Antibacterial gauze mask filter and preparation method thereof, and antibacterial gauze mask

A filter and mask technology, applied in the field of medical materials, can solve the problems of small pore size and high porosity, and achieve the effects of high porosity, easy access and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

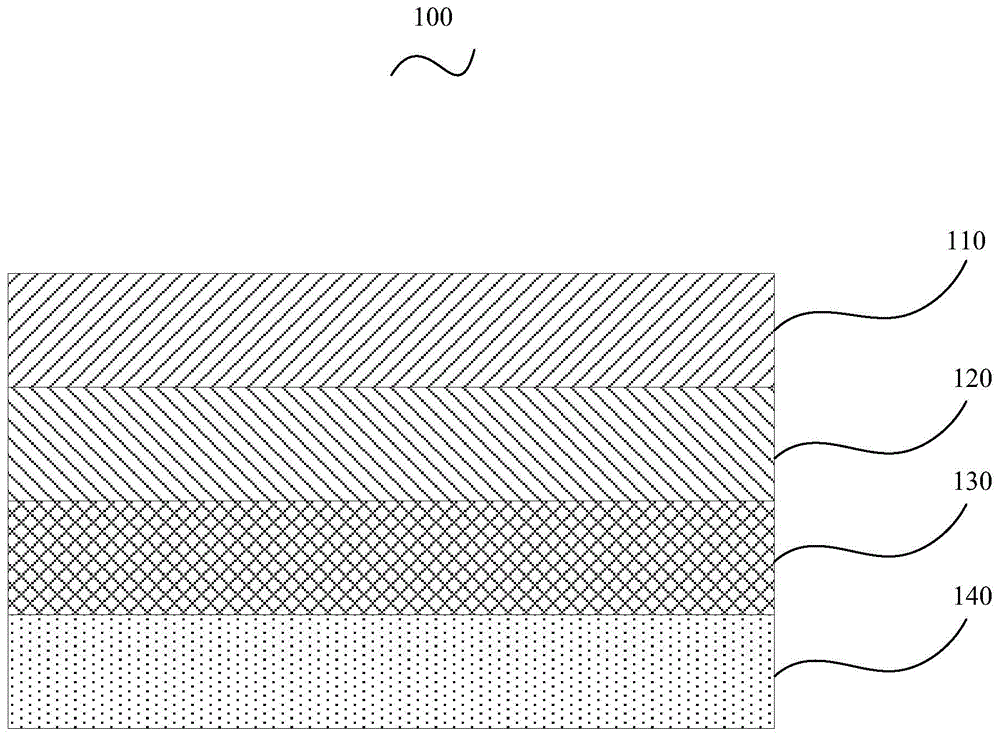

[0043] In addition, the present invention also provides a method for preparing an antibacterial mask filter, which includes the following steps: sequentially stitch or stitch the fiber surface layer 110, the base non-woven fabric layer 120, the electrospun fiber membrane layer 130, and the fiber inner layer 140. Compression connection, wherein the electrospun fiber membrane layer is made of polymer material and chitosan through electrostatic blending or blending to form a mixed solution, and electrostatic spinning.

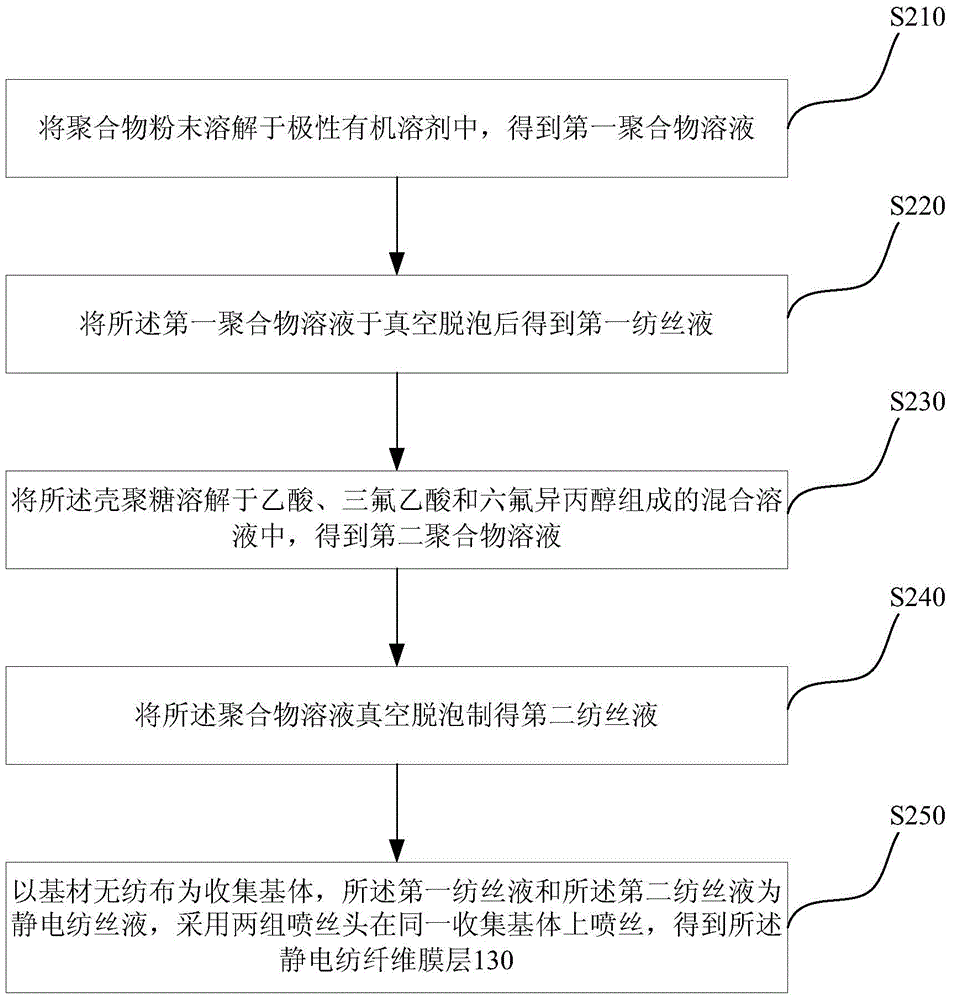

[0044] See figure 2 , Is a flow chart of the steps for preparing an electrospun fiber membrane layer provided by an embodiment of the present invention, including the following steps:

[0045] Step S210: Dissolve polymer powder in a polar organic solvent to obtain a first polymer solution, wherein the polymer powder is polyethersulfone, polysulfone, polyvinyl alcohol, polyethylene oxide, polylactic acid, polypropylene At least one of nitrile, polyurethane, polyvinylid...

Embodiment 1

[0072] Set the size of the mask filter element to be 110cm long and 75cm wide.

[0073] Among them, the first layer uses spunlace non-woven fabric on the top as the outer fiber layer, the second layer uses meltblown non-woven fabric as the collection matrix, and the fourth layer uses needle punched non-woven fabric as the fiber inner layer; The weight of the spunlace non-woven fabric, the second layer of meltblown non-woven fabric and the fourth layer of needle punched non-woven fabric is 15g / m 2 .

[0074] The filter sterilization layer of the third layer is prepared by the following method:

[0075] The film-forming polysulfone powder was dissolved in N-methylpyrrolidone, stirred at 60°C to obtain a polymer solution, and the polysulfone solution was vacuum degassed at 60°C for 4 hours to prepare a spinning solution. The concentration of polysulfone in the spinning solution is 10 wt%, and the rest is N-methylpyrrolidone.

[0076] The chitosan was dissolved in a 90wt% acetic acid sol...

Embodiment 2

[0082] Set the size of the mask filter element to be 125cm long and 80cm wide.

[0083] The first layer uses spunlace non-woven fabric on the top as the outer fiber layer, the second layer uses spunbonded non-woven fabric as the collection matrix, and the fourth layer uses bamboo charcoal fiber non-woven fabric as the fiber inner layer; the first layer of spunlace The weight of the non-woven fabric, the second layer of meltblown non-woven fabric and the fourth layer of needle punched non-woven fabric are all 25g / m 2 .

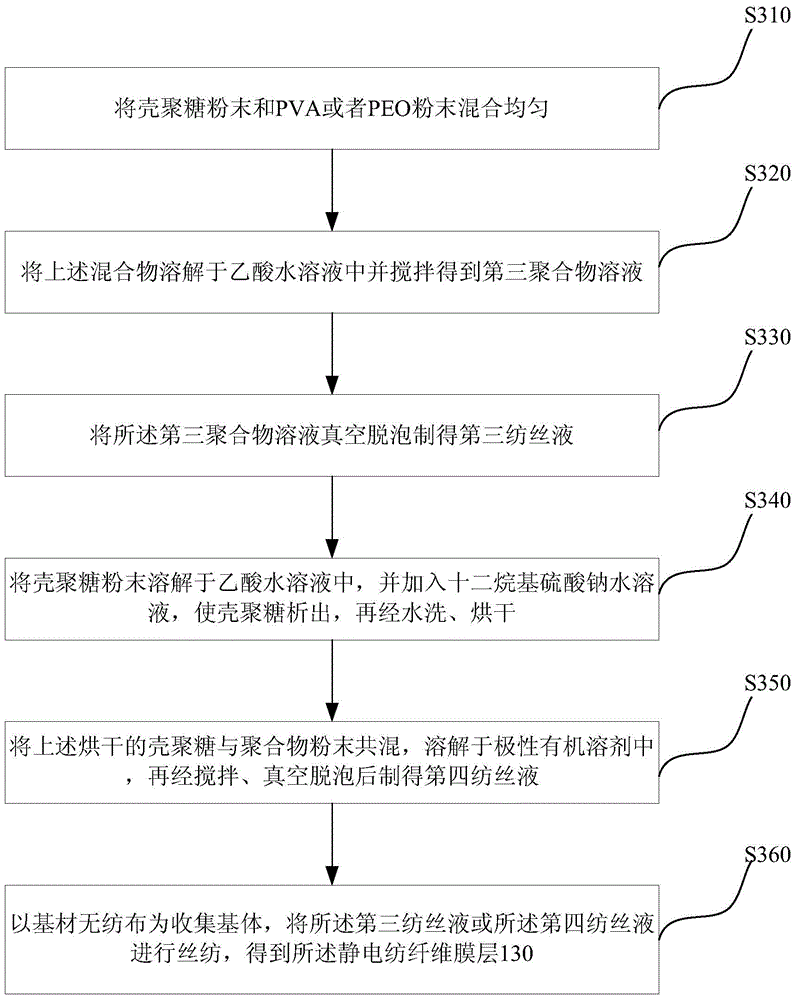

[0084] The filter sterilization layer of the third layer is prepared by the following method:

[0085] A certain amount of chitosan powder was dissolved in 2wt% acetic acid aqueous solution, and 5wt% sodium lauryl sulfate aqueous solution was poured into the chitosan solution, because the amine groups on the chitosan and lauryl sulfate The sulfate radical on the sodium can make the chitosan precipitate out, which is washed and dried for later use.

[0086] The dried c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com