Flexible ceramizable silicone rubber thermal insulation composite material and preparation method thereof

A ceramic silicone rubber and composite material technology, which is applied in chemical instruments and methods, rubber layered products, aerospace vehicle heat protection devices, etc., can solve the problem of poor resistance to high-speed particle airflow erosion, poor integrity, and peeling of thermal insulation materials To achieve the effect of improving the anti-high-speed air erosion performance, improving the structural integrity, and preventing large-scale shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

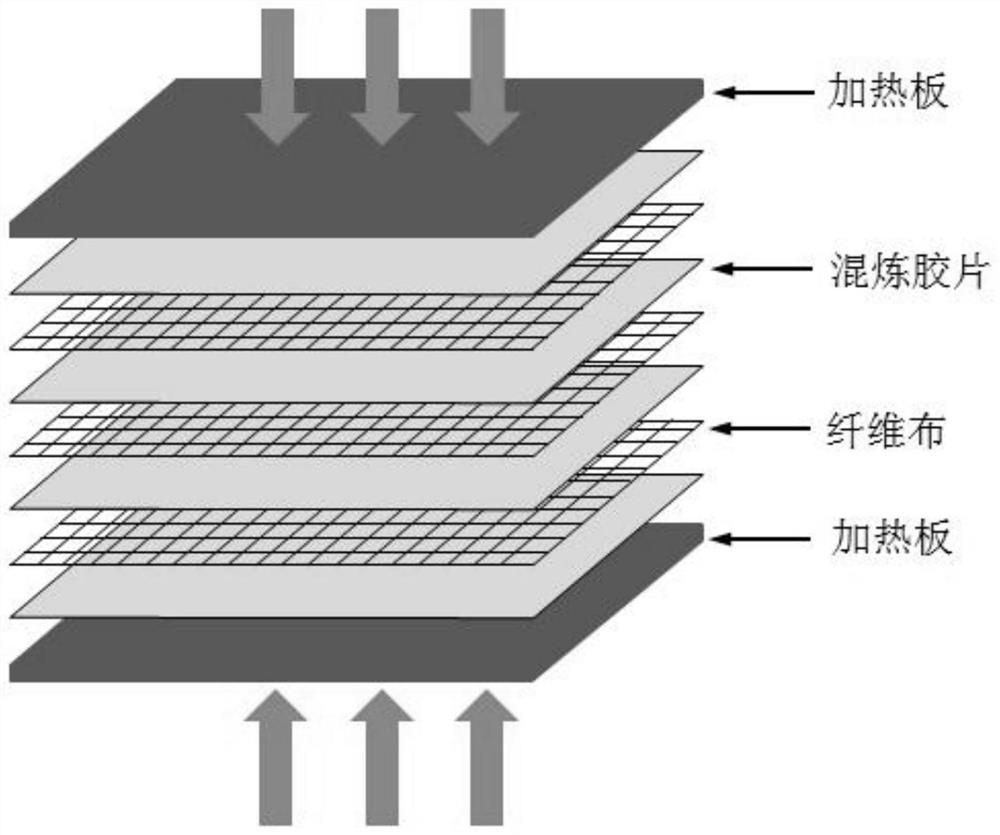

[0069] The specific steps of the preparation method of the flexible ceramizable silicone rubber thermal insulation composite material according to the embodiment of the present invention are as follows:

[0070] 1) Weigh the raw materials according to the proportion, for subsequent use;

[0071] 2) Put the silicone rubber into the open mill and knead it to the wrapping roller, then add fumed silica, ceramic powder, structure control agent, vulcanizing agent and mix evenly, and add fluxing agent as needed. After mixing uniformly, add short fibers. When the short fibers are chopped carbon fibers, chopped polyimide fibers or silicon carbide whiskers, add them after uniform mixing. When the short fibers are aramid pulp, add gas-phase dioxide. Silicon is added and mixed before mixing, fully mixed, and placed at room temperature for 24 hours, and then back-mixed and produced to obtain a mixed sheet;

[0072] 3) after the step 2) gained kneading sheet is cut into the same specificat...

Embodiment 1

[0075] A flexible and ceramizable silicone rubber heat-insulating composite material, the composite material is obtained by stacking and vulcanizing a kneaded sheet obtained by kneading silicone rubber and a fiber cloth, wherein the raw material components and mass parts of the kneaded sheet are: methyl 100 parts of vinyl silicone rubber, 30 parts of hydrophobic fumed silica, 30 parts of low melting point glass frit (softening point 460°C), 10 parts of graphite powder, 30 parts of zirconium silicide, 40 parts of talcum powder, 10 parts of chopped carbon fiber, 10 parts of hydroxy silicone oil, 2 parts of dicumyl peroxide. The fiber cloth used in the composite material is a carbon fiber mesh cloth (the side length of the mesh is 1 mm, and the thickness of the fiber cloth is 0.24 mm), and the number of stacked layers is 5 layers.

Embodiment 2

[0077] A flexible and ceramizable silicone rubber heat-insulating composite material, the composite material is obtained by stacking and vulcanizing a kneaded sheet obtained by kneading silicone rubber and a fiber cloth, wherein the raw material components and mass parts of the kneaded sheet are: methyl 100 parts of vinyl silicone rubber, 30 parts of hydrophobic fumed silica, 30 parts of low melting point glass frit (softening point 560°C), 40 parts of graphite powder, 60 parts of aluminum hydroxide, 30 parts of kaolin, 10 parts of zirconium carbide, short 15 parts of cut carbon fibers, 15 parts of hydroxy silicone oil, and 4 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane. The fiber cloth used in the composite material is a carbon fiber mesh cloth (the side length of the mesh is 1 mm, and the thickness of the fiber cloth is 0.24 mm), and the number of stacked layers is 5 layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com