Patents

Literature

42 results about "Filling fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The fill fraction determines the width of the active acquisition over a line. The beam modified line clock is generated by ScanImage to attenuate the laser power during the inactive portion of the scan.

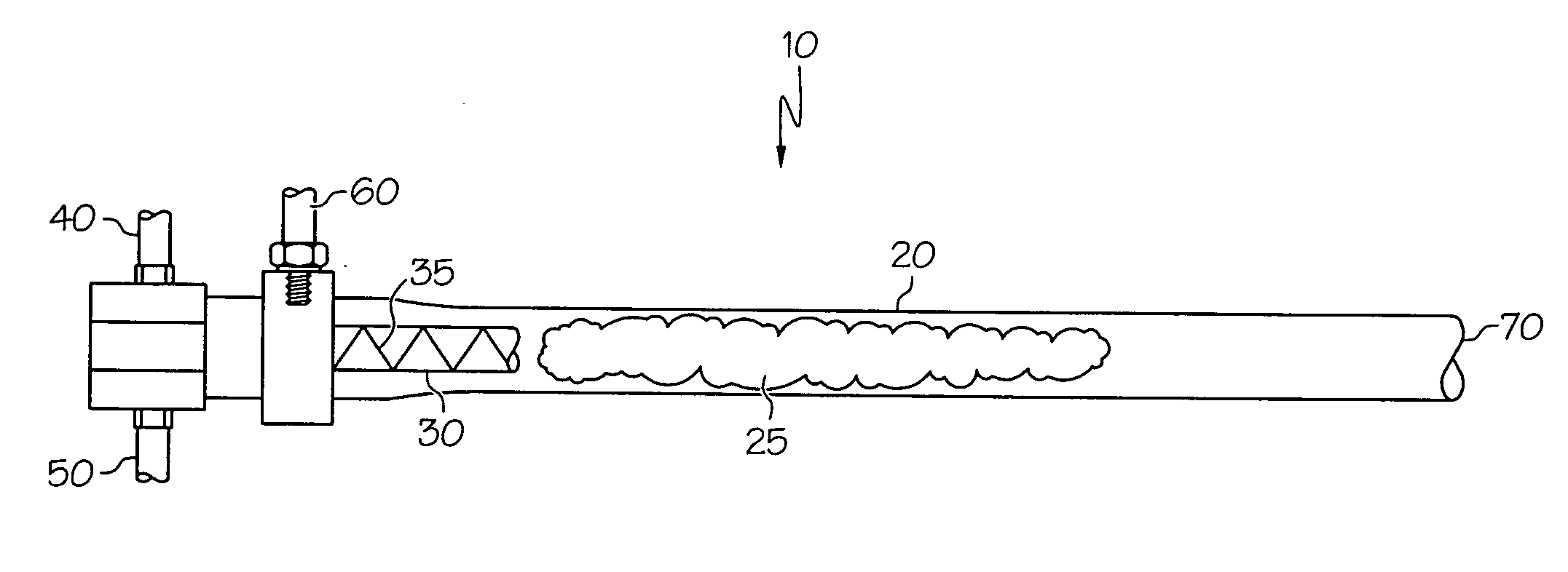

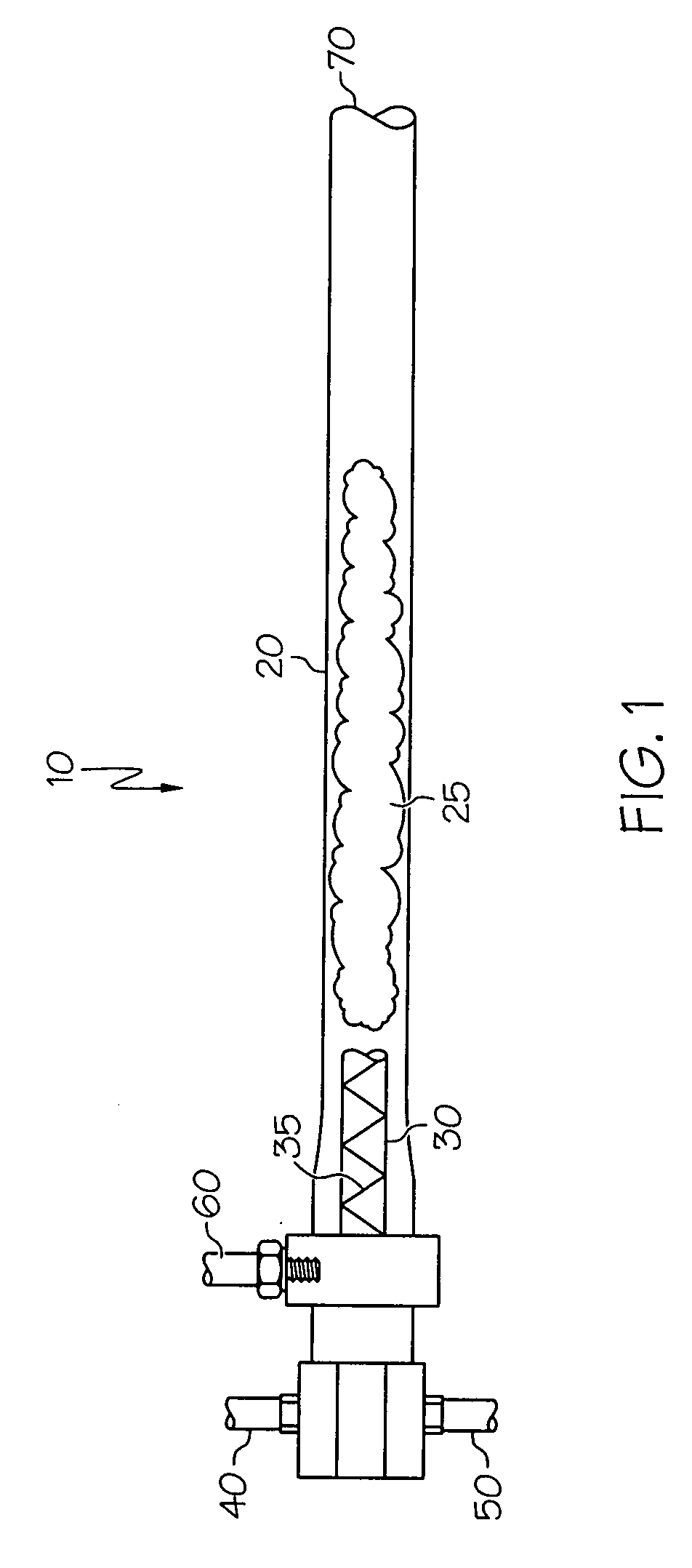

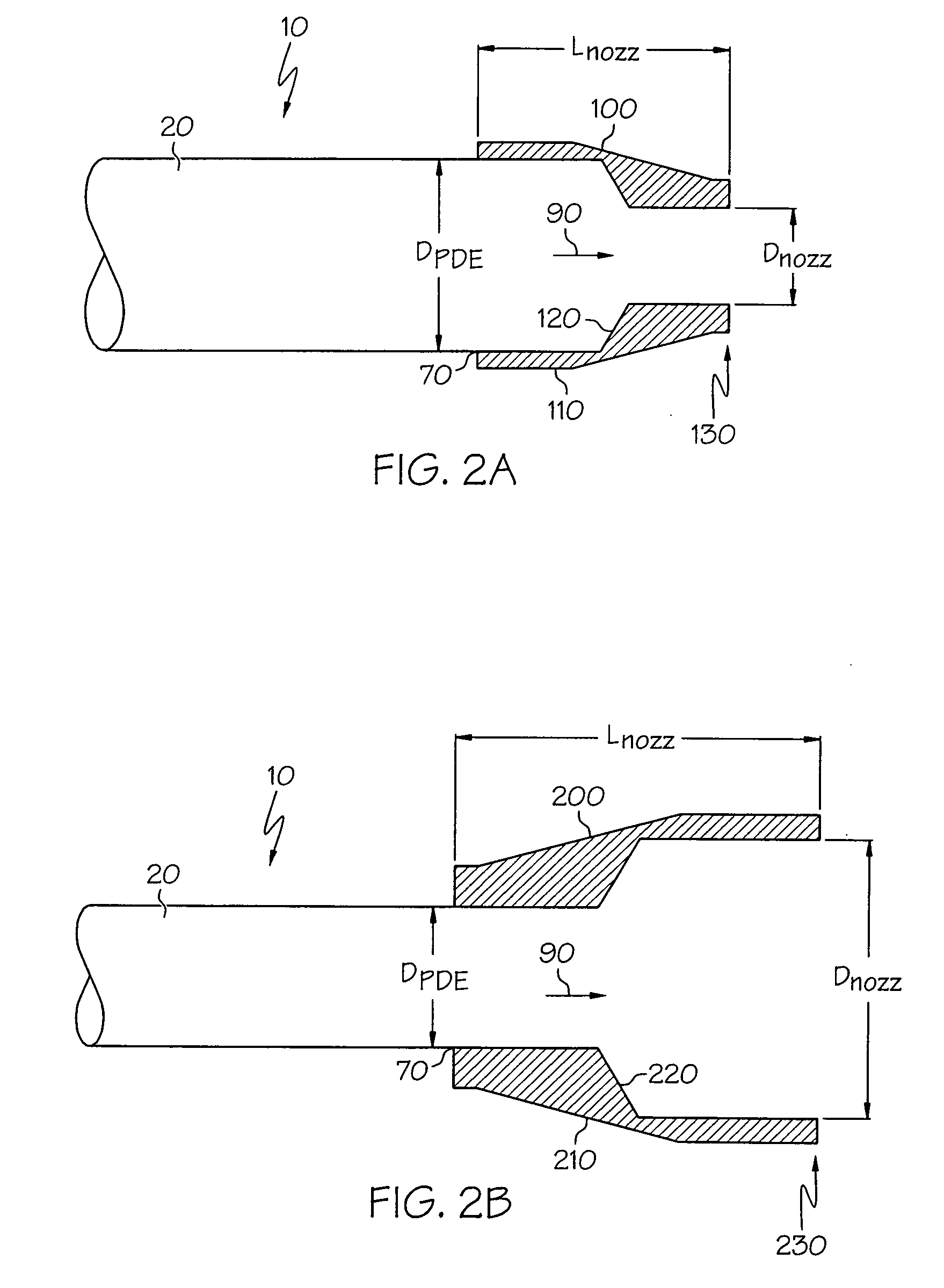

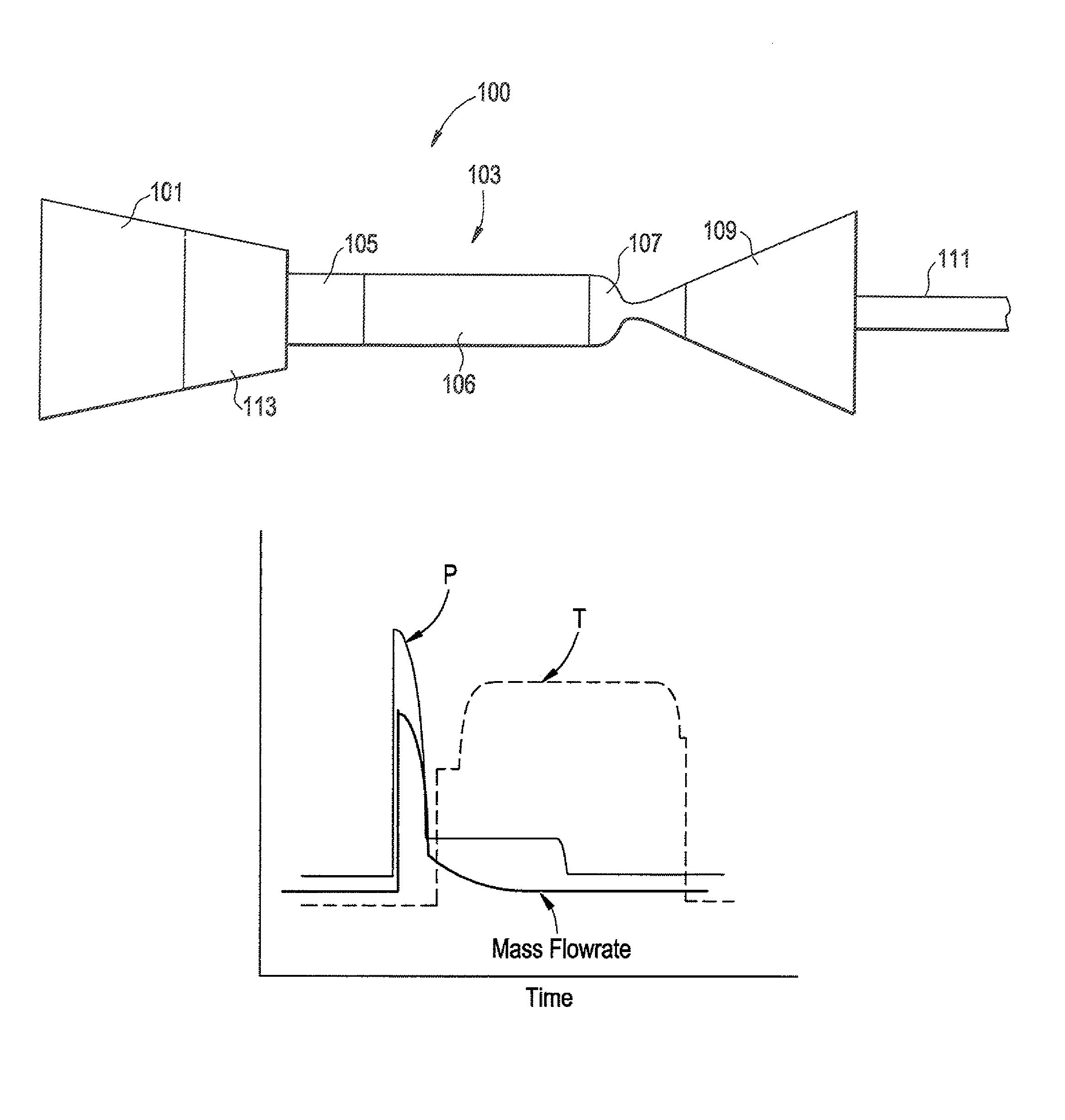

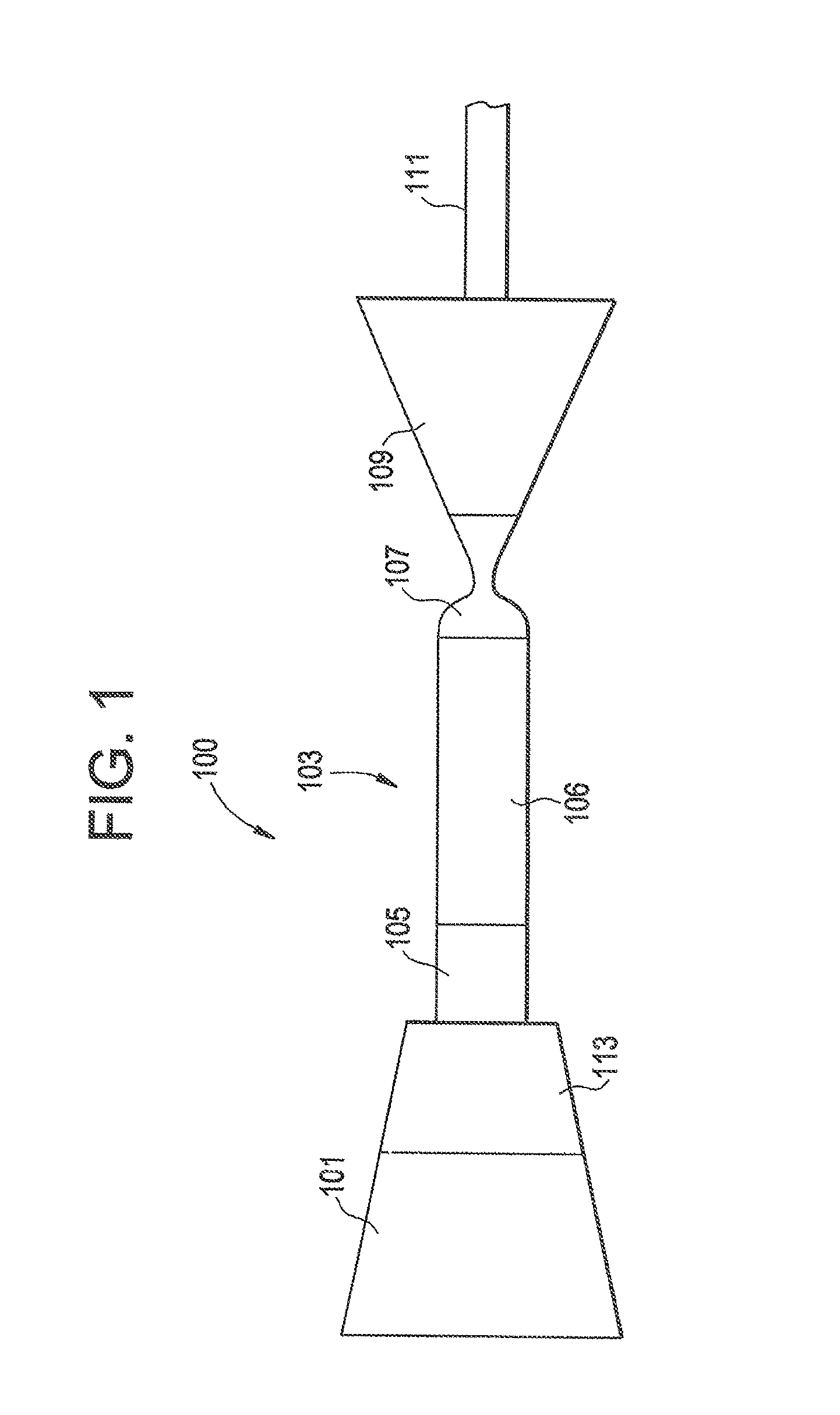

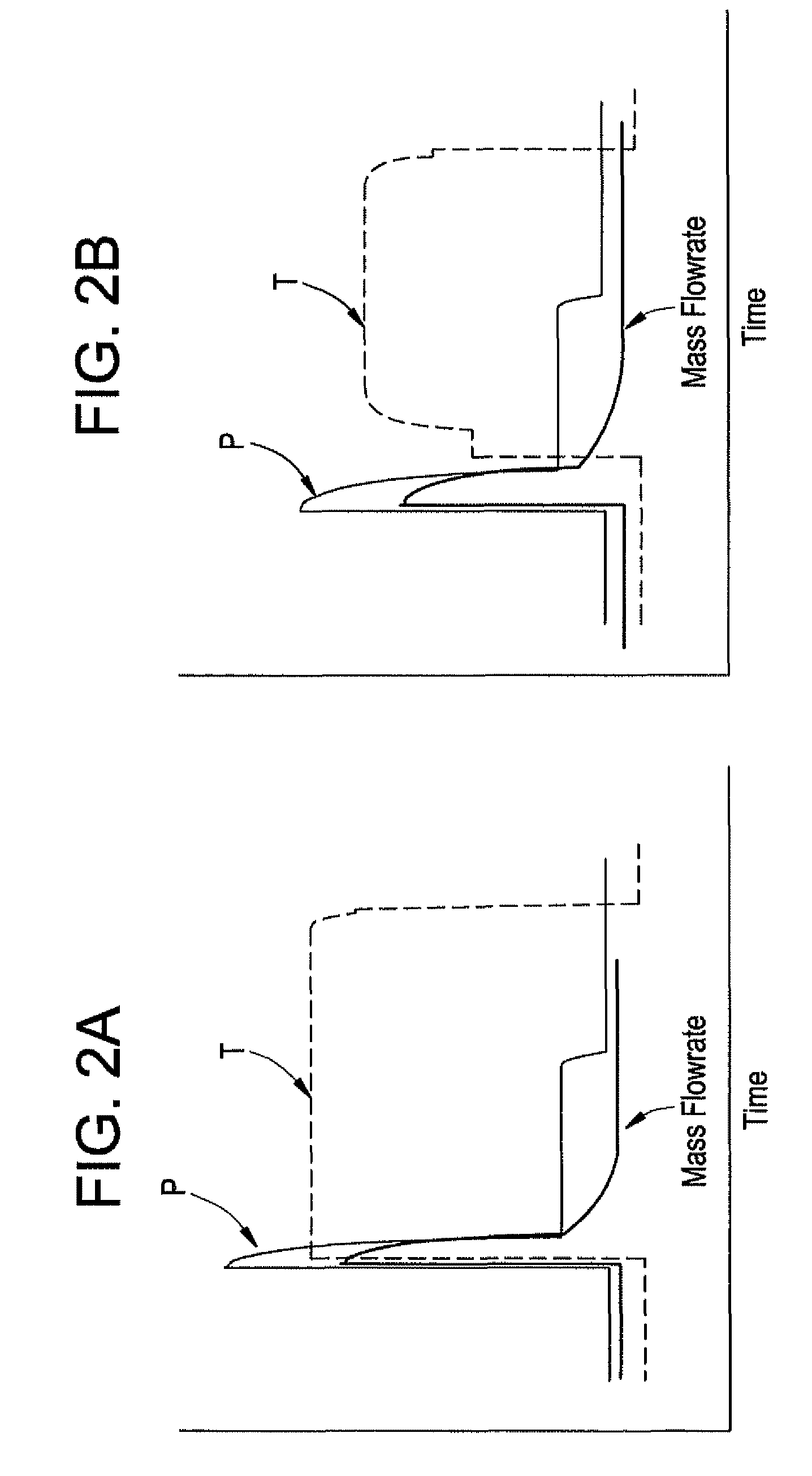

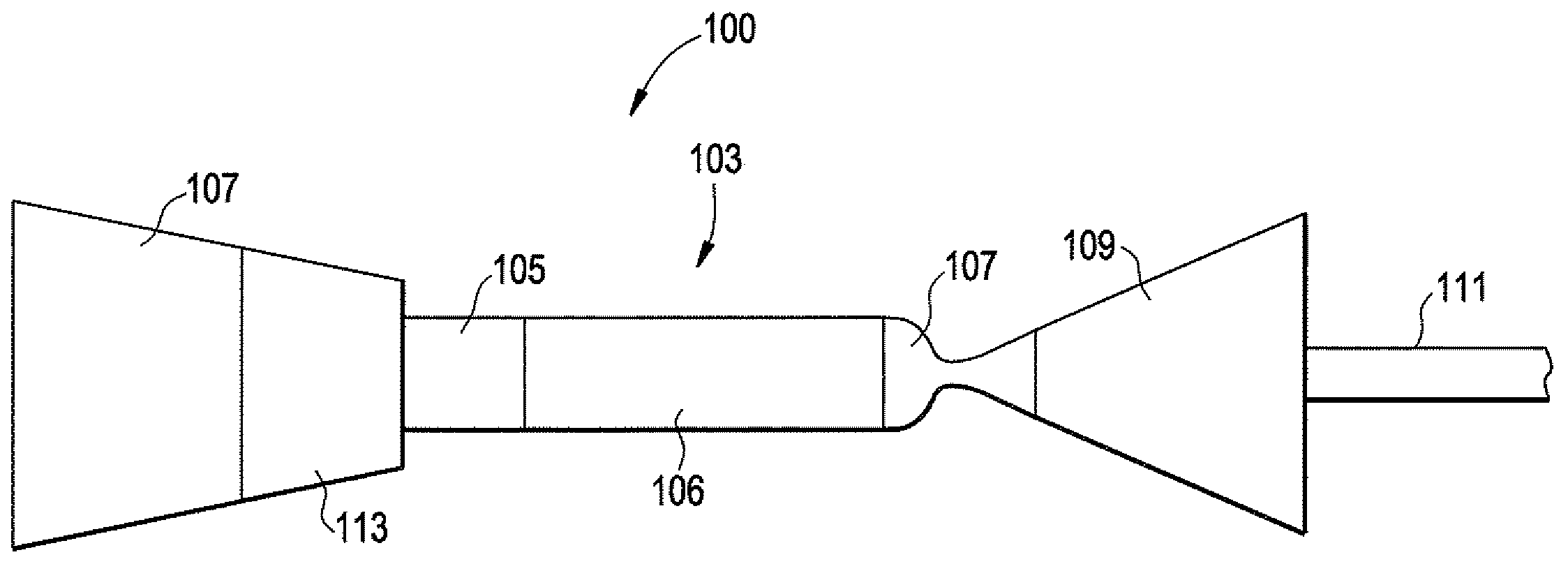

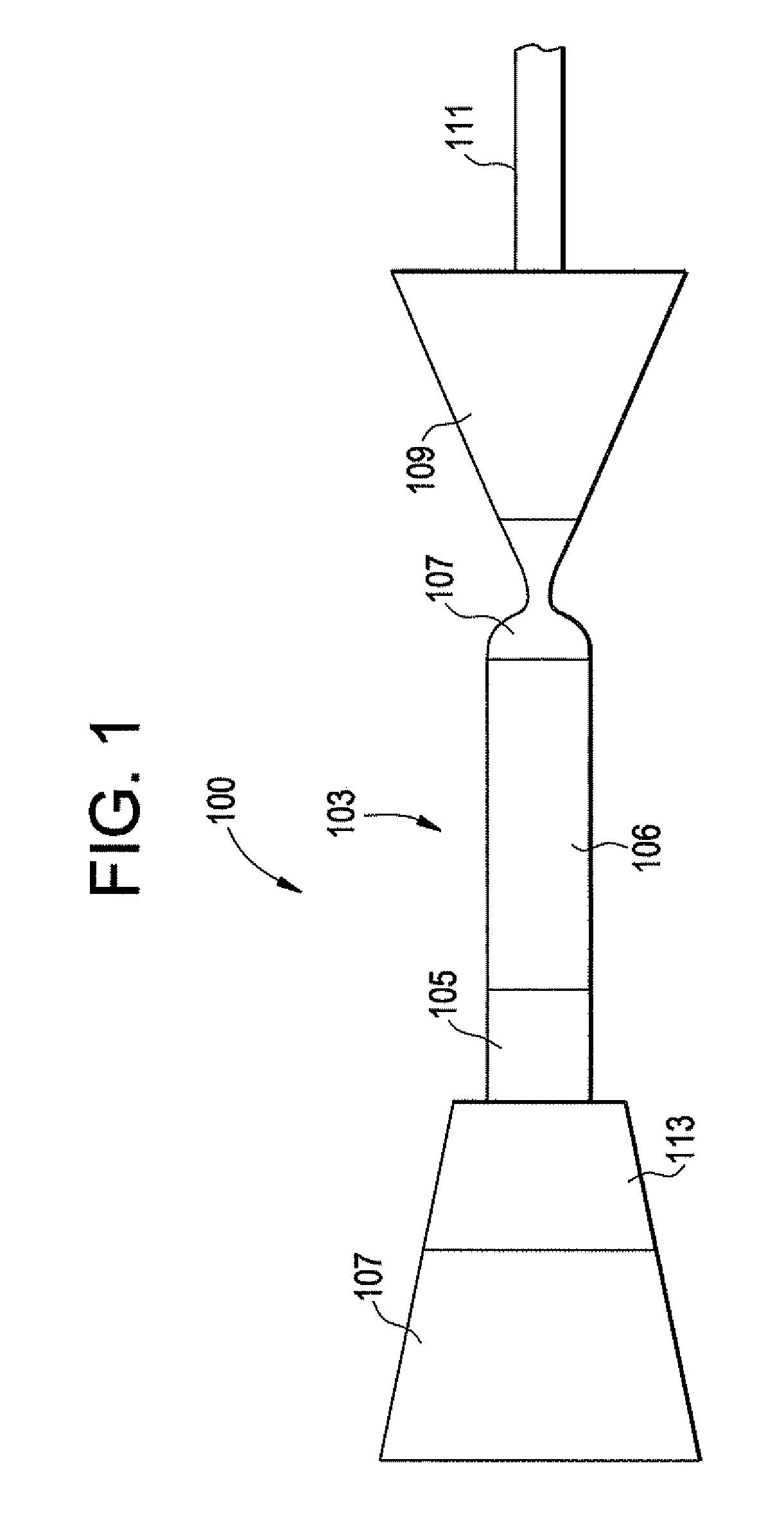

Performance improvements for pulse detonation engines

InactiveUS20090320446A1Reduce noiseImprove performanceEngine manufactureEngine fuctionsEquivalence ratioNoise reduction

A device and method for improving the performance of a pulse detonation engine. The device includes at least one of an exhaust structure and an ejector. The exhaust structure can be configured as a straight, converging or diverging nozzle device, and connected to the engine to control the flow of a primary fluid produced during a detonation reaction. The ejector is fluidly coupled to the engine, using the movement of the primary fluid to promote entrainment of a secondary fluid that can be mixed with the primary fluid. The secondary fluid can be used to increase the mass flow of the primary fluid to increase thrust, as well as be used to cool engine components. Device positioning, sizing, shaping and integration with other engine operating parameters, such as fill fraction, choice of fuel and equivalence ratio, can be used to improve engine performance. In addition to thrust augmentation and enhanced cooling, the disclosed device can be used for engine noise reduction.

Owner:UNIVERSITY OF CINCINNATI

Ultra-fine composite modified talc powder body, preparation method and uses thereof

InactiveCN101367962AOvercoming reunion tendenciesFilled tightlyPigmenting treatmentState of artUltra fine

The invention discloses a superfine compound modified talcum powder body, a preparation method and an application thereof. The powder body comprises the following materials by the weight portion: 60-75 portions of talcum powder, 25-35 portions of superfine heavy calcium carbonate powder, 1-2.5 portions of titanium ester coupling agent and 1-1.2 portions of stearic acid. The preparation method includes the following steps: the talc powder is added into a high-speed mixer, then the heavy calcium carbonate is added, the temperature is raised to 100-110 DEG C, the materials are heated for 5-10 minutes; the coupling agent is added, the temperature is raised to 160-165 DEG C, and the materials are heated for 6-10 minutes; the materials are cooled to 95-105 DEG C, and then the stearic acid is added, and mixed evenly to achieve the desired powder body. The powder body can be applied to facia materials and super-tough HIPS materials as well as military packaging materials. Compared with the prior art, the powder body produced by the method has big filling fraction, sound compatibility with other auxiliary materials and strong processing fluidity; in addition to the functions of filling and increment, the powder body can effectively improve the toughness and strength of products.

Owner:芜湖同达新材料科技有限公司

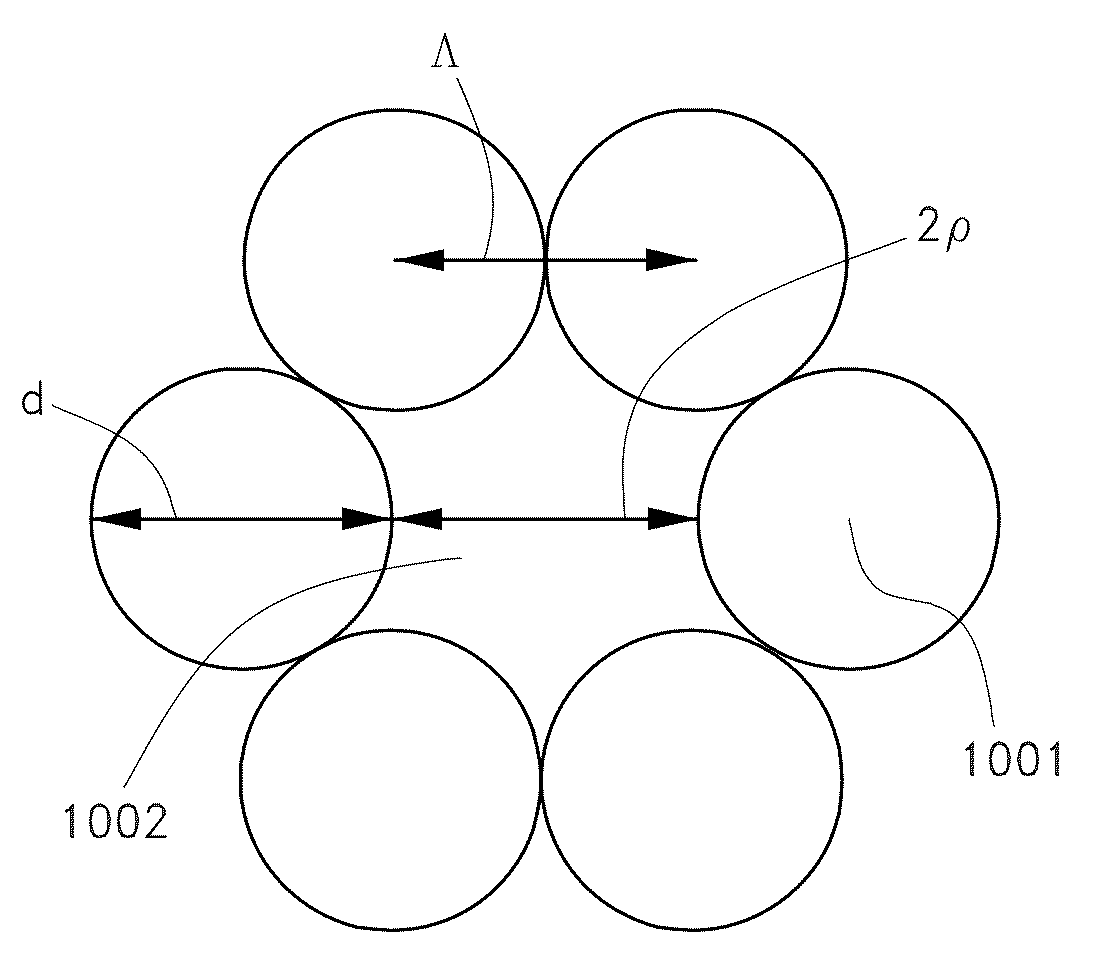

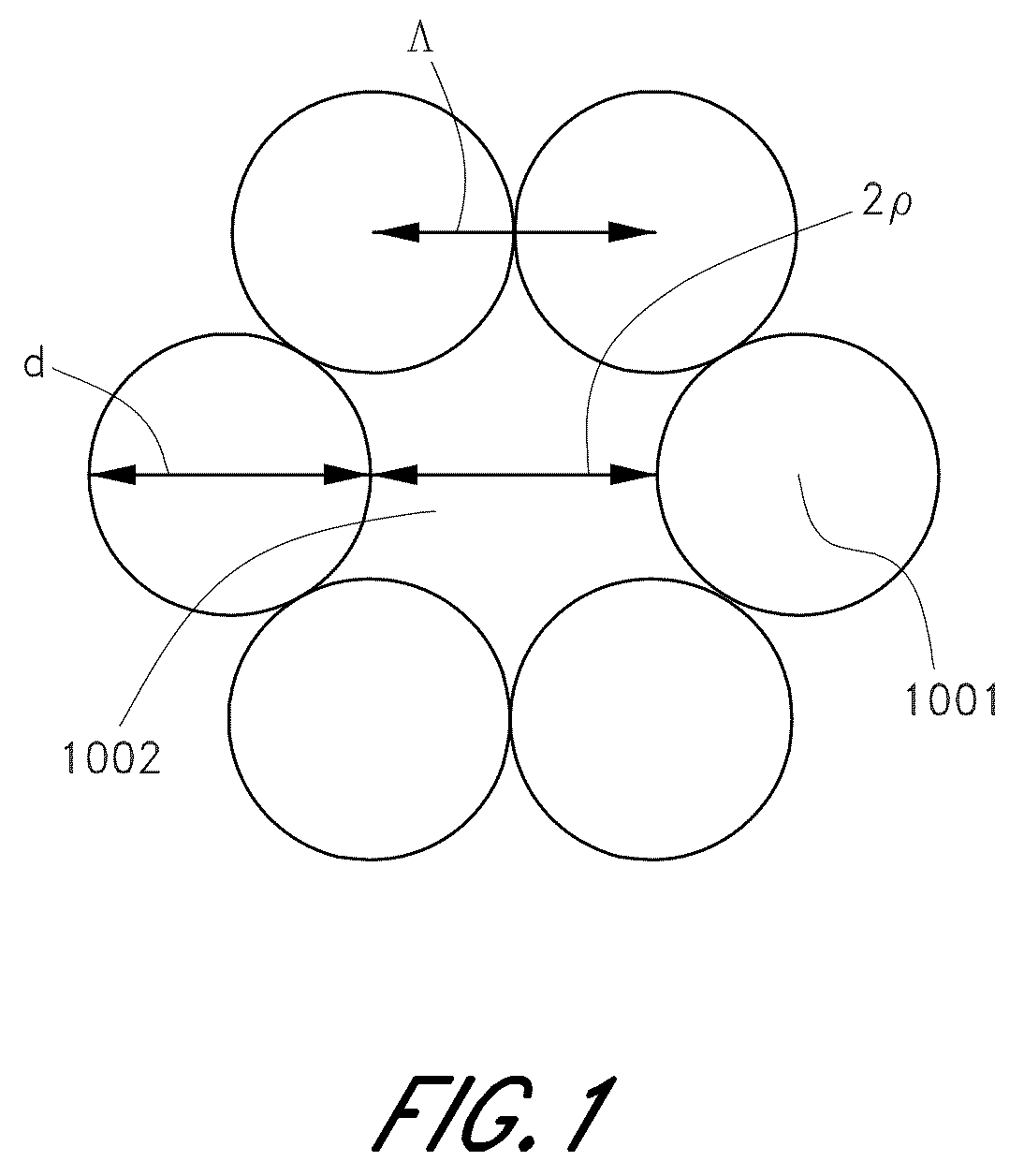

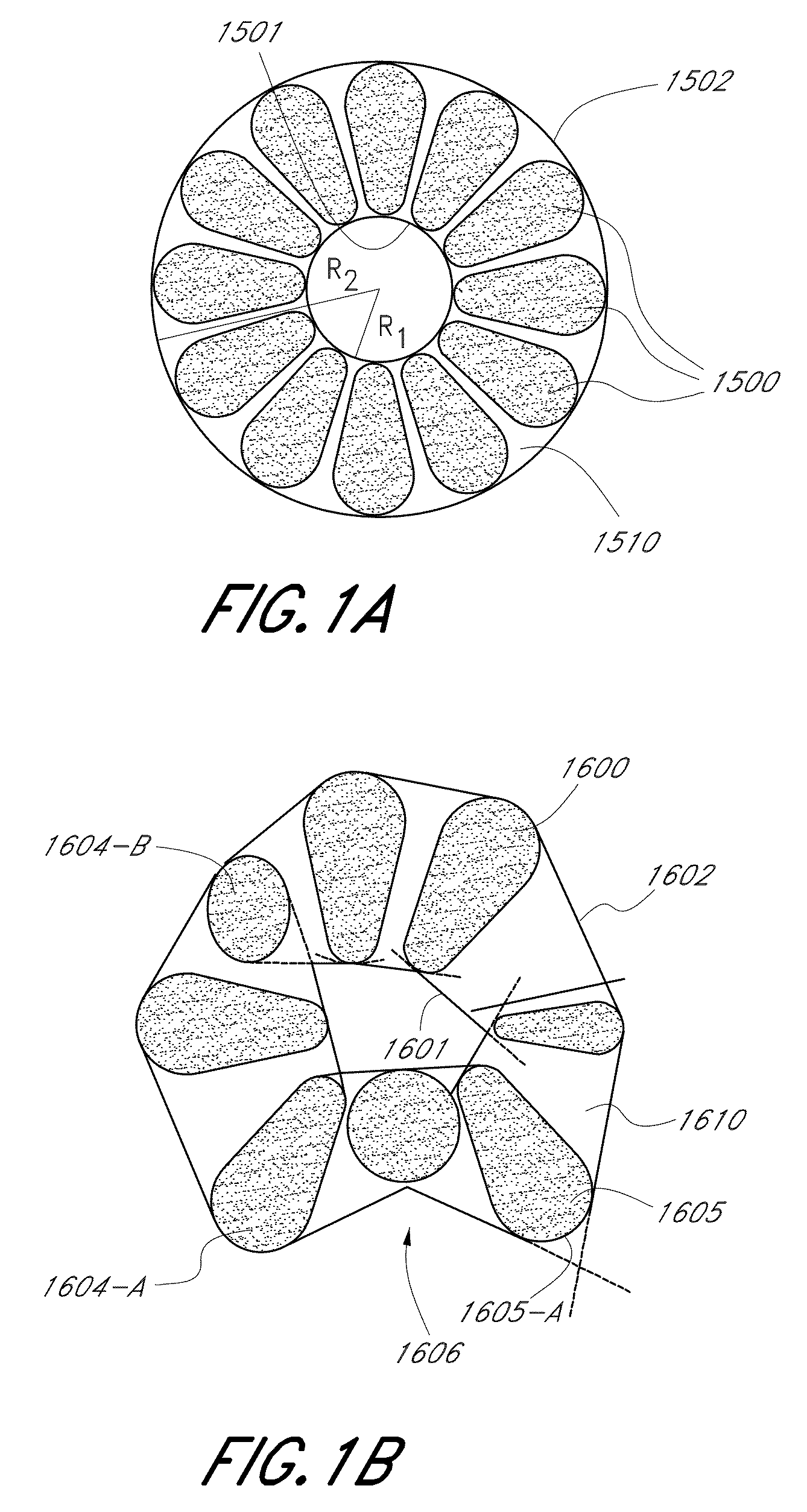

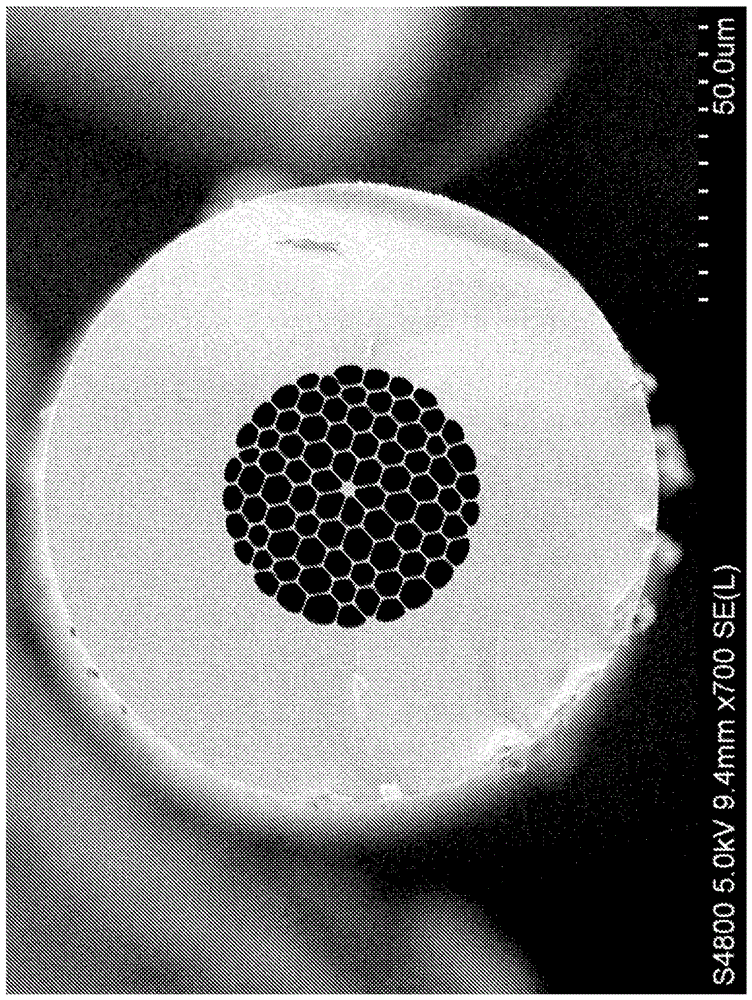

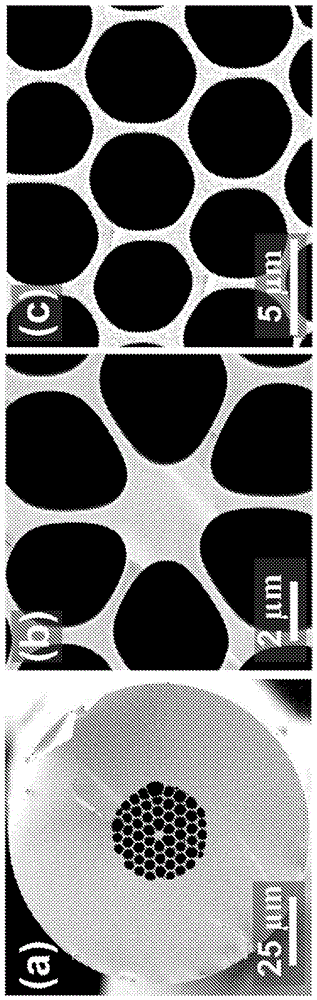

Ultra small core fiber with dispersion tailoring

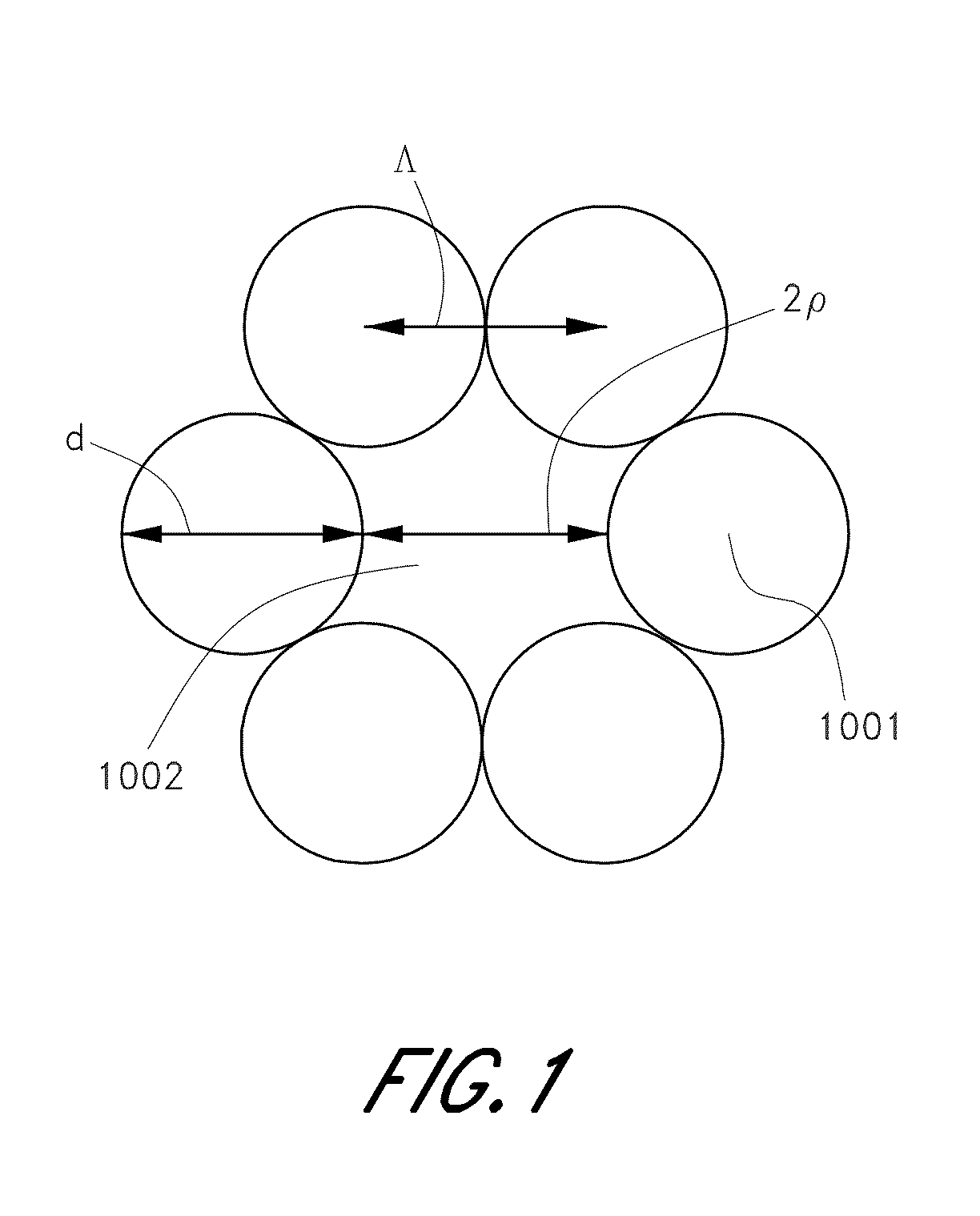

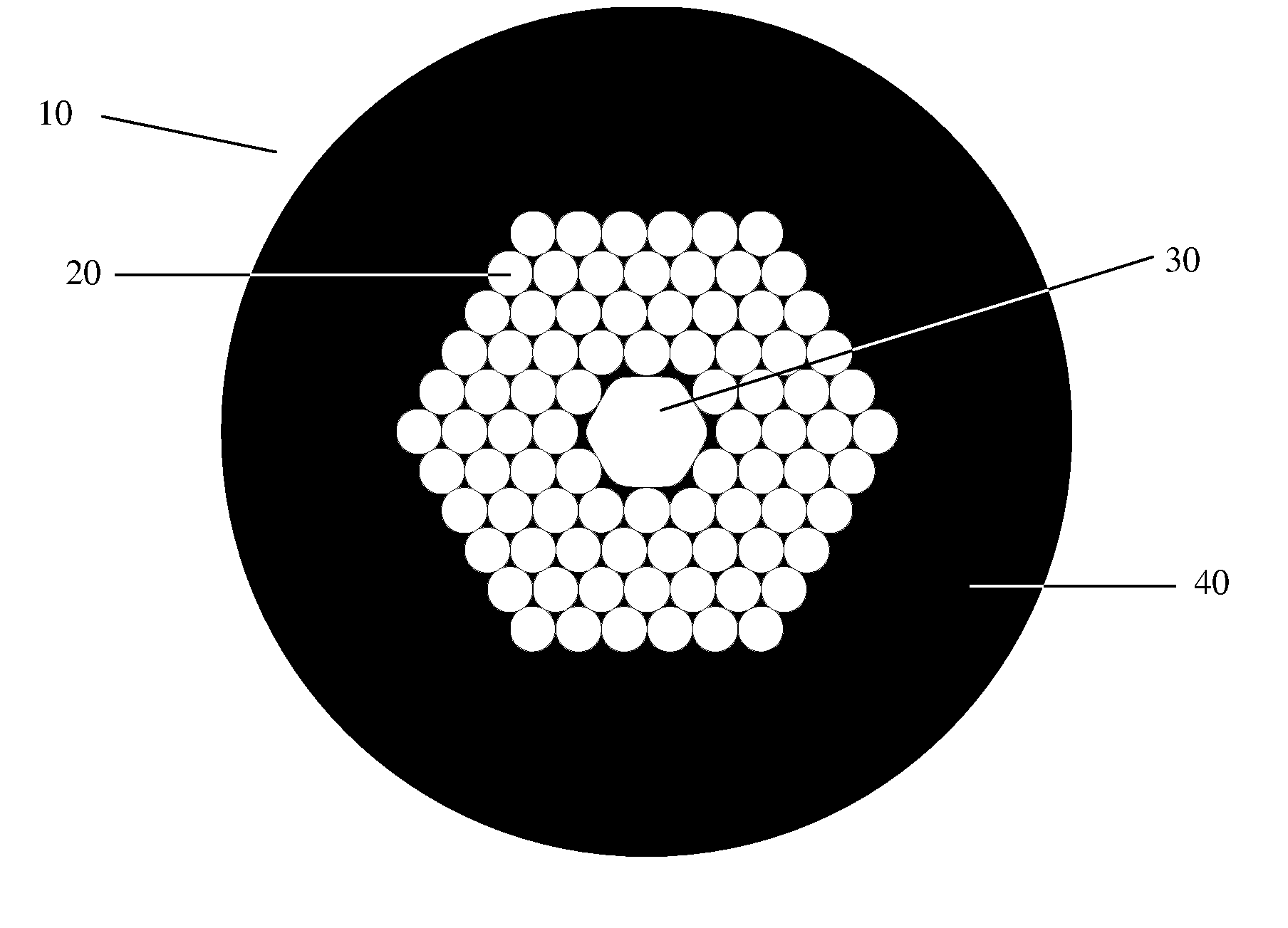

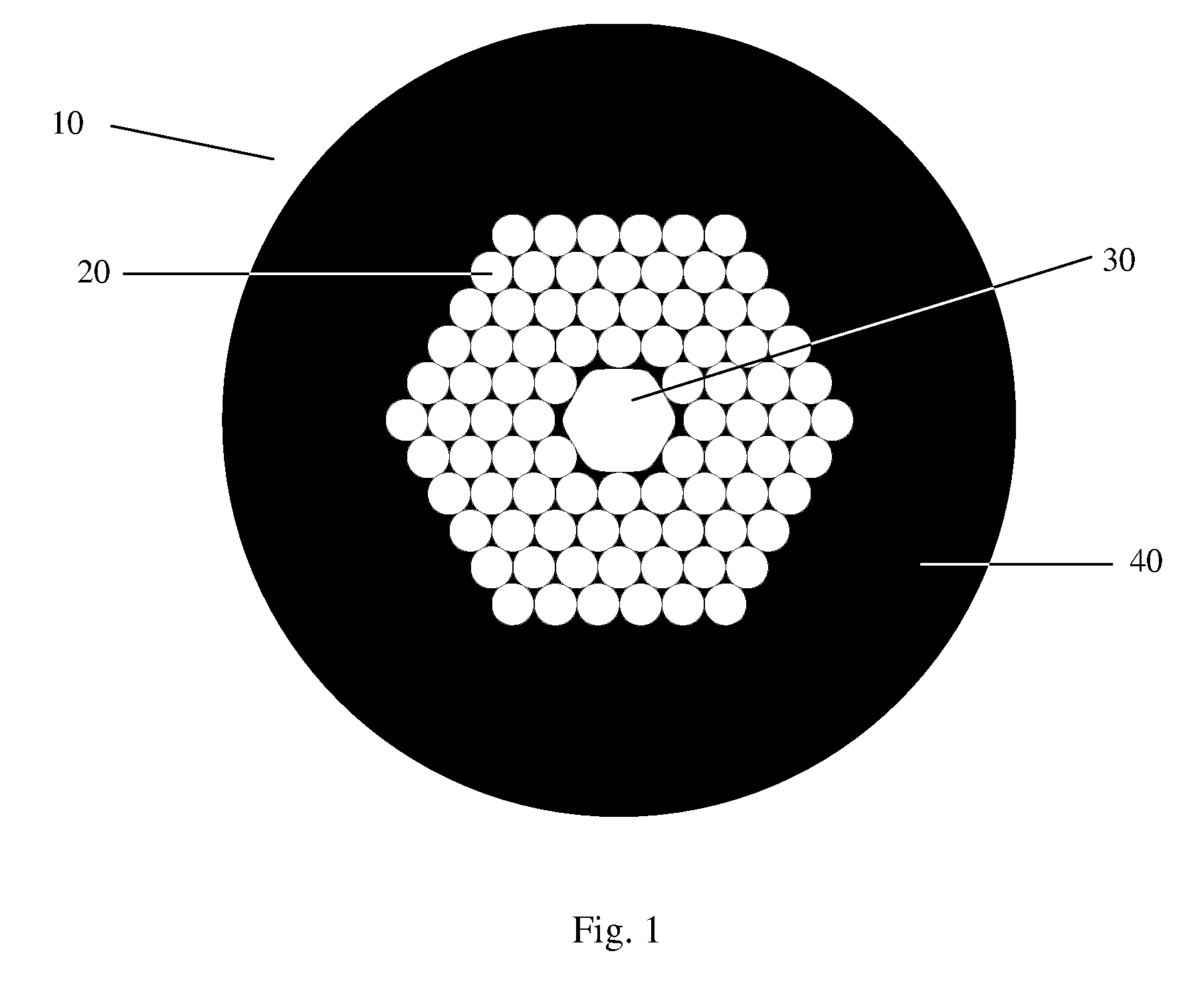

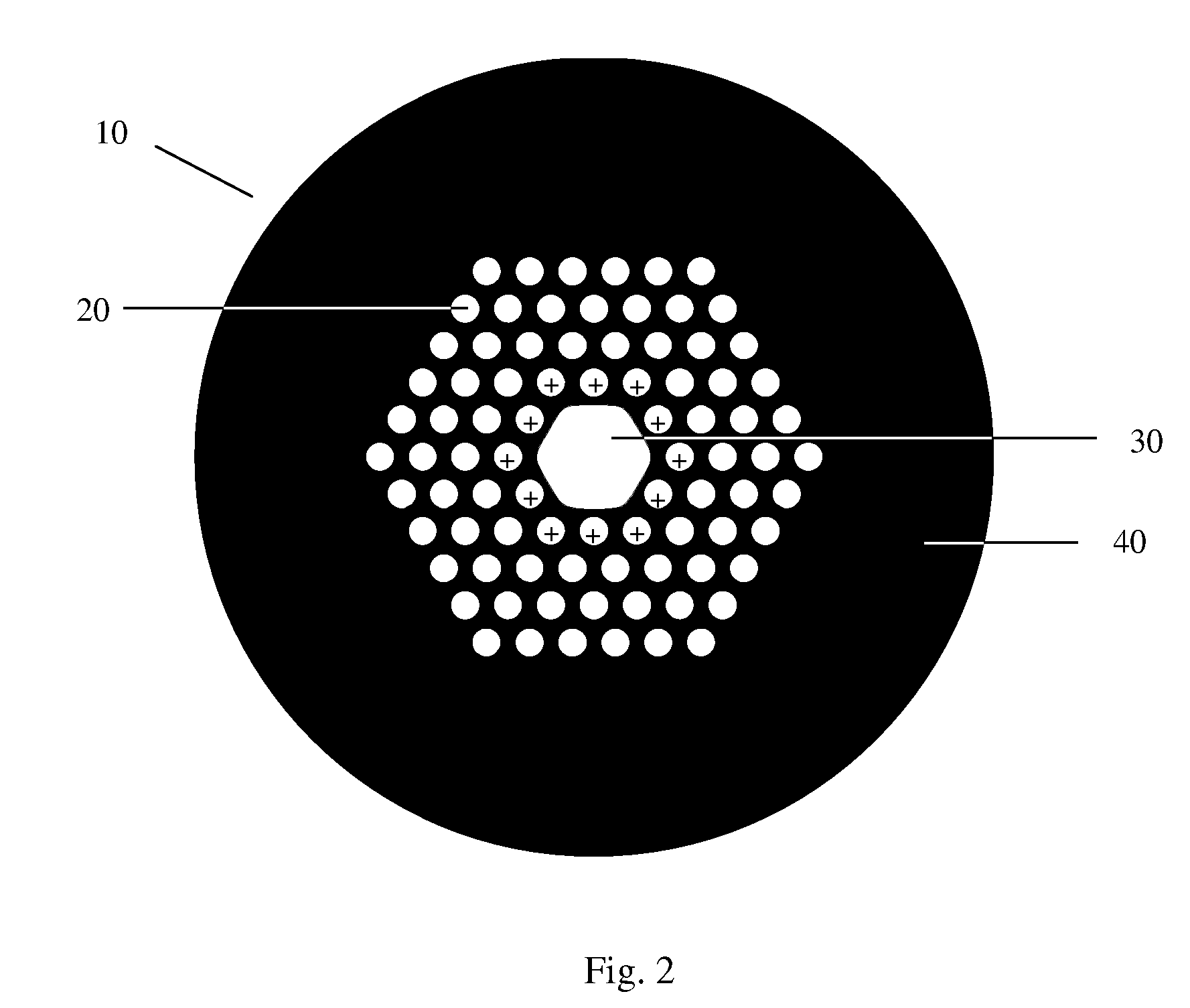

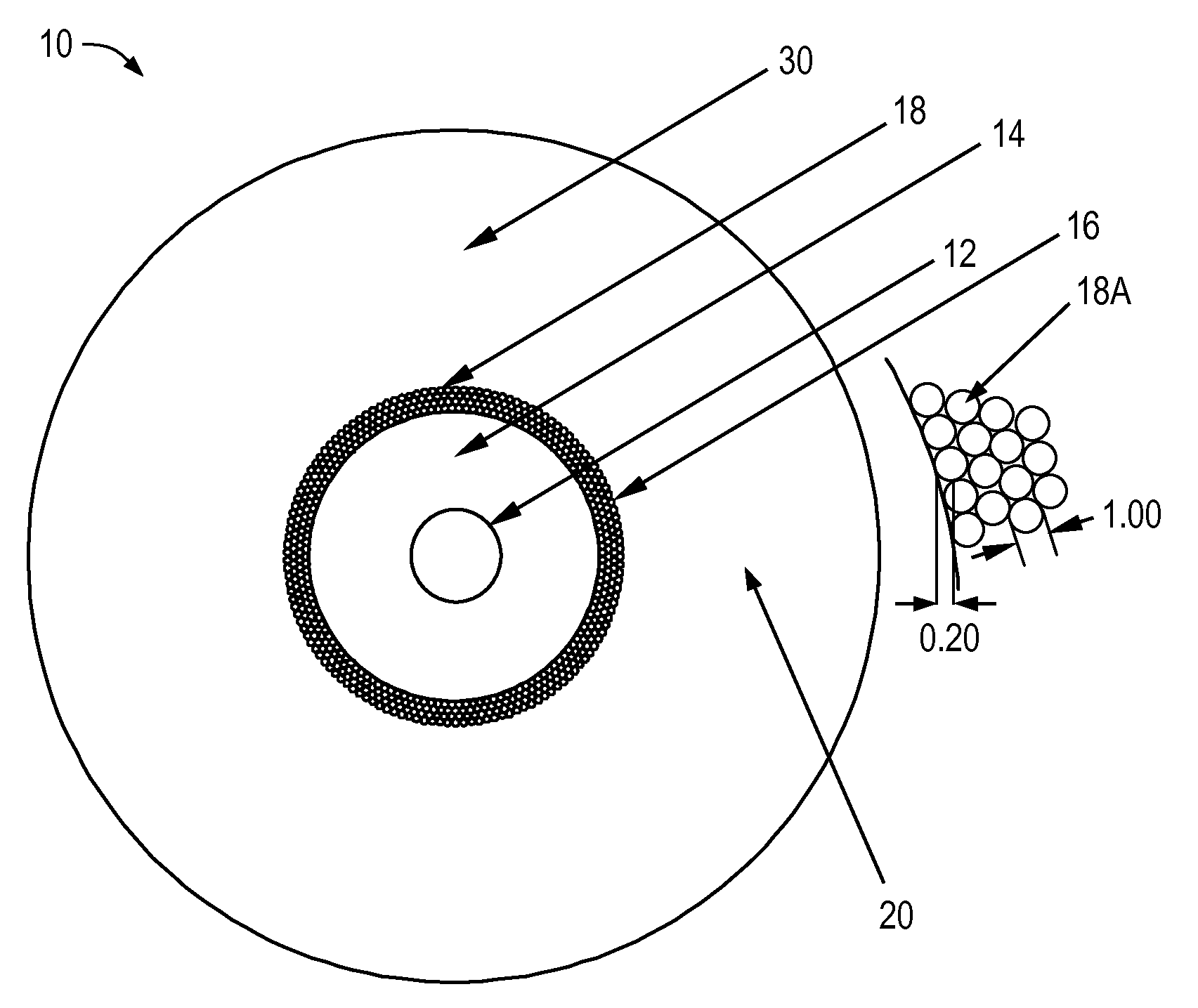

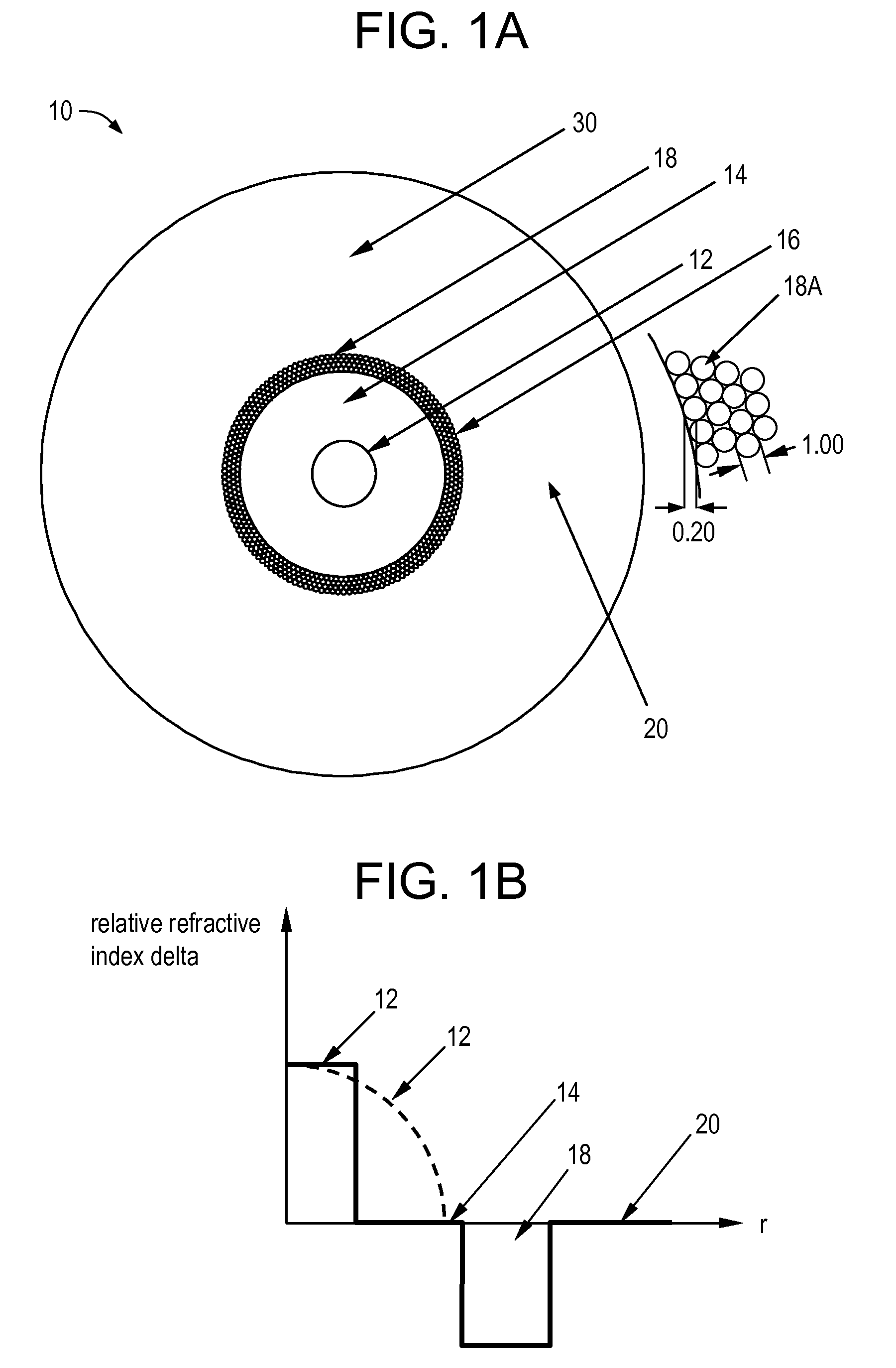

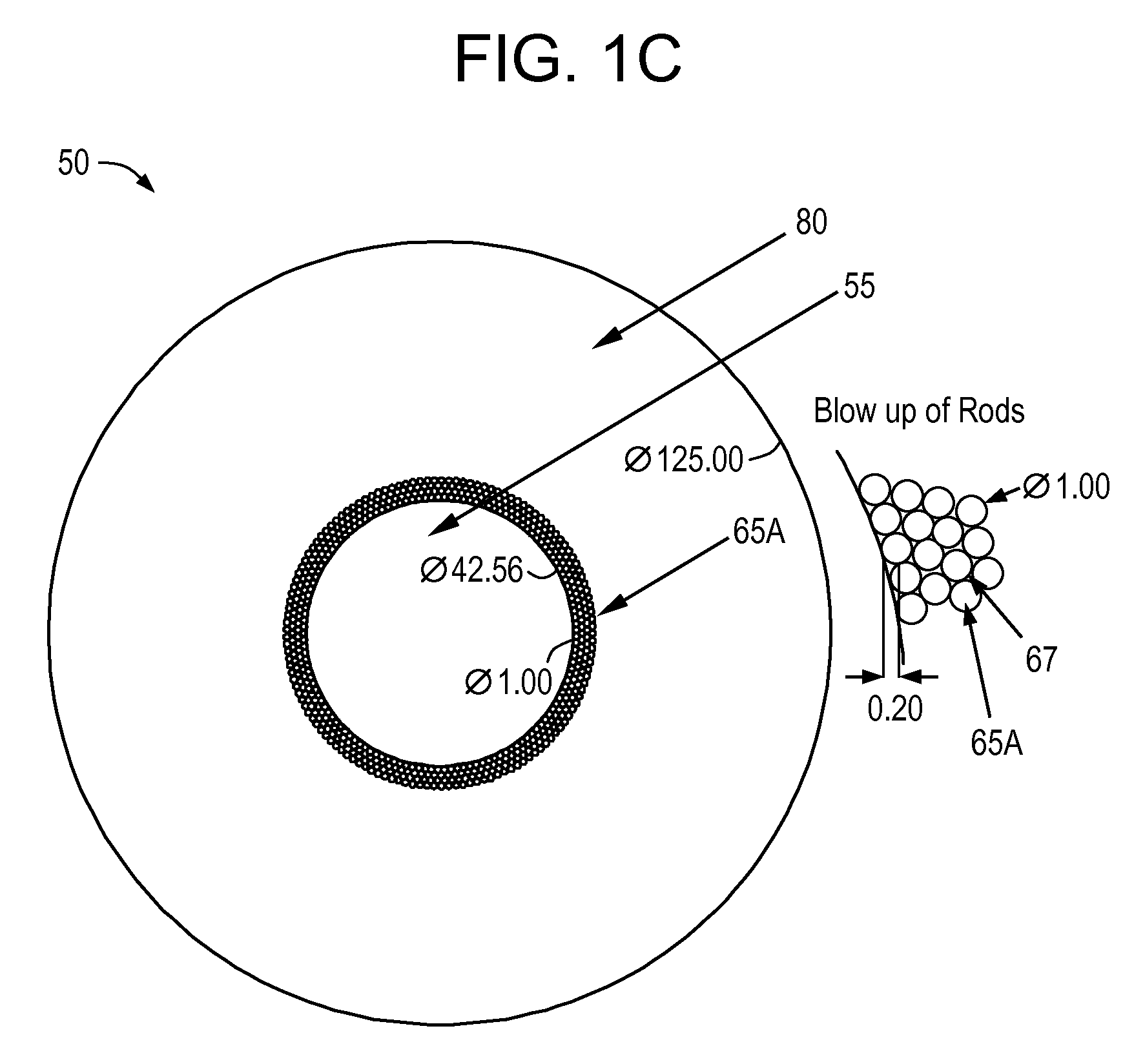

InactiveUS20090245729A1Low splice lossLow scattering lossLaser detailsOptical fibre with multilayer core/claddingFiberFrequency comb

Various embodiments of optical fiber designs and fabrication processes for ultra small core fibers (USCF) are disclosed. In some embodiments, the USCF includes a core that is at least partially surrounded by a region comprising first features. The USCF further includes a second region at least partially surrounding the first region. The second region includes second features. In an embodiment, the first features are smaller than the second features, and the second features have a filling fraction greater than about 90 percent. The first features and / or the second features may include air holes. Embodiments of the USCF may provide dispersion tailoring. Embodiments of the USCF may be used with nonlinear optical devices configured to provide, for example, a frequency comb or a supercontinuum.

Owner:IMRA AMERICA

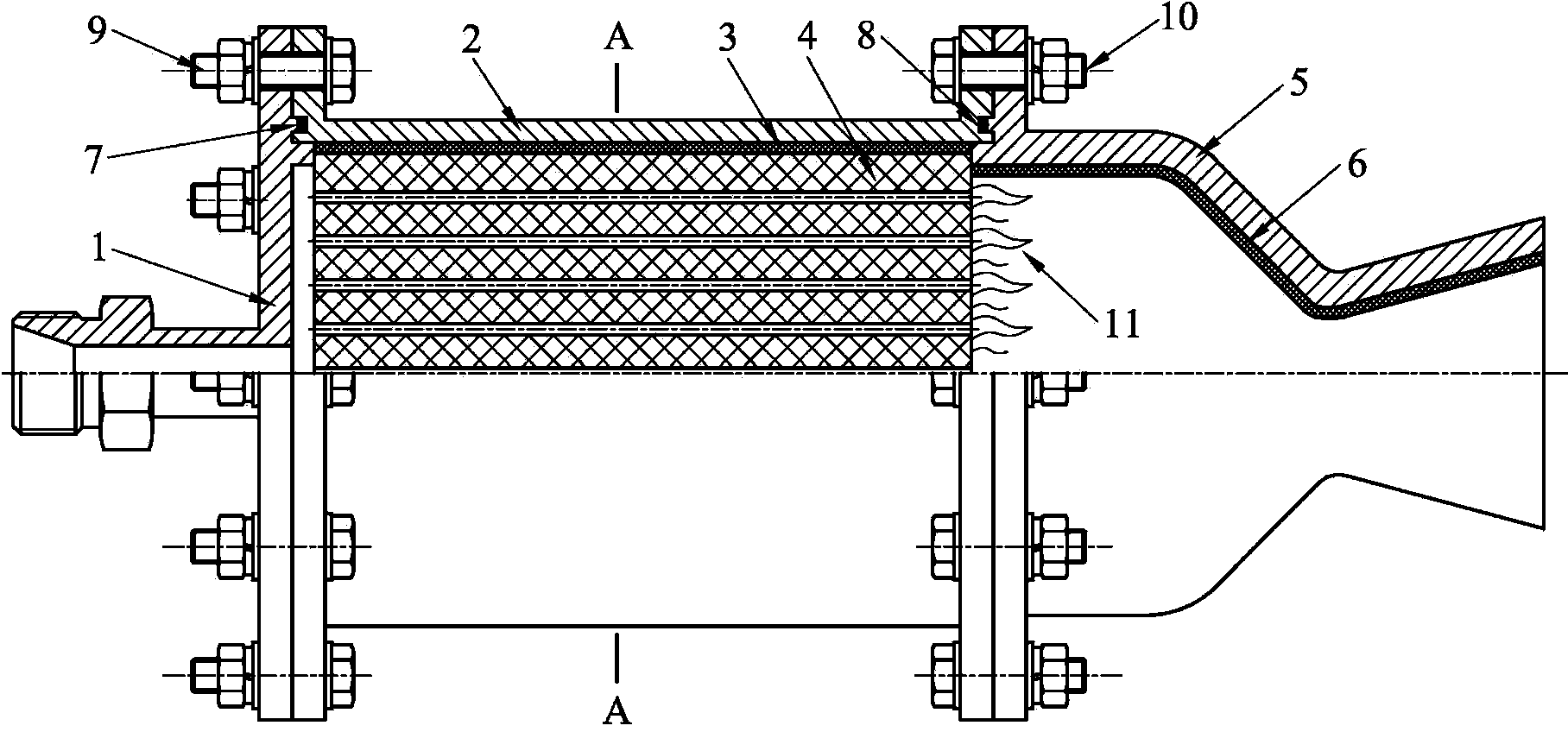

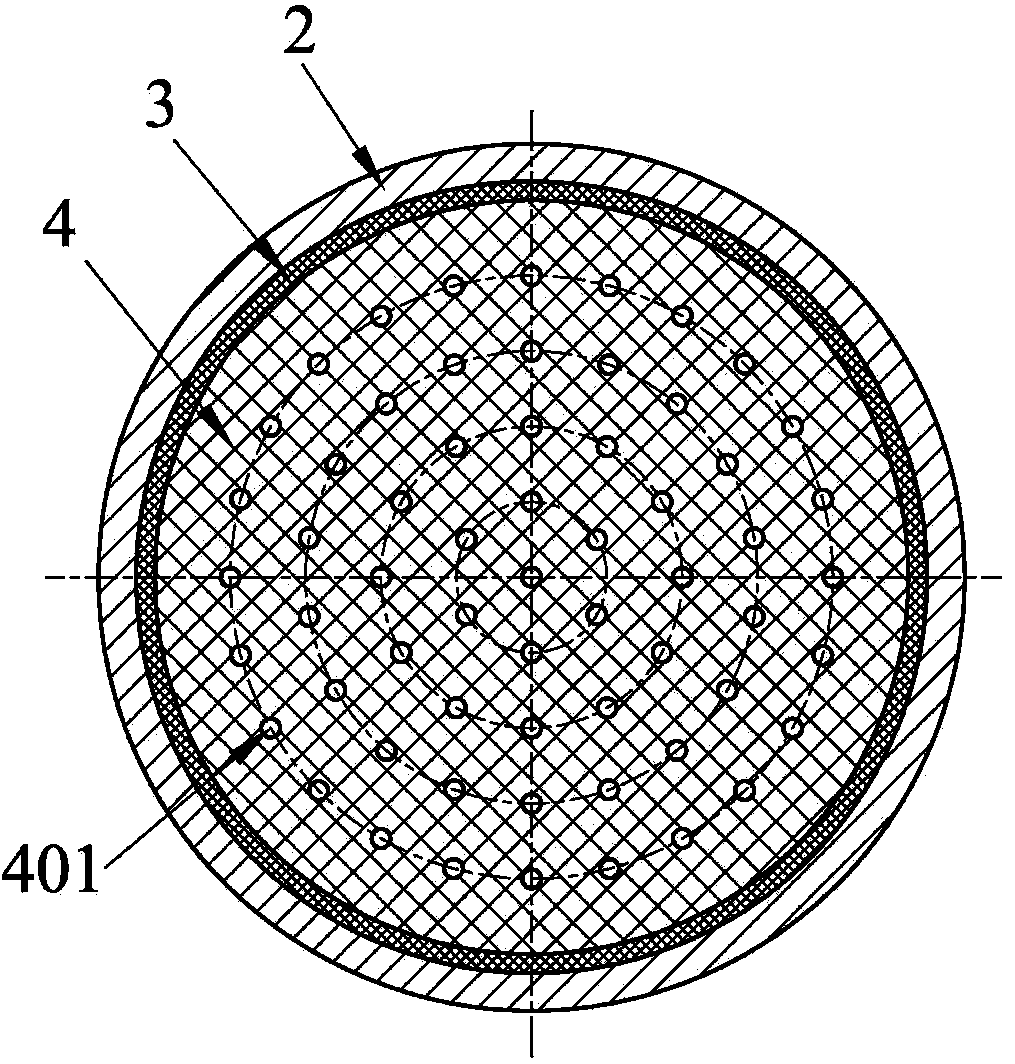

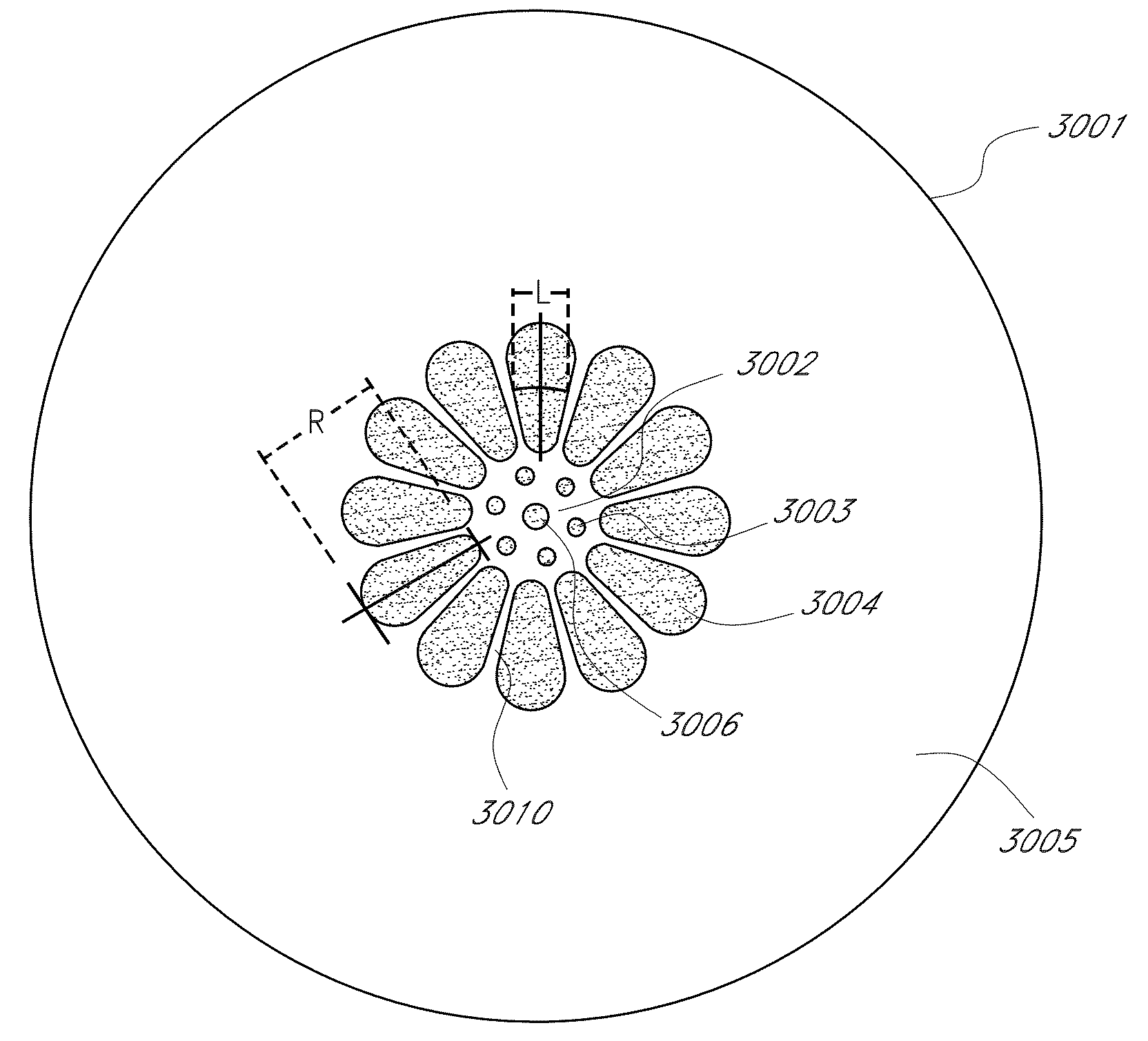

Axial injection end combustion solid-liquid rocket engine structure

ActiveCN103967653AMaintain a constant burning areaMaintain a constant oxygen-fuel ratioRocket engine plantsInlet channelCombustion

The invention discloses an axial injection end combustion solid-liquid rocket engine structure which comprises an engine head cover, a solid propellant shell, a solid propellant heat insulating layer, end combustion solid propellants, a spray pipe shell and a spray pipe heat insulating layer. The engine head cover is mounted at the front end of the solid propellant shell, the spray pipe shell is mounted at the rear end of the solid propellant shell, the engine head cover is provided with an air inlet channel, the end combustion solid propellants are coaxially arranged in the solid propellant shell, a constant volume cavity is formed between the front end faces of the end combustion solid propellants and the rear end face of the engine head cover, each end combustion solid propellant is provided with a plurality of axial injection holes with small diameters, the flow rate of oxidizing agents in the injection holes is high, and combustion reaction only occurs at the end faces of the end combustion solid propellants; the joint between the solid propellant shell and the engine head cover and the joint between the solid propellant shell and the spray pipe shell are respectively provided with a sealing structure, so that air impermeability of an engine is guaranteed; the heat insulating layers are arranged in the solid propellant shell and the spray pipe shell, so that thermal protection performance of the engine during operation is guaranteed. Thus, performance of the engine is improved, meanwhile the filling fraction of the engine is improved, the slenderness ratio of the engine is reduced, and the application rage of engine is widened.

Owner:BEIHANG UNIV

High Air Fraction Photonic Band Gap Fibers

A photonic band gap fiber and method of making thereof is provided. The fiber is made of a non-silica-based glass and has a longitudinal central opening, a microstructured region having a plurality of longitudinal surrounding openings, and a jacket. The air fill fraction of the microstructured region is at least about 40%. The fiber may be made by drawing a preform into a fiber, while applying gas pressure to the microstructured region. The air fill fraction of the microstructured region is changed during the drawing.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

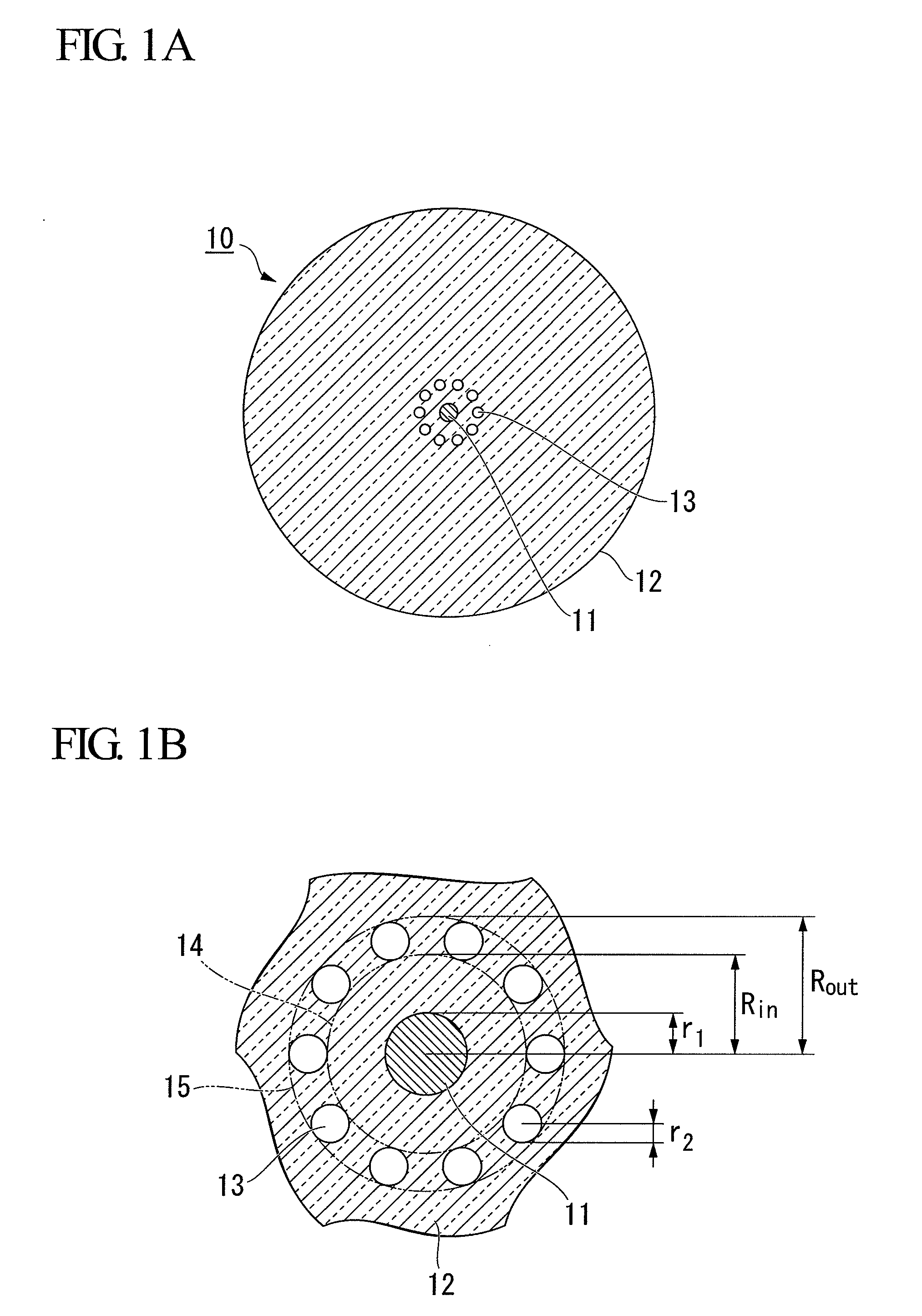

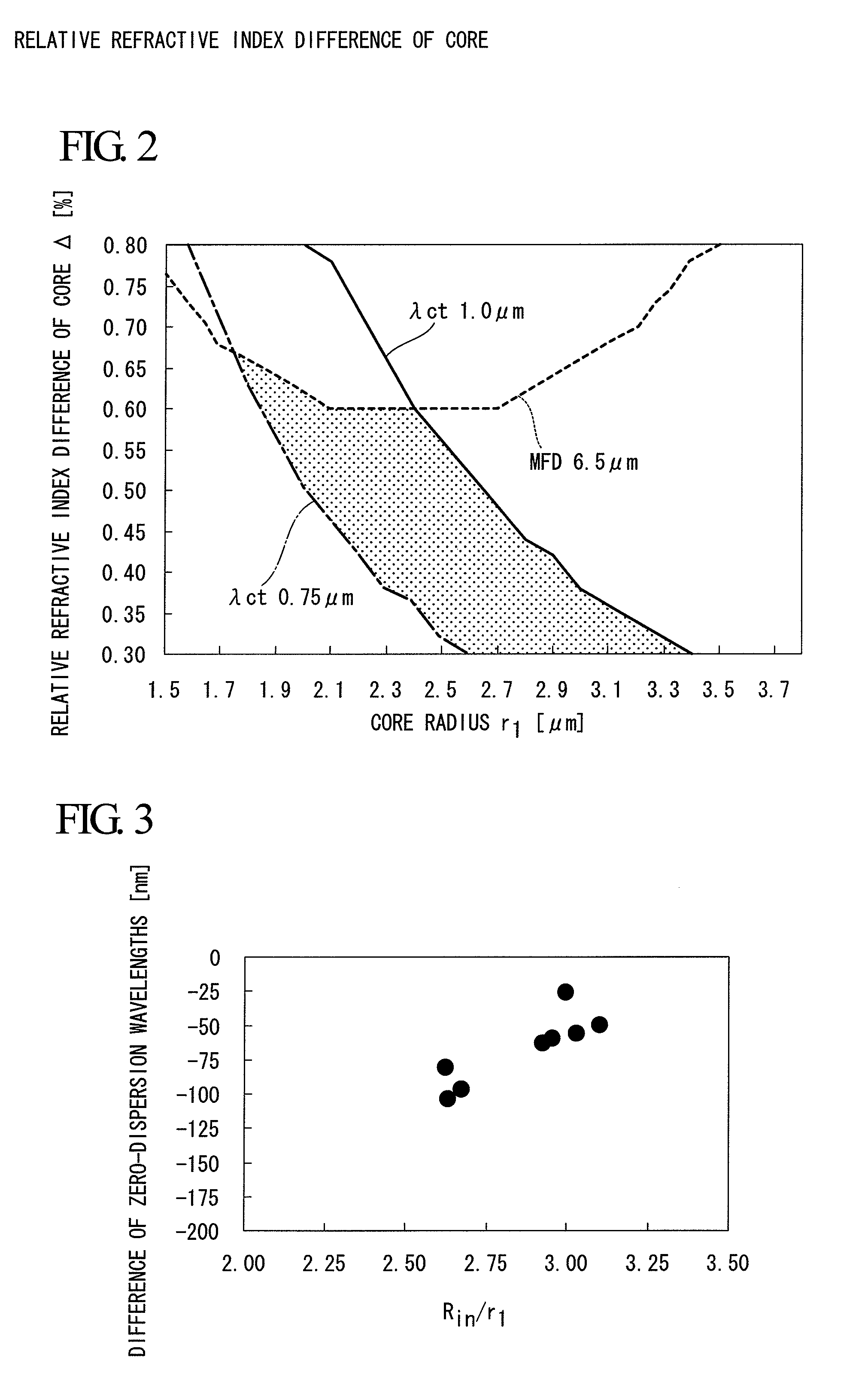

Holey single-mode optical fiber and optical transmission system using same

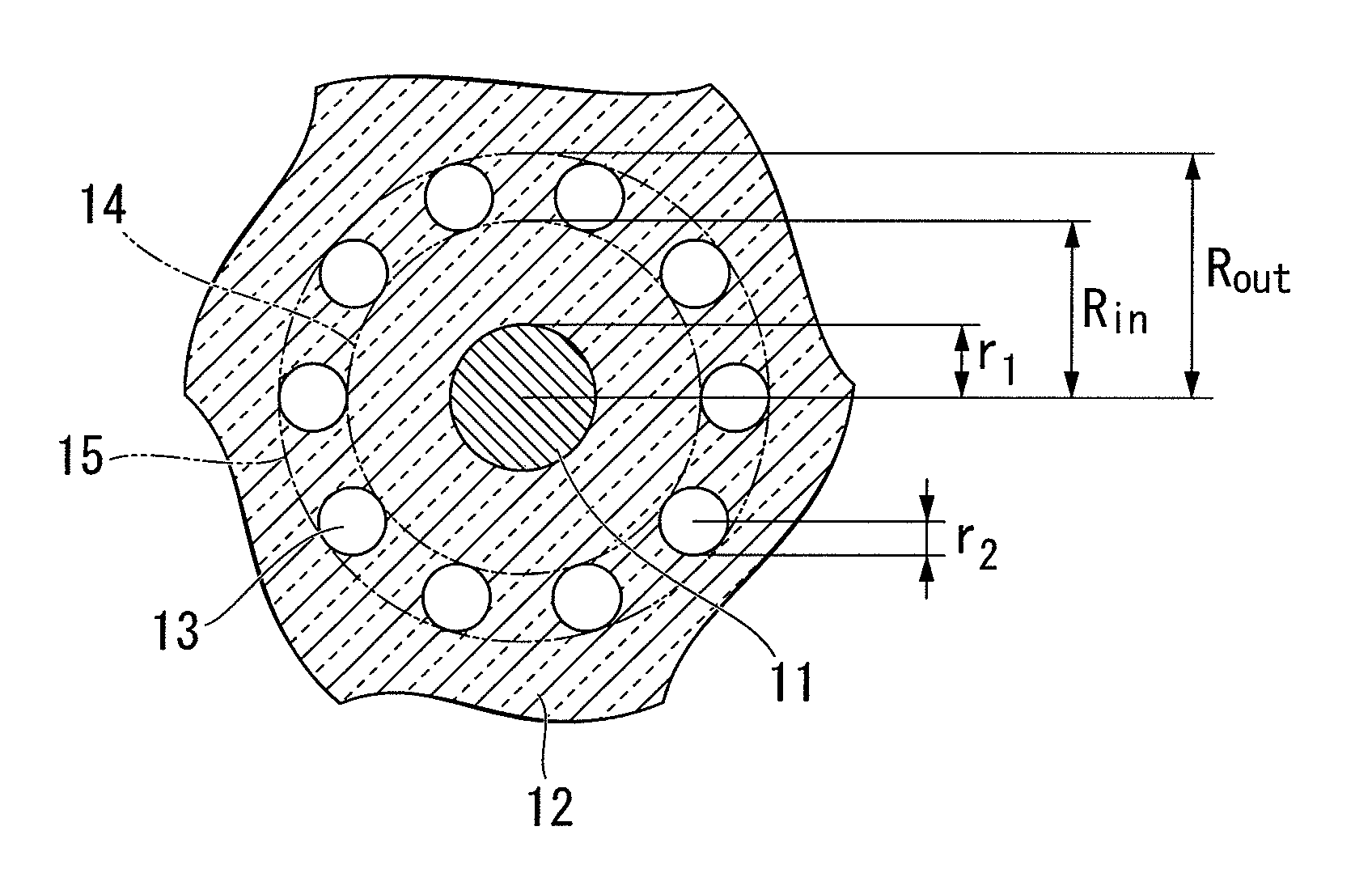

InactiveUS20120033923A1Easy to manufactureLow costCladded optical fibreOptical waveguide light guideZero-dispersion wavelengthRelative refractive index

Provided is a holey single-mode optical fiber including a core not having holes, and a clad having holes extending in a longitudinal direction, in which a refraction index of the core is larger than that of a portion of the clad other than the holes, a radius r1 of the core is within a range of 2.2 to 3.2 μm, a relative refraction index difference Δ of the core to the clad is within a range of 0.3 to 0.56%, a distance Rin between a center of the core and an inner edge of the holes is 2.0 to 3.5 times the radius r1 of the core, an air-filling fraction F is within a range of 30 to 50%, a cable cut-off wavelength is 1.0 μm or less, a zero-dispersion wavelength is within a range of 1260 to 1460 nm, and a bending loss characteristic at a bending radius of 10 mm is 10 dB / m or less.

Owner:THE FUJIKURA CABLE WORKS LTD +1

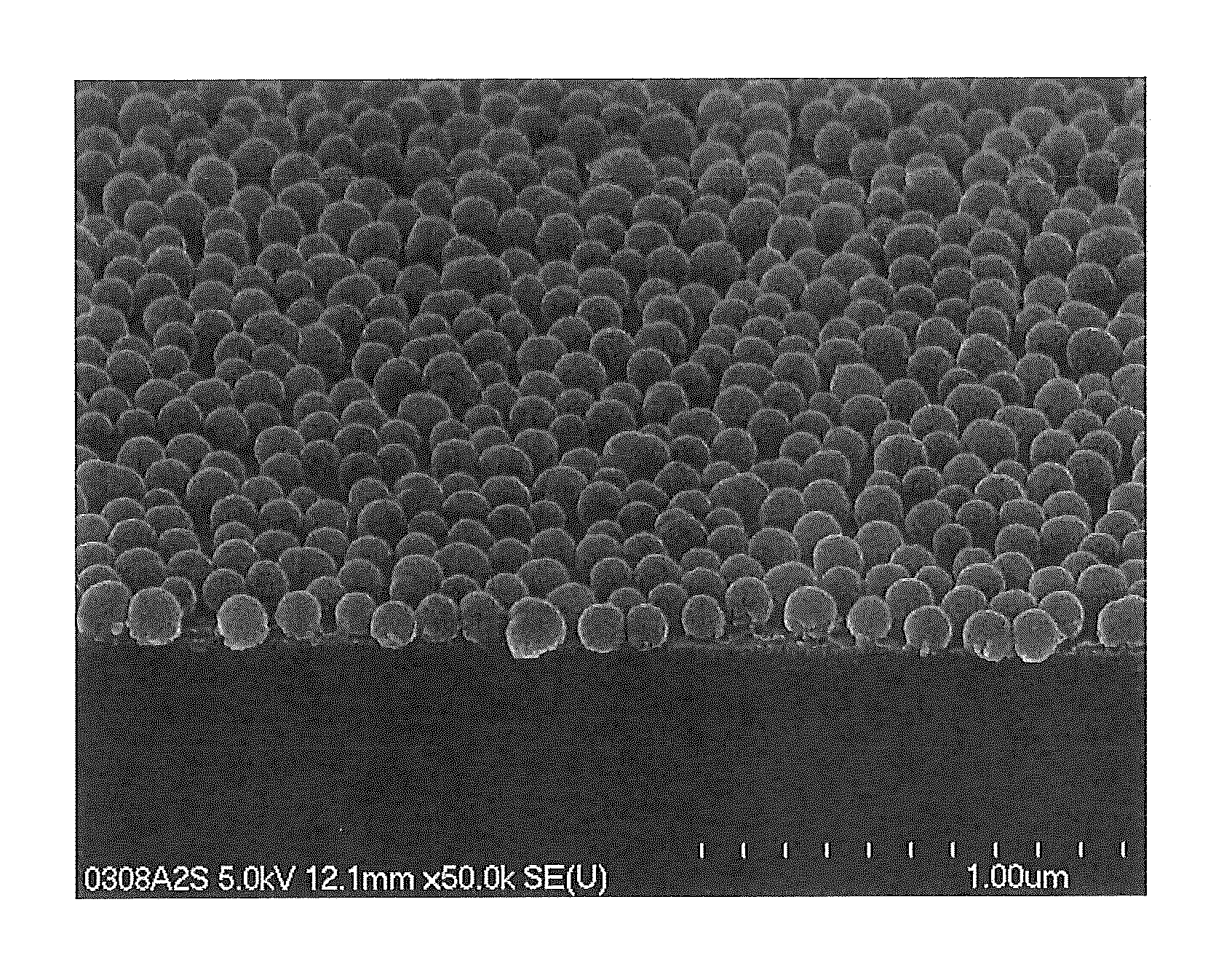

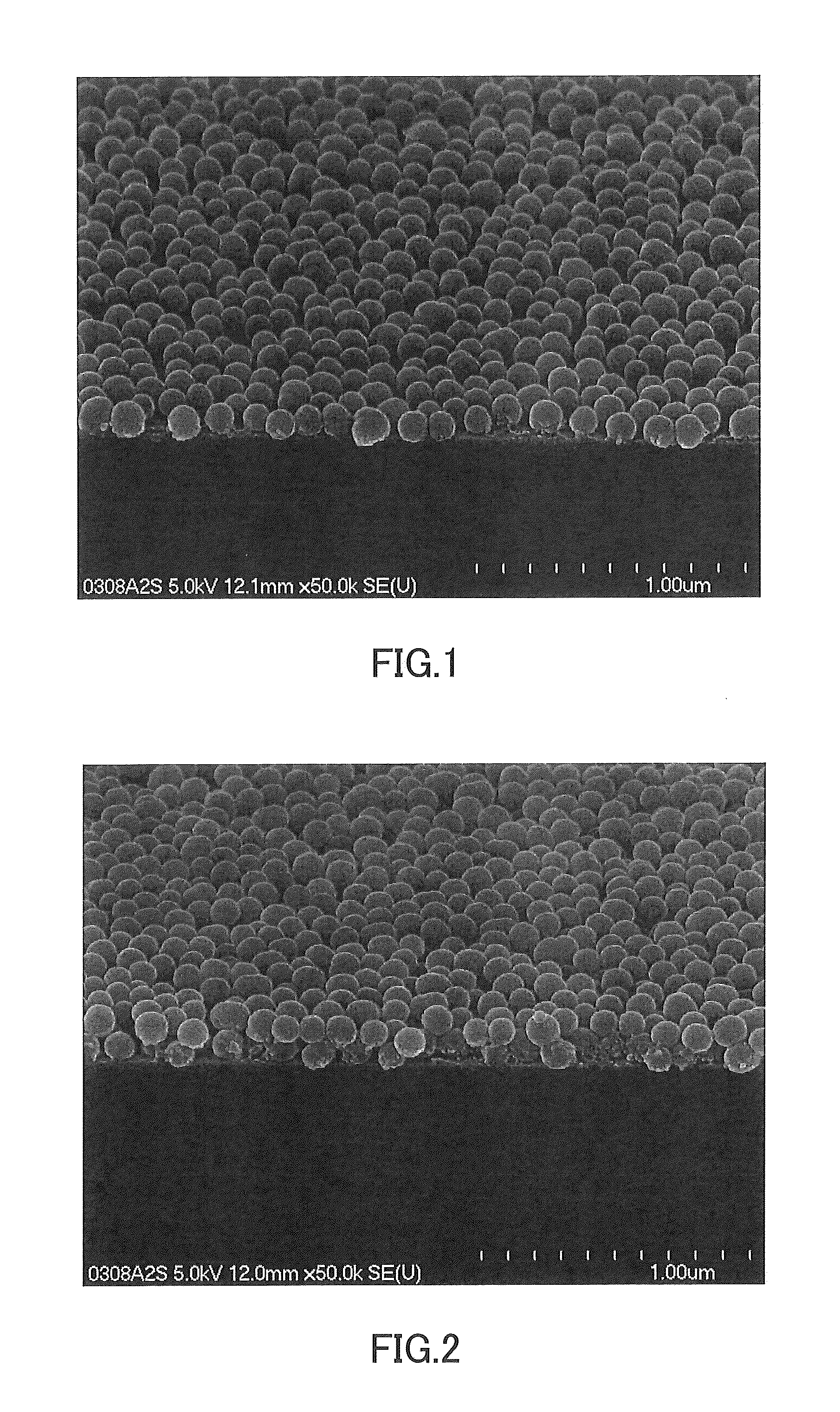

Cover glass for photoelectric conversion device

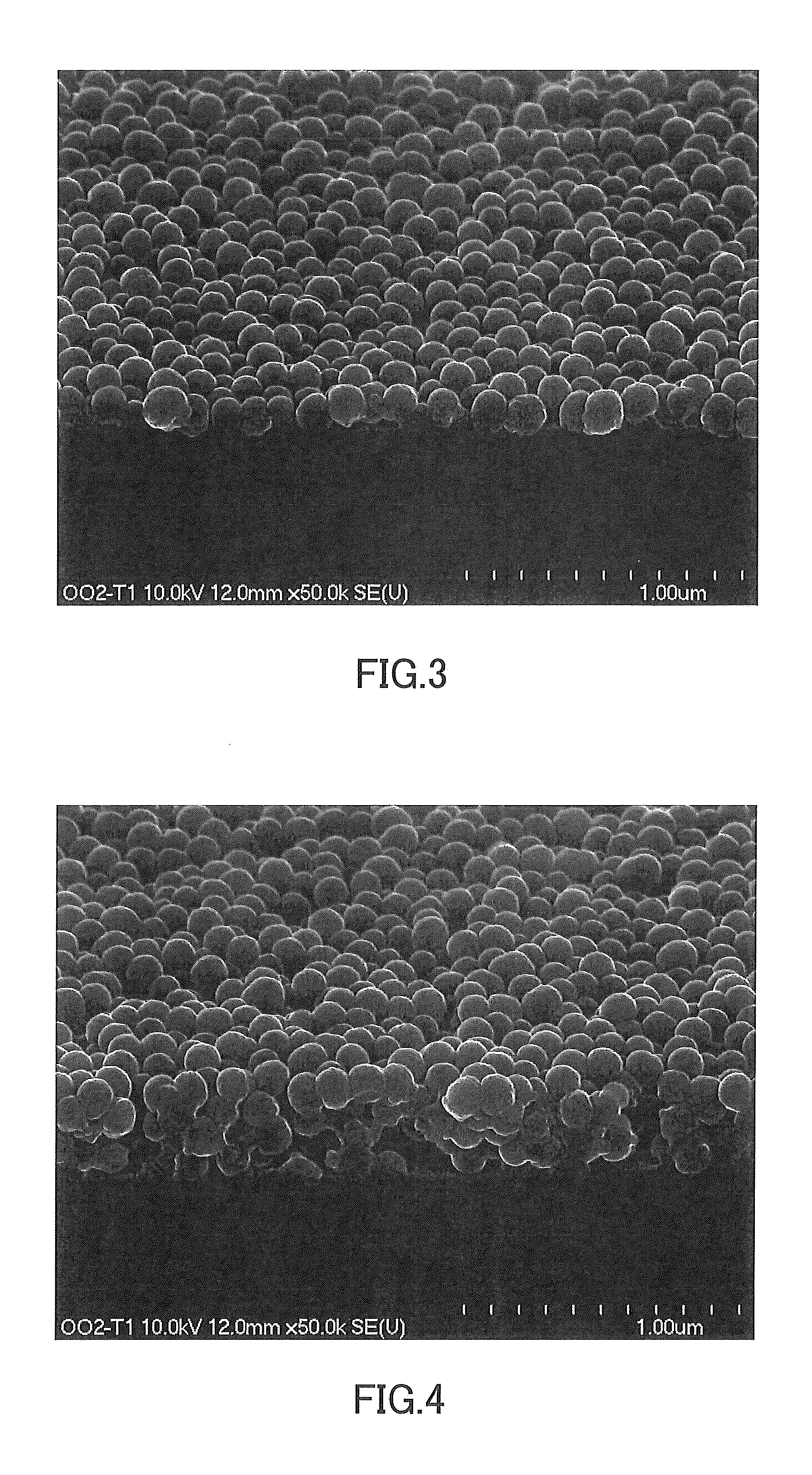

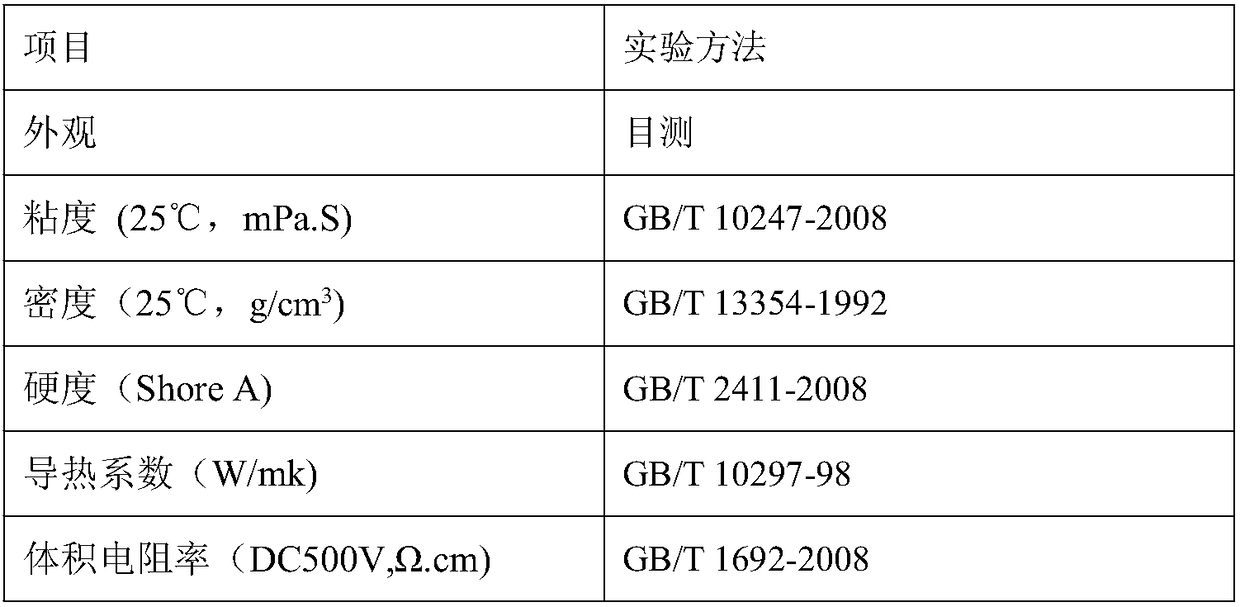

ActiveUS20150177425A1High transmittance gainImprove transmittanceDiffusing elementsProjectorsSilica particleSurface roughness

A cover glass of the present invention for photoelectric conversion devices includes a glass sheet having surface asperities and a reflection-reducing film formed over the surface asperities of the glass sheet. The surface asperities of the glass sheet have an average spacing Sm of 0.3 mm or more and 2.5 mm or less and an arithmetic average roughness Ra of 0.3 μm to 5 μm. The reflection-reducing film includes fine silica particles having an average particle diameter of 50 to 200 nm and a binder for the fine silica particles, and the fine silica particles are uniformly arranged in a single layer on peak portions of the surface asperities in such a manner that a filling fraction F is 35 to 65%. A transmittance gain is 2.37% or more, the transmittance gain being obtained by subtracting an average transmittance of the glass sheet as measured when light having wavelengths ranging from 380 to 1100 nm are incident on a face of the glass sheet that has the surface asperities, from an average transmittance of the cover glass as measured when light having the wavelengths are incident on a reflection-reducing film side of the cover glass. Thus, a cover glass for photoelectric conversion devices that exhibits a high transmittance gain is provided.

Owner:NIPPON SHEET GLASS CO LTD

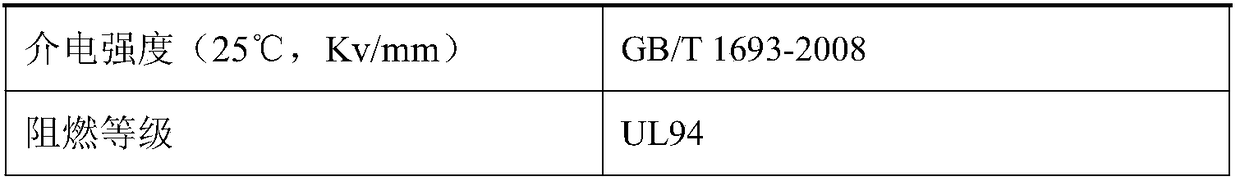

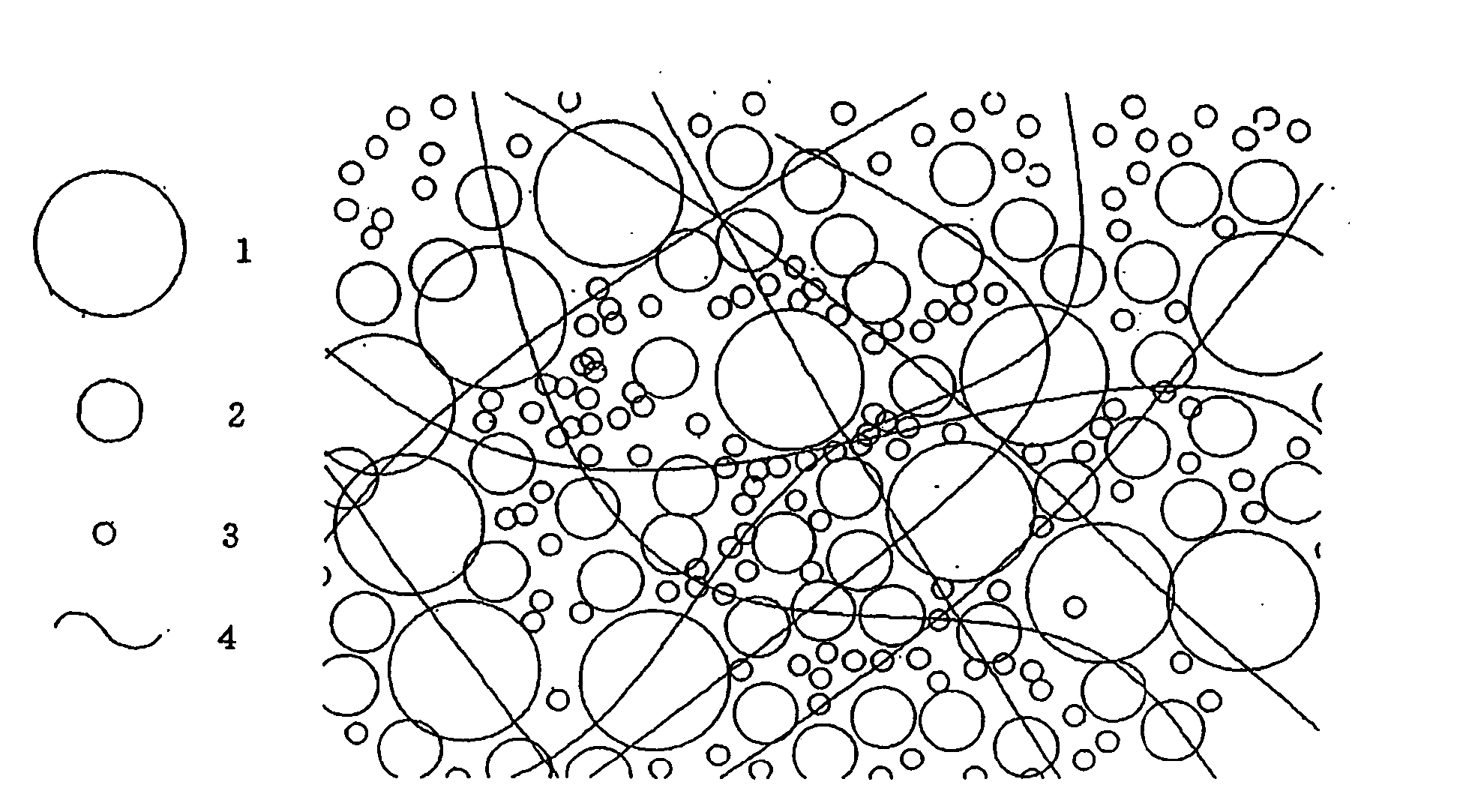

Two-component high-thermal-conductivity pouring sealant and preparation method thereof

InactiveCN108611049AFix compatibility issuesHigh thermal conductivityNon-macromolecular adhesive additivesHydrogenMass ratio

The invention provides a two-component high-thermal-conductivity pouring sealant and a preparation method thereof. The two-component high-thermal-conductivity pouring sealant is composed of a component A and a component B in a mass ratio of 1: 1. The component A comprises, by mass, 6 to 20 parts of vinyl silicone oil, 3 to 14 parts of hydrogen-containing silicone oil, 2 to 6 parts of dimethyl silicone oil, 0.01 to 0.04 part of an inhibitor, 0.2 to 1 part of an anti-settling agent, 3 to 25 parts of a flame retardant and 25 to 70 parts of modified silica micropowder. The component B comprises, by mass, 9 to 34 parts of vinyl silicone oil, 3 to 14 parts of dimethyl silicone oil, 0.1 to 0.5 part of a catalyst, 0.1 to 1.0 part of an anti-settling agent, 3 to 25 parts of a flame retardant and 25to 70 parts of modified silicon micropowder. According to the invention, a silane coupling agent is utilized for modifying the surface of the silicon micropowder so as to improve the compatibility between the silicon micropowder and the silicone oil and increase the filling fraction of the silicon micropowder; and at the same time, through the synergistic action of the flame retardant, the thermal conductivity of the modified silicon micropowder can be greatly performed, and the flame retardant performance of the prepared pouring sealant is improved, so the high-thermal-conductivity pouring sealant is prepared.

Owner:SHENZHEN MPD HITECH CO LTD

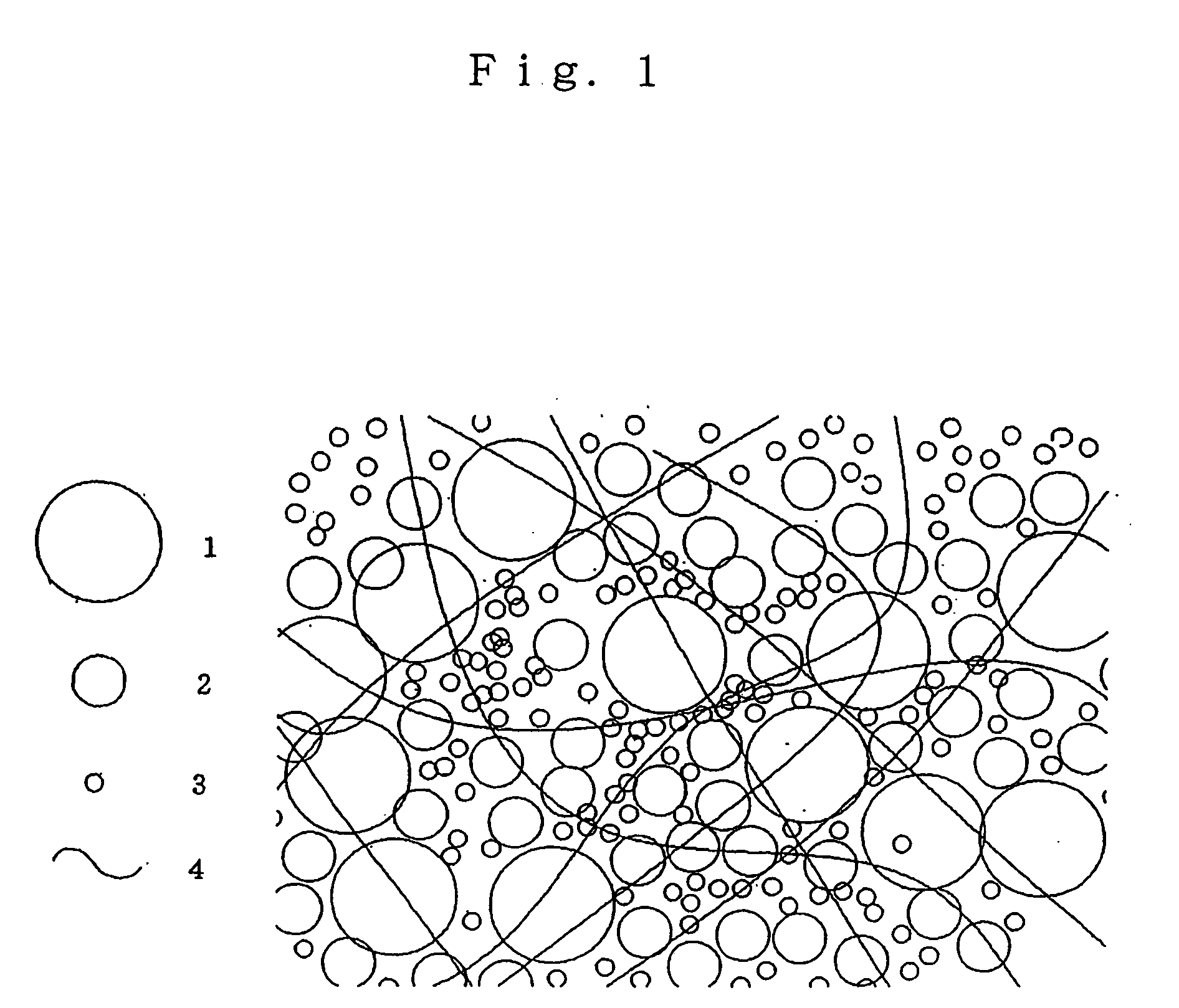

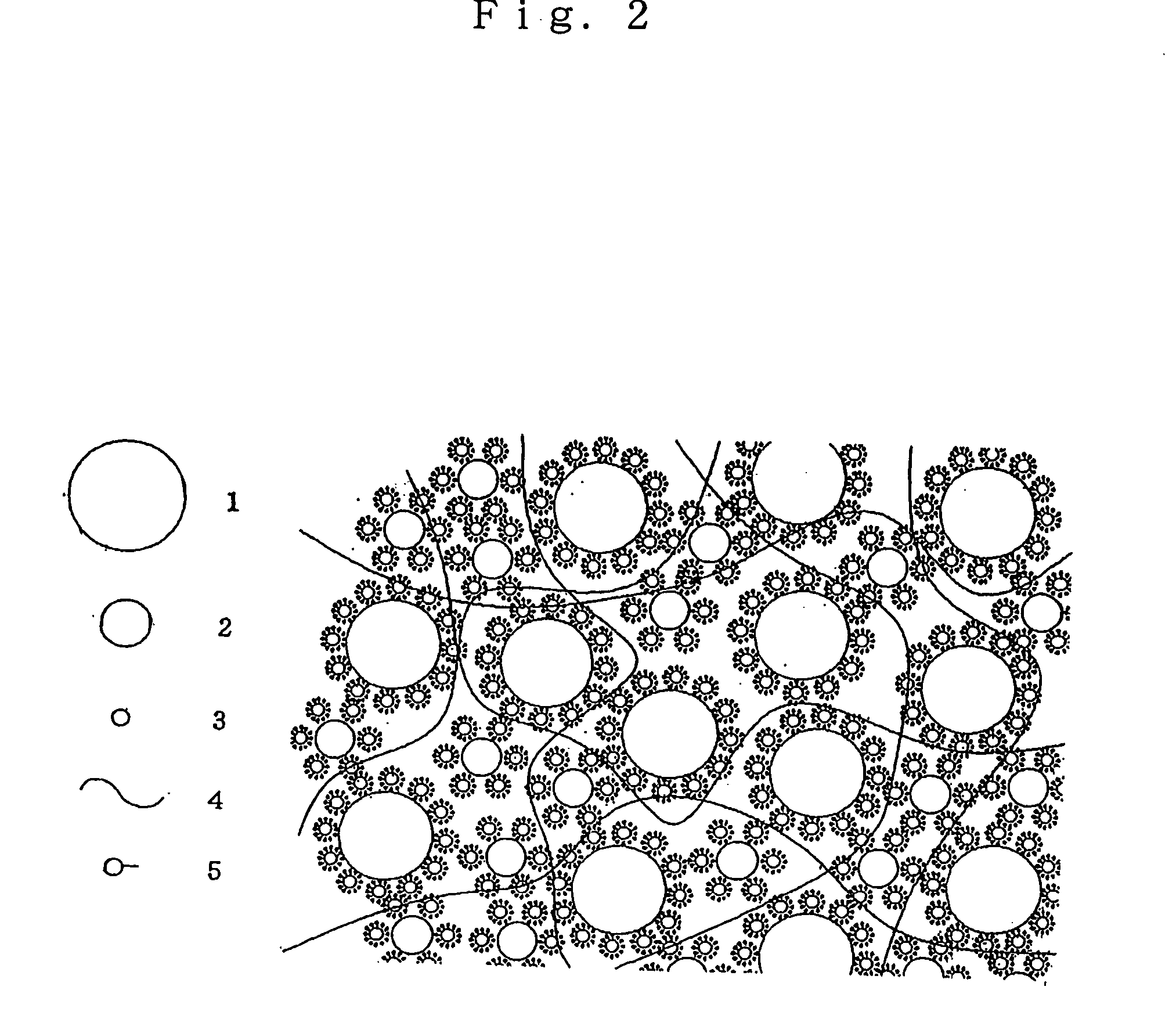

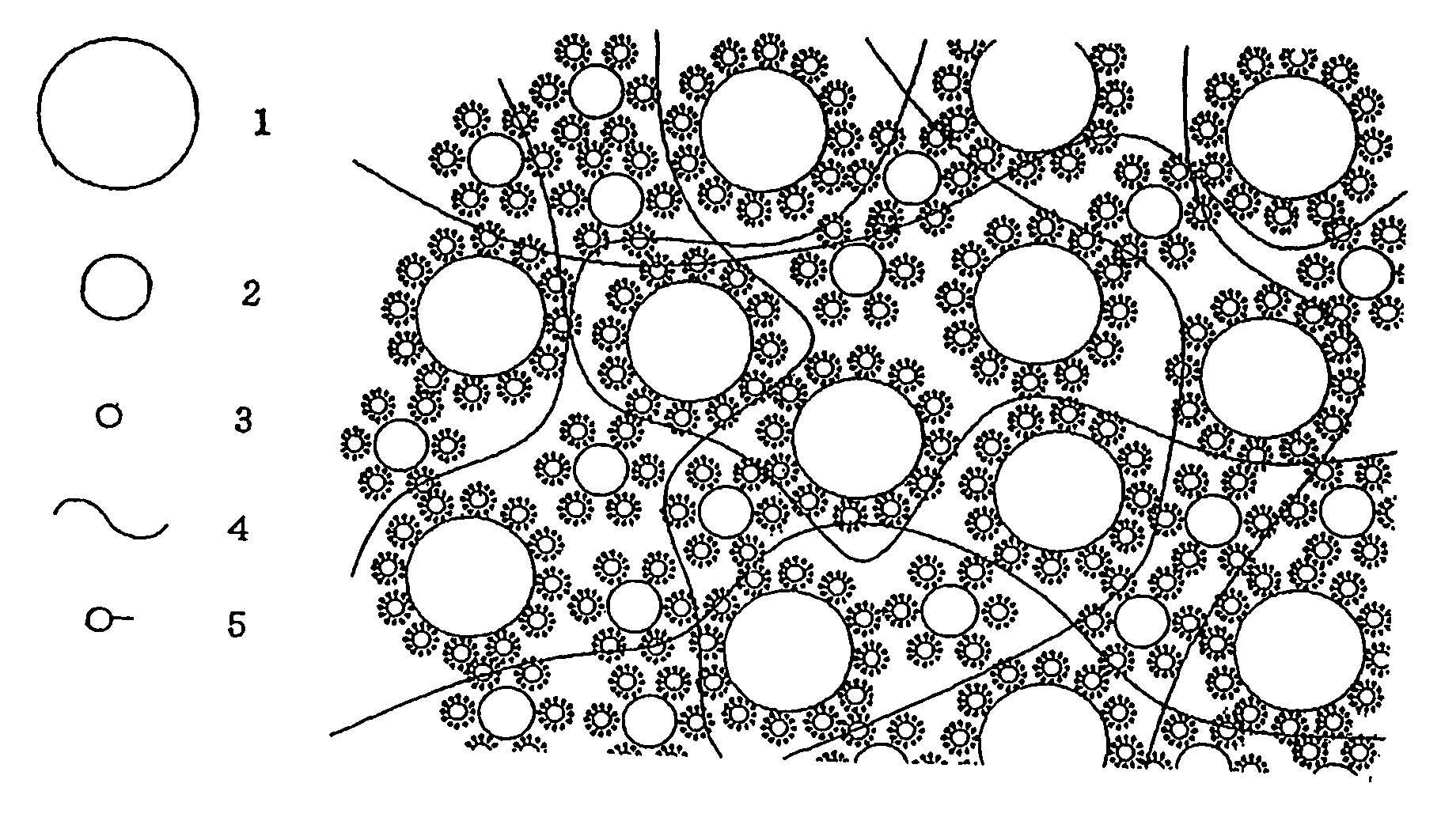

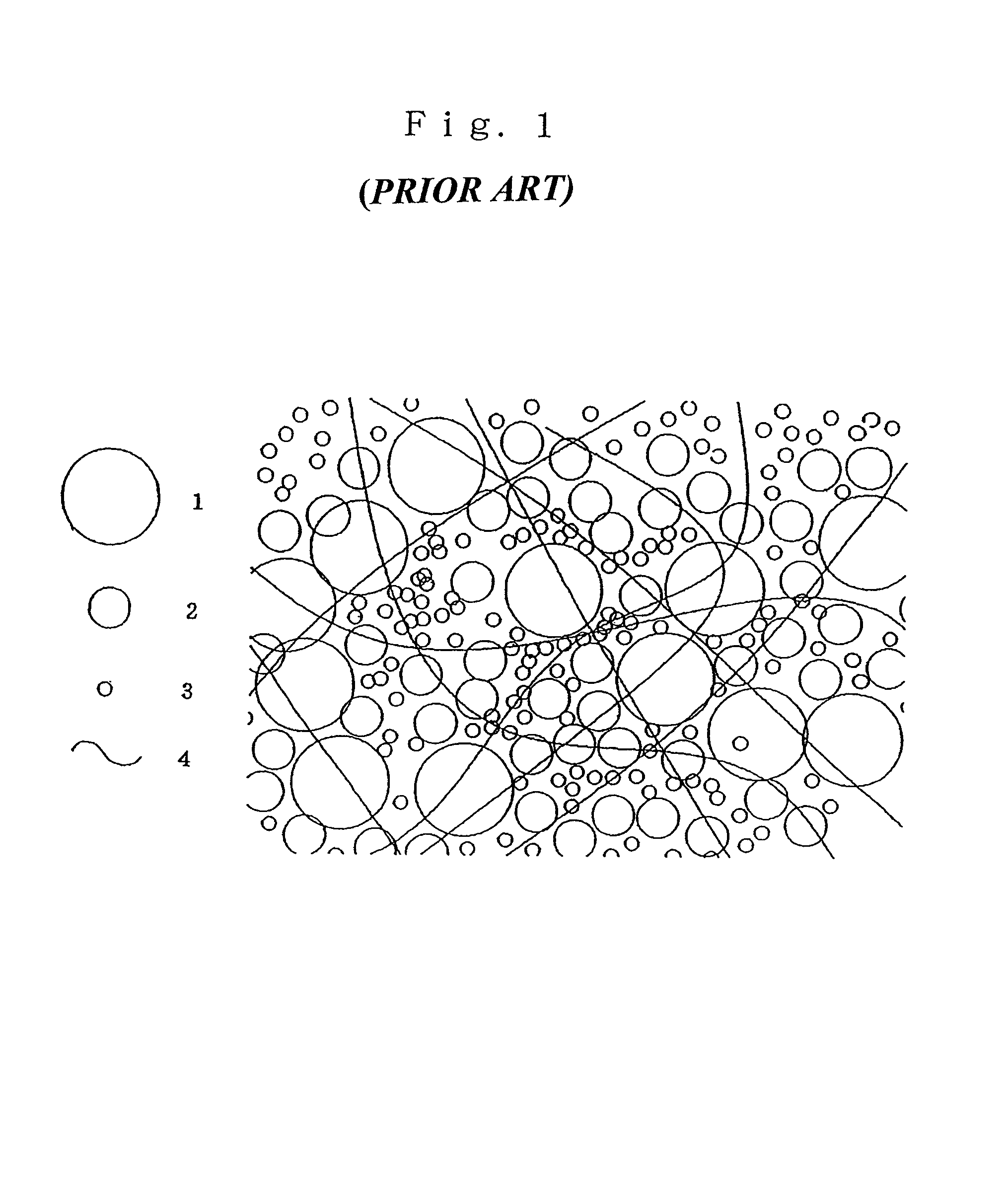

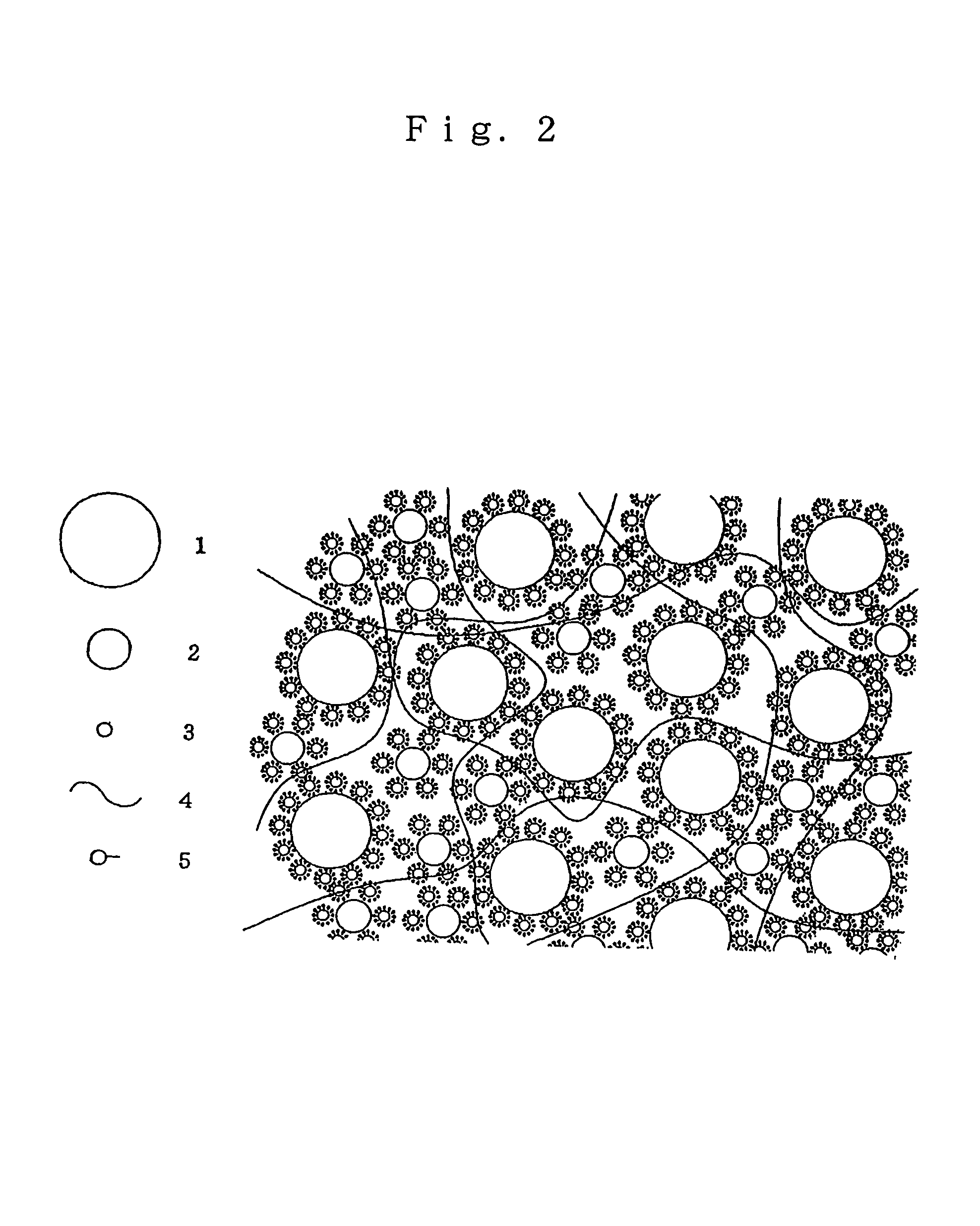

Electrode formulation for polarized electrode and method for preparation thereof, and polarized electrode using the eletrode formulation

InactiveUS20050116375A1Low viscosityFavorable packing ratioNon-metal conductorsElectrolytic capacitorsParticulatesActivated carbon

The present invention provides polarized electrodes that ensure a satisfactory packing ratio of activated carbon particles and conductive particulates and favorable contact between these and an electrolyte, and demonstrate high capacitance. The present invention relates to the following electrode materials for polarized electrodes: (1) electrode materials for polarized electrodes containing a rubber-based emulsion, activated carbon particles, conductive particulates, and a surfactant; and (2) electrode materials for polarized electrodes containing a dispersion of polytetrafluoroethylene, activated carbon particles, conductive particulates, and a surfactant, wherein the solid content is 25% by weight or more.

Owner:ITO JUNJI

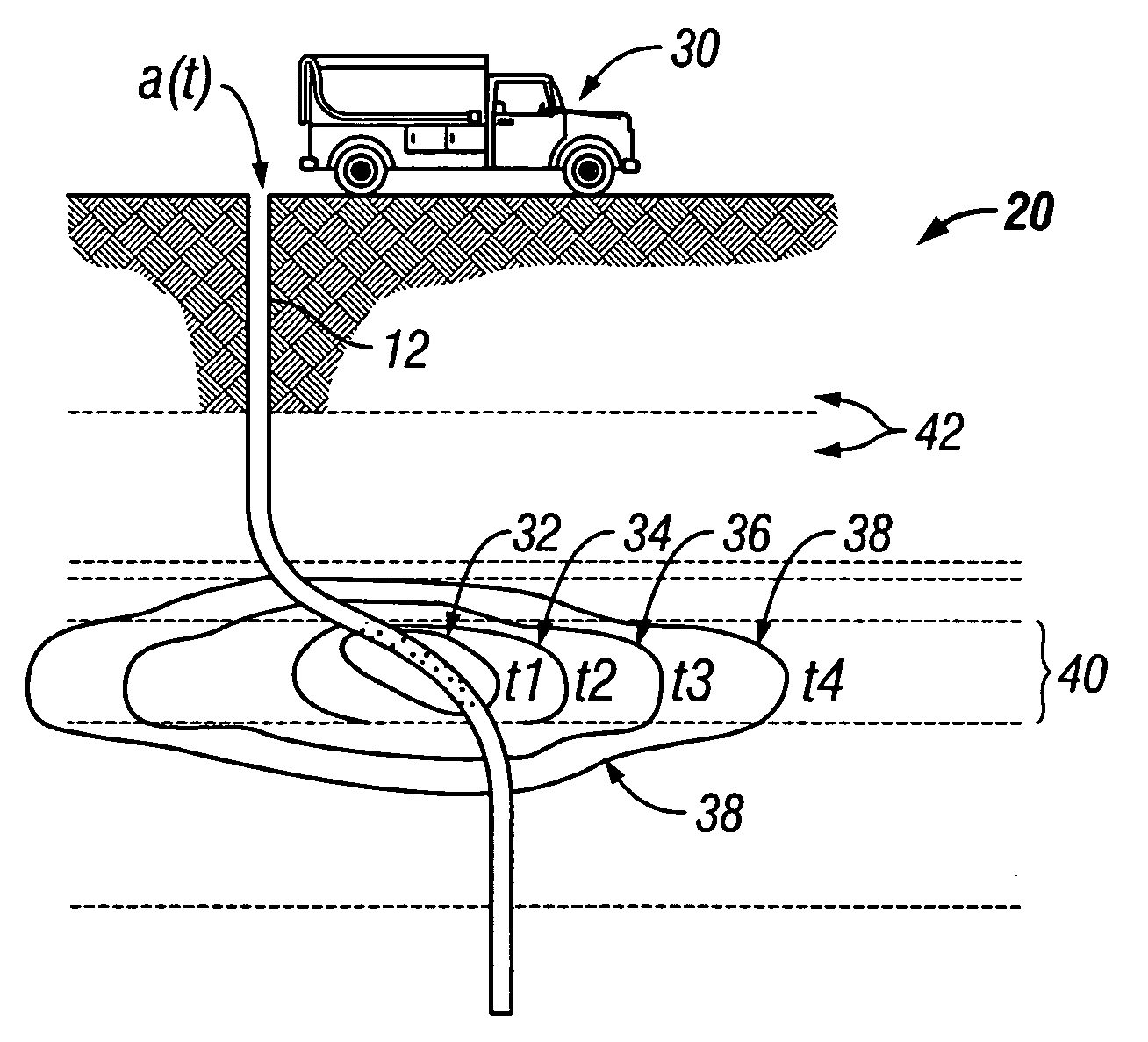

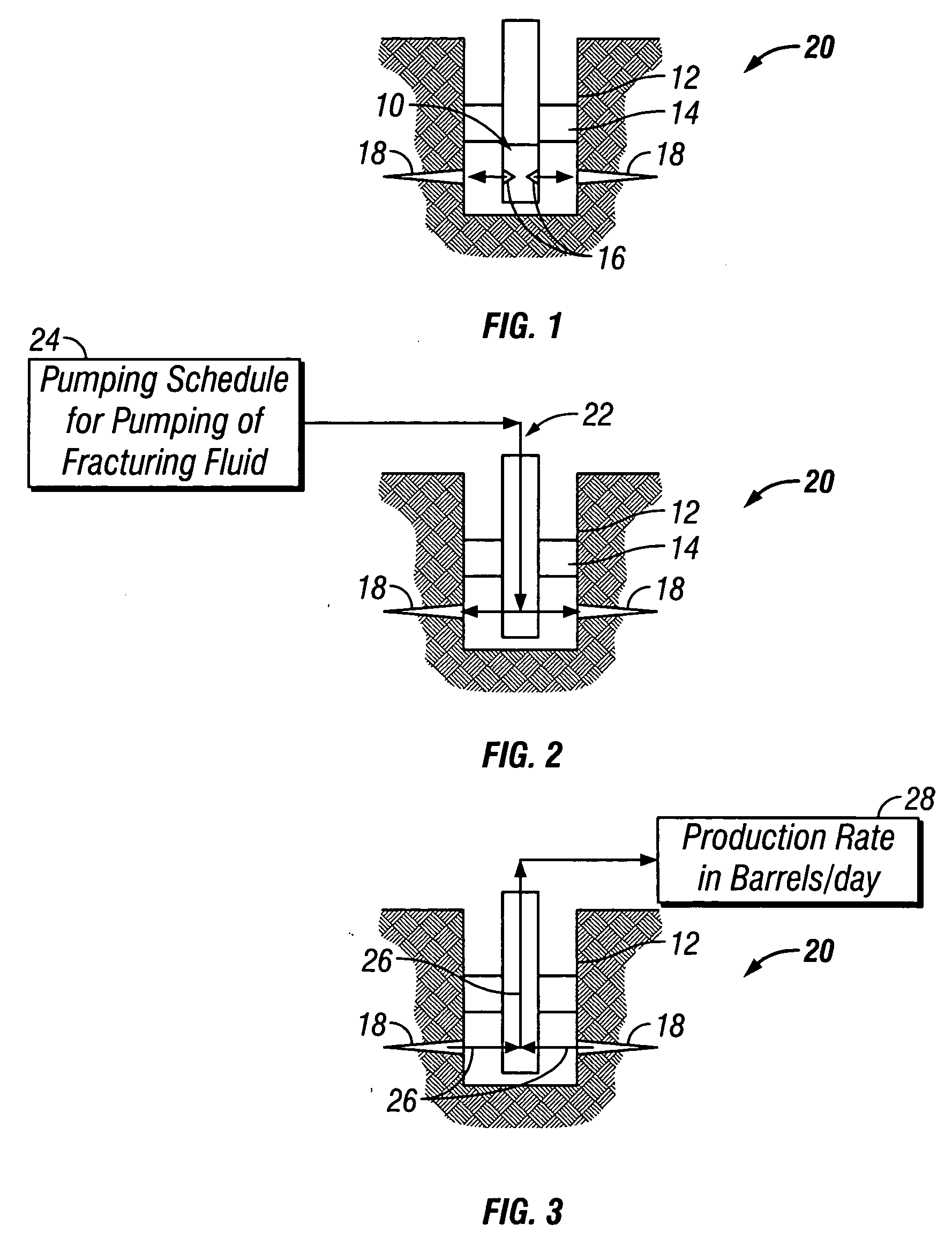

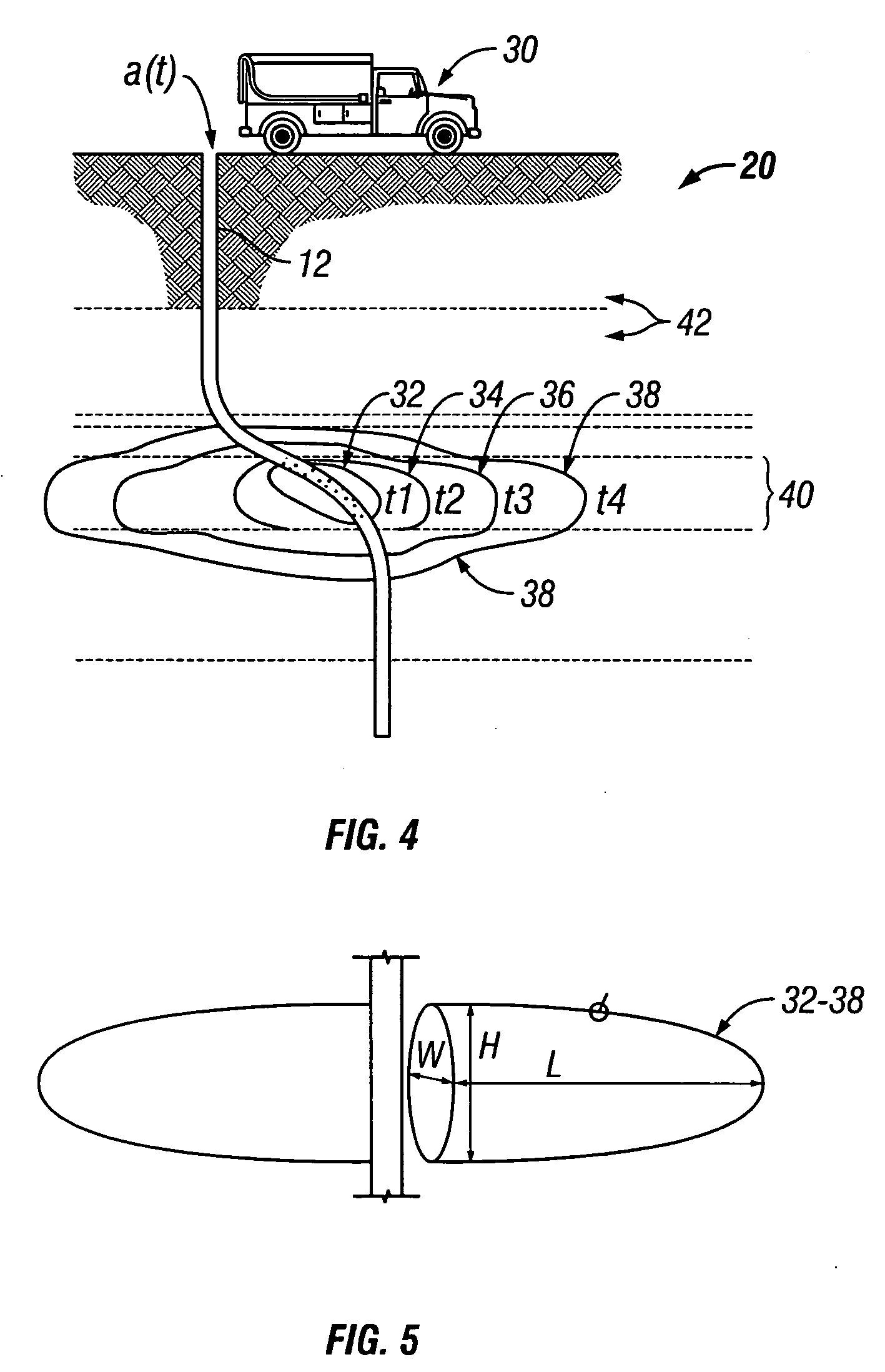

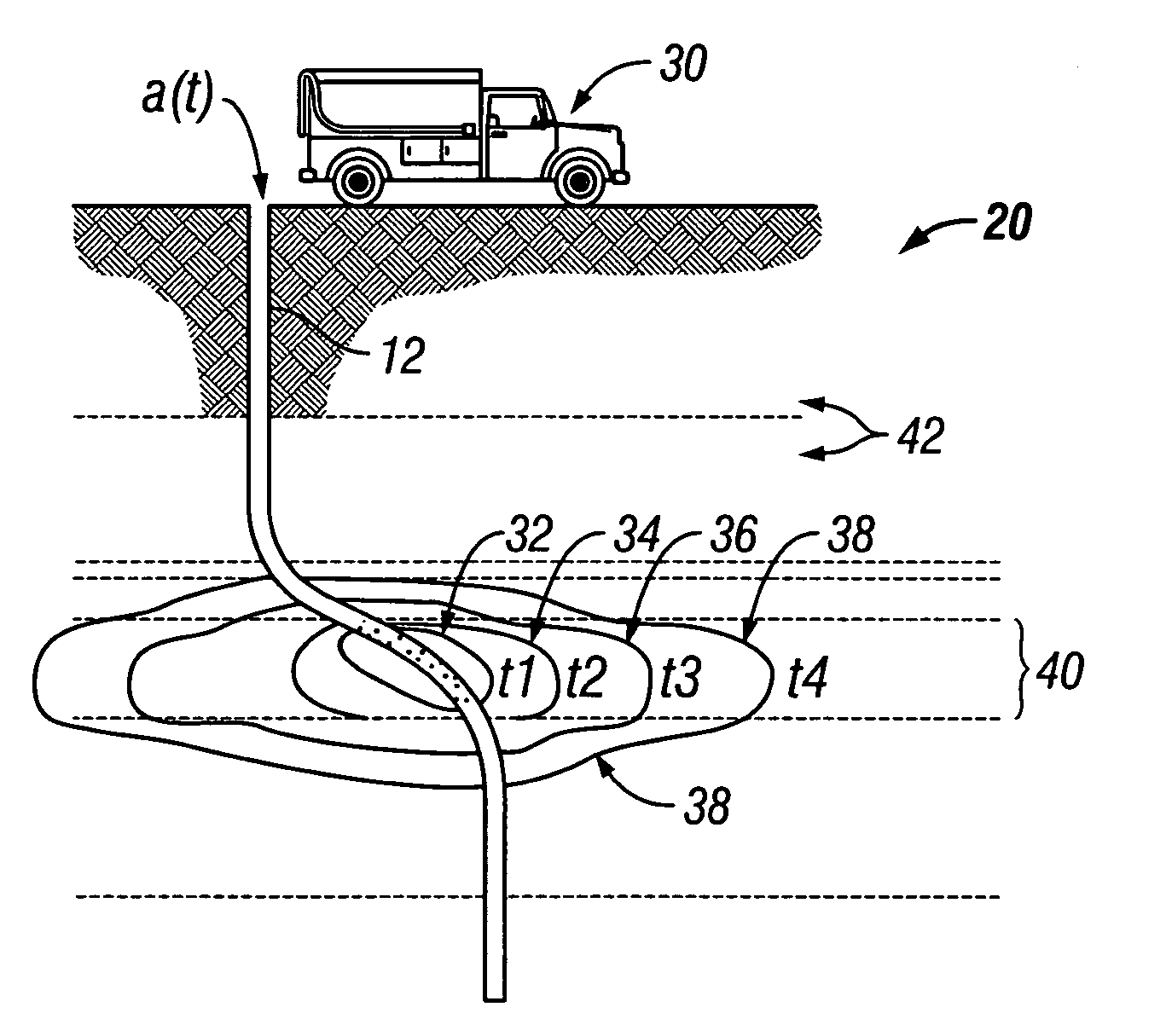

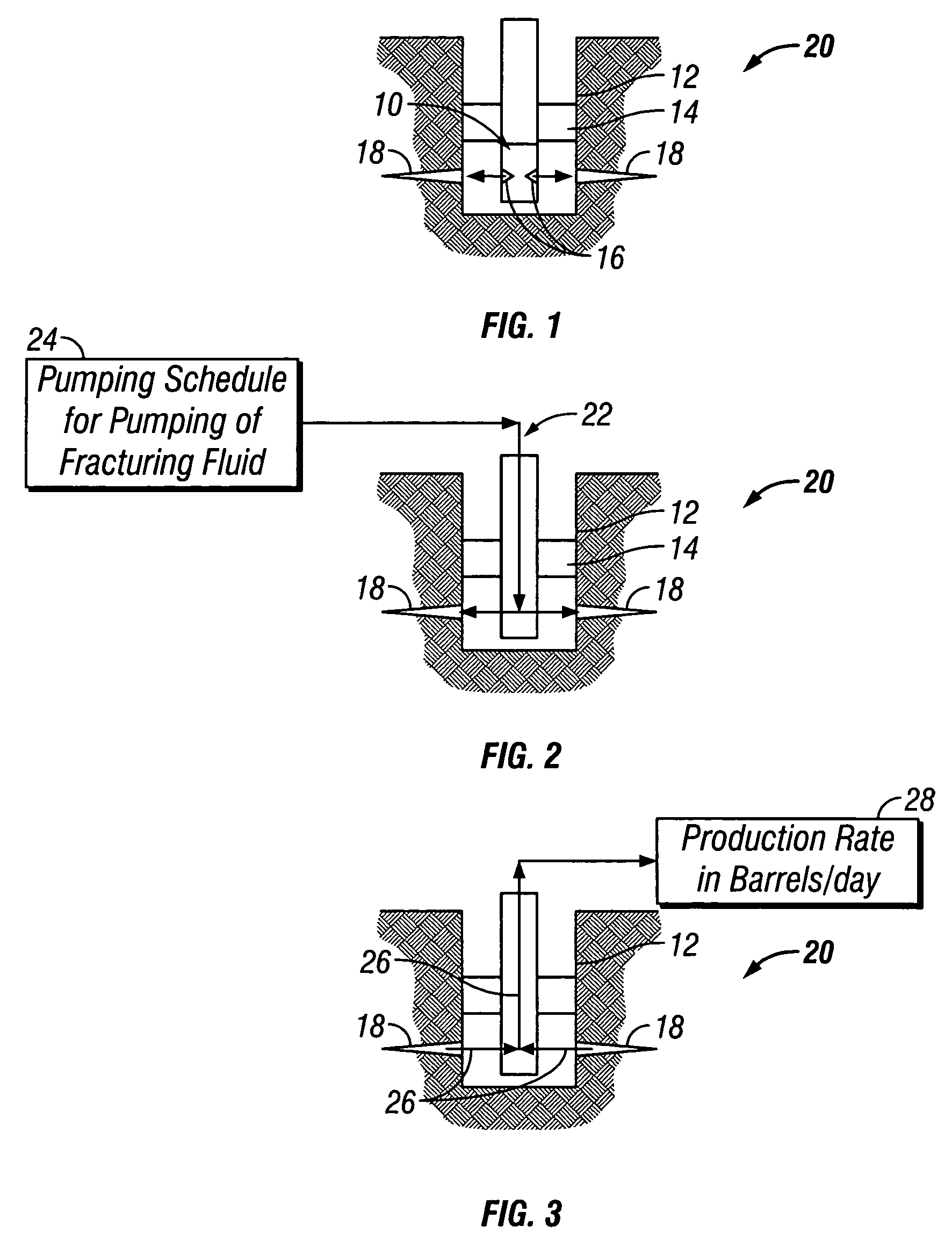

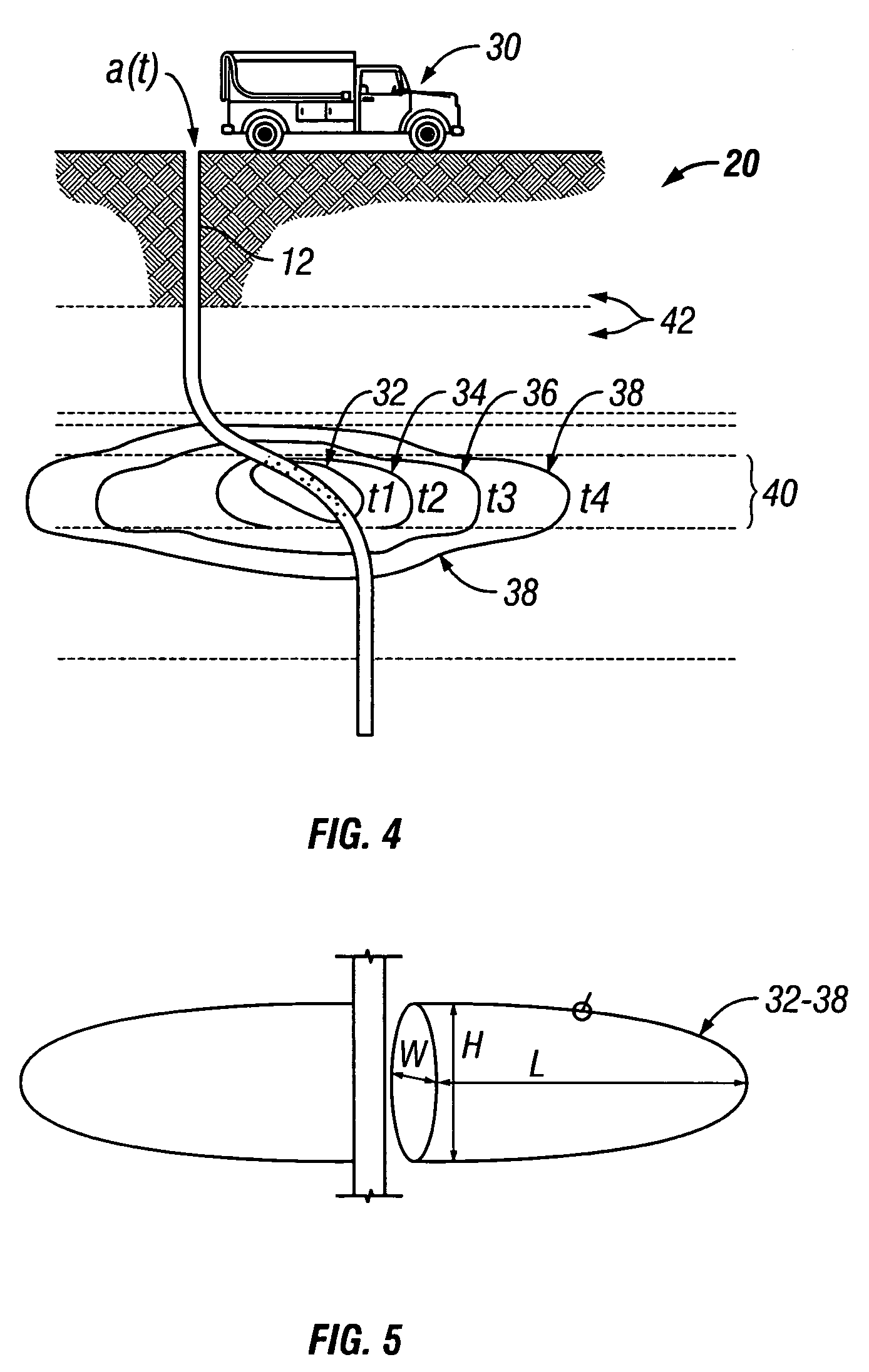

Method and apparatus and program storage device for front tracking in hydraulic fracturing simulators

A method and system and program storage device is adapted to continuously update a perimeter of a fracture footprint created in an Earth formation when a fracturing fluid fractures the formation penetrated by a wellbore. Two embodiments of a Volume of Fluid (VOF) software, adapted to be stored in a memory of a computer system, will locate the position of a fracture perimeter during the evolution of that fracture when the software is executed by the processor of the computer system. The two embodiments, called the ‘Marker VOF (MVOF)’ and the ‘Full VOF (FVOF)’ software, will continuously update the perimeter of the fracture footprint by updating a Fill Fraction for each tip element. The MVOF software will use a fill fraction mass balance integral equation to update the Fill Fraction for each tip element, and the FVOF software will use an integrated form of fluid flow equations to update the Fill Fraction for each tip element.

Owner:SCHLUMBERGER TECH CORP

Method for preparing an electrode material for a polarized electrode

InactiveUS7491352B2Smooth connectionLow viscosityHybrid capacitor electrodesElectrolytic capacitorsActivated carbonParticulates

The present invention provides polarized electrodes that ensure a satisfactory packing ratio of activated carbon particles and conductive particulates and favorable contact between these and an electrolyte, and demonstrate high capacitance. The present invention relates to the following electrode materials for polarized electrodes:(1) electrode materials for polarized electrodes containing a rubber-based emulsion, activated carbon particles, conductive particulates, and a surfactant; and(2) electrode materials for polarized electrodes containing a dispersion of polytetrafluoroethylene, activated carbon particles, conductive particulates, and a surfactant, wherein the solid content is 25% by weight or more.

Owner:ITO JUNJI

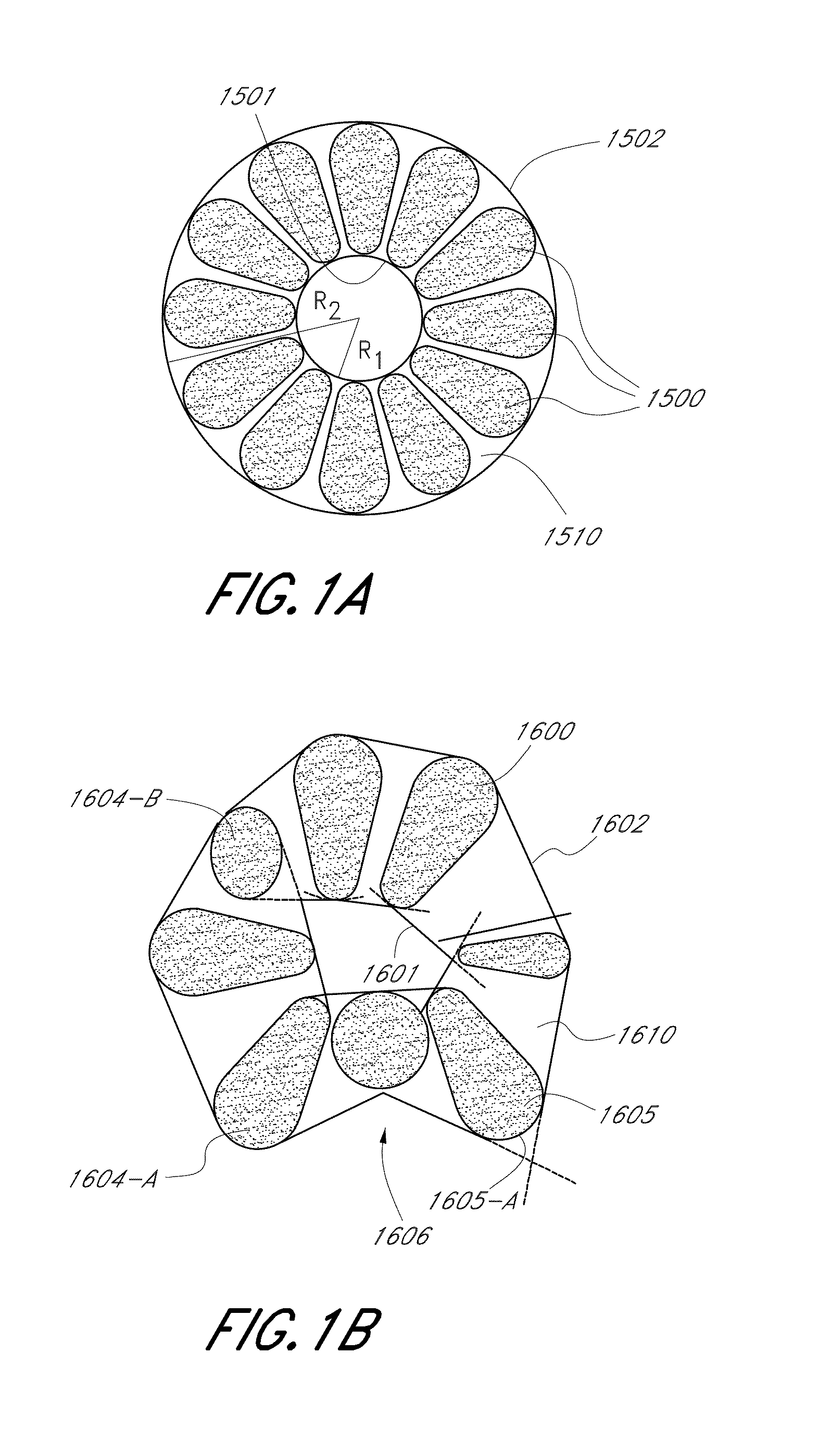

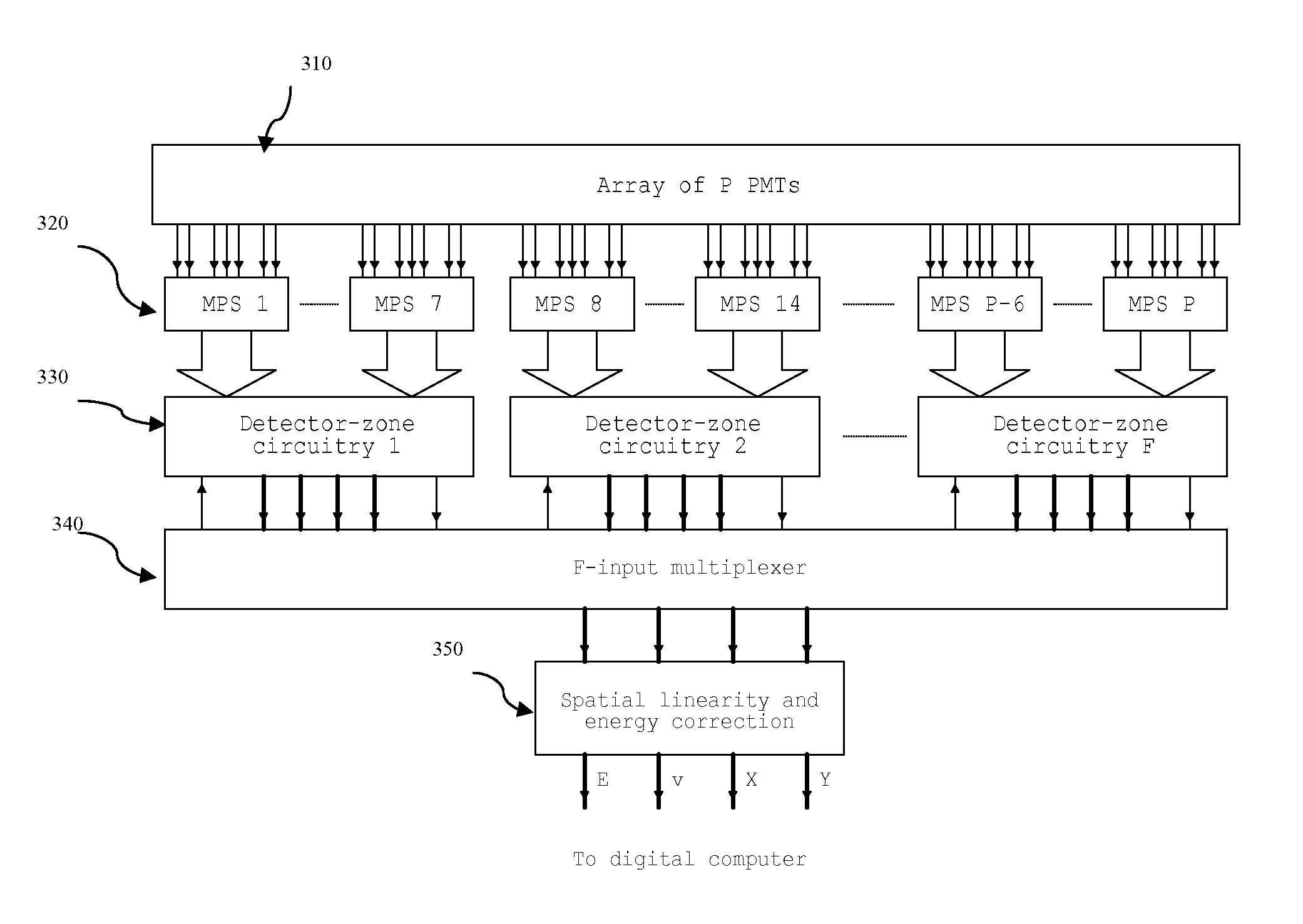

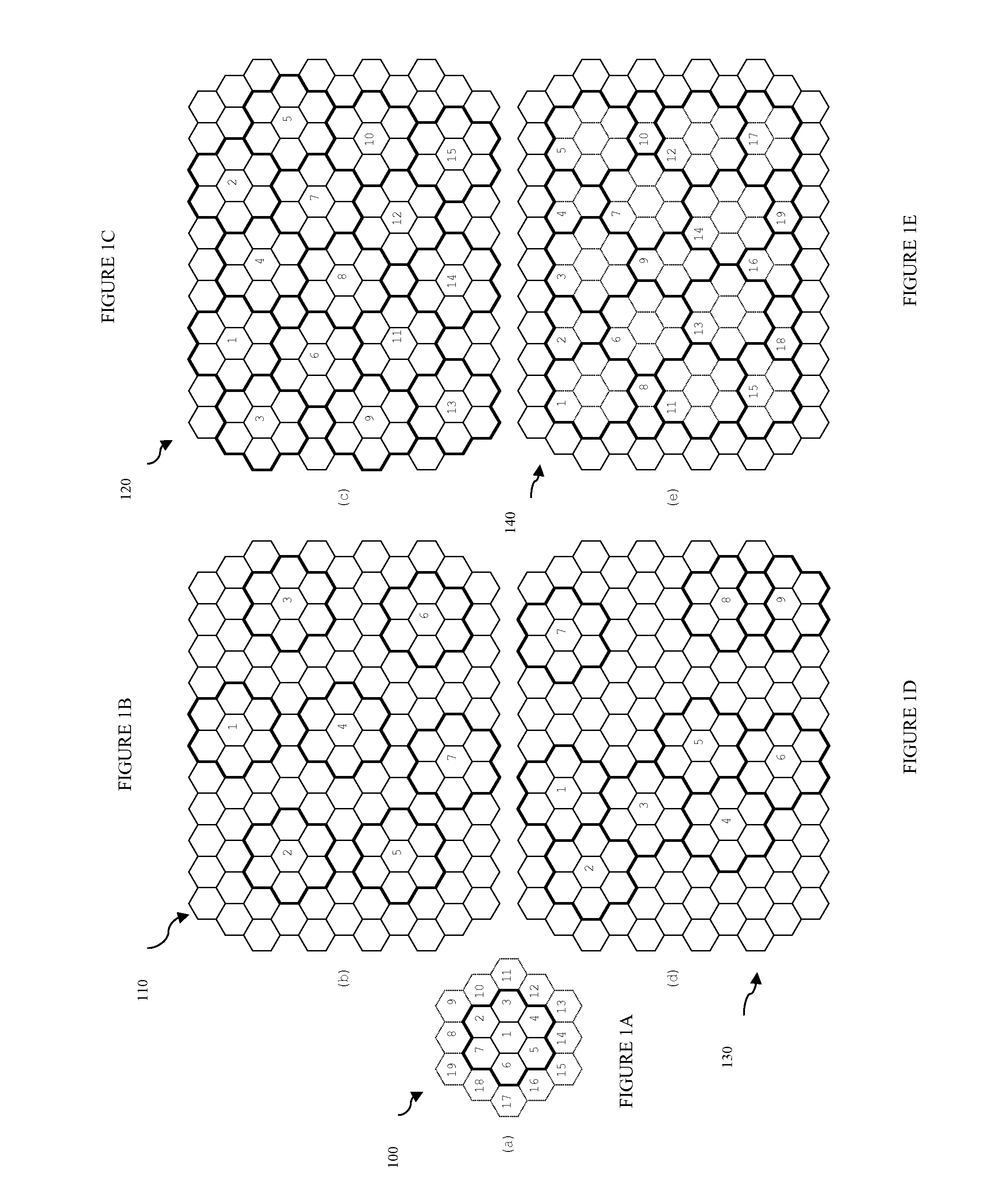

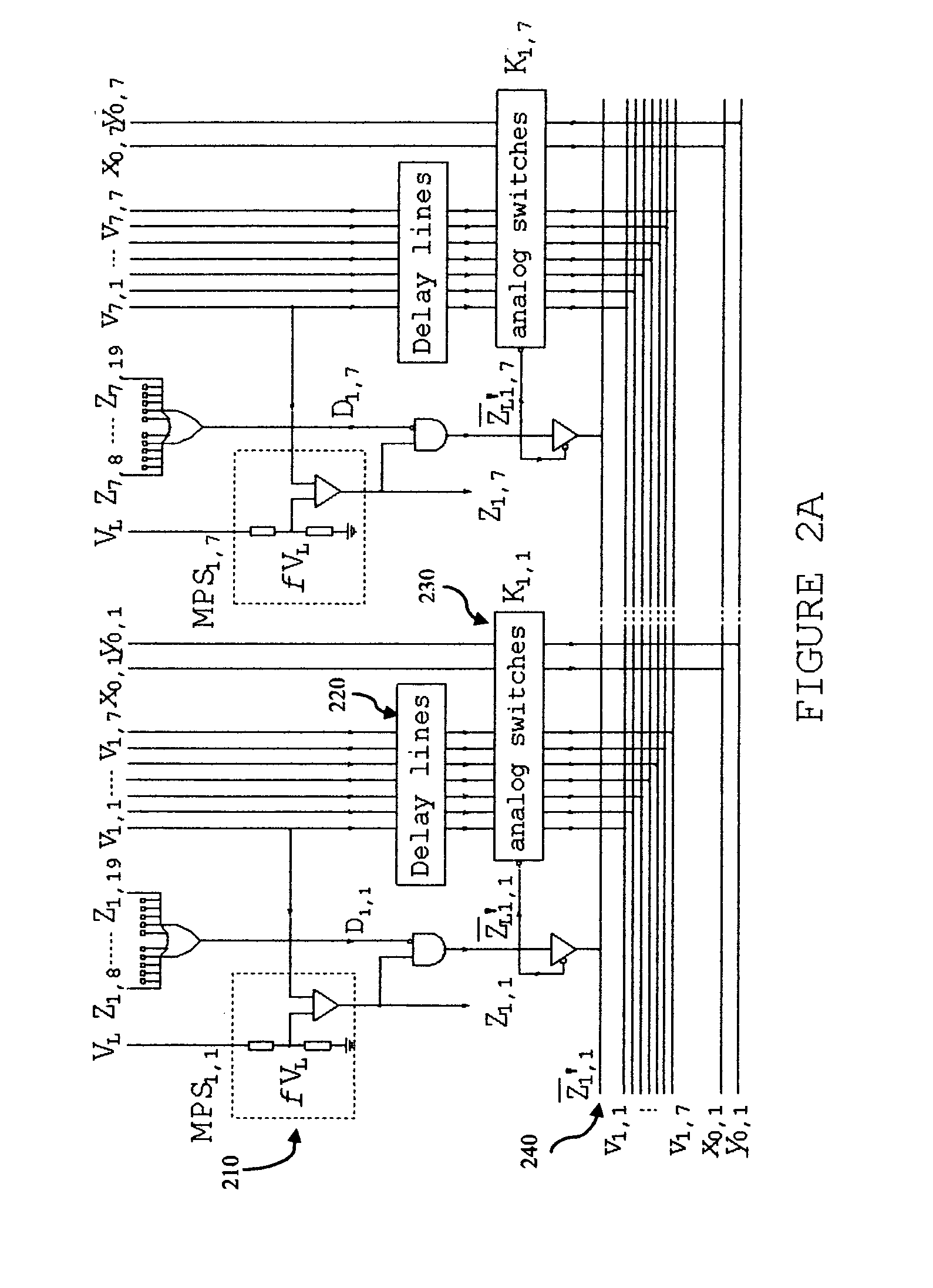

Method and system for nuclear imaging using multi-zone detector architecture

InactiveUS8809790B2Raise the ratioImprove resolutionMaterial analysis by optical meansRadiation intensity measurementFiberPhotodetector

A method and system for nuclear imaging normally involves detection of energy by producing bursts of photons in response to interactions involving incident gamma radiation. The detector sensitivity is increased by as much as two orders of magnitude, so that some excess sensitivity can be exchanged to achieve unprecedented spatial resolution and contrast-to-noise (C / N) ratio comparable to those in CT and MRI. Misplaced pileup events due to scattered radiation are rejected for each of the central groups to reduce image blurring, thereby further improving image quality. The reduction in detector thickness minimizes depth-of-interaction (DOI) blurring as well as blurring due to Compton-scattered radiation. The spatial sampling of the detector can be further increased using fiber optic coupling to reduce effective photodetector size. Fiber-optic coupling also enables to increase the packing fraction of PMTs to 100% by effectively removing the glass walls.

Owner:WOLDEMICHAEL TILAHUN WOLDESELASSIE

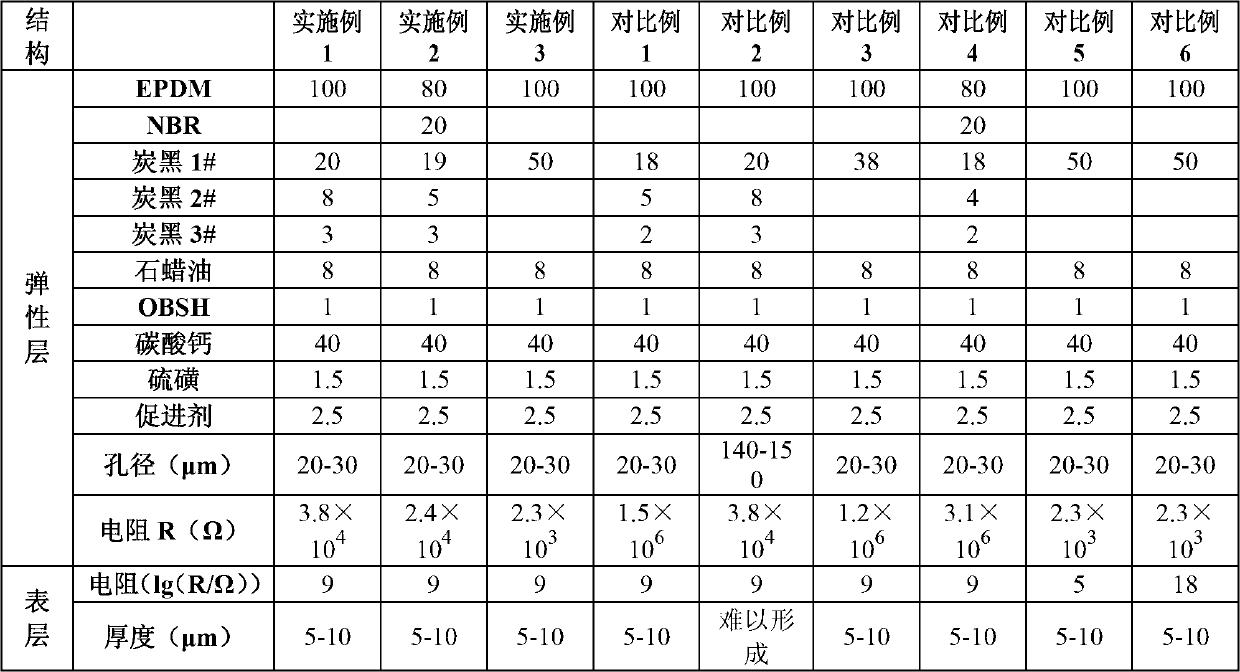

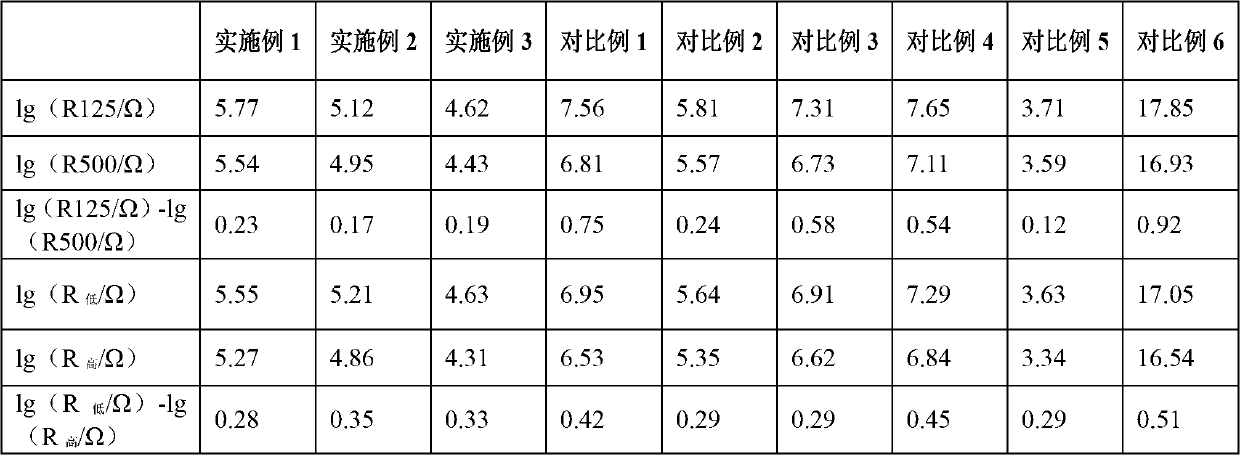

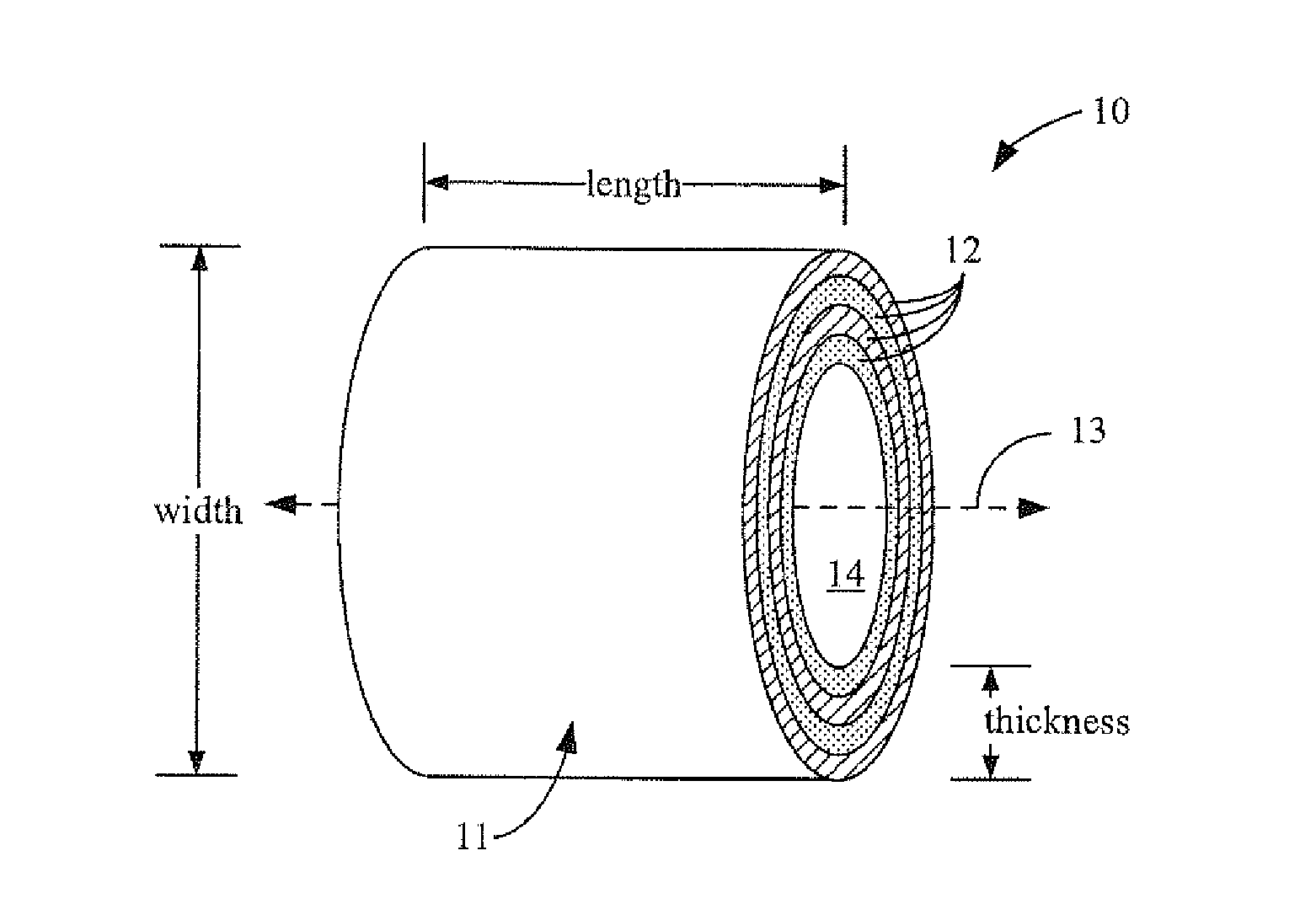

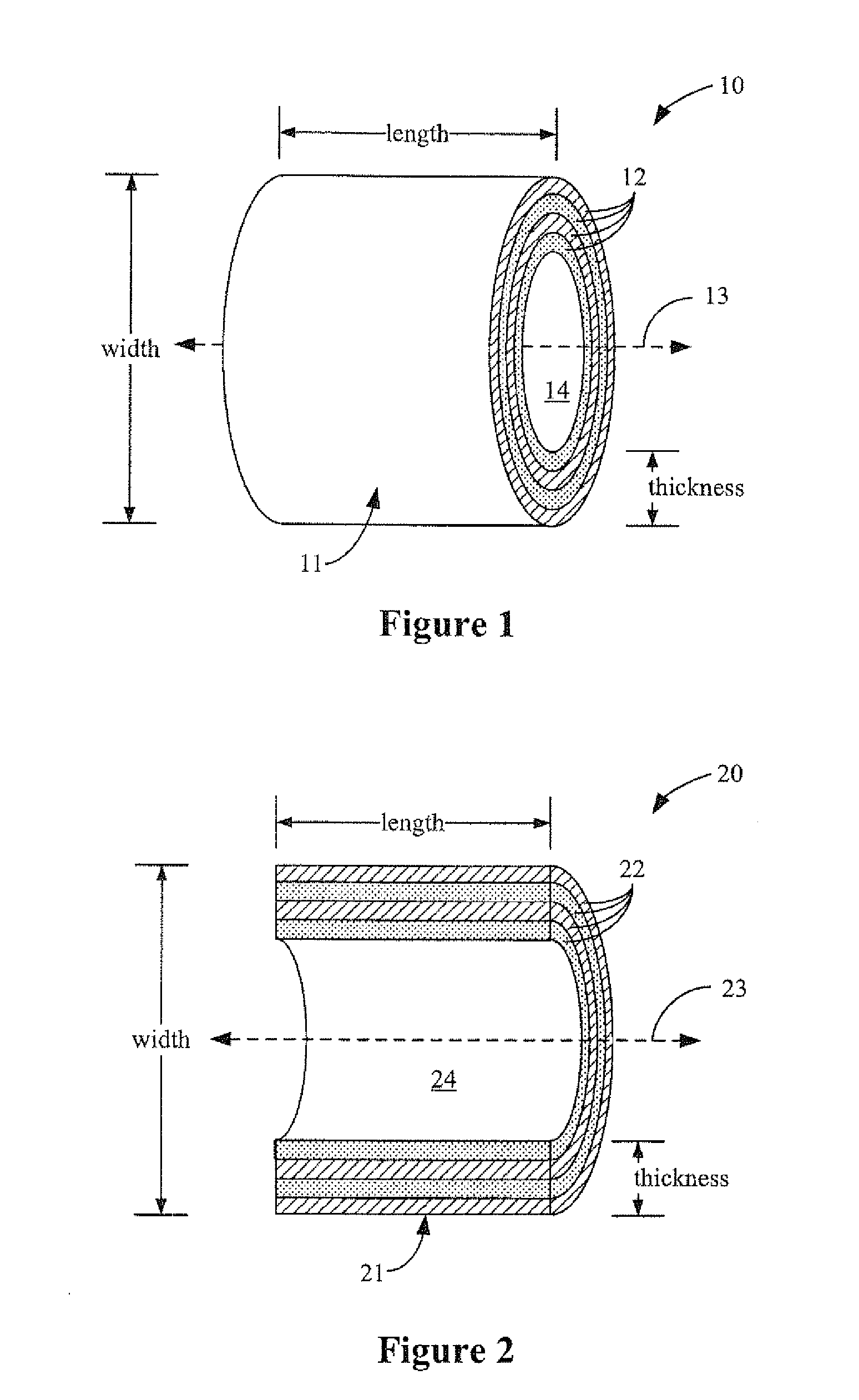

Conductive rubber roller and imaging device

ActiveCN103105761AMeet the resistance value requirementsLow voltage dependencePolyurea/polyurethane coatingsElectrographic process apparatusSurface layerBulk fill

The invention provides a conductive rubber roller. The conductive rubber roller comprises a metal shaft core, an elastic layer packed outside the metal shaft core and a surface layer formed outside the elastic layer, wherein the elastic layer consists of rubber A and at least one of conductive fillers filled in the rubber A; the threshold value range of the conductive fillers in the rubber is as follows: a conductive filler valve is greater than or equal to Zb and is less than or equal to Yb; and b / Yb+c / Yc+...q / Yx is greater than or equal to 1 if the filling fractions of the conductive fillers B, C,...X in the rubber A are respectively set to be b, c,...q. According to the conductive rubber roller provided by the invention, the filling number of the conductive fillers of the elastic layer is limited, and an integral resistance value of the rubber roller is adjusted according to the resistance difference between an inner layer structure and an outer structure layer, so that the conductive rubber roller is less in dependency to voltage, and is less fluctuated by the environment change, the resistance is even in distribution, and the increase of the rigidity of the rubber roller since a mass of the conductive fillers are filled into the elastic layer can be avoided; and therefore, not only can the cost of the material be reduced, but also the whole flexibility of the rubber roller can be guaranteed. The invention further discloses an imaging device which comprises the conductive rubber roller.

Owner:SHENZHEN LEPUTAI TECH CO LTD

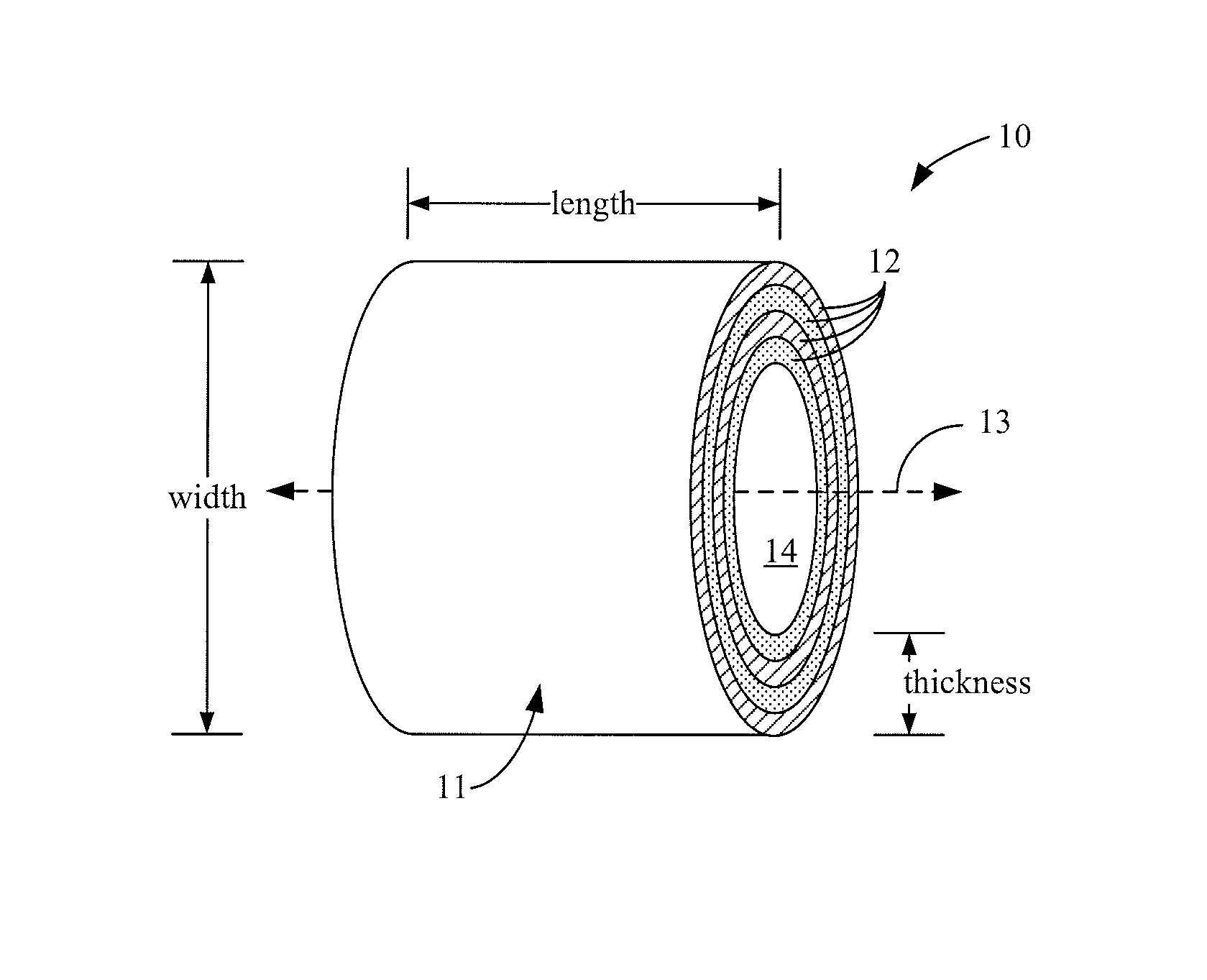

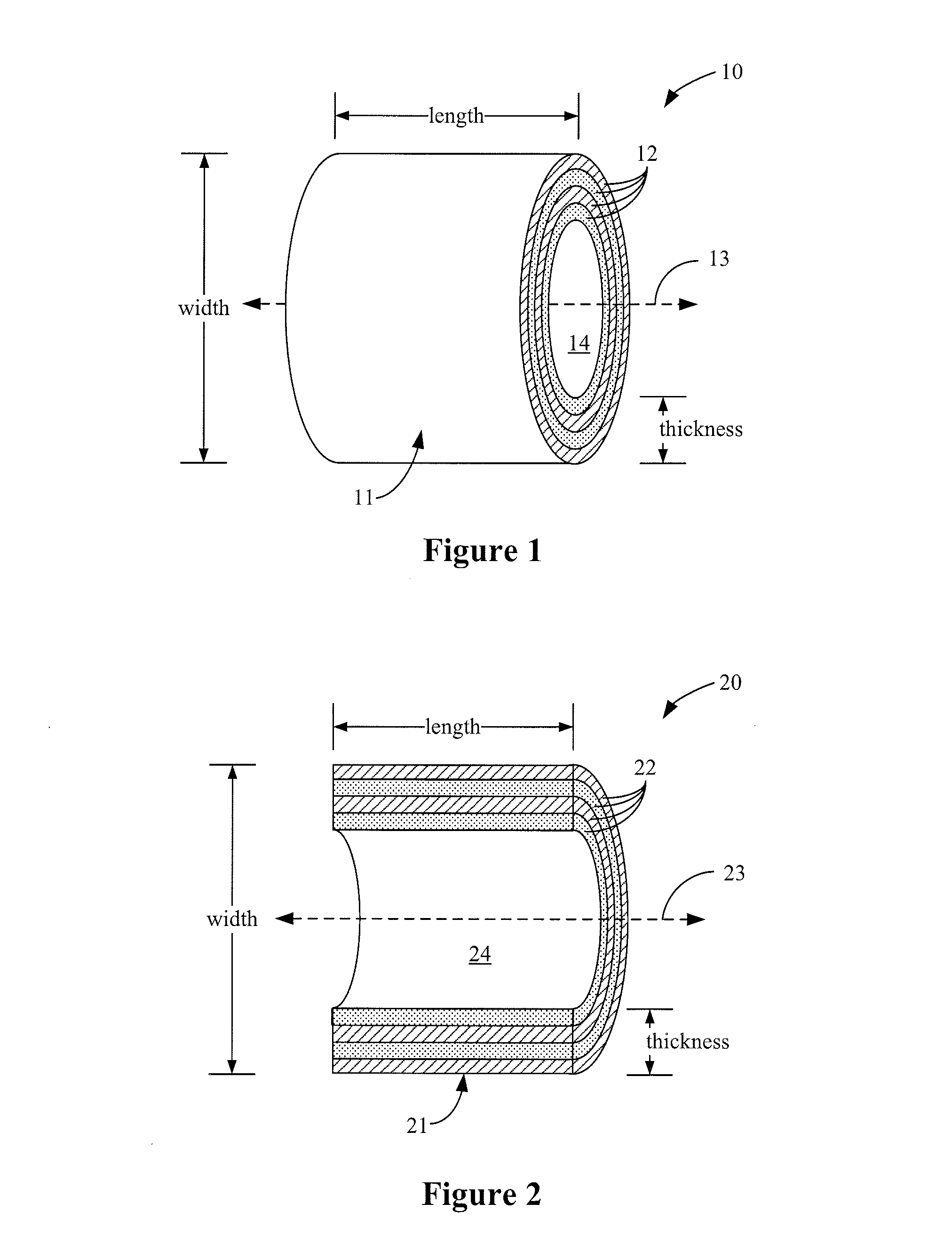

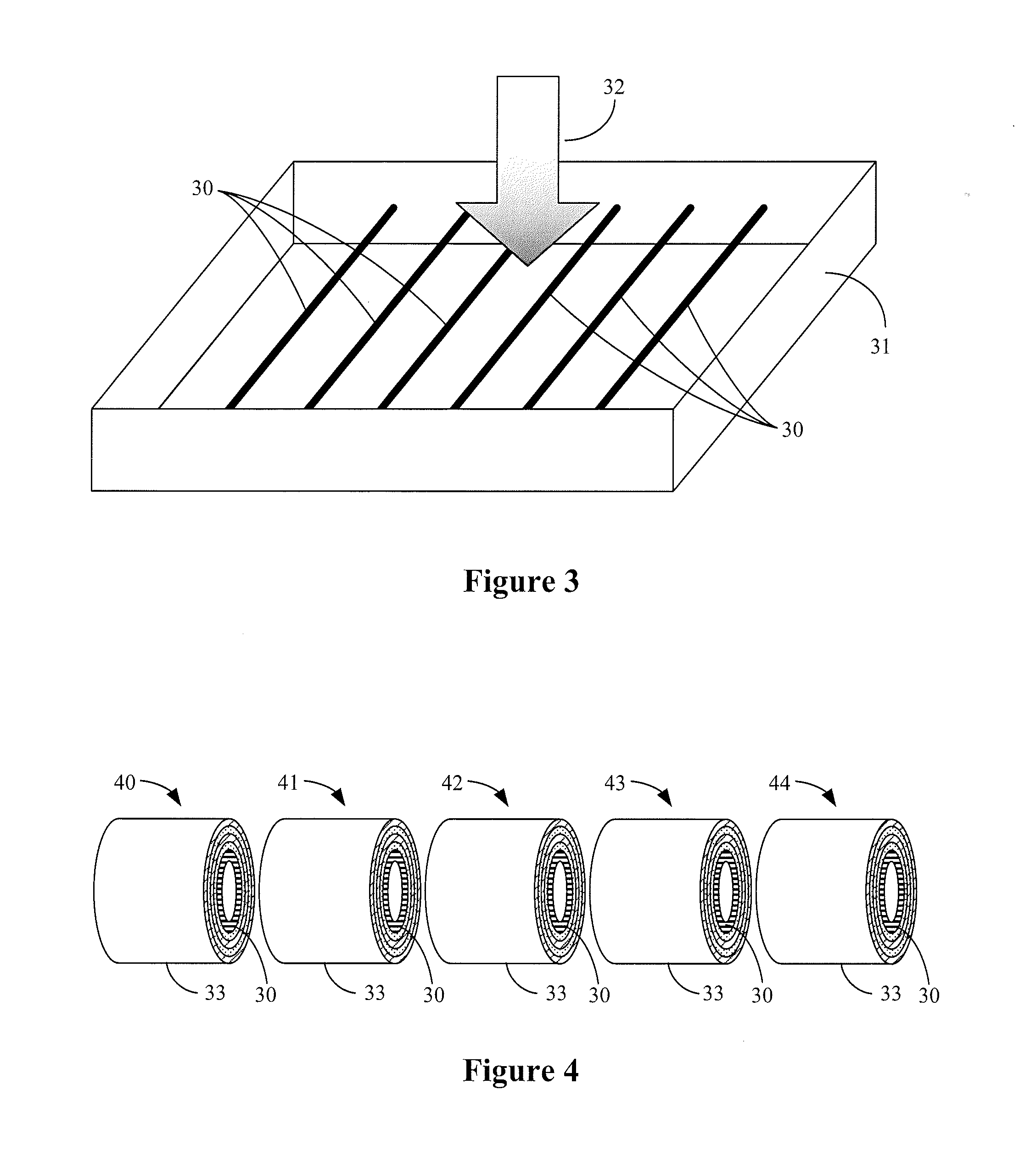

Layered reactive particles with controlled geometries, energies, and reactivities, and methods for making the same

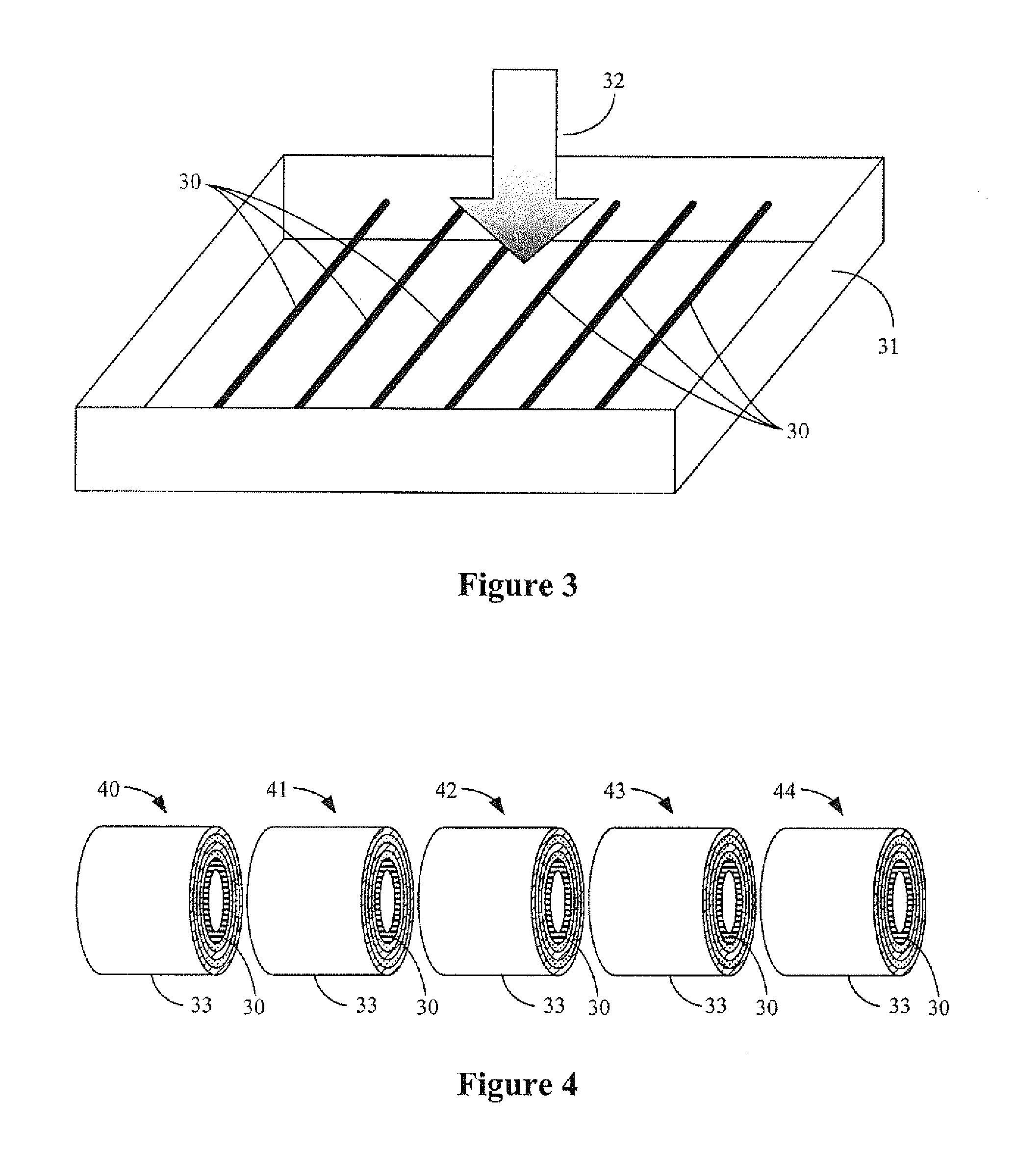

ActiveUS20140102605A1Easily tailored/controlledEasy to handleLayered productsVacuum evaporation coatingEngineeringEnergy density

An energetic composite having a plurality of reactive particles each having a reactive multilayer construction formed by successively depositing reactive layers on a rod-shaped substrate having a longitudinal axis, dividing the reactive-layer-deposited rod-shaped substrate into a plurality of substantially uniform longitudinal segments, and removing the rod-shaped substrate from the longitudinal segments, so that the reactive particles have a controlled, substantially uniform, cylindrically curved or otherwise rod-contoured geometry which facilitates handling and improves its packing fraction, while the reactant multilayer construction controls the stability, reactivity and energy density of the energetic composite.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Optical fiber and a method for making such

InactiveUS7769263B1Less expensiveLow costGlass making apparatusOptical fibre with multilayer core/claddingMaximum diameterOptical fiber cable

An optical fiber comprising: (i) a core; (ii) a cladding surrounding the core; wherein the cladding comprises a cladding ring that: (a) has a width W equal to or less than 10 microns; (b) includes at least 50 airlines, each airline having a maximum diameter or a maximum width of not more than 2 microns and more than 50% of said airlines have a length of more than 20 m; (c) has an air fill fraction of 0.1% to 10%, and (d) has an inner radius Rin and an outer radius Rout, wherein 6 μm≦Rin≦14 μm, and 8 μm≦Rout≦14 μm; and (iii) an outer cladding surrounding said cladding ring.

Owner:CORNING INC

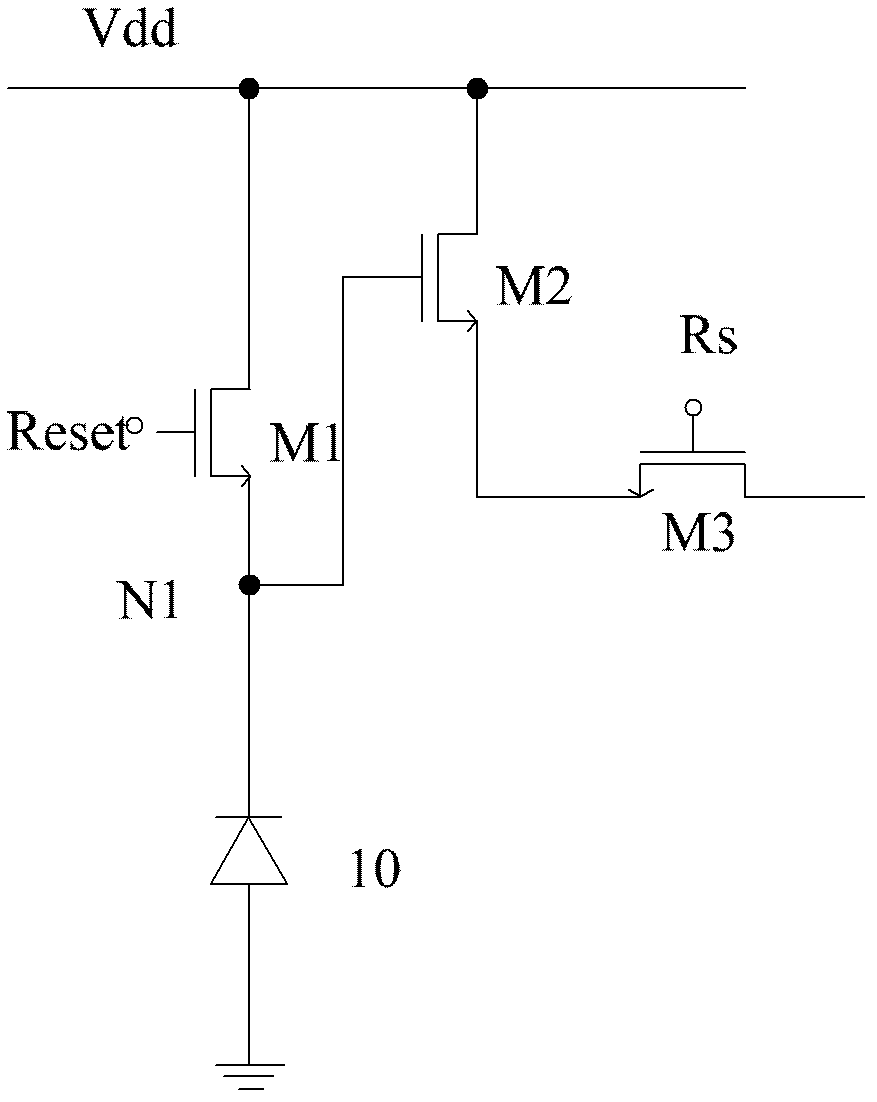

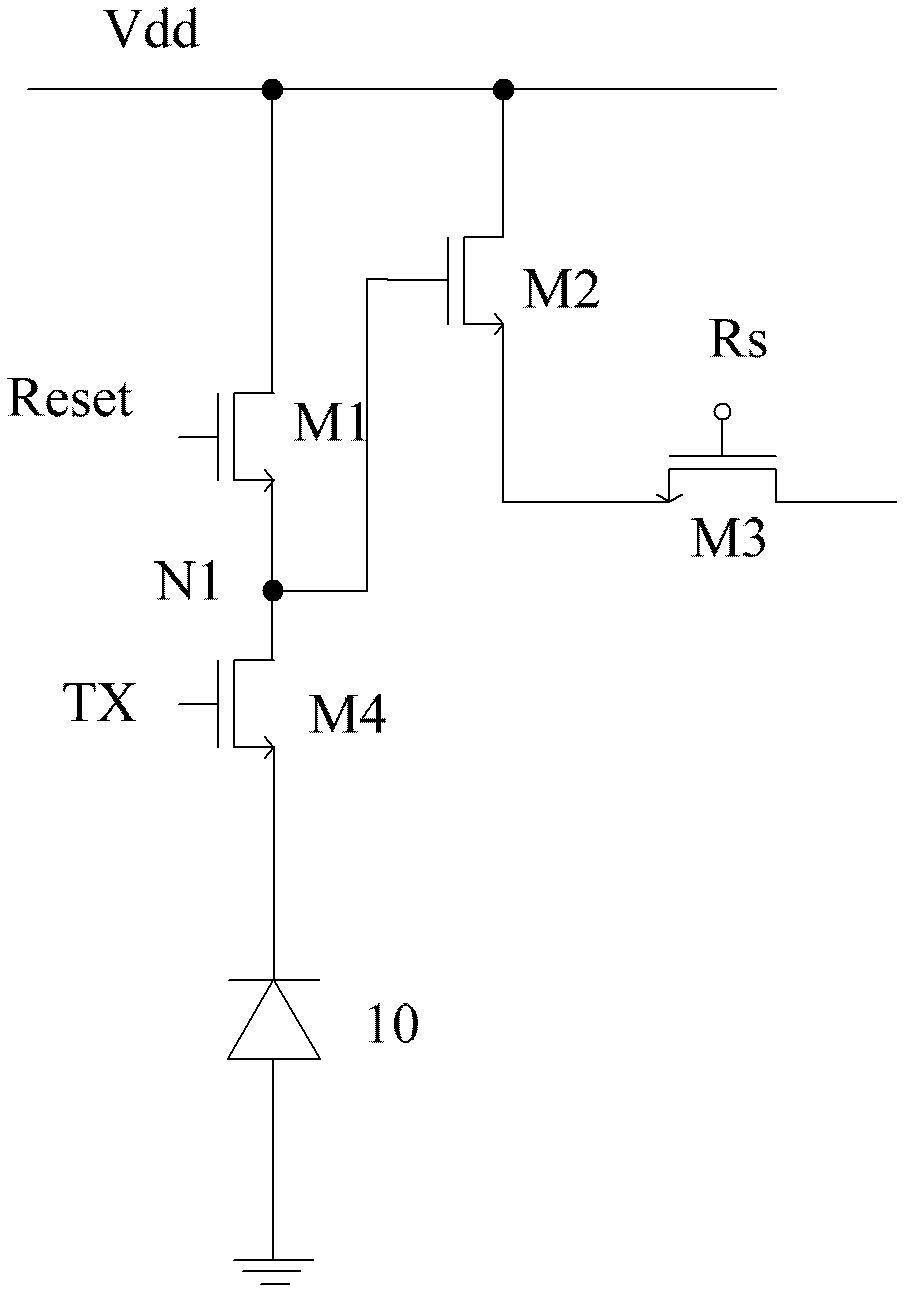

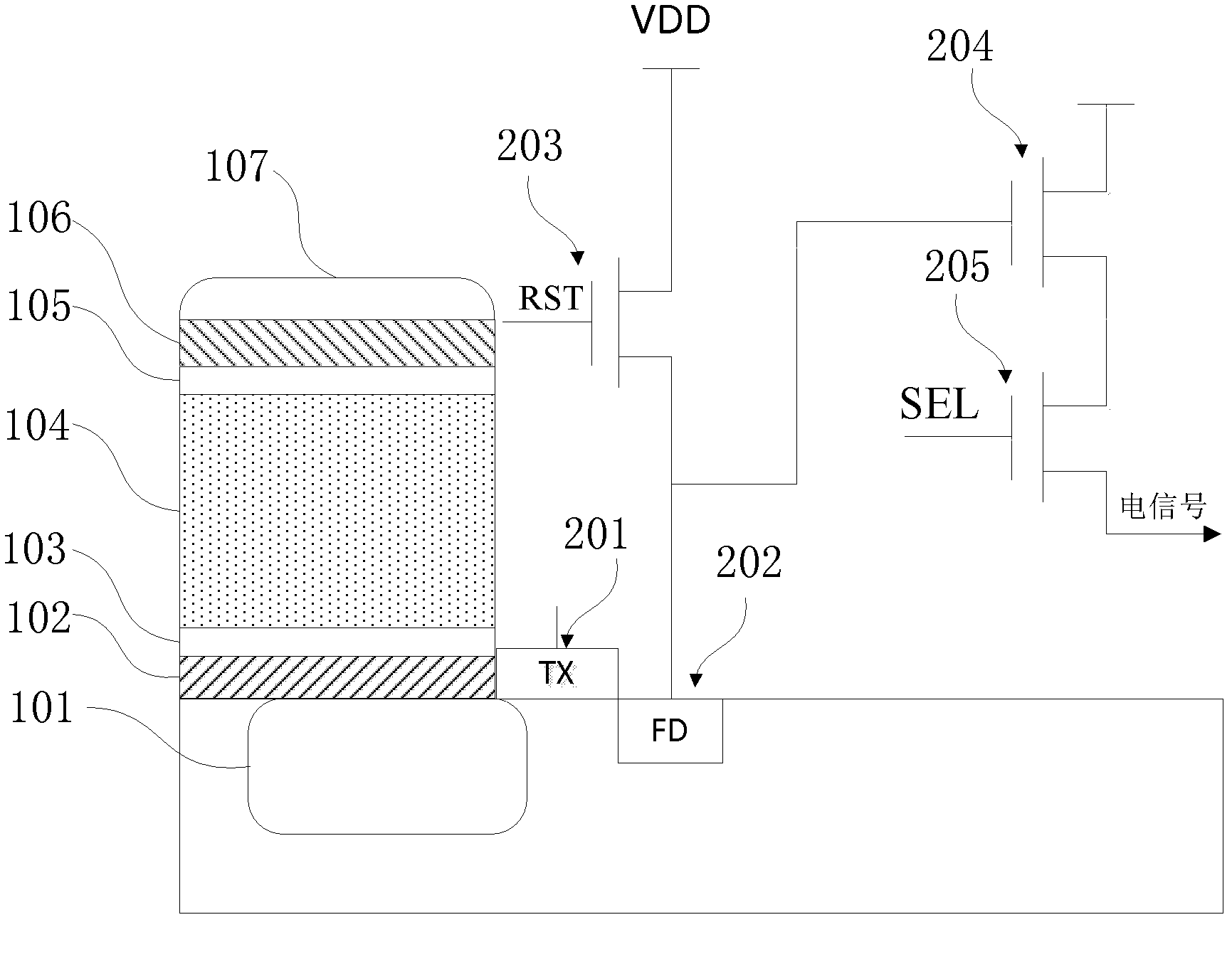

CMOS (Complementary Metal-Oxide-Semiconductor) image sensor

InactiveCN102637714AFill rate impactHighly integratedStatic indicating devicesRadiation controlled devicesCMOSEngineering

The invention provides a CMOS (Complementary Metal-Oxide-Semiconductor) image sensor in which a first polarizer, a liquid crystal layer with a transparent electrode structure, and a second polarizer, are all additionally arranged on a light-sensitive component, and the arrangement of the liquid crystals between can be changed by controlling the voltage of the transparent electrode so as to control the on and off of light. A light on-off structure is added in pixel structures in the CMOS image sensor, the light on-off structure can independently control the exposure integral time of each pixel structure and also can simultaneously expose all or part of pixel structures or simultaneously stopping exposing, thereby realizing a global exposure function without influencing a filling rate of the image sensor, and the integrated level of devices is improved. Moreover, the added light on-off structures can substitute the conventional shutter apparatus, so that the volume of the light-sensitive devices is reduced.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method and apparatus and program storage device for front tracking in hydraulic fracturing simulators

A method and system and program storage device is adapted to continuously update a perimeter of a fracture footprint created in an Earth formation when a fracturing fluid fractures the formation penetrated by a wellbore. Two embodiments of a Volume of Fluid (VOF) software, adapted to be stored in a memory of a computer system, will locate the position of a fracture perimeter during the evolution of that fracture when the software is executed by the processor of the computer system. The two embodiments, called the ‘Marker VOF (MVOF)’ and the ‘Full VOF (FVOF)’ software, will continuously update the perimeter of the fracture footprint by updating a Fill Fraction for each tip element. The MVOF software will use a fill fraction mass balance integral equation to update the Fill Fraction for each tip element, and the FVOF software will use an integrated form of fluid flow equations to update the Fill Fraction for each tip element.

Owner:SCHLUMBERGER TECH CORP

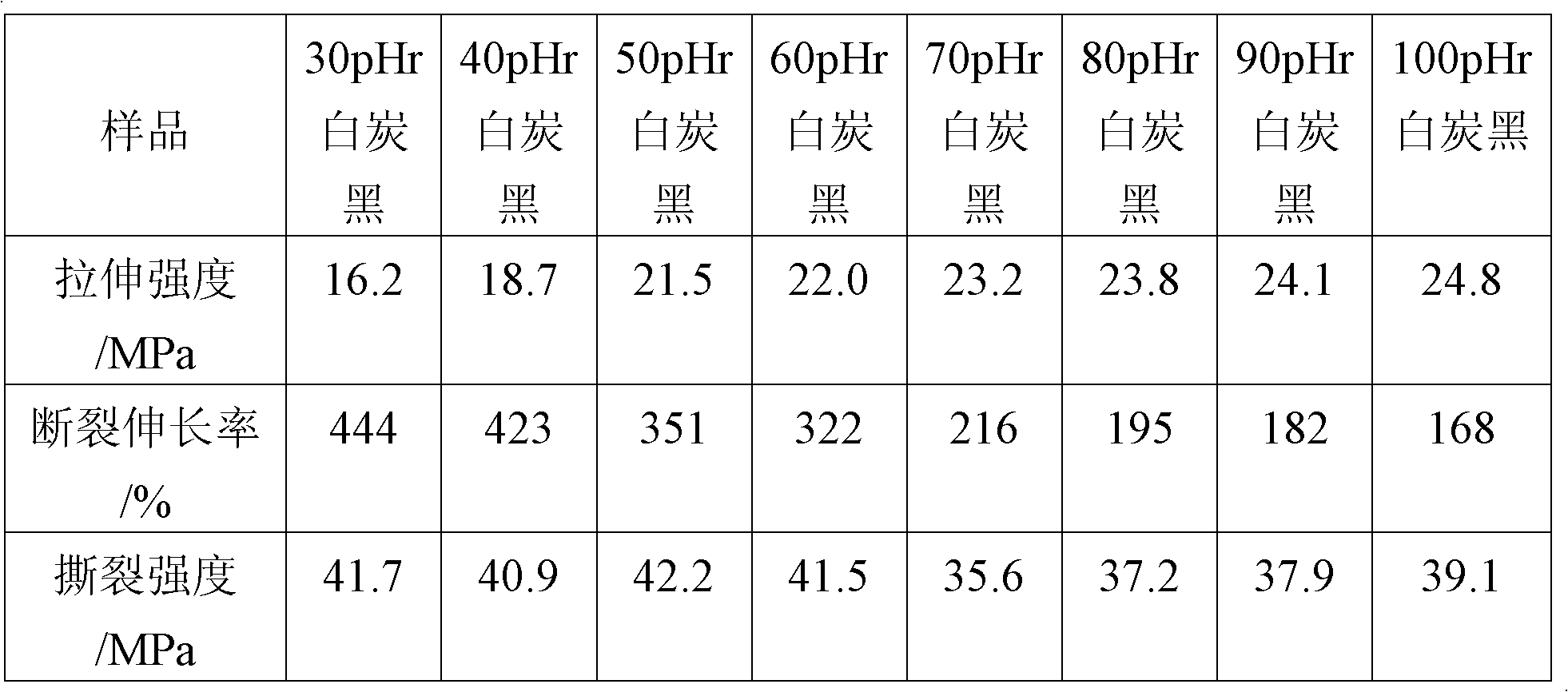

Rubber, preparation method thereof, rubber composition and vulcanized rubber

The invention relates to the field of rubbers, and discloses a rubber, a preparation method thereof, a rubber composition and a vulcanized rubber. The preparation method of the rubber comprises the following steps: adding white carbon black to a rubber solution in the rubber preparation process, uniformly mixing the rubber solution and the white carbon black, and then removing a solvent from the rubber solution. The rubber is prepared by the method, so the white carbon black has good dispersibility in a rubber base rubber, the filling fraction of the white carbon black greatly exceeds that ofa conventional carbon black mixing method, and the white carbon black still has good dispersibility, so the obtained rubber has excellent mechanical properties when used to manufacture tires, and hasa great industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultra small core fiber with dispersion tailoring

InactiveUS8165441B2Low splice lossLow scattering lossLaser detailsOptical fibre with multilayer core/claddingFiberFrequency comb

Various embodiments of optical fiber designs and fabrication processes for ultra small core fibers (USCF) are disclosed. In some embodiments, the USCF includes a core that is at least partially surrounded by a region comprising first features. The USCF further includes a second region at least partially surrounding the first region. The second region includes second features. In an embodiment, the first features are smaller than the second features, and the second features have a filling fraction greater than about 90 percent. The first features and / or the second features may include air holes. Embodiments of the USCF may provide dispersion tailoring. Embodiments of the USCF may be used with nonlinear optical devices configured to provide, for example, a frequency comb or a supercontinuum.

Owner:IMRA AMERICA

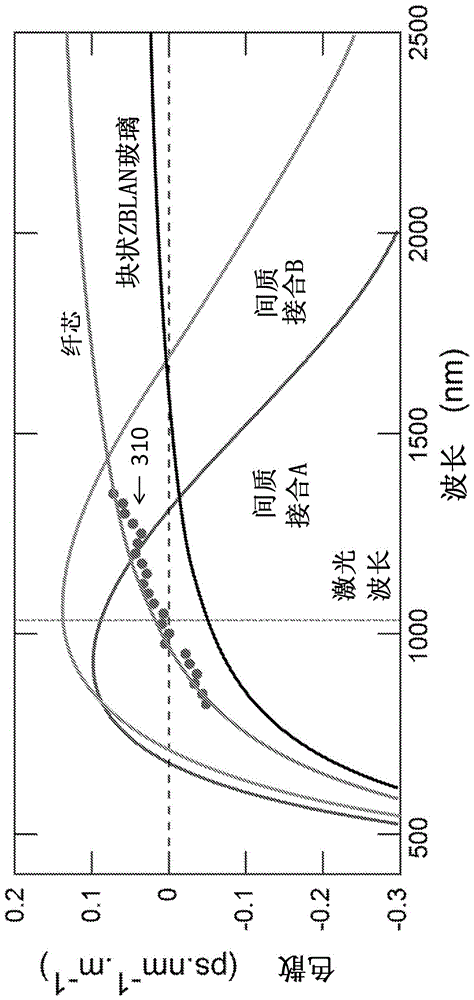

Supercontinuum system with microstructured photonic crystal fibers based on fluoride glass

InactiveCN105849986AActive medium shape and constructionNon-linear opticsGlass fiberPhotonic crystal

A fiber-based supercontinuum system including: a pump laser; a ZBLAN or other fluoride-based microstructured glass fiber; and control electronics; wherein the control electronics control the pump laser to generate laser pulses into the ZBLAN or other fluoride-based microstructured glass fiber. The fabrication of a ZBLAN photonic crystal fiber with sub-micron features and large air- filling fraction and the use of the fiber to generate a stable supercontinuum (200 to 2500nm) from 140fs, 1nJ pulses at 1042nm are disclosed.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

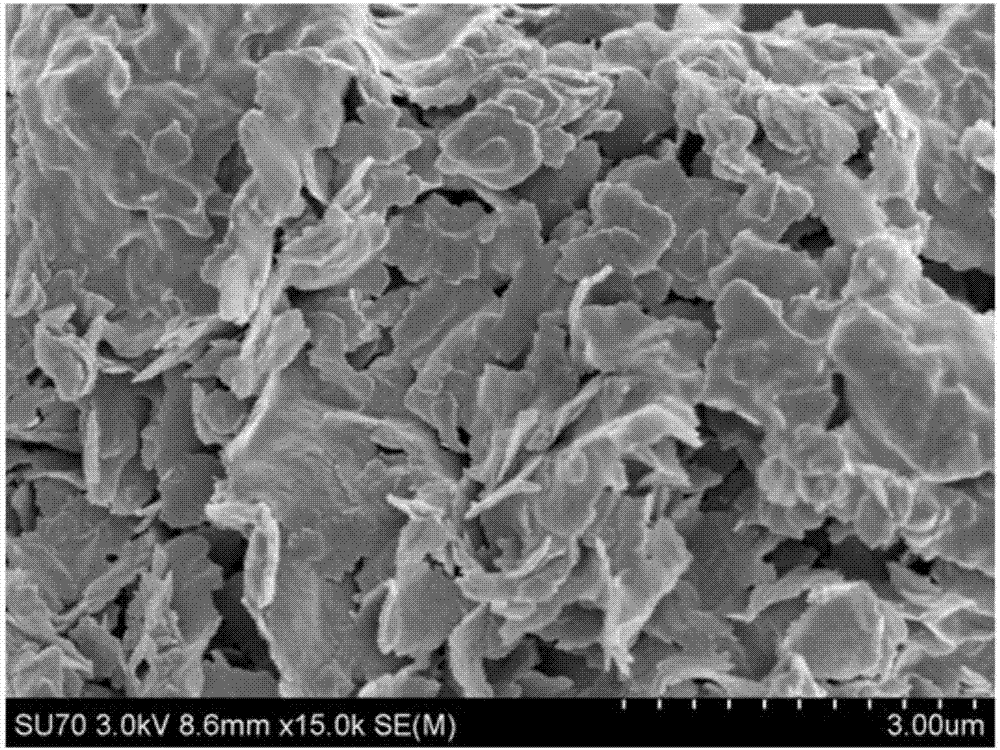

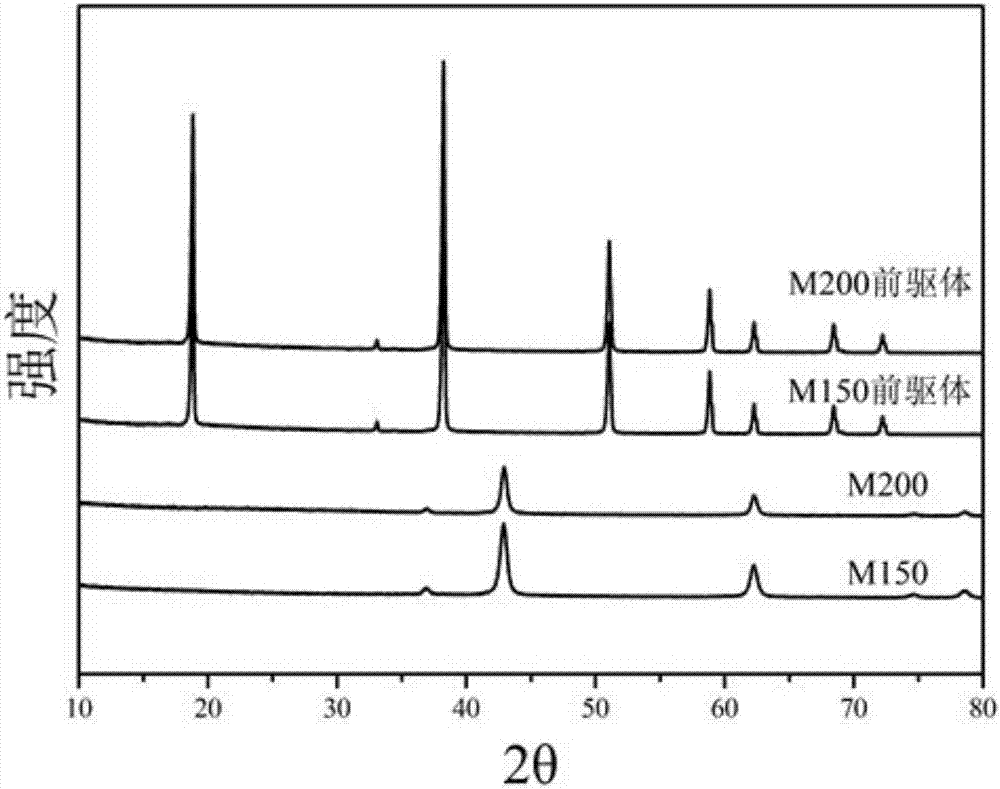

Magnetic wave-absorbing cement and preparation method thereof

InactiveCN108046688AImprove absorbing performanceGood weather resistance and corrosion resistanceSolid waste managementPortland cementMaterials science

The invention relates to a magnetic wave-absorbing cement and a preparation method thereof. The magnetic wave-absorbing cement includes a ground MnZn ferrite recycled material and Portland cement. Thefilling rate of the ground MnZn ferrite recycled material is 40-70vol%, and the particle diameter D50 of the ground MnZn ferrite recycled material is to 0.6-3microm. The invention also includes a preparation method of the magnetic wave-absorbing cement. According to the invention, cement is doped with the ground MnZn ferrite recycled material, after molding curing, the cement has a 15mm thicknesswave-absorbing ability up to -15dB or more within the frequency band of 8-18GHz, and the cost is very low.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

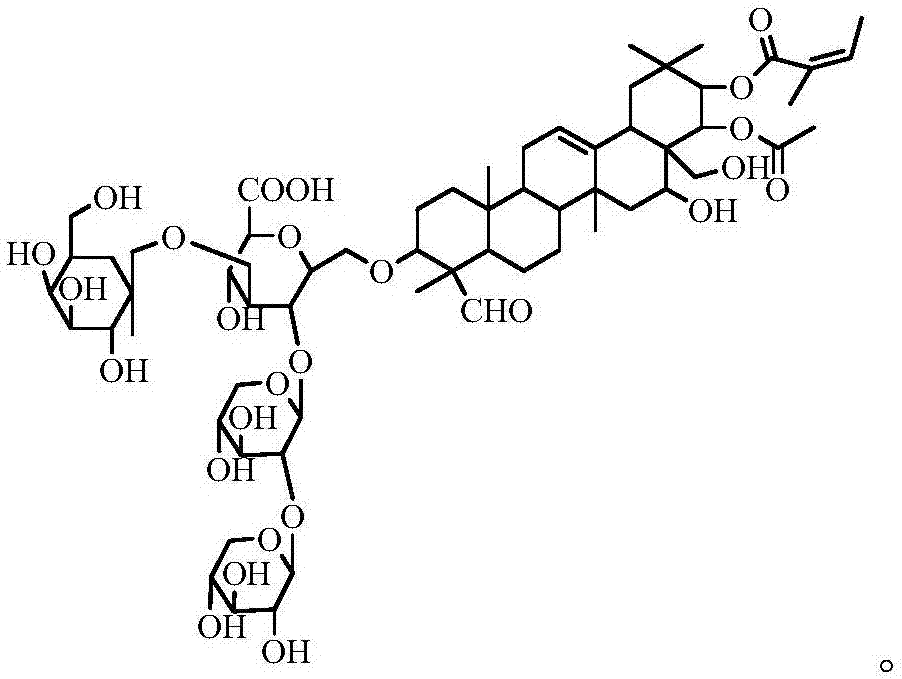

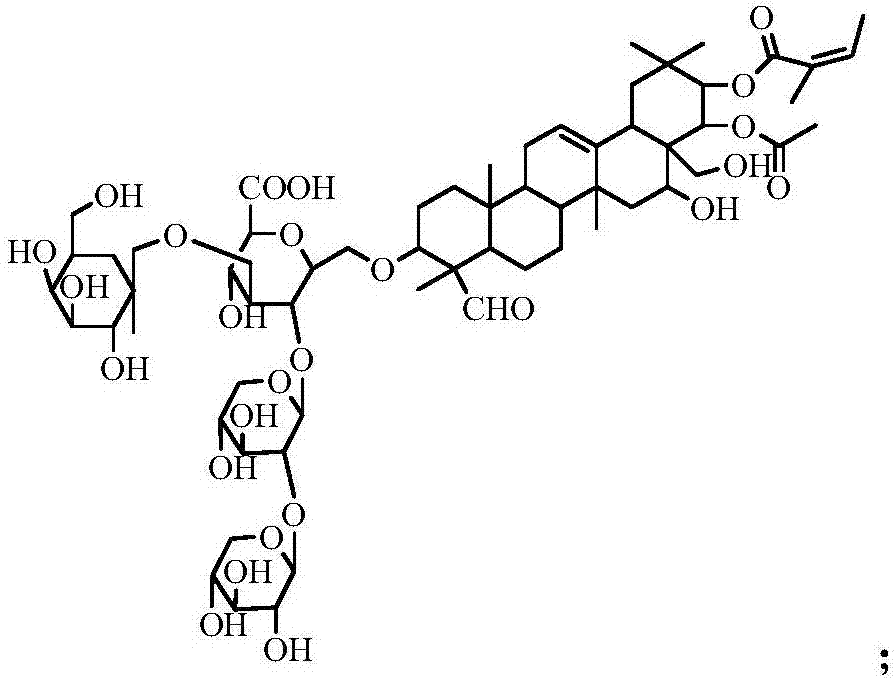

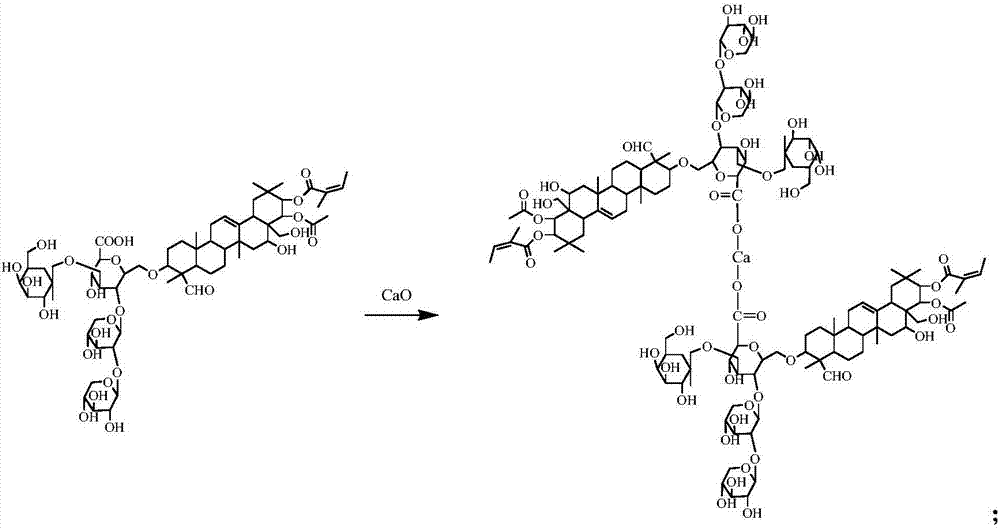

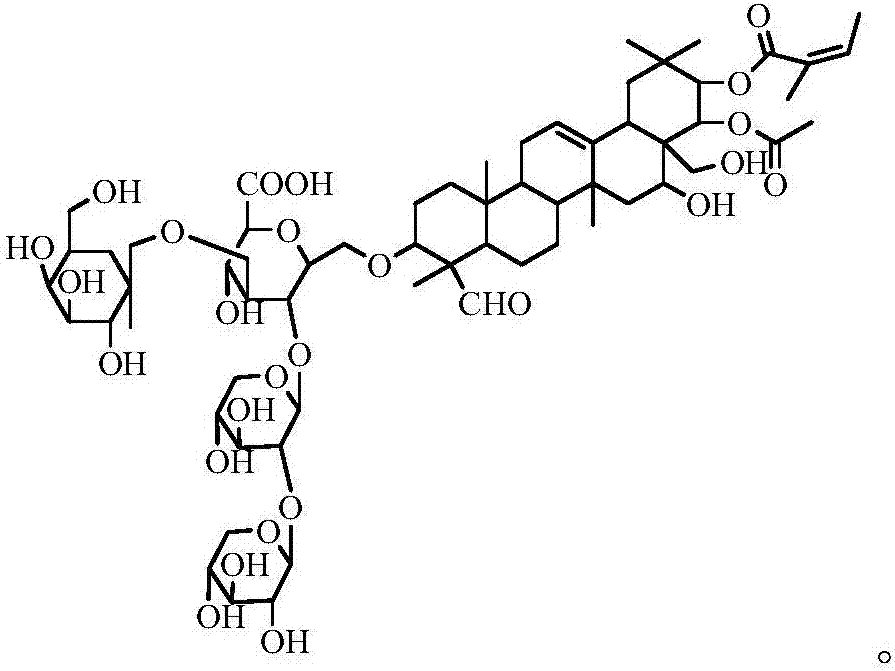

Tea saponin modified red mud and composite floor tile made from red mud and waste plastics

The invention discloses tea saponin modified red mud which comprises 7-13wt% of tea saponin and 87-93wt% of red mud. The tea saponin modified red mud is made by the following steps: adding red mud and tea saponin into a high-speed mixer at the temperature of 50 DEG C, stirring for 7-9 minutes, thereby obtaining the tea saponin modified red mud. The composite floor tile made from the tea saponin modified red mud and waste polydiphenyl ether plastics is made from the following raw materials in parts by weight: 14-25 parts of waste polydiphenyl ether plastics and 75-86 parts of tea saponin modified red mud. The making method of the composite floor tile comprises the following steps: drying, stirring by a stirrer, plastifying into sheets, performing mold pressing, cutting, thereby obtaining the composite floor tile. The surface property of the red mud is changed from hydrophilic to oleophilic by utilizing the tea saponin, so that the blending compatibility between the red mud and waste polydiphenyl ether and the binding property are greatly improved, and the performance of the composite floor tile is greatly improved. Meanwhile, the filling fraction of the red mud in the composite floor tile is increased, and the cost of the product is effectively reduced.

Owner:GUIZHOU UNIV

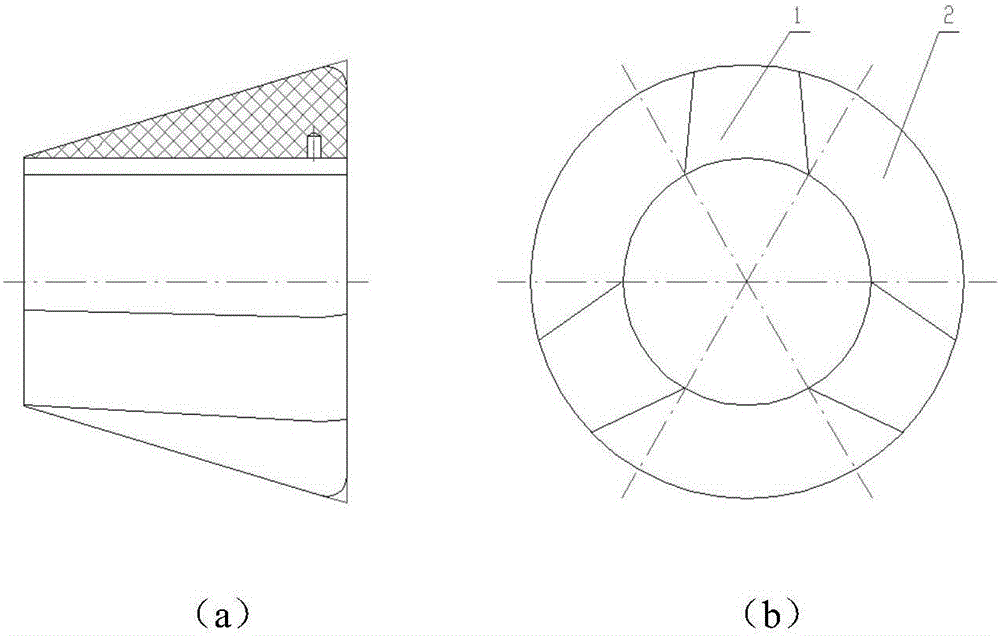

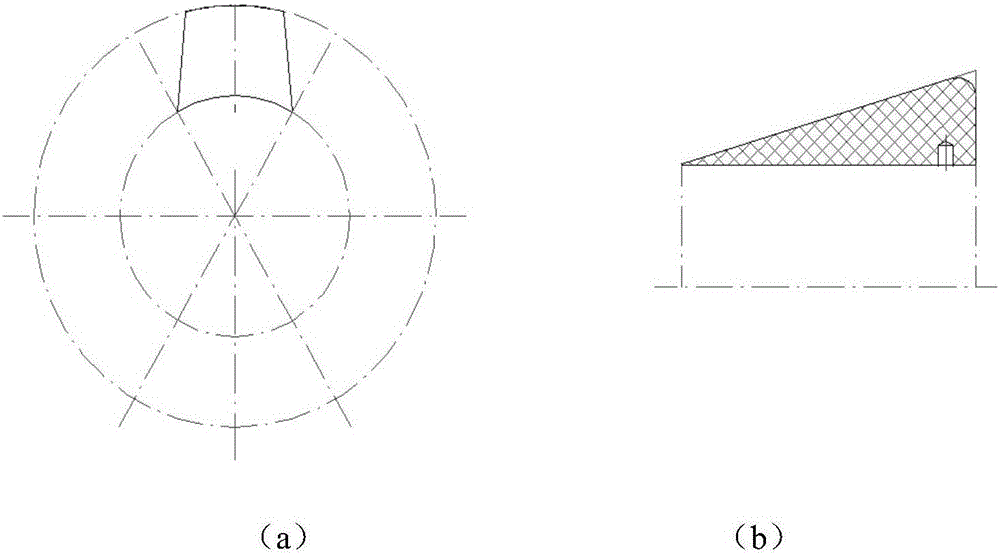

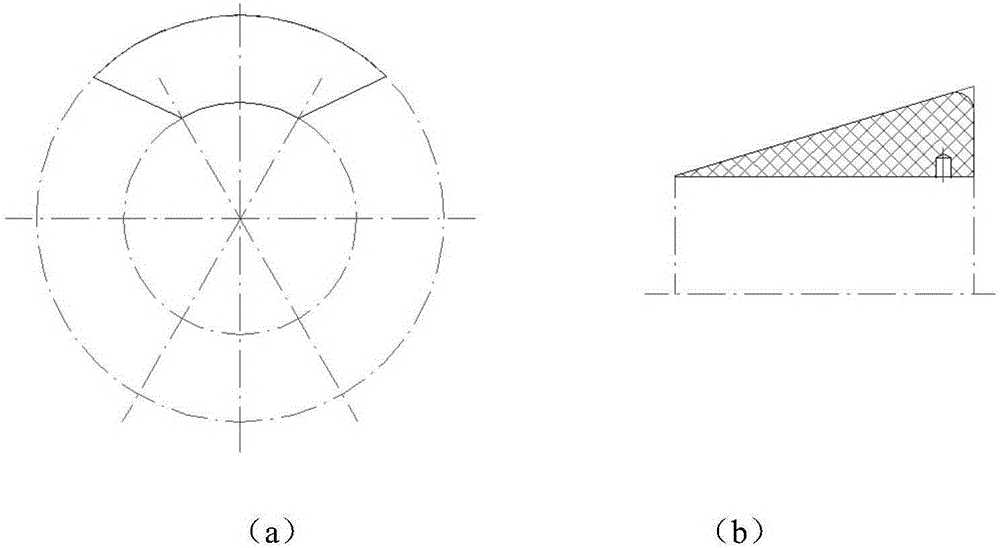

Detachable umbrella disc

InactiveCN107524545AReduce stress levelsGood effectRocket engine plantsStress concentrationStress level

The invention provides a detachable umbrella disc structure. A circular table is defined through alternated connection of three umbrella sections a and three umbrella sections B. The circular table is provided with a through hole in the axial direction, and the through hole is matched with a core die. According to the shape of the umbrella sections A on the bottom face of the circular table, the inner arc length is larger than the outer arc length. According to the shape of the umbrella sections B on the bottom face of the circular table, the inner arc length is smaller than the outer arc length. After the circular table is defined by the umbrella sections a and the umbrella sections B, the umbrella sections a and the umbrella sections B are coaxially bonded to the position, corresponding to grain stress concentration, on the charging core die. By means of the detachable umbrella disc structure, the stress level of a solid rocket engine charging structure can be reduced, a stress releasing structure is achieved, on the premise that the charging structure filling fraction is guaranteed, the stress level of the charging structure can meet the requirement for the integrity of a low-temperature work structure of an engine, and the problem about integrity of the engine low-temperature work charging structure is solved.

Owner:西安长峰机电研究所

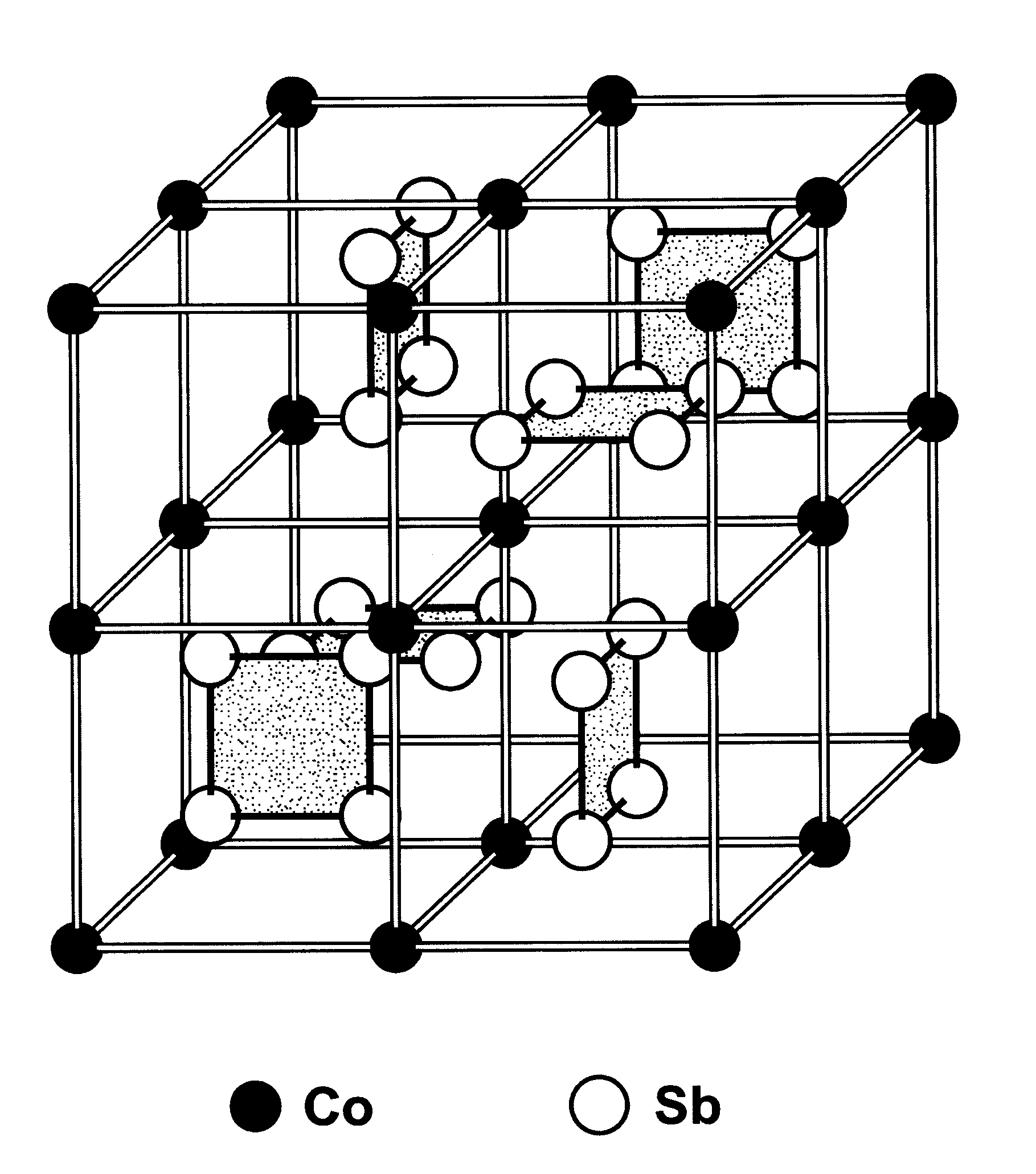

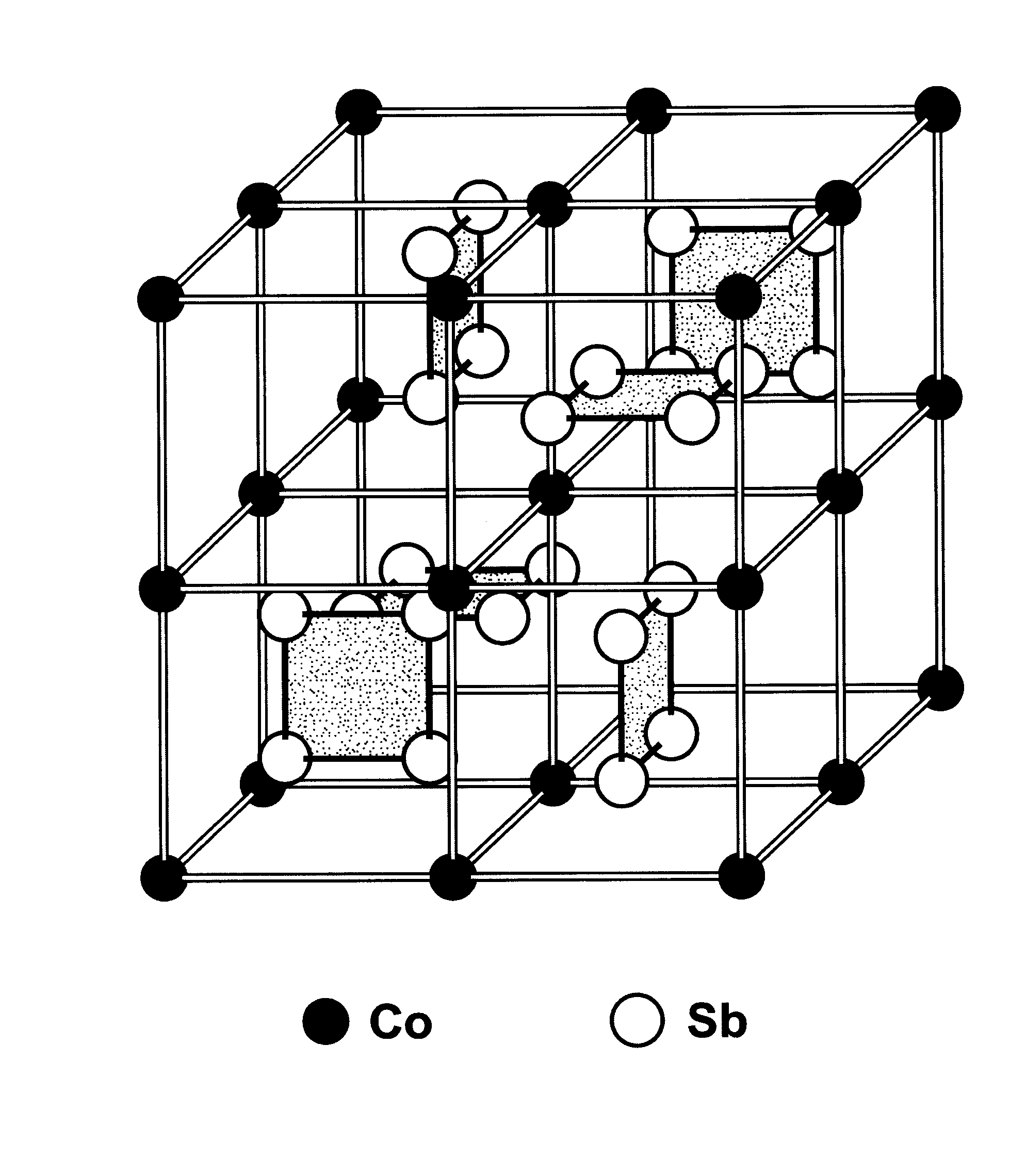

Potassium and Sodium Filled Skutterudites

InactiveUS20100111754A1Exceptional thermoelectric propertyImprove material performanceEnergy inputCobalt compoundsSkutteruditePotassium

Interstitial voids of the cubic CoSb3 type skutterudite structure can be filled with sodium and / or potassium atoms. Such filled skutterudites have the general formulas, KyCo4Sb12 and NayCo4Sb12, where y indicates the filling fraction of potassium and sodium, respectively, in the CoSb3 cubic crystal structure, and has a value greater than zero and less than one. Also sodium-filled and / or potassium-filled skutterudites of the general formula, (K, Na)yT4Pn12 are made, where T denotes Fe, Ru, Os, Co, Rh, or Ir; and “Pn” denotes one of the pnicogen elements P, As, or Sb. Again, y has values less than one.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Partial filling of a pulse detonation combustor in a pulse detonation combustor based hybrid engine

Owner:GENERAL ELECTRIC CO

Preparation method of styrene butadiene rubber liquid slurry added with white carbon black and product prepared by using same

The invention discloses a preparation method of styrene butadiene rubber liquid slurry added with white carbon black and a product prepared by using the same and relates to the technical field of performance improvement of high polymer composite materials such as rubber and the like. The slurry contains styrene butadiene latex and the white carbon black, wherein the mass ratio of the white carbon black to the styrene butadiene latex is 1-100%. The preparation method comprises the following steps: firstly, commonly stirring and premixing the white carbon black with water; then high shearing, dispersing and homogenizing the white carbon black water slurry to obtain a white carbon black-water suspension; subsequently, carrying out surface treatment on the white carbon black so that the surface of the white carbon black is organized; regulating the pH value of the suspension to 9-12; and finally, evenly mixing the suspension with the styrene butadiene latex to obtain the styrene butadiene latex liquid slurry added with the white carbon black. The white carbon black is uniformly dispersed in the slurry prepared by the method, thus the slurry can be directly processed to prepare a white carbon black modified styrene butadiene rubber; and the white carbon black modified styrene butadiene rubber with high filling fraction can also be used for the field of rubber reinforcing modification when serving as a filling material, and the mechanical property of the white carbon black modified styrene butadiene rubber is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

Layered reactive particles with controlled geometries, energies, and reactivities, and methods for making the same

ActiveUS8431197B2Easily tailored/controlledEasy to handleLayered productsVacuum evaporation coatingEngineeringEnergy density

An energetic composite having a plurality of reactive particles each having a reactive multilayer construction formed by successively depositing reactive layers on a rod-shaped substrate having a longitudinal axis, dividing the reactive-layer-deposited rod-shaped substrate into a plurality of substantially uniform longitudinal segments, and removing the rod-shaped substrate from the longitudinal segments, so that the reactive particles have a controlled, substantially uniform, cylindrically curved or otherwise rod-contoured geometry which facilitates handling and improves its packing fraction, while the reactant multilayer construction controls the stability, reactivity and energy density of the energetic composite.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

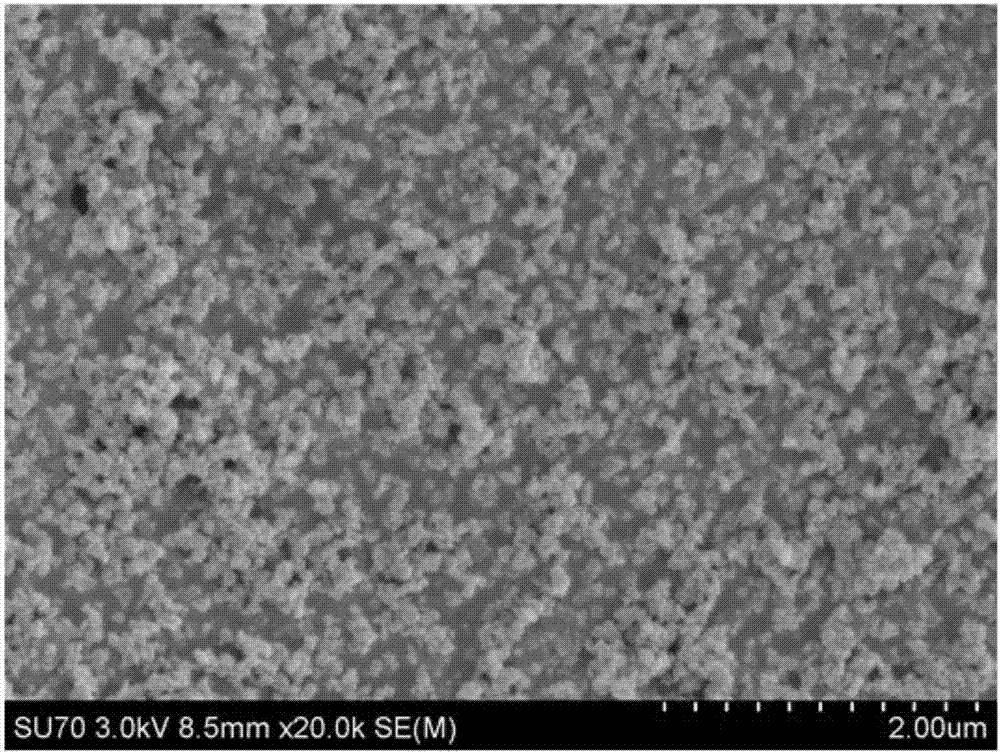

Preparation method of magnesium oxide/polystyrene composite dielectric material

ActiveCN107245152AHigh dielectric constantExcellent dielectric propertiesMagnesiaN dimethylformamidePolystyrene

The invention relates to the technical field of nano-composite materials, and aims at providing a preparation method of a magnesium oxide / polystyrene composite dielectric material. The method comprises the following steps: adding polystyrene to N,N-dimethylformamide, and stirring the polystyrene and N,N-dimethylformamide to obtain a transparent and clarified solution; dispersing magnesium oxide in a transparent and clarified solution to obtain a uniform suspension; and carrying out tape casting on the suspension, and drying the suspension at a temperature of 60 DEG C to obtain the film-like magnesium oxide / polystyrene composite dielectric material. The uniform distribution characteristic of the electric field in the magnesium oxide and polystyrene is used to improve the comprehensive dielectric properties of the composite material at a low filling volume. The preparation method has the advantages of simplicity, high operability, easiness in obtaining of raw materials, and suitableness for industrial production. The dielectric properties of the polymer-based composites can be adjusted by adjusting the volume fraction of a filled inorganic filler. The filled volume of the inorganic filler is small, and when the filling fraction is only 8%, the dielectric properties are improved, and the good toughness of the polymer can be kept.

Owner:ZHEJIANG UNIV

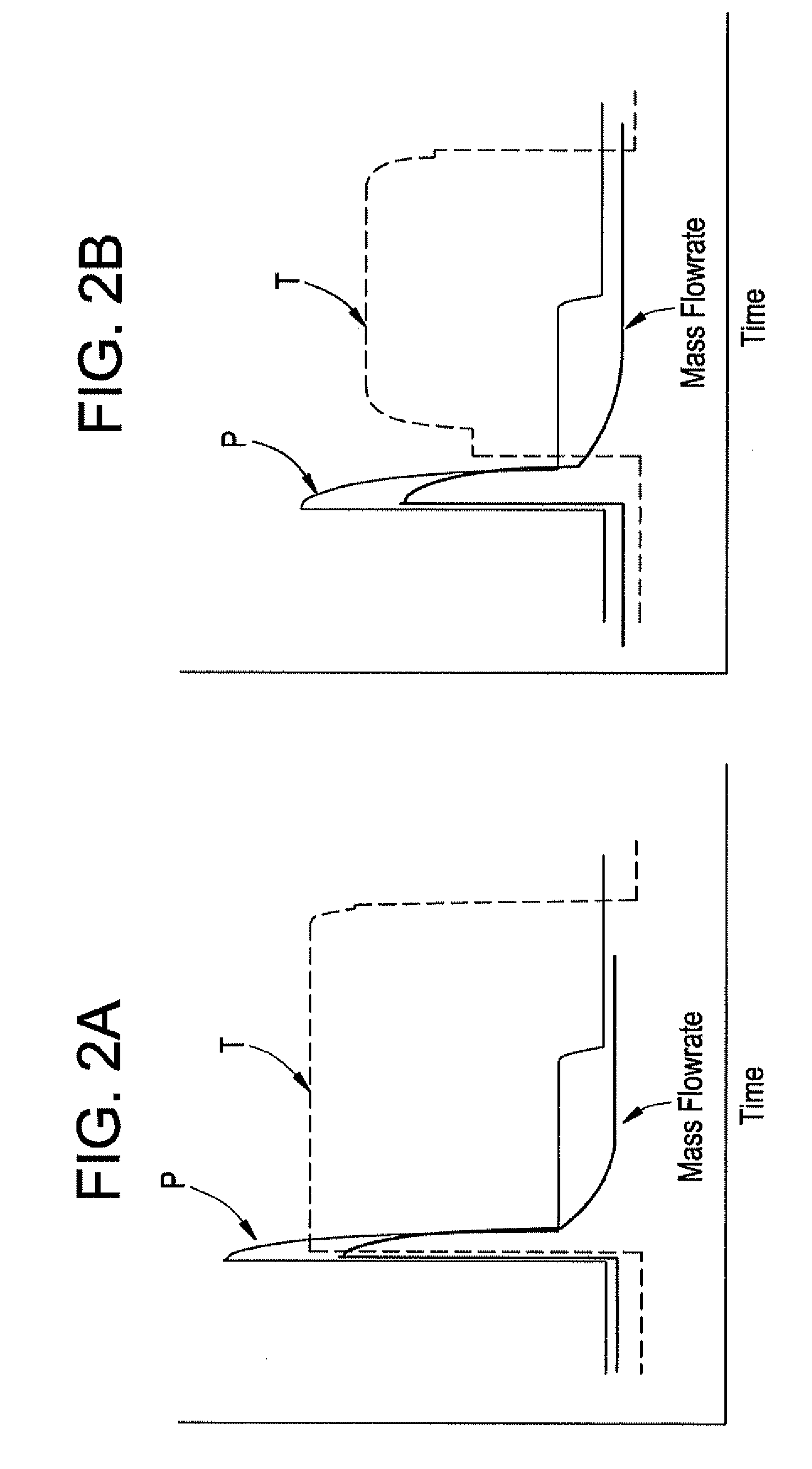

Partial filling of a pulse detonation combustor in a pulse detonation combustor based hybrid engine

An engine contains at least one pulse detonation combustor having a combustion chamber and an exit nozzle coupled to and downstream of the combustion chamber. During operation of the at least one pulse detonation combustor a detonation occurs within the combustion chamber and at least one of a fuel fill fraction and purge fraction of the at least one pulse detonation combustor are utilized to offset a temperature peak of said detonation from a pressure peak of said detonation. The fuel fill fraction is defined as 1−purge fraction, and the purge fraction is the ratio of the purge time of the at least one pulse detonation combustor to a sum of the purge time of the at least one pulse detonation combustor and a fuel fill time of the at Least one pulse detonation combustor.

Owner:GENERAL ELECTRIC CO

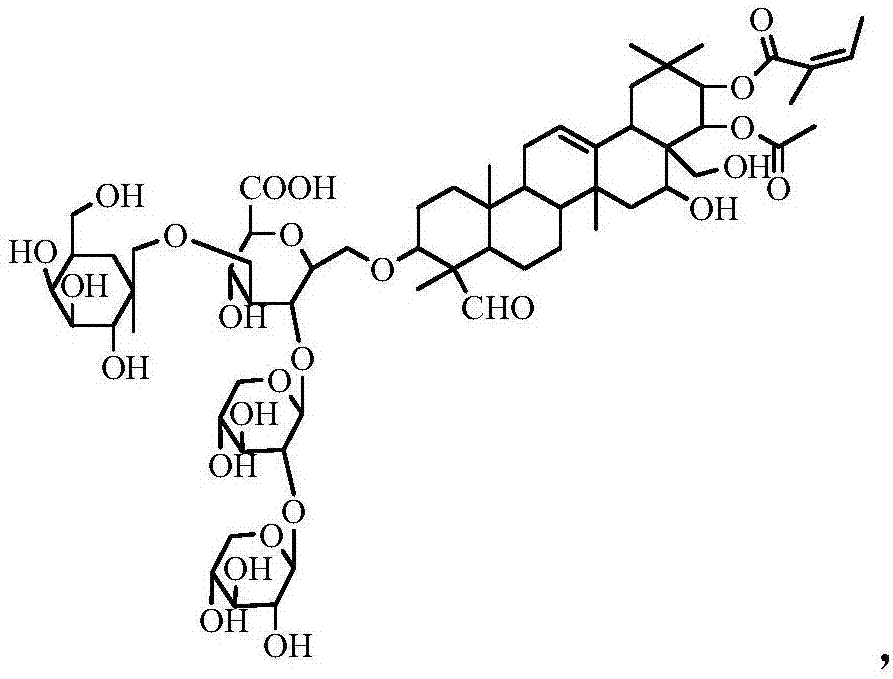

Tea saponin modified blast furnace slag and composite floor brick prepared from tea saponin modified blast furnace slag and waste plastic

The invention discloses tea saponin modified blast furnace slag which is prepared from 7-12wt% of tea saponin and 88%-93wt% of blast furnace slag. A preparation method for the tea saponin modified blast furnace slag comprises the following steps: adding the blast furnace slag and the tea saponin into a high-speed mixer at a temperature of 70 DEG C, and stirring for 7-9 minutes to obtain the tea saponin modified blast furnace slag. A composite floor brick prepared from the tea saponin modified blast furnace slag and waste polyformaldehyde plastic is prepared from the following raw materials in parts by weight: 15-20 parts of waste polyformaldehyde plastic and 80-85 parts of the tea saponin modified blast furnace slag; and the raw materials are dried, are stirred by a stirrer, are plastified into sheets, are subjected to mould pressing and are cut into sheets, so that the composite floor brick is formed. The surface property of the blast furnace slag is changed into lipophilicity from hydrophily through tea saponin, so that the co-blending compatibility and associativity of the blast furnace slag and the waste polyformaldehyde are improved greatly, and therefore, performances of the composite floor brick are improved greatly; and meanwhile, filling fraction of the blast furnace slag in the composite floor brick is increased, so that product cost is effectively reduced.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com