Patents

Literature

84results about How to "Avoid debonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

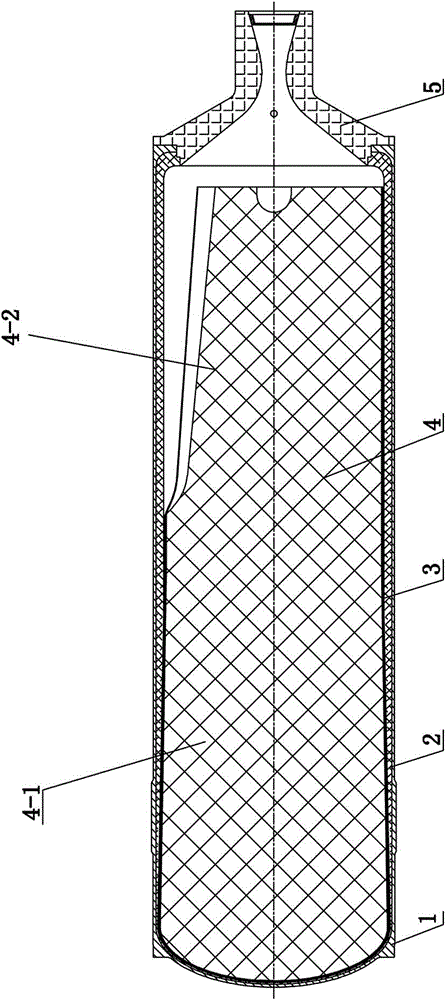

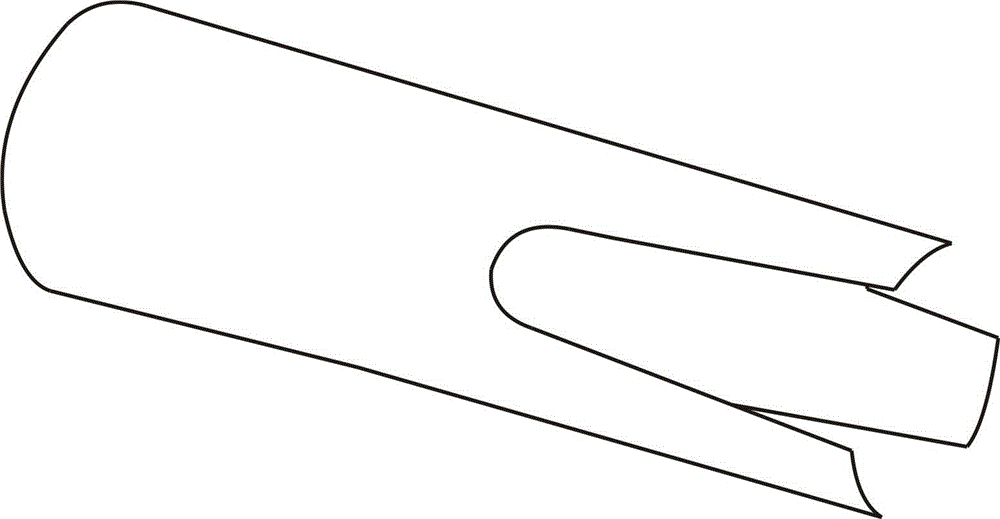

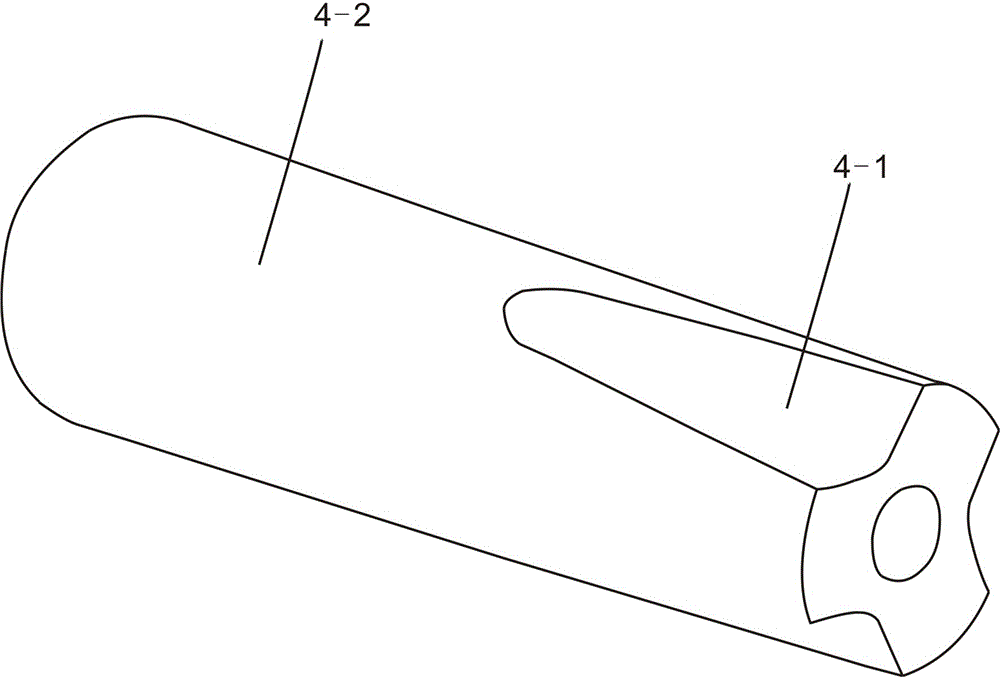

Solid rocket engine with high thrust ratio and manufacturing method thereof

ActiveCN105003355AImprove bonding qualityRelieve stress concentrationRocket engine plantsPhysicsCombustion chamber

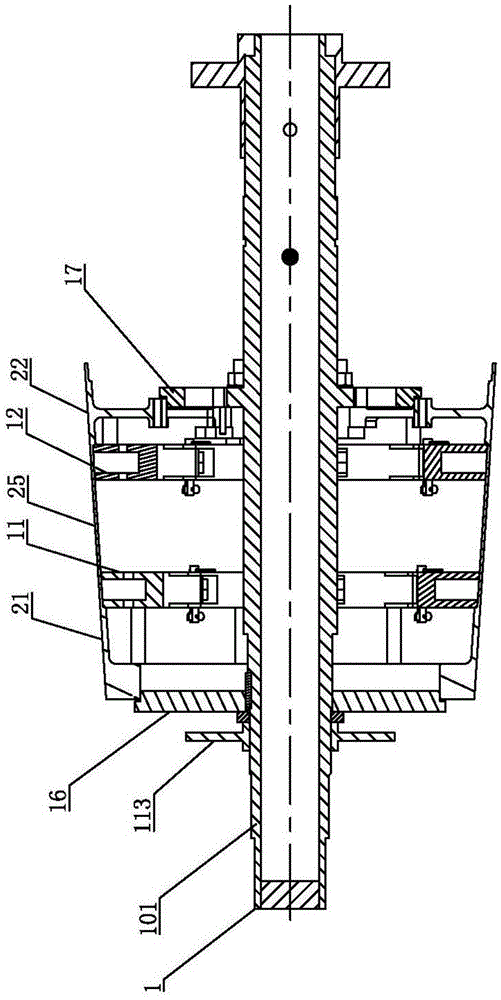

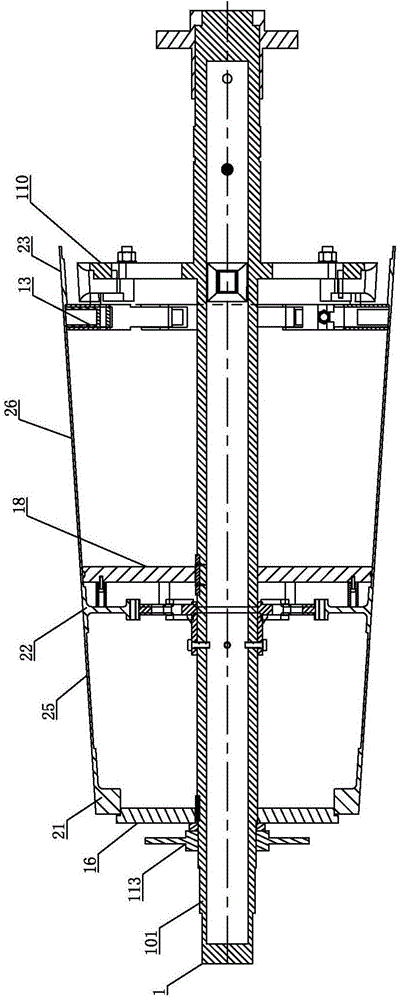

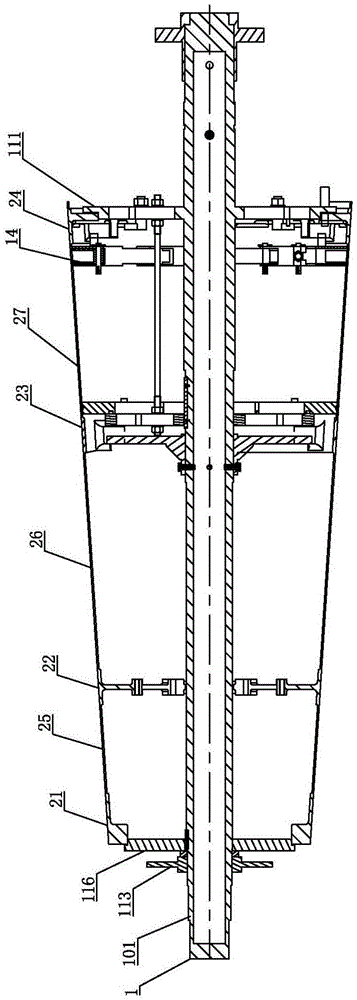

A solid rocket engine with a high thrust ratio comprises a combustion chamber shell. A heat insulated layer is pasted to the inner surface of the combustion chamber shell. A heat insulated sleeve is bonded to the outer surface of a grain and forms a whole with the grain. The grain with the heat insulated sleeve is arranged in the combustion chamber shell with the heat insulated layer in a free-filling mode. A spray pipe is arranged at the outlet end of the combustion chamber shell. The grain comprises a booster-stage three-arm type grain body and a cruising-stage end-burning grain body which are connected in series to form the integrated grain. The booster-stage three-arm type grain body and the cruising-stage end-burning grain body are grain bodies for four-component hydroxy-terminated polyb propellants of the same formula. By means of the solid rocket engine with the high thrust ratio and a manufacturing method thereof, the problem of a small thrust ratio can be solved, the high thrust ratio can be provided, working is table, and the structure and performance are reliable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

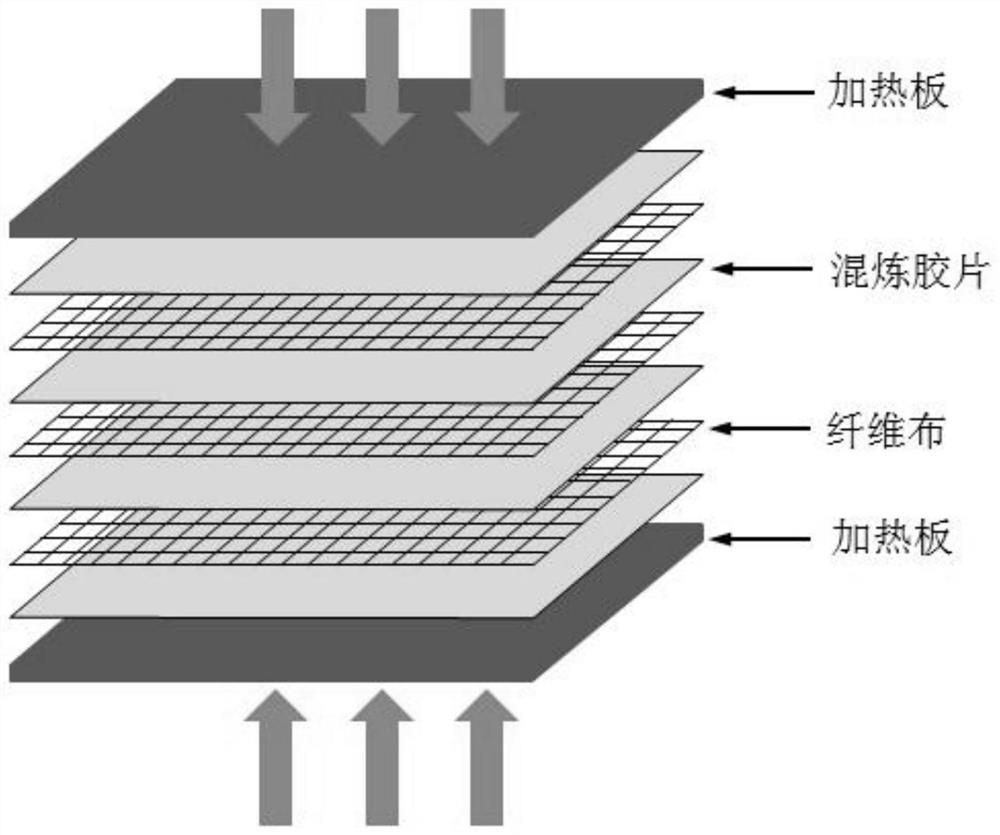

Flexible ceramizable silicone rubber thermal insulation composite material and preparation method thereof

PendingCN111761895AHigh mechanical strengthImprove anti-ablation performanceCosmonautic thermal protectionLaminationFiberVulcanization

The invention relates to a flexible ceramizable silicone rubber thermal insulation composite material and a preparation method thereof. The composite material is a silicone rubber / fiber cloth integralstructure, the silicone rubber is a support structure, and the fiber cloth penetrates through the silicone rubber; the composite material is obtained by stacking and vulcanizing mixed rubber sheets and fiber cloth at intervals, the mixed rubber sheets are obtained by mixing the silicone rubber, and the mixed rubber sheets are prepared from, by mass, 100 parts of the silicone rubber, 20-45 parts of fumed silica, 30-160 parts of ceramic powder, 0-40 parts of a fluxing agent, 6-20 parts of short fibers, 1-15 parts of a structure control agent and 1-4 parts of a vulcanizing agent. The ceramizablesilicone rubber composite material provided by the invention is good in flexibility, high in mechanical property, good in ablation resistance and resistant to high-speed airflow scouring, and can meet the requirements of the fields of aerospace and special fireproof engineering on fireproof, thermal-insulating and ablation-resistant thermal protection performance.

Owner:WUHAN UNIV OF TECH

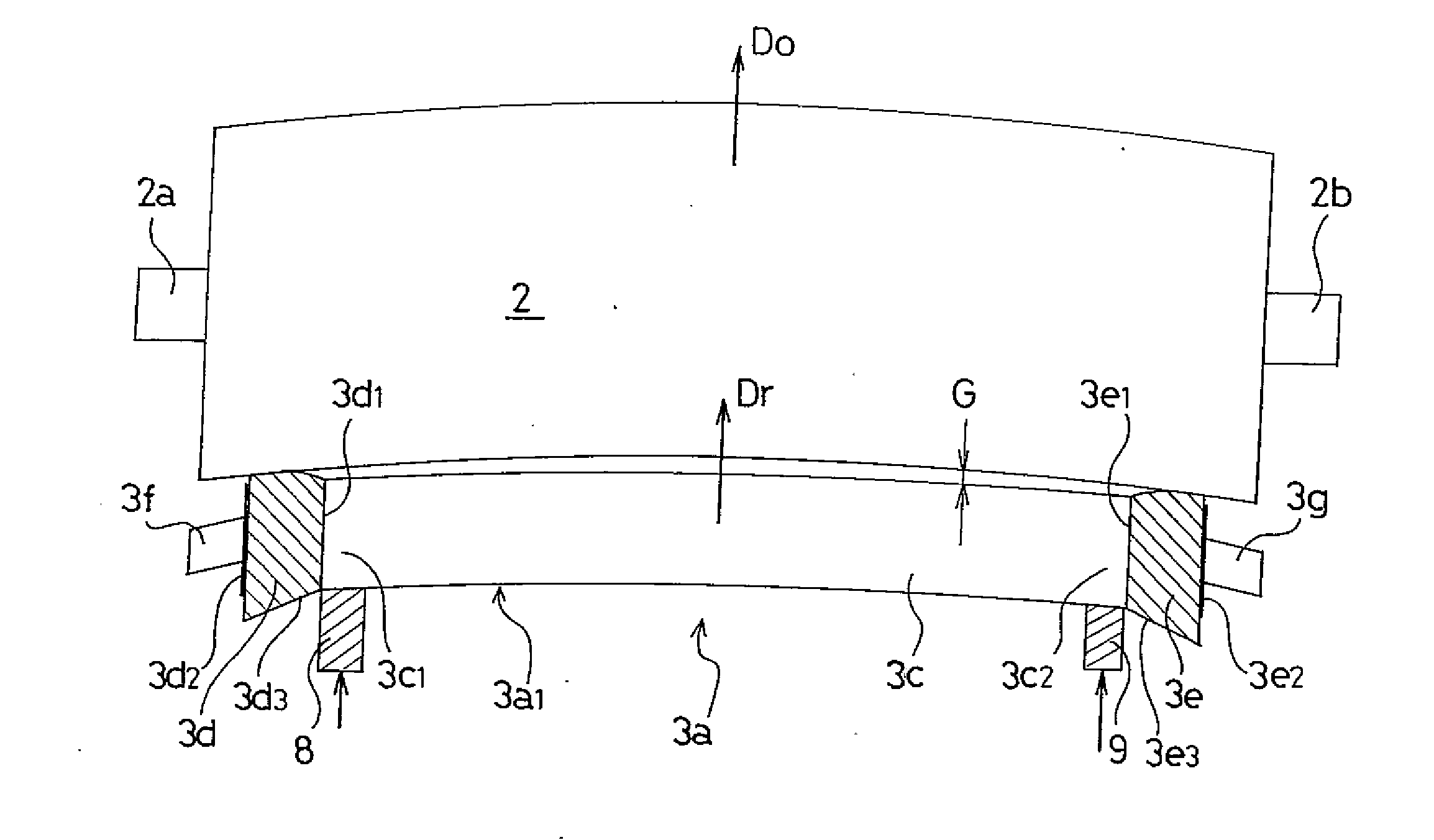

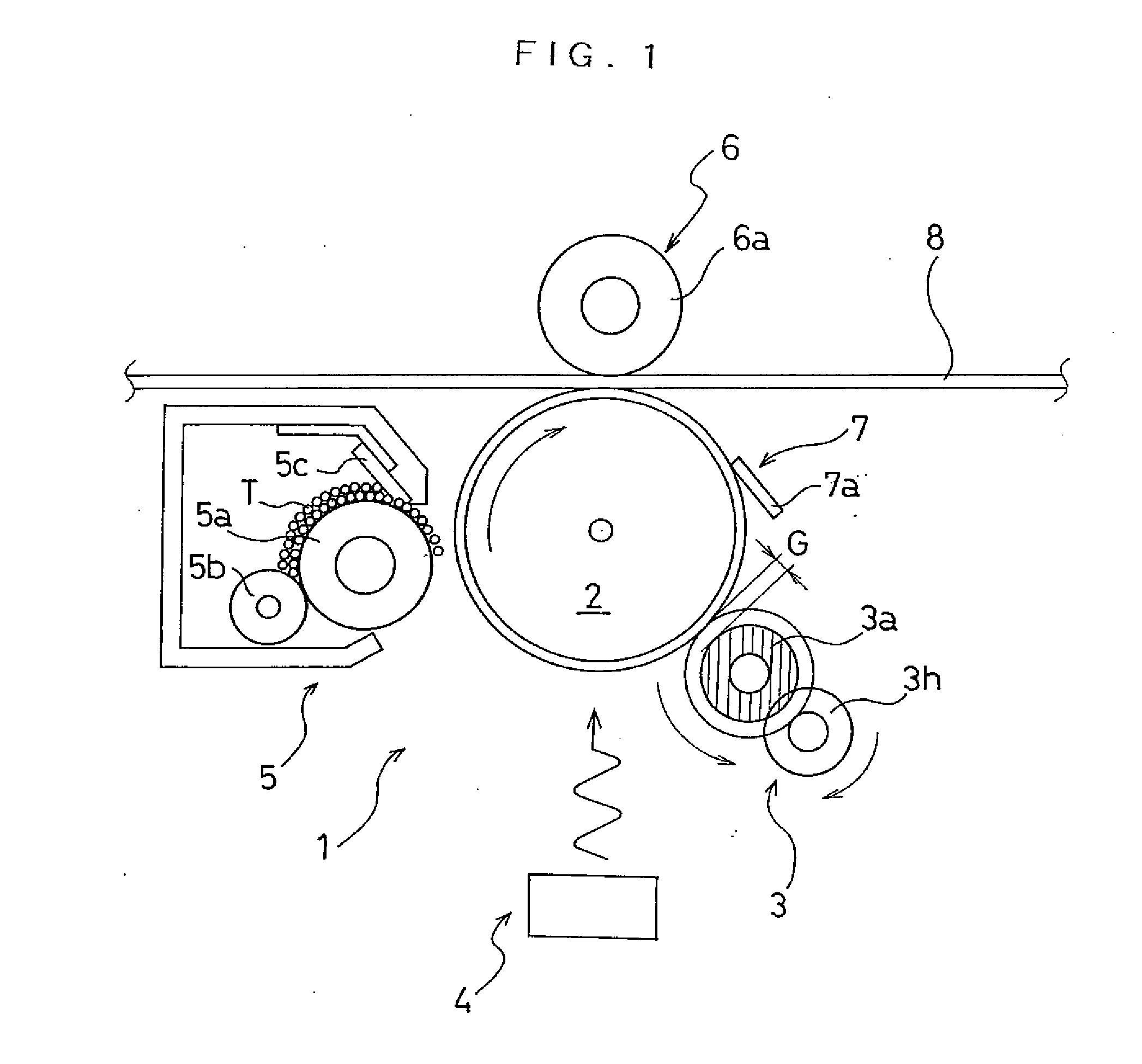

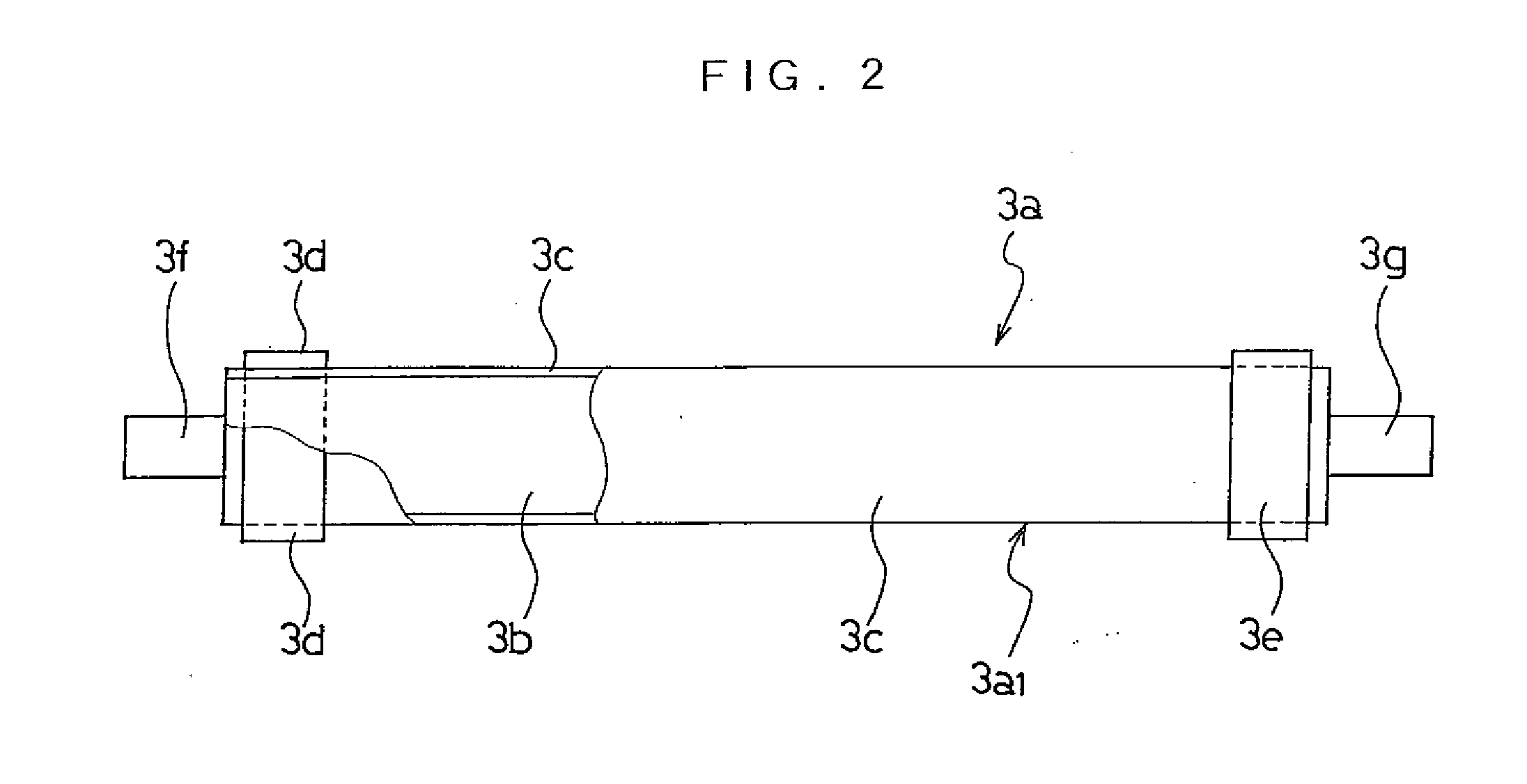

Charging Roller and Image Forming Apparatus with the Same

InactiveUS20070025766A1Molding stabilityAvoid easy deflectionElectrographic process apparatusCorona dischargeImage formationEngineering

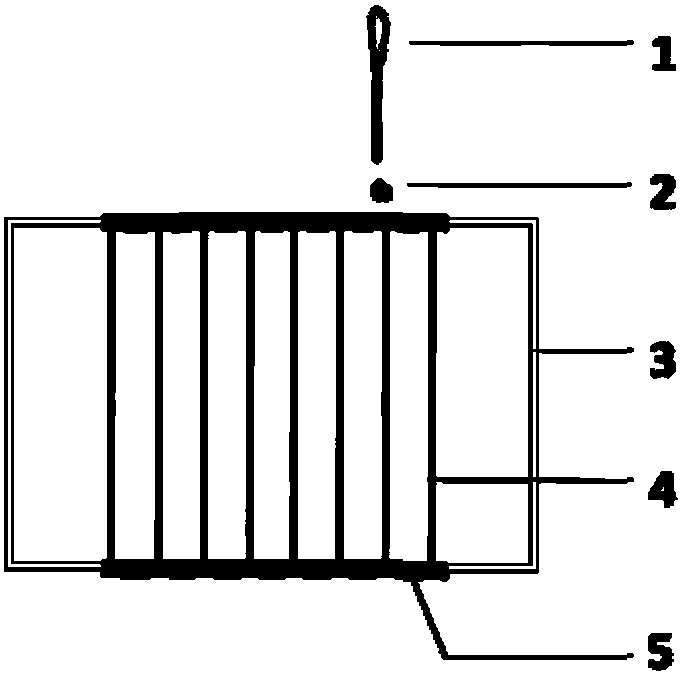

An image forming apparatus comprises: at least an image carrier of which rotary shafts extending from both ends thereof are rotatably supported on an apparatus body by bearings; and a charging roller having gap members fixed to both end portions thereof, respectively, wherein the gap members are brought in contact with the peripheral surface of the image carrier with some pressure to form a charge gap between the image carrier and the charging roller so that the charging roller charges the image carrier in non-contact state with the charge gap, and wherein the gap members are each formed to have a small-diameter portion on the inside thereof and a large-diameter portion on the outside thereof such that the respective small-diameter portions are positioned to face each other.

Owner:SEIKO EPSON CORP

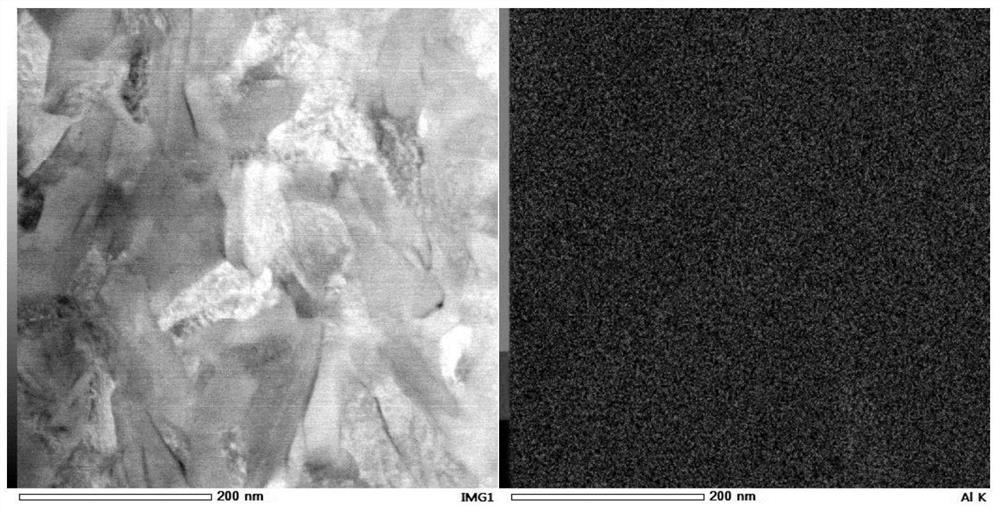

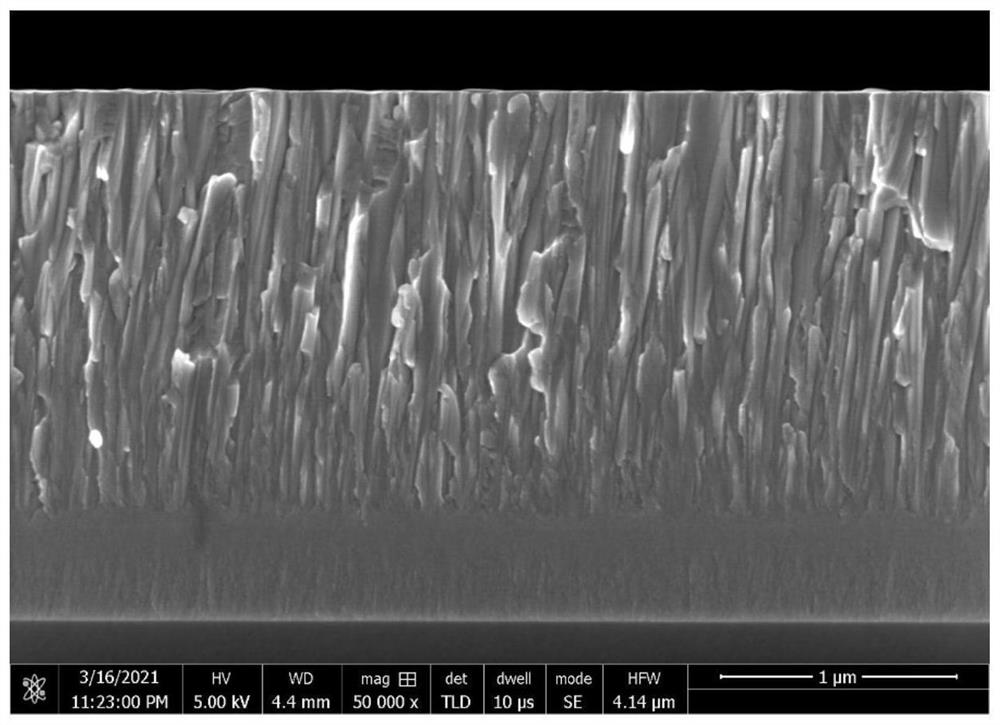

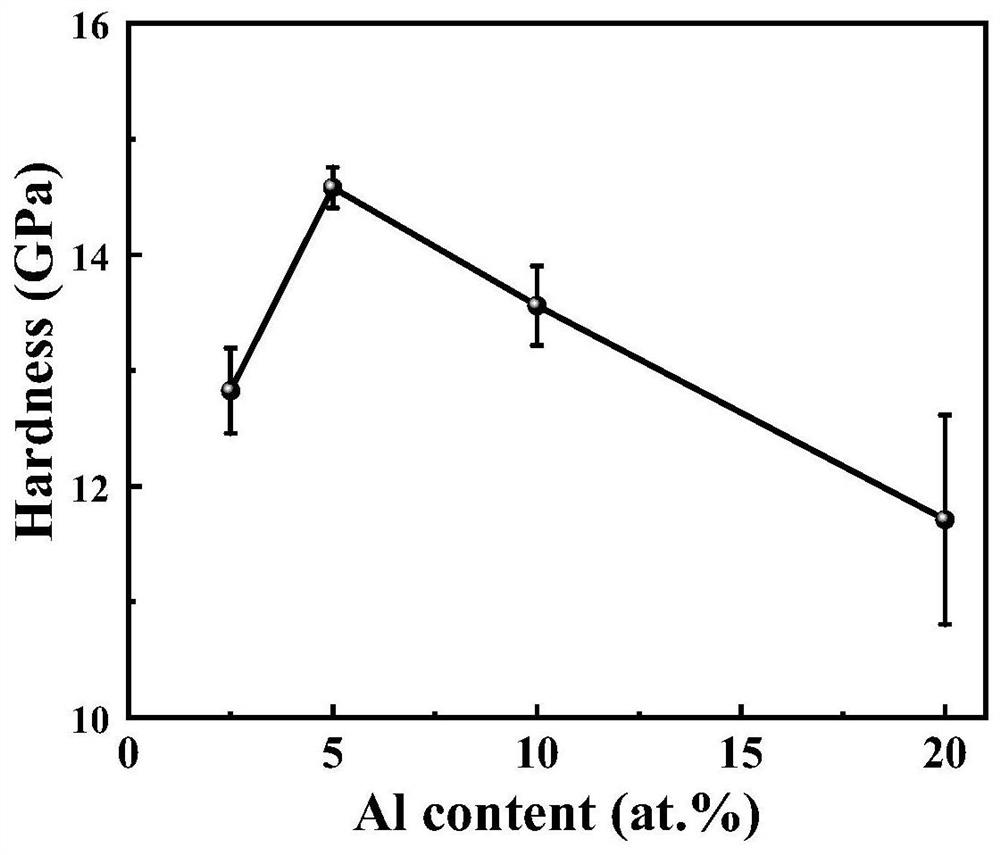

NbMoTaWAl refractory high-entropy alloy film and preparation method thereof

PendingCN113151795AImprove mechanical propertiesImprove antioxidant capacityVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy thin film

The invention discloses a NbMoTaWAl refractory high-entropy alloy film and a preparation method thereof. The NbMoTaWAl refractory high-entropy alloy film comprises the following components of, in percentage by atom, 2.4 at.% - 19.4 at.% of Al, and the balance Nb, Mo, Ta, W with an equal atomic ratio. The NbMoTaWAl refractory high-entropy alloy film is prepared on a single-side polished monocrystalline silicon substrate by adopting a magnetron sputtering and co-sputtering method, wherein a NbMoTaW alloy target adopts a direct-current power supply, and an Al target adopts a radio-frequency power supply. According to the NbMoTaWAl refractory high-entropy alloy film and the preparation method thereof, the content of Al in the NbMoTaWAl high-entropy alloy film is adjusted by controlling the deposition power, so that the agglomeration and reverse sputtering phenomena of target material elements are not prone to be caused, and a microstructure is uniform; after deposition is finished, the substrate is fully cooled in a high-vacuum coating chamber to obtain the NbMoTaWAl refractory high-entropy alloy film, and the obtained film is uniform in component and compact in structure; and the mechanical property and the oxidation resistance of the NbMoTaWAl high-entropy alloy film can be effectively improved through proper addition of the Al.

Owner:XI AN JIAOTONG UNIV

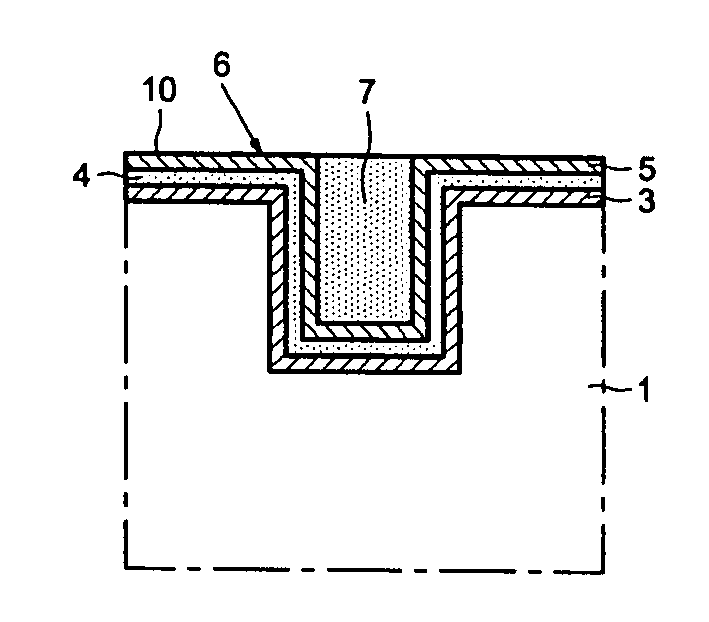

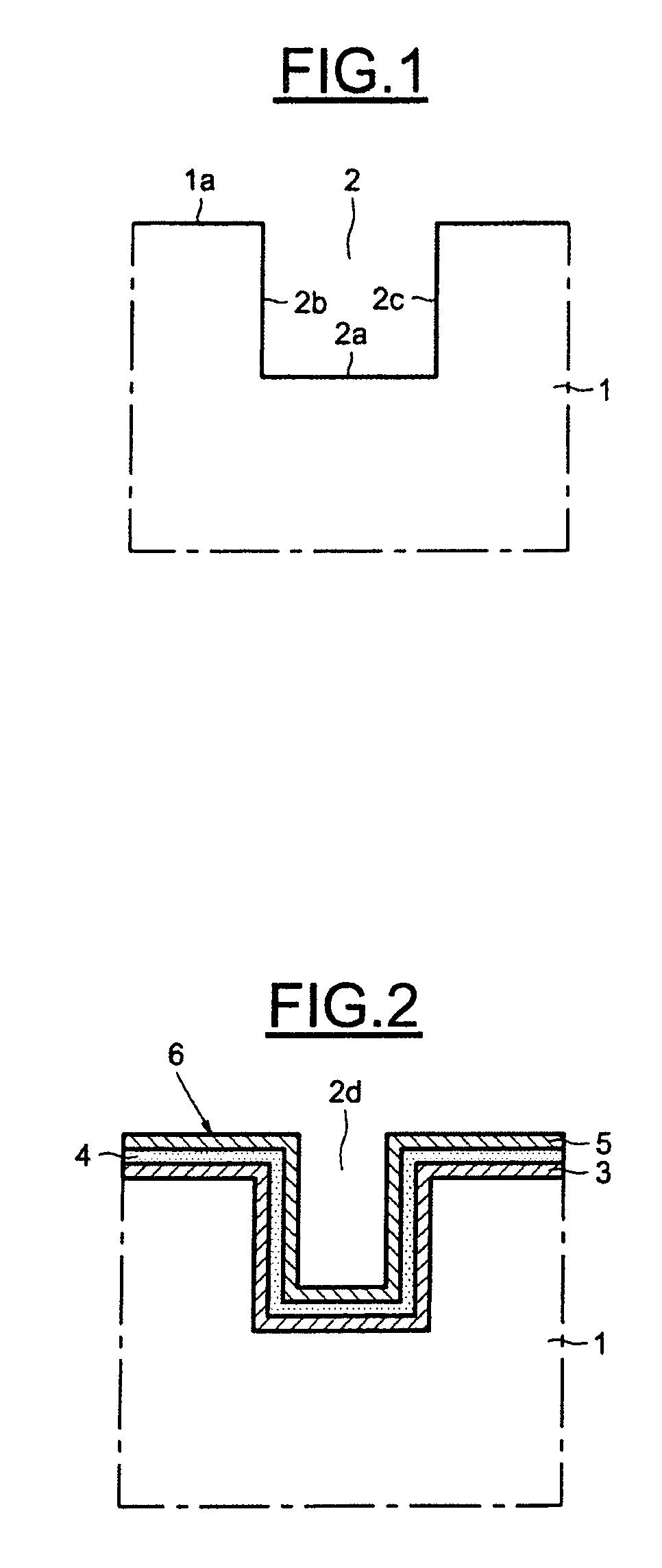

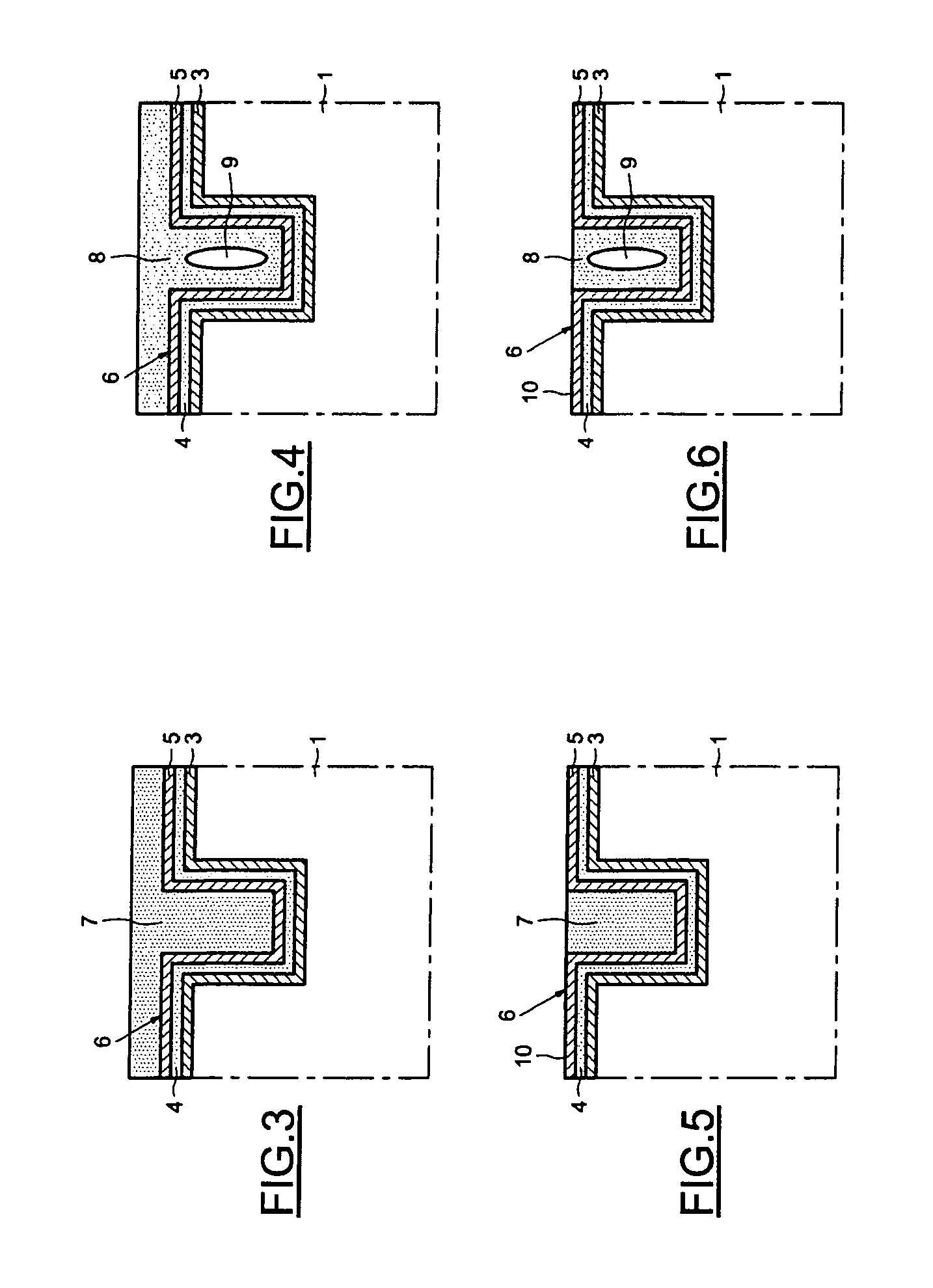

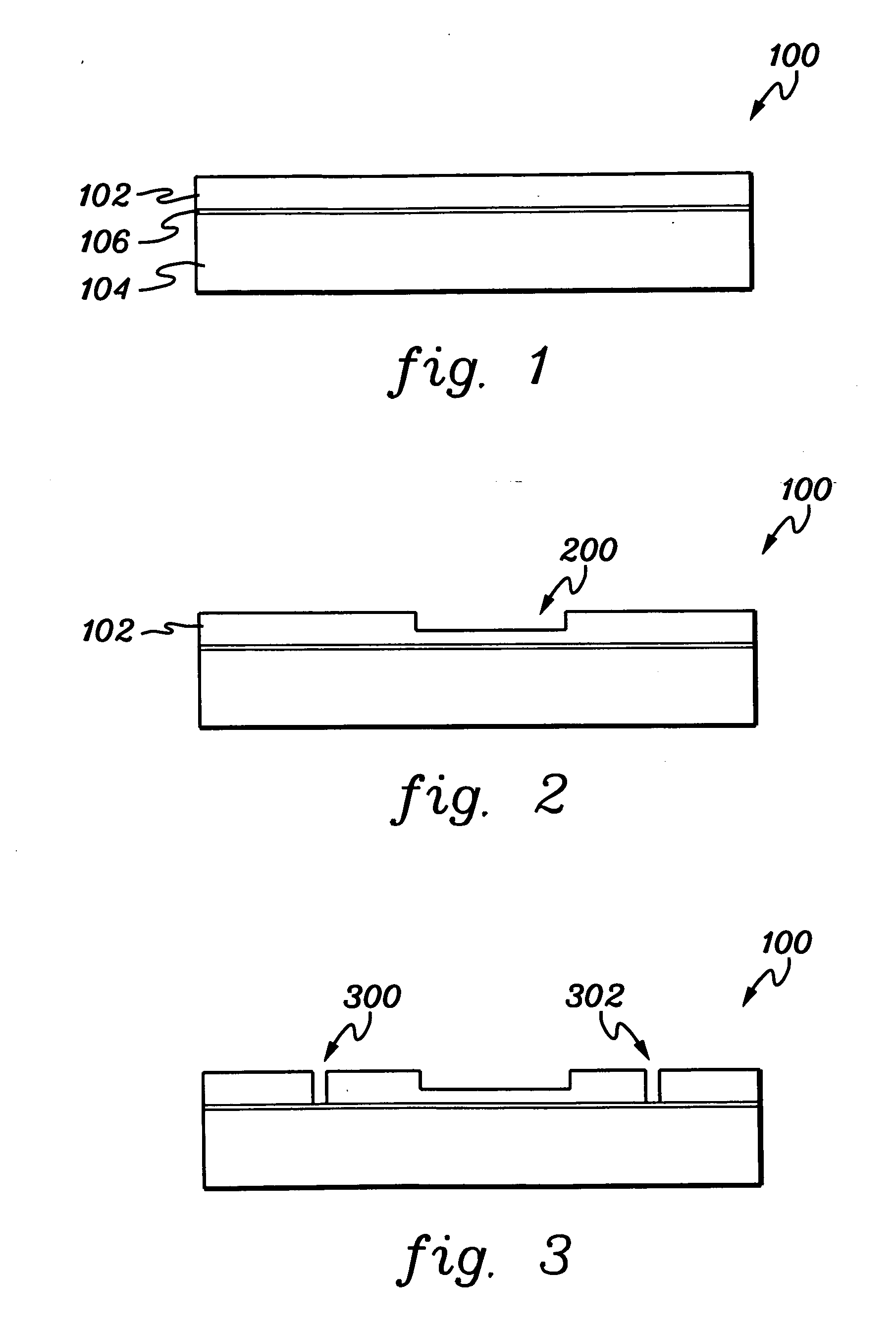

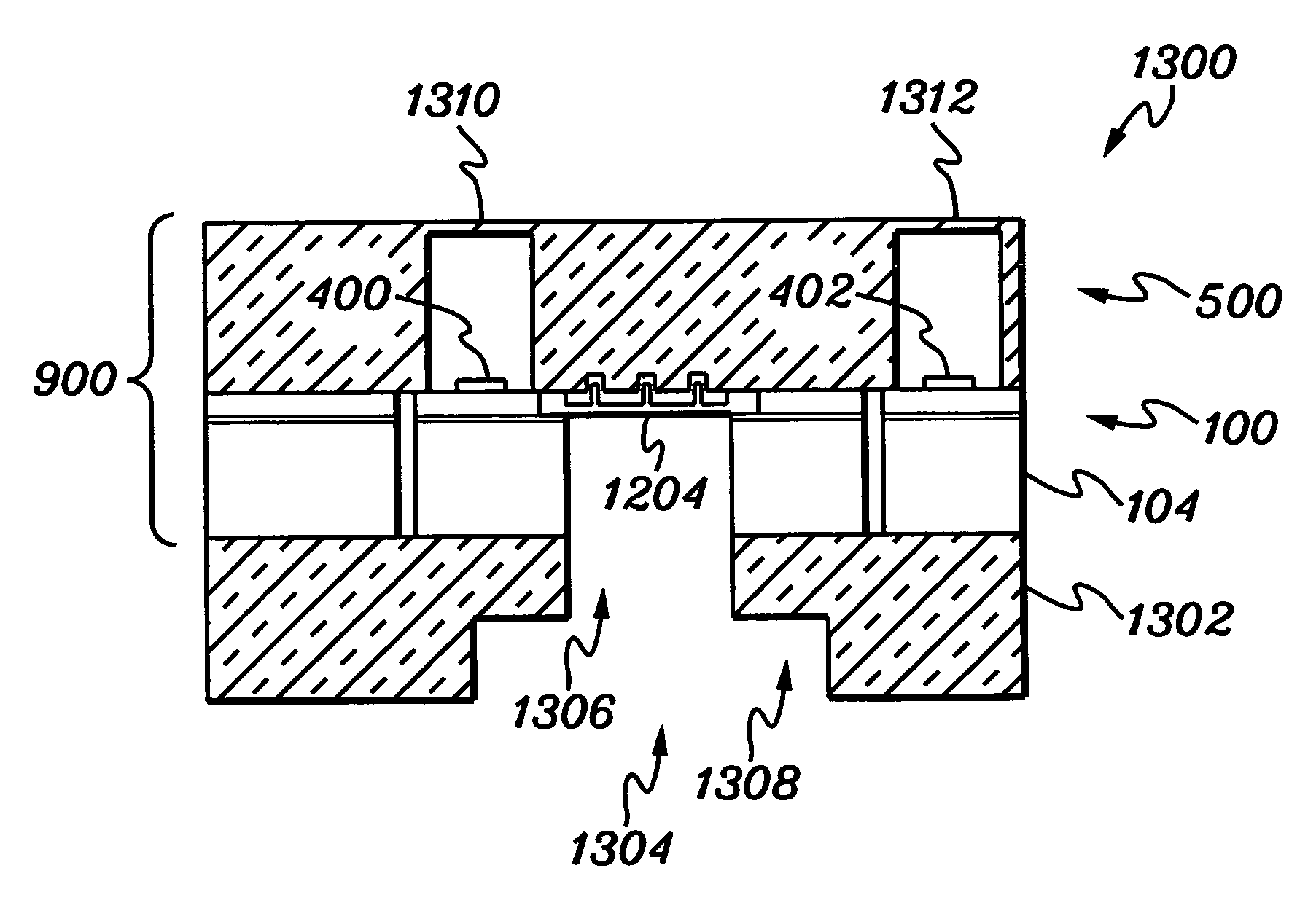

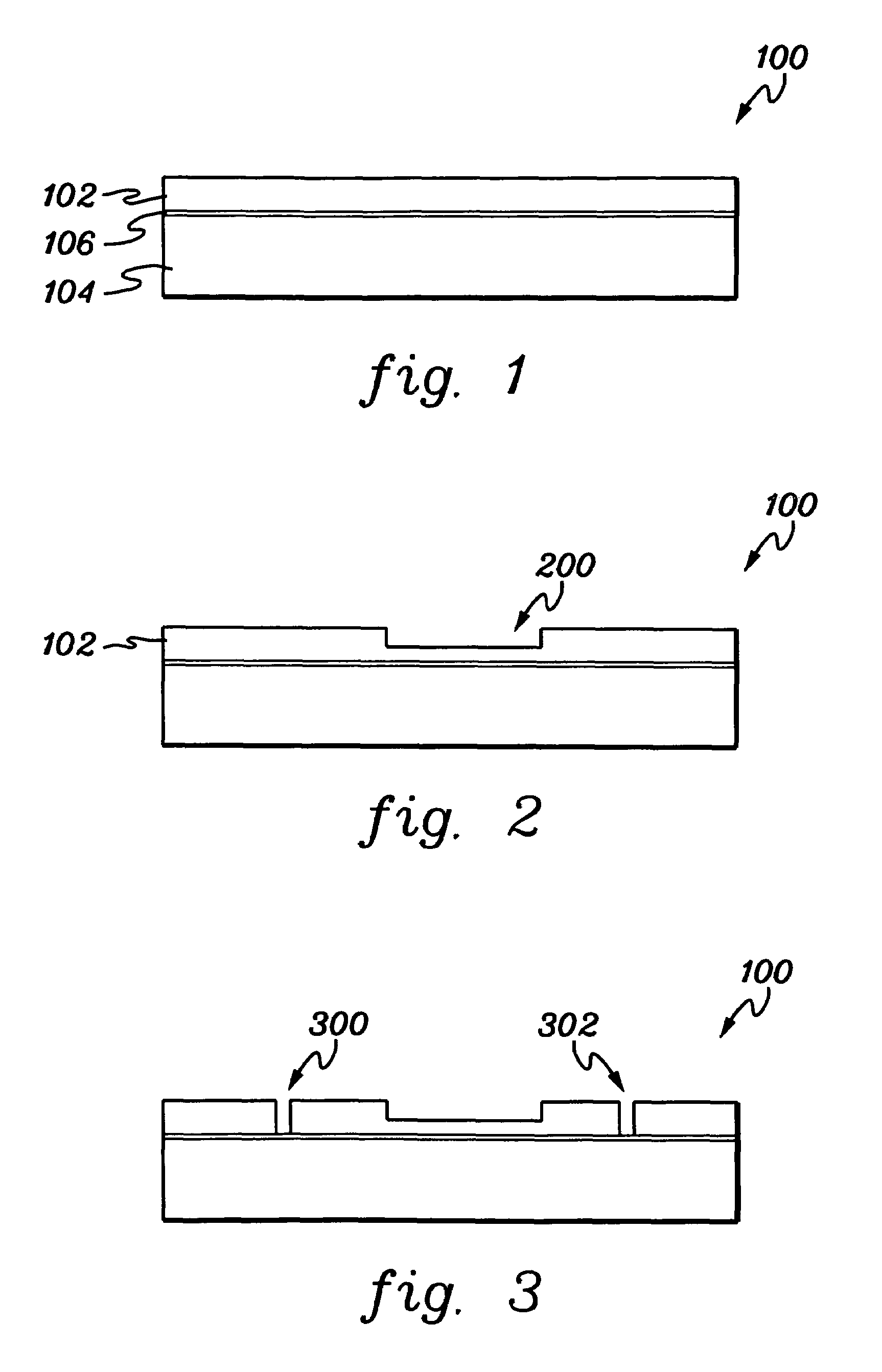

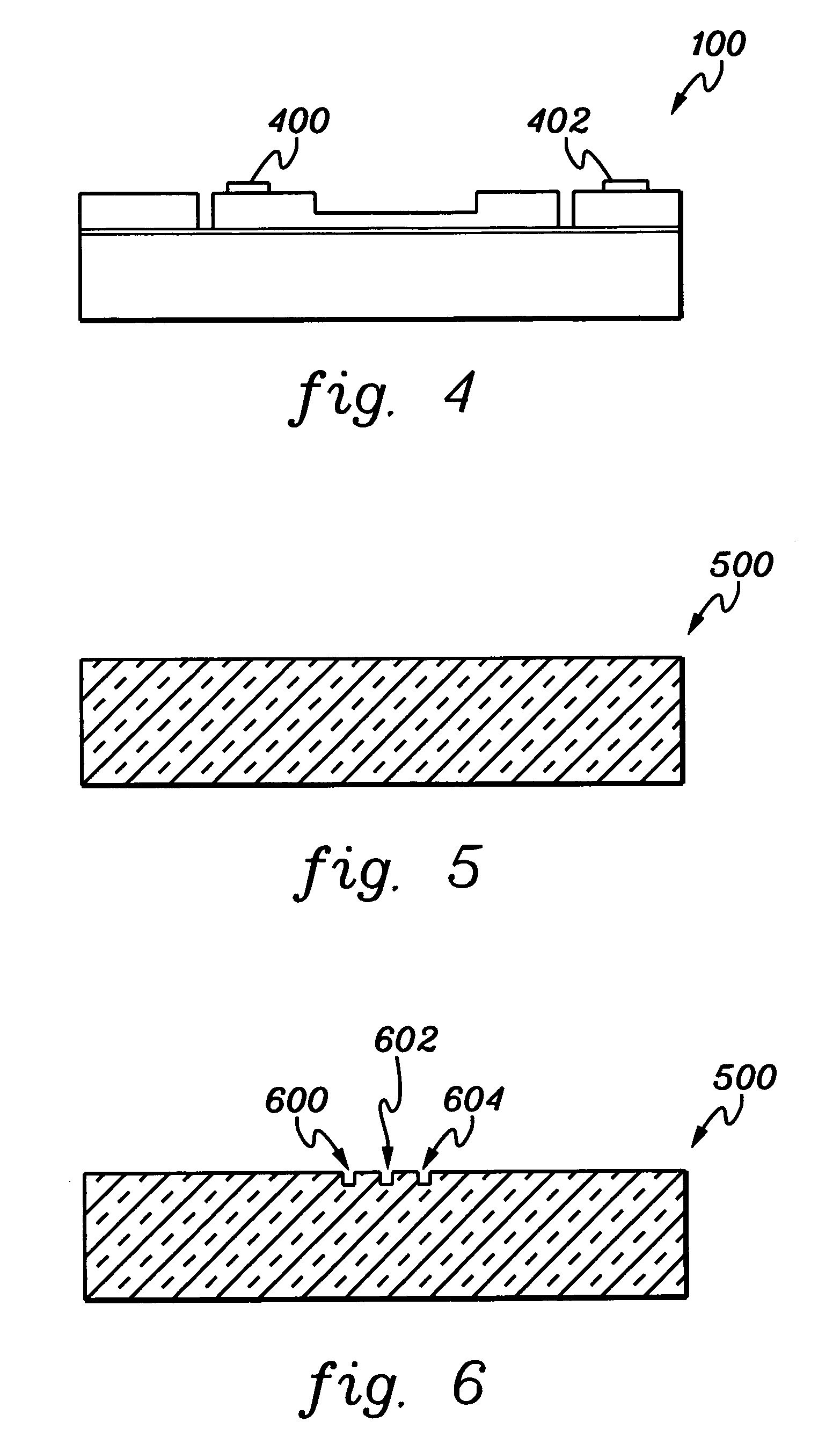

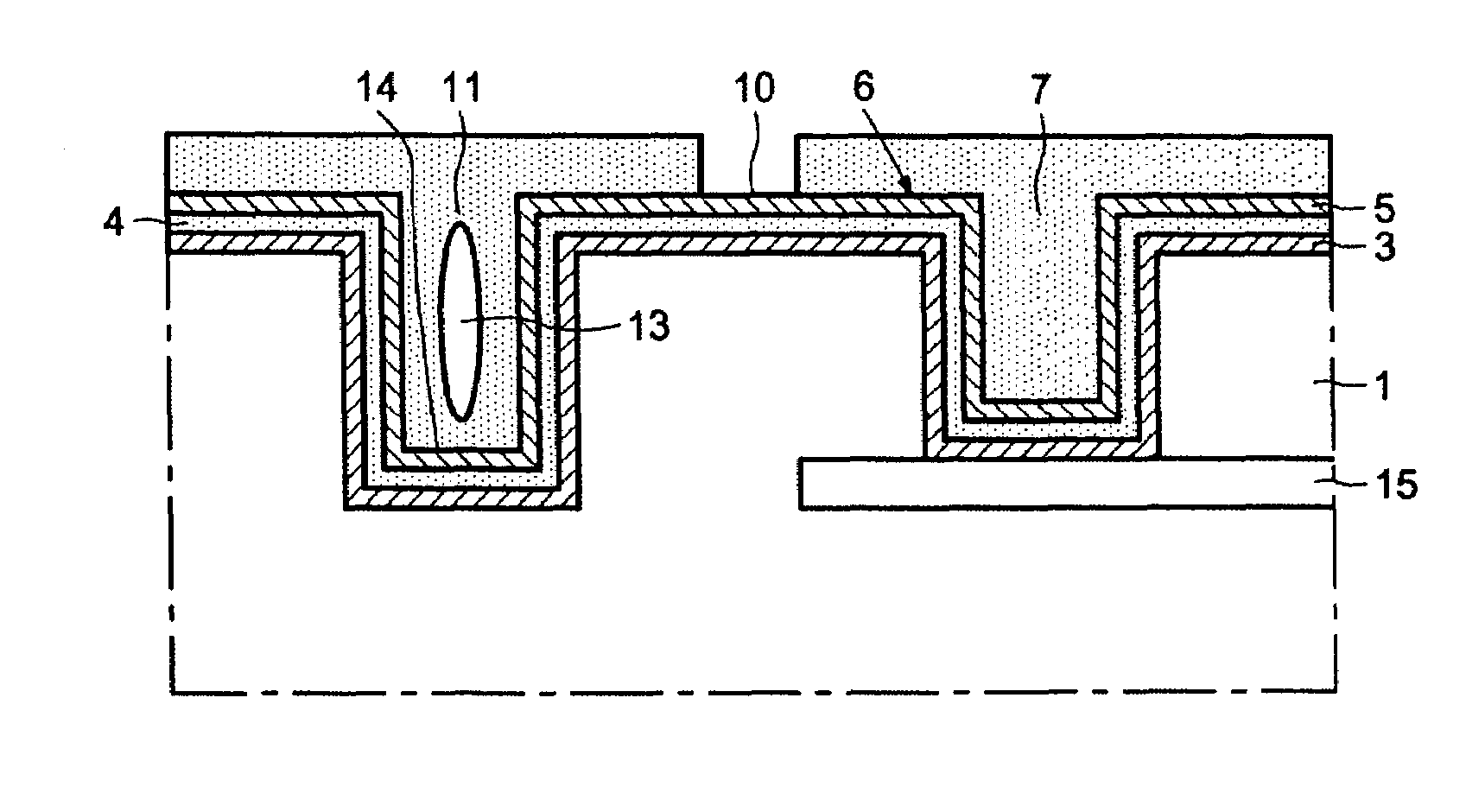

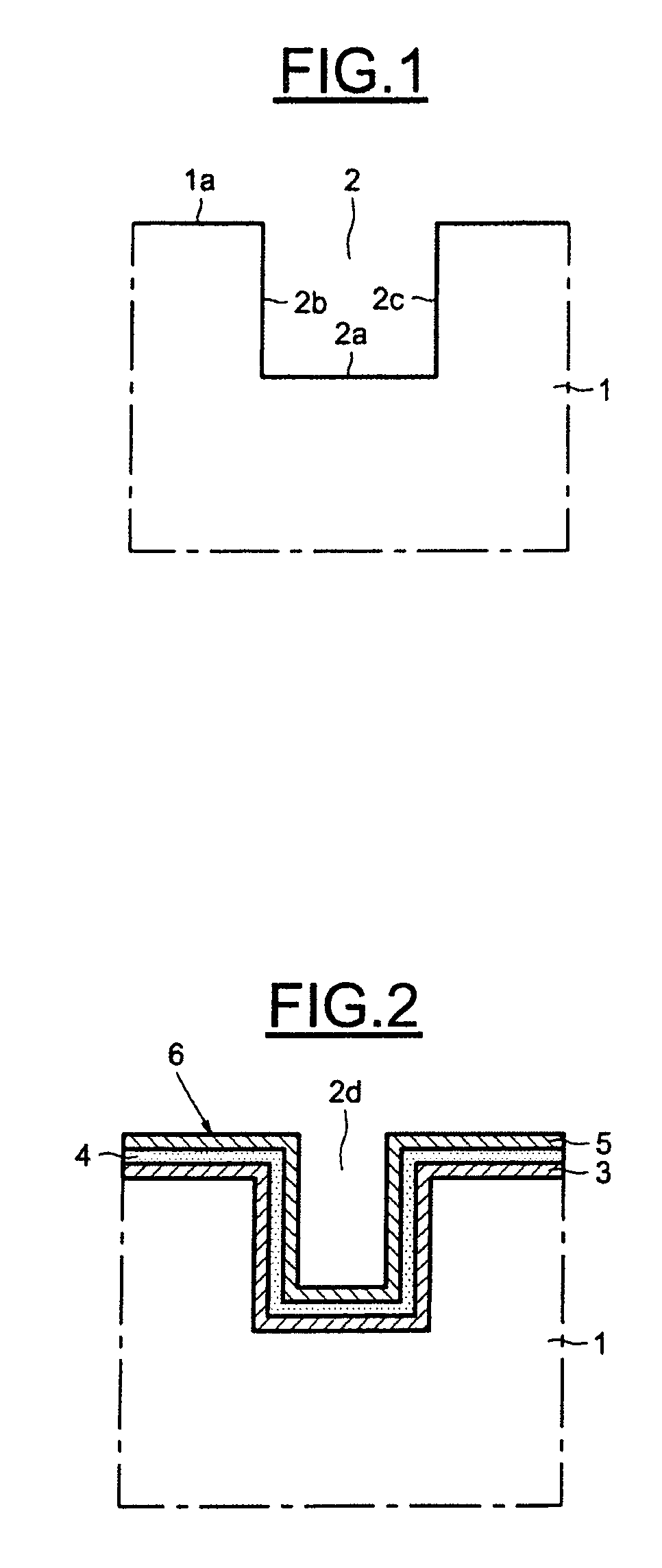

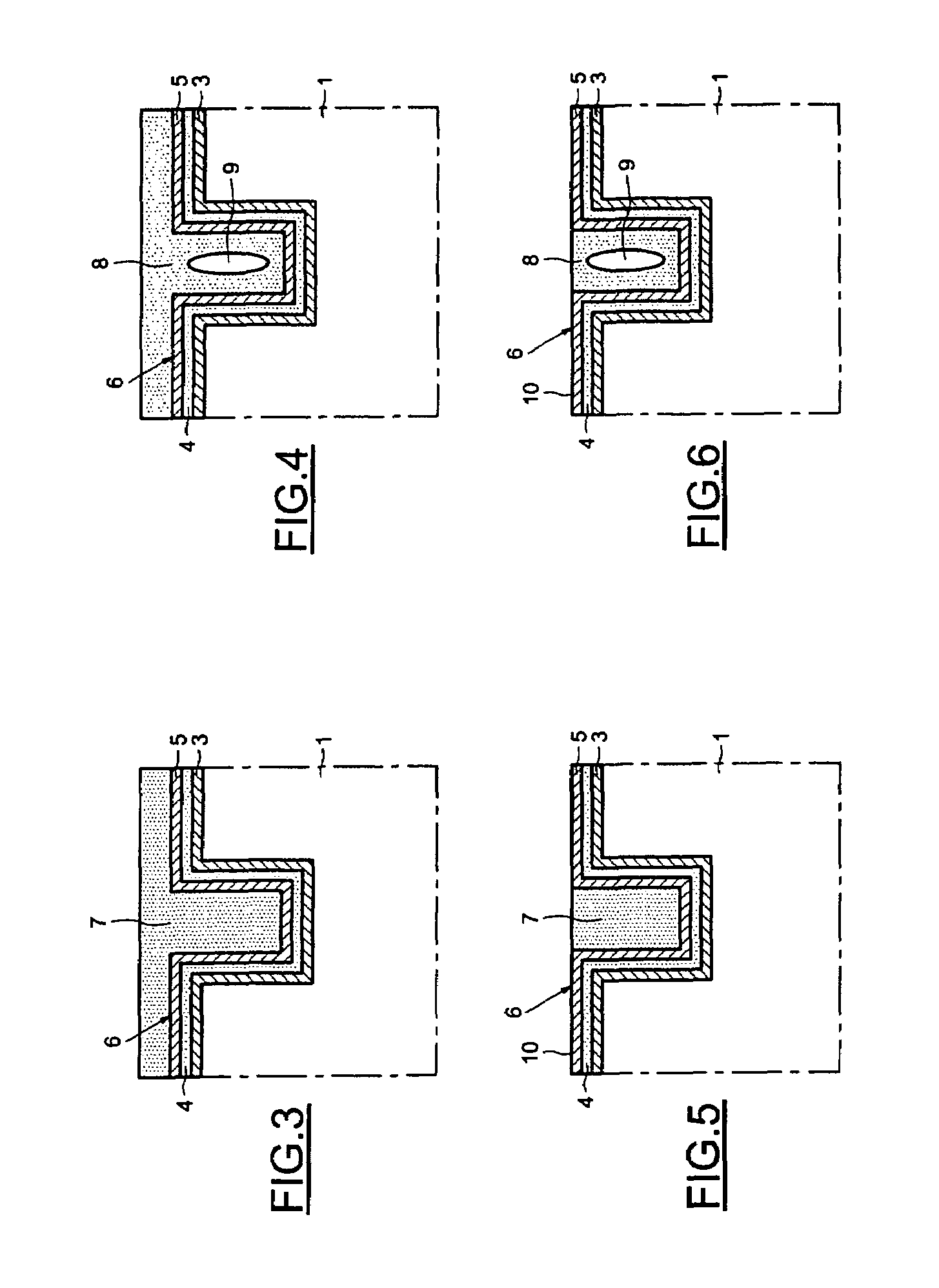

Integrated circuit comprising at least one capacitor and process for forming the capacitor

ActiveUS20060255427A1Absorbs stressImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingDielectric layerCapacitor

An integrated circuit includes at least one capacitor that is formed on a layer provided with at least one first trench. The capacitor, which is provided with a dielectric layer that separates two electrodes, conforms to the shape of the first trench, but leaves a part of the first trench unfilled. A material capable of absorbing stresses associated with the displacements of the walls of the trench is placed in the trench to fill the part of the first trench. A second trench is formed at least partly surrounding the first trench. This second trench is also at least partly filled with a material capable of absorbing stresses associated with the displacements of the walls of the second trench. A void may be included in the stress absorbing material which fills either of the first or second trenches.

Owner:STMICROELECTRONICS SRL +1

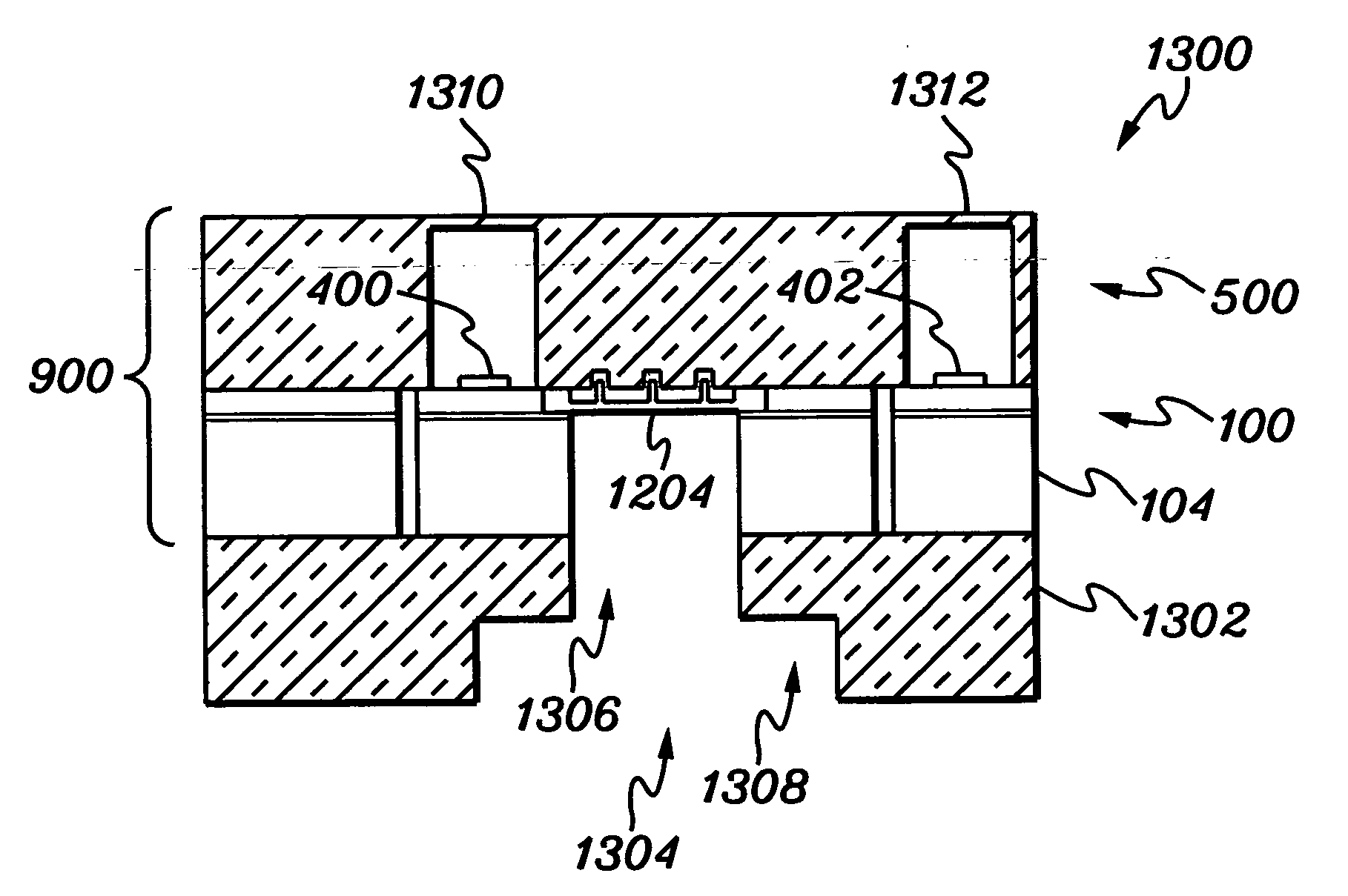

MEMS structure with anodically bonded silicon-on-insulator substrate

ActiveUS20060228823A1Avoid debondingSemiconductor/solid-state device manufacturingForming microstructural systemsSilicon membraneSoi substrate

A silicon-on-insulator (SOI) substrate is anodically bonded to a glass substrate in a MEMS structure with or without electrically bypassing the insulator layer by electrically comprising the silicon layers. The insulator layer serves as an etch stop to create a well-defined, thin silicon membrane for a sensor. A second glass substrate is anodically bonded to the other side of the SOI substrate, and debonding of the existing anodic bond prevented by eliminating any potential drop across the existing bonded surface.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

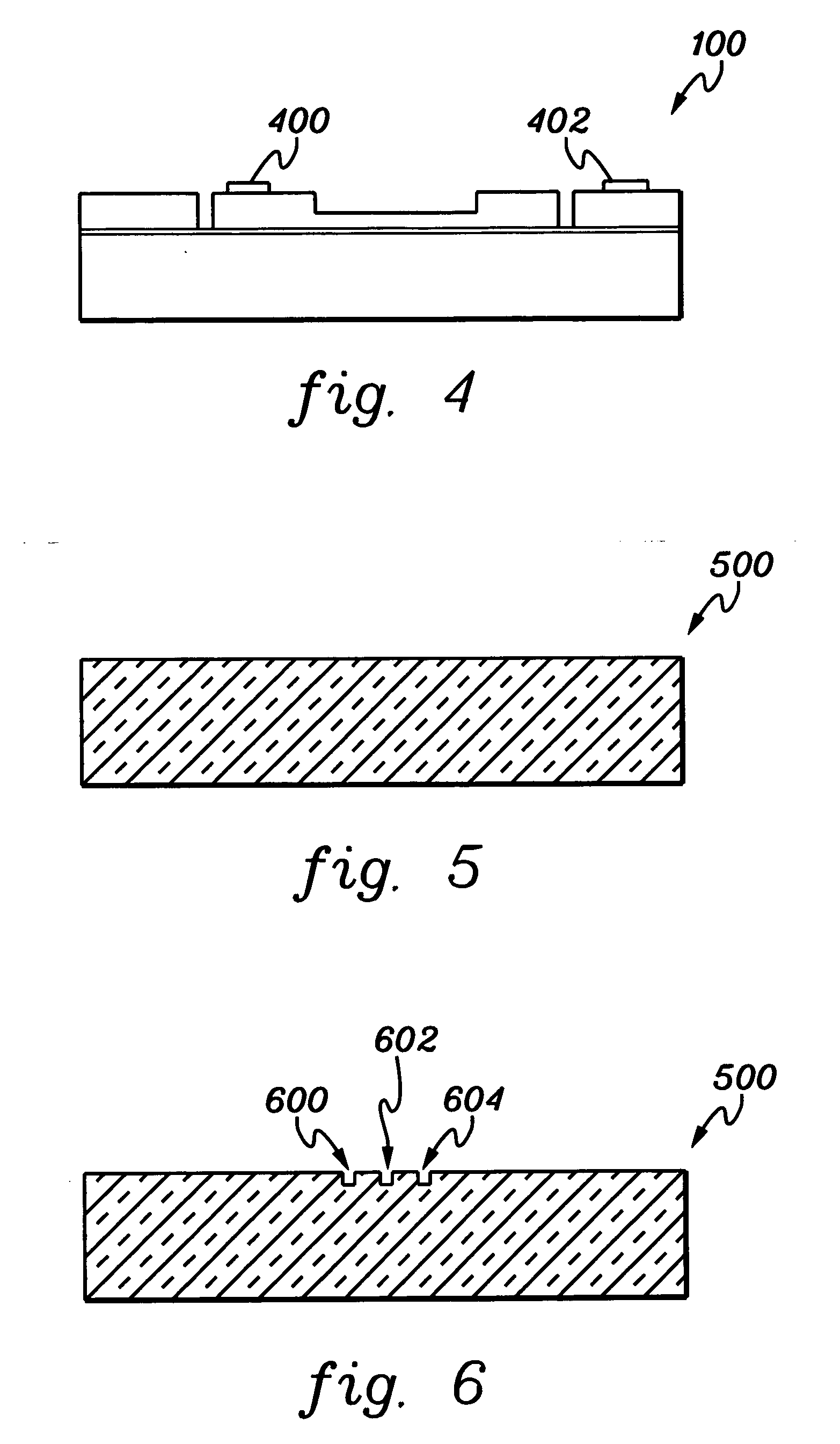

High efficiency composite expanding agent for high-strength self-stressing concrete filled steel tube and preparation method thereof

ActiveCN104909596AGood expansion performanceSwelling starts earlyHigh strength concreteUltimate tensile strength

The invention belongs to the building field, and concretely relates to a high efficiency composite expanding agent for a high-strength self-stressing concrete filled steel tube and a preparation method thereof. The high efficiency composite expanding agent comprises the following components by mass percentage: 22-40% of light calcined magnesia, 12-25% of active calcium oxide, 6-14% of calcined dolomite, 18-30% of sulphoaluminate cement clinker, 12-18% of natural gypsum and 2-6% of modified meerschaum powder. Through a design of hydration expansion characteristics of different components, expansion performance and high-strength concrete intensity are cooperated for development, expansion usefulness is high, water for hydration is little, expansion beginning time is early, and the expansion performance is stable, by introducing a maintenance material, problems of difficult maintenance of a steel pipe under enclosing condition and difficult supply of expanding agent and water for concrete hydration can be solved, and the high efficiency composite expanding agent is suitable for preparing the high-strength self-stressing concrete filled steel tube under enclosing condition of the steel pipe.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

MEMS structure with anodically bonded silicon-on-insulator substrate

ActiveUS7527997B2Avoid debondingSemiconductor/solid-state device manufacturingForming microstructural systemsSilicon membraneSoi substrate

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

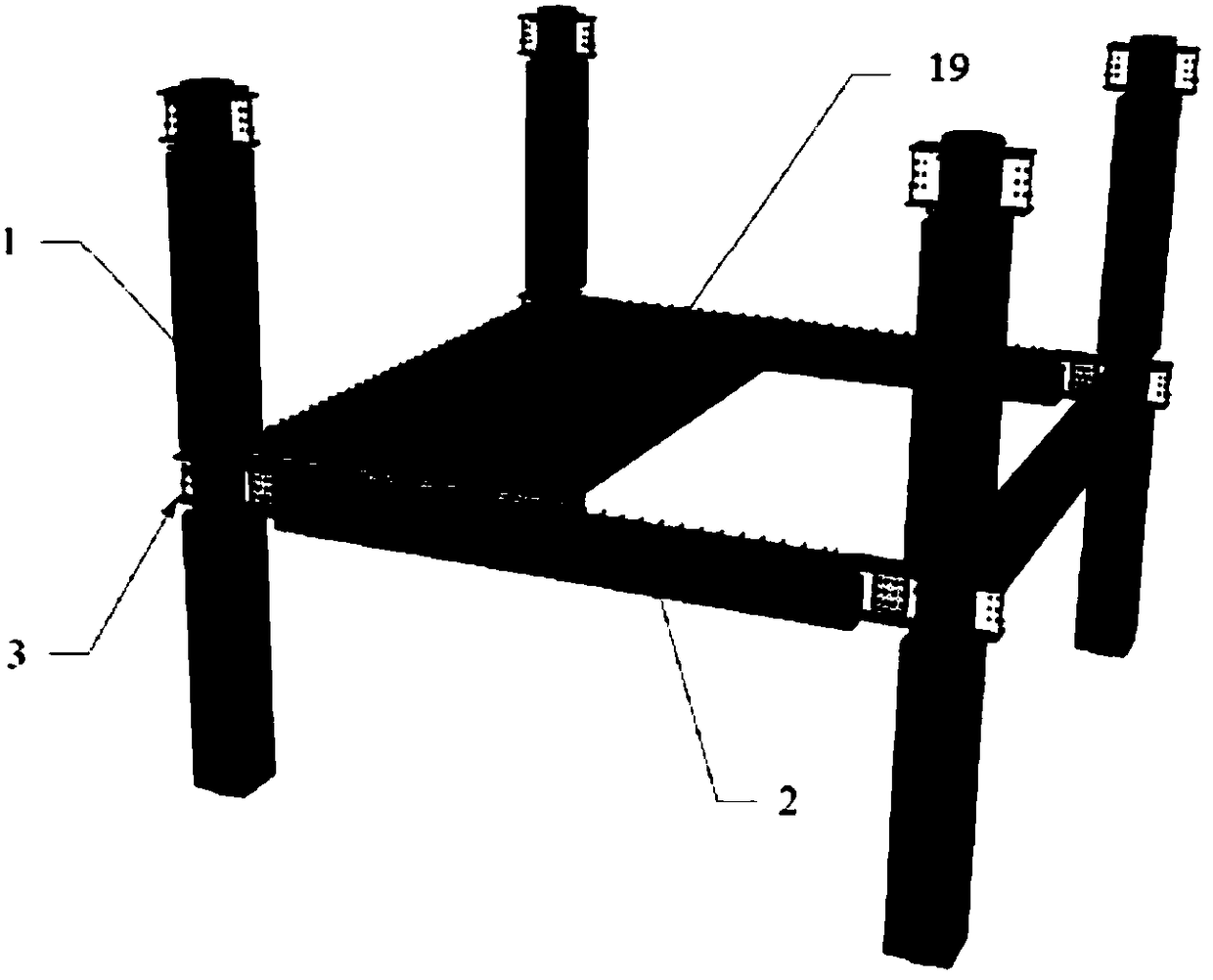

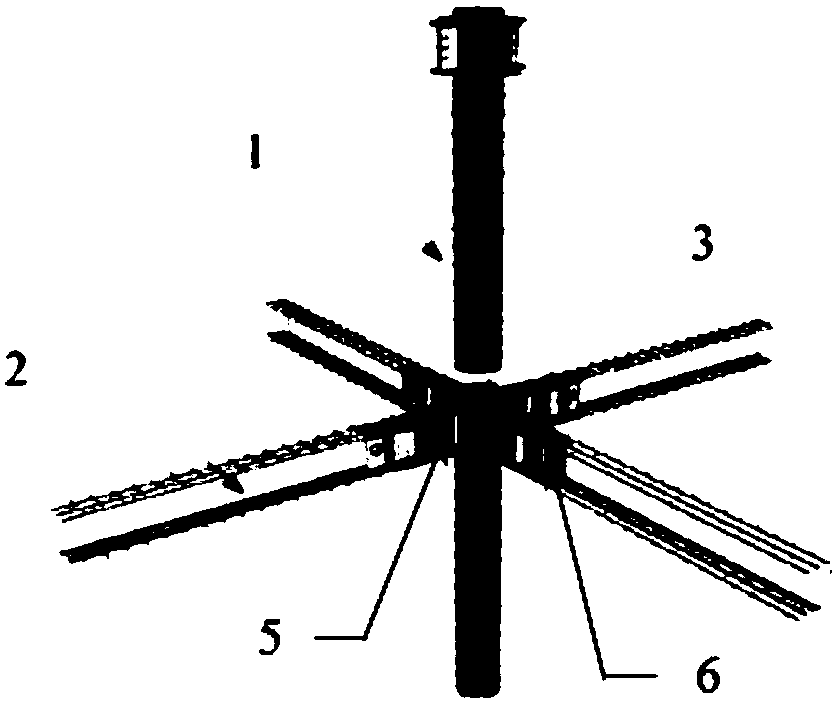

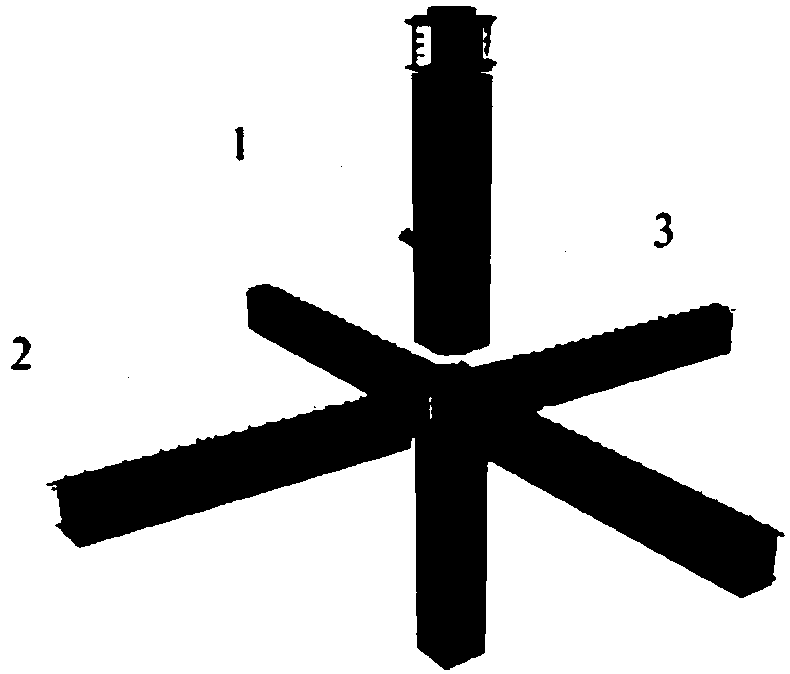

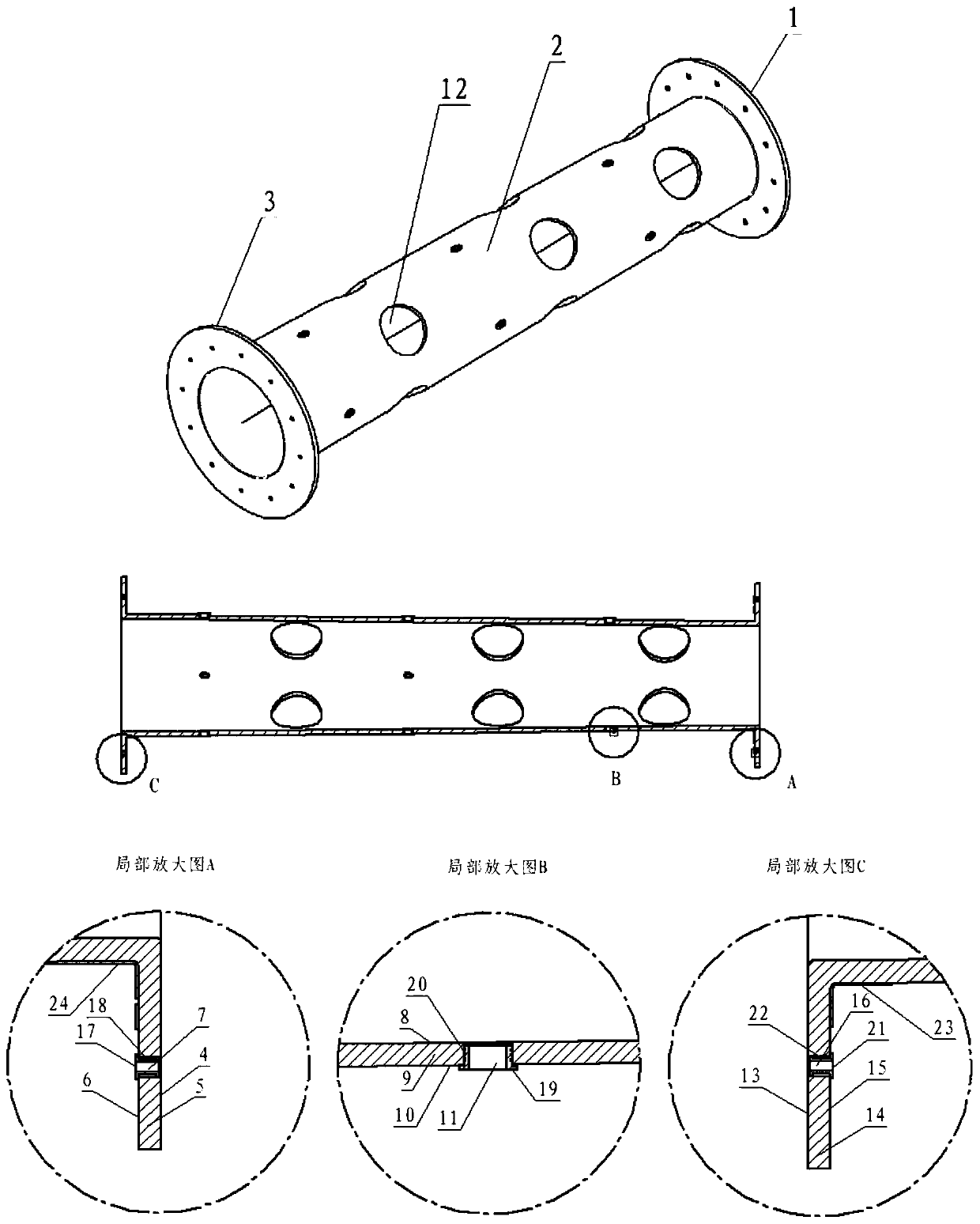

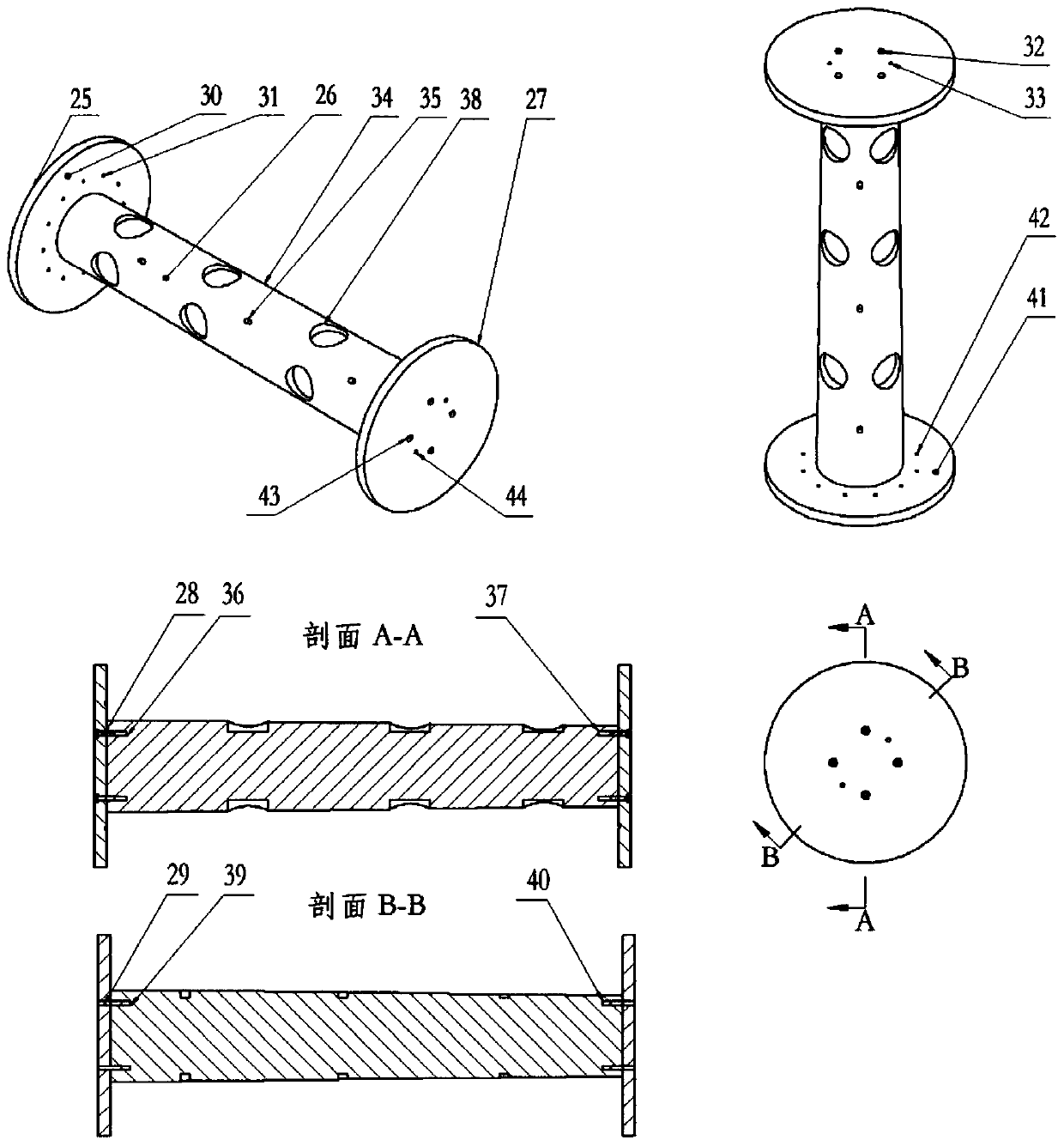

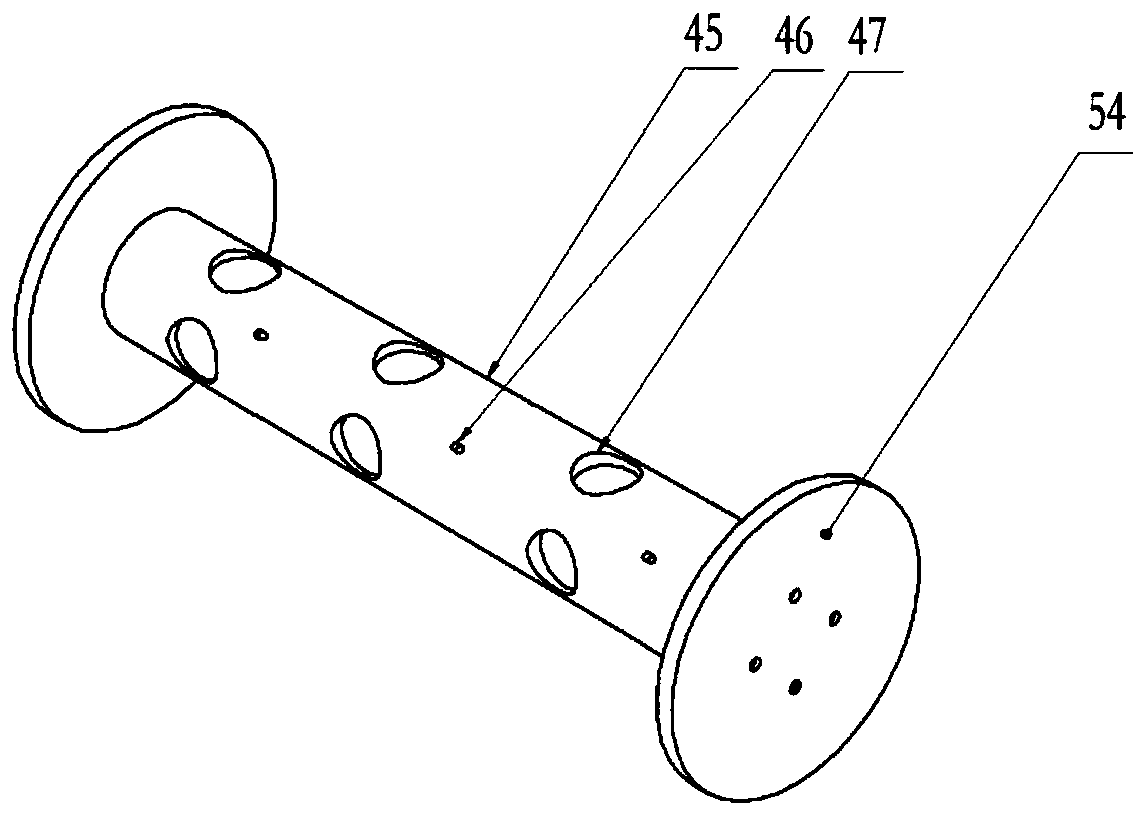

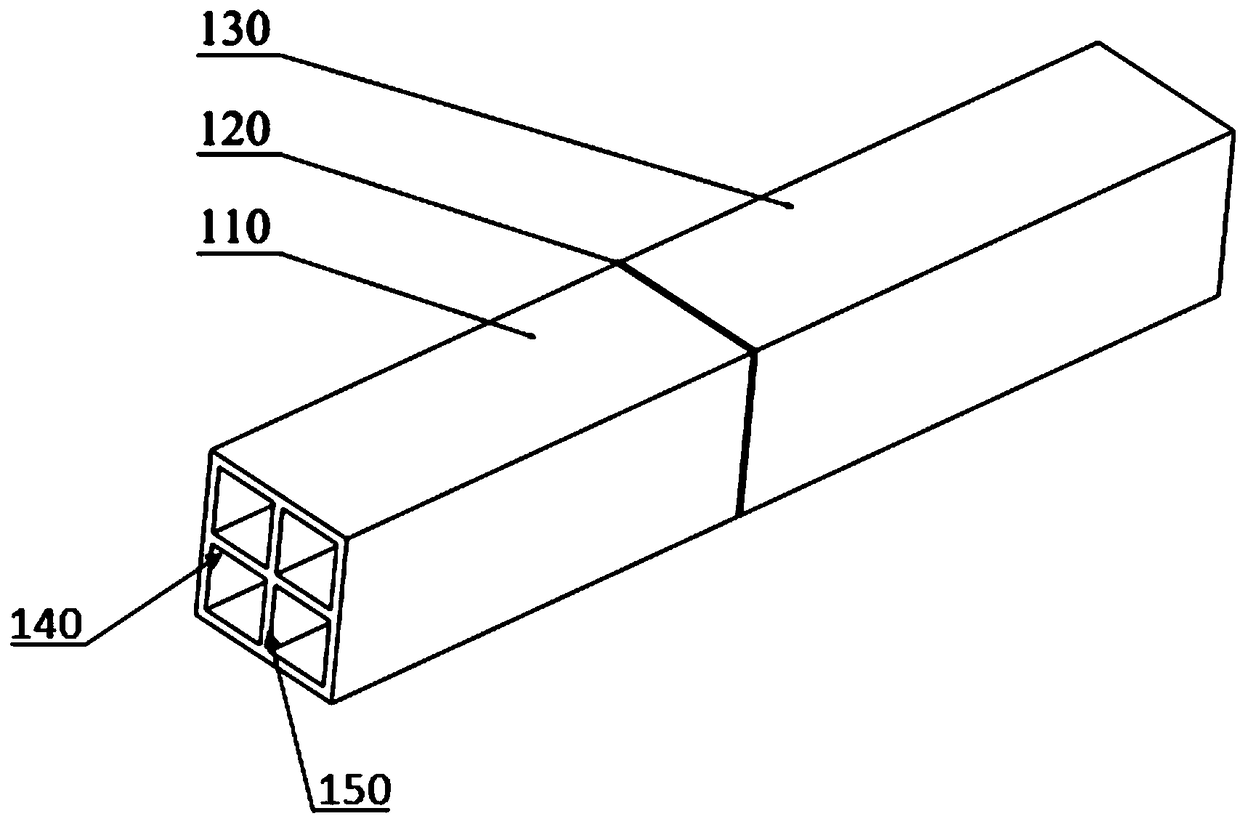

Prefabricated pre-stressed beam member, fabricated combined frame structure and installation method of fabricated combined frame structure

PendingCN108457422AReduce shipping weightSave on rental costsLoad-supporting elementsFloor slabSurface layer

The invention discloses a prefabricated pre-stressed beam member, a fabricated combined frame structure and an installation method of the fabricated combined frame structure. The fabricated combined frame structure comprises prefabricated column members with hollow steel pipes inside, prefabricated pre-stressed beam members, cast-in-place concrete inside the prefabricated column hollow steel pipes, a laminated floor slab prefabricated base plate and laminated surface layer concrete. The middle sections of the hollow steel pipes of the prefabricated column members are covered with concrete, anda beam-column joint zone provided with short H-shaped steel beams is arranged at both ends of each middle section. The prefabricated pre-stressed beam member comprises a concrete laminated pre-stressed beam and interposed H-shaped steel beams at both ends of the pre-stressed beam. The short H-shaped steel beams in the beam-column joint zone and the interposed H-shaped steel beams of the prefabricated pre-stressed beam member are combined by bolt welding or connected by bolting. Joints of the hollow steel pipes of the upper and lower sections of the prefabricated column members are connected by welding. The fabricated combined frame structure integrates the advantages of a steel structure and a prefabricated concrete structure, and has high installation efficiency and good safety, and manpower and material resources are greatly saved.

Owner:SOUTHEAST UNIV +2

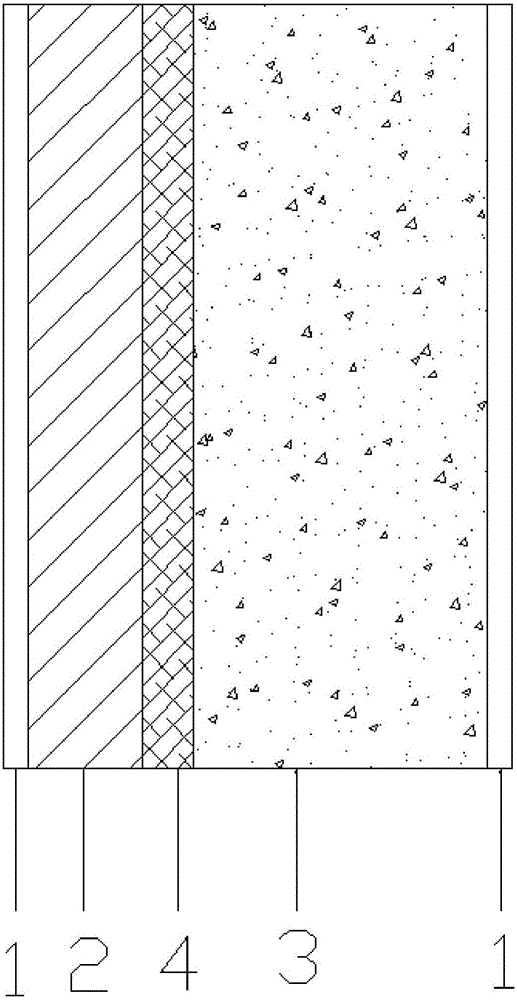

Heat preservation structure using vacuum insulated panels, and refrigerator

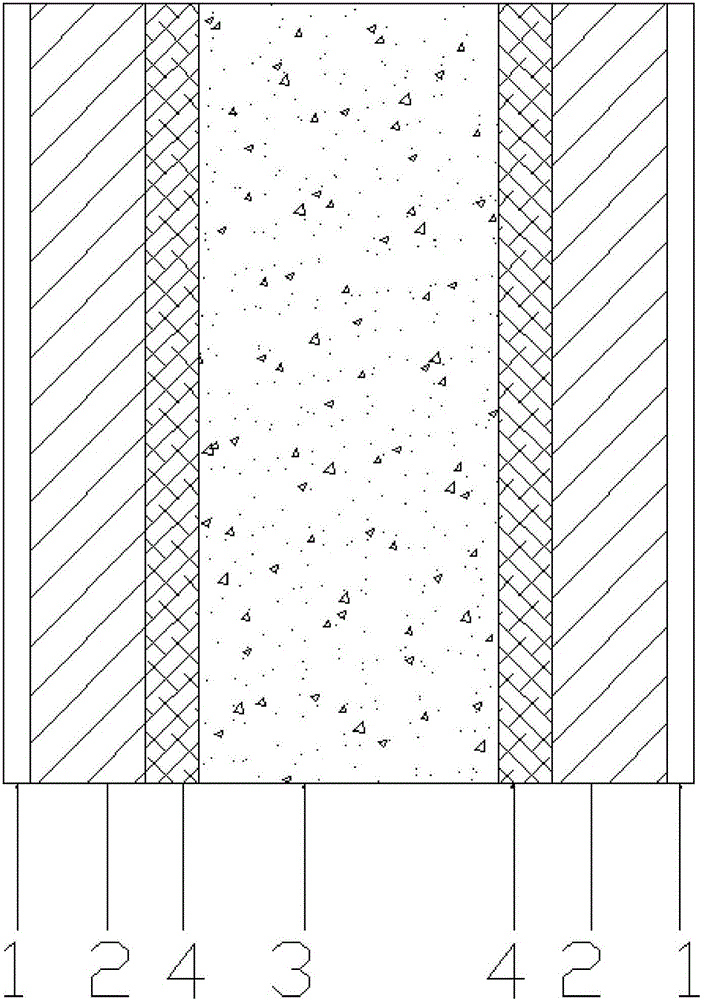

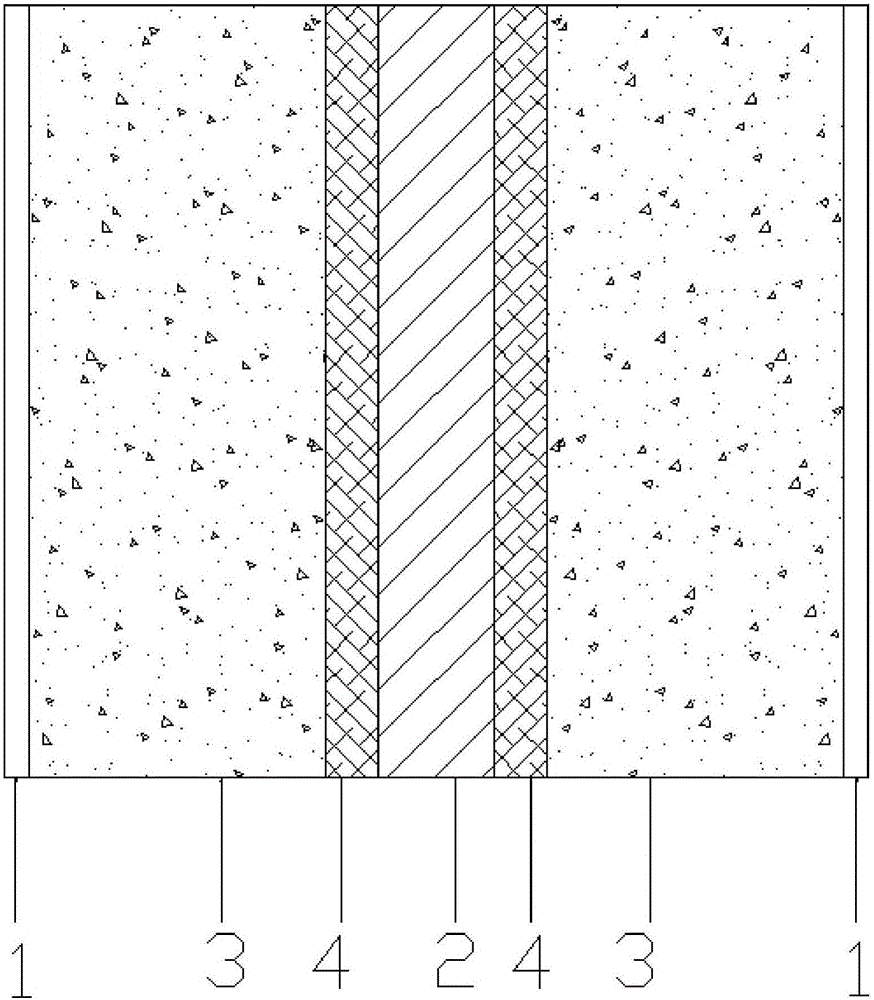

InactiveCN105927823AAvoid deformationAvoid debondingThermal insulationInsulation for cooling apparatusThermal expansionEngineering

The invention relates to the technical field of heat preservation devices, in particular to a heat preservation structure using vacuum insulated panels, and a refrigerator. The heat preservation structure using the vacuum insulated panels comprises two protective layers. At least one layer of the vacuum insulated panels and at least one foaming insulated layer are arranged between the two protective layers and are arranged in an alternate mode. An elastic material layer is arranged between each vacuum insulated panel and the corresponding foaming insulated layer. The heat preservation structure using the vacuum insulated panels, and the refrigerator have the beneficial effects that one elastic material layer is arranged between each vacuum insulated panel and the corresponding foaming insulated layer, the elastic material layers can absorb deformation generated by thermal expansion and chilling contraction, and the whole heat preservation structure is prevented from deformation; and the elastic material layers can have the function of tensioning the vacuum insulated panels and the foaming insulated layers, the debonding phenomenon is avoided, the adaptability of the heat preservation structure to high and low temperature environments is improved, and the reliability of the heat preservation structure and the reliability of thermal insulation properties are improved.

Owner:HEFEI HUALING CO LTD +1

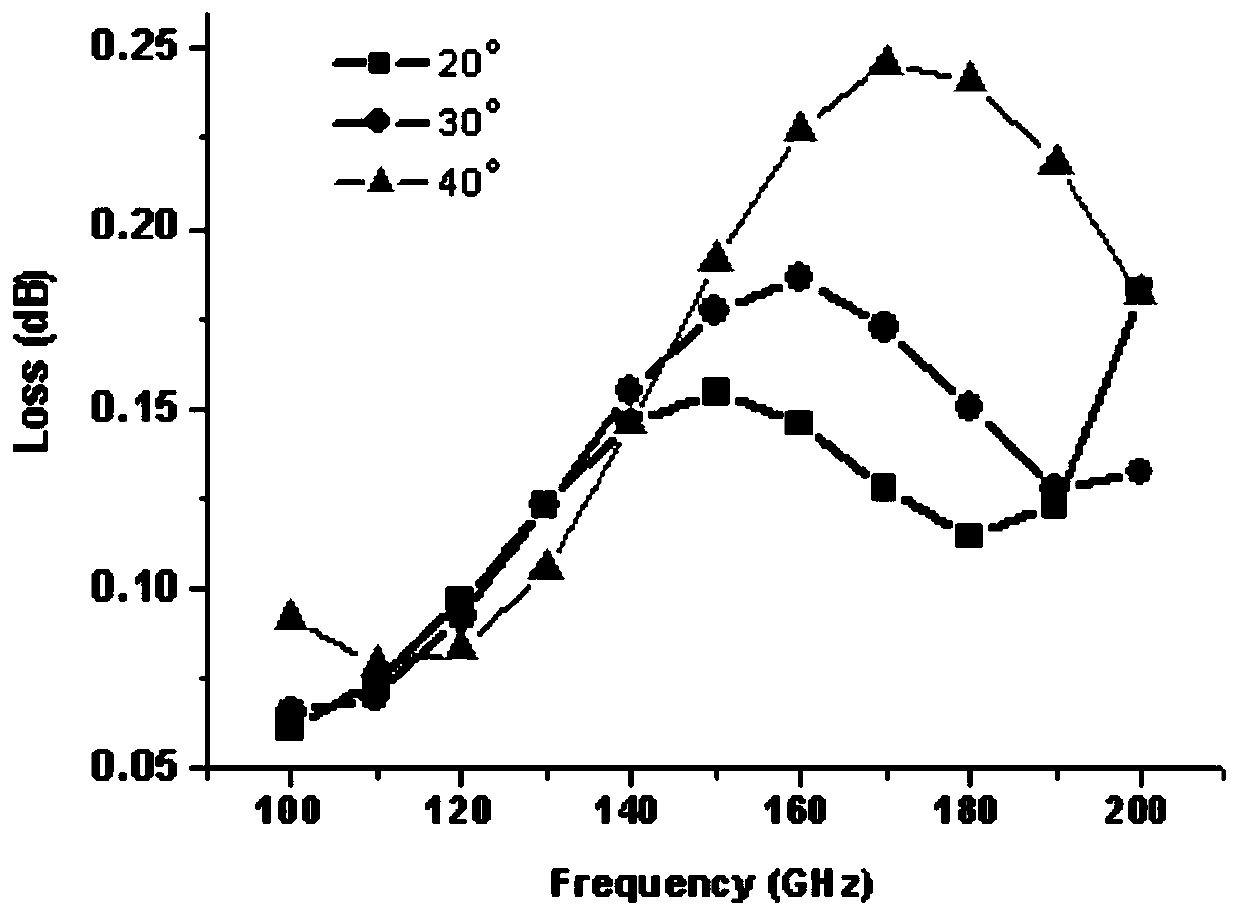

6G radome suitable for terahertz antenna and preparation method thereof

ActiveCN110350317AImprove temperature resistanceLightweightRadiating element housingsMaxillary gingivaBisphenol

The invention relates to a 6G radome suitable for a terahertz antenna and a preparation method thereof. The radome comprises an outer skin, a foam core layer, a middle skin, a foam core layer and an inner skin. The 6G radome is characterized in that the prepreg formed by combination of fiber reinforcement and resin is used as the skin material. As for the prpreg, the resin is polyphenylene ether modified bisphenol M cyanate ester resin and has the following dielectric properties: dielectric constant is less than or equal to 2. 6 and the loss factor is less than or equal to 0. 004. The fiber reinforcement is quartz fiber braid. The prepreg gum content is 30wt%-44wt%. The hot-pressing pot forming technology is used. The radome has high wave transmittance within the range of 100-200GHz and can meet the transmission performance requirements of the 6G antenna network within the terahertz band.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

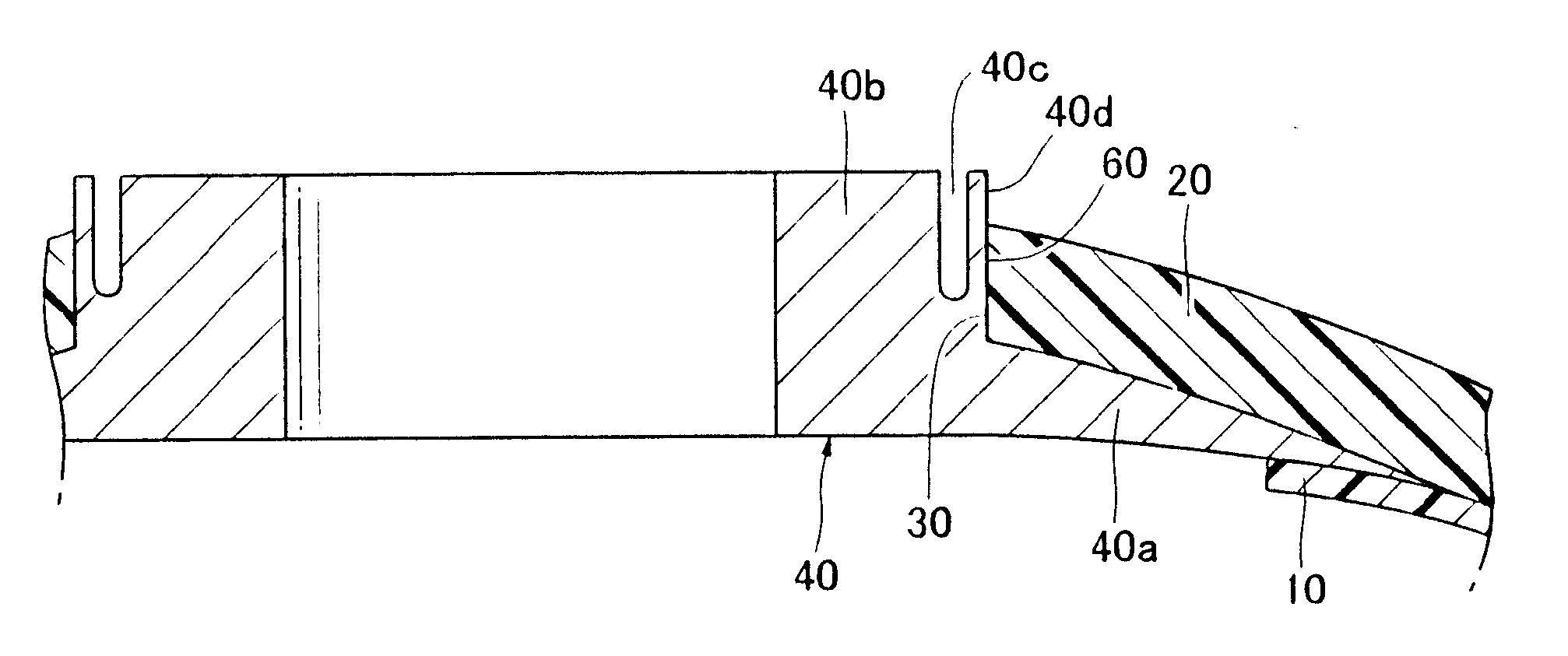

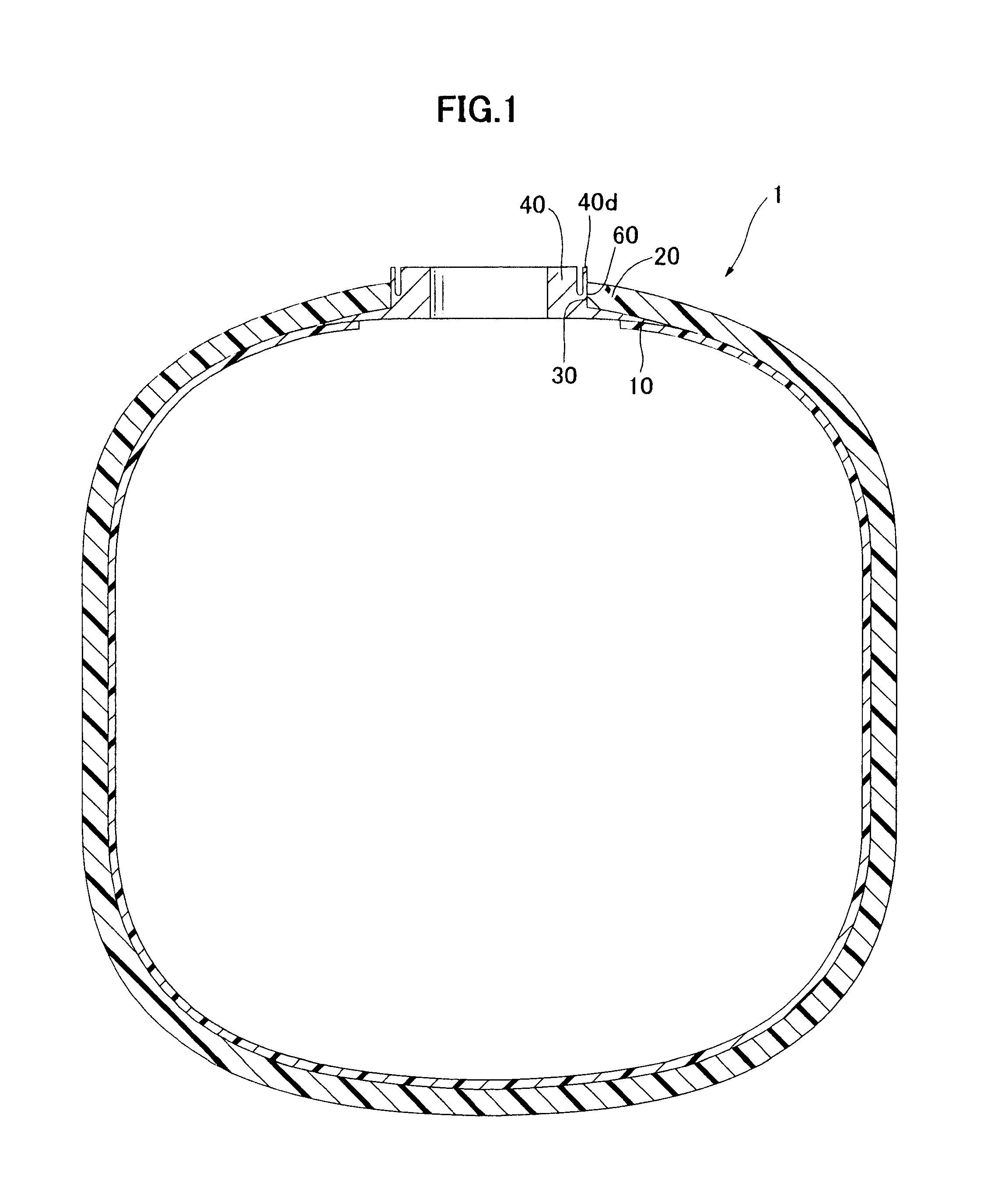

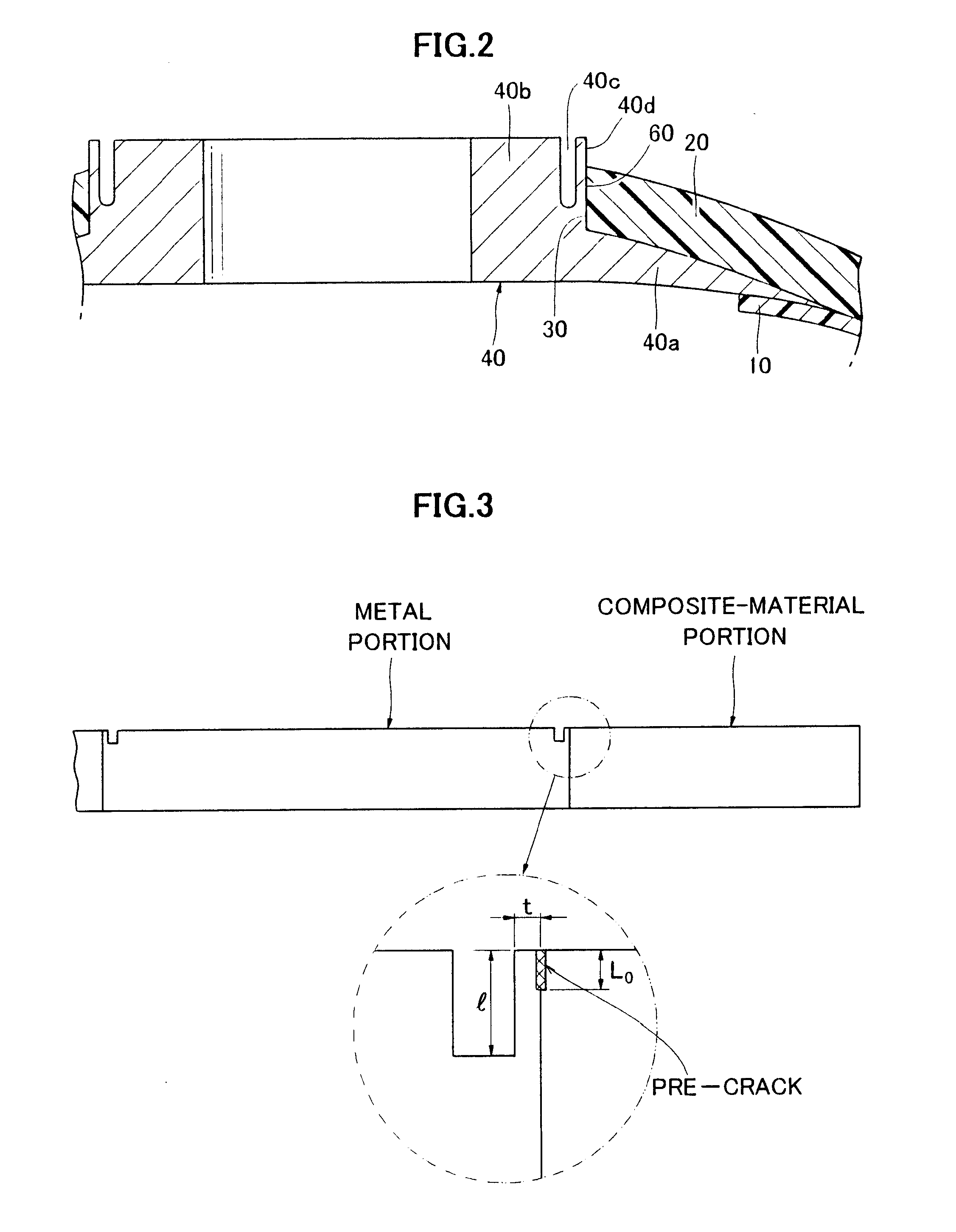

Bonding structure of metal member and composite-material member

InactiveUS20120325832A1Reduce stiffnessLower energy release rateCosmonautic vehiclesGas handling applicationsMetalMaterials science

Provided is a bonding structure of a metal member and a composite-material member which comprises a composite-material member and a metal member adhesively bonded to the composite-material member through an adhesive bonding surface therebetween. The metal member has a slit extending along the adhesive bonding surface to form a thin-walled portion between the adhesive bonding surface and the slit.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

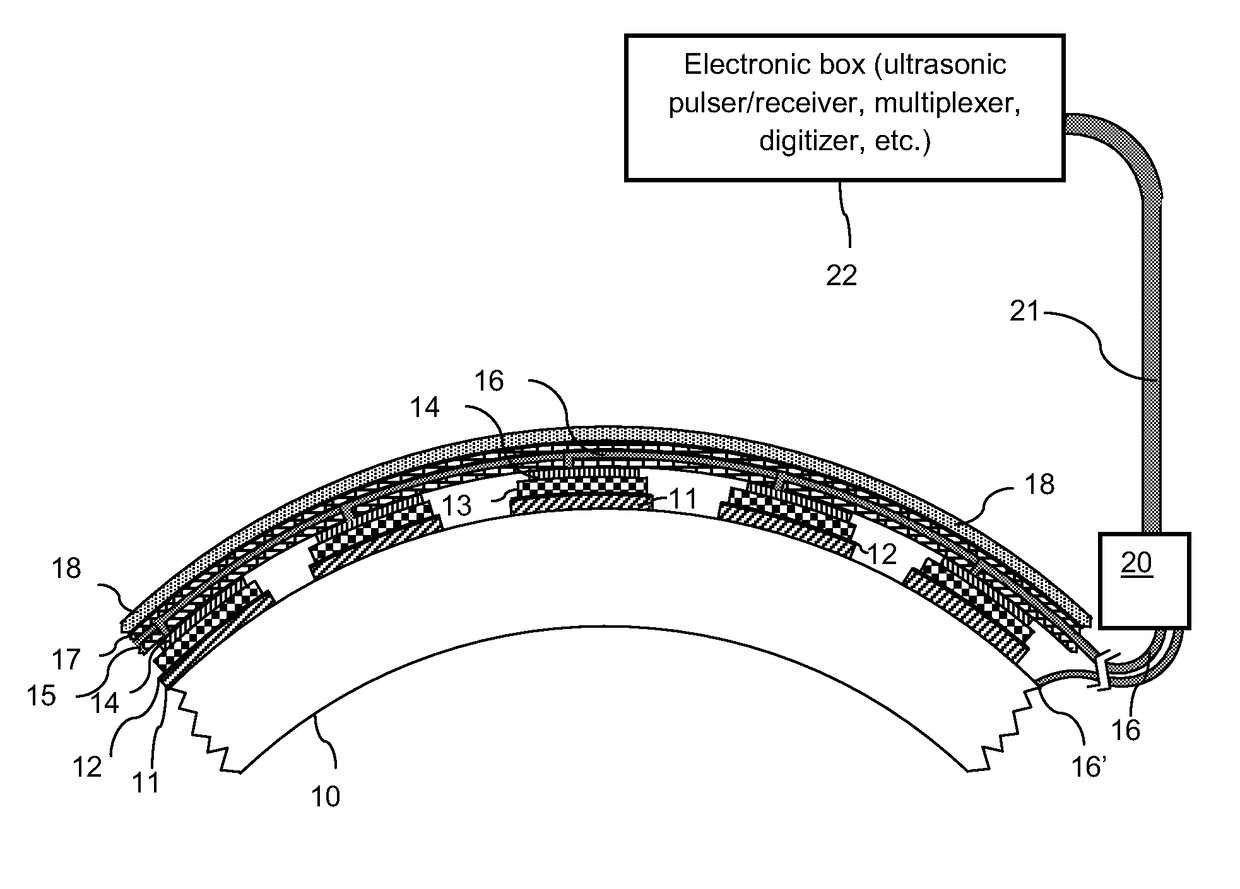

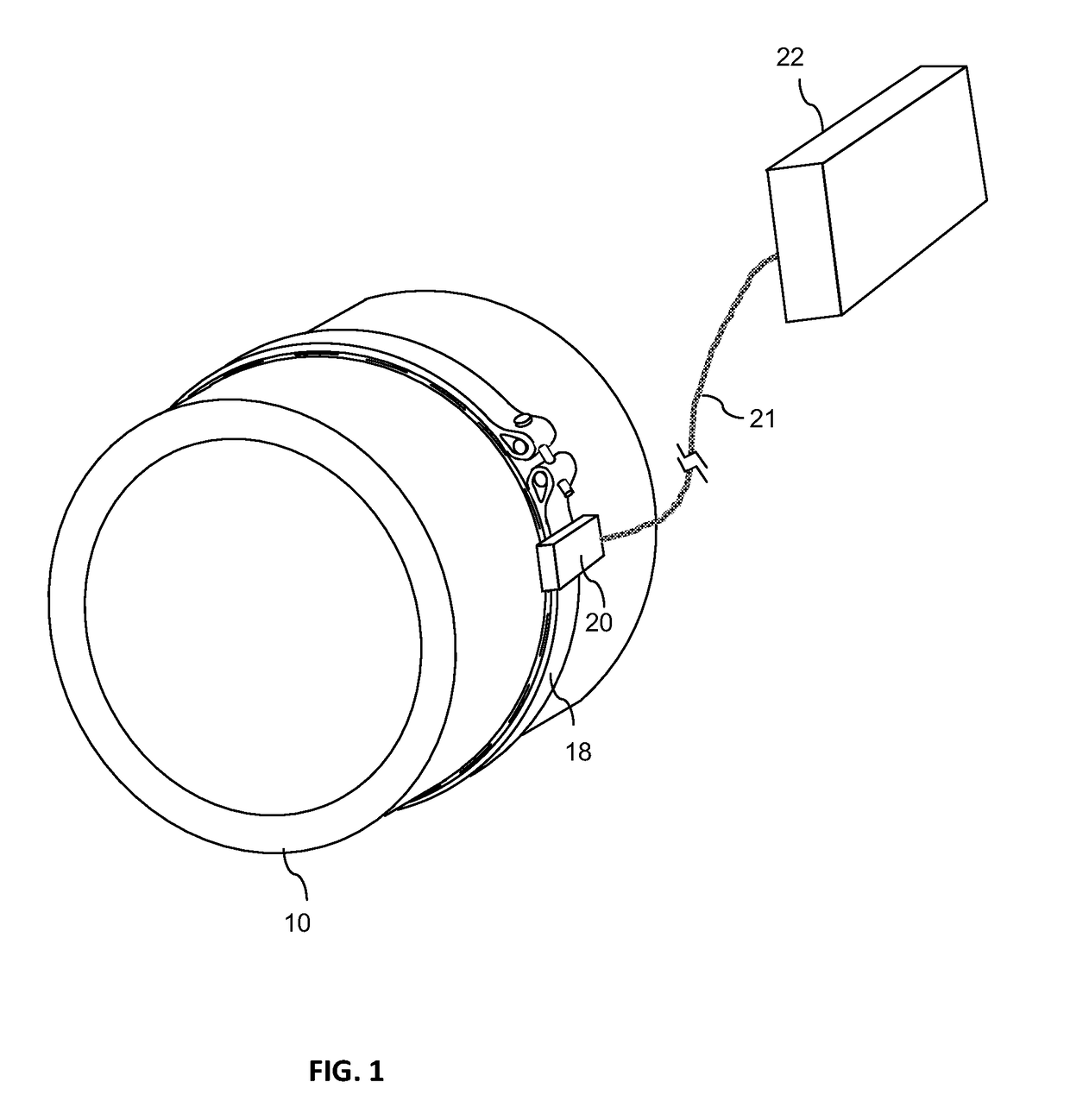

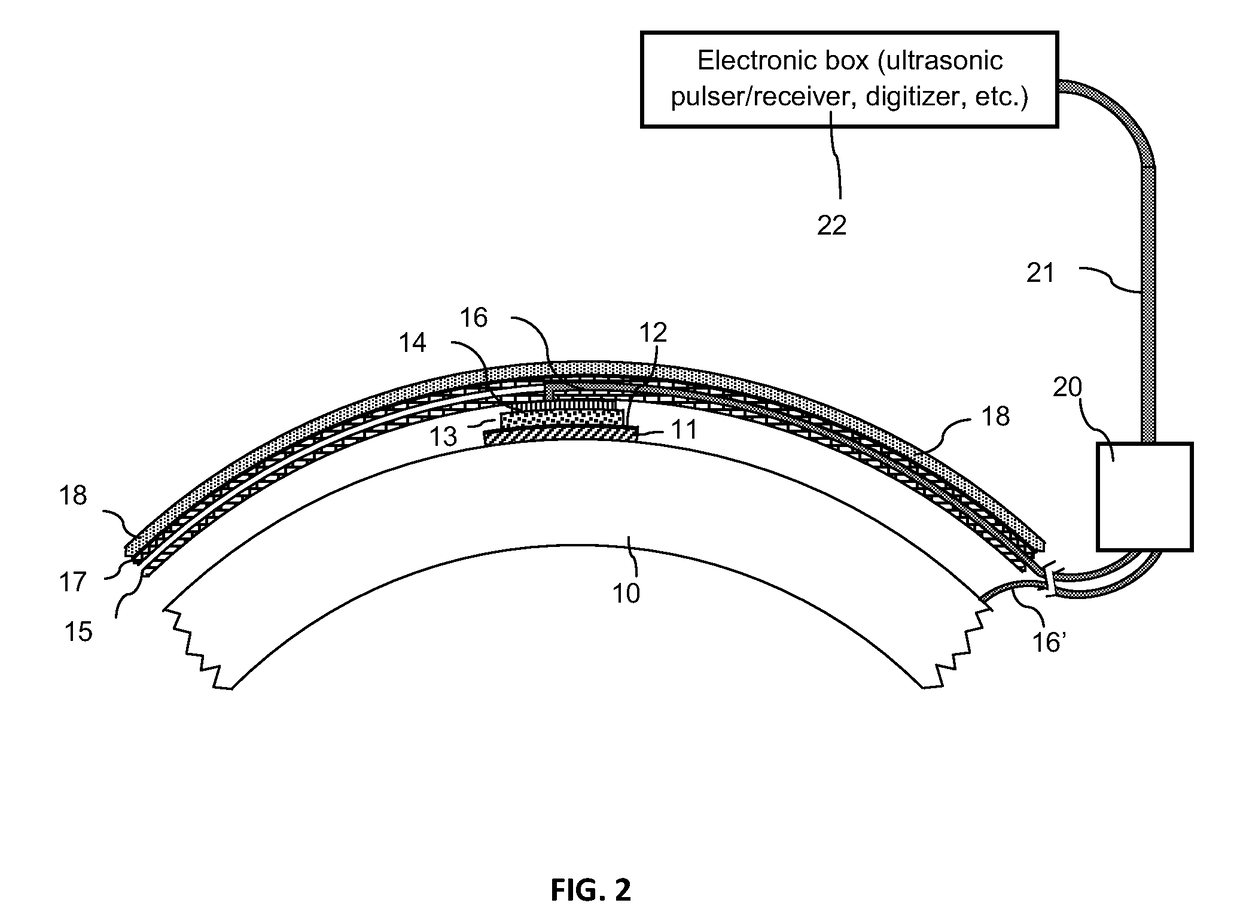

Ultrasonic transducer assembly and system for monitoring structural integrity

ActiveUS9618481B2Increased durabilityEnhanced signalMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceElectrical conductorUltrasonic sensor

In an ultrasonic transducer assembly, a conformable ultrasonic transducer has a piezoelectric layer and electrodes able to conform to curved surfaces, and a clamp for pressing the transducer into ultrasonic contact with a curved surface. Conformability is ensured with a thin, porous piezoelectric layer and suitable electrical conductors and insulators. The ultrasonic transducer may operate without further thermal shielding under harsh environments and / or at high temperatures.

Owner:NAT RES COUNCIL OF CANADA

Integrated circuit comprising at least one capacitor and process for forming the capacitor

ActiveUS7667292B2Improve electrical performanceAvoid debondingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringAbsorbent material

An integrated circuit includes at least one capacitor that is formed on a layer provided with at least one first trench. The capacitor, which is provided with a dielectric layer that separates two electrodes, conforms to the shape of the first trench, but leaves a part of the first trench unfilled. A material capable of absorbing stresses associated with the displacements of the walls of the trench is placed in the trench to fill the part of the first trench. A second trench is formed at least partly surrounding the first trench. This second trench is also at least partly filled with a material capable of absorbing stresses associated with the displacements of the walls of the second trench. A void may be included in the stress absorbing material which fills either of the first or second trenches.

Owner:STMICROELECTRONICS SRL +1

Primer coating for automobile composite material bonding and preparation method of primer coating

ActiveCN110591521AImprove toughnessIncrease chain ratioAdhesive processes with surface pretreatmentPolyester coatingsProduction linePolyolefin

The invention discloses a primer coating for automobile composite material bonding and a preparation method of the primer coating and belongs to the technical field of polyurethane adhesive bonding primer coatings. The primer coating comprises the following components in parts by weight: 10-30 parts of a silane coupling agent of which the content of an isocyanate group is 6-8wt%, 5-15 parts of a resin of which the content of an isocyanate group is 2-5wt%; 5-10 parts of polyolefin of which the content of an isocyanate group is 6-9wt%, 0-0.5 part of chloridized polyolefin is 20-45wt%, 5-10 partsof a powder aid, 0.5-1 part of a catalyst and 10-50 parts of a solvent. The primer coating is rapid in surface dry time, high in automobile composite material bonding and in addition, good in high temperature and high humidity performance; and when the primer coating is used together with a single-component polyurethane bonding adhesive, the space of a production line site can be saved, adhesiveapplication can be convenient, the production efficiency of automobile manufacturing can be improved, and the problems that a conventional single-component polyurethane adhesive primer coating cannotbe used on an automobile composite material and particularly is poor in high temperature and high humidity resistance can be solved.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Forming method for composite product formed by conical metal shell and conical glass reinforced plastic heat-proof layer

The invention discloses a forming method for a composite product formed by a conical metal shell and a conical glass reinforced plastic heat-proof layer. The forming method comprises the following steps: 1, forming the conical metal shell; 2, forming the conical glass reinforced heat-proof layer; and 3, sleeving the metal shell by the conical glass reinforced heat-proof layer. Due to the sleeving manner, an aluminum alloy and glass reinforced plastic heat-proof layer composite product is formed by sleeving, and various indexes are controlled when the conical metal shell and the conical glass reinforced plastic heat-proof layer are formed respectively, so that coaxiality between the metal shell and the glass reinforced plastic heat-proof layer is ensured, the quality, the center of mass, centroidal deviation and the roundness of the product are guaranteed, debonding is prevented, and the technical problems occurring when the small-taper long composite product is formed are solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Sample preparation method for testing tensile property of asphalt-based carbon fiber multifilament

The invention relates to a sample preparation method for testing the tensile property of an asphalt-based carbon fiber multifilament, and belongs to the technical field of material property testing. The method comprises the following steps: applying tension to wind a carbon fiber multifilament on a frame, and fixing the bent part of the multifilament on the frame with a fixing material; placing the frame with wound multifilament vertically along the extension direction of the multifilament, dripping a glue solution from the upper end of the frame to ensure that the dripped glue solution flowsfrom the upper end of the multifilament to the lower end along the multifilament until the multifilament is completely soaked to obtain a glue dipped multifilament frame; and curing the glue dipped multifilament frame, cutting the multifilament, and pasting a paper reinforcing sheet to obtain a tensile sample. According to the method provided by the invention, fiber damages in the operation process are avoided, the sample preparation efficiency is improved, the problem of fiber monofilament brittle fracture caused by the surface tension of the glue solution and the gravities of the glue solution and the multifilament is also avoided, the maximum developed strength of the multifilament is ensured, the accuracy of the tensile strength test value is greatly improved, and the tensile strengthdispersion coefficient is reduced.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

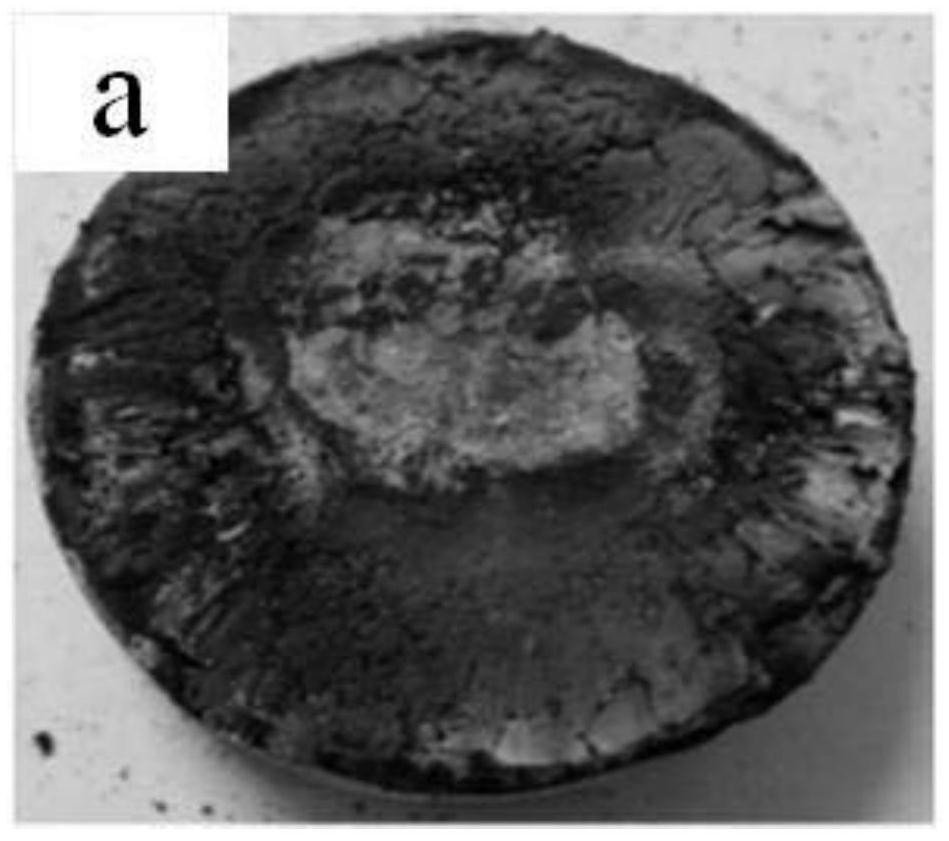

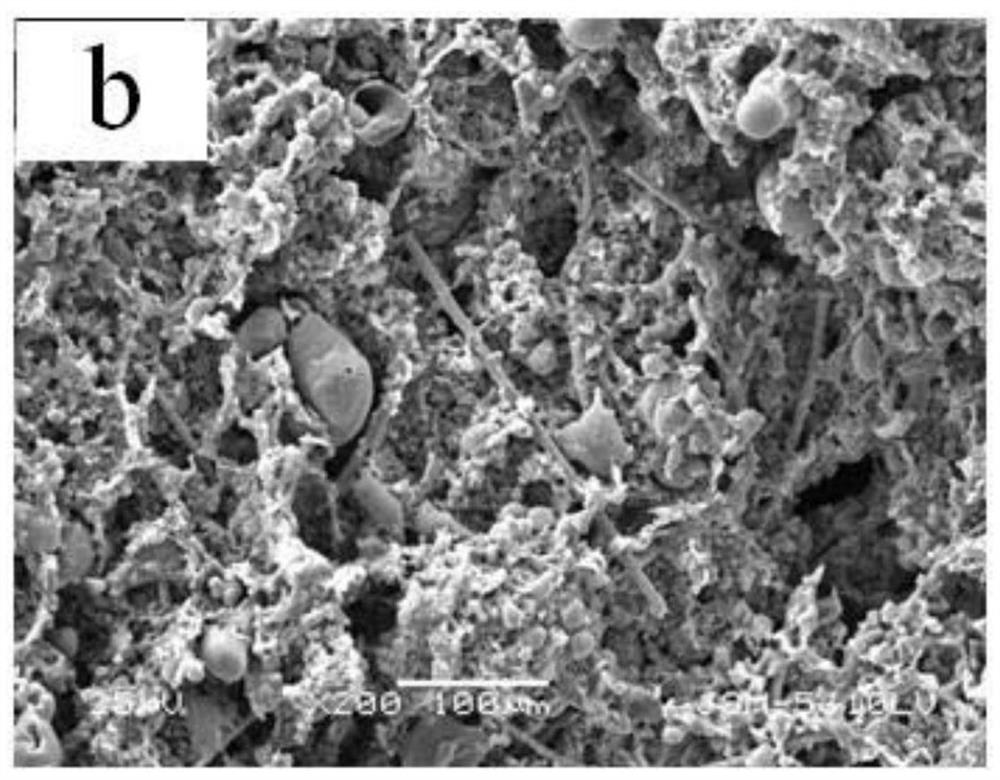

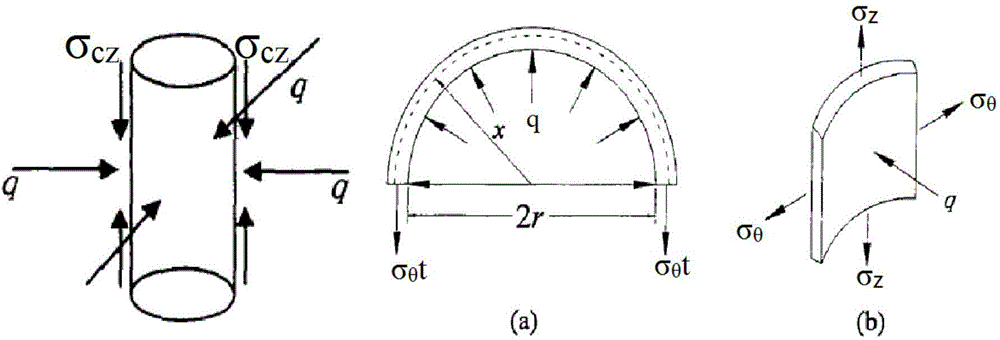

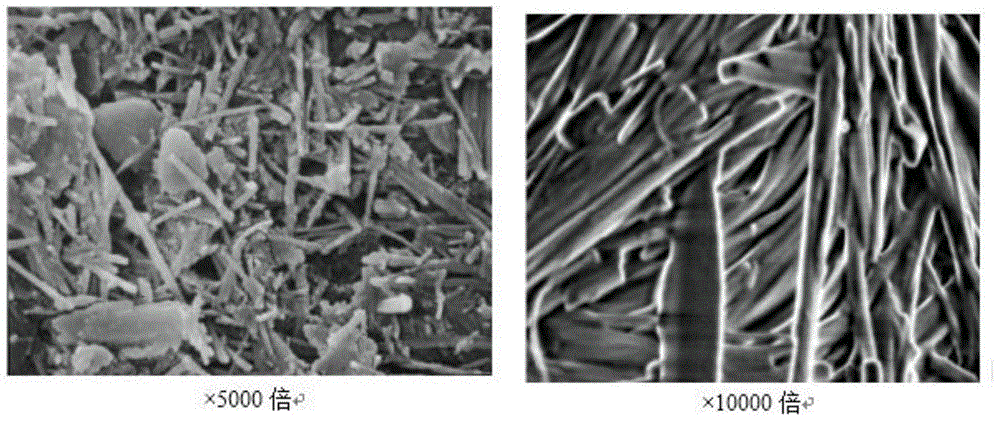

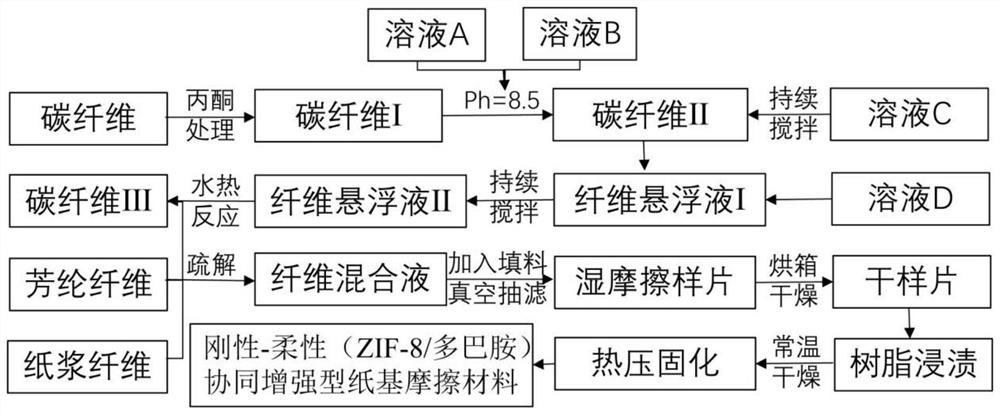

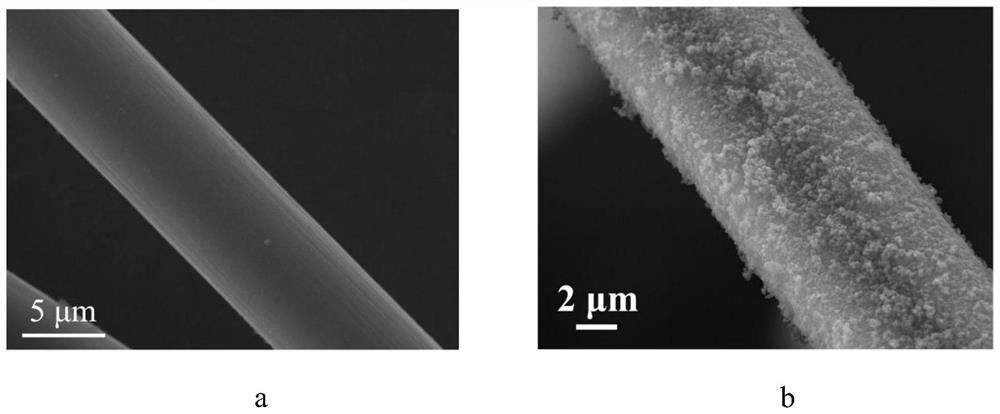

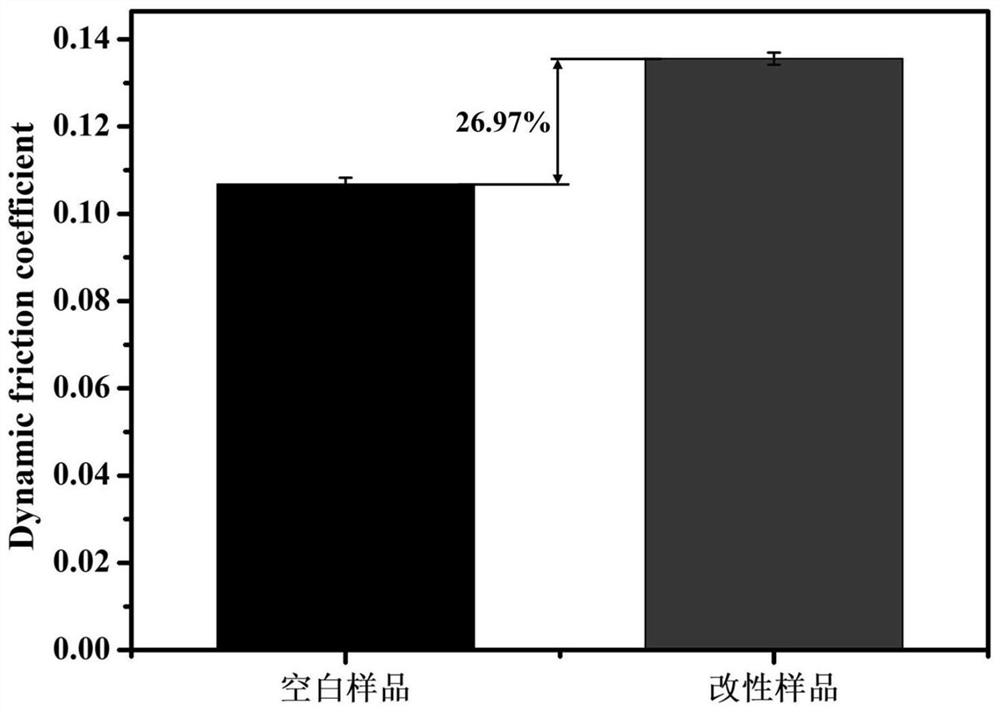

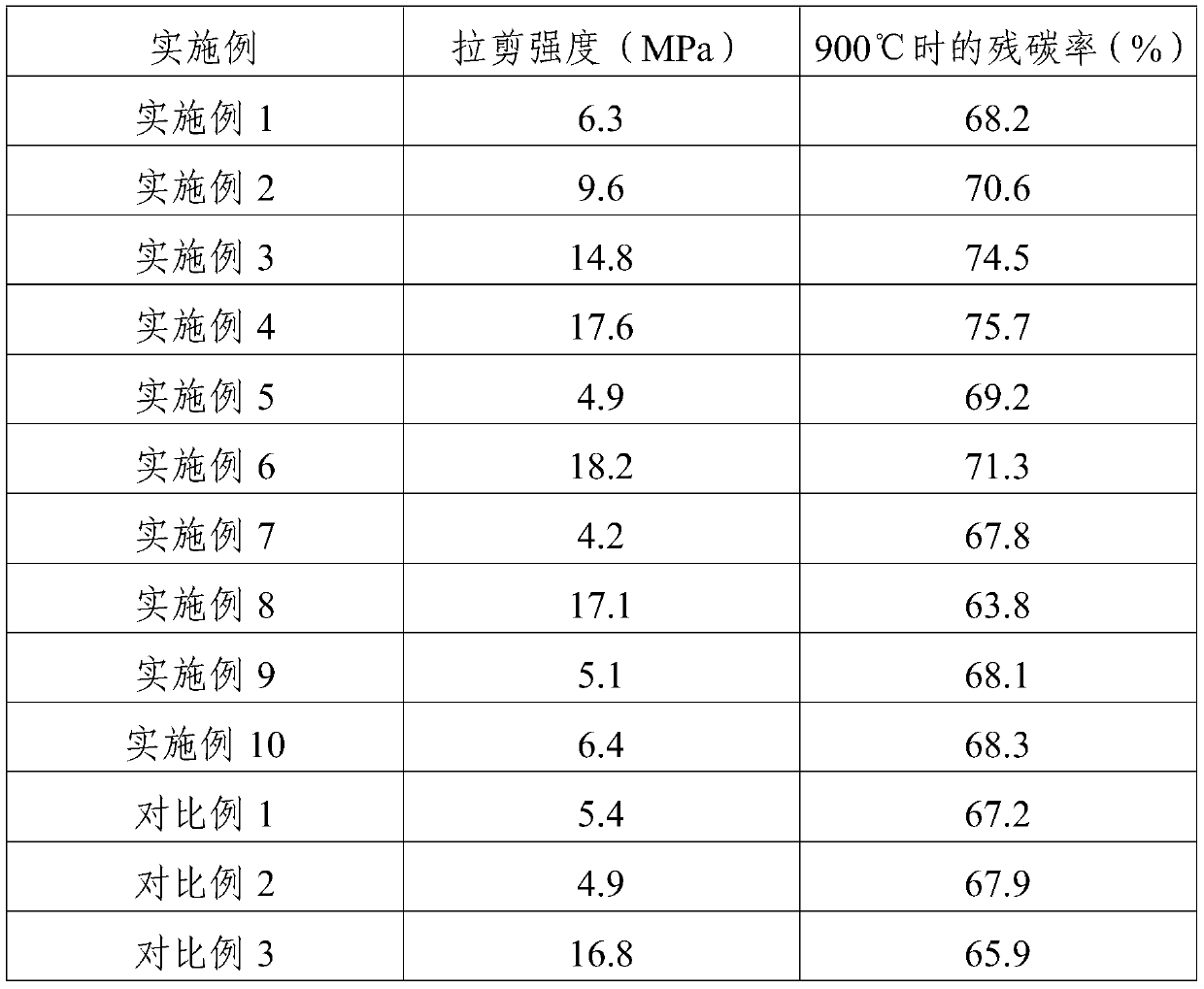

Rigid-flexible ZIF-8/dopamine synergistically enhanced paper-based friction material and preparation method thereof

ActiveCN113445360AImprove performanceEnhanced interface bindingNatural cellulose pulp/paperSpecial paperFiberCarbon fibers

The invention relates to a rigid-flexible ZIF-8 / dopamine synergistically enhanced paper-based friction material and a preparation method thereof. The preparation method comprises the steps that carbon fibers are sequentially placed in tris(hydroxymethyl)aminomethane (Tris buffer solution) and a dopamine solution, and a high-adhesion dopamine flexible film is formed on the surface of the carbon fibers; and then, a compact and uniform nano ZIF-8 crystal rigid layer grows on the surface of the carbon fiber in situ through a green hydrothermal reaction, a rigid-flexible interface enhancement structure is constructed through the modified carbon fiber and a resin matrix, and the ZIF-8 / dopamine synergistic enhancement type paper-based friction material is prepared. The dynamic friction coefficient of the prepared rigidity-flexibility (ZIF-8 / dopamine) synergistically enhanced paper-based friction material is increased from 0.1068 to 0.1356, the increase amplitude is 26.97%, the wear rate is decreased from 3.55*10<-8> cm<3>.J<-1> to 2.45*10<-8> cm<3>.J<-1>, and the decrease amplitude is 30.99%. The synergistic effect of a ZIF-8 / dopamine bi-component enhanced and constructed rigid-flexible interface enhanced structure is fully displayed, and the friction and wear performance of the paper-based friction material can be remarkably improved when the paper-based friction material is applied to the paper-based friction material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

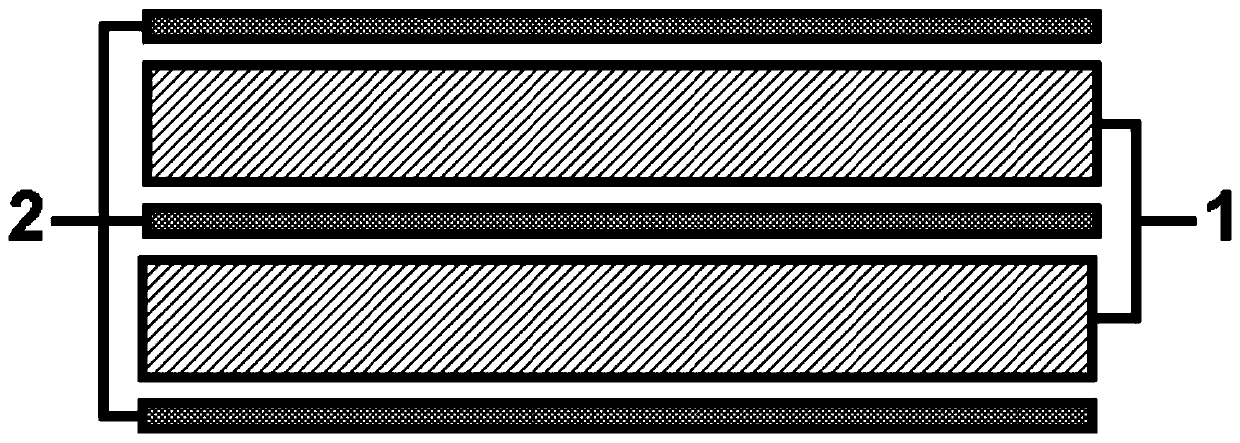

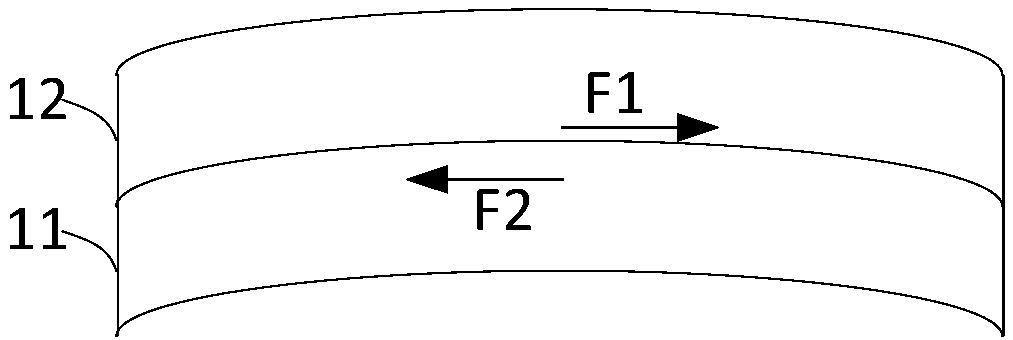

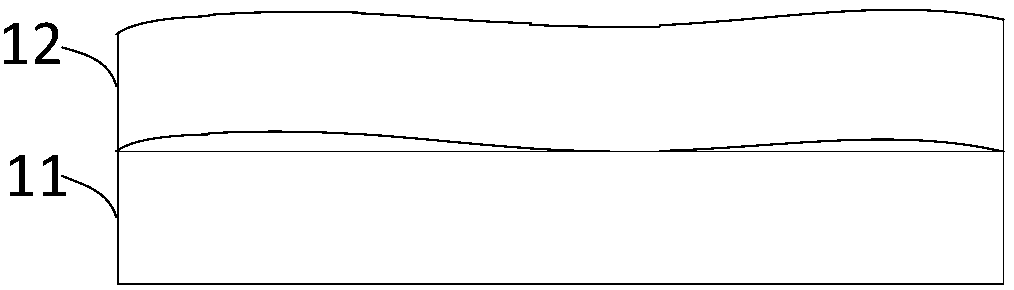

Flexible module and flexible display device

InactiveCN108346376AIncreasing the thicknessAvoid debondingIdentification meansFlexible displayFriction force

The invention discloses a flexible module and a flexible display device. The flexible module comprises a first membrane layer and a second membrane layer which are bonded to each other, and a first coarse structure is formed on the part of the surface of the side, facing towards the second membrane layer, of the first membrane layer; a second coarse structure is formed on the part of the surface of the side, facing towards the first membrane layer, of the second membrane layer; the first and second coarse layers are oppositely arranged and bonded with each other without the existing of clearances. The friction force between the first membrane layer and the second membrane layer is enhanced after the first and second membrane layers are bonded with each other due to the fact that the firstcoarse structure on the first membrane layer is in contact with the second coarse structure on the second membrane layer, and therefore the phenomenons of debonding and layering due to the fact that the first membrane layer and the second membrane layer slide towards each other in the bending process can be avoided.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

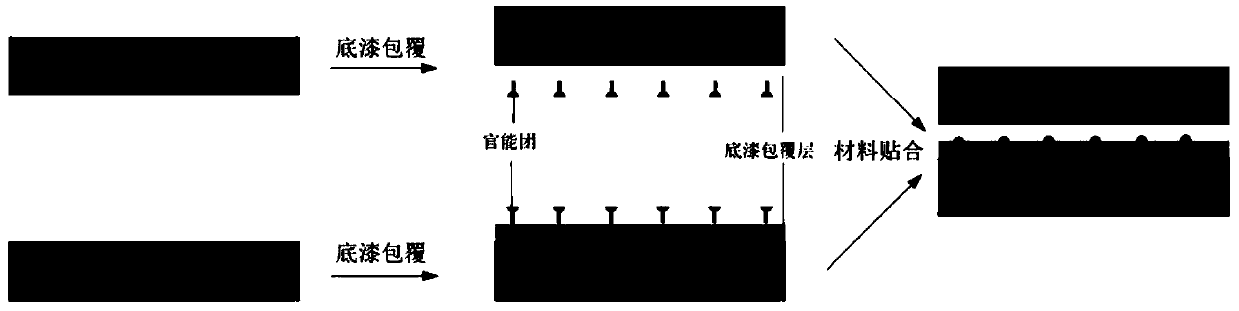

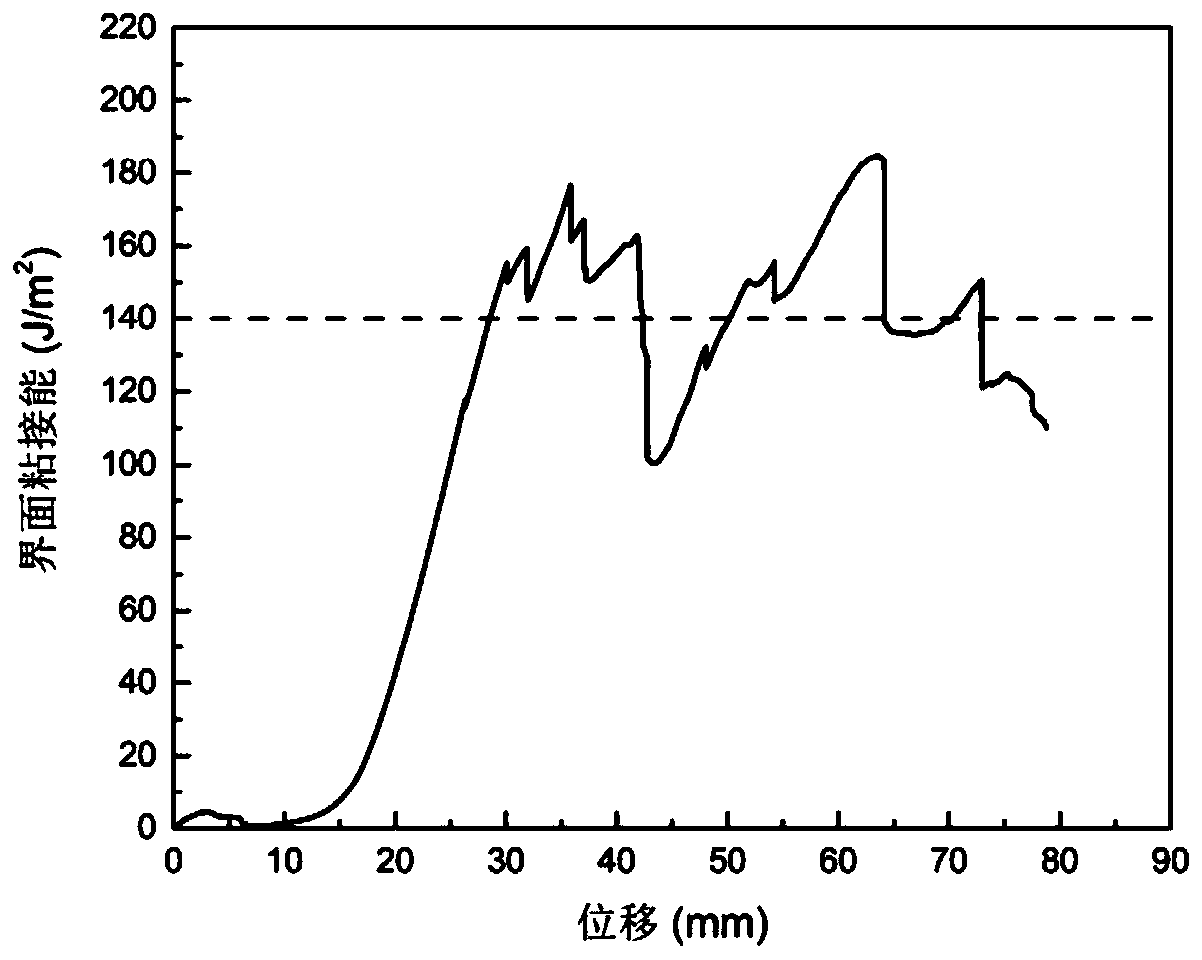

Bonding method for hydrogel and elastomer, and product and application thereof

ActiveCN111423603ADoes not reduce mechanical propertiesAvoid debondingConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsElastomerPolymer science

The invention provides a bonding method for hydrogel and elastomer, and a product and application thereof. The bonding method comprises the following steps: (1) coating: coating the surface of a molded hydrogel material with a hydrogel primer coating solution to obtain a hydrogel material with a primer coating, and coating the surface of the molded elastomer with the elastomer primer coating solution to obtain elastomer with a primer coating; and (2) bonding: bonding the hydrogel material with the primer coating obtained in the step (1) with the elastomer with the primer coating to finish bonding of the hydrogel and the elastomer. According to the preparation method, the surfaces of the molded hydrogel and the molded elastomer are coated with the primer coating, and a coating formed between the hydrogel and the elastomer can form a large number of stable and firm covalent bonds between the hydrogel and the elastomer material, so the debonding phenomenon of the whole device in the process of deformation is effectively avoided.

Owner:苏州凝智新材料发展有限公司

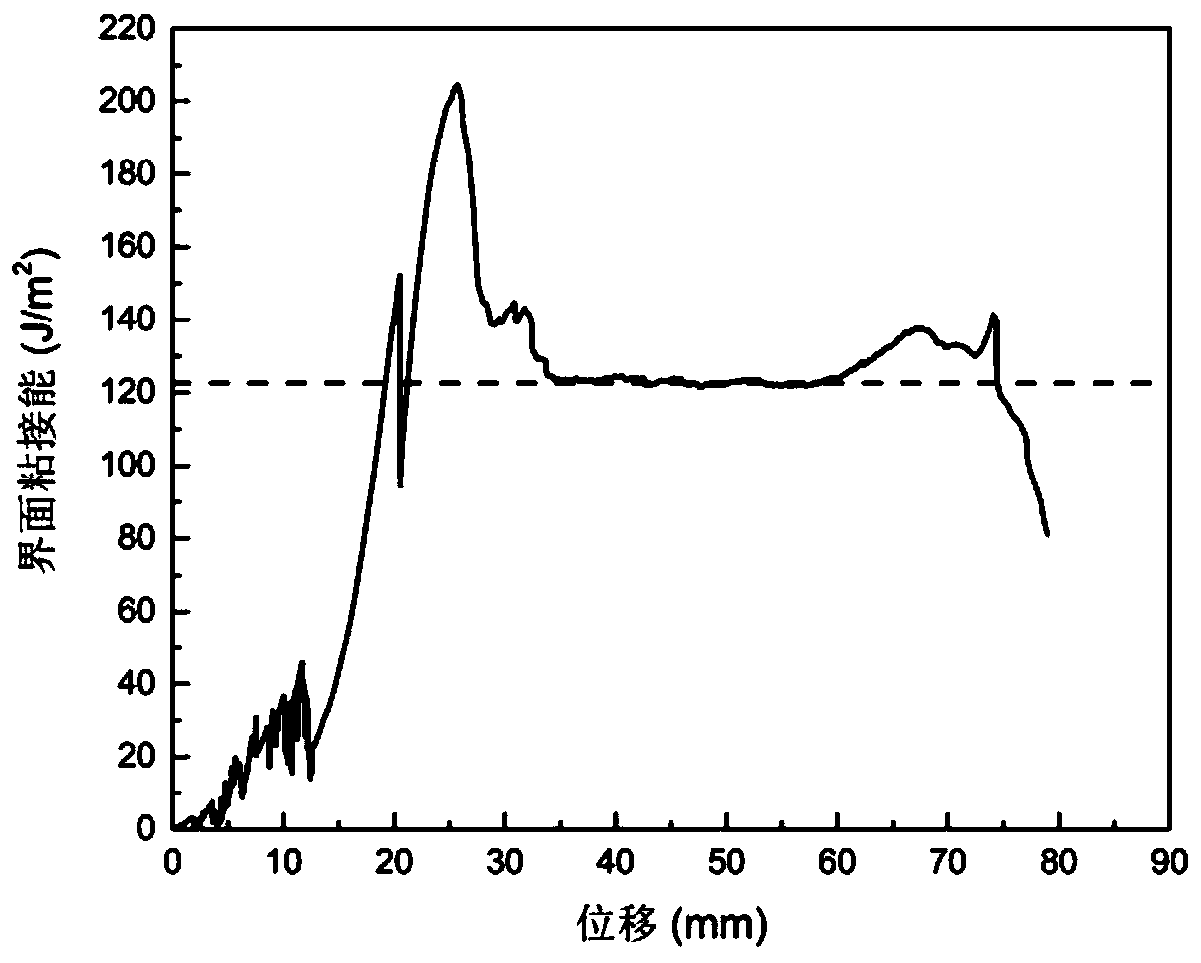

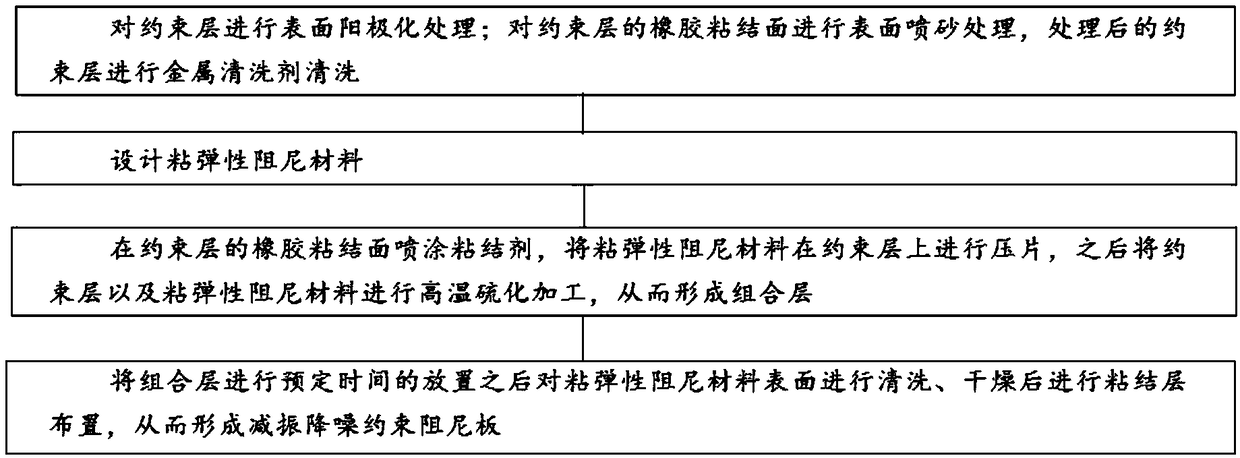

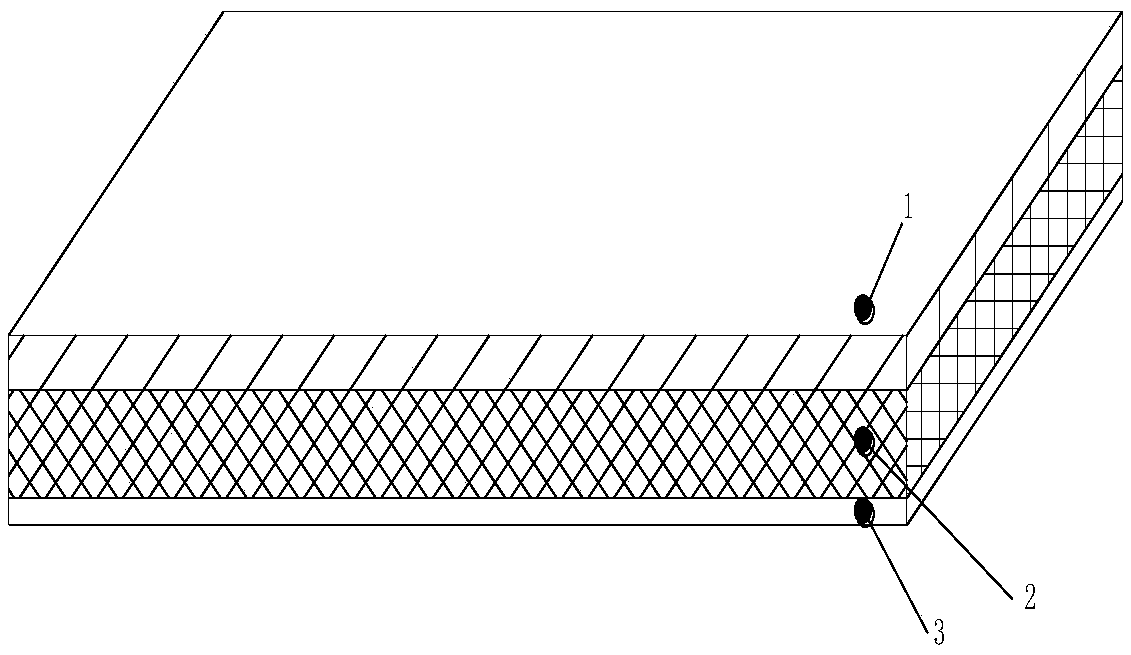

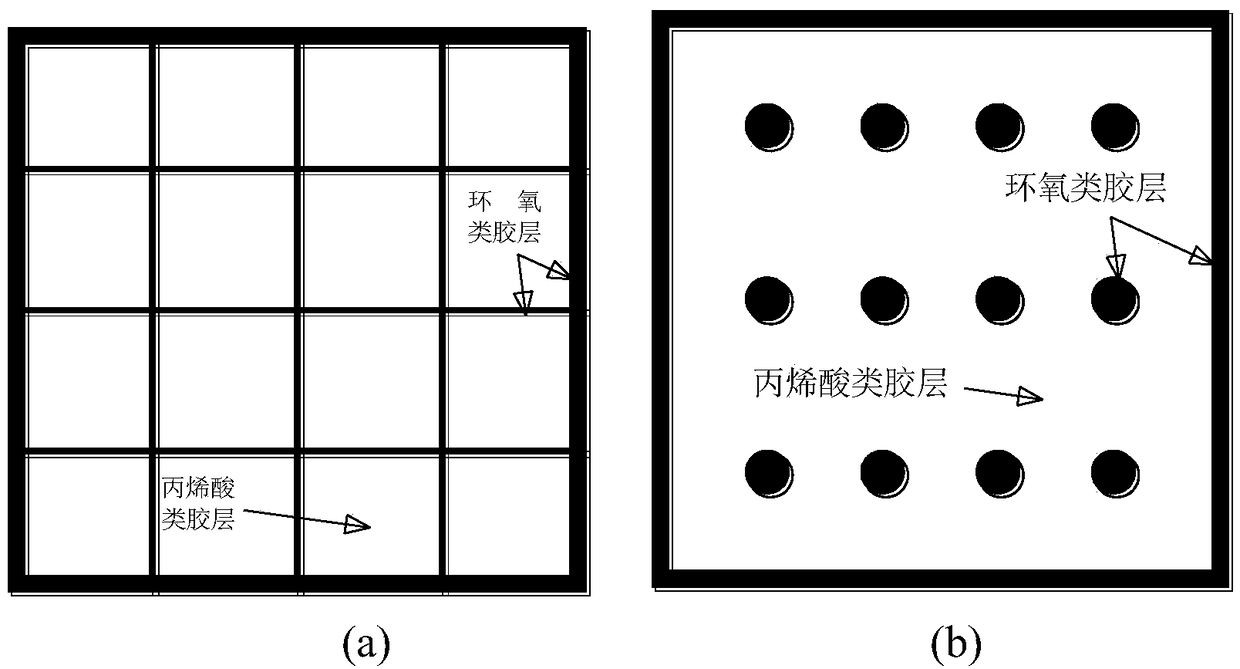

Vibration-attenuation and noise-reduction restrained damping plate manufacturing method and vibration-attenuation and noise-reduction restrained damping plate

InactiveCN109294470AMeet sound insulationWith sound insulationFilm/foil adhesivesVibration attenuationAbrasive blasting

The invention discloses a vibration-attenuation and noise-reduction restrained damping plate manufacturing method and the vibration-attenuation and noise-reduction restrained damping plate. The vibration-attenuation and noise-reduction restrained damping plate manufacturing method includes the following steps: carrying out surface anodization treatment of a restraint layer; carrying out surface sandblasting treatment of a rubber bonding surface of the restraint layer, and cleaning the treated restraint layer with a metal cleaning agent; designing a viscoelastic damping material; spraying the rubber bonding surface of the restraint layer with a binder, tabletting the viscoelastic damping material on the restraint layer, and then carrying out vulcanization processing of the restraint layer and the viscoelastic damping material at high temperature to form a composite layer; after placing the composite layer for a predetermined time, cleaning and drying the surface of the viscoelastic damping material, and then arranging a bonding layer, so as to form the vibration-attenuation and noise-reduction restrained damping plate.

Owner:CHINA AIRPLANT STRENGTH RES INST

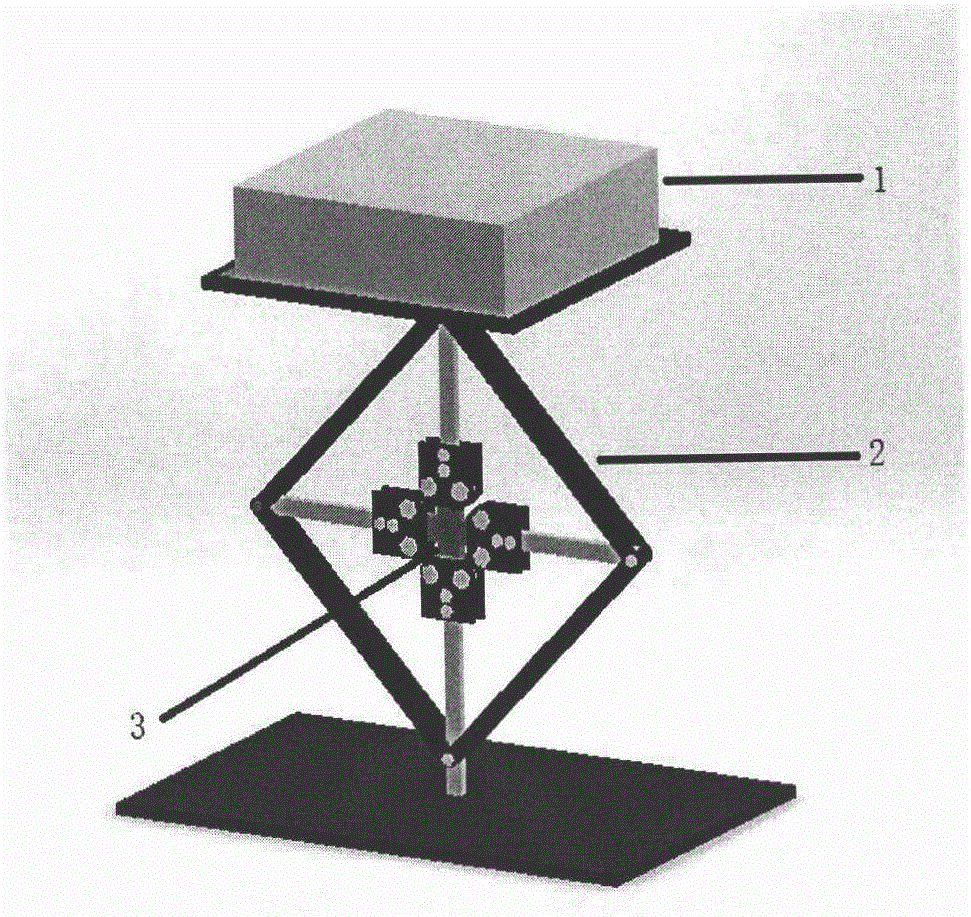

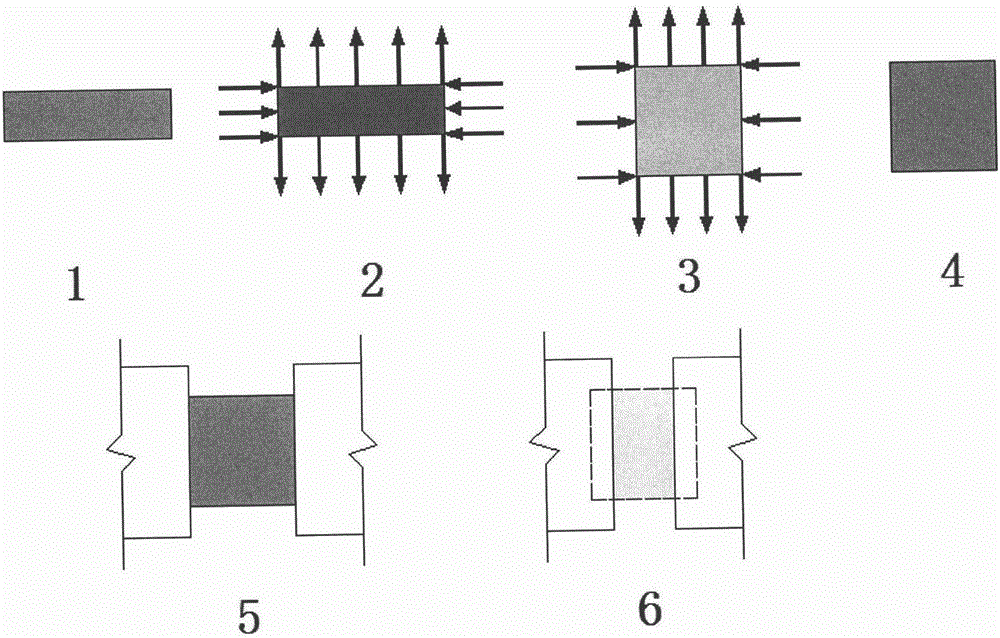

Single-stage double-shaft pre-deformation method for endowing pavement joint material with shape memory function

InactiveCN106638220AExtended service lifeImprove the quality of usePaving detailsSelf-healingPre strain

The invention provides a single-stage double-shaft pre-deformation method for endowing a pavement joint material with a shape memory function, belongs to the technical field of cement pavement, and solves the problem that existing single-stage single-shaft pre-deformation method can only endow the material with the shape memory function in one direction, and thus the material is poor in self-healing effect. A cruciform specimen of a shape memory polymer matrix composite is produced at first, pre-compaction deformation is performed along the vertical direction at the temperature higher than a glass-transition temperature, meanwhile prestretching deformation is performed along the horizontal direction, and thus the joint material is endowed with the shape memory function in both horizontal and vertical directions; then the shape memory effect of the joint material after pre-deformation is measured and further synthesized with other operational performance of the joint material to determine reasonable stretching and compression pre-strain values for endowing the joint material with the shape memory function. According to the pre-deformation method provided by the invention, the joint material actively adapt to cyclic change of the width of the cement pavement joint, usability and durability of the joint material are improved, and service life of the cement pavement is prolonged.

Owner:NANJING FORESTRY UNIV

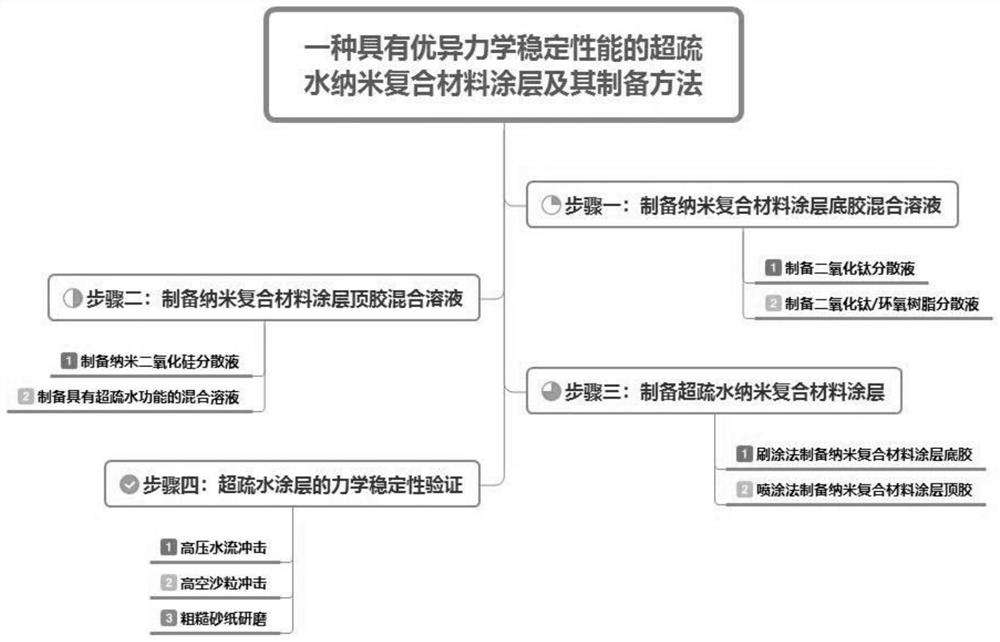

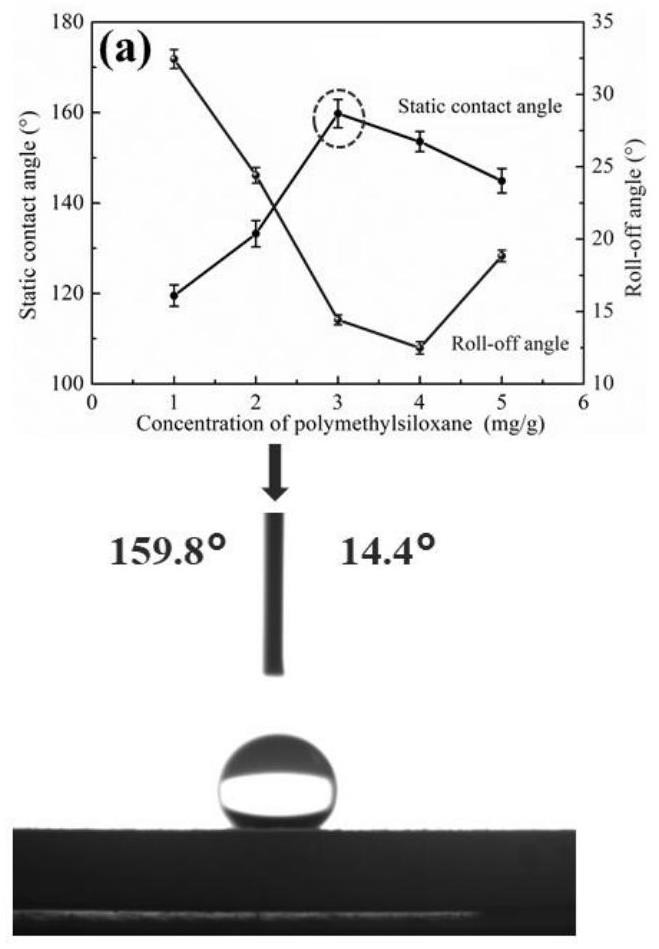

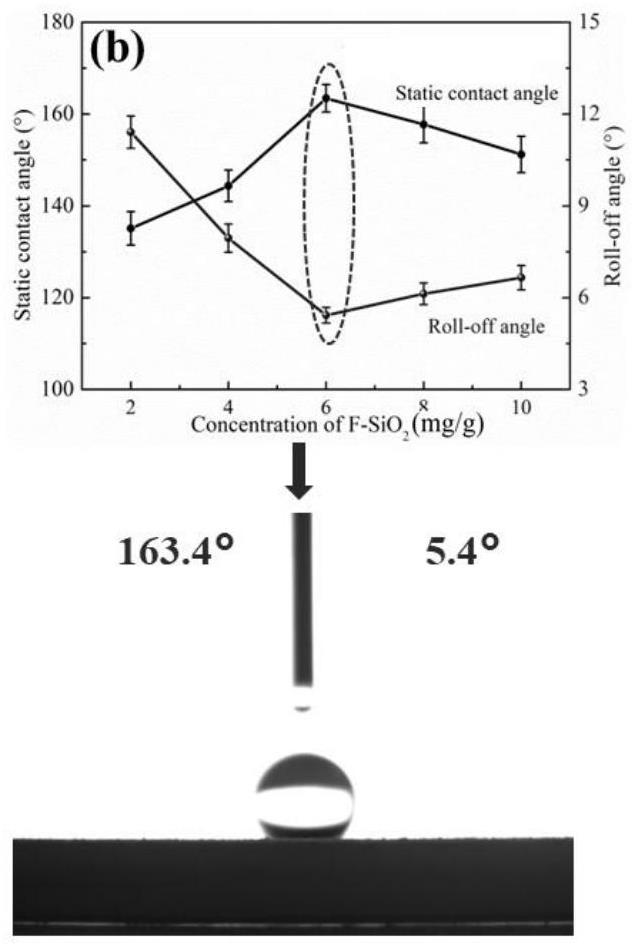

Super-hydrophobic nanocomposite coating with excellent mechanical stability and preparation method thereof

ActiveCN114686076AAvoid debondingReinforced Ultra-Sturdy" WeldingSpecial surfacesEpoxy resin coatingsEpoxyMicro nano

The invention discloses a super-hydrophobic nano composite material coating with excellent mechanical stability and a preparation method of the super-hydrophobic nano composite material coating, and belongs to the technical field of preparation of super-hydrophobic composite coating materials. The super-hydrophobic nano composite material coating comprises a bottom film and a top film, the bottom film is an epoxy resin film layer doped with titanium dioxide and attached to the surface of a substrate, and the top film is an epoxy resin film layer doped with modified silicon dioxide and polymethylsilsesquioxane and located on the bottom film. The epoxy resin in the top film of the composite coating not only can coat micro / nano particles to prevent the micro / nano particles from falling off during long-term realization of a super-hydrophobic function, but also can form three-dimensional spatial crosslinking with the epoxy resin in the bottom coating, so that interface debonding of the upper coating and the lower coating is prevented, super-stable'welding 'of an interface is enhanced, and the service life of a super-hydrophobic coating system is prolonged.

Owner:HARBIN INST OF TECH

Aramid skin-paper honeycomb sandwich cylinder shell structure, preparation method thereof and application thereof

ActiveCN110299598ASimple designReduce in quantityLamination ancillary operationsSynthetic resin layered productsEpoxyNomex

The invention relates to an aramid skin-paper honeycomb sandwich cylinder shell structure, a preparation method thereof and application thereof and particularly relates to a Kevlar49 aramid fiber woven fabric reinforced epoxy resin based composite material skin-Nomex perforated paper honeycomb sandwich cylinder shell structure applied to a spacecraft antenna sub-system support structure and a preparation method thereof, belonging to field of spacecraft composite material structures and the forming technology.

Owner:BEIJING SATELLITE MFG FACTORY

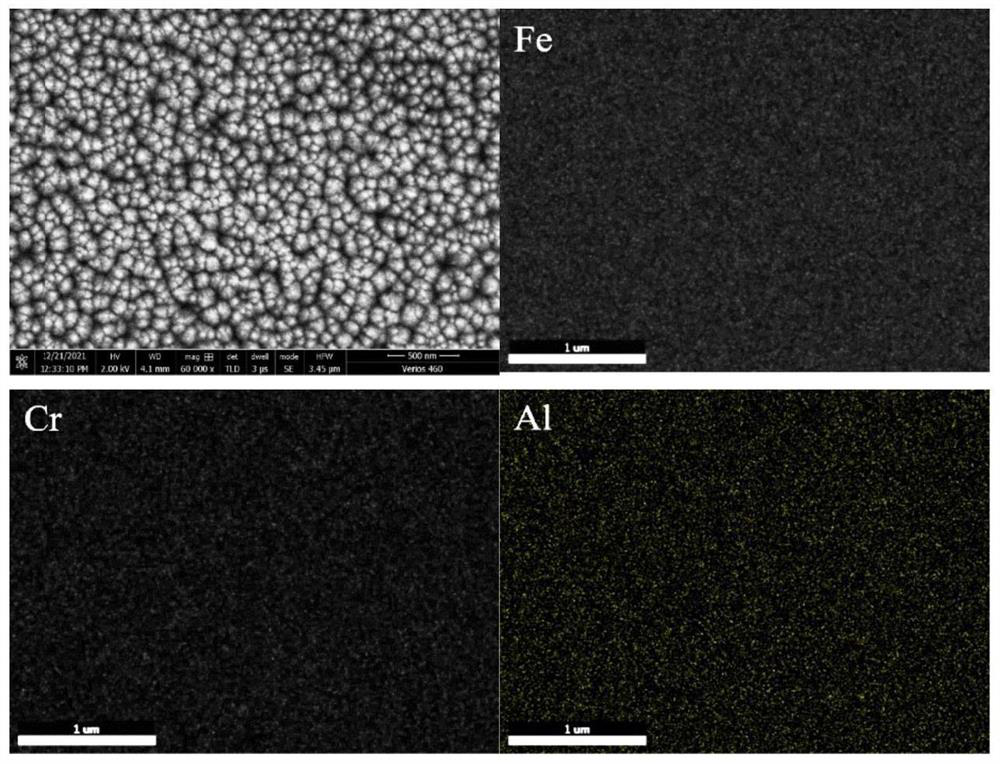

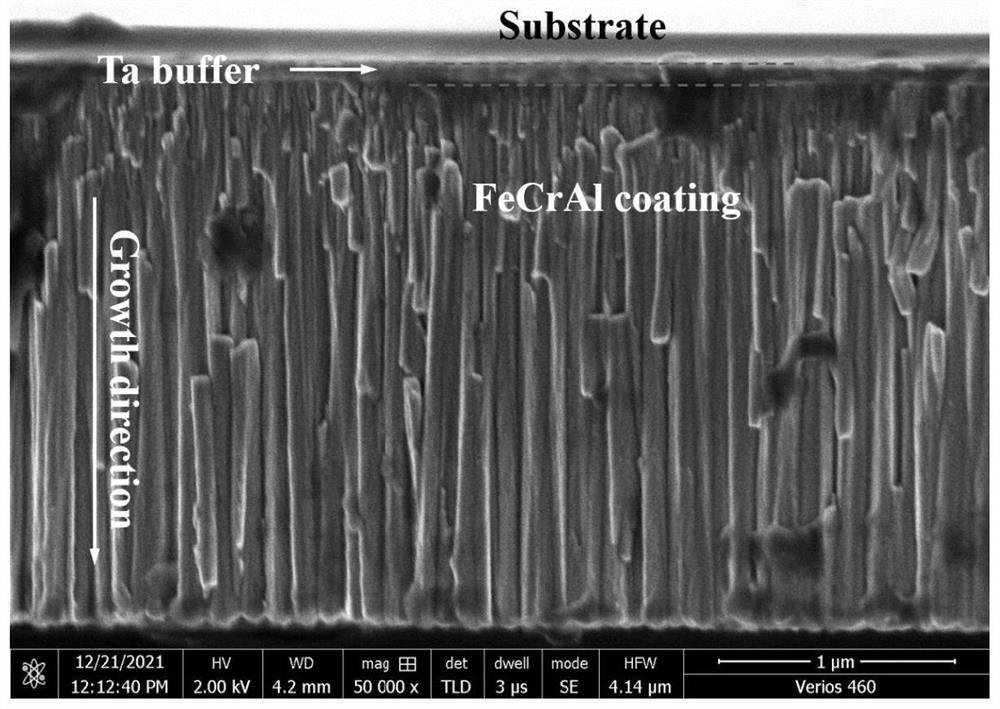

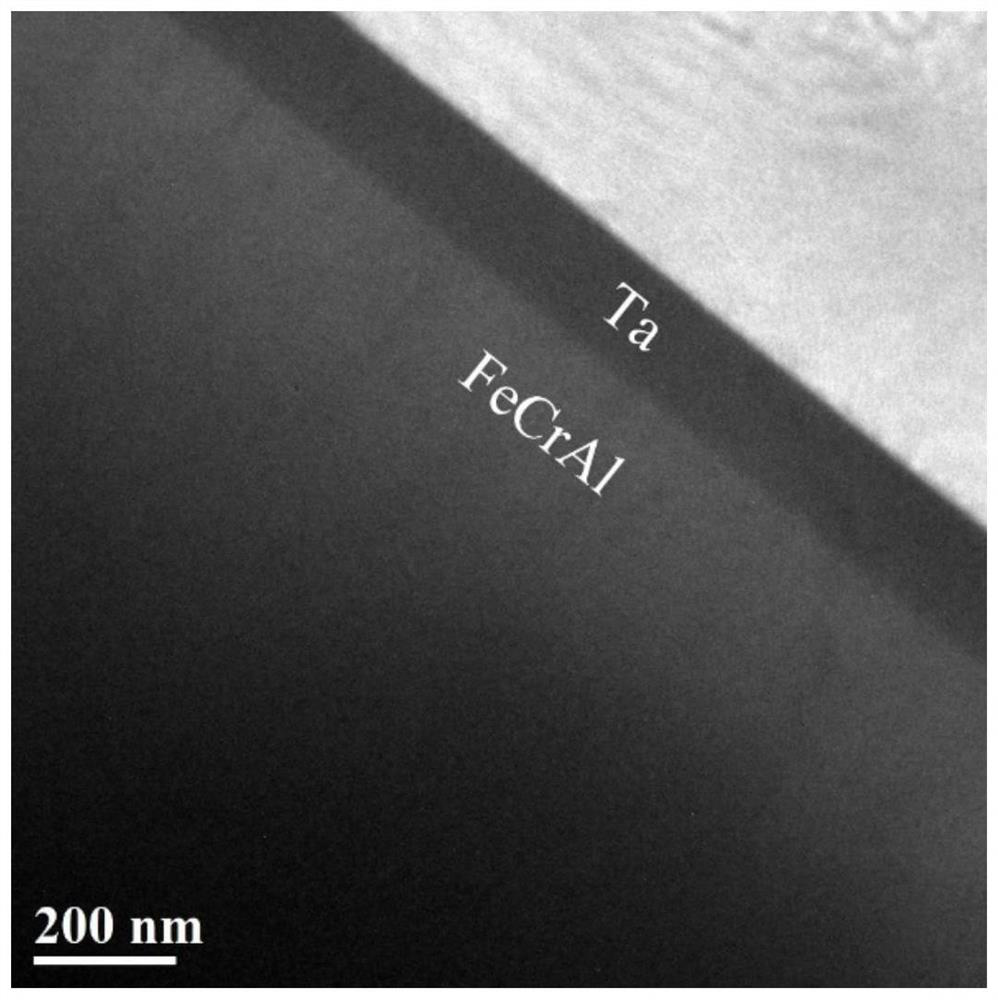

FeCrAl/Ta alloy coating and preparation method thereof

ActiveCN114657525ALow interdiffusion coefficientInterdiffusion barrierNuclear energy generationVacuum evaporation coatingBi layerDouble coating

The invention discloses a FeCrAl / Ta alloy coating and a preparation method thereof. The FeCrAl / Ta alloy coating comprises a Ta transition layer and a FeCrAl layer deposited on the surface of the Ta transition layer, and the atomic percent of the chemical components Fe: Cr: Al of the FeCrAl coating is 79: 10: 11 at%. The FeCrAl / Ta alloy coating is prepared on the polished zirconium alloy matrix by adopting a magnetron sputtering method, the Ta transition layer is deposited between the FeCrAl coating and the zirconium alloy matrix by controlling the deposition sequence of the Ta target and the FeCrAl alloy target, the middle transition layer prepared by the method is smooth in surface, few in defect and small in influence on the structure of the upper-layer coating, the interface of the double-layer coating is clear and stable, and the service life of the middle transition layer is prolonged. The film-substrate interface bonding performance is facilitated, and the obtained film is uniform in component and compact in structure; and the Ta intermediate transition layer is added, so that the service correlation of the FeCrAl coating can be effectively improved.

Owner:XI AN JIAOTONG UNIV

Thermal protection organic coating and preparing method thereof

ActiveCN109355014AAchieve long-term thermal protectionImprove mechanical propertiesFireproof paintsGlass fiberSilicon

The invention discloses a thermal protection organic coating and a preparing method thereof, and belongs to the field of thermal protection coatings. The thermal protection organic coating comprises,by mass, 150 parts of high-temperature-resistant paint, 18-22 parts of a curing agent and 0.8-1.2 parts of a catalyst. The high-temperature-resistant paint comprises, by mass, 100 parts of organic silicon resin, 28-32 parts of china filler. 18-22 parts of white carbon black and 18-22 parts of glass fiber. The organic coating has a ceramic reaction in the heated process to form a ceramic phase, andthe long-term heat protection under the kilosecond-scale hot environment of 500 DEG C is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

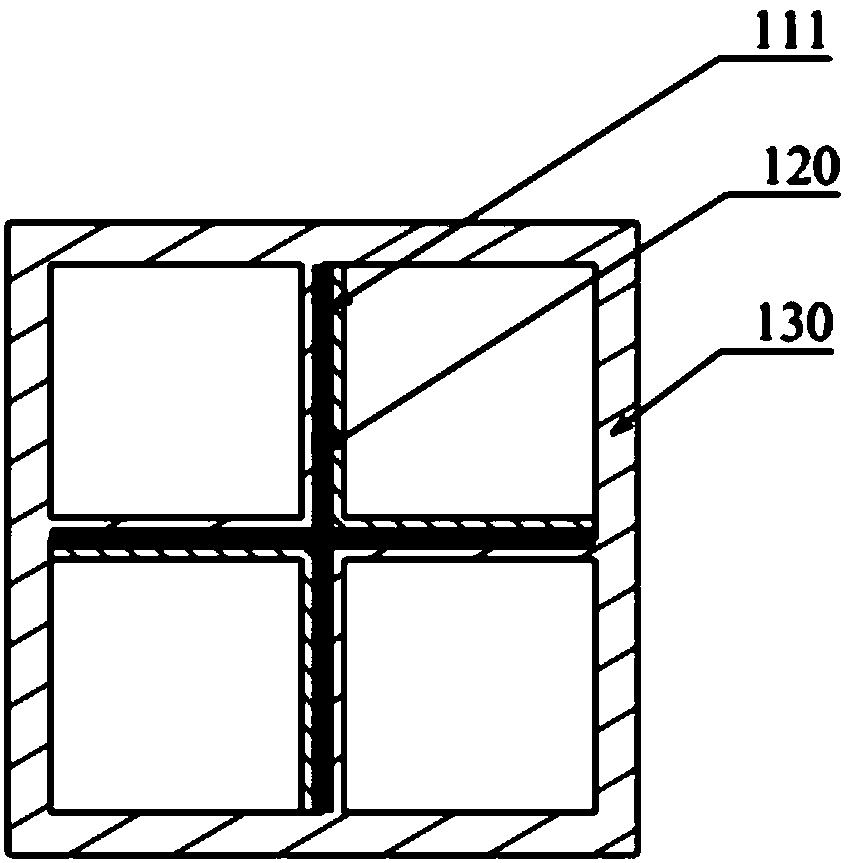

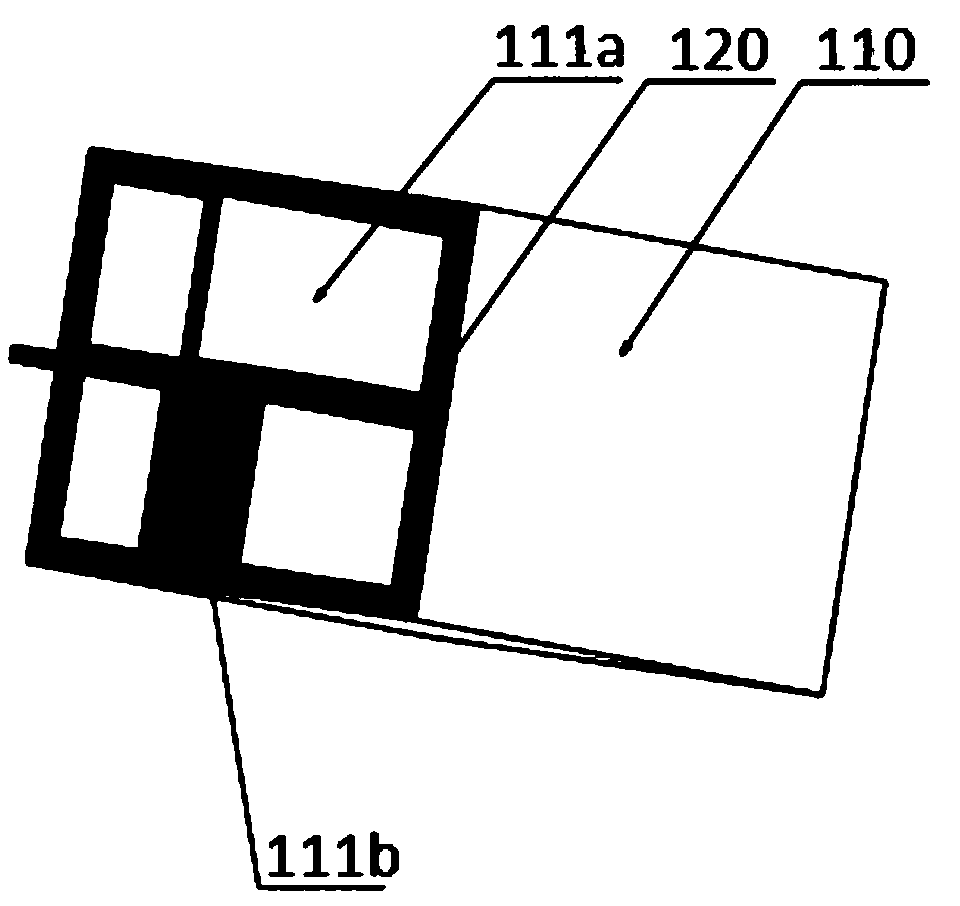

Aluminum alloy section mortise-tenon joint structure reinforced based on chemical coupling agent

PendingCN108980162AEfficient assemblyAvoid debondingMaterial gluingRod connectionsChinese charactersMortise and tenon

The invention discloses an aluminum alloy section mortise-tenon joint structure reinforced based on a chemical coupling agent. The aluminum alloy section mortise-tenon joint structure reinforced basedon the chemical coupling agent comprises a tenon body and a mortise body, wherein a tenon is integrally formed on one side of the tenon body; a mortise is arranged on one side of the mortise body; and the tenon body and the mortise body are made of aluminum alloy materials and are integrally formed. The aluminum alloy section mortise-tenon joint structure reinforced based on the chemical couplingagent comprises an outer frame, a horizontal support plate and a vertical support plate, wherein the vertical support plate is perpendicular to the horizontal support plate; the vertical support plate, the outer frame and the horizontal support plate form a cross section with the structure in the shape of a Chinese character 'tian'; the tenon and the mortise are arranged correspondingly; the tenon is clamped in the mortise; and the tenon and the mortise are adhered and fixed through the chemical coupling agent.

Owner:JILIN UNIV

Toughening type phenolic resin and preparation method thereof

The invention relates to toughening phenolic resin and a preparation method thereof. The toughening phenolic resin is prepared from, by weight, 100 parts of phenolic resin, 30-90 parts of carboxyl-terminated butadiene-acrylonitrile rubber, 15-45 parts of zirconium diboride and 0.3-0.8 part of a dispersing agent. The preparation method comprises the steps that 0.3-0.8 part of dispersing agent is dispersed in the solvent, and a dispersion solution is obtained; 100 parts of phenolic resin, 30-90 parts of carboxyl-terminated butadiene-acrylonitrile rubber and 15-45 parts of zirconium diboride aremixed to be uniform, and a mixture is obtained; the obtained mixture is divided into multiple parts, and then the multiple parts of mixture are added in the dispersion solution in sequence and stirredand dispersed to be uniform, and the toughening phenolic resin is obtained. Accordingly, the carboxyl-terminated butadiene-acrylonitrile rubber, zirconium diboride and other fillers are adopted for modifying the phenolic resin, and on the premise that it is guaranteed that the anti-ablation property of the toughening phenolic resin is not reduced, the problem that interface debonding occurs aftera resin-based composition material and a metal cabin are integrally formed is solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

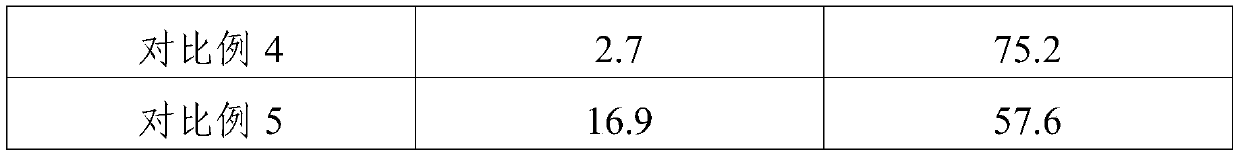

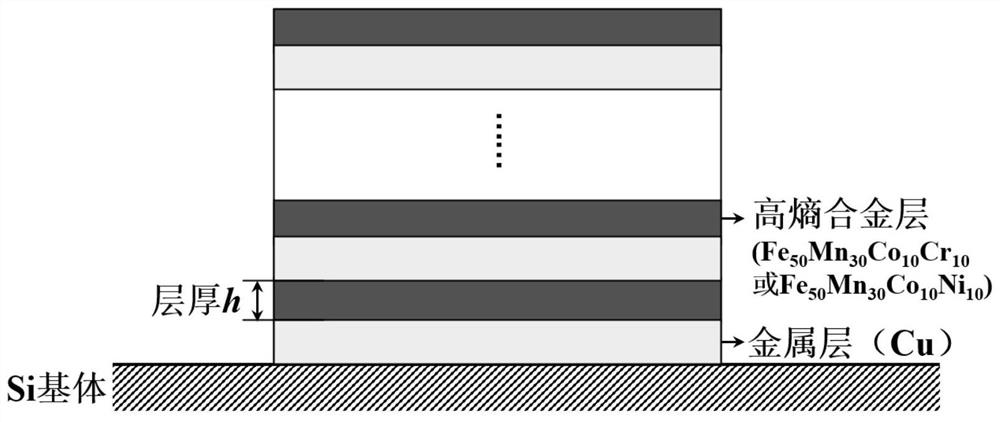

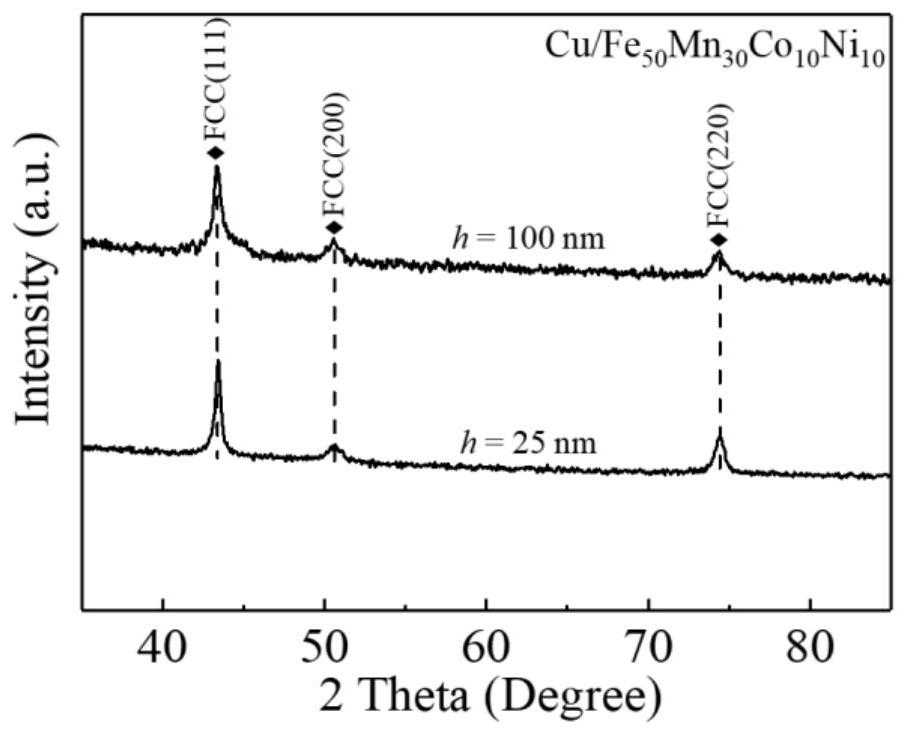

Pure metal/high-entropy alloy nano-multilayer film with controllable phase change characteristics and preparation method thereof

ActiveCN112481589AImprove bindingIncreased chance of ionizationVacuum evaporation coatingSputtering coatingSputteringHigh entropy alloys

The invention discloses a pure metal / high-entropy alloy nano-multilayer film with controllable phase change characteristics and a preparation method thereof. The preparation method comprises the following steps: alternately carrying out magnetron sputtering on the surface of a silicon substrate with an oxide layer removed through a pure metal target and a high-entropy alloy target to obtain the pure metal / high-entropy alloy nano-multilayer film, wherein the pure metal target is a Cu target, and the high-entropy alloy target is a Fe50Mn30Co10Cr10 target or a Fe50Mn30Co10Ni10 target; during magnetron sputtering, the Cu target and the high-entropy alloy target both adopt a direct-current power supply, the power is 200 W, and the deposition air pressure is 0.8-1.3 Pa; and the pure metal / high-entropy alloy nano-multilayer film is a Cu / Fe50Mn30Co10Cr10 nano-multilayer film or a Cu / Fe50Mn30Co10Ni10 nano-multilayer film. According to the preparation method, the preparation of the metal / high-entropy alloy nano-multilayer film with adjustable phase change is realized.

Owner:XI AN JIAOTONG UNIV

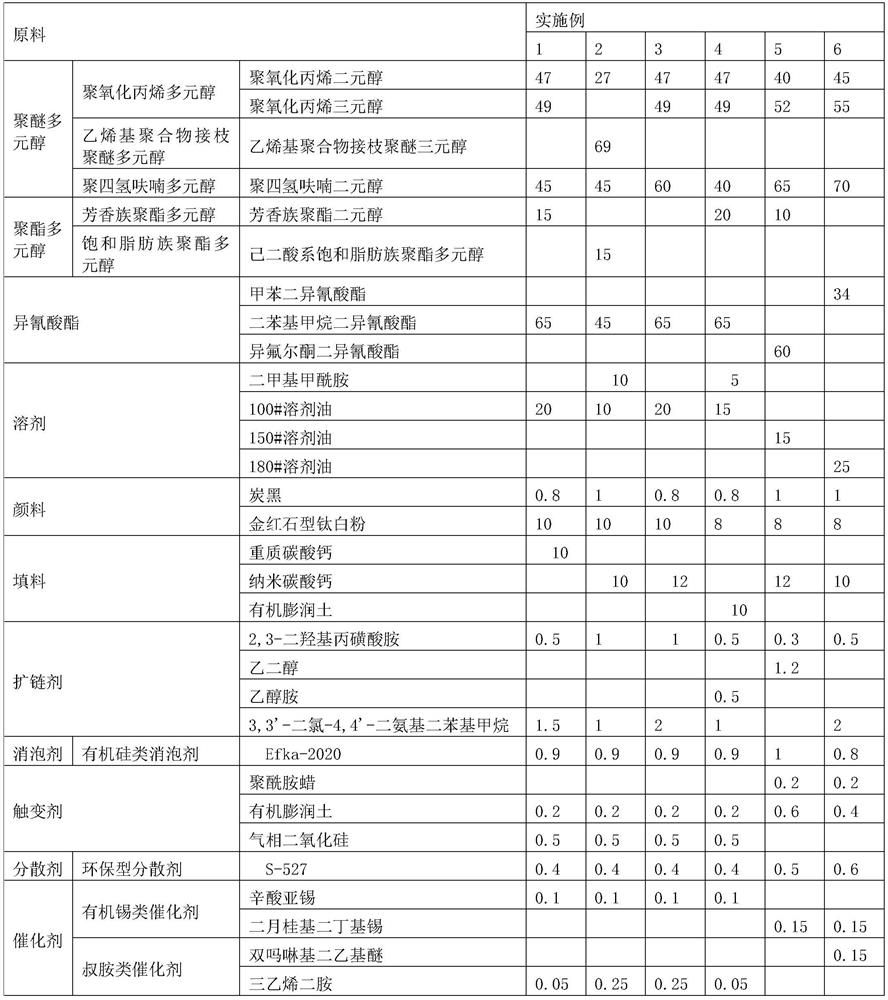

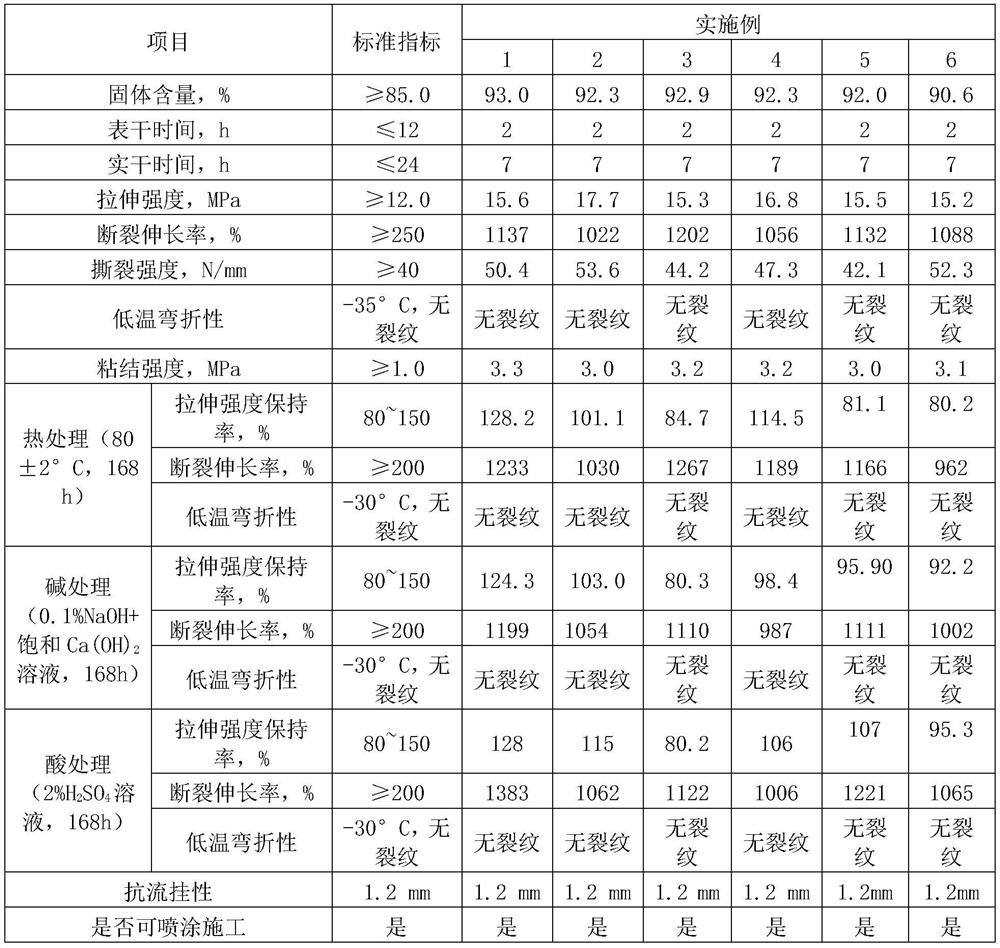

Spraying type polyurethane waterproof coating as well as preparation method and construction method thereof

PendingCN114316777AHigh tensile strengthImprove toughnessPolyurea/polyurethane coatingsFoundation engineeringPolyesterPolymer science

The invention discloses a spraying type polyurethane waterproof coating as well as a preparation method and a construction method thereof. The technical problem that a polyurethane waterproof coating in the prior art cannot have ultrahigh strength and ultrahigh toughness at the same time is solved. The polyurethane waterproof coating is prepared from the following raw materials in parts by weight: 136-170 parts of polyether polyol; 0 to 20 parts of polyester polyol; 34 to 65 parts of isocyanate; 15 to 25 parts of a solvent; 8.8 to 11 parts of pigment; 10 to 12 parts of filler; 1.5 to 3 parts of a chain extender; 0.8 to 1 part of a defoaming agent; 1.4 to 1.8 parts of a thixotropic agent; 0.4 to 0.6 part of a dispersing agent; and 0.15 to 0.35 part of a catalyst. The high-solid-content waterproof material has the characteristics of ultrahigh tensile strength, ultrahigh toughness and high solid content, is suitable for waterproofing of important projects such as railways, highways, bridges, tunnels, dams and the like, and is high in construction efficiency.

Owner:四川迈铁龙科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com