Growing method for duplex multi-quantum well luminescent layer structure and LED epitaxial structure

A technology of multiple quantum wells and growth methods, applied in the field of LED epitaxy design, can solve problems such as insufficient brightness of LED chips, achieve the effects of improving the low hole concentration, improving efficiency, and increasing recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The invention uses AixtronCruisIIMOCVD to grow high-brightness GaN-based LED epitaxial wafers. Using high-purity H 2 or high purity N 2 or high purity H 2 and high purity N 2 The mixed gas is used as carrier gas, high-purity NH3 is used as N source, trimethylgallium (TMGa) and triethylgallium (TEGa) are used as gallium source, trimethylindium (TMIn) is used as indium source, silane (SiH 4 ) as N-type dopant, trimethylaluminum (TMAl) as aluminum source, dimagnesocene (CP 2 Mg) is used as a P-type dopant, the substrate is (0001) sapphire, and the reaction chamber pressure is between 150mbar and 600mbar.

[0063] 1. Under the hydrogen atmosphere of 1000-1100℃, the pressure of the reaction chamber is controlled at 150-200mbar, and the sapphire substrate is treated at high temperature for 4-5 minutes;

[0064] 2. Lower the temperature to 540-570°C, control the pressure of the reaction chamber at 450-600mbar, and grow a low-temperature buffer layer GaN with a thickness o...

Embodiment 2

[0091] For the implementation steps, refer to Example 1 to obtain sample 4.

[0092] The comparison of growth parameters between Comparative Example 2 and Example 2 can be seen in Table 2 below.

[0093]Table 2 contrasts the growth parameters of Example two and Example two

[0094]

[0095] Then, take sample 3 and sample 4 to take the same treatment method as sample 1 and sample 2 and then test the photoelectric performance of sample 3 and sample 4, the parameters obtained can be found in Figure 6 . Figure 6 The vertical axis of is the brightness (Lm), and the horizontal axis is the distribution number of chip particles. The value corresponding to sample 4 is the upper thicker line, and the value corresponding to sample 3 is the lower thinner line. From Figure 6 According to the data, the brightness of sample 4 is 8-9% higher than that of sample 3. The growth method provided by this patent improves the light efficiency of large-size chips.

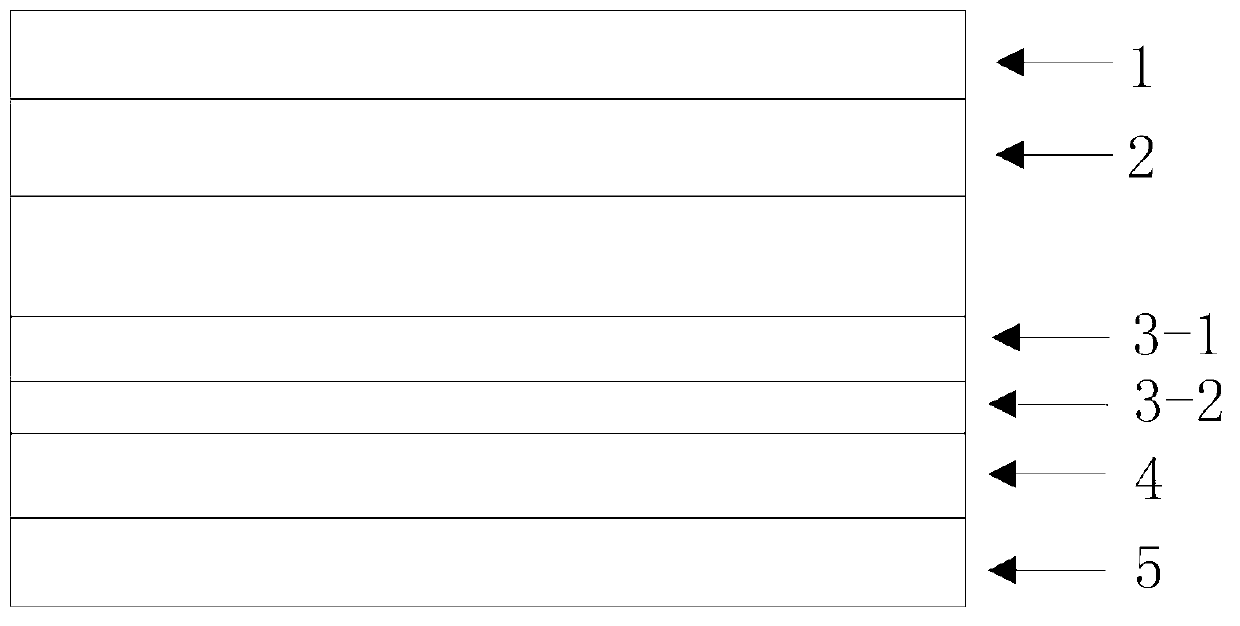

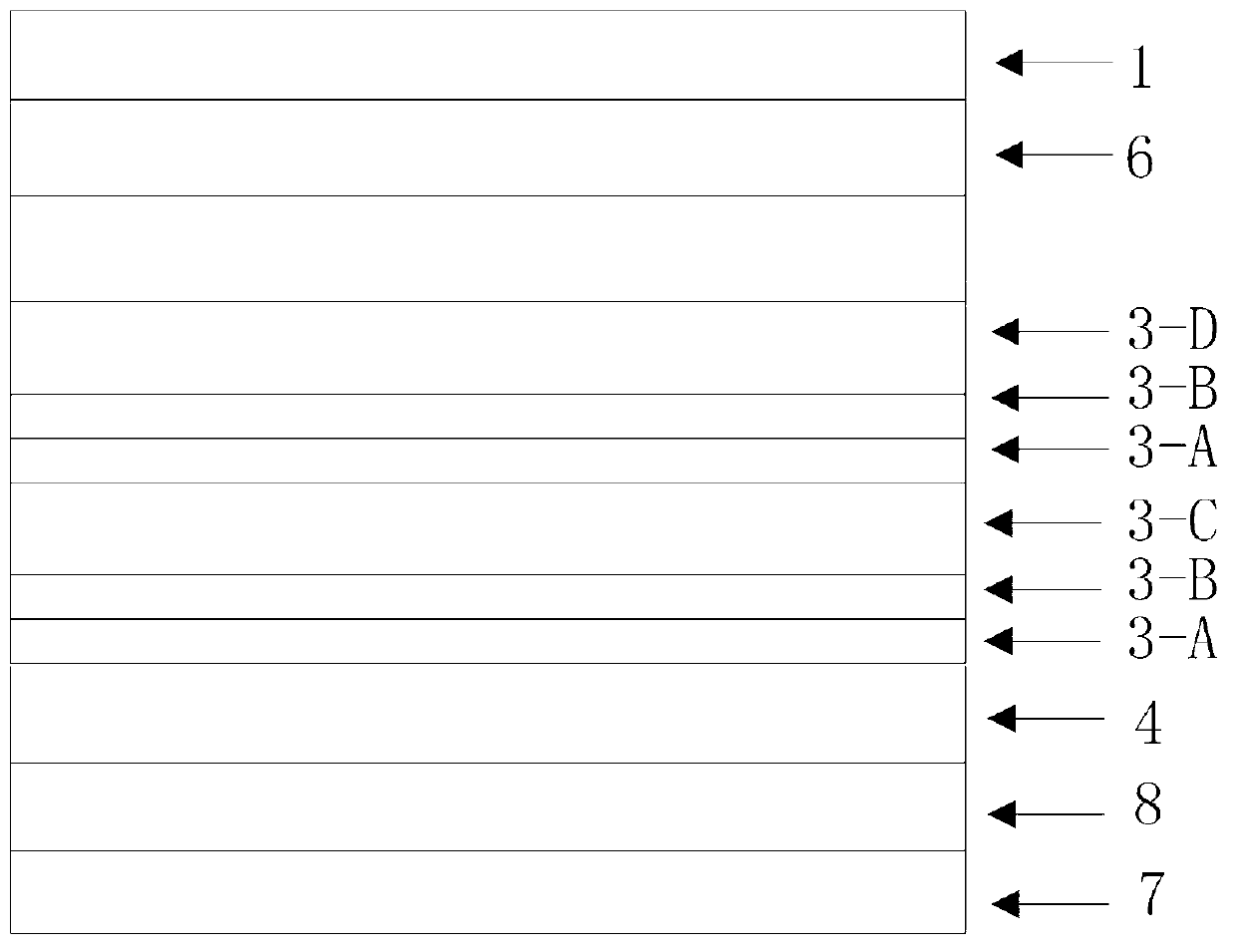

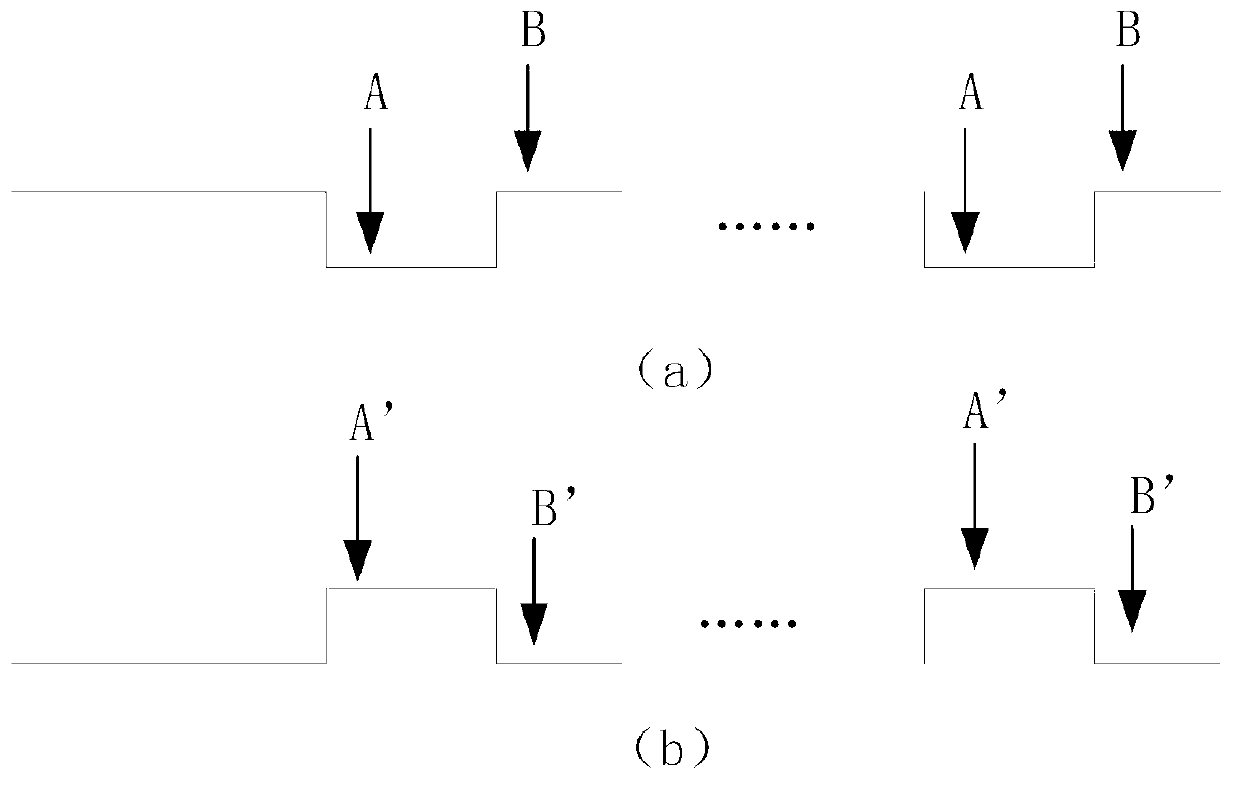

[0096] see figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com