Electronic beam cold hearth furnace

An electron beam cooling bed furnace and electron beam technology are applied in the field of metal smelting, which can solve the problems of great difference in volatilization speed and unfavorable production of titanium alloy ingots, save energy consumption, easily control the content and composition uniformity, and achieve melting High vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

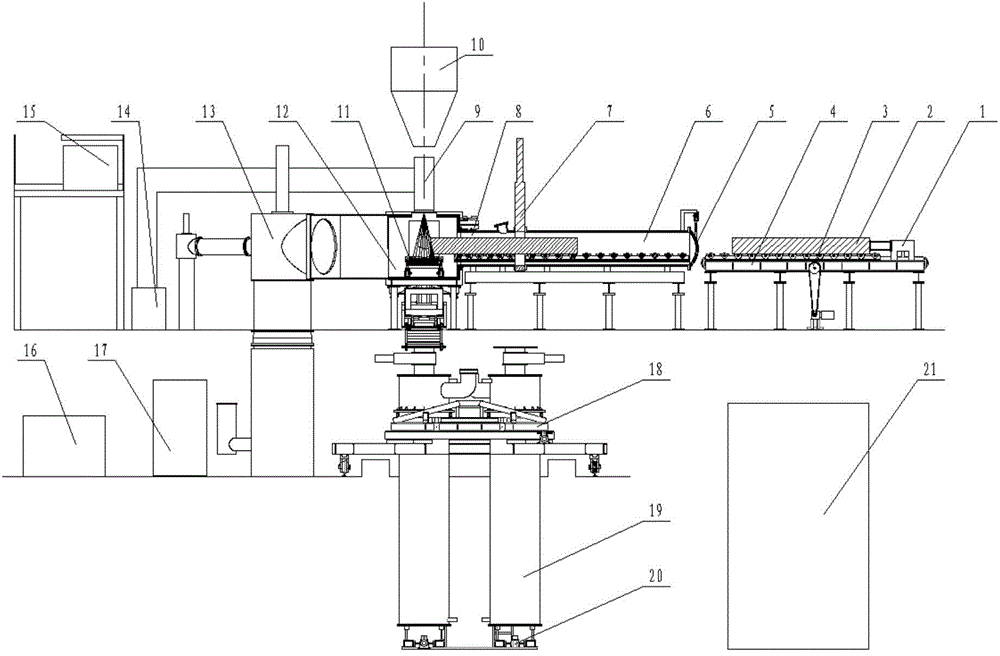

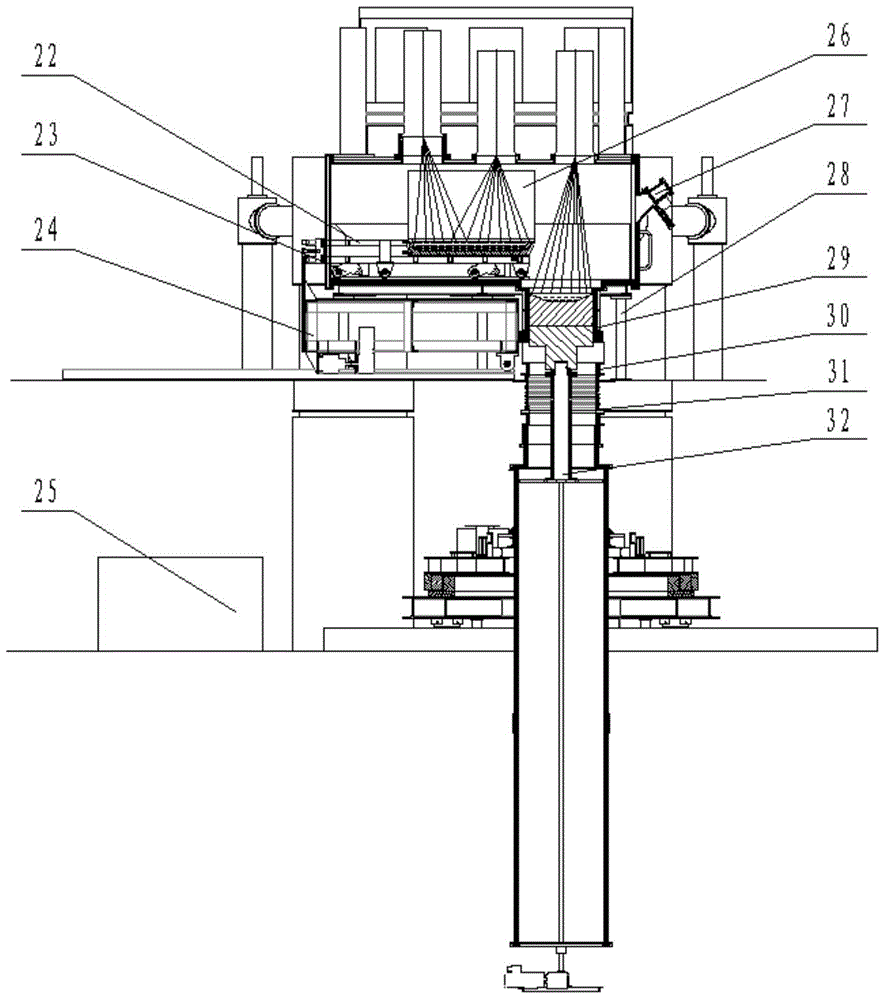

[0011] Such as Figure 1-2 The specific embodiment of the present invention is shown as shown in the electron beam cooling hearth furnace, which mainly includes a vacuum melting chamber 12, an electron gun 9, a power supply 14, a feeding system, a cooling bed 11, a crystallizer 29, an ingot dragging system, a vacuum system 13, Mixed working gas gas production and gas supply system 14 cooling system 25, hydraulic system 16, compressed air system 17 and electrical control system 21; there are three electron guns 9 and are installed on the upper part of the vacuum melting chamber 12, and the electron beams of the two electron guns 9 are positive For the cooling bed 11 located in the middle of the vacuum smelting chamber 12, the electron beam of another electron gun 9 faces the crystallizer 29 located at the lower part of the vacuum smelting chamber 12; Composition, the vertical chip feeding bin 10 is located on the upper part of the vacuum melting chamber 12; the horizontal conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com