Patents

Literature

182results about How to "Reduce stress effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

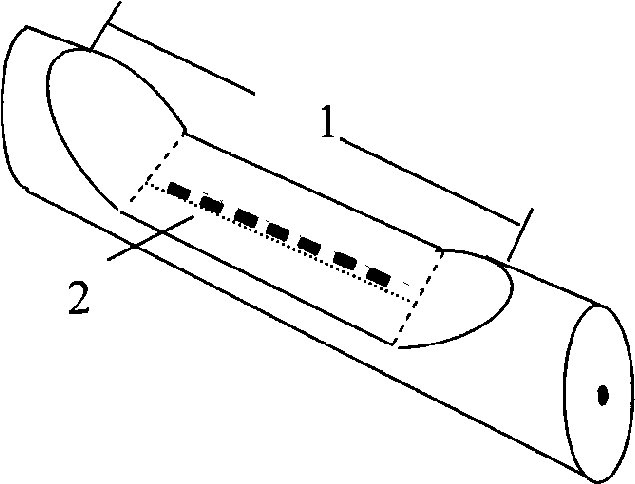

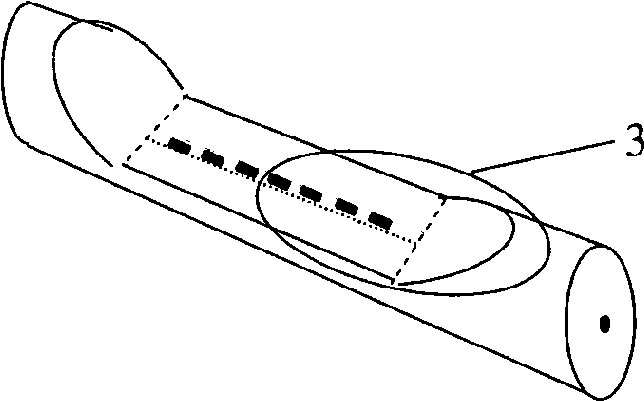

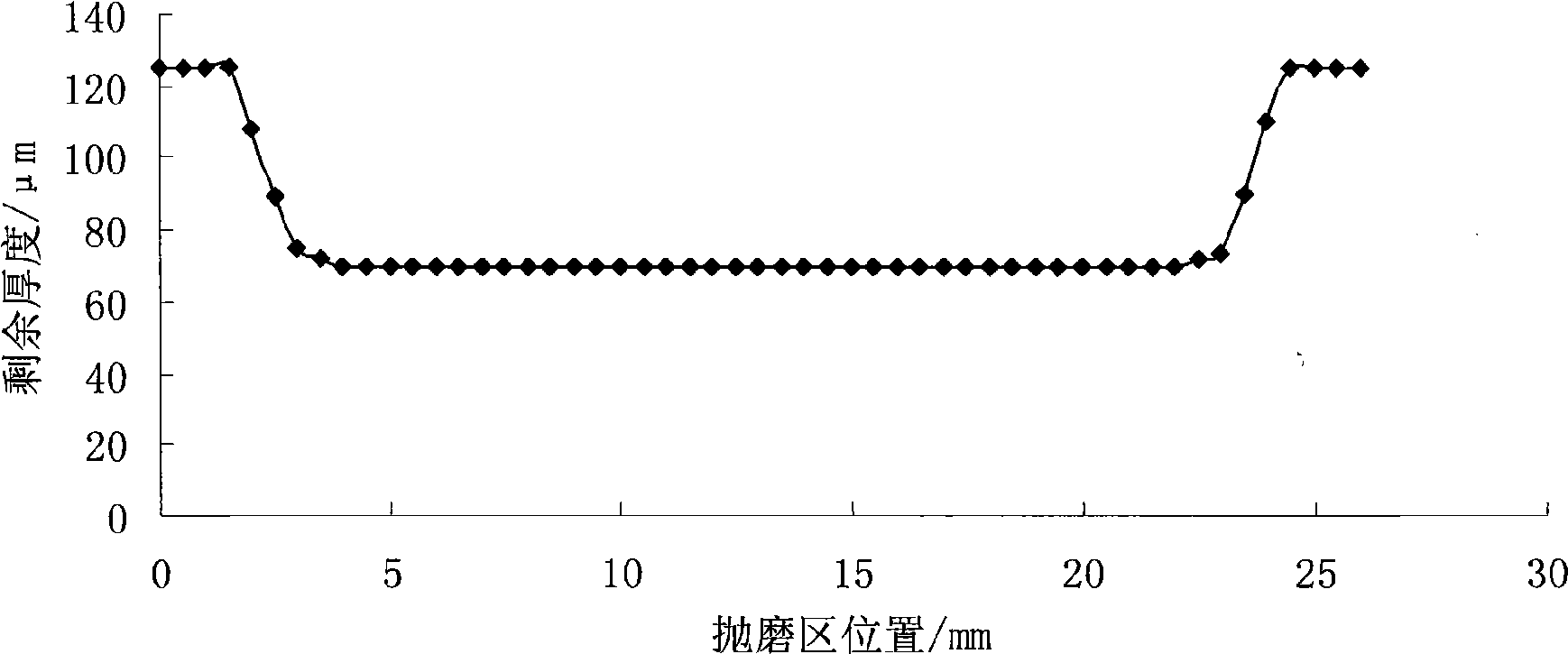

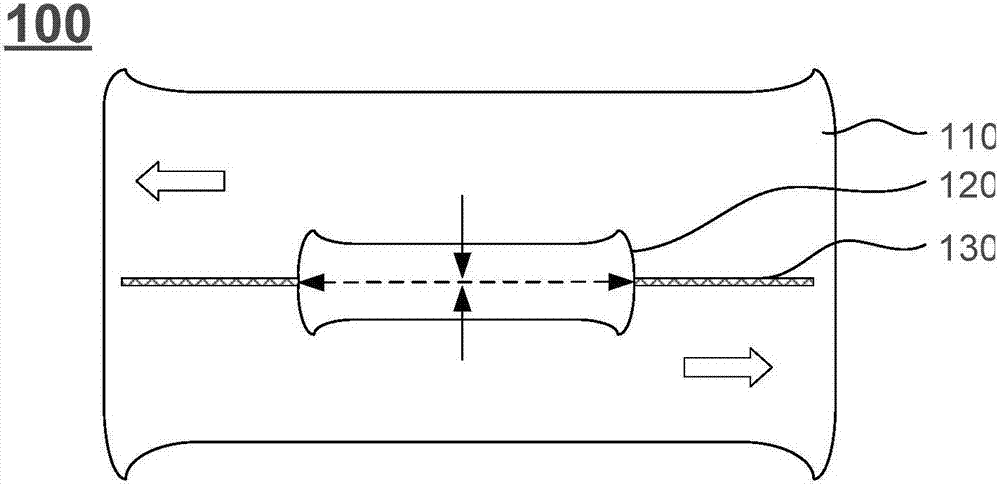

Optical fibre sensor and application thereof to refracting index and strain measurement

InactiveCN101545791AReduce stress effectsSuitable for monitoringPhase-affecting property measurementsUsing optical meansGratingMicrometer

The invention relates to the technical field of measurement and discloses an optical fibre sensor and an application thereof in refracting index and strain measurement. The optical fibre sensor is provided with a D-shaped optical fibre segment with D-shaped section on circular optical fibre and is characterized in that the distance between the flat surface of the D-shaped optical fibre segment and fibre core is 1-3 micrometers, and the D-shaped optical fibre segment is marked with Bragg fibre grating. The optical fibre sensor can be used for measuring the refracting index, and can also be used for measuring the refracting index and the strain simultaneously. The optical fibre sensor can better eliminate the stress influence while being used for measuring the refracting index and is especially suitable to monitor the solidifying process of polymer.

Owner:JINAN UNIVERSITY

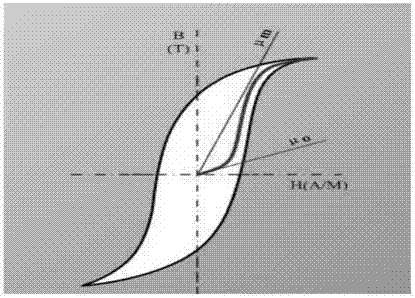

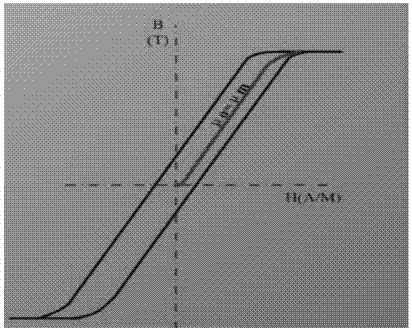

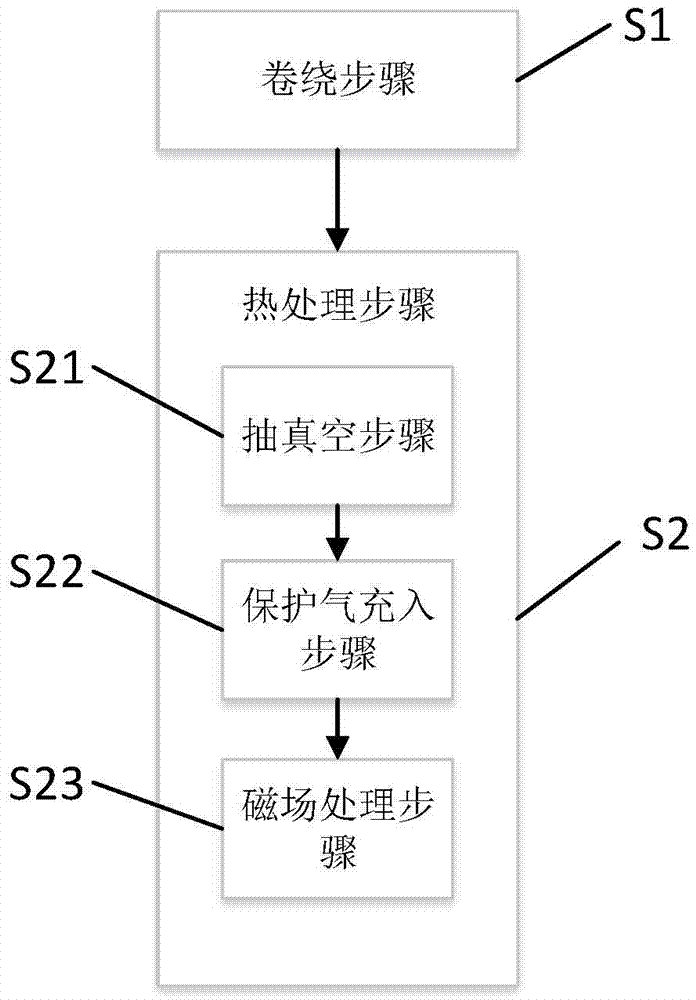

Heat treatment method for amorphous material or nanocrystalline material for magnetic shield sheet

InactiveCN106916928AImprove shielding effectReduce the saturation magnetostriction coefficientUnwanted magnetic/electric effect reduction/preventionMagnetic shieldAmorphous metal

The invention provides a heat treatment method for an amorphous material or a nanocrystalline material for a magnetic shield sheet. The heat treatment method comprises the following steps: a winding step of winding the amorphous strip material or the nanocrystalline strip material into magnetic cores with the needed dimensions, and a heat treatment step of arranging the amorphous magnetic cores or the nanocrystalline magnetic cores in a heat treatment furnace according to a certain rule and carrying out heat treatment, wherein magnetic field treatment is carried out during the heat treatment process. The shield performance of the magnetic shield sheet can be improved by virtue of a magnetic field-applied heat treatment process. In addition, a saturation magnetostriction constant is lowered after the magnetic field-applied heat treatment, so that the influence of stress is reduced, the magnetic conductivity is increased, the loss is reduced, and the charging efficiency is increased.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

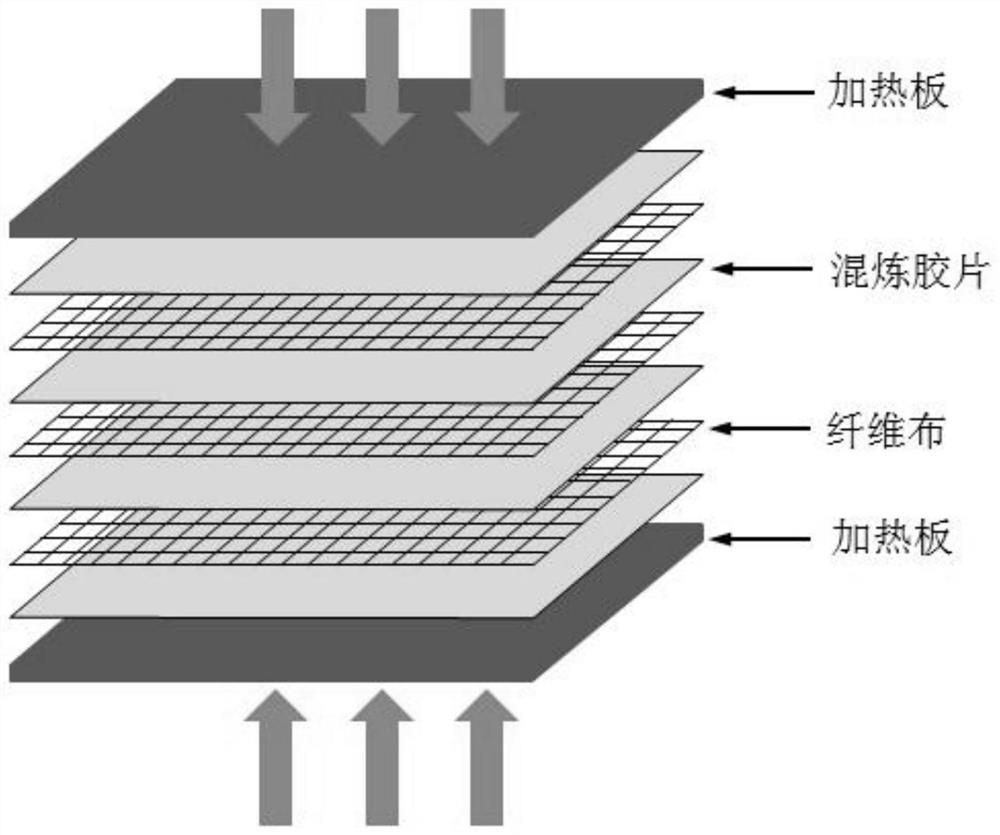

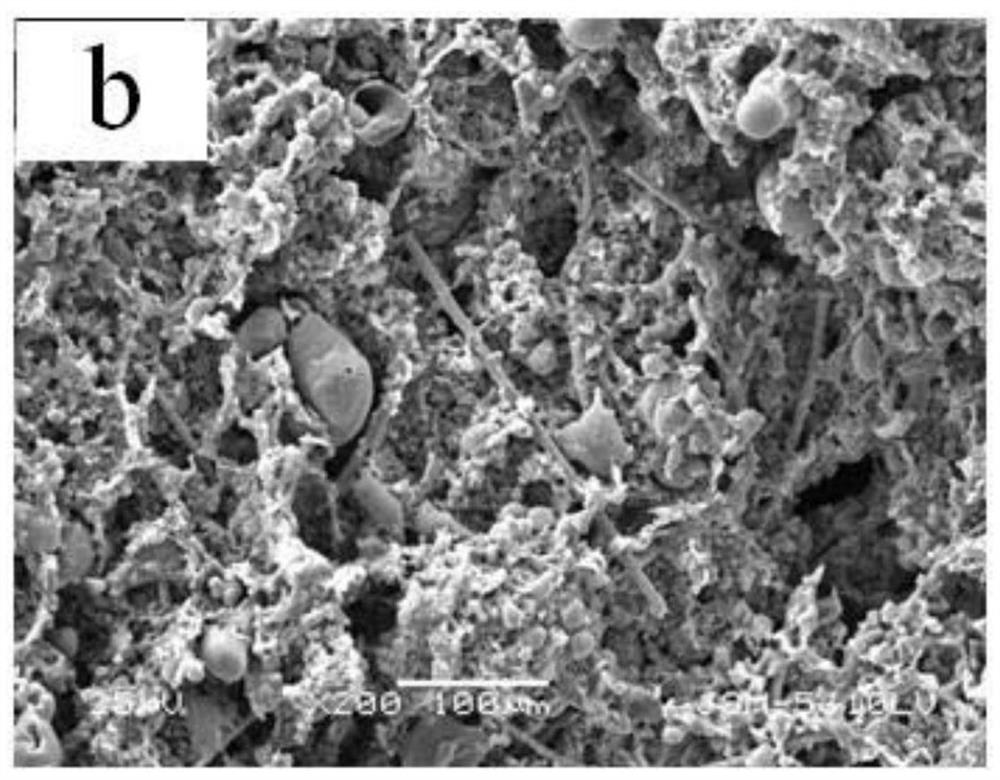

Flexible ceramizable silicone rubber thermal insulation composite material and preparation method thereof

PendingCN111761895AHigh mechanical strengthImprove anti-ablation performanceCosmonautic thermal protectionLaminationFiberVulcanization

The invention relates to a flexible ceramizable silicone rubber thermal insulation composite material and a preparation method thereof. The composite material is a silicone rubber / fiber cloth integralstructure, the silicone rubber is a support structure, and the fiber cloth penetrates through the silicone rubber; the composite material is obtained by stacking and vulcanizing mixed rubber sheets and fiber cloth at intervals, the mixed rubber sheets are obtained by mixing the silicone rubber, and the mixed rubber sheets are prepared from, by mass, 100 parts of the silicone rubber, 20-45 parts of fumed silica, 30-160 parts of ceramic powder, 0-40 parts of a fluxing agent, 6-20 parts of short fibers, 1-15 parts of a structure control agent and 1-4 parts of a vulcanizing agent. The ceramizablesilicone rubber composite material provided by the invention is good in flexibility, high in mechanical property, good in ablation resistance and resistant to high-speed airflow scouring, and can meet the requirements of the fields of aerospace and special fireproof engineering on fireproof, thermal-insulating and ablation-resistant thermal protection performance.

Owner:WUHAN UNIV OF TECH

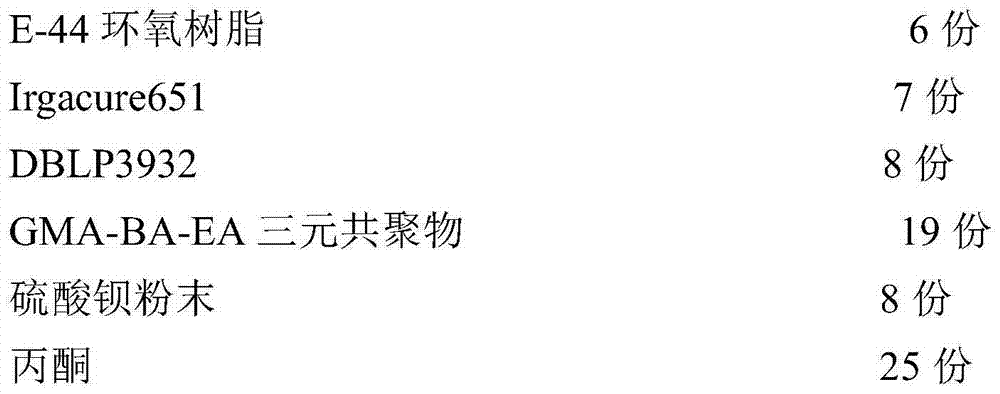

Alkaline-developable photosensitive solder resist ink for FPC, preparation method, application and product

InactiveCN104710871AGood workmanshipShorten drying timePrinted circuit detailsPhotomechanical apparatusEpoxyPhotoinitiator

The invention discloses an alkaline-developable photosensitive solder resist ink for FPC. The alkaline-developable photosensitive solder resist ink comprises alkali-soluble photosensitive resin, active diluent, pigment, epoxy resin, photoinitiator, flexibilizer and filler. The invention further discloses a preparation method for the alkaline-developable photosensitive solder resist ink used for FPC, application of the alkaline-developable photosensitive solder resist ink used for FPC and FPC products using the alkaline-developable photosensitive solder resist ink used for FPC. With the solder resist ink, a cured coating has high hardness, good adhesion on a substrate, good chemical resistance and good flexural endurance.

Owner:GUANGDONG DANBOND TECH

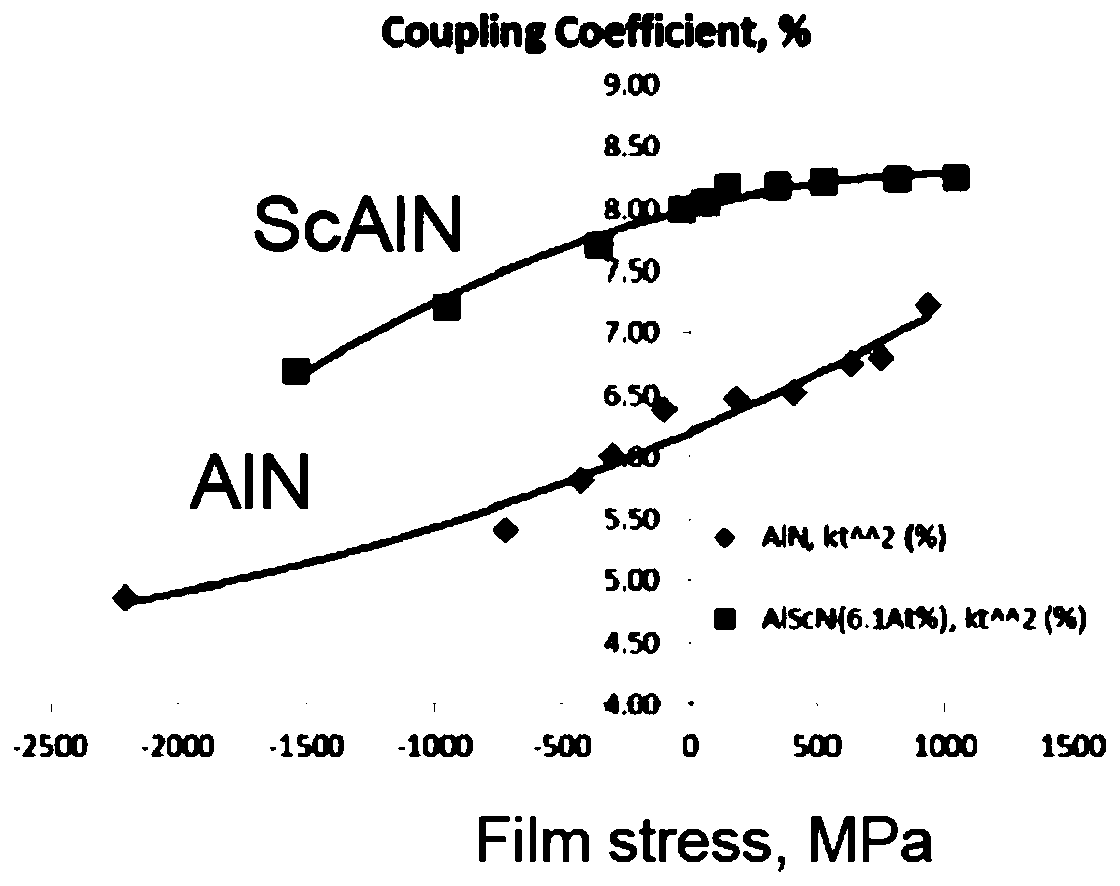

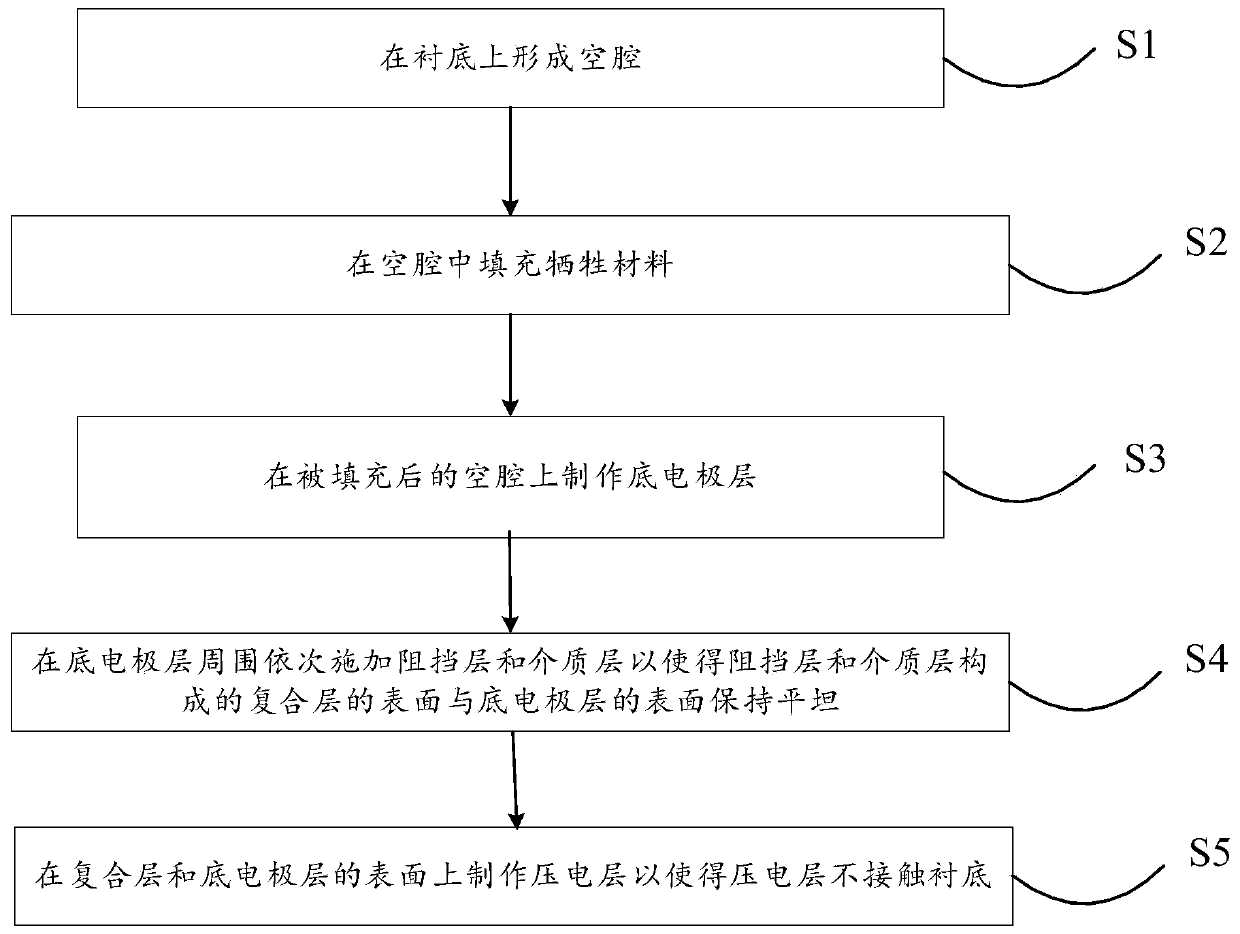

Flat piezoelectric layer structure of bulk acoustic wave resonator and manufacturing process

ActiveCN111162746AImprove Stress ConsistencyHigh quality factorImpedence networksElectromechanical coupling coefficientAcoustic wave

The invention discloses a flat piezoelectric layer structure of a bulk acoustic wave resonator and a manufacturing process. The manufacturing process comprises the following steps: forming a cavity ona substrate; filling a sacrificial material in the cavity; manufacturing a bottom electrode layer on the filled cavity; sequentially applying a barrier layer and a dielectric layer around the bottomelectrode layer to keep the surface of a composite layer formed by the barrier layer and the dielectric layer flat with the surface of the bottom electrode layer; and fabricating a piezoelectric layeron the surfaces of the composite layer and the bottom electrode layer so that the piezoelectric layer does not contact the substrate. The stress consistency of the piezoelectric layer is improved, the stress influence of the piezoelectric layer is reduced, an electromechanical coupling coefficient of a device is controlled within the optimal range, the quality factor of the resonator, the yield of the device and the consistency and reliability of the finished product of the device are improved, the effective resonance area is larger and closer to the cavity and does not exceed the cavity, andthe size of the device can be reduced. By arranging a seed layer and a passivation layer, the bottom electrode layer and the top electrode layer can be protected, the bottom electrode layer is manufactured inside the resonator, and the mechanical stability is maintained.

Owner:HANGZHOU JWL TECH INC

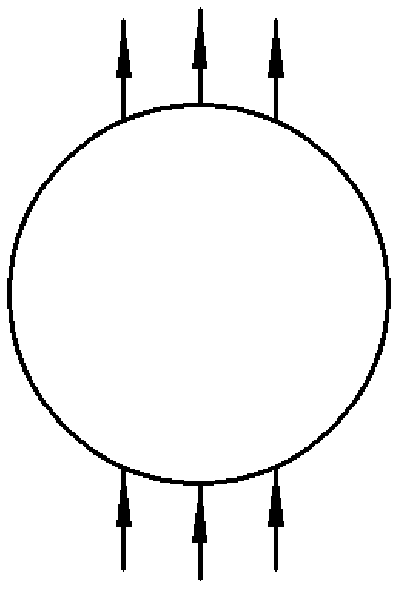

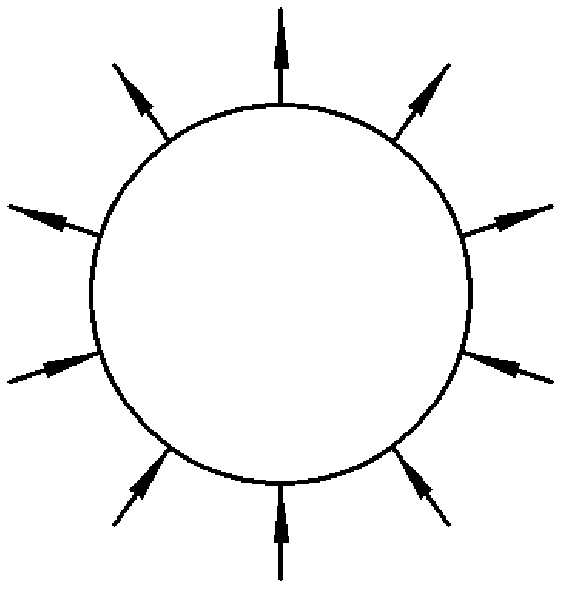

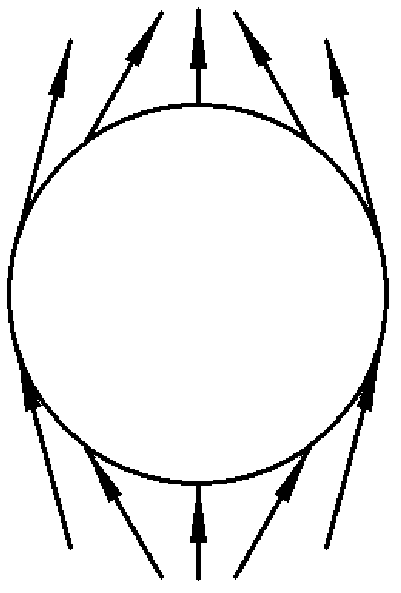

Passive radial supporting mechanism for primary mirror of optical telescope based on kinetic equilibrium

InactiveCN102508347AIncrease the number ofReduce stress effectsTelescopesMountingsSupporting systemKinematics

The invention relates to a passive radial supporting mechanism for a primary mirror of an optical telescope based on kinetic equilibrium. One end of a first-stage connecting rod of the mechanism is hinged with the rim of a primary mirror chamber, and the other end of the first-stage connecting rod is hinged with a second-stage connecting rod and a third-stage connecting rod at the same time; the other end of the second-stage connecting rod and the other end of the third-stage connecting rod are hinged with the rim of the primary mirror; and an included angle theta is formed between the second-stage connecting rod and the third-stage connecting rod. By a kinetic equilibrium system, the radial direction of the primary mirror is not restrained by an over-restraining characteristic, so that a stable equilibrium state is realized; when temperature is changed, the whole radial supporting system does micro motion in accord with a kinetic rule by using the change of the geometric size caused by thermal deformation of a connecting rod mechanism, so that stress caused by the thermal deformation among the primary mirror, the radial supporting mechanism and the primary mirror chamber is counteracted; therefore, the passive radial supporting mechanism is suitable for supporting primary mirrors made of materials with large thermal expansion coefficients and primary mirrors working under a relatively severe working environment.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

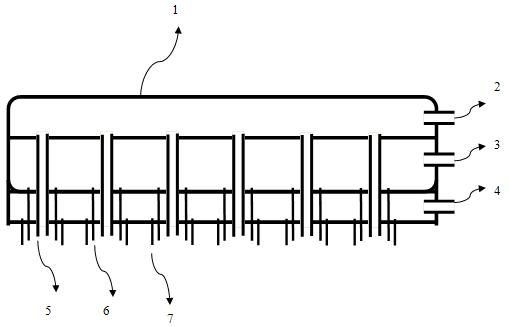

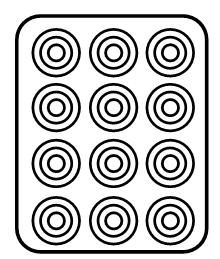

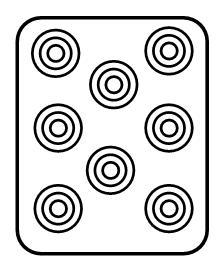

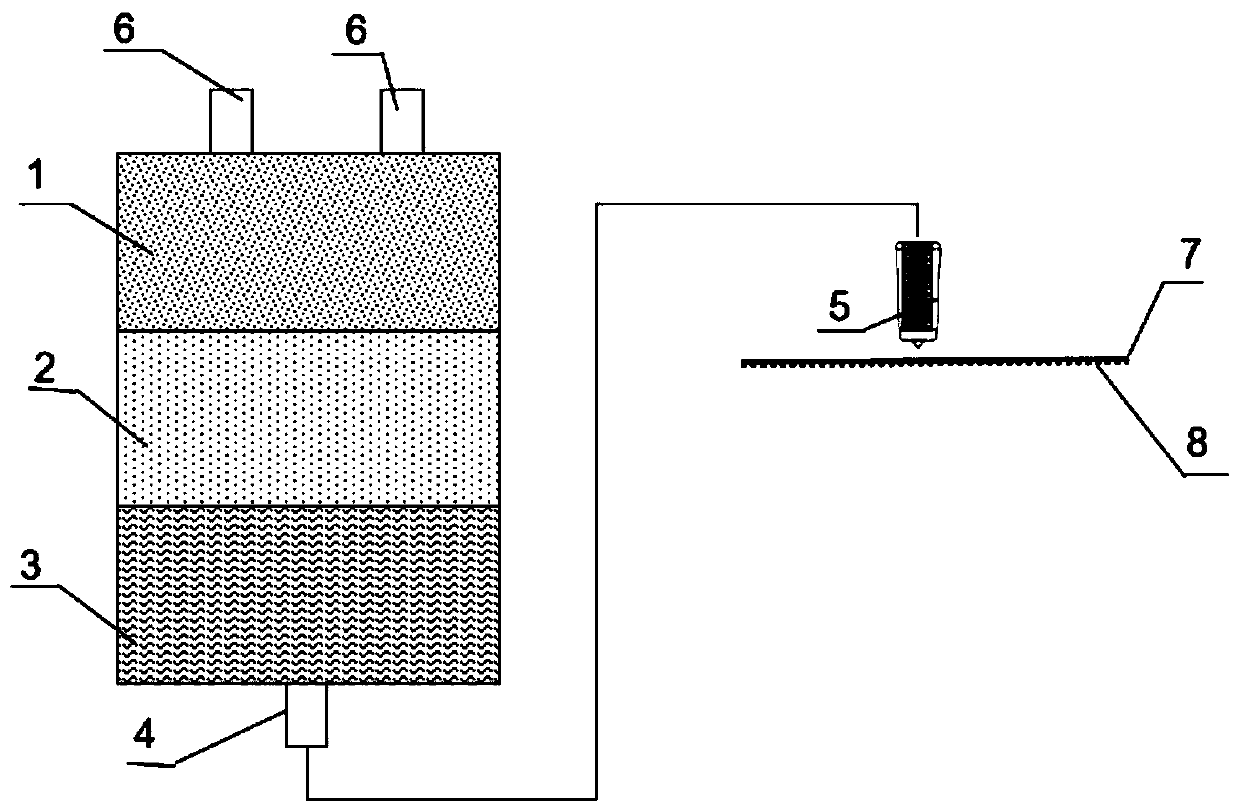

Multi-substrate large-size hydride vapor phase epitaxy method and device

ActiveCN102108547AEvenly distributedReduce stress effectsPolycrystalline material growthSemiconductor/solid-state device manufacturingVapor phaseEngineering

The invention provides a method for growing a GaN material on multiple substrates or large-size substrates simultaneously by a hydride vapor phase epitaxy (HVPE) technology, and also provides a device capable of implementing the method, in particular a nozzle used for providing a large-area growth area. When the method is applied to the device provided by the invention, more than 5 2-inch GaN substrates (depending on a constant temperature area range and the size of the nozzle) or more than one 4-inch or 6-inch substrate can be grown simultaneously. Due to the nozzle design, gallium oxide GaCl and ammonia NH3 are not mixed at the nozzle, pre-reaction at the nozzle is reduced, a pipeline is prevented from being blocked, the GaCl and the NH3 are only mixed on the surfaces of the substrates to form a uniform mixed layer, and the thickness uniformity and quality of GaN products are improved.

Owner:SINO NITRIDE SEMICON

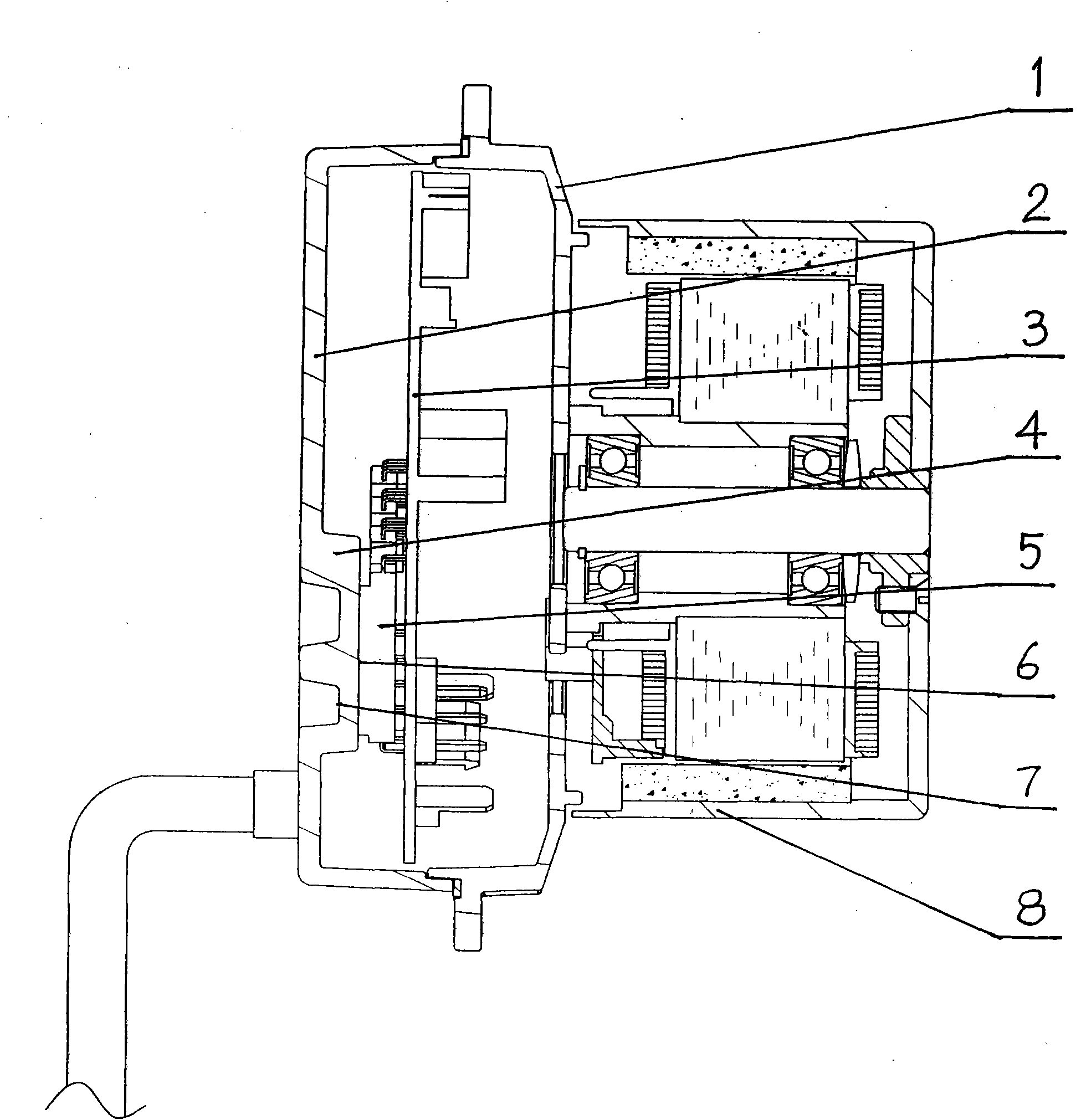

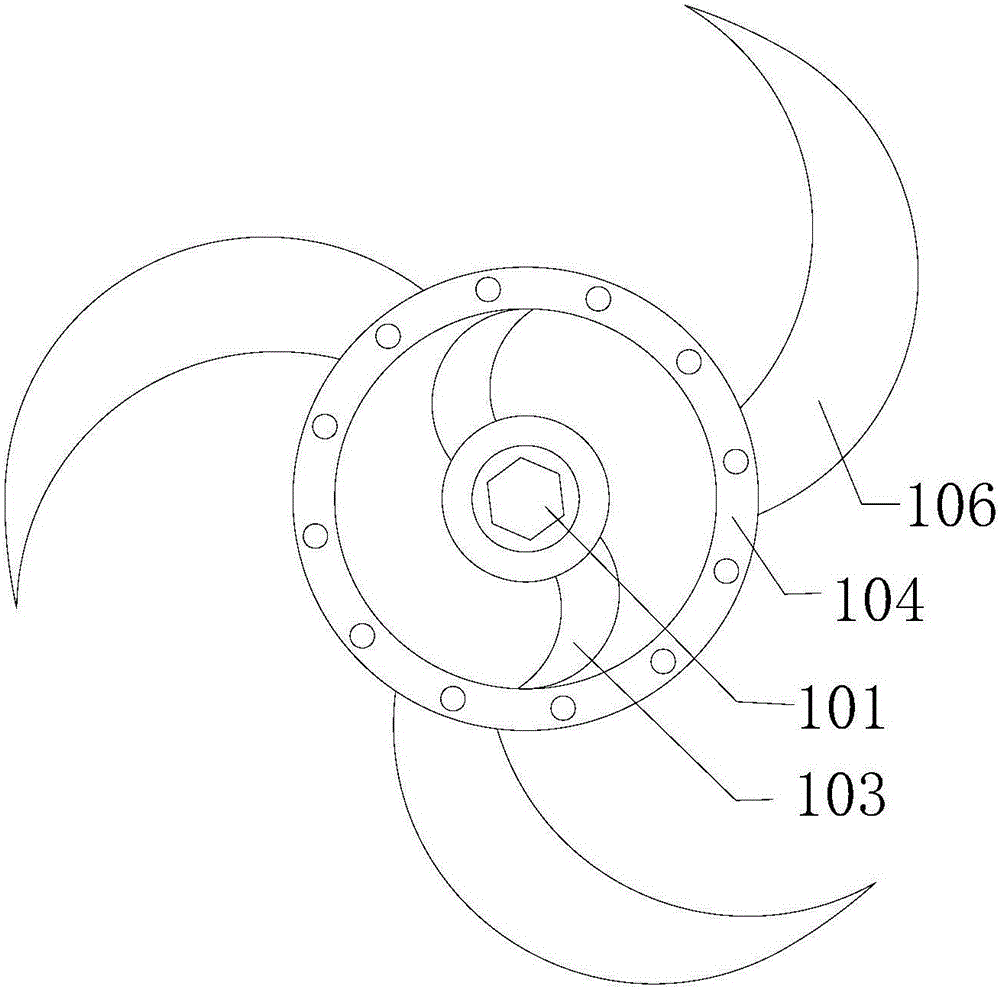

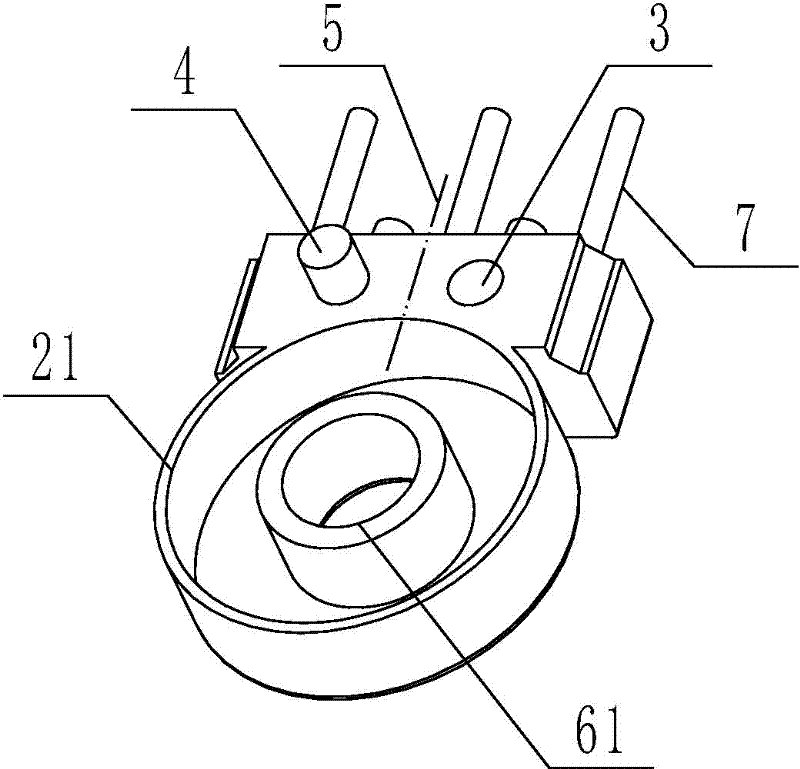

Radiating structure for outer-rotor direct-current brushless motor

InactiveCN102104296AImprove cooling effectIncrease cooling areaCooling/ventillation arrangementSupports/enclosures/casingsPhysicsConductor Coil

Owner:FOSHAN NANHAI DISTRICT DONGTANG ELECTRICAL MACHINERY FACTORY

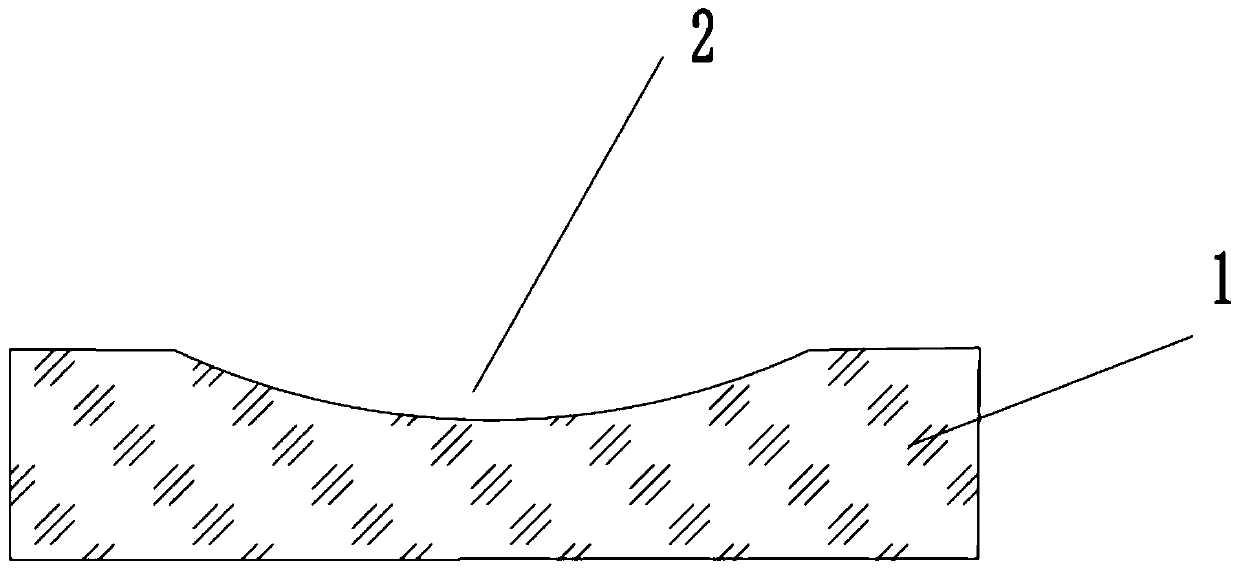

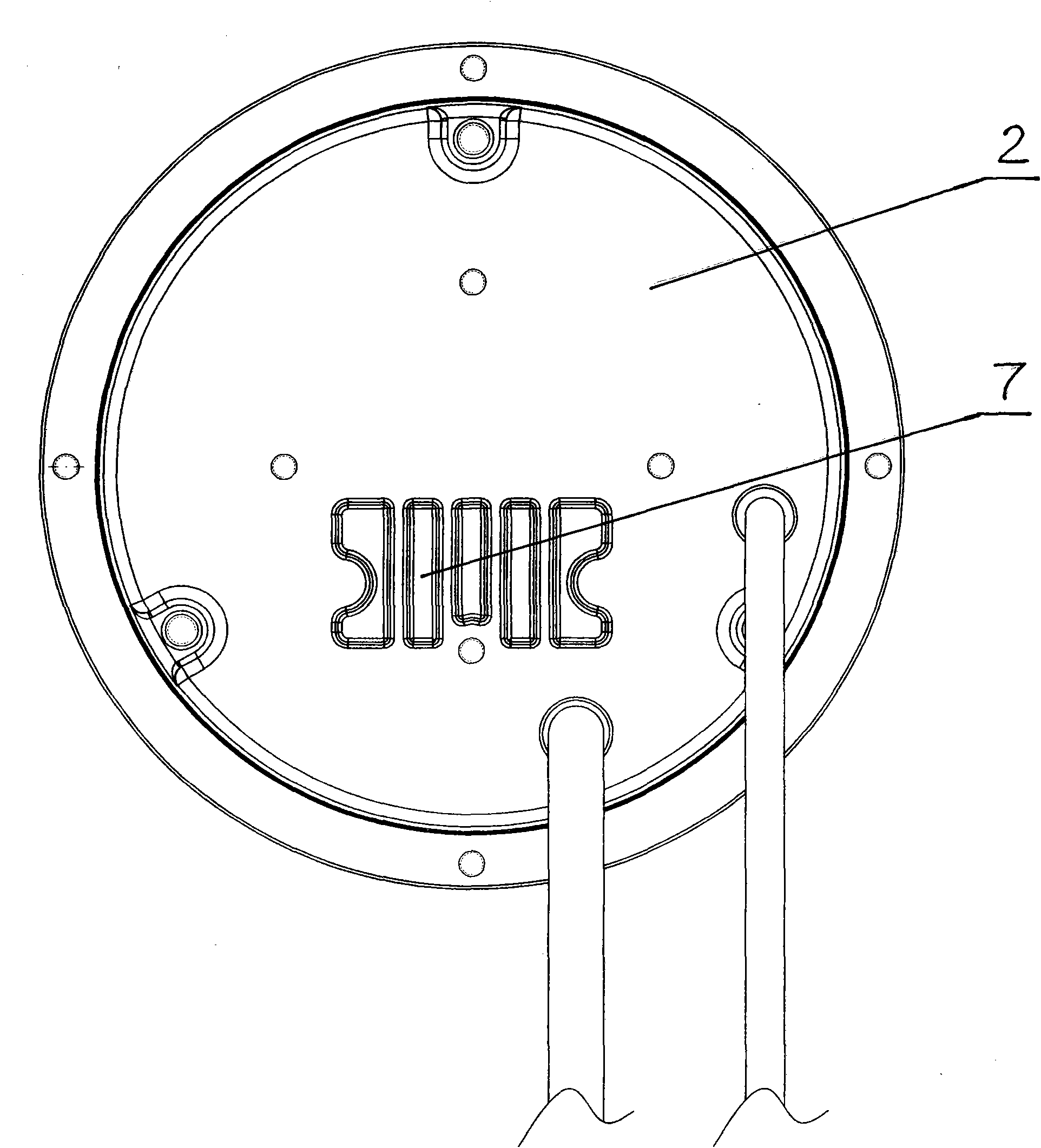

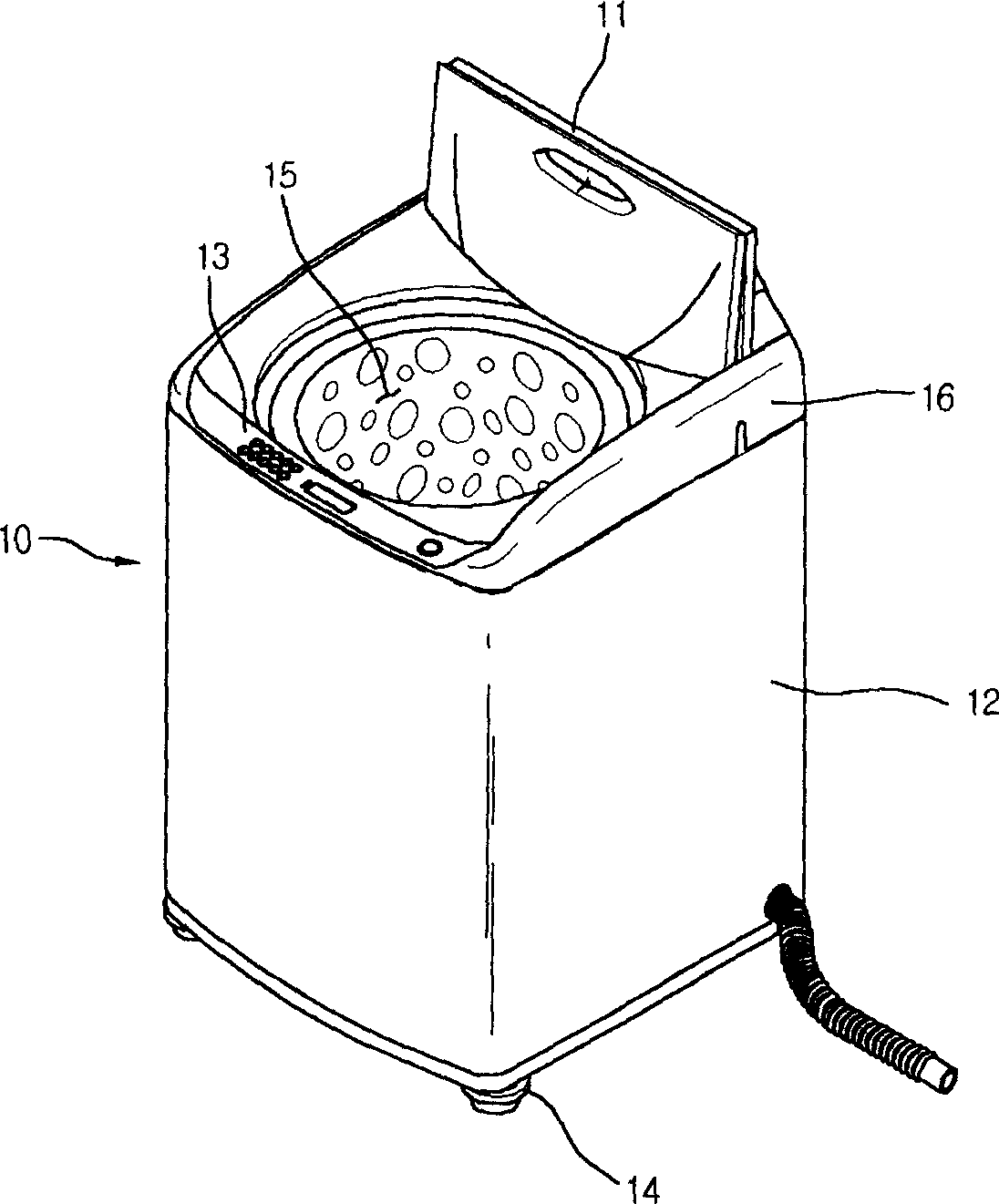

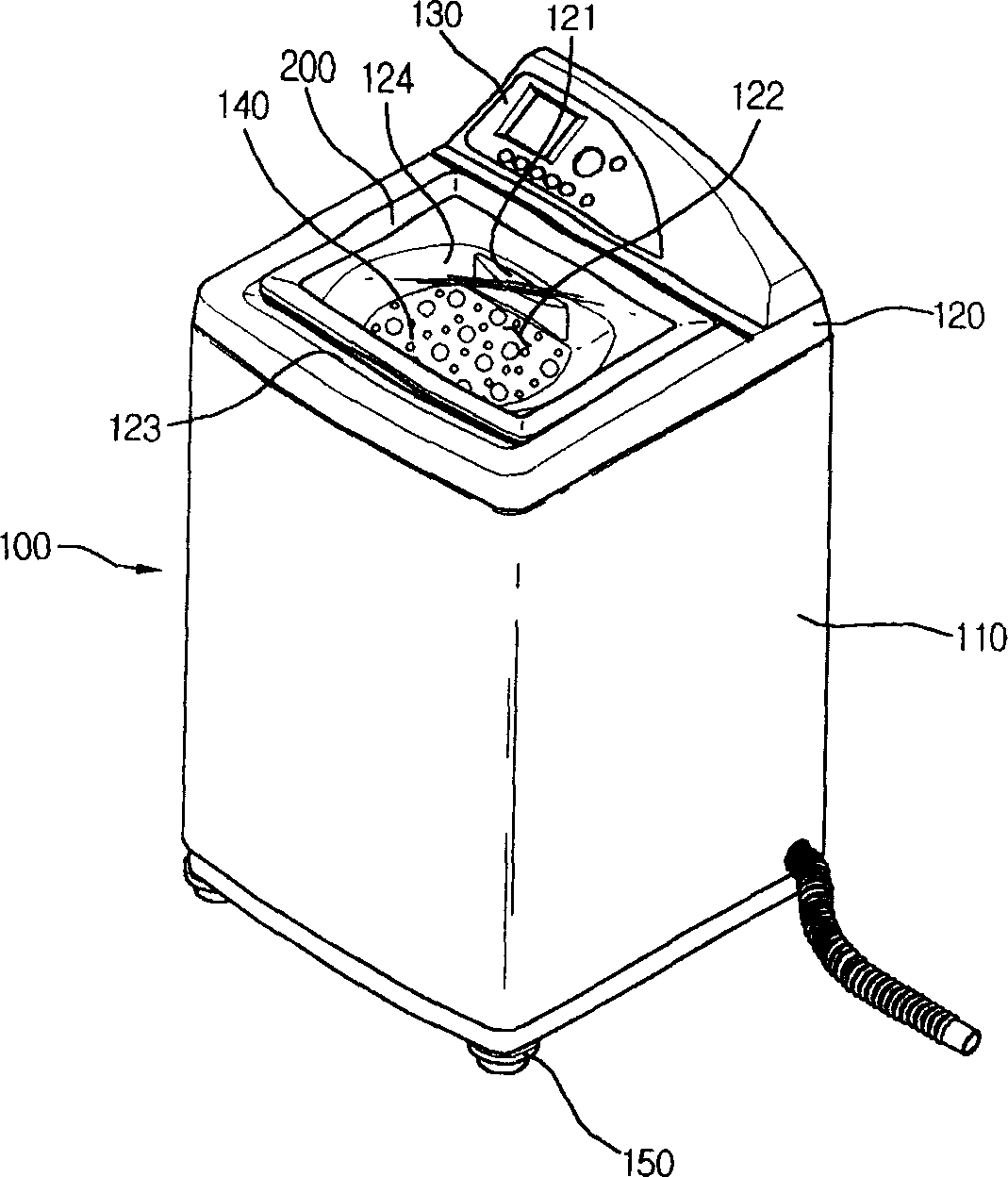

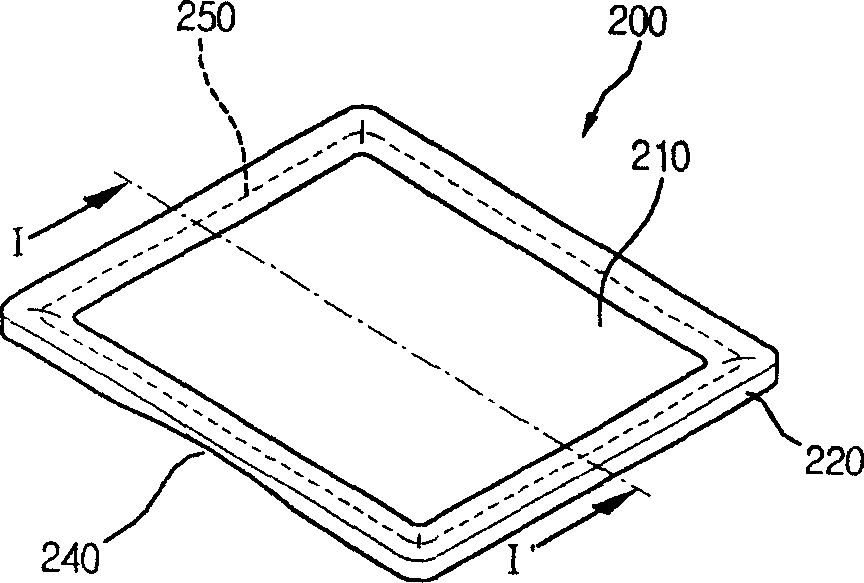

Washing machine lid structure and method for fabricating the same

InactiveCN1884672AWill not deformReduce stress effectsOther washing machinesTextiles and paperEngineering

The invention discloses a lid structure of washing machine, which comprises the following parts: lid body, buffer structure around lid body, lid around the buffer structure. The making method of lid comprises the following steps: tightening buffer structure around lid body; placing lid body with buffer structure in the mould; flowing resin composition in the mould; solidifying the resin composition; separating the mould; making buffer structure adsorb stress from lid.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

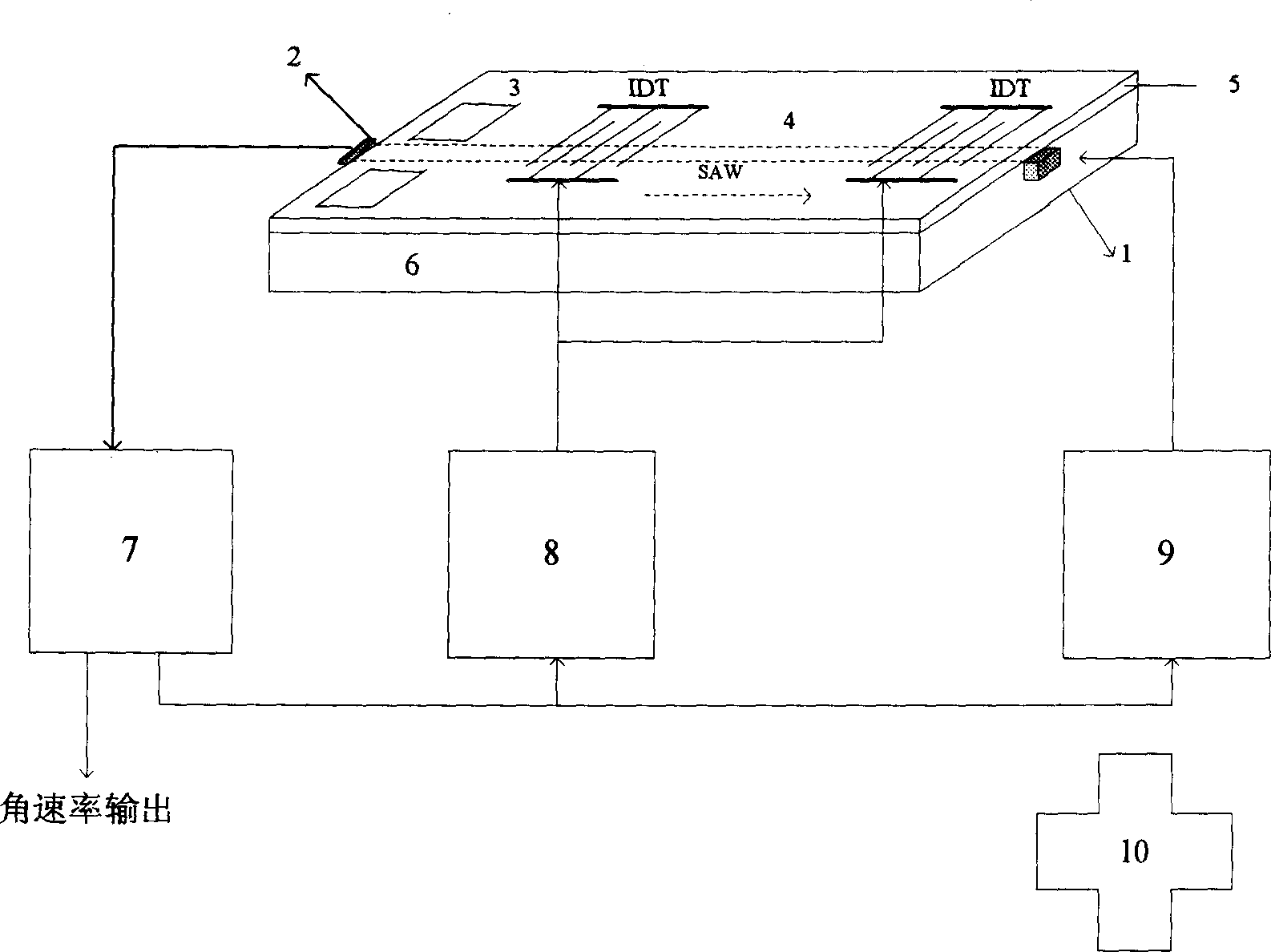

Micro photo-electro-mechanical gyro

InactiveCN1884972AImprove detection accuracyImprove anti-electromagnetic interference performanceSpeed measurement using gyroscopic effectsRotary gyroscopesGyroscopeGrating

The invention relates to a device of testing the rotation angular speed, relating to the acoustic wave technique, especially providing a micro optical mechanical gyroscope, wherein it is formed by laser source, acoustic surface wave sensor, optical waveguide, electric optical modulator, detector and signal processing system; it is characterized in that: it uses refractive optical signal to measure the angular speed of gyroscope rotation; the interdigital transducer (IDT) generates acoustic surface wave to change the refractive index of medium to form density grid, to refract the optical transmitted in waveguide on the acoustic grid; since the matter will generate Ge force when rotation to change the frequency characteristic parameter of acoustic wave; and the detector receives the first refracted light, to read out the angular speed sensitive to the Ge force from the changes of light intensity and phase. The invention can resist to vibration and electromagnetic interference, with wide temperature application and higher accuracy then present MEMS gyroscope, to test the inertia test unit.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

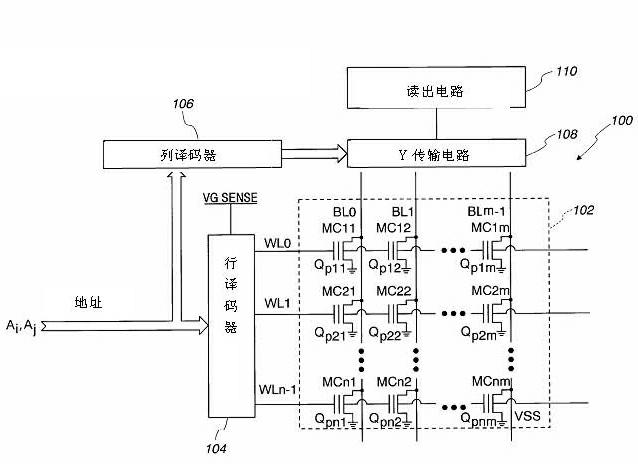

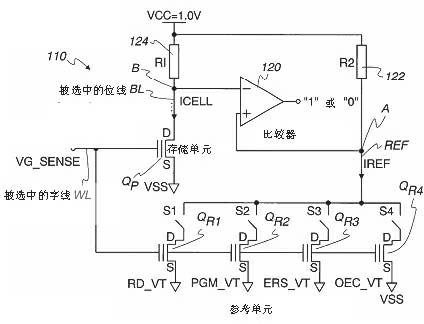

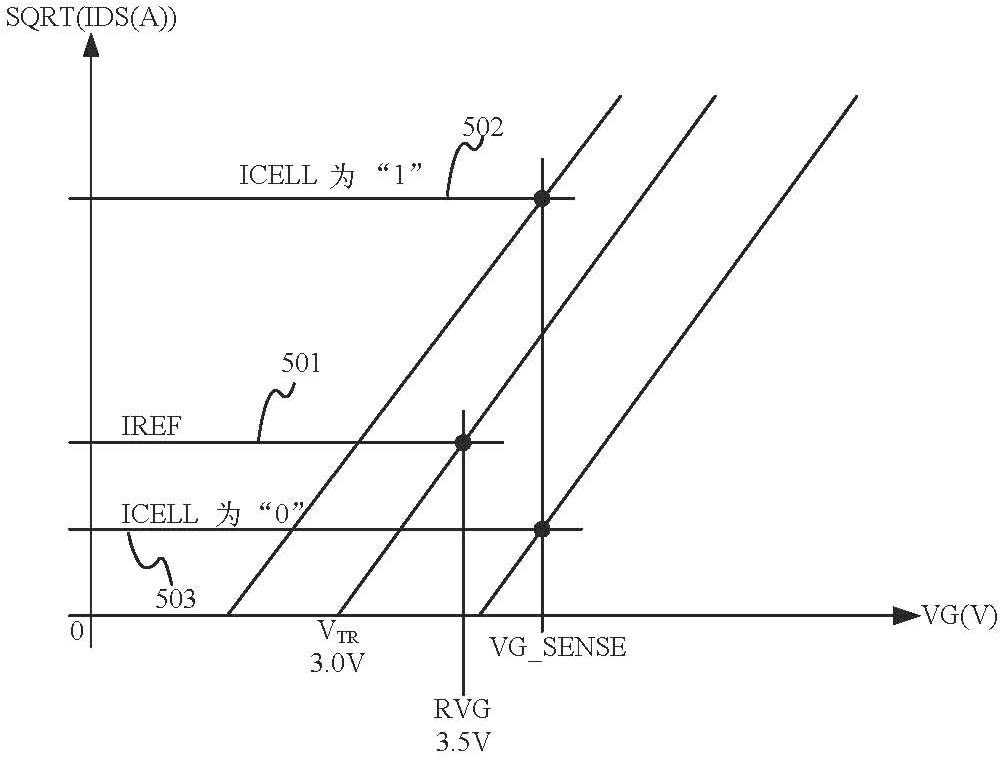

Readout circuit and readout method for electrically erasable read-only memory

ActiveCN102467967AImproved Threshold Voltage StabilitySave configuration timeRead-only memoriesElectricityComputer science

The invention relates to a readout circuit and a readout method for an electrically erasable read-only memory. The readout circuit comprises a comparator, a reference resistor, a sensing resistor, a reference unit and a storage unit, wherein the readout circuit is only configured with one reference unit, and the same reference unit is used in the process of reading operation; the threshold voltage of the reference unit is set into neutral threshold voltage; and the voltage on a reference unit control grid is set into a fixed value, so that the configuration time in the manufacturing process is obviously reduced, and the threshold added on a storage unit control grid is changed along with operating modes. Meanwhile, the voltage added on the storage unit control grid during the reading operation and programming verification operation is lower than that in the prior art, so that a stress effect of grid voltage is reduced, and the threshold voltage of the reference unit is set to a value approaching the neutral threshold voltage so as to be more stable.

Owner:SHANGHAI FUDAN MICROELECTRONICS GROUP

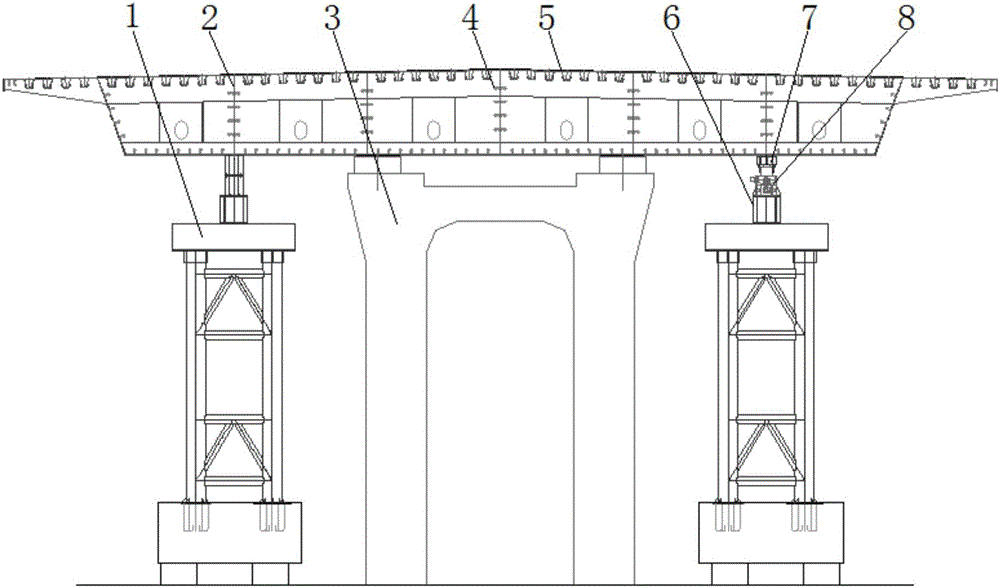

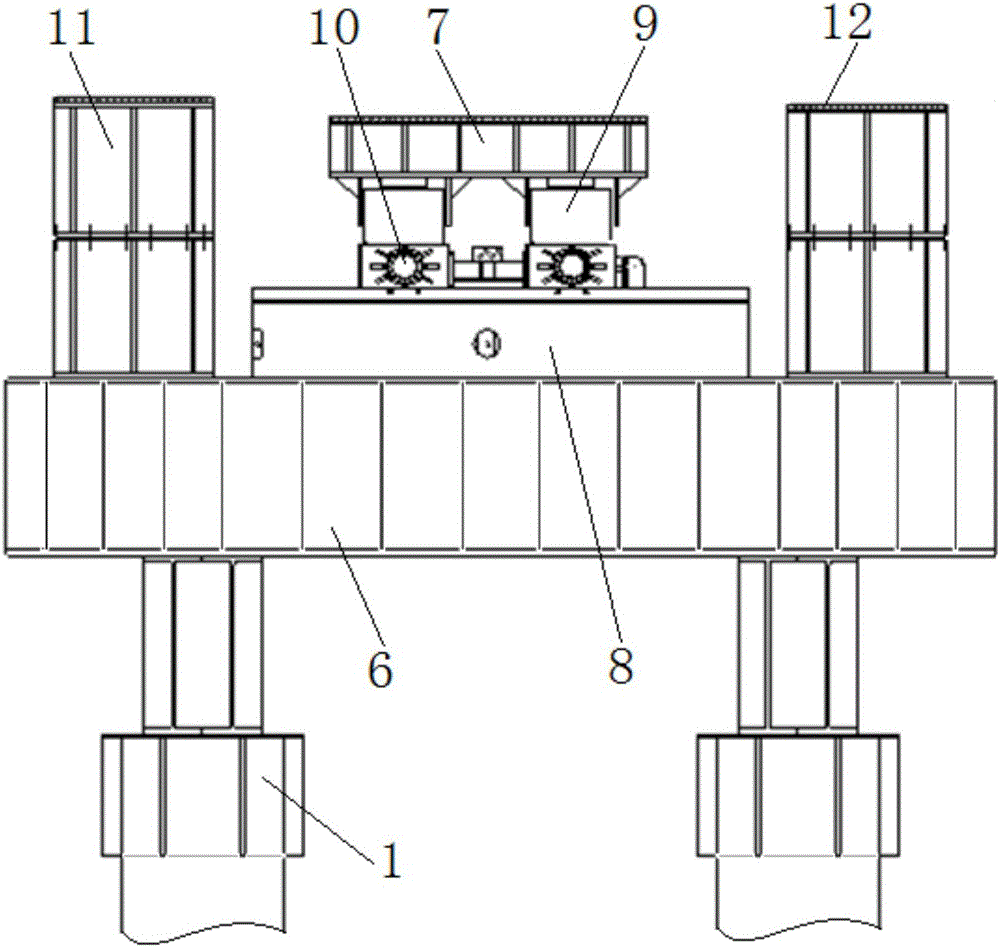

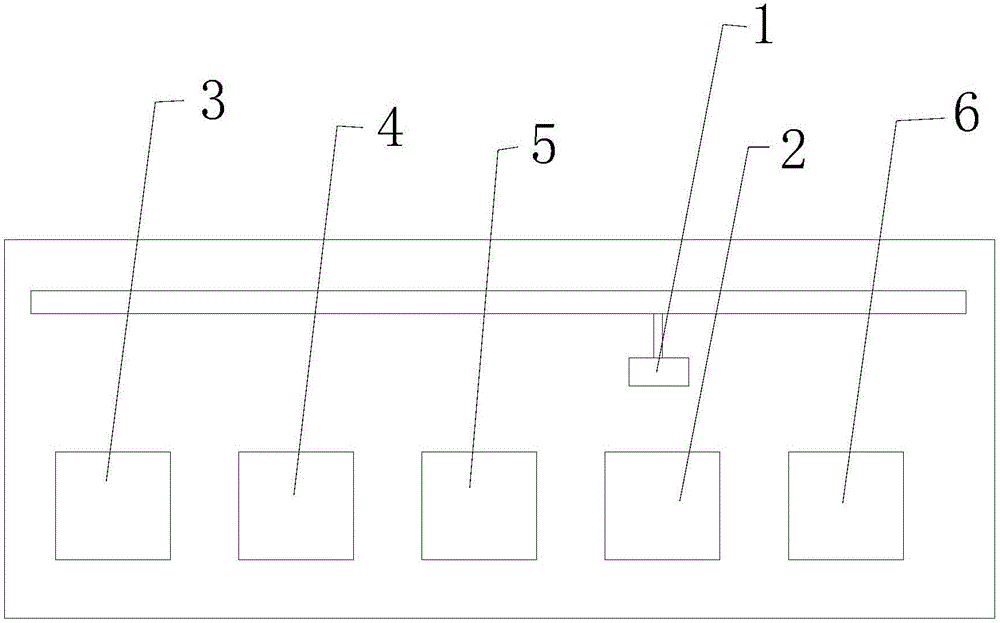

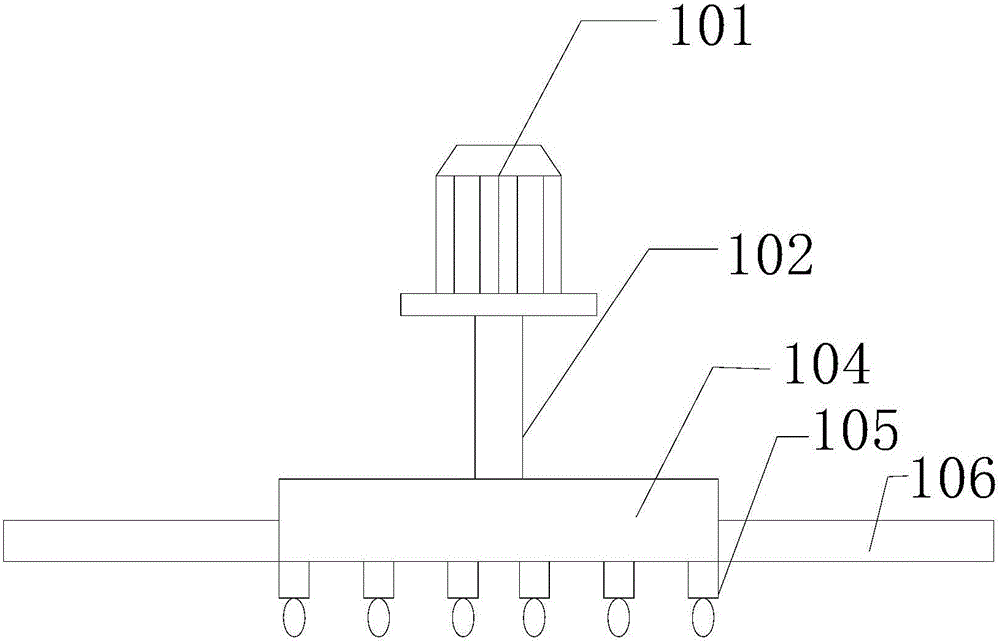

Steel box beam pushing and deviation correcting method for walking type multiple-point continuous pushing technique

The invention provides a steel box beam pushing and deviation correcting method for a walking type multiple-point continuous pushing technique. A multiple-point walking type pushing technology is adopted, and a plurality of walking type pushing devices are controlled in a centralized mode for synchronous construction, so that the construction speed is increased, and construction safety is ensured; and vertical jacking control is conducted in the jacking and falling processes, synchronous pushing control and central axis deviation correcting control are conducted in the translation process of a steel box beam, balance degree control and accumulative error control are continuously conducted in the whole pushing process, a pressure sensor, a displacement sensor and an optoelectronic switch monitor and detect the steel box beam pushing pressure and the central axis deviation distance in the pushing process in real time through color difference detection, and smooth construction is ensured.

Owner:HAIOD HEAVY ENG TECH

High-efficiency hot dip galvanizing production line

ActiveCN105861970AQuick removalEasy to salvageHot-dipping/immersion processesAcid washingEngineering

The invention discloses a high-efficiency hot dip galvanizing production line which comprises a lifting appliance, a zinc pot, an acid washing tank, a water washing tank, a cosolvent tank and a cooling tank. The high-efficiency hot dip galvanizing production line can quickly remove bubbles on the workpiece surface in the workpiece galvanizing process, can gather the zinc ash on the surface before the workpiece is taken out of the zinc pot so as to prevent the adhesive pollution, can enable the reflux motion of the acid liquor in the acid washing tank so as to increase the contact reaction rate between the acid liquor and acid-washed workpiece, can monitor the concentration of the acid liquor in real time, can enable the water washing of the workpiece to proceed more quickly and thoroughly, can enable the contact between the workpiece and cosolvent more uniformly and quickly, can eliminate the influence of the impurities and stains attached to the workpiece surface on the cosolvent treatment so as to effectively ensure the feed quality of the subsequent procedure, and can enable the water cooling heat transfer of the acid washing wastewater for the hot dip galvanizing cooling tank so as to save the water resources and enhance the wastewater utilization efficiency, thereby saving the production cost.

Owner:浙江慧钢技术发展股份有限公司

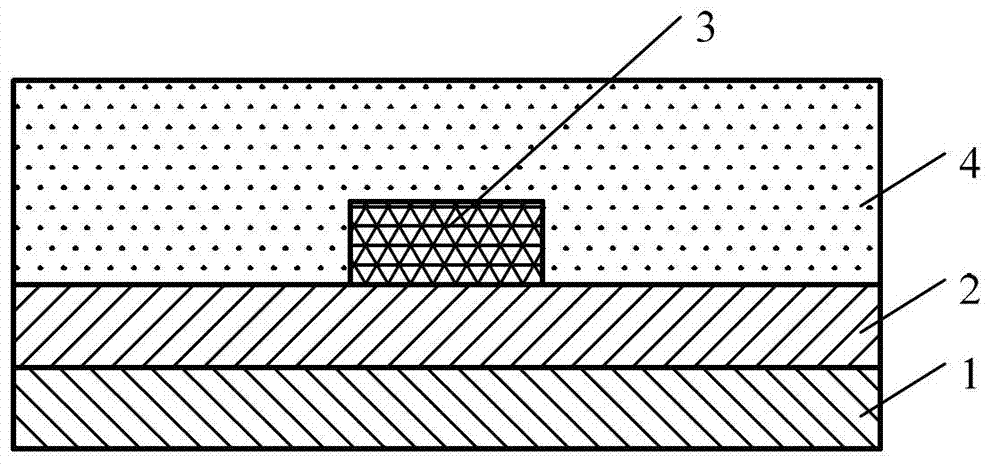

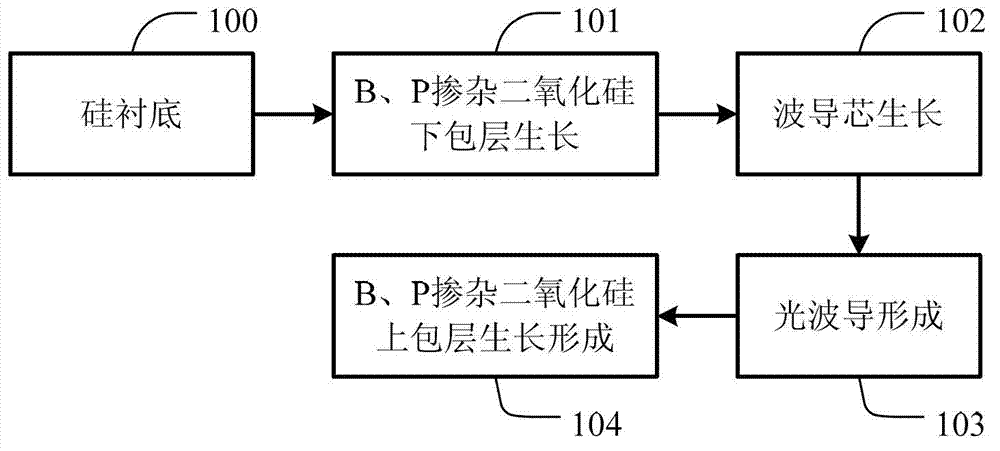

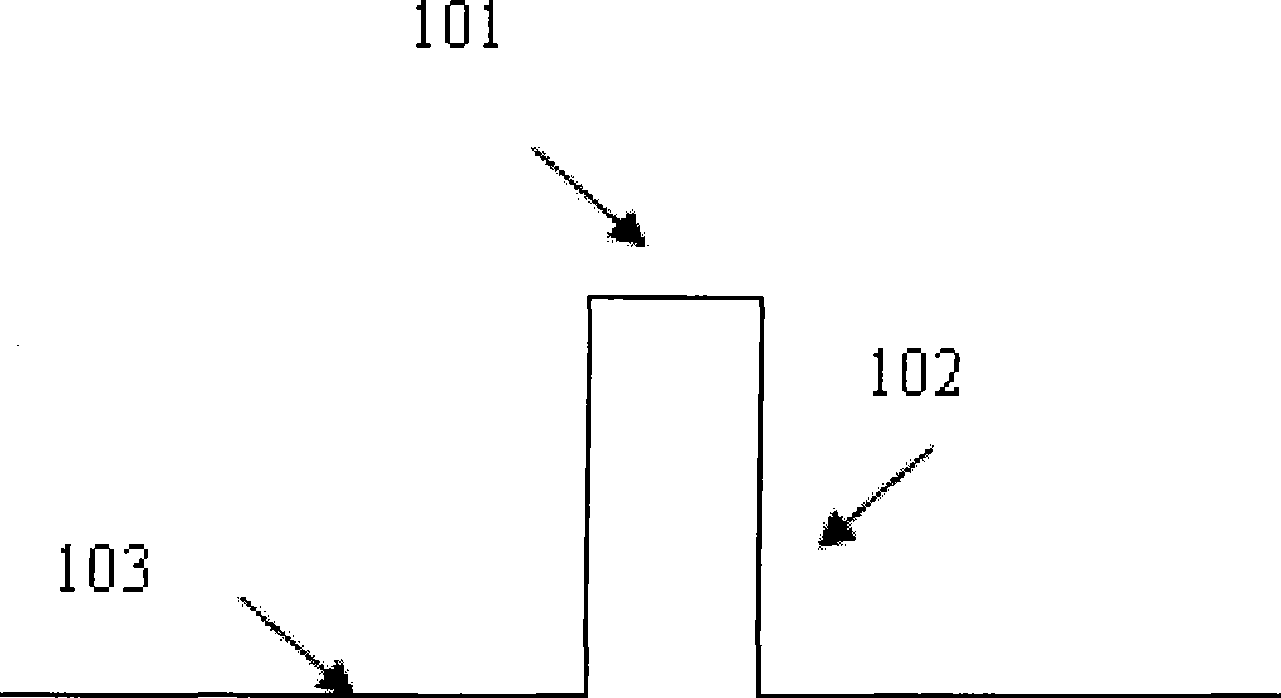

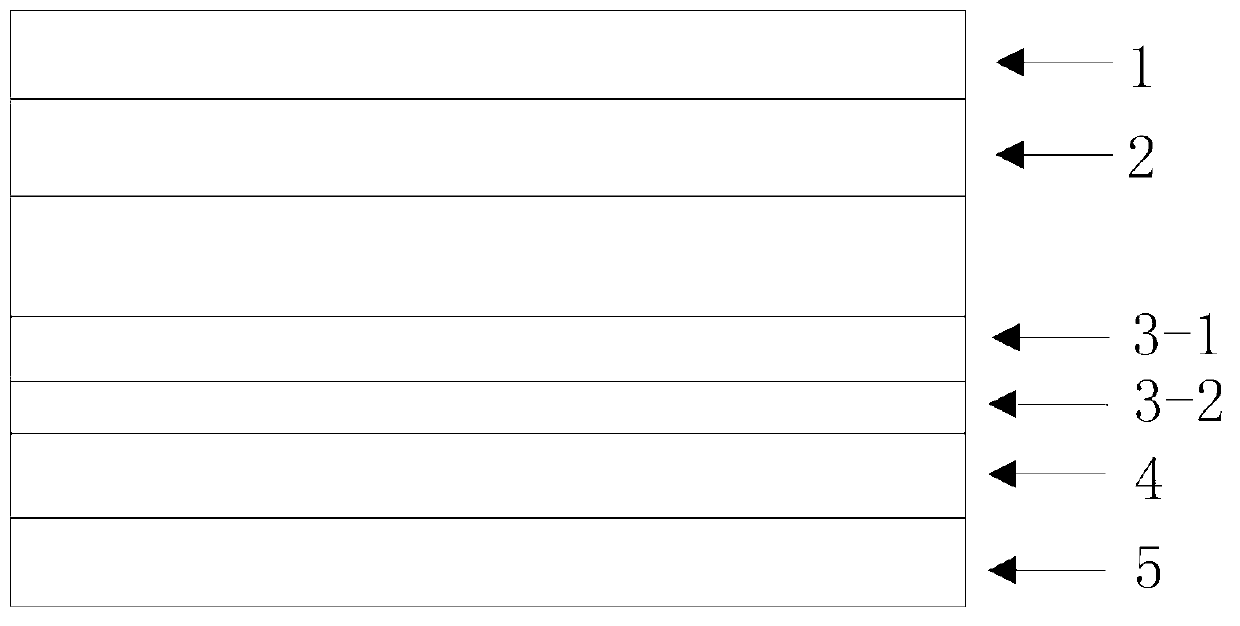

Array waveguide grating structure based on PLC (programmable logic controller) technique and manufacturing method thereof

InactiveCN102736177AReduce stress effectsLow polarization dependent lossOptical light guidesGratingProgrammable logic controller

The invention discloses an array waveguide grating structure based on a PLC (programmable logic controller) technique and a manufacturing method thereof. The manufacturing method comprises the following steps of: selecting a substrate, depositing and growing a B and P doped silica layer as a lower coating layer on the selected substrate by adopting a PECVD (plasma enhanced chemical vapor deposition) process; growing a waveguide core layer on the lower coating layer; preserving a waveguide core in a preset shape on the waveguide core layer, and corroding to remove the part except the waveguide core in the preset shape and to remain the waveguide core in the preset shape; and growing a B and P highly doped silica layer capable of completely covering the lower coating layer and the waveguide core as an upper coating layer on the lower coating layer and the waveguide core, so that the needed array waveguide grating structure based on the PLC technique is manufactured. By using the array waveguide grating structure based on the PLC technique and the manufacturing method thereof, which are provided by the invention, the defects of long growth period, high cost, bad product performance and the like in the prior art can be overcome, so as to realize the advantages of short growth period, low cost and good product performance.

Owner:无锡思力康光子科技有限公司

Oxyeleotris marmoratus food habit domestication method

InactiveCN101496499AReduce stress effectsImprove the living environmentClimate change adaptationPisciculture and aquariaFlowerpotAquaculture

The invention relates to a method for domesticating food habit of oxyeleotris marmoratus, which relates to the aquaculture. The gradual addition of artificial fodders into fresh and live baits or the addition of a phagostimulant into the artificial fodders needs to be avoided. An indoor cement pond has the water depth of 60cm and the water temperature of between 26 and 28 DEG C. The method is characterized in that: the method comprises the following steps: placing flower pots and tiles on the bottom of the domestication pond so as to facilitate the hiding of the oxyeleotris marmoratus, and covering the upper part of the domestication pond with a light-tight plastic plate; selecting adult fish with the body length of between 14 and 16cm as food habit domestication objects, and on the food habit domestication day, evenly mixing fish meal and water and making strip soft fodders which are gradually fed into the domestication pond according to the size of fish mouths; removing residual baits after the baits settle down into the water; turning off the indoor light source in the food habit domestication process, stopping running water stimulus, keeping a quiet food habit domestication environment, carrying out the food habit domestication one time respectively in the morning, at noon and in the afternoon, setting 30 to 40 minutes for each time of food habit domestication, and setting the food habit domestication quantity not above 1 percent of the body weight; and feeding soft artificial pellet fodders after 7-day continuous domestication, and then feeding artificial pellet fodders after 7-day continuous feeding of the soft fodders.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

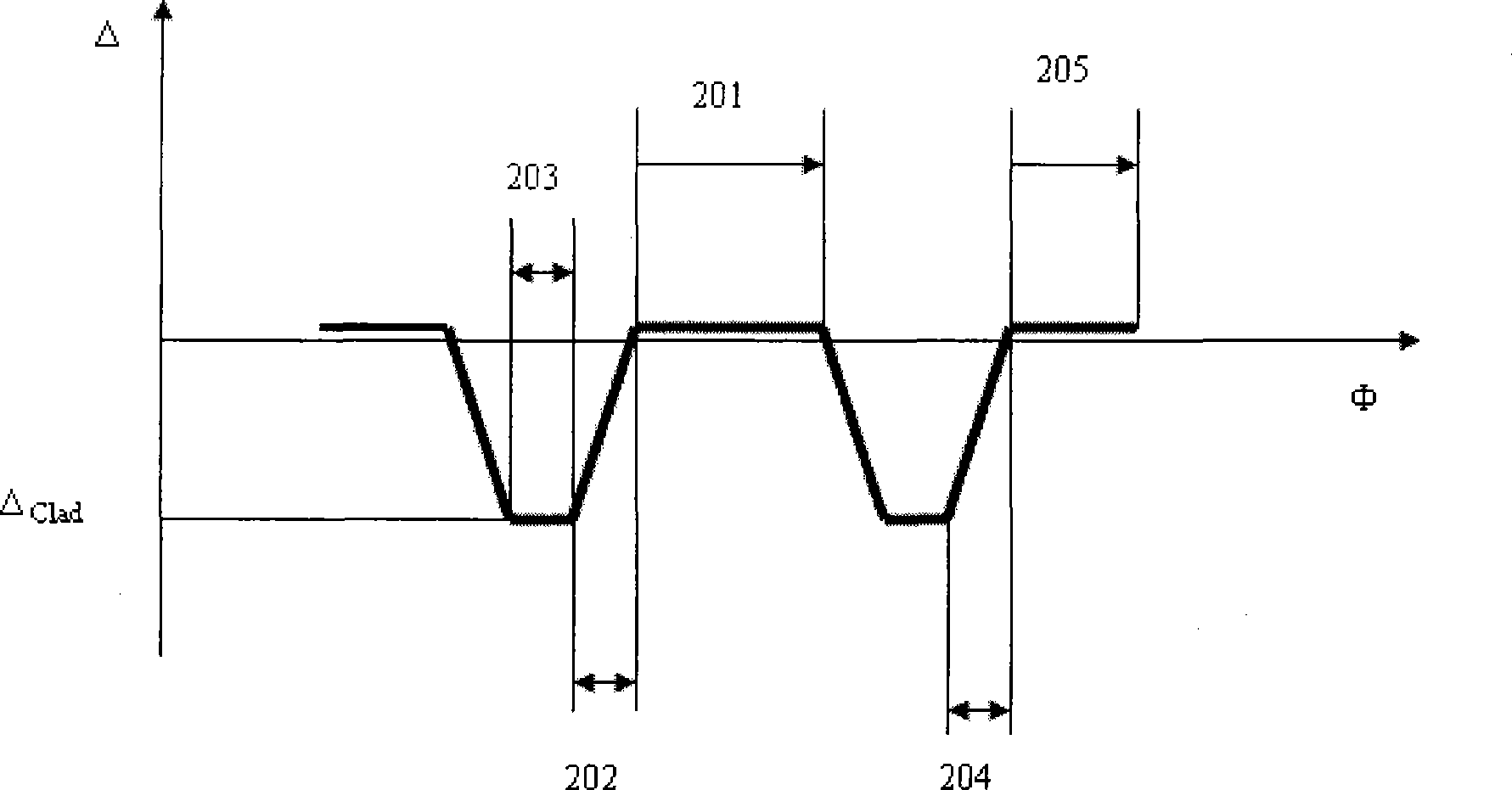

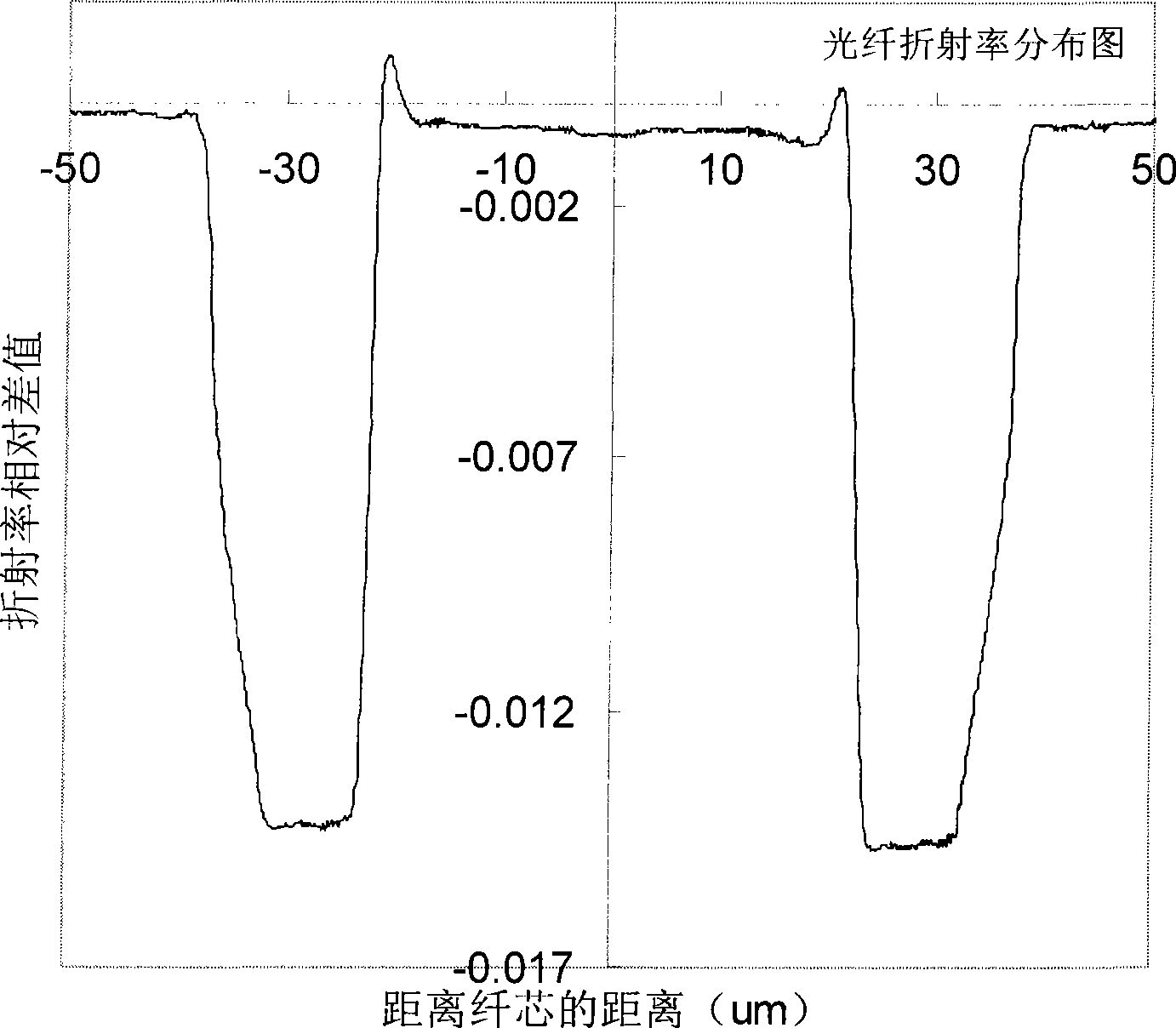

Novel ultraviolet transmission optical fiber and preparing method thereof

ActiveCN101414028AImprove transmission performanceGuaranteed transmission performanceGlass making apparatusOptical fibre with multilayer core/claddingRefractive indexUltraviolet

The invention relates to a novel ultraviolet transmission optical fiber and a preparation method thereof. The section structure of the ultraviolet transmission optical fiber comprises a pure silicon quartz fiber core layer, a fluorine-doped quartz depressed inner cladding layer and a pure silicon quartz outer cladding layer, a changing gradient refractive index structure is adopted on two transition layers between the depressed inner cladding layer and the pure quartz core layer as well as between the depressed inner cladding layer and the outer cladding layer. The optical fiber can be used in windows below 600nm, has lower attenuation in ultraviolet wavelength windows, and can keep stable transmission characteristics during use. The optical fiber has extensive application in the fields of industrial application, optical fiber sensing, optical fiber medical treatment and the like.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

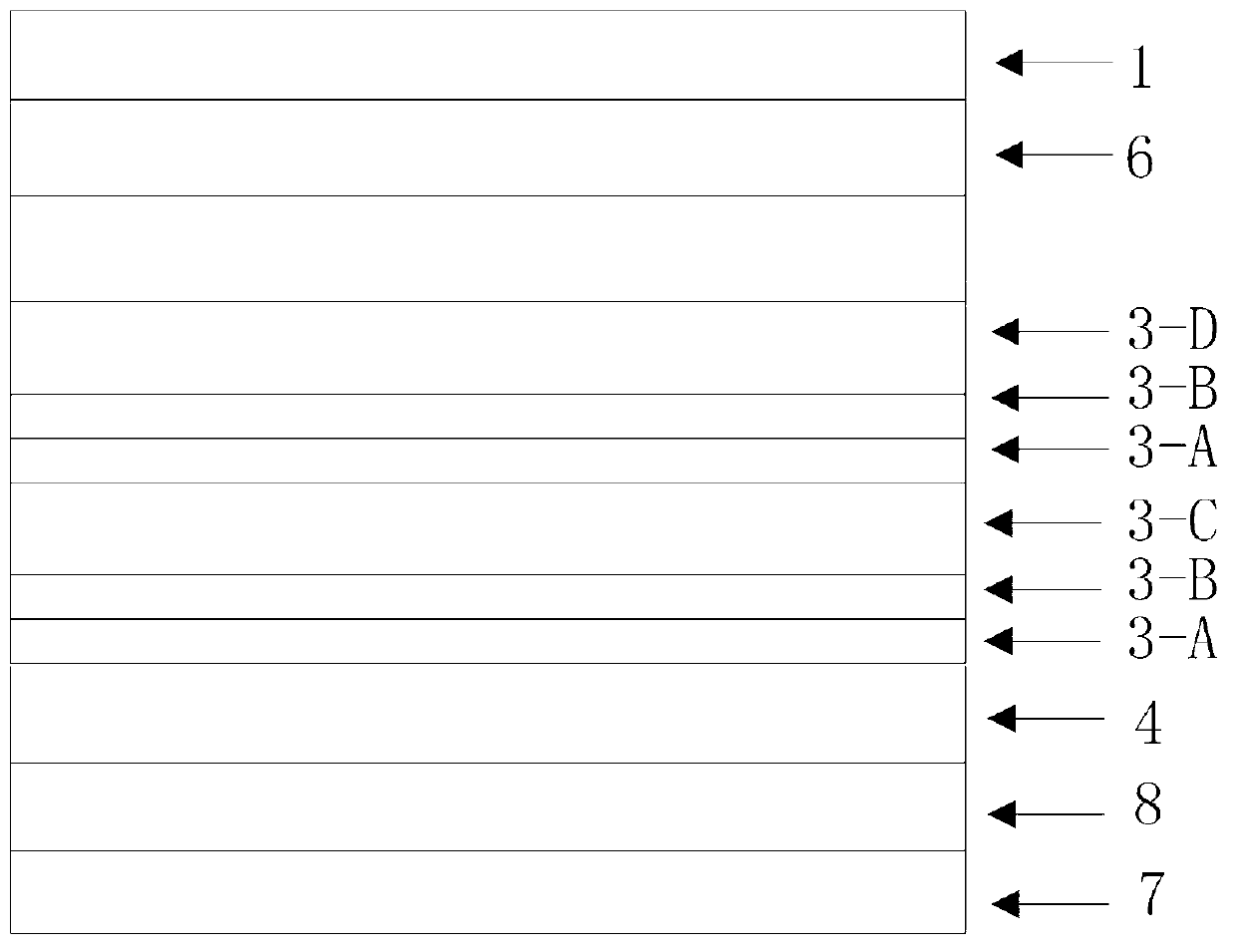

Growing method for duplex multi-quantum well luminescent layer structure and LED epitaxial structure

ActiveCN103346219AImprove light extraction efficiencyImprove compound rateSemiconductor devicesLarge sizeWave function

The invention provides a growing method for a duplex multi-quantum well luminescent layer structure and an LED epitaxial structure. A well luminescent layer of the epitaxial structure comprises six to eight unit layers, wherein each unit layer comprises a first well layer, a second well layer, a first epitaxial layer, a first well layer, a second well layer and a second epitaxial layer from top to bottom in sequence. According to the growing method for a duplex multiple-quantum well luminescent layer structure and the LED epitaxial structure, a duplex multiple-quantum well is adopted, the situation that separation of wave functions is caused by the stress of well layers and epitaxial layers in a traditional multi-quantum well is improved, and the situation that the hole concentration of the well layers is too low due to the epitaxial width in the traditional multi-quantum well is improved. Efficiency obtaining of the quantum well inside an LED chip is improved, the brightness of medium and small size LED chips is improved in macro view, and the lighting effects of large size LED chips are improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

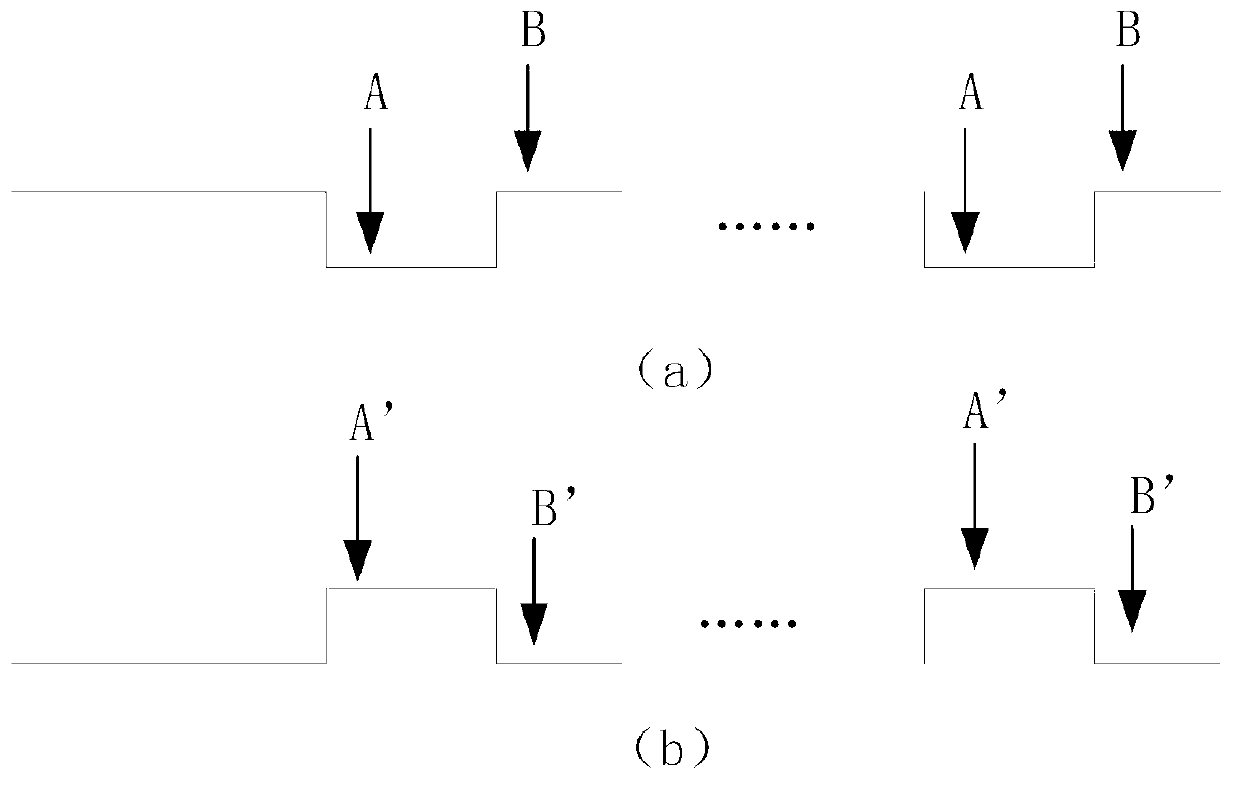

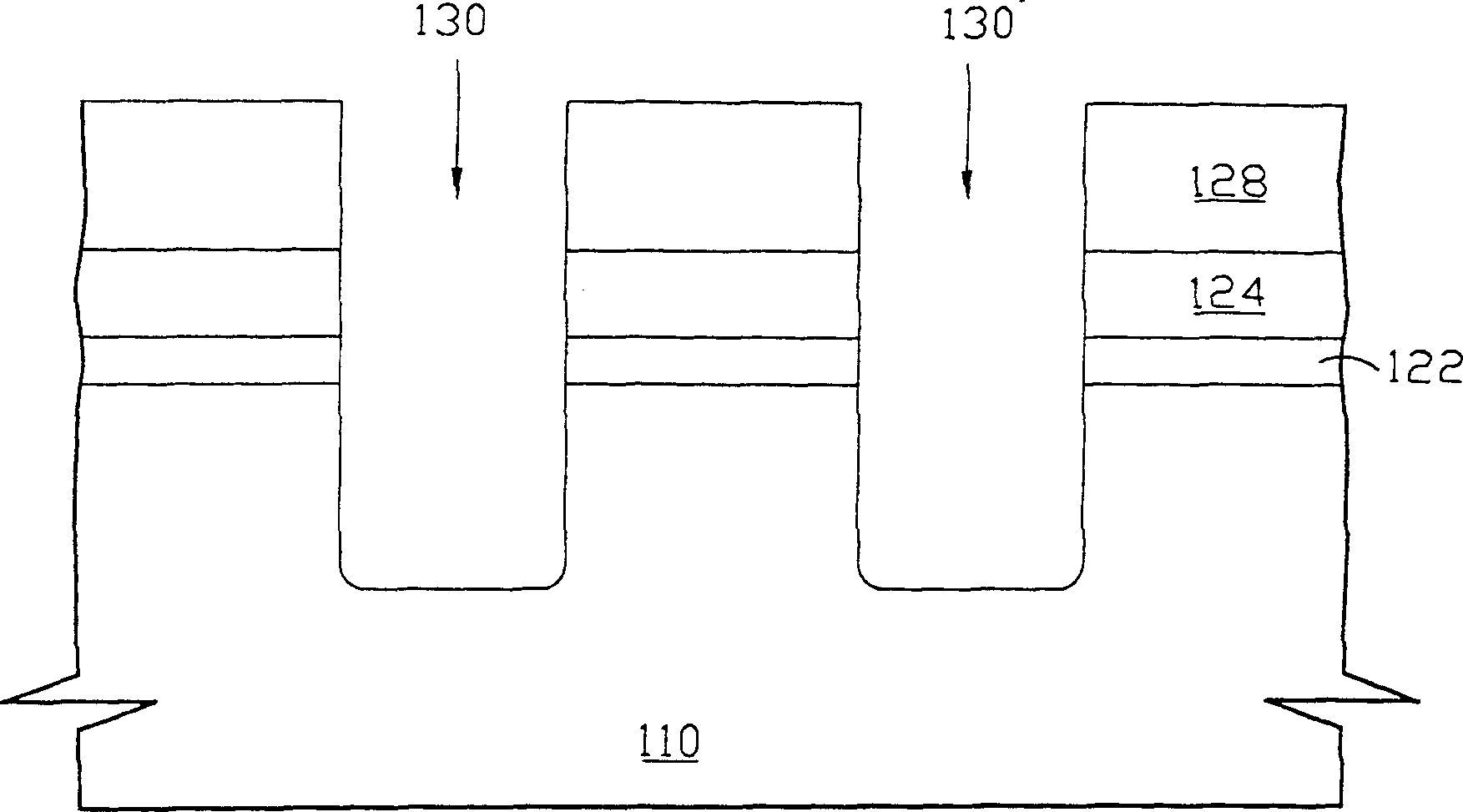

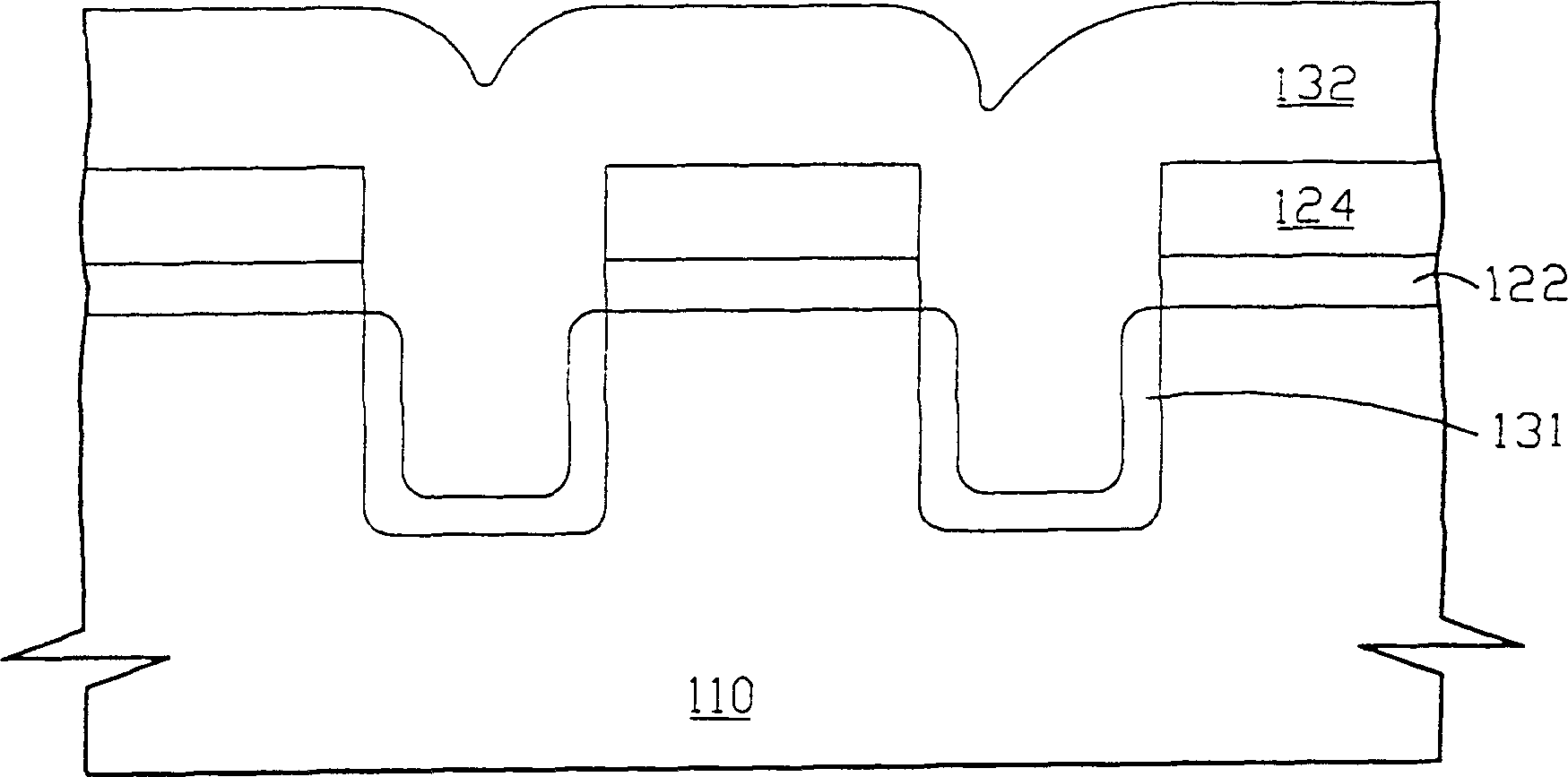

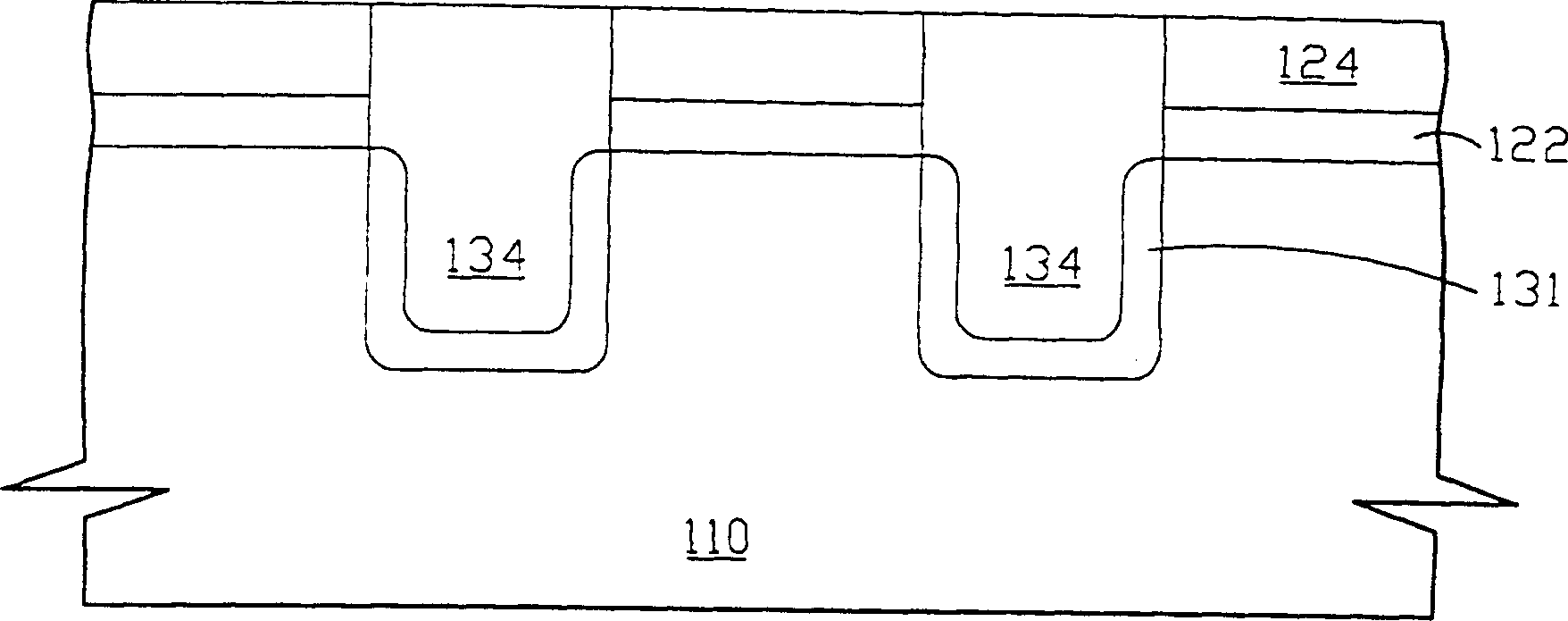

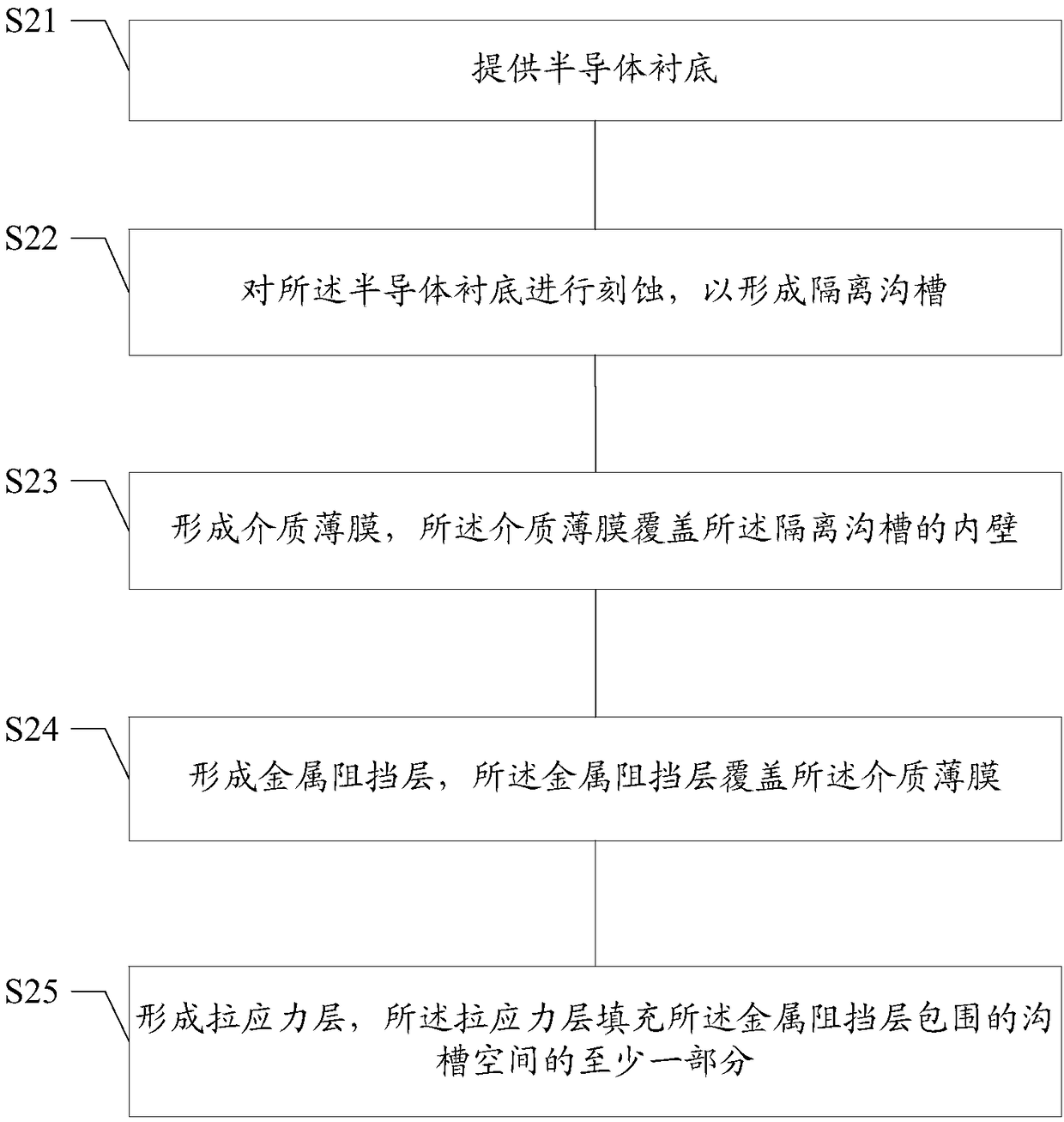

Method for eliminating stress and damage while forming isolation component

InactiveCN1450621AStress reliefEliminate damageSemiconductor/solid-state device manufacturingElectrical conductorStress relieving

This invention provides a method for eliminating stress and damage when forming a channeled isolation element including: providing a semi-conductor basic material to be etched to form a channeled structure, processing the channeled structure with high temperature annealing or quick heat annealing to eliminate stress of the channeled structure to reach the aim of avoiding the reduction of the reliability, semiconductive elements or annealing processing to a sidewall oxidation layer to eliminate the stress generated by the oxidation layer of the channeled structure.

Owner:MACRONIX INT CO LTD

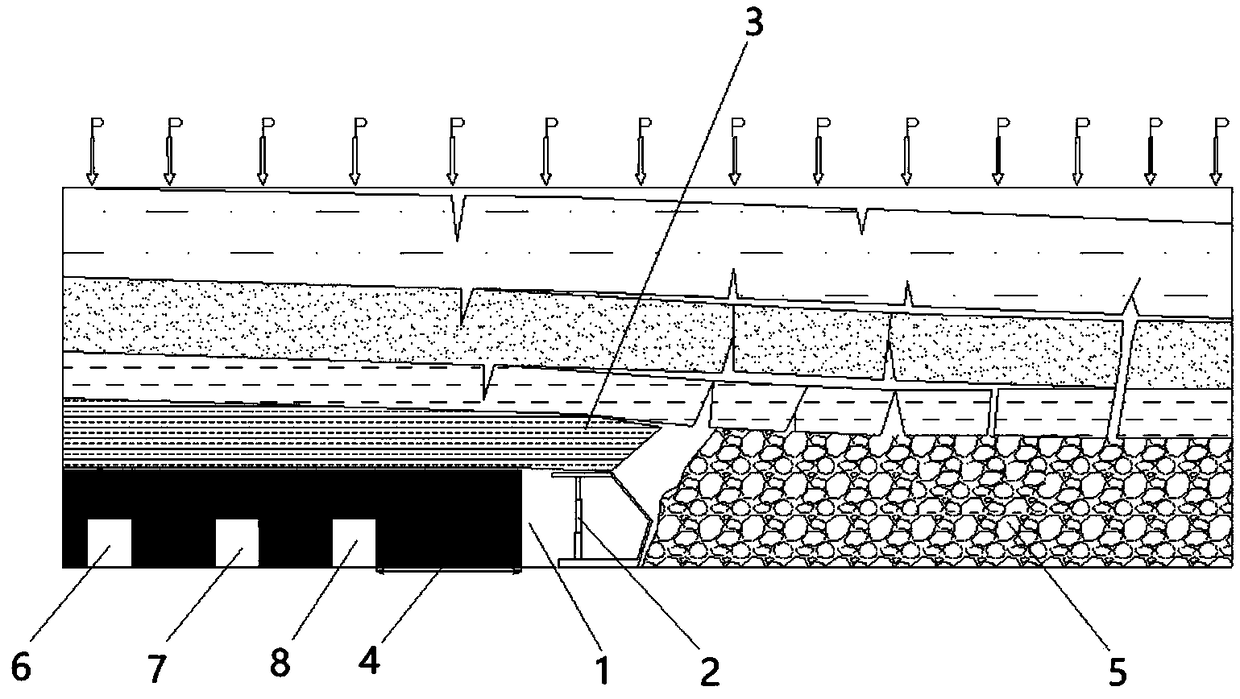

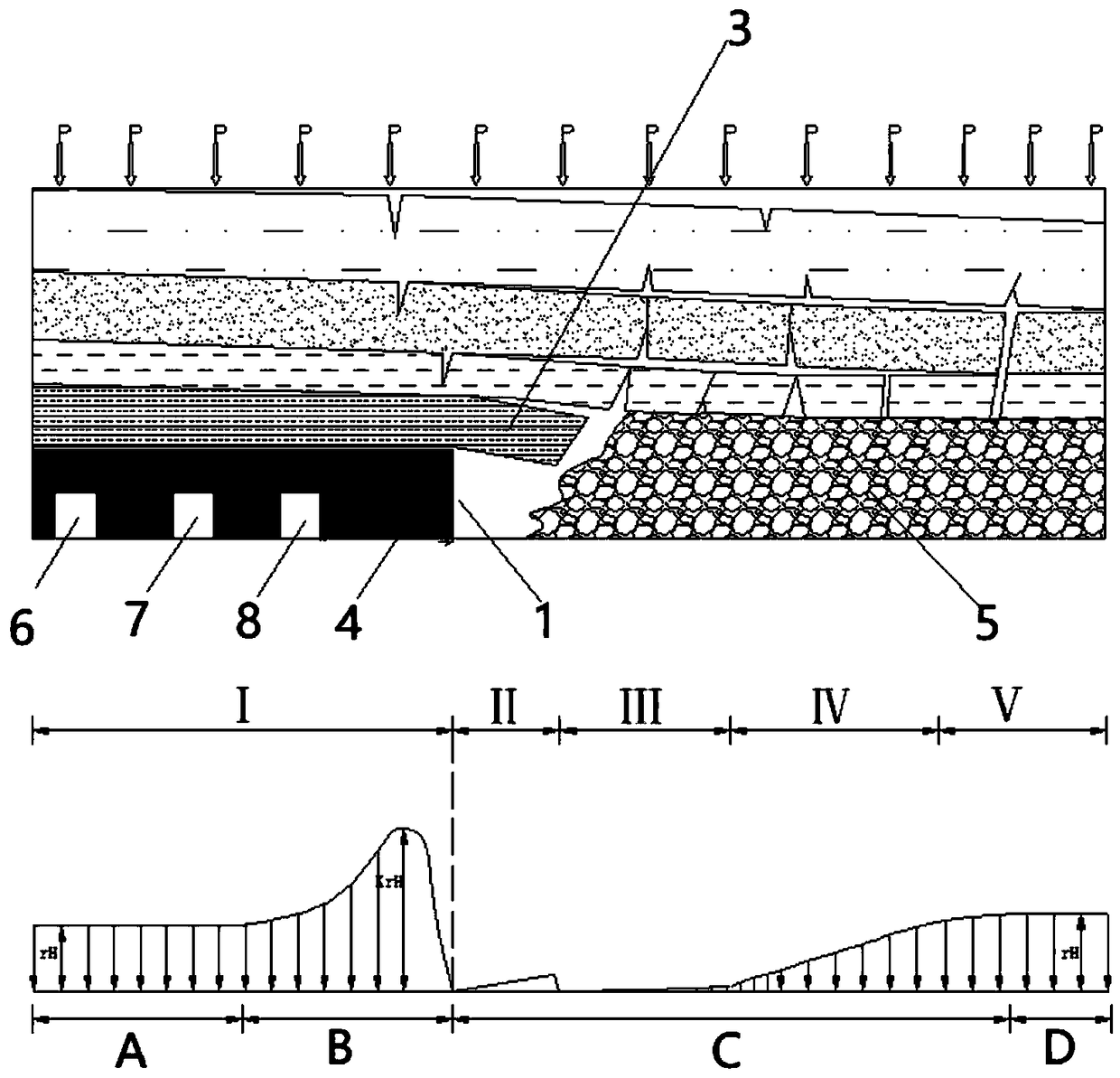

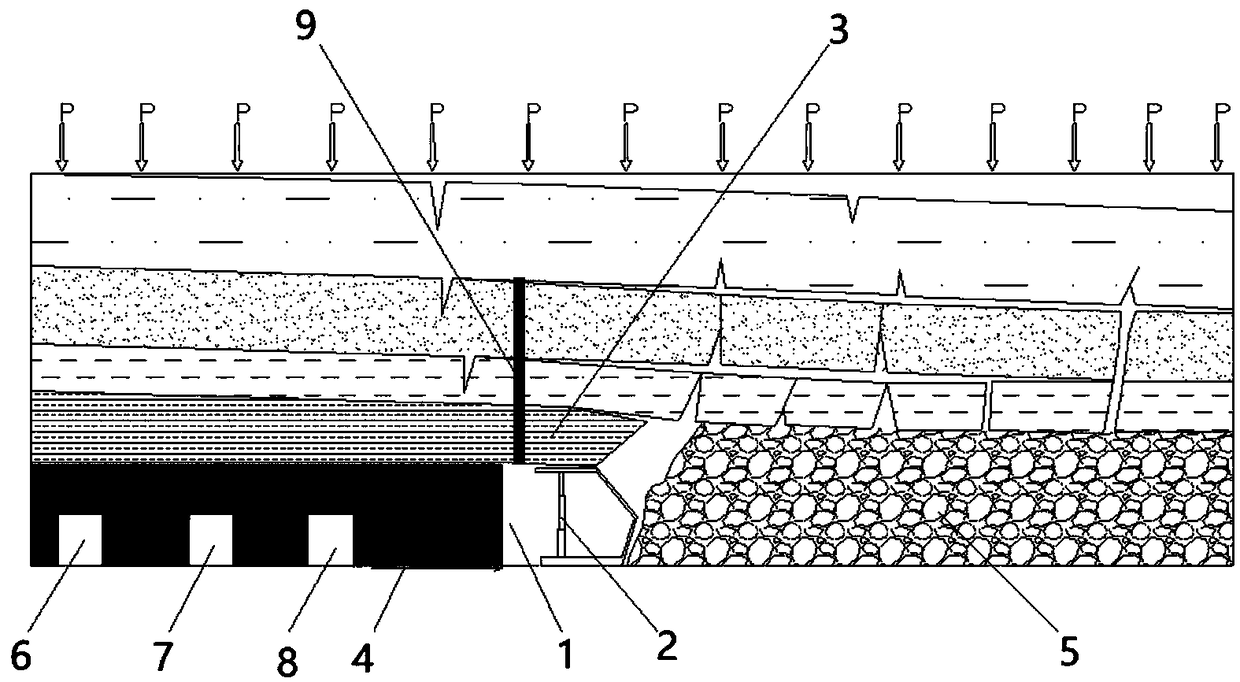

Roof cutting pressure relief protective method for exploitation stop face of fully mechanized working face

ActiveCN109209495AProtect security and stabilityResolve and eliminate stress effectsMining devicesProps/chocksMachining systemHigh stress

The invention relates to a roof cutting pressure relief protective method for an exploitation stop face of a fully mechanized working face, and belongs to the technical field of surrounding rock stability protection for a permanent tunnel by the fully mechanized working face. In the protection method, the exploitation stop face of the fully mechanized working face is preset between a coal mining tunnel area and a goaf, an overlying stratum layer over the exploitation stop face is cut vertically upwardly before that a three-machine system is evacuated from the exploitation stop face to obtain aroof cutting surface, the overlying stratum layer over the exploitation stop face is disconnected from the overlying stratum layer over the coal mining tunnel area by the roof cutting surface, so that when the three-machine system is used for support, stress connection between the overlying stratum layers over the exploitation stop face and the coal mining tunnel area is cut off rapidly. Influence of high stress of the overlying stratum layer over the exploitation stop face on stress of the overlying stratum layer over the coal mining tunnel area is eliminated effectively, a dynamic pressuresource acted on the tunnel is eliminated fundamentally, a large tunnel or a concentrated tunnel of the goaf is avoided from high concentrated stress, and the permanent tunnel is kept safe and stable for long time.

Owner:TIANDI SCI & TECH CO LTD +1

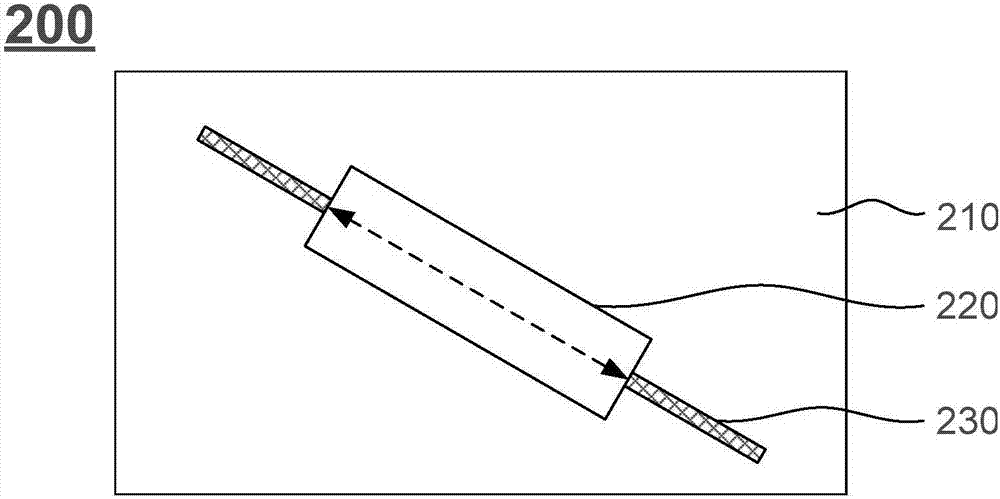

Flexible electronic device and manufacturing method therefor

ActiveCN107204342AGuaranteed electrical performanceGuaranteed rubbing resistanceFinal product manufactureDigital data processing detailsFlexible electronicsElectricity

The invention provides a flexible electronic device and a manufacturing method therefor. The electronic device comprises a flexible substrate and a device layer formed on the flexible substrate. The device comprises a semiconductor structure and a wire structure, which are connected with each other. The extending direction of the wire structure is consistent with the trench direction of the semiconductor structure. The extending direction of a first wire structure and the stretching direction of the flexible substrate form an inclined angle which is less than 90 degrees. According to the invention, the impact on the semiconductor structure and the first wire structure from stress is reduced to the minimum value through the adjustment of the trench direction of the semiconductor structure and the extending direction of the first wire structure, thereby guaranteeing the electrical performances and anti-kneading performances of the flexible electronic device.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

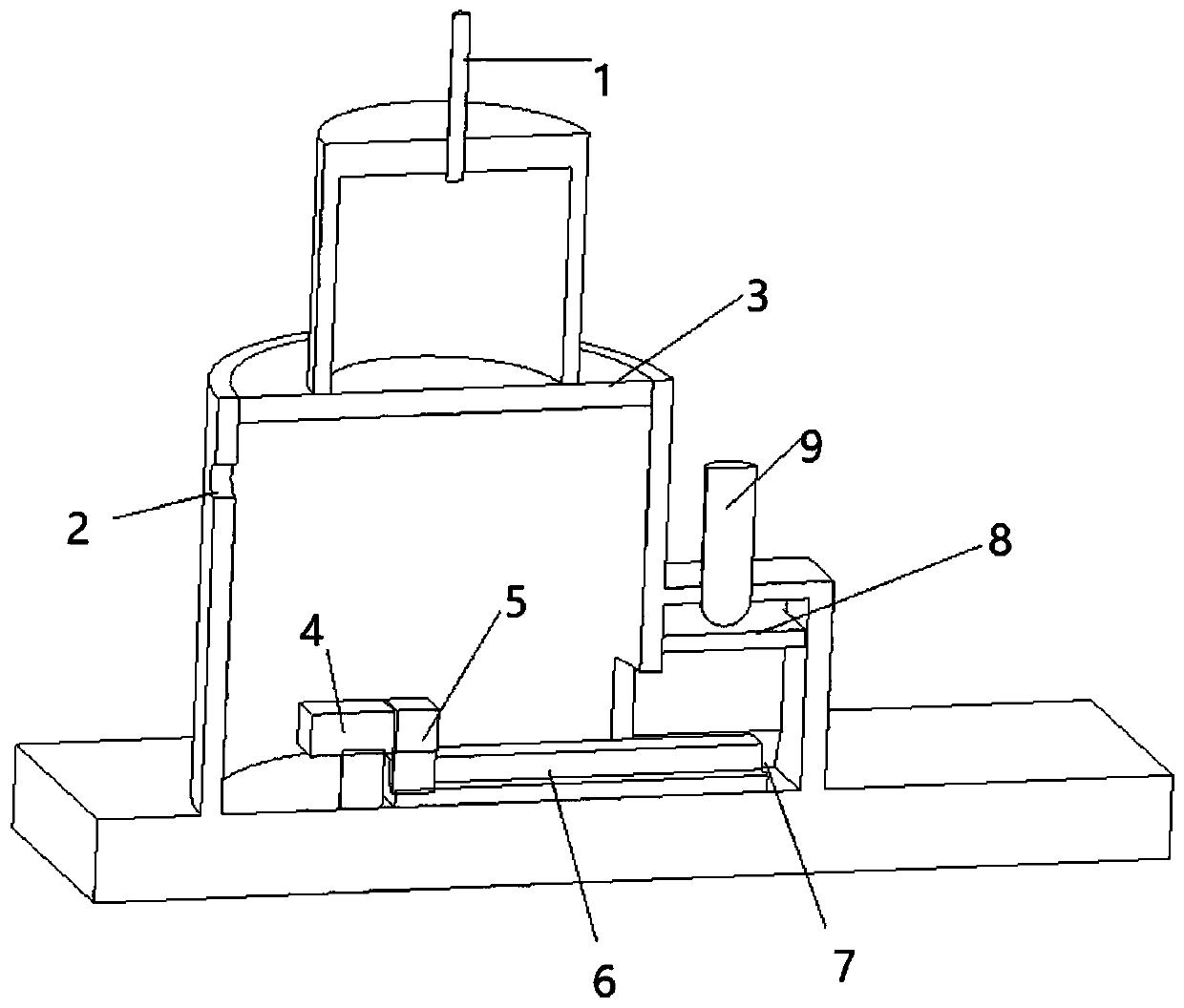

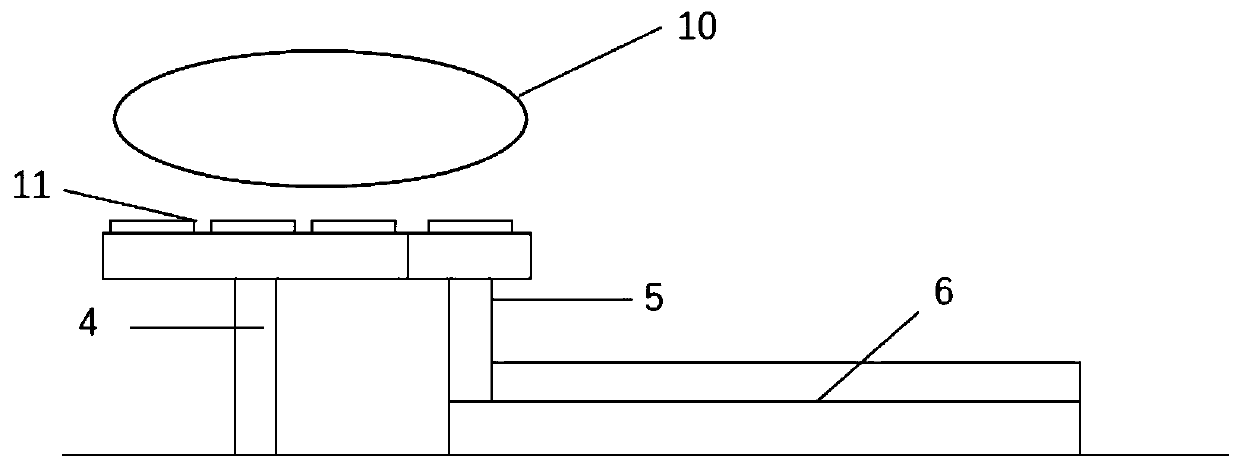

Chemical vapor deposition device comprising Raman spectroscopy in-situ measurement cavity

ActiveCN109852947AAddressing the Impact of DetectionReduce stress effectsRaman scatteringChemical vapor deposition coatingGas phaseChemical vapor deposition

The present invention relates to a chemical vapor deposition device comprising a Raman spectroscopy in-situ measurement cavity. The device comprises a transmission device, a reaction cavity for performing chemical vapor deposition reaction on a thin film material and a monitoring cavity for performing Raman spectroscopy in-situ monitoring on the thin film material; the reaction cavity communicateswith the monitoring cavity, a reaction base is arranged in the reaction cavity, and a Raman spectroscopy monitoring module is arranged in the monitoring cavity; the reaction base is used as a substrate for film material growth; the transmission device is used for controlling the reaction base to move between the reaction chamber and the monitoring chamber; and the Raman spectroscopy monitoring module is used for performing Raman spectroscopy in-situ monitoring on the thin film material moved into the monitoring cavity. The present invention provides the chemical vapor deposition device comprising the Raman spectroscopy in-situ measurement cavity, which solves the problem of in-situ Raman detection of the thin film under the condition that the growth of the thin film is not affected, and further can adjust the process in real time to reduce defects.

Owner:WUHAN UNIV

Dry flattening method for pure titanium strip coils by aid of common cold rolling mill

The invention discloses a dry flattening method for pure titanium strip coils by the aid of a common cold rolling mill. A pure titanium strip coil is fed into the common cold rolling mill after annealing treatment, and under conditions of the rolling speed of 15m / min to 50m / min, unit uncoiling tension of 1kg / mm2 to 10kg / mm2, unit rolling tension of 1.5kg / mm2 to 15kg / mm2 and rolling force of 100 tons to 400 tons, a working roll on the common cold rolling mill directly realizes dry flattening of the pure titanium strip coil in a constant rolling force control mode. By the dry flattening method, influence of stress is eliminated after the cold-annealed pure titanium strip coil is flattened by the common cold rolling mill in a dry manner, a board is flattened, unevenness of the board of the pure titanium strip coil after being flattened in the dry manner is smaller than or equal to 3mm / m, and relevant Chinese and American standard requirements and customer service requirements on various mechanical property indexes and surface quality can be met.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

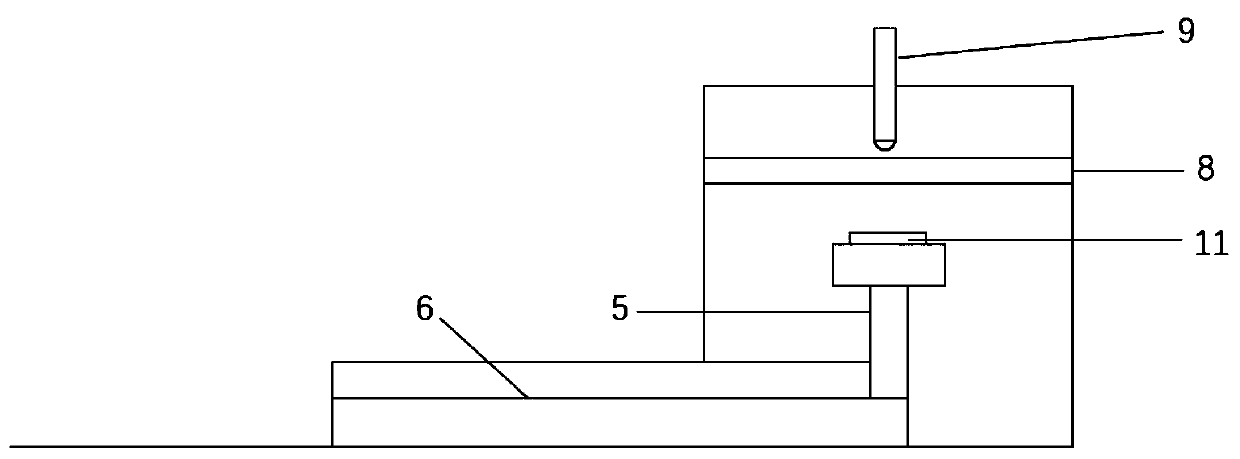

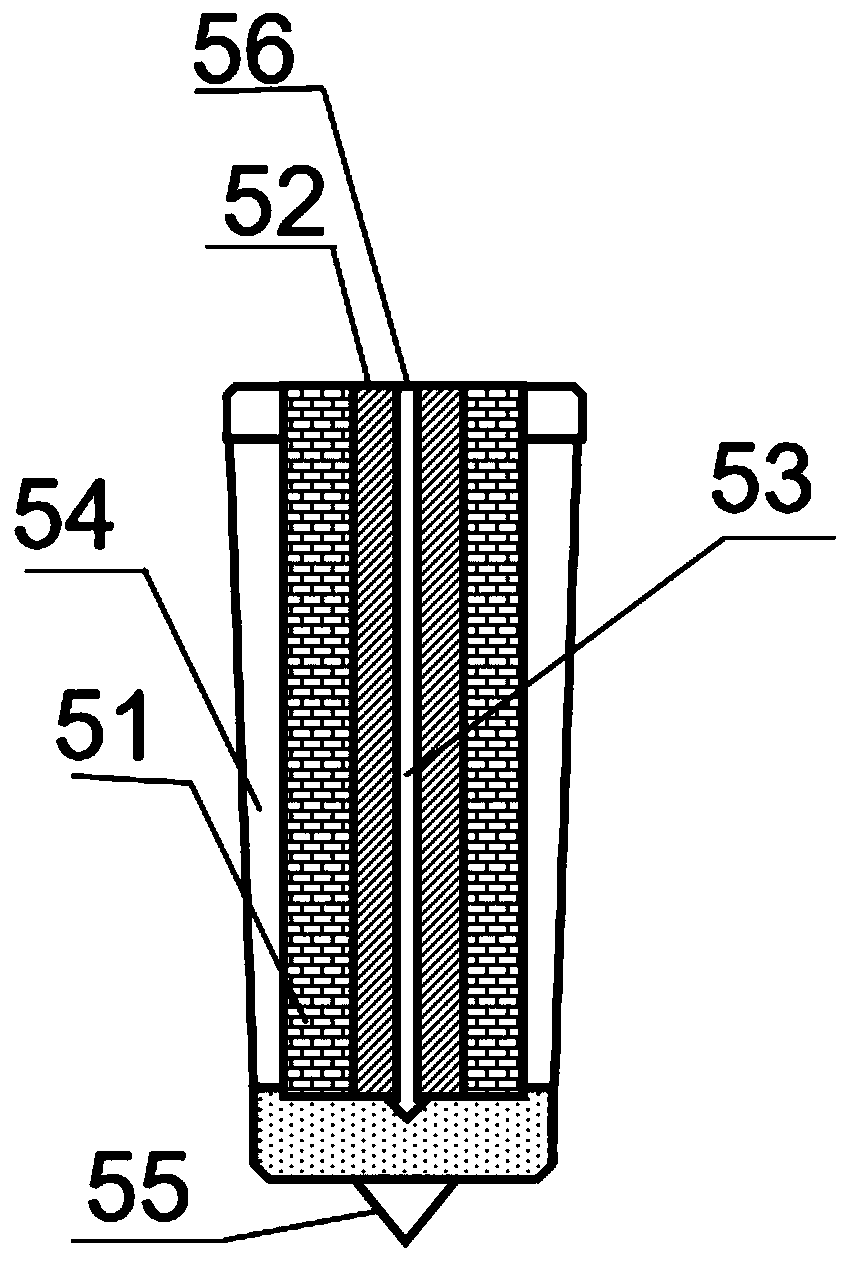

Spray type 3D printing device and method based on composite material

ActiveCN110355993AOvercome the problem of many internal defectsSimple structureAdditive manufacturing apparatus3D object support structuresSpray nozzleEngineering

The invention discloses a spray type 3D printing device and method based on a composite material, and belongs to the technical field of 3D printing. The problem that many internal defects of a 3D printing product in the prior art exist is solved. Powder of an object to be printed is thoroughly mixed through a mixing system, then raw materials are fully melted through a dispersion system, a meltingsystem and a cooling system, and printing is completed by an atomizing spray head after dispersion even distribution is carried out; a heating chamber in the spray head heats and melts a wire in a molten throat pipe, complete melting of the wire is further ensured, and liquid can stably flow after melting; and in addition, air pressure in an air supply passage is accurately controlled, the size and shape of jet nozzles of the spray head are intelligently selected according to the object to be printed, one from point spray, line spray and surface spray can be selected according to the conditions, uneven temperature release in the printing process is reduced, the influence of material stress is eliminated, the warpage of time is eliminated, the defects are reduced, and the processing efficiency is improved.

Owner:XI AN JIAOTONG UNIV

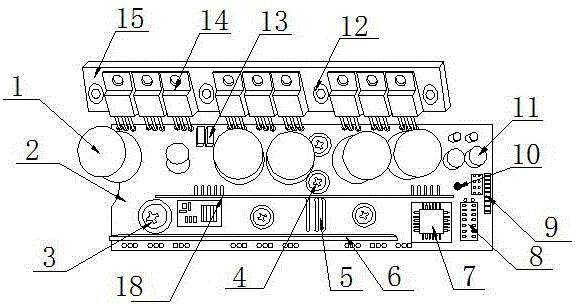

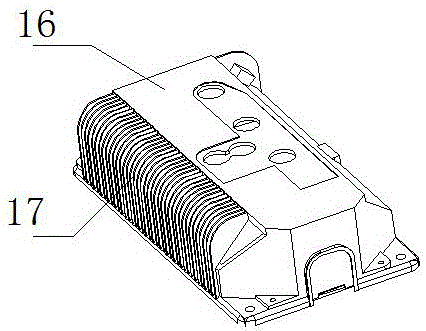

Power controller based on die-casting mould structure

InactiveCN106659038AImprove cooling effectImprove performanceCircuit arrangements on support structuresHermetically-sealed casingsPower controllerBridge type

The invention discloses a power controller based on a die-casting mould structure. The power controller comprises a large-current filtering element, a main PCB, a three-phase motor output terminal, a power input terminal, a current detection element, a bus bar, a master control MCU, a signal input filtering module, a wiring terminal, an indicating lamp, an auxiliary power supply discrete element, an elliptical positioning hole, an upper and lower bridge separation driver, a power switch tube, an aluminum substrate, an aluminum housing, heat dissipation teeth and a bridging type crossover auxiliary PCB. According to the technical scheme of the power controller in the invention, a double-row aluminum substrate and an aluminum shell are connected to improve heat dissipation effect, so that the thermal damage to the switch tube is reduced. Based on the bridging manner of PCBs, the current uniformity of power switch tubes connected in parallel is guaranteed to the greatest extent. Meanwhile, the large-current impact resistance of the entire circuit is improved. The power input terminal and three output terminals (U, V and W) are led out in the casting mode by using a copper column and the aluminum shell of a die-casting mould. Therefore, the problem that water flows into the incoming and outgoing lines and the structure of a common controller in the prior art can be solved.

Owner:刘军

Conductive Mg-P co-doped Cu2V2O7-graphene negative thermal expansion material and preparation method thereof

InactiveCN111170295AImprove conductivityImprove mechanical propertiesGraphenePhosphorus compoundsThermal dilatationElectron scattering

The invention relates to the technical field of negative thermal expansion materials, and discloses a conductive Mg-P co-doped Cu2V2O7-graphene negative thermal expansion material and a preparation method thereof. The conductive Mg-P co-doped Cu2V2O7-graphene negative thermal expansion material comprises the following formula raw materials: graphene oxide, CuO, MgO, V2O5 and NH4H2PO4. According tothe conductive Mg-P co-doped Cu2V2O7-graphene negative thermal expansion material and the preparation method thereof, Cu2V2O7 has a stable linear negative thermal expansion coefficient, a centrosymmetric monoclinic phase structure is formed by doping Cu2V2O7 with Mg, under temperature variation, the Mg-O bond generates a vibration effect, the internal coupling effect of the Cu2V2O7 crystal is improved, a linear chain-shaped monoclinic phase in the crystal is destroyed, oxygen atoms form a new arrangement in the crystal lattice, local collapse occurs, the Cu2V2O7 is enabled to show a negativethermal expansion phenomenon, P atoms replace part of V atoms, the grain size of Cu2V2O7 is reduced, the bond energy of P-O bonds is larger than that of V-O bonds, stress in Cu2V2O7 lattices is reduced, lattice distortion is reduced, the electron scattering probability and the high-frequency dielectric constant are reduced, and therefore the conductivity of Cu2V2O7 is enhanced.

Owner:管玲飞

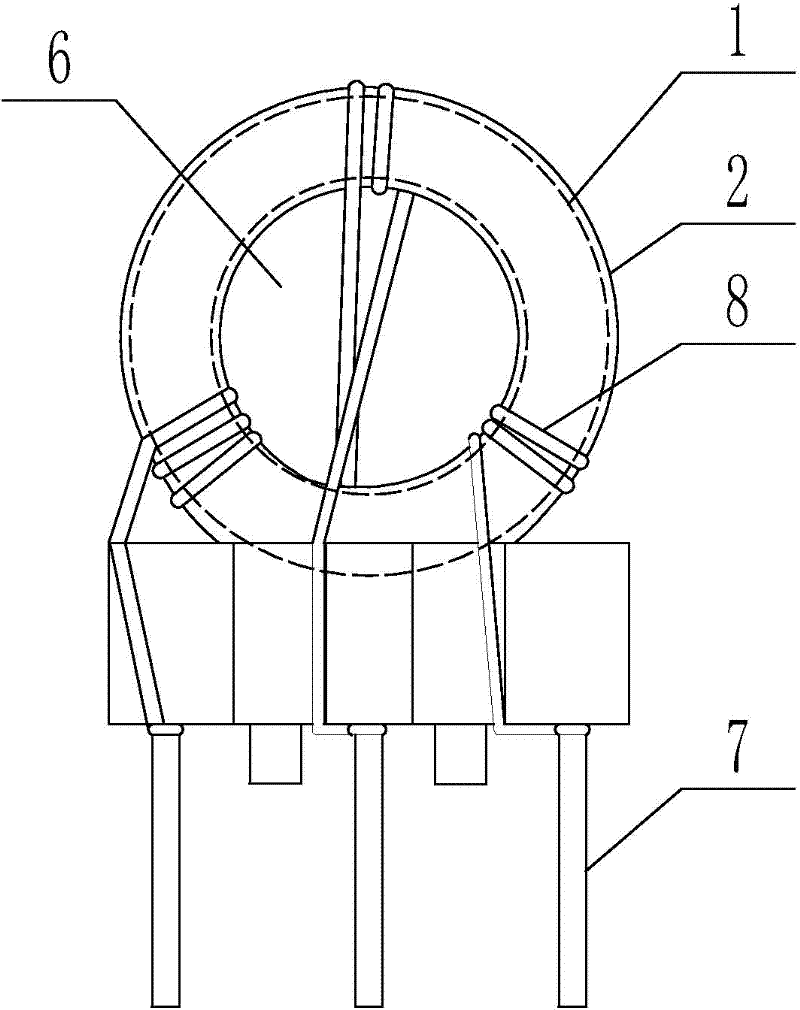

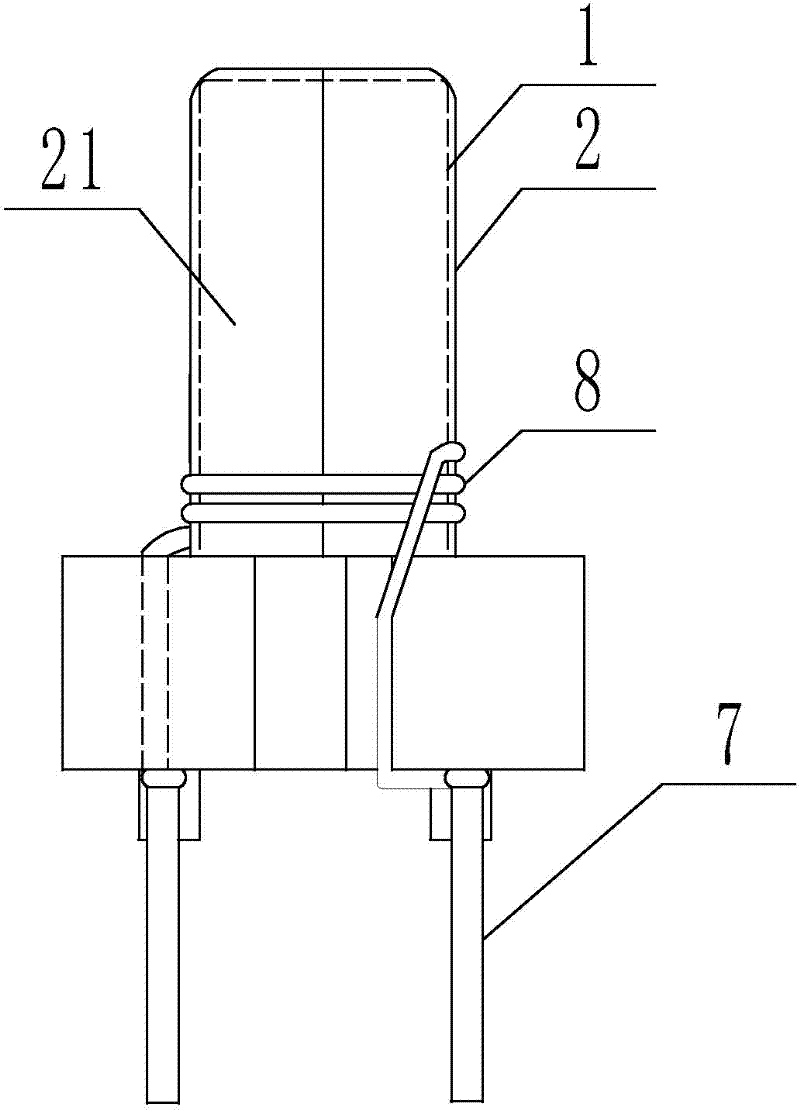

Transformer with shell and magnetic ring

InactiveCN102360860ASimple structureEasy to useTransformers/inductances casingsFixed transformersTransformerCopper wire

The invention relates to a transformer with a shell and a magnetic ring. The transformer comprises the magnetic ring and an insulated shell; the magnetic ring is arranged in the insulated shell; a winding hole is formed in the shell; a central hole of the magnetic ring corresponds to the winding hole; the shell is provided with a plurality of pins; multiple groups of copper wires are wound outside the shell; the copper wires pass through the winding hole and are wound outside the shell; and the ends of the copper wires are connected with the pins. The invention relates to the transformer with the shell and the magnetic ring, and in the transformer, insulation paint is not needed to be sprayed on the surface of the magnetic ring, and copper wire direct pins are not adopted.

Owner:宝电电子(张家港)有限公司

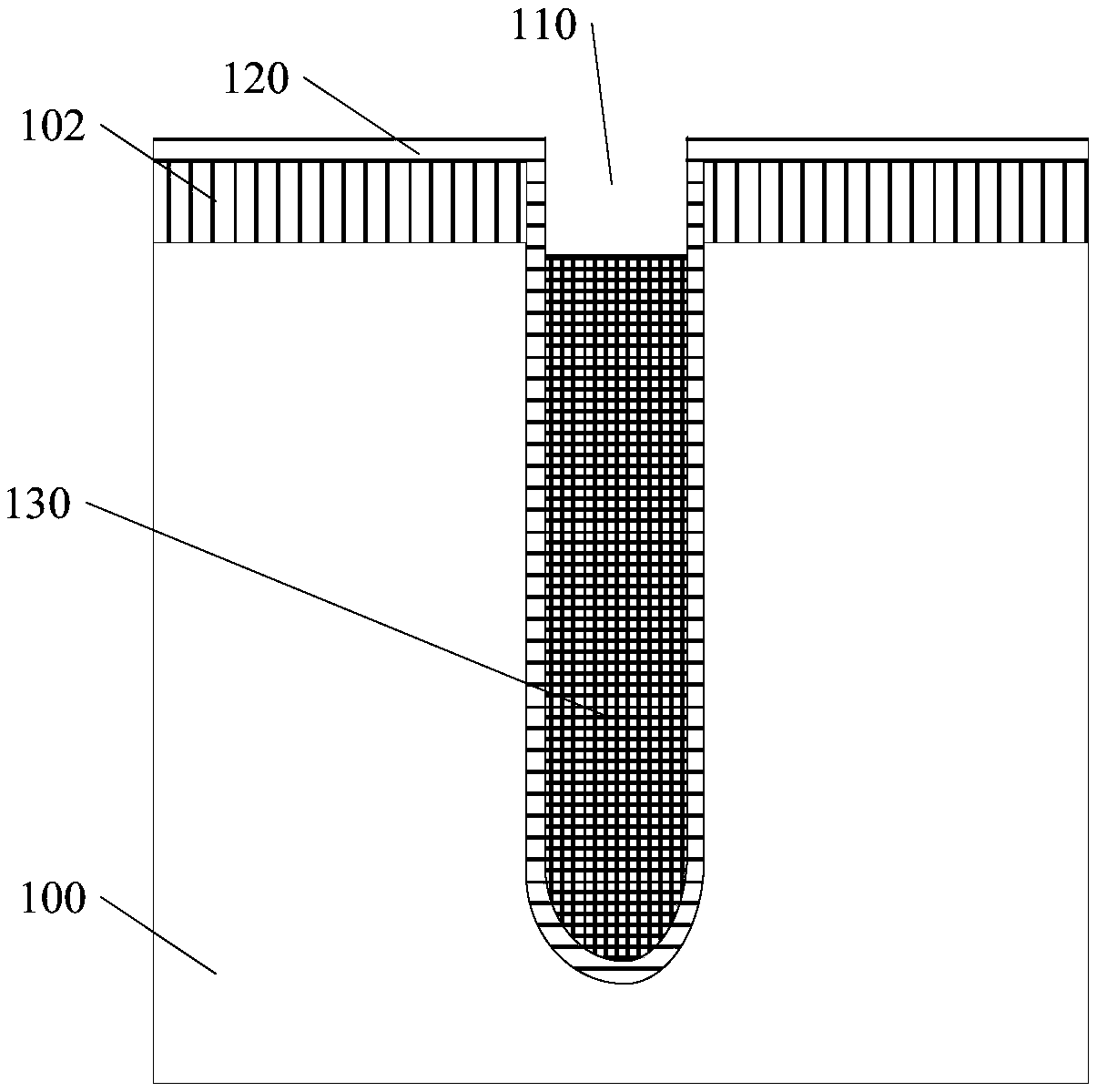

Method for machining key part on semiconductor encapsulation equipment

The invention relates to a method for machining a key part on semiconductor encapsulation equipment. A rectangular Peek plate is located and clamped on a bench clamp of a vertical milling machine, andthe lower surface, the upper surface and the side faces are subjected to rough machining; the lower surface and the upper surface are subjected to rough machining on a grinding machine; the upper surface is machined through a stainless steel four-blade milling cutter, and bottom holes of threaded holes are drilled in the upper surface through a twist drill; bottom holes of bolt holes and stainless steel locating holes are subjected to rough machining through a four-blade tungsten steel milling cutter; bottom holes of black light sensing original points are drilled in the upper surface throughthe twist drill, and assembly holes of the black light sensing original points are machined through a drill bit; the lower surface is subjected to finish machining through the stainless steel four-blade milling cutter; stainless steel bushes are mounted on the bottom holes of the stainless steel locating holes; black PEEK cylinders are mounted on the bottom holes of the black light sensing original points; the stainless steel bushes of the stainless steel locating holes are subjected to rough machining through the four-blade tungsten steel milling cutter, the stainless steel locating holes are subjected to finish machining through the four-blade tungsten steel milling cutter, and the stainless steel locating holes are formed; the upper surface and the lower surface are subjected to finishmachining through a tungsten steel grinding wheel; and an encapsulation position groove is subjected to rough machining through the four-blade tungsten steel milling cutter.

Owner:KERUI AUTOMATION TECH SUZHOU

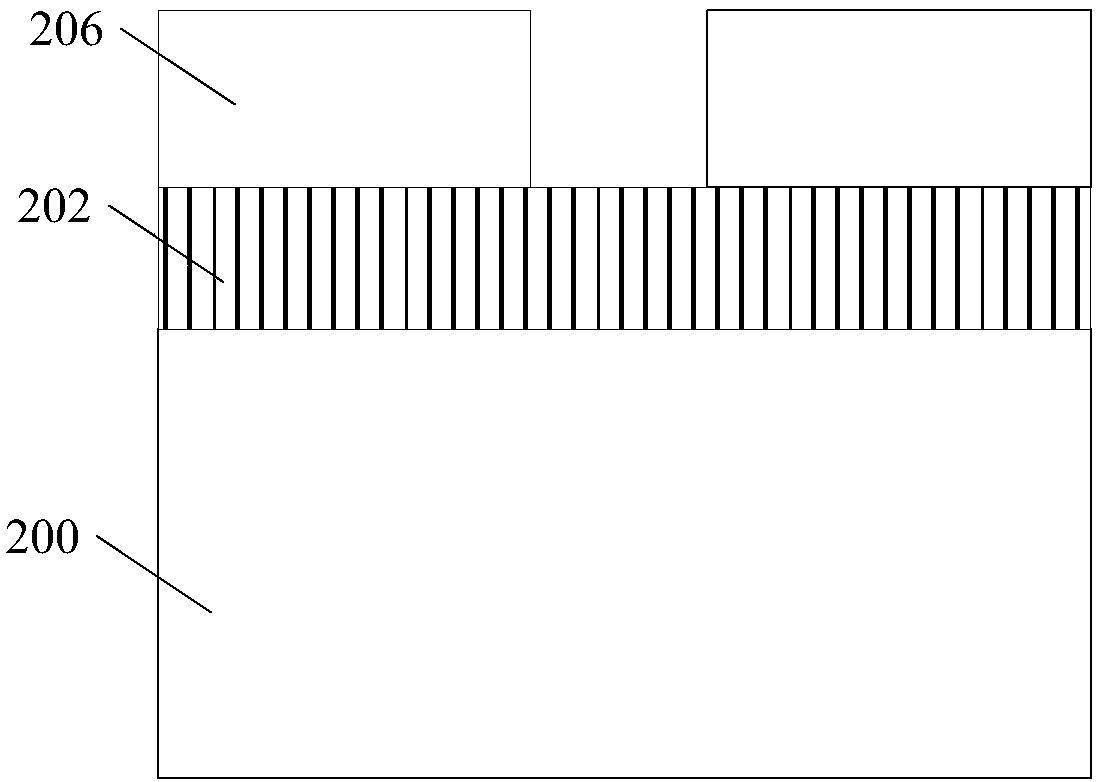

Image sensor and forming method thereof

InactiveCN108281444AImproved interface trap densityImprove performanceSolid-state devicesRadiation controlled devicesFilling materialsTension stress

The invention discloses an image sensor and a forming method thereof. The forming method includes: providing a semiconductor substrate; etching the semiconductor substrate to form an isolating groove;forming a medium thin film which covers the inner wall of the isolating groove; forming a metal blocking layer which covers the medium thin film; forming a tensile stress layer which fills at least apart of groove space surrounded by the metal blocking layer. By the forming method, compressive stress generated on the semiconductor substrate by a filling material in deep-groove isolation can be lowered.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

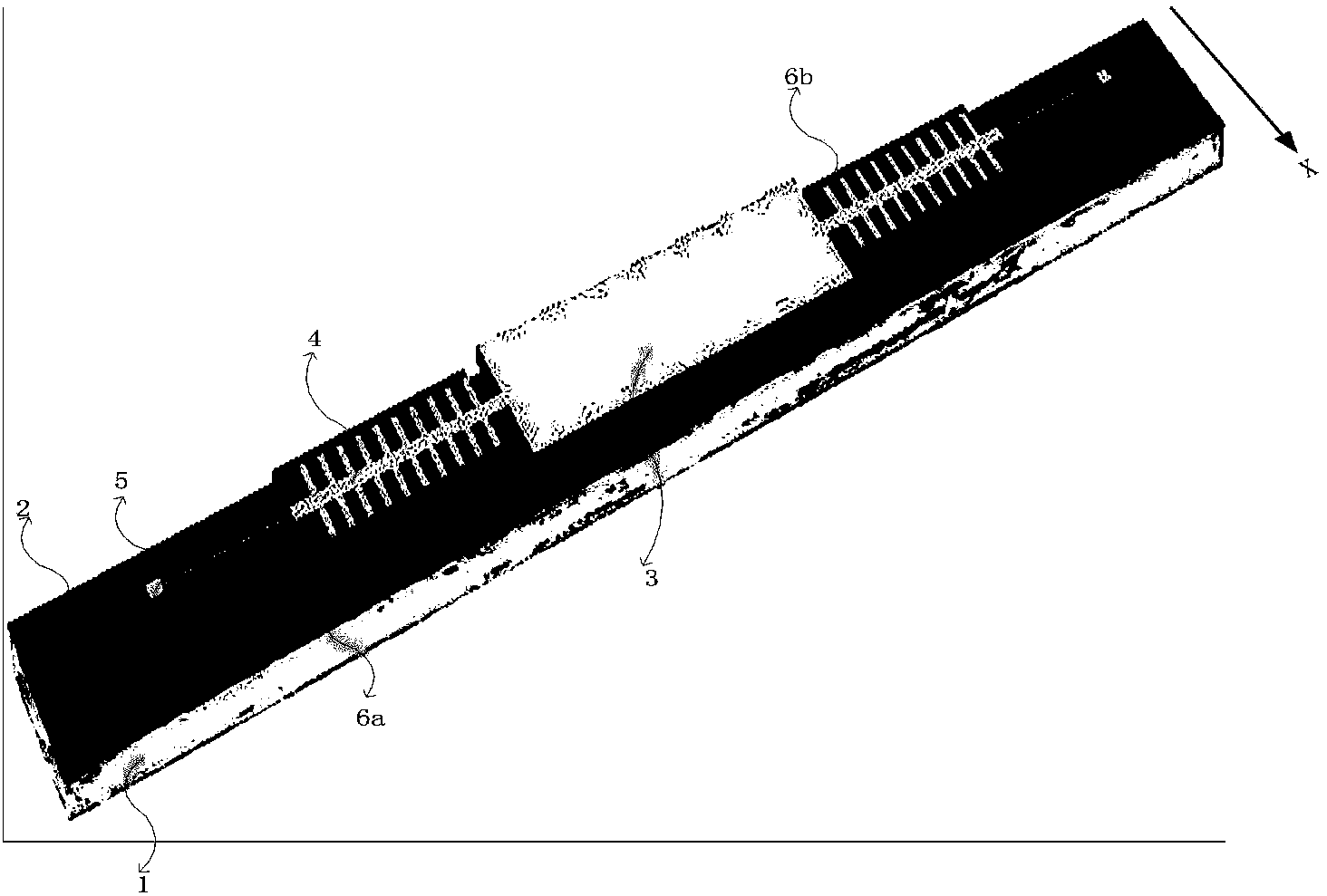

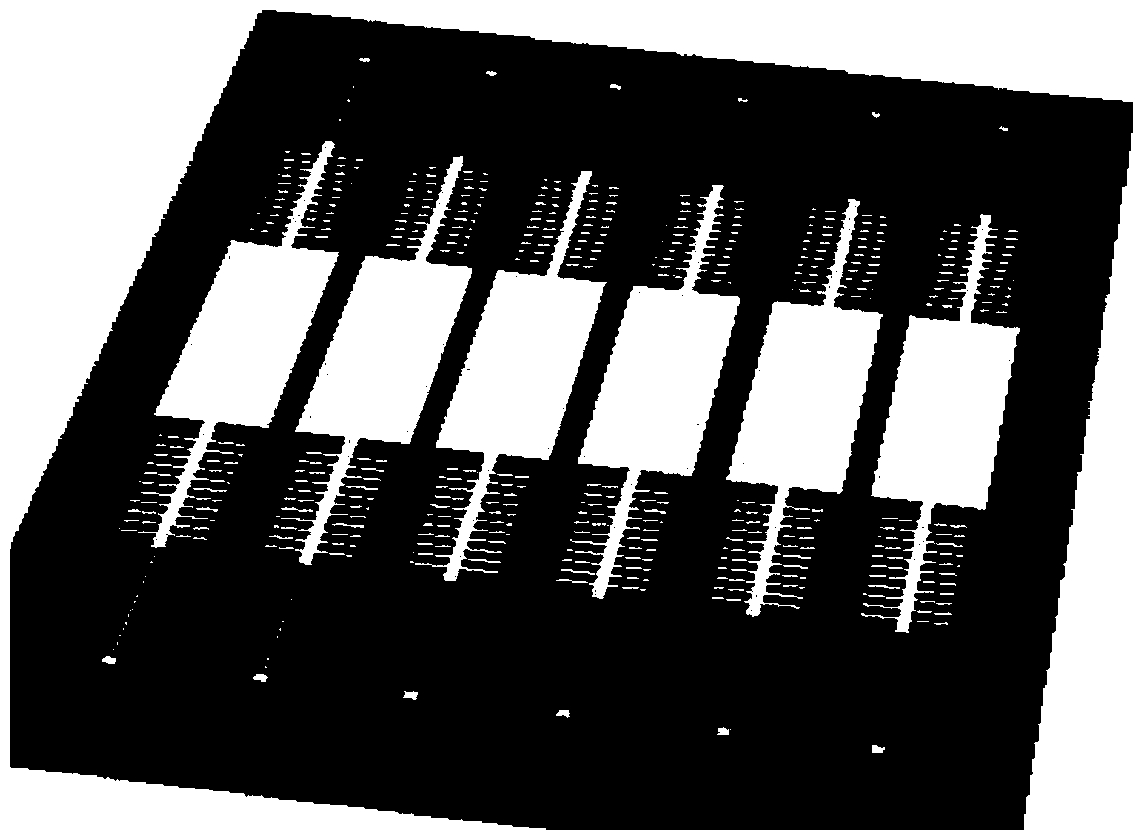

Movable MEMS large turning angle blazed grating light modulator based on double-layer comb drive

InactiveCN103901609ALower unit costReduce volumePiezoelectric/electrostrictive devicesFlexible microstructural devicesBlazed gratingComb drive

The invention relates to the technical field of MEMS light modulators, in particular to an MEMS blazed grating light modulator and an array. Double-layer comb drive is adopted by the movable MEMS large turning angle blazed grating light modulator and the double-layer comb drive position is located on flexible support beams at the two ends of an optical grating mirror face. When a plurality of movable blazed grating light modulators are used for forming the array, each movable MEMS large turning angle blazed grating light modulator under double-layer comb drive can be controlled by a drive circuit to independently work and a gap between every two optical grating mirror faces is small. According to the structure, an optical grating can be made to deflect to the two sides at a large angle and has the advantages of being large in deflection angle, high in diffraction efficiency, high in tuning frequency and resistant to adhesion. The optical grating light modulator and the array of the optical grating light modulators can be applied to the fields of spectrometers, optical communication, accurate measurement, laser shaping, displaying and the like.

Owner:CHONGQING UNIV

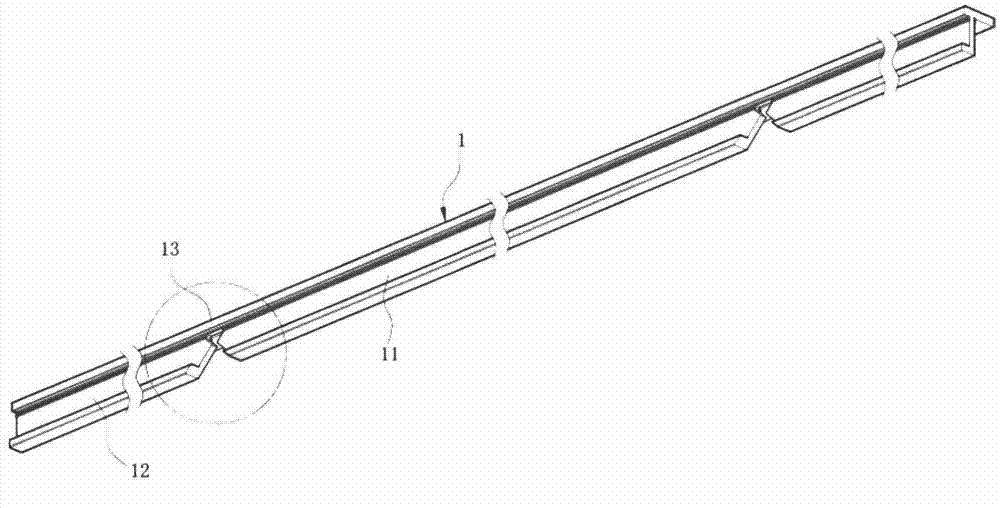

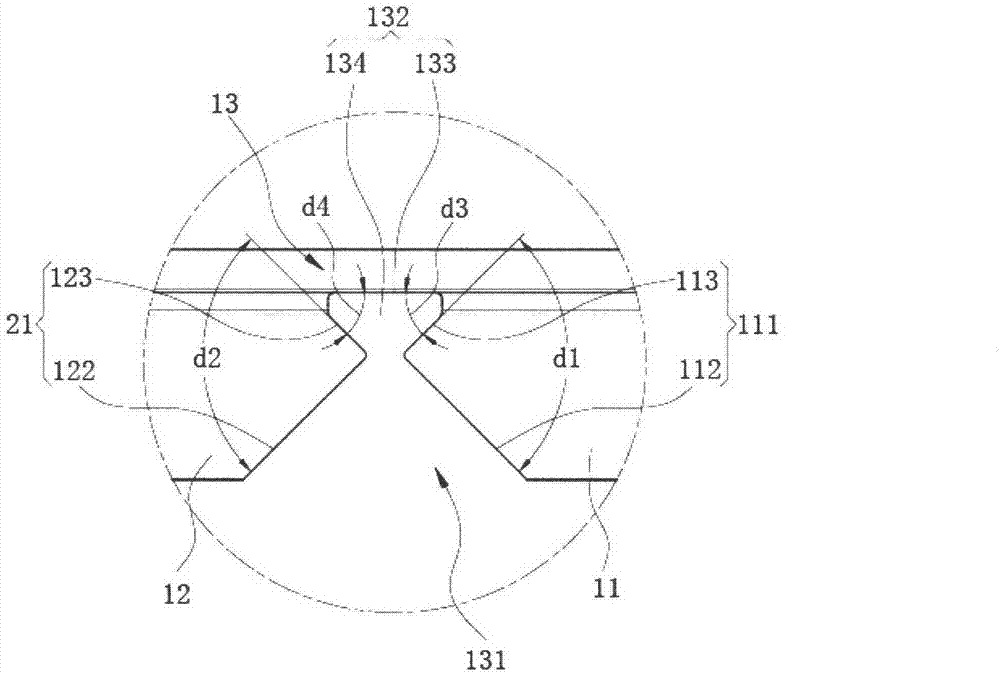

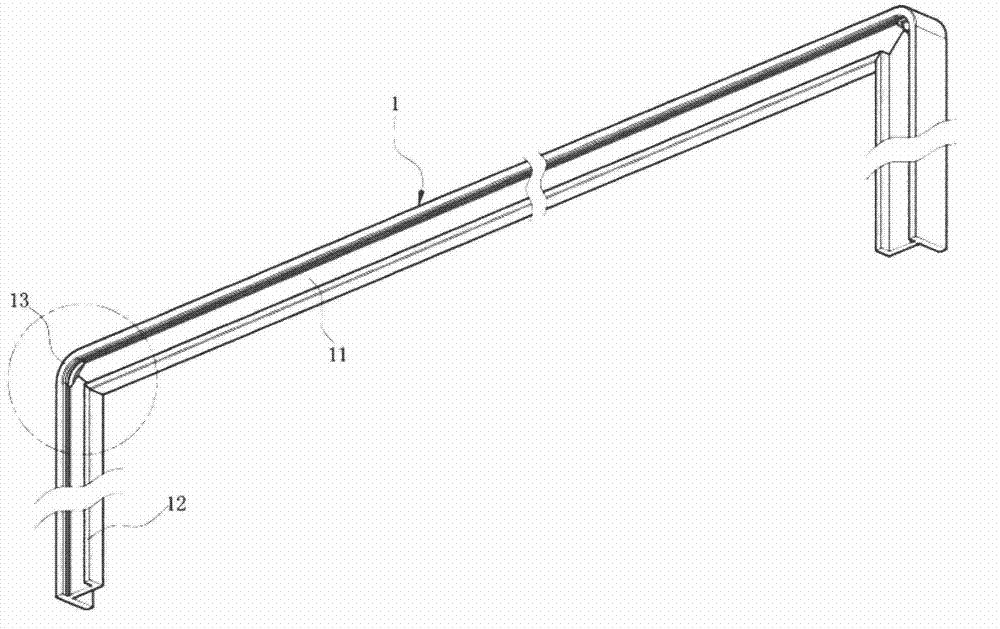

Monitor support and preparation method thereof

The invention discloses a monitor support. The support is used for assembling a monitor. The monitor support comprises a body, wherein the body comprises a first supporting section and a second supporting section, the first supporting section and the second supporting section are connected through a bending section, the first supporting section comprises a first combination portion and a second combination portion, the second supporting section comprises a first combination portion and a second combination portion, first combination portions and second combination portions are matched, the bending section comprises a bending buffering region, the bending buffering region comprises a bridge connecting portion and a compressed buffering space, two ends of the bridge connecting portion are respectively connected to the first supporting section and the second supporting section, the compressed buffering space is defined by first combination portions, second combination portions and the bridge connecting section, a bearing space is formed between the first supporting section and the second supporting section when the first supporting section and / or the second supporting section are / is bent inwards, and the monitor is located in the bearing space. The support has the advantages of being capable of eliminating effect of stress caused by stamping and bending. The invention also discloses a preparation method of the monitor support.

Owner:KUNSHAN WANHER PRECISION ELECTRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com