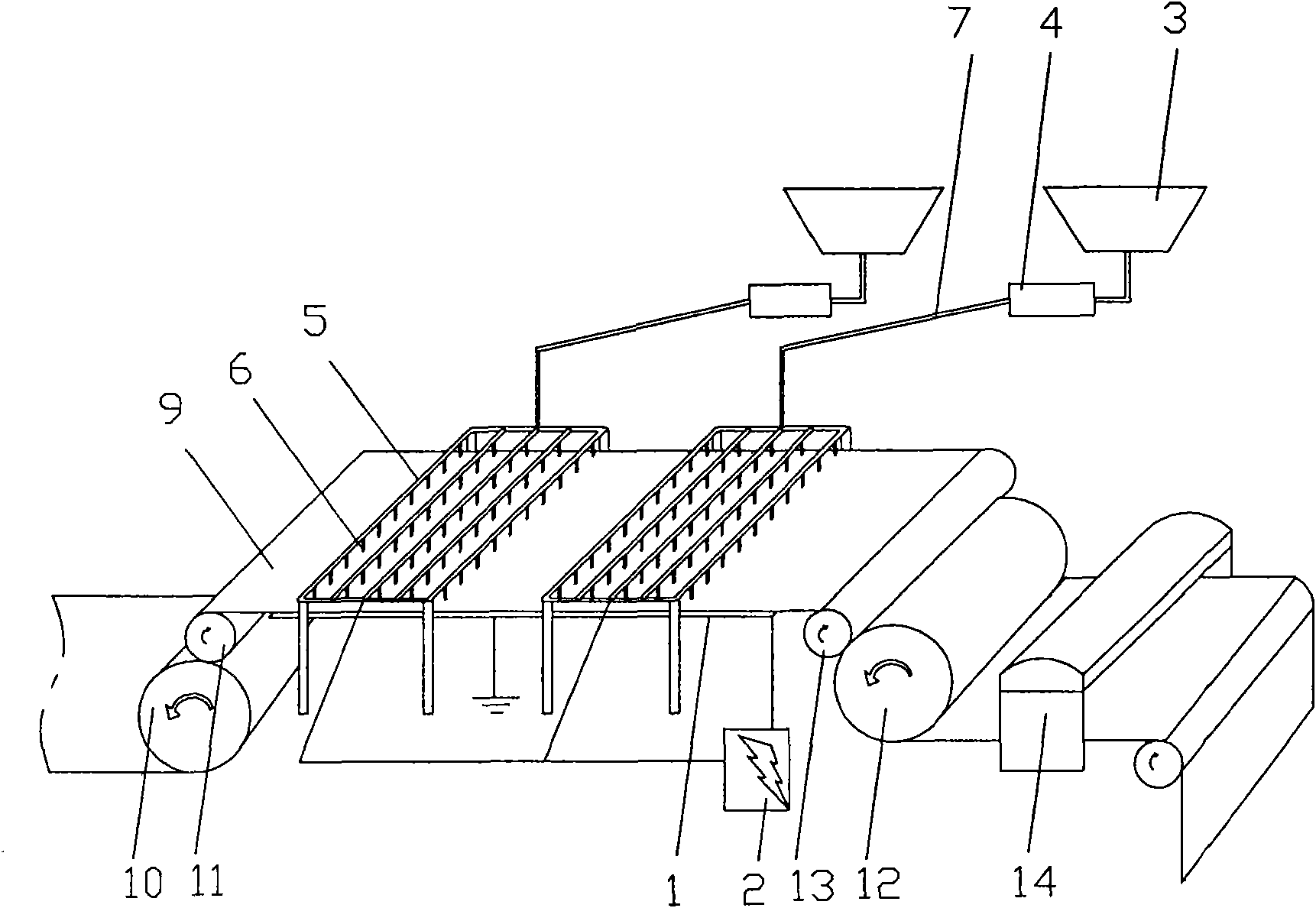

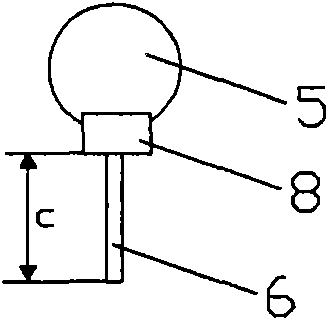

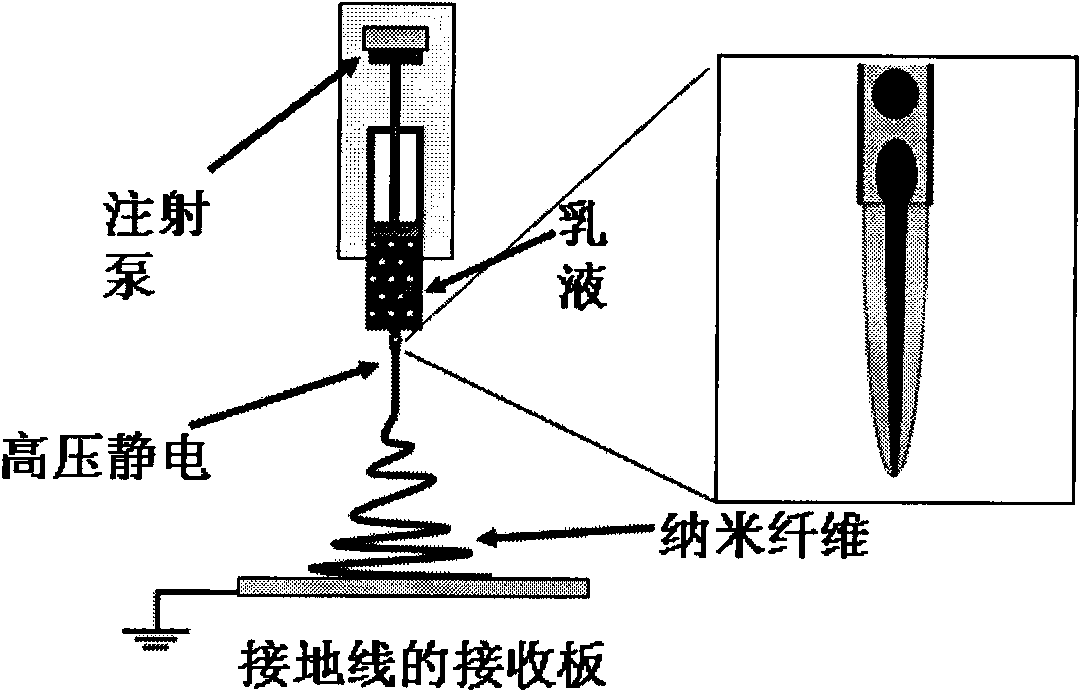

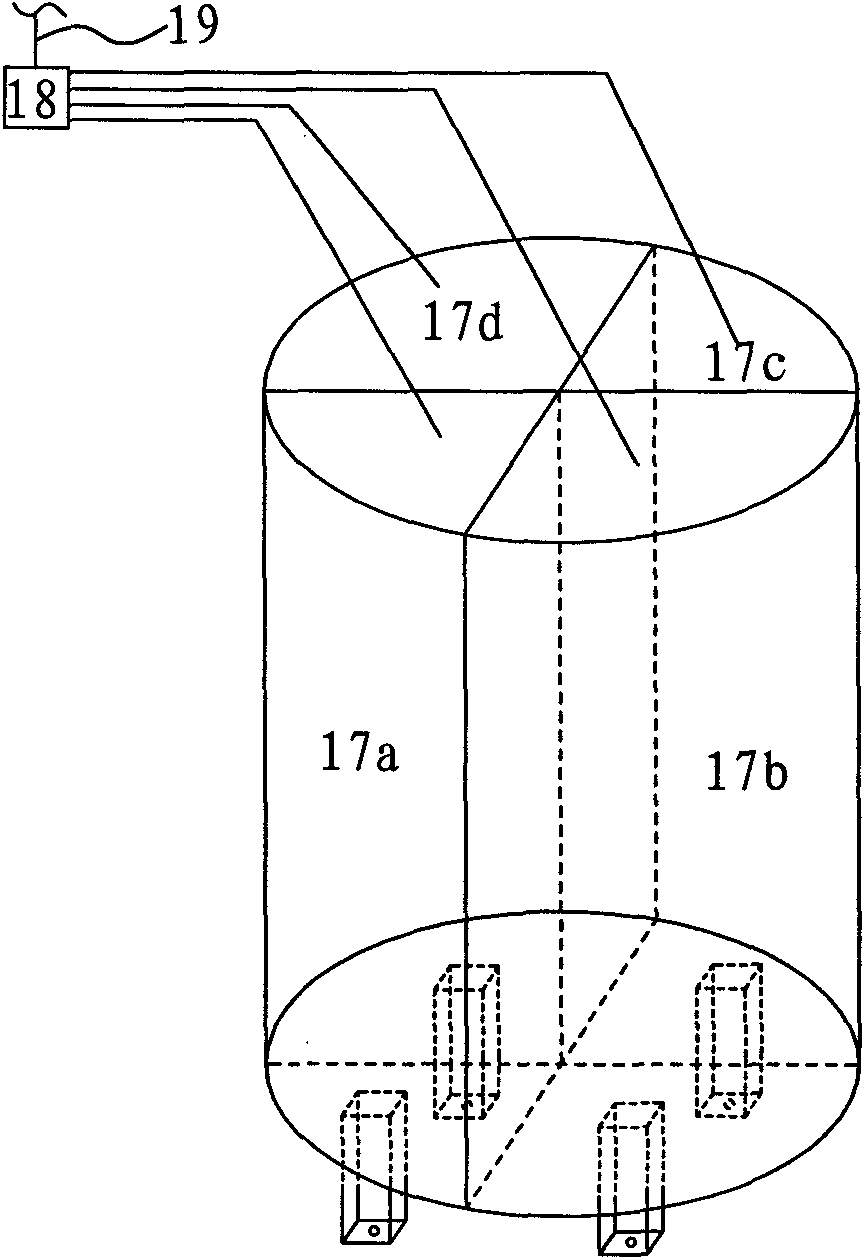

The present invention discloses an array multi-nozzle electrospinning device, including an electrospinning liquid supply apparatus, an electrospinning liquid spinning apparatus, a receiving electrode plate, an electrospun fiber transport apparatus and a high voltage electrostatic generator, the electrospinning liquid spinning apparatus includes effusers and nozzles, the nozzles are array-arranged; the electrospun fiber transport apparatus includes a feed roller apparatus and a discharge roller apparatus disposed on two ends of the receiving electrode plate respectively; the electrospun fiber receiving material is transported to the space between the electrospinning liquid spinning apparatus and the receiving electrode plate by the feed roller apparatus, and the discharge roller apparatus transports the received electrospun fiber out; the invention provided device can produce electrospun fiber membrane in large scale, and can produce both single polymer electrospun fiber membrane and multiple polymers blended layered electrospun fiber membrane for one time, and can obtain a electrospun fiber membrane with specific topological pattern by changing electrospun fiber receiving material conveniently, which satisfies various application requirements of electrospun fiber materials.

Owner:JIANGSU CHANGJIYONG BIOTECH CO LTD

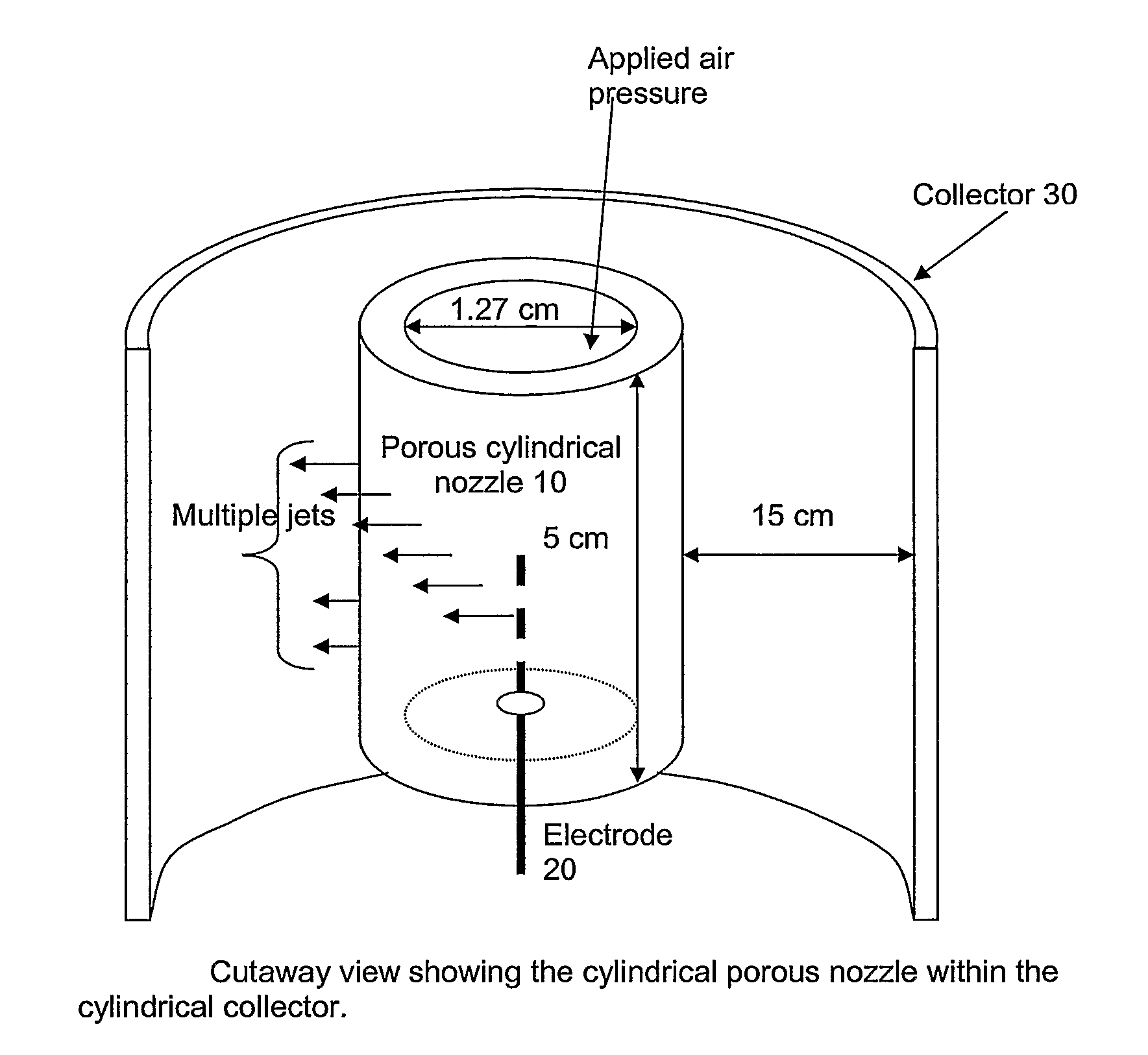

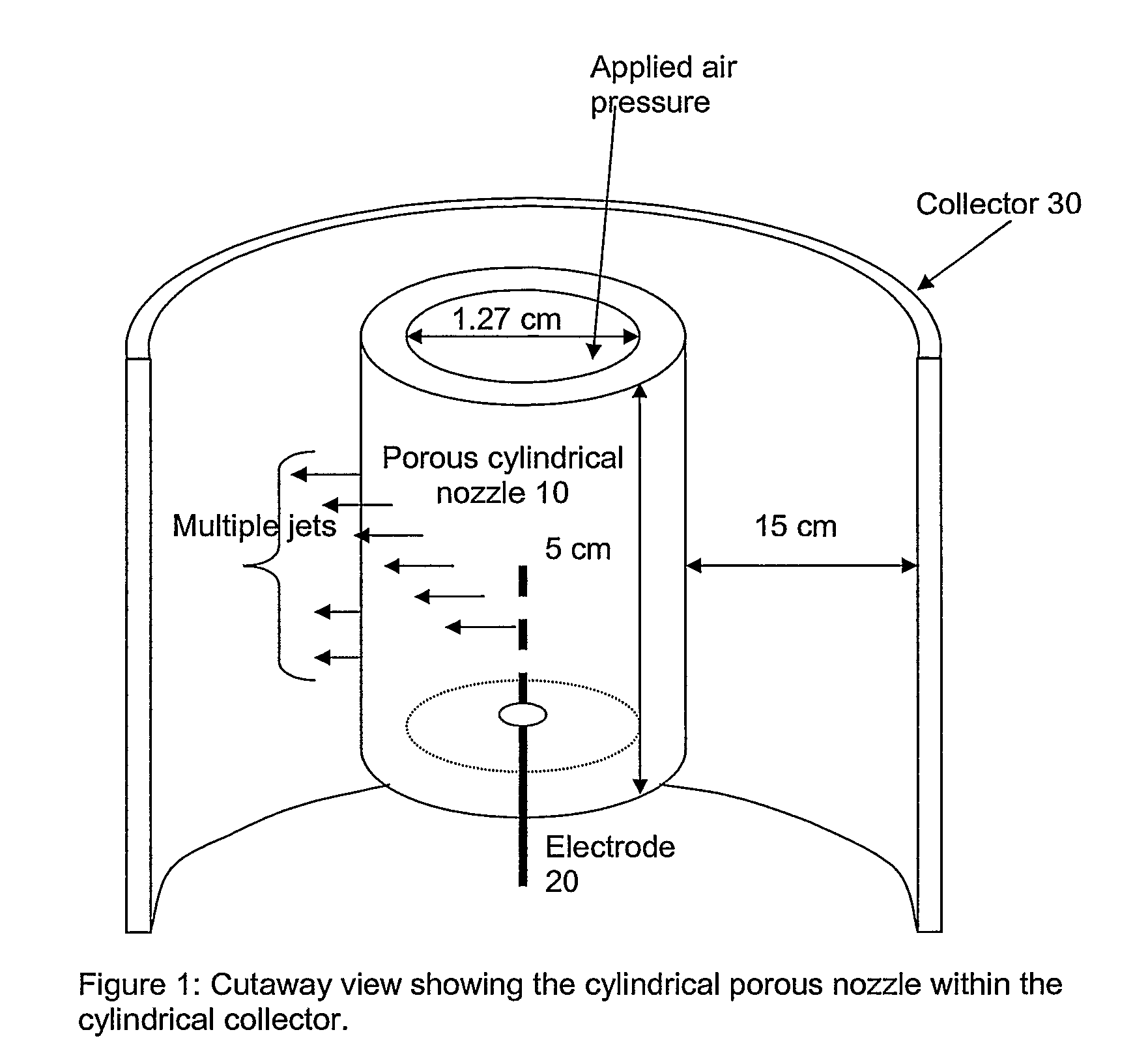

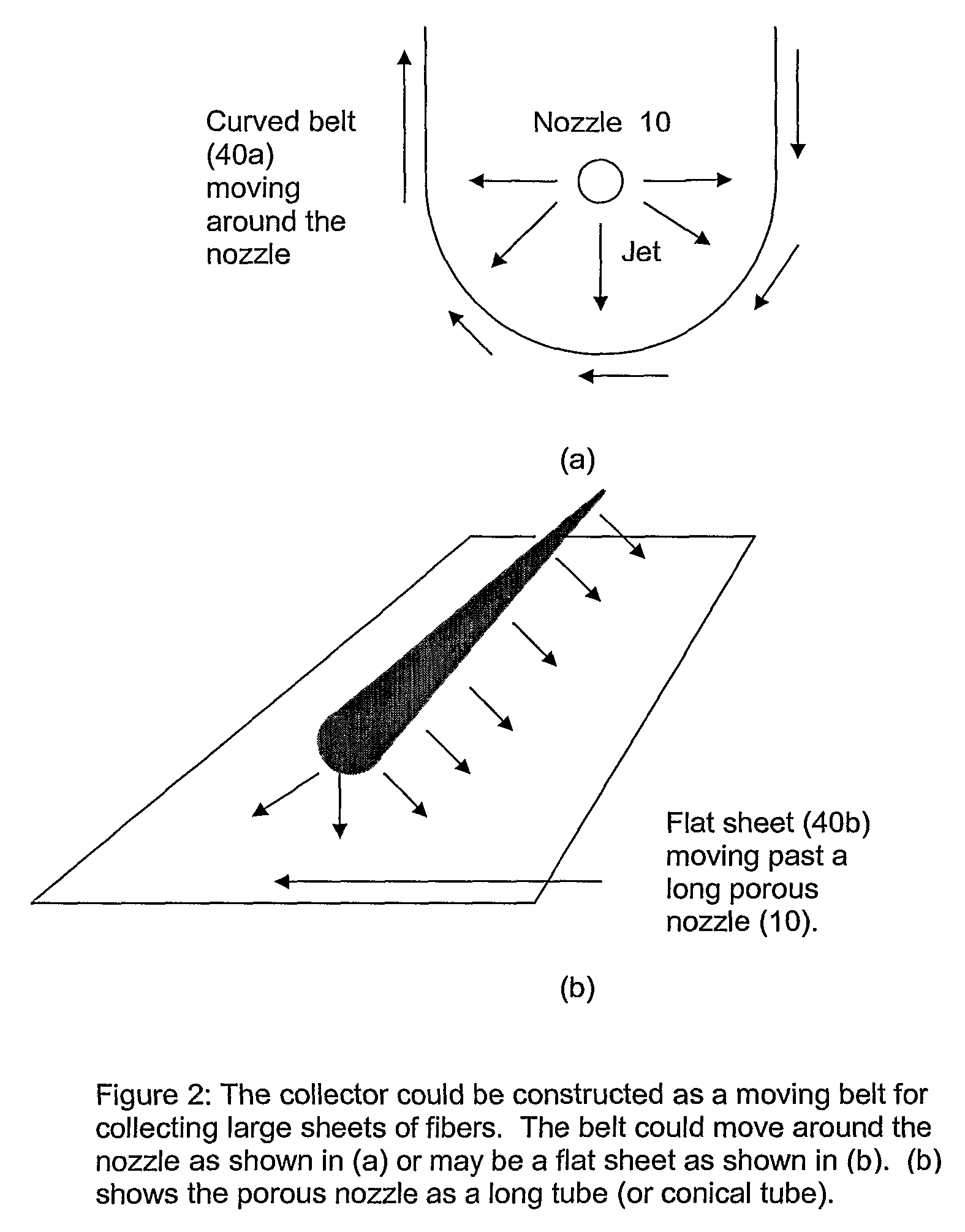

Method and device for producing electrospun fibers

The present invention relates to methods for producing fibers made from one or more polymers or polymer composites, and to structures that can be produced from such fibers. In one embodiment, the fibers of the present invention are nanofibers. The present invention also relates to apparatus for producing fibers made from one or more polymers or polymer composites, and methods by which such fibers are made.

Owner:AKRON THE UNIV OF

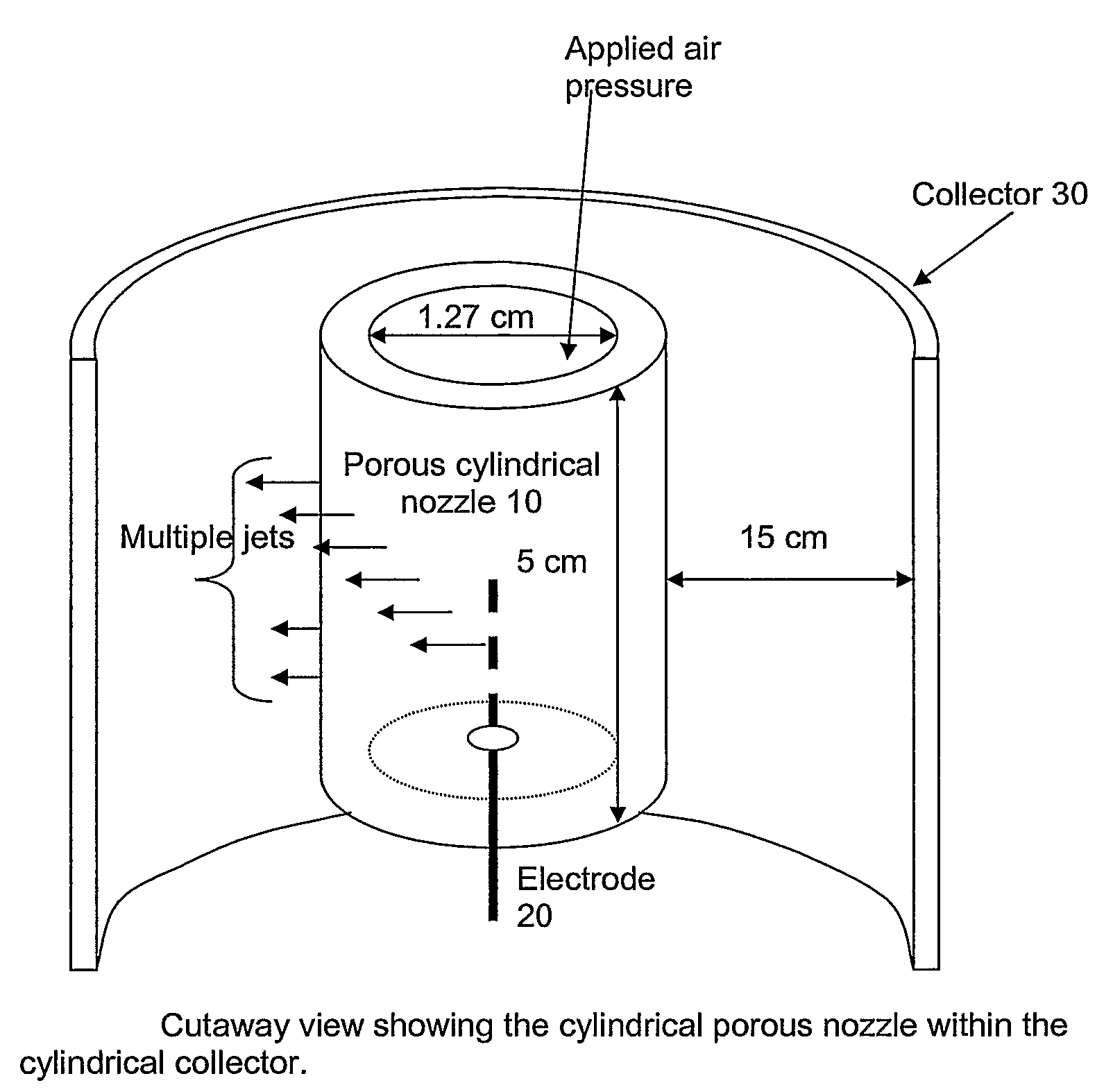

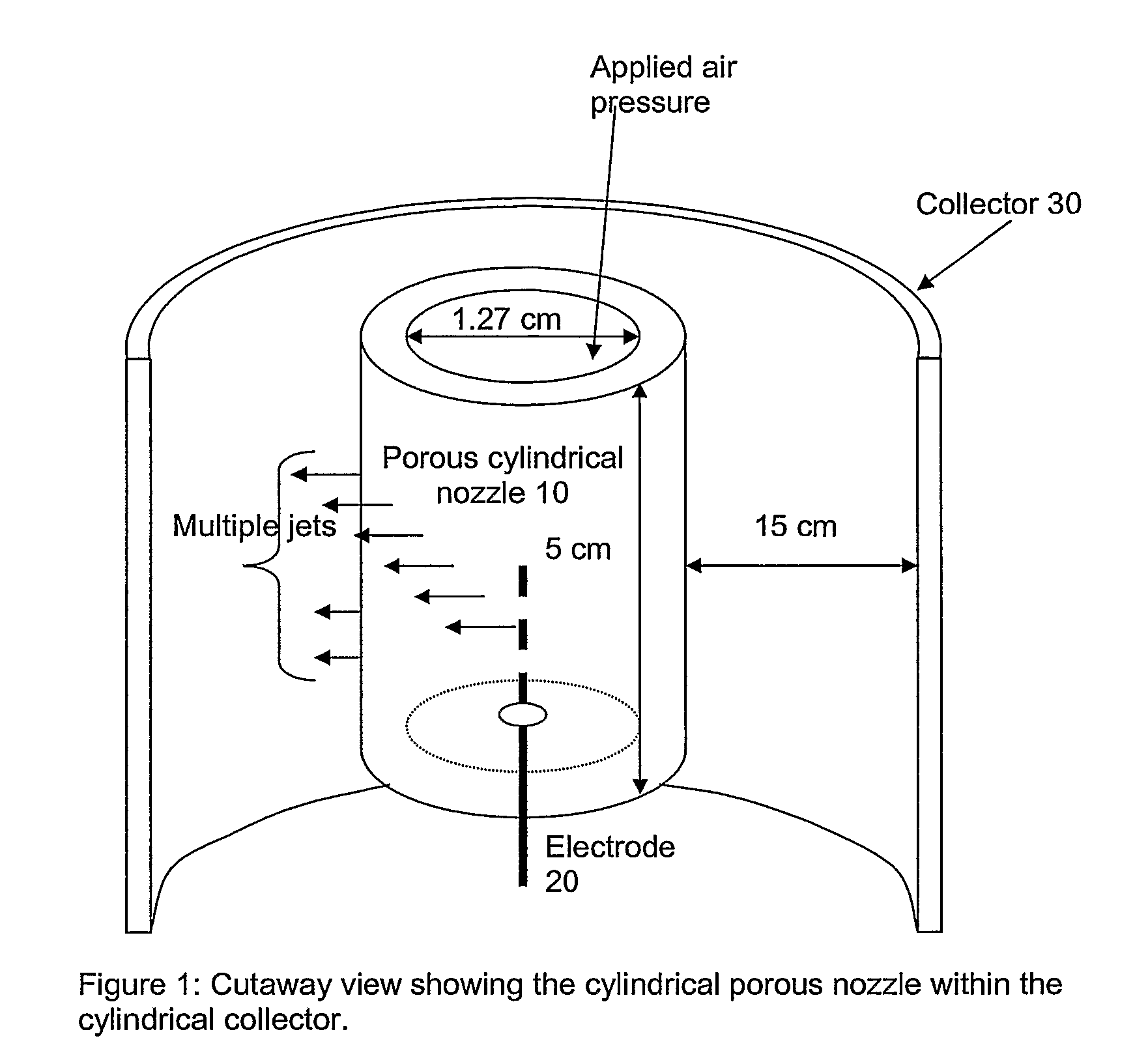

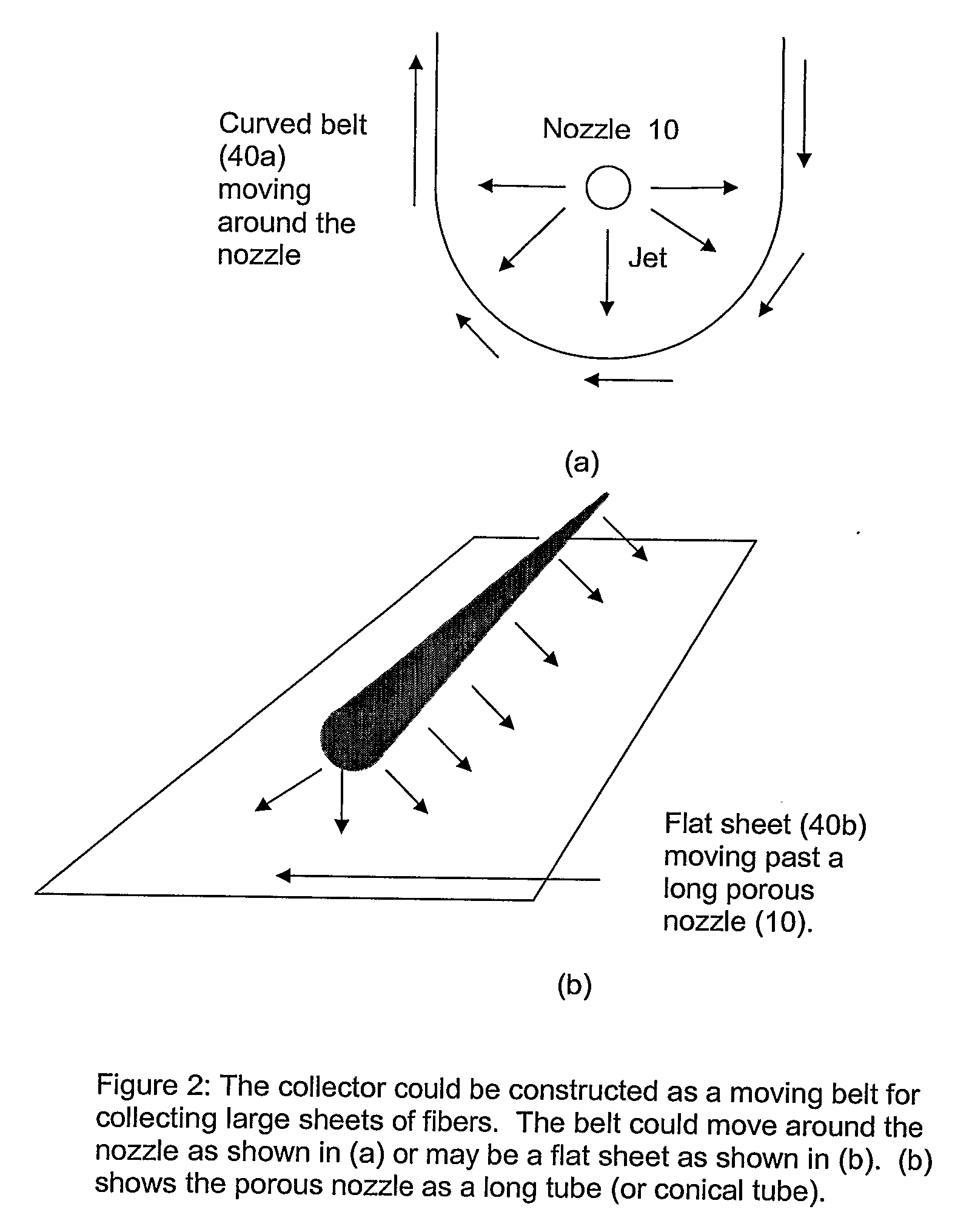

Method and Device For Producing Electrospun Fibers and Fibers Produced Thereby

The present invention relates to methods for producing fibers made from one or more polymers or polymer composites, and to structures that can be produced from such fibers. In one embodiment, the fibers of the present invention are nanofibers. The present invention also relates to apparatus for producing fibers made from one or more polymers or polymer composites, and methods by which such fibers are made.

Owner:AKRON THE UNIV OF

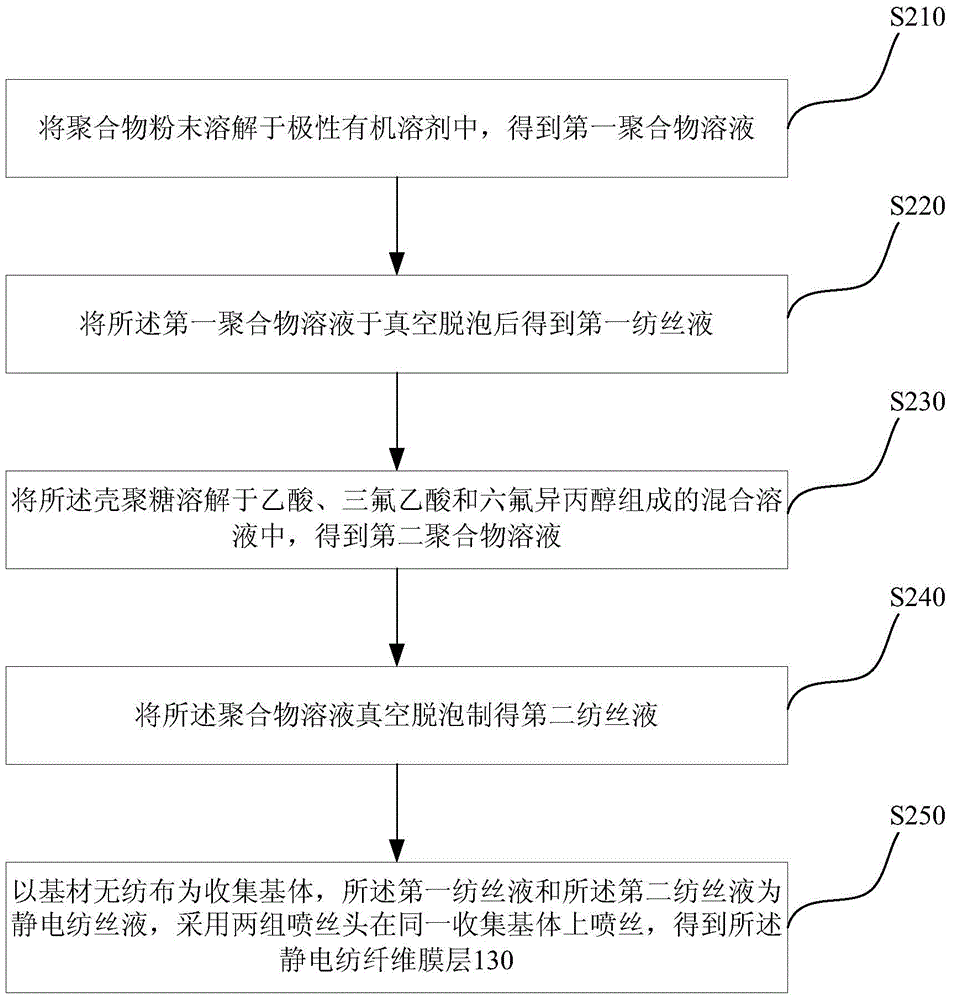

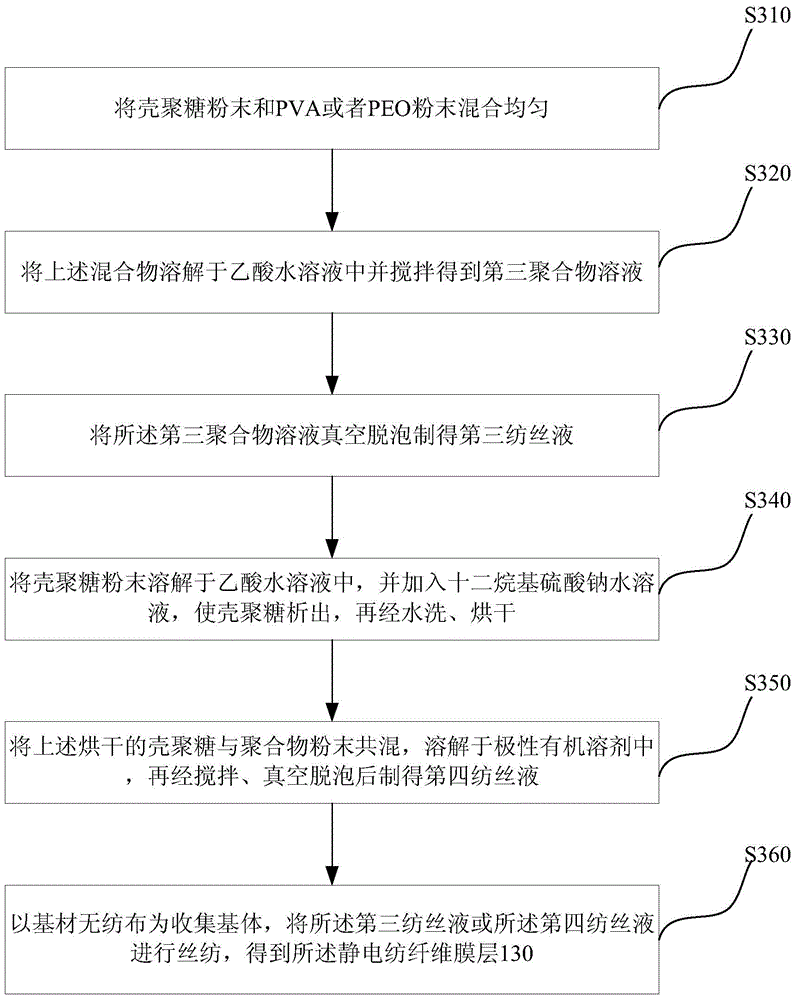

Antibacterial gauze mask filter and preparation method thereof, and antibacterial gauze mask

ActiveCN104083946ABarrier entrySimple structureLayered productsFiltration separationFiberSurface layer

The invention provides an antibacterial gauze mask filter. The antibacterial gauze mask filter comprises a fiber surface layer, a base material non-woven fabric layer, an electrostatic spinning fiber membrane layer and a fiber lining which are sequentially connected, wherein the electrostatic spinning fiber membrane layer consists of polymer material and chitosan. With the adoption of small pore diameter and high porosity of the electrostatic spinning fiber membrane, the antibacterial gauze mask filter can effectively prevent PM2.5 from entering the body; meanwhile, due to the chitosan in the electrostatic spinning fiber membrane layer, the antibacterial gauze mask filter has bacteria resistance and bacteriostasis. In addition, the invention also provides a preparation method of the antibacterial gauze mask filter and an antibacterial gauze mask.

Owner:上海展恒环保科技有限公司

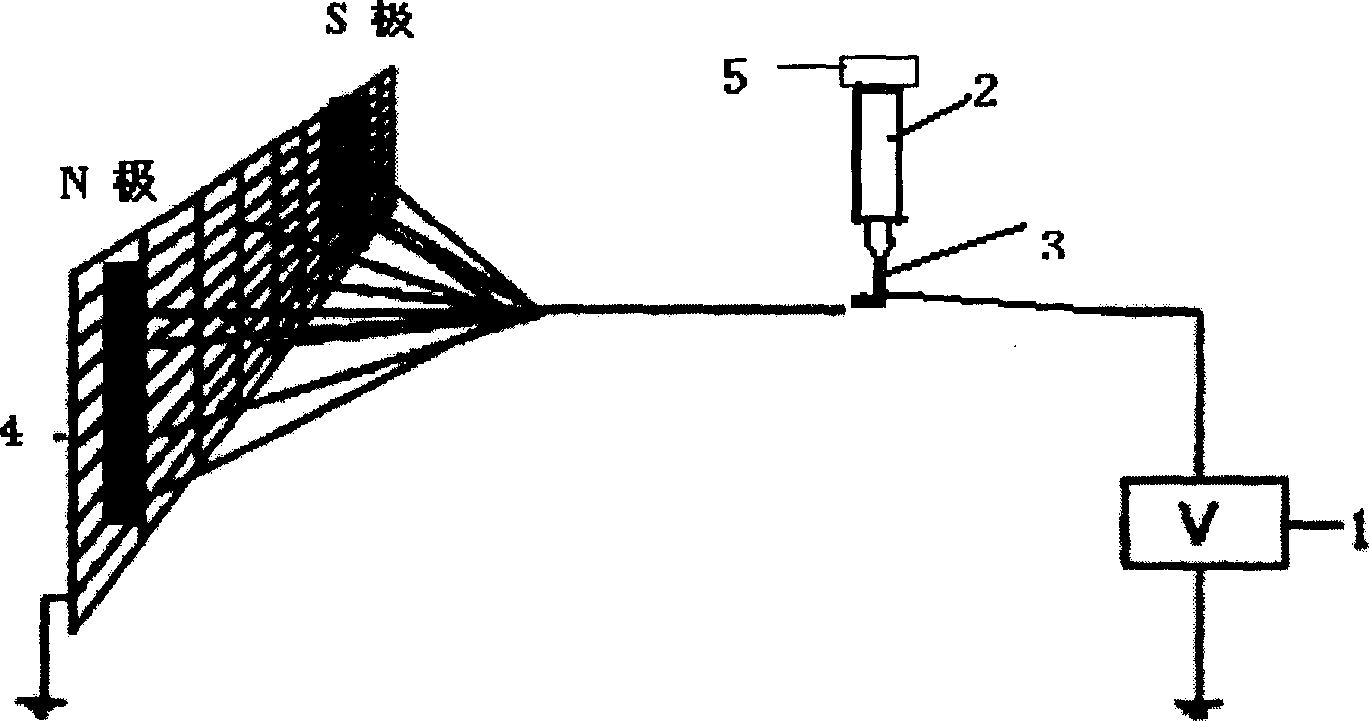

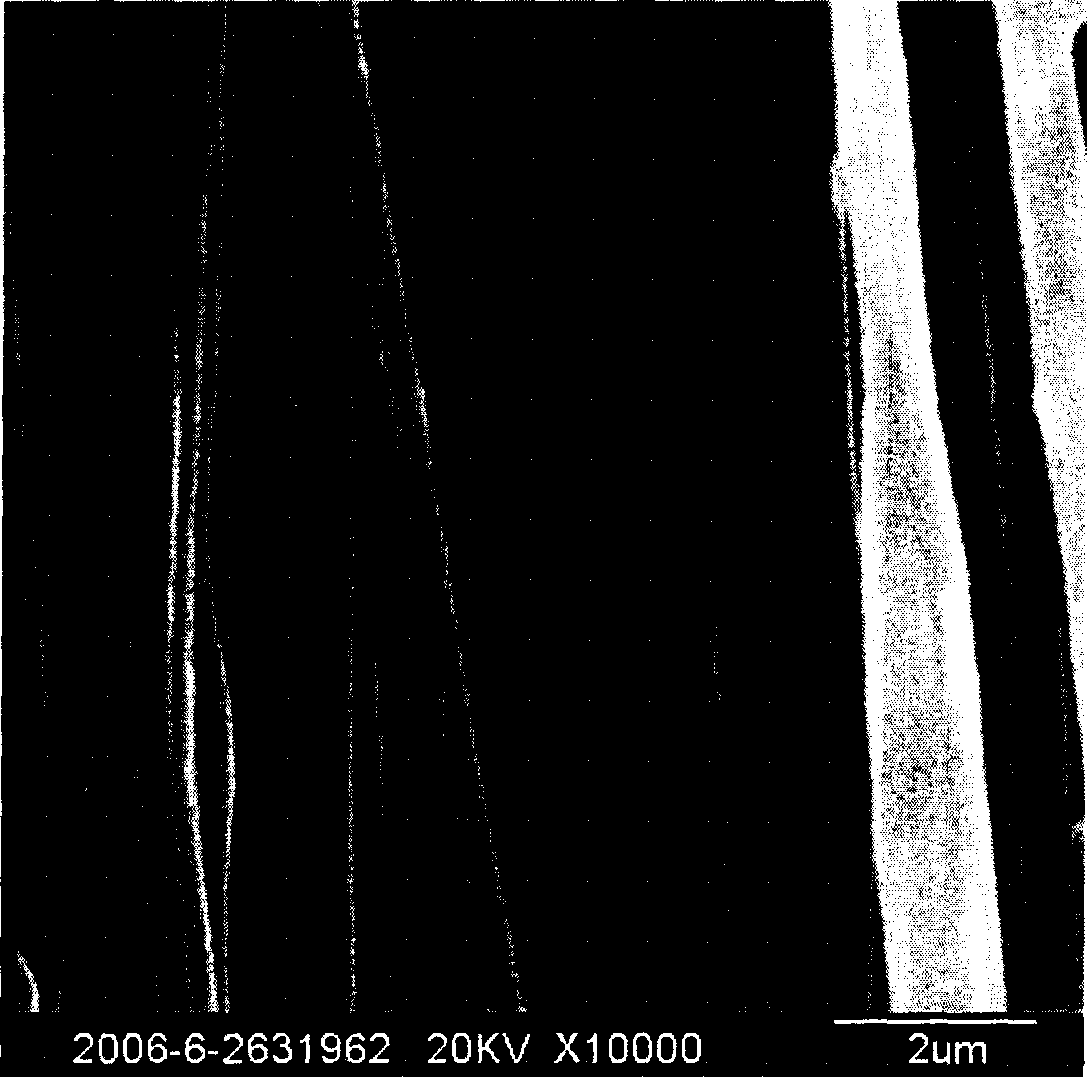

Directional magnetic electrical spinning Nano fibers, preparation method and equipment needed

InactiveCN1873064ASimple preparation processEasy to operate and repeatFilament/thread formingMonocomponent polyesters artificial filamentNormal positionEngineering

A method for preparing directional magnetic nanofiber of electric-spinning type includes utilizing Fe3O4 magnetic fluid and high polymer solution as raw material and applying normal position composite means to carry out electric-spinning under certain conditions, setting magnetic field at receiving unit to use magnetic field to induce high polymer nanofiber containing Fe3O4 to be directionally arranged along magnetic field direction for obtaining nanofiber being set with diameter of 100-600nm and being directionally arranged along magnetic direction. The device for realizing said method is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing chitosan-based silver-loaded composite antimicrobial superfine fiber membrane

InactiveCN103705969ABroad-spectrum antibacterialImprove antibacterial propertiesAbsorbent padsNon-woven fabricsFiberPolyvinyl alcohol

The invention provides a method for preparing a chitosan-based silver-loaded composite antimicrobial superfine fiber membrane. The method is characterized by particularly comprising the following steps: 1, adding silver nitrate powder into an acetic acid aqueous solution with the mass fraction of 50-90%, stirring to dissolve to obtain a solution, weighing and adding chitosan and polyoxyethylene or polyvinyl alcohol powder into the solution, and stirring to obtain a spinning solution; and 2, adding the spinning solution into an electrostatic spinning device, carrying out electrostatic spinning under the conditions that the voltage is 10-20kv, the spinning solution injecting speed is 0.1-1.0mL / h, the receive distance is 8-30cm, the spinning temperature is 20-50 DEG C and the relative humidity is 10-55%, carrying out vacuum drying on the obtained white nanofiber membrane for 12-36 hours, and removing the residual solvent to obtain the chitosan-based silver-loaded composite antimicrobial superfine fiber membrane. The electrospun fiber membrane has the advantages of a certain mechanical property, good antimicrobial property and water absorbing ability and can be used for the fields of wound surface nursing and medical dressings with different anti-infection requirements through designing the compositing ratio of the chitosan and the nanometer silver.

Owner:DONGHUA UNIV

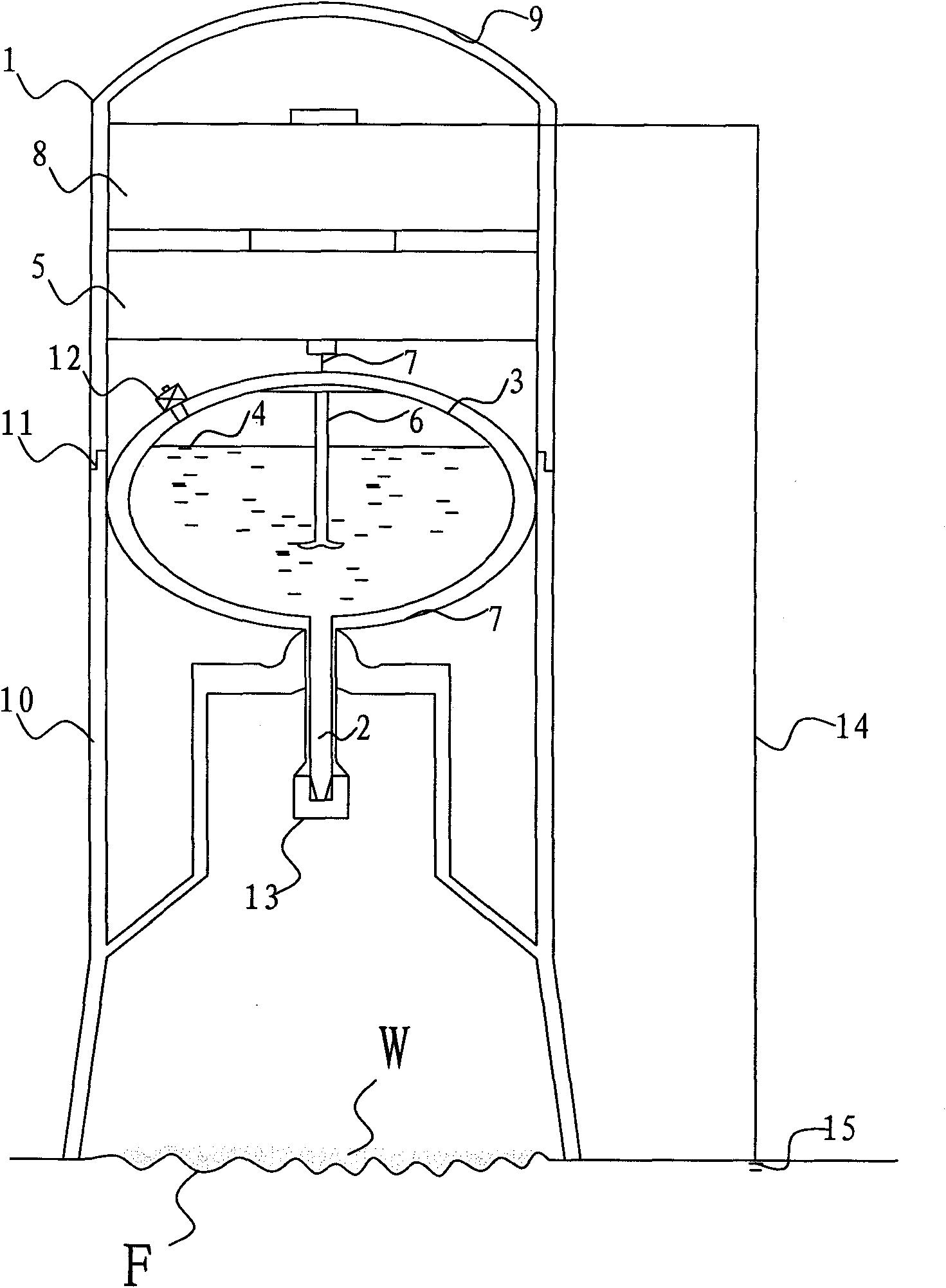

Apparatus and Method for Producing Electrospun Fibers

InactiveUS20080296808A1Artificial filaments from cellulose solutionsElectric discharge heatingFiberBiomedical engineering

An apparatus for making electrspun fibers comprises a collector that may be submerged in a coagulation bath. The collector may be automatically movable between a first position and a second position, wherein at least a portion of the collected fibers are submerged in a coagulation bath in the first position and spaced apart from the coagulation bath in the second position. The collector may be a rotating collector. A process for making electrospun fibers comprises electrospinning a dispersion and collecting a plurality of electrospun fibers, followed by submerging the collected fibers in a coagulation bath.

Owner:CORNELL RES FOUNDATION INC

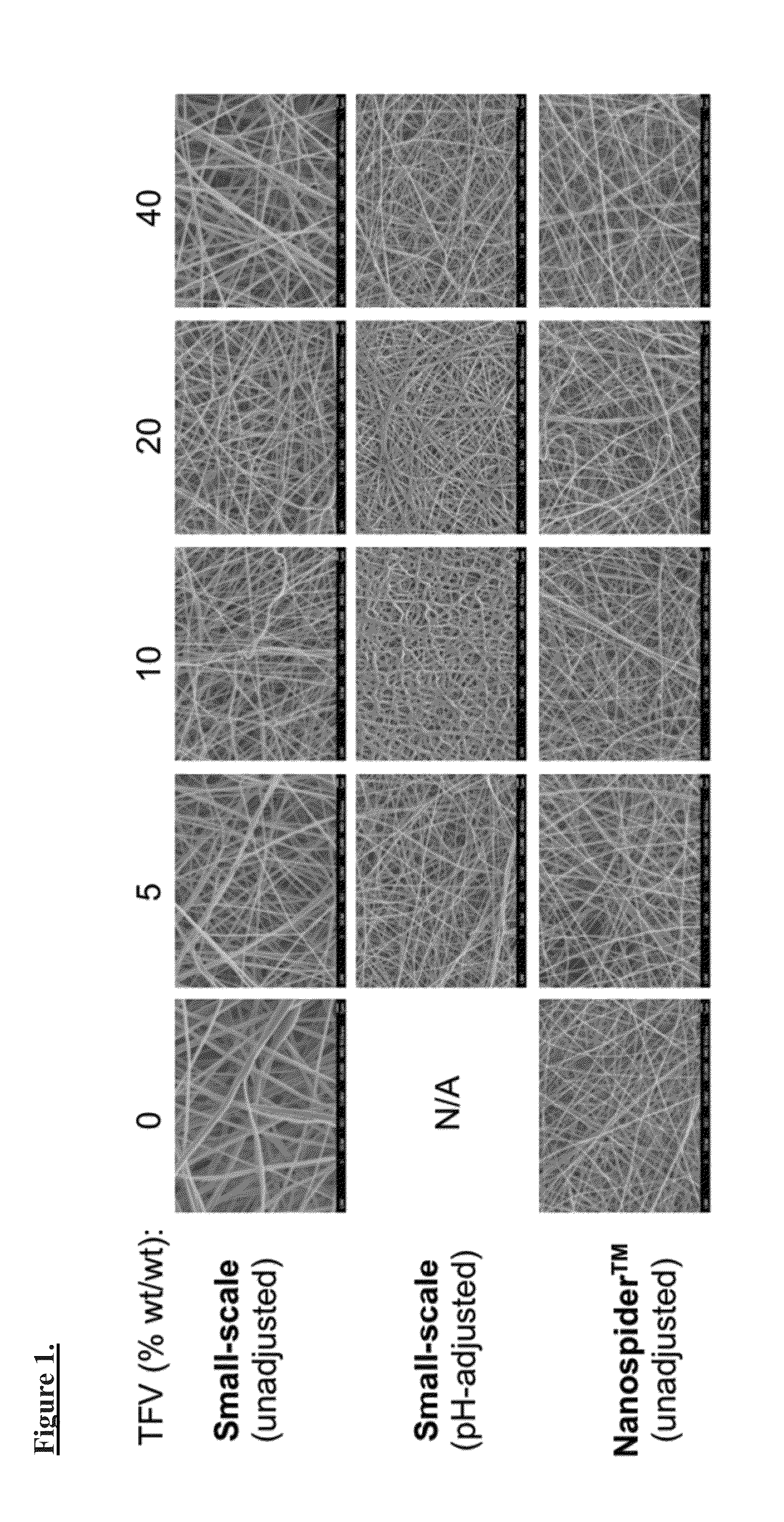

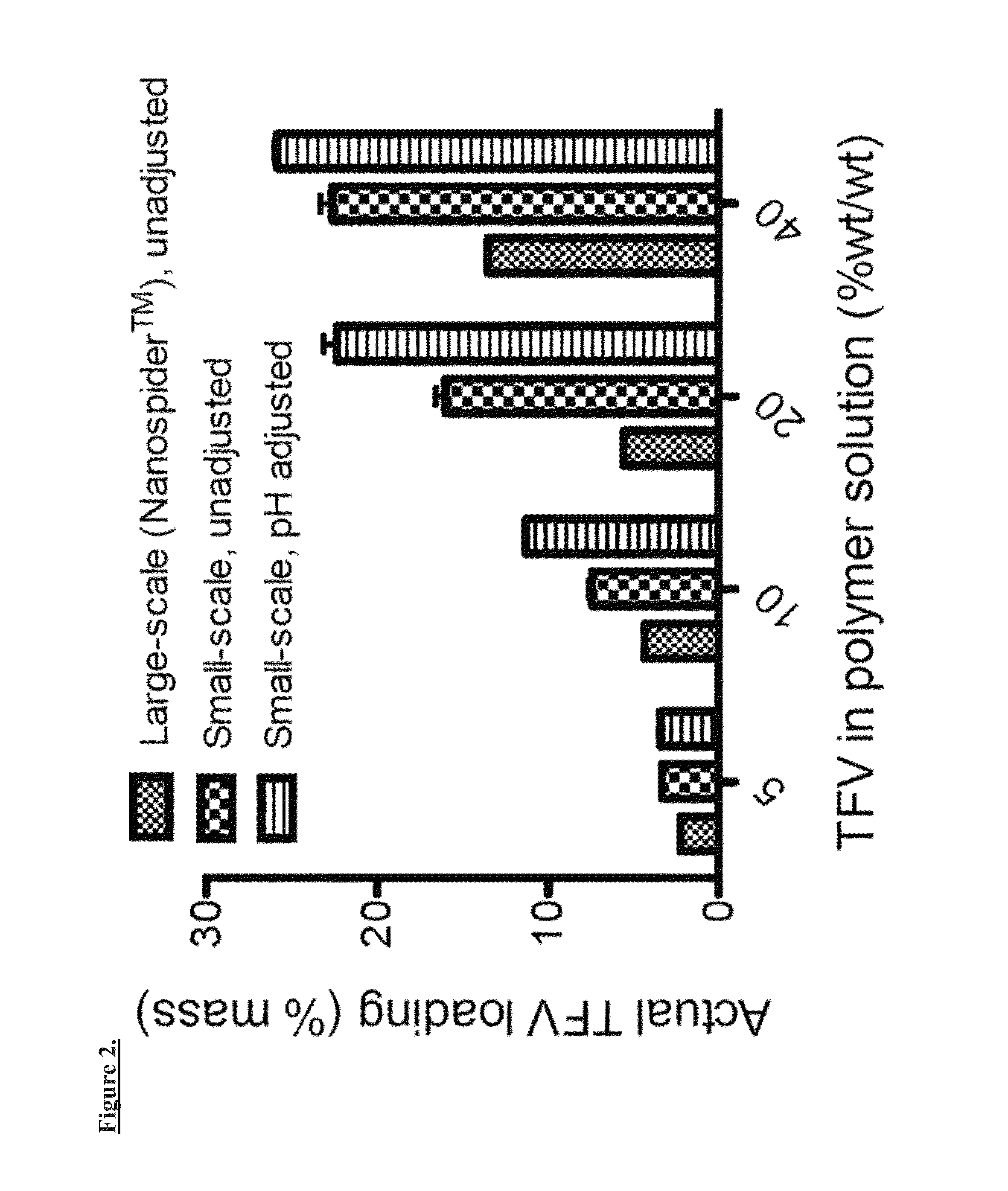

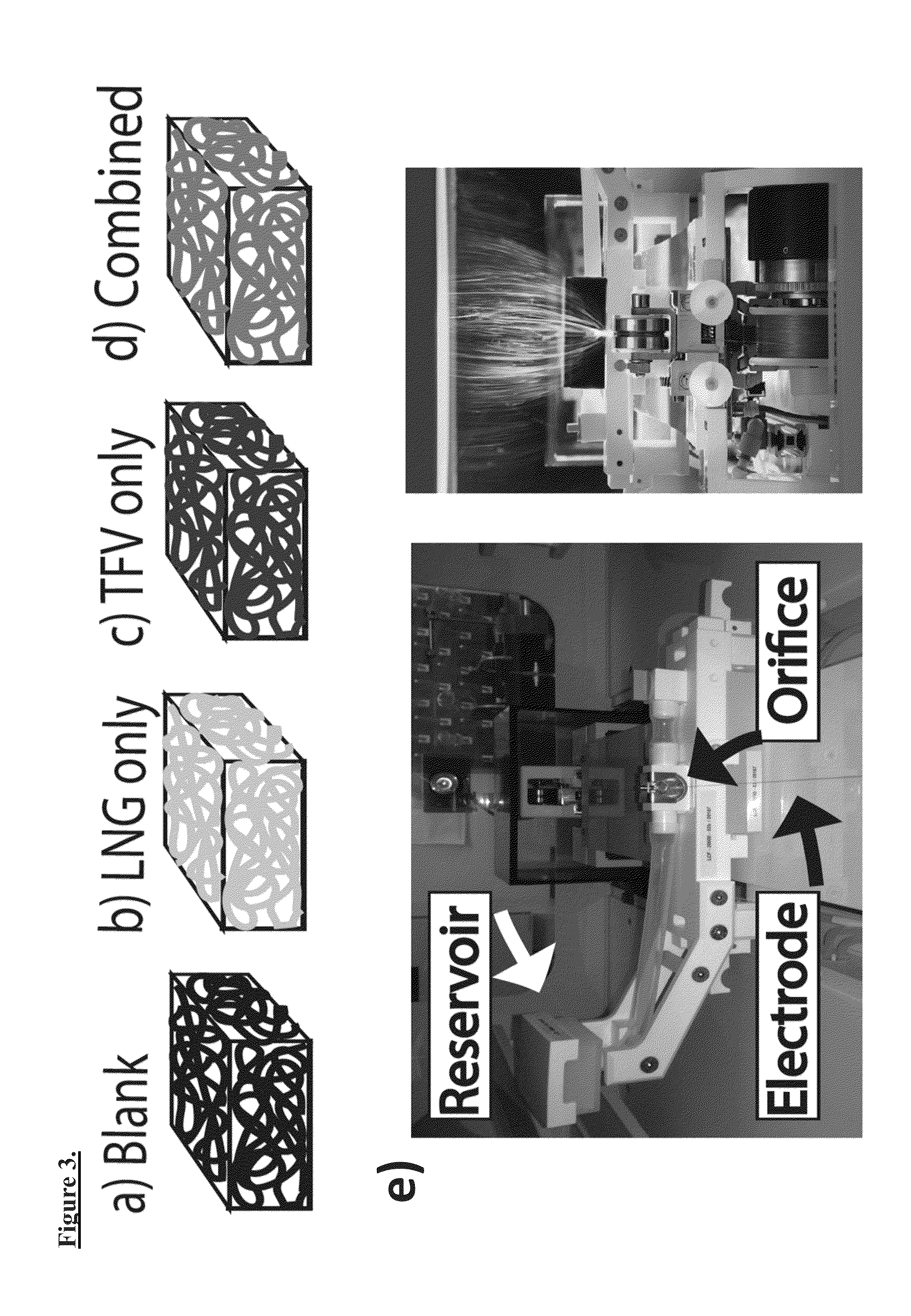

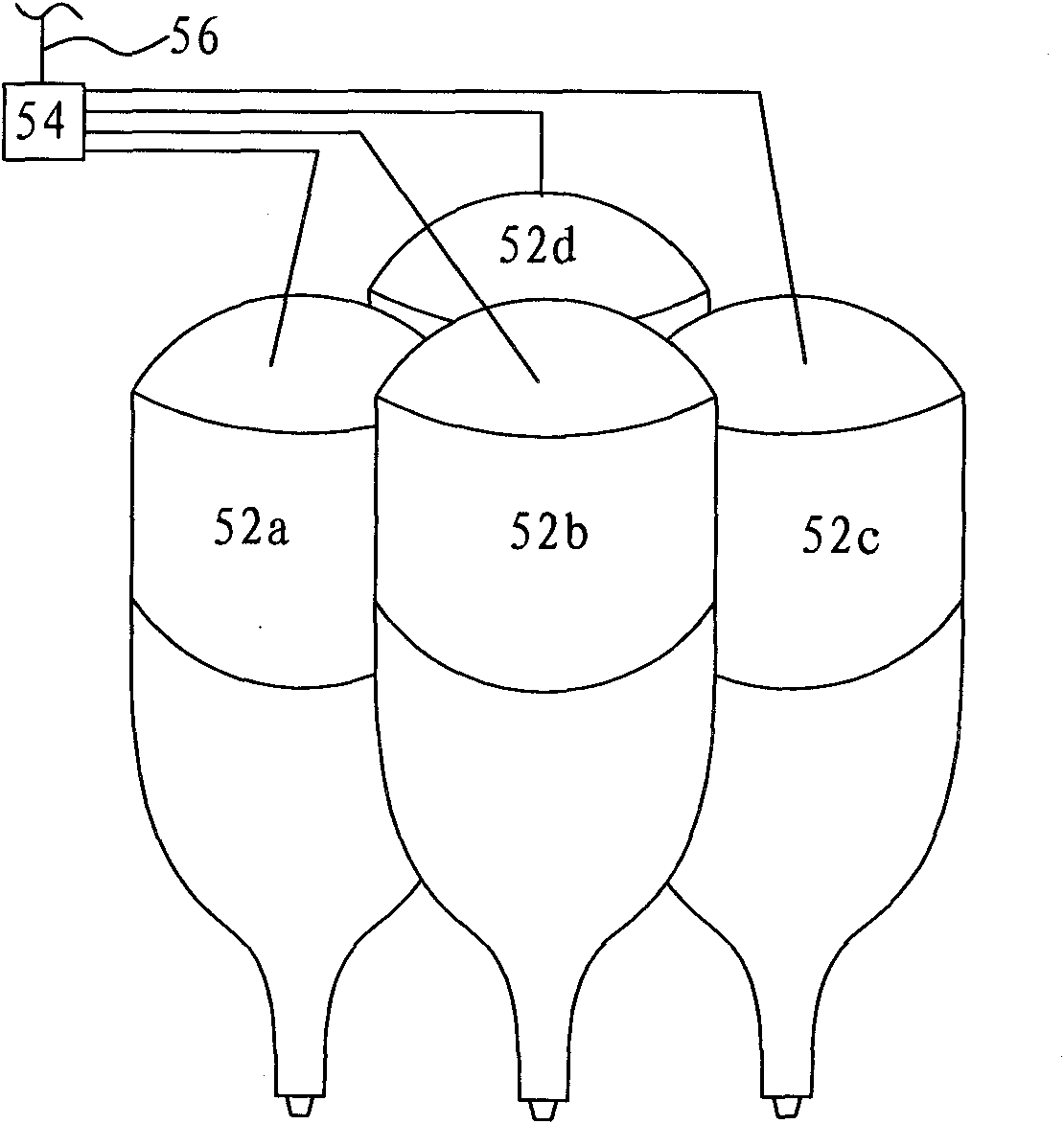

Vaginal matrices: nanofibers for contraception and prevention of HIV infection

Described are drug delivery systems incorporating electrospun fibers that comprise and deliver physicochemically diverse drug compounds. Such fibers provide significant advantages in drug agent release, such as adaptability for solid dosage delivery to mucosal tissues. This is in addition to allowing for controlled drug release. Systems and methods for large-scale electrospinning productivity are described, including novel microarchitectures allowing for variable pharmacokinetics in drug release.

Owner:UNIV OF WASHINGTON CENT FOR COMMERICIALIZATION

Viral fibers

InactiveUS20050180992A1Improve the level ofHigh surface energyMicroorganismsNanomedicineFiberLiquid crystalline

Long rod shaped M13 viruses were used to fabricate one dimensional (1D) micro- and nanosized diameter fibers by mimic the spinning process of the silk spider. Liquid crystalline virus suspensions were extruded through the micrometer diameter capillary tubes in cross-linking solution (glutaraldehyde). Resulting fibers were tens of micrometers in diameter depending on the inner diameter of the capillary tip. AFM image verified that molecular long axis of the virus fibers were parallel to the fiber long axis. Although aqueous M13 virus suspension could not be spun by electrospinning, M13 viruses suspended in 1,1,1,3,3,3-hexafluoro-2-propanol were spun into fibers. After blending with highly water soluble polymer, polyvinyl 2-pyrolidone (PVP), M13 viruses was spun into continuous uniform virus blended PVP (virus-PVP) fibers. Resulting virus-PVP electrospun fibers showed intact infecting ability to bacterial hosts after suspending in the buffer solution.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Particle filter system incorporating nanofibers

A filtration device including a filtration medium having a plurality of nanofibers of diameters less than 1 micron formed into a fiber mat in the presence of an abruptly varying electric field. The filtration device includes a support attached to the filtration medium and having openings for fluid flow therethrough. A device for making a filter material. The device includes an electrospinning element configured to electrospin a plurality of fibers from a tip of the electrospinning element, a collector opposed to the electrospinning element configured to collect electrospun fibers on a surface of the collector, and an electric field modulation device configured to abruptly vary an electric field at the collector at least once during electrospinning of the fibers. A method for making a filter material. The method provides a support having openings for fluid flow therethrough, electrospins nanofibers across an entirety of the openings, and abruptly varies an electric field at the collector at least once during electrospinning of the fibers.

Owner:RES TRIANGLE INST

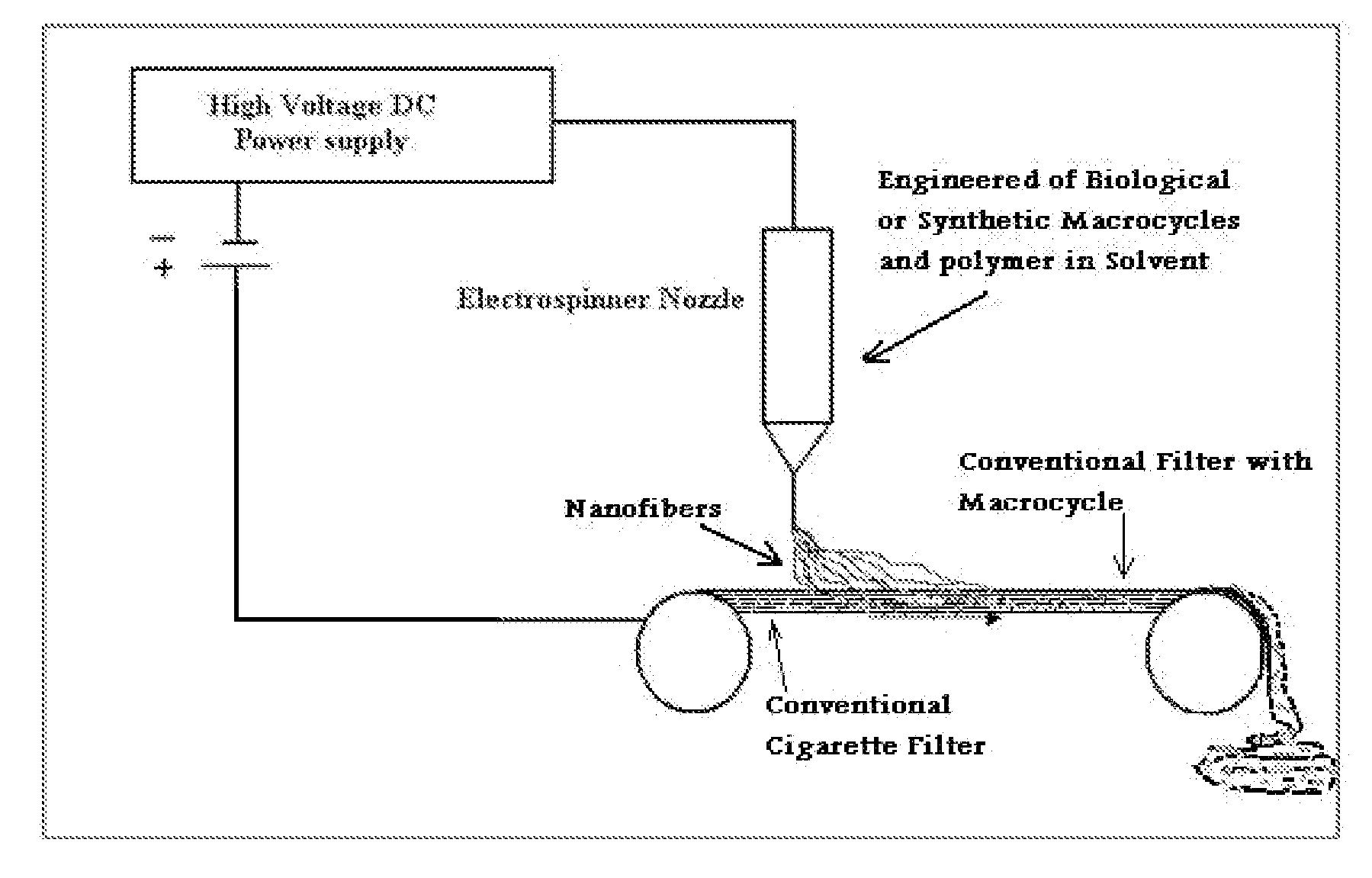

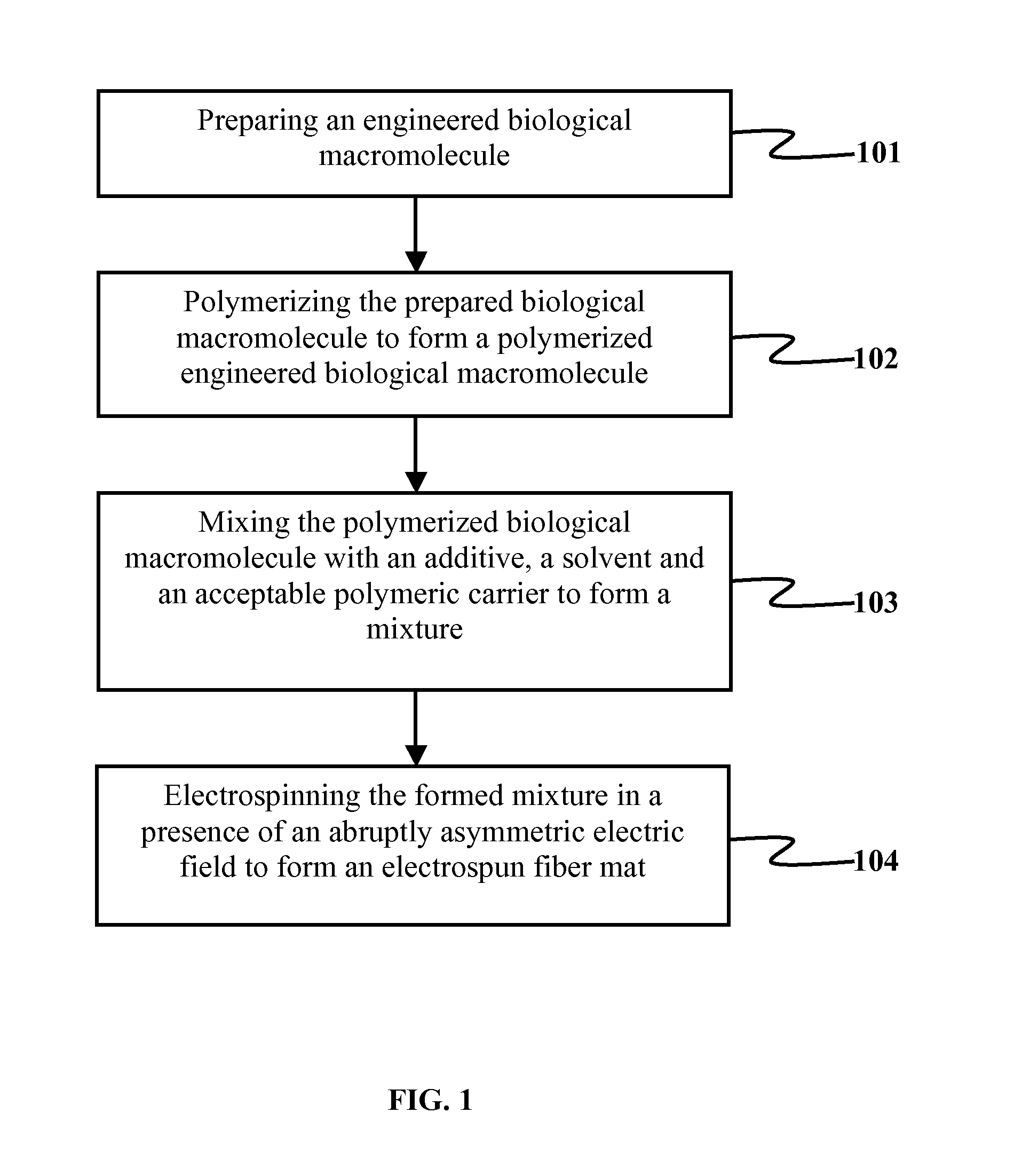

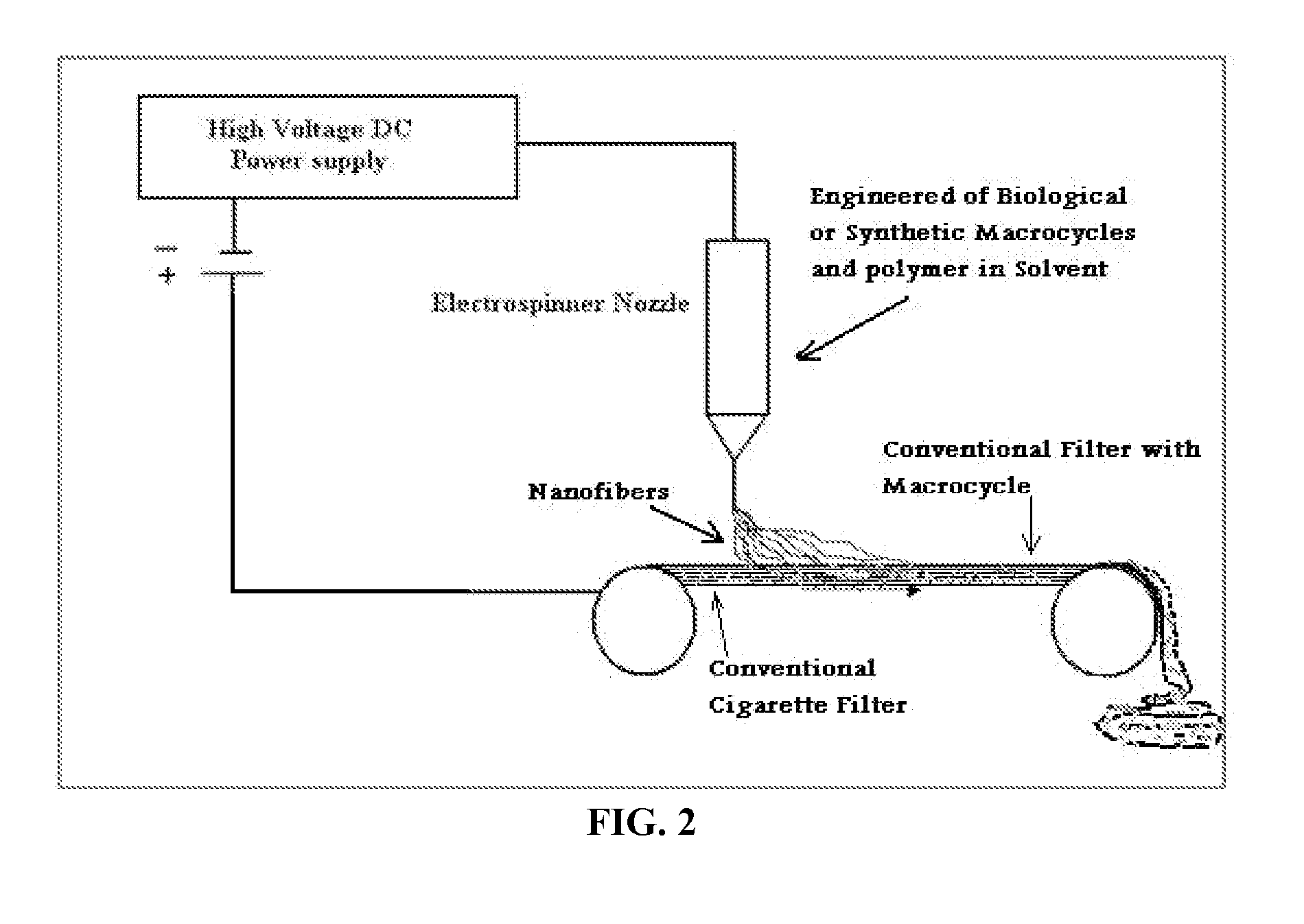

Nanostructural filter for removing toxic compounds

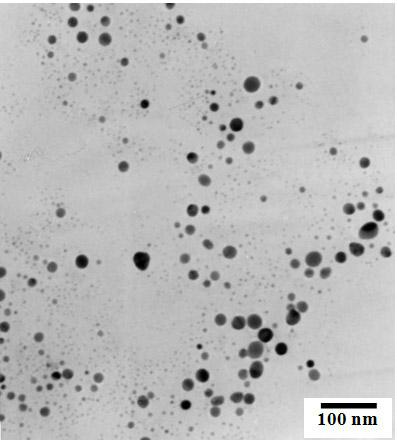

The various embodiments herein provide an electrospun fiber mat filter comprising a cigarette filter containing macrocycle for removing toxic compounds from a toxic material, wherein the toxic material comprises liquid, gas, and cigarette smoke and a method of synthesizing the same. The electrospun fiber mat cigarette filter comprises a biological, organic or synthetic macrocycle, plurality of additives, a solvent and an acceptable polymeric carrier. The biological macromolecules are engineered polyhemoglobin and / or chlorophyll. The biological, organic, or synthetic macrocycle are electrospun with the acceptable polymeric carrier in presence of an abruptly asymmetric electric field to form an electrospun fiber mat. The electrospun fiber mat is made up of networks of plurality of nanofibers.

Owner:GHANAVI JALALEDIN

Fibroin-silver-nanoparticle composite material and preparation method thereof

The invention belongs to the technical field of composite materials and particularly provides a fibroin-silver-nanoparticle composite material and a preparation method thereof. The fibroin-silver-nanoparticle composite material comprises fiber (including electrospinning fiber), film, hydrogel and three dimensional porous materials. The preparation method comprises the following steps: after fibroin solution and silver nitrate solution are mixed, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight, and then the material is formed and prepared; or fibroin is prepared into different forms of materials first, then the materials are soaked in silver nitrate water solution, and finally, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight. According to the invention, fibroin is taken as material matrix and the reducing agents and stabilizing agents of silver-nanoparticles, and no other chemical agent is required to be added; and the preparation process is simple, energy-saving and environment-friendly, and the material has various forms.

Owner:FUDAN UNIV

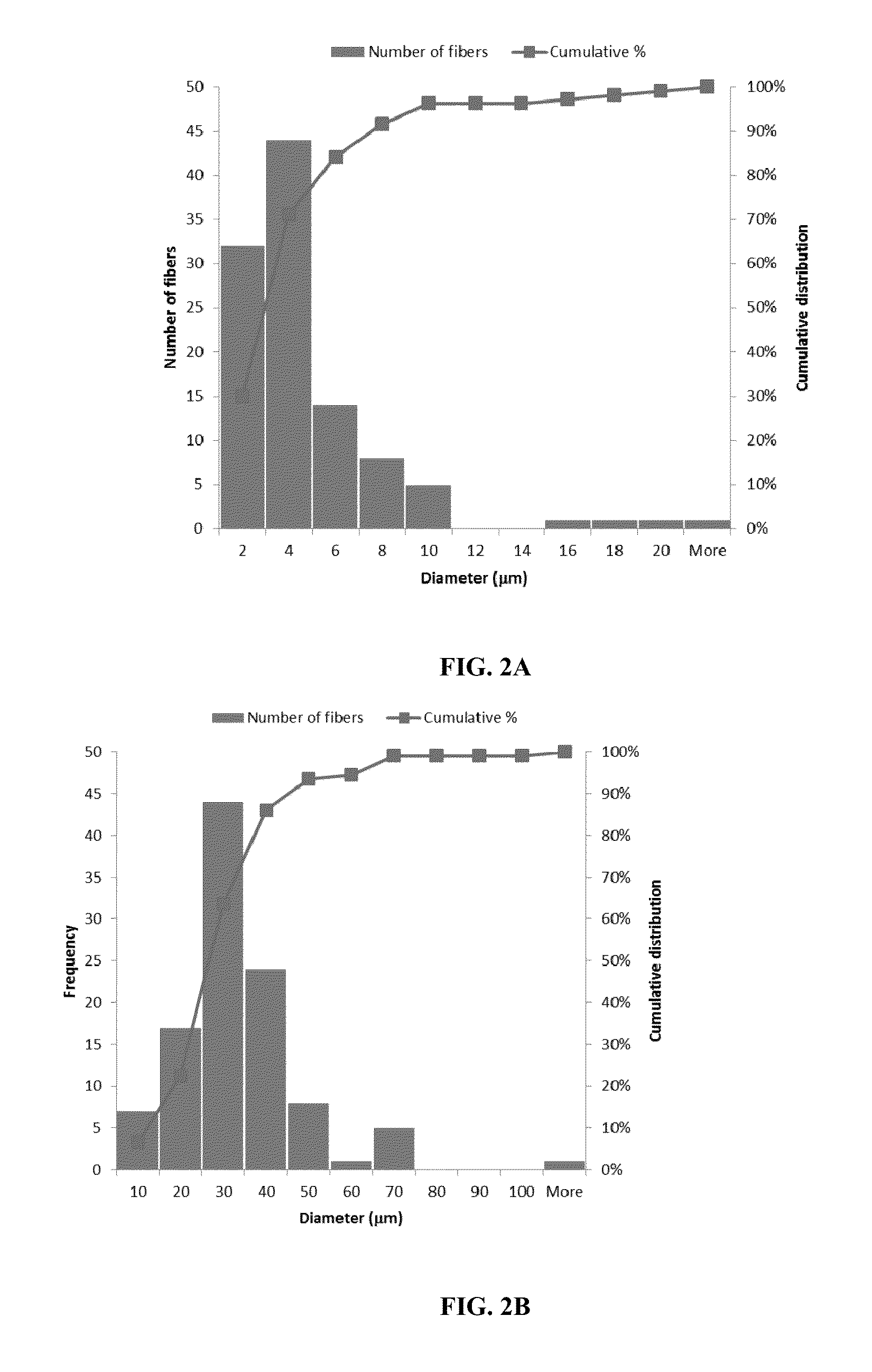

Ultrafine Electrospun Fibers of Poly-4-Hydroxybutyrate and Copolymers Thereof

ActiveUS20140277572A1Large specific surface areaHigh degreeSuture equipmentsLayered productsPolymer sciencePolymer solution

Methods to produce structures containing ultrafine fibers with average diameters from 10 nm to 10 μm and more preferably from 50 nm to 5 μm, have been developed. These methods produce ultrafine fibers without substantial loss of the polymer's weight average molecular weight. The ultrafine electrospun fibers have an unexpectedly higher degree of molecular orientation, and higher melt temperature than fibers derived by dry spinning. In the preferred embodiment, the polymer comprises 4-hydroxybutyrate. The ultrafine fibers are preferably derived by electrospinning. A solution of the polymer is dissolved in a solvent, pumped through a spinneret, subjected to an electric field, and ultrafine fibers with a high degree of molecular orientation are collected. These structures of ultrafine fibers can be used for a variety of purposes including fabrication of medical devices.

Owner:TEPHA INC

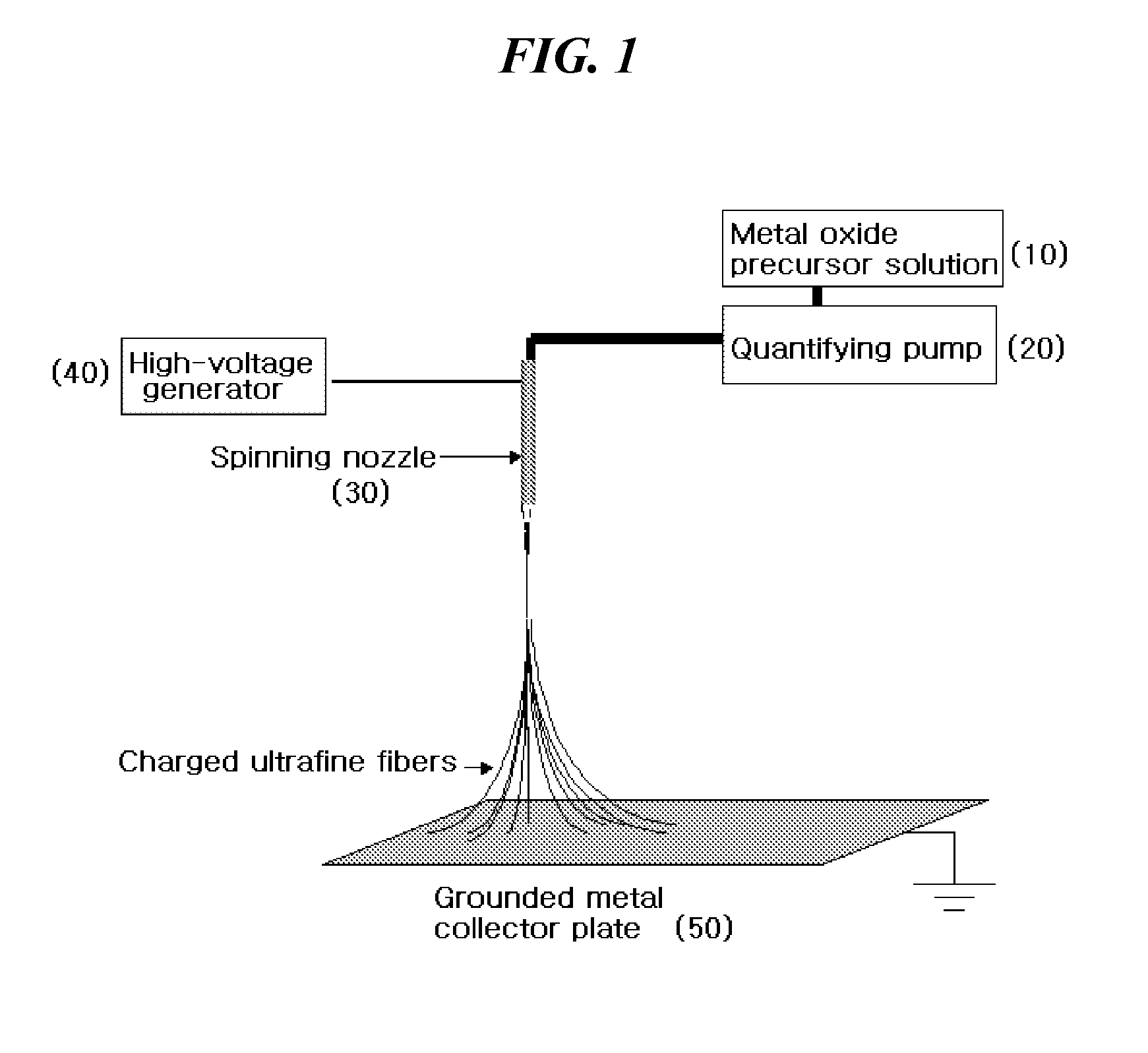

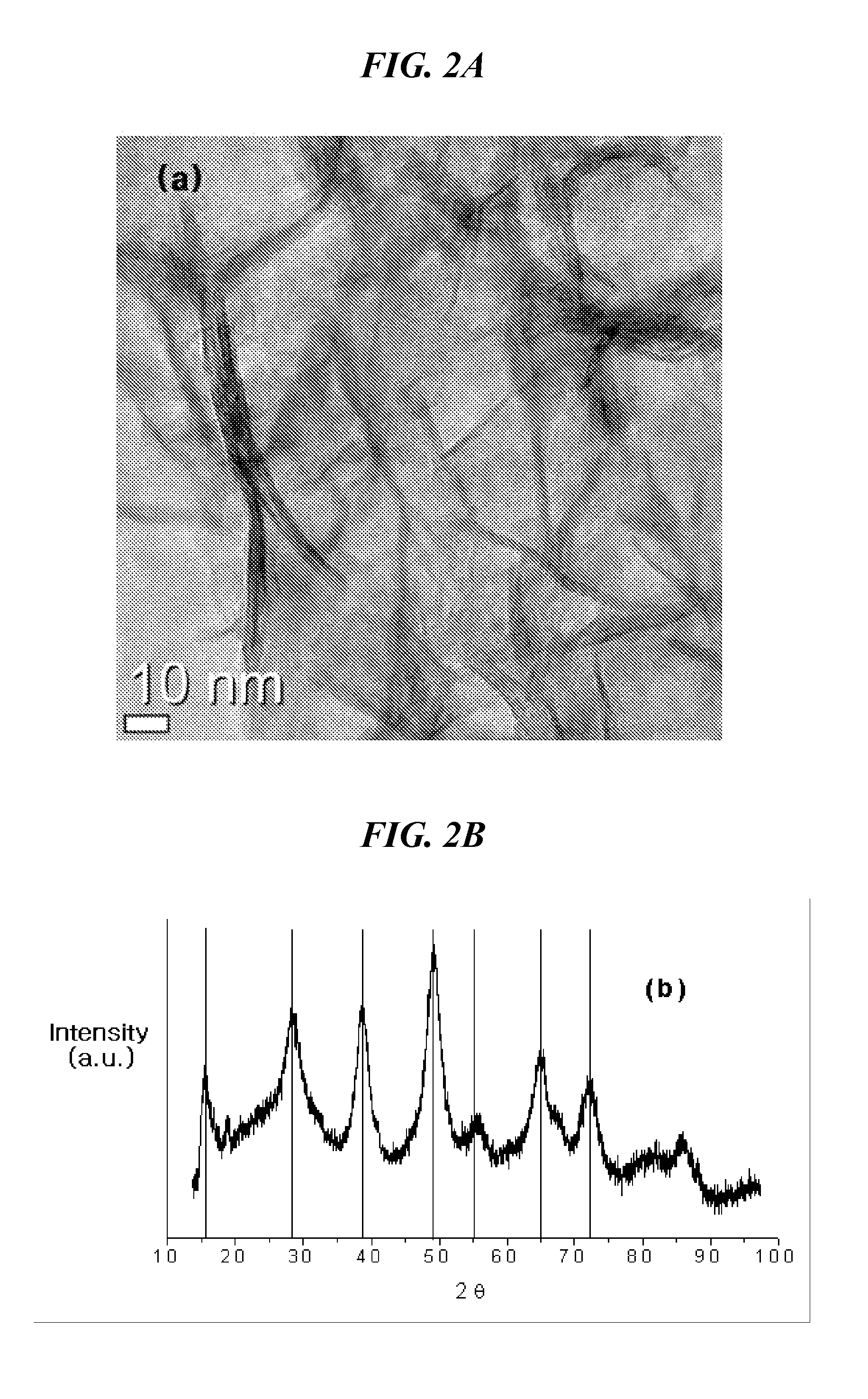

Ultrafine continuous fibrous ceramic filter and method of manufacturing same

InactiveUS20110266213A1Increase flow rateExtend your lifeMaterial nanotechnologySemi-permeable membranesPolymer resinSpinning

An ultrafine continuous fibrous ceramic filter, which comprises a filtering layer of a fibrous porous body, wherein the fibrous porous body comprises continuous ultrafine fibers of metal oxide which are randomly arranged and layered, and powdery nano-alumina incorporated into the ultrafine fibers or coated thereon, the ultrafine fibers being obtained by electrospinning a spinning solution comprising a metal oxide precursor sol-gel solution, and optionally, a polymer resin, and sintering the electrospun fibers, in which the ultrafine fibers have an average diameter of 10˜500 nm, and the fibrous porous body has a pore size of maximum frequency ranging from 0.05 to 2 μm, exhibits high filtration efficiency at a high flow rate, and can be regenerated.

Owner:KOREA INST OF SCI & TECH

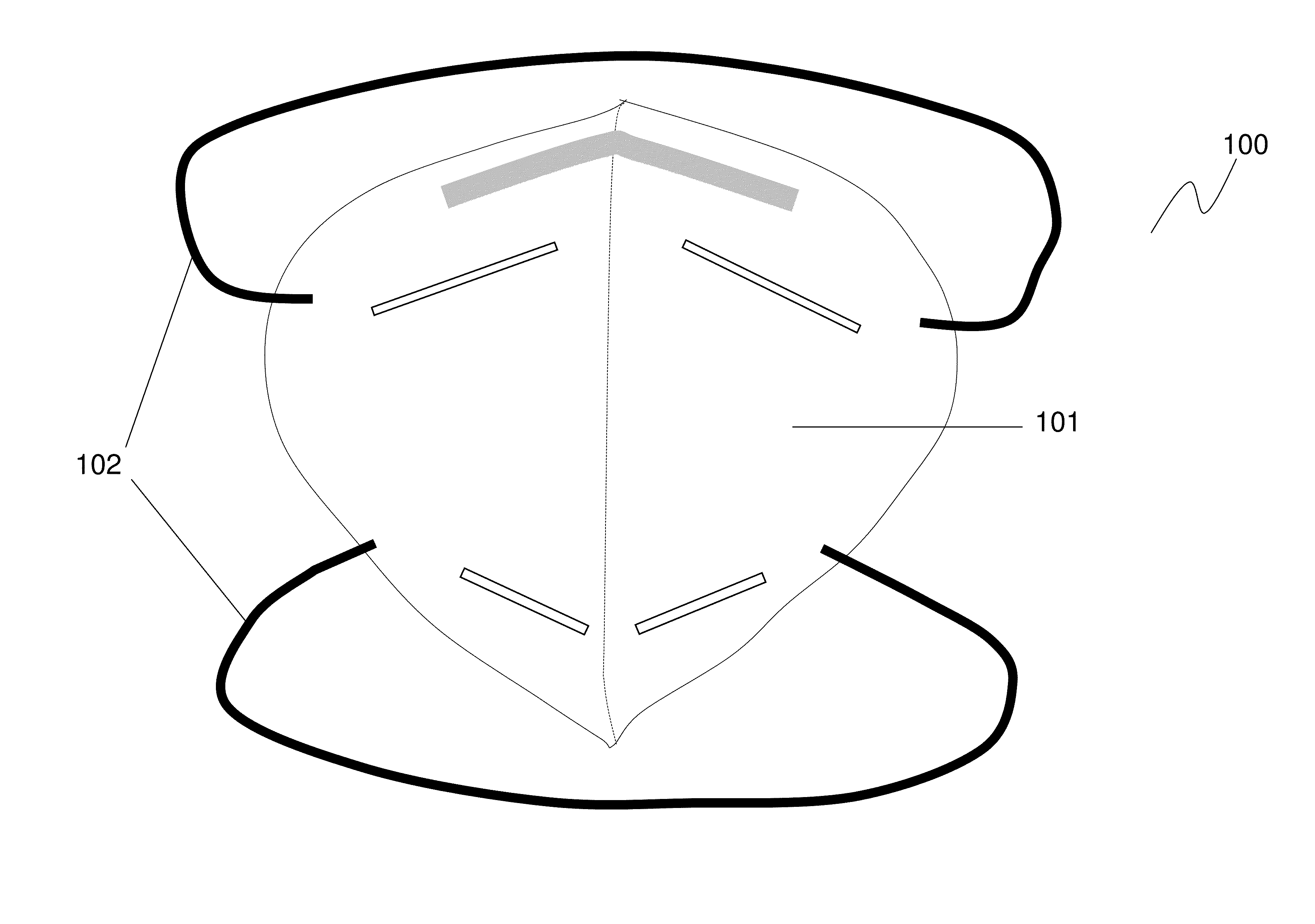

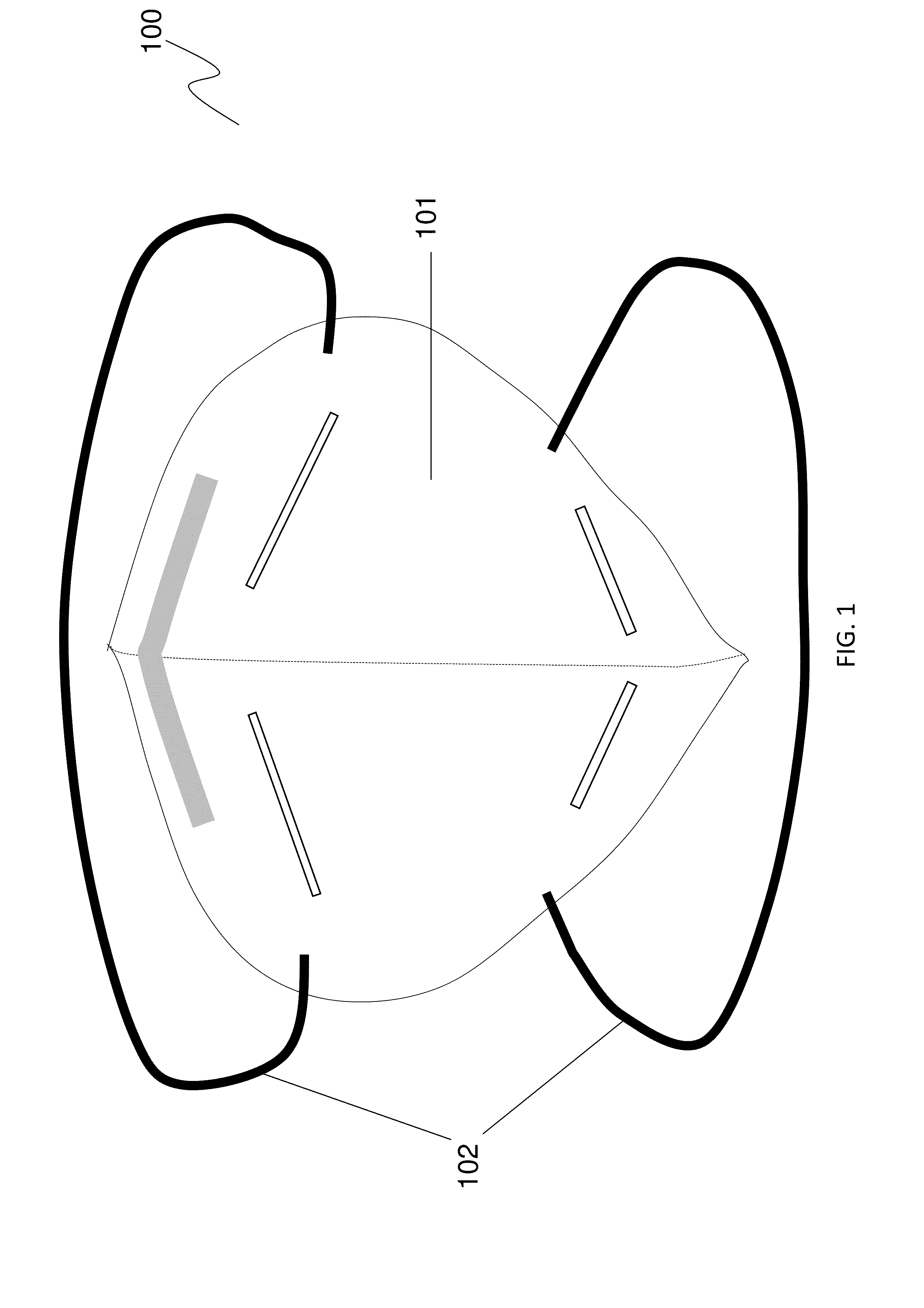

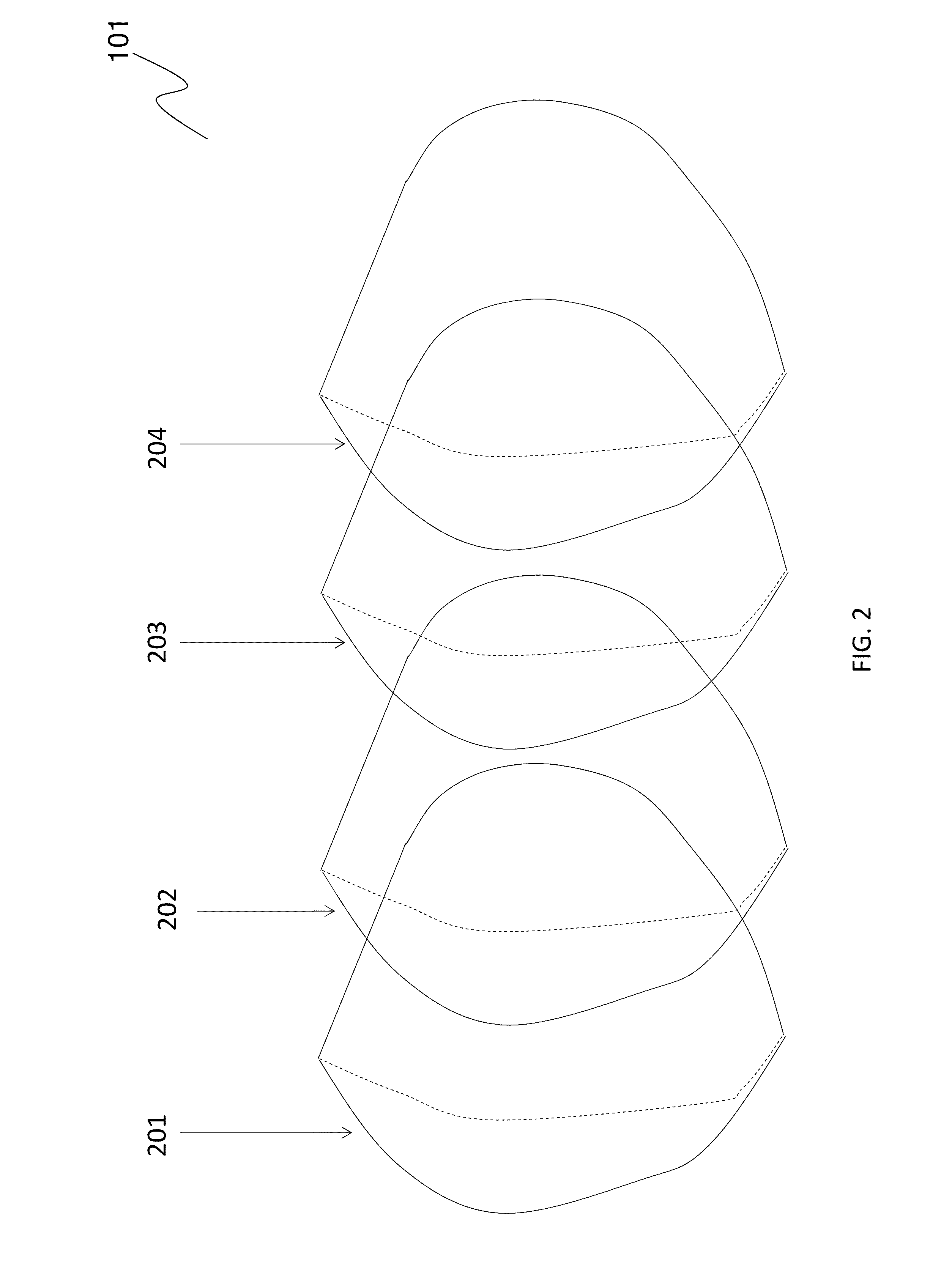

Protective masks with coating comprising different electrospun fibers interweaved with each other, formulations forming the same, and method of producing thereof

ActiveUS20160174631A1Improve face sealImprove sealingBiocideInorganic active ingredientsFiberRespirator

The present invention provides a protective mask comprising an ultrafine fibrous coating comprising partially gelled submicron fibers interweaved with nanofibers and a biocide encapsulated in, surface-attached onto, blended with, physically trapped, and / or chemically linked to said submicron fibers and nanofibers. In an example, a microfibrous substrate with the coating assembles with other microfibrous substrates to form a protective mask having N95 level of protection and bacteria-killing capability.

Owner:PROFIT ROYAL PHARMA LTD

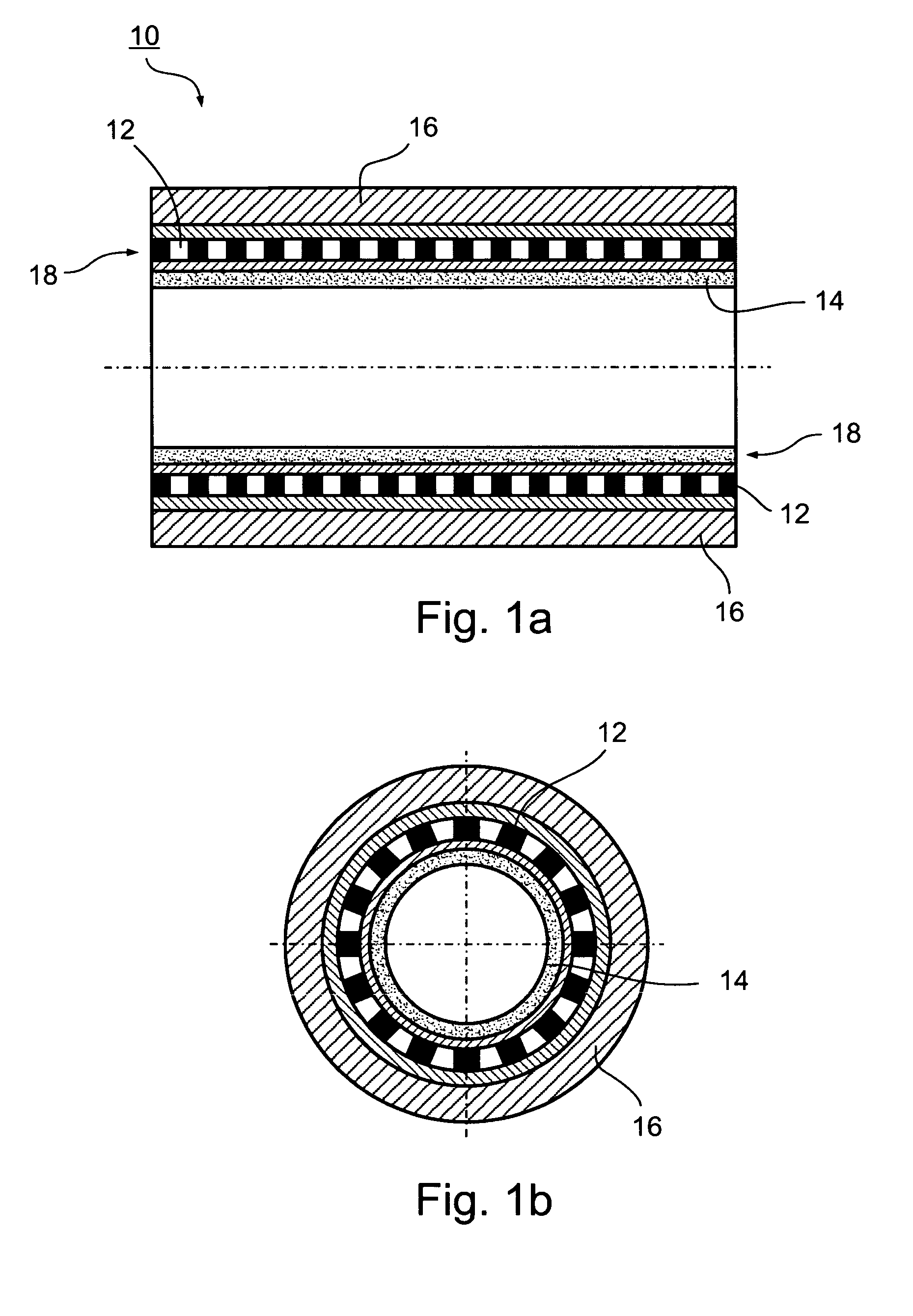

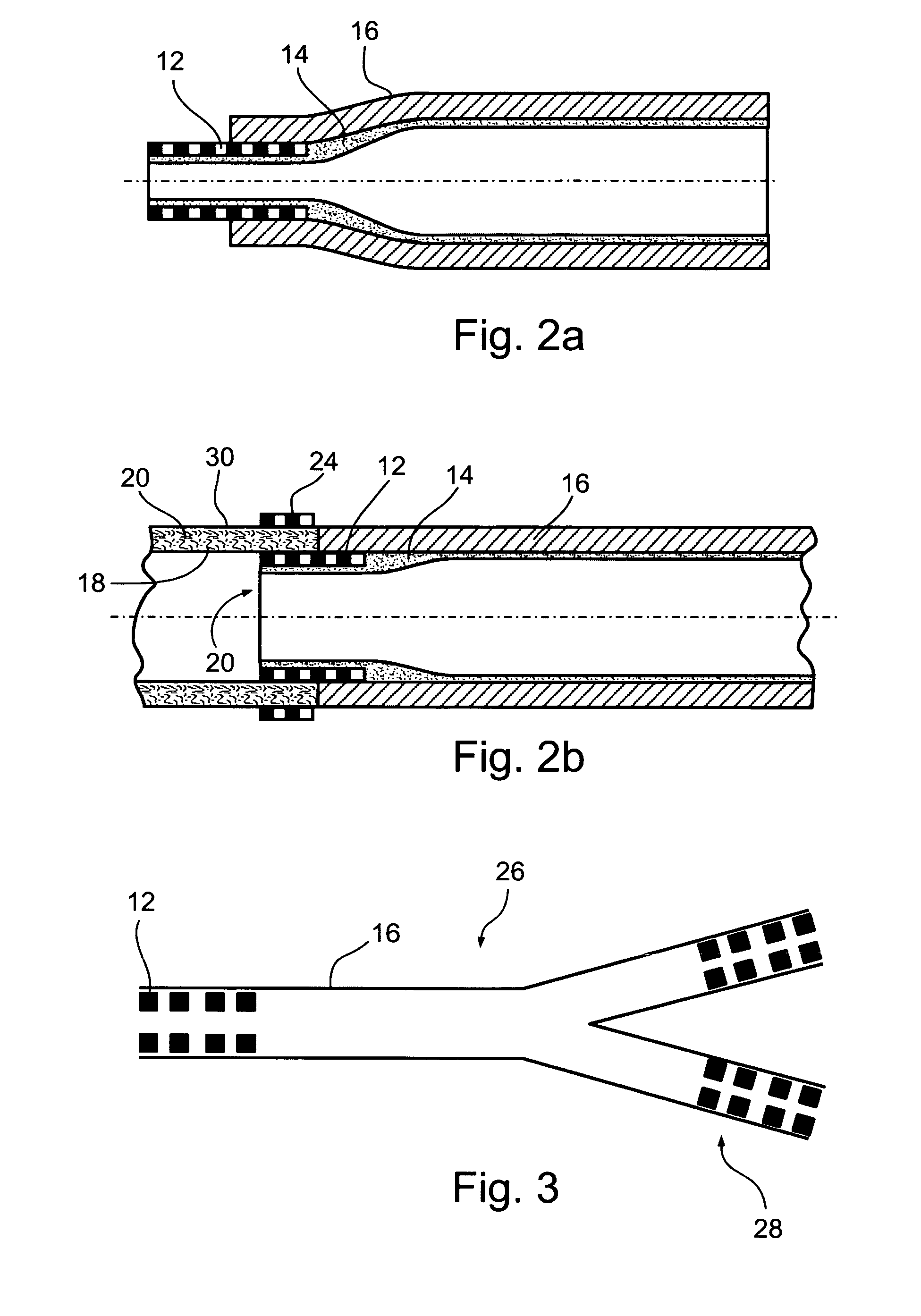

Vascular Prosthesis with Anastomotic Member

A medical device for implantation in a vessel is disclosed. The medical device comprises at least one anastomotic member, at least partially interposing a non-woven liner of electrospun fibers and a non-woven cover of electrospun fibers. The at least one anastomotic member is designed for engaging at least one end of the medical device to a wall of the vessel upon implantation of the medical device within the vessel.

Owner:NICAST LTD

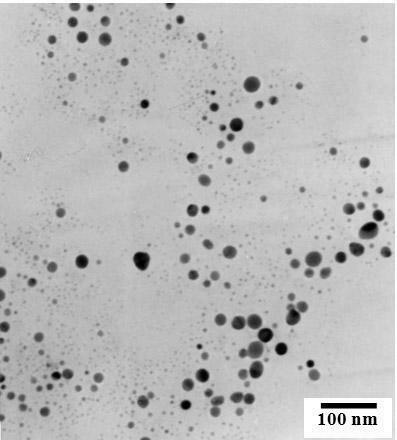

Method for preparing alginate microsphere/high polymer composite nanometer fiber by electrostatic spinning

InactiveCN101555637AConvenient sourceEasy to operateWet spinning methodsMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a method for preparing an alginate microsphere / high polymer composite nanometer fiber by electrostatic spinning. The method comprises the following steps of: dissolving alginate or alginate blend in distilled water or super purified water to obtain uniform alginate aquagel and water phase solution A; evenly mixing a surface activate agent and an organic solvent to obtain oil phase solution B; mixing the water phase solution A and the oil phase solution B according to a volume ratio of 1:10-15 with the addition of 0.1 to 0.5ml of calcium chloride solution, and shaking and evenly mixing the mixture to obtain mixed solution; adding a high polymer spinning material into the mixed solution for electrostatic spinning to obtain the alginate microsphere / high polymer composite nanometer fiber. The preparation method has simple operation and excellent economic benefit, is friendly to environment and is applicable to large-scale production; and the method combines the microsphere into the nanometer fiber, so that the prepared fiber performs excellence in both mechanical performance and slow release property compared with common electrospun fibers and has wider application prospect.

Owner:DONGHUA UNIV

Nonwoven fiber materials

The present invention provides electrospun fibrous materials with various potential applications in the healthcare industry. Unique fiber morphologies are provided, which can allow the fibrous materials to exhibit a range of desirable properties. The electrospun fibrous materials are advantageously biocompatible and may be tailored for certain specific applications, e.g., by the incorporation of one or more therapeutic agents. Exemplary materials described herein can be employed in controlled, localized drug delivery, tissue engineering, and wound healing applications.

Owner:NORTH CAROLINA STATE UNIV

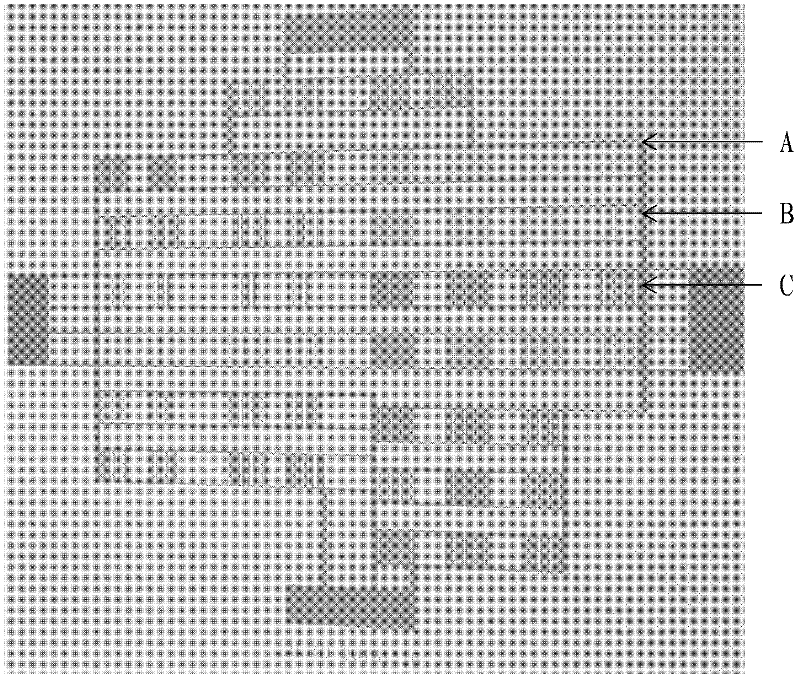

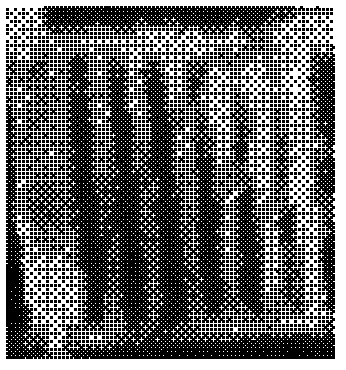

Method for preparing micro-nano-scale patterned electrospun fiber membrane

InactiveCN102260963AEasy to processHigh degree of automationNew-spun product collectionFilament/thread formingFiberMicro nano

The invention relates to a method for preparing a micro-nano-scale patterned electrospun fiber membrane. The method comprises the following steps: A) using a computer to draw a required pattern through layout design software; B) inputting the pattern into a micro-electrical mechanical system and using the micro-electrical mechanical system to deposit metal onto a non-metal base material according to the input pattern so as to get a receiving plate with the micro-nano-scale pattern; and C) taking the receiving plate with the micro-nano-scale pattern as the receiving plate of an electrospinning device and performing electrostatic spinning so as to get the micro-nano-scale patterned electrospun fiber membrane. By adopting the method, the patterned electrospun fiber membrane with micro-nano-scale minimal unit size of the pattern can be prepared, and the patterned electrospun fiber membrane has good application prospects in repair and manufacturing of micro-electronic devices, sensors, ultrafine filters and human tissues. Furthermore, the preparation process is simple and convenient, the degree of automation is high and the processed pattern is precise, controllable and good in repeatability.

Owner:SOUTHWEST JIAOTONG UNIV

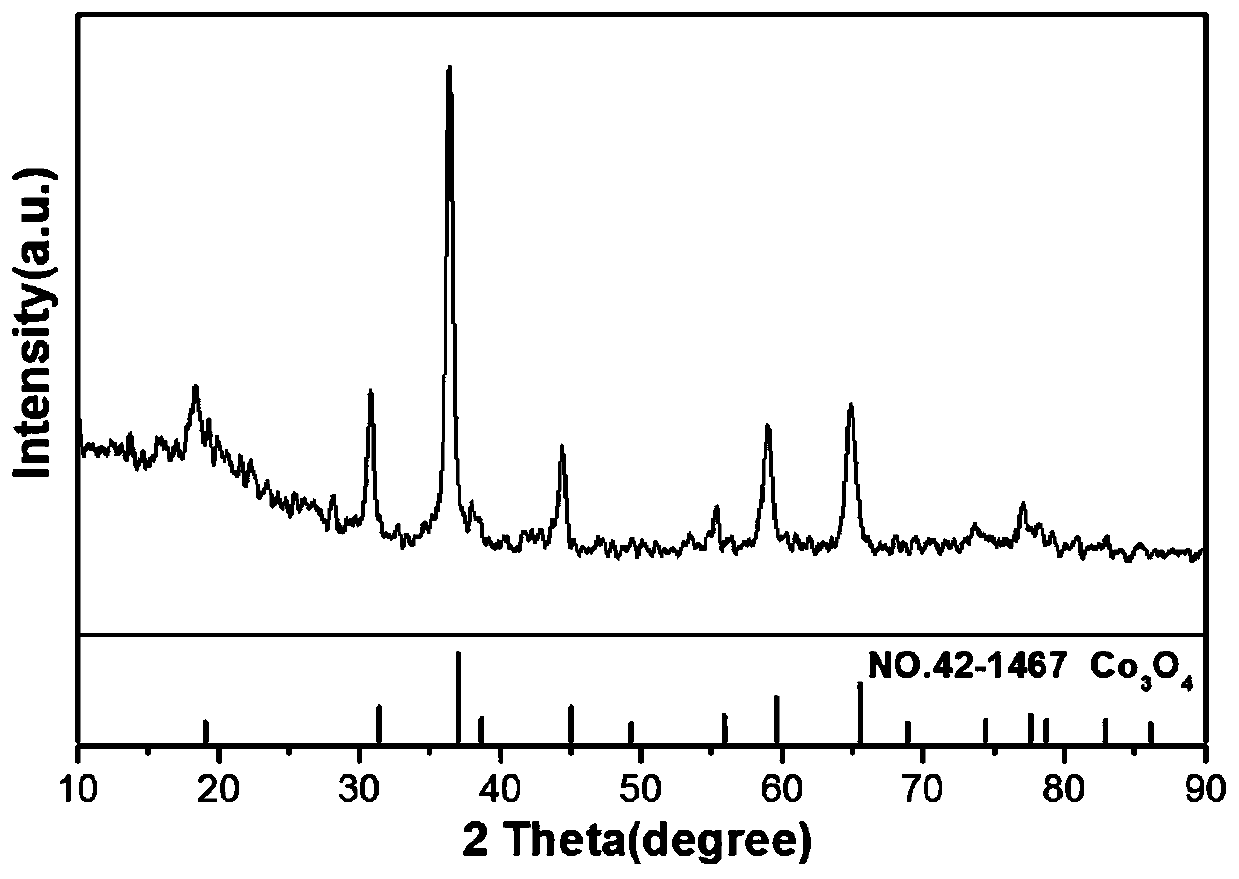

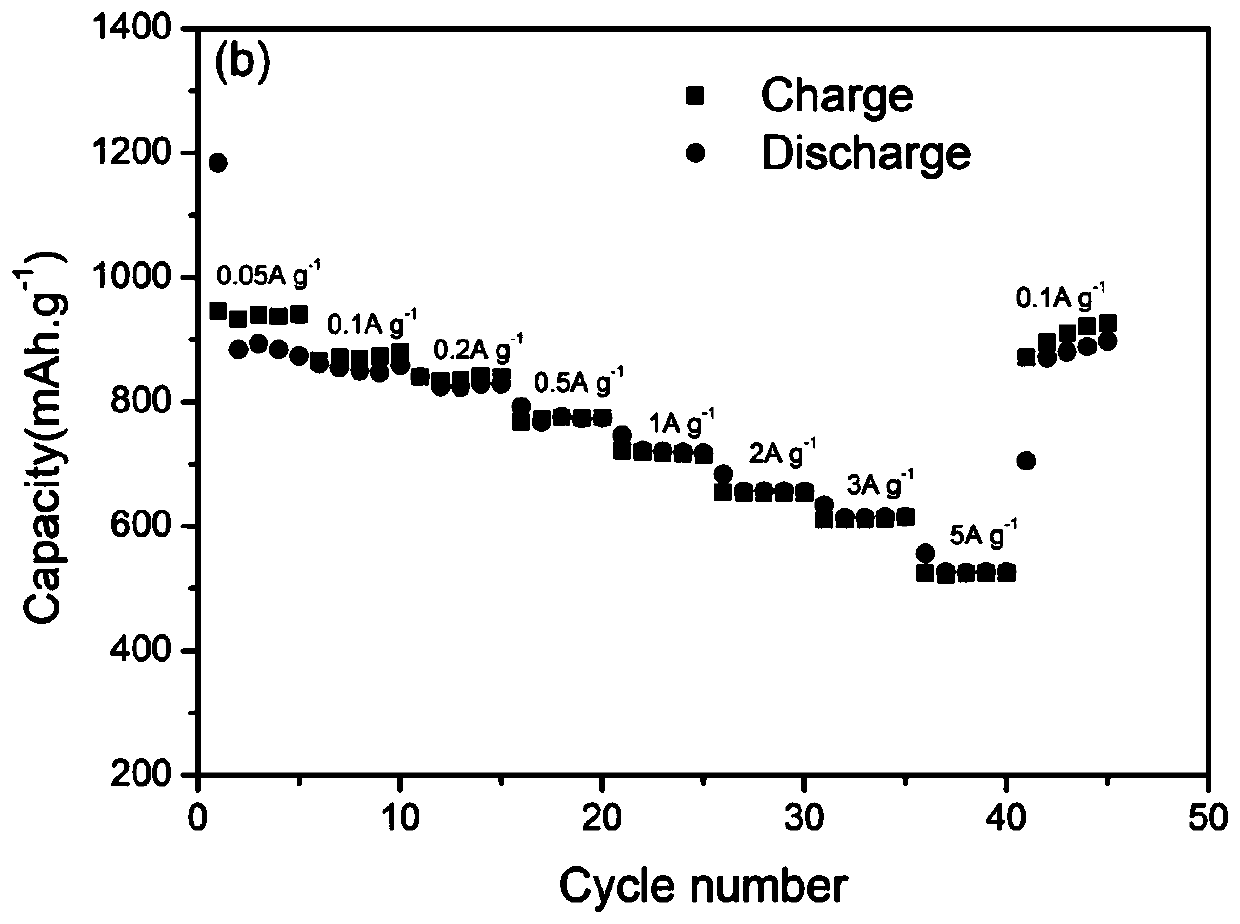

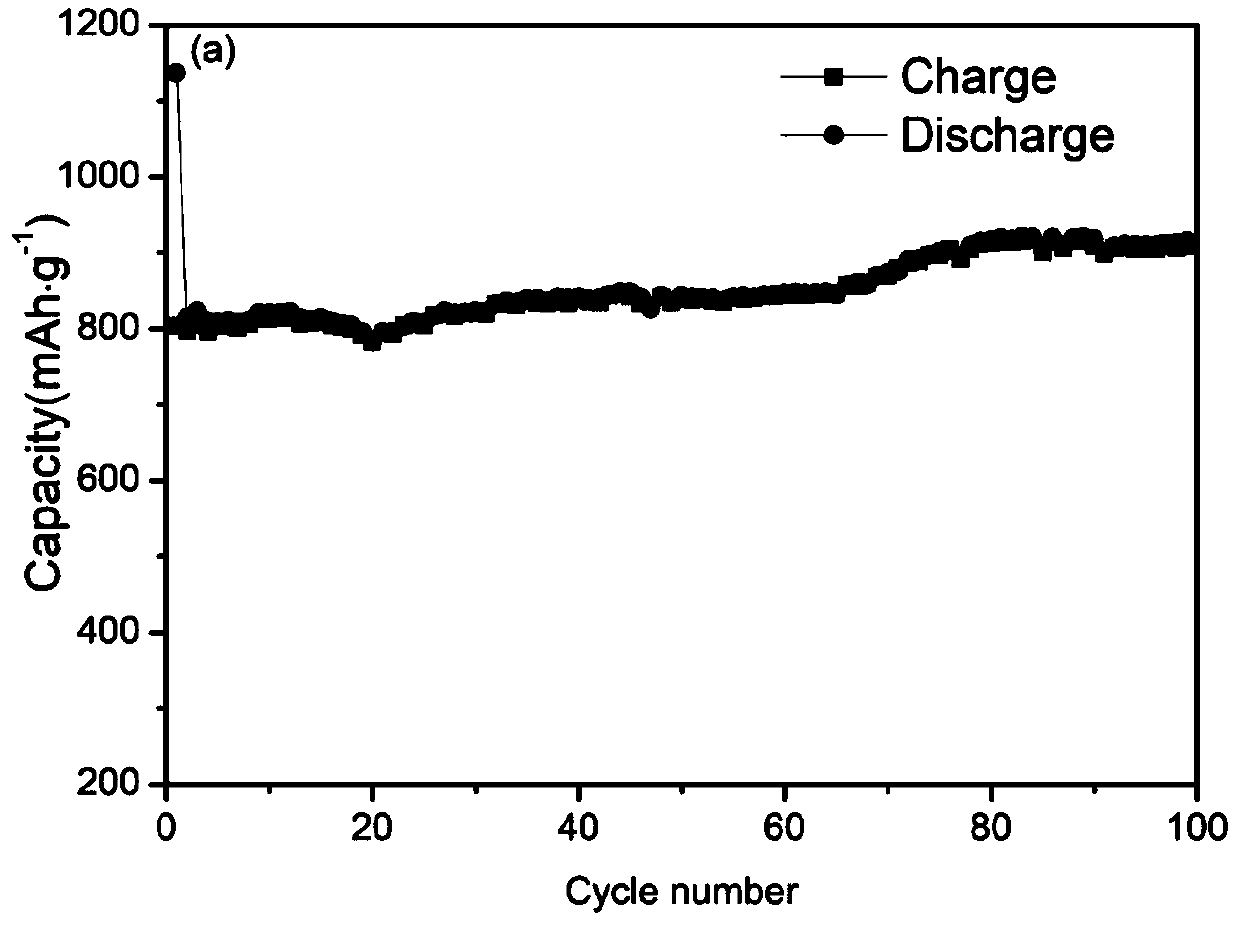

Cobalt oxide carbon nanofiber flexible electrode material derived from MOF for lithium ion batteries and preparation method thereof

InactiveCN110137461AImprove flexibilityImprove cycle stabilityMaterial nanotechnologyFilament/thread formingCarbonizationCarbon nanofiber

The invention provides a cobalt oxide carbon nanofiber flexible electrode material derived from MOF for lithium ion batteries and a preparation method thereof. Carbon nanofibers containing ZIF-67 areobtained by electrospinning with a mixture of polyacrylonitrile and a metal organic frame material ZIF-67 as a precursor solution, and then, a Co3O4 carbon nanofiber flexible electrode material is synthesized through pre-oxidation, carbonization and oxidation heat treatment of electrospun fibers. The flexible electrode material prepared in the invention not only has good conductivity and cyclic stability of carbon materials (900mAh g<-1> after 100 cycles at the current density of 200mA g<-1>, but also has good rate performance (a capacity of 550mA g<-1> can still be maintained at the current density of 5000mA g<-1>) and the characteristics of high specific capacity of Co3O4.

Owner:SHAANXI UNIV OF SCI & TECH

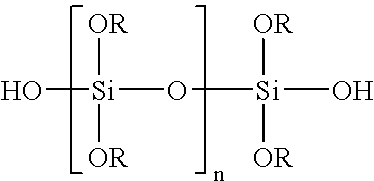

Polymer electrospun fibers, preparation method thereof and application thereof

InactiveCN101805940AExcellent liquid absorptionEasy to operateFilament/thread formingAbsorbent padsFiberPolymer chemistry

The invention discloses polymer electrospun fibers, which comprise the following components in percentage by mass: 80 to 100 percent of polymer and 0 to 20 percent of pH regulator, wherein the polymer is a hydrophilic polymer and / or slightly hydrophilic polymer. The fibers have better liquid absorptivity than the traditional fibers and can be widely used. The preparation method is simple in operation, can be adjusted according to actual needs and is suitable for industrial production. The invention also discloses a medicinal compound or fiber dressing prepared by using the polymer electrospun fibers, and the medicinal compound or the fiber dressing can be directly used for treating wounds and / or protecting the wounded from pollution. Compared with the traditional dressing, the medicinal compound or the fiber dressing have the advantages of reducing pains in the wounded, along with convenient removal.

Owner:ZHEJIANG UNIV

Organic-inorganic electrospun fibers

InactiveUS20080207798A1Less distortionMinimize distortionElectric discharge heatingPrinted circuit aspectsFiberMaterials science

Owner:PPG IND OHIO INC

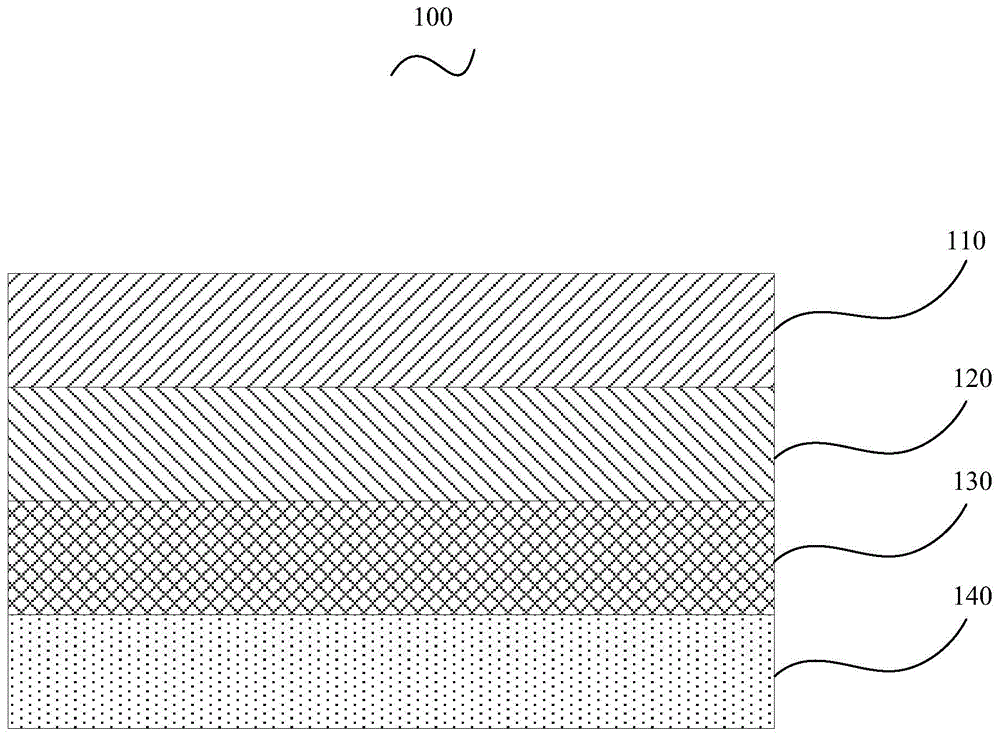

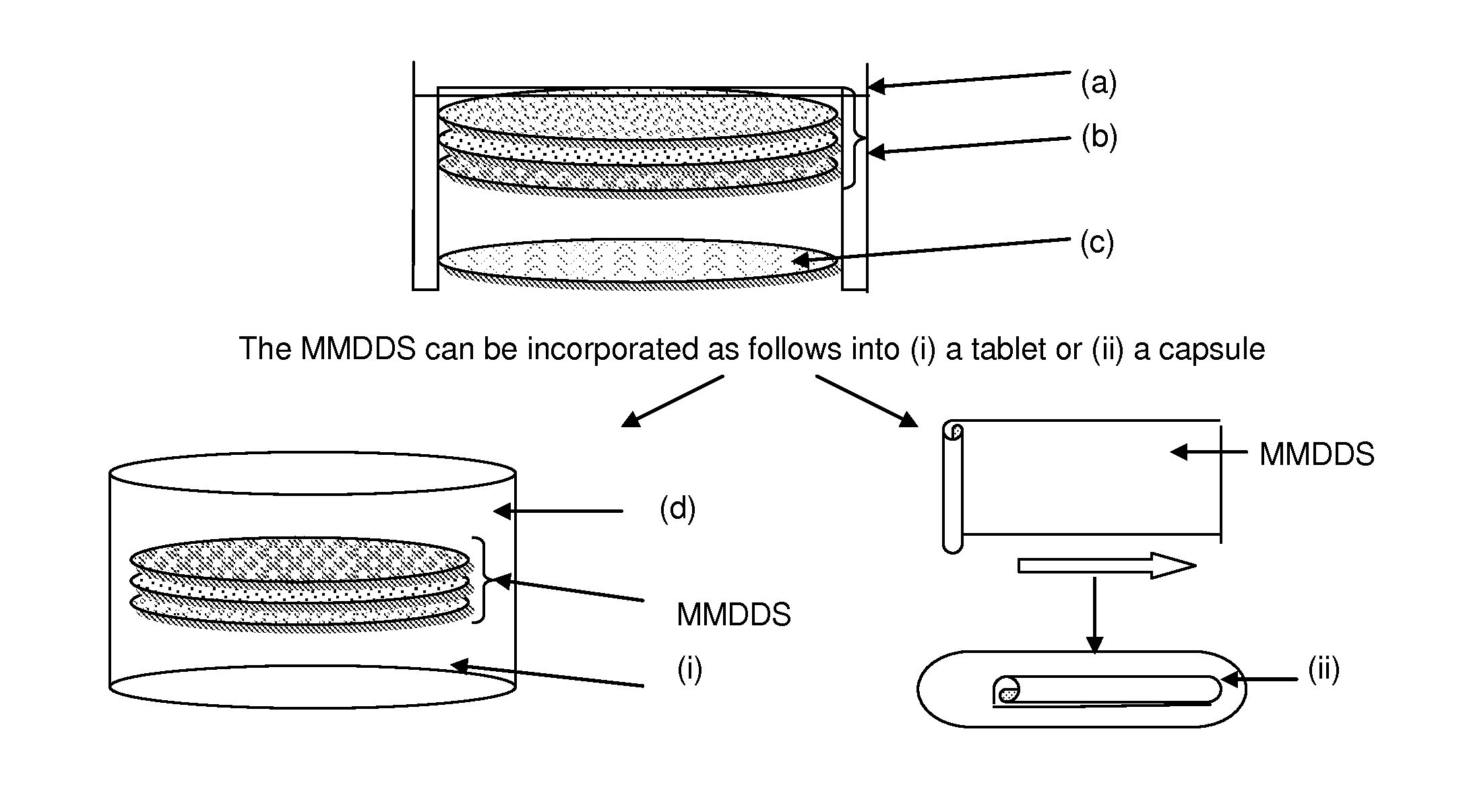

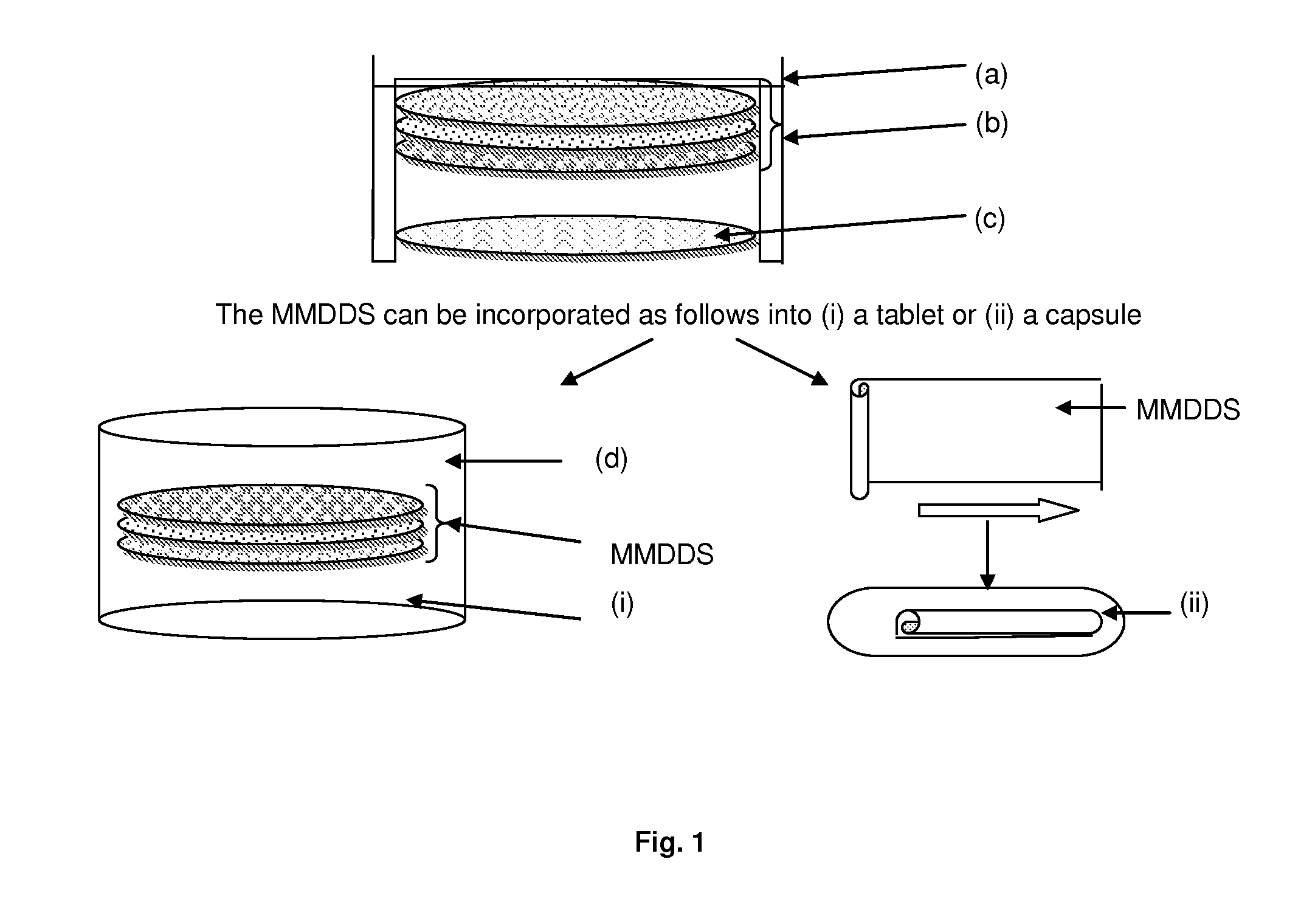

Pharmaceutical dosage form

InactiveUS20130337022A1Reduce releaseReduce deliveryBiocidePeptide/protein ingredientsActive agentMucoadhesion

A pH responsive and mucoadhesive pharmaceutical dosage form for the release of a pharmaceutically active agent is described. The dosage form includes a mucoadhesive layer for site-specific mucoadhesion, a water-insoluble outer layer, and an intermediate layer including one or more pharmaceutically active agents for site-specific delivery. The different membranous layers perform different functions in order to create a drug delivery system which is able to deliver a drug to a specific site, for a particular period of time and with a specific drug release pattern. The dosage form can have two or more intermediate layers, each layer comprising an active agent. The mucoadhesive layer can also include an active agents. The dosage form is preferably an oral or buccal delivery form for release of the active agent into the gastro intestinal tract. The intermediate layer can be an electrospun fibrous membrane layer containing the active agent.

Owner:UNIVERSITY OF THE WITWATERSRAND

Viral fibers

Long rod shaped M13 viruses were used to fabricate one dimensional (1D) micro- and nanosized diameter fibers by mimic the spinning process of the silk spider. Liquid crystalline virus suspensions were extruded through the micrometer diameter capillary tubes in cross-linking solution (glutaraldehyde). Resulting fibers were tens of micrometers in diameter depending on the inner diameter of the capillary tip. AFM image verified that molecular long axis of the virus fibers were parallel to the fiber long axis. Although aqueous M13 virus suspension could not be spun by electrospinning, M13 viruses suspended in 1,1,1,3,3,3-hexafluoro-2-propanol were spun into fibers. After blending with highly water soluble polymer, polyvinyl 2-pyrolidone (PVP), M13 viruses was spun into continuous uniform virus blended PVP (virus-PVP) fibers. Resulting virus-PVP electrospun fibers showed intact infecting ability to bacterial hosts after suspending in the buffer solution.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com