Patents

Literature

156results about How to "Improve compound rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

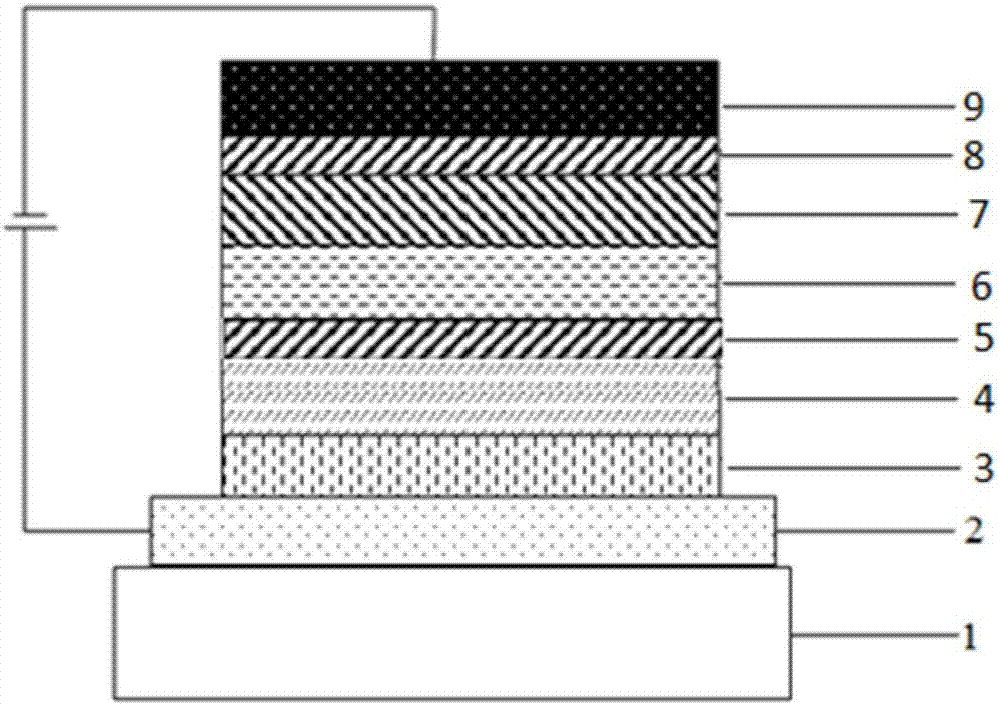

Boron-containing organic light emission diode device and preparation method thereof

ActiveCN107507921AReduced singlet-triplet energy level differenceDelayed fluorescenceSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionTriplet state

Owner:JIANGSU SUNERA TECH CO LTD

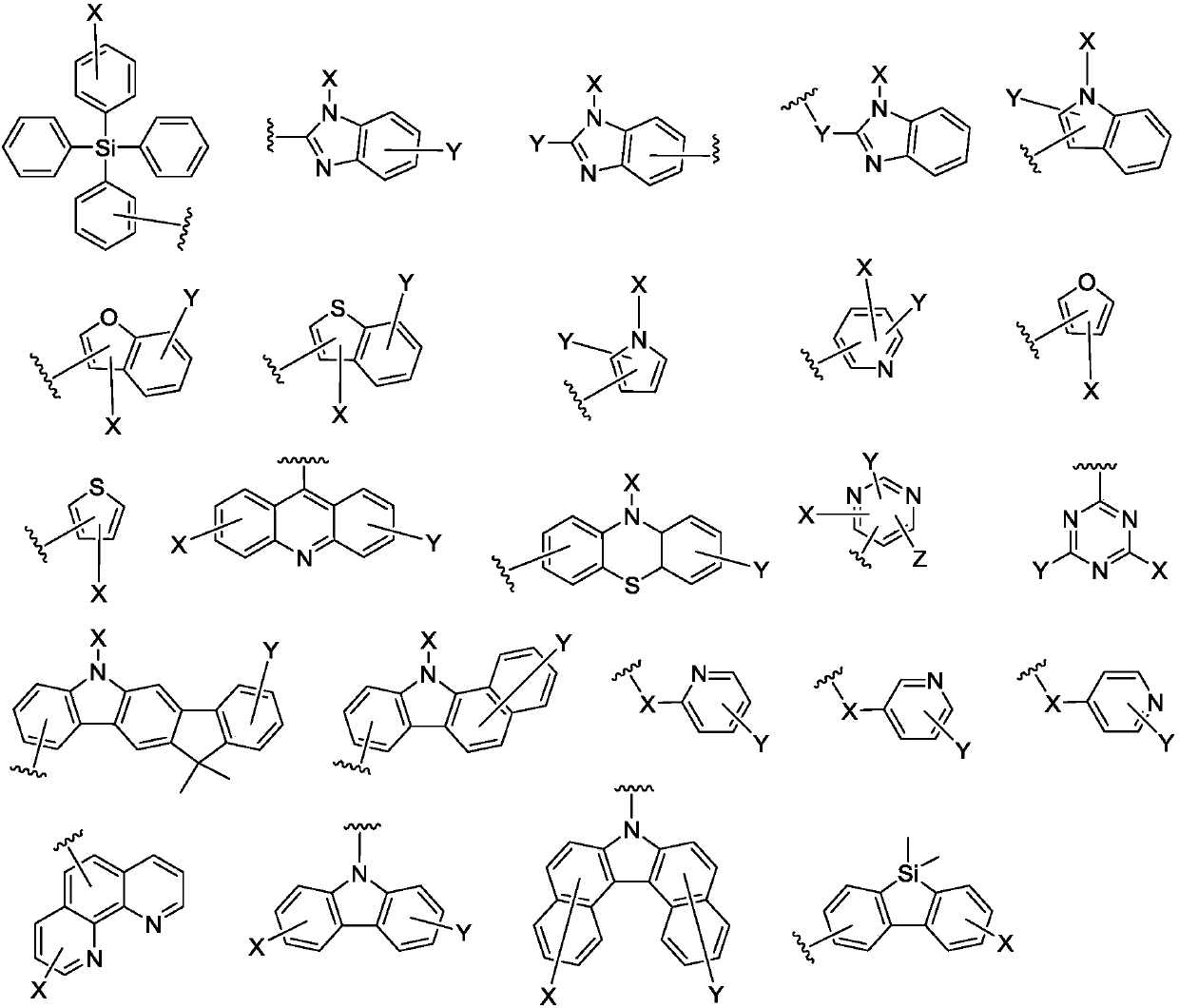

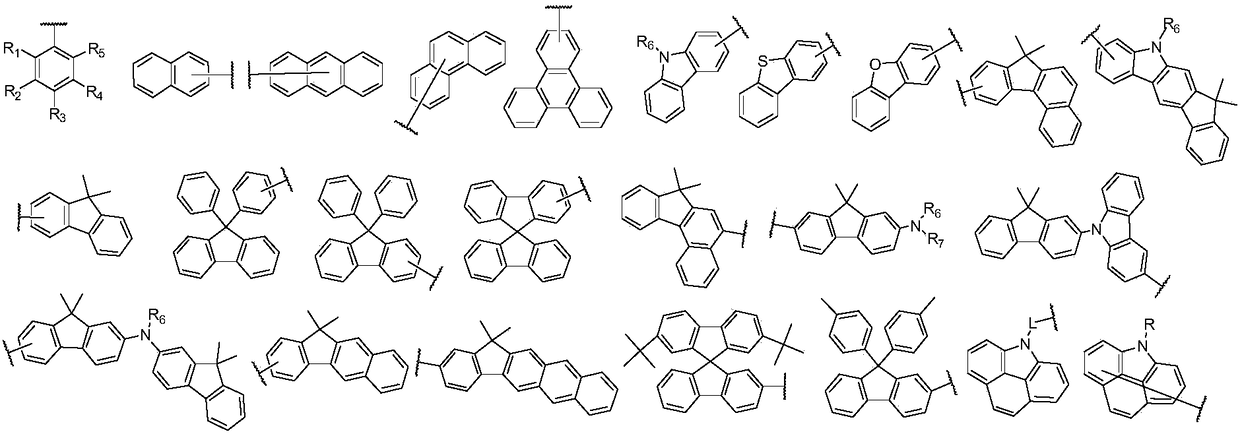

Organic compound, electronic element comprising same, and electronic device

ActiveCN111018797AIncrease space volumeHigh glass transition temperatureOrganic chemistrySolid-state devicesArylSimple Organic Compounds

The invention relates to the technical field of organic photoelectric materials, and in particular, relates to an organic compound, an electronic element containing the same and an electronic device.The compound has a structure represented by a chemical formula 1', wherein one of R1, R2, R3 and R4 is a group defined in the specification, and the other three are selected from substituents such asalkyl, halogen and cyano; one of R5, R6, R7 and R8 is a group defined in the specification, the other three are selected from substituents such as alkyl, halogen and cyano, Y and Y1 are respectively and independently a group defined in the specification, and L and L1 are single bonds, aryl, heteroaryl and the like. By using the organic compound in an electronic component, the driving voltage, luminous efficiency, and life of the electronic component are improved.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

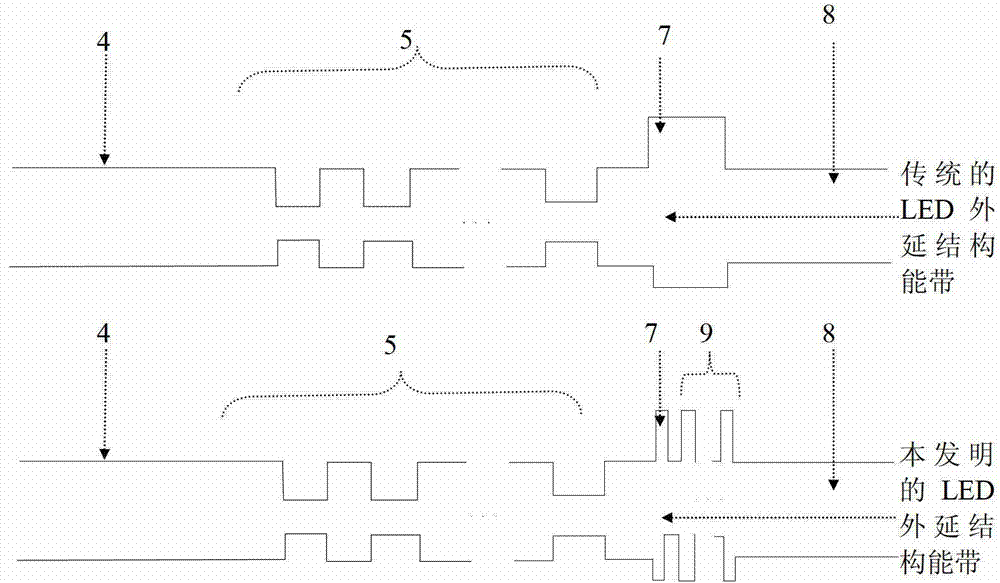

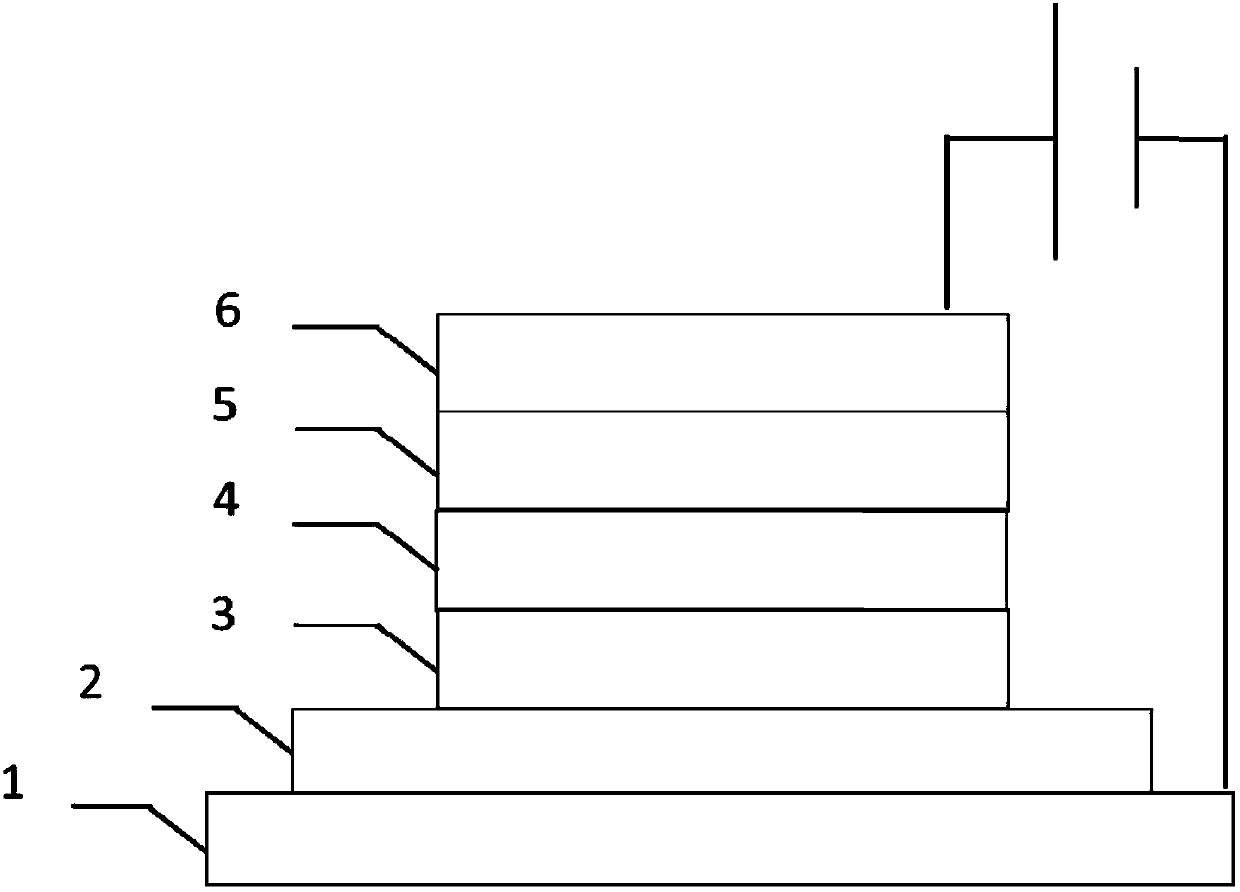

LED (Light Emitting Diode) epitaxial structure with P (Positive) type superlattice and preparation method thereof

ActiveCN103050592AStop SpillFacilitate horizontal expansionSemiconductor devicesPotential wellHigh density

The invention discloses an LED (Light Emitting Diode) epitaxial structure with a P (Positive) type superlattice and a preparation method thereof. The epitaxial structure comprises a substrate, wherein a GaN (Gallium Nitride) buffer layer, an undoped GaN layer, an n (negative) type GaN layer, a multi-quantum well luminous layer, a first P type GaN layer, a P type AlGaN (Aluminium Gallium Nitride) electronic blocking layer and a second P type GaN layer are sequentially arranged on the substrate from bottom to top, and the P type superlattice formed by a PInGaN (P type Indium Gallium Nitride) potential well layer and a PAlGaN potential barrier layer in a periodic interactive overlapping way is arranged between the P type AlGaN electronic blocking layer and the second P type GaN layer. The PInGaN potential well layer in the P type superlattice generates and constrains a great number of holes for the formation of a two-dimensional hole high-density state; the PAlGaN potential barrier layer hinders the escape of the holes; in such a way, the transverse spreading of the holes is improved, the electron overflow can be prevented, the hole injection efficiency is increased and the electron and hole recombination probability is improved; and therefore, the brightness of a chip can be improved by 5-10%.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Rubber composition and pneumatic tire using the same

InactiveUS20070167555A1Reduce fuel consumptionReduce consumptionSpecial tyresTyre beadsSilicon dioxidePolybutadiene

A rubber composition containing (i) a conjugated diene-based rubber gel having a toluene swelling index of 16 to 70, (ii) a diene-based rubber such as natural rubber, polyisoprene rubber, aromatic vinyl-conjugated diene copolymer rubber and / or polybutadiene rubber, and (iii) an optional carbon black and / or silica and (a) a pneumatic tire using this composition as a high hardness reinforcing layer extending from a bead along a tire sidewalls, in which the fluidity and dimensional stability at the time of extrusion are improved, while maintaining a sufficient hardness of a high hardness reinforced rubber, (b) a pneumatic tire using this composition as two ends of a tire tread extrudate, maintaining a flex fatigue of the two ends of the tread, in which the extrudability and extrusion dimensional stability are improved and (c) a pneumatic tire using the composition as a 1.5 mm to 6 mm thick undertread, in which a high elasticity and relatively thick gauge undertread, and excellent processability and steering stability are provided.

Owner:THE YOKOHAMA RUBBER CO LTD +1

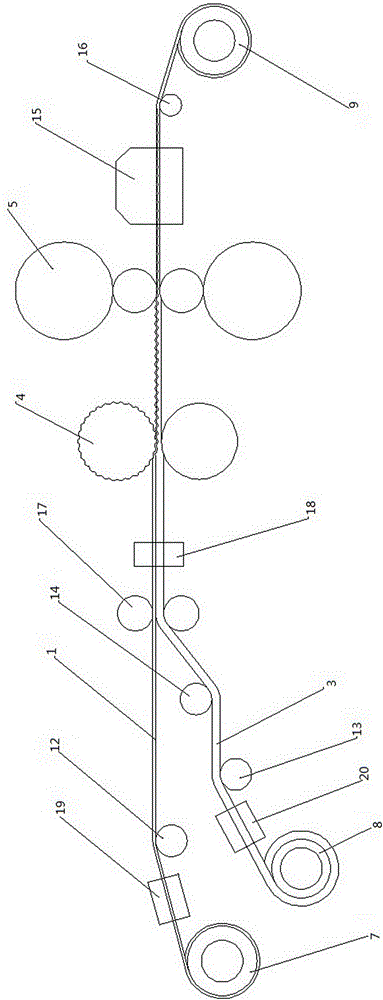

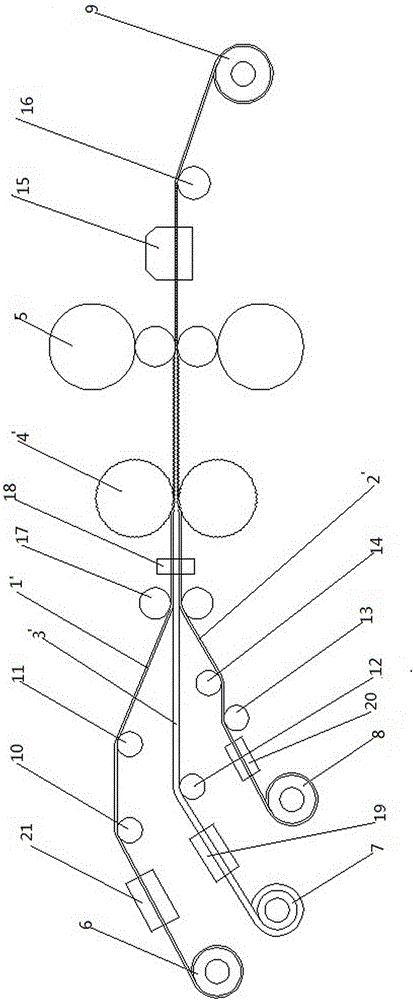

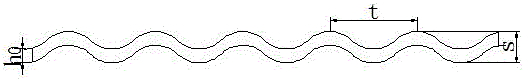

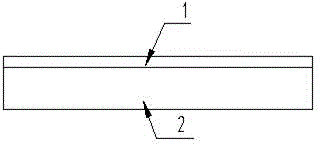

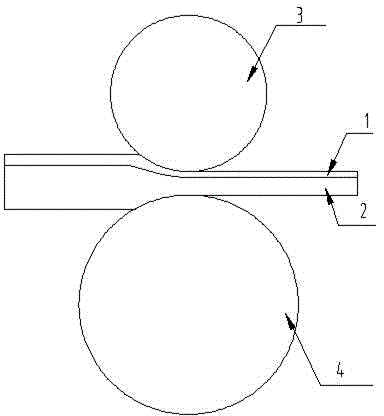

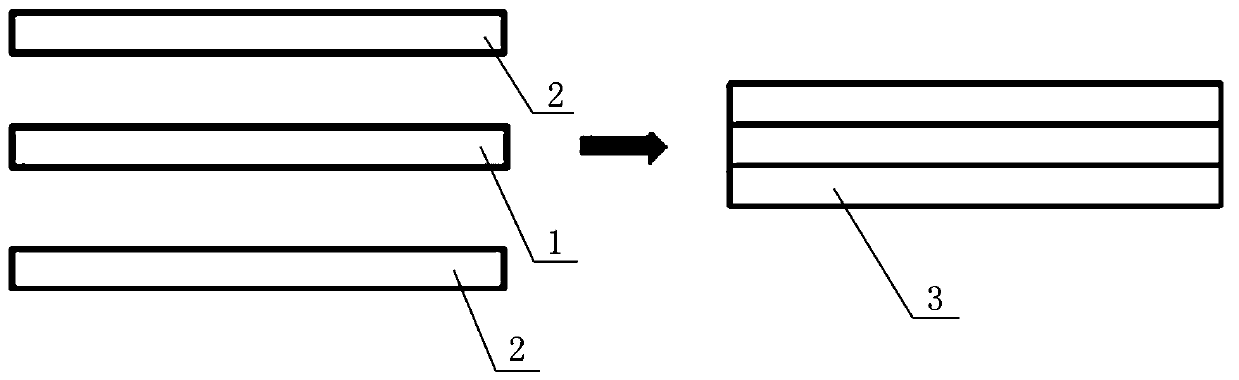

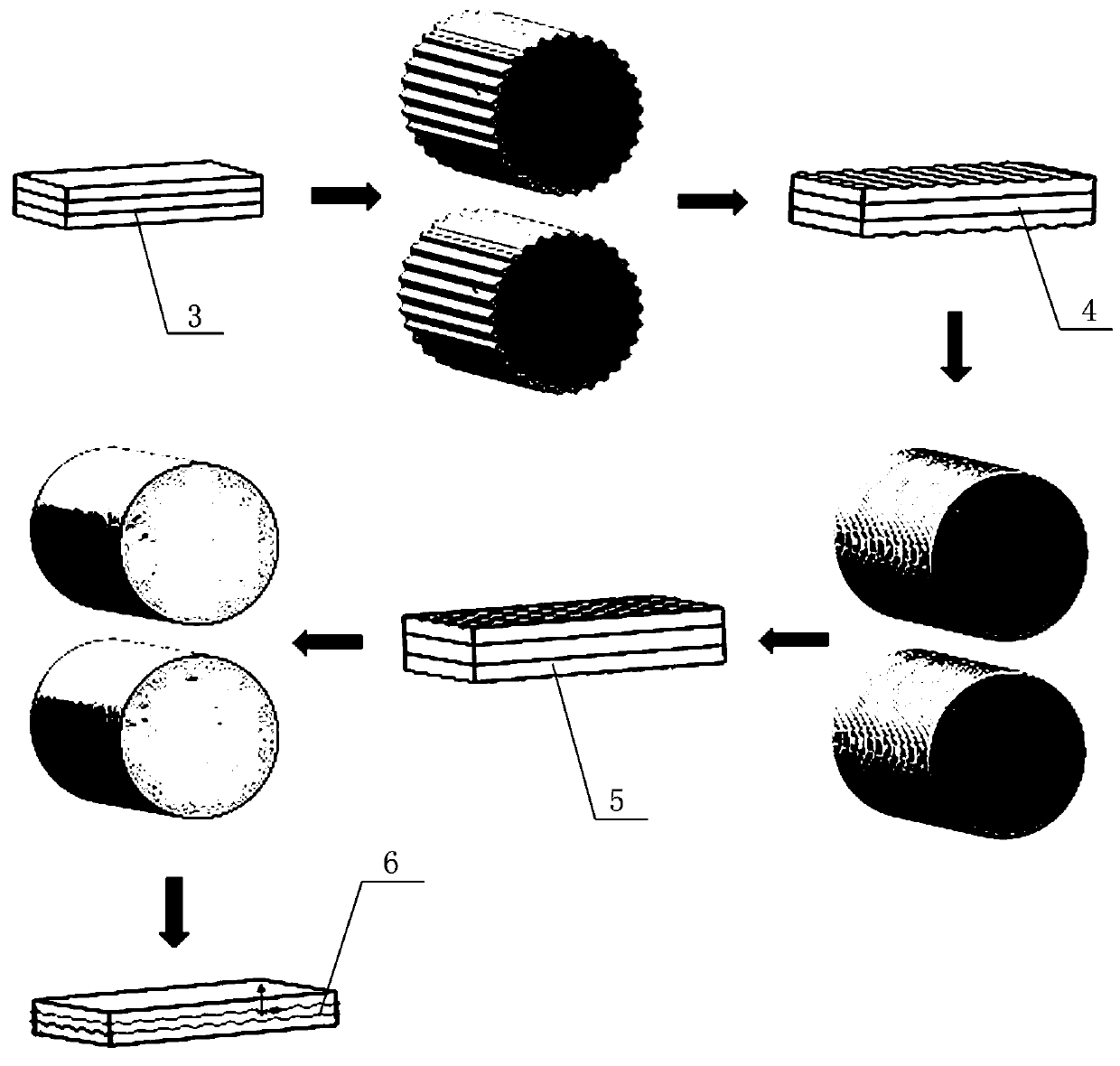

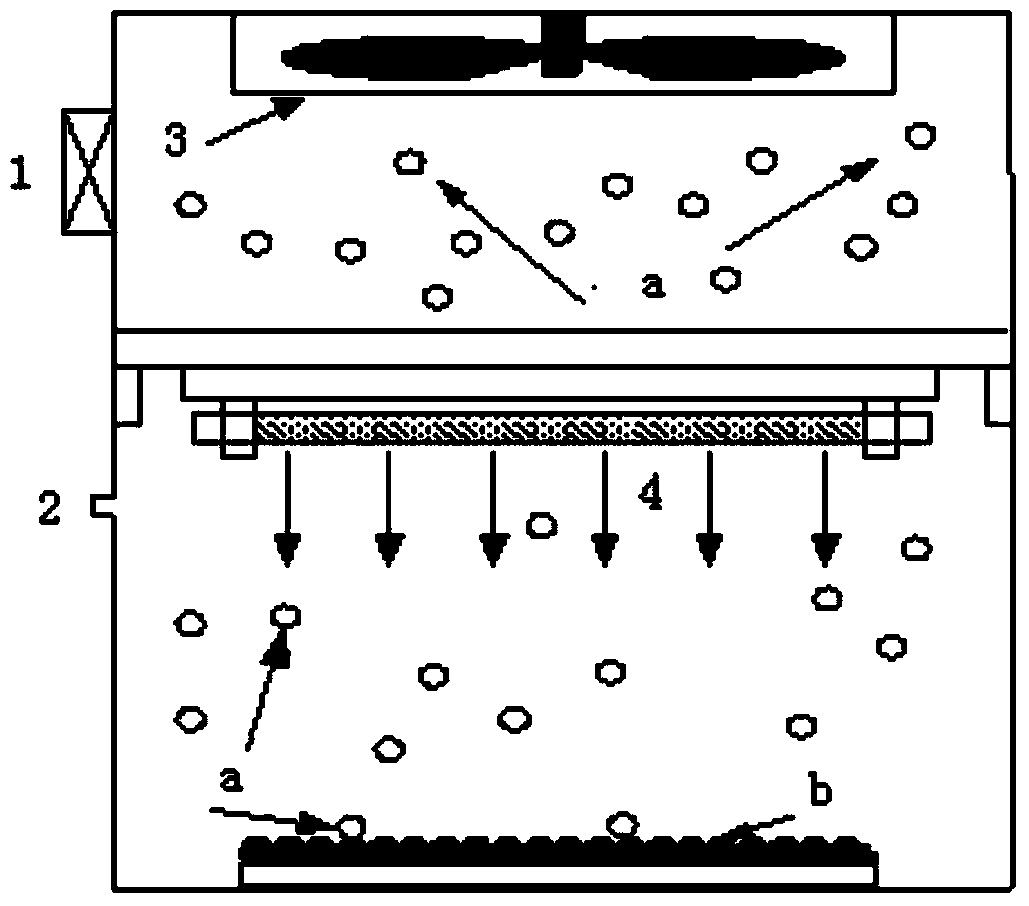

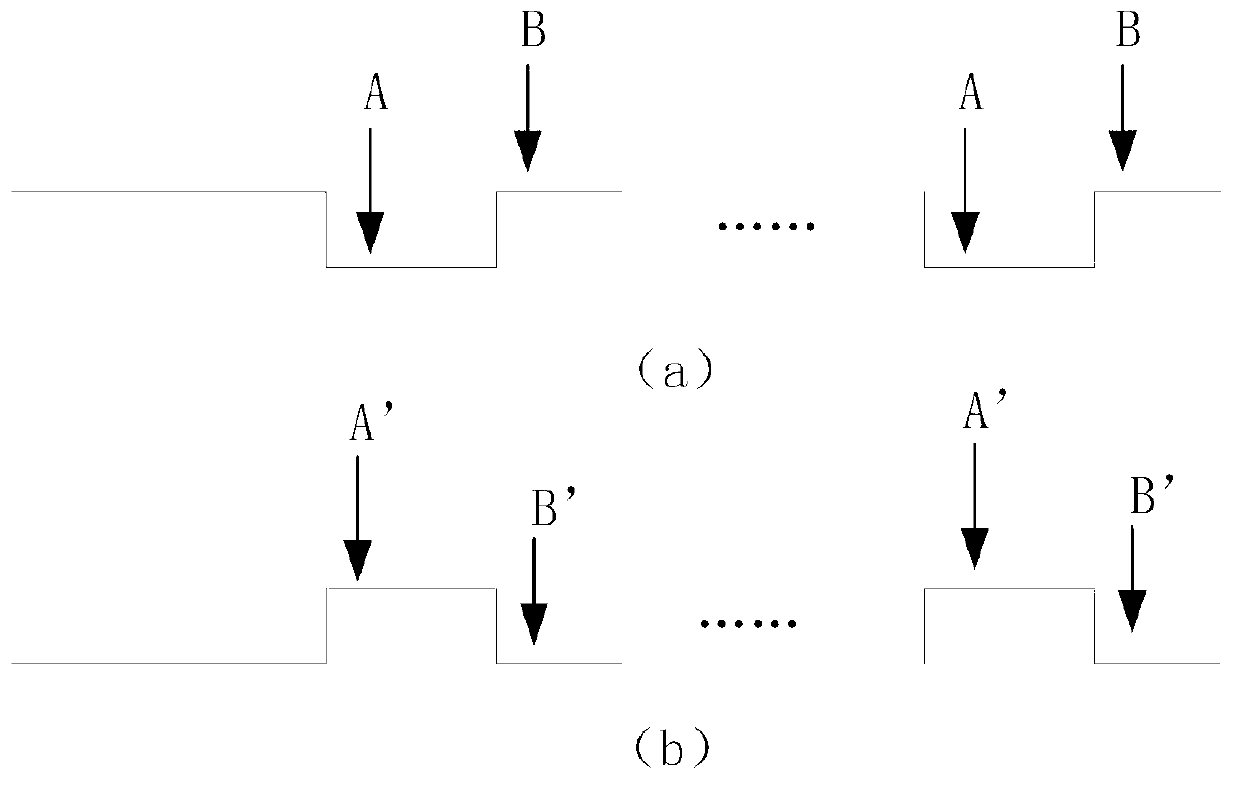

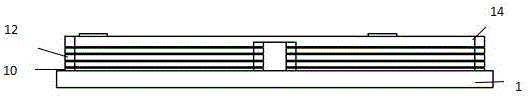

Device and method for producing metal composite sheet strips through corrugated-flat continuous rolling

ActiveCN105057386AHigh bonding strengthUniform deformationMetal rolling arrangementsCrazingContinuous annealing

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

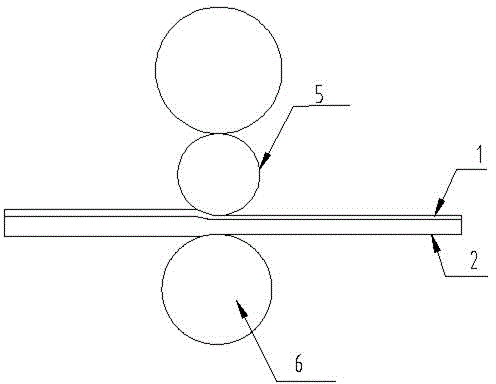

Method for rolling copper-aluminum double-layer composite plate

ActiveCN104959382AReduce residual stressIncrease the amount of plastic deformationAuxillary arrangementsMetal rolling arrangementsComposite plateCopper

The invention discloses a method for manufacturing a copper-aluminum double-layer medium-thick composite plate through a cold rolling manner. The method comprises following steps: 1) cleaning an aluminum plate and a copper plate in an immersion manner, removing oil of the plates, drying the plates, and cleaning the composite surfaces of the plates; 2) stacking and compressing the copper plate and the aluminum plate, and riveting the plates at a rolling bite end; 3) rolling the copper-aluminum composite plate blank through a two-roller roughing mill; 4) rolling the copper-aluminum composite plate through a three-roller intermediate mill; 5) rolling the copper-aluminum composite plate through a four-roller finishing mill; 6) rolling the copper-aluminum composite plate through a six-roller finishing mill to reach the required thickness; and 7) annealing the copper-aluminum composite plate. According to the invention, rolling is carried out through the rolling mills provided with working rolls having different roll diameters, so that the plastic deformation is increased, the composite ratio is improved, and a plate shape problem of the copper-aluminum double-layer medium-thick composite plate is solved as the working rolls are different in linear speed.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing metal composite plate through double corrugated roll cross rolling

ActiveCN110421000AHigh bonding strengthReduce residual stressMetal rolling arrangementsComposite plateMetal

The invention relates to the technical field of metal composite plate rolling, particularly to a method for preparing a metal composite plate through double corrugated roll cross rolling, and aims atsolving the technical problems that warping, cracking and low elongation rate are prone to occurring after existing metal composite plates are rolled. According to the technical scheme, the method comprises the following steps of 1, selecting a base plate and a cover plate to manufacture a metal composite plate blank; 2, feeding into a two-high rolling mill a for a first rough rolling to obtain ametal composite plate a, wherein an upper surface, a lower surface and a bonding surface of the metal composite plate a are all unidirectional ripples; 3, feeding into a two-high rolling mill b for asecond rough rolling to obtain a metal composite plate b, wherein an upper surface, a lower surface and a bonding surface of the metal composite plate b are all cross ripples; 4, feeding into a two-high rolling mill c for a flat rolling to obtain a metal composite plate c, wherein an upper surface and a lower surface of the metal composite plate c are both flat surfaces and a bonding surface of the metal composite plate c is a cross ripple; and 5, carrying out heat treatment, straightening, trimming and segmentation to prepare the finished metal composite plate.

Owner:TAIYUAN UNIV OF TECH

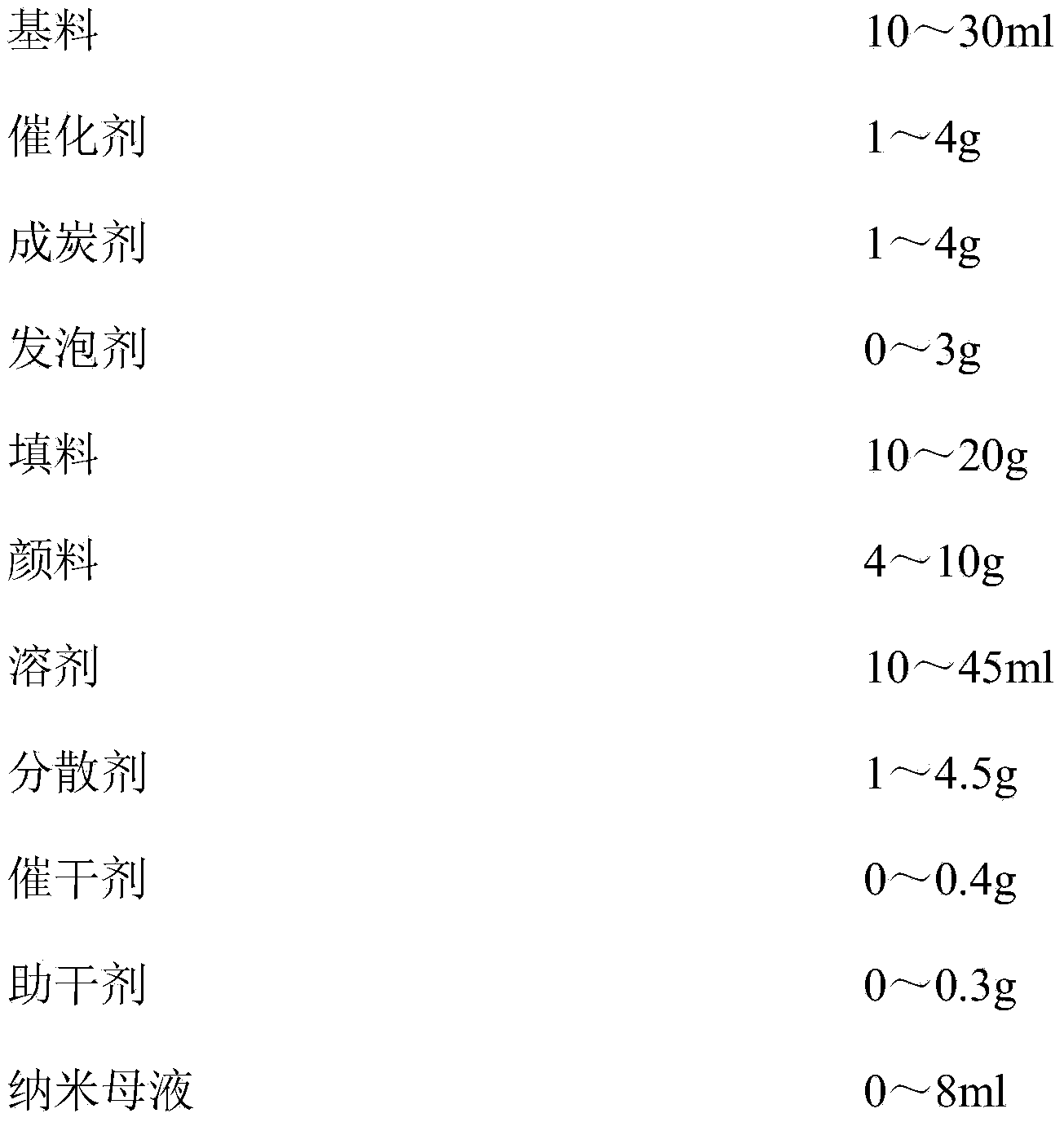

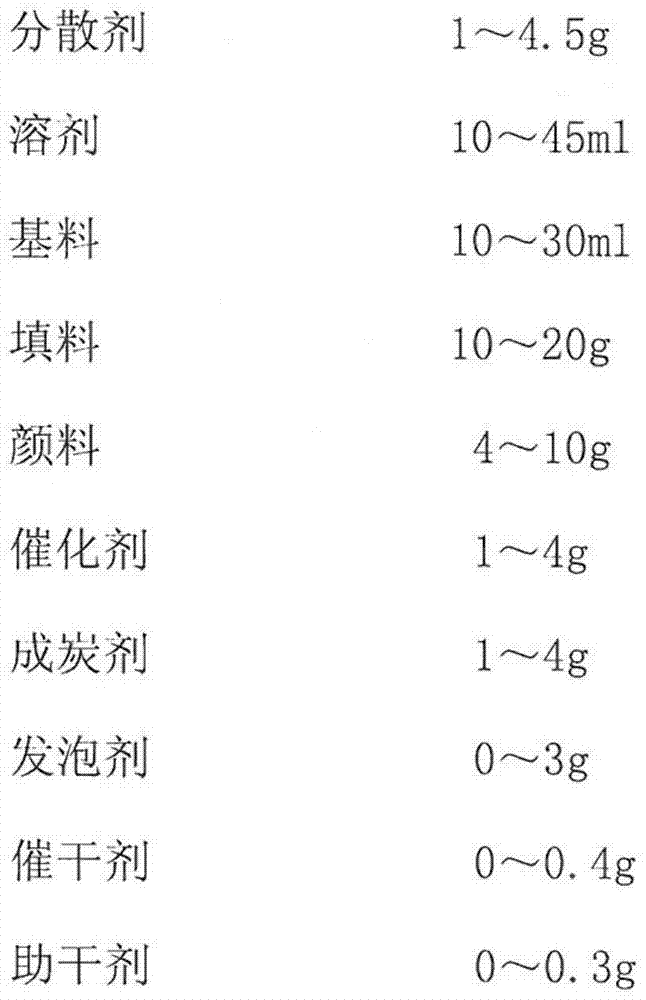

Fire-retardant coating with photo-catalytic performance and preparation method thereof

The invention discloses a fire-retardant coating with photo-catalytic performance and a preparation method thereof, belonging to the field of fire-retardant coatings. The coating comprises a base material, a catalyst, a charring agent, a foaming agent, a filler, a pigment, a solvent, a dispersant, a drier, a drying aid, a nano mother solution and the like, wherein the base material is aluminum dihydrogen phosphate, the catalyst is ammonium polyphosphate, the charring agent is pentaerythritol, the foaming agent is melamine, the filler is ultra-fine slag powder, the pigment is Cu-La / TiO2, the solvent is water, the dispersant is a BYK180 polymeric dispersant, the drier is lead oxide, the drying aid is zinc powder, and the nano mother solution is a nano SiO2 mother solution. The fire-retardant coating disclosed by the invention reduces the environment pollution to the maximum extent by using industrial waste residues as the filler; meanwhile, the coating has a function of realizing photocatalytic degradation of formaldehyde gas under a visible light source to endow conventional fire-retardant coatings with a brand-new function, and the fire-retardant coating accords with the development trend of national green ecological building materials.

Owner:镇江新智生物科技有限公司

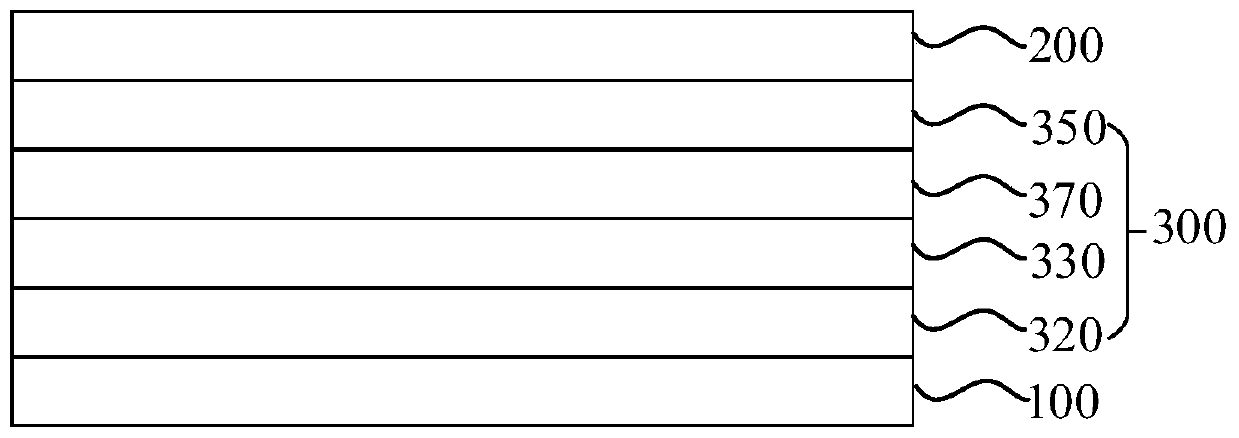

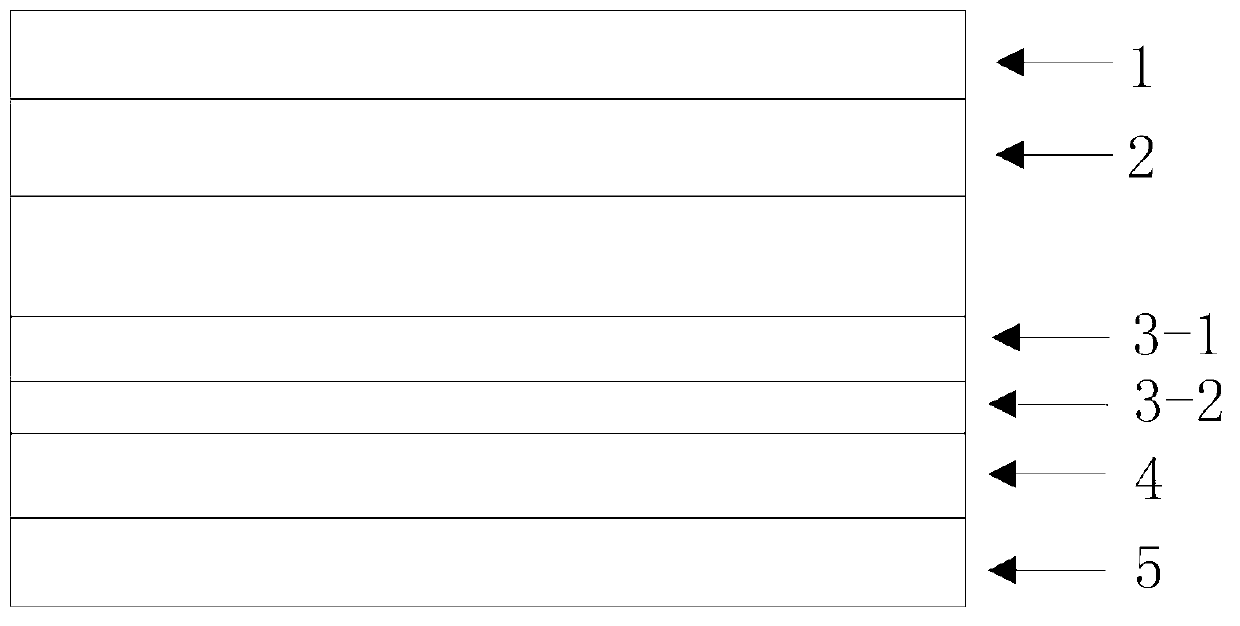

Epitaxial structure of a light emitting diode and its manufacturing method

InactiveCN102299223AIncrease the restrictive effectLow mobilitySemiconductor devicesQuantum wellCompound structure

The invention discloses an epitaxial structure of a light-emitting diode and a manufacturing method thereof. On a GaAs substrate layer, there are a Bragg reflection layer, a first-type confinement layer, an active layer, a second-type confinement layer, and a current spreading layer in sequence from bottom to top. , the active layer is composed of n sets of quantum wells and quantum barriers alternately, where 100≥n≥2, and the barrier height in the same quantum barrier is a gradual distribution or the barrier height between different quantum barriers It is a gradual distribution; its manufacturing method includes the following steps: select GaAs as the substrate layer, and grow a Bragg reflection layer, a first-type confinement layer, an active layer, a second-type confinement layer, and a current spreading layer sequentially on the GaAs substrate layer, wherein The active layer is formed by alternately growing n groups of quantum wells and quantum barriers, and the quantum barriers are made of (AlxGa1-x)yIn1-yP group III and V compounds, where 1≥x≥0.5, and the invention enhances the quantum barrier’s effect on electrons The confinement effect increases the recombination rate of electrons and holes in the quantum well, thereby increasing the brightness of the light-emitting diode.

Owner:XIAMEN CHANGELIGHT CO LTD

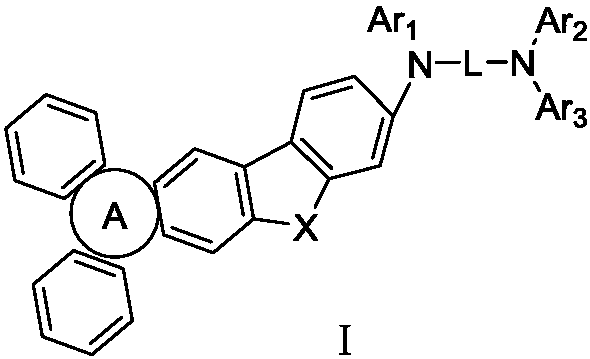

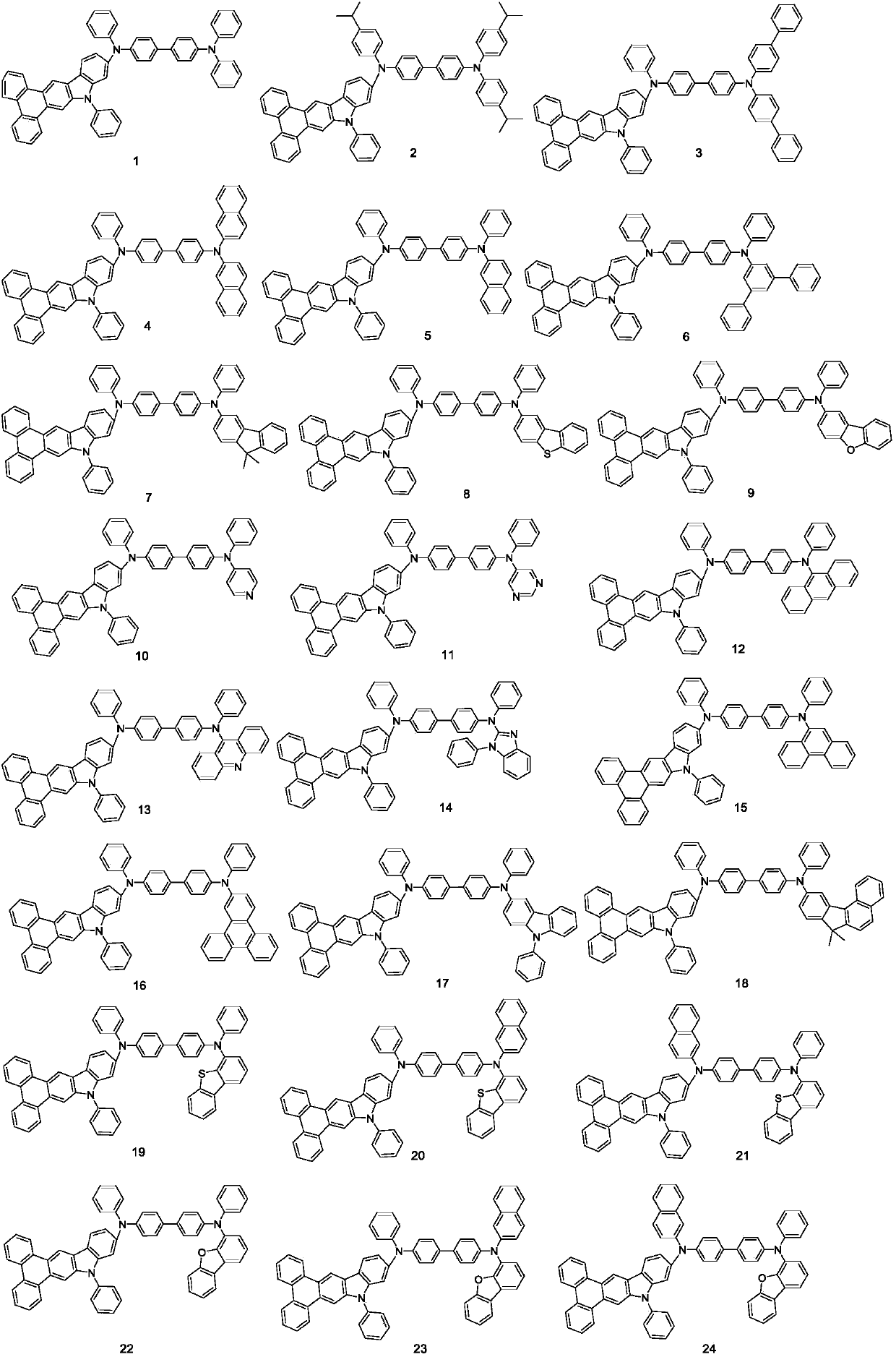

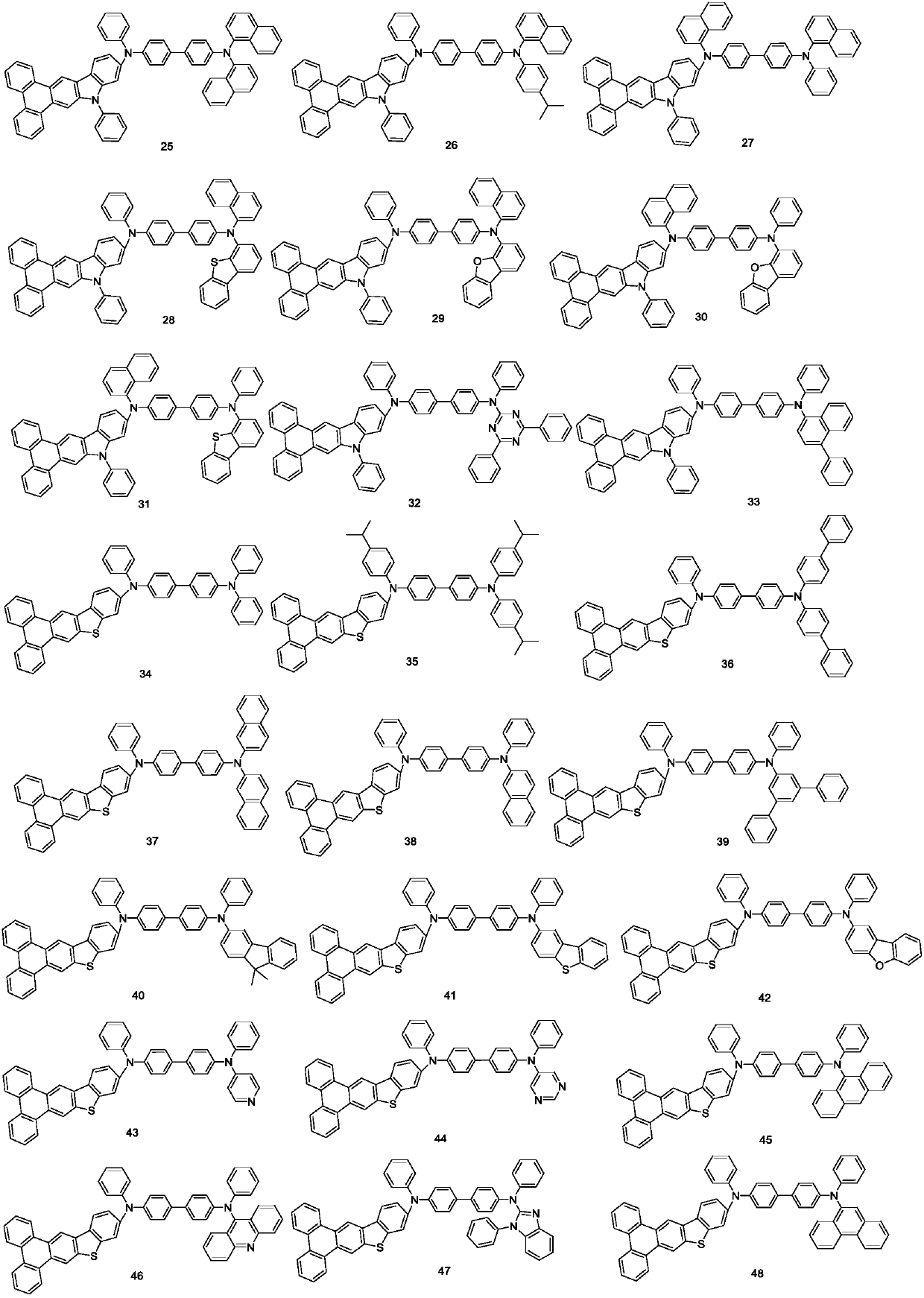

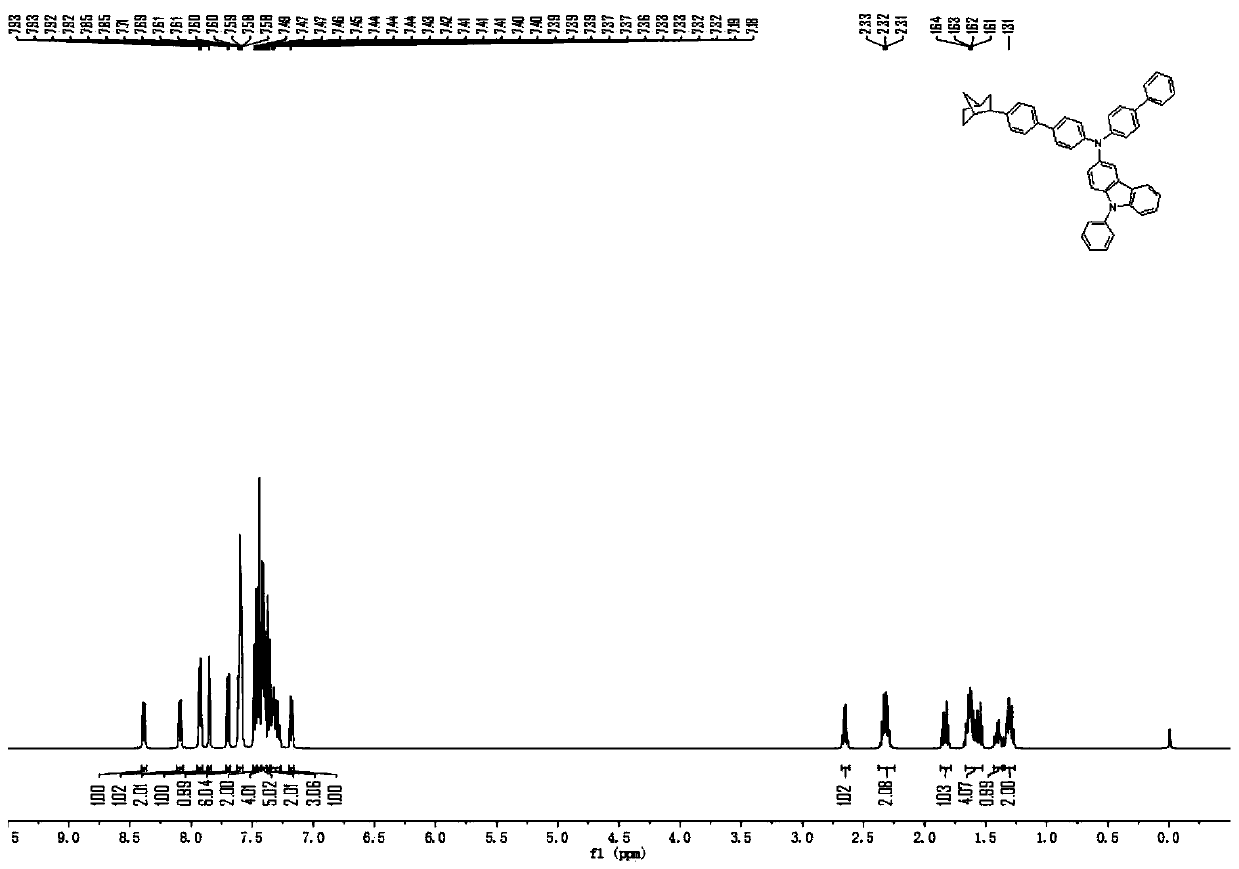

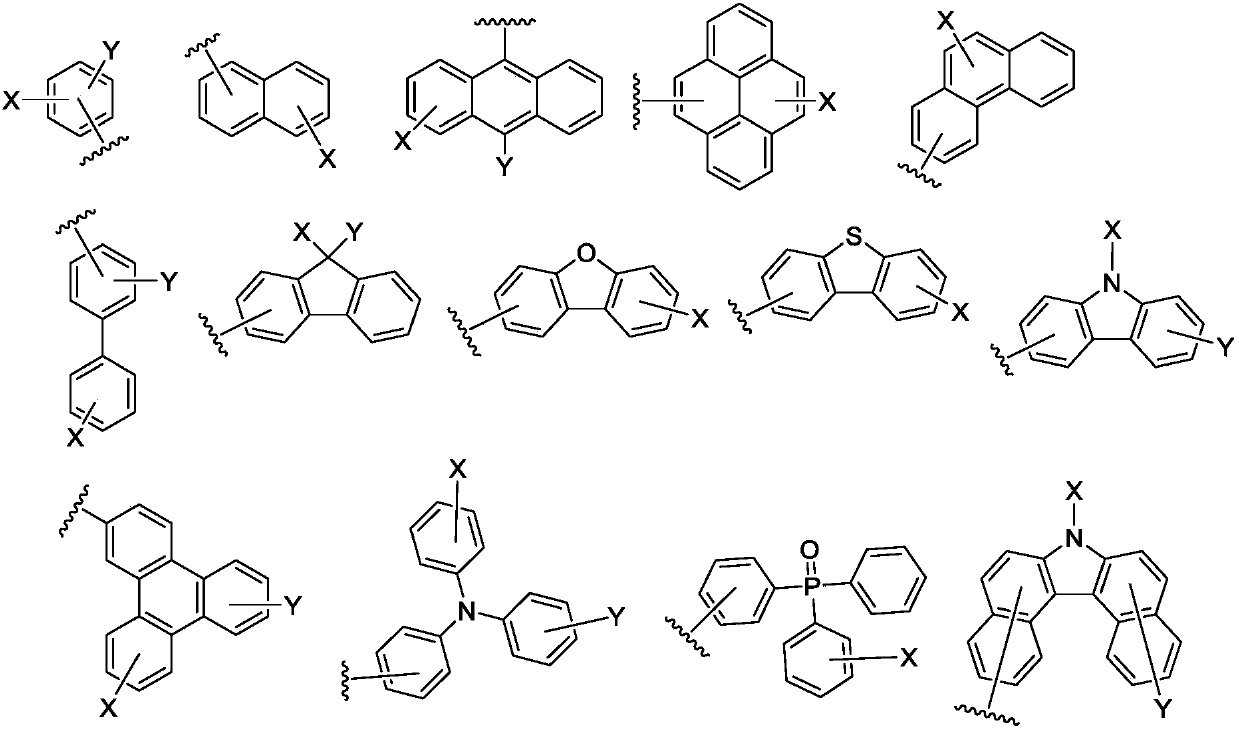

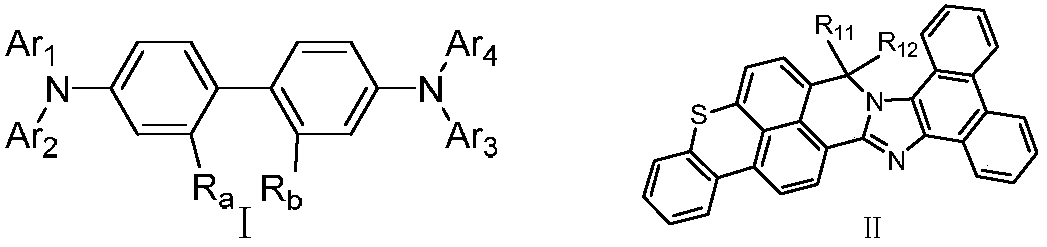

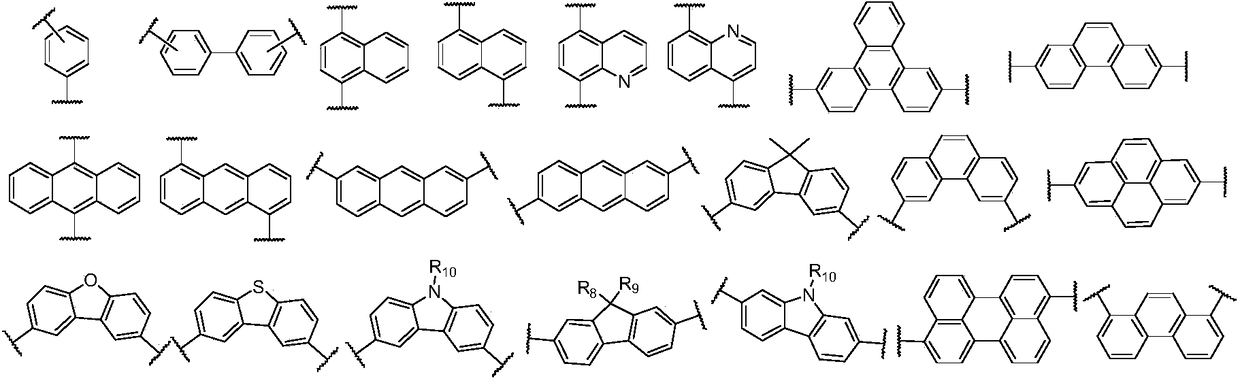

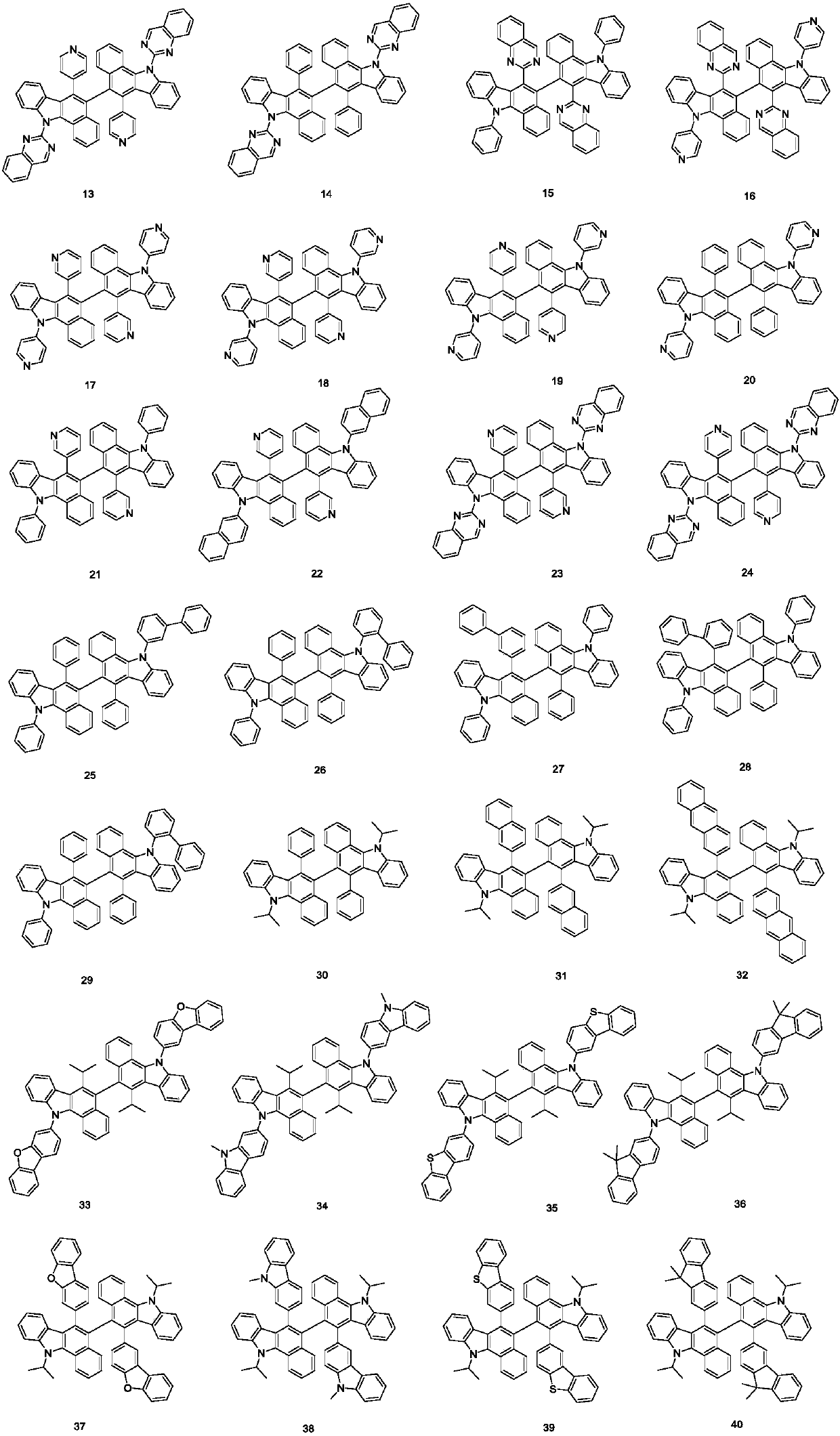

Arylamine compound and organic luminescent device thereof

InactiveCN108129380AStrong transmission abilityIncrease transfer rateOrganic chemistrySolid-state devicesCarbazoleChemical compound

The invention provides an arylamine compound and an organic luminescent device thereof, and relates to the technical field of organic photoelectric materials. The arylamine compound is obtained by connecting substituted or un-substituted carbazole, benzothiophene and a thick derivative of benzofuran onto an arylamine main body, so that with cavity transmission ability is relatively strong, good thermal stability is good, good film-forming property is good and synthesis is simple and easy easy-to to-operate synthesis. The arylamine compound can be applied to the organic luminescent device as acovering layer of or a cavity transmission layer, so that the problem that carrier transmission in the organic luminescent device is unstable and light out-coupling efficiency is low in the organic luminescent device can be effectively solved; and the organic luminescent device has the advantages of being high in luminescent efficiency and long in service life.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

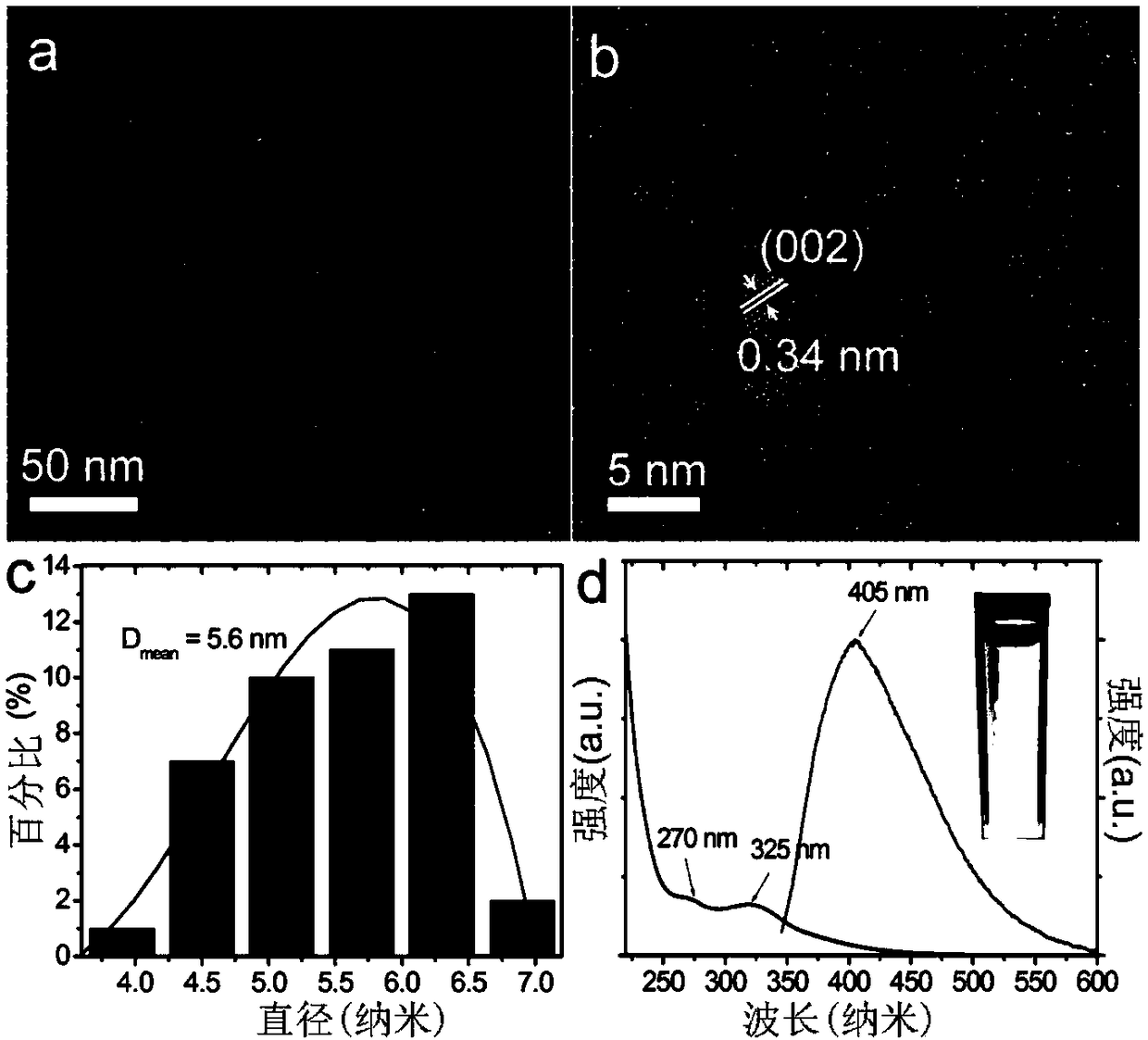

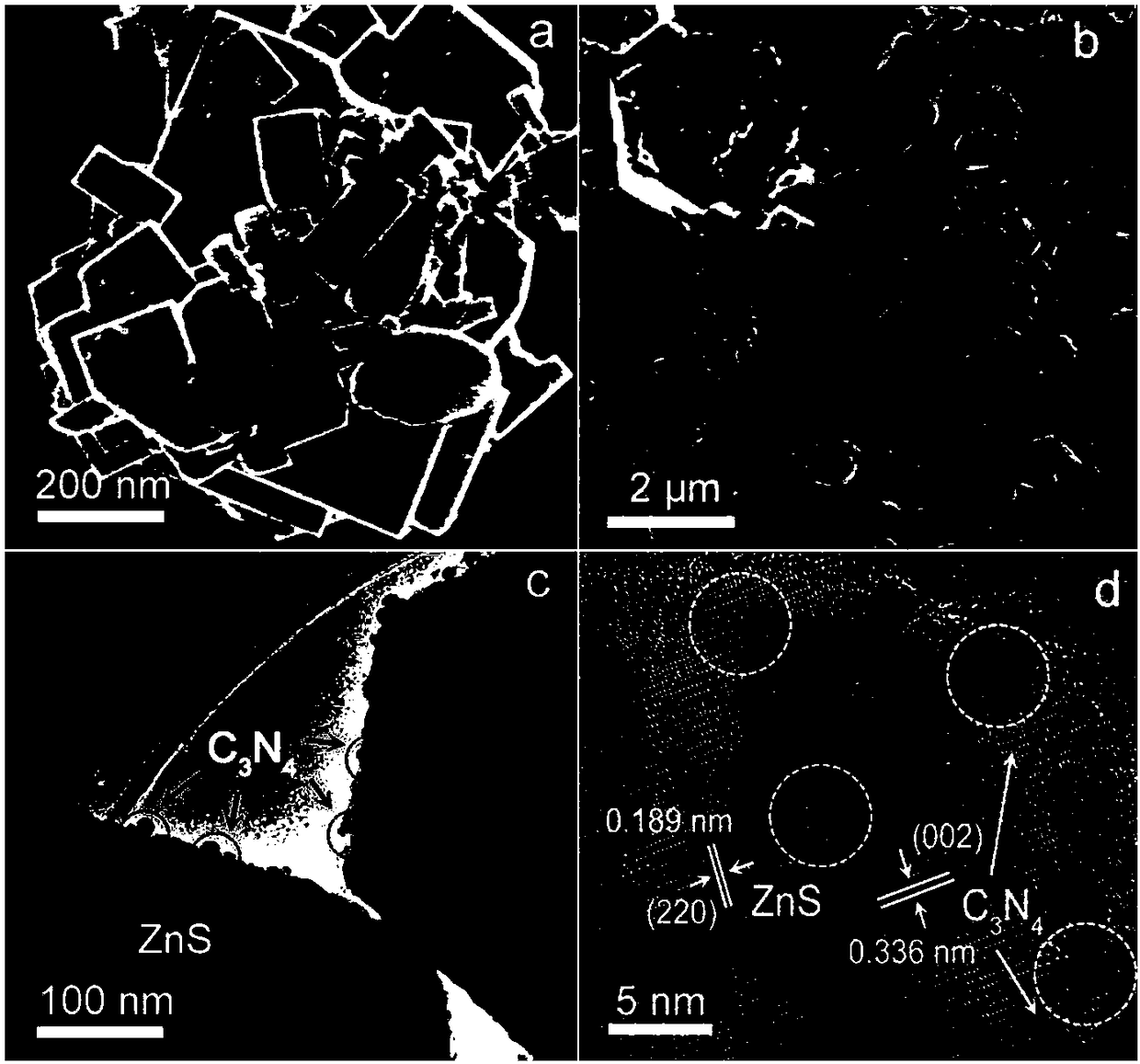

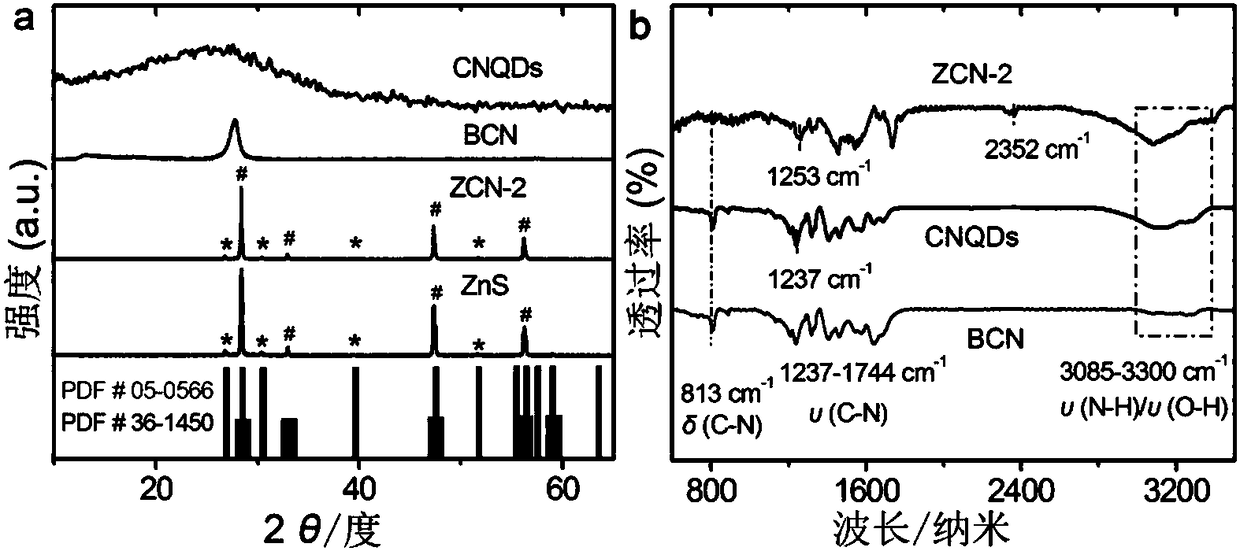

Graphene nitrogen carbide quantum dot modified ZnS micrometer composite material as well as preparation method and application thereof

ActiveCN108246331AGood water solubilityVisible light response ability is strongCatalyst activation/preparationHydrogen productionCatalytic effectHydrogen production

The invention provides a graphene nitrogen carbide quantum dot modified ZnS micrometer composite material as well as a preparation method and application thereof and belongs to the technical field ofsemiconductor composites. The method comprises the following steps: preparing ZnS(en)0.5 nanosheets; adding amino compounds into a porcelain boat, and raising the temperature and reacting in a tube furnace so as to obtain bulk phase g-C3N4 powder; finally, mixing and stirring the ZnS(en)0.5 nanosheets and the g-C3N4 powder, and carrying out a hydrothermal reaction in a reactor, thereby obtaining the graphene nitrogen carbide quantum dot modified ZnS micrometer composite material. The invention further provides application of the graphene nitrogen carbide quantum dot modified ZnS micrometer composite material serving as a photocatalyst. The photocatalyst can reach hydrogen production activity of 5600u mol h-1g-1 under visible light and has excellent photocatalytic stability, the hydrogen production activity is 140 times that of the ZnS under the same condition, and after four cycles, the catalytic effect is not obviously decreased.

Owner:NORTHEAST NORMAL UNIVERSITY

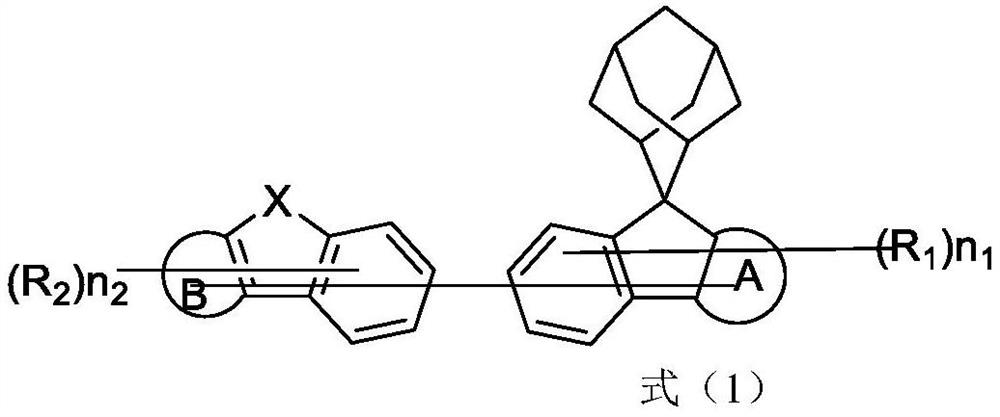

Compound, organic electroluminescent device and electronic device

ActiveCN111961038AMacromolecular structure has strong rigidityImprove rigiditySilicon organic compoundsOrganic chemistry methodsSimple Organic CompoundsOrganic electroluminescence

The invention provides an organic compound, an organic electroluminescent device and an electronic device. The chemical structure of the organic compound comprises an adamantane spirofluorene ring anda dibenzo five-membered ring, and the organic compound has an excellent energy transfer function, can be used as a luminescent layer material in an electroluminescent device, improves the efficiencyof the organic electroluminescent device and prolongs the service life of the organic electroluminescent device.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

Electron transport material, preparation method thereof and light emitting diode

ActiveCN109935714AImprove solubilityImprove the problem that the current density is too high relative to the hole layerSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeCharge injection

The invention belongs to the technical field of materials, and specifically relates to an electron transport material, a preparation method thereof and a light emitting diode. The electron transport material comprises metal oxide nanoparticles and PMMA, wherein the metal oxide nanoparticles and the PMMA are connected through an alkoxy silane coupling agent containing an amino at the tail end of anon-alkoxy carbon chain; one end of the silane coupling agent is connected with the metal oxide nanoparticles through -Si(O-)3, and the other end of the silane coupling agent is connected with PMMA through -NH-CO-. The electron transport material is used for preparing an electron transport layer, can improve a phenomenon of uneven electron-hole injection of a light emitting diode device, and thuscan achieve an effect of balanced charge injection through adjusting the injection ratio of electrons and holes in a light emitting layer, so that an electron transport layer with the electron injection capacity being adjustable, thus the recombination rate of the holes and electrons in the light emitting layer can be increased, and the light emitting efficiency is improved.

Owner:TCL CORPORATION

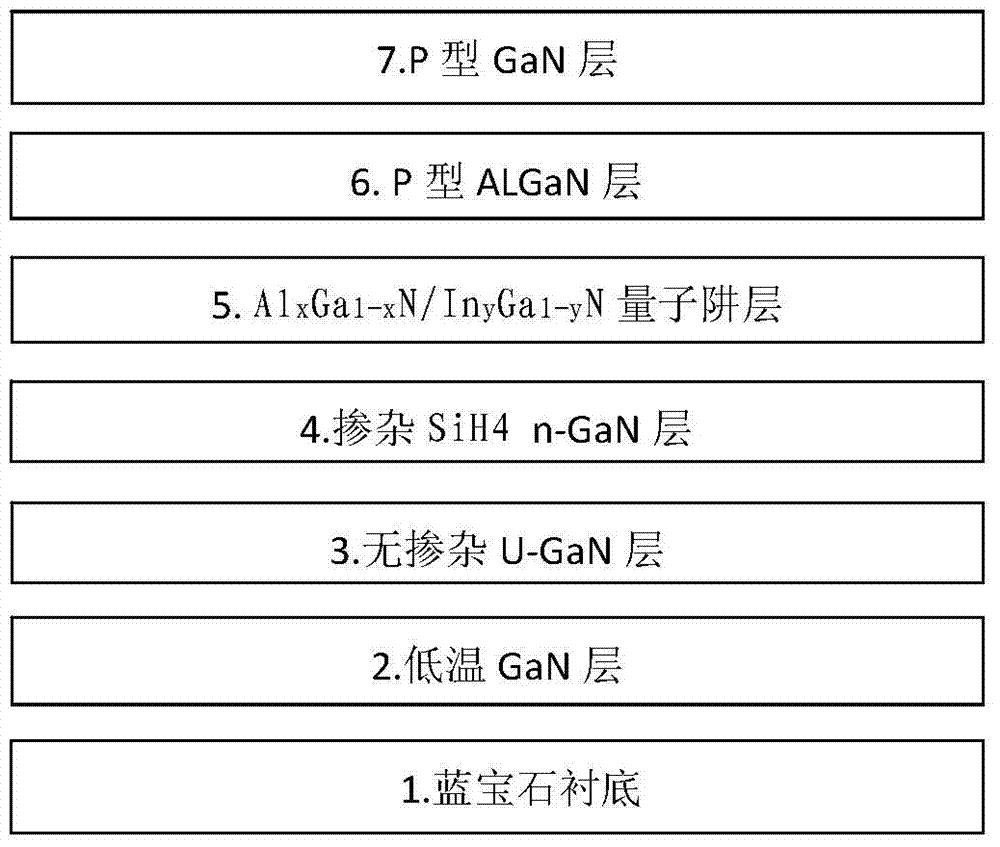

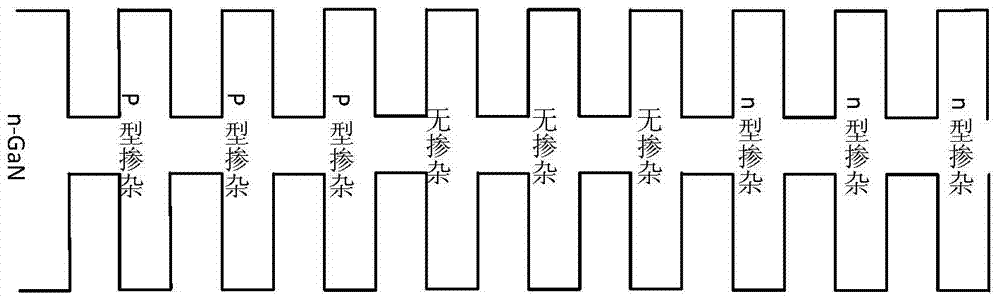

Epitaxial growth method for improving LED lighting efficiency

InactiveCN104332544AImprove luminous efficiencyComposite Luminous Efficiency DecreaseSemiconductor devicesQuantum wellP type doping

The invention provides a novel LED epitaxial growth method which can effectively improve the lighting efficiency of LED epitaxial structures. The method comprises the links of N-GaN layer growth, multi-quantum well layer growth and P-GaN layer growth, wherein the multi-quantum well layer is of a structure of a plurality of pairs of AlxGa <1-x> N / InyGa <1-y> N, wherein x is more than 0 and less than 1, and y is more than 0 and less than 1; the multi-quantum well layer growth link includes three growth stages in sequence, wherein the AlxGa1-xN quantum barrier is subjected to p type doping in the first stage, the AlxGa1-xN quantum barrier is not doped in the second stage, and the AlxGa1-xN quantum barrier is subjected to n type doping in the third stage; a p type doped AlGaN stopping layer grows, and then the P-GaN layer growth link is performed.

Owner:西安利科光电科技有限公司

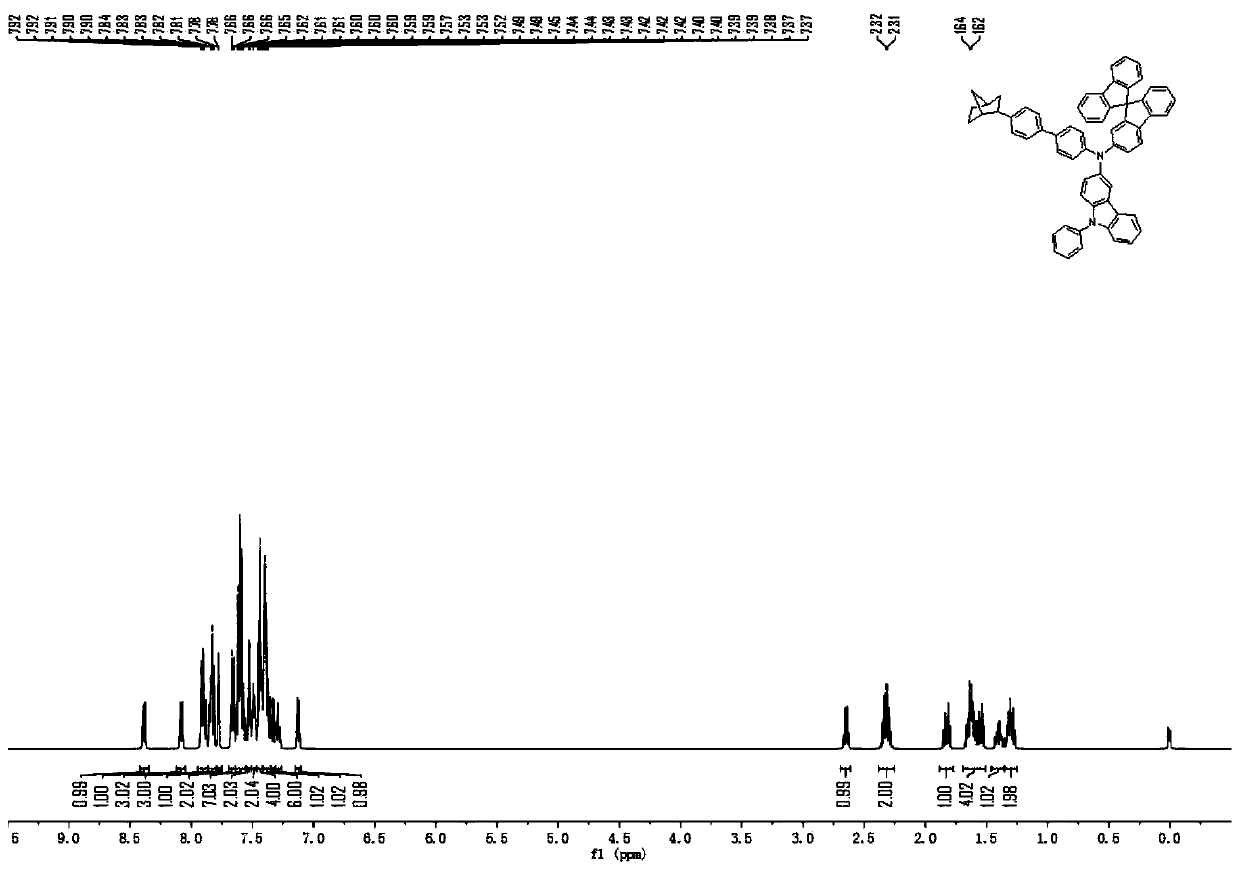

Aromatic amine compound and organic electroluminescent devices thereof

ActiveCN110845394AHigh glass transition temperatureHigh triplet energy levelOrganic chemistrySolid-state devicesOrganic electroluminescenceOptoelectronic materials

The invention provides an aromatic amine compound and organic electroluminescent devices thereof, and relates to the technical field of organic photoelectric materials. According to the invention, a specific heteroaryl group and a bicyclic heptane group are introduced into a triarylamine structure to obtain the aromatic amine compound disclosed by the invention; the aromatic amine compound has good hole transport capability, high glass transition temperature, excellent thermal stability, excellent film-forming property, high refractive index and simple synthesis process, can be applied to theorganic electroluminescent devices as a hole transport layer and / or a covering layer, can effectively solve the problems of poor thermal stability, low luminous efficiency and short service life of the organic electroluminescent devices; and the advantages of high luminous efficiency and long service life of the organic electroluminescent devices are achieved.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

Fire retardant coating with photocatalytic performance and preparation method thereof

InactiveCN104744976AReduce environmental pollutionLow costFireproof paintsPhotocatalytic degradationSolvent

The invention discloses a fire retardant coating with photocatalytic performance and a preparation method thereof. The fire retardant coating is obtained by mixing and stirring a base material, a catalyst, a charring agent, a foaming agent, filler, a pigment, a solvent, a disperser, a dryer, a drying aid and a nano-mother solution. By adopting the preparation method provided by the invention, the environment pollution can be furthest reduced, the recycling economical production of the product can be realized and about 20% of the cost can be reduced; the fire retardant coating prepared by the invention has excellent performances of high strength, rapid hardness, washing resistance, water resistance, alkali resistance and freezing resistance, particularly has an outstanding feature of degrading the formaldehyde gas in the room through photocatalysis and has a natural, non-toxic, pollution-free environment-friendly safety performance.

Owner:CHINA MCC17 GRP

Deep UV LED

PendingCN107180899AImprove internal quantum efficiencyIncrease transmit powerSemiconductor devicesElectron holeQuantum efficiency

The invention provides a deep UV LED, which includes a substrate; an undoped buffer layer located on the surface of the substrate; an N type AlGaN layer on the undoped buffer layer and far away from the surface of the substrate; a multi-quantum well structure on the undoped buffer layer and far away from the surface of the substrate; and a P type AlGaN structure on the multi-quantum well structure and far away from the surface of the substrate, wherein the V type Al component of the P type AlGaN structure is gradually changed. The P type AlGaN structure with the gradually changed V type Al component is subjected to polarization doping. The Al component in the P type AlGaN structure with the gradually changed V type Al component is different from the Al component in the multi-quantum well structure. The P type AlGaN structure with the gradually changed V type Al component is far away from a P type GaN layer on the surface of the substrate. Based on the P type AlGaN structure with the gradually changed V type Al component, obtained electron holes are higher in concentration. Therefore, the internal quantum efficiency and the emission power of the UV LED are improved.

Owner:GUANGDONG UNIV OF TECH

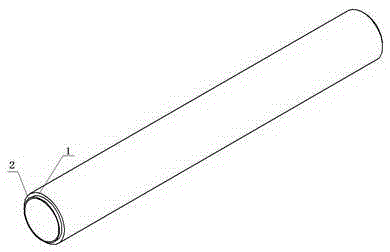

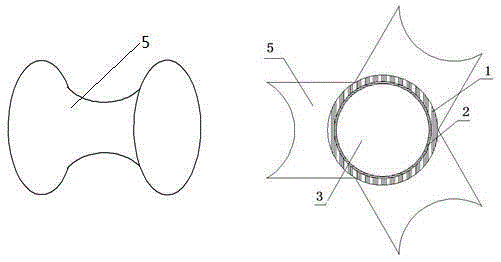

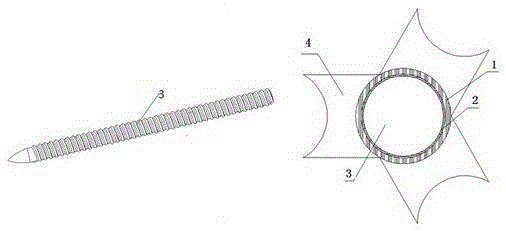

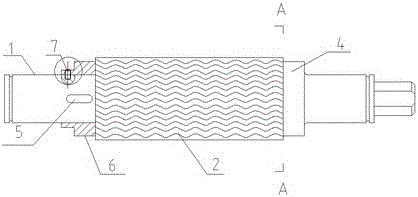

Process for rolling inner-corrugated combined surface metal composite tube

The invention provides a process for rolling an inner-corrugated composite surface metal composite tube. The process for rolling the inner-corrugated composite surface metal composite tube comprises the steps: selecting a metal parent tube and a metal coated tube, and manufacturing a tube blank by combining the coated tube outside and the parent tube inside, wherein the deformation resistance of the coated tube is smaller than the deformation resistance of the parent tube; rolling the manufactured composite tube blank in a composite roughing mill, in which a spiral corrugated mandril is mounted, thereby obtaining a composite tubular billet, the inner surface and the composite surface of which have a spiral corrugated shape, wherein the spiral corrugated shape can be circular arc, ellipse, sine wave, triangle, trapezoid or rectangle, the corrugated height is (0.1-10) times of the thickness of the coated tube, and the width of the corrugated is (3-20) times of the height of the corrugated; putting the composite tubular billet in a composite finishing mill, in which a smooth circular hole is formed, to roll the corrugated shape of the inner surface to be level and round till the required tube wall thickness is obtained, thereby obtaining a composite tube. According to the process for rolling the inner-corrugated composite surface metal composite tube, by utilizing corrugated composite surfaces of the roughly rolled coated tube and parent tube, the difference of metal plastic deformation caused by dissimilar metal deformation resistance difference is solved, the composite strength and force of metal layers are increased, and the composite rate is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

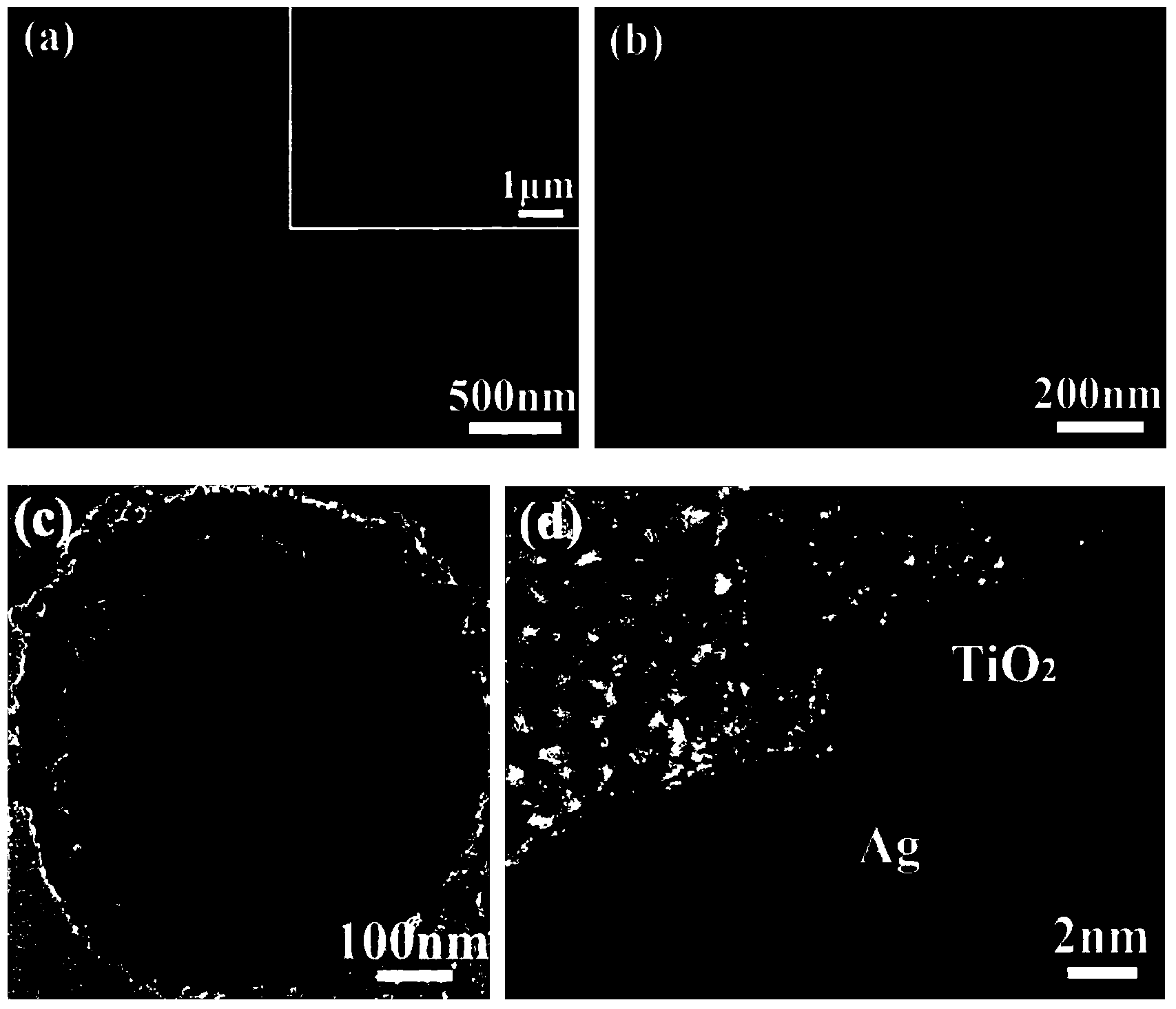

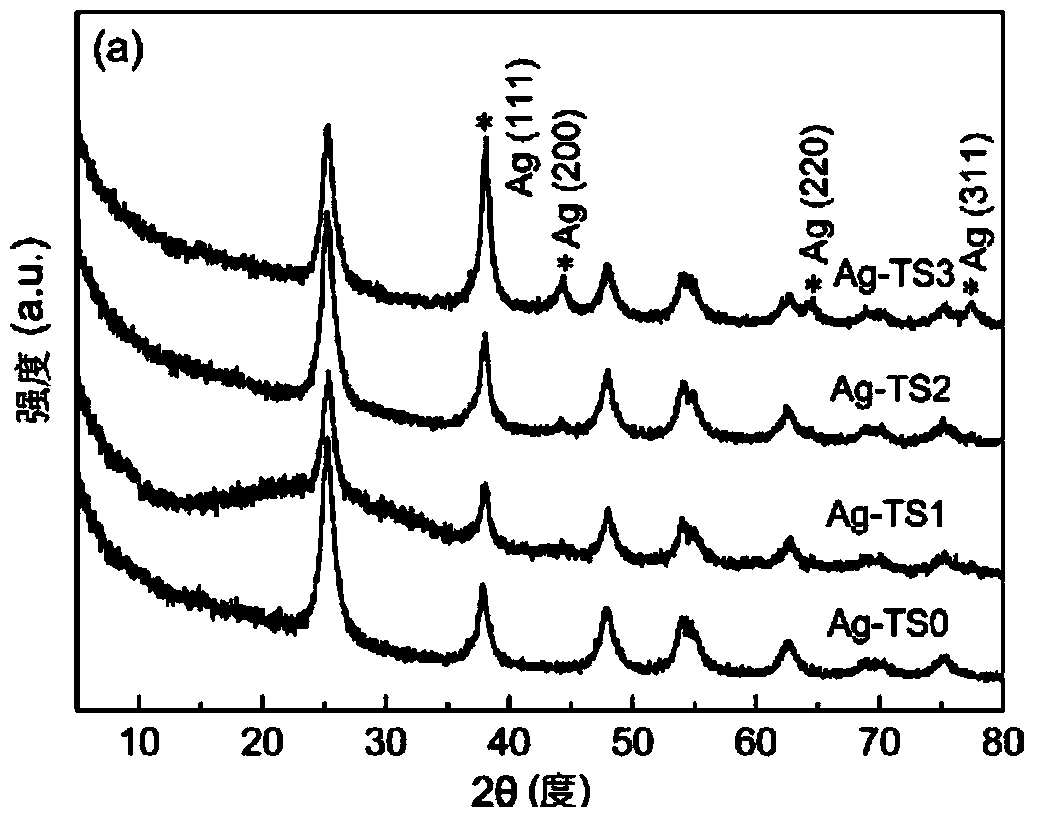

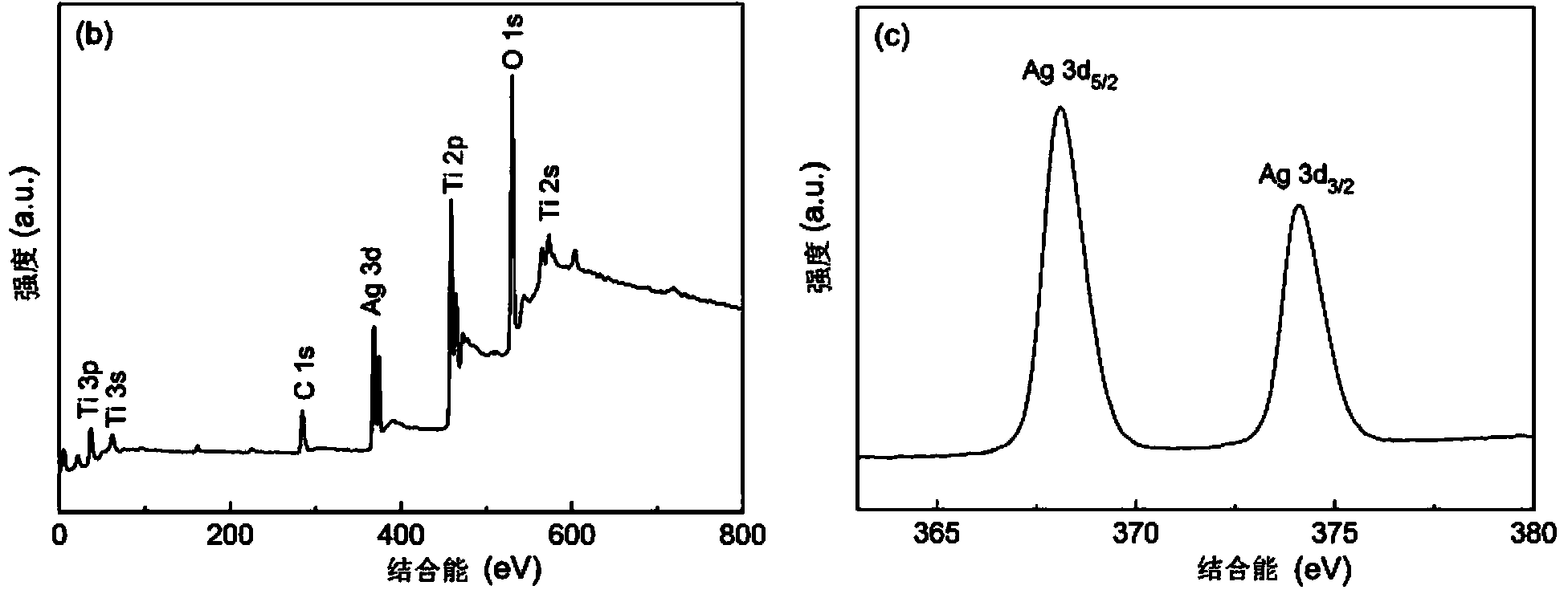

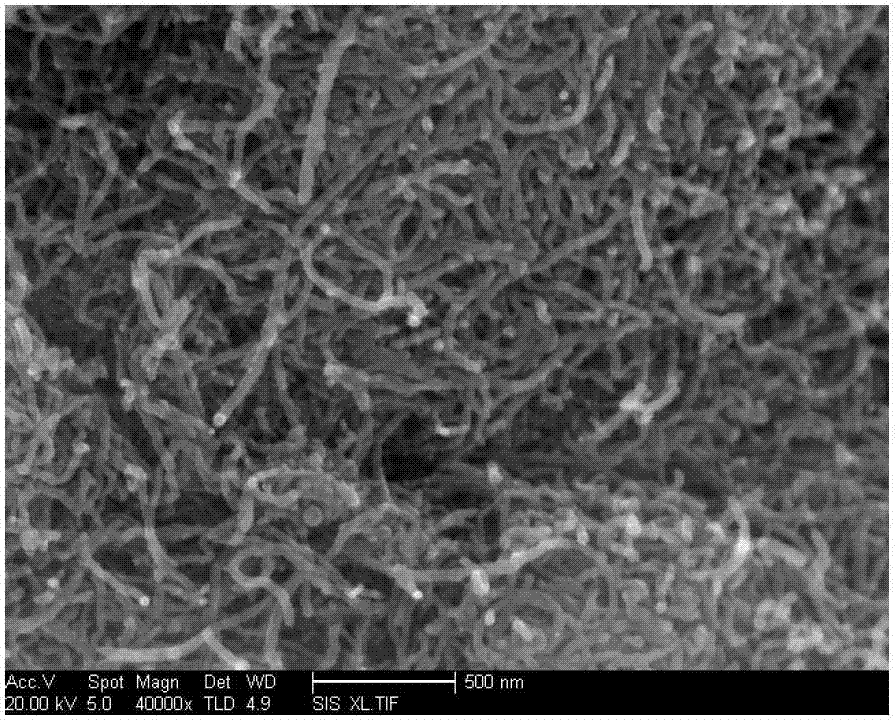

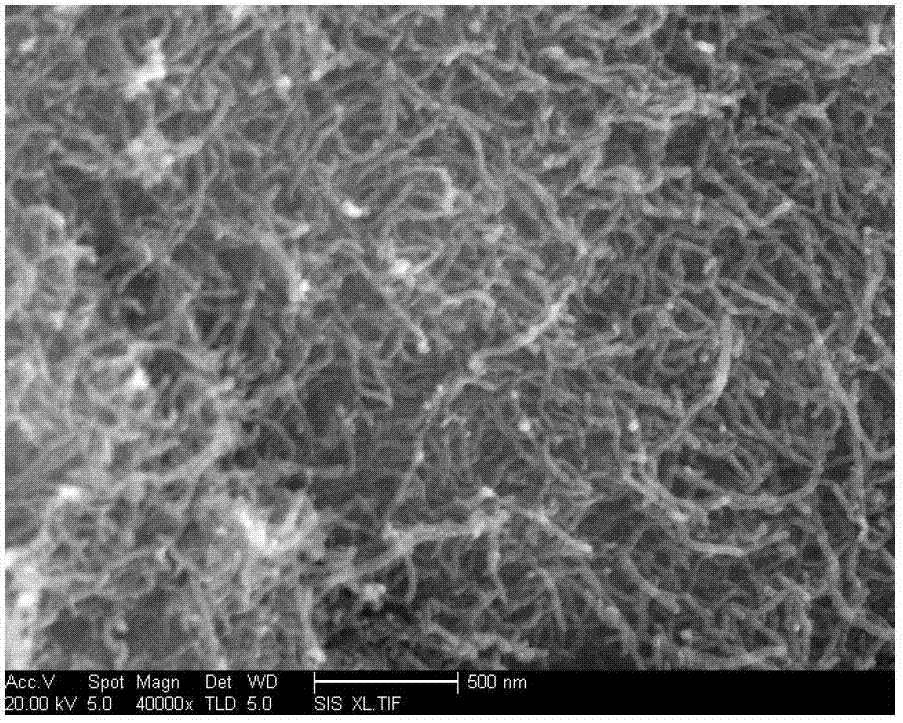

Titanium dioxide-silver composite ball adopting core-shell structure as well as preparation method and application of ball

ActiveCN103816897ALarge specific surface areaWith photocatalytic degradation performanceWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsUltraviolet lightsPhotocatalytic degradation

The invention discloses a titanium dioxide-silver composite ball adopting a core-shell structure as well as a preparation method and an application of the ball. The diameter of a ball shell of the ball adopting the core-shell structure ranges from 0.5 mu m to 1 mu m, the diameter of a ball core ranges from 0.4 mu m to 0.8 mu m, and the ball comprises, in percentage by weight, 85 %-95 % of titanium dioxide and 5 %-15 % of silver; and the ball shell and the ball core are composited by titanium dioxide nano-particles and silver nano-particles, the diameter of each titanium dioxide nano-particle ranges from 8 nm to 12 nm, and the diameter of each silver nano-particle ranges from 20 nm to 100 nm. According to the method, titanyl sulfate, urea and silver nitrate are added into an ethanol water solution with the concentration of 45%-55% according to the molar ratio of (1.5-2.5): (3.5-4.5): (0.044-0.22), and a mixed solution is obtained; the molar ratio of titanyl sulfate in the mixed solution to ethanol in the ethanol water solution is 1: (50-250); and then, the mixed solution is placed in an airtight microwave heating state and reacts at the temperature ranging from 160 DEG C to 200 DEG C, and a target product is prepared. The titanium dioxide-silver composite ball can be widely applied to ultraviolet light catalytic degradation of water polluted by hexavalent chromium or methylthionine chloride.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

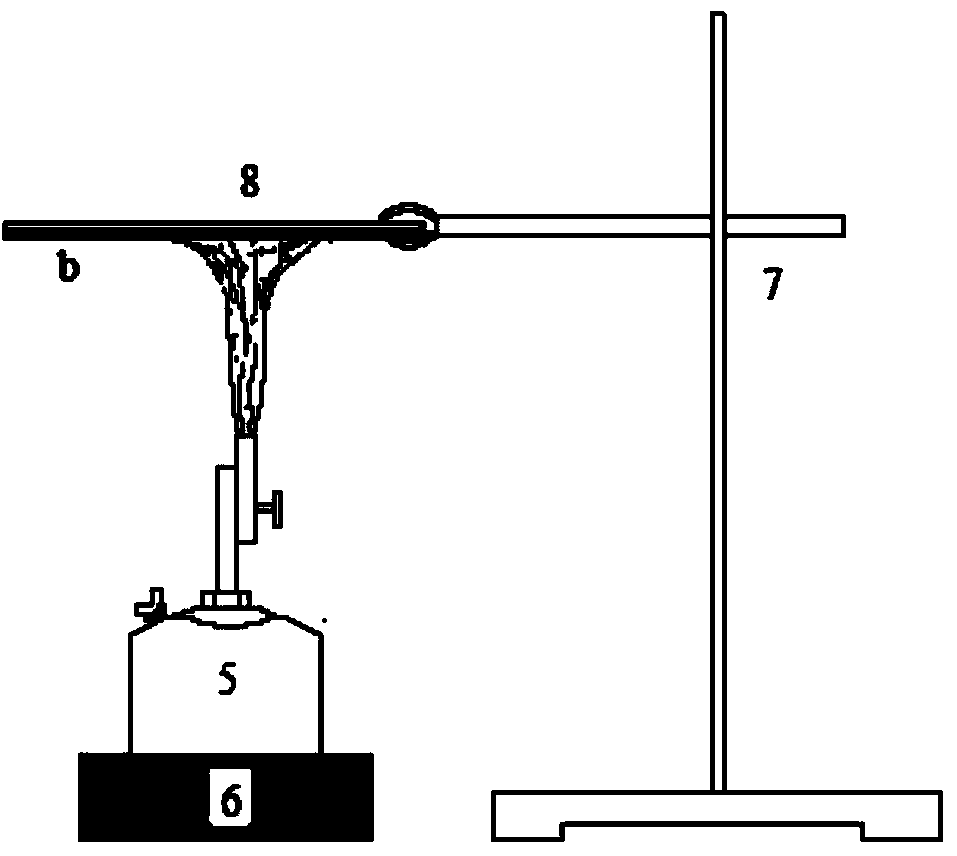

Preparation method of hydroxylated multi-wall carbon nanotube-polysilane composite material

The invention provides a preparation method of a hydroxylated multi-wall carbon nanotube-polysilane composite material, relates to a preparation method of a multi-wall carbon nanotube-polysilane composite material, and aims to solve the problems that the synthesis steps are complicated, the reaction is difficult to control and the repetitiveness is poor in the existing preparation method of a multi-wall carbon nanotube-polysilane composite material and the prepared multi-wall carbon nanotube-polysilane composite material is low in silicon element content. The method comprises the following steps: 1, purifying to obtain a purified multi-wall carbon nanotube; 2, performing hydroxylation reaction on the purified multi-wall carbon nanotube to obtain a hydroxylated multi-wall carbon nanotube; 3, grafting the hydroxylated multi-wall carbon nanotube with a silane monomer to obtain a silane-multi-wall carbon nanotube; and 4, performing polymerization reaction to obtain the hydroxylated multi-wall carbon nanotube-polysilane composite material. The invention is mainly used for the preparation of the hydroxylated multi-wall carbon nanotube-polysilane composite material.

Owner:HARBIN UNIV OF SCI & TECH

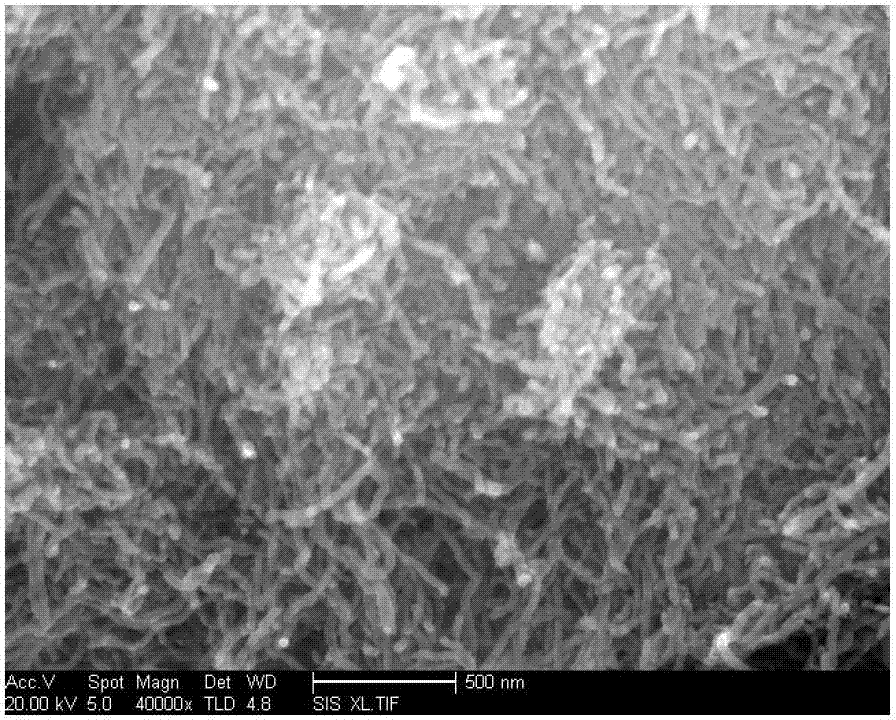

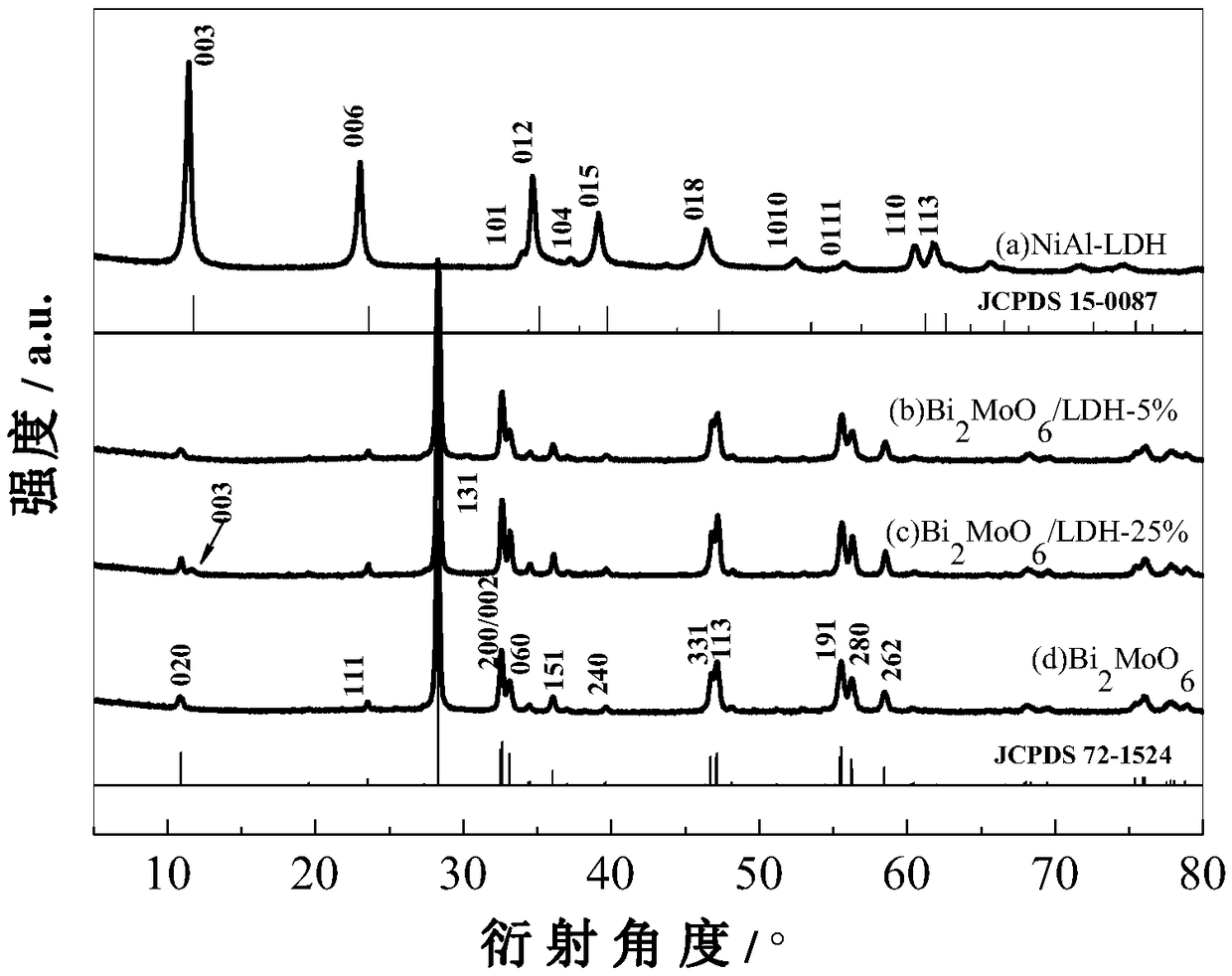

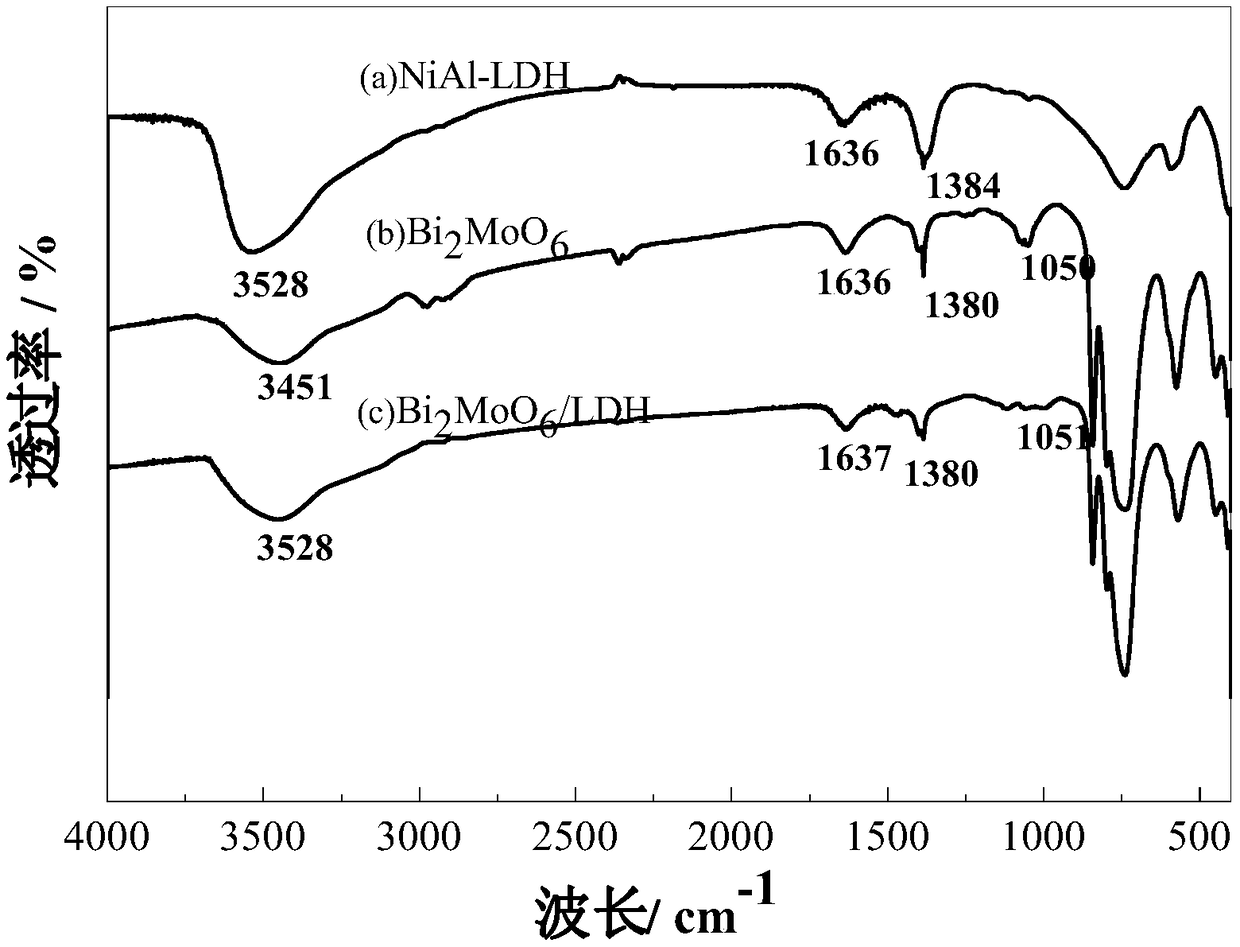

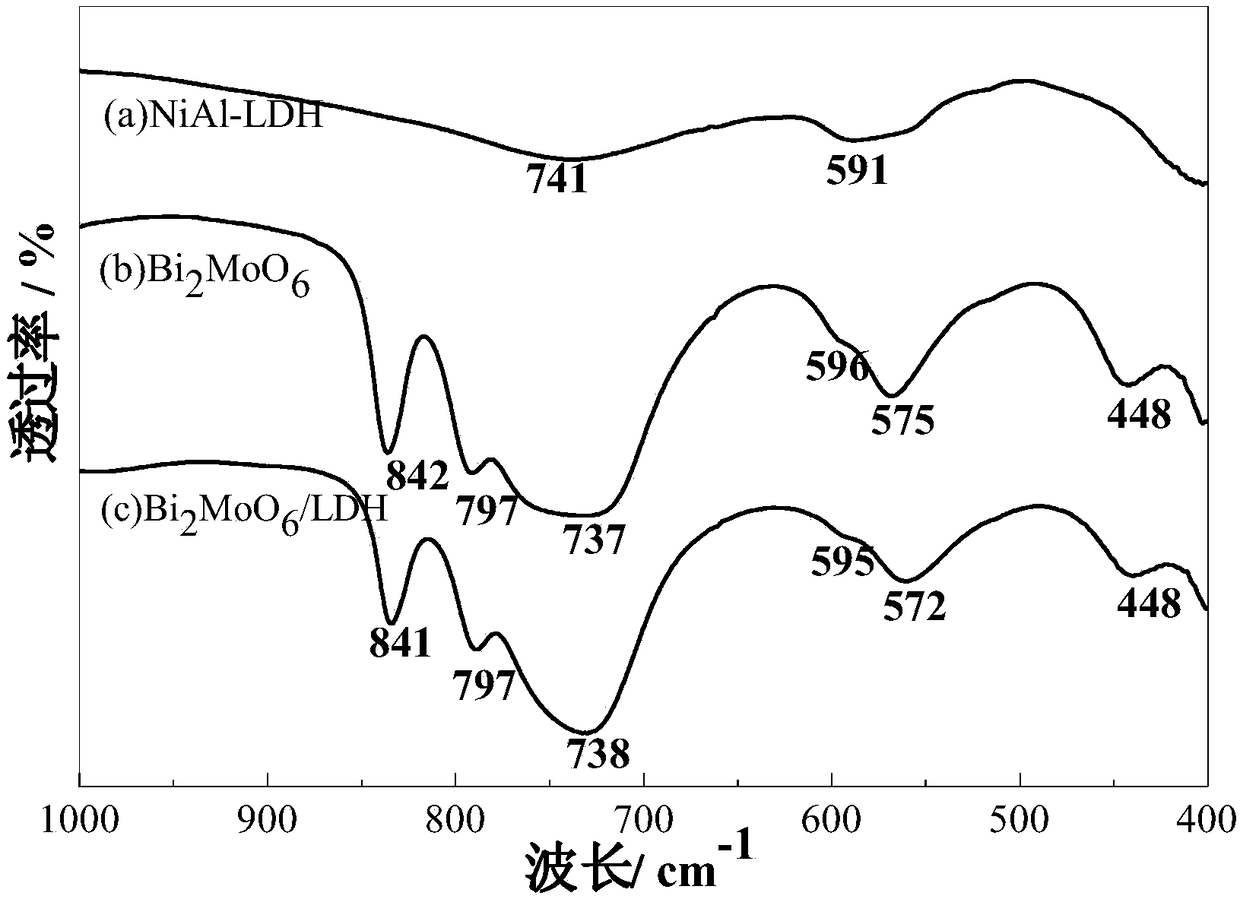

Hydrotalcite and bismuth molybdate heterojunction composite photocatalyst as well as preparation method and application thereof

ActiveCN109317137AFully contactedEvenly distributedWater/sewage treatment by irradiationWater contaminantsHydrotalciteBismuth preparation

The invention discloses a hydrotalcite and bismuth molybdate heterojunction composite photocatalyst as well as a preparation method and application thereof. The catalyst is formed by assembling and compounding nickel-aluminum hydrotalcite nanosheets and bismuth molybdate nanosheets layer-by-layer by virtue of the interlayer electrostatic effect through a hydrothermal method. The preparation methodcomprises the following steps: firstly preparing Bi2MoO6; secondarily synthesizing a Bi2MoO6 / NiAl-LDH semiconductor composite material: weighing Bi2MoO6 according to a formula, dissolving the weighedBi2MoO6 in water, and ultrasonically processing for standby use; then weighing Ni(NO3)2-6H2O and Al(NO3)3-9H2O according to a molar ratio of 2 to 1, adding a chelating agent, dissolving in water, andadjusting the pH to be alkaline by using CH4N2O; uniformly mixing and stirring the two solutions, adding the mixed solution into a reaction kettle, and heating and reacting for 48 hours at 100 to 150DEG C; after the reaction is ended, naturally cooling to the room temperature, centrifuging, washing, and drying to obtain the hydrotalcite and bismuth molybdate heterojunction composite photocatalyst. The semiconductor composite material is high in catalytic activity under the visible light; the lamellar self-assembling synthetic method has certain instruction significance for the synthesis andapplication of other photocatalysts.

Owner:YANCHENG INST OF TECH

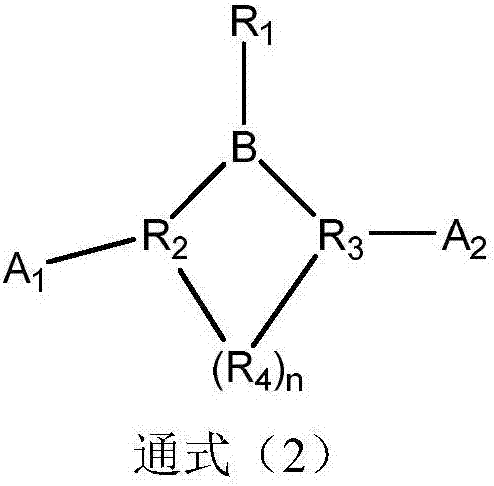

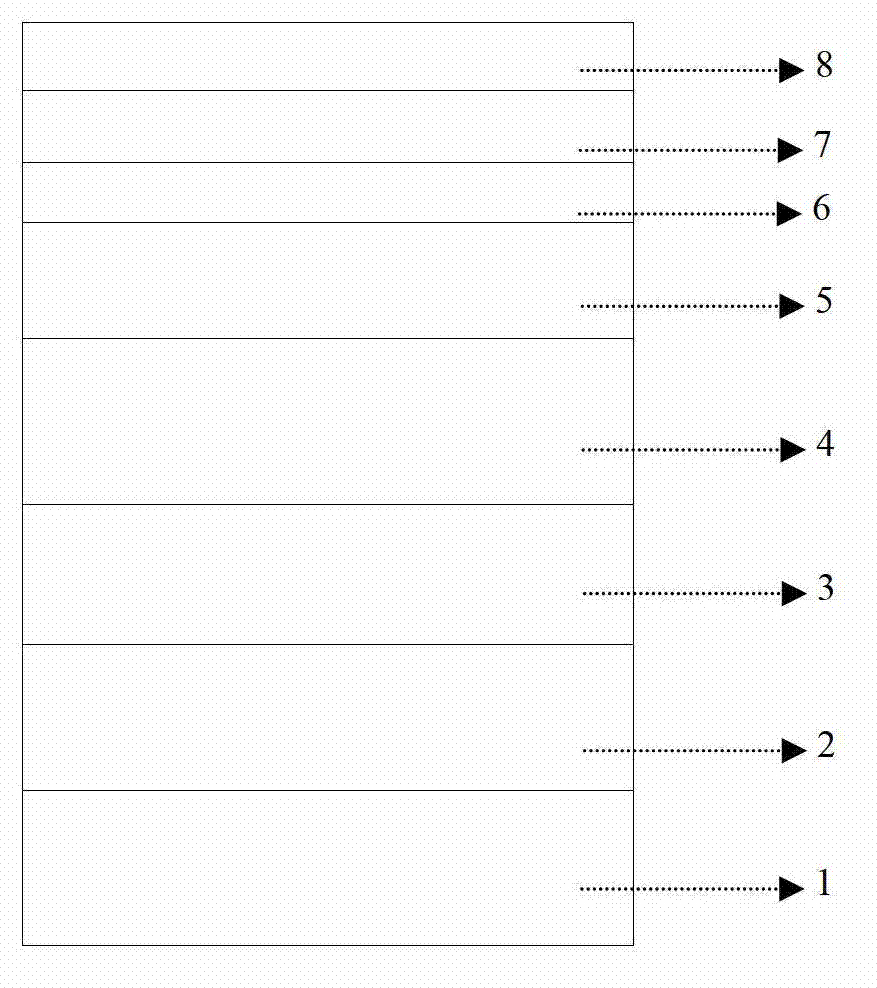

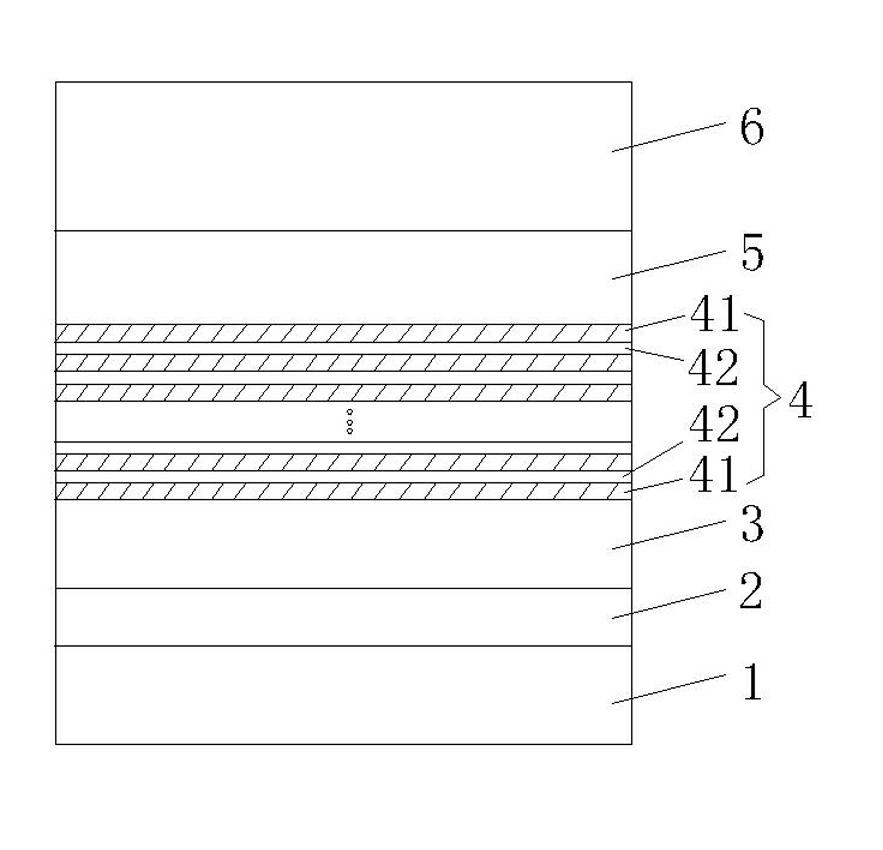

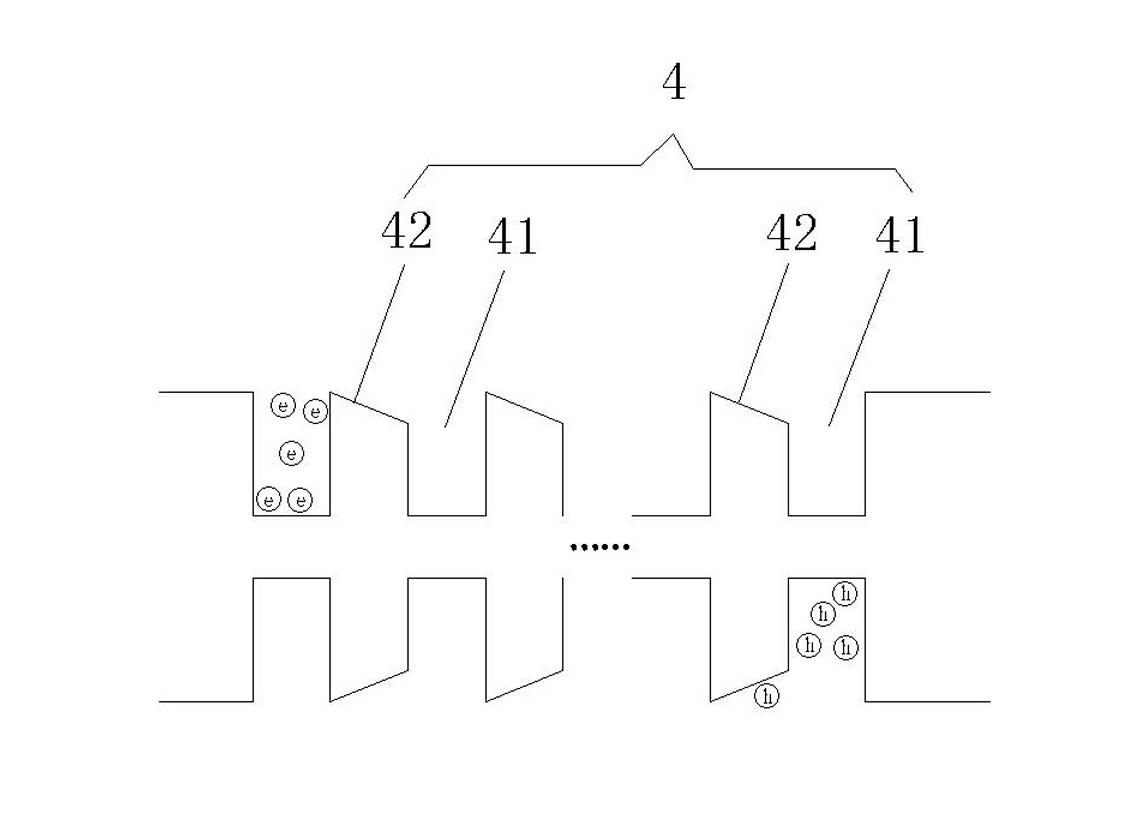

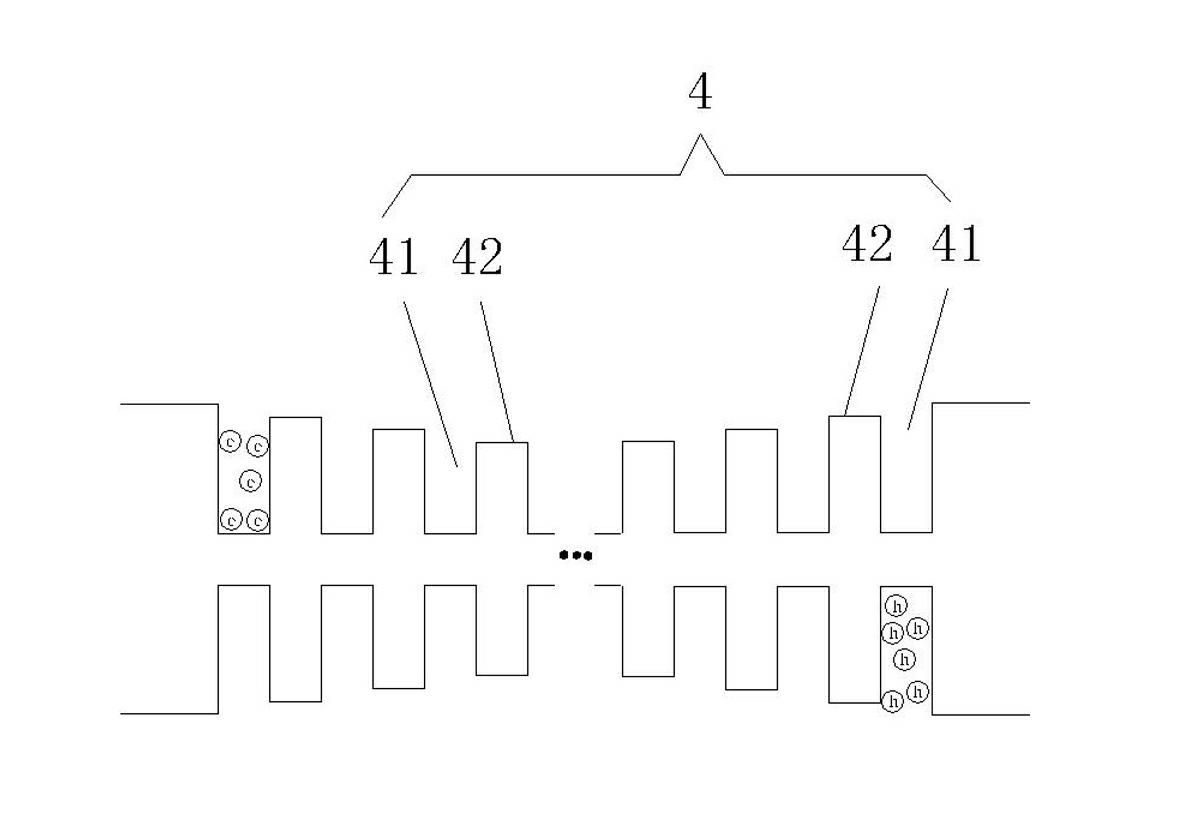

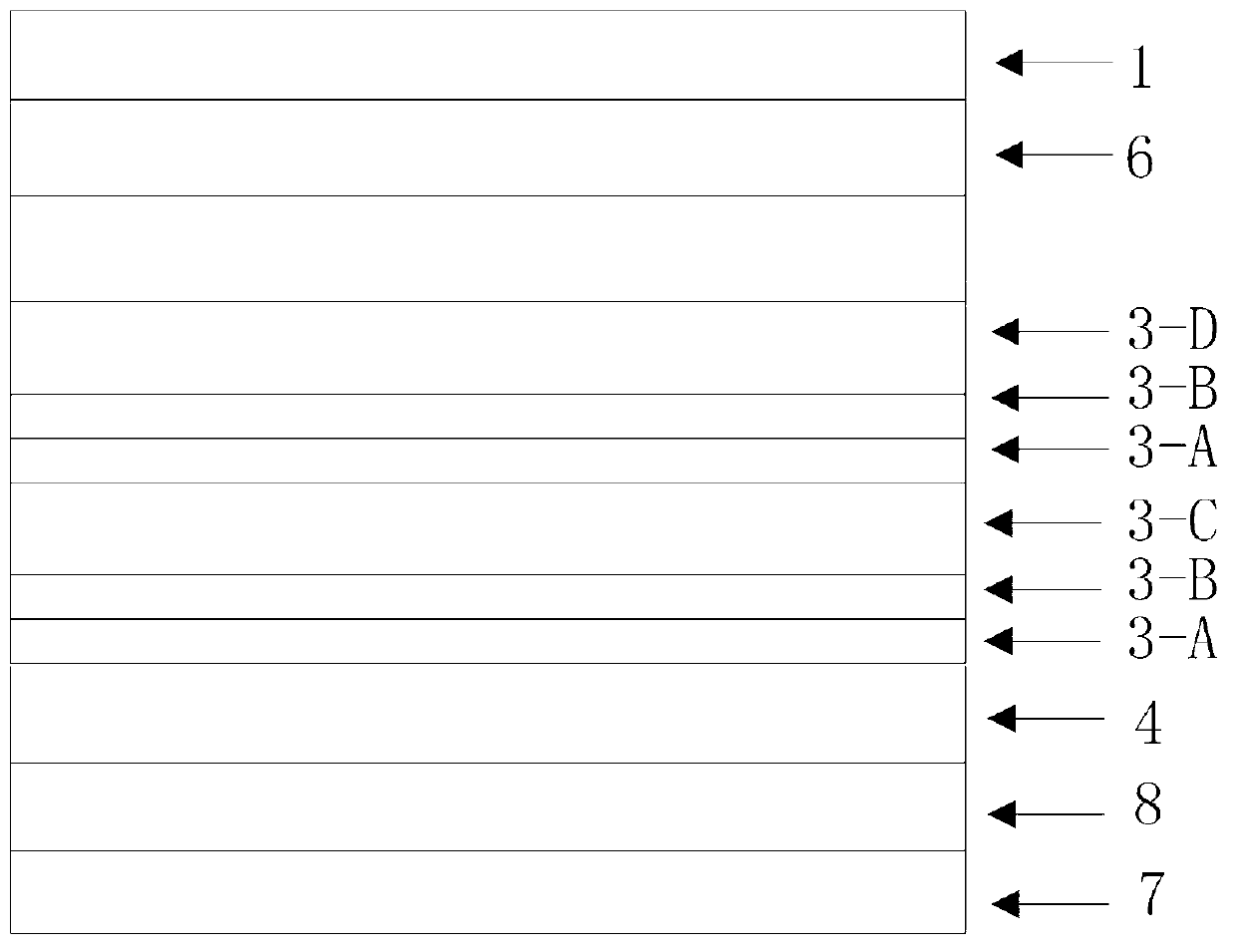

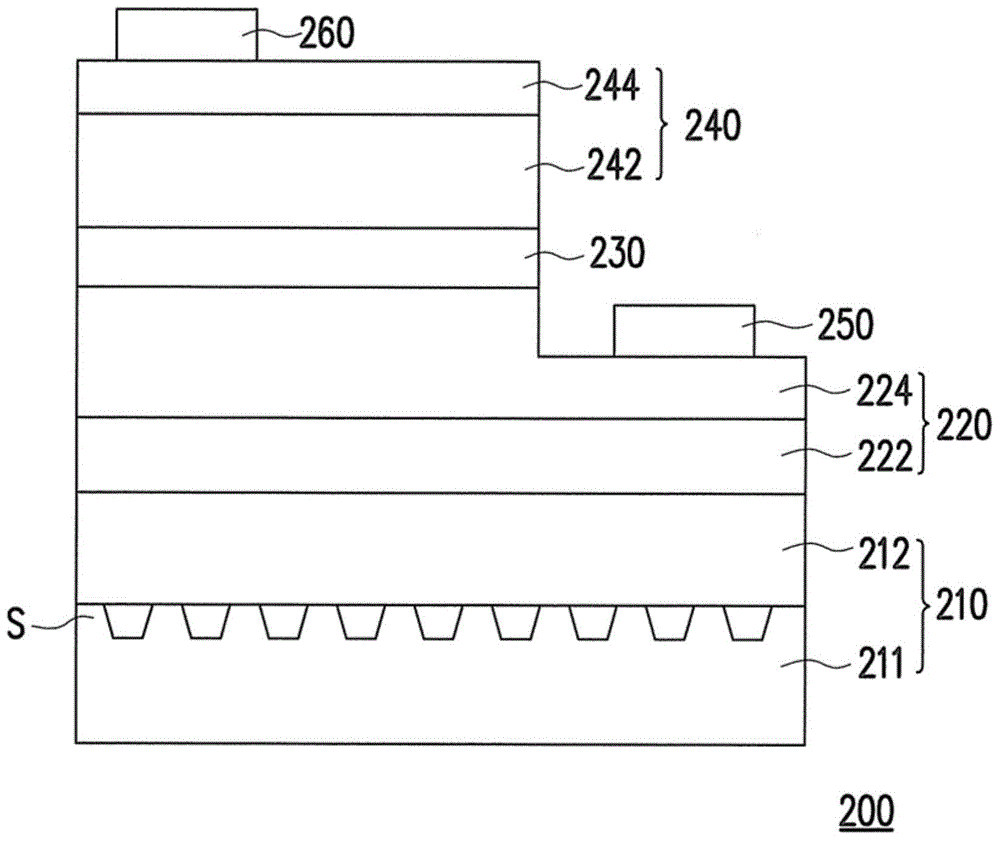

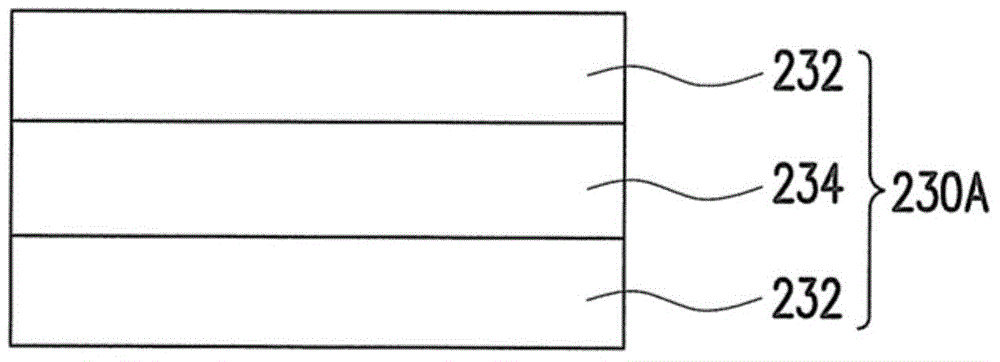

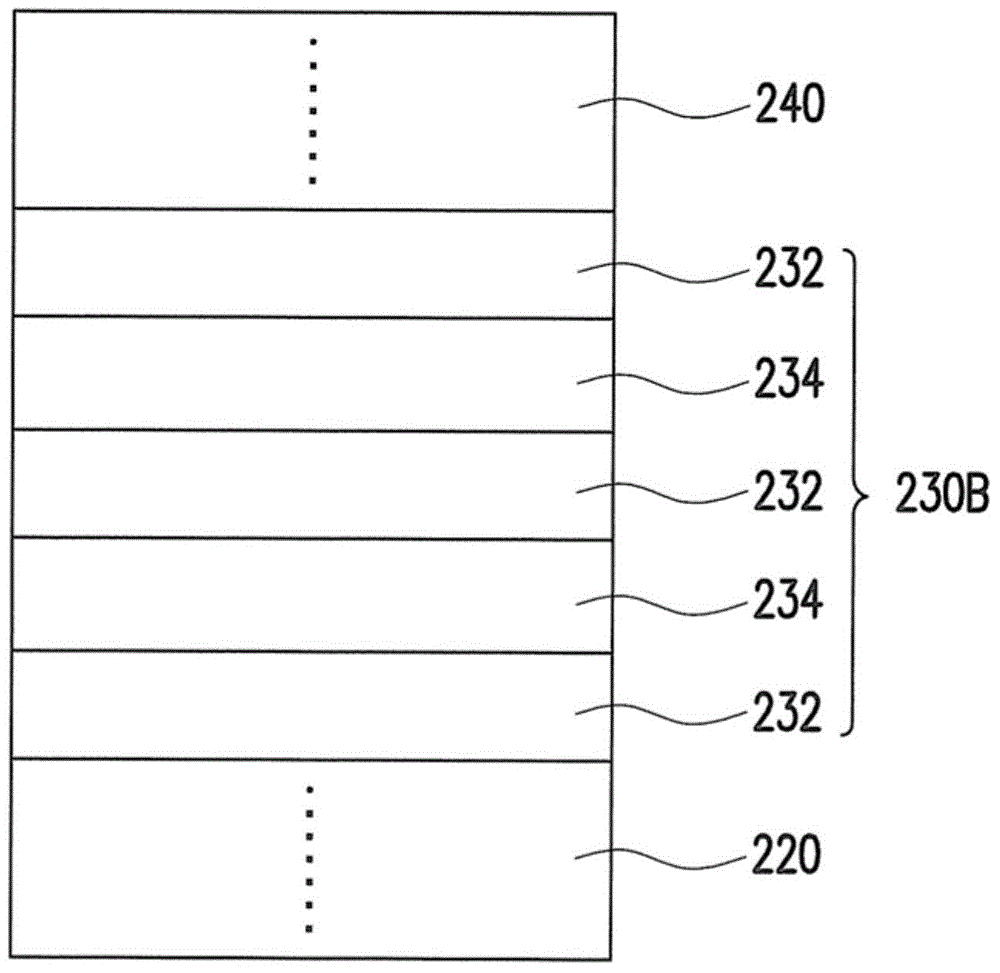

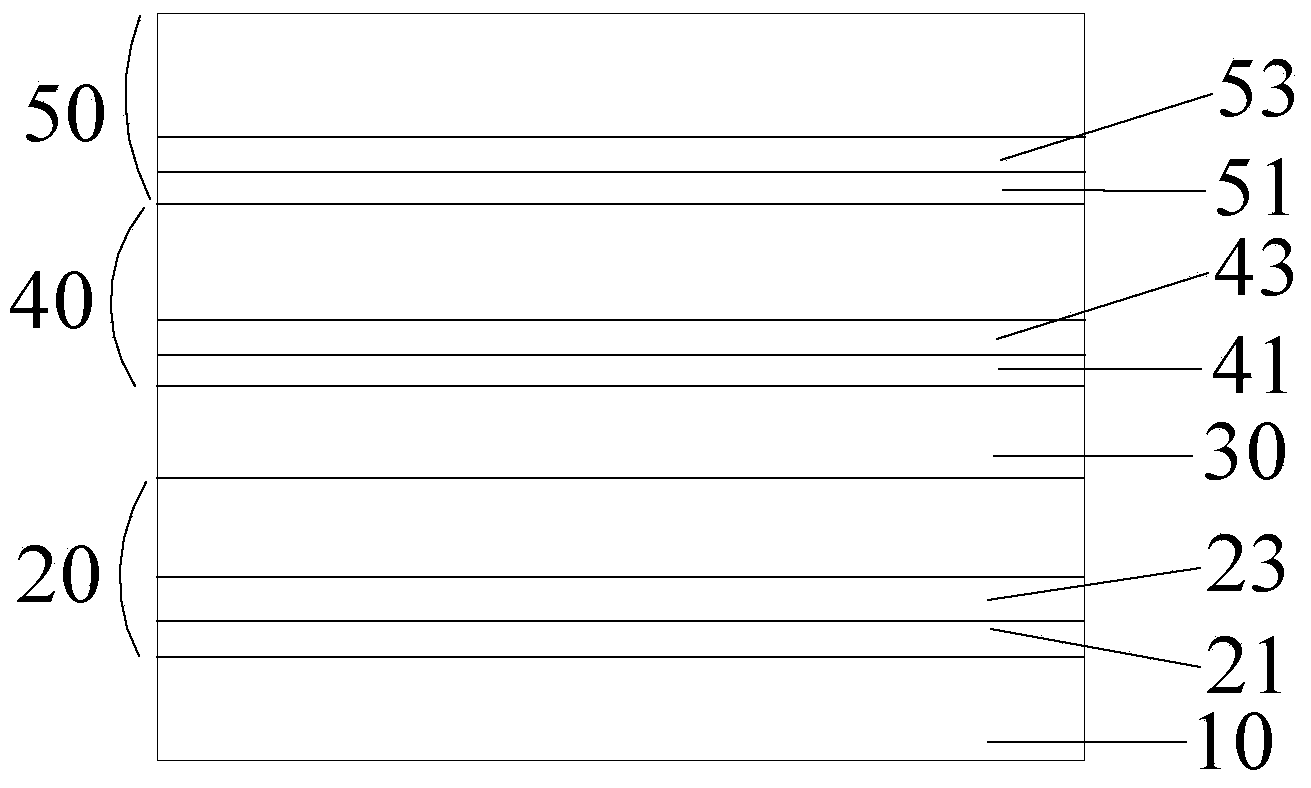

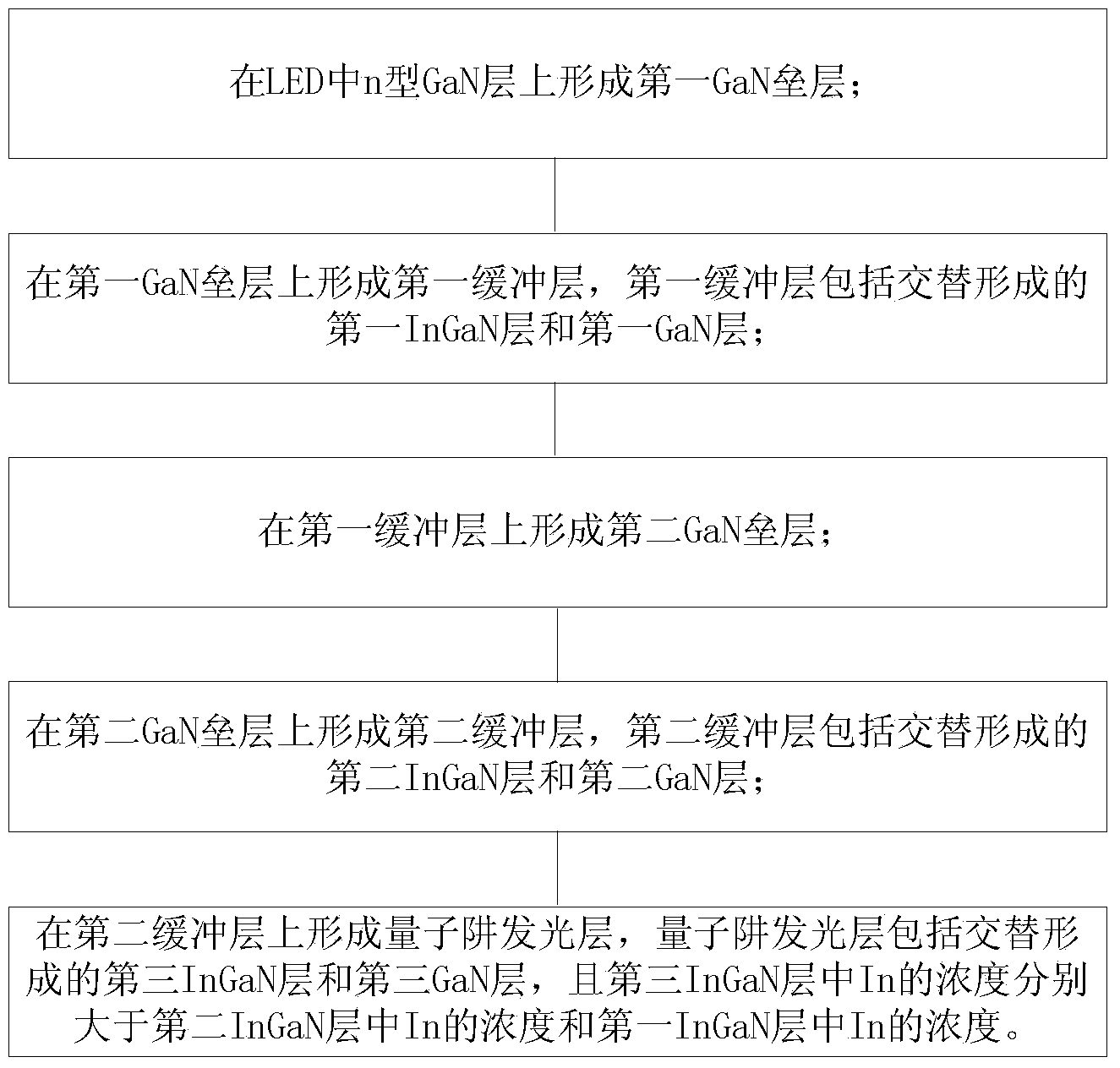

Growing method for duplex multi-quantum well luminescent layer structure and LED epitaxial structure

ActiveCN103346219AImprove light extraction efficiencyImprove compound rateSemiconductor devicesLarge sizeWave function

The invention provides a growing method for a duplex multi-quantum well luminescent layer structure and an LED epitaxial structure. A well luminescent layer of the epitaxial structure comprises six to eight unit layers, wherein each unit layer comprises a first well layer, a second well layer, a first epitaxial layer, a first well layer, a second well layer and a second epitaxial layer from top to bottom in sequence. According to the growing method for a duplex multiple-quantum well luminescent layer structure and the LED epitaxial structure, a duplex multiple-quantum well is adopted, the situation that separation of wave functions is caused by the stress of well layers and epitaxial layers in a traditional multi-quantum well is improved, and the situation that the hole concentration of the well layers is too low due to the epitaxial width in the traditional multi-quantum well is improved. Efficiency obtaining of the quantum well inside an LED chip is improved, the brightness of medium and small size LED chips is improved in macro view, and the lighting effects of large size LED chips are improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

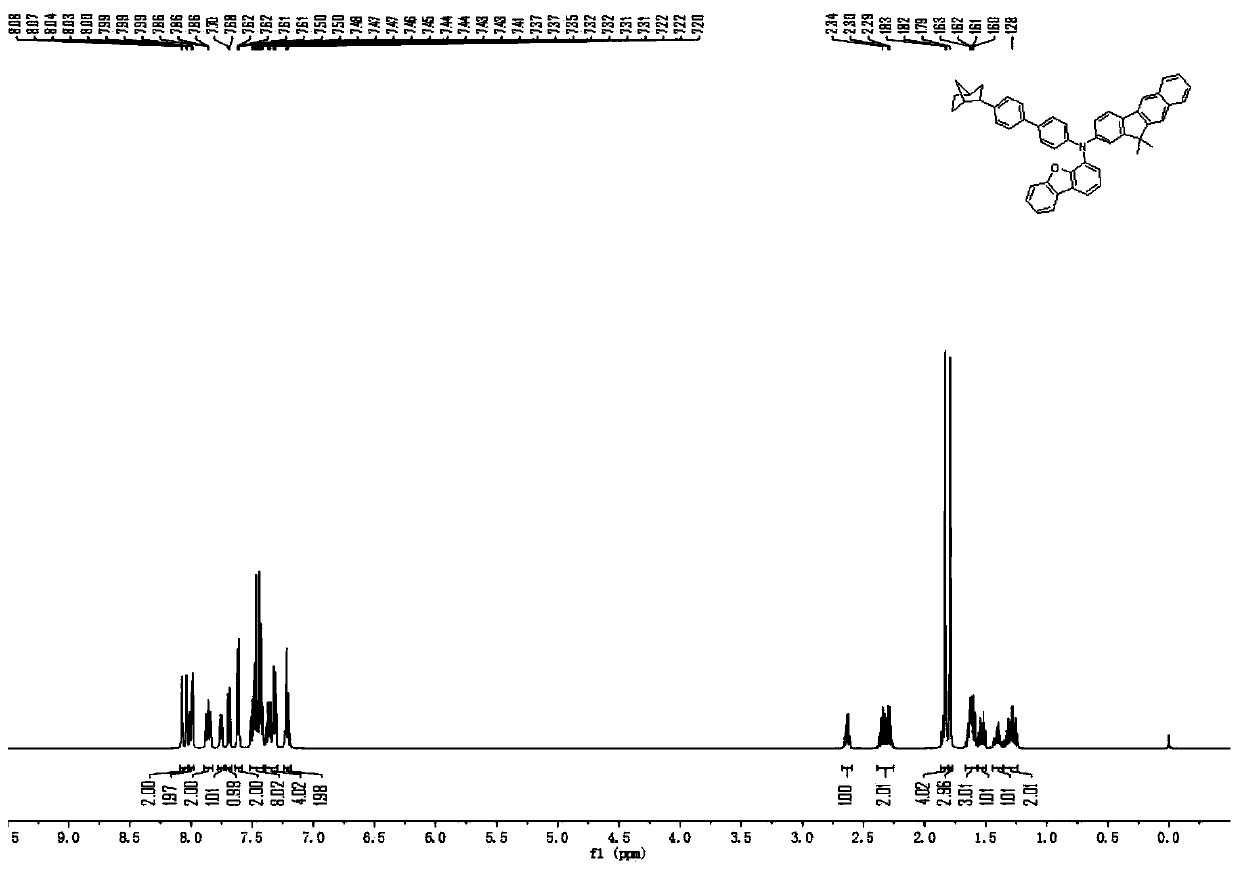

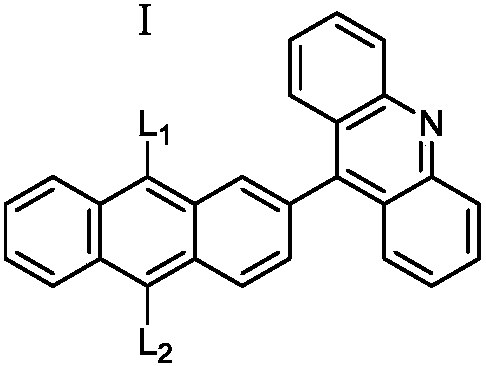

Anthracene-containing compound, synthesis method thereof, and organic electroluminescent device

InactiveCN107602467ASolution to short lifeImprove luminous efficiencySilicon organic compoundsSolid-state devicesAnthraceneAcridine

The invention provides an anthracene-containing compound, a synthesis method thereof, and an organic electroluminescent device, and relates to the technical field of organic photoelectric materials. In the invention, different ligands are connected to a main structure formed by connecting anthracene and acridine, thus regulating molecular weight, [pi]-conjugation degree and electrophilicity of thematerial, enhancing charge transmission capability, balancing carrier injection and increasing glass transition temperature. The compound is not liable to crystallize and has good film forming performance. The synthesis method is simple and easy to carry out. The compound can be used for producing the organic electroluminescent device, especially as a luminescent layer main body and an electron transfer layer material in the organic electroluminescent device. The organic electroluminescent device has high luminous efficiency and long service life.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

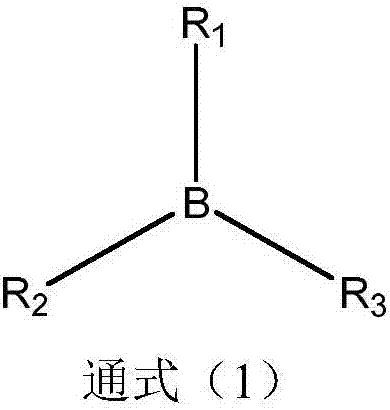

OLED (organic light-emitting device)

InactiveCN108658837AIncrease productionIncrease profitOrganic chemistrySolid-state devicesOrganic light emitting deviceOrganic electroluminescence

The invention discloses an OLED (organic light-emitting device) and relates to the technical field of organic light-emitting. The OLED is obtained from the compound in the general formula I as a holetransport layer and the compound in the general formula II as an electron transport layer. By means of an electron transport layer material and a hole transport layer material, electron migration speed of the electron transport layer can be increased, and the probability of carrier injection and recombination in the light emitting layer is increased by properly adjusting the hole transport layer,so that light-emitting efficiency of the device is increased and the service life of the device is prolonged; the driving voltage of the OLED can also be effectively reduced, and the problems of low light-emitting efficiency, short service life and high driving voltage in the prior art are solved; the materials are OLED material with excellent performance.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

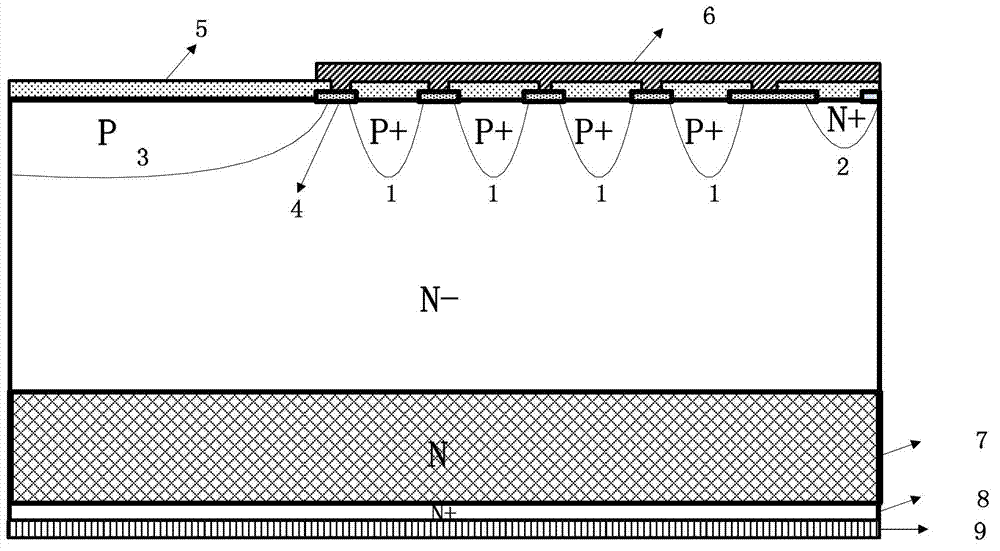

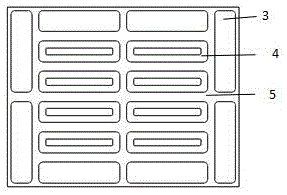

Preparation method of power device

ActiveCN103839805AImprove compound rateReduce tail currentSemiconductor/solid-state device manufacturingSemiconductor devicesCharge carrierAmorphous silicon

The invention discloses a preparation method of a power device, and belongs to the technical field of semiconductors. The method comprises the steps that an N type doped A-Si thin film layer is deposited on the upper surface of an N+ type substrate to form an N type A-Si field stop layer, after high temperature annealing, an N- epitaxial layer is formed on the N type A-Si field stop layer through an eptiaxial method, then an SiO2 thin film layer is formed on the upper surface of the N- eptiaxial layer, an annular area is exposed on the upper surface of the SiO2 thin film layer to form a protecting ring structure of a terminal; an annular area at the outermost periphery is exposed on a stop ring of the terminal, and then N+ type ion implantation and annealing are conducted to form a terminal area. According to the preparation method of the power device, the N type layer is formed through eptiaxial A-Si to be used as a field stop layer of the power device, rest carriers can be combined quickly, outward manifestation is that trailing currents which enable the power device to be shut off are shortened, shut-off time is shortened, and shut-off loss is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +2

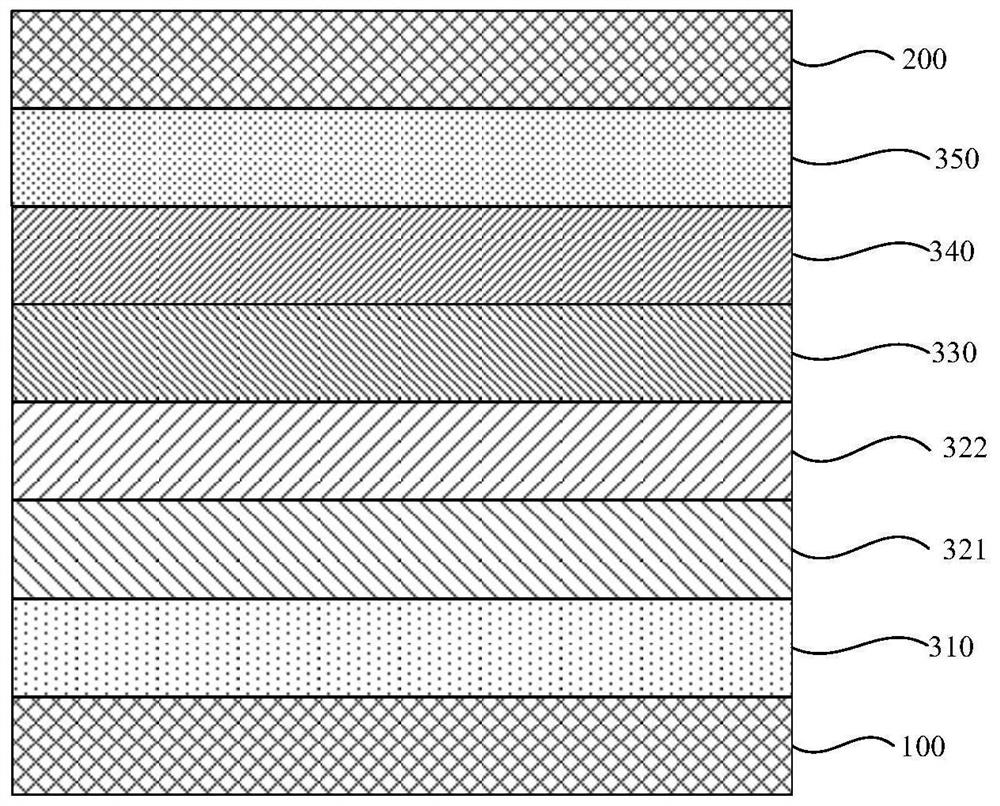

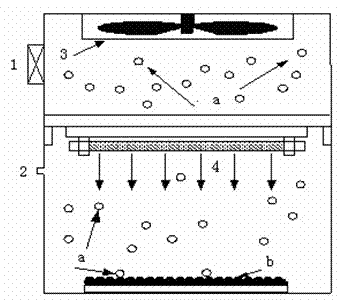

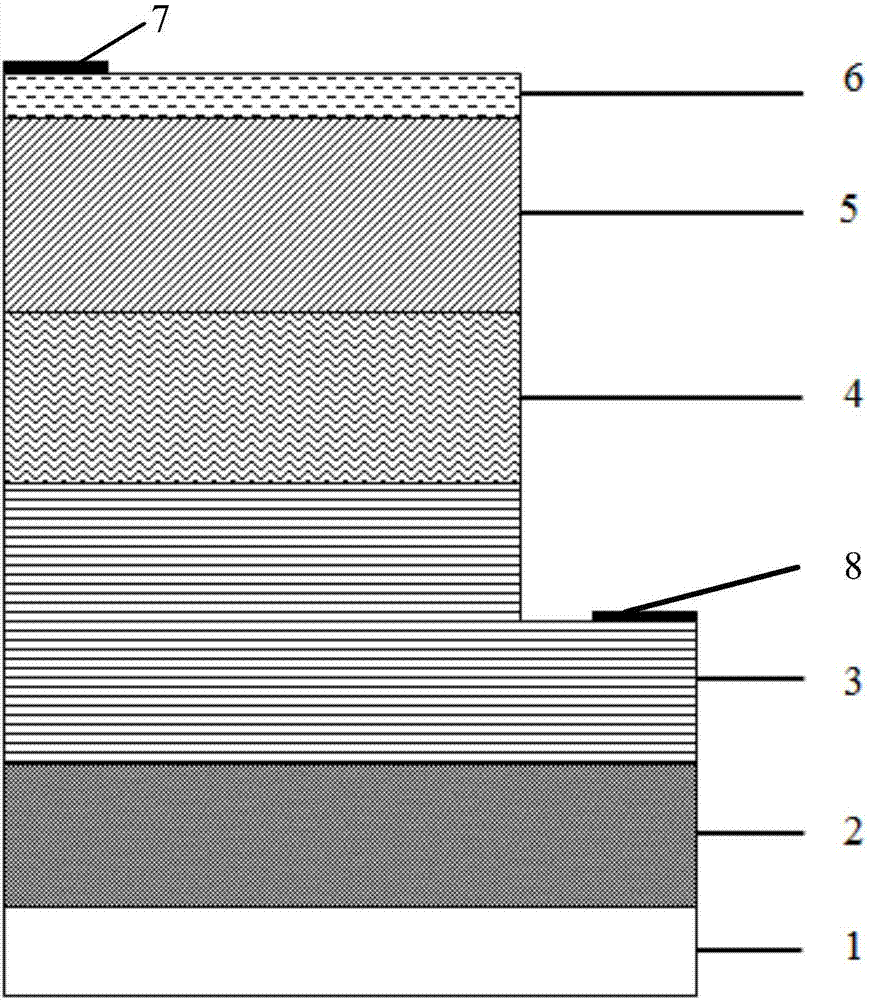

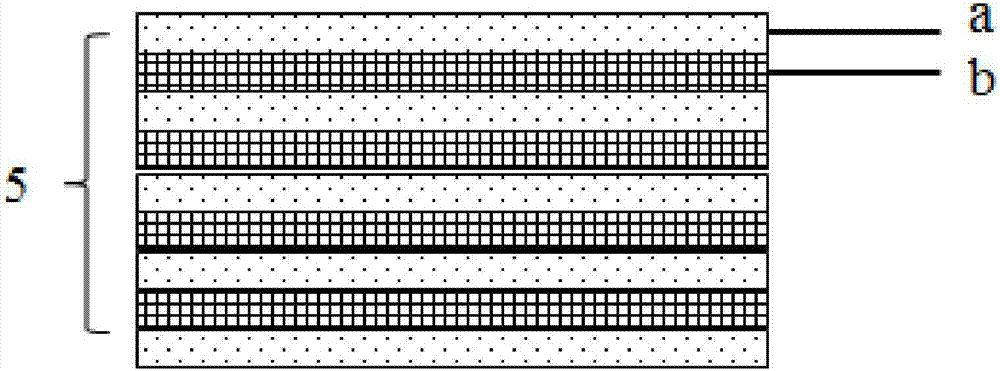

Luminescent device with illumination and communication double functions

ActiveCN105161581AImprove thermal conductivityImprove featuresSemiconductor devicesElectron holeQuantum well

The invention discloses a luminescent device with illumination and communication double functions. The luminescent device sequentially comprises a substrate layer, a buffer layer, an n-type layer, a quantum well layer, a p-type layer and a transparent electrode layer, wherein the n-type layer is used for generating electrons; the quantum well layer is compounded with electron holes; the p-type layer is used for generating holes; and a plurality of communication luminous chip core particles for forming a circular structure and a plurality of illumination chip core particles are deposited on the substrate layer. By the chip core particles in the circular structure, the electron holes of the quantum well layer compounded with the electron holes are evenly compounded to reach high compound rate, therefore, the technical effects of high speed and wide band of the device are reached; meanwhile, the chip core particles form the circular structure; the area and the volume of the chip core particles are reduced; and the response rate of the device is improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

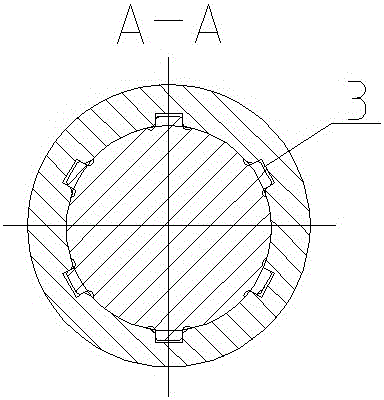

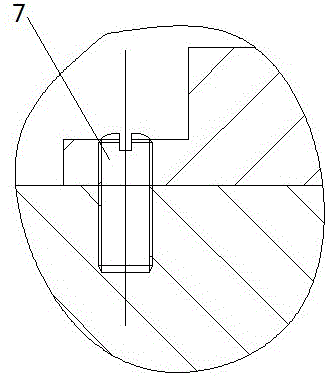

Combined type roller for rolling wave form corrugated composite boards

InactiveCN106734214ASolve deviationIncrease contact areaRollsMetal rolling arrangementsWave formComposite slab

The invention discloses a combined type roller for rolling wave form corrugated composite boards and belongs to the technical field of rollers. The combined type roller for rolling wave form corrugated composite board belts comprises a roller shaft, a roller shell, a spline, a flat key, a locking check ring and a screw. The combined type roller is structurally characterized in that an external spline is arranged on the roller shaft, an internal spline groove is formed in the roller shell, the roller shell is arranged on the roller shaft, the spline plays a role in positioning and is a rectangular spline, the outer surface of the roller shell is in a wave form corrugation shape, the metal composite board belts with wave form corrugation can be rapidly rolled, the contact area of a metallic matrix can be increased by using the wave form corrugation roller for making blanks, the combination strength of composite board interfaces can be enhanced, and the recombination rate of composite board interfaces can be increased; a step-shaped shaft shoulder is arranged at one end of the roller shaft and axially fixes the roller shell; and locking positioning, in the axial and radial directions of the roller shaft, of the other end of the roller shell is achieved through the cooperation of the flat key, the locking check ring and the screw. According to the combined type roller, the centring precision of the roller is high, the stability of centring is extremely high, axial roller shifting is prevented, the roller shell can be rapidly dismounted, and the assembling period of the combined type roller is shortened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

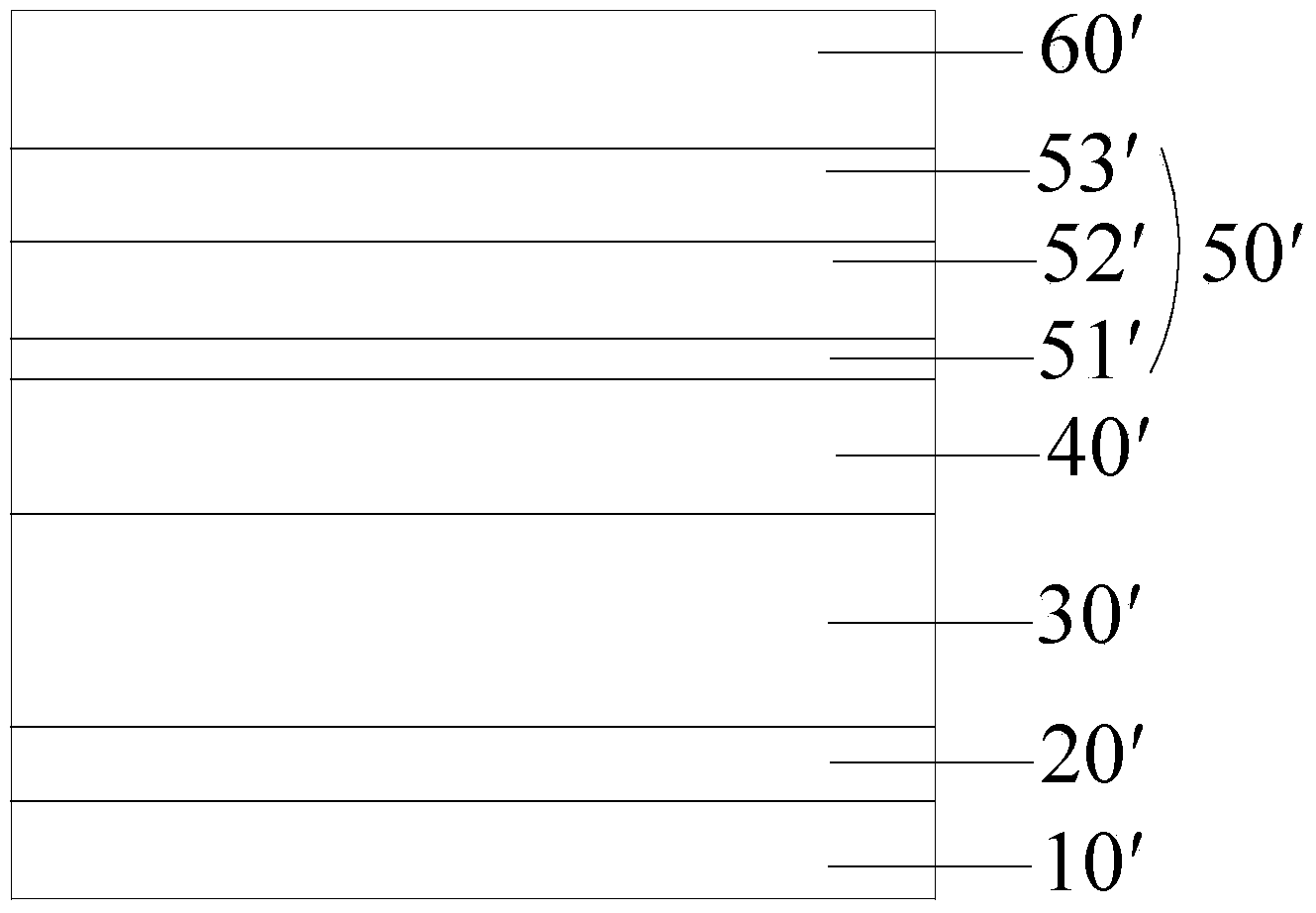

Light emitting diode

ActiveCN103824919AReduce defect densityHigh luminous intensityThin material handlingSemiconductor devicesLength waveLight-emitting diode

A light emitting diode device may include a carrier, a p-type and n-type semiconductor layers, an active layer, a first electrode and a second electrode. The carrier has a growth surface and at least one nano-patterned structure on the growth surface, in which the carrier includes a substrate and a semiconductor capping layer disposed between the substrate and the n-type semiconductor layer. The n-type semiconductor layer and the p-type semiconductor layer are located over the growth surface of the carrier. The active layer is located between the n-type and p-type semiconductor layers, in which a wavelength [lambda] of light emitted by the active layer is 222 nm<=[lambda]<=405 nm, and a defect density of the active layer is less than or equal to 5*1010 / cm2. The first and second electrodes are respectively connected to the n-type and p-type semiconductor layers. A carrier for carrying a semiconductor layer is also provided.

Owner:LITE ON TECH CORP

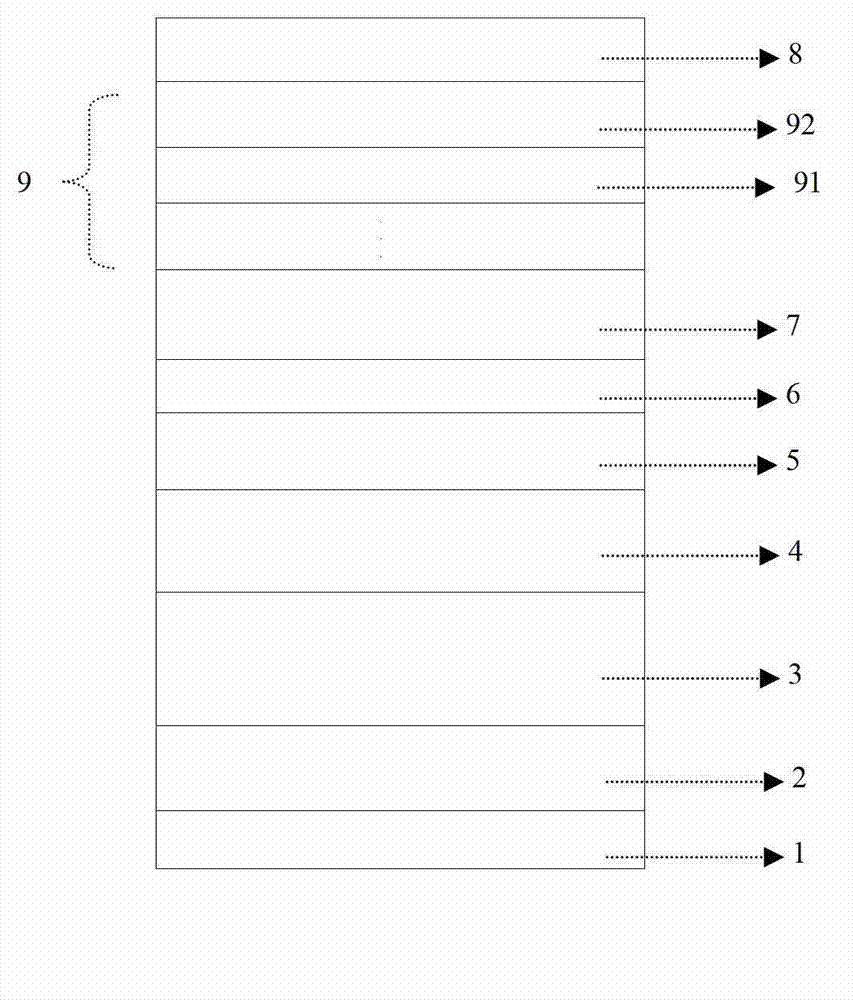

LED quantum well structure, manufacture method of the same, and LED epitaxial wafer comprising the same

ActiveCN104064644AImprove crystal qualityImprove luminous efficiencySemiconductor devicesQuantum wellOptoelectronics

The invention discloses an LED quantum well structure, a manufacture method of the same, and an LED epitaxial wafer comprising the same. The structure comprises: a first GaN barrier layer arranged on an n-type GaN layer in an LED; a first buffer layer arranged on the first GaN barrier layer and including a first InGaN layer and a first GaN layer arranged alternately; a second GaN barrier layer arranged on the first buffer layer; a second buffer layer arranged on the second GaN barrier layer and including a second InGaN layer and a second GaN layer arranged alternately; and a quantum well light emitting layer arranged on the second buffer layer and including a third InGaN layer and a third GaN layer arranged alternately. The In concentration of the third InGaN layer is greater than that of the second InGaN layer and greater than that of the first InGaN layer. The crystal quality of the quantum well light emitting layer of the structure is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

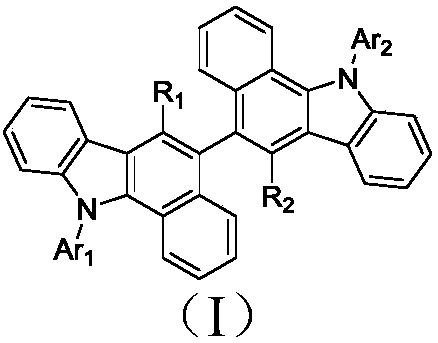

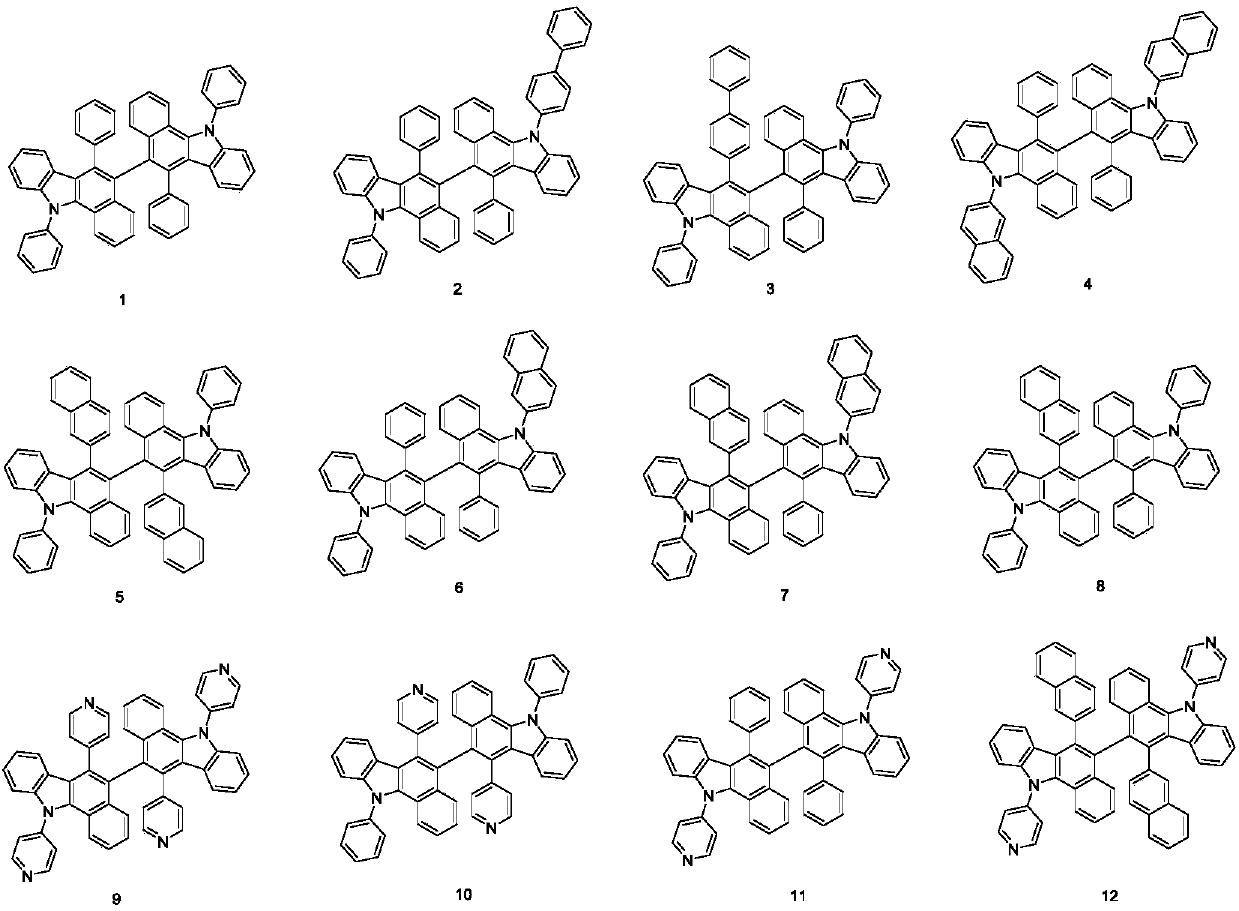

Benzo-carbazole compound and organic light-emitting device thereof

InactiveCN107698489AImprove injection balanceImprove compound rateOrganic chemistrySolid-state devicesBenzeneCarbazole

The invention provides a benzo-carbazole compound and an organic light-emitting device thereof, belongs to the technical field of organic light-emitting materials, and solves the problems of low light-emitting efficiency and short service life of a device in the prior art. Carrier injection balance is improved by adjusting groups R1, R2, Ar1 and Ar2 on benzo-carbazole, and the recombination rate of electrons and holes on a light-emitting layer is increased. The organic light-emitting device prepared by the benzo-carbazole compound, particularly a main material serving as the light-emitting layer of the organic light-emitting device has the advantages of higher light-emitting efficiency and obviously prolonged service life, and the organic light-emitting device is superior to an existing common OLED (organic light emitting diode) device.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com