Patents

Literature

126results about How to "Strong intermolecular forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tax stamp ink digital ink jet and preparation method thereof

InactiveCN1687260AImprove dispersion stabilityGood storage stabilityInksDyeing processFiberPolymer science

The present invention uses polycarboxylic acid type high-molecular copolymer as dispersing agent and fixing agent to prepare superfine pigment ink as ink-jet printing ink. It is characterized by that the pigment dispersing agent and fixing agent are made into the same compound, after it is jetted and printed, the high temperature can be used to fix the pigment on the fibre and obtain required fastness. The average grain size of pigment granules prepared by said method is less than 300 nm.

Owner:SUNVIM GROUP

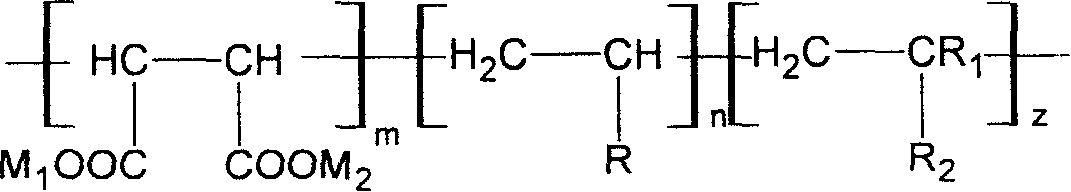

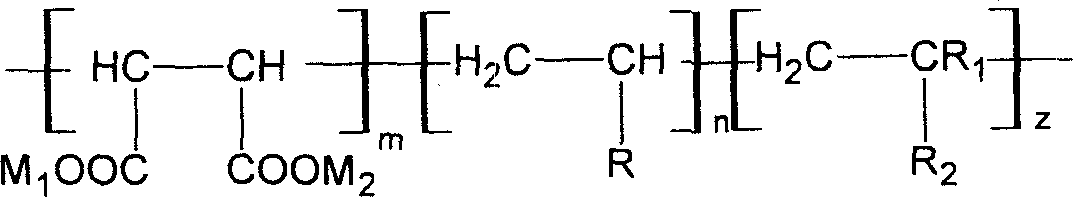

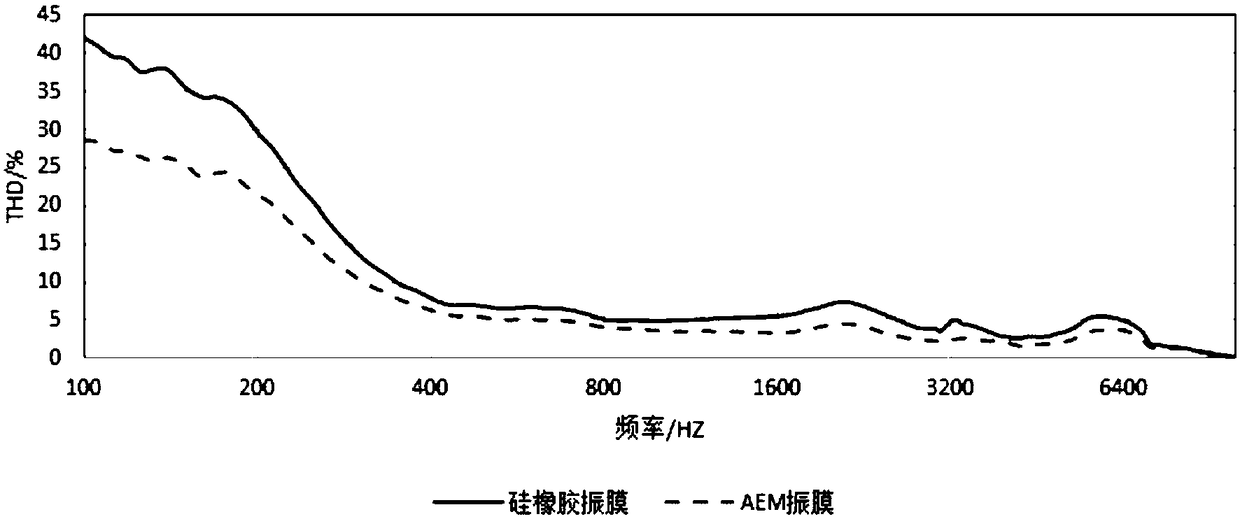

Diaphragm for sounding device, sounding device and assembling method thereof

PendingCN109218924AImprove loss factorReduced chemical structure symmetryDiaphragm extensionsPlane diaphragmsChemical structureCarboxylic acid

The invention discloses a diaphragm for a sounding device, a sounding device and an assembling method thereof. The diaphragm includes a diaphragm layer prepared by subjecting at least one of an ethylene-acrylate copolymer and an ethylene-acrylic ester-carboxylic acid copolymer to crosslinking reaction. The molecular structure of the diaphragm includes a vinyl-acrylic group. The group reduces the chemical structure symmetry of a material, reduces tacticity, and increase steric hindrance, so that the diaphragm has a high loss factor and the sounding device has a good damping effect.

Owner:GOERTEK INC

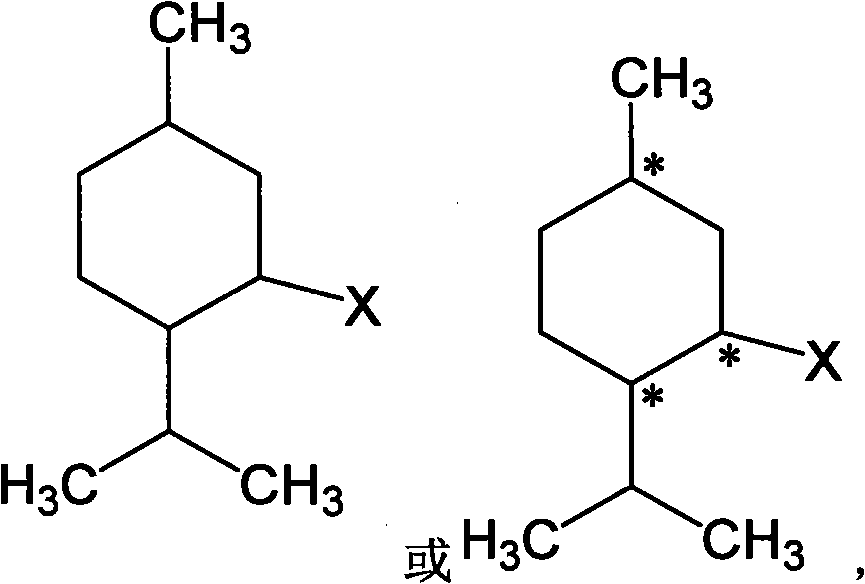

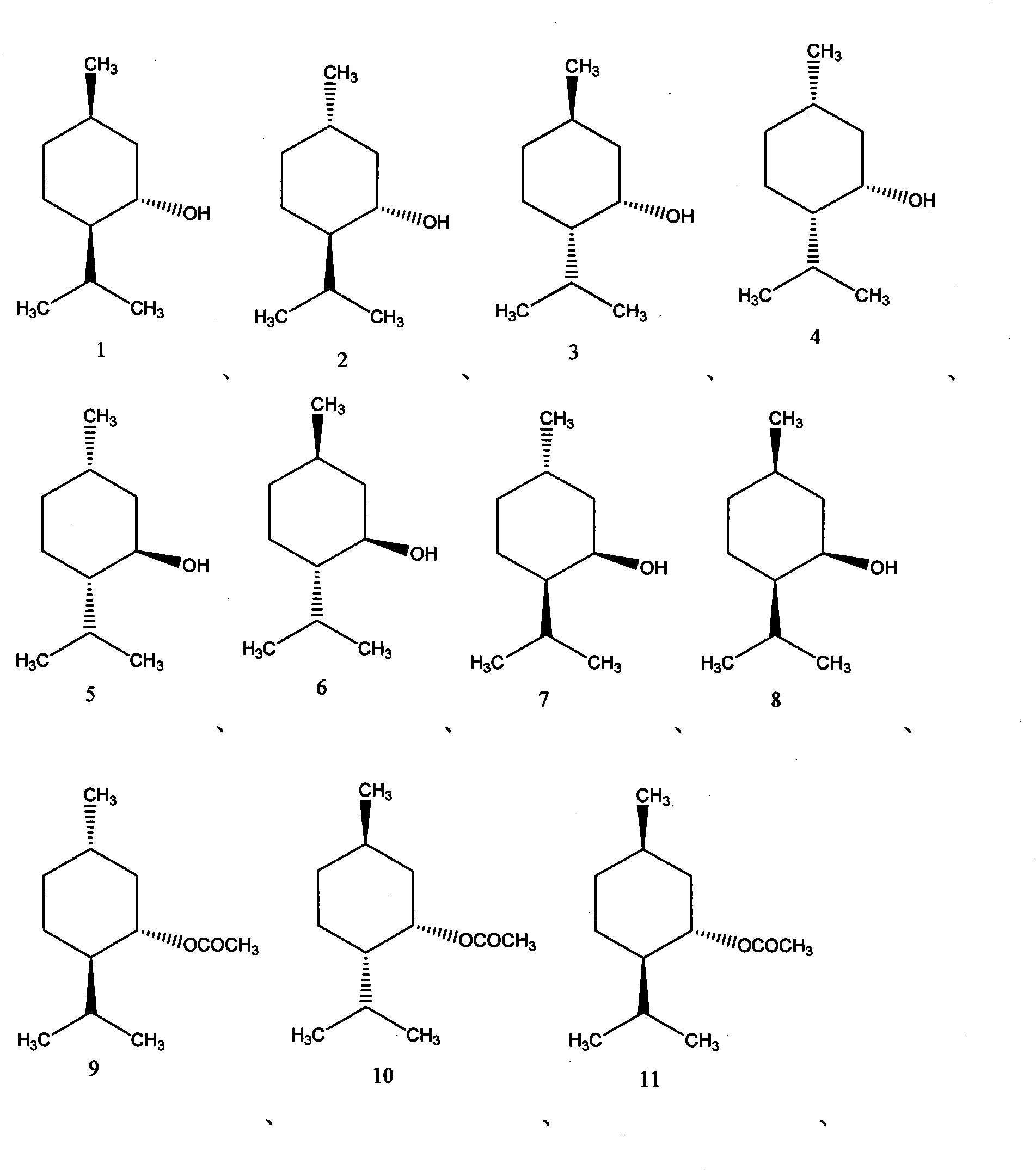

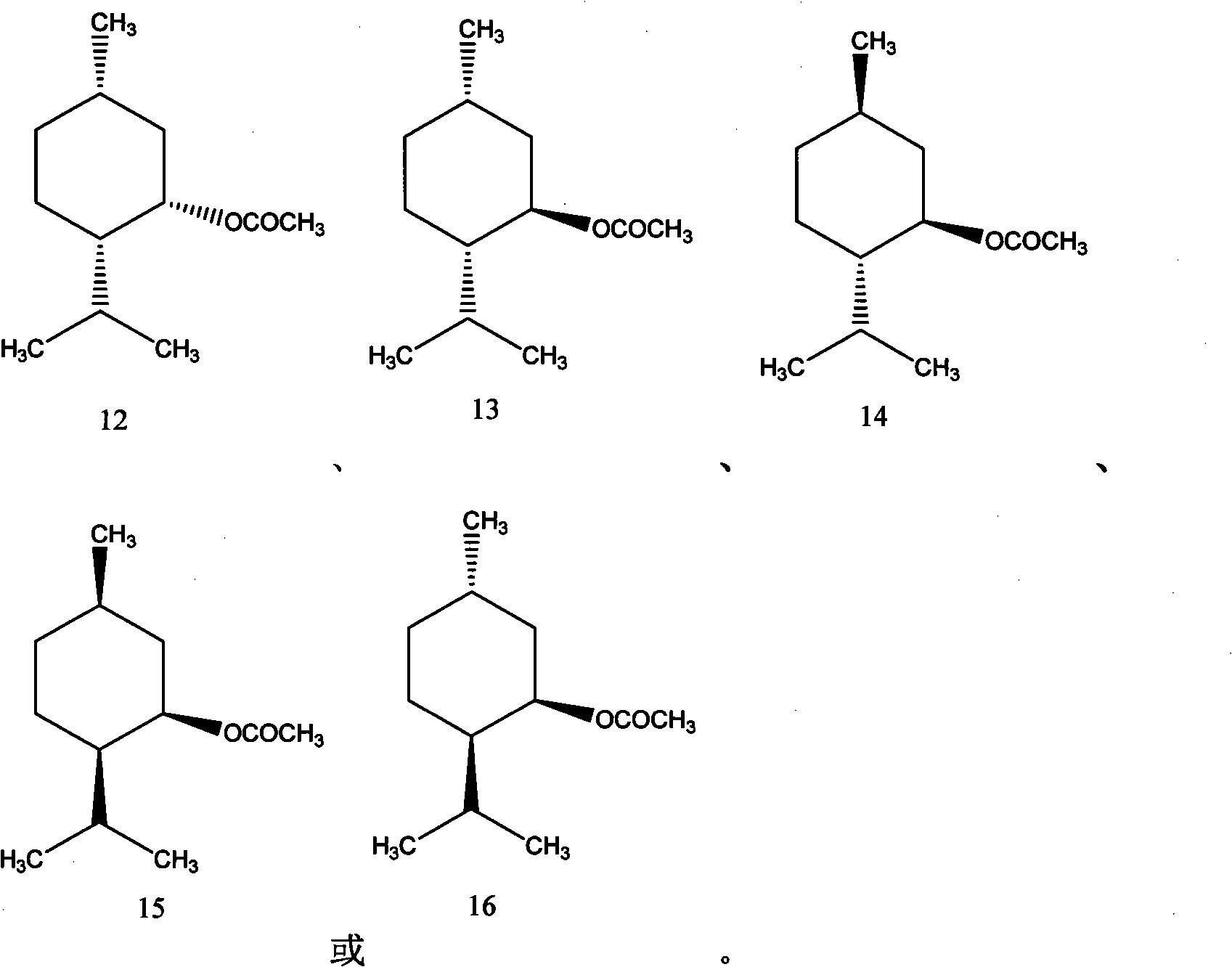

Application of menthol and derivatives thereof as cultural relic excavation site reinforcing material

The invention relates to application of menthol and derivatives thereof used as novel materials for the site temporary reinforcement of fragile cultural relics in the process of cultural relic excavation and a reinforcing method thereof. The reinforcing method comprises the following steps of: covering a fiber fabric on a cultural relic fragment to be reinforced; heating, melting or dissolving the menthol or the derivative thereof into an organic solvent; sprinkling or coating the obtained fusant (solution) on the covered fabric; and after solidifying the fusant or volatilizing the solvent in the solution, obtaining a temporary reinforced body. The obtained solid can be directly removed from the site and can not be broken or damaged. If a menthol derivative reinforcing agent needs to be removed, the reinforced body is just heated so that the reinforcing agent is volatilized. The invention is suitable for the extraction of shed colour paintings in the terracotta warriors and is also suitable for protective extraction of stone cultural relic fragments, rock paintings and wall paintings and the extraction of lacquer cultural relic fragments, wooden cultural relic fragments, paper cultural relics and cotton fibre cultural relics.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +2

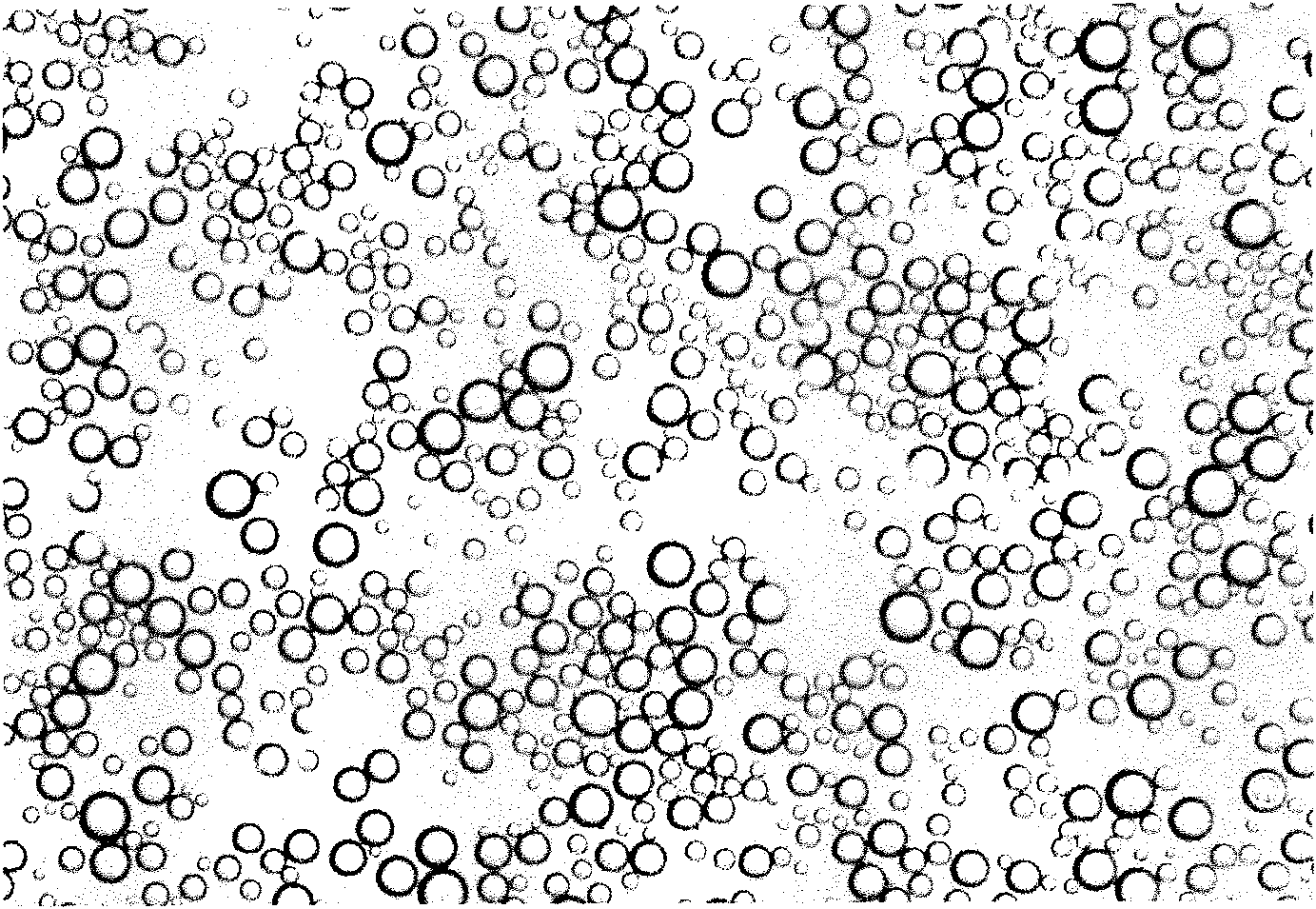

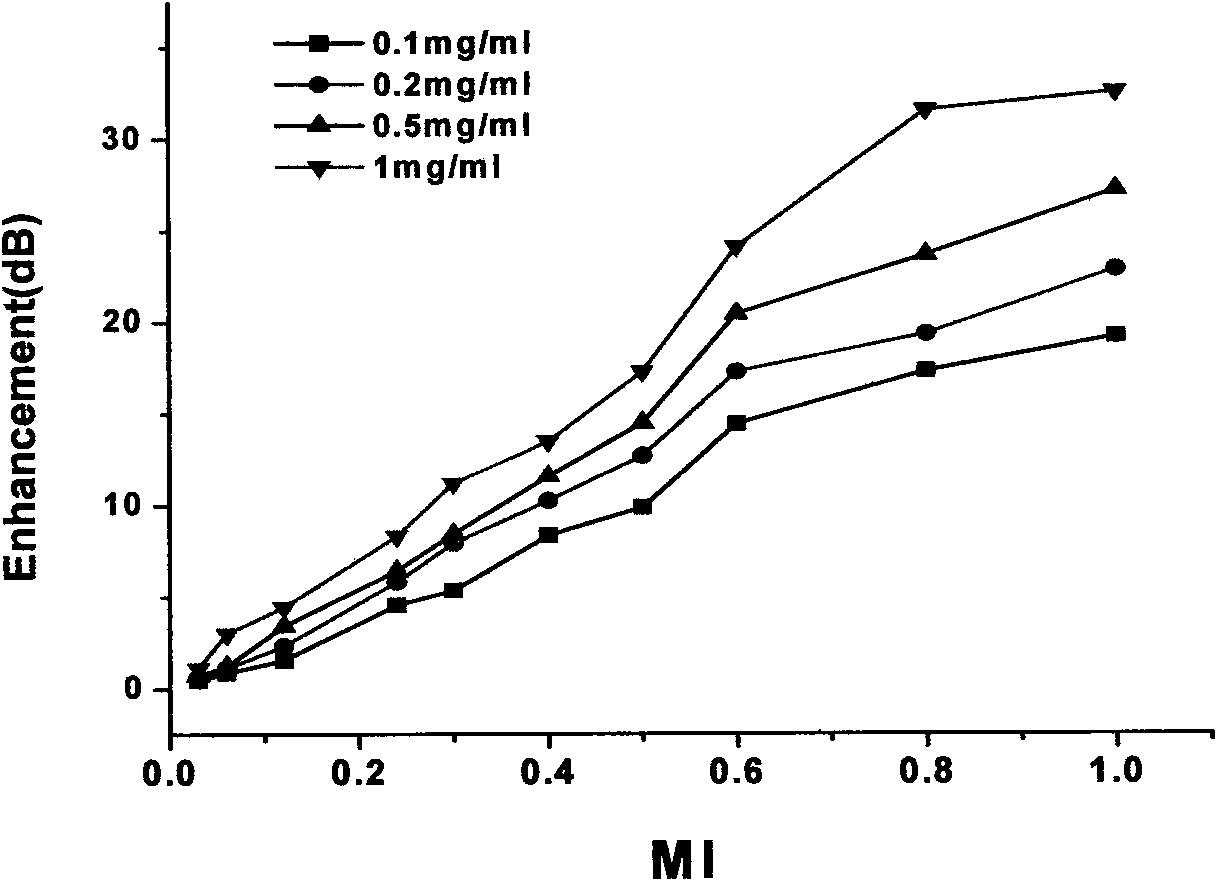

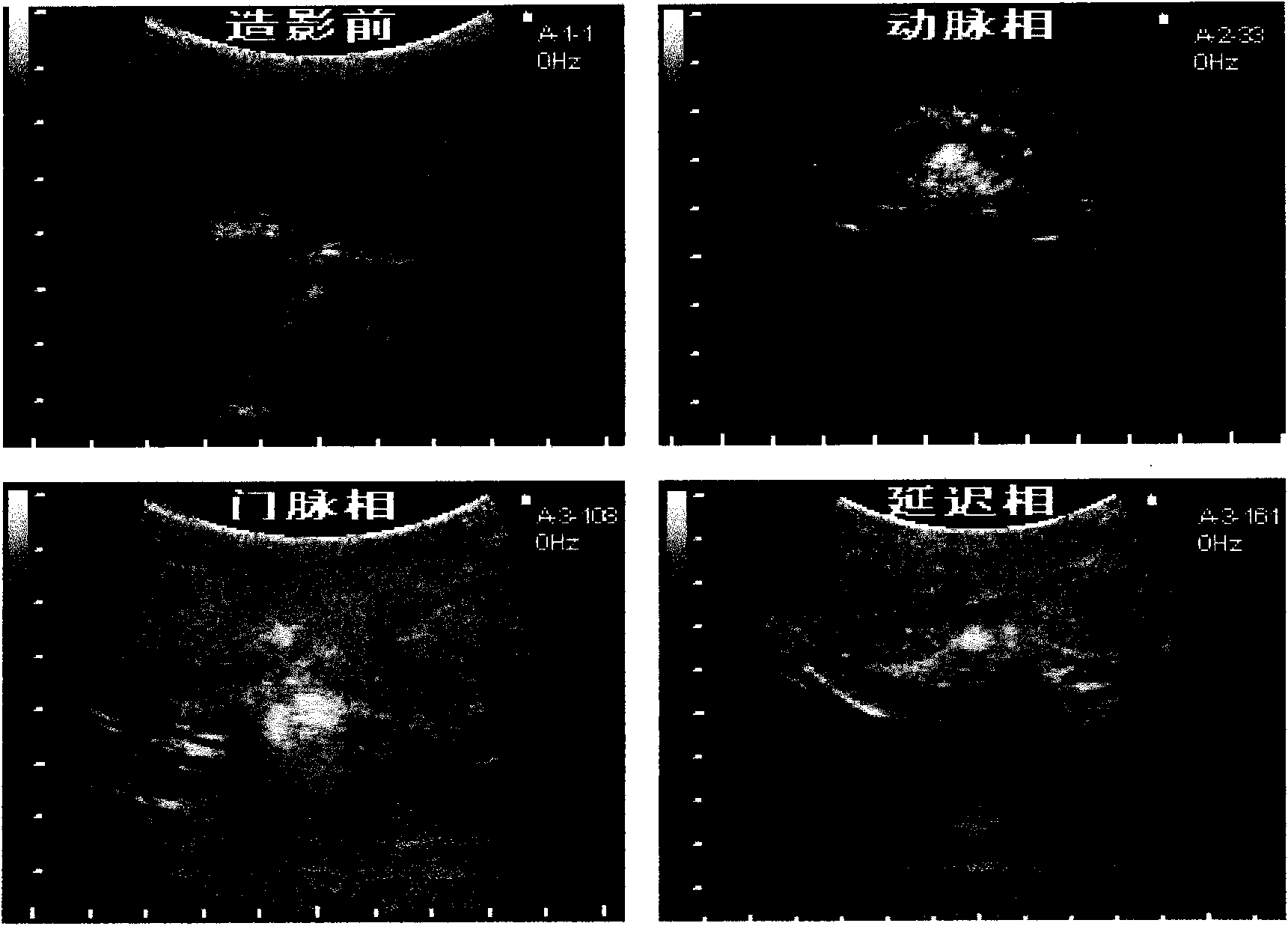

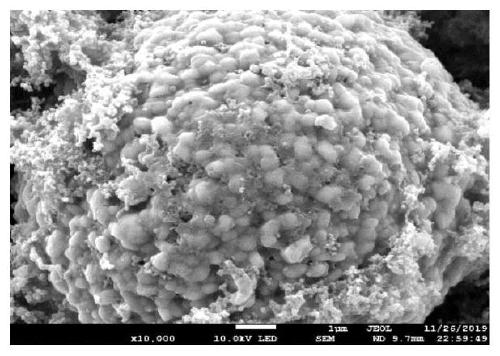

Novel PLGA-PEG-PLGA multipolymer microbubble ultrasound contrast agent and preparation method thereof

InactiveCN101574530AMeet the basic requirementsGood backscattering propertiesEchographic/ultrasound-imaging preparationsUltrasound contrast mediaPlga peg plga

The invention discloses a novel PLGA-PEG-PLGA multipolymer microbubble ultrasound contrast agent and preparation method thereof. The microbubble ultrasound contrast agent is provided with an outer housing prepared from the polymer material PLGA-PEG-PLGA, the components of the inner core of gas include perfluoropropane, decafluorobutane or sulphur hexafluoride, and the like, and the molecular weight of the PLGA-PEG-PLGA multipolymer ranges from 2000 to 20000 dal. The preparation of the agent adopts the double emulsion method, and after being frozen and dried, gas molecules are led into microbubbles. The multipolymer microbubble contrast agent has favorable backscattering performance, shows the enhanced effect of ultrasonic contrast during in vivo and in vitro experiments, is safe and nontoxic, and meets the requirement of the ultrasound contrast agent.

Owner:FUJIAN MEDICAL UNIV UNION HOSPITAL

Flexible cell based on metallic oxide/graphene composite macroscopic fibers and preparation method

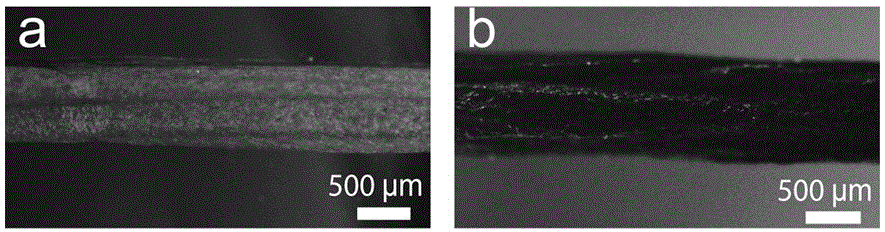

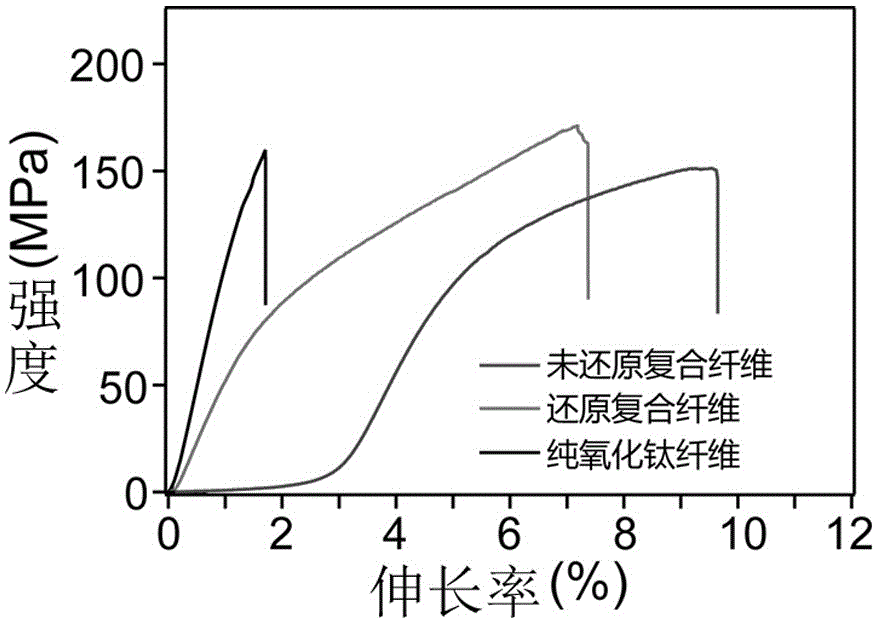

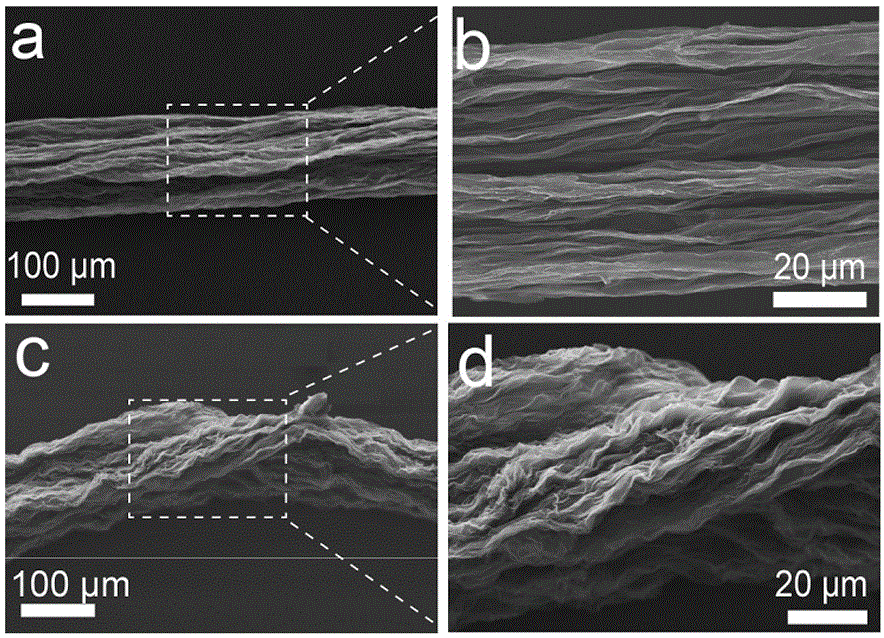

ActiveCN107180947AGood mechanical propertiesExcellent electrochemical performanceFinal product manufactureCell electrodesCvd grapheneHydroiodic acid

The invention relates to a flexible cell based on metallic oxide / graphene composite macroscopic fibers and a preparation method. The preparation method comprises the following steps: after mixing an anionic metal oxide aqueous solution with graphene oxide to obtain a spinning solution, adding the spinning solution in wet spinning equipment to obtain nascent fibers; repeatedly washing the obtained nascent fibers with deionized water, and drying the nascent fibers to obtain metallic oxide and graphene oxide composite fibers; reducing the metallic oxide and graphene oxide composite fibers with hydroiodic acid, and then washing and drying the metallic oxide and graphene oxide composite fibers to obtain the metallic oxide and graphene composite fibers; placing the composite fibers, lithium lines and lithium manganate loaded carbon cloth fibers in a shrinkable tube in parallel; and adding diaphragms and electrolyte so that half cells and total cells can be assembled respectively. The preparation process is simple and controllable, and large-scale production is facilitated. The metallic oxide and graphene composite fibers which are prepared by the preparation method for the first time have unlimited prospects in the field of energy storage of flexible cells.

Owner:SUZHOU UNIV

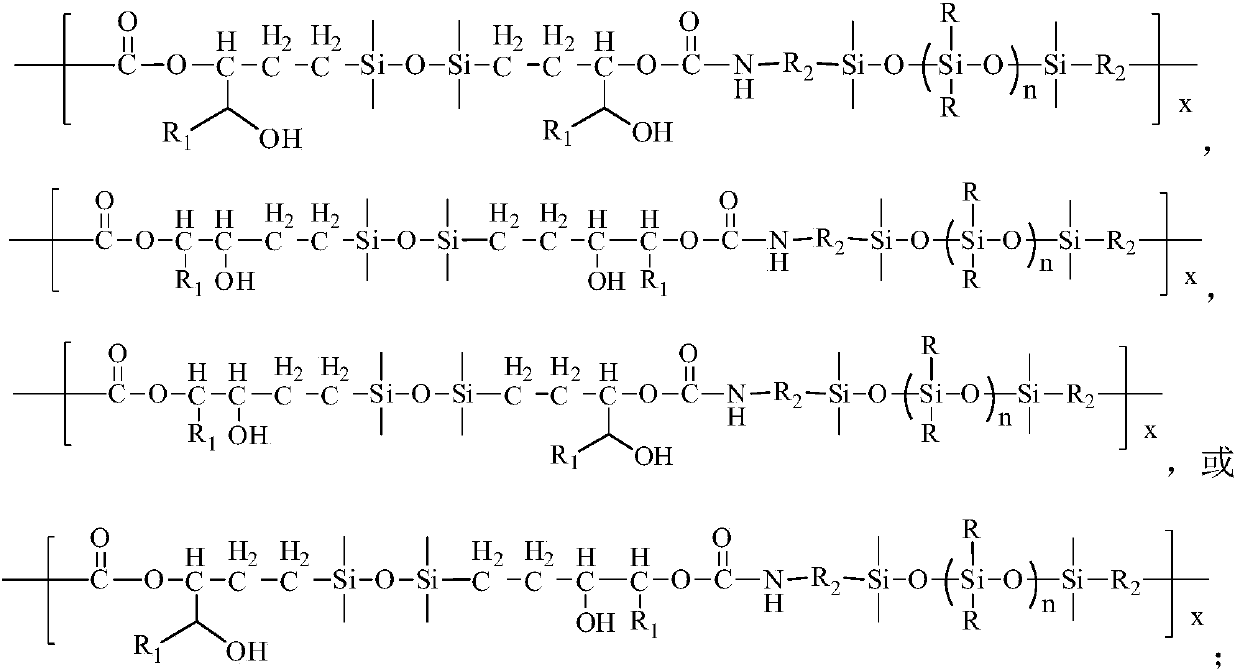

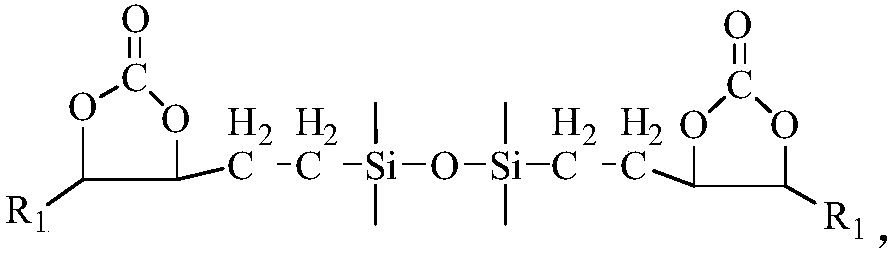

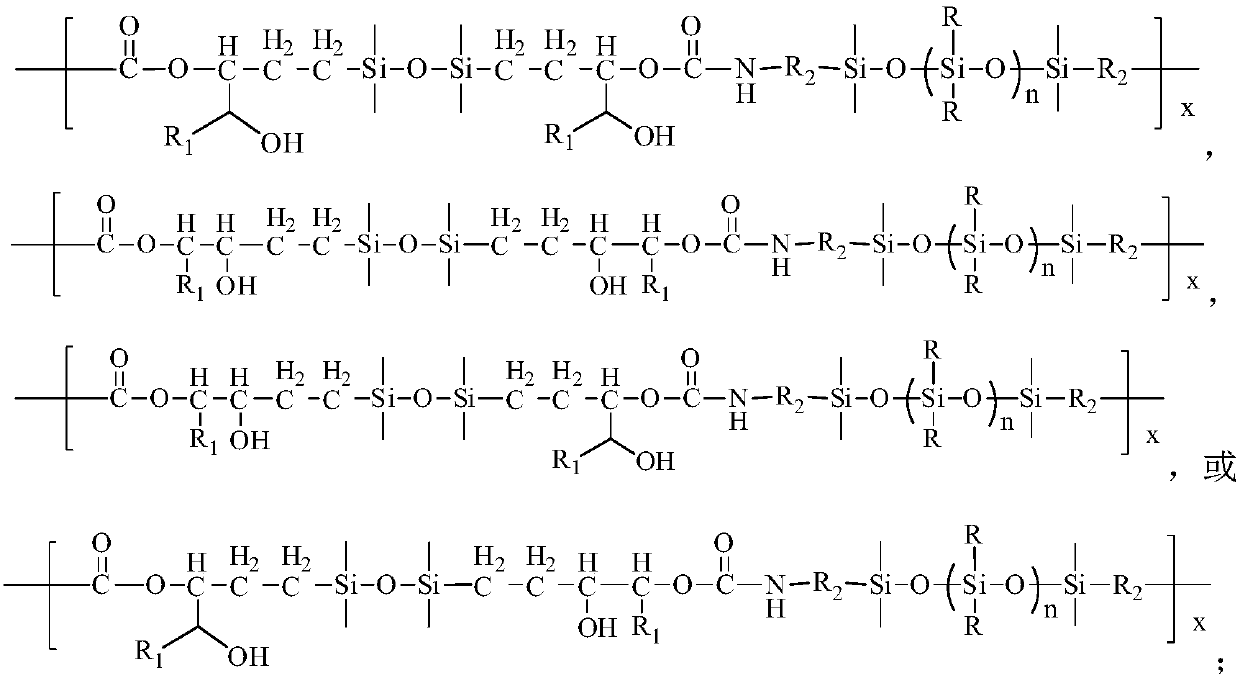

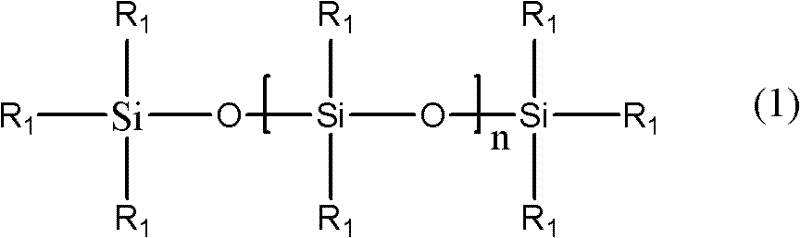

Non-isocyanate organosilicon-polyurethane block copolymer and synthesis method thereof

The invention relates to a non-isocyanate organosilicon-polyurethane block copolymer and a synthesis method thereof, in particular to an addition polymerization reaction of alpha, omega-aminoalkylpolysiloxane and cyclic carbonate in a solvent. The non-isocyanate organosilicon-polyurethane block copolymer prepared by the invention avoids the use of diisocyanate as a toxic raw material, the production process and the product are safe and environmentally friendly, and a hydroxyl group on a beta carbon atom in a urethane segment and a carbonyl group form an intramolecular hydrogen bond, so that the copolymer has strong molecular force, and thus the hydrolysis resistance, chemical resistance and anti-permeability of the copolymer are more excellent; the block copolymer molecular structure can be designed according to the polysiloxane chain length and the cyclic carbonate structure so as to meet the application of the copolymer in the fields of antifouling flash coatings, leather, textiles,papermaking, fiber processing, medical devices and the like.

Owner:QINGDAO UNIV OF SCI & TECH

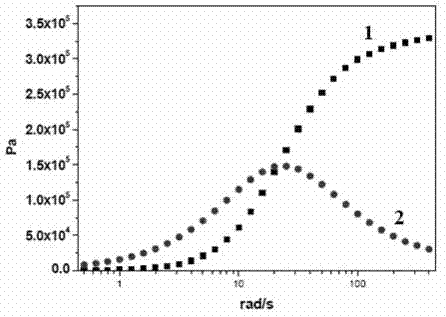

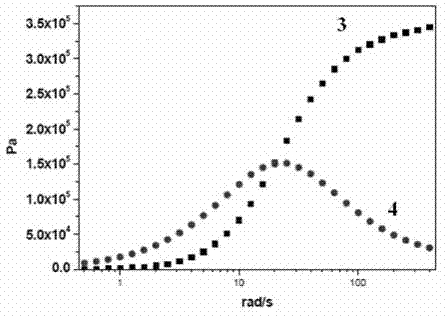

Preparation method of intelligent stress response material

The invention provides a preparation method of an intelligent stress response material, and the preparation method comprises the following steps of: (A) mixing organic polydimethylsiloxane, a boron-containing compound, a difunctional chain extender and a functional modifier, and reacting and drying to obtain an intelligent stress response material precursor; and (B) carrying out post processing on the intelligent stress response material precursor to obtain the intelligent stress response material, wherein the post processing is one or more of heating, microwave radiation, dispersant mixing, dispersant removal, extrusion and rolling. The intelligent stress response material provided by the invention has the advantages of better stress response capacity, high energy absorption rate and self-repairing property.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

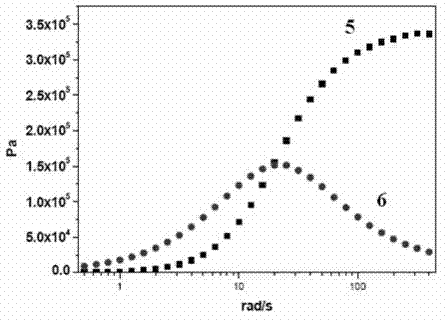

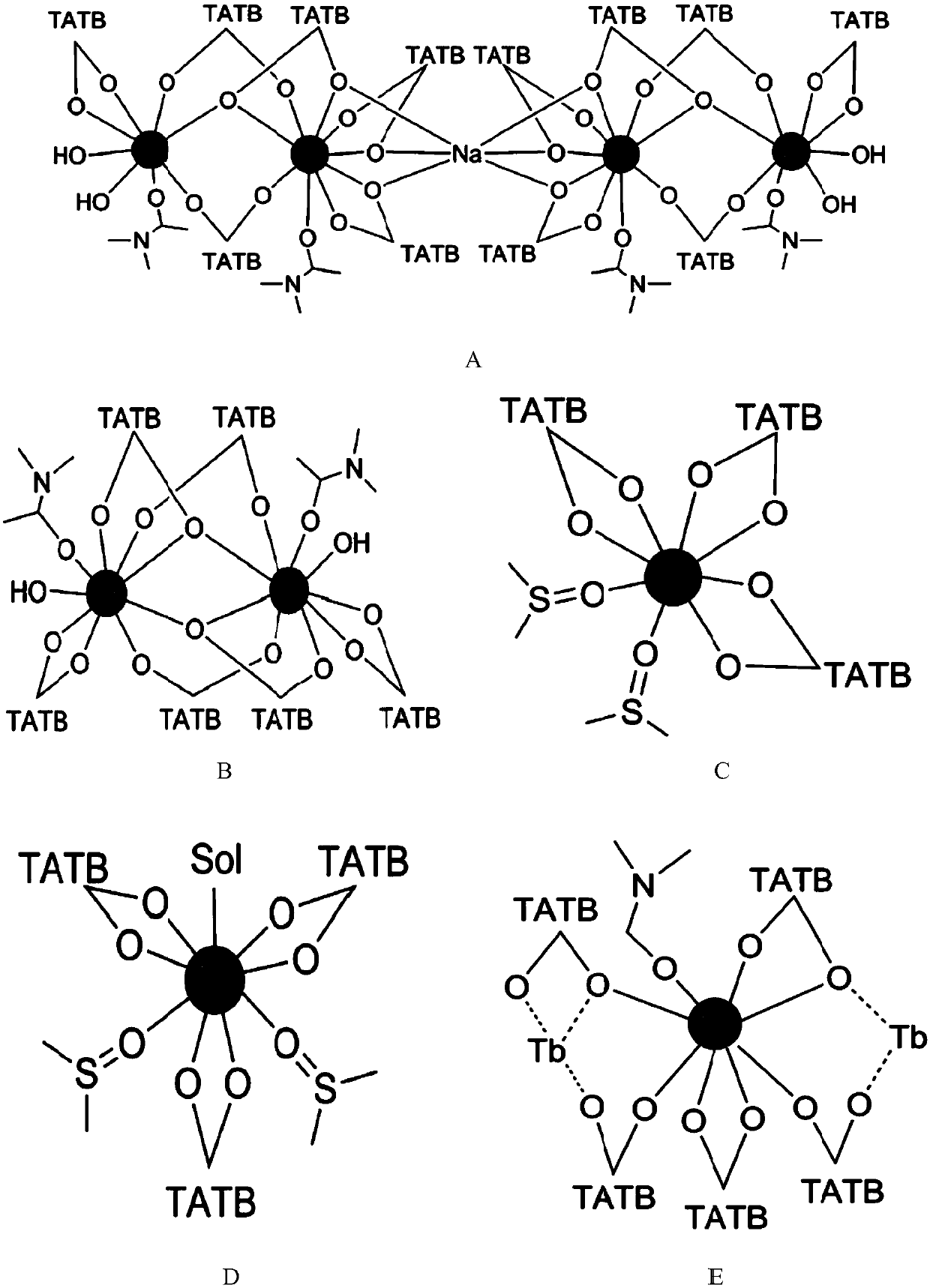

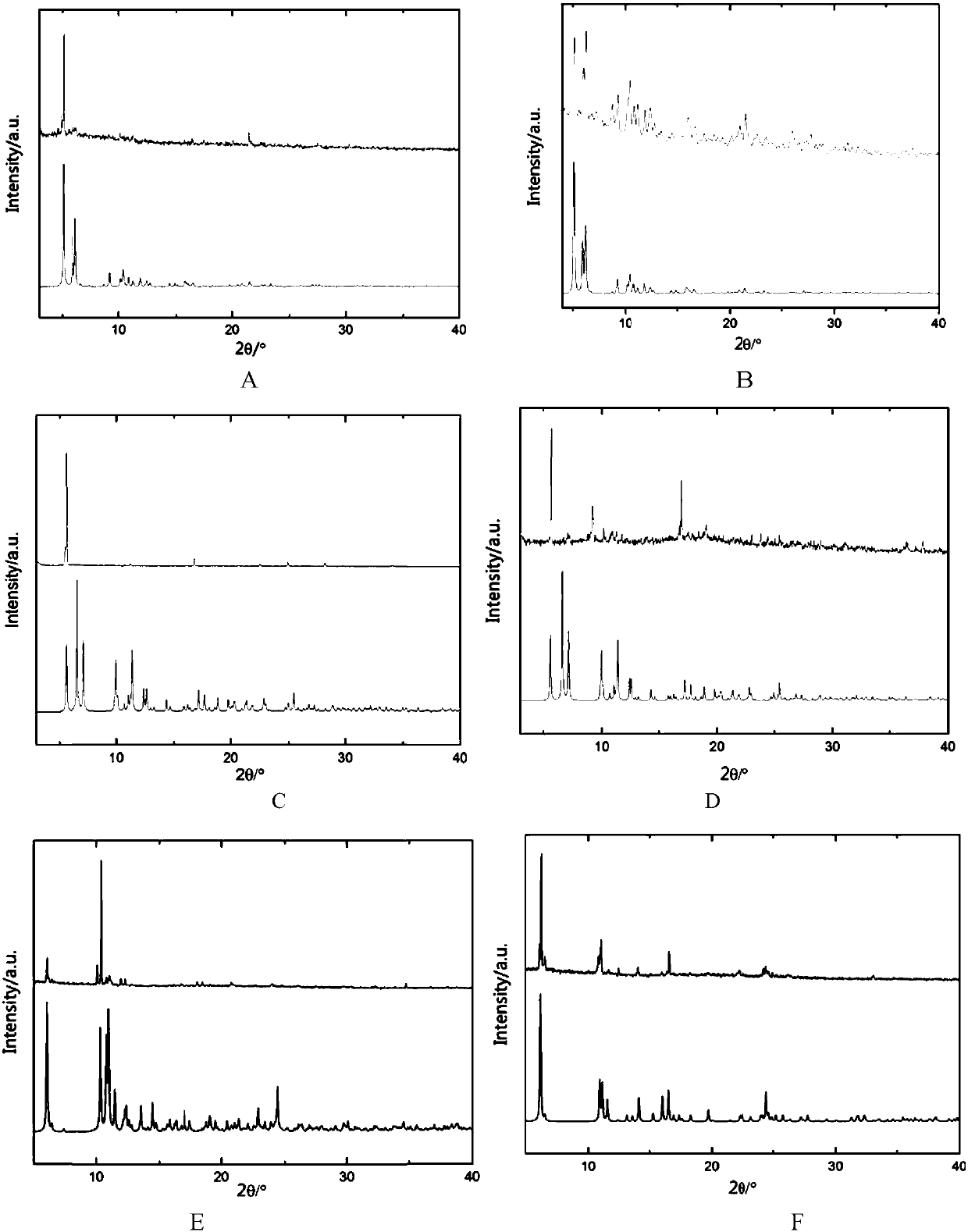

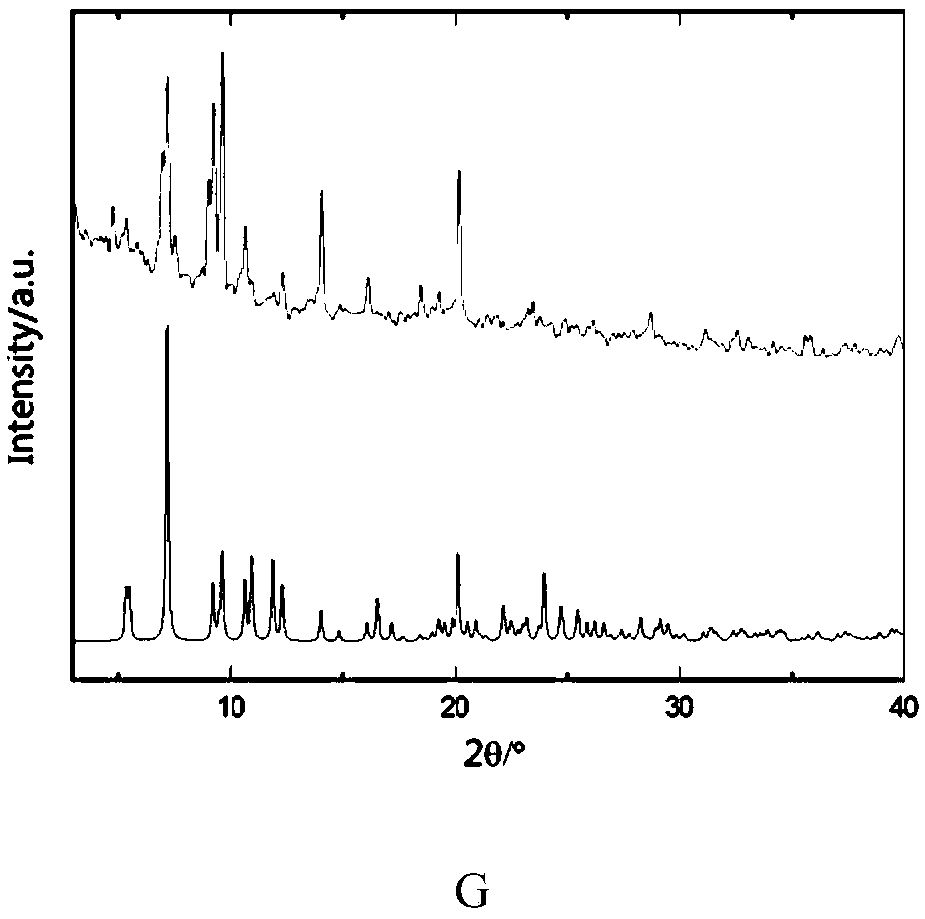

Rare earth metal organic framework material with high quantum yield and preparation method thereof

ActiveCN108912337AReduce distanceReduce strong effectsLuminescent compositionsQuantum yieldRare-earth element

The invention belongs to the field of luminescent materials, and relates to a rare earth metal organic framework material and a synthesis method thereof. The rare earth metal organic framework material is constructed with deprotoned 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine as ligands, with rare earth metal ions as luminescent centers by pi-pi interaction of the ligands or C-H-pi interaction of the ligands and a solvent. The distance between the centers of aromatic rings corresponding to the pi-pi interaction of the ligands is 5 Angstroms, the interaction of the ligand molecules is enhanced,the rigidity of a material skeleton is increased, the loss of energy on the skeleton is reduced, the energy transfer from the ligands to the rare earth metals is also enhanced, the energy utilizationefficiency is greatly enhanced, and thus high quantum yield is obtained. The luminescent metal organic frame material has high energy utilization rate, and the quantum yield of the luminescent metal organic frame material is increased from less than 60% to 99.9% compared with that of a conventional rare earth metal organic frame material.

Owner:SUN YAT SEN UNIV

Polyurethane foam as well as preparation method and application thereof

The invention provides polyurethane foam as well as a preparation method and application thereof. The polyurethane foam is prepared from a component A and a component B, wherein the component A is prepared from 100 parts by weight of polyaryl polymethylene isocyanate and 10 to 15 parts by weight of mixed foaming agent; the mixed foaming agent is prepared from methylformate and 10 to 18 parts by weight of toluene diisocyanate and prepolymers thereof; the component B is prepared from 100 parts by weight of premixed polyether polyols, 1 to 2 parts by weight of composite catalyst, 1 to 2.5 parts by weight of water, 1 to 3 parts by weight of surfactant and 10 to 16 parts by weight of multielement foaming agent. According to the polyurethane foam provided by the invention, the problem that the methylformate has a swelling effect on the polyurethane foam is solved by adopting two schemes: firstly, by adopting a multielement foaming agent system, i.e., the foaming agent contains a variety of components, and the swelling effect of the methylformate is weakened by the characteristics of different foaming agents; secondly, by adding the toluene diisocyanate and the prepolymers thereof into the polyisocyanates in the component A, the strength of foam products can be improved.

Owner:HEFEI HUALING CO LTD +2

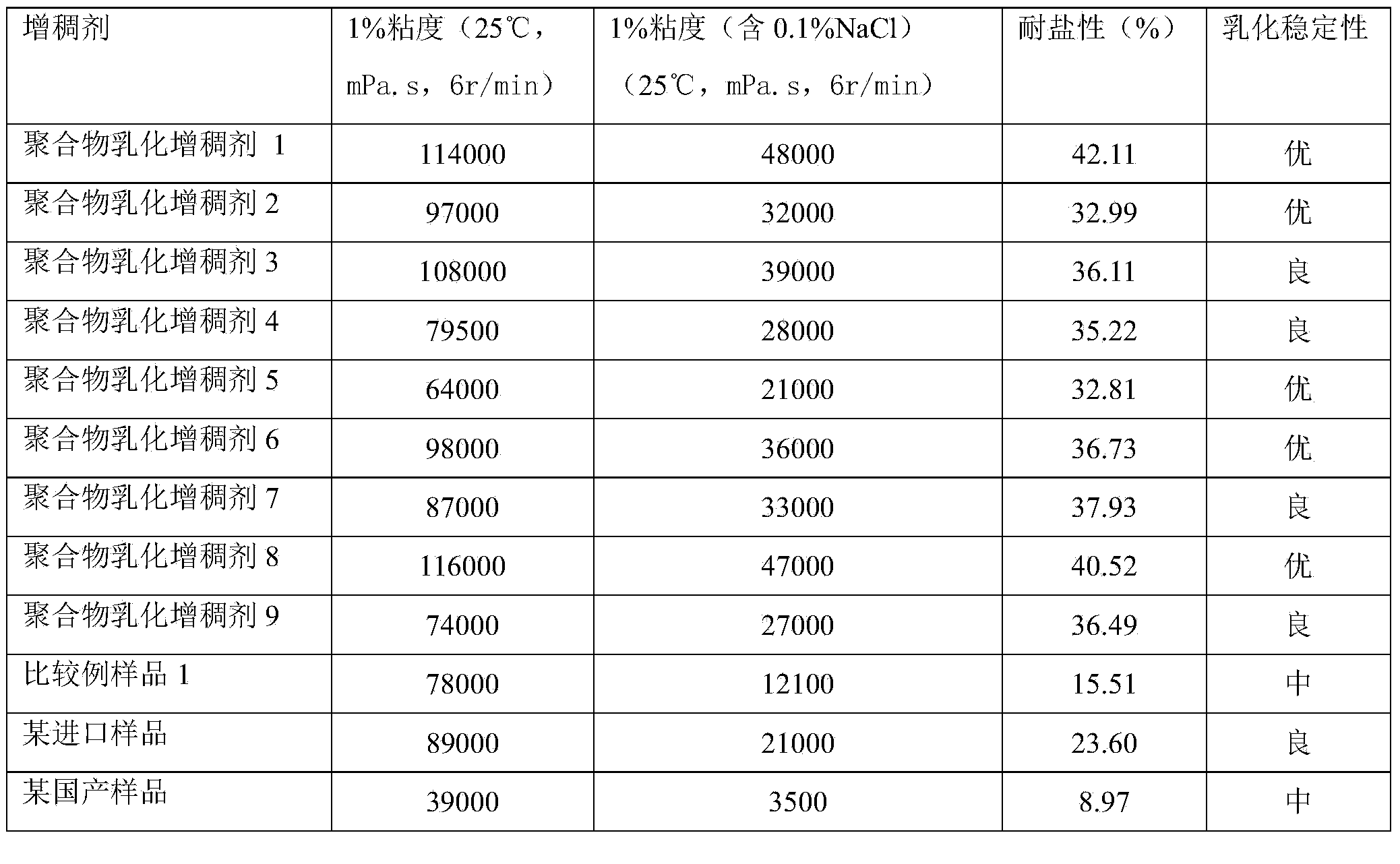

Polymer emulsifying and thickening agent and preparation method thereof

The invention discloses a polymer emulsifying and thickening agent and a preparation method thereof. The polymer emulsifying and thickening agent contains a plurality of polymerization monomers, wherein each polymerization monomer contains the following components in percentage by mass: 30.0-99.9% of anionic monomers and 0.1-10.0% of amphoteric cationic monomers; the anionic monomers are one or at least two selected from acrylic acid, methacrylic acid and 2-acrylamide-2-methylacrylsulfonate; the amphoteric cationic monomers are one or at least two selected from N, N-dimethyl-N-dodecyl methylallyl ammonium chloride, N, N-dimethyl-N-tetradecyl methylallyl ammonium chloride, N, N-dimethyl-N-dodecyl allyl ammonium chloride and N, N-dimethyl-N-dodecyl tetradecyl allyl ammonium chloride; and the weight-average molecular weight of the polymer emulsifying and thickening agent is 2000-6000 thousands. The polymer emulsifying and thickening agent is good in thickening and emulsifying effects and salt resistance, high in swelling speed and low in preparation cost and can be produced on a large scale.

Owner:广州星业科技股份有限公司

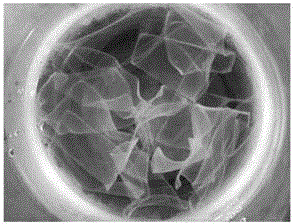

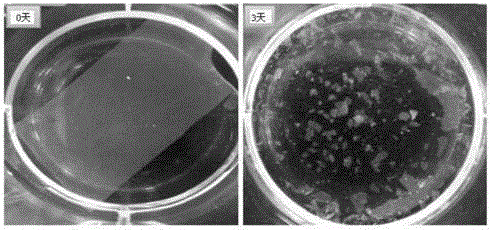

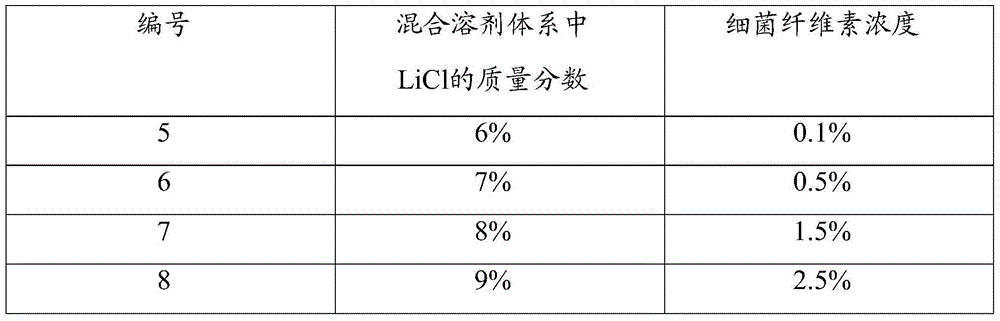

Transparent reproductive bacterial cellulose reproductive membrane as well as preparation method and application thereof

ActiveCN104587516AHigh crystallinityStrong intermolecular forcesAbsorbent padsProsthesisLithium chlorideCellulase

The invention provides a transparent reproductive bacterial cellulose reproductive membrane. The crystallinity of the transparent reproductive bacterial cellulose reproductive membrane is not more than 40%; the transparent reproductive bacterial cellulose reproductive membrane comprises the bacterial cellulose and a cellulase dispersed in the bacterial cellulose, wherein the mass ratio of the cellulase to the bacterial cellulose is 1:(10-100). The invention also provides a preparation method and application of the transparent reproductive bacterial cellulose reproductive membrane. The preparation method of the transparent reproductive bacterial cellulose reproductive membrane comprises the steps of to dissolving the bacterial cellulose by adopting an N, N-dimethylacetamide / lithium chloride mixed dissolving system, after reproducing the membrane, compounding the cellulase, thereby obtaining the degradable reproductive bacterial cellulose reproductive membrane with good transparency.

Owner:SHENZHEN INST OF ADVANCED TECH

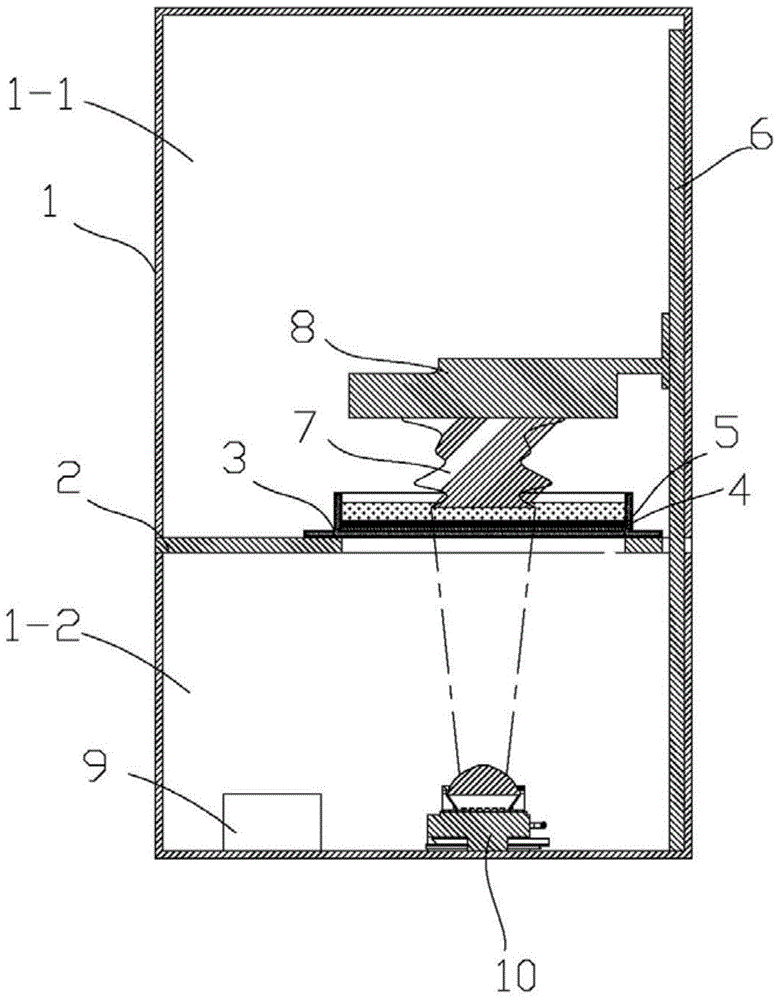

Printing method adopting photo-curing 3D printer and 3D printing system

ActiveCN104890246AHigh forming precisionStrong intermolecular forcesAdditive manufacturing apparatusThin layerIntermolecular force

The invention provides a printing method adopting a photo-curing 3D printer. The printing method comprises a single-layer printing step: setting of cross section patterns; setting of a scanning area; rotation display; irradiation curing. According to the printing method adopting the photo-curing 3D printer, liquid photosensitive resin has certain viscosity, so that the locally cured part can apply larger intermolecular force to the liquid photosensitive resin, the liquid photosensitive resin is pulled to formed thin layers and gaps in the bottom of a photosensitive resin tank, and follow-up photo-curing is facilitated. Thus, the printing method has the high forming precision and the high forming speed 20-100 times that of an existing printing method.

Owner:广西玉林市由你造科技有限公司

Aliphatic polyester-nano hydroxyapatite composite material and preparation method thereof

The invention belongs to the field of preparation of a nano composite material, and especially relates to an aliphatic polyester-nano hydroxyapatite composite material and a preparation method thereof. The preparation method comprises the following steps: 1) employing coprecipitation and a hydrothermal method or a sol-gel / static spinning method, synthesizing a hydroxy apatite nano rod or nano fiber, 2) realizing surface cladding modification on nano hydroxy apatite through dopamine oxidation auto-polymerization; and 3) employing a solution blending method, the aliphatic polyester / nano hydroxy apatite composite material film or a porous support can be prepared. The method has advantages of mild modification condition, simple operation, and obvious modification effect, the aliphatic polyester-coated hydroxy apatite is uniformly dispersed in an aliphatic polyester matrix, interface bonding property is improved, the mechanical properties of the aliphatic polyester-coated hydroxy apatite composite material is obviously improved, and the composite material can be used in relative filed of bone tissue regeneration restoration.

Owner:BEIJING UNIV OF CHEM TECH

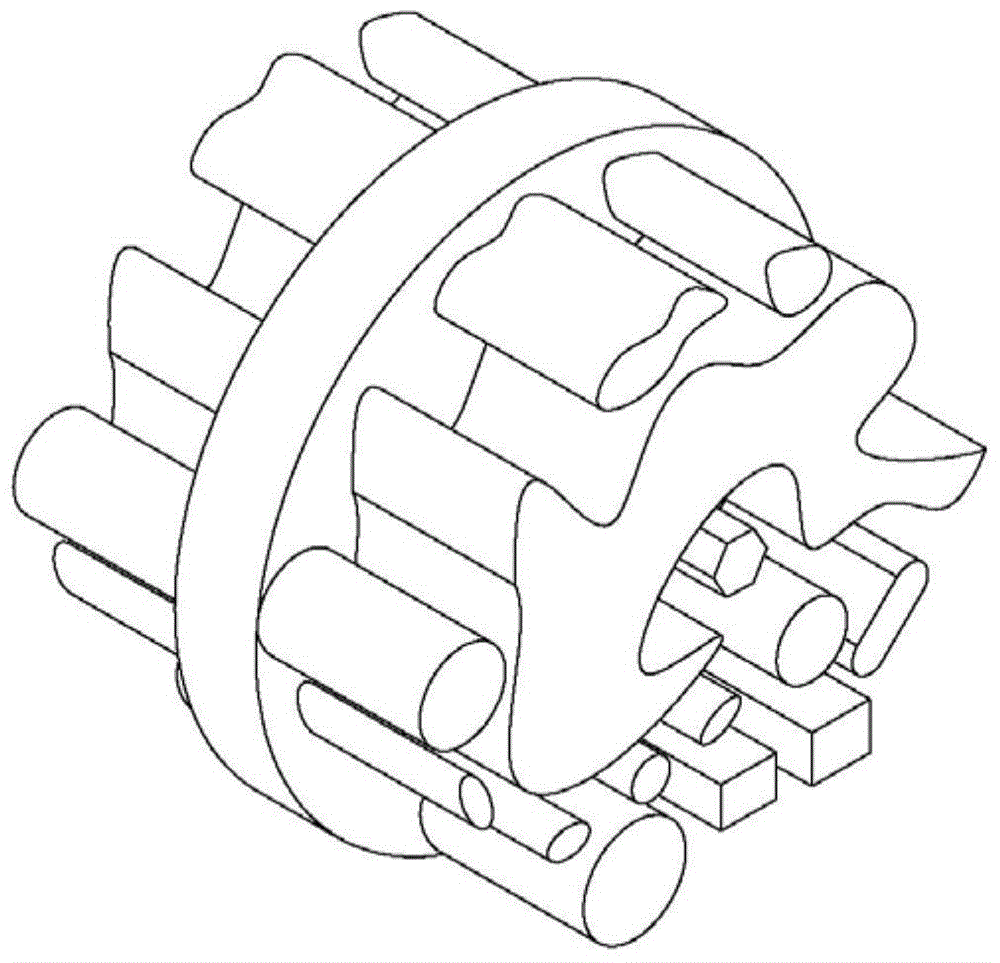

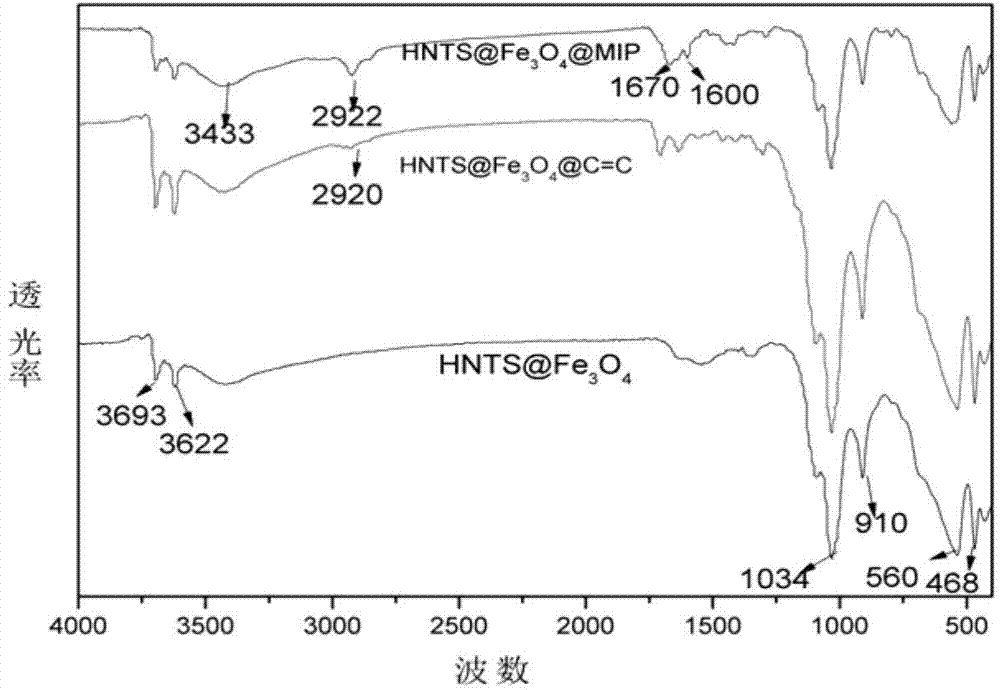

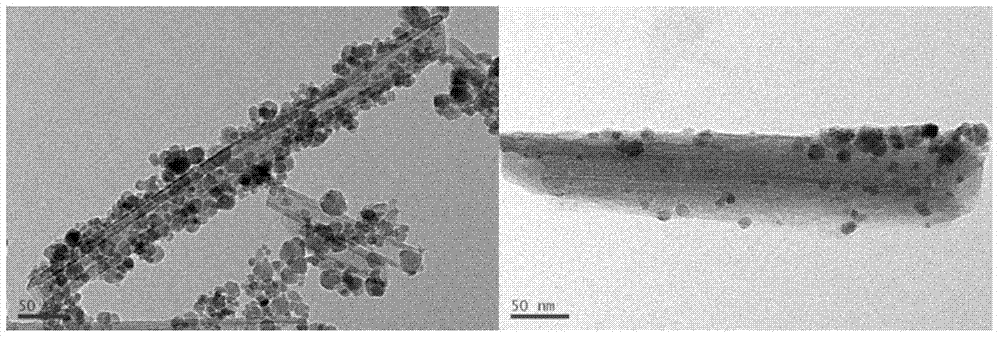

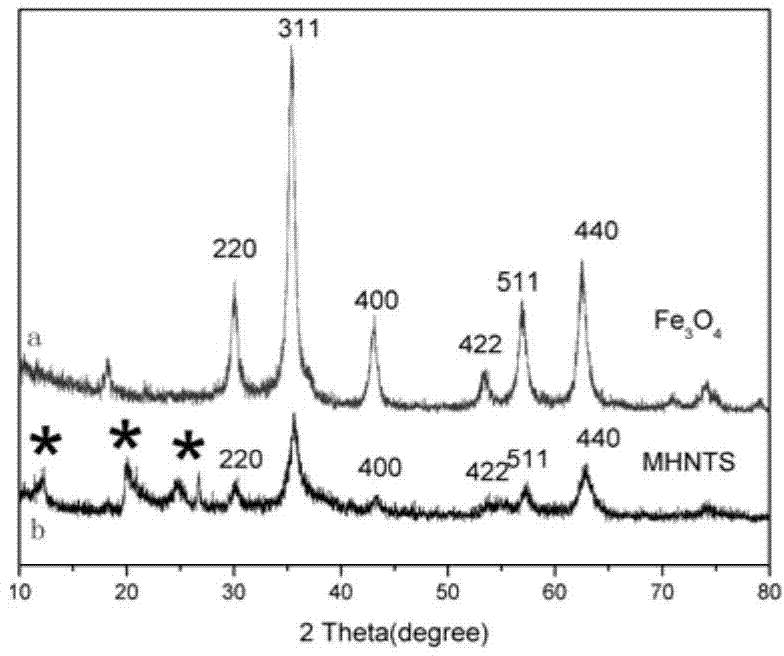

Method for preparing magnetic halloysite molecularly imprinted polymer with specific adsorption to 2,4-dichlorophenoxyacetic acid

The invention discloses a method for preparing a magnetic halloysite molecularly imprinted polymer with specific adsorption to 2,4-dichlorophenoxyacetic acid. The preparation method comprises the following steps: preparing magnetic halloysite nano-tubes by using corroded halloysite nano-tubes by a coprecipitation method; reacting the magnetic halloysite nano-tubes and methacrylate in methylbenzene to obtain magnetic halloysite nano-tubes with double-bond-modified surfaces; after polymerizing the magnetic halloysite nano-tubes with double-bond-modified surfaces, the polymerized monomers and a crosslinker by taking the 2,4-dichlorophenoxyacetic acid as a template, then removing the 2,4-dichlorophenoxyacetic acid to obtain the magnetic halloysite molecularly imprinted polymer with specific adsorption to the 2,4-dichlorophenoxyacetic acid. The raw materials used in the preparation method are low in cost; the preparation method is easy to operate and easy to implement; the prepared magnetic halloysite molecularly imprinted polymer is stable in structure, has specific adsorption to the 2,4-dichlorophenoxyacetic acid, and can effectively separate and remove the 2,4-dichlorophenoxyacetic acid from a complex system.

Owner:CENT SOUTH UNIV

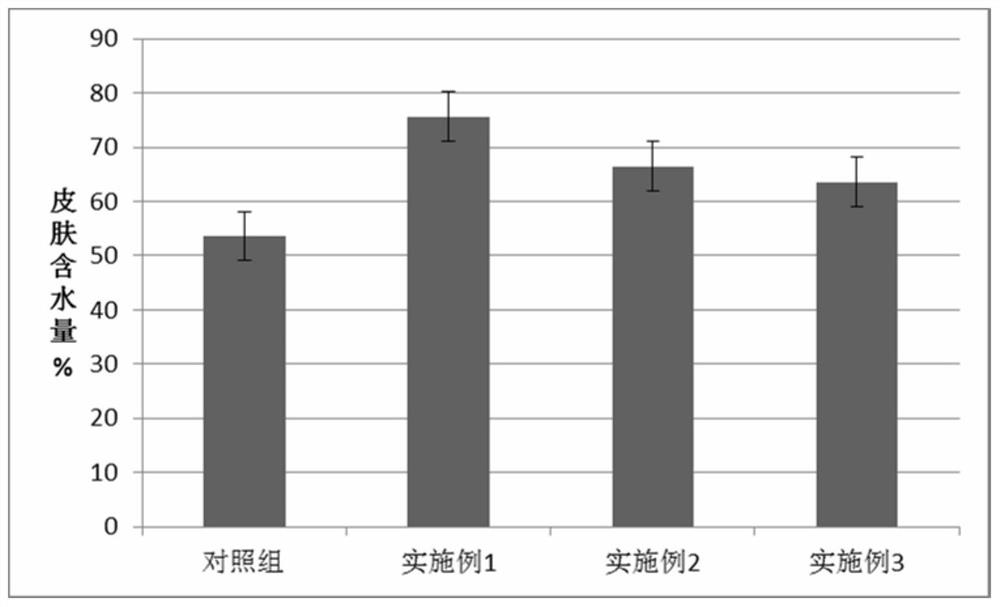

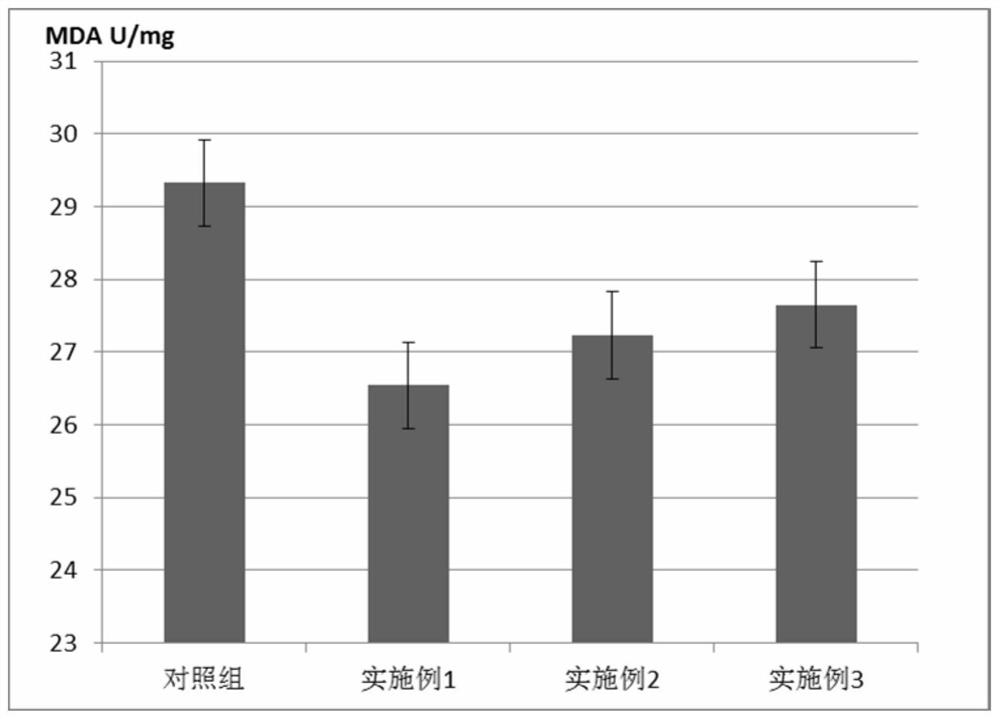

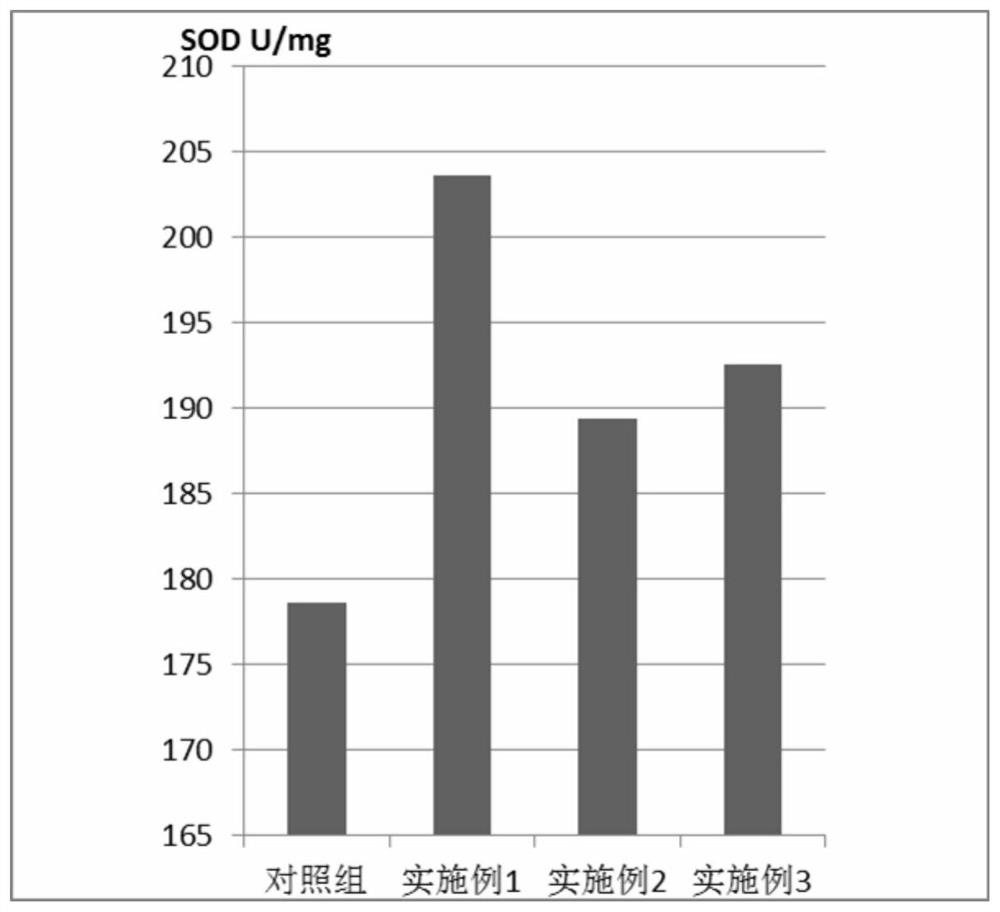

Hyaluronic acid composite polypeptide beverage and preparation method thereof

ActiveCN112998168AIncrease SOD activityGood flexibilityNatural extract food ingredientsFood ingredient functionsBiotechnologyFruit juice

The invention relates to the field of preparation of health-care drinks, and discloses a hyaluronic acid composite polypeptide drink and a preparation method thereof. The hyaluronic acid composite polypeptide beverage comprises the following components in percentage by weight: 0.01%-0.05% of fish collagen peptide, 5%-10% of litchi concentrated juice, 5%-15% of high fructose corn syrup, 0.1%-0.2% of a plant extract, 0.1%-0.3% of fruit juice powder, 0.01%-0.05% of olive powder, 0.01%-0.05% of inulin and the balance of a liquid solvent. The liquid solvent is a mixed solution of sodium hyaluronate and chitosan. The liquid solvent contains the following components in percentage by weight: 0.2%-0.5% of sodium hyaluronate and 0.1%-1.0% of chitosan. The beverage disclosed by the invention can achieve the effects of supplementing individual nutrition, improving skin moisture and delaying skin aging.

Owner:绿优品(福建)健康科技研发中心有限公司

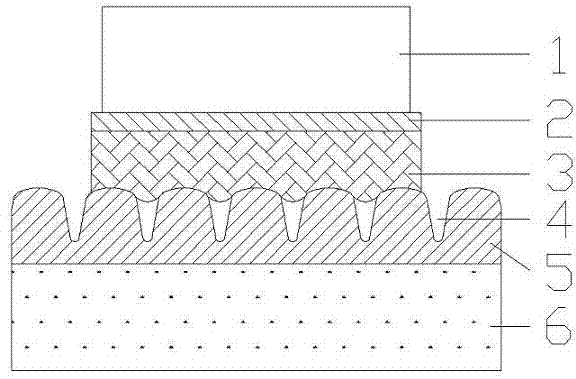

Metal-based circuit board with ultrahigh heat-conducting property and preparation method thereof

ActiveCN103118487AImprove adhesionHigh peel strengthConductive pattern formationCircuit susbtrate materialsHeat conductingEngineering

The invention discloses a metal-based circuit board with ultrahigh heat-conducting property. The circuit board comprises a base material layer, a composite heat-conducting insulating layer attached to the surface of the base material layer, and a conducting circuit layer printed by a printed electronics technology, wherein the composite heat-conducting insulating layer comprises a substrate layer and an insulating layer; the upper surface of the substrate layer is attached to the insulating layer; and the lower surface of the substrate layer is attached to the surface of the base material layer. The invention also discloses a preparation method for the metal-based circuit board with the ultrahigh heat-conducting property. By the metal-based circuit board with the ultrahigh heat-conducting property, the defects of low breakdown voltage resistance and peel strength, non-uniform thickness of a conducting circuit, and the like are overcome while the heat transfer requirement is met.

Owner:南京安迪工业科技有限公司

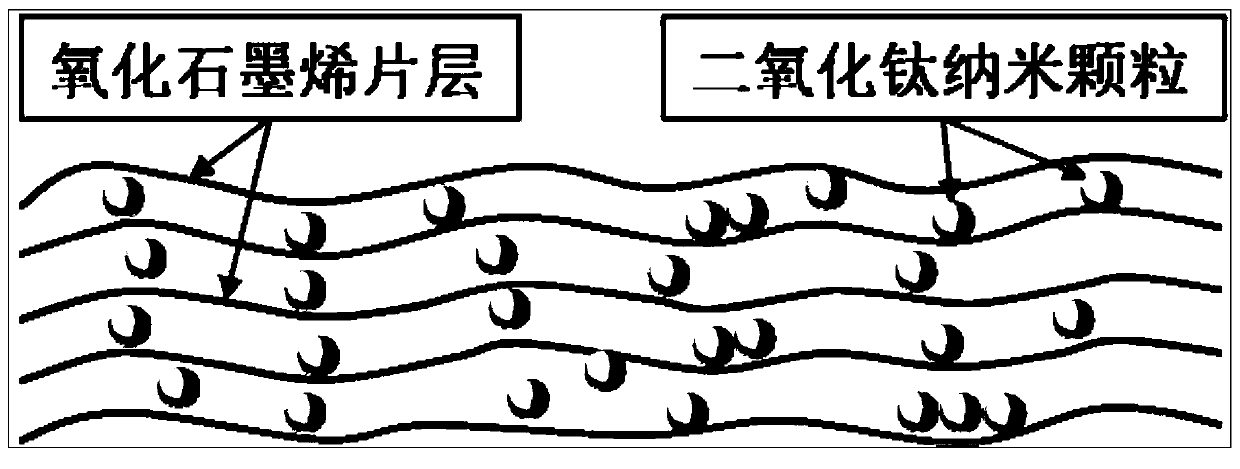

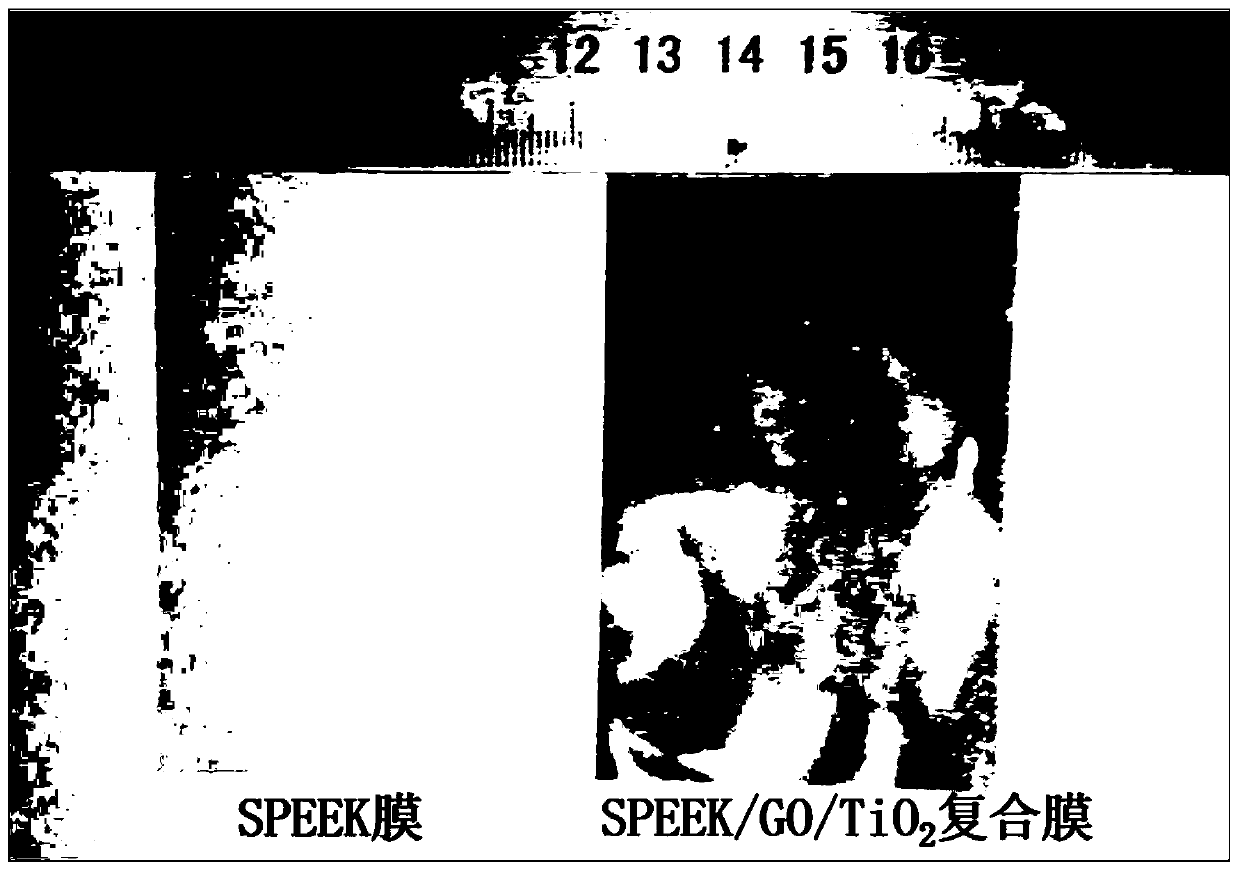

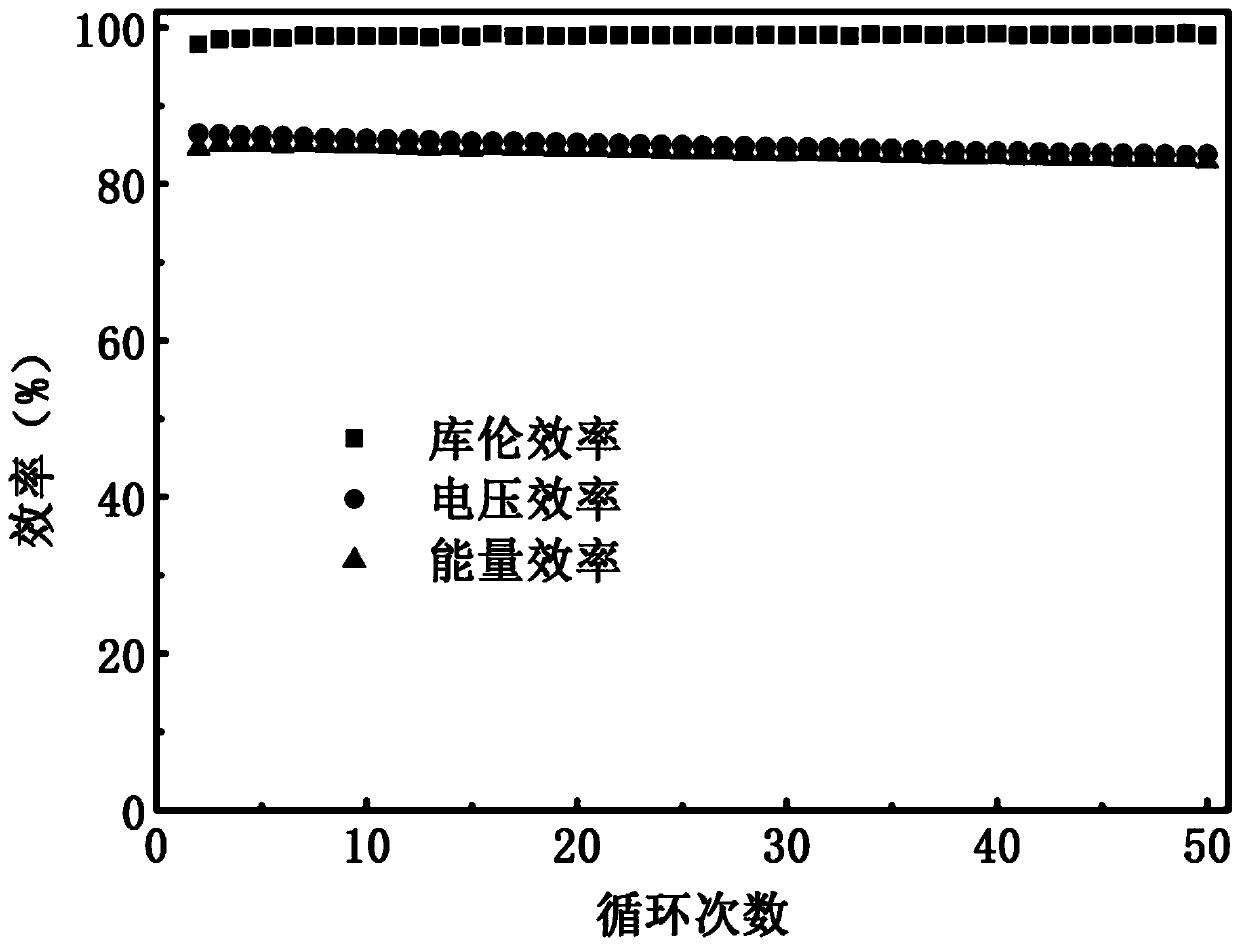

Preparation method for selecting SPEEK/GO/TiO2 composite ion selection membrane in nanometer insertion layer

ActiveCN110350223AImprove conductivityImprove conduction abilityRegenerative fuel cellsVanadium redox batteryIon permeation

The invention relates to the field of a diaphragm for an all-vanadium oxygen-reduction redox flow battery, in particular to a preparation method for selecting a sulfonated polyetheretherketone / graphene oxide / titanium dioxide nanometer particle composite ion selection membrane in a nanometer insertion layer. By the preparation method, the problems of vanadium ion permeation seriousness, poor ion selectivity and high cost of a proton exchange membrane in an existing commercial diaphragm are solved. The low-cost sulfonated polyetheretherketone (SPEEK) is used as a base film, a graphene oxide / titanium dioxide nanometer particle (GO / TiO2) insertion layer composite material is used for controlling an ion selection conduction passage, and the SPEEK / GO / TiO2 composite ion selection membrane is prepared by a film formation method such as dispersion step by step and solution pouring. The composite ion selection membrane prepared by the invention has the advantages of favorable ion selection conductivity, excellent vanadium ion blocking performance, favorable mechanical property, chemical stability and excellent single VRB battery performance and the like and is widely applied to the field ofthe all-vanadium oxygen-reduction redox flow battery.

Owner:山东奥德储能科技有限公司

Self-repairing graft copolymer based on hydrogen bond action and preparation method of self-repairing graft copolymer

The invention discloses a self-repairing graft copolymer based on a hydrogen bond action and a preparation method of the self-repairing graft copolymer and belongs to the technical field of polymer materials. The preparation method comprises the following steps: 1) preparing a polymer macromonomer of which the end group is provided with double bonds; and 2) preparing the self-repairing graft copolymer, namely carrying out a free radical polymerization reaction on a second monomer and the polymer macromonomer of which the end group is provided with the double bonds in the step 1) under the action of a free radical polymerization initiator to prepare the self-repairing graft copolymer with a "comb-type" structure or a "centipede-type" structure or a "three-chain-type" structure or a "barbed-wire-type" structure. The self-repairing graft copolymer has relatively good thermodynamic properties and a self-repairing function.

Owner:WUHAN TEXTILE UNIV

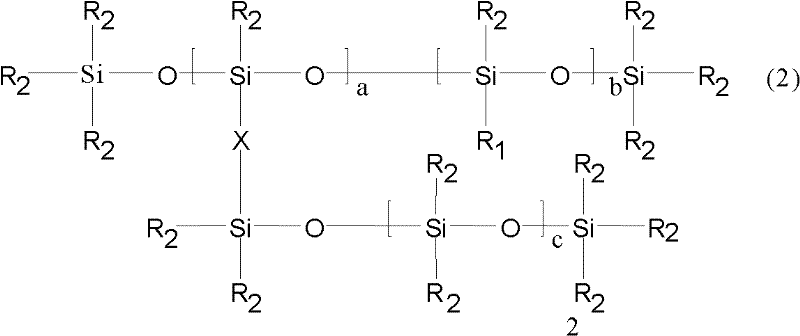

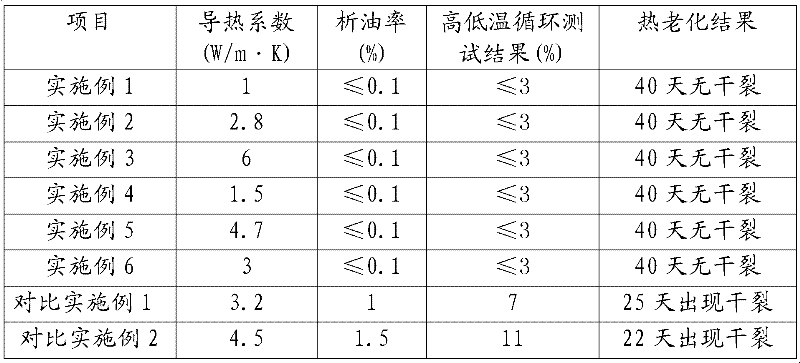

Macromolecule heat conduction material and preparation method thereof

InactiveCN102532902ALow costExcellent dielectric propertiesHeat-exchange elementsElectricityMaterials science

The invention relates to a macromolecule heat conduction material, which is composed of matrix resin and a heat conduction filler. The weight ratio of the matrix resin and the heat conduction filler is 100: 300-1100. A preparation method of the macromolecule heat conduction material is further disclosed. Heat conductivity coefficient of the long-wetting macromolecule heat conduction material is adjustable in 1-6.0W / m.K, the macromolecule heat conduction material can be used for heat dissipation of high-power electronic products, can be used for design and development of civil electronic products in a large amount, is low in cost and good in dielectric performance, and simultaneously has insulation and sealing effects.

Owner:YANTAI DARBOND TECH

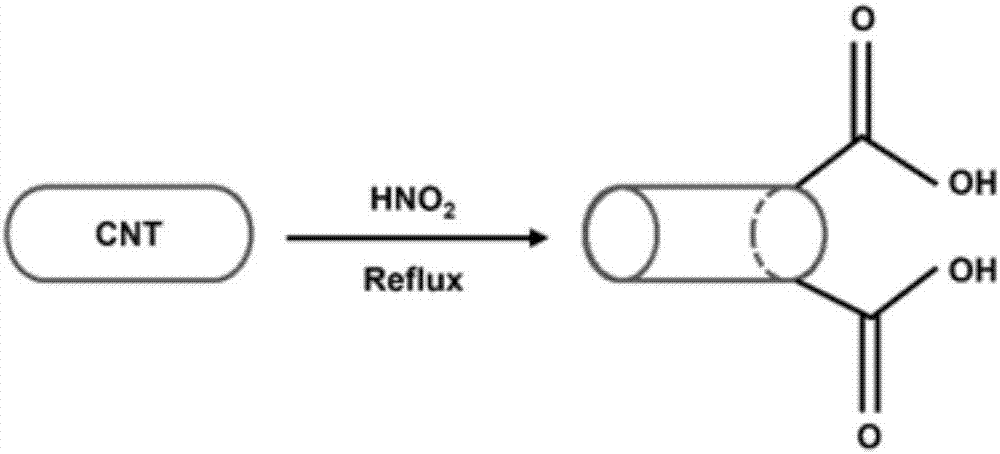

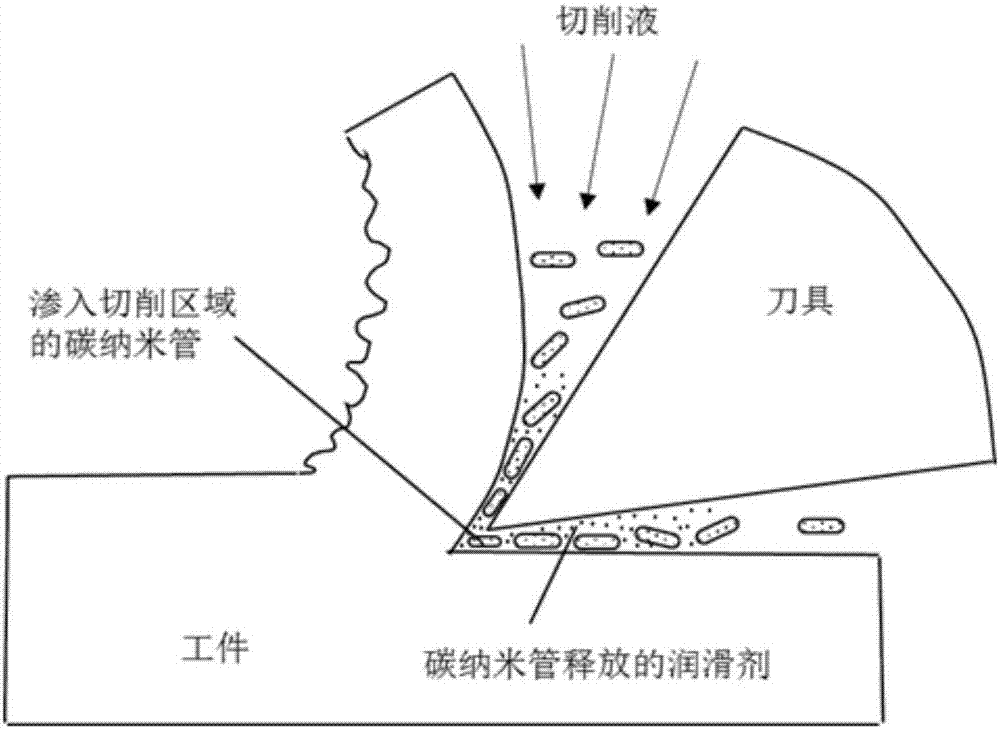

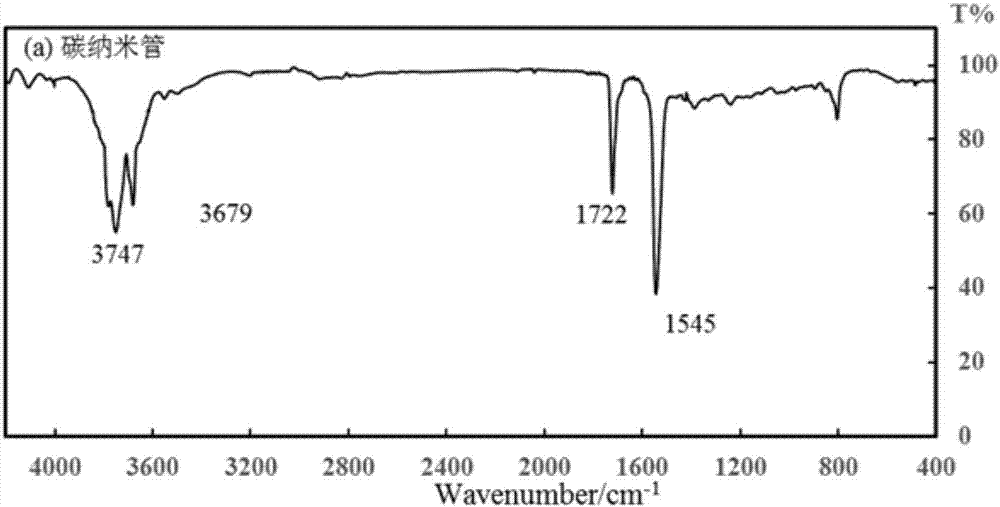

Water-based nano-fluid cutting fluid prepared via adding of carbon nanotube compound, and preparation method thereof

InactiveCN107353990AImprove thermal conductivityImprove dispersion stabilityLubricant compositionSolubilityWater based

The invention belongs to the technical field of cutting fluid, and discloses a water-based nano-fluid cutting fluid prepared via adding of a carbon nanotube compound, and a preparation method thereof. The water-based nano-fluid cutting fluid comprises, by mass, 0.5 to 2% of the carbon nanotube compound, 1 to 2% of methyl stearate, 0.5% of sodium dodecyl benzene sulfonate, 0.5% of OP-10, 1 to 2% of sodium benzoate, 0.5% of 2-n-octy1-4-isothiazoline-3-one, 1% of triethanolamine, 0.1 to 0.5% of disodium ethylene diamine tetraacetate, and the balance deionized water. The carbon nanotube compound is a one-dimensional nanocomposite prepared via adding a lubricant additive into the cavity of carbon nanotube obtained via acidifying treatment. According to the preparation method, the carbon nanotube compound is taken as an additive of the water-based nano-fluid cutting fluid, so that cutting fluid thermal conductivity is improved; the carbon nanotube compound possesses certain dissolvability and excellent dispersibility in the cutting fluid, so that the lubrication performance of the water-based nano-fluid cutting fluid is improved. The water-based nano-fluid cutting fluid is used for processing, workpiece quality is improved at same working conditions, cutter wearing is reduced, and cutting fluid quality is increased.

Owner:SUZHOU INST OF INDAL TECH

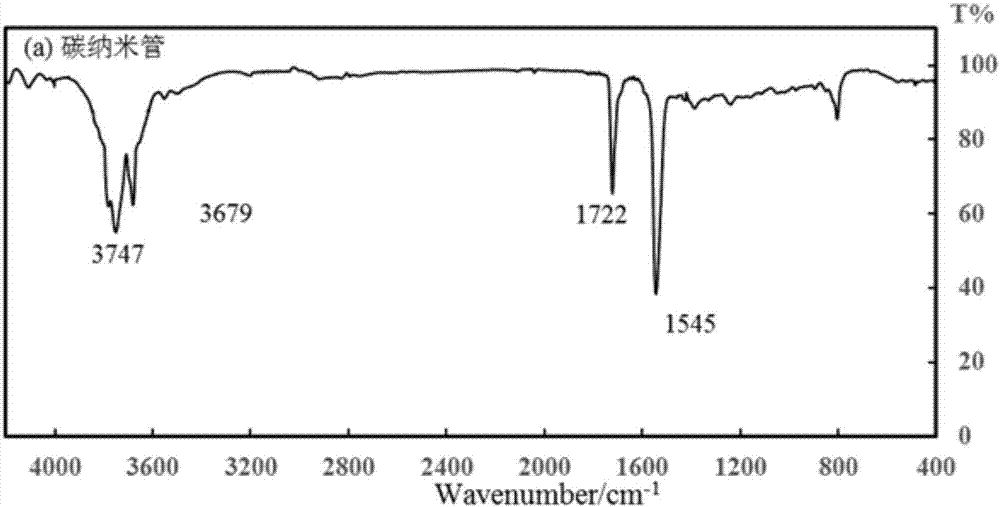

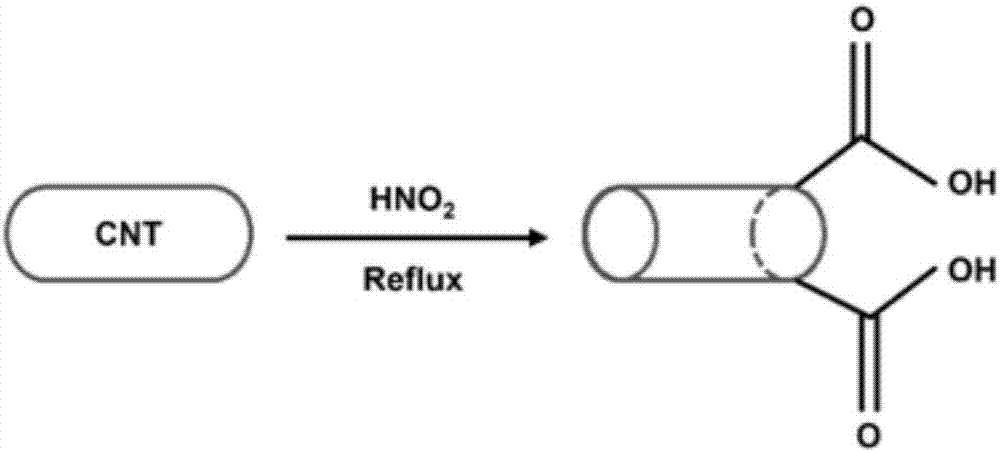

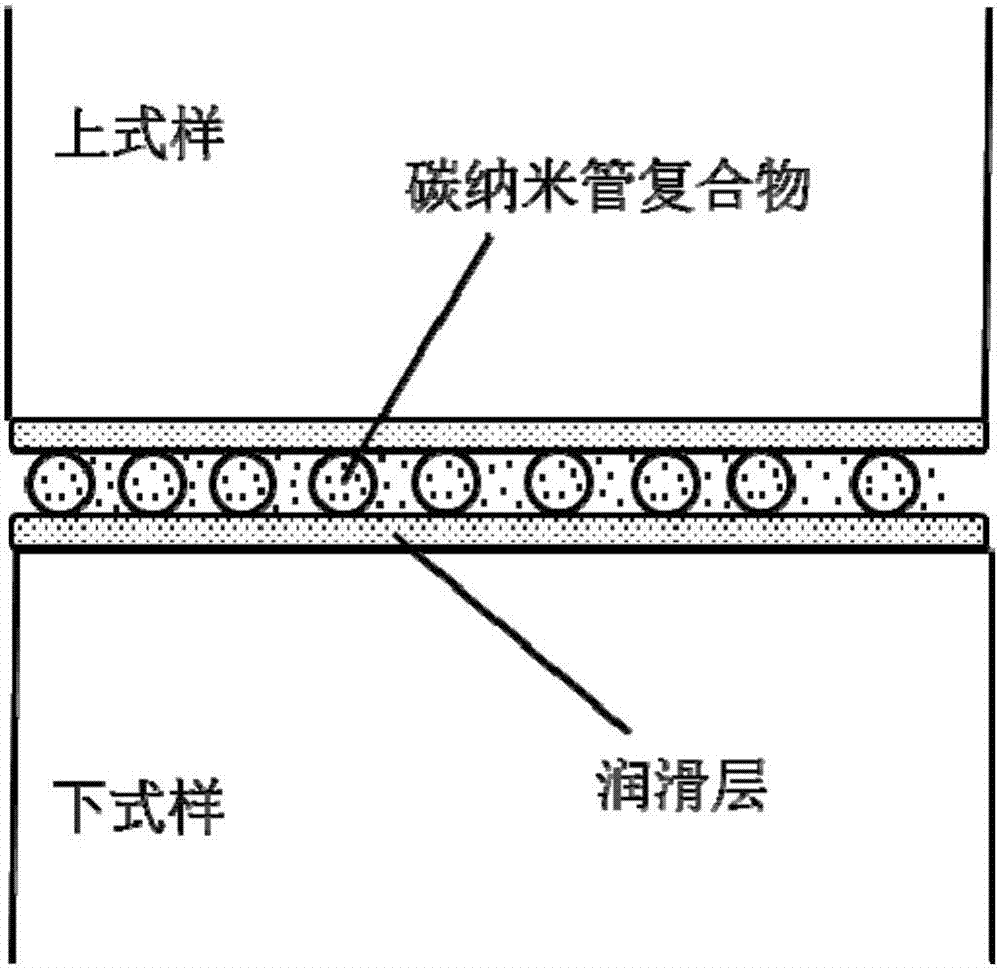

Carbon nano tube complex filled with lubricant additive as well as preparation method and application of carbon nano tube complex

InactiveCN107287003AImprove dispersion stabilityImprove the lubrication effectAdditivesNanometreCompound s

The invention belongs to the technical field of lubricants and discloses a carbon nano tube complex filled with a lubricant additive and a preparation method of the carbon nano tube complex. The complex is a one-dimensional nano composite material obtained by filling an oiliness additive or an extreme pressure additive into inner cavities of carbon nano tubes subjected to acidizing treatment, and the complex comprises 80-90 parts of carbon nano tubes and 10-20 parts of the oiliness additive or 10-20 parts of the extreme pressure additive. The complex serving as a lubricant additive can permeate into a friction area along with base fluid. The carbon nano tubes are extruded, deformed and broken in the friction process, the lubricant additive can be released, and a lubricating film is produced through physical or chemical adsorption so as to achieve a lubricating effect, so that the antifriction, wear-resistant and extreme pressure properties of the carbon nano tubes are improved. The complex disclosed by the invention further serves as an additive of certain commercial lubricating oil. Compared with lubricating oil added with pure carbon nano tubes, the lubricating oil added with the complex according to a proper ratio has the advantages that the friction coefficient of the lubricating oil can be obviously reduced, the wear is reduced, and the maximum non-seizure load of the lubricating oil is improved.

Owner:SUZHOU INST OF INDAL TECH

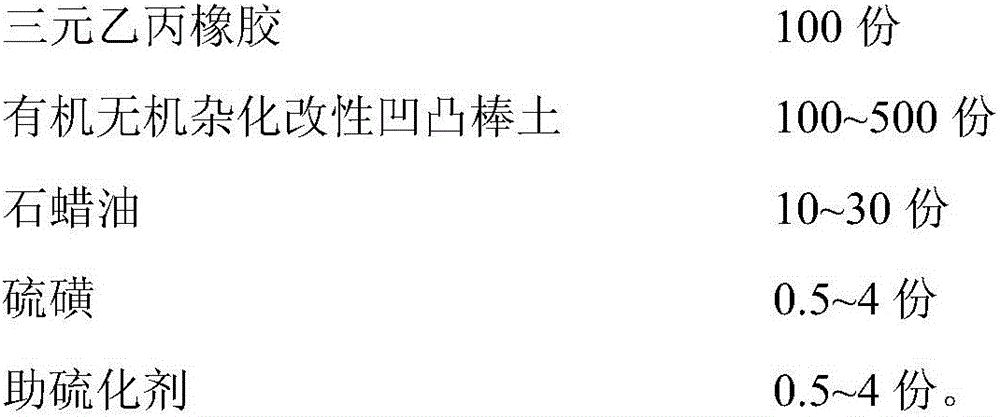

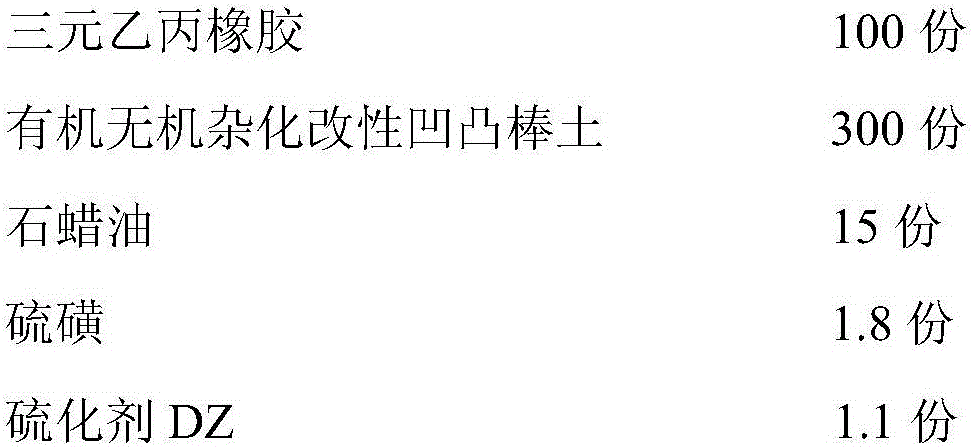

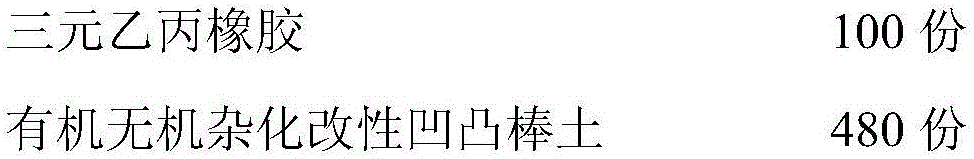

Organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite

InactiveCN106832612AIncrease filling volumeGood compatibilityEthylene-propylene-diene-monomerSilicon

The invention discloses an organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite. The invention develops a novel organic silicon coupling reagent which is combined with a silicon sol and an organic inorganic hybridized surface modified attapulgite. The novel organic silicon coupling reagent is used for filling and modifying ethylene propylene terpolymer, so that the organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite with high performance can be acquired. The organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite provided by the invention is prepared from the following raw materials in parts by weight: 100 parts of ethylene propylene terpolymer, 100-500 parts of organic inorganic hybridized modified attapulgite, 10-30 parts of paroline, 0.5-4 parts of sulphur and 0.5-4 parts of vulcanizing agent.

Owner:江苏中业登泰新材料科技有限公司

Wafer plasma cutting protection liquid, preparation method and application thereof

ActiveCN113652128AImprove thermal stabilityReduce crystallization tendencySolid-state devicesSemiconductor/solid-state device manufacturingWaferOrganosolv

The invention provides a wafer plasma cutting protection liquid, a preparation method and application thereof. The wafer plasma cutting protection liquid comprises the following components in parts by weight: 5-40 parts of a water-soluble resin, 0.1-2 parts of a wetting agent, 0.1-2 parts of a defoaming agent, 0.1-2 parts of a free radical capturing agent, 5-20 parts of an organic solvent, and 34-89.7 parts of water. The wafer plasma cutting protection liquid can quickly form a film on the surface of a wafer, and has good heat resistance and removability. During wafer processing, by using the protection liquid, condensed silicon steam or other chippings generated in the processing process can be effectively prevented from being deposited on the surface of a chip. According to the invention, the wafer plasma cutting protection liquid has high thermal stability, the situation that the surface of a wafer is directly exposed to the external environment due to the fact that a protection film is decomposed when plasma cutting is carried out under the thermal effect of laser cutting or the high working temperature can be avoided, and the reliability and the yield of products are effectively improved.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

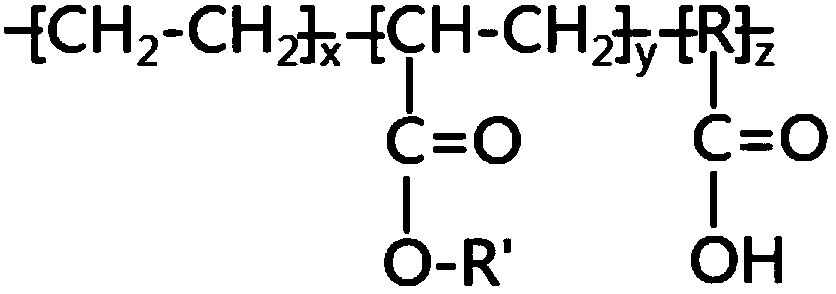

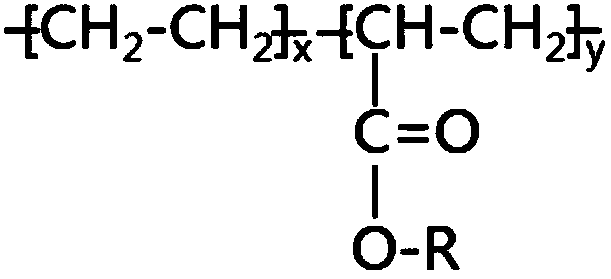

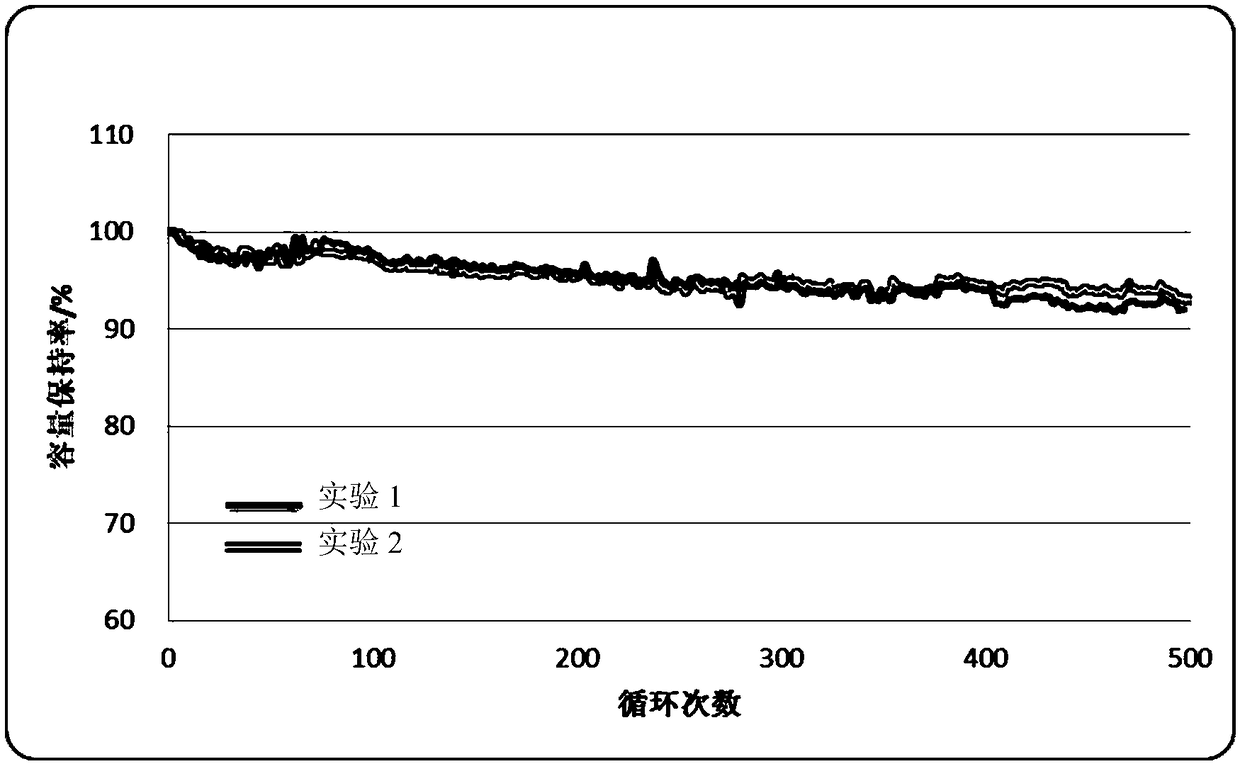

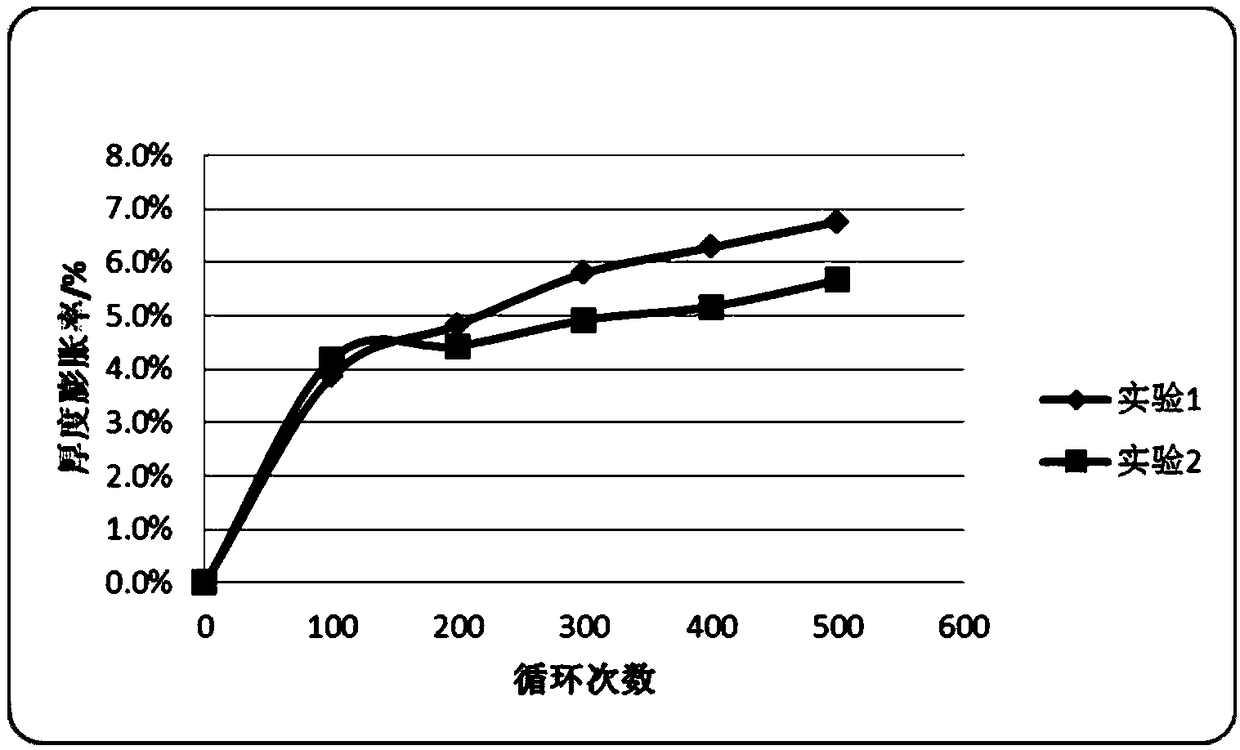

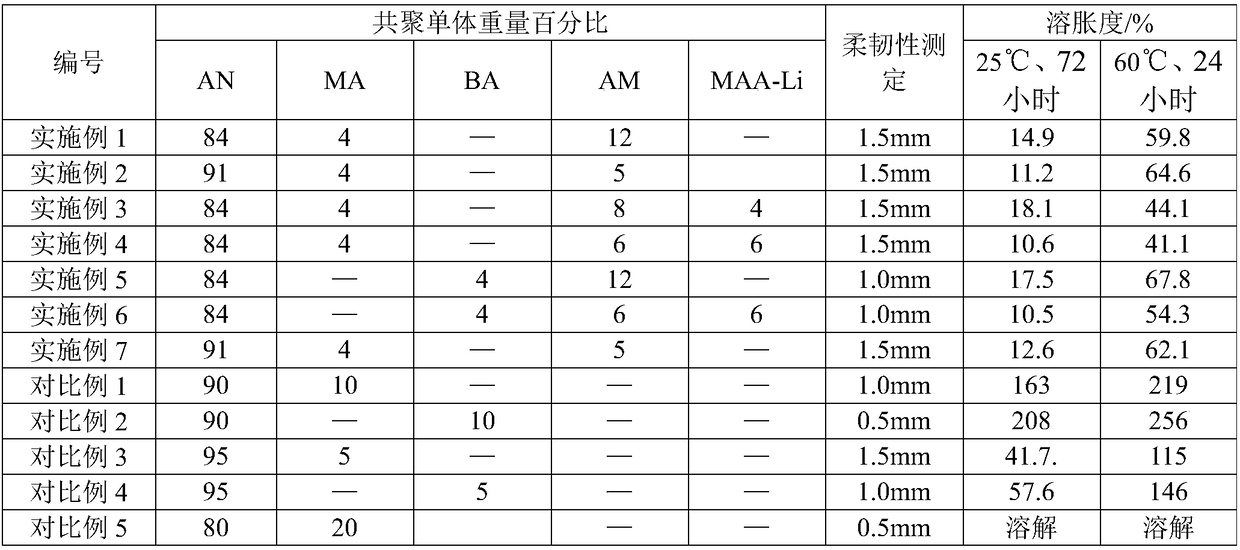

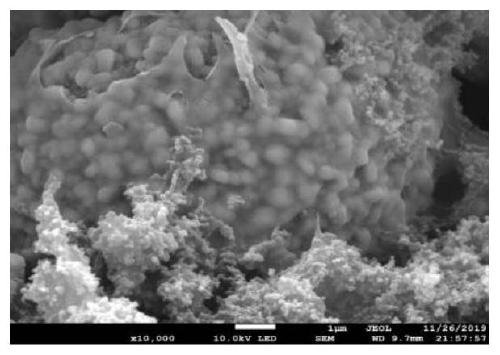

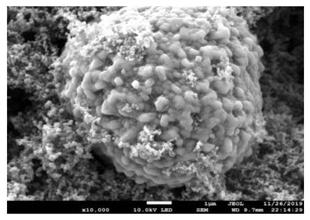

Acrylonitrile copolymer binder and its application in lithium-ion batteries

ActiveCN106220779BStrong adhesionStrong intermolecular forcesNitrile polymer adhesivesSecondary cellsAdhesiveAcrylonitrile

The invention relates to an acrylonitrile copolymer binder and its application in lithium ion batteries, belonging to the field of lithium ion batteries. The technical problem solved by the present invention is to provide an acrylonitrile copolymer adhesive, the acrylonitrile copolymer adhesive comprises the following structural units in weight percentage: 78% to 95% of acrylonitrile units, 1 to 10% of acrylate units %, 2-15% of acrylamide units. The adhesive of the present invention uses acrylonitrile monomer as the main body, and adds acrylate monomer, highly polar acrylamide monomer or acrylate monomer to acrylonitrile to carry out copolymerization, thereby maintaining acrylonitrile polymerization At the same time, the strong adhesion force or intermolecular force of the substance molecules endows the polymer film with flexibility, electrolyte affinity and appropriate swelling degree in the electrolyte, so as to adapt to the electrode active material during the charging and discharging process. The volume of intercalation and extraction of lithium ions changes periodically, thereby improving the energy density and cycle performance of lithium-ion batteries.

Owner:SICHUAN INDIGO TECH CO LTD

High-temperature-resistant adhesive for lithium ion battery and battery pole piece applying the adhesive

PendingCN111403745AImprove adhesionStrong intermolecular forcesCell electrodesSecondary cellsImideAdhesive

The invention discloses a high-temperature-resistant adhesive for a lithium ion battery and a battery pole piece applying the adhesive. The preparation method comprises the following steps: adding diamine containing functional groups and dicarboxylic anhydride according to a certain ratio for solution polycondensation; preparing a polyimide precursor-polyamic acid solution with a certain concentration, uniformly mixing the polyimide precursor-polyamic acid solution with an active substance and a conductive agent, coating the surface of a current collector with the obtained mixture, and carrying out programmed heating heat treatment to make polyamic acid undergo a thermal imide cyclization reaction in order to form polyimide in order to prepare the lithium ion battery pole piece with polyimide as a binder. The polyimide adhesive containing the functional group prepared by the invention is excellent in high-temperature resistance; the polyimide adhesive is simple in preparation method and good in chemical stability, the bonding strength of the polyimide adhesive can be improved by regulating and controlling the variety and proportion of functional groups and increasing flexible chainsegments, it is guaranteed that a pole piece can be dried and dewatered at high temperature, the cycle performance and safety performance of a battery are improved, and the polyimide adhesive has wide application prospects in the field of high-temperature-resistant, high-safety and high-specific-energy lithium ion batteries.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Preparation method of Chinese herbal medicine wall-broken decoction pieces

InactiveCN111840337AImprove permeabilityGood modification effectInorganic non-active ingredientsPlant ingredientsChemical solutionMedicine

The invention provides a preparation method of Chinese herbal medicine wall-broken decoction pieces, which comprises the following steps: step 1, pretreatment of traditional Chinese medicinal materials: (1) surface modification: treating the traditional Chinese medicinal materials in a plasma box for 1-3 minutes under the conditions that the working current is 0.2-1A and the air pressure is 1-2 Mpa, and then performing proton irradiation treatment for 2-4 minutes. According to the method, the traditional Chinese medicinal materials are modified in a surface physics and solution chemistry combined mode, plasma and proton irradiation treatment is adopted for surface modification, the surface microstructure of the traditional Chinese medicinal materials can be damaged, and a basis is providedfor subsequent chemical solution modification.

Owner:广东汇群中药饮片股份有限公司

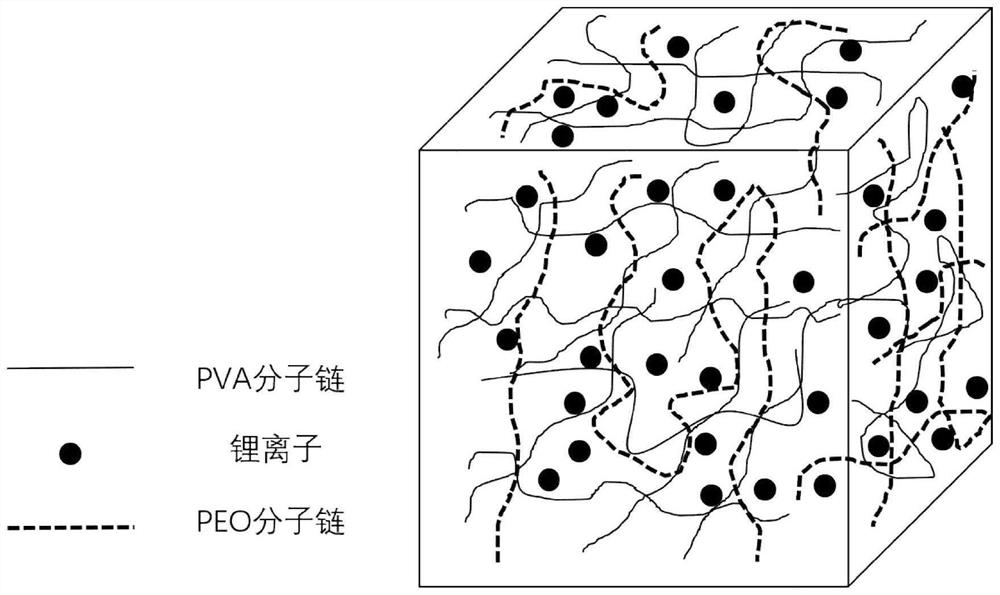

Preparation method of PVA/Li<+>/PEO interpenetrating network structure composite gel electrolyte

ActiveCN111668539AImprove complexation abilityMacromolecular chain polarityFinal product manufactureSecondary cells servicing/maintenancePolymer sciencePolyvinyl alcohol

The invention discloses a preparation method of a PVA / Li<+> / PEO interpenetrating network structure composite gel electrolyte, which comprises the steps of dissolving polyvinyl alcohol PVA in deionizedwater, and carrying out freeze crosslinking; immersing the prepared polyvinyl alcohol PVA into a lithium salt solution, and enabling lithium ions to be fully immersed into a polyvinyl alcohol PVA system; then introducing ethylene oxide EO into the PVA / Li<+> system, and carrying out ring opening polymerization and crosslinking on ethylene oxide to prepare the PVA / Li<+> / PEO interpenetrating networkstructure composite gel electrolyte; and preparing a PVA / Li<+> / PEO interpenetrating network structure composite gel electrolyte membrane, wherein the conductivity and mechanical properties of the PVA / Li<+> / PEO interpenetrating network structure composite gel electrolyte membrane are higher than those of PVA / Li<+> and PEO / Li<+> polymer electrolytes. The preparation method has great application potential in lithium batteries and air batteries.

Owner:NORTHWEST UNIV(CN)

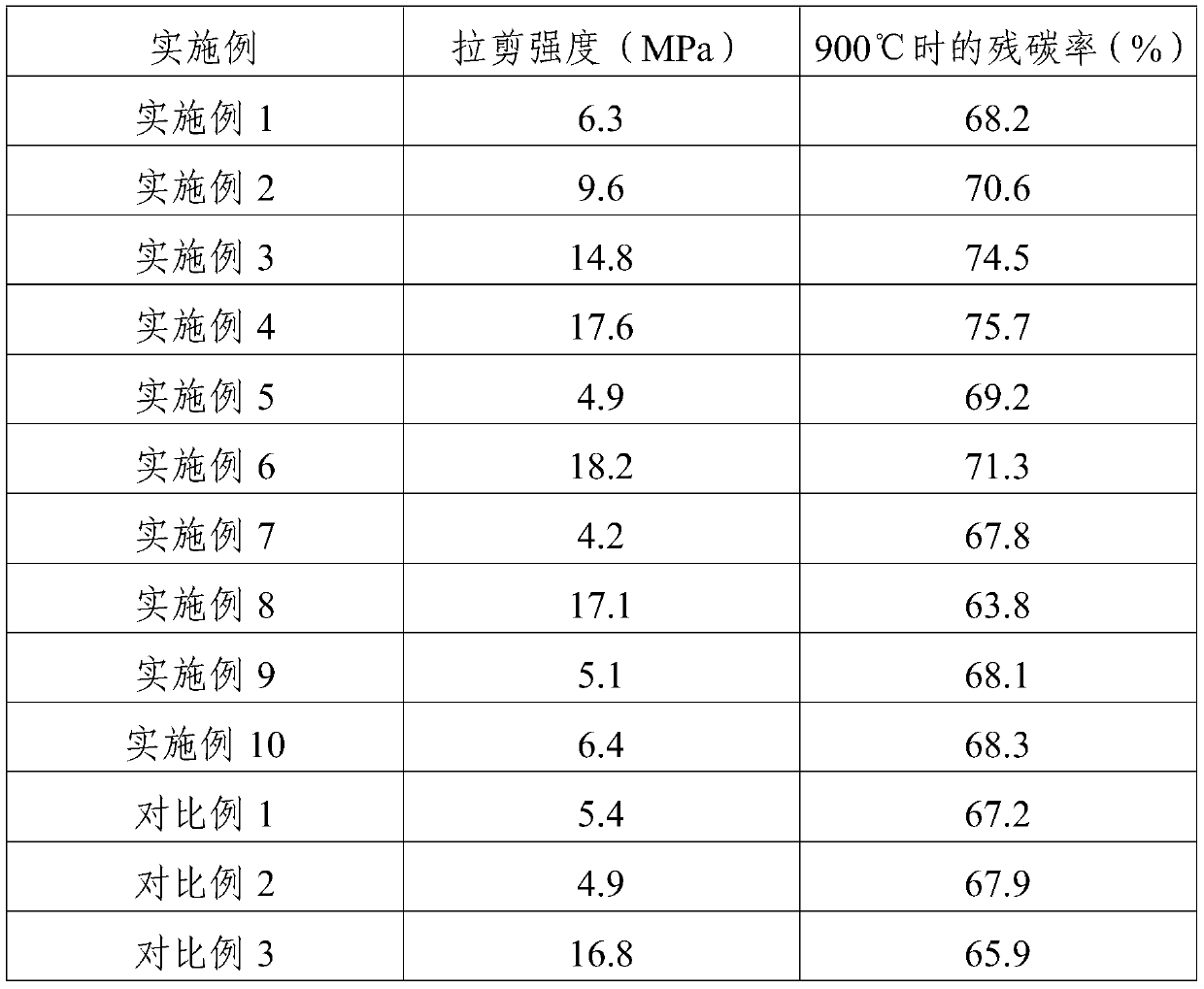

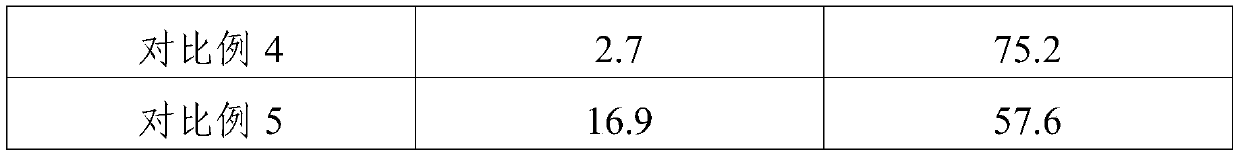

Toughening type phenolic resin and preparation method thereof

The invention relates to toughening phenolic resin and a preparation method thereof. The toughening phenolic resin is prepared from, by weight, 100 parts of phenolic resin, 30-90 parts of carboxyl-terminated butadiene-acrylonitrile rubber, 15-45 parts of zirconium diboride and 0.3-0.8 part of a dispersing agent. The preparation method comprises the steps that 0.3-0.8 part of dispersing agent is dispersed in the solvent, and a dispersion solution is obtained; 100 parts of phenolic resin, 30-90 parts of carboxyl-terminated butadiene-acrylonitrile rubber and 15-45 parts of zirconium diboride aremixed to be uniform, and a mixture is obtained; the obtained mixture is divided into multiple parts, and then the multiple parts of mixture are added in the dispersion solution in sequence and stirredand dispersed to be uniform, and the toughening phenolic resin is obtained. Accordingly, the carboxyl-terminated butadiene-acrylonitrile rubber, zirconium diboride and other fillers are adopted for modifying the phenolic resin, and on the premise that it is guaranteed that the anti-ablation property of the toughening phenolic resin is not reduced, the problem that interface debonding occurs aftera resin-based composition material and a metal cabin are integrally formed is solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

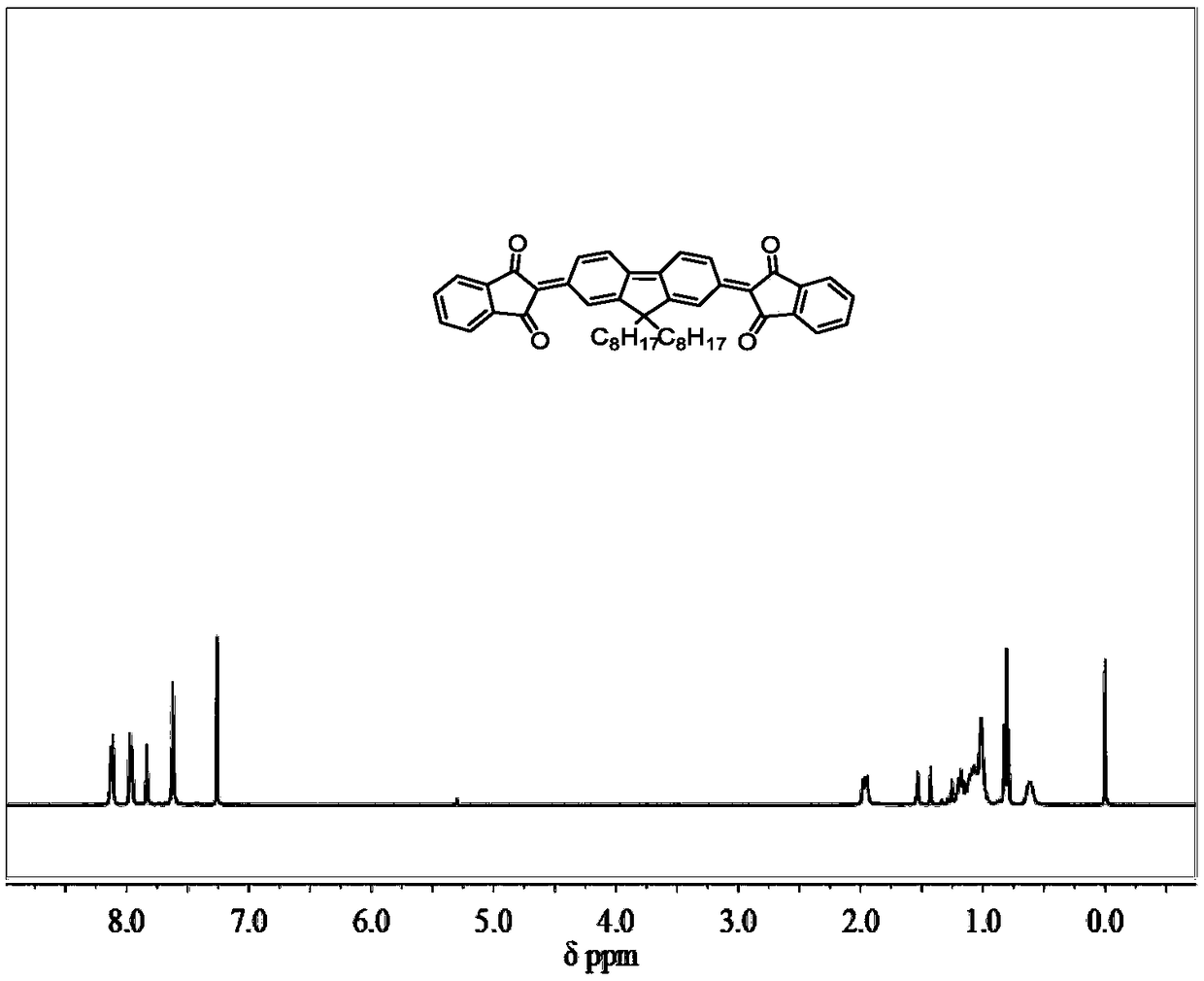

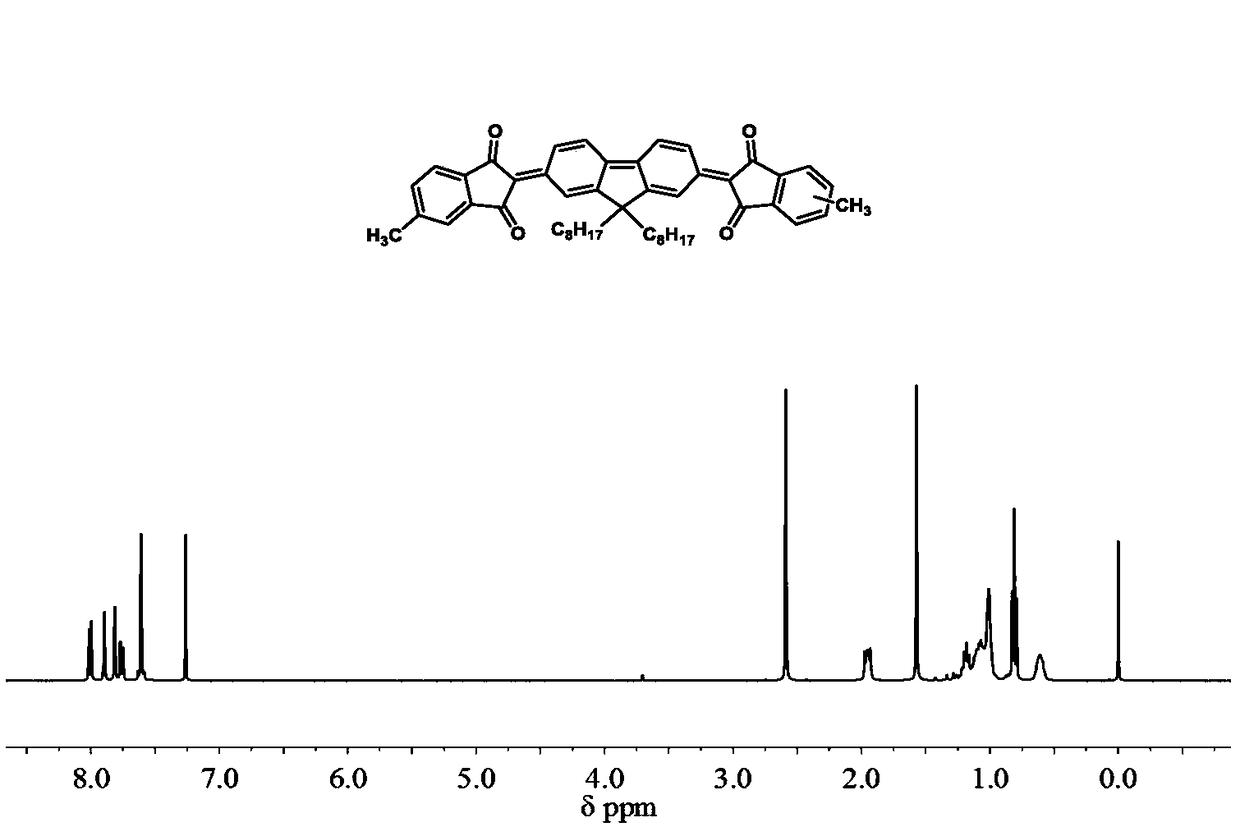

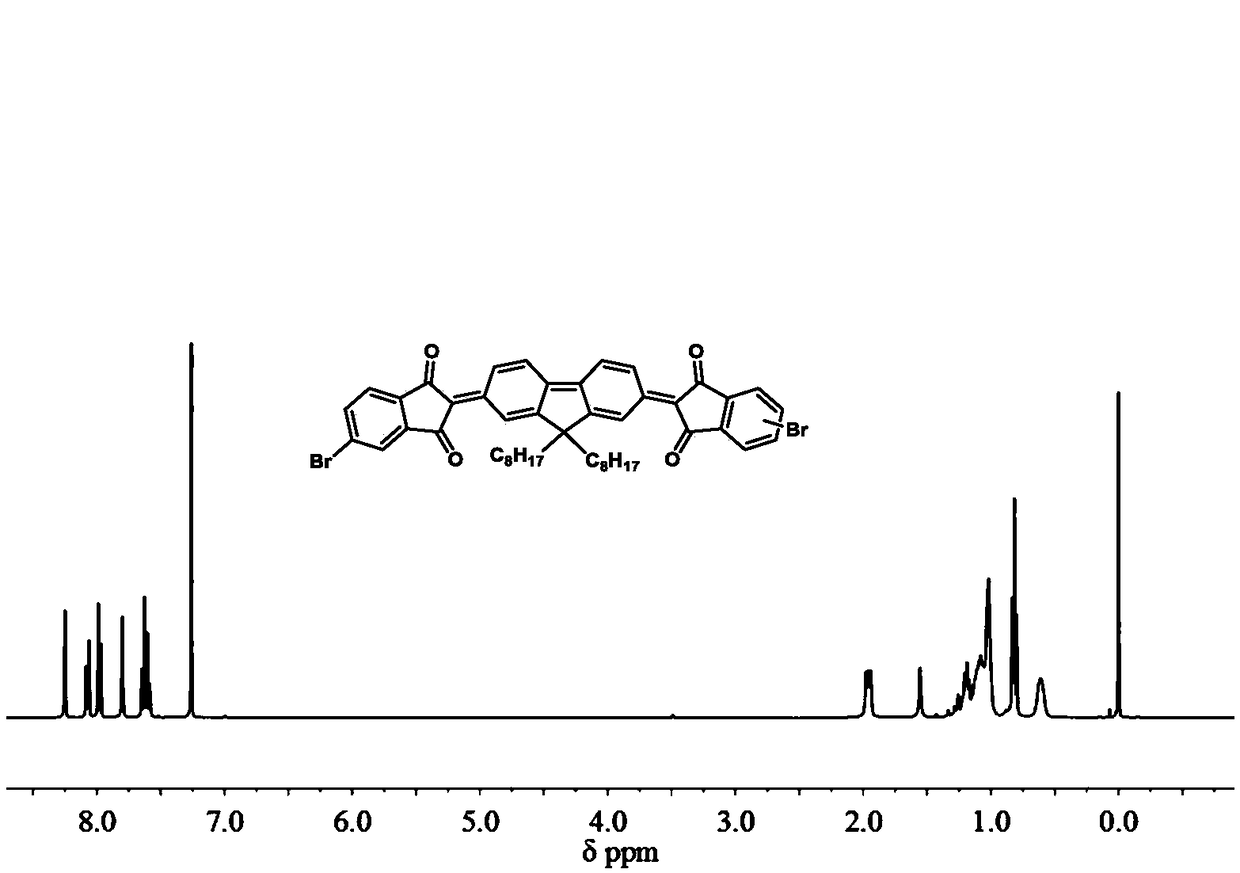

Quinoid compounds and preparation method and applications thereof

ActiveCN108774119AGood planarityLower LUMO levelOrganic compound preparationSolid-state devicesOrganic solar cellSemiconductor materials

Quinoid compounds and a preparation method and applications thereof are disclosed. The general structure of the compounds is shown in the description. The structures of the compounds can be easily modified, and the compounds have characteristics of good molecular skeleton planarity, high self-assembling capability, low energy level of the highest unoccupied orbit (LUMO), narrow band gaps, and insensitivity to water and oxygen, and therefore the compounds as organic semiconductor materials can greatly improve hole and electron transmission capability so that the compounds are applied as n type(electron transmitting) materials and bipolar materials (capable of transmitting holes and electrons) into organic field effect transistors, organic solar cells, perovskite solar cells, organic thermoelectric and organic light-emitting devices, and the like.

Owner:TIANJIN UNIV

Printing and scratch-resistant black thermoplastic low-smoke halogen-free flame-retardant polyolefin cable sheathing compound

ActiveCN106905593BSatisfy Reliable Bonding RequirementsStrong adhesionPlastic/resin/waxes insulatorsPolyesterPolyolefin

The invention relates to a printed wiping-resistant black thermoplastic low-smoke zero-halogen flame-retardant polyolefin cable sheathing material and belongs to the technical field of sheathing material for wire and cable. The sheathing material comprises 100 parts of matrix resin, 120 to 180 parts of flame retardant, 1.0 to 2.0 parts of polyester coupling agent, 0.03 to 0.08 parts of initiator, 1 to 3 parts of lubricant, 0.5 to 2.5 parts of antioxidant, 1.0 to 3.0 parts of surfactant, 2 to 3 parts of black masterbatch. The base resin is composed of the following raw materials in proportions, by weight: 70 to 90 parts of ethylene copolymer and 10 to 30 parts of polymer compatibilizer; the flame retardant is composed of the following raw materials in proportions, by weight: 90 to 140 parts of aluminum hydroxide and 30 to 60 parts of magnesium hydroxide. The sheathing material has the advantages that the requirements of a reliable combination of ink and sheathing surface is satisfied, an ink adhesion force is improved, a limit oxygen index of the material is enhanced, a wetting of the ink on the plastic surface is improved and a logo on the sheathing material is not easy to be wiped to remove.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com