Patents

Literature

1174results about How to "Improve the purification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

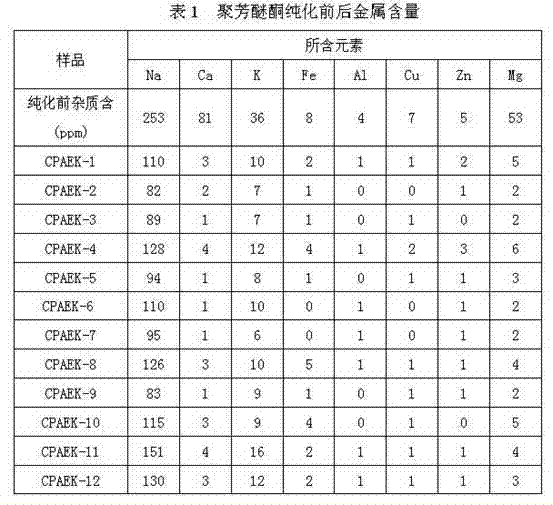

Method for reducing metal impurities in poly(aryl ether ketone) polymer

The invention belongs to the technical field of polymer material, and relates to a method, used in a production process, for reducing metal impurities in poly(aryl ether ketone). The method comprises the following steps: 1) purification: fully mixing poly(aryl ether ketone) with hydroxy ethidene diphosphonic acid aqueous solution with mass concentration of 0.1-2% at 40-100 DEG C for 0.5-3 h, wherein time for mixing and stirring is preferably 1-2 h, and filtering; 2) washing: washing the purified poly(aryl ether ketone) with distilled water, until conductivity of the aqueous solution is below 20 muS / cm; and 3) drying: drying the washed poly(aryl ether ketone) at 120-140 DEG C for 4-6 h to obtain poly(aryl ether ketone) with metal impurities removed. The method can not only reduce content of the metal impurities in the poly(aryl ether ketone) and improve product quality; besides the used reagents have excellent chemical stability, small dosage, and no self toxicity or pollution, can be treated with biochemical degradation in a later period of production, and will not harm the environment.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

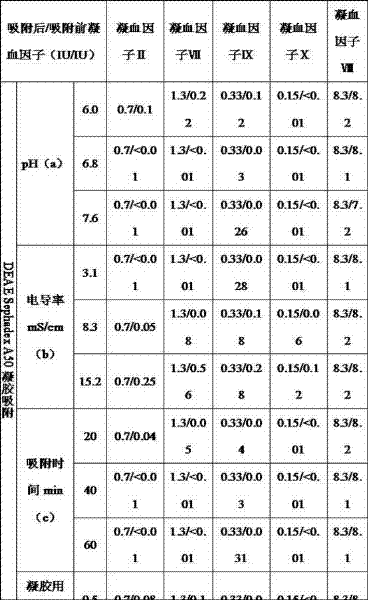

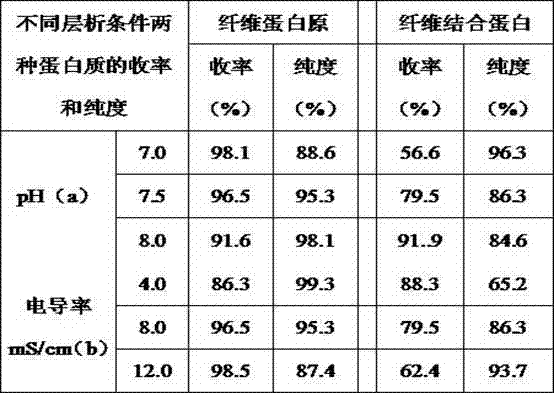

Method for preparing blood coagulation factor ⅷ, fibrinogen and fibronectin by cryoprecipitation

ActiveCN102295696AIncrease profitHigh yield and purityFactor VIIConnective tissue peptidesFibrinBlood plasma

The invention relates to the field of blood products, in particular to a process method for preparing three kinds of blood products from cryoprecitation, and aims to provide a complete separation and purification process for respectively and sequentially preparing the three kinds of blood products, i.e. a coagulation factor VIII, fibrinogen and fibronectin, from the cryoprecitation. The process method is implemented by the following technical scheme that the process method comprises the preparation steps of cryoprecitation dissolution, gel adsorption, precipitation of the fibrinogen and the fibronectin, two-step ion exchange chromatography and glycin / sodium chloride precipitation and inactivation of virus. The process method has the beneficial effects that the three kinds of useful blood products, i.e. the coagulation factor VIII, the fibrinogen and the fibronectin, can be separated and extracted from the cryoprecitation sequentially; and the utilization rate of blood plasma is greatly improved.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD

Crucible for electronic industry and method for purifying high-purity quartz sand as lining material

The invention discloses a crucible for the electronic industry and a method for purifying high-purity quartz as a lining material. The method for purifying the high-purity quartz sand comprises the following steps of: oredressing, water quenching, flotation, scouring, magnetic separation, high-temperature vacuum treatment, chlorination, superconductive purification, electric separation, ultrasonic treatment, rectification and purification and electric screening. The purification method provided by the invention has the advantages of simple process and remarkable purification effect; and the obtained high-purity quartz is used for a high-purity quartz crucible and the lining material in the electronic industry and improves the industrial value of quartzite.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

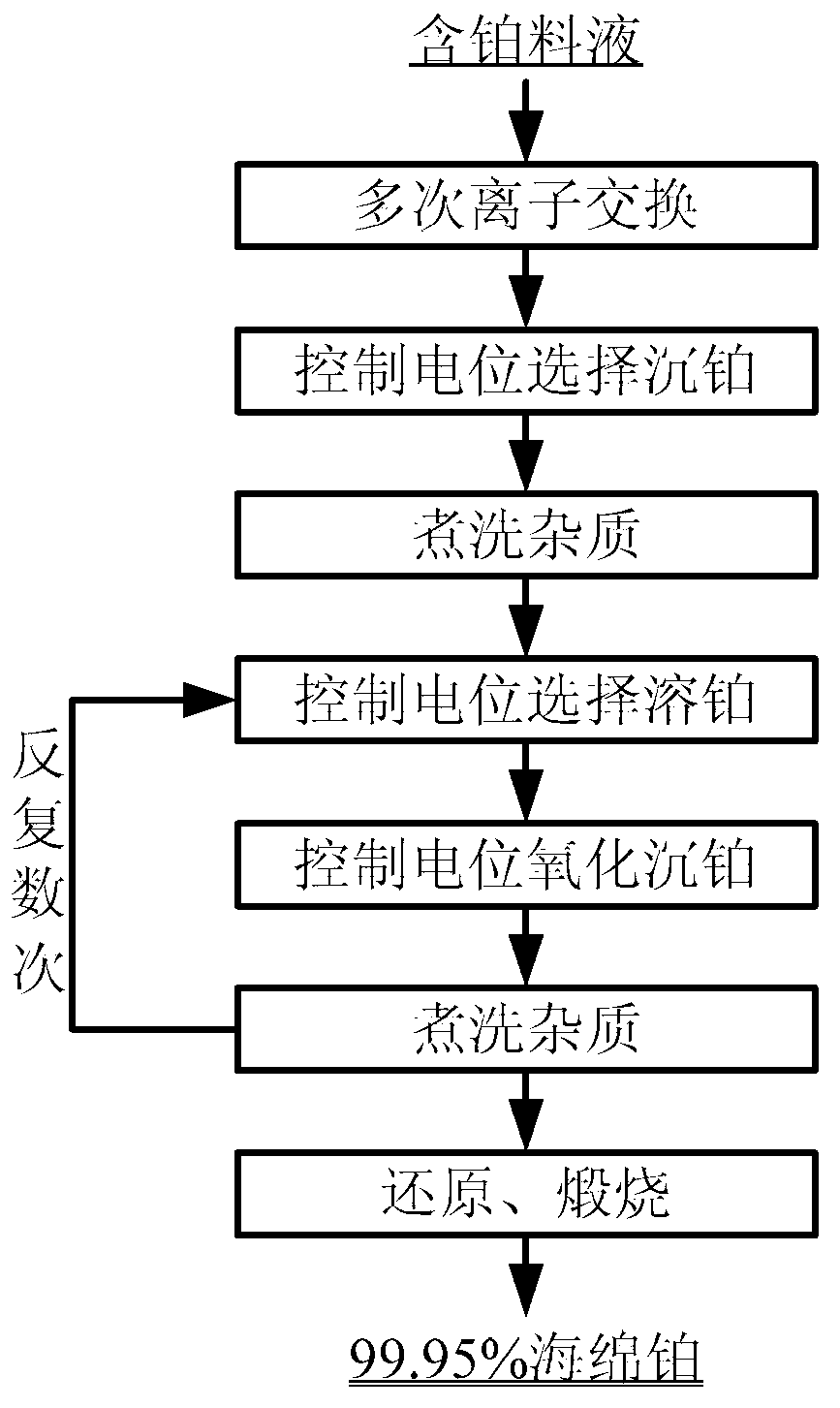

Method for separating and purifying platinum by adopting holding potential

ActiveCN102797018AHigh purityHigh recovery ratePhotography auxillary processesProcess efficiency improvementIon exchangeCalcination

The invention mainly relates to a novel method for separating and purifying platinum from complex platinum family metal solution. Base metal impurities in the solution are removed through ion exchange, pure platinum family metal solution can be obtained, ammonium chloride precipitate platinum is added under a certain oxidation-reduction potential, the electric potential is adjusted, precipitate containing platinum is reduced by a specific reducing agent, the platinum deposit is enabled to be resolved, then the oxidation-reduction potential is adjusted again, the platinum is oxidized to be high valence state again, the ammonium chloride is added so as to enable the platinum to be deposited again, the process of precipitation and resolution are repeated in such a way according to the complexity of raw materials until the ammonium chloroplatinate deposit with purity meeting the requirements can be obtained, and high-purity spongy platinum is obtained from the qualified ammonium chloroplatinate through the processes of reduction, washing, calcination and the like. The method has the advantages of short process, simplicity in operation, and high platinum recovery.

Owner:GUIYAN RESOURCE YIMEN

New process for purifying and manufacturing microcrystalline graphite product

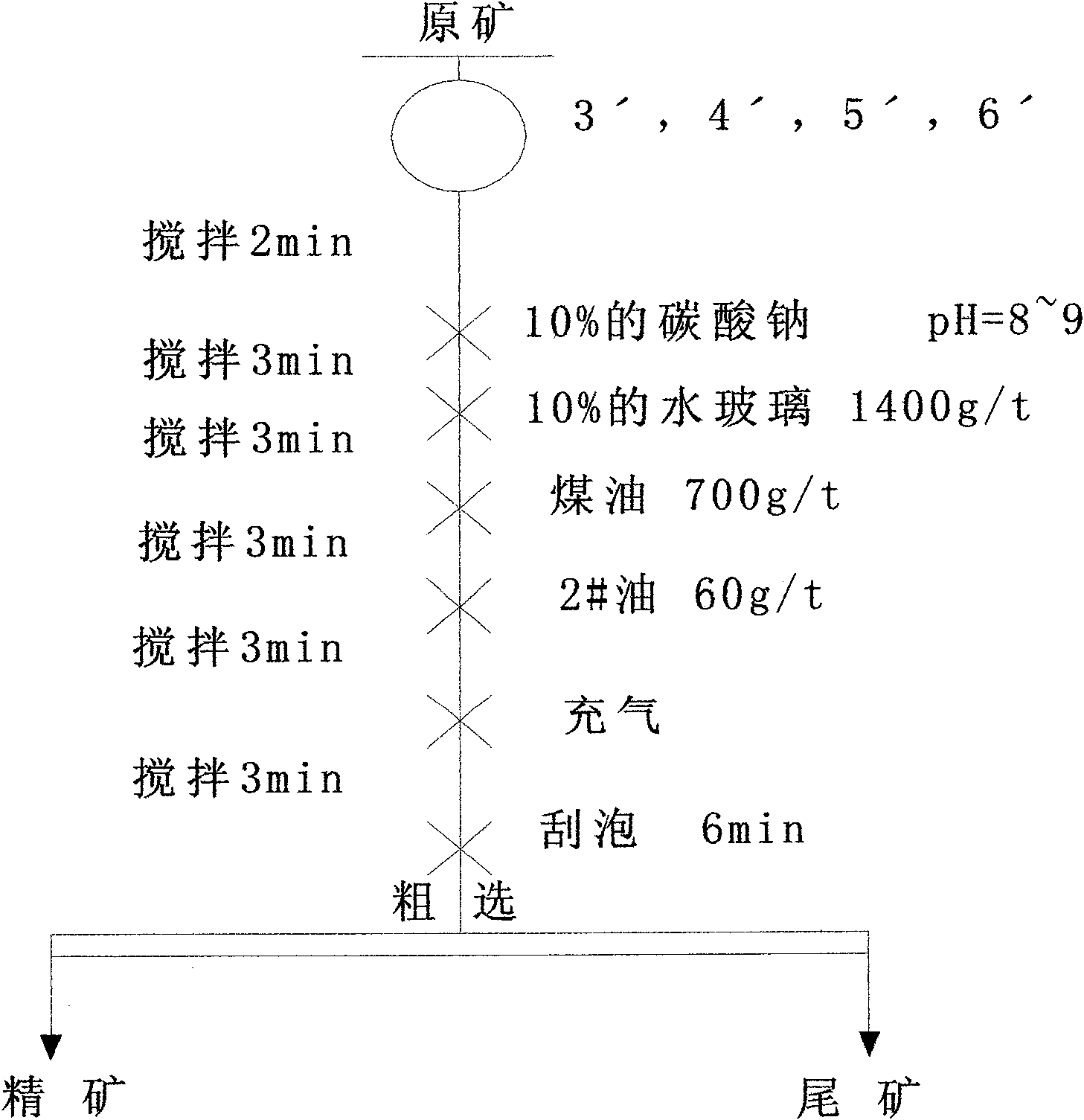

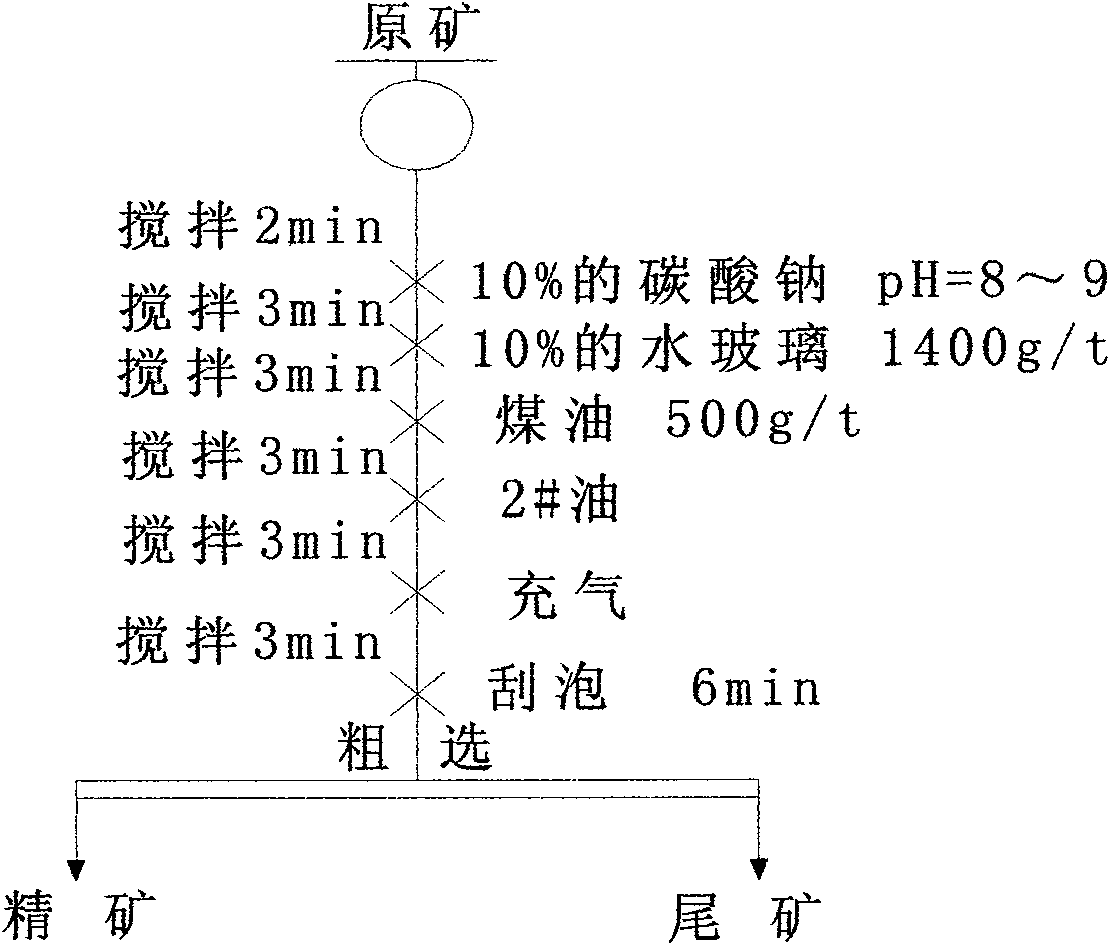

The invention discloses a new process for purifying and manufacturing a microcrystalline graphite product, which comprises the following steps: adding calcined lime and water into graphite ore of which the grinding fineness is -200 meshes and the pass rate is above 90 percent after fine grinding, stirring uniformly and making pH of graphite ore slurry containing the calcined lime above 9; adding water glass to stir, adding kerosene to stir, finally adding pine oil to stir, inflating and scraping to perform rough concentration, and collecting roughly concentrated fine ore and tail ore of graphite; adding water glass into the roughly concentrated fine ore to stir, adding kerosene to stir, adding pine oil to stir, inflating and scraping to perform primary fine concentration, and collecting finely concentrated fine ore; adding water glass into the primarily finely concentrated fine ore to stir, adding kerosene to stir, adding pine oil to stir, inflating and scraping to perform secondary fine concentration, and collecting flotation graphite fine ore; adding NaOH solution into the flotation graphite fine ore for mixing, roasting, washing with water to neutral, performing acid leaching with hydrochloric acid, washing with water, dewatering and drying to obtain a high-carbon graphite product with the fixed carbon content in the graphite up to 98.74 percent.

Owner:FUJIAN FUYOU GRAPHITE TECH

Purification process for preparing high-purity coenzyme Q10

ActiveCN101987815AImprove adsorption capacitySimple and fast operationQuinone separation/purificationDesorptionSolvent

The invention relates to a purification process for preparing high-purity coenzyme Q10 from crude coenzyme Q10 extracts obtained from thallus fermentation, which belongs to the technical field of compound separation purification. The purification process is characterized by sequentially comprising the following steps of: carrying out adsorbent resin adsorption, elution, concentration, crystallization and recrystallization on the crude coenzyme Q10 extracts; then, carrying out chromatography on a silicagel column; and purifying and refining by using a petroleum ether -aether or normal hexane-ethyl acetate mixed solvents as eluant. The invention has the following advantages that by adopting an adsorbent resin, good adsorption performance can be exerted on the coenzyme Q10, the desorption operation is simple, the stability is good, and the adsorbent resin can be reused many times; and by combining the adsorbent resin with the silica gel chromatography method, the silica gel utilization rate is high, the required silica gel is low quantity and can maintain good purification effect after being reused more than 10 times, the waste quantity of the silica gel is small, and the solvents can be recycled so that the purpose of environment protection is achieved. The production operation is simple and convenient, and the purity of the obtained coenzyme Q10 is higher than or equal to 98 percent.

Owner:EAST CHINA UNIV OF SCI & TECH +1

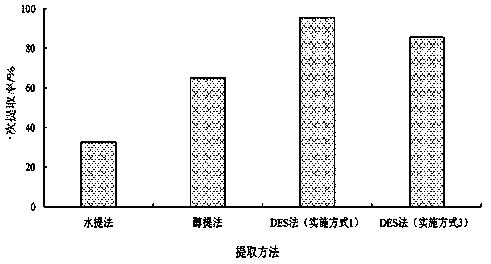

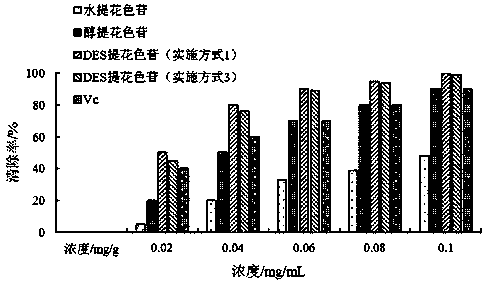

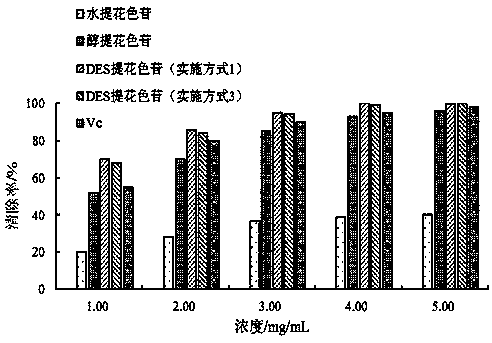

Method for extracting anthocyanin from plant

ActiveCN107383115ARaw materials are cheap and easy to getReduce extraction timeSugar derivativesOther chemical processesOrganic solventFiltration membrane

The invention relates to the field of edible pigment and discloses a method for extracting anthocyanin from a plant. The method comprises the following steps: pulverizing the plant containing the anthocyani and adding a deep-eutectic solvent; extracting anthocyanin extracting liquid by an electrostatic field ultrasonic extraction method; adding an attapulgite loaded chitosan crosslinked cyclodextrin compound into the anthocyanin extracting liquid to obtain an anthocyanin compound precipitate adsorbed on the attapulgite loaded chitosan crosslinked cyclodextrin compound; dissolving the anthocyanin compound precipitate in an organic solvent to perform desorption and centrifugation to obtain anthocyanin supernatant containing the organic solvent; enabling the anthocyanin supernatant to pass through a microporous filtration membrane to obtain a purified anthocyanin solution containing the organic solvent; and removing the organic solvent from the anthocyanin solution and removing the redundant water to obtain a target product anthocyanin. The deep-eutectic solvent serves as an extracting solvent, so the method is green and environment-friendly, and the extraction rate is high; and the anthocyanin is purified and separated by the attapulgite loaded chitosan crosslinked cyclodextrin compound, so the process is simple and the purification and separation efficiency is high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

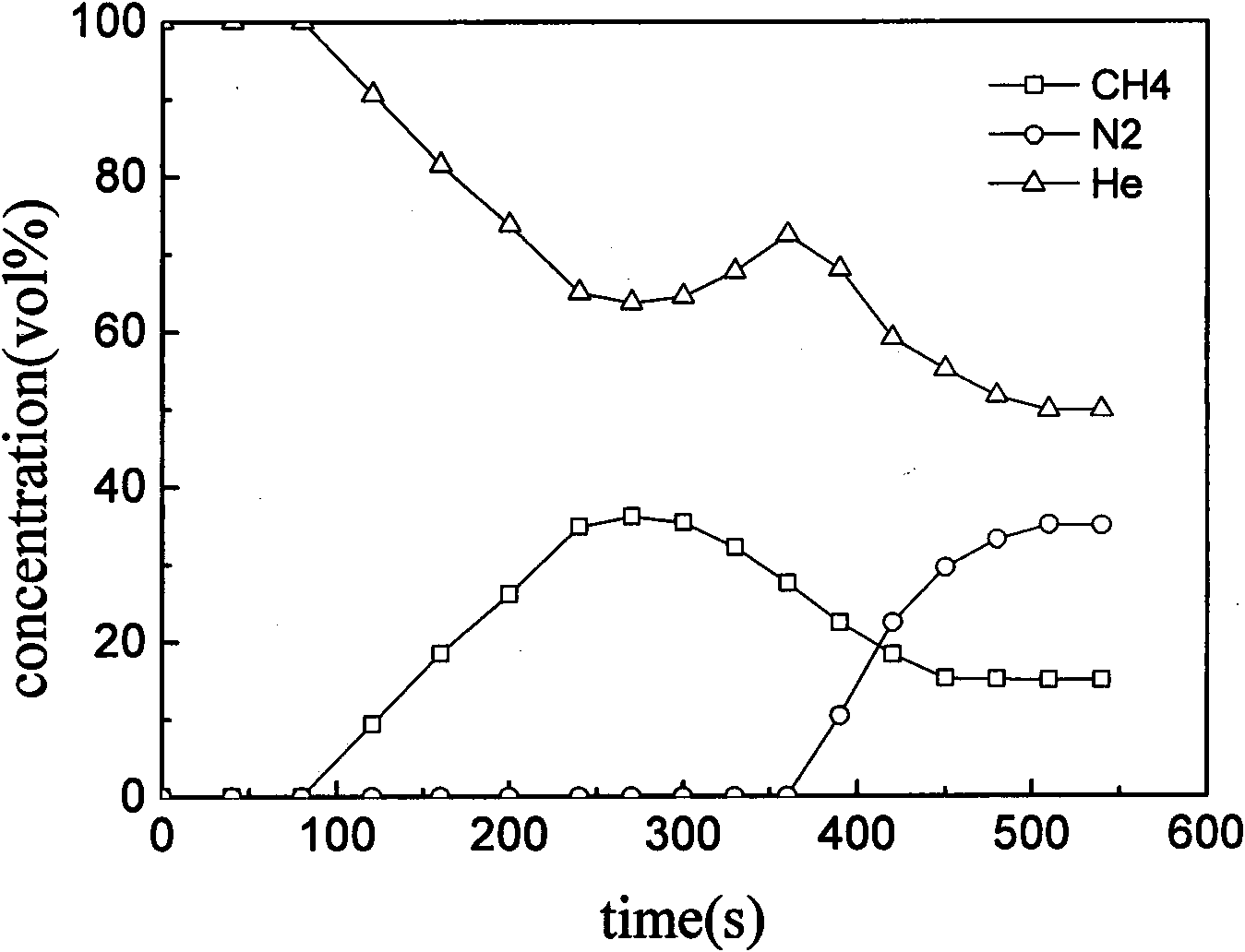

Preparation method of coal-based granular activated carbon with molecular sieving effect and application thereof in pressure-transformation adsorption and separation concentrated gas

InactiveCN101653721AIncrease concentrationImprove the purification effectOther chemical processesDispersed particle separationAdhesiveWater vapor

The invention relates to a preparation method of coal-based granular activated carbon with molecular sieving effect and an application thereof for concentrating strongly adsorptive components of methane, carbon dioxide, and the like in mixed gas with methane and carbon dioxide by a direct deflating step and an inverse vacuum pumping step. The preparation method of coal-based granular activated carbon comprises the following steps: (a) pulverizing coal; (b) adding adhesives of coal tar, and the like into coal powder, and evenly mixing by adding water; (c) molding cylindrical granules, and drying; (d) carbonizing the molded cylindrical granules under nitrogen protection; (e) activating the carbonized cylindrical granules by vapor under the nitrogen protection; and (f) cooling the carbonizedcylindrical granules at room temperature, cleaning by water, and drying after the carbonized cylindrical granules are discharged. The prepared coal-based granular activated carbon has low cost, low pollution, low density and high adsorption performance after being loaded and can be used for a pressure-transformation adsorption technology to effectively concentrate gas components with different adsorption abilities in the mixed gas in a direct deflating process.

Owner:CHONGQING UNIV

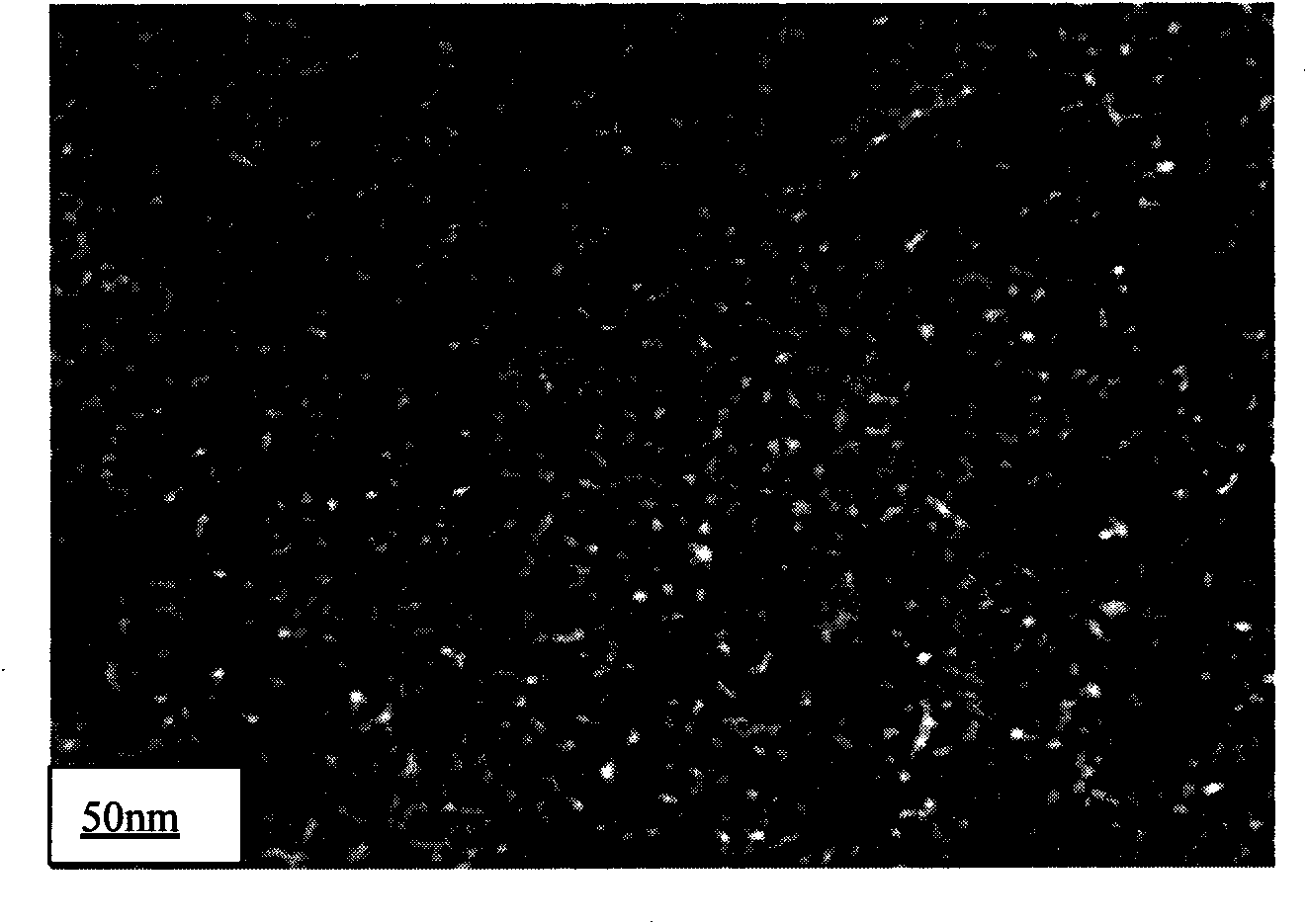

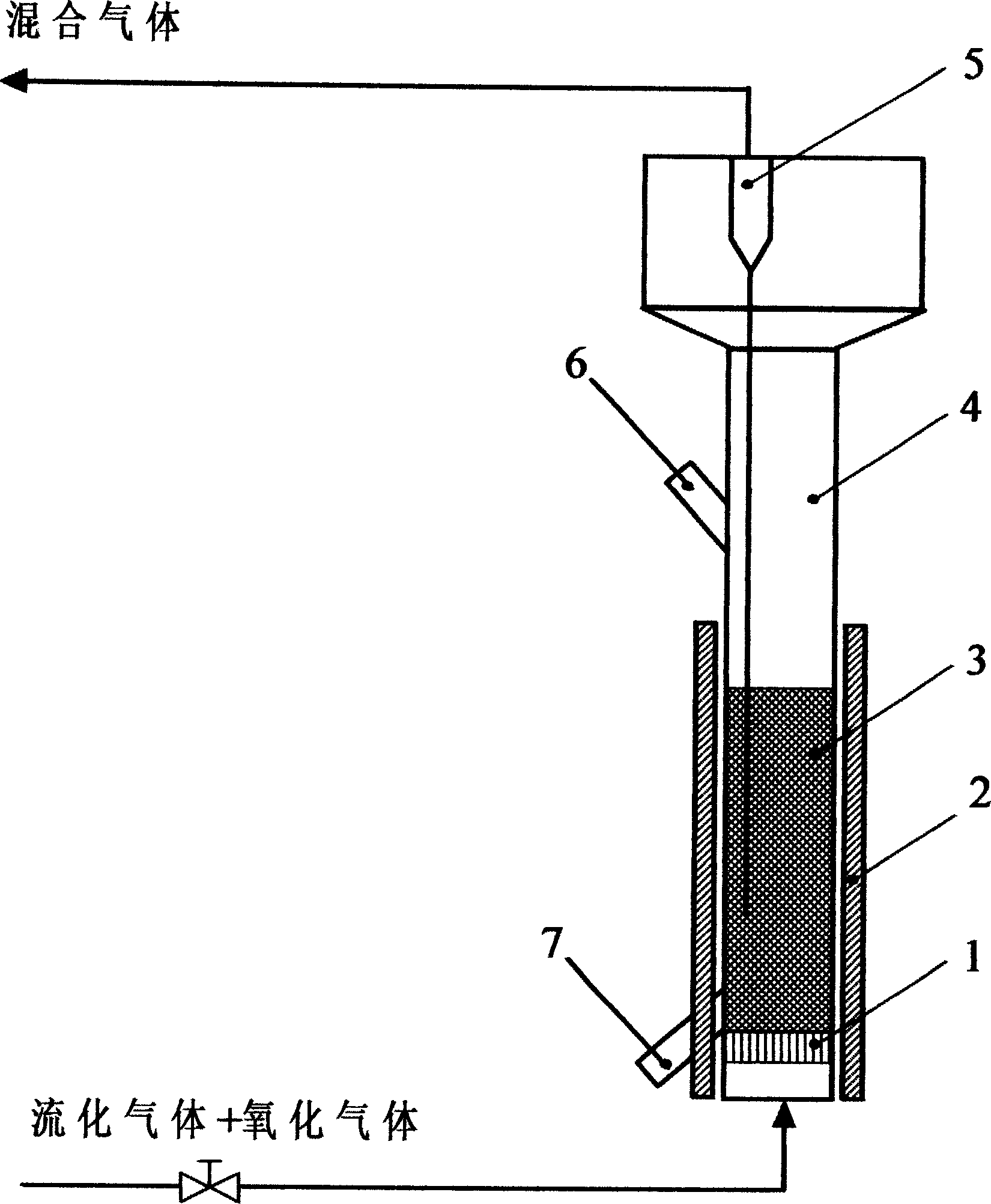

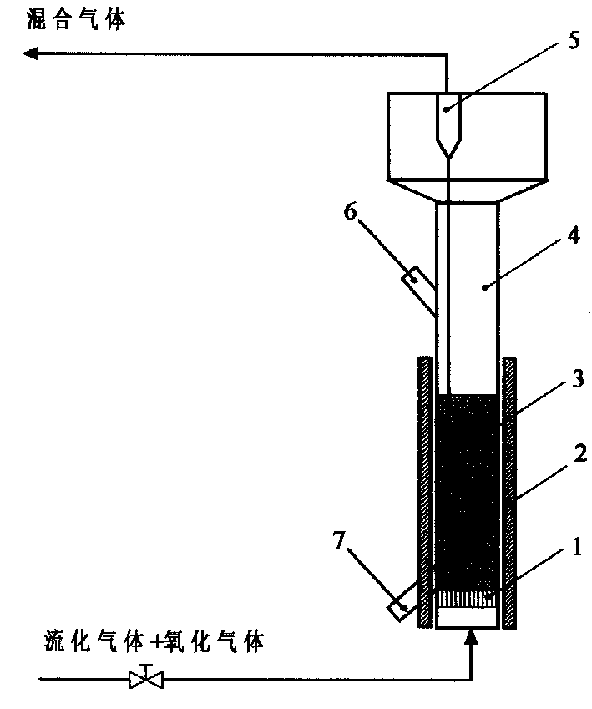

Purification method of carbon nano pipe and its device

InactiveCN1475438ALarge amount of processingEasy loading and unloadingChemical/physical processesPurification methodsGas phase

An equipment for purifying the carbon nanotubes is a nano aggregating fluidized-bed reactor composed of gas distributor, fluidized bed, gas-solid separator, feeding inlet and discharging outlet. Its process features that the oxidizing gas and fluidized gas are introduced to said reactor from its bottom to make the solid material in fluidized state, and the raw carbon nanotubes are fluidized and selectively oxidized to remove the amorphous carbon and the carbon coated on the surface of catalyst.

Owner:TSINGHUA UNIV

Purification method for high-purity natural graphite

The invention discloses a purification method for high-purity natural graphite. A method for purifying graphite at high temperature is adopted, and the high-purity graphite is prepared by high temperature reaction, chemical purification, washing and dehydration. An oxidizer and a complexing agent are reacted with the natural graphite, impurities in the raw material are removed, and the graphite with low content of trace element and stable properties is obtained. In the process, the graphite raw material with the carbon content of more than 60 percent is purified, and the graphite with the purity of over 99.9991 percent, ash content of less than 1PPM and the trace elements of less than 0.5PPM is obtained; and the method has the advantages that: the process is simple, and is easy to operate; the production efficiency is high; the power consumption is low; large processing equipment is not needed; and the production cost is saved.

Owner:LUOYANG GUANQI INDAL & TRADE

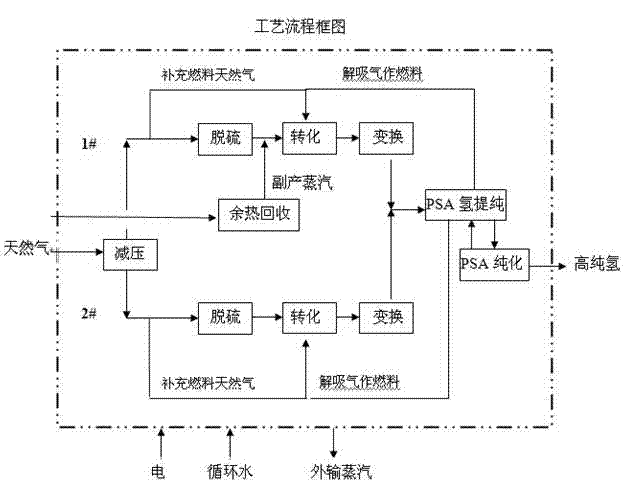

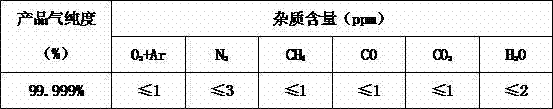

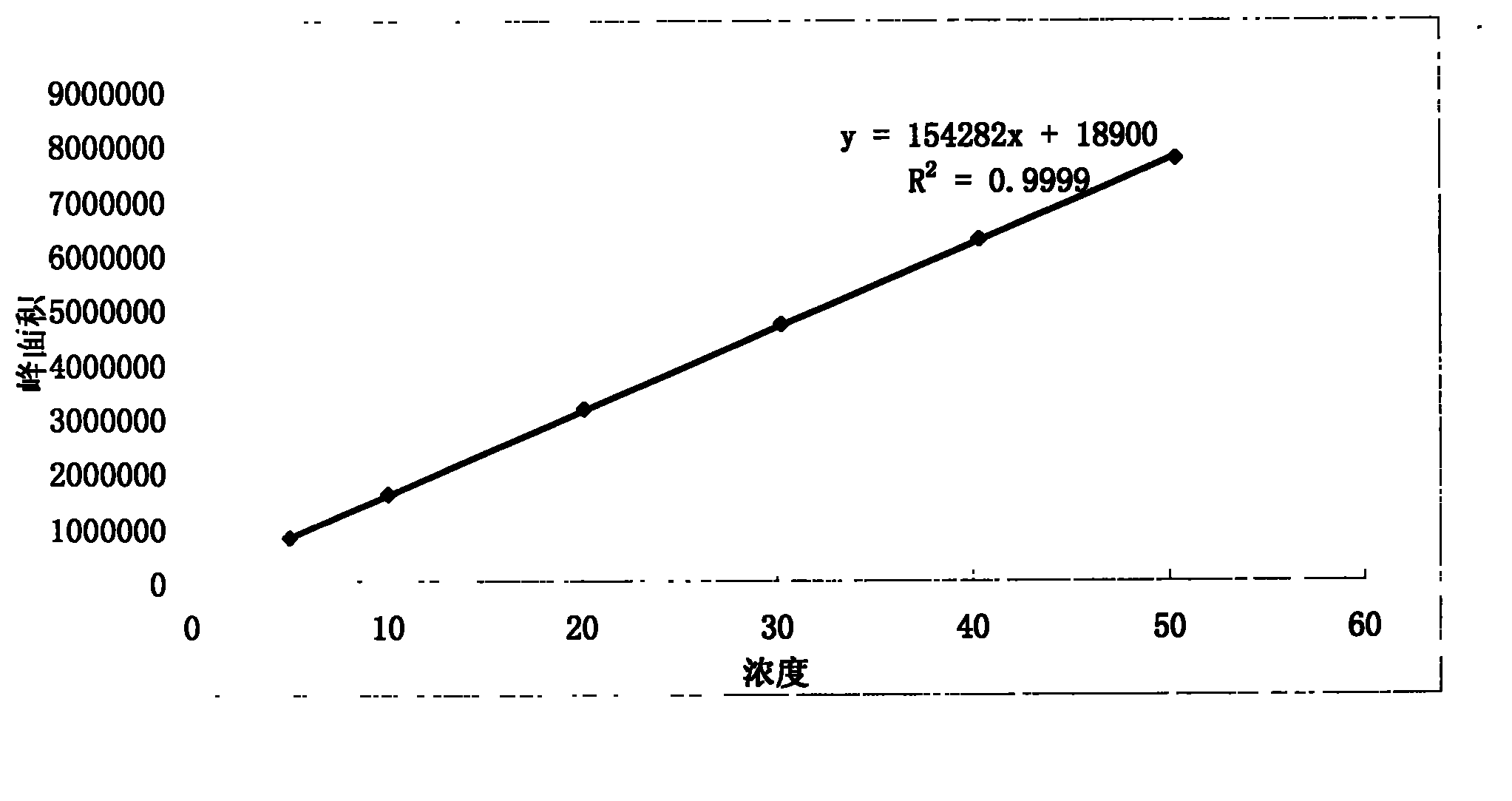

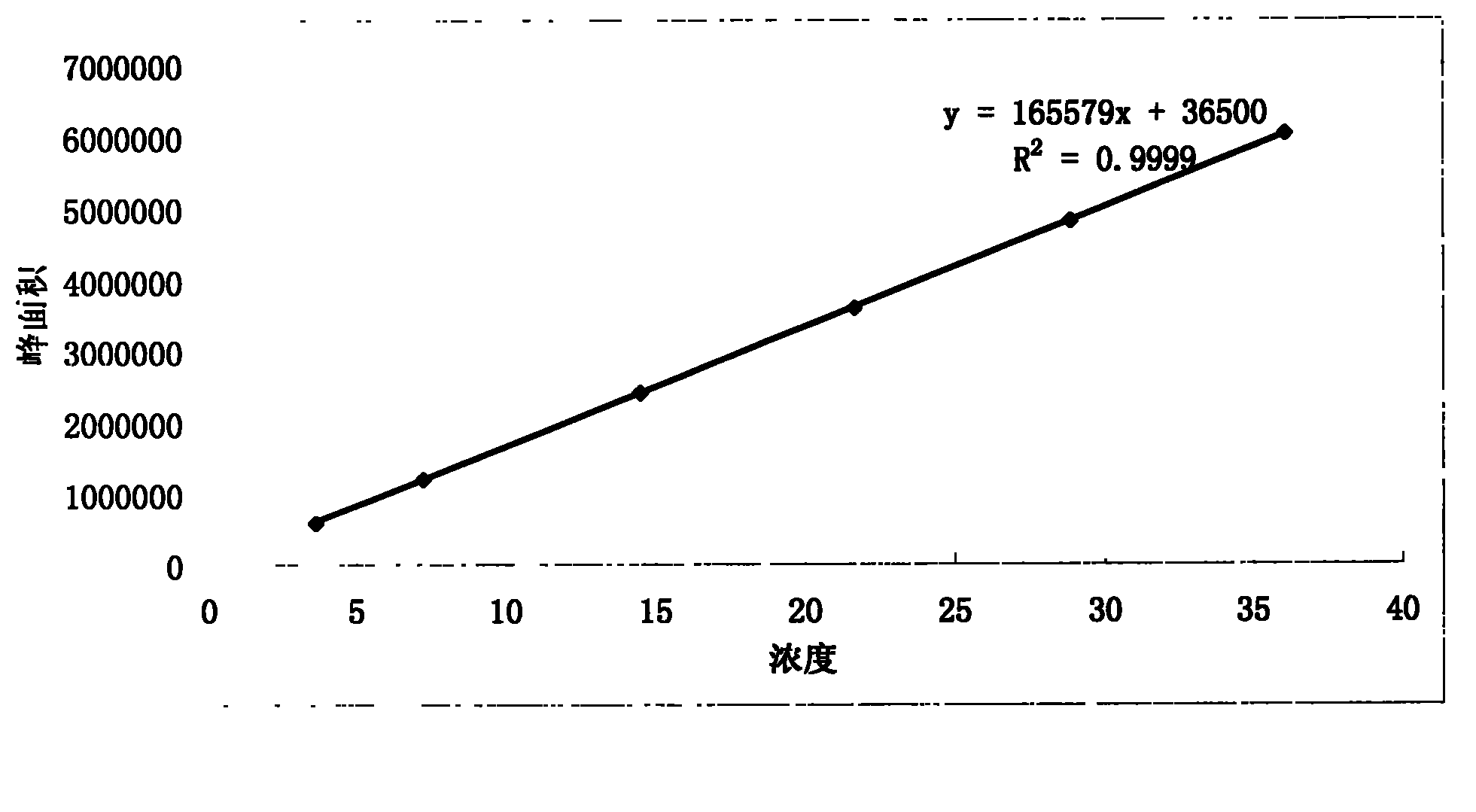

Method for synthesis and purification of hydrogen from natural gas

InactiveCN102849680AImprove conversion efficiencyImprove the purification effectHydrogen separation using solid contactBulk chemical productionHydrogenSulfur

The invention discloses a method for synthesis and purification of hydrogen from natural gas. According to the invention, hydrogenation catalysis is used to remove sulfur in natural gas; both CO-MO hydro-conversion and ZnO desulfurization technology are employed for treatment of feed gas; methane reacts with water vapor at a high temperature in the presence of the conversion catalyst NiO to produce mixed gas of H2, CO, CO2, etc.; the mixed gas of H2, CO and CO2 obtained in conversion procedure of water vapor undergoes a water gas reaction in a shifting furnace filled with a high temperature shift catalyst Fe2O3; CO further reacts with water vapor, and the majority of CO is converted into CO2 and H2; two-stage purification at an ordinary hydrogen section and a purification section is carried out. With the method, H2 with a high purity of more than 99.999% can be obtained.

Owner:SUZHOU JINHONG GAS CO LTD

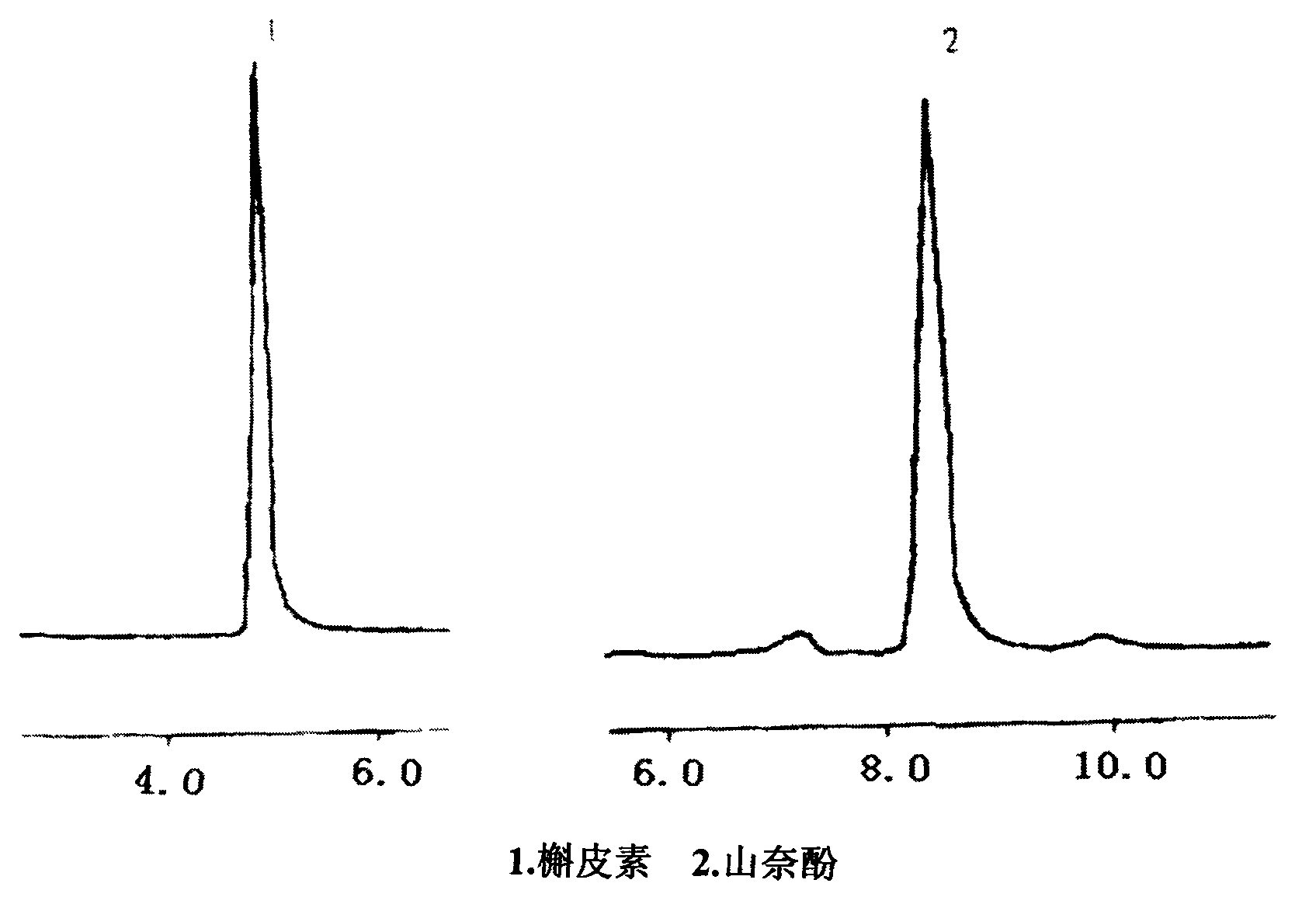

Medlar general flavones extracting and purifying technology and medlar general flavone detecting method as well as applications of medlar general flavone

ActiveCN103006899AGood purification effectLow costComponent separationAntinoxious agentsRefluxMicrowave

The invention belongs to a medlar general flavone extracting and purifying technology and a medlar general flavone detecting method as well as applications of medlar general flavone. At present, the method for preparing medlar general flavones comprises a reflux extracting method, an ultrasonic wave extracting method and a microwave extracting method. According to the extracting and preparing method of flavones in medlar leaves disclosed in 201010542616.3, a colloid breaking-in technique, a high-pressure homogenizing technique and a membrane separation and combination application technique are adopted, and the preparation is complex and long time is consumed. The invention aims to research the medlar general flavone extracting and purifying technology, the medlar general flavone detecting method as well as applications of the medlar general flavone. The technical scheme provided by the invention comprises the following steps of conducting an extracting technology: drying and crushing medlar, adding alcohol, extracting and combining filter liquor, concentrating, and extracting, thereby obtaining a medlar flavone rough extract; and conducting an extracting and purifying technology: purifying the rough extract by adopting porous resin D101, and further purifying the flavones by adopting polyamide. The medlar general flavone extracting and purifying technology, the medlar general flavone detecting method as well as applications of the medlar general flavone provided by the invention have the effects that general flavones are extracted as well as polysaccharide is obtained, effective ingredients of medlar are extracted fully, and foundation for large-scale industrial production is laid.

Owner:陕西方舟制药有限公司

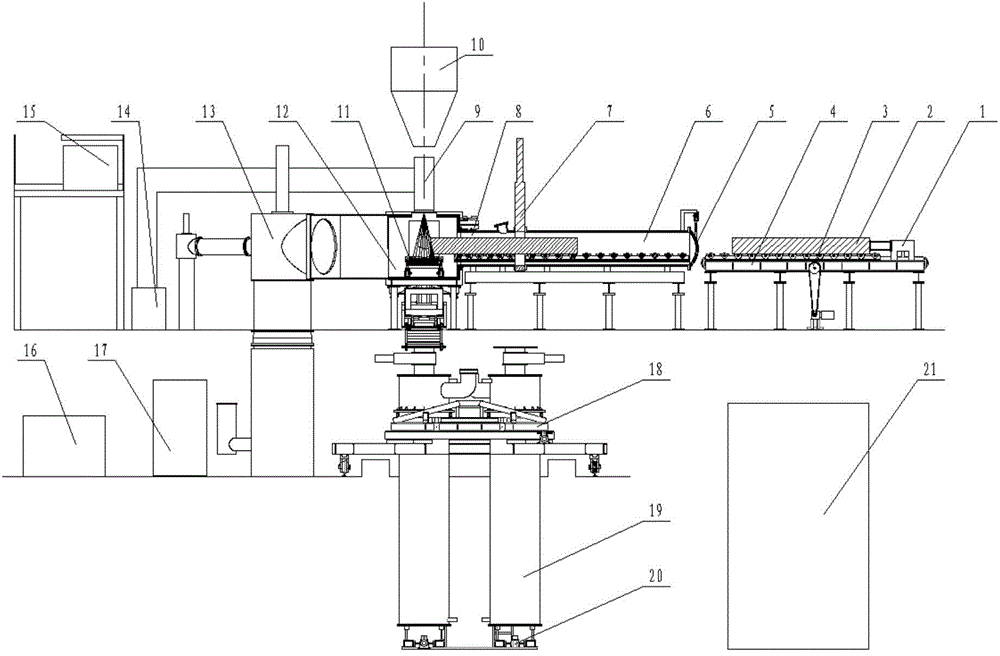

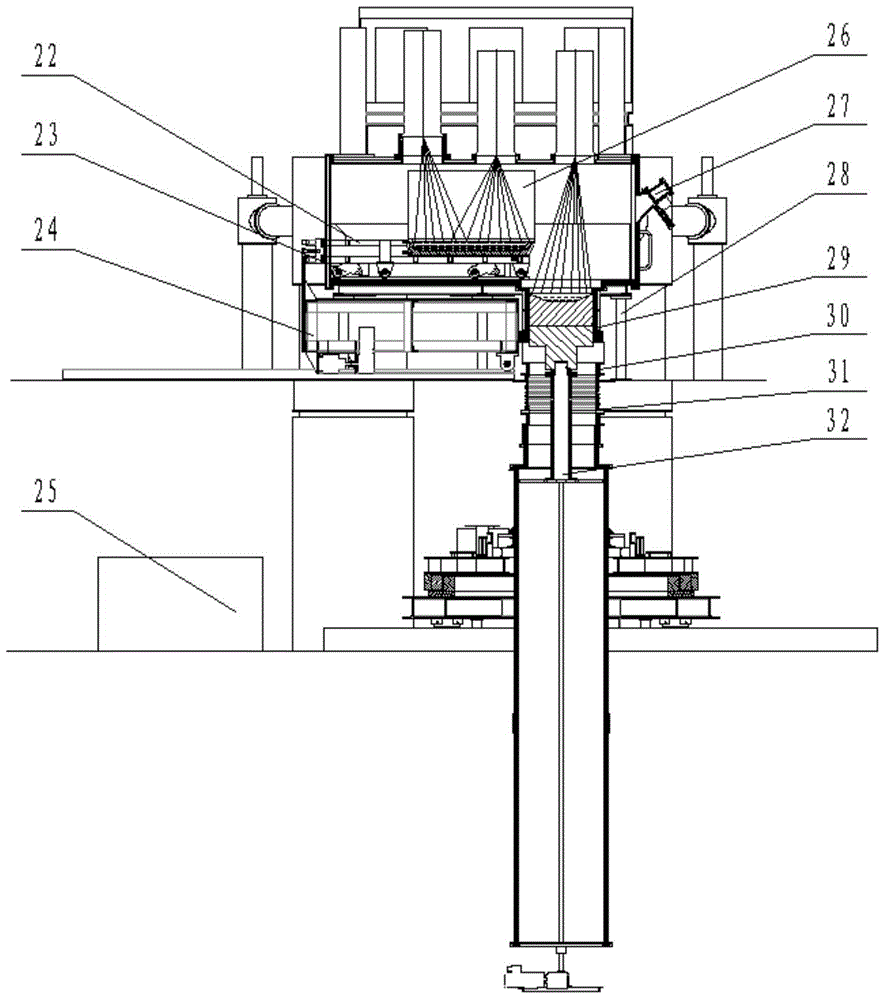

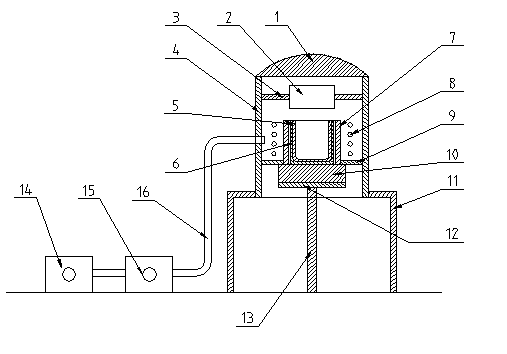

Electronic beam cold hearth furnace

The invention relates to an electronic beam cold hearth furnace, belonging to the field of metal smelting, especially rare metal smelting. According to the electronic beam cold hearth furnace, one side of a vacuum melting chamber system which is taken as a basal body is connected with a horizontal feeding system, a vacuum system is arranged on the other side of the vacuum melting chamber system, three sets of electronic gun systems and a vertical scrap feeding system are arranged at the top of the melting chamber, a cold hearth system and a protective hood are arranged inside the melting chamber, a crystallizer system is arranged at the bottom of the melting chamber, and a continuous ingot dragging system is arranged at the bottom of the crystallizer system; a cooling system is used for cooling structures and components needing to be cooled. The electronic beam cold hearth furnace can be widely applied to melting of reactive metals including titanium, zirconium and the like, refractory metals including tungsten, tantalum, niobium and the like, and special steel; the electronic beam cold hearth furnace has the characteristics of being high in melting vacuum degree, and good in purification effect; the electronic beam cold hearth furnace can be used for producing products, which cannot be produced by other equipment, especially on the aspects of aviation and aerospace needing titanium and titanium alloy materials; titanium residues can be recovered and molten into a titanium material, meeting the using requirements, through the electronic beam cold hearth furnace, and the energy consumption can be saved by 20%-30% in the process compared with that of a traditional technological process.

Owner:宝鸡市凯博真空科技有限公司

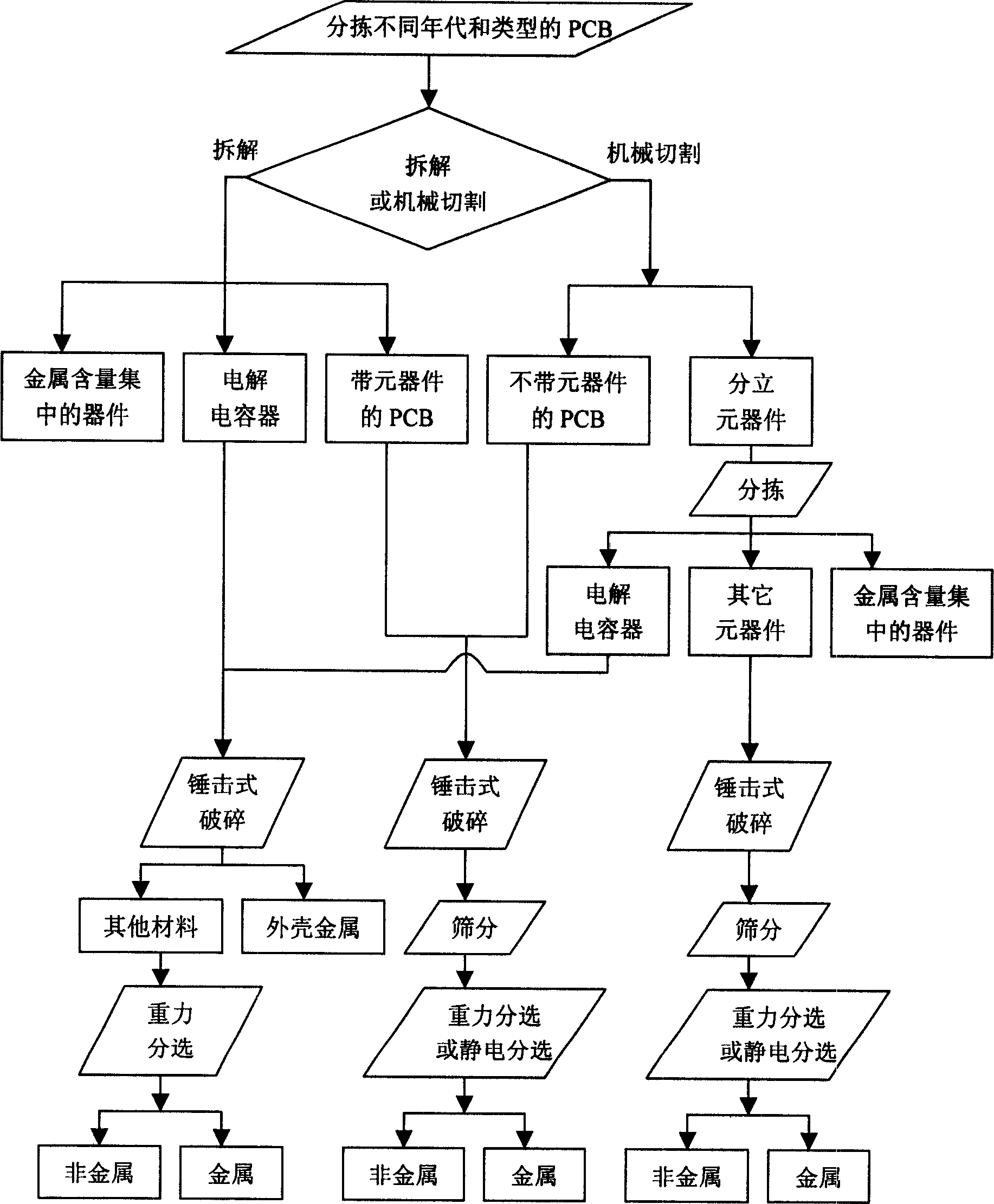

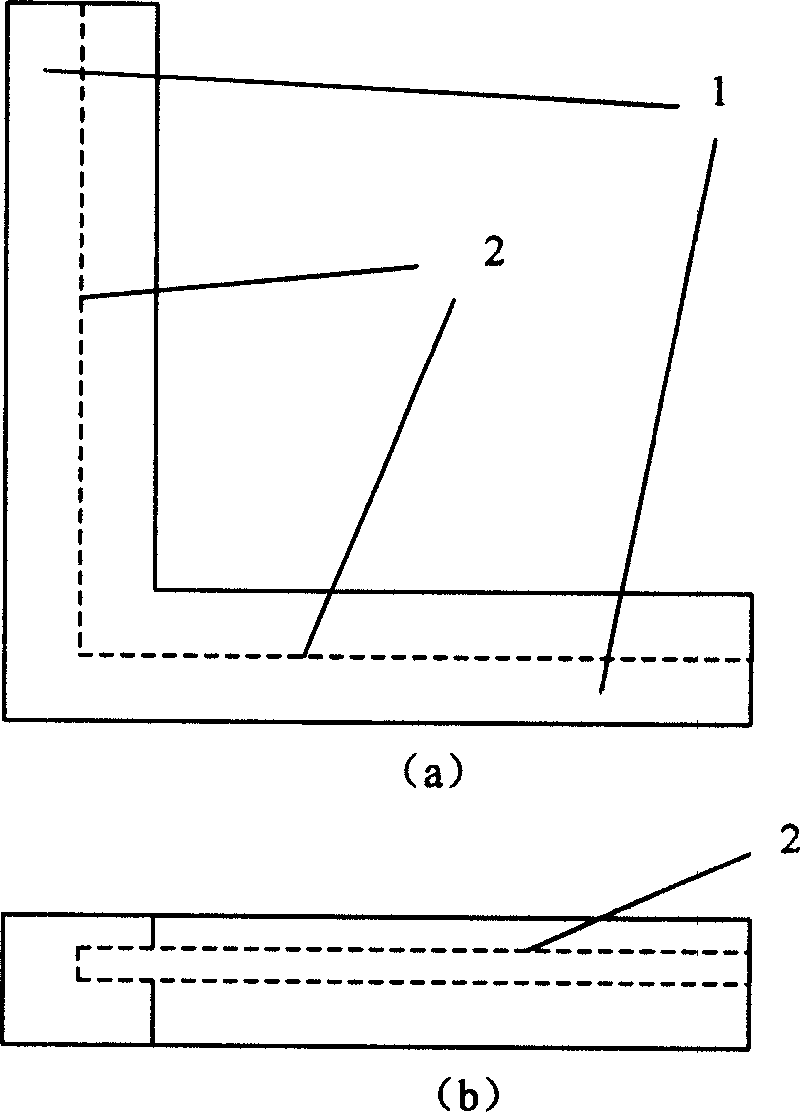

Recovering and treating process for waste printed circuit board and special clamp

InactiveCN1586746AConducive to secondary development and utilizationEasy to purifySolid waste disposalPositioning apparatusElectrolysisResource recovery

The present invention belongs to the field of electric appliance resource recovering and reusing technology. The technological process of recovering and treating waste printed circuit board includes the following steps: sorting printed circuit boards; separating electrolytic capacitor and other elements and devices mechanically from the printed circuit board; crushing printed circuit board, sieving and separating metal and non-metal gravitationally or electrostatically; crushing electrolytic capacitor, separating the shell metal, separating metal and non-metal of electrolytic capacitor gravitationally, crushing other elements and devices, separating metal and non-metal of other elements and devices gravitationally. The special clamp for separating electrolytic capacitor and other elements and devices mechanically from the printed circuit board is an L-shaped one with continuous single-end notches in two arms.

Owner:BEIJING UNIV OF TECH

Method for extracting anthocyanins from purple sweet potato

The invention discloses a method for clarifying an anthocyanin extracting solution from purple sweet potato by a flocculating agent. The method comprises the following steps: using purple sweet potato powder as a raw material and acidulated ethanol as a solvent, extracting repeatedly at a certain temperature, carrying out solid-liquid separation, collecting supernate, adding the flocculating agent to remove flocculates, such as polysaccharides, proteins, pectins and the like, out of the extracting solution to obtain a clear liquid, concentrating the clear liquid under reduced pressure to remove ethanol; and carrying out adsorption and desorption by using macroreticular resin and finally refining by using an ultrafiltration membrane to obtain a purple sweet potato pigment with a high color value. According to the invention, the flocculating agent is applied to the clarifying process of the crude extracting solution of anthocyanins from purple sweet potato to remove most of impurities; then the anthocyanins from purple sweet potato are refined further by the macroreticular resin and the ultrafiltration membrane, and finally the pigment which is stable in color and luster and property and the like is obtained.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Polysilicon purification method and device by reverse induced solidification

InactiveCN102849743AInhibited DiffusionImprove the purification effectSilicon compoundsPurification methodsIngot

The invention relates to a polysilicon purification method and a polysilicon purification device by reverse induced solidification, falling into the technical field of metallurgy purification. The method comprises the steps of heating and melting silicon material into molten silicon through an induction coil; reducing power of the induction coil; downwardly pulling ingot through a water-cooled rotation rod to solidify molten silicon from bottom to top; starting a powder spreading device when solidification reaches 80-90%, to spread high-purity silicon powder in the upper layer molten silicon, and realize rapid reverse solidification of the upper layer molten silicon by using the high-purity silicon powder as nucleating agent; cutting off the upper layer reverse-solidified part after complete solidification, and collecting the lower layer casting ingot as high-purity silicon casting ingot. At solidification final stage, by the above rapid reverse solidification of upper layer molten silicon having high impurity content, diffusion of high-content impurities from the upper layer molten silicon toward the solidified low-concentration region during temperature holding process is effectively suppressed, to realize the objective of polysilicon purification by reverse induced solidification.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Preparation method for high-purity melted quartz powder material

The invention discloses a preparation method for a high-purity melted quartz powder material. The method comprises the following steps of comprehensively removing impurities from crude vein quartz mine, namely performing rough crushing, manual selection, electrostatic impurity removal, fine crushing and screening, high-gradient magnetic separation, acid washing impurity removal, washing and air-drying to obtain clean quartz sand; placing the clean quartz sand in an active gas melting furnace for purification, namely introducing active gas in the high-temperature melting furnace to obtain a high-purity melted quartz block; crushing the melted quartz block into powder by using a centrifugal crusher, and performing high-gradient magnetic separation on the powder to obtain high-purity melted quartz powder. According to the method, quartz powder with purity of 99.99 percent can be obtained.

Owner:中材高新江苏硅材料有限公司

Method for purifying alpha,omega-dihydroxy-polydimethylsiloxane

The invention discloses a method for purifying alpha,omega-dihydroxy-polydimethylsiloxane, which comprises the following steps: injecting raw material 107 rubber into a film evaporator, and carrying out primary purification at 170-220 DEG C under the absolute pressure of 50-90 Pa; and injecting into a short-range distiller, carrying out secondary purification at 160-200 DEG C under the absolute pressure of 20-50 Pa, thereby obtaining the product. The method disclosed by the invention can effectively eliminate low-molecular polymers in the 107 rubber, and also can recycle the low-molecular polymers. The removal rate of low-molecular polymers in the alpha,omega-dihydroxy-polydimethylsiloxane product treated by the method disclosed by the invention is up to more than 99%; in general cases, the content of low-molecular polymers in the alpha,omega-dihydroxy-polydimethylsiloxane product treated by the method disclosed by the invention is 50-120 ppm; and room-temperature cured electronic silicon rubber made from the high-purity 107 rubber can enhance the properties and quality of electronic and electric appliances.

Owner:MAOMING XINLONG TECH

Sugar production process using boiler flue gas as clarificant

InactiveCN1654682AGood purification effectLess investment in equipmentPurification using alkaline earth metal compoundsLime productionChemistryFlue gas

The present invention is sugar refining process with boiler fume as the clarifier, and the sugar refining process includes the steps of extracting crude sugar liquid, purifying crude sugar liquid and producing high quality sugar. During purifying crude sugar liquid, calcium oxide or regenerated filtering mud are added, and boiler fume with CO2 content of 6-17 is introduced for reaction with calcium oxide or regenerated calcium oxide to produce calcium carbonate adsorbing non-sugar impurity in the sugar liquid, with the volume ratio between boiler fume and crude sugar liquid being 100-300, and the mass ratio between boiler fume and calcium oxide or regenerated filtering mud being 5-30. The present invention has high sugar liquid purifying effect, sugar liquid purity raised by 2-13 %, reduced lime consumption, reduced CO2 exhaust of boiler, and raised economic utility and environment utility.

Owner:SOUTH CHINA UNIV OF TECH

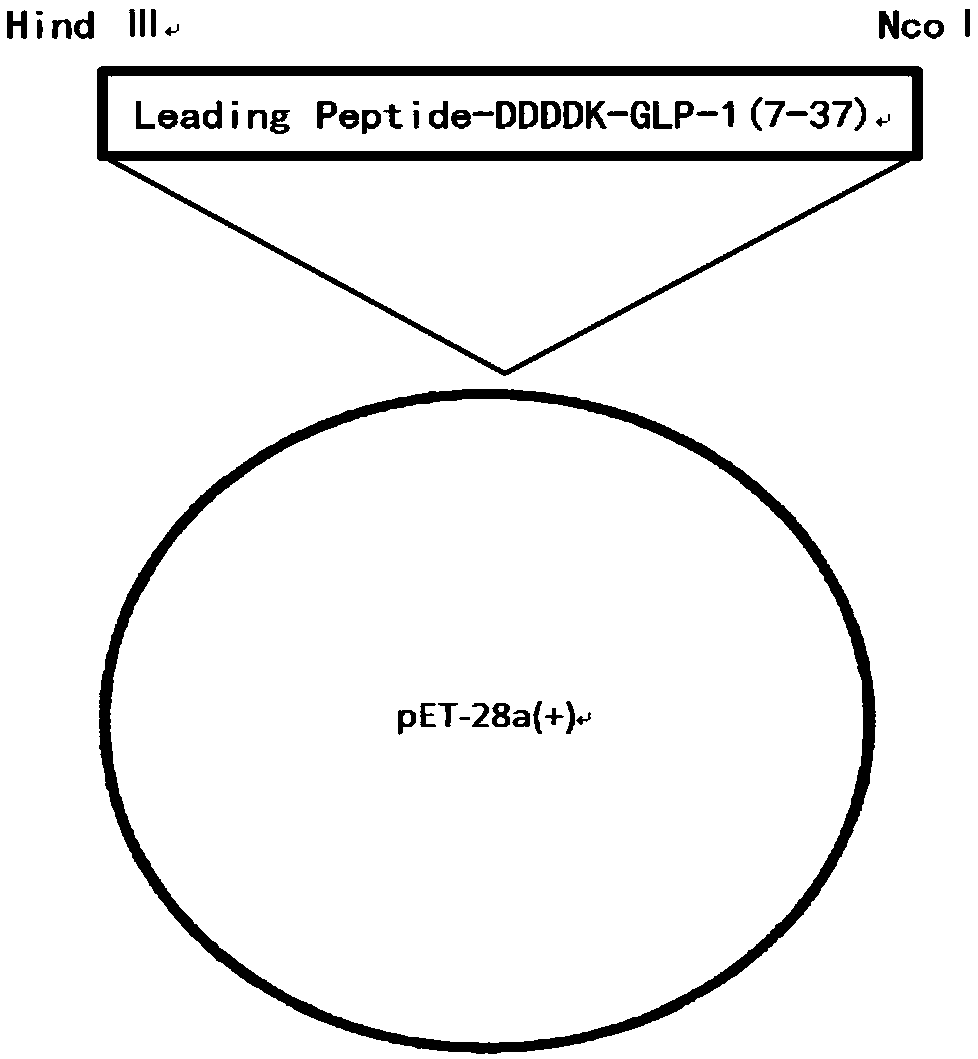

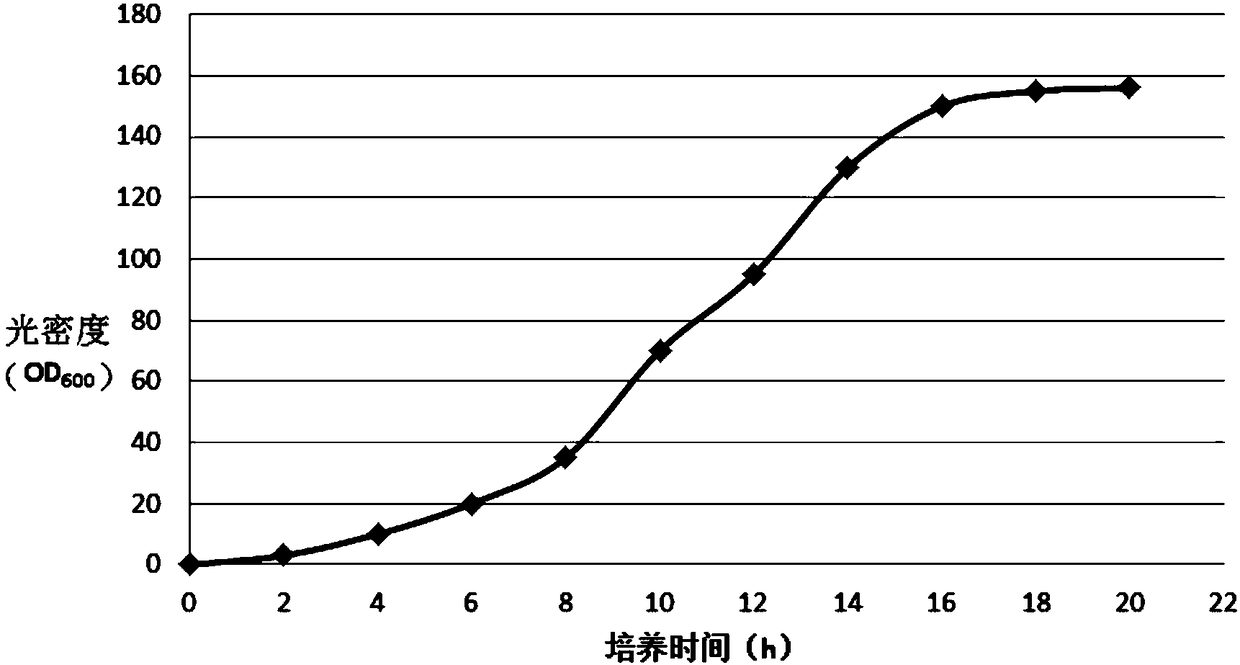

Preparation method of liraglutide intermediate polypeptide

ActiveCN108191981ALow costHigh expressionPolypeptide with localisation/targeting motifBacteriaHigh concentrationEscherichia coli

The invention belongs to the technical field of preparation methods of polypeptides and particularly relates to a preparation method of liraglutide intermediate polypeptide GLP-1 (glucagon-like peptide-1) (7-37). The method comprises the following main steps: constructing recombinant liraglutide engineering bacteria, expressing liraglutide intermediate fusion protein in a form of an inclusion bodyunder Echerichia coli induction, and performing denaturation, renaturation, enzyme digestion, separation and purification to obtain the liraglutide intermediate polypeptide GLP-1 (7-37). Expression is changed into intracellular insoluble inclusion body expression by changing recombinant sequence signal peptides, and expression quantity is increased greatly; the washed inclusion body is subjectedto alkali dissolution, a large quantity of denaturant is not needed, the inclusion body with high concentration of protein concentration being 20-30 g / L is added to an inclusion body dissolution buffer, denaturation and renaturation time does not exceed 1 h, and enzyme digestion can be performed after dissolution; procedures are reduced, operation volume is reduced, reagent cost is reduced, and industrialized enlargement is facilitated; UniSP-50XS cation exchange is adopted for separation and purification, and separation degree is high. The purity of the liraglutide intermediate polypeptide prepared with the method reaches 87% or higher, and the yield is higher than 85%.

Owner:AMPHASTAR NANJING PHARMA

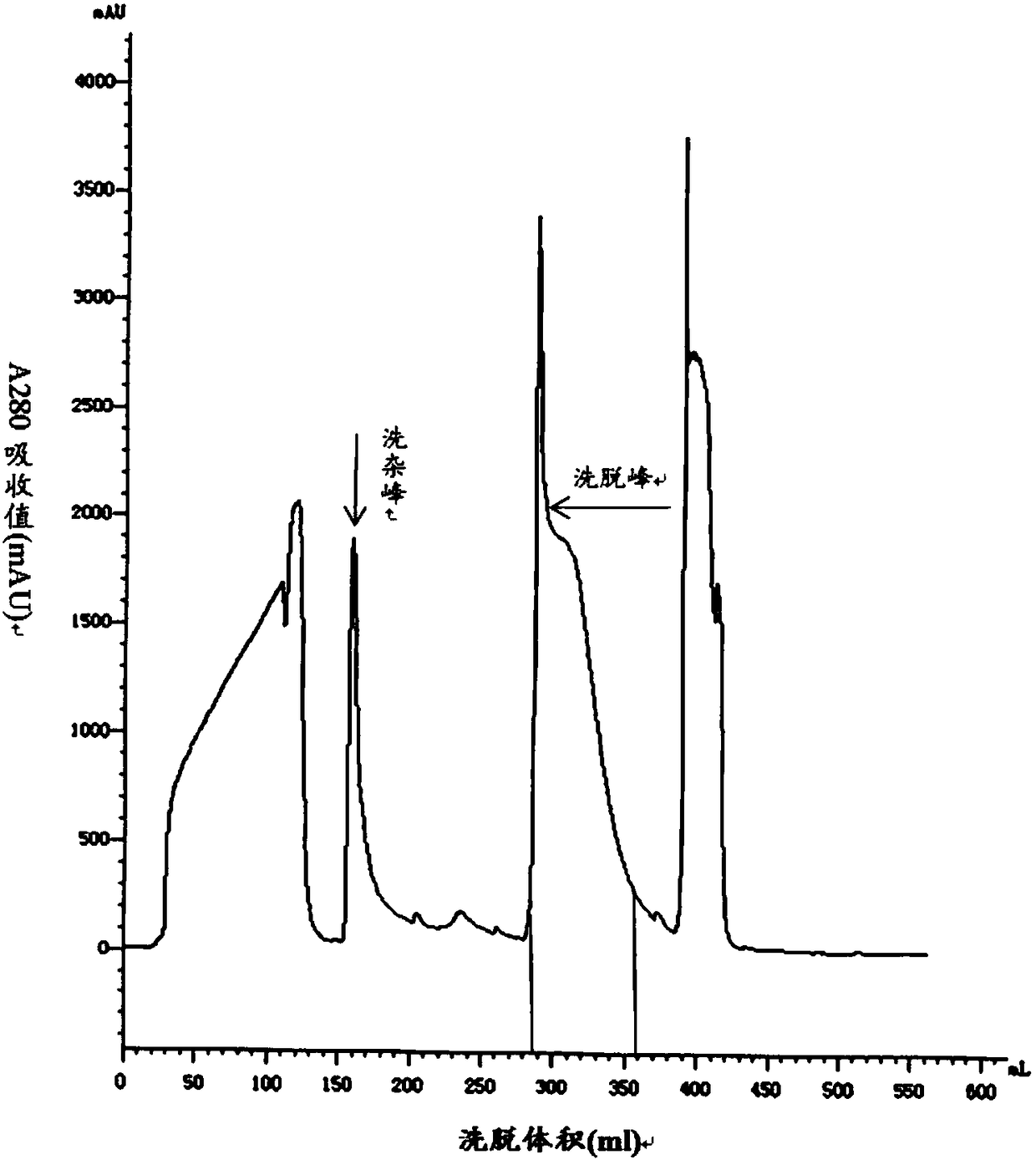

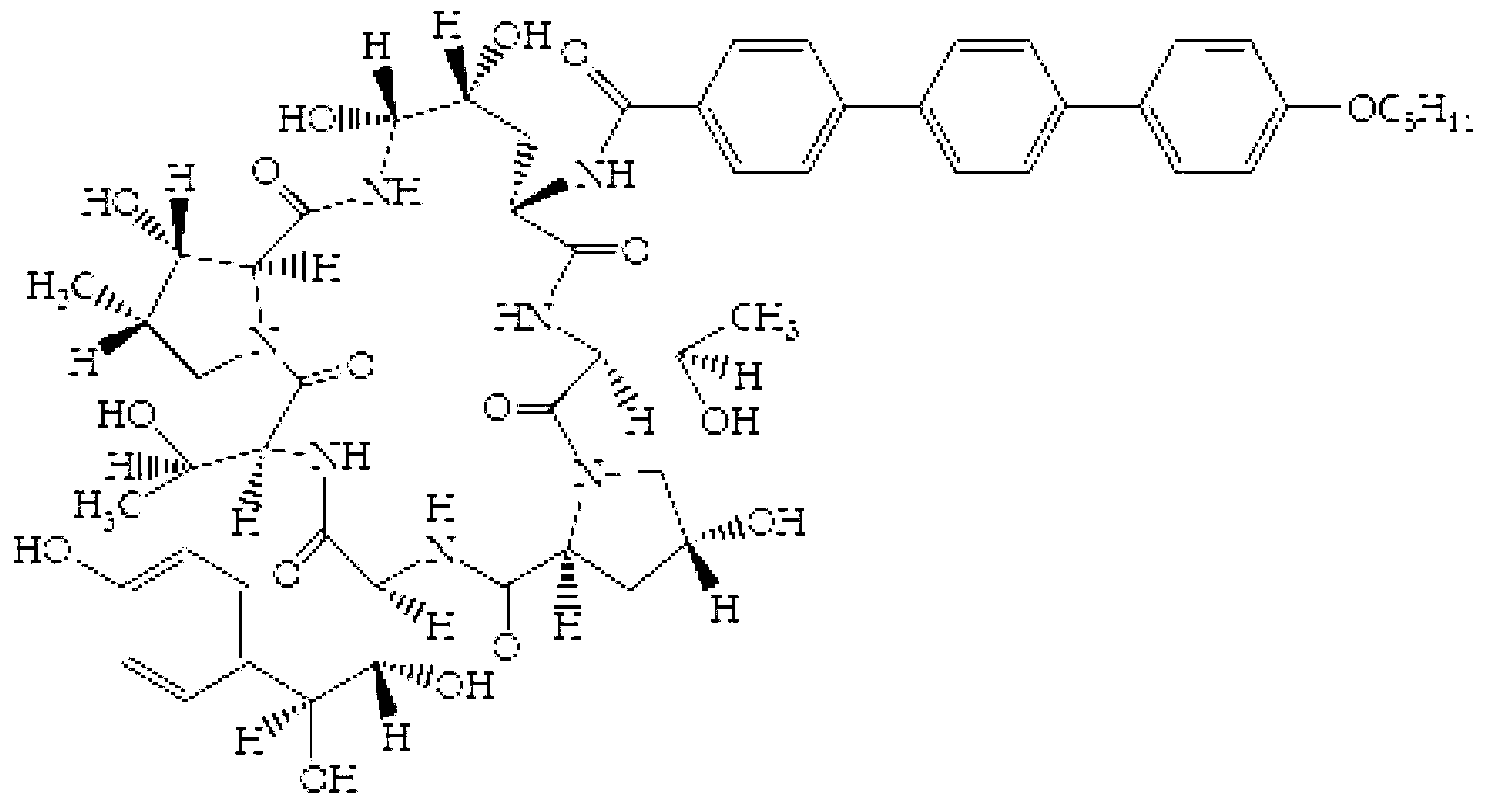

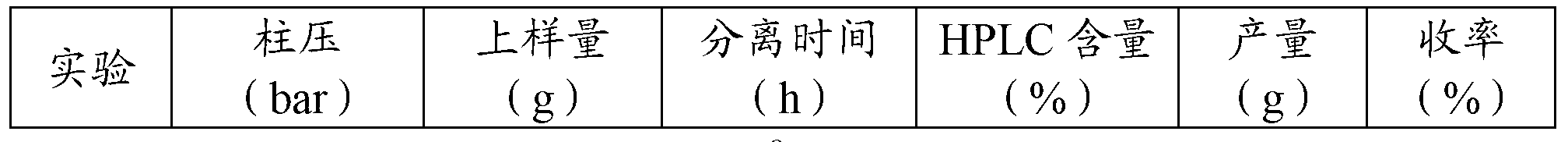

Purification method of echinocandins antifungal drug anidulafungin

ActiveCN103193868ASimple stepsEasy to recyclePeptide preparation methodsEchinocandinPurification methods

The invention discloses a purification method of echinocandins antifungal drug anidulafungi. The method comprises the following steps of: (1) preparing a dry sample: adding organic solvent in a crude product of the anidulafungin to dissolve the crude product, adding silica gel after the crude product of the anidulafungin is adequately dissolved, and uniformly mixing and drying the mixture to obtain the anidulafungin dry sample; (2) pressurizing and eluting: uniformly filling the anidulafungin dry samples in the top end of a chromatographic column with silica gel, pressurizing and eluting the chromatographic column with the anidulafungin dry samples by adding elution solvent, utilizing a high-effective liquid phase chromatography to monitor, and collecting the elution solution with the anidulafungin content being greater than 98 percent; and (3) concentrating: concentrating the elution solution with the anidulafungin content being greater than 98 percent until dryness to obtain a pure product with the anidulafungin content being greater than 98 percent. By adopting the column chromatography, simplicity in operation is realized, and the equipment cost is low; the organic solvent with low toxicity and low boiling point is adopted as the elution solution, so that the subsequent recycling treatment is simple, and the environmental pressure can be greatly reduced; and the purification separation time is short, the purification effect is good, the purification yield is high, and the purification method is applicable to industrialized mass production.

Owner:NCPC NEW DRUG RES & DEV

Preparation method for high-purity fused quartz powder material applied to quartz ceramic crucible

InactiveCN102219226AGood purification effectSimplify the cleaning processSilicaResource utilizationCrucible

The invention discloses a preparation method for high-purity fused quartz powder material applied to quartz ceramic crucible. The preparation method comprises the following steps: taking common vein quartz or hypergene quartz gravel of vein quartz as raw material, and adding the step of fused purification and rolling ball crushing based on the comprehensive impurity removing, and finally preparing high-purity fused powder material applied to quartz ceramic crucible. In the invention, the resource utilization ratio of the vein quartz is improved to more than 80% from about 50%, the SiO2 content of high-purity quartz sand produced by the common quartz ore achieves to more than 99.99%, the element impurity content is controlled in 30ppm, the liquidity of powder slurry with 85%-90% of solid containing content achieves to 120g / s.

Owner:SINOMA JIANGSU SOLAR ENERGY NEW MATERIALS

Preparation method of high purity ammonium rhenate

ActiveCN108408785ALow Tl contentMeet the requirements of low Tl contentRhenium compoundsRheniumPerrhenic acid

The invention discloses a preparation method of high purity ammonium rhenate, the method comprises the following steps of S1, dissolving ammonium rhenate in pure water to obtain an ammonium rhenate solution and adjusting pH value to 7 to 10, then performing oxidation and precipitation in sequence, and centrifuging to obtain an ammonium rhenate solution without containing TI; S2, after performing concentration and crystallization on the ammonium rhenate solution without containing TI, performing oxidation volatilization to obtain a perrhenic acid solution; S3, exchanging the perrhenic acid solution by adopting a cation exchange resin for removing impurities; S4, adding ammonia water into the perrhenic acid solution subjected to adsorption and impurities removal and performing concentrationand crystallization to obtain the high purity ammonium rhenate. According to the preparation method of the high purity ammonium rhenate disclosed by the invention, TI<+> in the ammonium rhenate solution is oxidized into TI<3+>, a harmful impurity TI is removed through a synergistic effect of hydrolytic precipitation of TI<3+> and adsorption packaging of a flocculating agent, then trace TI and other impurity elements are removed through oxidation volatilization, ion exchange and concentration crystallization to obtain the high purity ammonium rhenate with low TI content, the high purity ammonium rhenate meets the requirements of rhenium with low TI content in aeronautical material.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for enriching and purifying cannabidiol

PendingCN110156568ALow costPromote regenerationOrganic chemistryOrganic compound preparationChemical industryMicrowave

The invention belongs to the technical field of chemical industry, relates to a method for enriching and purifying cannabidiol, and particularly relates to a method for purifying cannabidiol by usingmicrowave countercurrent extraction, macroporous adsorption resin adsorption and column chromatography. The method has the following advantages: 1, the microwave extraction is adopted, ethanol is usedas a solvent, a part of fat oils is removed, the extraction time is greatly reduced, the production efficiency is improved, and the method is simple; 2, the macroporous resin regeneration is convenient and rapid, and is suitable for large production, the cost is greatly reduced, most impurities are removed by water elution, and the operation is simple; and 3, the macroporous resin and silica gelcolumn chromatography are combined, the separation and purification effect is good, and the product purity is greatly improved. The method adopts microwave countercurrent extraction, macroporous resinseparation and purification, and column chromatography to carry out further purification, the product purity is greatly improved, and finally the cannabisdiol with a content of more than 65% and thecannabisdiol final product with a content of more than 90% are obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

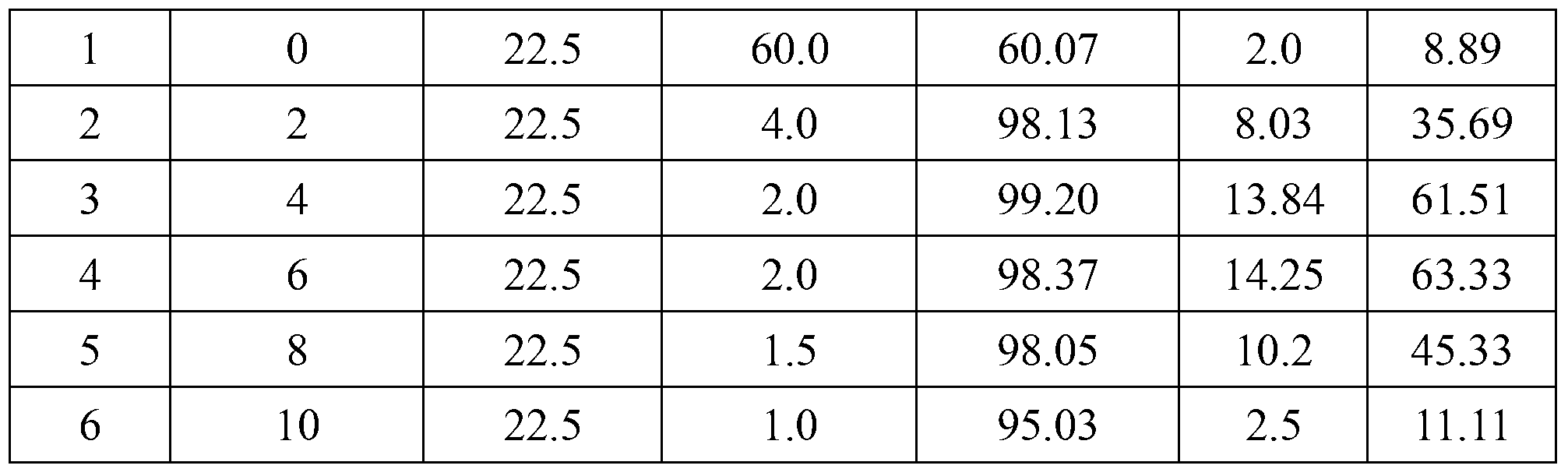

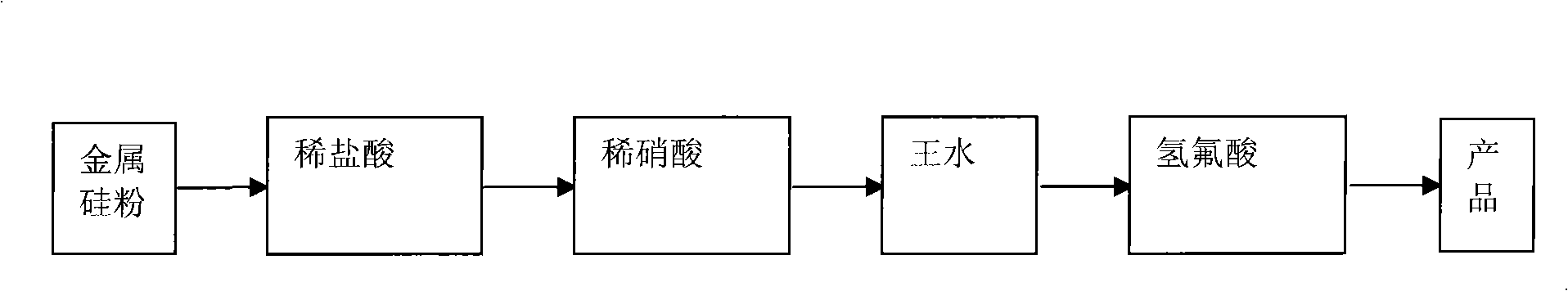

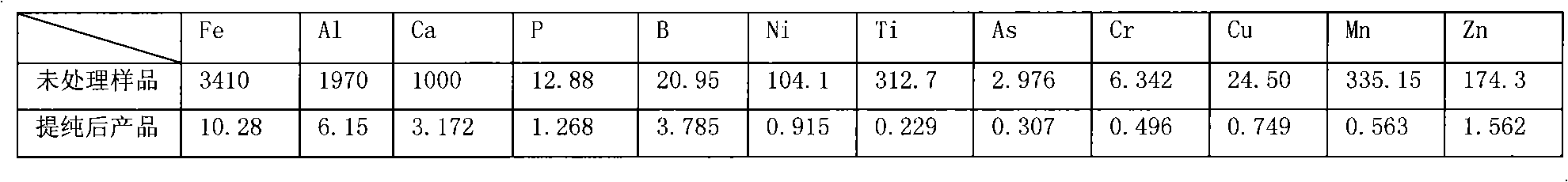

Preparation of low-phosphorus solar-grade polysilicon

The invention discloses a method for preparing low phosphorous solar-grade polycrystalline silicon. The method combines a high-temperature smelting method and a wet purification method, and comprises the steps as follows: metallic silicon powder is uniformly mixed with metallic calcium powder and is smelted at a high temperature under a high-pure argon atmosphere with fluidity; a part of phosphorus in the metallic silicon can be gasified, escape with flowing argon and be separated from the metallic silicon; at the same time, the phosphorus can react with the metallic calcium to generate calcium phosphide which is easily dissolved in acid; and the wet purification method is used after the high-temperature smelting method to reduce the content of phosphorus, other non-metallic impurities and various metallic impurities to the solar-grade polycrystalline silicon level after processing the metallic silicon for 8 hours respectively through 4.0 mol / L hydrochloric acid, 3.0 mol / L nitric acid, aqua regia and 0.35 mol / L hydrofluoric acid at a temperature of 80 DEG C under an ultrasonic oscillation atmosphere, thereby acquiring the low phosphorous solar-grade polycrystalline silicon. The method has the advantages of low cost, simple process and good purification effect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

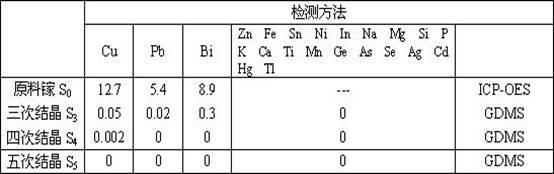

Large-scale production method for preparing high purity gallium

ActiveCN102618734AEnsure consistencyImprove the purification effectProcess efficiency improvementLiquid metalProcess conditions

The invention discloses a large-scale production method for preparing high purity gallium, which adopts a partial crystallization purification technique to implement the operation, and comprises the following steps of: placing a seed crystal of metal gallium into the bottom part of a crystallization vessel; filling liquid metal gallium into the crystallization vessel; cooling the bottom part of the crystallization vessel, and setting the technical conditions of the fractional crystallization that a temperature gradient is 1.1 to 1.4 DEG C / cm and the temperature is kept uniform in the horizontal direction; and maintaining an average crystallization speed of 3.3 to 4.2g / min and a crystallization interception ratio of 75 to 90 percent. Compared with the prior art, the method has good purification effect, high conversion efficiency, low consumption of electric power and no application of chemical agent and can realize the mass production.

Owner:朝阳金美镓业有限公司

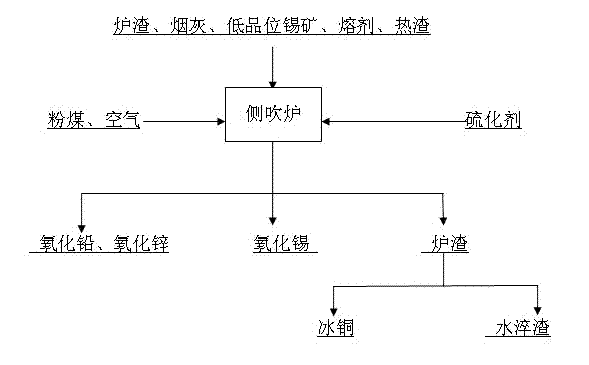

Process for recovering copper and zinc and tin and lead by utilizing side blown converter at the bottom

The invention discloses a process for recovering copper, zinc, tin and lead by utilizing a side blown converter at the bottom. The process is characterized in that materials dosed and mixed from slag, ash, low-grade tin ore and flux are selected for use, the water content of the dosed and mixed materials is <= 3%, the dosed and mixed materials are stand-by, hot slag of a reduction furnace is added into a side blown converter, the dosed and mixed materials are added to the side blown converter, mixed with the hot slag of the reduction furnace for reduction smelting, the tin content of the hot slag of the reduction furnace and the dosed and mixed materials which are added into the side blown converter is more than 3%, and the silicic acid degree of the slag is 1-1.2. In the first stage, the lead and the tin are volatilized in the reduction smelting mode, and lead oxide and tin oxide are obtained through dust collection. In the second stage, vulcanizing agents are added, tin sulfide is volatilized, and tin oxide is obtained after dust collection. In the third stage the slag and the copper settles and are separated to obtain copper matte and waste slag, the slag is quenched through water, and the copper matte is cast into ingots. The process for recovering the copper, the zinc, the tin and the lead by utilizing the side blown converter at the bottom is strong in adaptability, capable of separating out valuable metal such as the copper, the lead, the zinc and the tin through one-step smelting, high in direct recovery rate, and low in valuable metal containing rate of the slag.

Owner:江西自立环保科技有限公司

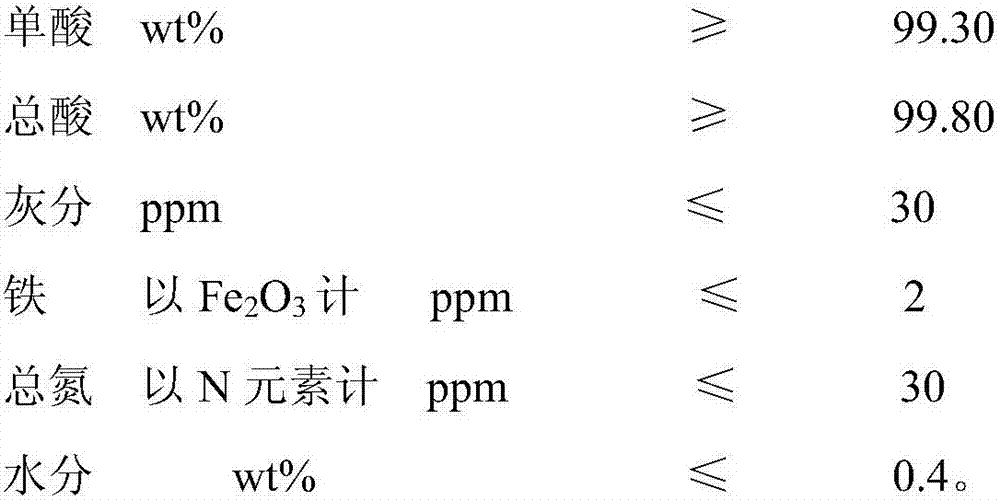

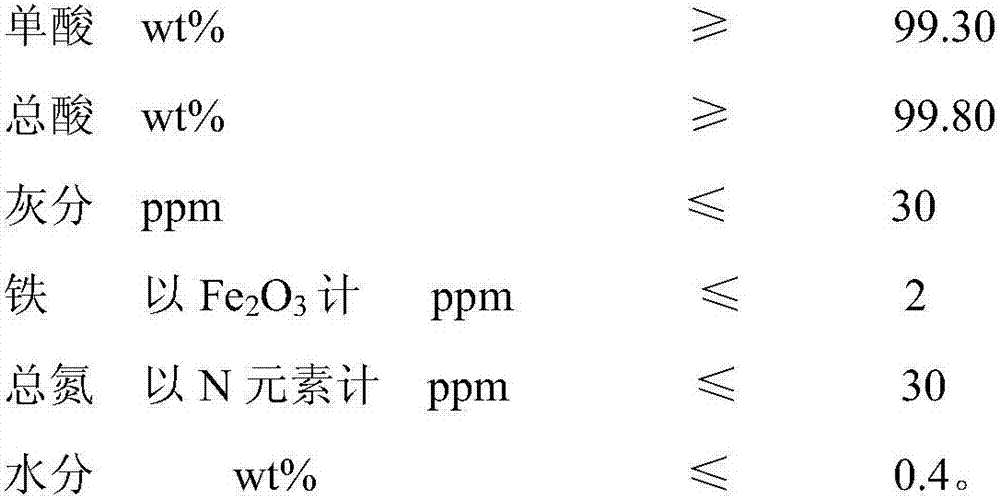

Refining and purifying method of long carbon chain dicarboxylic acid

InactiveCN108003015AReduce out-of-phase nucleation issuesGood crystal formCarboxylic compound separation/purificationCarboxylic acidCarbon chain

The invention provides a refining and purifying method of long carbon chain dicarboxylic acid. The refining and purifying method is characterized in that the raw material moisture content of a long chain binary acid coarse product is controlled to be smaller than or equal to 1.0 wt%; the content of solvent acetic acid is larger than or equal to 95.0 wt%; the crystallization process adopts three-section gradient cooling, and induction seed crystal is added after second-section cooling to induce crystallization; crystalized filter cake is firstly sprayed by acetic acid, is next washed by water and is then subjected to centrifugal filtering; then the filter cake is washed by the water at environment temperature; an acetic acid solvent generated in the refining process is totally recycled through an azeotropic distillation method; a cleaning solution and a mother solution which are generated in the refining process are totally recycled. The refining and purifying method, high in product yield, low in refining cost and high in purity, of long carbon chain dicarboxylic acid is provided. The total acid content of long carbon chain dicarboxylic acid after being refined and purified reaches99.90%, the single acid content reaches 99.45%, the total nitrogen content reaches 6ppm, the ferric ion content reaches 0.5 ppm, the ash content is smaller than or equal to 10 ppm, and the moisture content is smaller than or equal to 0.16%. The purifying comprehensive yield reaches 98.64%. All quality technical indexes meet a user's requirements.

Owner:ZIBO GUANGTONG CHEM

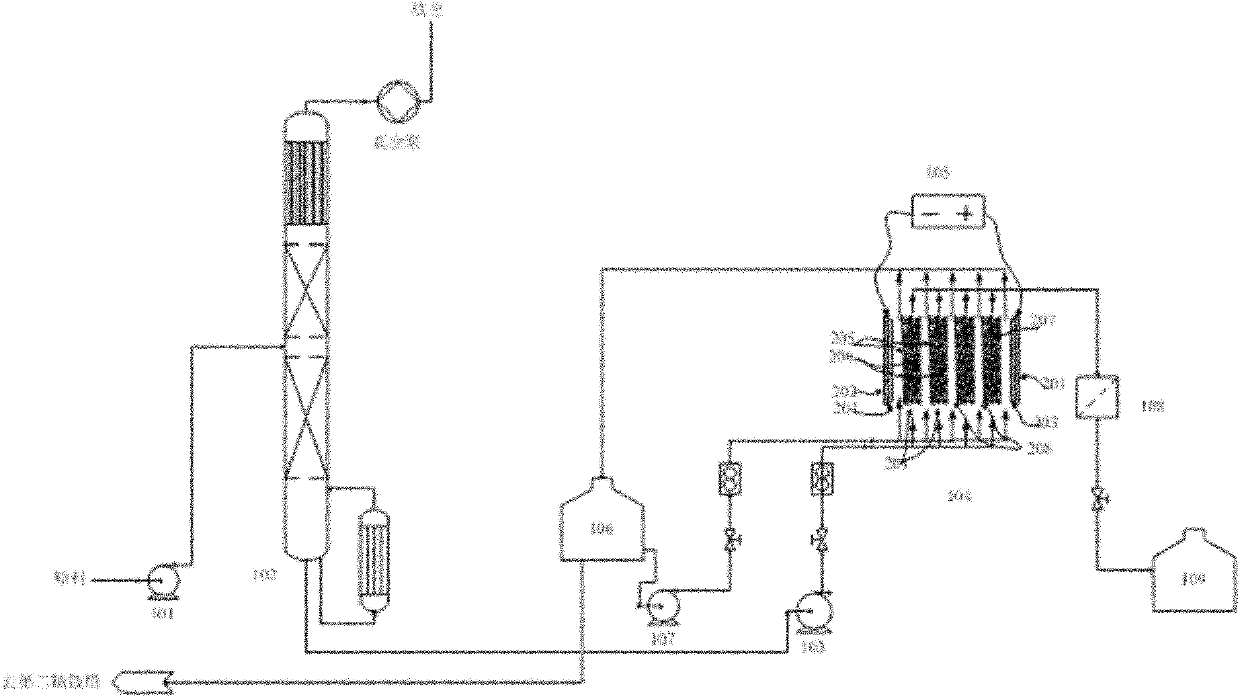

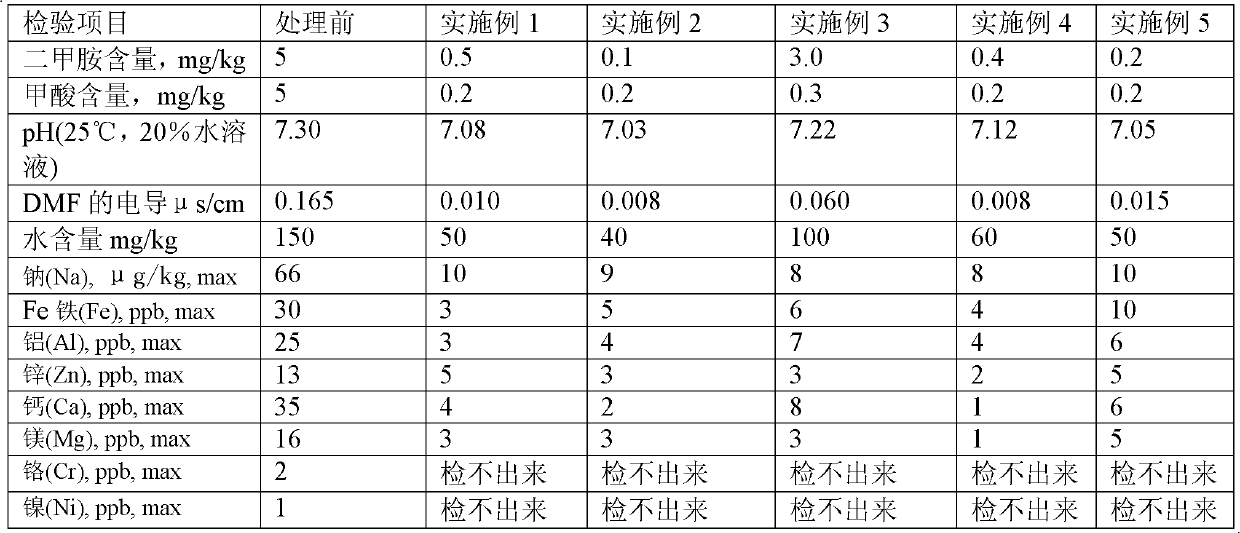

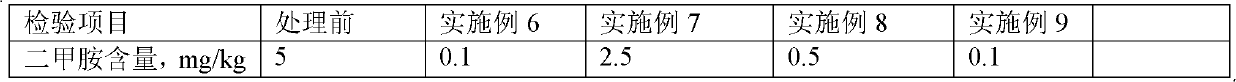

Purifying method for electronic-grade N,N-dimethylformamide

InactiveCN101993387AReduce contentReduce conductanceCarboxylic acid amide separation/purificationN dimethylformamideIon exchange

The invention discloses a purifying method for electronic-grade N,N-dimethylformamide, which is characterized in that the industrial-grade dimethylformamide (DMF) is decompressed and rectified; the material of a decompressing and rectifying tower is stainless steel; the operating pressure is between 8.7 and 27.2 kPa; the operating temperature is from 80 to 110 DEG C; the formic acid with low boiling point, the water and the dimethylamine impurities in the DMF are eliminated from the top of the tower; the DMF from the bottom of the rectifying tower enters a continuous electric deionizing device; and the metal ions, the formic acid, the organic amine and the salt impurities generated by the formic acid and the organic amine in the N,N-dimethylformamide are eliminated by utilizing ion exchange resins and the coupling technique of electrodialysis under an electric field. The invention provides a producing process with the advantages of good purification effect and low energy consumption, and the continuous production purity reaches the purity requirements of electronic chemicals. Thus, the content of the impurity metal ions in the DMF product is lower than 10ppb, the content of the dimethylamine, the formic acid and the electrolyte impurity capable of being ionized is lower than 0.5ppm, the electric conductance of the product DMF is less than 0.010 mu second / cm, and the obtained DMF product can be used for the electronic industries of copper-clad plates and the like.

Owner:TIANJIN UNIV

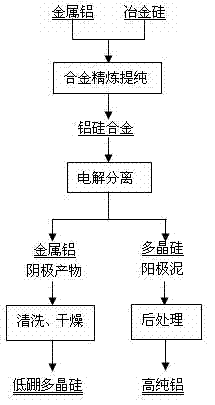

Electrochemical double refining purification method for high purity silicon and high purity aluminum

InactiveCN102534666AEfficient removalImprove the purification effectElectrolysis componentsPolycrystalline siliconElectrochemistry

The invention belongs to the technical field of purification of silicon and aluminum, particularly relates to an electrochemical double refining purification method for high purity silicon and high purity, which includes the following detailed steps: 1 refining and purifying alloy: mixing raw materials of metal aluminum and metallurgy silicon are smelted by adopting an alloy refining method, impurity boron in metallurgy silicon is removed, and aluminum-silicon alloy is obtained; 2 electrolytic separating: aluminum-silicon alloy serves as an anode, stainless steel serves as a cathode, low temperature fused salt serves as electrolyte, constant current electrolysis is conducted, anode mud gathered in the anode is polycrystalline silicon, and aluminum is gathered in the cathode; and 3 post-processing: the polycrystalline silicon gathered in the anode is smashed, acid pickled to remove impurities, washed by deionized water, filtered and dried to obtain low-boron polycrystalline silicon, the aluminum gathered in the cathode is washed and dried to obtain high purity aluminum. The electrochemical double refining purification method can effectively remove the impurity boron in the metallurgy silicon, is good in purification effect and high in environment-friendly benefit. Recycling rate of the aluminum is above 93%, and purity of the aluminum is above 99.999%.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com