Washing machine lid structure and method for fabricating the same

A manufacturing method and washing machine technology, applied in the field of washing machines, can solve the problems of no setting stress, deformation of cover shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

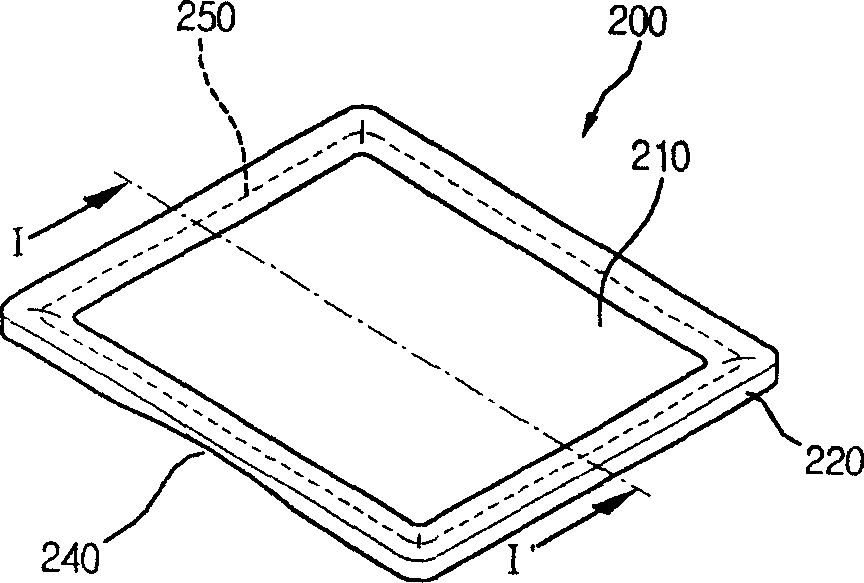

[0026] Hereinafter, specific embodiments according to the present invention will be described in detail with reference to the accompanying drawings. However, the rights of the present invention are not limited to the above-described embodiments. Without exceeding the technical scope of the present invention described in the claims, those skilled in the relevant industries can easily propose other inventions or other embodiments included in the scope of the present invention by making various deformations and modifications.

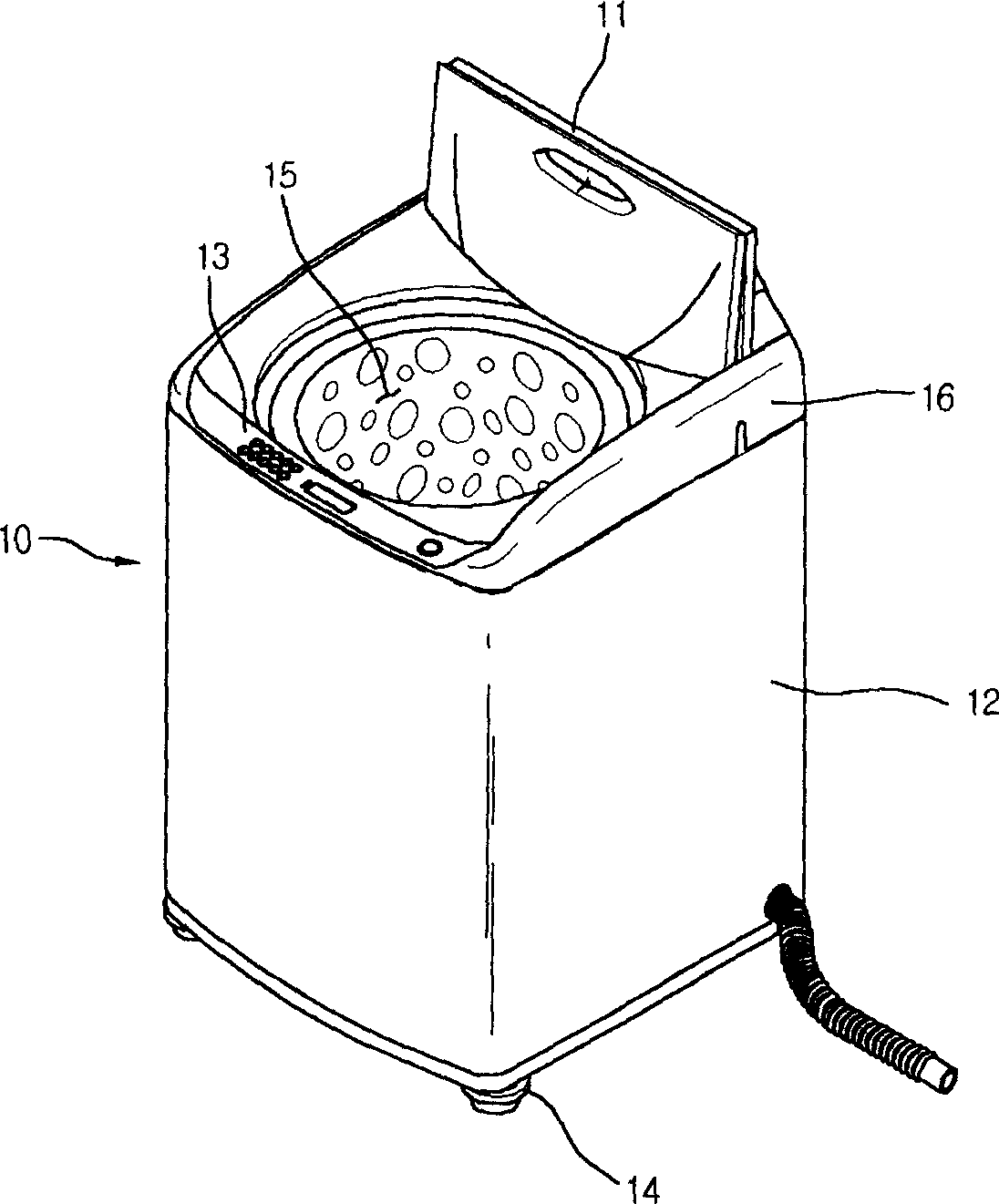

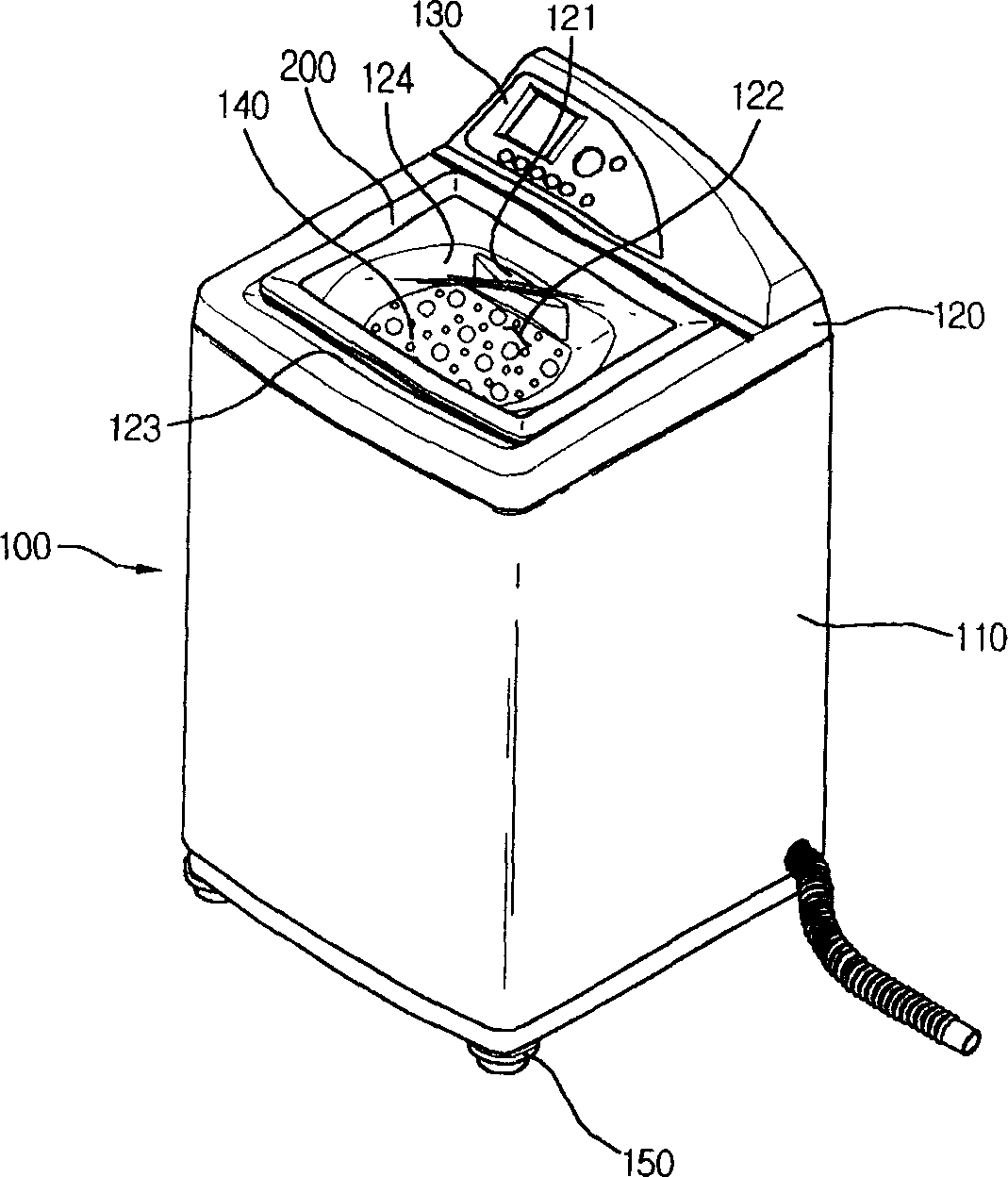

[0027] figure 2 It is a schematic perspective view showing a washing machine provided with a cover structure according to the idea of the present invention.

[0028] refer to figure 2 , the washing machine 100 equipped with the cover structure according to the present invention includes the following parts: a casing 110 that protects internal components and forms an external shape; a top cover 120 that is arranged on the top of the casing 110; 110, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com