Optical fibre sensor and application thereof to refracting index and strain measurement

A technology of optical fiber sensor and refractive index, which is applied in the field of measurement, can solve the problems that the influence of stress cannot be well eliminated, and the simultaneous measurement of refractive index and stress cannot be realized, and achieve the effects of strong practicability, good mechanical strength, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

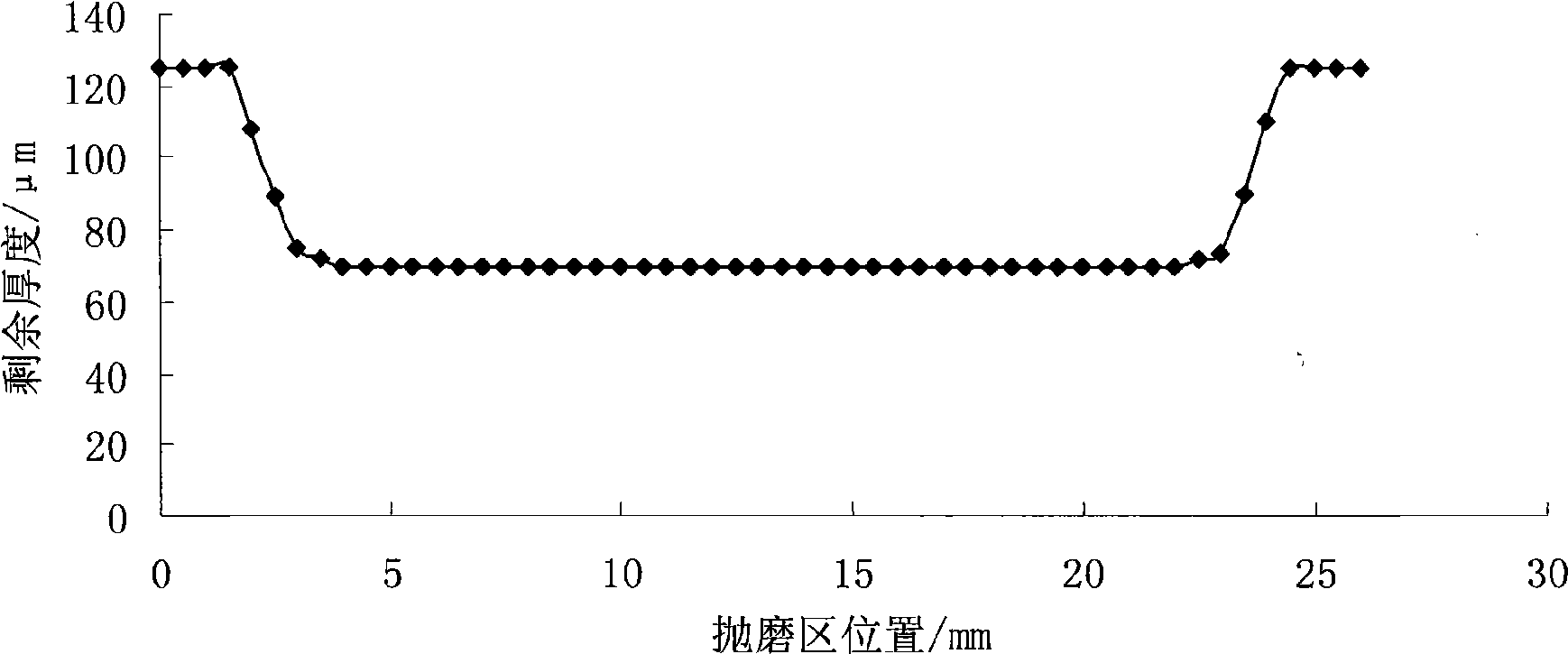

[0068] The fiber gratings used to make side-polished fiber grating sensors are fabricated by phase masking. The length of the grating is 15mm, and the central wavelength of the grating is 1547.76nm. After using the side polishing method of the wheel-type optical fiber, the polishing depth was measured with a filament measuring instrument with a measurement accuracy of 0.1 μm. The measured data are as follows: image 3 , where the abscissa is the axial position of the fiber, in mm, and the ordinate is the remaining thickness of the side-polished FBG, in μm. It can be seen that the length of the polishing area of the side-polished fiber grating is 22mm, the length of the D-type fiber section (the flat part of the polishing area) is 17mm, and the grating area engraved with the grating is located in the middle of the D-type fiber section, ensuring The influence of the outside world on the Bragg wavelength of the side-polished fiber grating is consistent, and the chirp effect is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com