Image sensor and forming method thereof

An image sensor, tensile stress technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems affecting the performance of semiconductor devices, increase in interface trap density, etc., to improve interface trap density, improve speed performance, and improve motion. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the prior art, deep trench isolation is used to potentially suppress blooming and suppress optical crosstalk. The deep trench isolation usually uses a titanium nitride film as a filling material, or a stacked structure of titanium nitride and tungsten as a filling material.

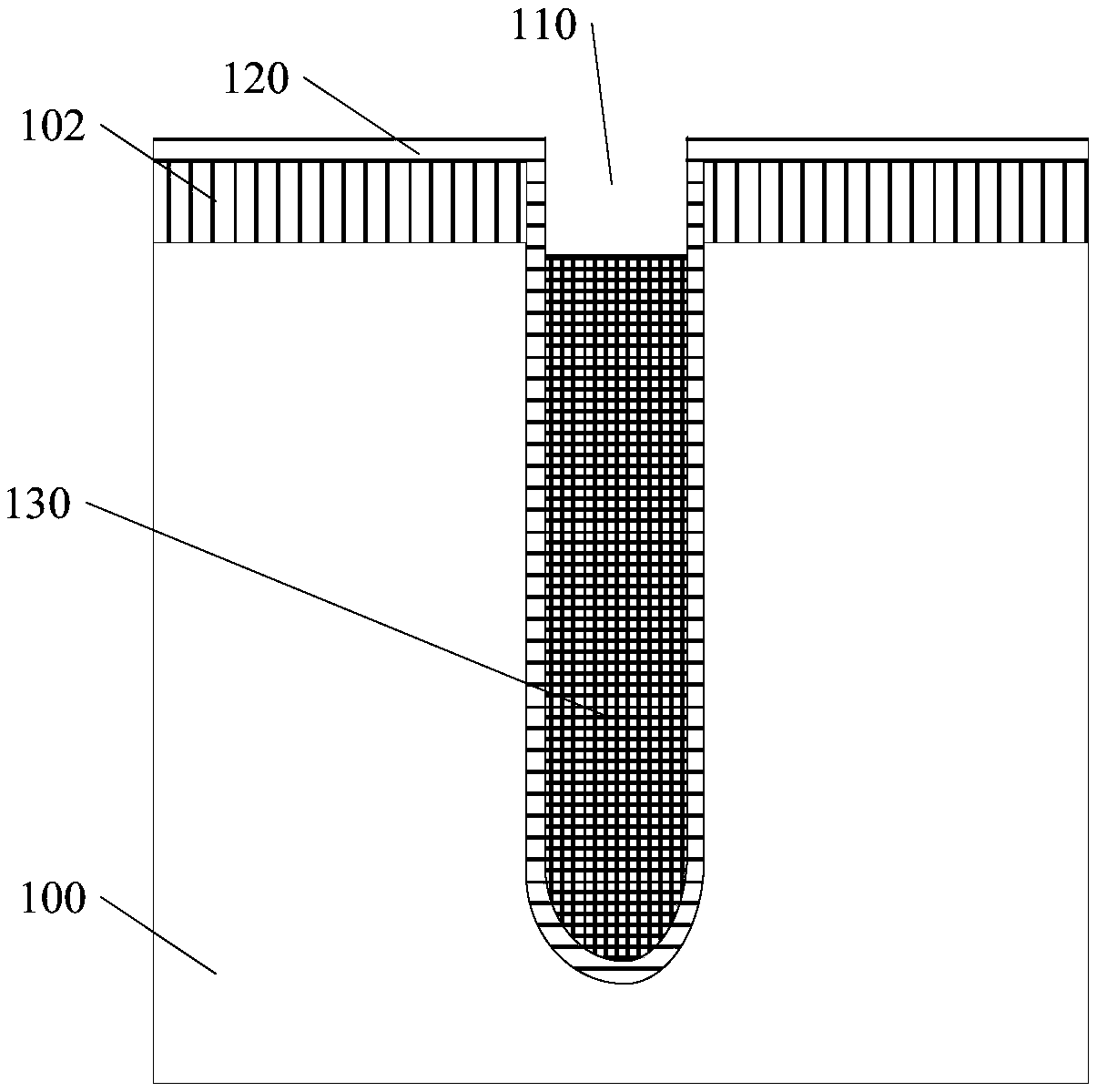

[0035] refer to figure 1 , figure 1 It is a schematic cross-sectional structure diagram of an image sensor in the prior art. The image sensor may include a semiconductor substrate 100 , a protective layer 102 , an isolation trench 110 , a dielectric film 120 and an alloy material layer 130 .

[0036] Specifically, a protective layer 102 is formed on the surface of the semiconductor substrate 100, and then a patterned mask layer is formed on the surface of the protective layer 102. Using the patterned mask layer as a mask, the protective layer 102 and the semiconductor substrate 100 are etched to form the isolation trench 110 .

[0037] Further, a dielectric film 120 is formed in the isolatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com