Technique for preparing hypophosphorous acid through bipolar membrane electroosmosis method

A bipolar membrane electrodialysis and hypophosphorous acid technology, which is applied in the direction of electrodialysis, hypophosphorous acid, phosphorus oxyacid, etc., can solve the problems of industrial scale-up difficulties and achieve easy industrial scale-up, low energy consumption, and no secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

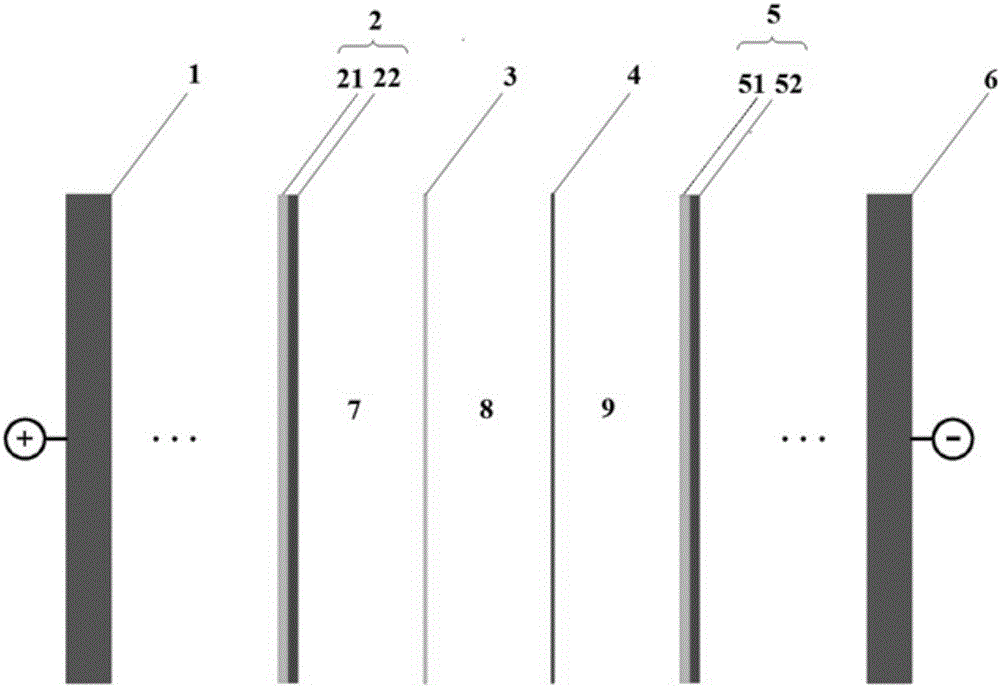

Image

Examples

Embodiment 1

[0049] Put 200 liters of sodium hypophosphite solution with a concentration of 50g / L into the salt chamber storage tank of the bipolar membrane electrodialysis device, put 200 liters of deionized water into the acid chamber and the alkali chamber storage tank respectively, and open the Circulation pump, electrolysis after electrification. Heat exchangers are used to cool the liquid in each chamber. During the electrolysis process, the temperature is controlled at 20°C. During the electrolysis process, the voltage between the anode and the cathode is controlled to be 105-110V. It can be seen that the voltage of the matching unit is (105-110V) / 60=1.75-1.83V, the current is 96-100A, it can be seen that the current density is (96-100A) / (400×800×10 -6 m 2 )=300-312.5A / m 2 . As the current of the bipolar membrane electrodialysis decreases, the sodium hypophosphite concentrate is continuously added to the salt storage tank to keep the concentration of sodium hypophosphite in the ...

Embodiment 2

[0052] Put 200 liters of sodium hypophosphite solution with a concentration of 80g / L into the salt chamber storage tank of the bipolar membrane electrodialysis device, put 200 liters of deionized water into the acid chamber and the alkali chamber storage tank respectively, and open the Circulation pump, electrolysis after electrification. A heat exchanger is used to cool the liquid in each chamber, and the temperature is controlled at 25°C during the electrolysis process. During the electrolysis process, the voltage between the anode and the cathode is controlled to be 105-110V. It can be seen that the voltage of the matching unit is 1.75-1.83V, the current is 100-110A, and the current density is 312.5-343.75A / m 2 . As the current of the bipolar membrane electrodialysis decreases, the sodium hypophosphite concentrate is continuously added to the salt storage tank to keep the concentration of sodium hypophosphite in the salt storage tank at about 80 g / L during the entire elect...

Embodiment 3

[0055] Put 200 liters of sodium hypophosphite solution with a concentration of 100g / L into the salt chamber storage tank of the bipolar membrane electrodialysis device, put 200 liters of deionized water into the acid chamber and the alkali chamber storage tank respectively, and open the Circulation pump, electrolysis after electrification. A heat exchanger is used to cool the liquid in each chamber, and the temperature is controlled at 30°C during the electrolysis process. During the electrolysis process, the voltage between the anode and the cathode is controlled to be 105-110V. It can be seen that the voltage of the matching unit is 1.75-1.83V, the current is 110-117A, and the current density is 343.75-365.625A / m 2 . As the current of the bipolar membrane electrodialysis decreases, the sodium hypophosphite concentrate is continuously added to the salt storage tank to keep the concentration of sodium hypophosphite in the salt storage tank at about 100g / L during the entire el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com