Method for preparing high-purity sodium hypophosphite

A pure sodium hypophosphite, sodium hypophosphite technology, applied in the direction of hypophosphorous acid, phosphorus oxyacid, etc., can solve the problems of cumbersome production process and high production cost, achieve obvious purification effect, simplify production process and reduce equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

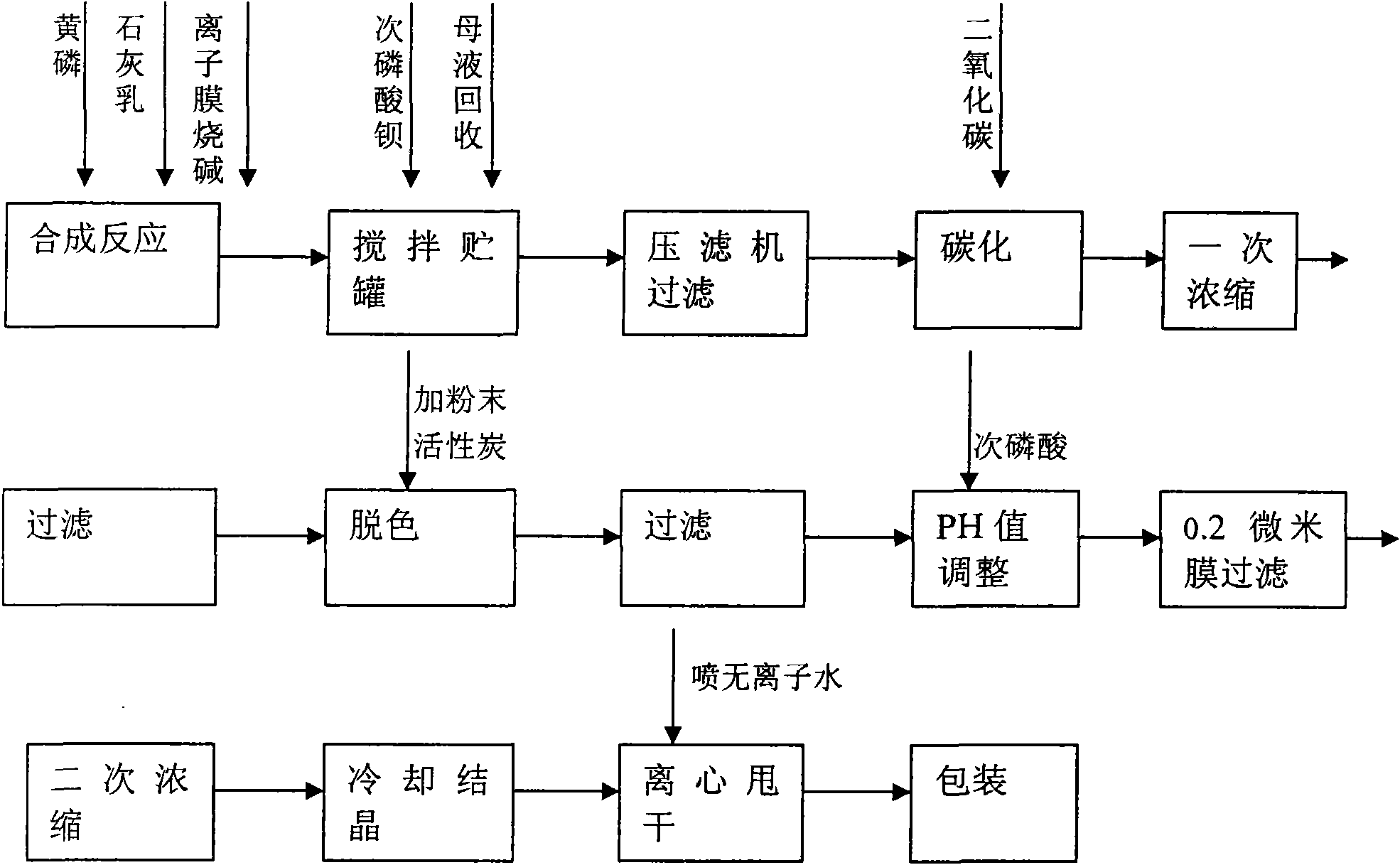

Image

Examples

Embodiment

[0014] 1. Add yellow phosphorus, lime, 32% ion-exchange membrane caustic soda and water into the reaction kettle at a ratio of 100:70:290:500, and the reaction is completed at a temperature of 45°C-92°C for about 1 hour. Sodium hypophosphite solution and calcium phosphite precipitate were obtained, and the clear liquid was taken to measure sulfate ion 0.06mg / L. Use ionic membrane caustic soda to reduce the content of chloride ions and sulfate ions in the product.

[0015] 2. Pour the finished feed solution into a storage tank with stirring, and add 100 kg of barium hypophosphite that has been prepared at a ratio of 1:10 of barium:sodium, and add 100 kg of the crystallized mother liquor quantitatively at the same time. kg into the storage tank, stirred for 10 minutes, and filtered through a filter press. Measured sulfate radical 0.004mg / L.

[0016] 3. The filtered clear liquid is carbonized in the carbonization kettle to control the calcium content to 0.05mg / L.

[0017] 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com