Developing roller and imaging device

A developing roller and elastomer technology, applied in corona discharge devices, instruments, electrical components, etc., can solve the problems of poor environmental stability of rubber, large compression set, and poor processability of chloroether rubber, and achieve excellent Environmental stability and voltage stability, avoiding unevenness of printed images, the effect of uniform electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Regarding the preparation method of the conductive agent, all solid mixing methods are applicable to the present invention, specifically the following steps can be adopted: first, the powder or flake solids of the two components are ground and pulverized on a three-roll machine, and then respectively according to a certain The ratio is such that the two solids can be mixed and ground evenly on a three-roller machine.

[0036] In the preparation process of the conductive elastomer 2 in the developing roller of the present invention, the crosslinking agent can be selected from elemental sulfur, selenium, tellurium, sulfur-containing compounds such as dimorpholine disulfide, dimorpholine tetrasulfide, alkylphenol monosulfide, etc. It can also be organic peroxides such as benzoyl peroxide, di-tert-butyl peroxide, dicumyl peroxide, etc., or quinones, amines, and resinous compounds. These crosslinking agents can be used alone or in combination of two or more.

[0037] In the...

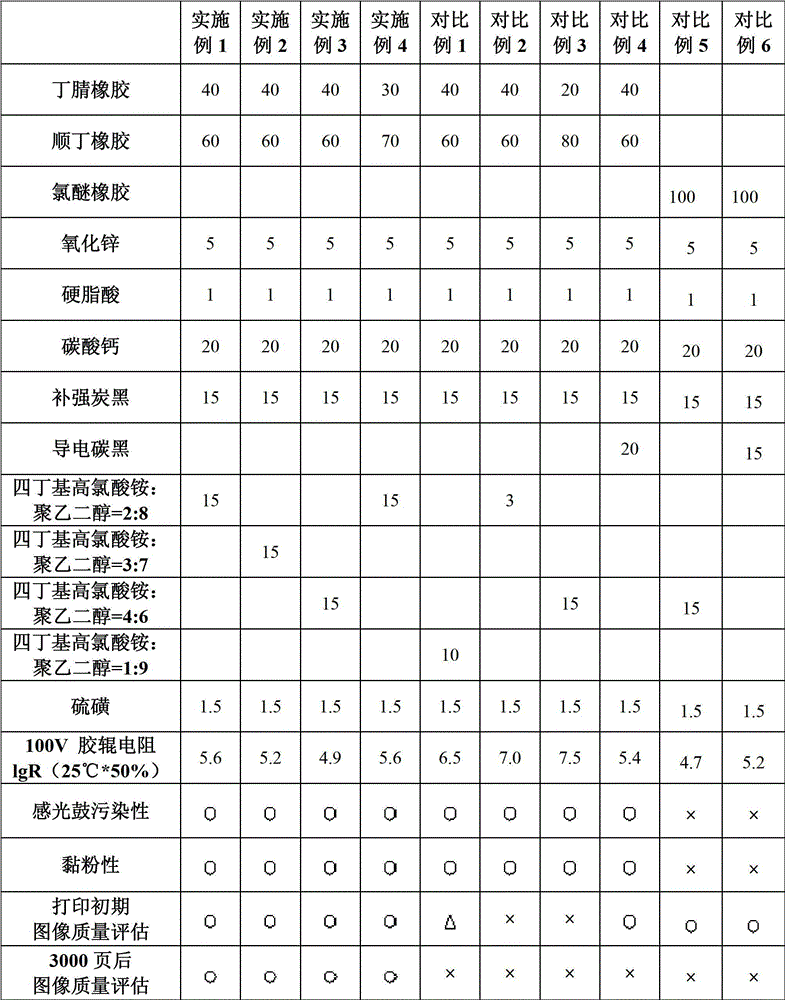

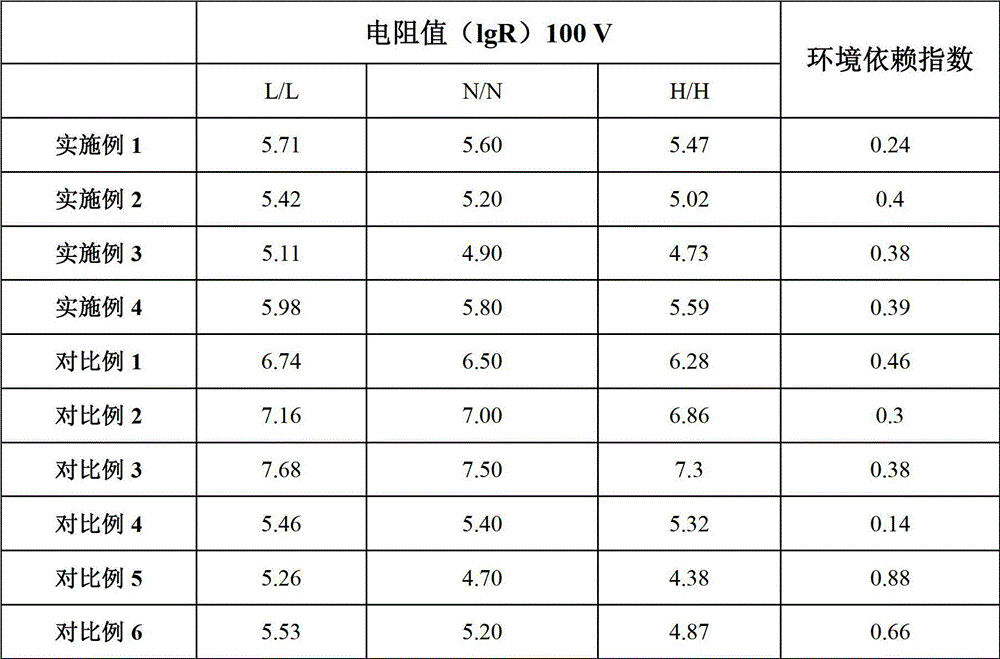

Embodiment 1

[0046] 40 parts of nitrile rubber, 60 parts of butadiene rubber; 5 parts of zinc oxide, 1 part of stearic acid, 20 parts of calcium carbonate, 15 parts of 1# carbon black (reinforcing carbon black), ion conductive agent (tetrabutyl high Ammonium chlorate:polyethylene glycol=2:8) 10 parts, sulfur 1.5 parts, and they were mixed evenly in an open rubber mixer or a closed rubber mixer to obtain a conductive rubber composition.

[0047] Then the conductive rubber composition is molded by extruder, and the metal shaft core 1 is inserted in the middle during the molding process to form a rubber roller with a metal shaft core in the middle and a conductive elastomer on the outer layer.

[0048] Finally, put the preformed rubber roller into the vulcanization tank, heat it for 1.5h at 150°C and a pressure of 0.4MPa, and make the rubber roller truly shaped through the vulcanization and cross-linking reaction, and use a grinding wheel to grind off the outer layer of the rubber roller. And...

Embodiment 2

[0050] 40 parts of nitrile rubber, 60 parts of butadiene rubber; 5 parts of zinc oxide, 1 part of stearic acid, 20 parts of calcium carbonate, 15 parts of 1# carbon black (reinforcing carbon black), ion conductive agent (tetrabutyl high Ammonium chlorate:polyethylene glycol=3:7) 10 parts, sulfur 1.5 parts, and they were mixed uniformly in an open rubber mixer or a closed rubber mixer to obtain a conductive rubber composition.

[0051] Then the conductive rubber composition is extruded into shape, and a metal shaft core is inserted in the middle during the molding process to form a rubber roller with a metal shaft core in the middle and a conductive elastic body on the outer layer.

[0052] Finally, put the preformed rubber roller into the vulcanization tank, heat it for 1.5h at 150°C and a pressure of 0.4MPa, and make the rubber roller truly shaped through the vulcanization and cross-linking reaction, and use a grinding wheel to grind off the outer layer of the rubber roller. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com