Growth method of granular SiC (silicon carbide) single crystals

A silicon carbide single crystal and growth method technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of loss of cutting consumables, high hardness of SiC crystal, and increased production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

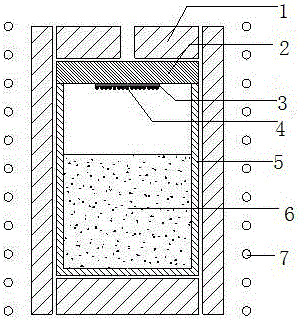

[0028] Aiming at the above-mentioned problems in the prior art, the present invention provides a method for growing a granular silicon carbide single crystal, by coating a high-carbon content polymer on a porous graphite plate, and uniformly distributing small particle SiC seeds on the surface of the polymer The non-coated surface of the porous graphite plate is fixed on the upper cover of the graphite crucible, the SiC powder is placed on the bottom of the graphite crucible, the upper cover of the crucible is placed opposite to the SiC powder, and the graphite crucible is placed in an induction heating fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com