Organic inorganic hybridized modified attapulgite ethylene propylene terpolymer composite

A technology for modifying attapulgite and EPDM rubber, which is applied in the field of EPDM rubber composite materials, can solve problems such as difficulties in realizing the industrialization of a polymerization process, and achieve good rubber rheological processing performance and good compatibility. , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using coupling agent CH 3 (CH 2 ) 15 Si(OCH 3 ) 3For attapulgite treatment, the dosage of coupling agent is 0.3% of attapulgite; for attapulgite treatment with alkaline silica sol (solid content: 25%), the dosage of alkaline silica sol is 3.5% of attapulgite. The specific treatment process is: the attapulgite is sprayed with the above-mentioned organic silicon coupling agent while stirring in a high-speed mixer, and mixed at a high speed of 95°C for 30 minutes; then sprayed with silica sol, and mixed at a high speed of 125°C for 90 minutes to obtain an organic-inorganic hybrid Modified attapulgite.

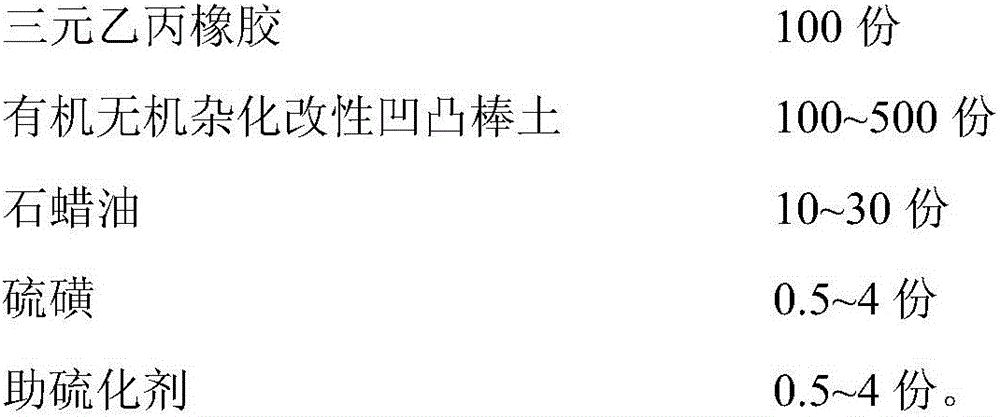

[0026] The formula of EPDM rubber material is:

[0027]

[0028] The EPDM compound of the above formula was mixed in a rubber internal mixer at room temperature for 40 minutes, and then kneaded in an open mixer to form thin slices, which were cut as required and placed in a flat mold with a thickness of 10mm. The flat mold with EPDM rubber inside is vulcanized in a...

Embodiment 2

[0030] Using coupling agent [CH 3 (CH 2 ) 17 ] 2 Si(OCH 2 CH 3 ) 2 For attapulgite treatment, the dosage of coupling agent is 0.4% of attapulgite; for attapulgite treatment with alkaline silica sol (solid content: 28%), the dosage of alkaline silica sol is 5.5% of attapulgite. The specific treatment process is: the attapulgite is sprayed with the above-mentioned organic silicon coupling agent while stirring in a high-speed mixer, and mixed at a high speed of 90°C for 30 minutes; then sprayed with silica sol, and mixed at a high speed of 115°C for 90 minutes to obtain an organic-inorganic hybrid Modified attapulgite.

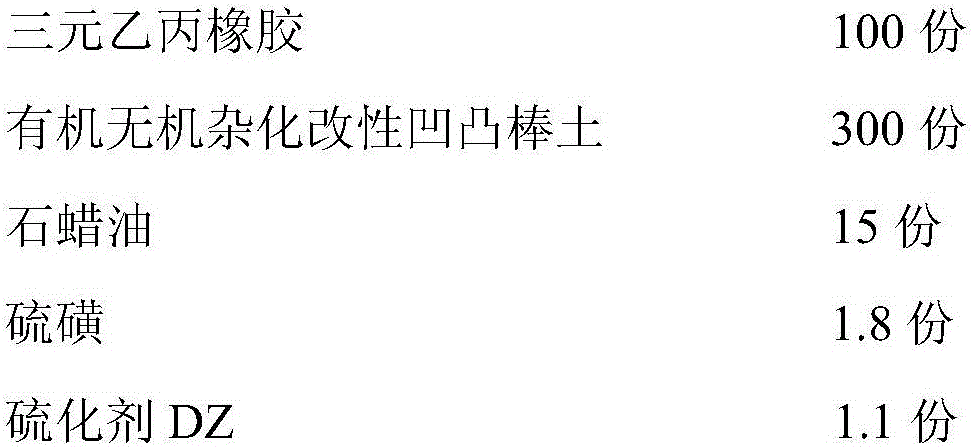

[0031] The formula of EPDM rubber material is:

[0032]

[0033]

[0034] The EPDM rubber material of the above formula was mixed in a rubber internal mixer at room temperature for 55 minutes, and then rolled into thin slices with an open mixer, cut as required and placed in a flat mold with a thickness of 12mm. The flat mold with EPDM rubber inside...

Embodiment 3

[0036] Using coupling agent [CH 3 (CH 2 ) 19 ] 3 SiOCH 2 CH 3 For attapulgite treatment, the dosage of coupling agent is 0.15% of attapulgite; for attapulgite treatment with alkaline silica sol (solid content: 22%), the dosage of alkaline silica sol is 7.5% of attapulgite. The specific treatment process is: the attapulgite is sprayed with the above-mentioned organic silicon coupling agent while stirring in a high-speed mixer, and mixed at a high speed of 90°C for 30 minutes; then sprayed with silica sol, and mixed at a high speed of 125°C for 90 minutes to obtain an organic-inorganic hybrid Modified attapulgite.

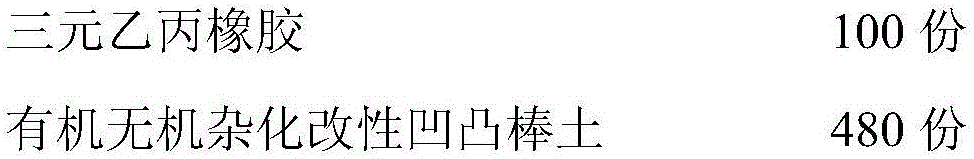

[0037] The formula of EPDM rubber material is:

[0038]

[0039] The EPDM rubber material of the above formula was mixed in a rubber internal mixer at room temperature for 38 minutes, then rolled into thin slices with an open mixer, cut as required and placed in a flat mold with a thickness of 13 mm. The flat mold with EPDM rubber inside is vulcanized in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com