ZnO substrate-based graphene CVD direct epitaxial growth method and manufactured device

A technology of epitaxial growth and graphene, applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as damage, affecting graphene material and device performance, graphene film pollution, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

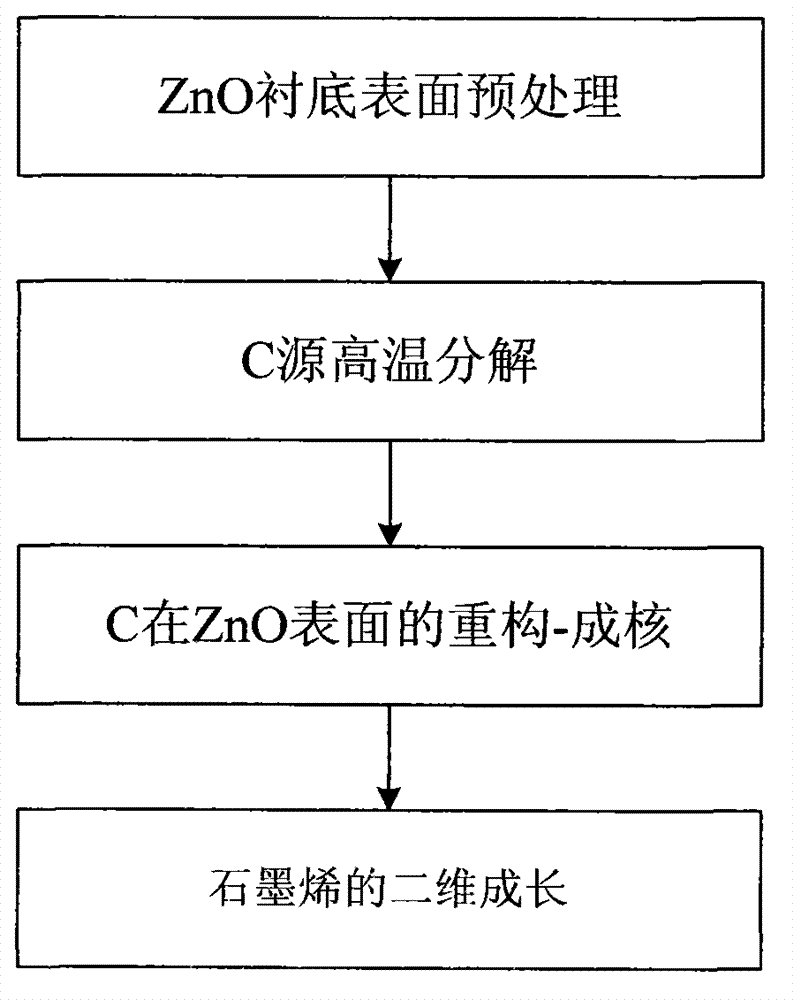

Method used

Image

Examples

Embodiment 1

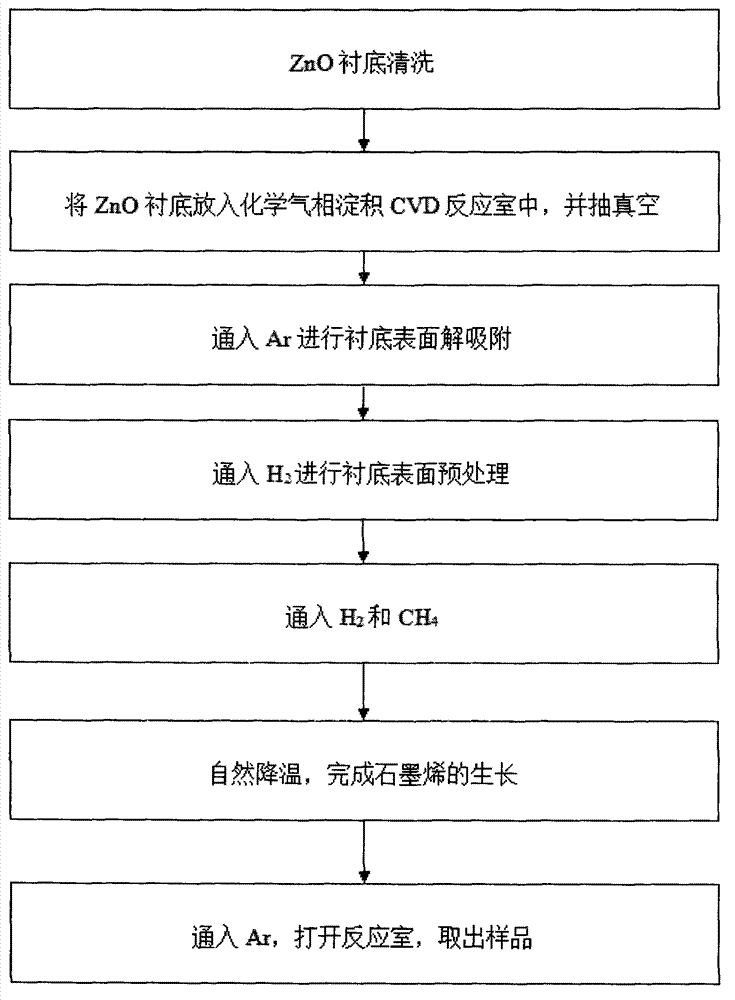

[0020] Example 1 A graphene film is prepared on a zinc oxide substrate.

[0021] (1) Put the ZnO substrate into acetone, ethanol and deionized water successively for cleaning, each time for 10 minutes, take out the substrate from the deionized water, and dry it with high-purity nitrogen (99.9999%).

[0022] (2) Put the ZnO substrate into the chemical vapor deposition CVD reaction chamber, draw a vacuum to 10 -5 Torr, to remove the residual gas in the reaction chamber;

[0023] (3) Pass high-purity Ar into the reaction chamber, keep the temperature at 150°C for 10 minutes, and then evacuate to 10 -5 Torr, discharge the adsorbed gas on the substrate surface.

[0024] (4) Introduce H into the reaction chamber 2 Perform substrate surface pretreatment, gas flow rate 1sccm, reaction chamber vacuum 0.1Torr, substrate temperature 900°C, treatment time 1min;

[0025] (5) Pass H into the reaction chamber 2 and CH 4 , keep H 2 and CH 4 The flow ratio is 10:1, H 2 Flow 20sccm, CH...

Embodiment 2

[0028] Example 2 prepares a graphene film on a zinc oxide substrate.

[0029] (1) Put the ZnO substrate into acetone, ethanol and deionized water successively for cleaning, each time for 8 minutes, take out the substrate from the deionized water, and dry it with high-purity nitrogen (99.9999%).

[0030] (2) Put the ZnO substrate into the chemical vapor deposition CVD reaction chamber, draw a vacuum to 10 -6 Torr, to remove the residual gas in the reaction chamber;

[0031] (3) Pass high-purity Ar into the reaction chamber, keep the temperature at 250°C for 30 minutes, and then evacuate to 10 -6 Torr, discharge the adsorbed gas on the substrate surface.

[0032] (4) Introduce H into the reaction chamber 2 Perform substrate surface pretreatment, gas flow rate 20sccm, reaction chamber vacuum 1Torr, substrate temperature 1000°C, processing time 10min;

[0033] (5) Pass H into the reaction chamber 2 and CH 4 , keep H 2 and CH 4 The flow ratio is 2:1, H 2 Flow 200sccm, CH ...

Embodiment 3

[0036] Example 3 Prepare a graphene film on a zinc oxide substrate.

[0037] (1) Put the ZnO substrate into acetone, ethanol and deionized water successively for cleaning, each time for 10 minutes, take out the substrate from the deionized water, and dry it with high-purity nitrogen (99.9999%).

[0038] (2) Put the ZnO substrate into the chemical vapor deposition CVD reaction chamber, draw a vacuum to 10 -6 Torr, to remove the residual gas in the reaction chamber;

[0039] (3) Pass high-purity Ar into the reaction chamber, keep the temperature at 100°C for 20 minutes, and then evacuate to 10 -6 Torr, discharge the adsorbed gas on the substrate surface.

[0040] (4) Introduce H into the reaction chamber 2 Perform substrate surface pretreatment, gas flow rate 10sccm, reaction chamber vacuum 0.5Torr, substrate temperature 950°C, processing time 5min;

[0041] (5) Pass H into the reaction chamber 2 and CH 4 , keep H 2 and CH 4 The flow ratio is 5:1, H 2Flow 100sccm, CH 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com