Light emitting diode

A technology for light-emitting diodes and semiconductors, which is applied in thin material processing, semiconductor devices, electrical components, etc. It can solve the problems of reducing luminous intensity and difficult to realize the coalescence of nitride semiconductor layers, so as to increase the recombination rate and reduce the defect density. , the effect of increasing the luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

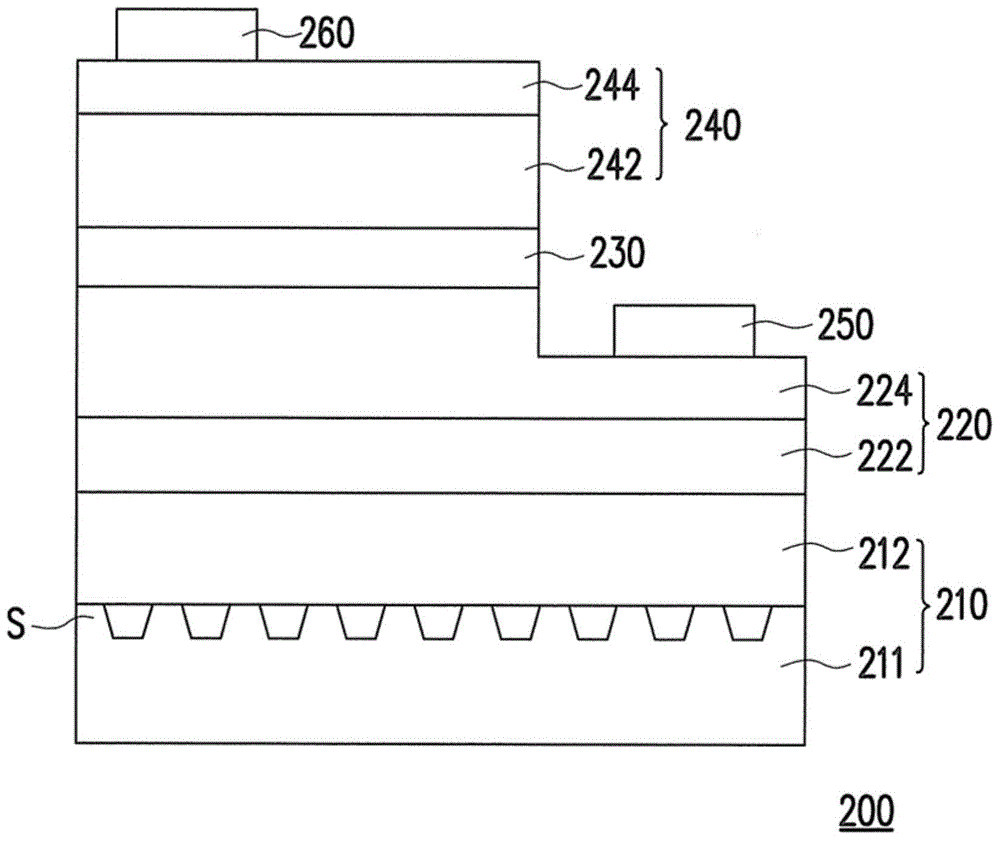

[0082] In this embodiment, by having several quantum barrier layers of an active layer doped with an n-type dopant (where the number of doped quantum barrier layers satisfies a specific relationship), or by having The minimum doping concentration at the quantum barrier layer doped with an n-type dopant close to the p-type semiconductor, or by making the doping concentration of the quantum barrier layer doped with an n-type dopant satisfy a certain relationship, n-type dopants can compensate for the effects of defects on carriers. Accordingly, the recombination rate of carriers of the LED device can be enhanced. Therefore, by using any of the aforementioned techniques, the luminous efficiency of the LED device in the embodiments can be significantly increased in the wavelength range of 222nm to 405nm.

[0083] Figure 11A is an optical simulation diagram of a comparative example of an LED device according to a comparative example in an exemplary embodiment of the present inve...

Embodiment II

[0094] In this embodiment, through one of the three quantum barrier layers closest to the p-type semiconductor layer (which has a thickness greater than that of the other two quantum barrier layers), or the quantum potential in the active layer The thickness of the barrier layer satisfies a specific relationship, the electron-hole pairs can be evenly distributed in the active layer, the probability of electron-hole recombination can be increased, and the luminous intensity of the LED device in the wavelength range of 222nm to 405nm can be significantly improved.

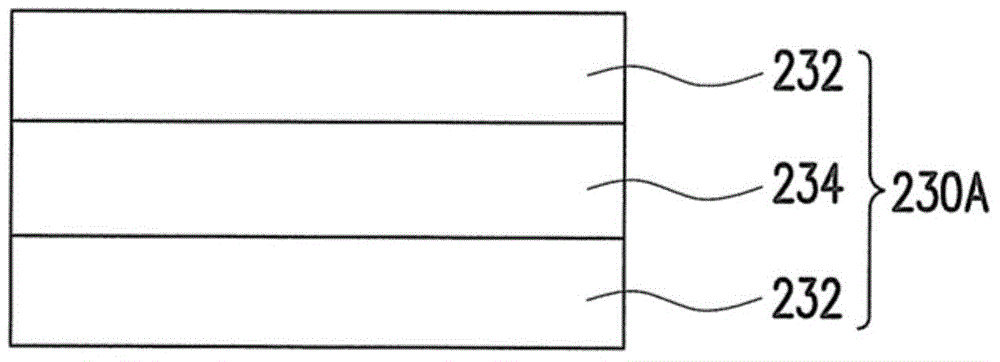

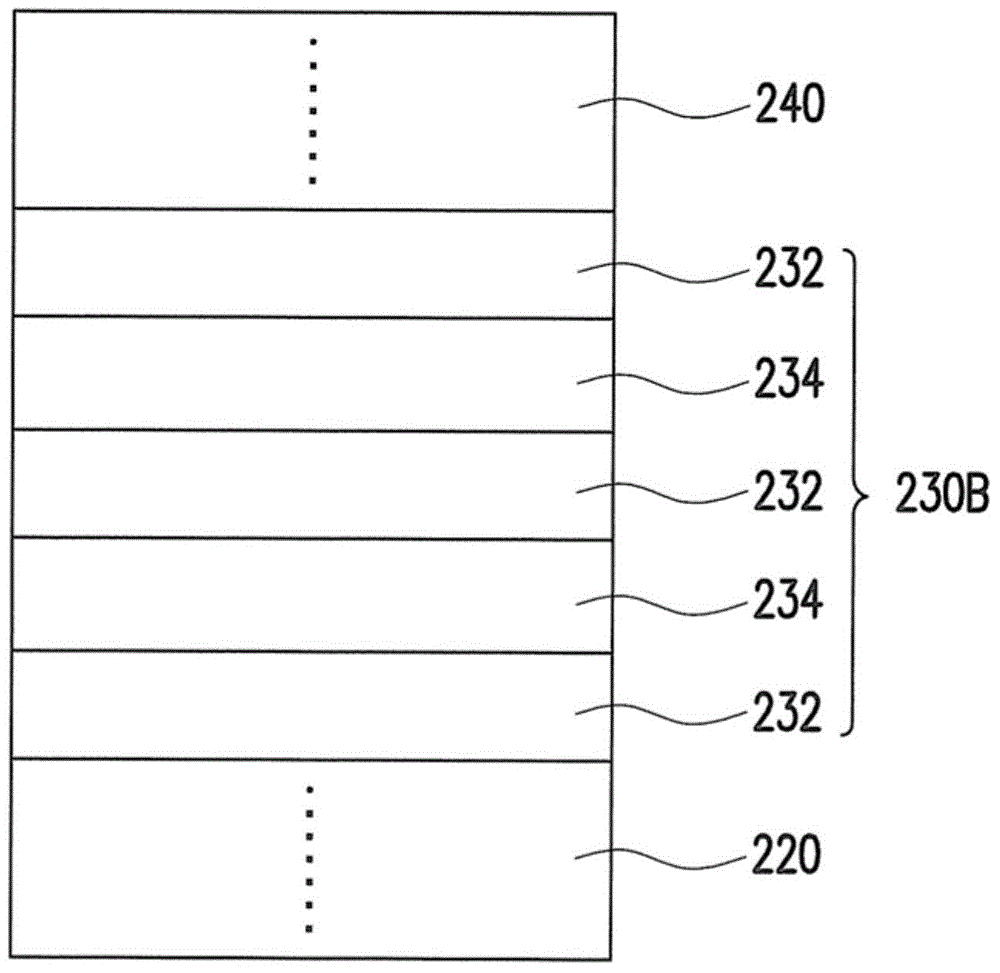

[0095] According to this embodiment, it is assumed that the active layer 230 of the LED device 200 has image 3 The structure shown, and a current of 300mA and a current of 700mA were applied. Under these conditions, the luminous intensity of the LED device 200 is provided in Table 3 when the thickness (unit: nm) of the quantum barrier layers 232 a - 232 f at different positions is changed. Herein, the thickness of ...

Embodiment III

[0111] Figure 14 It is a schematic cross-sectional view of an LED device in an exemplary embodiment of the present invention. Figure 14 The structure of the LED device 300 depicted in is similar to figure 1 LED device 200 is depicted in , except that electron barrier layer 270 and interlayer 280 are located between active layer 230 and p-type semiconductor layer 240 . Figure 15 for Figure 14 An enlarged schematic cross-sectional view of the active layer in the LED device depicted in . Figure 15 The structure of the active layer 230 depicted in is similar to image 3 The structure of the active layer 230 depicted in , except that the order of the quantum barrier layers 232a-232f from the p-type semiconductor layer 240 is 232a, 232b, 232c, 232d, 232e and 232f, and from the p-type semiconductor layer 240 The quantum wells 234a to 234e are counted in sequence as 234a, 234b, 234c, 234d and 234e, and the electron barrier layer 270 and the interlayer 280 are located between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com