Toughening type phenolic resin and preparation method thereof

A phenolic resin and toughening technology, which is applied in the field of toughened phenolic resin and its preparation, can solve the problems of unabated ablation resistance and debonding of the interface, so as to improve the ablation resistance, increase the interface area, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

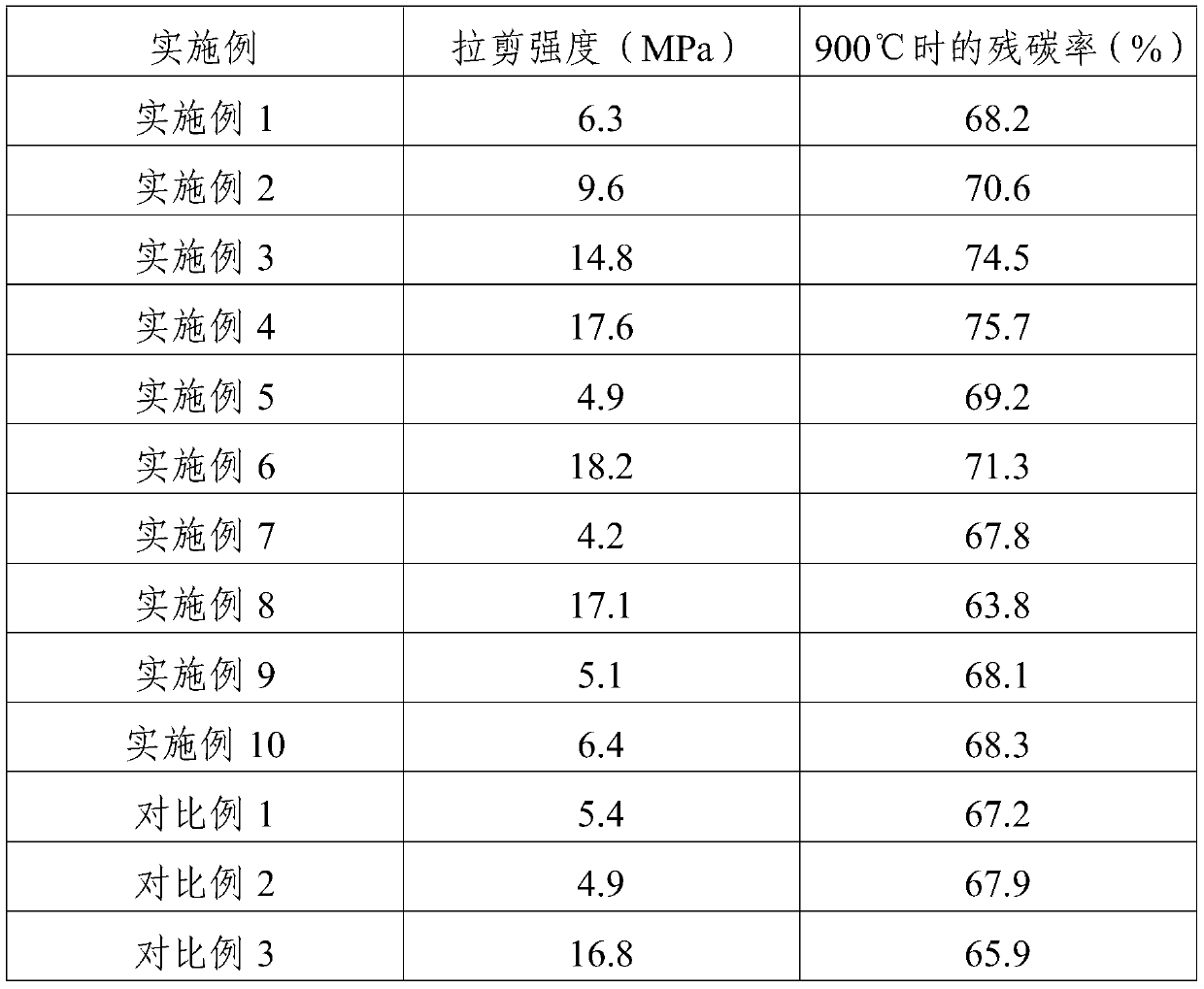

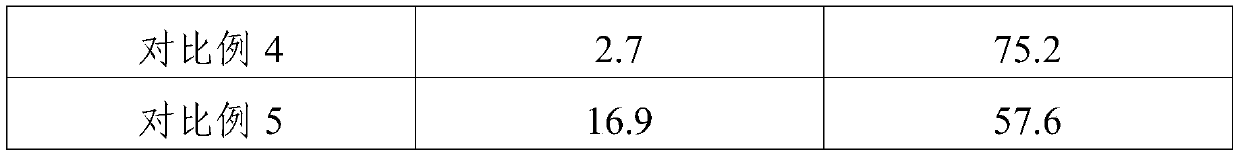

Examples

preparation example Construction

[0036] The present invention provides the preparation method of the toughening type phenolic resin described in the first aspect of the present invention in the second aspect, described method comprises the steps:

[0037] (1) Disperse 0.3 to 0.8 parts (such as 0.3, 0.4, 0.5, 0.6, 0.7 or 0.8 parts) of dispersant in a solvent to obtain a dispersion;

[0038] (2) 100 parts of phenolic resin, 30 to 90 parts (such as 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85 or 90 parts) carboxyl-terminated nitrile rubber and 15 to 90 parts 45 parts (such as 15, 20, 25, 30, 35, 40 or 45 parts) of zirconium diboride are mixed uniformly to obtain a mixture;

[0039] (3) Divide (for example, equally divide) the mixture obtained in step (2) into multiple parts (two parts and more than two parts), and then add multiple parts of the mixture into the dispersion liquid obtained in step (1) and stir Disperse evenly to obtain toughened phenolic resin.

[0040] In particular, "parts" in the present in...

Embodiment 1

[0052] ① Weigh 1 kg of absolute ethanol in a container, add 2.5 g of dispersant in the absolute ethanol solvent and disperse and dissolve with ultrasonic waves to obtain a dispersion.

[0053] ② Weigh 500g of boron phenolic resin powder, 150g of carboxy-terminated nitrile rubber powder, and 75g of zirconium diboride powder in another container, and use a stirring paddle to stir and pre-mix for 0.5h to ensure uniform stirring to obtain a mixture; wherein, the The carboxyl-terminated nitrile rubber powder is selected from nano carboxyl-terminated nitrile rubber powder with an average particle diameter of 50-100 nm.

[0054] ③ Divide the well-mixed mixture into 4 parts, and add them to the dispersion liquid obtained in ① one by one, stir and ultrasonically disperse for 15 minutes each time, until finally all the mixture is added, and the resin composition is stirred evenly to obtain Toughened phenolic resin.

[0055] After the toughened phenolic resin in this example is cured, t...

Embodiment 2

[0057] ① Weigh 1 kg of absolute ethanol in a container, add 2.5 g of dispersant in the absolute ethanol solvent and disperse and dissolve with ultrasonic waves to obtain a dispersion.

[0058] ② Weigh 500g of boron phenolic resin powder, 250g of carboxyl-terminated nitrile rubber powder, and 125g of zirconium diboride powder in another container, and use a stirring paddle to stir and pre-mix for 0.5h to ensure uniform stirring to obtain a mixture; wherein, the The carboxyl-terminated nitrile rubber powder is selected from nano carboxyl-terminated nitrile rubber powder with an average particle diameter of 50-100 nm.

[0059]③ Divide the well-mixed mixture into 4 parts, and add them to the dispersion liquid obtained in ① one by one, stir and ultrasonically disperse for 15 minutes each time, until finally all the mixture is added, and the resin composition is stirred evenly to obtain Toughened phenolic resin.

[0060] After the toughened phenolic resin in this example is cured, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com