Aluminum alloy section mortise-tenon joint structure reinforced based on chemical coupling agent

A technology of aluminum alloy profile and connecting agent, which is applied in the direction of connecting components, rod connection, material gluing, etc., can solve the problems of low strength, large mechanical connection defects, high thermal conductivity of aluminum alloy, etc., and achieve high strength and rigidity, Avoid debonding and facilitate the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

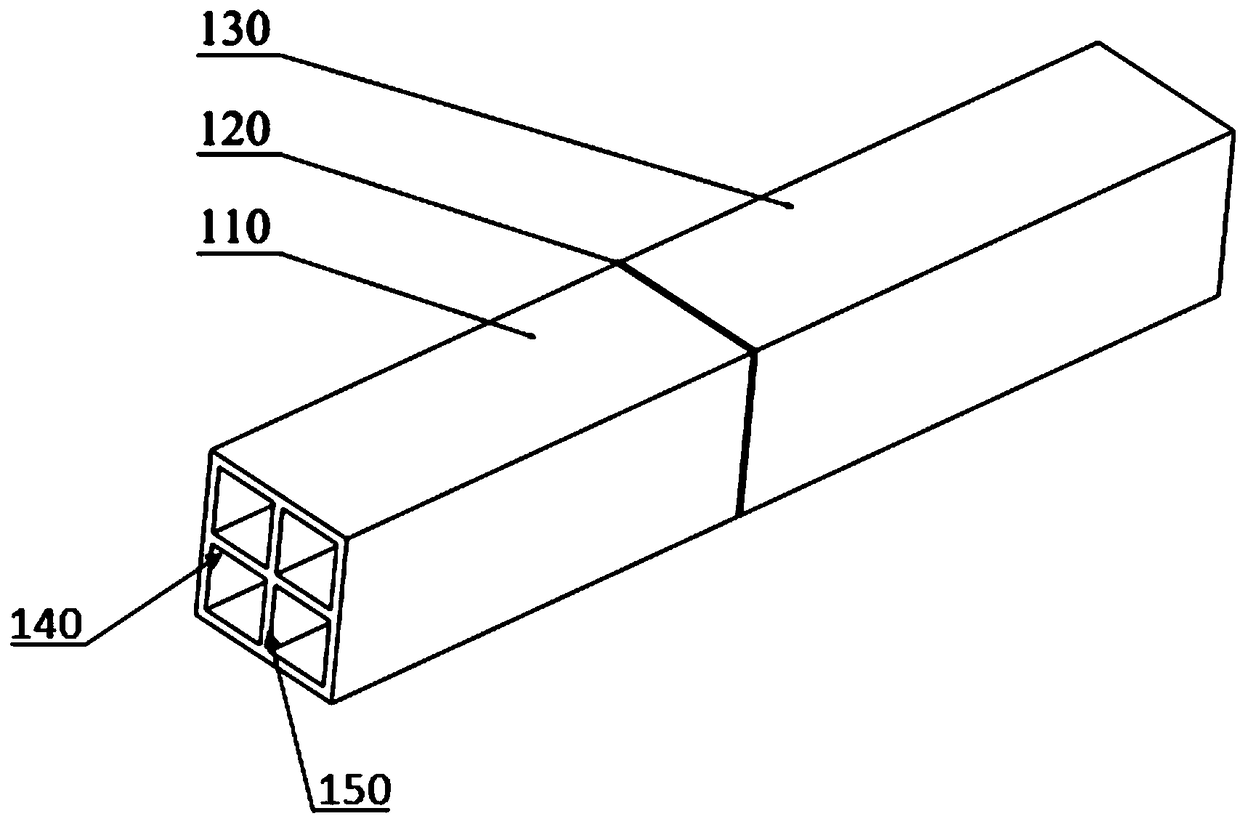

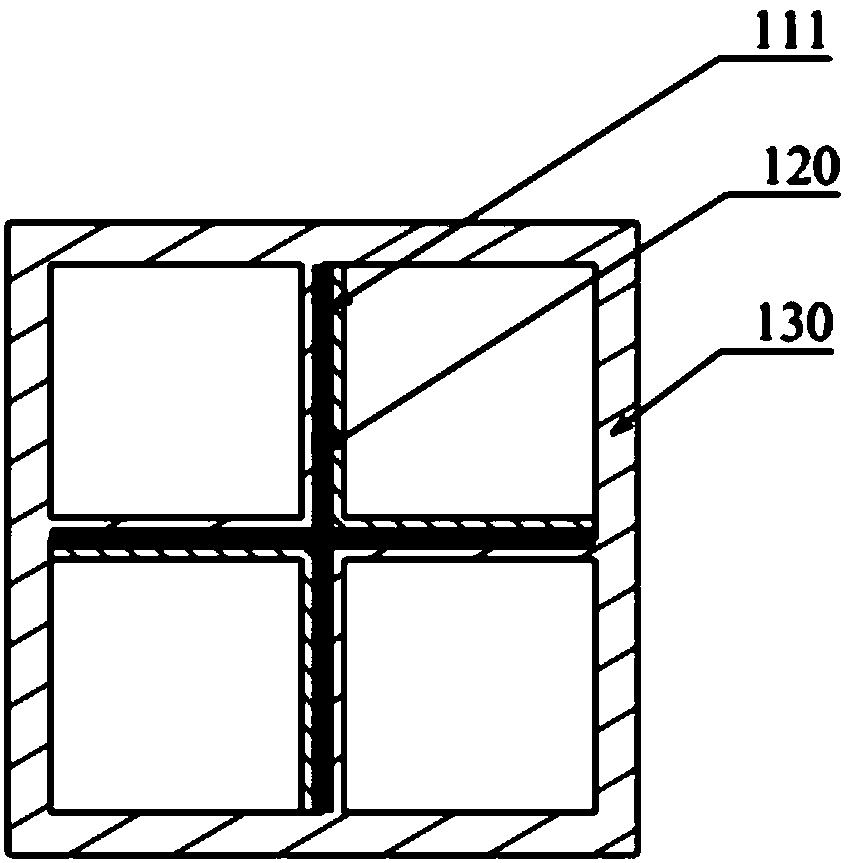

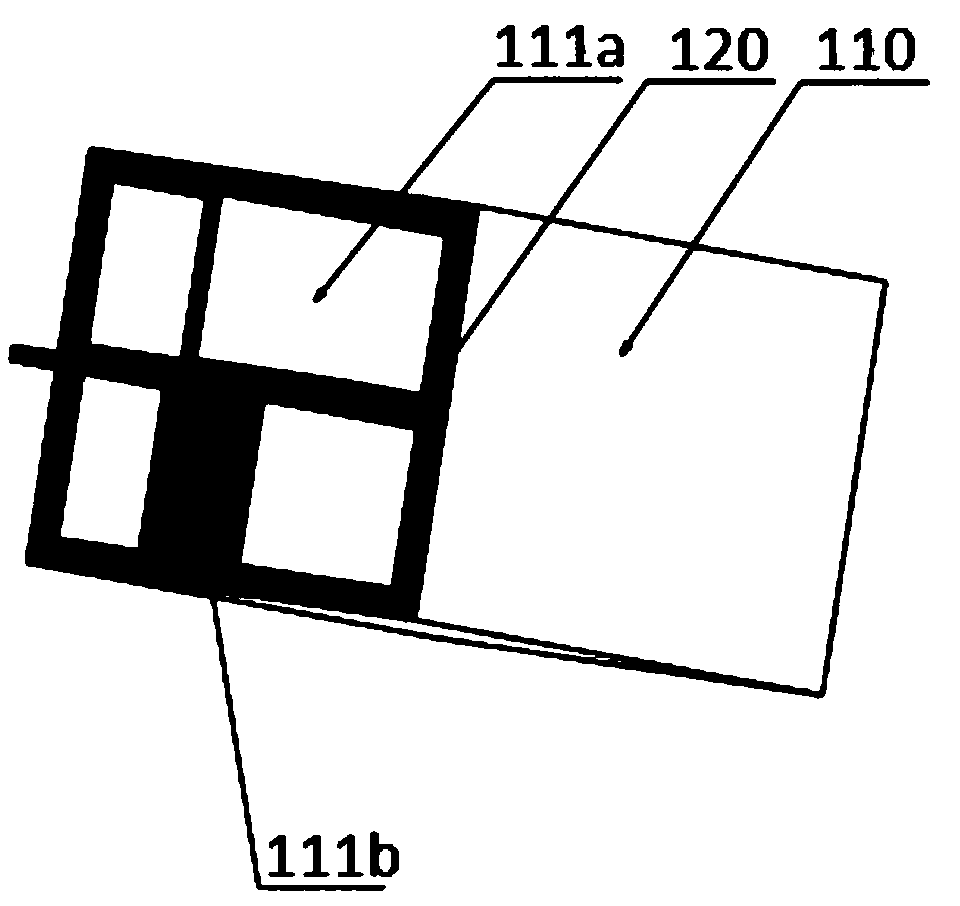

[0054] Such as Figure 1-8 As shown, the present invention provides an aluminum alloy profile mortise and tenon structure reinforced by a chemical bonding agent. Its main structure is a horizontal mortise and tenon structure, including a mortise and tenon body 110 and a mortise and tenon body 130. One side of the mortise and tenon body 110 is integrally formed. A mortise head is provided, and a mortise eye is provided on one side of the mortise piece body 130; wherein, the mortise piece body 110 and the mortise piece body 130 are made of aluminum alloy, and are integrally formed. Both the mortise piece body 110 and the mortise piece body 130 include: an outer frame, a horizontal Support plate 140, vertical support plate 150; the vertical support plate 150 is vertically arranged with the horizontal support plate 140, and forms a cross-section of a cross-section with the outer frame and the horizontal support plate 140. Closed in the mortise, the tenon and the mortise are bonded...

Embodiment 2

[0060] Such as Figures 9 to 14 As shown, the present invention provides an aluminum alloy profile mortise and tenon structure reinforced by a chemical bonding agent. Its main structure includes a mortise body 210 and a mortise body 230 . Mortise eyes are set on one side; wherein, the mortise body 210 and the mortise body 230 are made of aluminum alloy and are integrally formed. Both the mortise body 210 and the mortise body 230 include: an outer frame, a horizontal support plate 240, a vertical support Plate 250; the vertical support plate 250 and the horizontal support plate 240 are vertically arranged, and form a cross-section of a Tian-shaped structure with the outer frame and the horizontal support plate 240. and the mortise are bonded and fixed by chemical bonding agent 220.

[0061] In another embodiment, one side of the tenon body 210 is recessed inwardly to form a tenon composed of a first concave portion 212 and a first protruding portion 211 .

[0062] The mortise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com