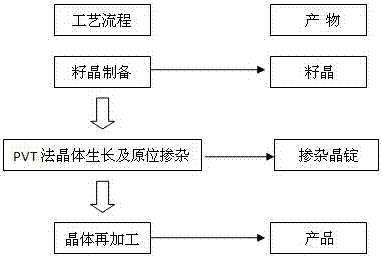

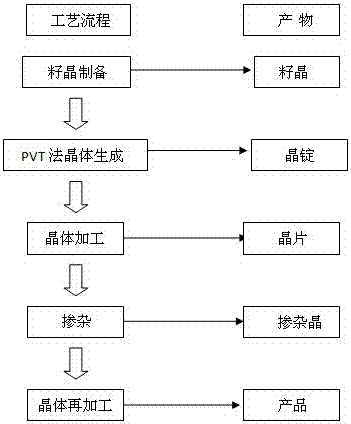

A kind of in-situ doping method for preparing semiconductor single crystal material by pvt method

A single crystal material, in-situ doping technology, applied in the field of in-situ doping, can solve the problems of increased process complexity, expensive equipment, crystal structure damage, etc., to achieve large-scale production, reduce crystal structure loss, uniform The effect of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

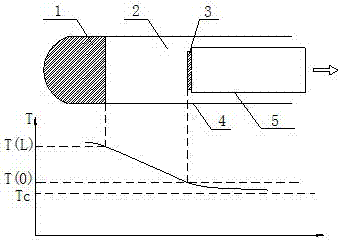

[0012] Indium-doped N-type low-resistance cadmium sulfide single crystal was prepared by PVT method.

[0013] The growth of cadmium sulfide single crystal adopts PVT crystal growth furnace with two temperature zones. The temperature zones from the raw material end to the substrate end are respectively the first temperature zone and the second temperature zone. The quartz single crystal material is used as the substrate and the indium simple substance is used as the doping source. The elemental indium is mixed with cadmium sulfide source powder in powder state and placed in the raw material area 1. The temperature area during crystal growth is set at 1000°C and 960°C. After the growth process is completed, the growth tube is taken out, and the N-type low temperature crystal doped with indium element can be obtained. single crystal cadmium sulfide.

example 2

[0015] Chlorine-doped N-type low-resistance cadmium sulfide single crystals were prepared by PVT method.

[0016] Cadmium sulfide single crystal growth adopts PVT crystal growth furnace with two temperature zones. The temperature zones from the raw material end to the substrate end are respectively one temperature zone and two temperature zones. Quartz single crystal material is used as the substrate and cadmium chloride is used as the doping source , cadmium chloride is mixed with cadmium sulfide source powder in powder state and placed in raw material zone 1, the temperature zone during crystal growth is set to 1010°C and 980°C, after the growth process is completed, the growth tube is taken out to obtain chlorine-doped N type low resistance cadmium sulfide single crystal.

example 3

[0018] Al-doped N-type low-resistance CdSe single crystals were prepared by PVT method.

[0019] The growth of cadmium selenide single crystal adopts PVT crystal growth furnace with two temperature zones. The temperature zones from the raw material end to the substrate end are respectively the first temperature zone and the second temperature zone. The quartz single crystal material is used as the substrate and the aluminum element is used as the doping source. The elemental aluminum is mixed with cadmium selenide source powder in powder state and placed in the raw material area 1. The temperature area during crystal growth is set to 950 ° C and 900 ° C. After the growth process is completed, the growth tube is taken out to obtain aluminum-doped N type low resistance cadmium selenide single crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com