Method for growing epitaxial wafer of GaN-based light emitting diode

A light-emitting diode and growth method technology, which is applied in the growth field of GaN-based light-emitting diode epitaxial wafers, can solve the problems of weak current expansion ability of NP layer, poor antistatic ability of epitaxial wafers, and reduction of light output from the front of the chip, so as to ensure the front The effect of light output, uniform crystal laying, and better current expansion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

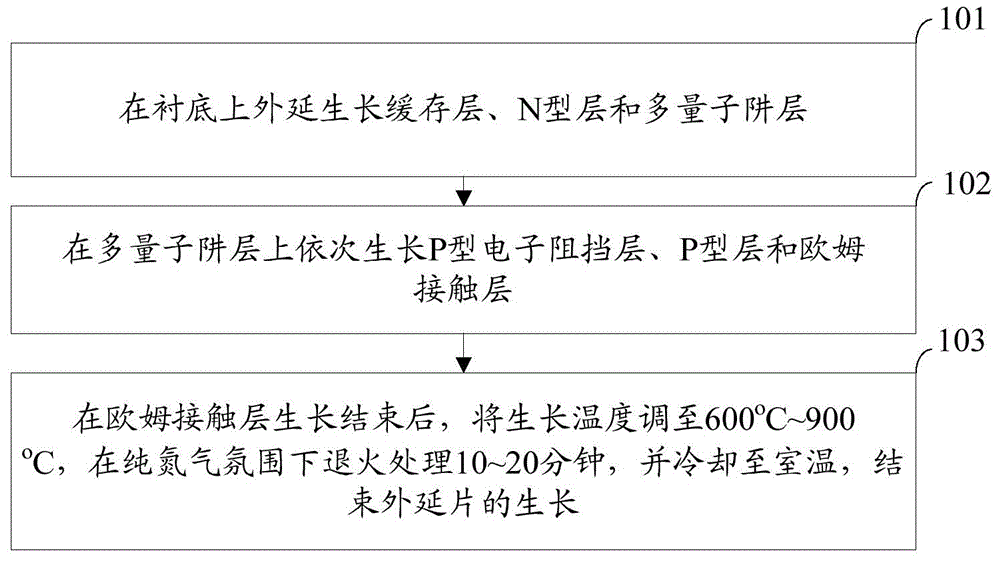

[0024] An embodiment of the present invention provides a method for growing a GaN-based light-emitting diode epitaxial wafer, see figure 1 , the method includes:

[0025] Step 101: epitaxially growing a buffer layer, an N-type layer and a multi-quantum well layer on the substrate.

[0026] Wherein, the substrate is a material suitable for the growth of gallium nitride and other semiconductor epitaxial materials, such as gallium nitride single crystal, sapphire, single crystal silicon, silicon carbide single crystal, and the like.

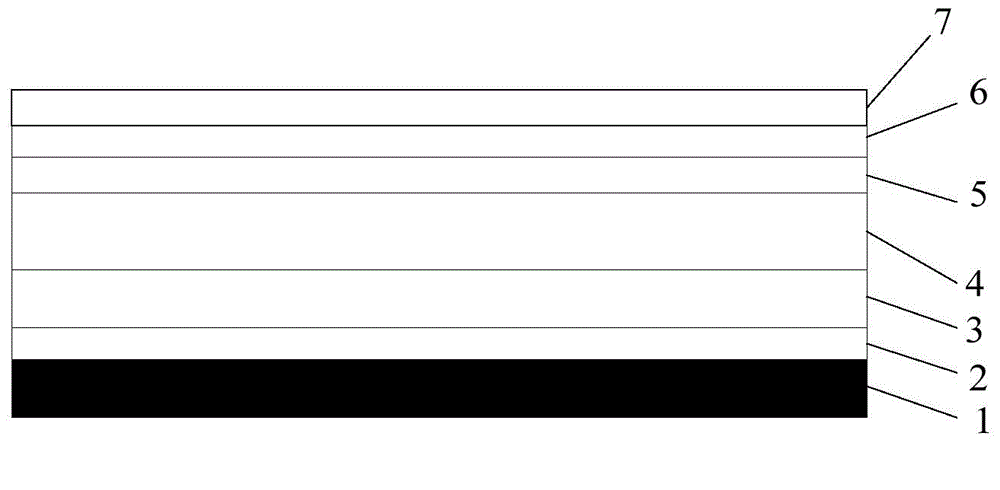

[0027] Specifically, the buffer layer may be one or more layers (ie composite buffer layer). When the buffer layer is a composite buffer layer, it may include a low temperature buffer layer and a high temperature buffer layer. As an example, the composition of the low-temperature buffer layer can be GaN, with a thickness of 15nm to 30nm, preferably 20nm; the composition of the high-temperature buffer layer can be high-temperature undoped GaN, with...

Embodiment 2

[0041] An embodiment of the present invention provides a method for growing a GaN-based light-emitting diode epitaxial wafer. In this embodiment, the N-type layer includes a high-temperature N-type GaN layer and a high-temperature N-type GaN current spreading layer. The growth temperature of the high-temperature N-type GaN layer is It is 1100℃, and the doping concentration of Si is 5×10 18 cm -3 , the growth temperature of the high-temperature N-type GaN current spreading layer is 1100°C, and the doping concentration of Si is 2×10 17 cm -3 , the multi-quantum well layer is composed of twelve 3nm In 0.18 Ga 0.82 A multilayer quantum well composed of N quantum well layer and 12 10.5nm GaN quantum barrier layers, and the P-type electron blocking layer is P-type Al 0.16 Ga 0.84 N layer, in which the doping concentration of Mg is 5×10 17 cm -3 , the P-type layer is a Mg-doped GaN layer, and the concentration of Mg doping is 5×10 19 cm -3 , the growth pressure is 600torr, t...

Embodiment 3

[0045] The embodiment of the present invention provides a method for growing a GaN-based light-emitting diode epitaxial wafer, wherein the buffer layer, N-type layer, multiple quantum well layer, P-type electron blocking layer and ohmic contact layer are the same as in Embodiment 2, and the same as in Embodiment 2. The difference between the two is that the growth pressure of the P-type layer is changed to 700torr, and the flow rate of TMGa is adjusted to 20sccm.

[0046] Similarly, after the growth of the epitaxial wafer is completed, semiconductor processing techniques such as cleaning, deposition, and photolithography are continued to be performed on the epitaxial wafer to produce an LED chip with a single chip size of 10×25 mil, and the LED chip is subjected to the same conditions as in Example 2. The results obtained are: the test current is 60mA, the operating voltage is 3.05V, the brightness is 110mw, and the 4KV antistatic ability is 93%. Compared with the epitaxial waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com