Thermal protection organic coating and preparing method thereof

An organic coating and thermal protection technology, applied in coatings, fire-retardant coatings, etc., can solve the problems of pulverization, influence of temperature resistance of resin matrix, disintegration, etc., and achieve excellent mechanical properties and bonding properties, good bonding force, Solve the effect of easy poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Wherein, the silicone resin preparation method shown in formula (1) comprises:

[0059] Mix 20 parts by mass of tetraethyl orthosilicate, 10-20 parts by mass of water, and 80-90 parts by mass of ethanol evenly, add 0.5-1 part by mass of hydrochloric acid with a mass concentration of 37%, and react at 70°C-80°C for 30-40min , add 100-110 parts by mass of methylphenyldimethoxysilane, react at 70°C-80°C for 100-120min, add 5-6 parts by mass of divinyltetramethyldisiloxane, and react at 70°C-80°C The reaction was carried out for 100-120 minutes, the solvent was removed under reduced pressure, and ethyl acetate was added for extraction three times to obtain a silicone resin.

[0060] The porcelain-forming filler can be at least one of alumina, mica or titanium oxide, preferably alumina; the curing agent is preferably high hydrogen-containing silicone oil, and its molecular structure is as shown in formula (2):

[0061]

[0062] Wherein, n=3-10.

[0063] The preferred pl...

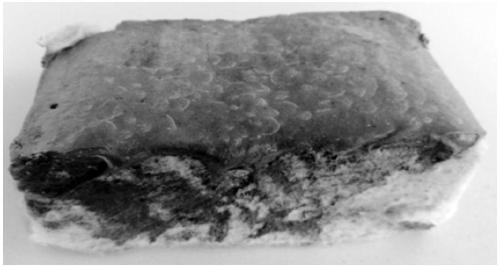

Embodiment 1

[0082] The present embodiment provides a thermal protection organic coating, comprising the following steps:

[0083] (1) Preparation of silicone resin:

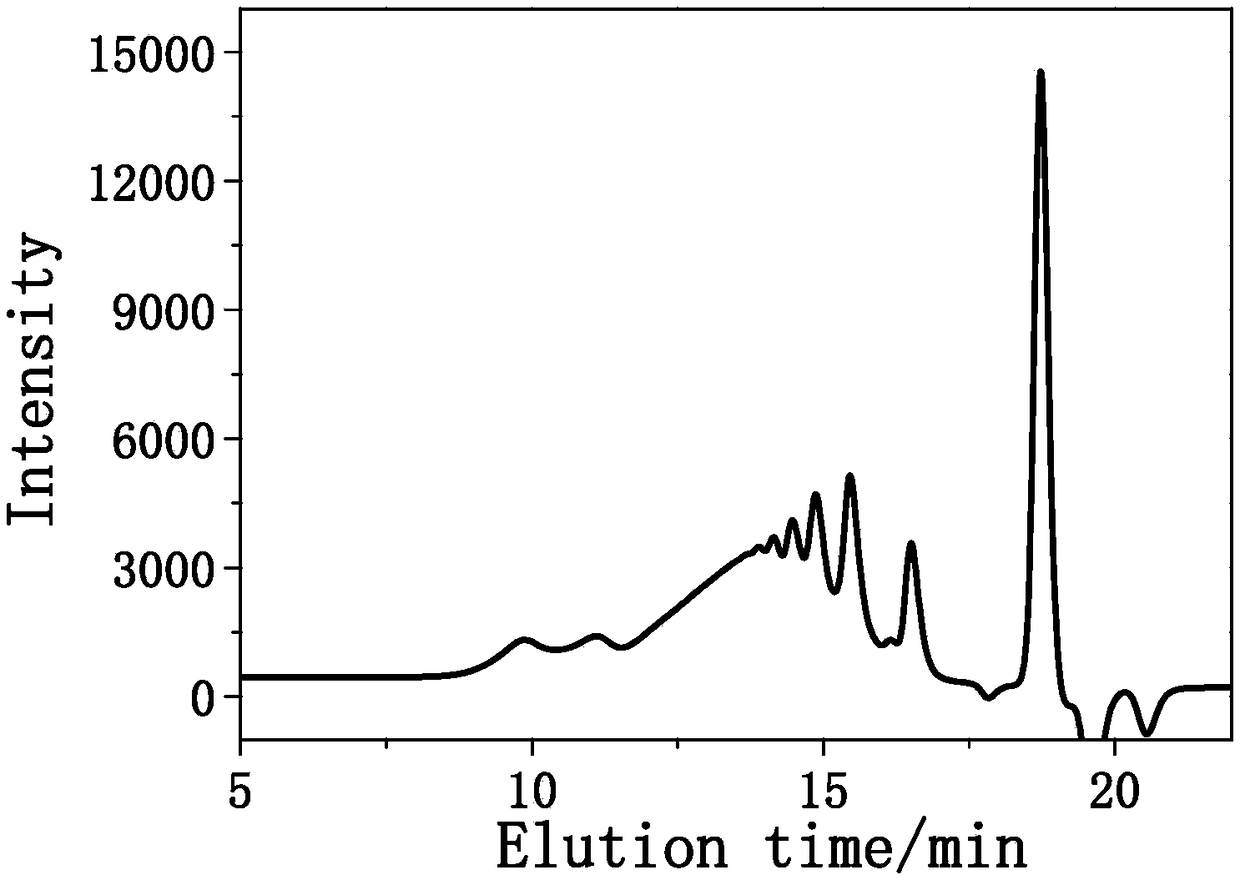

[0084] Mix 20g of ethyl orthosilicate, 15g of water, and 85g of ethanol evenly, add 1g of hydrochloric acid with a mass concentration of 37%, react at 80°C for 30min, then add 100g of methylphenyldimethoxysilane, and react at 80°C for 120min , then add 5g of divinyltetramethyldisiloxane, react at 80°C for 120min, remove the solvent under reduced pressure, add ethyl acetate for extraction three times, and obtain a silicone resin with the molecular formula shown in formula (1), wherein, X = 10, y = 30; image 3 The silicone resin gel permeation chromatogram provided for the present embodiment;

[0085] (2) Preparation of high temperature resistant coatings:

[0086] Add 1 kg of the silicone resin prepared in step (1), 0.3 kg of alumina, 0.2 kg of white carbon black and 0.2 kg of glass fiber into the stirred tank, and grind ...

Embodiment 2

[0092] The present embodiment provides a thermal protection organic coating, comprising the following steps:

[0093] (1) Preparation of silicone resin:

[0094] Mix 20g of ethyl orthosilicate, 15g of water, and 85g of ethanol evenly, add 1g of hydrochloric acid with a mass concentration of 37%, react at 80°C for 30min, add 100g of methylphenyldimethoxysilane, and react at 80°C for 120min, Add 5g of divinyltetramethyldisiloxane, react at 80°C for 120min, remove the solvent under reduced pressure, add ethyl acetate for extraction three times, and obtain a silicone resin with the molecular formula shown in formula (1), where X=10 ,y=30;

[0095] (2) Preparation of high temperature resistant coatings:

[0096] Add 1 kg of the silicone resin prepared in step (1), 0.28 kg of alumina, 0.18 kg of white carbon black and 0.18 kg of glass fiber into the stirred tank, and grind 4 times with a three-roller mill to obtain a high temperature resistant coating.

[0097] (3) preparation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com