Patents

Literature

87results about "Hypophosphorous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing calcium hypophosphite

The invention relates to the production method of calcium hypophosphite; the production method includes the following technical steps: 1. material preparing which is detailed as follows: deionized water is firstly added in a mixer, unslaked lime powder, the weight of which accounts for 4% of the deionized water, is added under the stirring condition to prepare lime cream, and the lime cream is pumped into a reaction kettle by a pump, ready for use; 2. first neutralization reaction; 3. second neutralization reaction; 4. concentration which is detailed as follows: a vacuum pump of a concentration kettle is started, the filtrate from the second neutralization reaction is pumped into the concentration kettle in virtue of the vacuum in the kettle and is concentrated at vacuum condition after a steam valve is opened; 5. drying and packaging step is detailed as follows: the materials are put in a centrifuge for spin drying when the temperature of the feed liquid in a cooling kettle is below 60 DEG C to obtain the finished product with 92-95% of calcium hypophosphite, then the material is put into a dryer and dried for 20-25 min by the hot air with the temperature of 60-80 DEG C to obtain refined calcium hypophosphite finished product with the content of over 99.0 %. The production method has the advantages of low equipment investment, short process flow and simple production principle. Due to high quality, the finished product produced can be used as food additive, pharmaceuticals and chemical agents.

Owner:江苏和纯化学工业有限公司

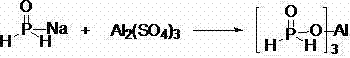

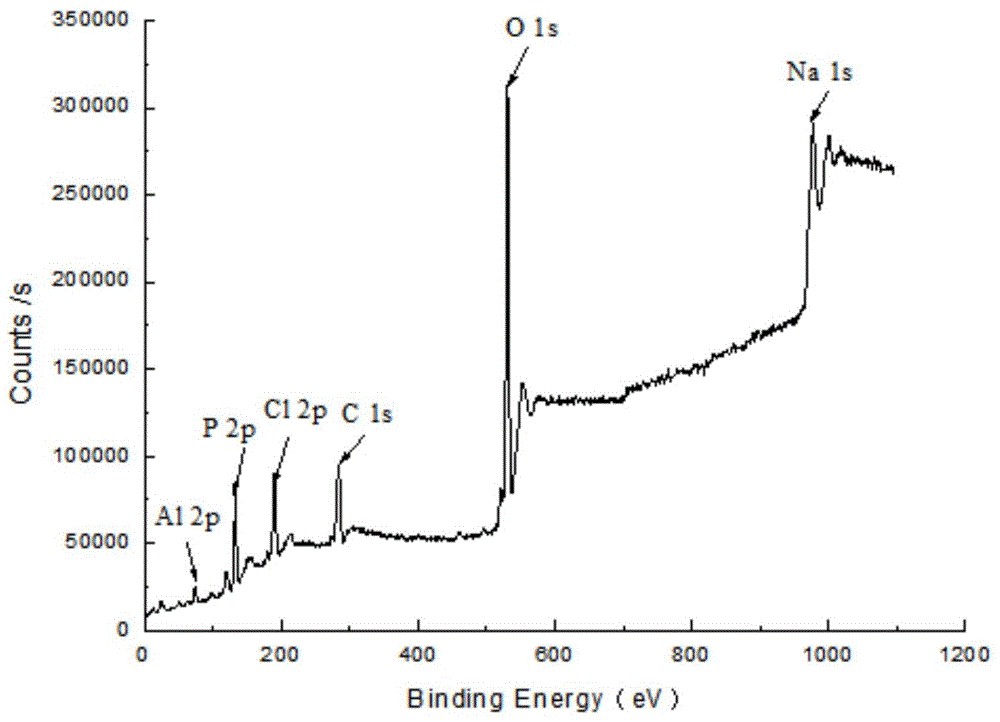

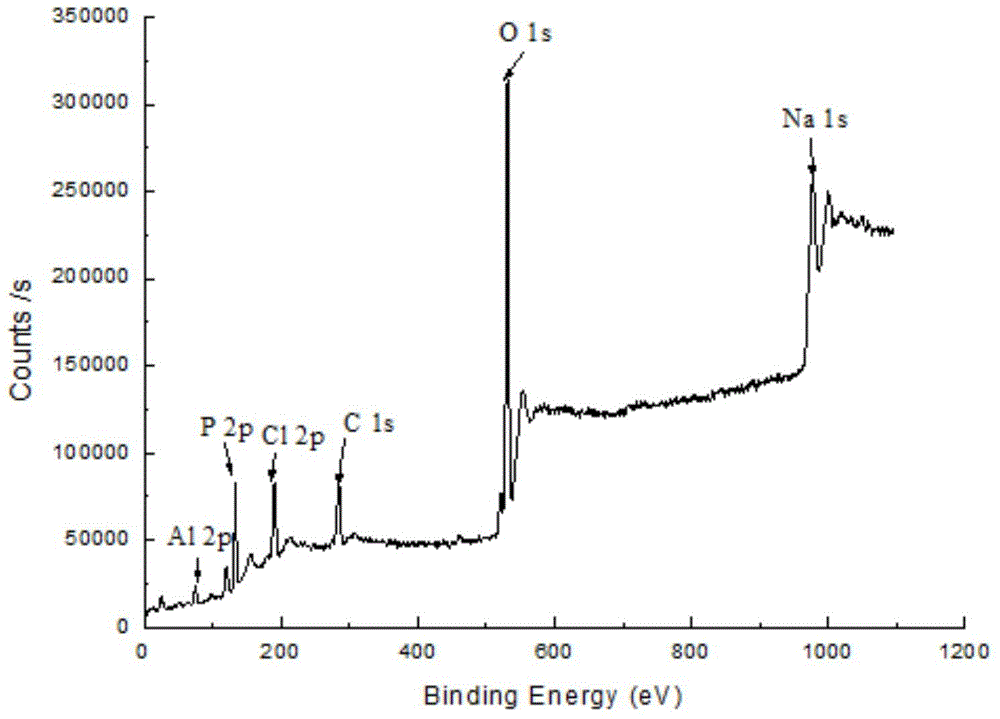

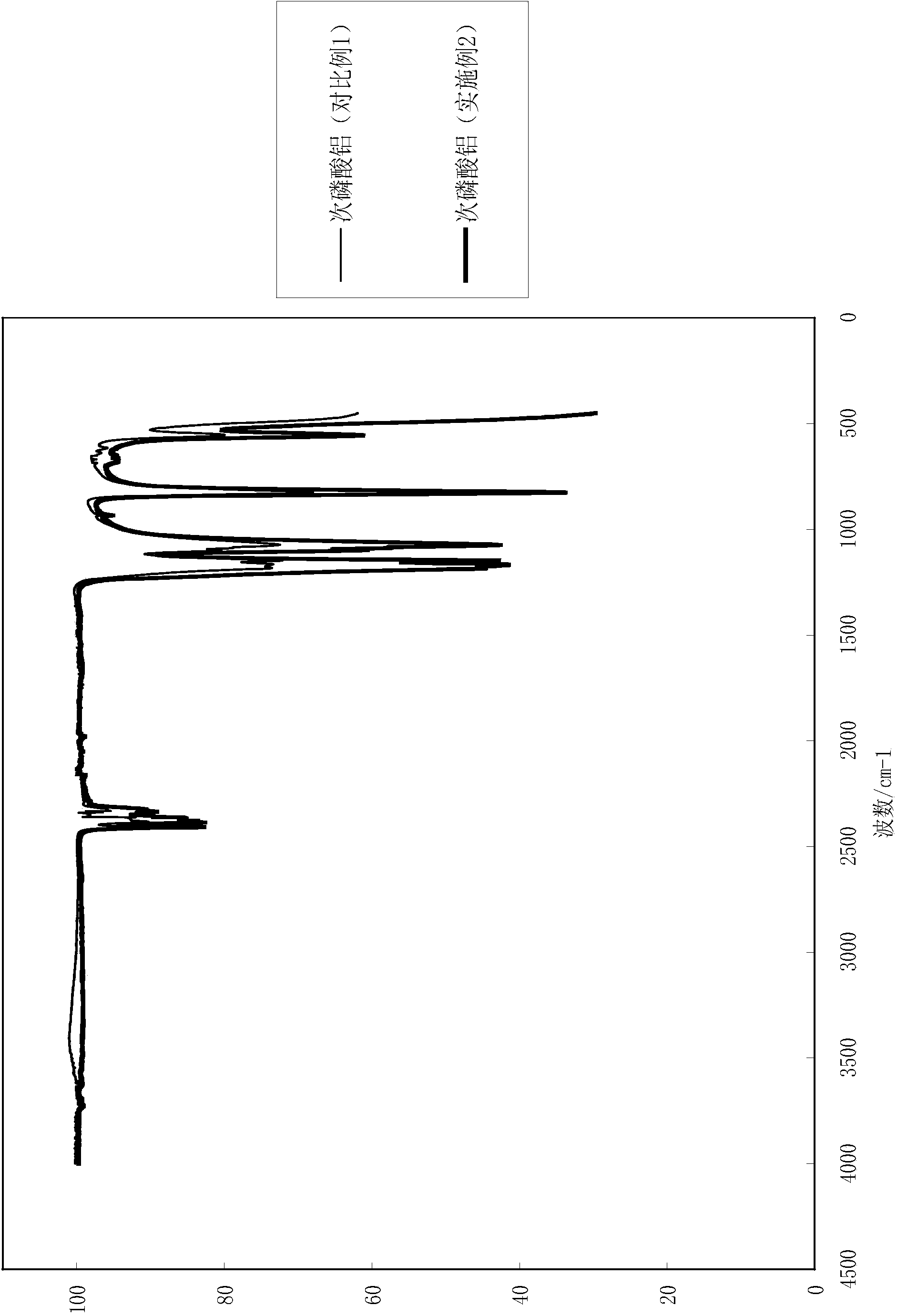

Method for preparing aluminum hypophosphite

The invention relates to a method for preparing aluminum hypophosphite. The method includes the following steps of firstly, preparing sodium hypophosphite solution with concentration of 2-6mol / L, adjusting pH (potential of hydrogen) to be 3-5 preferentially within 3-6.5; secondly, preparing aluminum sulfate solution; and thirdly, subjecting the sodium hypophosphite solution and the aluminum sulfate solution to reaction by heating on the acid condition to generate aluminum hypophosphite. The aluminum sulfate is added into the sodium hypophosphite solution for reaction within a certain temperature range, so that harms caused by volatilization of hypophosphorous acid during preparing of the aluminum hypophosphite are avoided, operation is simplified, yield of products is high, cost is low and industrialization is easy to realize.

Owner:NANJING NORMAL UNIVERSITY

Rare earth metal hypophosphite and preparation method and application of rare earth metal hypophosphite

InactiveCN102838098AHigh densityImprove thermal stabilityHypophosphorous acidMetal chlorideMetal nitrate

The invention discloses rare earth metal hypophosphite higher in density and high in thermal stability, and a preparation method and an application of the rare earth metal hypophosphite as a flame retardant in a polymer material. The formula of the rare earth metal phosphate is Ln(H 2PO2)3(H2O).The preparation method of the rare earth metal hypophosphite comprises the steps of dissolving hypophosphite in water, adding sodium hydroxide to the solution to allow the pH of the solution to be 3.0-4.0, adding rare earth metal nitrate or an aqueous solution of rare earth metal chloride salt to be solution, stirring for 3-4 hours at 40-60 DEG C, cooling, filtering and washing to a reaction product, and obtaining the rare earth metal hypophosphite after drying. A halogen-free flame retardant polymer composite taking the rare earth metal hypophosphite as the flame retardant comprises the following components by mass percent: 40-90% of polymer and 10-25% of rare earth metal hypophosphite.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

Method for producing sodium hypophosphite

ActiveCN101172591AHigh recovery rateImprove operating conditionsHypophosphorous acidSlagNitrogen gas

The invention is a method for producing sodium hypophosphite, which is characterized in that the process steps include batching, reaction, filtration, first concentration, adjustment, second concentration, cooling and crystallization, and centrifugal packaging. Advantages: Put the measured liquid caustic soda into the lime milk tank, mix it with water and quicklime, and pump it into the reaction kettle together. In this way, it is not necessary to disassemble the liquid alkali pipeline frequently, thereby reducing the unfavorable factors affecting normal production; the reactor is emptied with nitrogen, which should be evacuated with steam, which is easy to operate and does not require additional equipment; replace the old-fashioned plate with a diaphragm press filter Frame filter. The water content of the filter cake is reduced from 45-50% to 35-40%, and the filter cake content of 1-1.5% sodium hypophosphite is reduced to 0.4-0.8%. The reduction of the water content of the filter cake not only improves the recovery rate of sodium hypophosphite, but also improves the operating conditions of slag unloading; the ratio of yellow phosphorus per kettle is changed from 90 to 100kg to 150kg, which greatly increases the output of a single device.

Owner:江苏和纯化学工业有限公司

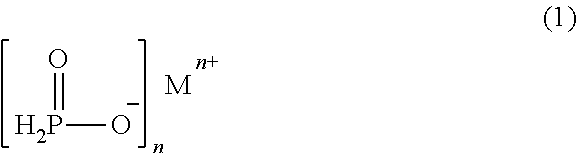

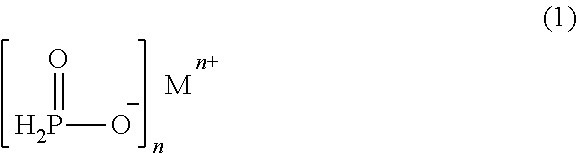

Flame retardant polymer compositions comprising stabilized hypophosphite salts

InactiveUS20130324646A1Improve flame retardant performanceGroup 5/15 element organic compoundsConductive materialPolymer scienceGram

A flame retardant polymer composition is described. The composition includes at least one polymer and a hypophosphite salt, wherein the hypophosphite salt is heat stabilized so that when it is heated for 3 hours at 298° C. under a flow of argon flushing at rate 58 mL / min, it generates less than 0.5 mL of phosphine per gram of hypophosphite salt. The flame retardant polymer composition can also include at least one additive that improves the flame retardant properties of the composition.

Owner:RHODIA OPERATIONS SAS +1

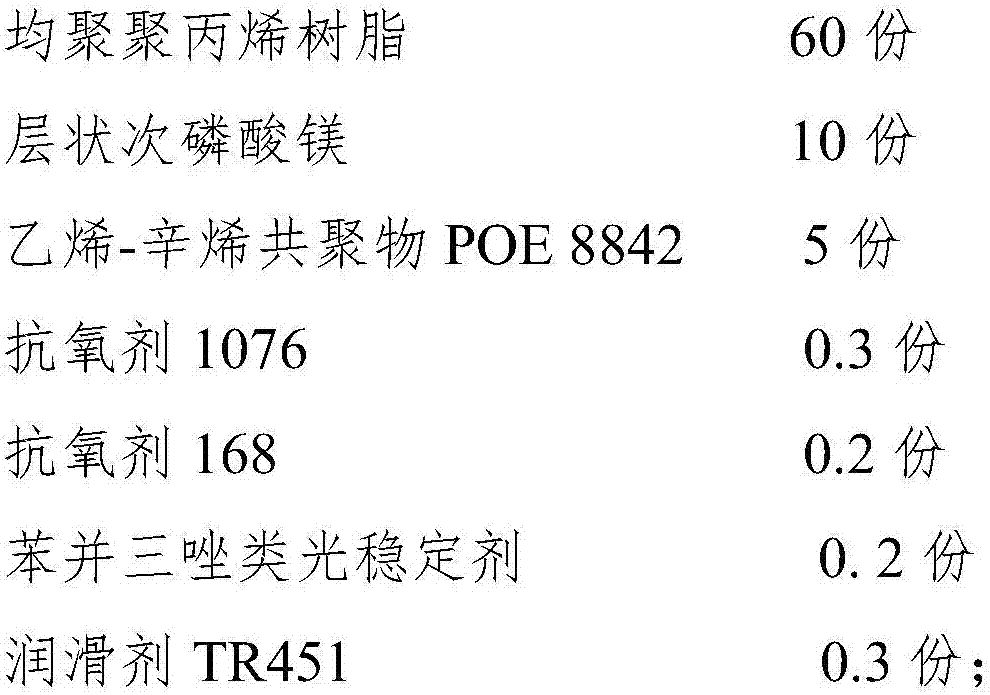

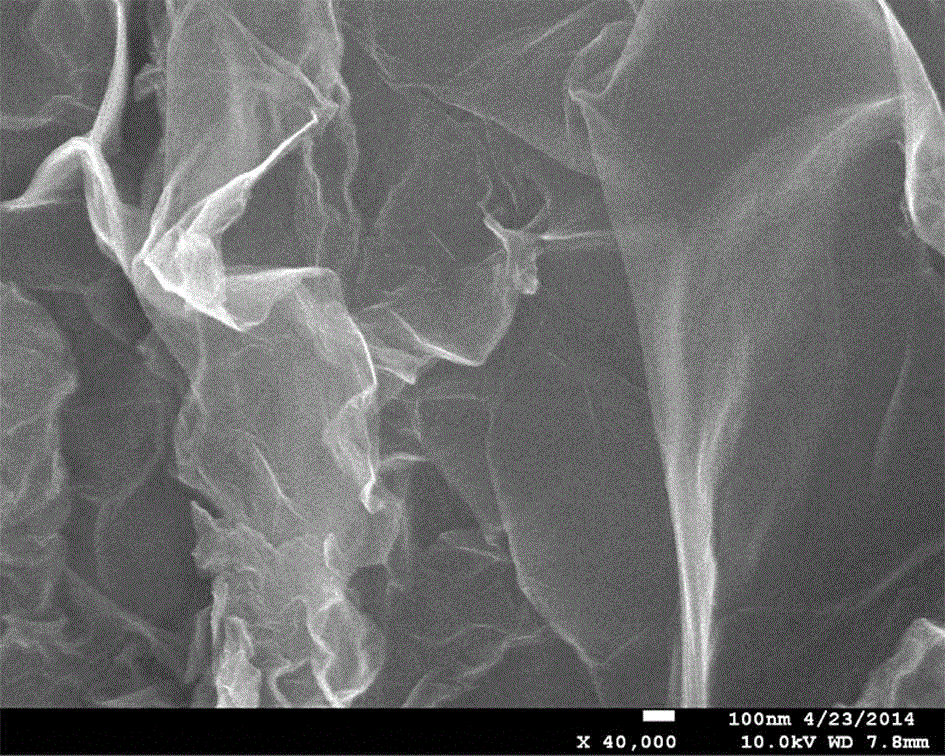

Layered-hypophosphite flame-retardant and reinforced polypropylene composite material and preparation method thereof

InactiveCN107254106AImprove bending strengthHigh strengthNanotechnologyHypophosphorous acidDispersityPolypropylene composites

The invention provides a layered-hypophosphite flame-retardant and reinforced polypropylene composite material and a preparation method thereof and relates to the technical field of high polymer materials. The layered-hypophosphite flame-retardant and reinforced polypropylene composite material is prepared by polypropylene resin, layered hypophosphite, a toughening agent, antioxidant, a light stabilizer and a lubricating agent. The preparation method has the advantages that the layered hypophosphite is synthesized through a hydrothermal method, layered hypophosphite nanosheets are well combined with a polypropylene matrix and are evenly distributed in the polypropylene matrix and good in dispersity, influence on material mechanical performance is low, and polypropylene composite material prepared by adding the layered hypophosphite is high in strength and good in thermal stability.

Owner:ORINKO NEW MATERIAL CO LTD

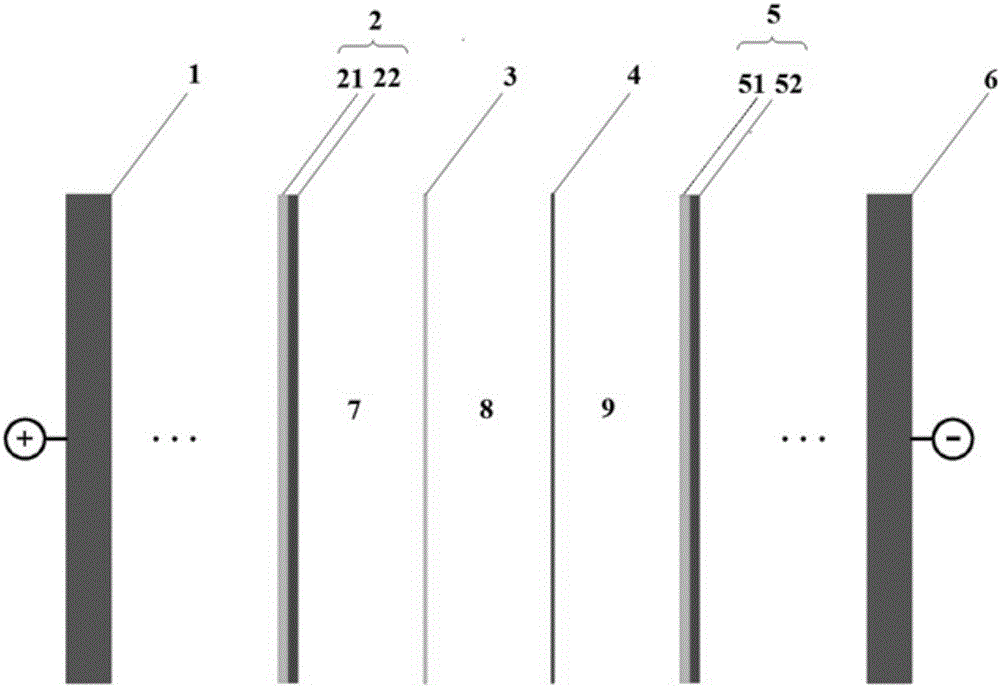

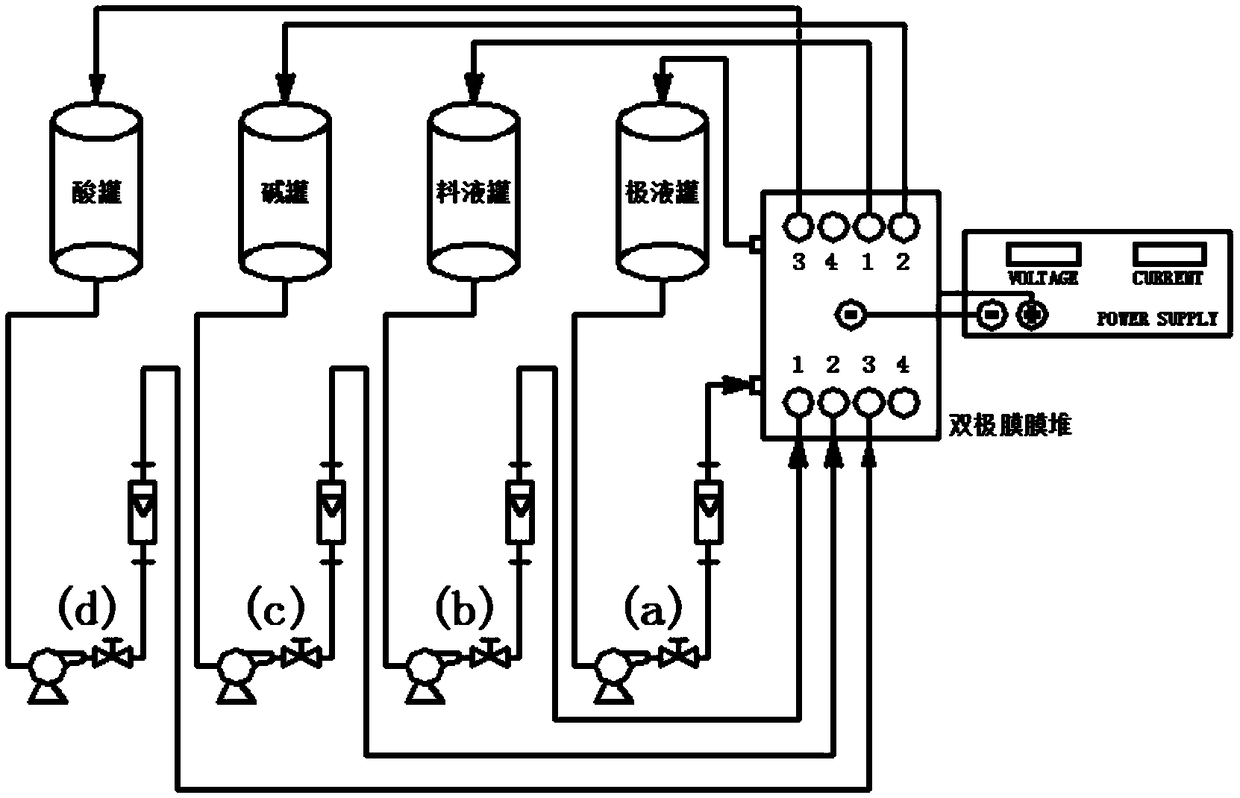

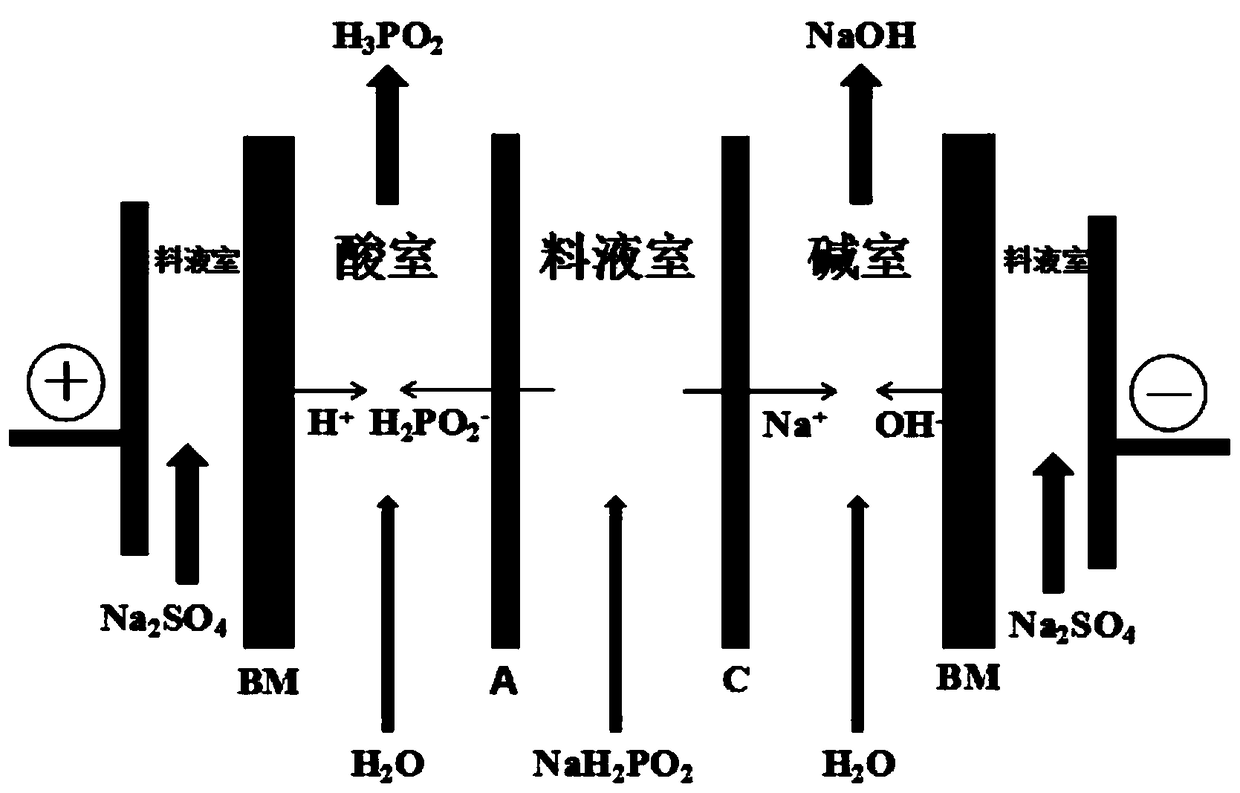

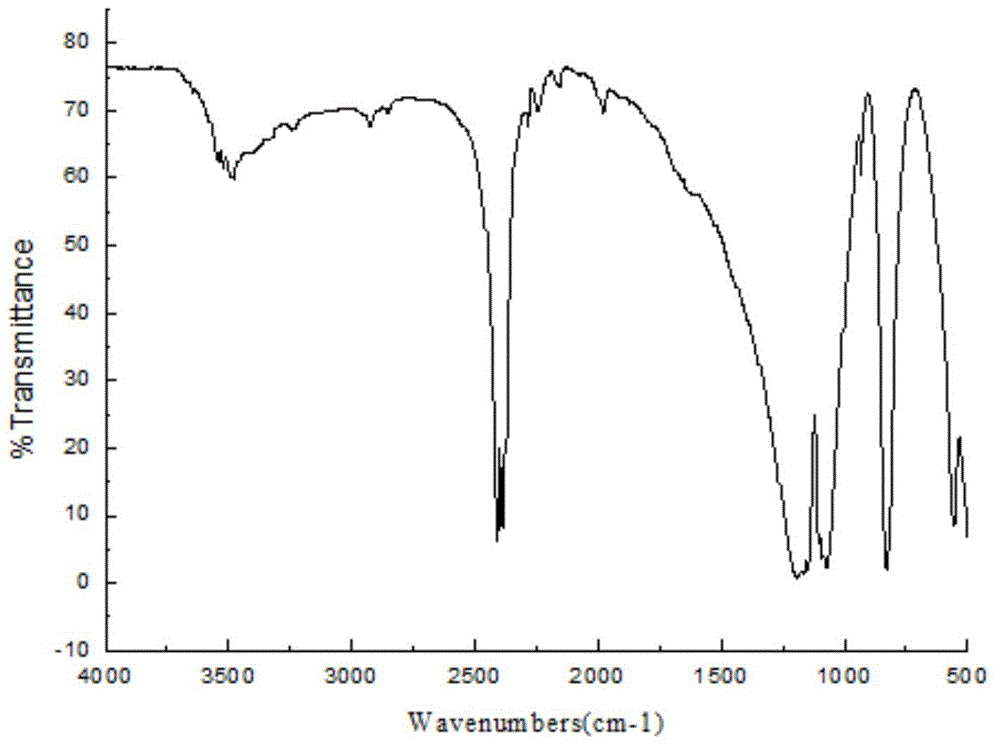

Technique for preparing hypophosphorous acid through bipolar membrane electroosmosis method

ActiveCN105688676AEasy to useSimple processElectrodialysisHypophosphorous acidPhosphoric acidPhosphinic Acids

The invention relates to a technique for preparing hypophosphorous acid through a bipolar membrane electroosmosis method. Sodium hypophosphite and deionized water are taken as raw materials; a sodium hypophosphite solution is put into a salt chamber of a bipolar membrane electroosmosis device; the deionized water is respectively put into an acid chamber and an alkali chamber; the liquid in the three chambers is pumped into the bipolar membrane electroosmosis stack for circulating; and the bipolar membrane electroosmosis device is started for performing bipolar membrane electroosmosis, so as to prepare the hypophosphorous acid and sodium hydroxide solution. The technique for preparing hypophosphorous acid, provided by the invention, is simple, low in energy consumption, mild in technical condition and free from secondary pollution, and multiple sets of grouping units can be repeatedly assembled and formed into a membrane stack between a pair of electrodes, so that the technique can be easily amplified industrially. The prepared hypophosphorous acid can be directly used as a product applied to the production raw material of sodium hypophosphite; the content of sodium ions in the hypophosphorous acid solution can be further reduced through refining; and the acquired sodium hydroxide solution can be used for adjusting the pH value in the production process of the sodium hypophosphite.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

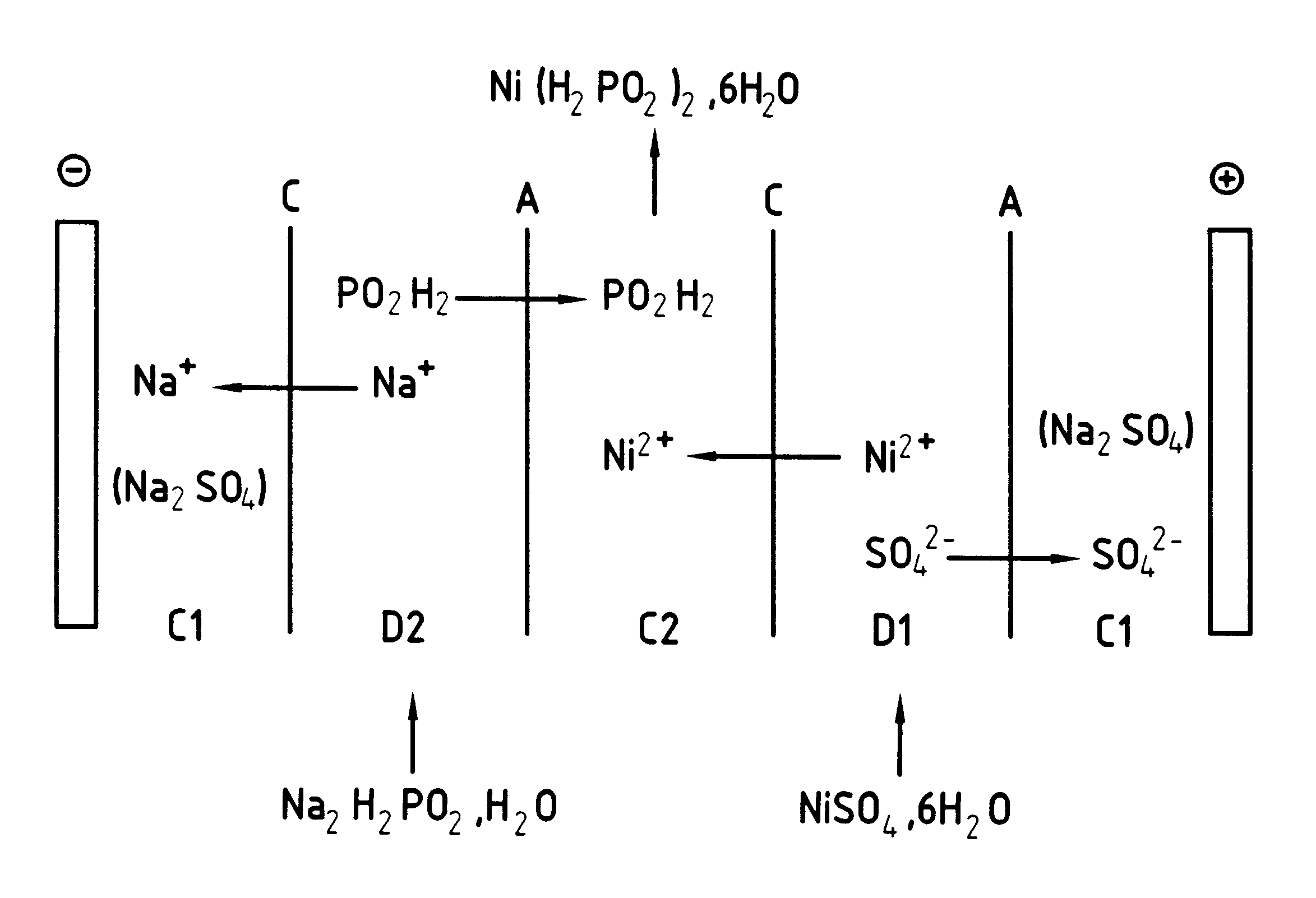

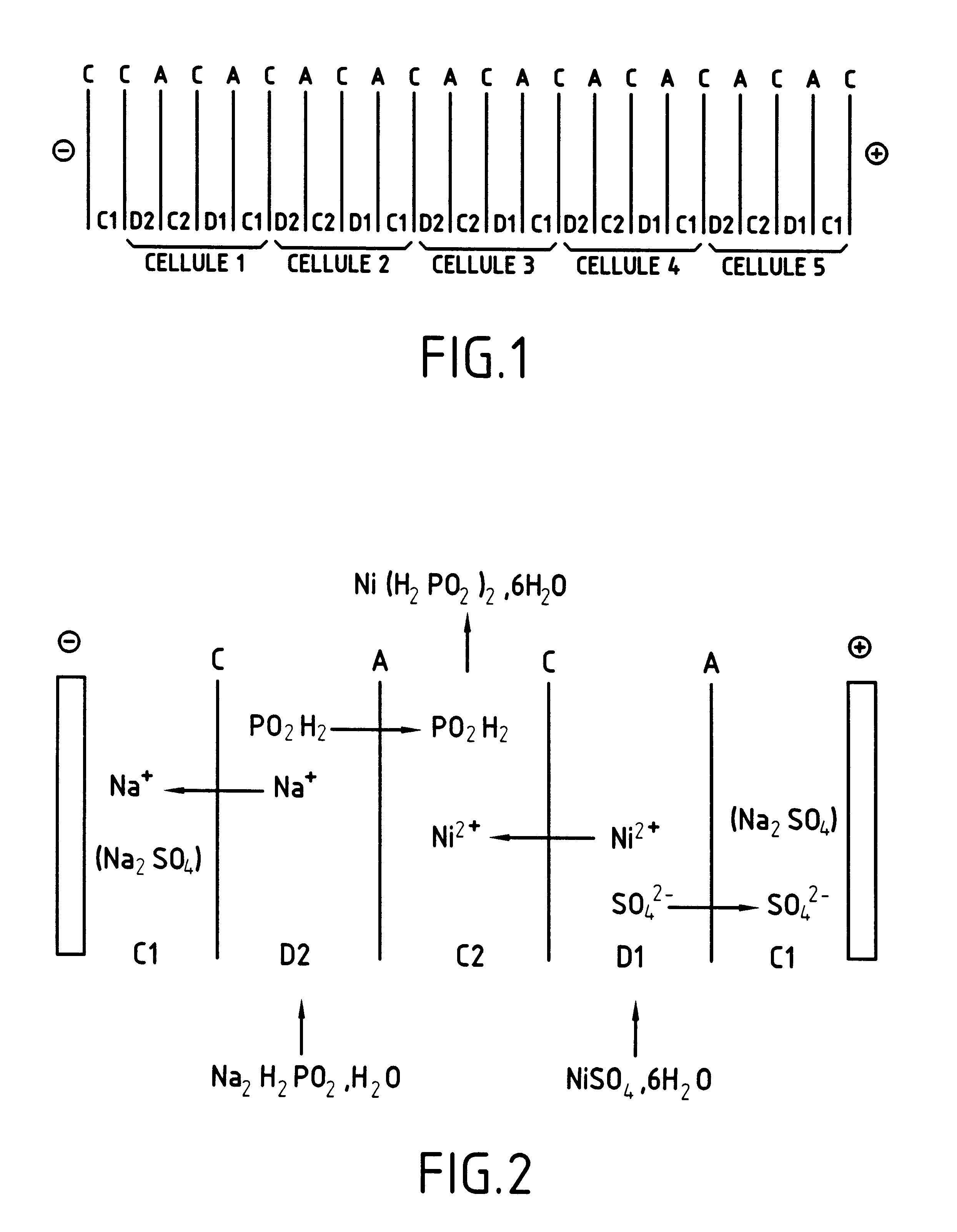

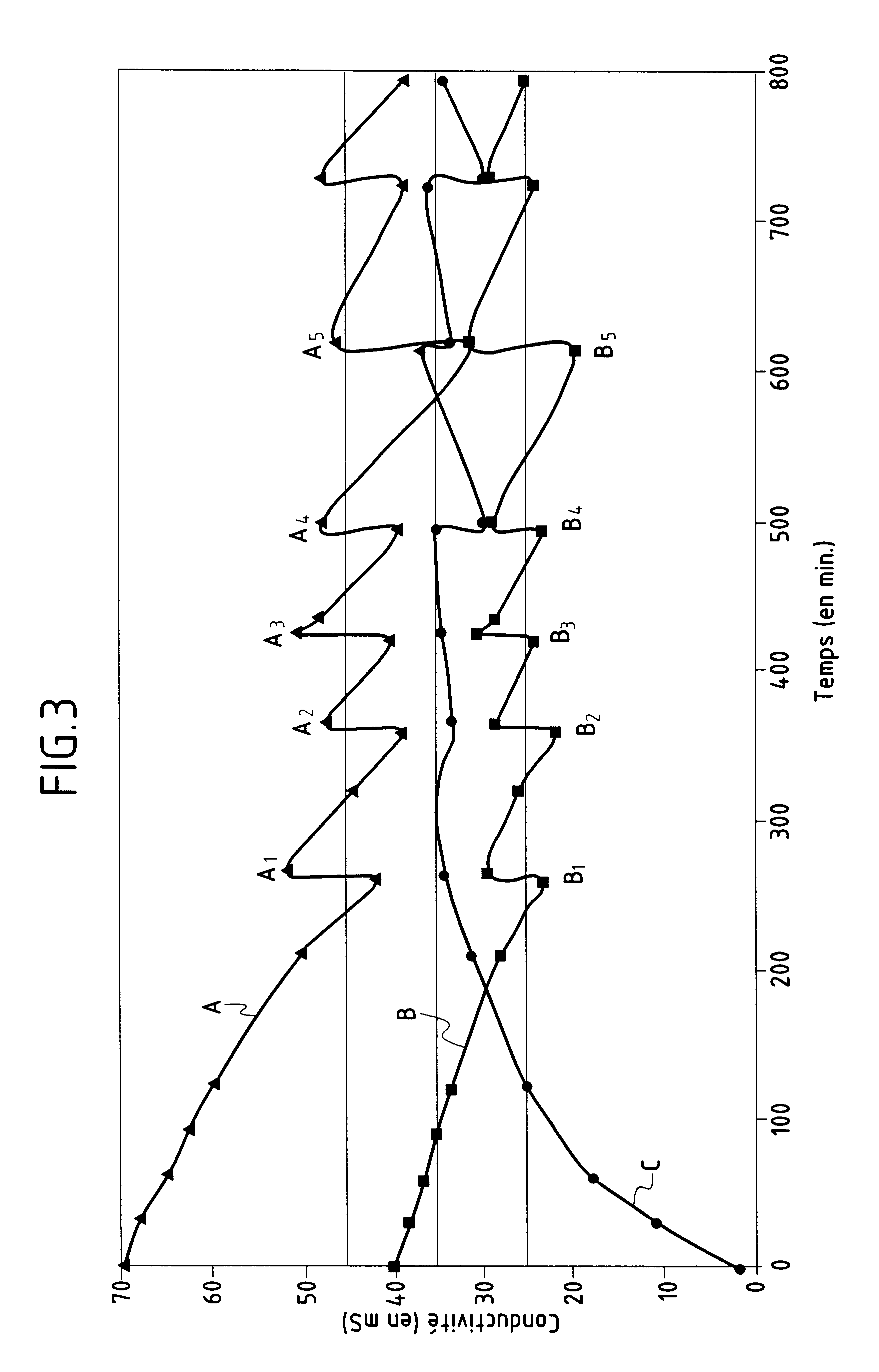

Method of manufacturing nickel hypophosphite by the electro-membrane technique

InactiveUS6200448B1Improve concentrationElectrolysis componentsVolume/mass flow measurementElectricitySulfate

The method of manufacturing nickel hypophosphite from a solution of hexahydrated nickel sulfate and a solution of monohydrated sodium hypophosphite by an electro-membrane technique, consists:a) in introducing respectively the hexahydrated nickel sulfate solution and the monohydrated sodium hypophosphite solution into each of two dilution circuits of four-compartment electrodialysis cells formed by alternating stacks of cationic and anionic homopolar membranes in an electrodialysis apparatus having an anode and a cathode that are insoluble;b) in applying an electrical current from the anode to the cathode without regulating the pH of the solutions contained in the dilution and concentration circuits but regulating the electricity supply, either in voltage or in current; andc) in recovering a hexahydrated nickel hypophosphite solution from one of the concentration circuits.

Owner:ETAB A RICHARD

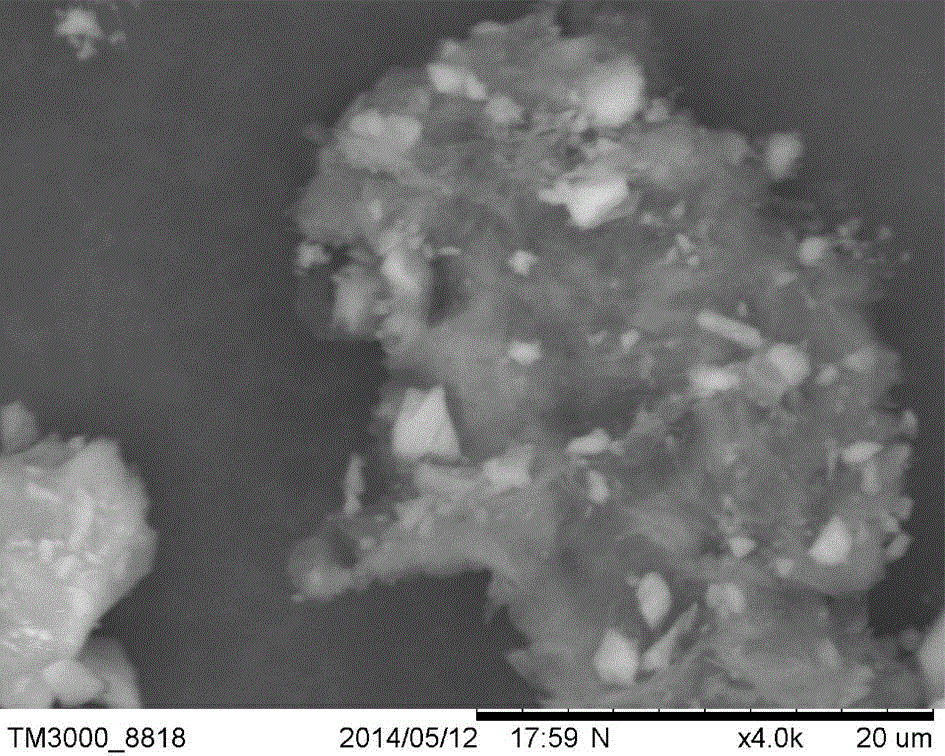

Preparation method and application of inorganic hybrid flame retardant with high thermal stability

InactiveCN104877169AImprove thermal stabilityImprove flame retardant performanceHypophosphorous acidLimiting oxygen indexOxygen

The invention discloses a preparation method of an inorganic hybrid flame retardant with high thermal stability. The preparation method comprises the following steps: a), preparing oxidized graphene suspending liquid; b), adding soluble aluminium salt into the oxidized graphene suspending liquid, controlling the concentration of the soluble aluminium salt to be 50-400 mmol / L, uniformly stirring, adding soluble phosphinate at the temperature of 0-80 DEG C, and stirring, so as to obtain reaction liquid, wherein the molar ratio of the soluble aluminium salt to the soluble phosphinate is 1:(3-4); c), enabling the reaction liquid to be subjected to hydrothermal reaction for 3-12 h at the temperature of 170-190 DEG, and cooling, filtering, washing and drying the obtained product, so as to obtain the inorganic hybrid flame retardant with high thermal stability. In addition, the invention also discloses a PBT composite material comprising the flame retardant. The preparation method for the flame retardant, provided by the invention, is simple, mild in reaction condition, high in productivity and low in price, and facilitates large-scale production and control; an experiment result shows that the PBT composite material, prepared by adding the flame retardant into PBT, has the advantages of being high in limited oxygen index, good in anti-dripping effect, high in char forming property and thermal stability, good in heat insulation performance and the like; the comprehensive flame retardancy of the flame retardant is excellent.

Owner:HEBEI UNIVERSITY

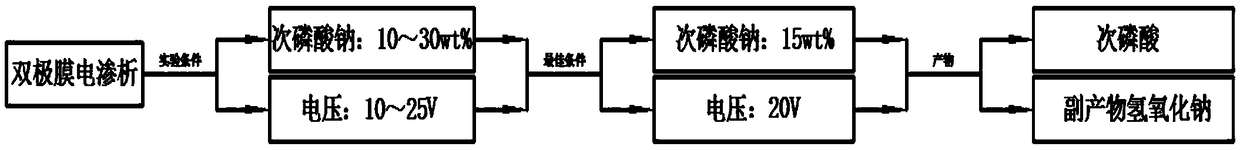

Bipolar membrane electrodialysis method for preparing hypophosphorous acid from sodium hypophosphite

InactiveCN108636123AHigh yield productionOptimum production process conditionsElectrodialysisHypophosphorous acidPhosphoric acidReaction temperature

The present invention discloses a bipolar membrane electrodialysis method for preparing hypophosphorous acid from sodium hypophosphite. The method comprises the following steps: (1) a sodium hypophosphite aqueous solution with a mass fraction of 10 wt%-30 wt% is prepared; (2) the sodium hypophosphite aqueous solution is added into a material liquid tank; 3 wt% of a sodium sulfate solution is addedinto an electrode liquid tank; and pure water at equal volume is added into an alkali tank and an acid tank; (3) a bipolar membrane electrodialysis device is turned on; voltage is controlled at 10 V-25 V; reaction temperature in each compartment is controlled to be 20 DEG C-40 DEG C for electrodialysis; and end of reaction is reached when content of hydrogen ions titrated by a sodium hydroxide standard solution in an acid chamber is no longer increased; and (4) a hypophosphorous acid solution in the acid tank is taken to be concentrated and crystallized to obtain hypophosphorous acid crystals. The whole technology basically realizes zero discharge. The hypophosphorous acid prepared by the provided bipolar membrane electrodialysis method has high yield. The bipolar membrane electrodialysismethod has remarkable environmental benefits and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

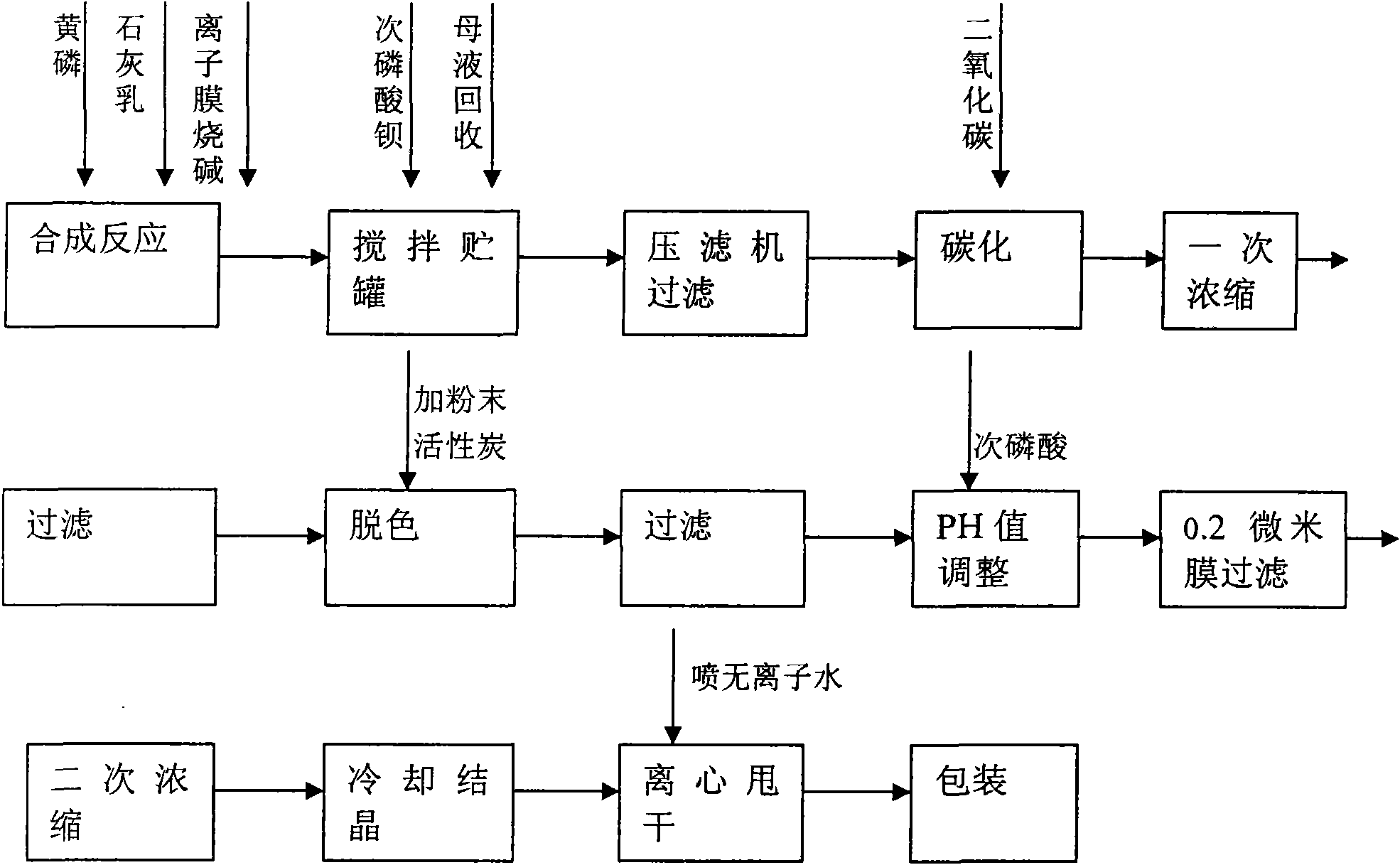

Process for purifying sodium hypophosphite

ActiveCN101332981AImprove product qualityGuaranteed stabilityHypophosphorous acidChemical reactionPurification methods

The invention relates to a purification method of sodium hypophosphite product, which includes the following technical steps: (1) material proportioning, (2) chemical reaction, (3) filtering, (4) concentration for first time, the concentration being 26-28 Baume degrees, (5) base adjustment working section and acid adjustment working section, (6) concentration for second time, materials being concentrated to 48.6-48.7 Baume degrees after being heated by steam; (7) cooling, crystallization, centrifugation and packaging. The purification method of the invention has the advantages that: the quality of the sodium hypophosphite product is greatly improved by adopting cheap barium salt to remove the sulfate in feed liquid and the stability of product quality is also guaranteed; acid adjusting filtrate is filtered by a filter with the pore diameter of 5-15 microns instead of a cloth filter, thus eliminating the tiny impurities in the water solution of the product and further improving the quality of the product.

Owner:江苏和纯化学工业有限公司

Method of using glufocinate byproduct waste residue to prepare aluminum hypophosphite

InactiveCN106986318ASmall particle sizeImprove lipophilicityHypophosphorous acidReaction ratePhosphoric acid

The invention discloses a method of using glufocinate byproduct waste residue to prepare aluminum hypophosphite. The method includes following steps: (1), slowly adding a glufocinate industrial byproduct into water, sufficiently stirring, filtering to remove filter residue, and taking filtrate for standby use; dissolving sodium hypophosphite in water to prepare a sodium hypophosphite solution, and adding hydrochloric acid to adjust pH value of the sodium hypophosphite solution to 3-6; (2), taking the filtrate and the sodium hypophosphite solution according to a reactant molar feeding ratio of sodium hypophosphite to aluminum chloride being (4-5):1; (3), putting the sodium hypophosphite solution in a container provided with a snake-shaped condensing pipe, heating to 30-50 DEG C, and dropwise adding the filtrate while stirring at a high speed; after dripping of the filtrate is finished, finishing reaction while slowly stirring; (4), subjecting a reaction product obtained in the step (3) sequentially to separating, washing and drying to obtain powdery white solid which is a product containing aluminum hypophosphite. Therefore, by optimizing the process of using the glufocinate byproduct waste residue to prepare aluminum hypophosphite, a reaction system has the advantages of mild reaction and high reaction rate.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

High grade sodium hypophosphite preparation method

The present invention relates to the preparation process of high grade sodium hypophosphite. The preparation process with industrial level sodium hypophosphite as material and active carbon as adsorbent includes silver chloride precipitation to eliminate chlorine ion, barium sulfate precipitation to eliminate sulfate radical ion, sulfide precipitation to eliminate heavy metal ion, addition of small amount of high grade hypophosphorous acid to eliminate micro amount of arsenic, cationic exchanging to prepare high grade sodium hypophosphite solution, decompression enriching, cooling to crystallize, filtering and drying. The product has low contents of hypophosphorous acid, sulfate, chloride, iron and lead. The product may find its wide application in manufacture, electronic industry, national defense industry and other hi-tech fields.

Owner:NANKAI UNIV

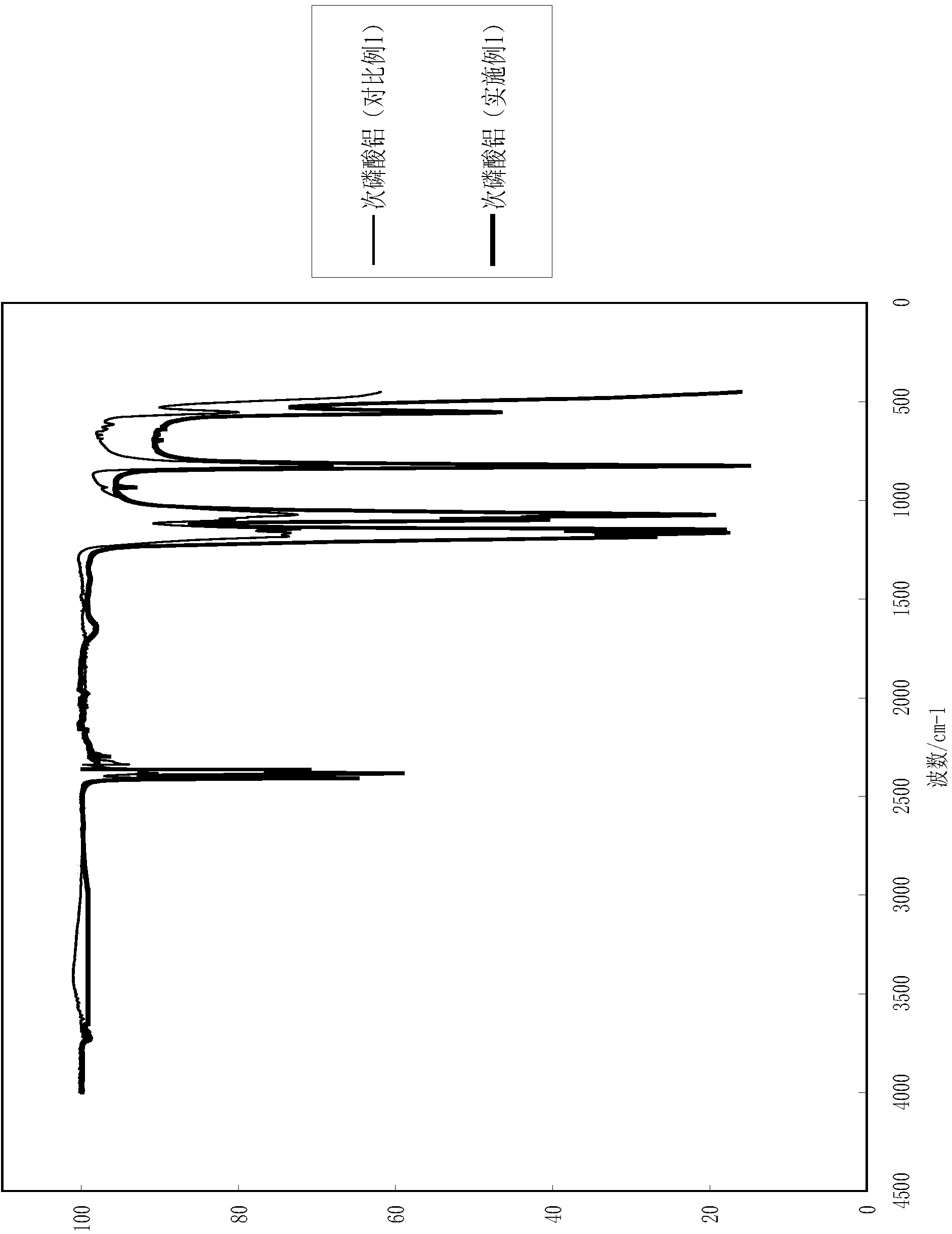

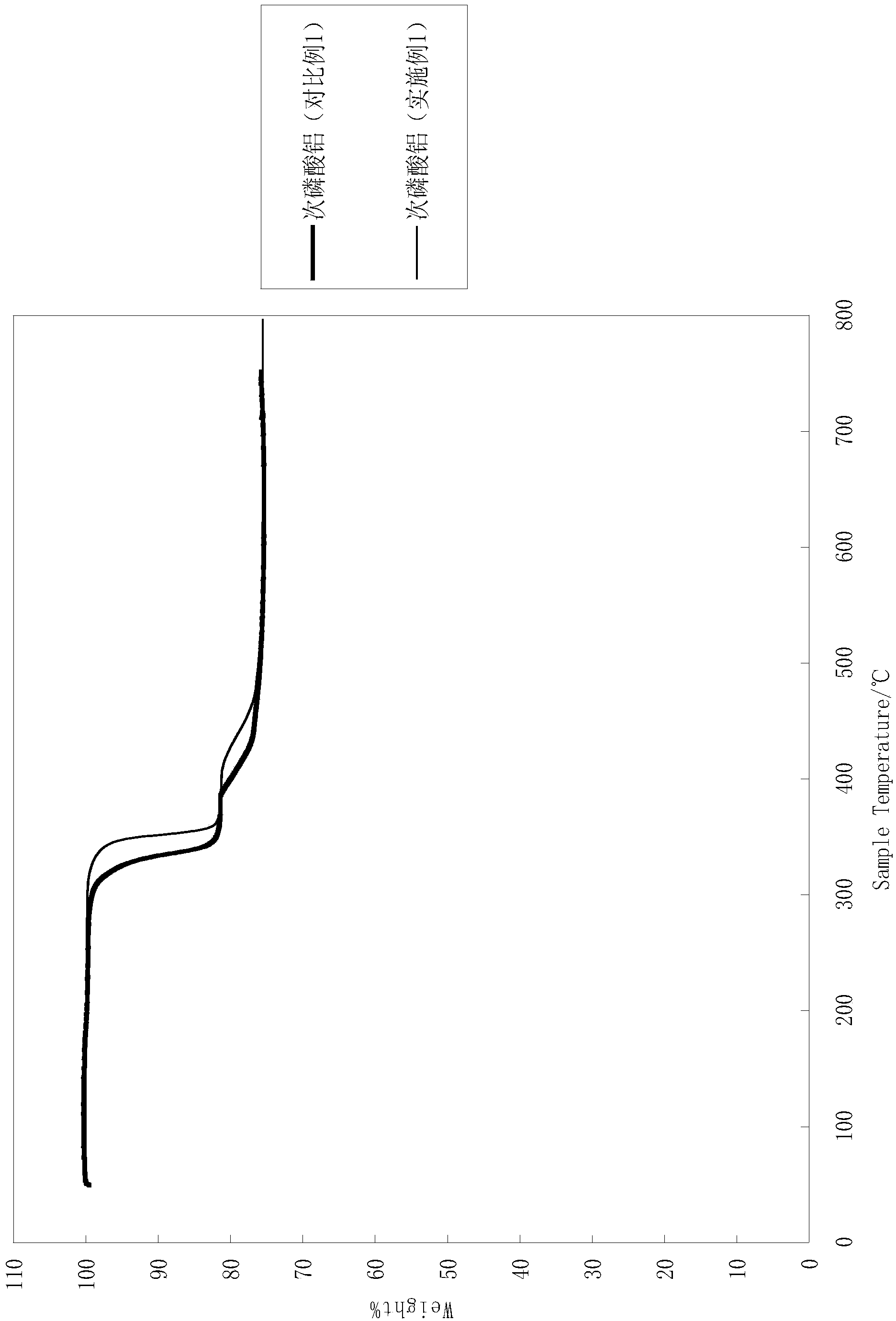

Preparation method of aluminum hypophosphite

The invention relates to a preparation method of aluminum hypophosphite. The method comprises the following steps: firstly, preparing a water solution of sodium hypophosphite; secondly, preparing an ethanol solution of aluminum chloride; thirdly, preparing aluminum hypophosphite: firstly heating the water solution of sodium hypophosphite to be 80-90 DEG C, then slowly adding the ethanol solution of aluminum chloride into the water solution of sodium hypophosphite, enabling the molar ratio of sodium hypophosphite to aluminum chloride to be (4-12):1, then performing heating reflux reaction, and treating reaction liquid after the reaction, so as to obtain the aluminum hypophosphite. The method has the advantages that ethyl alcohol serves as the solvent of aluminum chloride, the synthesis technology is simple, the requirement on reaction equipment is low, products obtained hardly contain hazardous substance sodium chloride residue, and the flame retardant property of the aluminum hypophosphite is good.

Owner:WUHAN UNIV OF TECH

Method for preparing aluminum hypophosphite

ActiveCN103496681AShort reaction cycleSimple processHypophosphorous acidAluminium hydroxideHeat stability

The invention discloses a method for preparing aluminum hypophosphite. The method comprises the following steps that a certain amount of aluminum hydroxide is added to a reaction kettle with a stirring function, a certain amount of water is further added, the mixture is thoroughly stirred, and therefore the added materials are evenly scattered. An appropriate amount of hypophosphorous acid is dripped to the mixture at the temperature of 50 DEG C-100 DEG C and the reaction is kept for 3h-8h; the temperature of the mixture is reduced to the indoor temperature, the mixture is filtered and dried, and therefore the aluminum hypophosphite is obtained, wherein the volume of the water: the number of moles of the aluminum hydroxide: the number of moles of hypophosphorous acid = 1L: 1mol-2mol: 2mol-8mol. According to the method for preparing the aluminum hypophosphite, the yield is high, the technology is simple and easy to conduct, cost is low, the performance cost ratio is high, the obtained product is good in heat stability, and the application prospect is good.

Owner:湖南美莱珀科技发展有限公司

Method for joint production of hypophosphite of calcium, magnesium and aluminum

InactiveCN106006589AThe synthetic process route is simpleAvoid harmHypophosphorous acidSodium Hypophosphite MonohydrateMagnesium salt

The invention relates to a method for joint production of hypophosphite of calcium, magnesium and aluminum. The method provided by the invention employs sodium hypophosphite, a calcium salt, and a magnesium salt to carry out double decomposition reaction to prepare calcium hypophosphite and magnesium hypophosphite, and avoids the harm of using hypophosphorous acid as the reactant, also gives consideration to the technological shortcoming that after preparation of calcium hypophosphite and magnesium hypophosphite, a lot of hypophosphite still exists in waste liquid and cannot be completely extracted, after preparation of calcium hypophosphite and magnesium hypophosphite, a joint production technique is employed for the first time to prepare hypophosphite of aluminum. The preparation method has the advantages of mild reaction conditions, little pollution, pure product, high utilization rate of hypophosphite ions, high comprehensive yield, greatly reduced cost, and simple and practicable process route, and is convenient for mass production.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method for preparing tetrakis(hydroxymethyl)phosphonium chloride from phosphine generated in sodium hypophosphite production

ActiveCN101143878ASmall doseSmall foamingGroup 5/15 element organic compoundsHypophosphorous acidToxic gasAbsorption column

The present invention relates to a method which uses the phosphine generated in the process of producing sodium hypophosphite to prepare tetrakis (hydroxymethyl) phosphonium chloride. From the waste gas generated in the process of producing the sodium hypophosphite, the phosphine is collected and stored; aqueous solution is prepared with formaldehyde and hydrochloric acid according to the molar ratio of 4.05 to 4.15:1; the aqueous solution is pumped into an absorption column by an erosion-resistant pump and is sprayed down from the top of the column, the phosphine gas in a gas vessel is pumped into the absorption column by a gas pump, a synthesis reaction is carried out under the condition of temperature between 40 DEG C and 50 DEG C, the reaction formula is 4HCHO plus HCL plus PH3=(HOCH2)4PCL, and finally, the tetrakis (hydroxymethyl) phosphonium chloride is prepared. The prepared tetrakis (hydroxymethyl) phosphonium chloride is a quaternary alkylphosphonium salt bactericidal algicide, which does not pollute environment. The formaldehyde and the hydrochloric acid can thoroughly absorb the phosphine, thus realizing zero emission of toxic gas. The present invention resolves the problem of environmental pollution caused by the waste gas generated in the process of producing sodium hypophosphite.

Owner:江苏和纯化学工业有限公司

Method for producing aluminium hypophosphite by adopting reaction extrusion process

InactiveCN103879979ARapid responseShort reaction timeHypophosphorous acidAluminium hydroxideMicrometer

The invention discloses a method for producing aluminium hypophosphite by adopting a reaction extrusion process. The method comprises the following steps: (1) uniformly mixing hypophosphite and aluminium salt or hypophosphorous acid and aluminium hydroxide or hypophosphorous acid and aluminium oxide, and carrying out reaction extrusion on a double screw extruder; (2) aging a product obtained from the step (1) at 20-80 DEG C for 4-48 hours, and then washing, filtering and drying the product to obtain the aluminium hypophosphite. According to the method, a reactant can be fast reacted due to high torque and high rotation speed of the double screw extruder, so that the reaction time can be shortened, and the energy consumption can be reduced; an aluminium hypophosphite granule with the grain diameter less than 10 micrometers can be obtained.

Owner:广东宇星阻燃新材股份有限公司

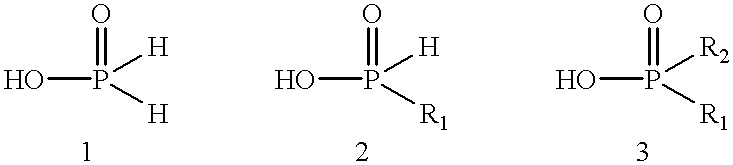

Process for preparing phosphinic acids

InactiveUS6388125B1Group 5/15 element organic compoundsHypophosphorous acidPhosphinic AcidsPhosphinous acid

The present invention relates to a process for the preparation of phosphinic acids from alkali metal phosphinates, which comprises reacting alkali metal phosphinates in a polar solvent with an inorganic mineral acid and then separating off the phosphinic acid formed.

Owner:CLARIANT GMBH

Method for producing hypophosphorous acid

ActiveCN101181983AIncrease production capacitySuitable for mass productionHypophosphorous acidSulfate radicalsFiltration

The invention relates to a method of producing hypophosphorous acid, which comprises the following steps: a. a portion of concentrated sulfuric acid is put into a reaction vessel, in which two portions of hypophosphorous acid are fed, and then the mixture solution is stirred and reacts for 1-2 hours; b. after the reaction is finished, residue and feed liquid are separated by a centrifuge, the feed liquid separated is 70-75 percent of the hypophosphorous acid by content and the residue is sodium sulfate; c. adequate barium hydroxide solution is added into the feed liquid of the hypophosphorous acid separated, which causes sulfate radical to generate barium sulfate deposition, and the barium sulfate is removed through filtration, thus obtaining the hypophosphorous acid; d. the concentration of the hypophosphorous acid obtained in the step c is adjusted to 50 percent by adding water and then the solution obtained is packed, thus obtaining the hypophosphorous acid product. The invention uses the concentrated sulfuric acid and sodium hypophosphite to generate the hypophosphorous acid and the sodium sulfate through reaction, and the technique process does not cause environmental problems such as wastewater, etc. Furthermore, the velocity ratio of double decomposition reaction is very fast, thus being especially applicable for mass production and greatly improving the production capacity of the hypophosphorous acid.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Method for preparing high-purity sodium hypophosphite

InactiveCN101555002AGood purification effectSimple production processHypophosphorous acidPhosphoric acidSolvent

The invention provides a method for preparing high-purity sodium hypophosphite, which comprises the following processing steps: matching materials, wherein, the high-purity sodium hypophosphite is prepared from the following components according to proportioning by weight: 100 portions of yellow phosphorus, 70 portions of lime, 290 portions of ionic-membrane caustic soda and 500 portions of water; evenly mixing the components and reacting to obtain sodium hypophosphite solution and calcium phosphate precipitation; adding barium hypophosphate prepared from hypophosphorous acid and barium carbonate to the sodium hypophosphite solution, and evenly mixing the solution; improving the purity of the product solution by a method of adding powdered activated carbon for decoloring and adsorbing chloride ions; filtering with a membrane filtering machine with the pore diameter being 0.2 mum, so as to trap the tiny impurities; and additionally arranging a spraying system on a centrifuge and washing crystals with de-ionized water solvent. The invention has the advantages that the crystals are sprayed and washed at the time of centrifugal separation, and the mother solution adhered to the surfaces of the crystals can be washed away, thereby ensuring the obvious purification effect; the method can remove the cumbersome and low-efficiency preparation process, simplify the preparation process and reduce the preparation cost; and the content of the product can reach 103.56%.

Owner:JIANGSU DANAI CHEM

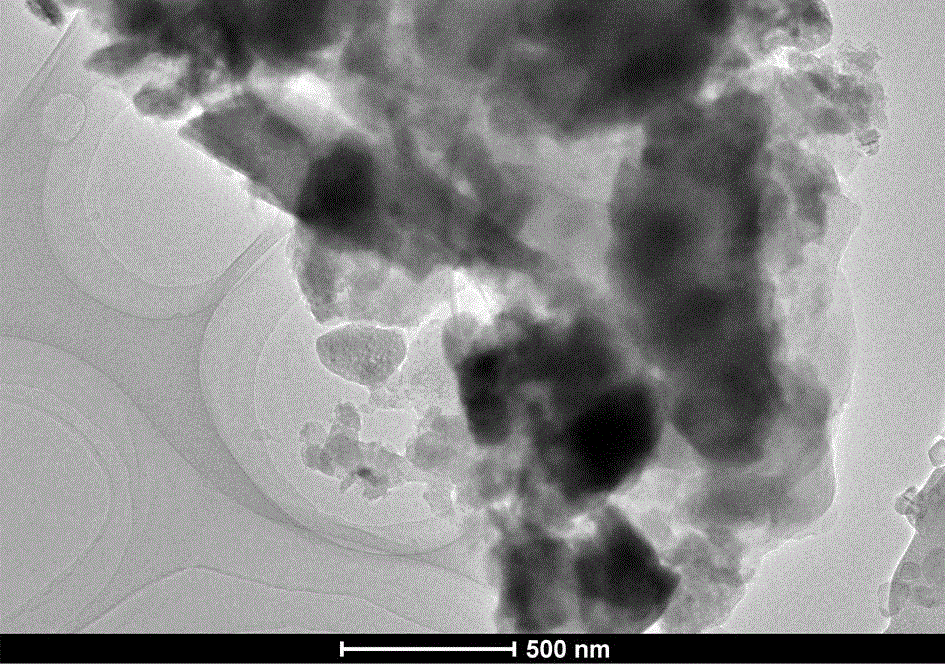

Preparation method for nanometer aluminum hypophosphite

InactiveCN107337187AHigh yieldGood dimensional stabilityNanotechnologyHypophosphorous acidWater solubleColloid

The invention discloses a preparation method for nanometer aluminum hypophosphite, belonging to the technical field of preparation of nanometer materials. The preparation method comprises the following steps: a) adding an aqueous solution of sodium hypophosphite and cetyltrimethylammonium bromide into an organic continuous-phase solvent and carrying out a reaction at 50 to 95 DEG C so as to obtain a water-in-oil reversed-phase microemulsion containing sodium hypophosphite, wherein the microemulsion is named as liquid A; b) adding a water-soluble aluminum salt solution and cetyltrimethylammonium bromide in another organic continuous-phase solvent and carrying out a reaction at 50 to 95 DEG C so as to obtain a water-in-oil reversed-phase microemulsion containing a water-soluble aluminum salt, wherein the microemulsion is named as liquid B; c) mixing the liquid A with the liquid B, adjusting a molar ratio of sodium hypophosphite to the water-soluble aluminum salt at 80 to 95 DEG C and under atmospheric pressure, carrying out heating and refluxing, and then carrying out a reaction in a nanometer microemulsion reactor so as to obtain a nanometer aluminum hypophosphite colloid; and d) carrying out separation, purification and drying on the nanometer aluminum hypophosphite colloid so as to obtain nanometer aluminum hypophosphite powder. According to the invention, the method employs a reversed-phase microemulsion process to prepare uniform and stable nanometer aluminum hypophosphite so as to overcome deficiencies of the conventional methods and processes.

Owner:HUNAN UNIV OF TECH

Method for preparing nickel hypophosphite

InactiveUS6030593APhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesIon exchangePhosphinic Acids

PCT No. PCT / FR96 / 01233 Sec. 371 Date Aug. 19, 1998 Sec. 102(e) Date Aug. 19, 1998 PCT Filed Aug. 2, 1996 PCT Pub. No. WO97 / 12836 PCT Pub. Date Apr. 10, 1997Nickel hypophosphite is prepared by ion exchange on a carboxylic between nickel sulphate and hypophosphorous acid. The product thus obtained, both in the form of an aqueous solution and of a crystalline salt, is intended in particular for the preparation of chemical nickel plating baths.

Owner:CECA SA

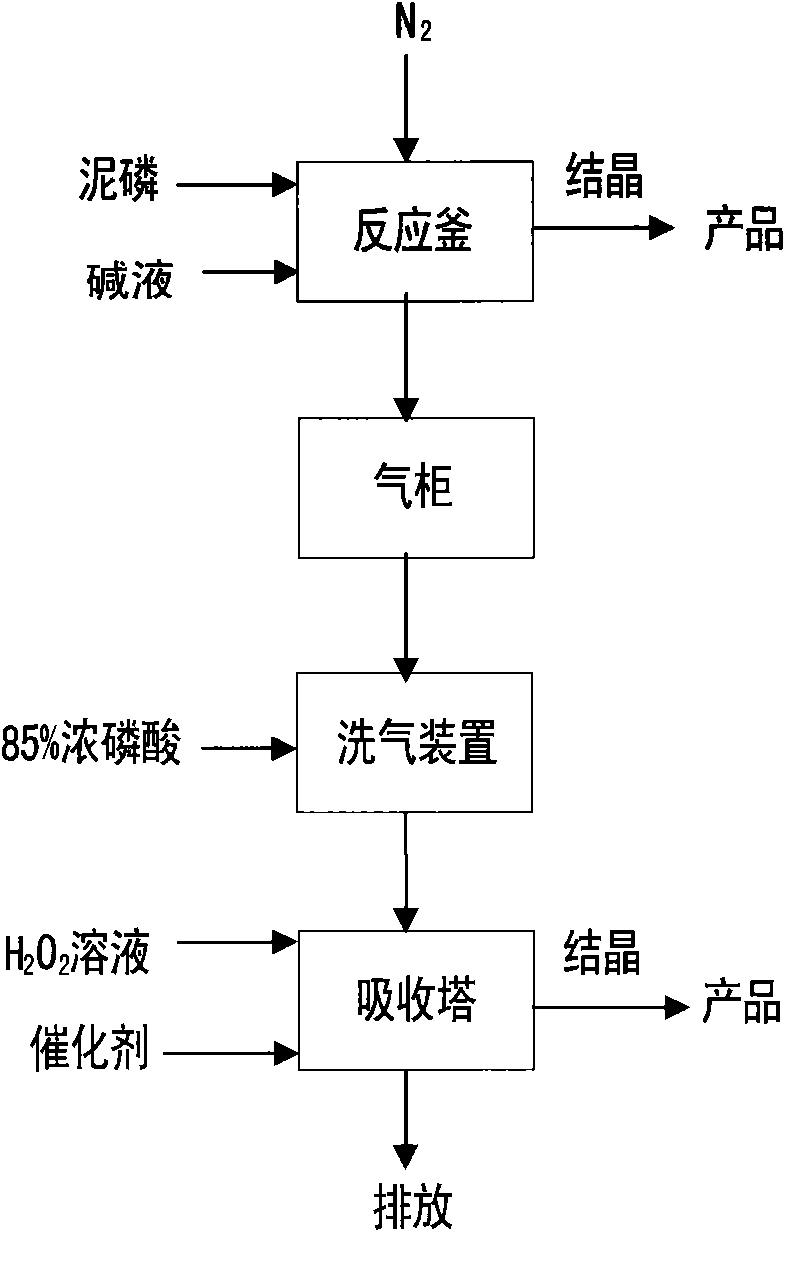

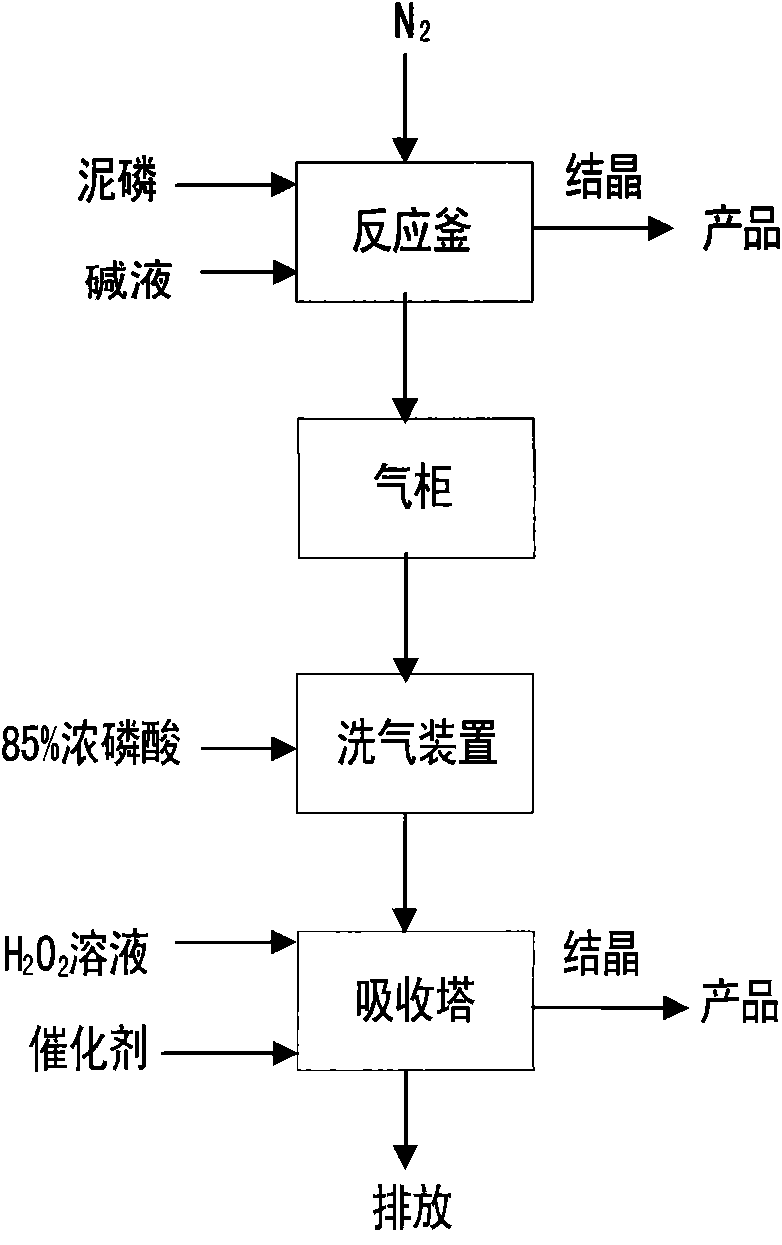

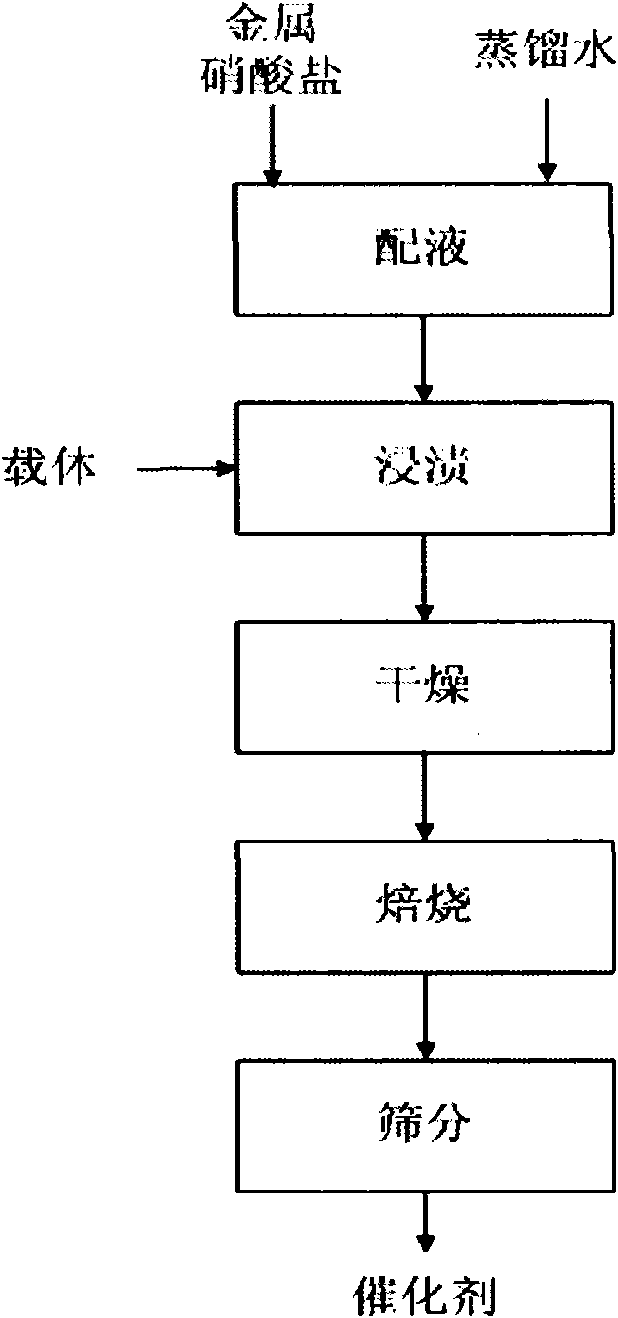

Heterogeneous catalytic oxidation method for treating tail gas generated in sodium hypophosphite preparation process from sludge phosphorus

InactiveCN101811682AImprove stabilityReduce dosageDispersed particle separationPhosphorous acidHigh concentrationHigh absorption

The invention relates to a method for treating waste slag in a yellow phosphorus production process, in particular to a heterogeneous catalytic oxidation method for treating high-concentration phosphine tail gas generated in a sodium hypophosphite preparation process from sludge phosphorus and belongs to the technical field of industrial waste gas purification treatment. The method comprises the following steps: heating the sludge phosphorus and lye in proportion to a temperature of between 75 and 95 DEG C under the condition of oxygen isolation, performing a reaction with stirring, collecting and washing the generated phosphine, absorbing the phosphine by using solution of hydrogen peroxide in the presence of a filter cake of a nitrate catalyst, wherein the mass ratio of the catalyst to the absorption liquid is 1-20 to 1,000, and reacting to form sodium hypophosphite and sodium phosphite products. The method can reduce the air pollution caused by the phosphine tail gas, have high absorption efficiency of the phosphine, and can increase the output of the sodium hypophosphite products.

Owner:KUNMING UNIV OF SCI & TECH

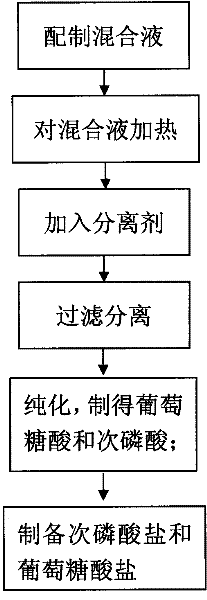

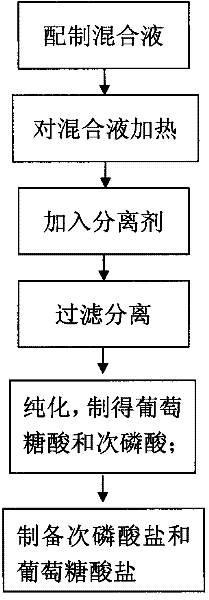

Method for preparing hypophosphorous acid (salt) and gluconic acid (salt) from glucose phosphate serving as raw material

InactiveCN102190578AEasy to getLow costCarboxylic acid salt preparationHypophosphorous acidPhosphateGluconic acid

The invention discloses a method for preparing hypophosphorous acid (salt) and gluconic acid (salt) from glucose phosphate serving as a raw material, which comprises the following steps of: (1) preparing raw materials: preparing subphosphate or acid phosphate and glucose, and taking water as a solvent; (2) heating: continuously heating mixed solution at the temperature of more than or equal to 100DEG C under the air pressure of more than or equal to 0.01MPa for more than 10 minutes; (3) separating: adding a separating agent, concentrating, and separating to obtain crude products of gluconic acid salt and hypophosphorous acid salt; (4) purifying: filtering to remove precipitates to obtain gluconic acid, adding a gas or a solvent capable of reacting with the hypophosphorous acid salt into aqueous solution of the separated hypophosphorous acid salt, and filtering to remove precipitates to obtain hypophosphorous acid; (5) preparing the hypophosphorous acid salt: reacting the hypophosphorous acid with basic oxide or hydroxide to obtain the hypophosphorous acid salt; and (6) preparing the gluconic acid salt: reacting the gluconic acid with basic oxide or hydroxide to obtain the gluconicacid salt. The production process is environment-friendly and harmless, raw materials are readily available, the cost is low, the yield is high, the period is short and the safety is achieved.

Owner:石允生

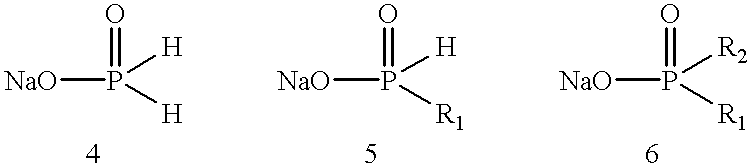

Process for stabilizing hypophosphite

InactiveUS20120208942A1PhosphatesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPolymer sciencePhosphate

A process for stabilizing hypophosphite salt is provided, which comprises the following steps: a) washing the hypophosphite salt at least one time under a controlled pH value of 4-11, preferably 5-8, as the said hypophosphite salt in an aqueous solution and / or in a solid state; and b) drying the said hypophosphite salt under reduced pressure to remove the volatiles. The process can prevent or minimize the formation of a dangerous quantity of phosphine from hypophosphite salts, more particularly in the flame retardant of the application. The flame retardant polymer composition is also provided, which comprises a polymer and the hypophosphite salt stabilized by the above process.

Owner:SOLVAY (CHINA) CO LTD

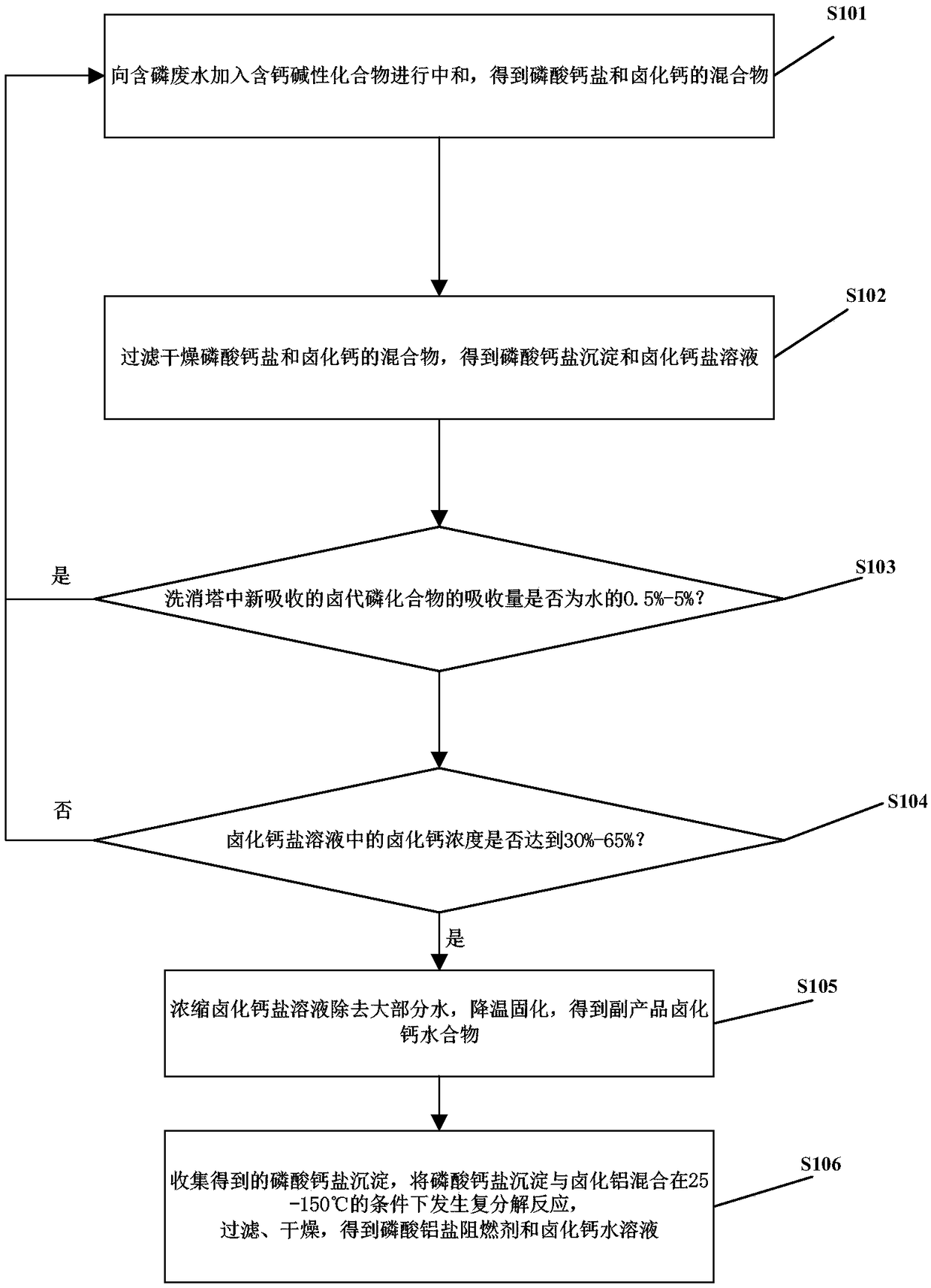

Phosphorus-containing wastewater recycling and waste resource utilization method

InactiveCN109293058AAvoid generatingAvoid physical resourcesCalcium/strontium/barium chloridesWater contaminantsCalcium biphosphateResource utilization

The invention provides a phosphorus-containing wastewater recycling and waste resource utilization method, which comprises: adding a calcium-containing alkaline compound into phosphorus-containing wastewater, and neutralizing to obtain the mixture of a calcium phosphate salt and calcium halide; filtering the mixture to obtain a calcium phosphate salt precipitate and a calcium halide salt solution,adjusting the pH value of the calcium halide salt solution, returning the calcium halide salt solution as a decontamination agent to a decontamination tower, and continuously carrying out decontamination on a halogenated phosphorus compound; when the calcium halide concentration in the calcium halide salt solution reaches a set value, concentrating the calcium halide salt solution, and carrying out cooling solidifying to obtain a calcium halide hydrate; and collecting the calcium phosphate salt precipitate, carrying out a mixing reaction on the calcium phosphate salt precipitate and aluminumhalide, filtering, and drying to obtain an aluminum phosphate salt flame retardant and a calcium halide aqueous solution. The method of the invention has advantages of low cost, easy industrial production, turning of waste into treasure and other practicalities, and further has high value.

Owner:HONGHU YITAI TECH CO LTD

Method for preparing aluminum hypophosphite via continuous reaction crystallization process

InactiveCN104163412AIncrease production capacityHigh degree of automationHypophosphorous acidSodium Hypophosphite MonohydrateSodium phosphates

The invention relates to a method for preparing aluminum hypophosphite via a continuous reaction crystallization process. According to the technical scheme, the method comprises the following steps: continuously adding a 50-80wt% sodium hypophosphite solution and 50-60wt% soluble aluminum salt solution into a reaction crystallizer, controlling the average residence time of the materials in the continuous reaction crystallizer for 1 to 5 hours, further discharging a mother liquor I of aluminum hypophosphite from the bottom of the crystallizer and sending the mother liquor I of aluminum hypophosphite into an ager for aging 0 to 3 hours, then further discharging the mother liquor I from the bottom of the ager, and carrying out centrifugal separation, washing and drying so as to obtain an aluminum hypophosphite crystal with the purity greater than 99.0% and a crystallized mother liquor II; finally, evaporating and crystallizing the crystallized mother liquor II so as to obtain a coarse product sodium salt and a crystallized mother liquor III; returning the crystallized mother liquor III into the continuous reaction crystallizer for circulating. Based on the continuous reaction crystallization process, the method has the advantages of simple process, moderate operating condition, low energy consumption, stable aluminum hypophosphite quality and the like, and is easy to industrialize.

Owner:WUHAN UNIV OF SCI & TECH

Sodium hypophosphite evaporation process

InactiveCN109650475AAchieve continuous evaporationSimple and fast operationWater/sewage treatment by heatingWater/sewage treatment apparatusVapor–liquid separatorSodium Hypophosphite Monohydrate

The invention discloses a sodium hypophosphite evaporation process. A sodium hypophosphite aqueous solution is evaporated by using a three-effect evaporation device. The process includes the followingconcrete process steps: sodium hypophosphite is added into a first-effect evaporator with an appropriate flow rate, secondary steam generated by evaporation is separated by a first-effect gas-liquidseparator in the first-effect evaporator and then enters a second-effect evaporator, the secondary steam generated in the second-effect evaporator is separated by a second-effect gas-liquid separator,enters a third-effect evaporator, is evaporated by the third-effect evaporator, is separated by a third-effect gas-liquid separator, enters a condenser for condensation and then is discharged; and aconcentrate of the first-effect gas-liquid separator is pumped into the third-effect evaporator through a first-effect discharging pump located at the bottom, a concentrate of the third-effect gas-liquid separator in the third-effect evaporator is pumped into the second-effect evaporator through a third-effect discharging pump located at the bottom, and a concentrate in the second-effect gas-liquid separator is pumped into a crystallization kettle through a second-effect discharging pump after reaching a prescribed concentration. The sodium hypophosphite evaporation process can realize continuous evaporation of the sodium hypophosphite and is simple in operation and stable in discharging concentration.

Owner:CHANGSHU NEW TECH CHEM

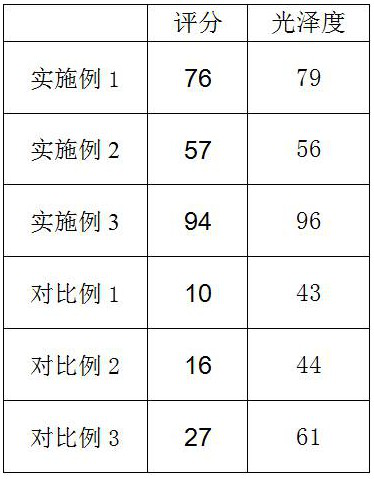

Ceramic tile with copper metal texture and preparation method thereof

The invention relates to the field of ceramic tile production, provides a ceramic tile with copper metal texture and a preparation method thereof, and is used for providing a ceramic tile with copperimitation texture. The ceramic tile with the copper metal texture is prepared from 5-8 parts by mass of iron phosphate, 20-25 parts by mass of hybrid aluminum hypophosphite, 6-8 parts by mass of quartz, 40-60 parts by mass of albite, 1-3 parts by mass of calcined kaolin, 3-7 parts by mass of aluminum oxide, 2-5 parts by mass of calcined talc, 3-5 parts by mass of zinc oxide and 8-12 parts by massof high-boron frit. The materials are mixed and then subjected to ball milling to obtain glaze, and the glaze is applied to a green body to form ground coat; transparent glaze is applied to the groundglaze, firing is conducted for 20-24 h, and the ceramic tile with the copper metal texture is obtained. The metal texture can be improved, and particularly, the ceramic tile has the texture and colorsimilar to those of copper.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com