Electrochemical double refining purification method for high purity silicon and high purity aluminum

A refining and electrochemical technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve problems such as large consumption of reagents, large amount of alloys, material circulation, and energy consumption problems, and achieve high environmental protection benefits and good purification effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments and drawings, but the present invention is not limited to specific embodiments.

[0019] Implementation column 1

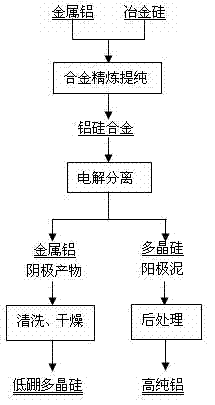

[0020] A method for electrochemical double refining and purification of high-purity silicon and high-purity aluminum, the operations such as silicon, aluminum alloy refining, electrolytic separation and related post-treatment are carried out according to the following steps:

[0021] (1) Alloy refining and purification: the segregation coefficient of impurities decreases with the decrease of temperature. Using the alloy refining and purification method to configure silicon and aluminum into an alloy can effectively reduce the liquidus temperature of the alloy melt, thereby suppressing impurities such as boron in the melt, and improving the purity of silicon as the primary crystal phase. Alloy refining method is used to smelt the mixed raw materials of metal alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com