Patents

Literature

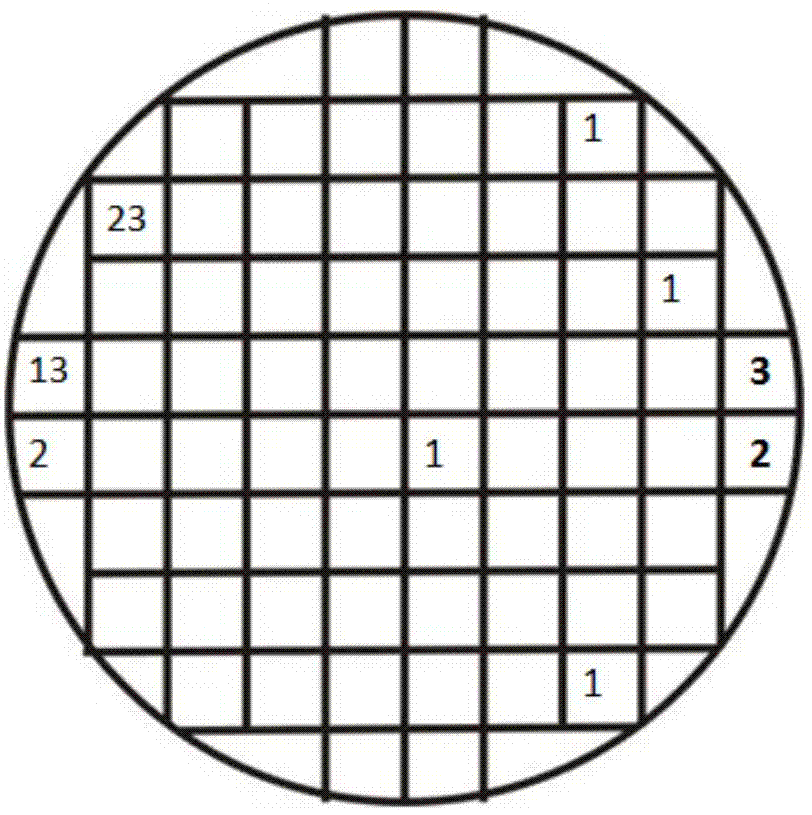

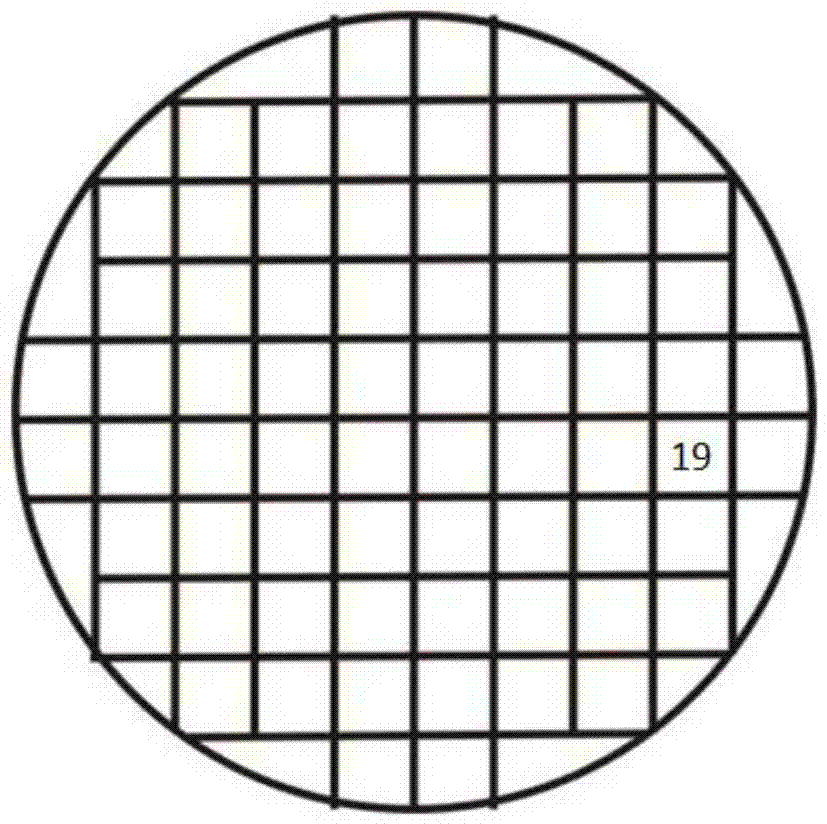

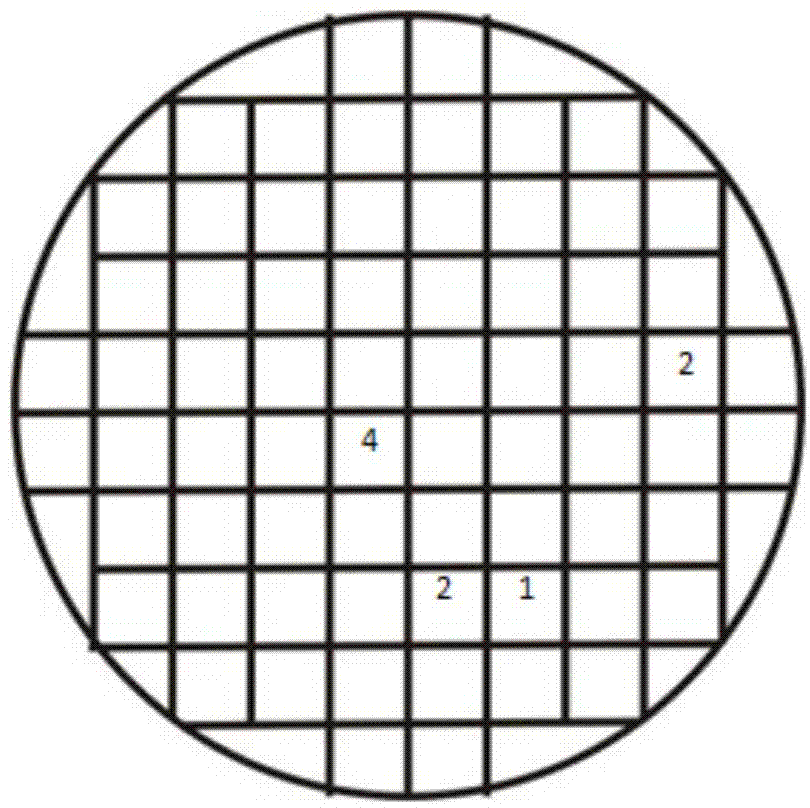

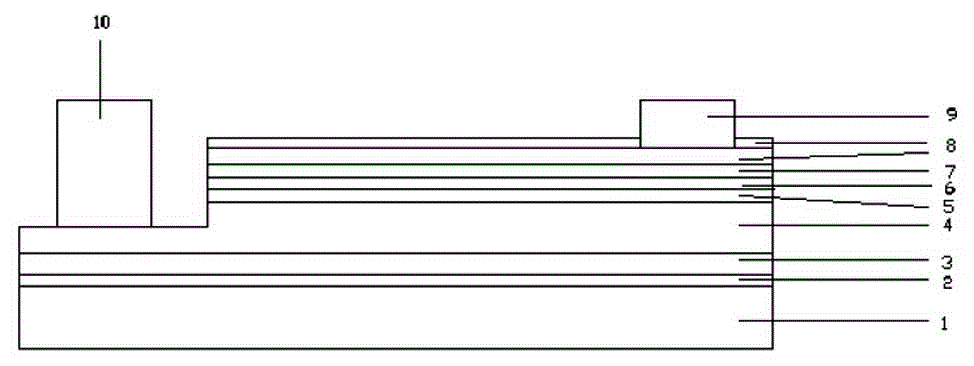

88 results about "Growth pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

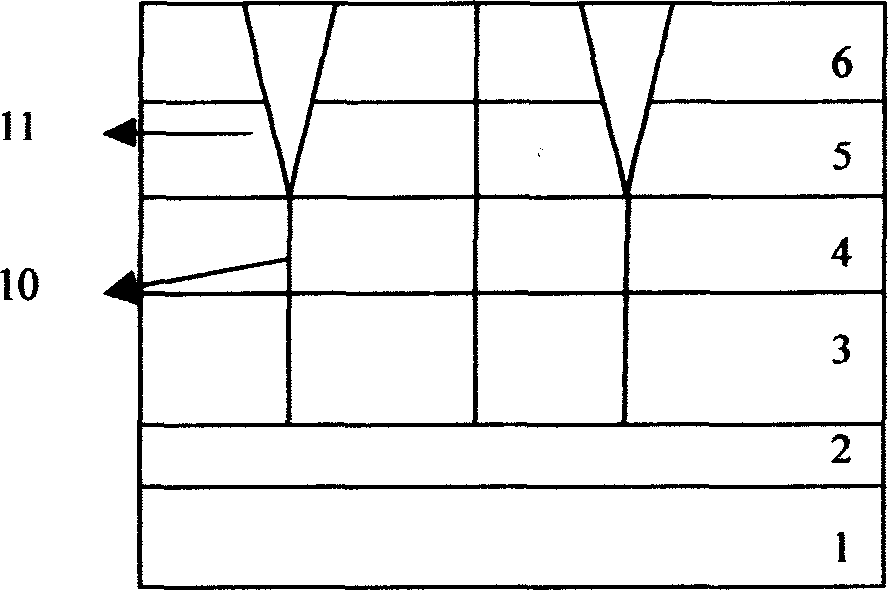

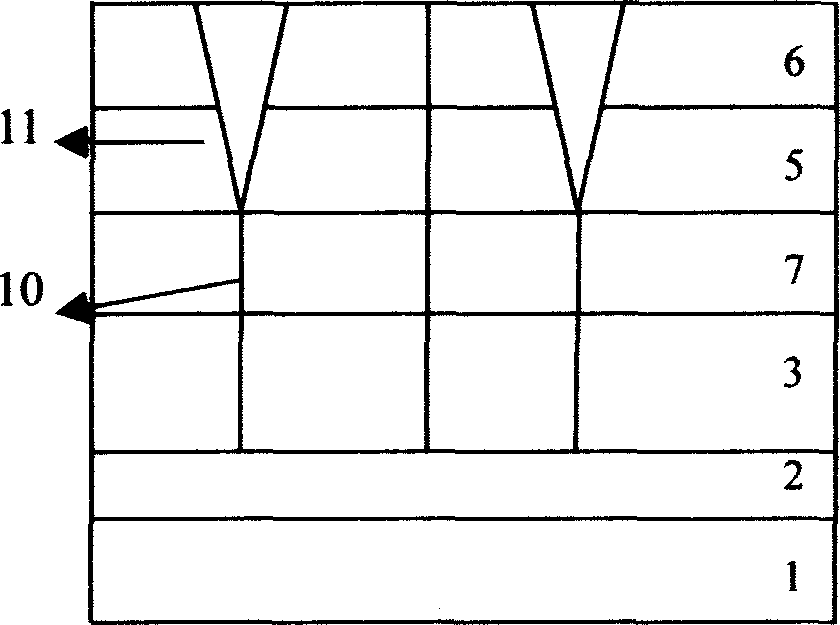

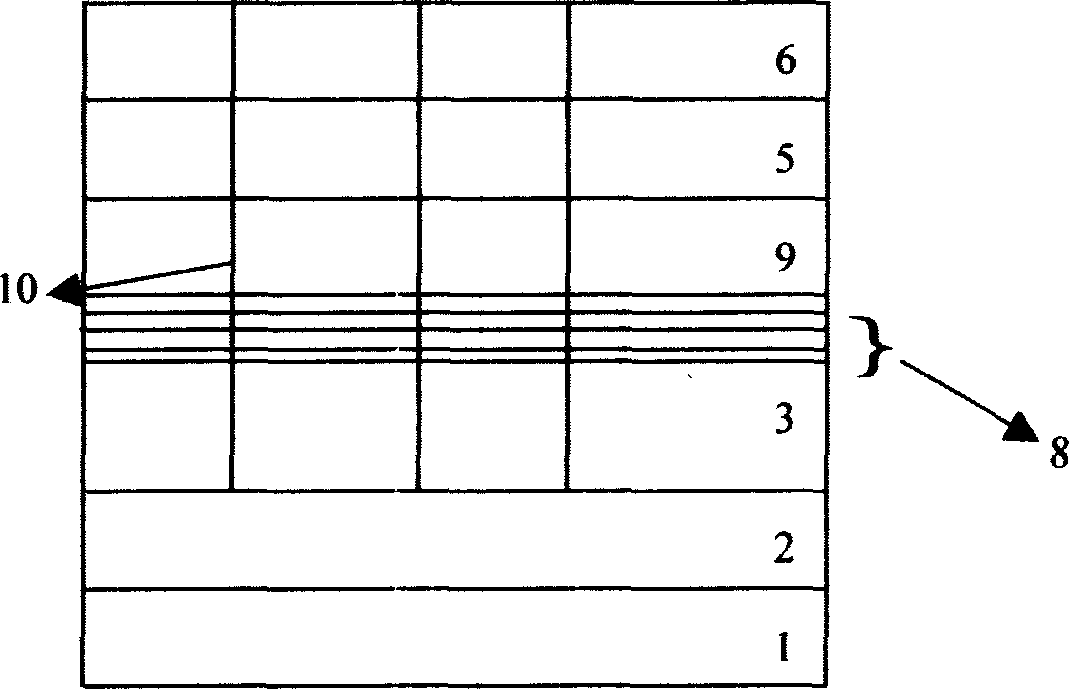

Method for avoiding or reducing V-defect of blue-green light LED material

ActiveCN1905222AAvoid or reduce V-shaped defectsAvoid or reduce the occurrence ofSemiconductor devicesGreen-lightLight-emitting diode

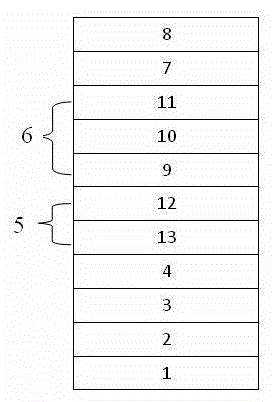

The invention is a method for avoiding or reducing V-type defect of blue-green light emitting diode material which has in turn sapphire substrate, low-temperature grown GaN buffer layer, high-temperature grown n-GaN layer, InGa1-Yn / GaN multi-quantum trap layer, and p-Alx Ga1-xN / p-GaN layer, characterized in that: there is a grown n-AlxGa1-xN / GaN superlattice layer between the high-temperature grown n-GaN layer and InGa1-Yn / GaN multi-quantum trap layer, where 0<x<1, the growth temperature is between 1100deg.C and 1200deg.C, the pressure is 30Torr-100Torr, the AlxGa1-xN layer is 1nm-5nm thick, the GaN layer is 1nm-5nm thick, the periodicity is 5-10, the doping concentration is between 1*1016cm-3 and 1*1018cm-3; there is also a weak n-type doped GaN layer between the high-temperature grown n-GaN layer and InGa1-Yn / GaN multi-quantum trap layer, where the growth temperature is 1150 deg.C-1200 deg.C, the growth pressure is 30Torr-80Torr, and the thickness is 1m-50nm, the doping concentration is between 1*1016cm-3 and 5*1017cm-3. And it can avoid or reduce V-type defect and reverse leakage current generated by this.

Owner:HC SEMITEK SUZHOU

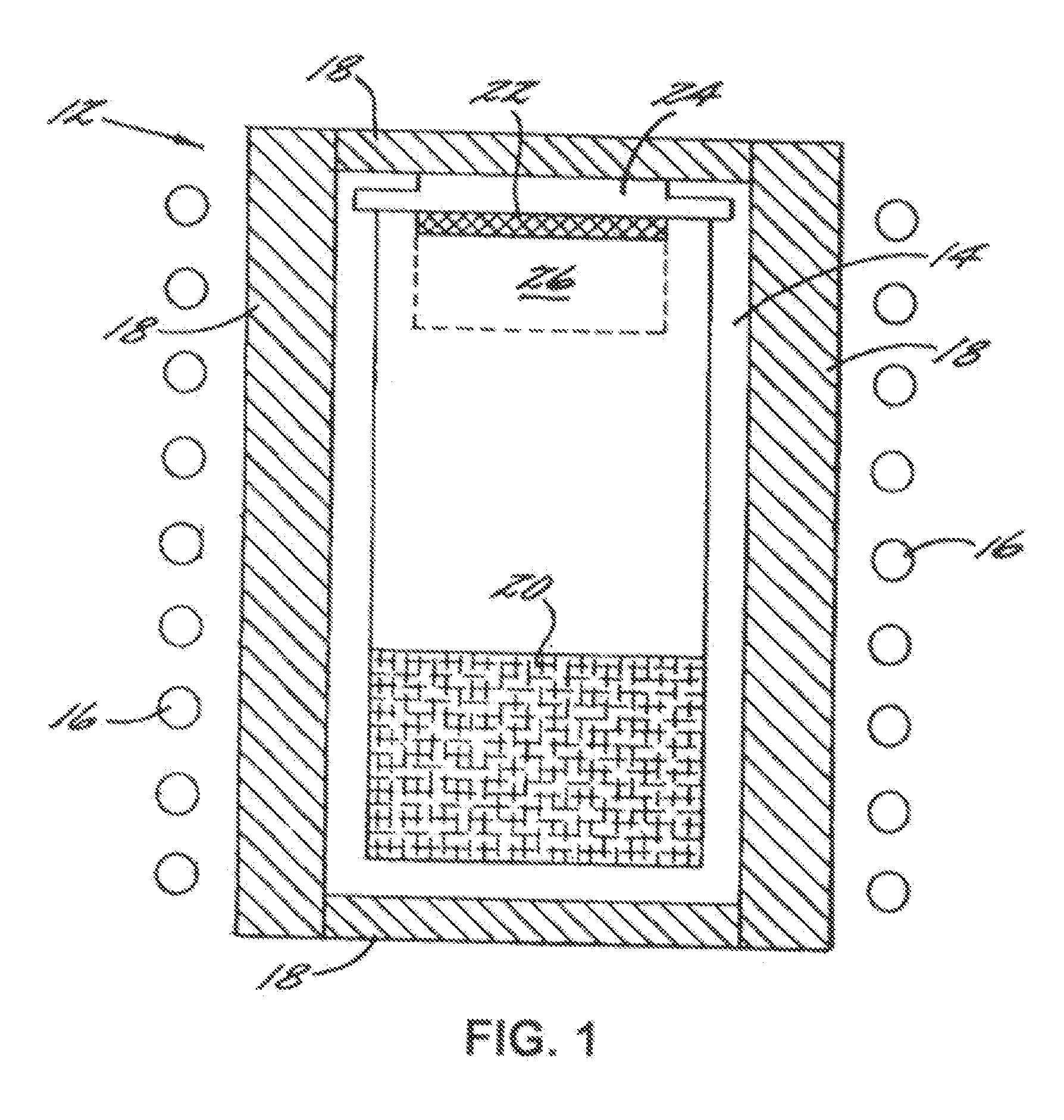

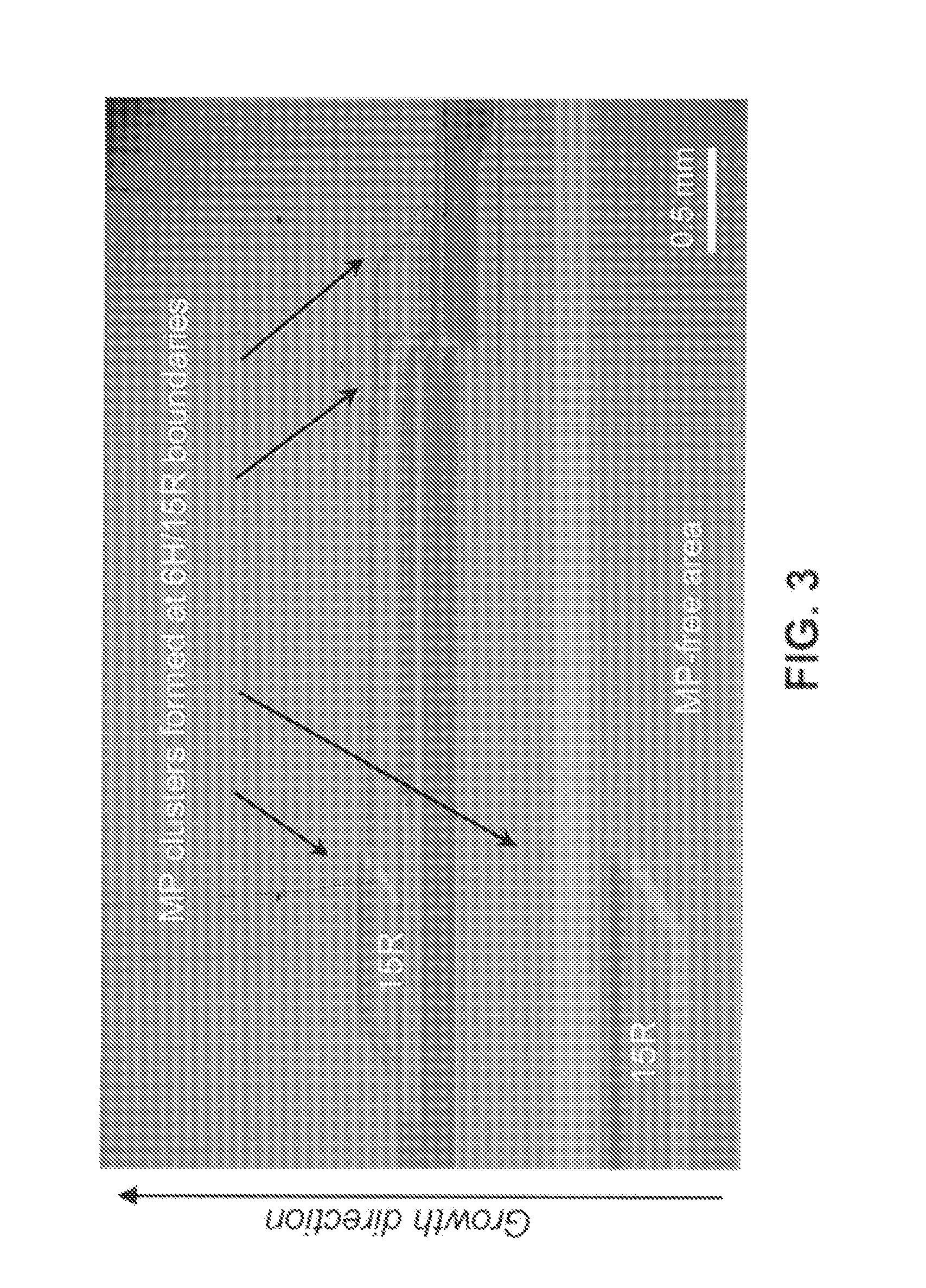

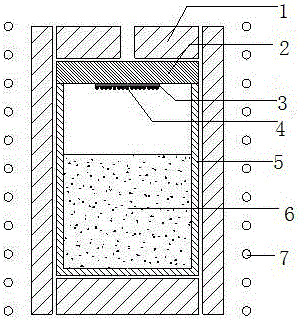

Micropipe-free silicon carbide and related method of manufacture

ActiveUS20080067524A1Reduce instabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingSource materialCrucible

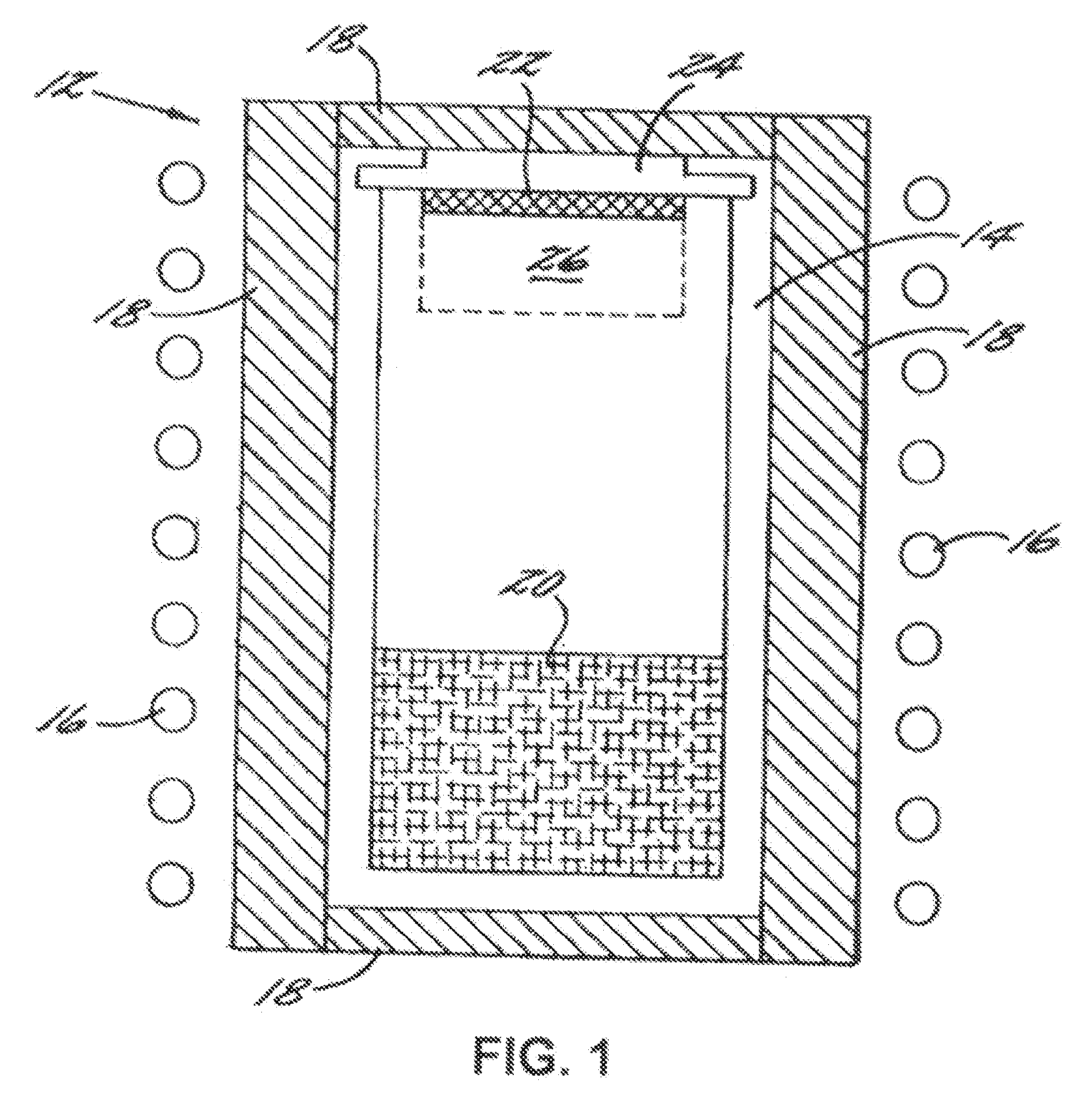

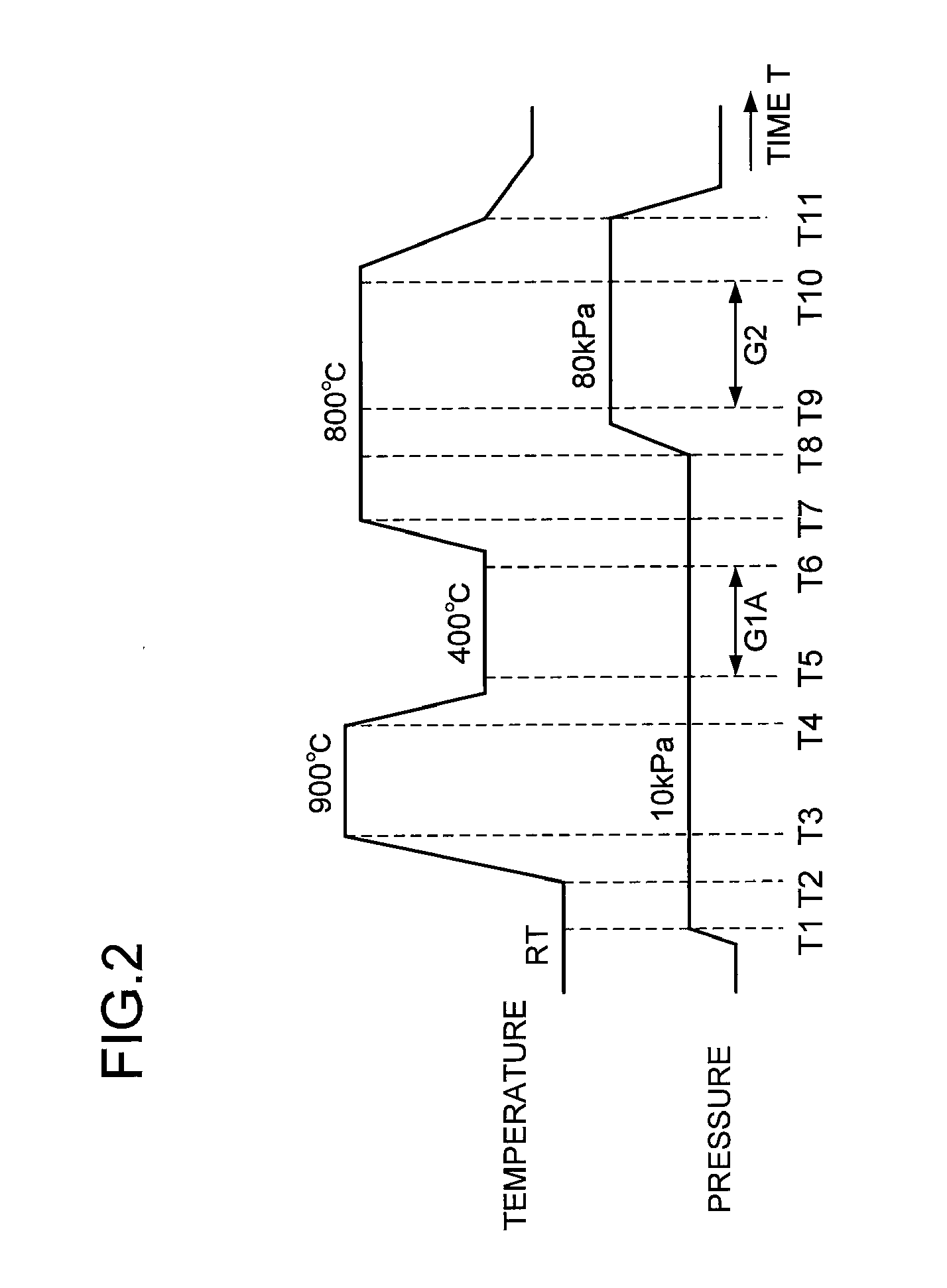

Micropipe-free, single crystal, silicon carbide (SiC) and related methods of manufacture are disclosed. The SiC is grown by placing a source material and seed material on a seed holder in a reaction crucible of the sublimation system, wherein constituent components of the sublimation system including the source material, reaction crucible, and seed holder are substantially free from unintentional impurities. By controlling growth temperature, growth pressure, SiC sublimation flux and composition, and a temperature gradient between the source material and the seed material or the SiC crystal growing on the seed material during the PVT process, micropipe-inducing process instabilities are eliminated and micropipe-free SiC crystal is grown on the seed material.

Owner:CREE INC

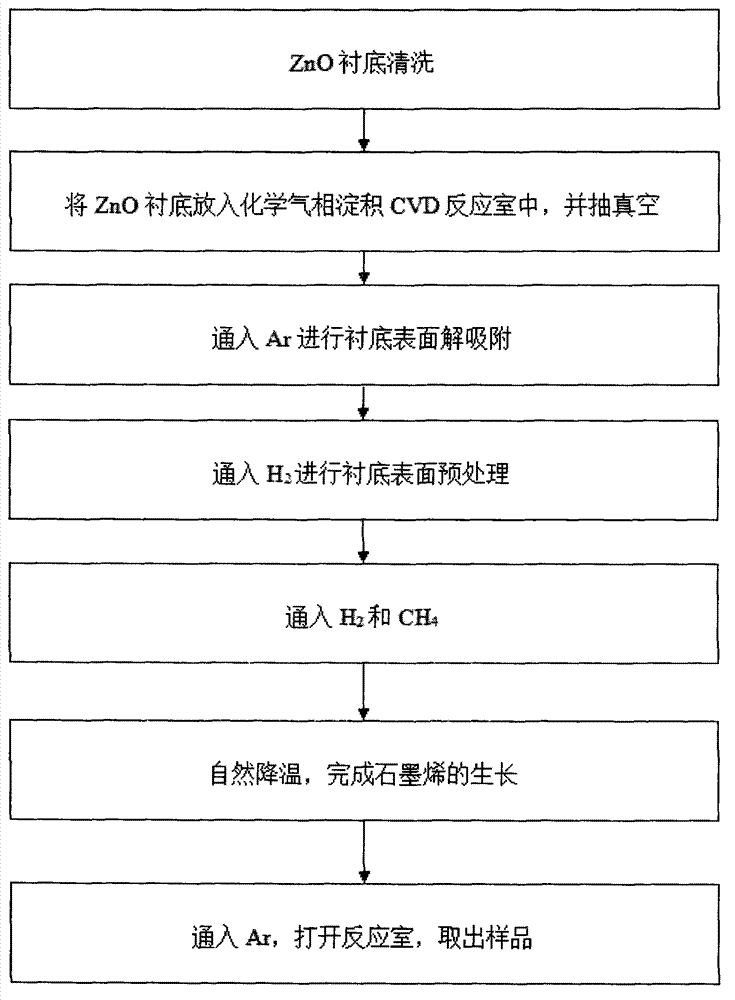

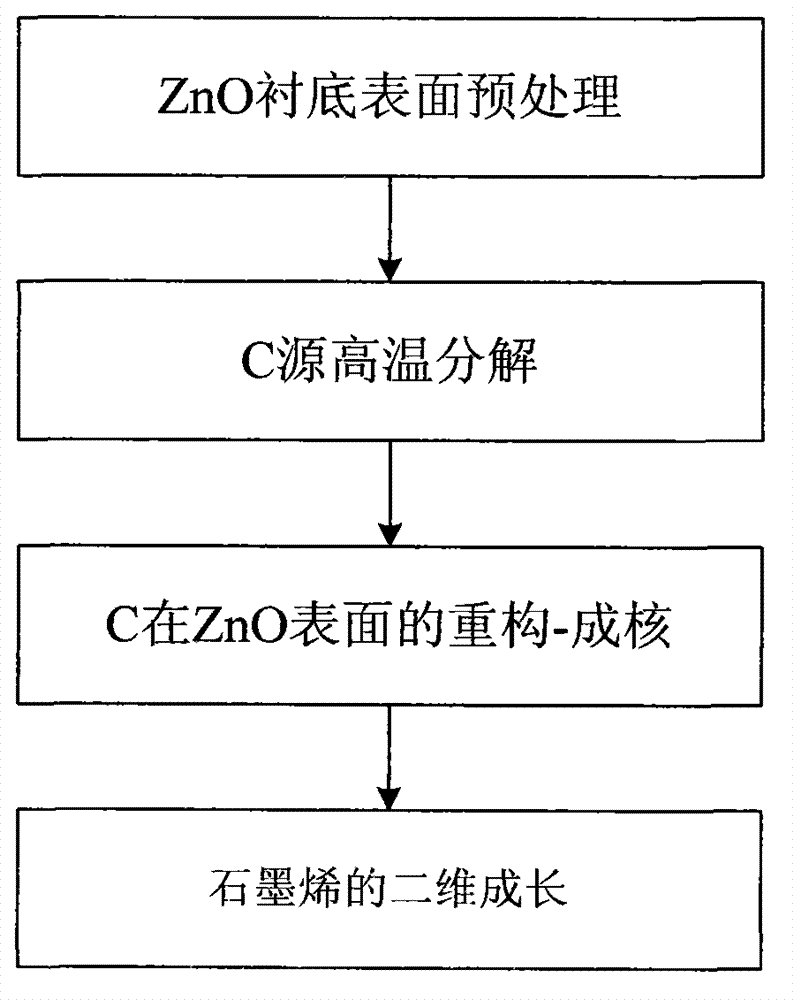

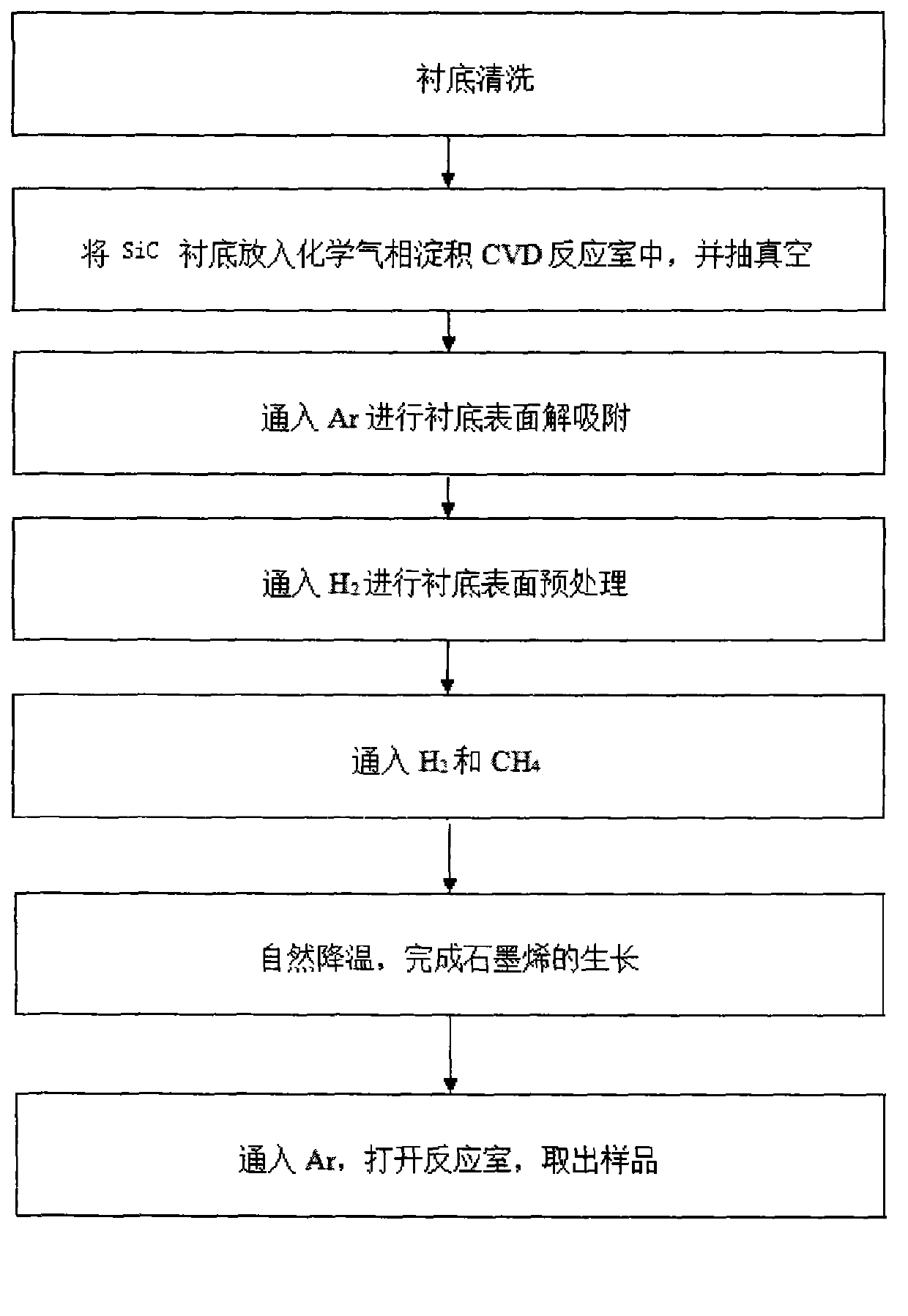

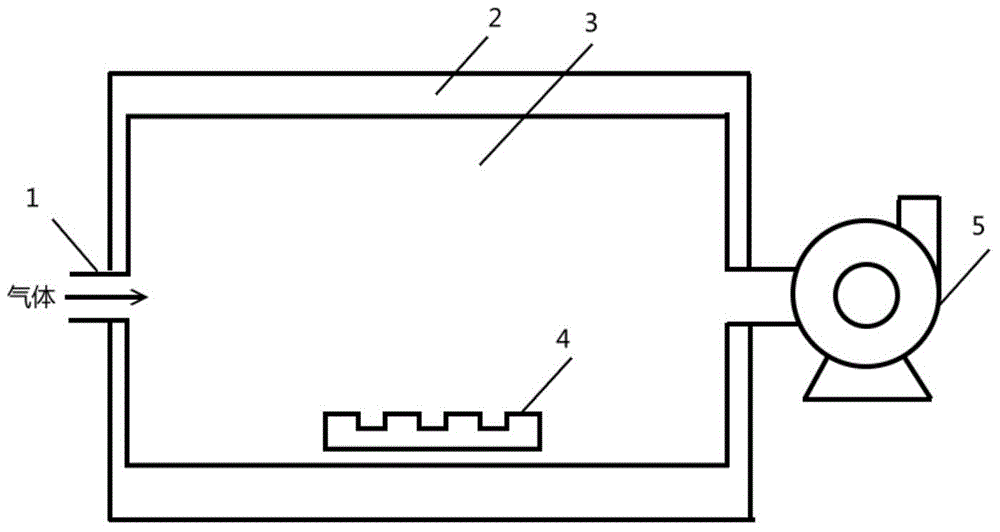

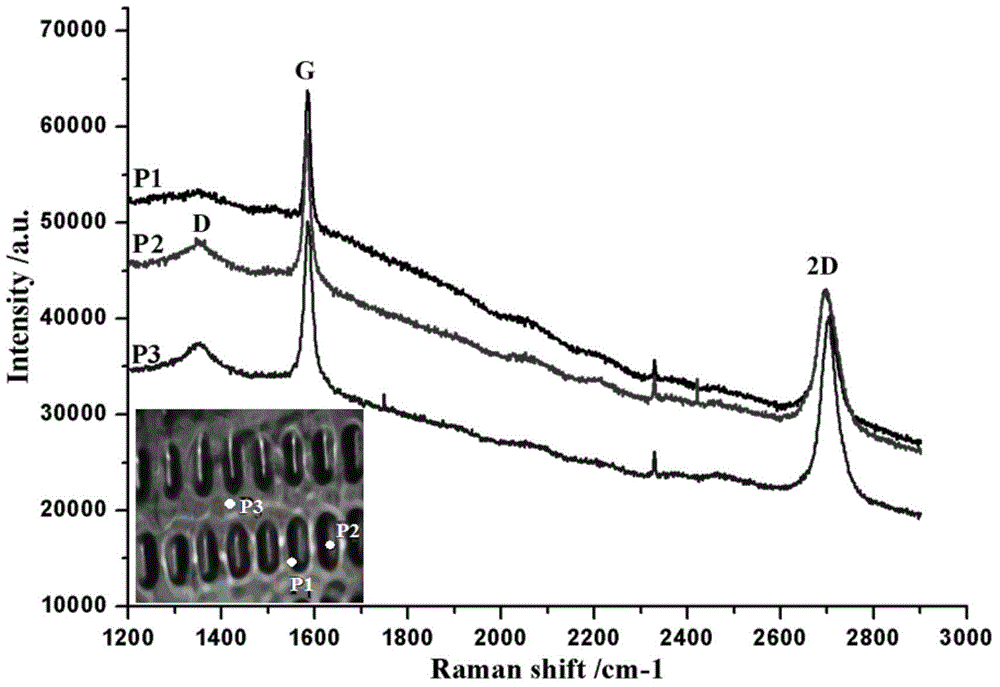

ZnO substrate-based graphene CVD direct epitaxial growth method and manufactured device

InactiveCN102903616AAvoid destructionSemiconductor/solid-state device manufacturingFrom chemically reactive gasesCvd grapheneMetal

The invention discloses a ZnO substrate-based graphene CVD direct epitaxial growth method. By adopting an II-VI family compound semiconductor ZnO as a substrate, through reasonably preprocessing the ZnO substrate, regulating the growth pressure, flow and temperature, the optimization of the graphene growth is realized, graphene directly grows on the ZnO without using metal as a catalyst, the growing graphene is not transferred, provides a material for a ZnO-graphene structure device, and can be directly used for manufacturing various devices, thus electrical properties and reliability of the devices are improved, and complexity of device manufacture is lowered. According to the ZnO substrate-based graphene CVD direct epitaxial growth method, a large-area graphene material with semiconductor cleanness can be grown.

Owner:XIDIAN UNIV

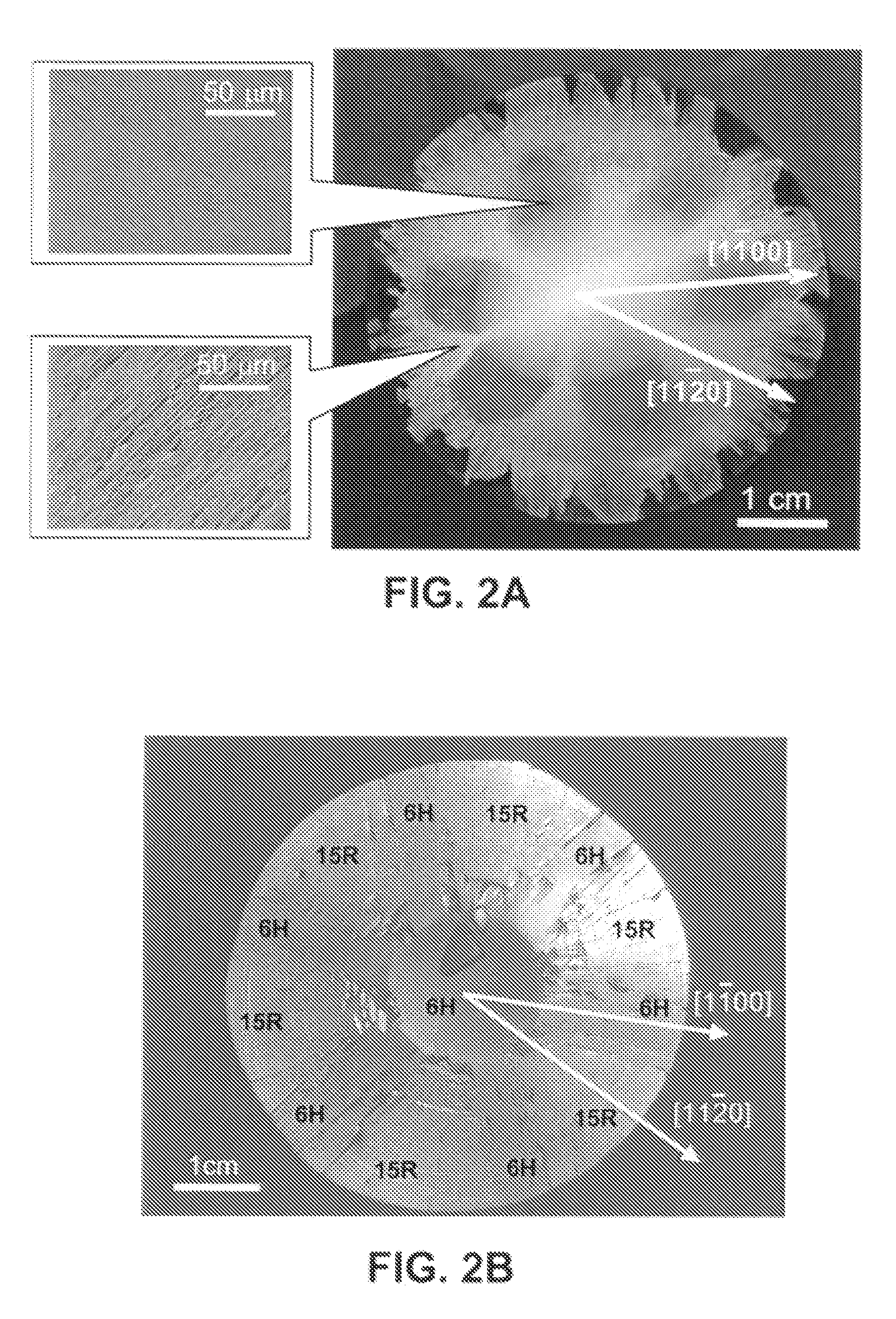

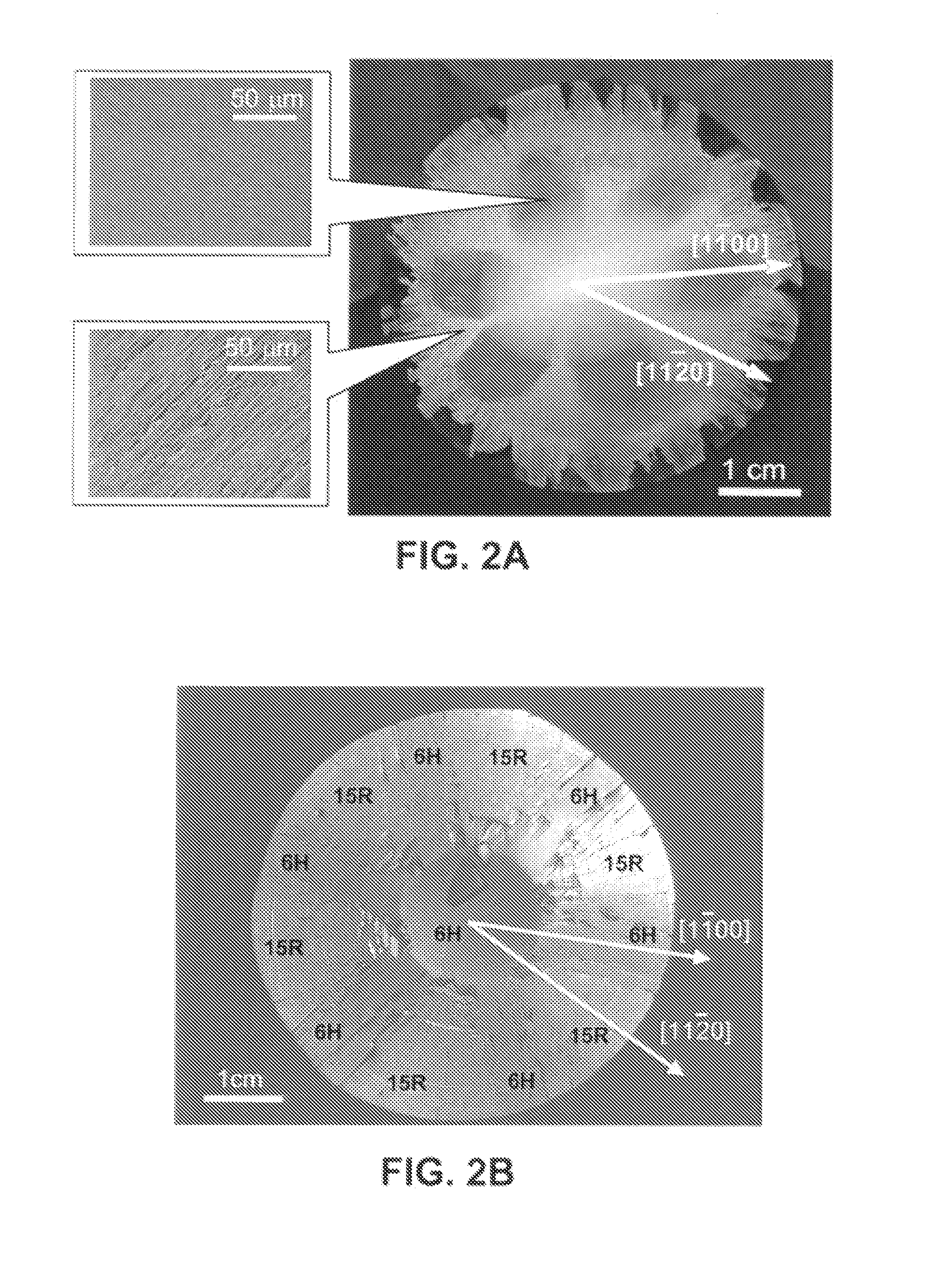

Growth method for reducing density of micro-tubes in large-sized high-quality SiC single crystal

ActiveCN103590101AReduce the amount requiredNo polytypePolycrystalline material growthUnder a protective fluidSingle crystalNitrogen doped

The invention relates to a growth method for reducing density of micro-tubes in a large-sized high-quality SiC single crystal. A sublimation method is used in a SiC single crystal furnace to grow the SiC single crystal, the air is vacuumized to 10<-4> Pa-10<-2> Pa before growth, the growth pressure is 5-50 mbar, the temperature is 2100-2400 DEG C, the rate is 10-500 mum / h, high-purity nitrogen is introduced into a growth chamber for 2-10 hours when the crystal grows for 20-24 hours, the same nitrogen is introduced again after an interval of 20 hours, the process is periodically repeated to obtain the intermittently nitrogen-doped SiC single crystal, the obtained SiC single crystal does not have the defects of cavity, silicon drop, polytype and the like, and the density of the micro-tubes is greatly reduced. The growth method achieves the objectives of reducing the density of the micro-tubes to the lowest and even to the level of zero micro-tube.

Owner:SHANDONG UNIV

LED of novel quantum well structure and method for manufacturing LED

InactiveCN103985798ASimple structureIncrease the chances of matchingSemiconductor devicesQuantum efficiencyElectron

The invention discloses an LED of a novel quantum well structure. The LED comprises a substrate and an epitaxial layer structure formed on the substrate. The LED is characterized in that the epitaxial layer structure comprises luminous-layer multiple quantum wells, and well layers and barrier layers of the luminous-layer multiple quantum wells are respectively formed by combining one or more of single-component InGaN, gradually-deformed component InGaN, step-shaped component InGaN, concave component InGaN, convex component InGaN and delta type component InGaN, wherein the In content and the Al content of the mixed quantum wells are achieved by changing parameters such as the In source flow, the Al source flow, growth temperature and growth pressure. According to the structure of the LED, the polarization effect in the GaN-based LED quantum wells is improved, wave function overlap of electrons and holes is enlarged, and therefore internal quantum efficiency of the LED is promoted, and the efficient droop effect of the LED under a high current is weakened.

Owner:GUANGDONG DELI PHOTOELECTRIC

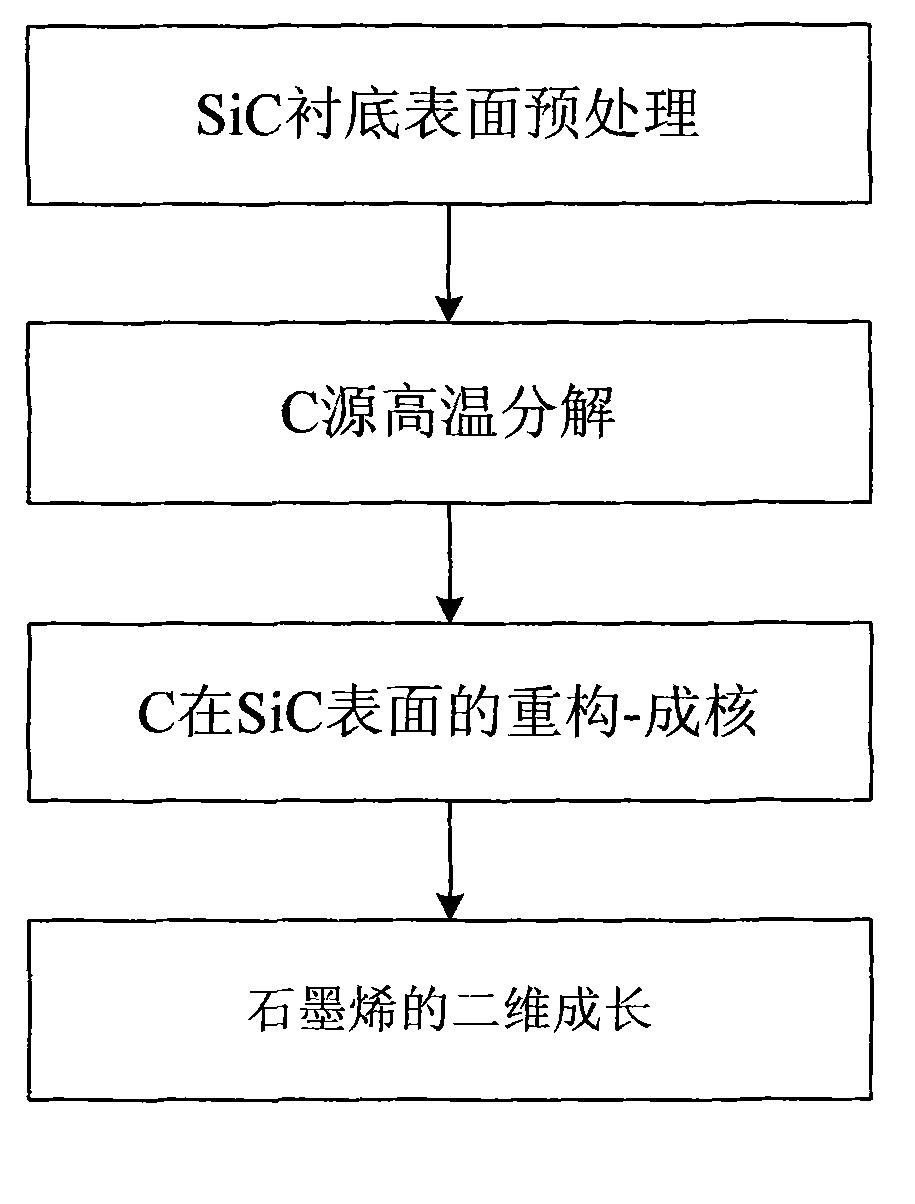

SiC substrate-based graphene CVD (Chemical Vapor Deposition) direct epitaxial growth method and manufactured device

InactiveCN102891074AAvoid destructionSemiconductor/solid-state device manufacturingCvd grapheneSic substrate

The invention discloses a SiC substrate-based graphene CVD (Chemical Vapor Deposition) direct epitaxial growth method. By using a semiconductor SiC as a substrate and reasonably preprocessing the SiC substrate, the growth pressure, the flow and the temperature are regulated, graphene directly grows on the SiC substrate without using metal as a catalyst, the growing graphene does not need to be transferred and can be directly used for manufacturing various kinds of devices, so that electrical properties and the reliability of the devices are improved, and the complexity of device manufacture is lowered. According to the SiC substrate-based graphene CVD direct epitaxial growth method, a large-area graphene material with semiconductor cleanness can grow, the growth preparation of the large-area graphene material without transfer can be used, and a material is provided for the manufacture of a silicon carbide-graphene device.

Owner:XIDIAN UNIV

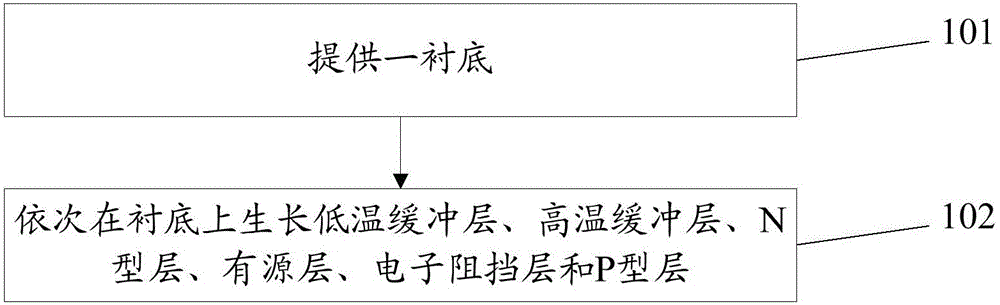

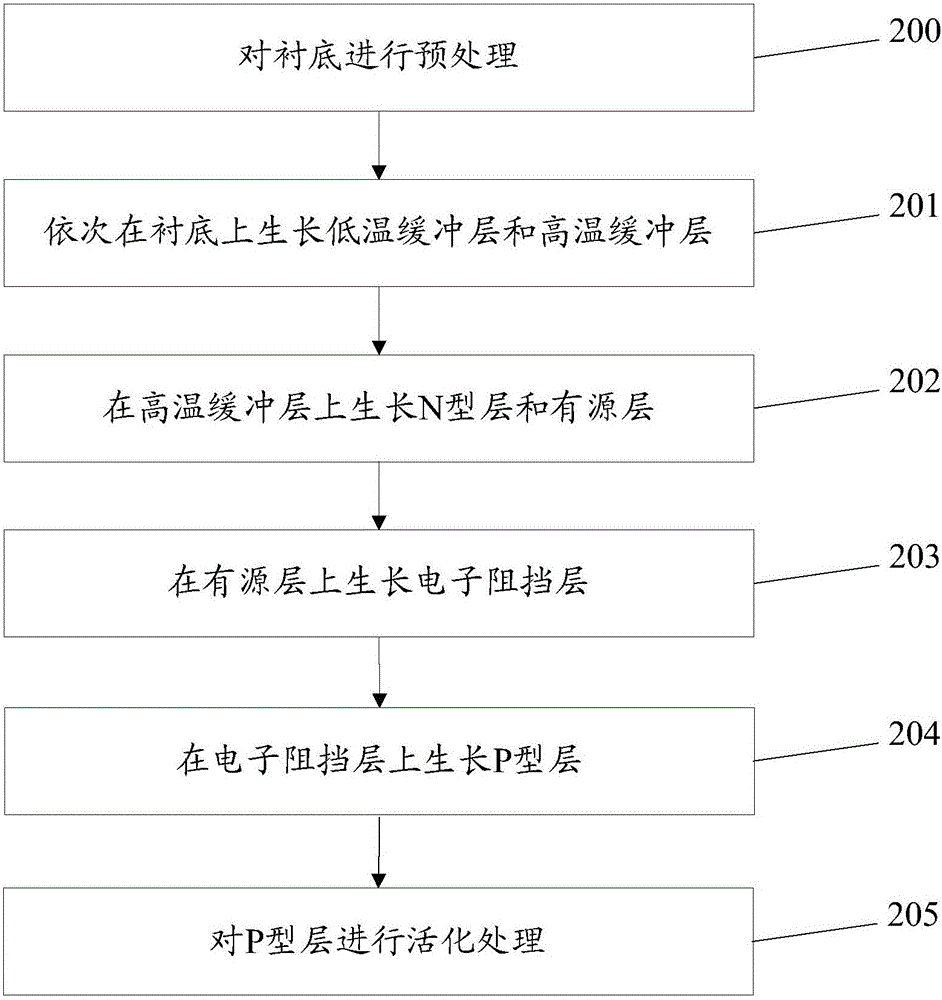

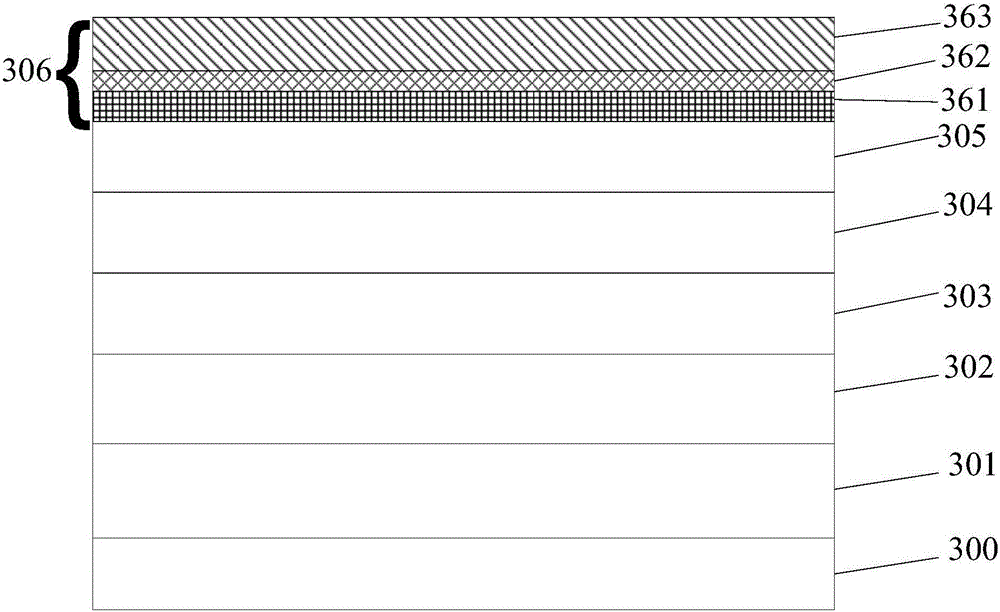

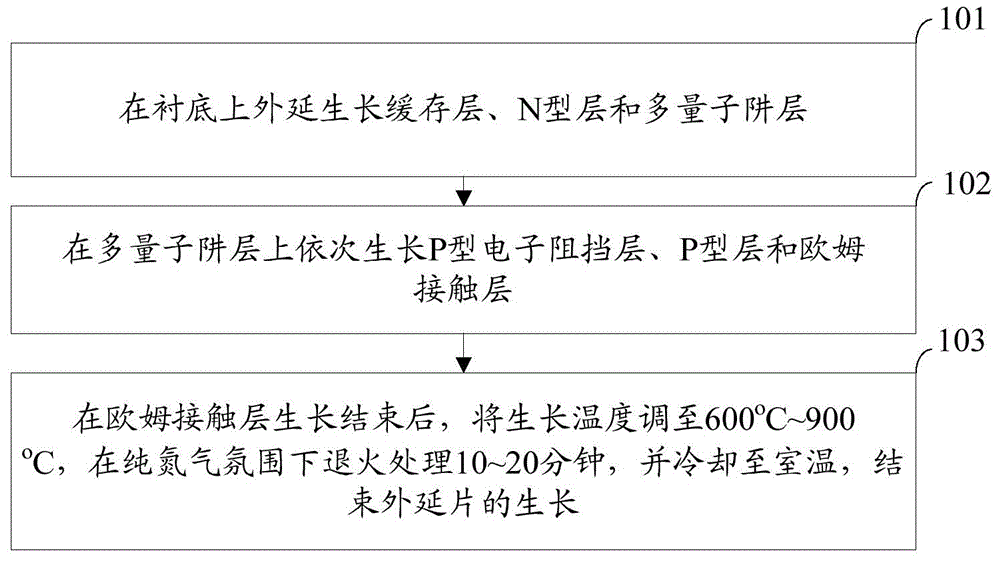

Manufacturing method of light-emitting diode epitaxial wafer and light-emitting diode epitaxial wafer

ActiveCN105679893ASlow growth ratePromote growthSemiconductor devicesElectron blocking layerActive layer

The invention discloses a manufacturing method of a light-emitting diode epitaxial wafer and the light-emitting diode epitaxial wafer, and belongs to the field of light-emitting diodes. The method comprises the steps as follows: a substrate is provided; and a low-temperature buffer layer, a high-temperature buffer layer, an N-type layer, an active layer, an electron blocking layer and a P-type layer sequentially grow on the substrate. The manufacturing method is characterized in that the P-type layer grows as follows: a first GaN sub-layer with a first thickness and a first Mg doping concentration grows on the electron blocking layer at a first growth temperature, a first growth pressure and a first growth rate; a second GaN sub-layer with a second thickness and a second Mg doping concentration grows on the first GaN sub-layer at a second growth temperature, a second growth pressure and a second growth rate; and a third GaN sub-layer with a third thickness and a third Mg doping concentration grows on the second GaN sub-layer at a third growth temperature, a third growth pressure and a third growth rate.

Owner:HC SEMITEK SUZHOU

Method for directly and conformally covering graphene film on full surface of substrate with three-dimensional structure

ActiveCN104018136ASimple and fast operationShort preparation cycleChemical vapor deposition coatingGas phaseShielding gas

The invention discloses a method for directly and conformally covering a graphene film on the full surface of a substrate with a three-dimensional structure. The method comprises the steps of placing a cleaned and dried substrate with a three-dimensional structure in a vacuum cavity of a chemical vapor deposition device, and exhausting air in the cavity; then, filling protective gas into the cavity; next, heating the cavity to the graphene growth temperature; introducing carbon source gas and protective gas taking a current-carrying effect, maintaining the air pressure at the graphene growth pressure, and enabling graphene to directly grow on the surface of the substrate with the three-dimensional structure; after the growth of graphene is ended, stopping introducing the carbon source gas into the cavity, cooling the cavity to 10-30 DEG C in the existence of the protective gas and at the graphene growth pressure, and taking out the substrate with the three-dimensional structure to obtain the substrate with the continuous and uniform graphene film covered on the full surface. The method disclosed by the invention is simple and convenient in operation, short in manufacturing period, low in manufacturing cost and capable of directly covering the continuous and uniform high-quality graphene film on the full surface of the substrate with the complex three-dimensional structure.

Owner:重庆石墨烯研究院有限公司

Micropipe-free silicon carbide and related method of manufacture

ActiveUS20080083366A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSource materialCrucible

Owner:CREE INC

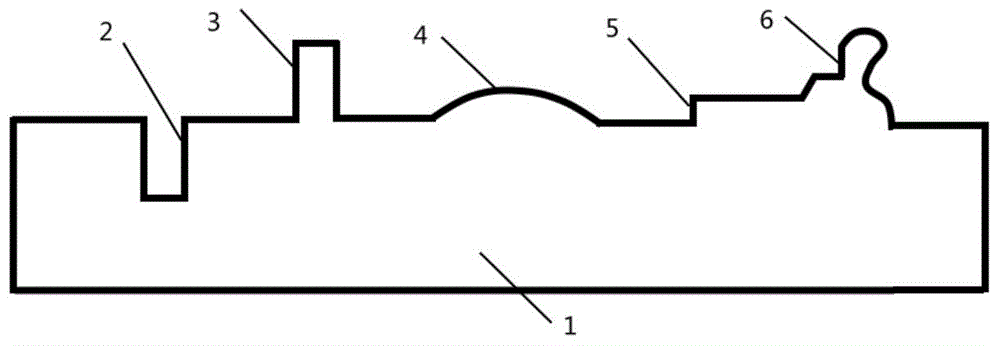

LED chip structure efficiently matched with ZnO thin film and manufacturing method of LED chip structure

InactiveCN104465910ALow working voltageImprove voltage highSemiconductor devicesContact layerHigh voltage

The invention discloses an LED chip structure efficiently matched with a ZnO thin film. The LED chip structure comprises a substrate and an epitaxial layer formed on the substrate. The LED chip structure is characterized in that the epitaxial layer comprises a contact layer and a ZnO transparent conductive layer formed on the contact layer, the contact layer is a superlattice layer composed of a layer of one kind of material or two kinds of materials or three kinds of materials of intrinsic AlxInyGa1-x-yN, P-type AlxInyGa1-x-yN and N-type AlxInyGa1-x-yN. Meanwhile, a manufacturing method of the contact layer is introduced, and the content of the contact layer is achieved by changing the parameters such as In source flow, Al source flow, the growth temperature and the growth pressure. According to the provided ZnO-LED chip structure, the problems such as high voltages, poor ESD and large electric leakage occurring when ZnO serves as the transparent conductive layer are solved, the LED chip structure has the advantages of being good in contact, low in voltage and little in light absorption, and thus the light extraction rate of LED devices is effectively increased.

Owner:GUANGDONG DELI PHOTOELECTRIC

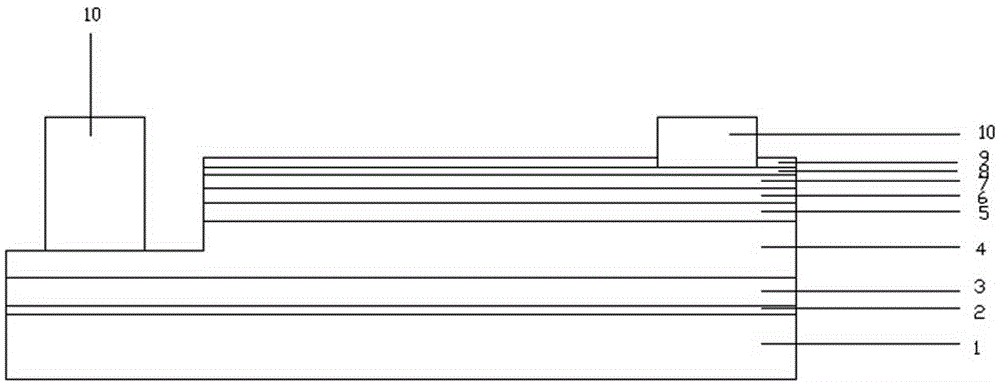

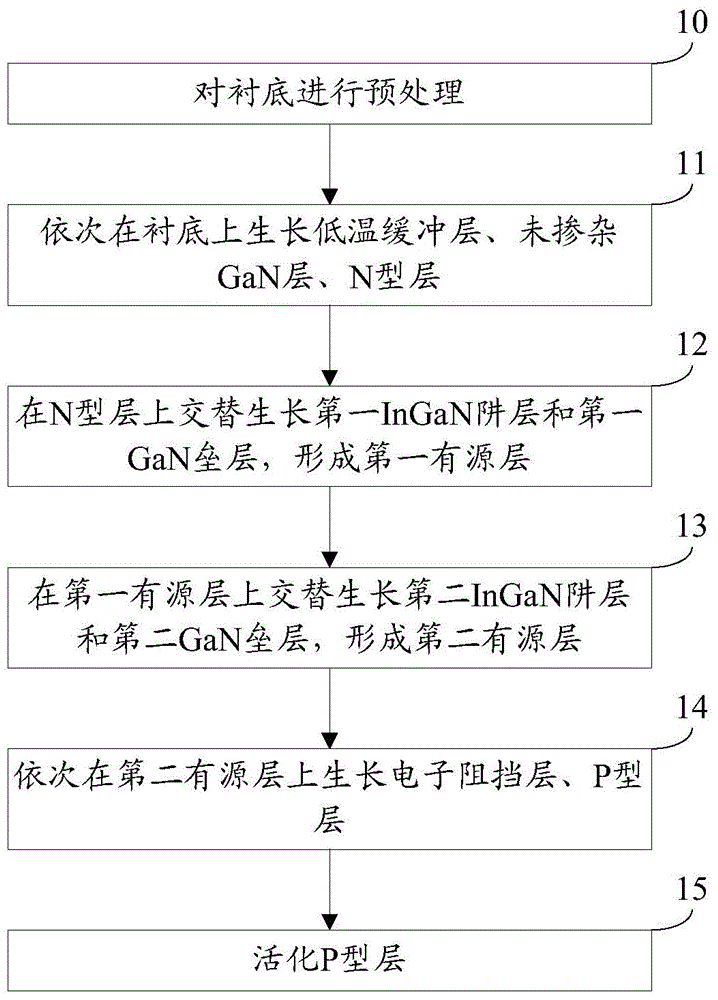

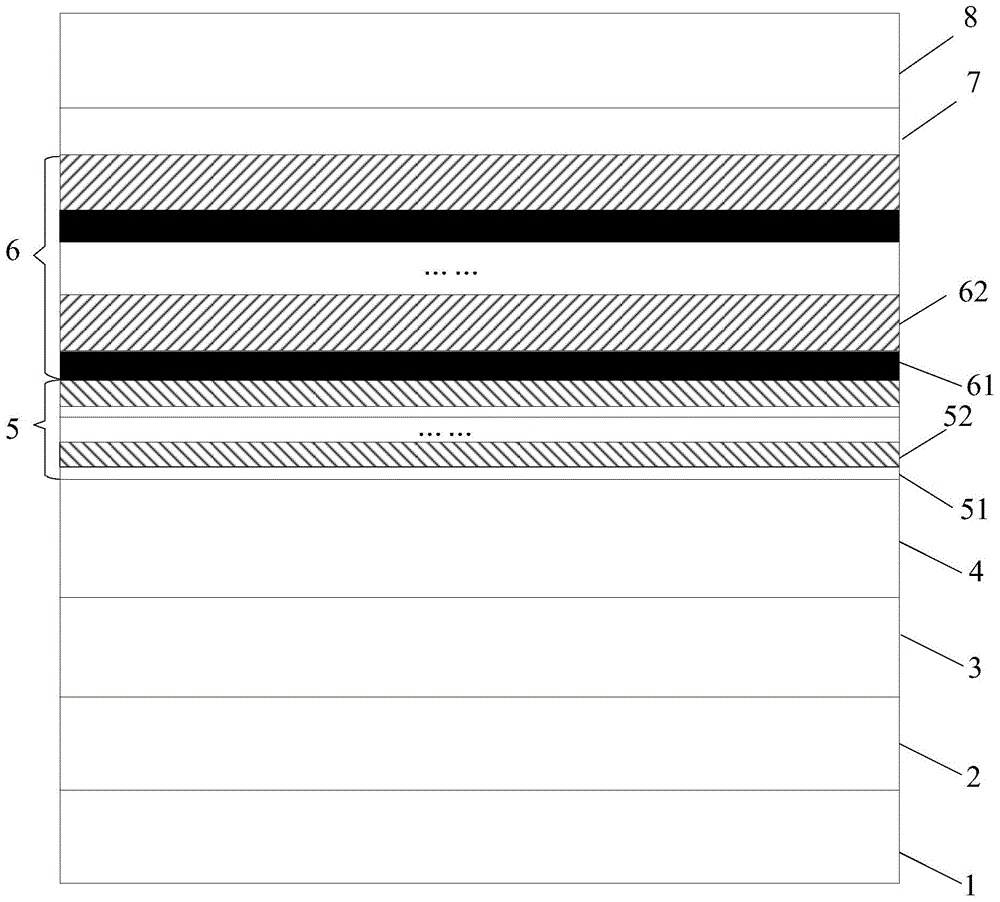

Growth method for light-emitting diode epitaxial wafer and epitaxial wafer

The invention discloses a growth method for a light-emitting diode epitaxial wafer and an epitaxial wafer, belonging to the technical field of a semiconductor. The growth method comprises the following steps of: sequentially growing a low-temperature buffer layer, a non-doped GaN layer and an N-type layer on a substrate; alternatively growing a first InGaN pit layer and a first GaN barrier layer on the N-type layer to form a first active layer; alternatively growing a second InGaN pit layer and a second GaN barrier layer on the first active layer to form a second active layer; and sequentially growing an electron blocking layer and a P-type layer on the second active layer, wherein the growth pressure of the second active layer is lower than the growth pressure of the first active layer, the growth speed of the second active layer is lower than the growth speed of the first active layer, the thickness of the second active layer is smaller than the thickness of the first active layer, and the growth pressure, the growth speed and the thickness of the second InGaN pit layer are gradually reduced, slowed and decreased along the growth direction of the light-emitting diode epitaxial wafer. The epitaxial wafer is high in luminous efficiency.

Owner:HC SEMITEK SUZHOU

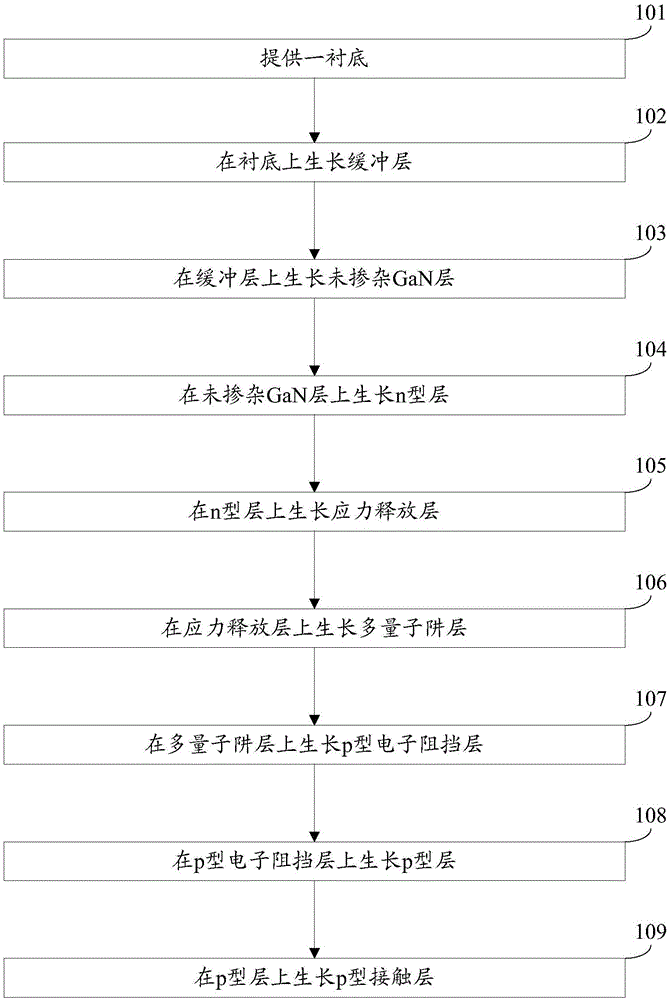

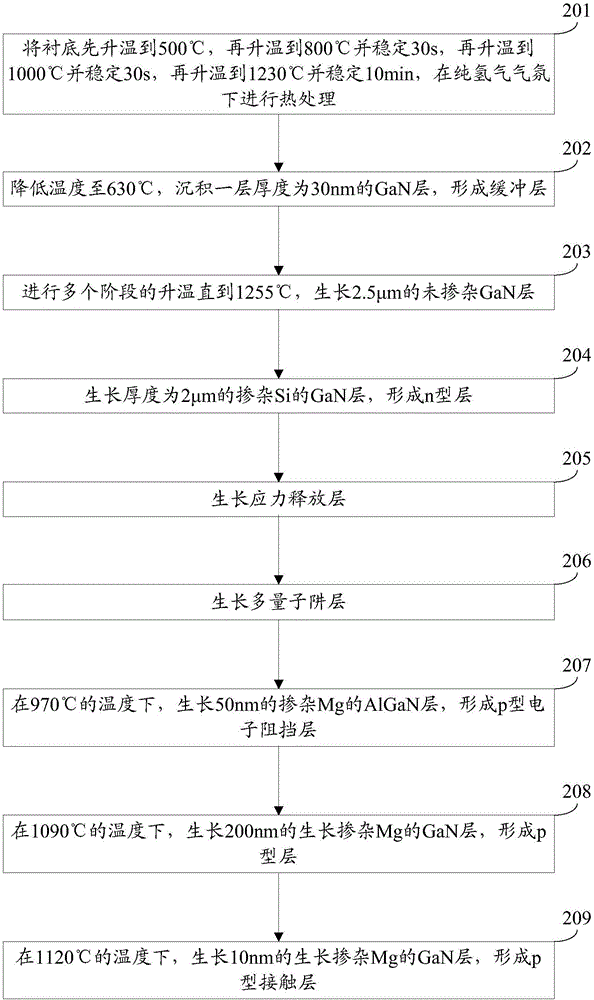

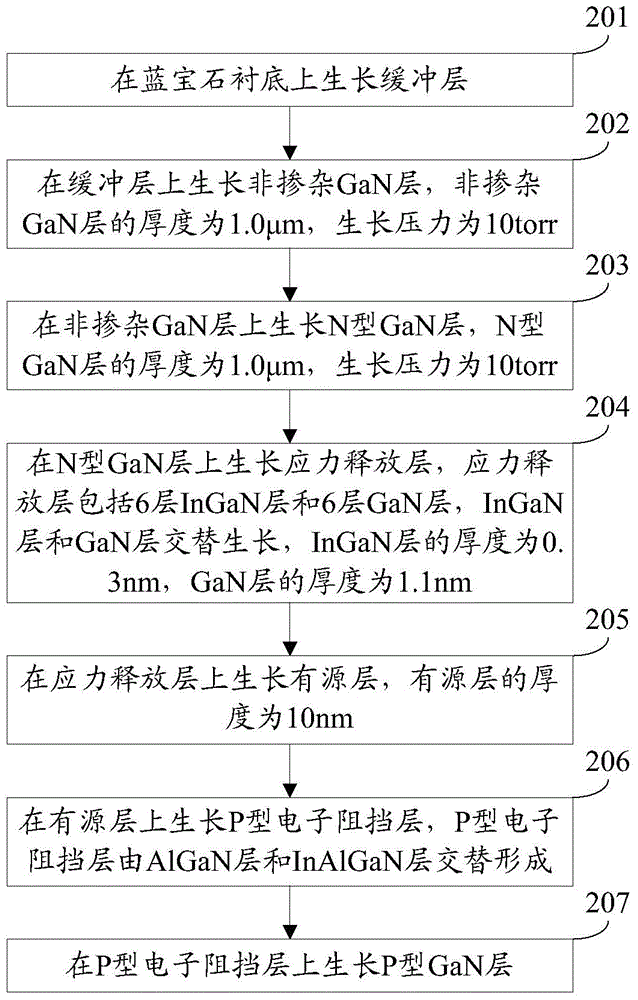

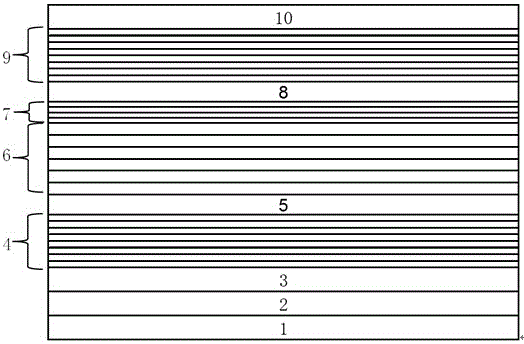

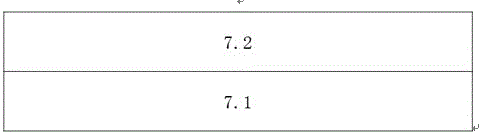

Growing method of GaN-based light emitting diode epitaxial wafer

ActiveCN106711295AReduce growth stressSmall temperature differenceSemiconductor devicesQuantum wellContact layer

The invention discloses a growing method of a GaN-based light emitting diode epitaxial wafer, and the growing method belongs to the technical field of semiconductors. The growing method comprises the steps of: providing a substrate; and successively growing a buffer layer, an un-doped GaN layer, an n-type layer, a stress release layer, a multi-quantum well layer, a p-type electron blocking layer, a p-type layer and a p-type contact layer on the substrate, wherein the stress release layer comprises a first sub-layer, a second sub-layer and a third sub-layer which are successively grown on the n-type layer, the first sub-layer is an In<x>Ga<1-x>N layer doped with Si, 0<=x<1, the second sub-layer comprises In<y>Ga<1-y>N layers and GaN layers which are laminated alternately, 0<y<1, the third sub-layer is an In<z>Ga<1-z>N layer doped with Si, 0<=z<1, the growth pressure of the second sub-layer is lower than that of the first sub-layer, and the growth pressure of the third sub-layer is lower than that of the first sub-layer. The growing method of the GaN-based light emitting diode epitaxial wafer improves the warping degree and enhances the crystal quality and the photoelectric performance.

Owner:HC SEMITEK ZHEJIANG CO LTD

Silver nanowire composite transparent conductive film and preparation method thereof

ActiveCN108091414AImprove conductivitySimple processConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersComposite filmOxygen

The invention relates to a silver nanowire composite transparent conductive film and a preparation method thereof. The transparent conductive film comprises transparent glasses, a first layer of silver nanowire conductive layer laminated on the glass and a zinc oxide protective layer which covers silver nanowires and is prepared by an ultrasonic spraying method. The transparent conductive film andthe preparation method have the advantages of (1) reducing a growth temperature to 200 DEG C to 260 DEG C, (2) reducing the growth pressure of a reaction chamber to 10pa to 500 pa, and (3) using an inert gas to be a carrier gas to reduce the proportion of oxygen in the reaction chamber to improve the corrosion of the silver nanowires by oxygen at a heating temperature during a zinc oxide growth process. The composite film prepared by the invention has simple process, a zinc oxide film growth process is a crystallization process, an additional annealing process is not needed, the adhesion between the silver nanowires and the glass is improved, the conductive performance and lives of the silver nanowires are improved, and the large-area preparation and industrial production are easy to realize.

Owner:ZHEJIANG OCEAN UNIV

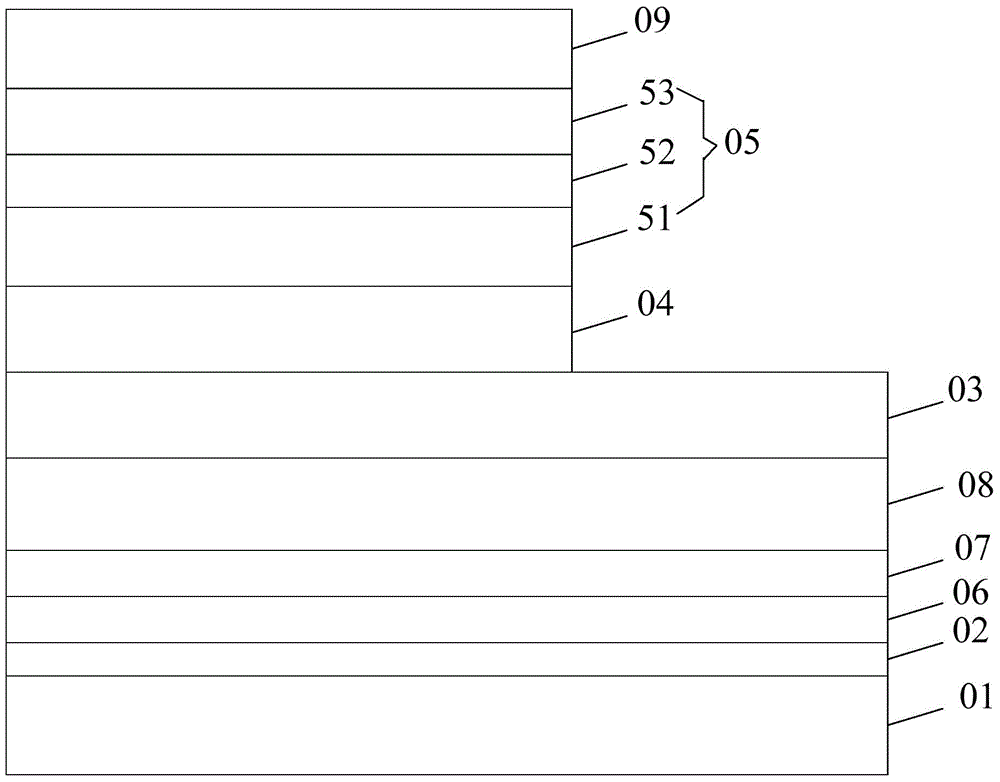

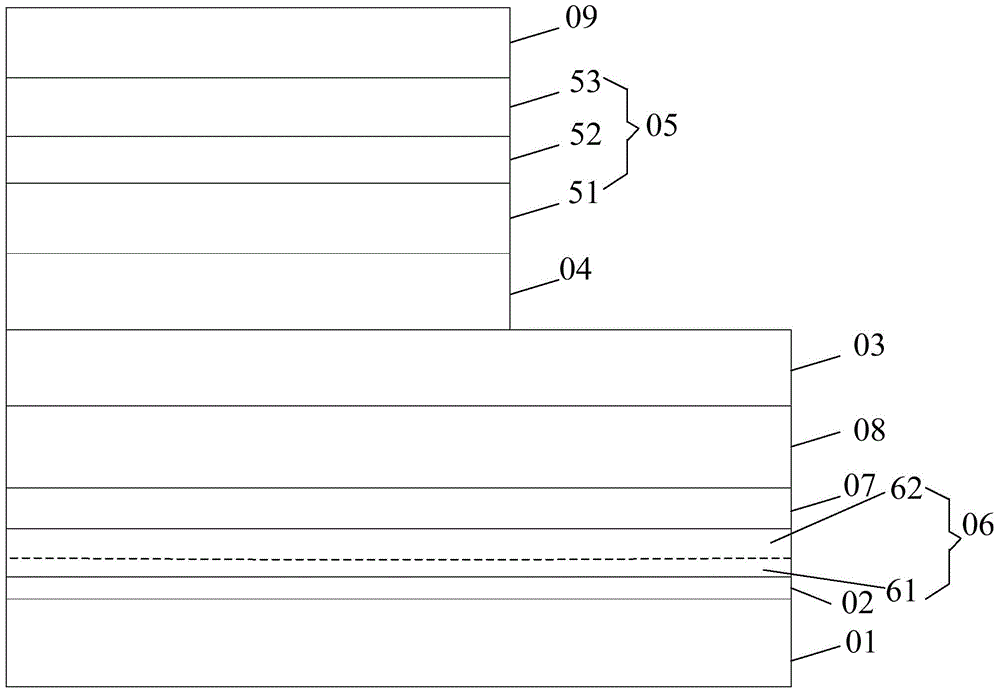

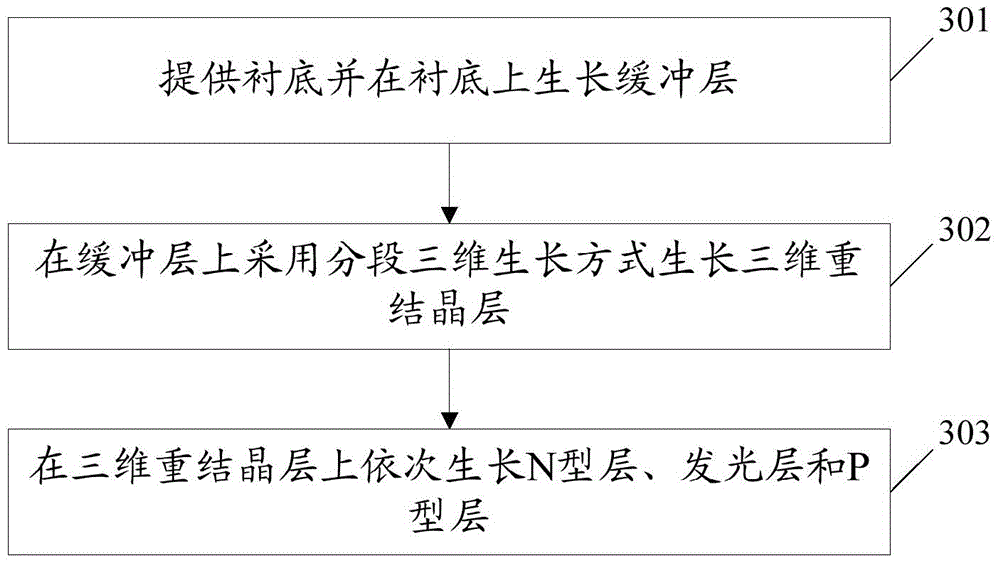

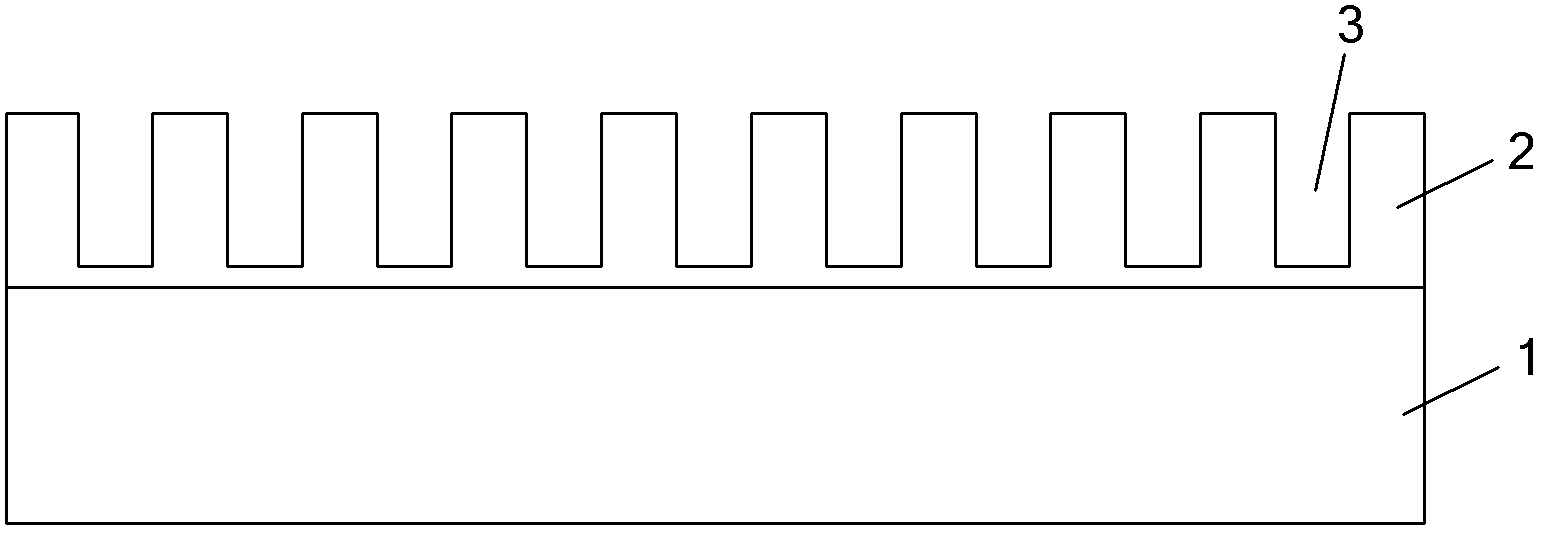

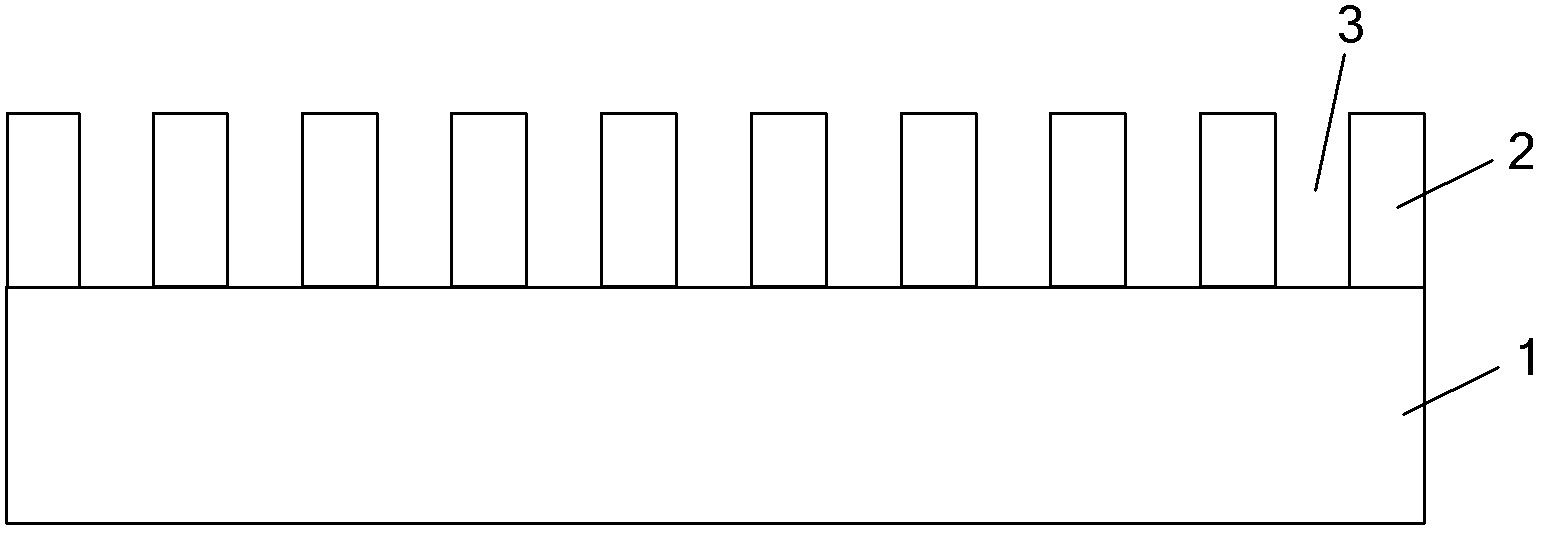

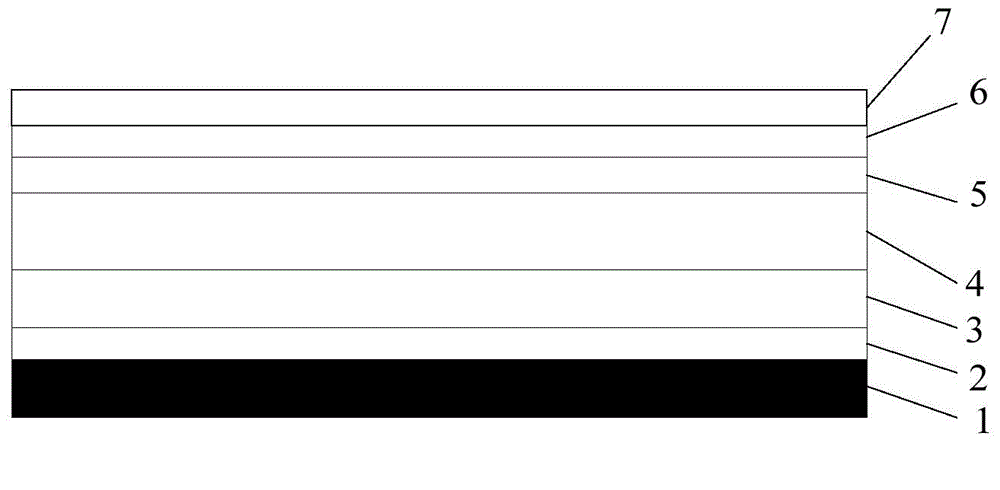

Light emitting diode epitaxial wafer and manufacture method thereof

ActiveCN104091873AImprove luminous efficiencyGood for radiative recombinationSemiconductor devicesQuantum wellSingle crystal

The invention discloses a light emitting diode epitaxial wafer and a manufacture method thereof, and belongs to the field of a light emitting diode. The epitaxial wafer comprises a substrate, and a buffer layer, an N-type layer, a luminescent layer and a P-type layer which successively cover the substrate. The epitaxial wafer further comprises a three-dimensional recrystallization layer. The three-dimensional recrystallization layer grows between the buffer layer and the N-type layer and is a GaN layer generated by use of a sectionalized three-dimensional growth mode, wherein the growth pressure of the segments of the three-dimensional recrystallization layer are different. According to the invention, the three-dimensional recrystallization layer is grown between the buffer layer and the N-type layer, polycrystalline recrystallizations generated by the buffer layer are GaN monocrystallines, these monocrystallines become bigger and bigger gradually to form a nucleus island, and a sectionalized growth mode is employed, the bottom-layer wire dislocation density is effecitvley reduced, the bottom-layer growth quality of GaN epitaxy growth is improved, a quite good bottom-layer condition is provided for the growth of a subsequent quantum well layer, radiative recombination of cavities and electrons is facilitated, and the LED luminescence efficiency is improved.

Owner:HC SEMITEK SUZHOU

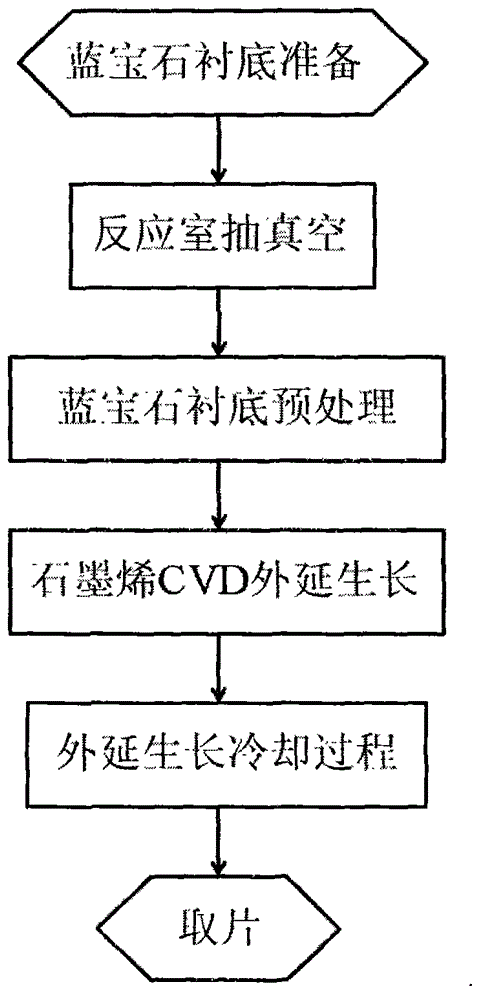

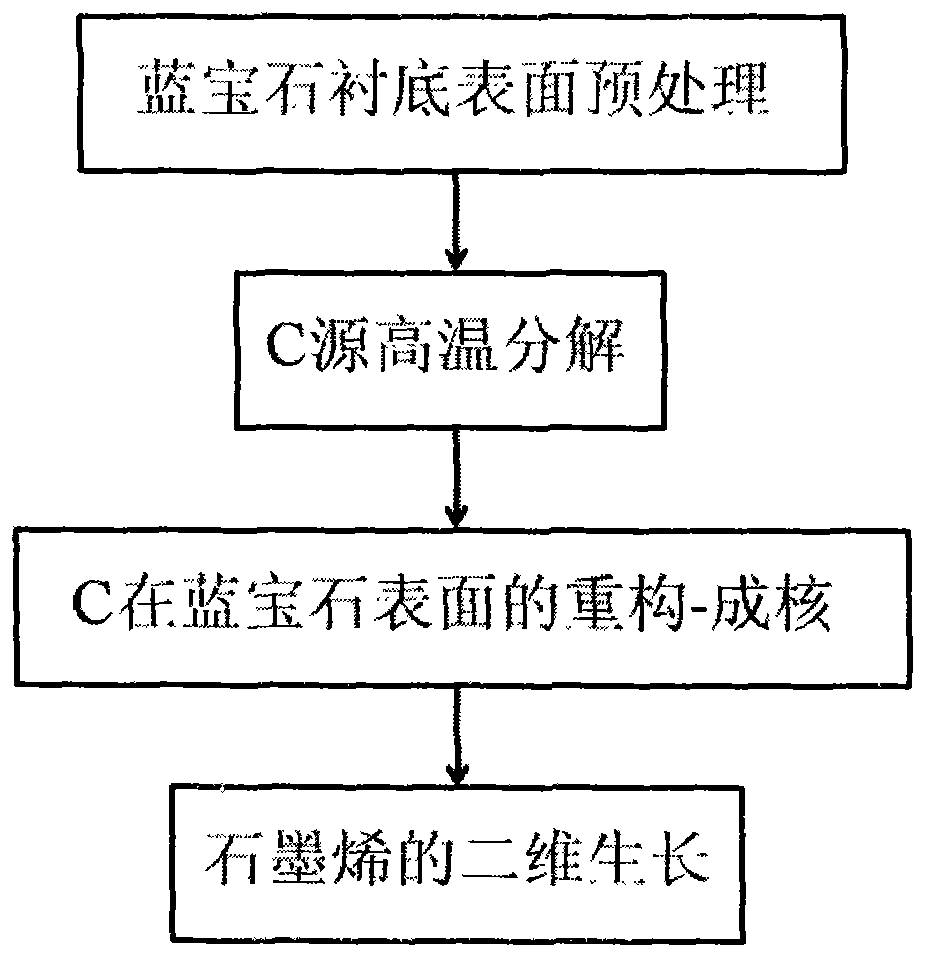

Graphene CVD (chemical vapor deposition) direct epitaxial growth method based on sapphire substrate and device fabricated with method

InactiveCN102915913AImprove reliabilityExcellent electrical propertiesSemiconductor/solid-state device manufacturingThermal chemical vapor depositionControllability

The invention discloses a graphene CVD (chemical vapor deposition) direct epitaxial growth method based on a sapphire substrate. Sapphire is used as the substrate, the sapphire substrate is reasonably pre-processed, and the growth pressure, the flow rate and the temperature are regulated, so that the graphene can directly grow on the sapphire without metals as the catalyst, and the grown graphene can be directly used to fabricate various devices without being transferred, so that the electrical characteristics and reliability of the device can be enhanced, and the complexity of fabrication of the device can be reduced. The large-area graphene material with semiconductor cleanliness is grown, the controllability of a single layer is more than 80%, and the area of a wafer is up to 8 inches.

Owner:XIDIAN UNIV

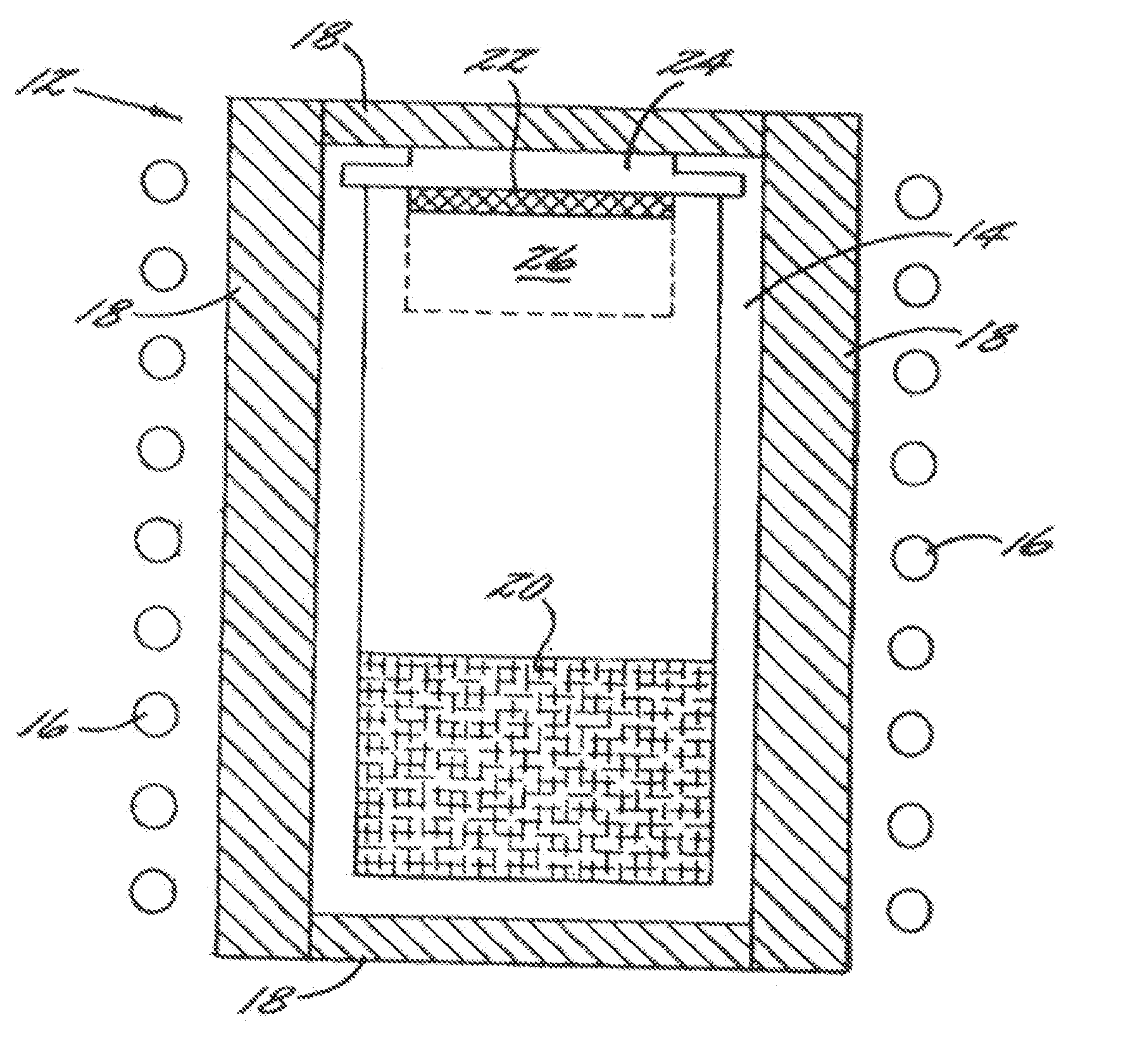

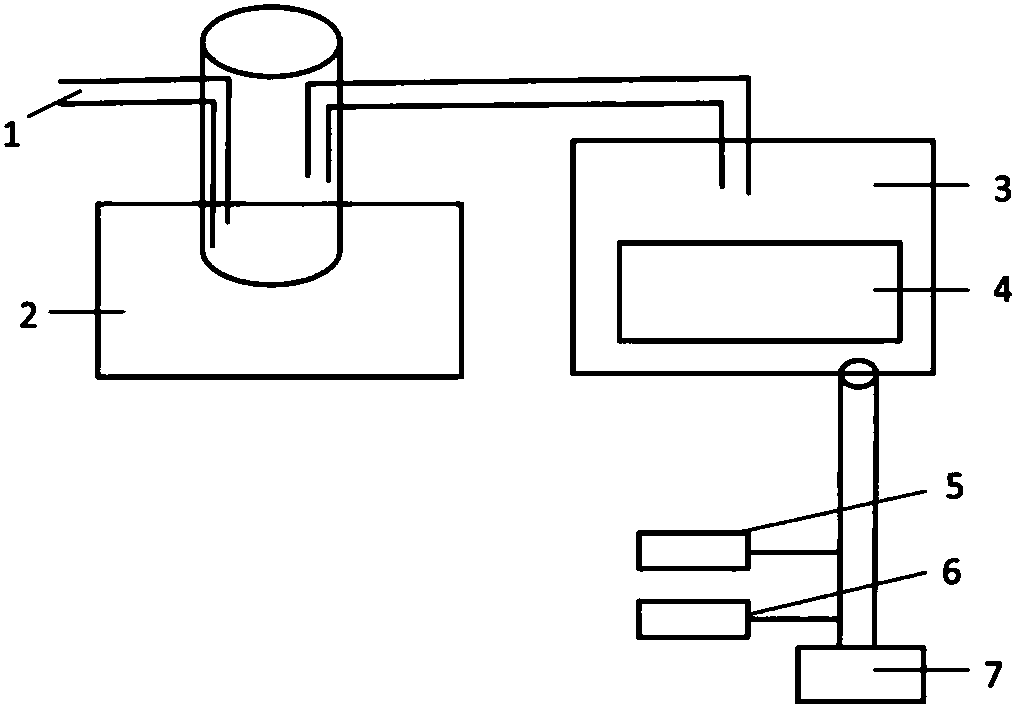

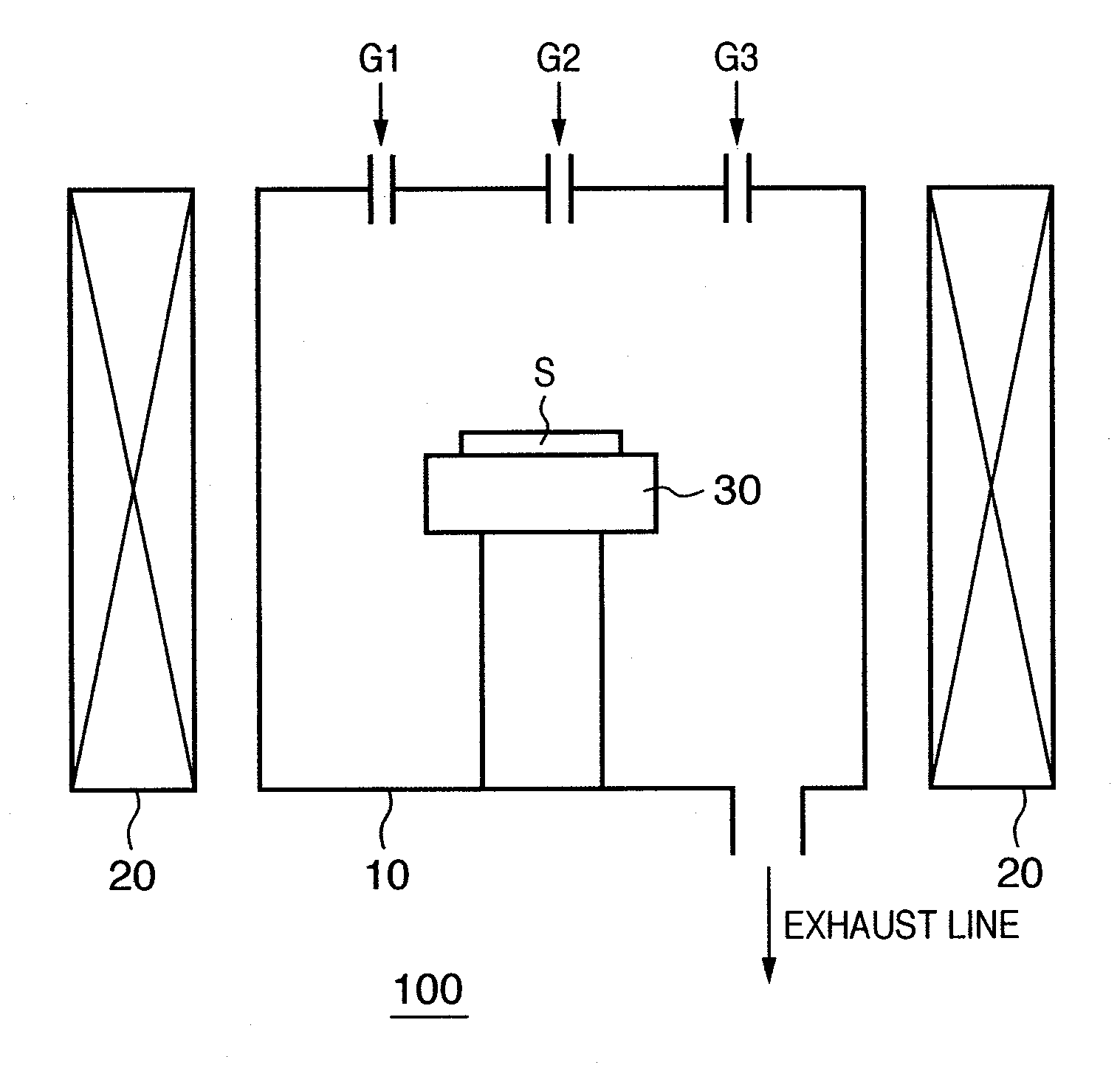

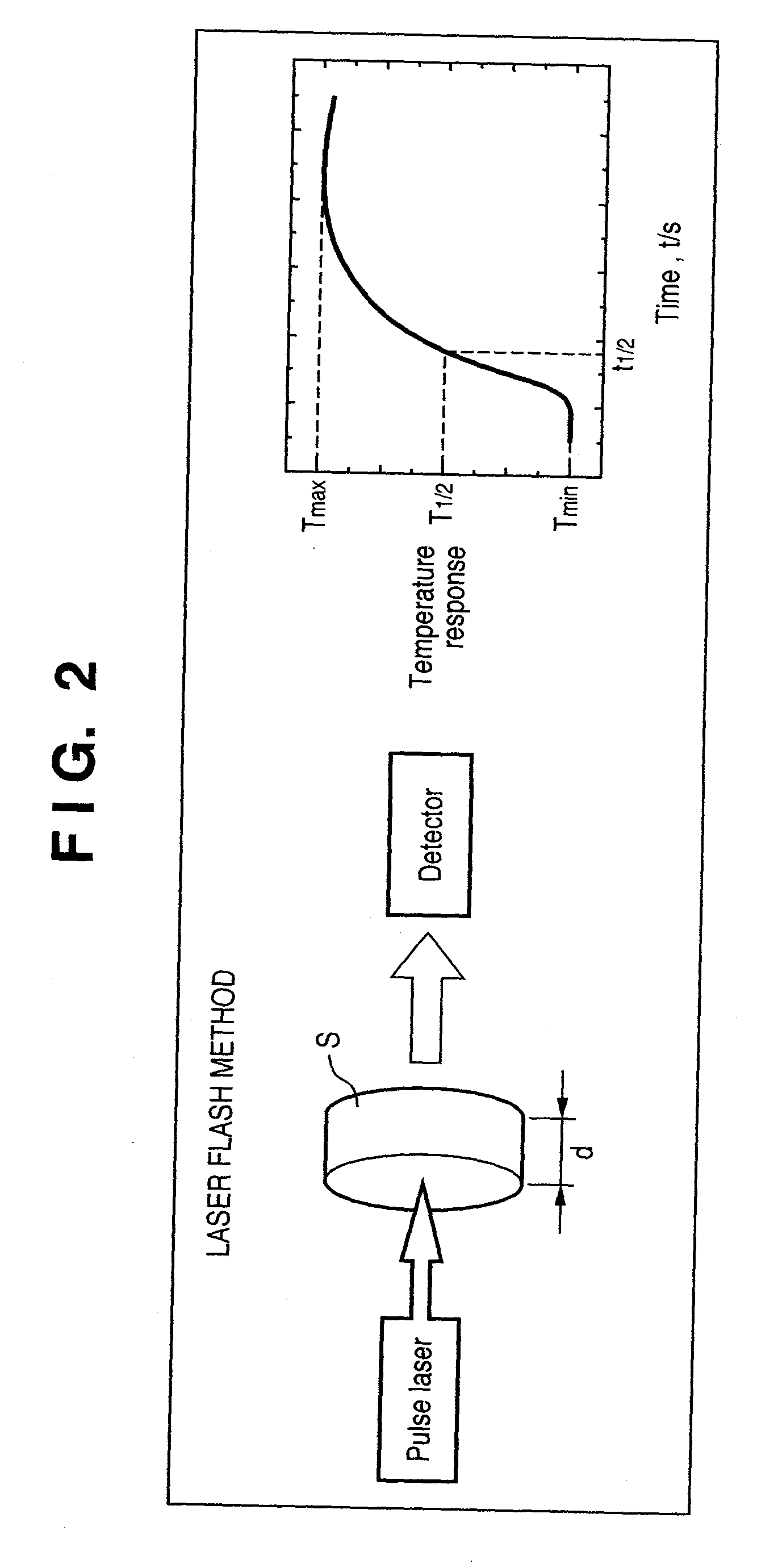

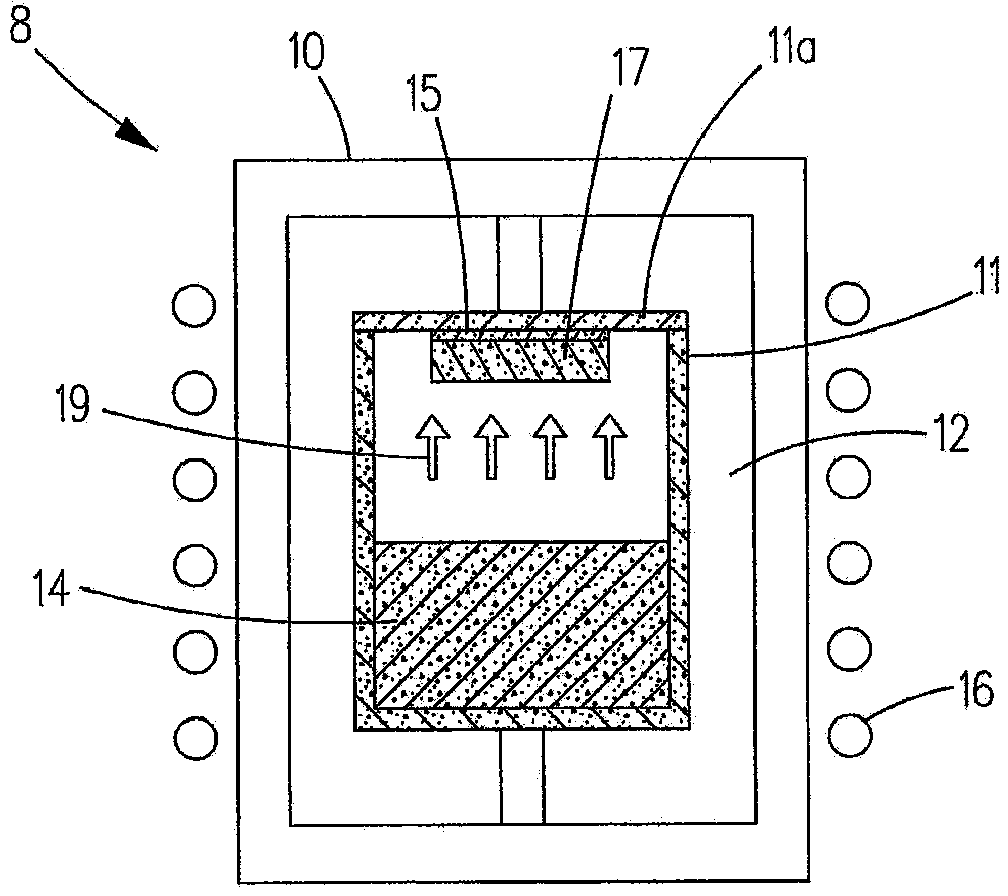

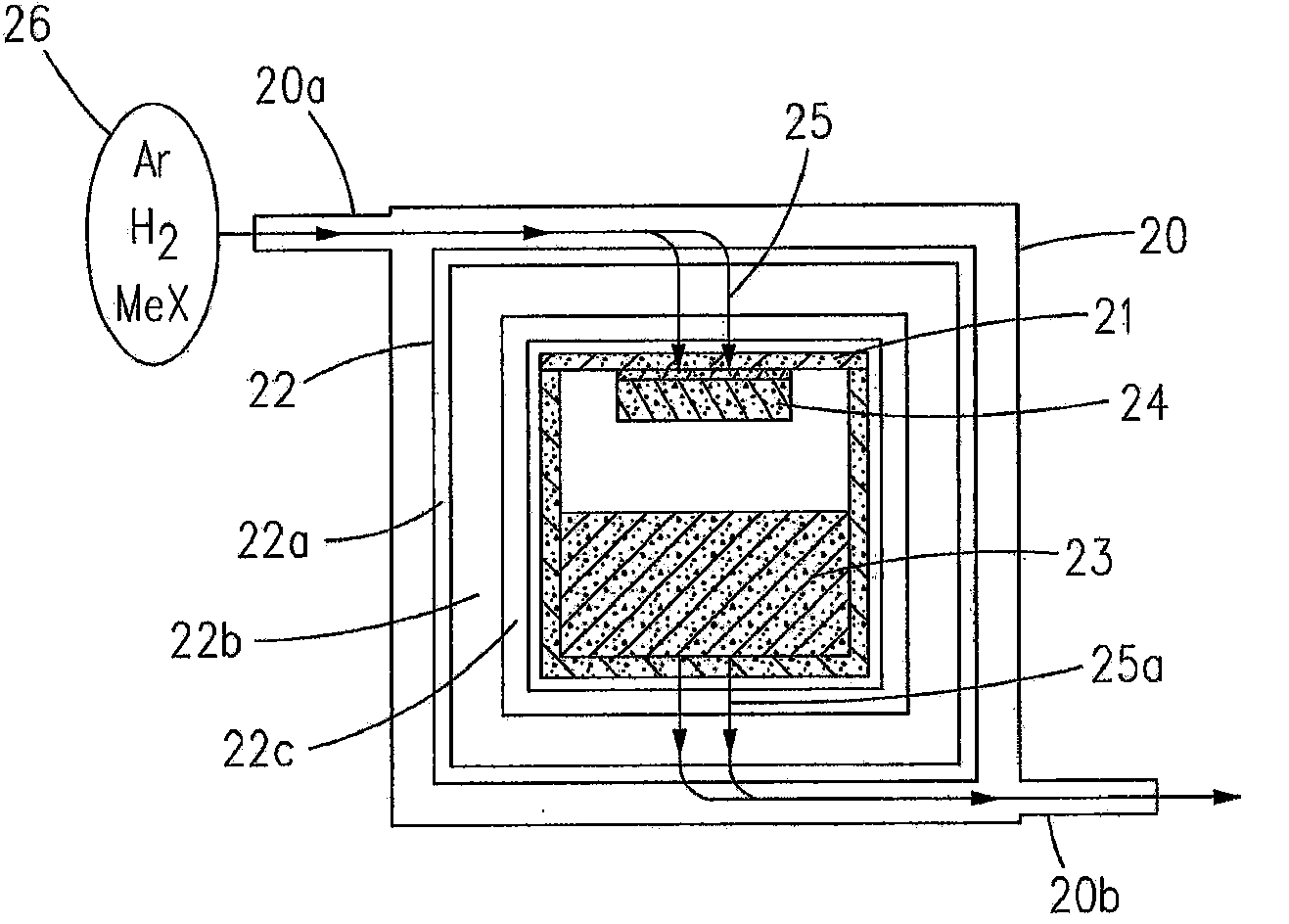

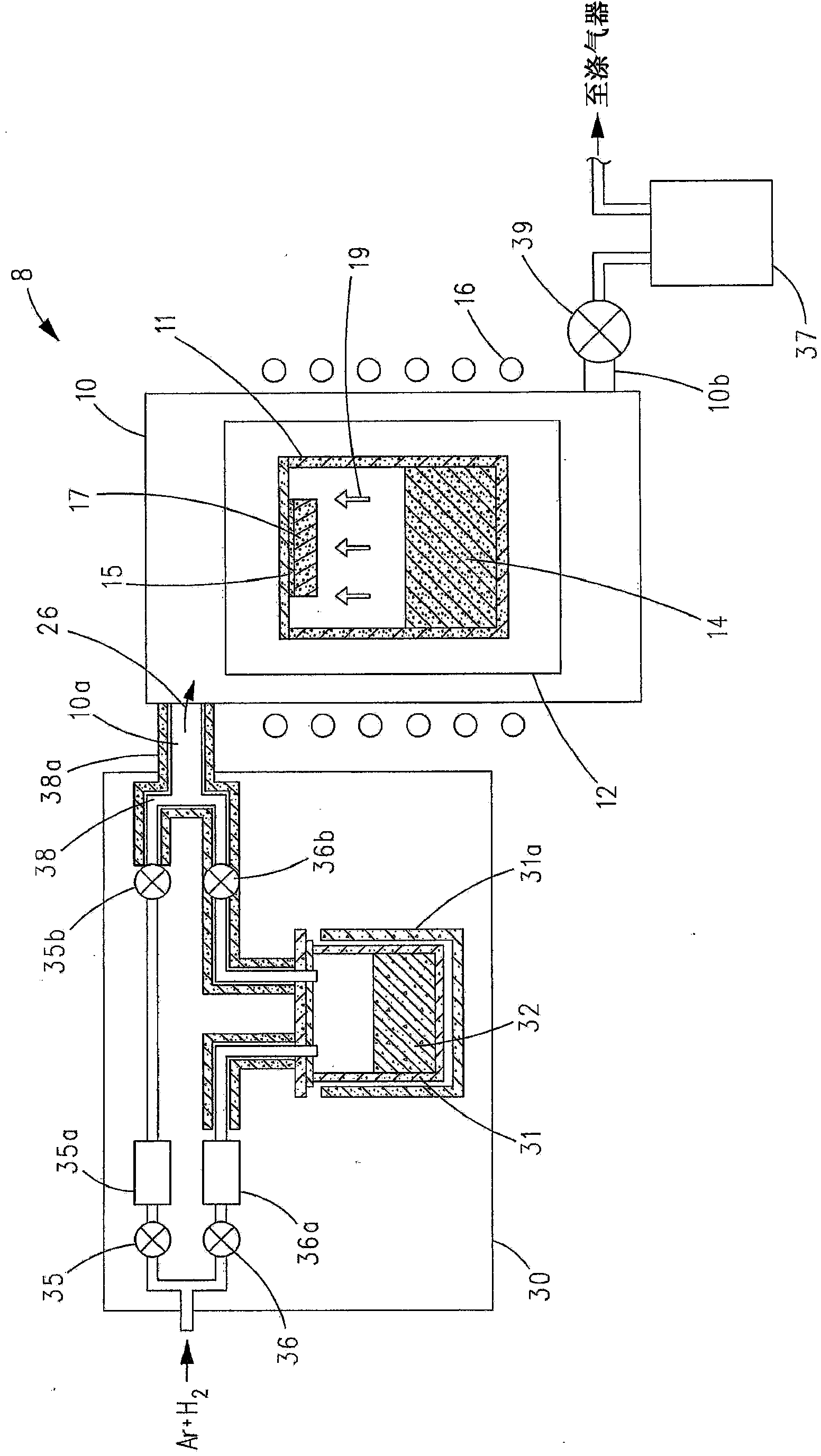

Gallium nitride-based material and method of manufacturing the same

ActiveUS20090081110A1Improve thermal conductivityPolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsGallium nitrideVapor phase

Disclosed is a method of manufacturing a GaN-based material having high thermal conductivity. A gallium nitride-based material is grown by HVPE (Hydride Vapor Phase Epitaxial Growth) by supplying a carrier gas (G1) containing H2 gas, GaCl gas (G2), and NH3 gas (G3) to a reaction chamber (10), and setting the growth temperature at 900 (° C.) (inclusive) to 1,200 (° C.) (inclusive), the growth pressure at 8.08×104 (Pa) (inclusive) to 1.21×105 (Pa) (inclusive), the partial pressure of the GaCl gas (G2) at 1.0×104 (Pa) (inclusive) to 1.0×104 (Pa) (inclusive), and the partial pressure of the NH3 gas (G3) at 9.1×102 (Pa) (inclusive) to 2.0×104 (Pa) (inclusive).

Owner:MITSUBISHI CHEM CORP +1

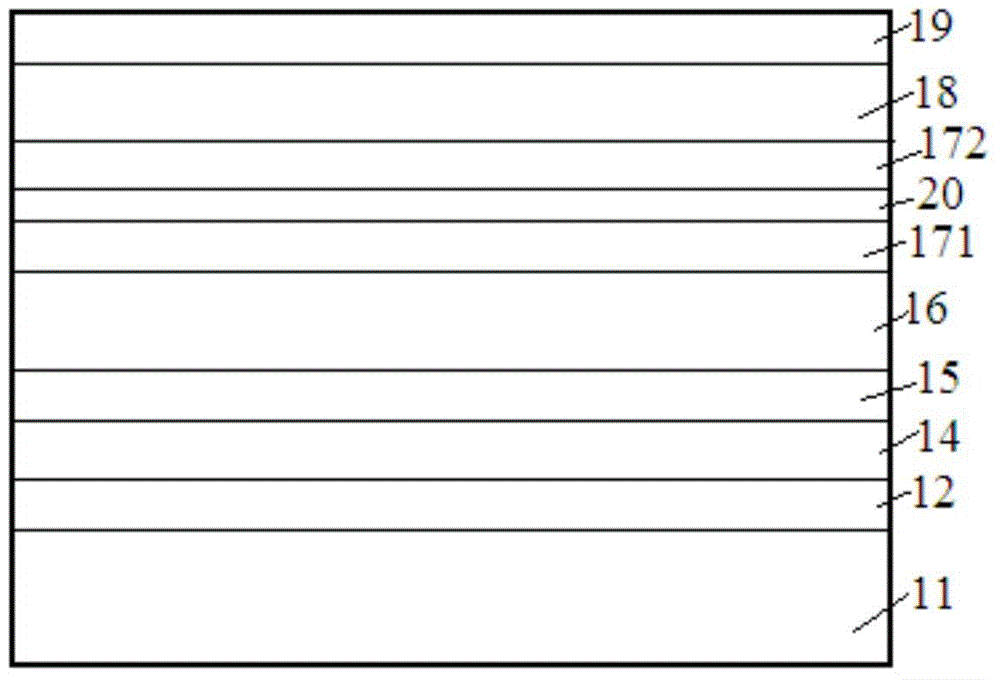

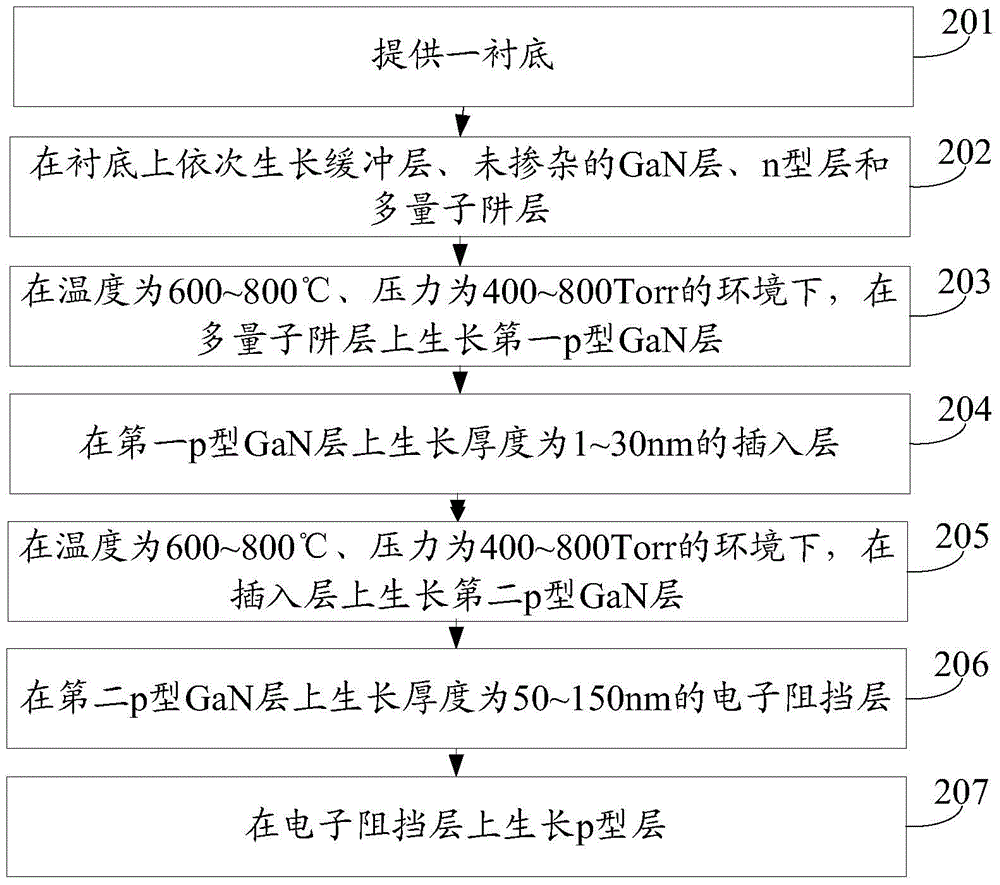

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN104009140AFast vertical growthDoes not affect activitySemiconductor devicesHigh pressureElectron blocking layer

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method of the light emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a nucleating layer, a buffer layer, an undoped GaN layer, an n-type layer, a multiple-quantum-well layer, a first p-type GaN layer, a second p-type GaN layer, an electron barrier layer and a p-type layer, wherein the nucleating layer, the buffer layer, the undoped GaN layer, the n-type layer, the multiple-quantum-well layer, the first p-type GaN layer, the second p-type GaN layer, the electron barrier layer and the p-type layer grow upwards on the substrate. The thickness of the electron barrier layer ranges from 50 nm to 150 nm, the growth temperature of the first p-type GaN layer ranges from 600 DEG C to 800 DEG C, the growth pressure of the first p-type GaN layer ranges from 400 Torr to 800 Torr, the growth temperature of the second p-type GaN layer ranges from 800 DEG C to 1000 DEG C, the growth pressure of the second p-type GaN layer ranges from 50 Torr to 500 Torr. The first p-type GaN layer growing under high pressure and low temperature is arranged, and a hole injection channel is provided, so that hole injection efficiency is improved; through the second p-type GaN layer growing under low pressure and high temperature, crystalline quality is improved, the thickness of the electron barrier layer is limited, and hole injection efficiency is improved.

Owner:HC SEMITEK SUZHOU

Vanadium compensated, SI SiC single crystals of NU and PI type and the crystal growth process thereof

In a crystal growth apparatus and method, polycrystalline source material and a seed crystal are introduced into a growth ambient comprised of a growth crucible disposed inside of a furnace chamber. In the presence of a first sublimation growth pressure, a single crystal is sublimation grown on the seed crystal via precipitation of sublimated source material on the seed crystal in the presence of a flow of a first gas that includes a reactive component that reacts with and removes donor and / or acceptor background impurities from the growth ambient during said sublimation growth. Then, in the presence of a second sublimation growth pressure, the single crystal is sublimation grown on the seed crystal via precipitation of sublimated source material on the seed crystal in the presence of a flow of a second gas that includes dopant vapors, but which does not include the reactive component.

Owner:II VI

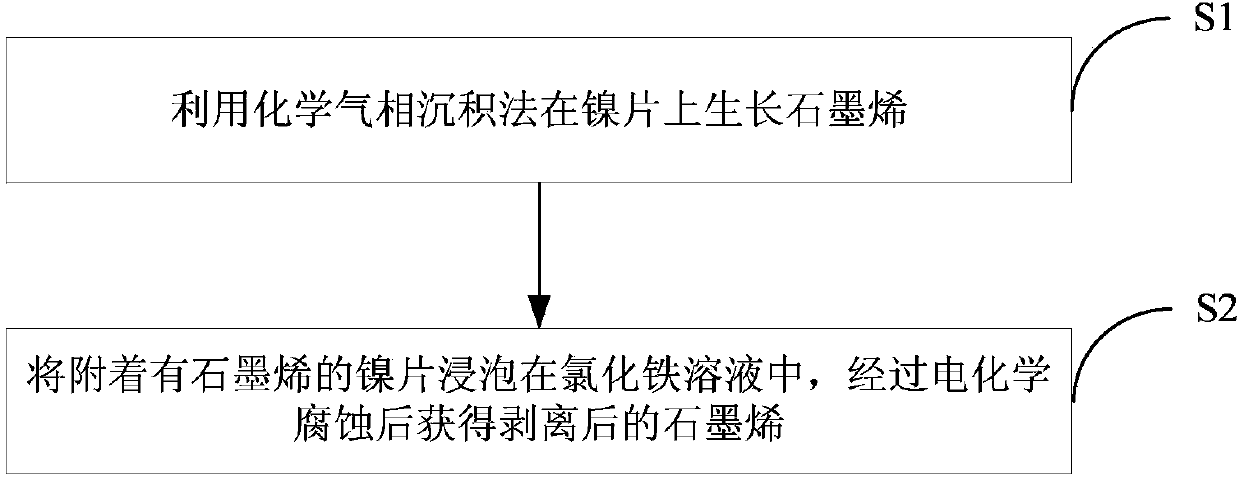

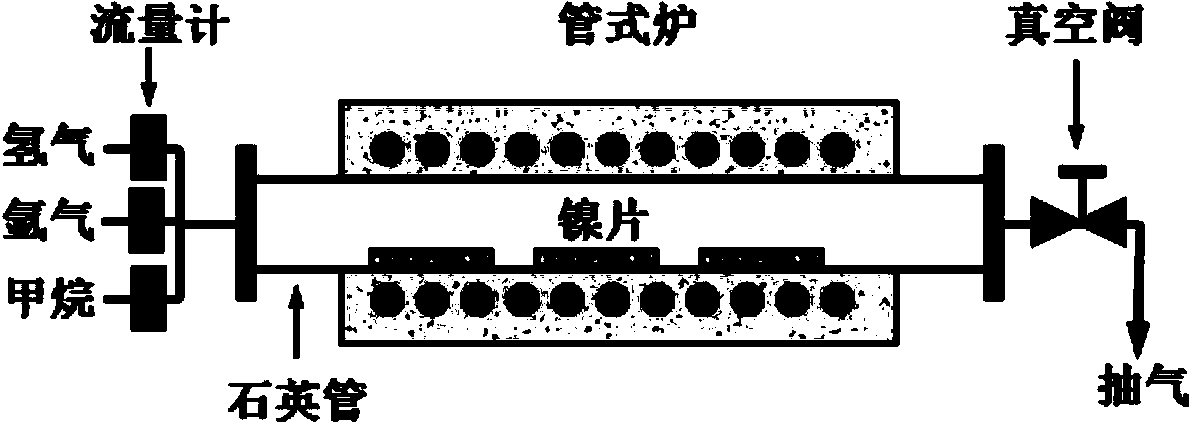

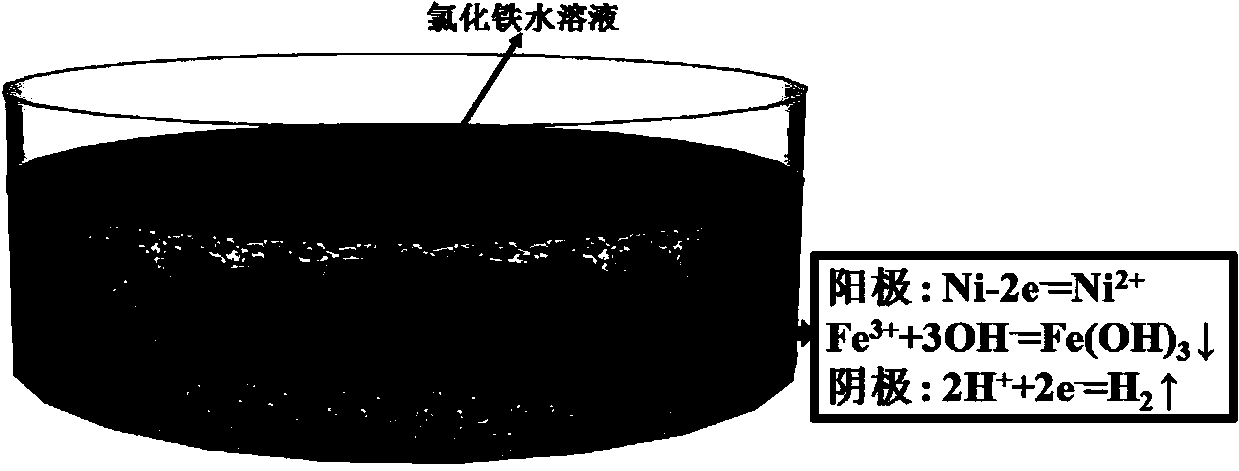

Method for fast stripping of graphene

The invention provides a method for fast stripping of graphene. The method includes the steps: S1, growing graphene on a nickel sheet by a chemical vapor deposition method with the growth temperature of 750 DEG C-1000 DEG C and the growth time of 10-30 minutes, during growth, introducing gases comprising 10-80 sccm of methane and 5-10 sccm of hydrogen gas, and keeping the growth pressure of the atmospheric pressure; and S2, immersing the nickel sheet attached with graphene in a ferric chloride solution, and carrying out electrochemical corrosion to obtain the stripped graphene. Graphene can be stripped from the substrate nickel sheet without damage and within a time from tens of seconds to a few minutes. A new rapid way is provided for basic research and application of graphene. The method is simple in operation, and can quickly transfer graphene to any substrate; the stripped graphene has no damage and no impurities; and the nickel sheet having graphene stripped can be continued to be used for preparing graphene.

Owner:HUAZHONG UNIV OF SCI & TECH

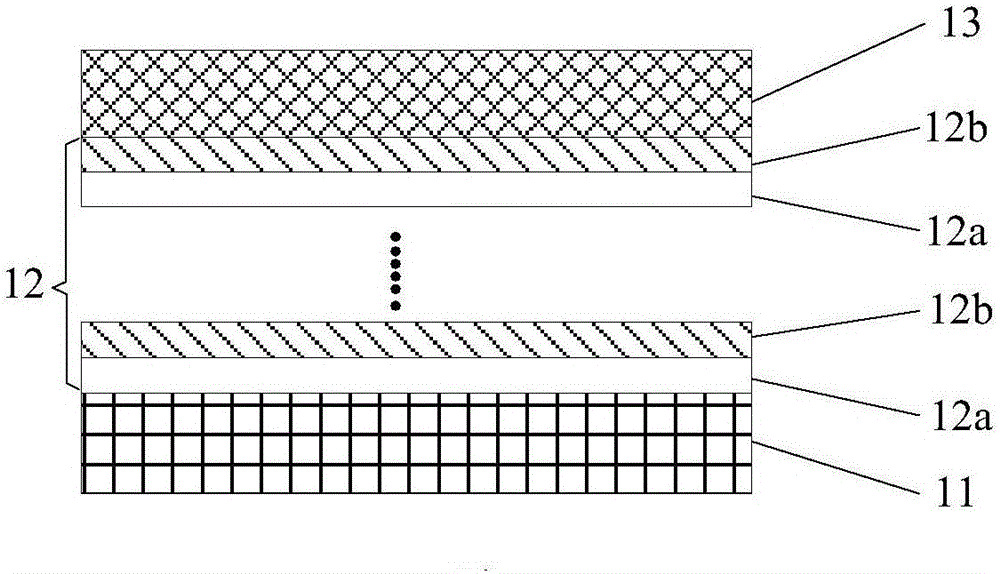

LED epitaxial structure with high hole injection efficiency

The invention discloses an LED epitaxial structure with high hole injection efficiency, and relates to the technical field of light emitting diode epitaxy. The LED epitaxial structure sequentially comprises a substrate, a GaN buffer layer, a non-doped GaN layer, an N-type GaN layer, a multiple-quantum well, an electron blocking layer, a P-type GaN layer and a P-type contact layer from bottom to top, wherein the multiple-quantum well comprises an InGaN layer and a GaN layer, the structure of the LED epitaxial structure is characterized in that the electron blocking layer sequentially comprises a p-type Al<x>Ga<1-x>N layer, an AlN layer and a p-type In<y>Ga<1-y>N layer from bottom to top, x is more than 0 but less than or equal to 0.3, y is more than 0 but less than or equal to 0.2, the electronic blocking layer comprises 8-12 growth periods, the growth pressure is 100-200Torr, and the electronic blocking layer is grown in a nitrogen environment. The electron blocking layer comprises the p-type Al<x>Ga<1-x>N layer, the AlN layer and the p-type In<y>Ga<1-y>N superlattice layer, hole concentration and mobility are improved by stress and by reducing alloy scattering, and the luminous efficiency of a light emitting diode is improved.

Owner:NANTONG TONGFANG SEMICON +1

InGaN epitaxy film and growth method and application in solar cell

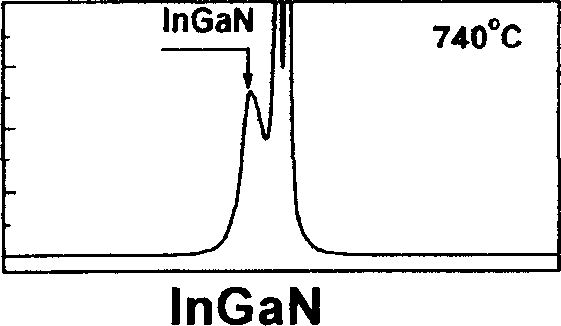

InactiveCN1885494AQuality improvementPromote crystallizationPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalSolar cell

The high-crystal InGaN monocrystal epitaxial membrane comprises: with MOCVD system, at 500-700Deg, growing the 20-200nm low-temperature GaN buffer on sapphire substrate, growing high-crystal 1-80 mum InxGa1-x (0<=x<=1); then, growing high-quality InxGa1-xN on buffer layer at 500-1050Deg; wherein, controlling the growth pressure in 0-700Torr,special in 300-700Torr. As an application, the solar cell uses the In0.3Ga0.7N film, and MSM electrode structure.

Owner:NANJING UNIV

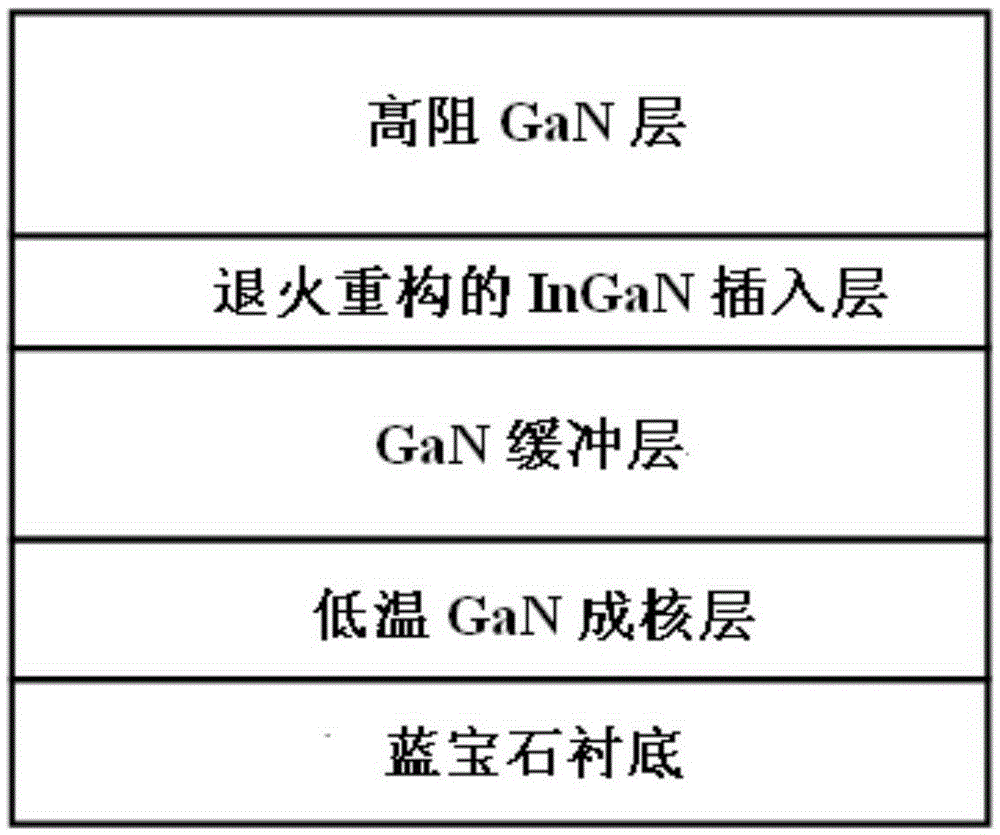

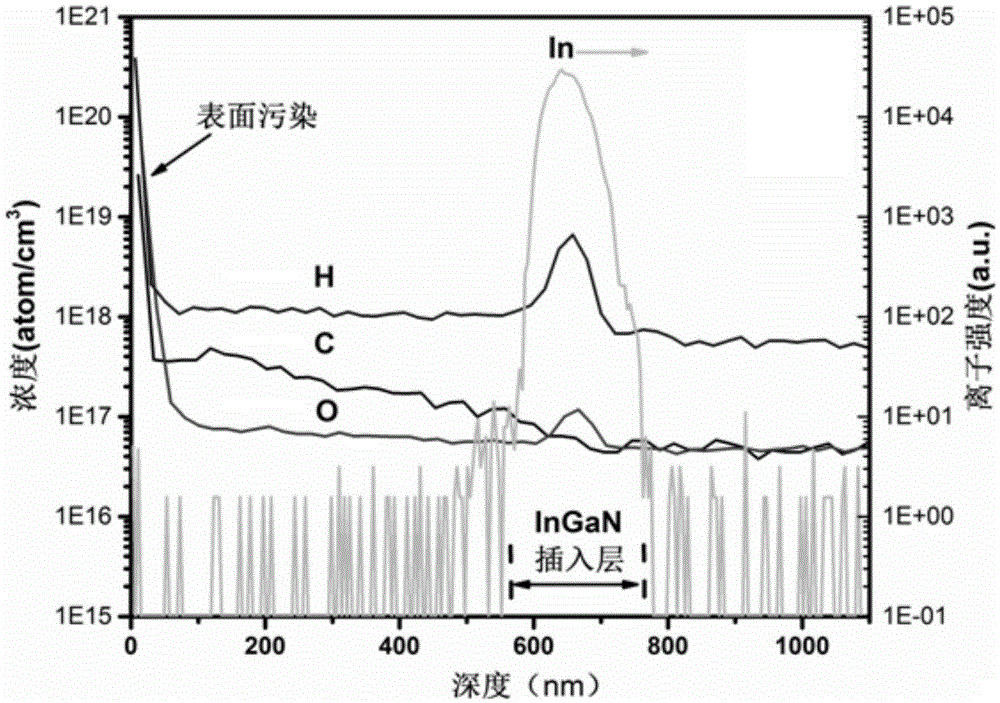

Unintentionally doped high resistance GaN film with InGaN insertion layer and preparation method thereof

InactiveCN105390532AStructural scienceReasonable structureSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceOptoelectronics

The present invention provides an unintentionally doped high resistance GaN film with an InGaN insertion layer and a preparation method thereof. The unintentionally doped high resistance GaN film comprises a substrate, a low-temperature GaN nucleation layer, a GaN buffer layer, an InGaN insertion layer reconstructed by annealing and a high resistance GaN layer which are orderly arranged from bottom to top. Through introducing the InGaN insertion layer and carrying out high-temperature annealing, in the condition of not reducing GaN growth pressure and ensuring high crystal quality of the film, an appropriate amount of edge dislocations is introduced, a small amount of screw dislocations is increased, by using the edge dislocations, the carbon acceptor in a reaction chamber is induced into the GaN film, thus background electrons are compensated, and the high resistance GaN film is realized.

Owner:DALIAN UNIV OF TECH +1

Method of growing zinc-oxide-based semiconductor and method of manufacturing semiconductor light emitting device

InactiveUS20100064966A1Reduce defect densityQuality improvementPolycrystalline material growthFrom chemically reactive gasesWater vaporSingle crystal

A method includes the steps of, using water vapor and a metalorganic compound not containing oxygen, (a) performing crystal growth at a low growth temperature and at a low growth pressure in the range of 1 kPa to 30 kPa to form a low-temperature grown single-crystal layer; and (b) performing crystal growth at a high growth temperature and at a pressure higher than the low growth pressure to form a high-temperature grown single-crystal layer on the low-temperature grown single-crystal layer.

Owner:STANLEY ELECTRIC CO LTD

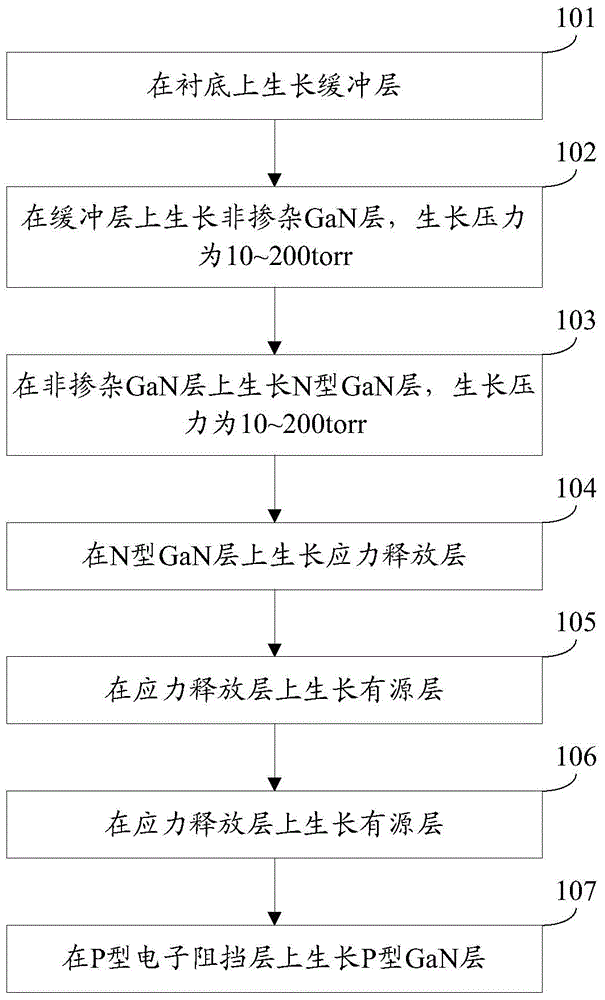

Manufacturing method of light emitting diode epitaxial wafer

ActiveCN104617192AReduce growth stressSmall temperature differenceSemiconductor devicesTemperature differenceElectron blocking layer

The invention discloses a manufacturing method of a light emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The manufacturing method includes: sequentially growing a buffer layer, an undoped GaN layer, an N-type GaN layer, a stress release layer, an active layer, a P-type electron barrier layer and a P-type GaN layer on a substrate, wherein the growth pressure of the undoped GaN layer and the N-type GaN layer is 10-200torr. According to the manufacturing method, the growth pressure of the undoped GaN layer and the N-type GaN layer is limited to be10-200torr, so that the growth speeds of the undoped GaN layer and the N-type GaN layer are slow, and thereby heat can be uniformly transmitted along the growth direction of the epitaxial layer by a basal disc arranged at the bottom of the substrate, temperature difference between the upper and lower surfaces of the epitaxial wafer when the undoped GaN layer and the N-type GaN layer grow is reduced, the concave deformation of the epitaxial wafer is relieved, the temperature of the periphery of the epitaxial wafer can reach required temperature, and the quality of crystals at the periphery of the epitaxial wafer is improved.

Owner:HC SEMITEK SUZHOU

Growth method of granular SiC (silicon carbide) single crystals

ActiveCN106480503AEasy to operateImprove productivityPolycrystalline material growthFrom condensed vaporsPolymeric surfaceCoated surface

The invention provides a growth method of granular SiC (silicon carbide) single crystals to solve problems in the prior art. A porous graphite plate is coated with polymers with high carbon content, granulated SiC seed crystals are uniformly arranged on the surfaces of the polymers, the non-coated surface of the porous graphite plate is fixed on an upper cover of a graphite crucible, SiC powder is put at the bottom of the graphite crucible, the upper cover of the crucible and the SiC powder are arranged oppositely, the graphite crucible is put in an induction heating furnace for growth of SiC single crystals, the growth temperature ranges from 1,800 DEG C to 2,400 DEG C, the growth pressure ranges from 1*10<-4> Pa to 1*10<4> Pa, and the granular SiC single crystals are obtained. Accordingly, the granular SiC single crystals can be obtained directly, cutting operation is avoided, the granular SiC single crystals can be directly taken as raw materials of SiC gems, the productivity is improved, and the production cost is reduced.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

GaN-based LED epitaxy structure and preparation method thereof

InactiveCN105206714AImprove wavelength uniformityImprove matchSemiconductor devicesQuantum wellLength wave

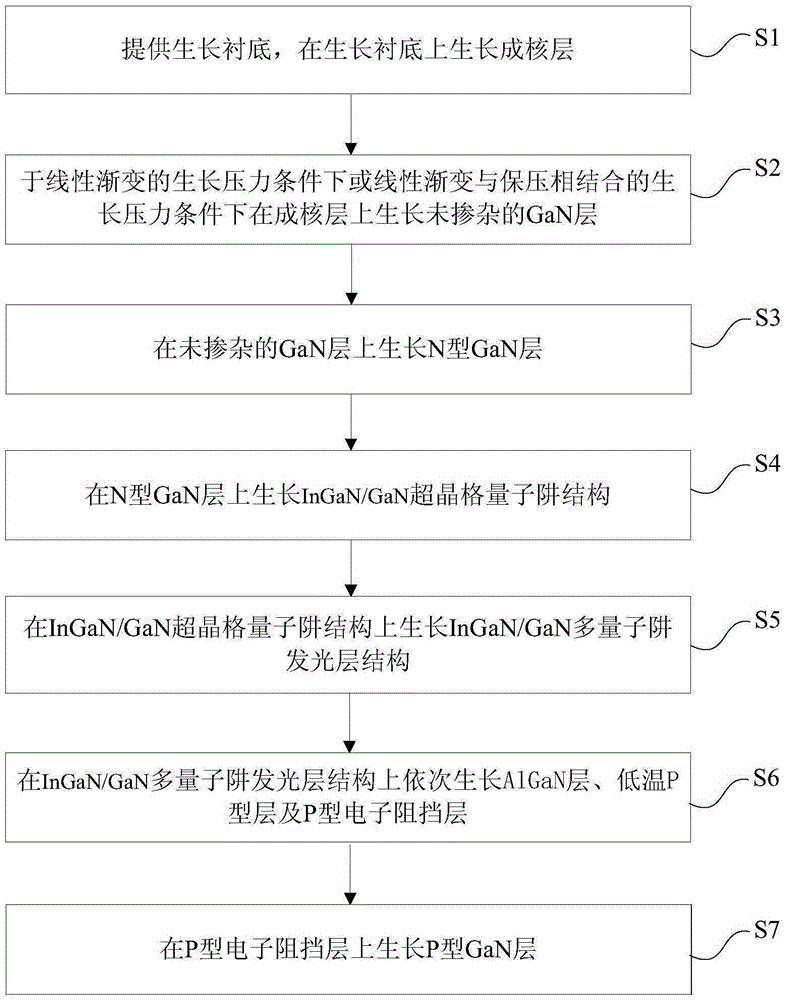

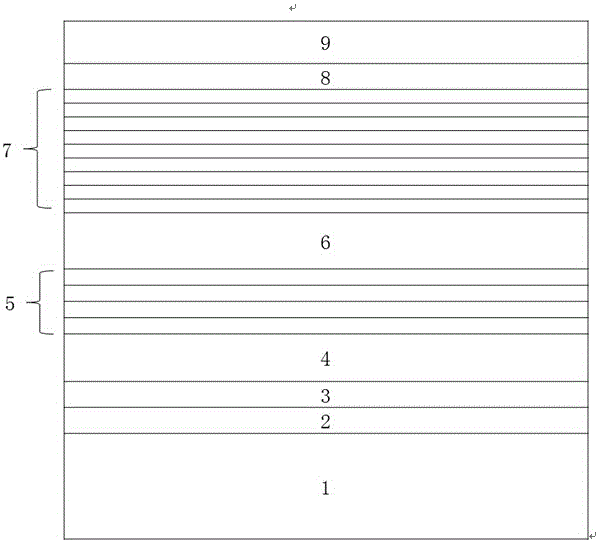

The invention provides a GaN-based LED epitaxy structure and a preparation method thereof. The method comprises the following steps: providing a growth substrate, and growing a nucleating layer on the growth substrate; growing an undoped GaN layer on the nucleating layer under a condition of linear-gradient growth pressure or a condition of the growth pressure with linear gradient and pressure maintaining being combined; growing an N-type GaN layer on the undoped GaN layer; growing an InGaN / GaN superlattice quantum well structure on the N-type GaN layer; growing an InGaN / GaN multi-quantum-well luminescent layer structure on the InGaN / GaN superlattice quantum well structure; growing an AlGaN layer, a low-temperature P-type layer and a P-type electron blocking layer on the InGaN / GaN multi-quantum-well luminescent layer structure in sequence; and growing a P-type GaN layer on the P-type electron blocking layer. Warpage degree of the epitaxy structure in the growing process can be changed by adjusting the growth pressure conditions; and the method is large in amplitude in adjusting the warpage degree, so that it is convenient to find an appropriate warpage degree to enable the epitaxy structure to be well matched with a carrier disc when growing the multi-quantum-well luminescent layer structure, and wavelength uniformity of the single epitaxy structure is effectively improved.

Owner:ENRAYTEK OPTOELECTRONICS

LED epitaxial structure with warpage adjusting structure layer and growth method thereof

ActiveCN105679898AImprove uniformity of growing conditionsImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesTorrGrowth pressure

The invention relates to an LED epitaxial structure with a warpage adjusting structure layer and a growth method thereof. The warpage adjusting structure layer is inserted between a high-temperature GaN layer and a high-temperature N-type GaN layer of an LED. The structure is an Si3N4 / GaN / AlGaN / GaN superlattice layer, the periodic number of the structure is 1-40, the monocyclic thickness is 31-1930 nm, the growth temperature is 700-1200 DEG C, and the growth pressure is 50-200 torr, wherein the growth conditions of an Si3N4 layer and an AlGaN layer can be the same and can also be different; when the growth conditions of the Si3N4 layer and the AlGaN layer are different, coordination is carried out to adjust the warpage degree in the growth process of the epitaxial wafer by changing the transition condition of a middle GaN layer and adjusting the thickness of the Si3N4 layer, the flow rate of SiH4, the thickness of the AlGaN layer and Al component, so that the on-chip parameter uniformity of LED epitaxial wafer product single-chips is improved, and the yield of the LED epitaxial wafer is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

NMOS (N-channel metal oxide semiconductor) device, with GaAs material growing in silicon grooves, based on ART (aspect radio trapping ) structure

ActiveCN103177971AConstraint extensionReduce defectsSemiconductor/solid-state device manufacturingSemiconductor devicesTrappingDislocation

The invention discloses a preparation method of an NMOS (N-channel metal oxide semiconductor) device and the corresponding NMOS device. The preparation method includes the steps of S1, selecting a silicon substrate which deviates 6-10 degrees in a direction from (100) to (111), and growing a SiO2 layer on the silicon substrate; S2, etching the SiO2 layer to form a plurality of grooves with aspect ratio larger than 2 on the SiO2 layer, and allowing the bottom of each groove to be exposed out of the silicon substrate; S3, under a growth pressure of 100-150 mBar, using a MOCVD (metal organic chemical vapor deposition) process to sequentially grow a barrier layer, a buffer layer and a top layer in each groove; and S4, producing a source, a drain and a grid on each top layer. Mismatch dislocation at an interface and antiphase domain boundary are stopped at a SiO2 wall, hetero-junction interface defect extension is restrained effectively, epitaxial layer quality is improved, and good device quality is achieved when an epitaxial layer is used at the substrate of the NMOS.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Gallium-nitride-based maser epitaxial structure and growth method thereof

InactiveCN106207754APromote structural changeImprove and fix leaksLaser detailsSemiconductor lasersMaserRefractive index

The invention discloses a gallium-nitride-based maser epitaxial structure and a growth method thereof. The gallium-nitride-based maser epitaxial structure sequentially comprises a substrate, a nucleating layer, a high-temperature GaN layer, a n-type GaN / AlGaN superlattice optical limiting layer, a n-type waveguide layer, a luminous layer, a pAlxGa1-xN / pInyGa1-yN superlattice electron blocking layer, a P-type GaN waveguide layer, a P-type GaN / AlGaN superlattice optical limiting layer and a surface ohmic contact layer from bottom to top. The growth method includes the steps that all the layers sequentially grow on the substrate, the growth pressure of the pAlxGa1-xN / pInyGa1-yN superlattice electron blocking layer is 80 torr to 260 torr, and the growth temperature of the pAlxGa1-xN / pInyGa1-yN superlattice electron blocking layer is 800 DEG C to 1,000 DEG C. According to the gallium-nitride-based maser epitaxial structure and the growth method thereof, a pAlGaN / pInGaN superlattice electron blocking layer is adopted, the pressure stress led by growth of a pAlGaN layer is relieved through the tensile stress led by growth of a pInGaN layer, growth of the pAlGaN layer is facilitated, energy band structure change caused by the pAlGaN layer can also be improved, electron accumulation is improved, the electron leakage problem is solved accordingly, and the refractive index of the pAlGaN layer can be increased.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Method for growing epitaxial wafer of GaN-based light emitting diode

The invention discloses a method for growing an epitaxial wafer of a GaN-based light emitting diode, and belongs to the field of a light emitting diode. The method comprises successively growing a buffer layer, an N-type layer, a multi-quantum well layer and a P-type layer on a substrate, wherein the P-type layer is grown by use of a high-pressure low-speed growth mode, the growth pressure of the P-type layer is 400torr to 760torr, the flow of TMGa is lower than 90sccm, the flow of TEGa is lower than 2000sccm, and the thickness of the P-type layer is 10nm to 60nm. According to the invention, through adoption of high-pressure low-speed growth, the crystal quality is quite good, the defect density caused by crystal lattice mismatch is substantially reduced, electric leakage channels between the NP layers are reduced, the current expansion capability of the NP layers is better, breakdown points are reduced, the antistatic capability of the epitaxial wafer is enhanced, requirements are met simply by growing a quite thin P-type layer, the light absorption amount of the P-type layer with a quite small thickness is smaller, and the light emitting amount of the front surface of a chip and the light emitting efficiency of a device are guaranteed.

Owner:HC SEMITEK SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com