Conductive rubber roller and imaging device

A technology of conductive rubber rollers and conductive fillers, which is applied in corona discharge devices, conductive coatings, circuits, etc., can solve problems such as rising product costs and increasing product defect rates, and achieve cost savings, uniform resistance distribution, and low-voltage change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

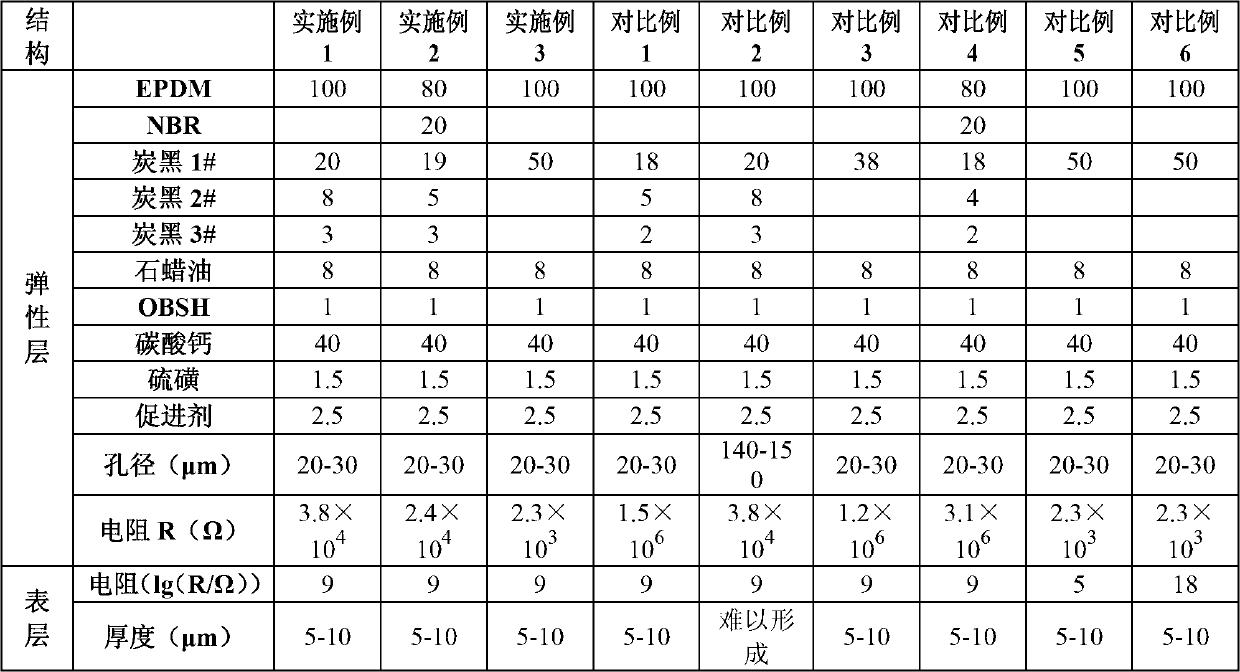

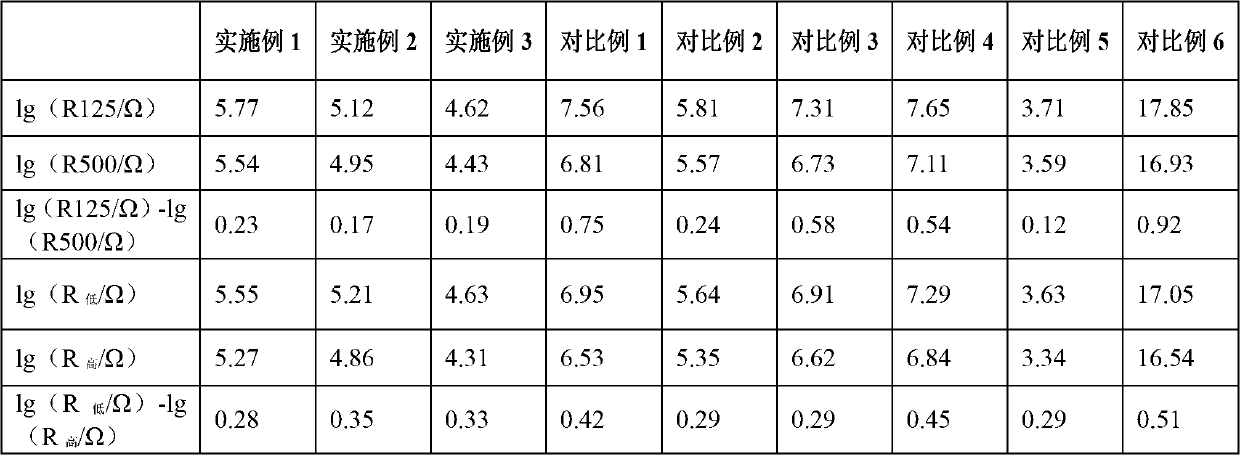

Embodiment 1

[0056] 100 parts of ethylene-propylene-diene copolymer (EPDM), 20 parts of 1# carbon black, 8 parts of 2# carbon black, 3 parts of 3# carbon black, 1 part of foaming agent OBSH, 8 parts of paraffin oil, light carbonic acid 40 parts of calcium, 1.5 parts of sulfur, 2.5 parts of vulcanization accelerator, the threshold range of 1# carbon black in EPDM is 35≤1# carbon black 阈 ≤40; the threshold range of 2# carbon black in EPDM is 18≤2# carbon black 阈 ≤20; the threshold range of 3# carbon black in EPDM is 9≤3# carbon black 阈 ≤10. Namely: b / Y b +c / Y c +………x / Y x =20 / 40+8 / 20+3 / 10=1.2>1.

[0057] Mix it uniformly with an open rubber mixer or a closed rubber mixer according to a conventional method to obtain a rubber composition I.

[0058] Then the rubber composition I is molded with an extruder according to the standard that the outer diameter is 16mm and the inner hole is 5mm, then passes through a microwave vulcanization box, adjusts the microwave power and the conveying spee...

Embodiment 2

[0061] 80 parts of ethylene-propylene-diene copolymer (EPDM), 20 parts of acrylonitrile-butadiene rubber (NBR), 19 parts of 1# carbon black, 5 parts of 2# carbon black, 3 parts of 3# carbon black, hair 1 part of foaming agent OBSH, 8 parts of paraffin oil, 40 parts of light calcium carbonate, 1.5 parts of sulfur, 2.5 parts of vulcanization accelerator, and the threshold range of 1# carbon black in EPDM:NBR=80:20 is 34≤1# carbon black 阈 ≤38; the threshold range of 2# carbon black in EPDM:NBR=80:20 is 16≤2# carbon black 阈 ≤18; the threshold range of 3# carbon black in EPDM:NBR=80:20 is 7.5≤3# carbon black 阈 ≤8.5. Namely: b / Y b +c / Y c +………x / Y x =19 / 38+5 / 18+3 / 8.5=1.13>1.

[0062] Mix it uniformly with an open rubber mixer or a closed rubber mixer according to a conventional method to obtain a rubber composition I.

[0063] Then the rubber composition I is molded with an extruder according to the standard that the outer diameter is 16mm and the inner hole is 5mm, then passes t...

Embodiment 3

[0066] 100 parts of ethylene-propylene-diene copolymer (EPDM), 50 parts of 1# carbon black, 1 part of foaming agent OBSH, 8 parts of paraffin oil, 40 parts of light calcium carbonate, 1.5 parts of sulfur, 2.5 parts of vulcanization accelerator, Among them, the threshold range of 1# carbon black in EPDM is 35≤1# carbon black 阈 ≤40. Namely: b / Y b +c / Y c +………x / Y x =50 / 40=1.25>1.

[0067] Mix it uniformly with an open rubber mixer or a closed rubber mixer according to a conventional method to obtain a rubber composition I.

[0068] Then the rubber composition I is molded with an extruder according to the standard that the outer diameter is 16mm and the inner hole is 5mm, then passes through a microwave vulcanization box, adjusts the microwave power and the conveying speed so that the foaming pore diameter is 20-30 μm after vulcanization, and after the molding is completed Put a metal shaft core (diameter = 6mm) in the middle to form a preform with a metal shaft core in the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com