Patents

Literature

337results about How to "Avoid overgrowth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

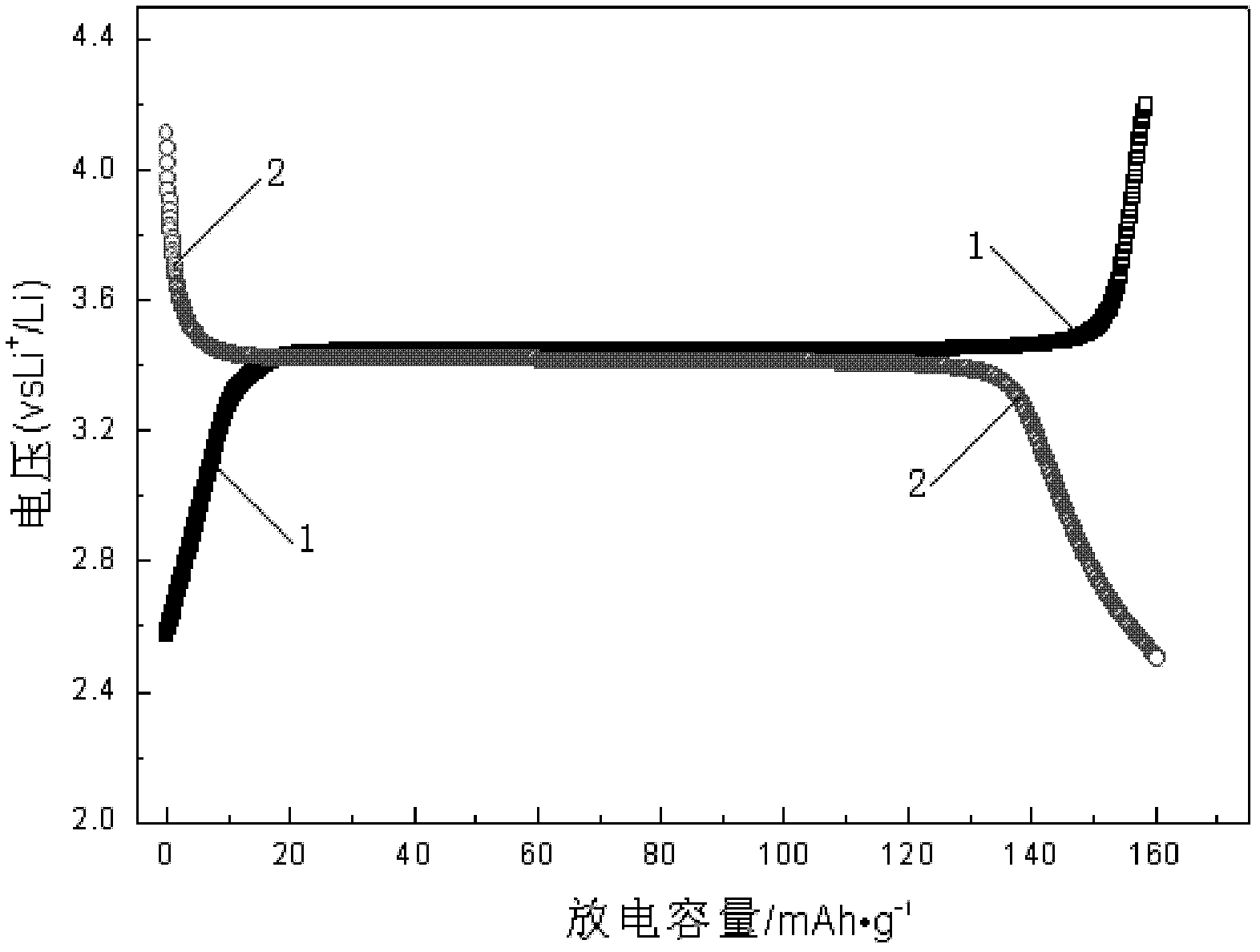

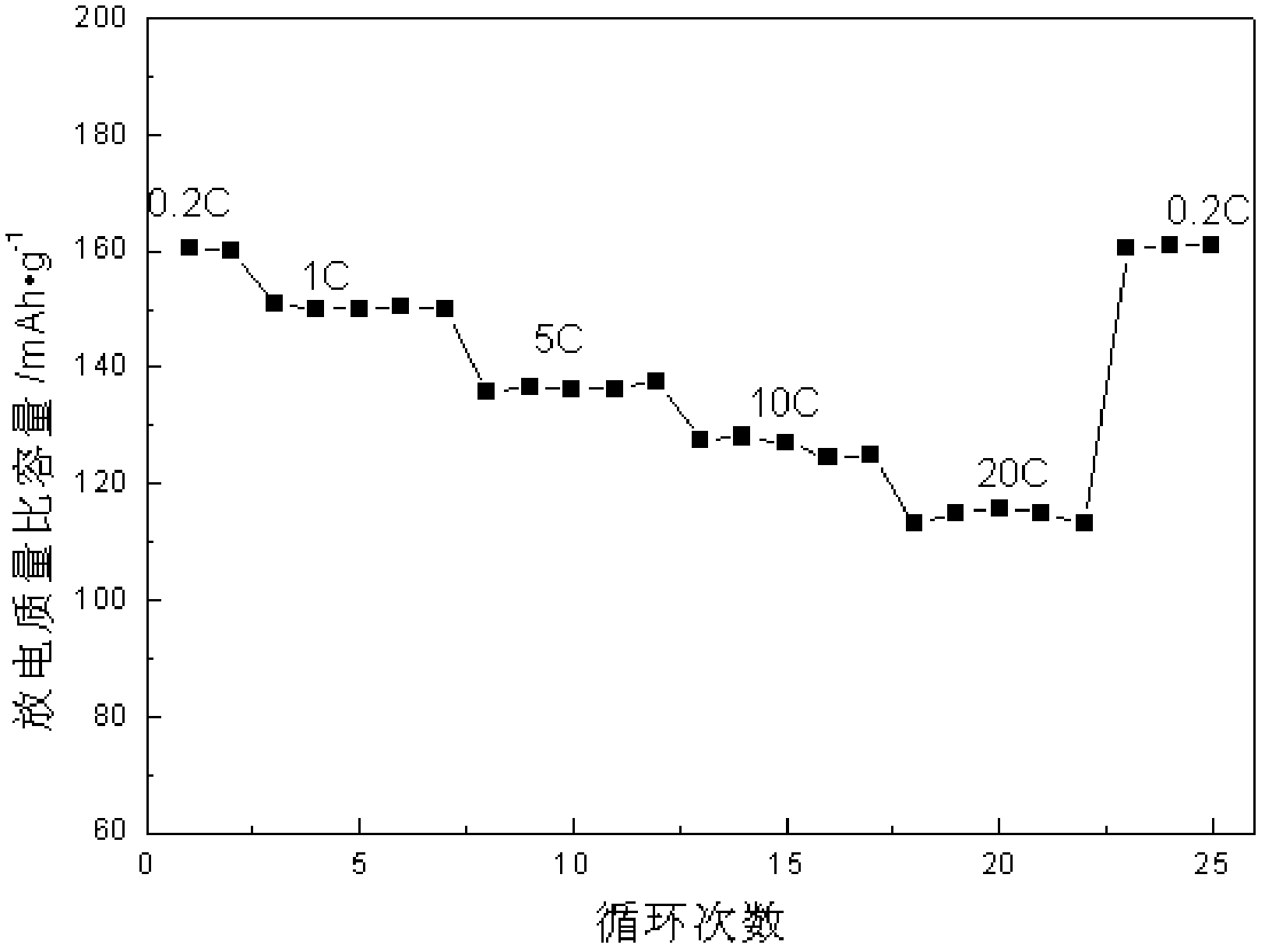

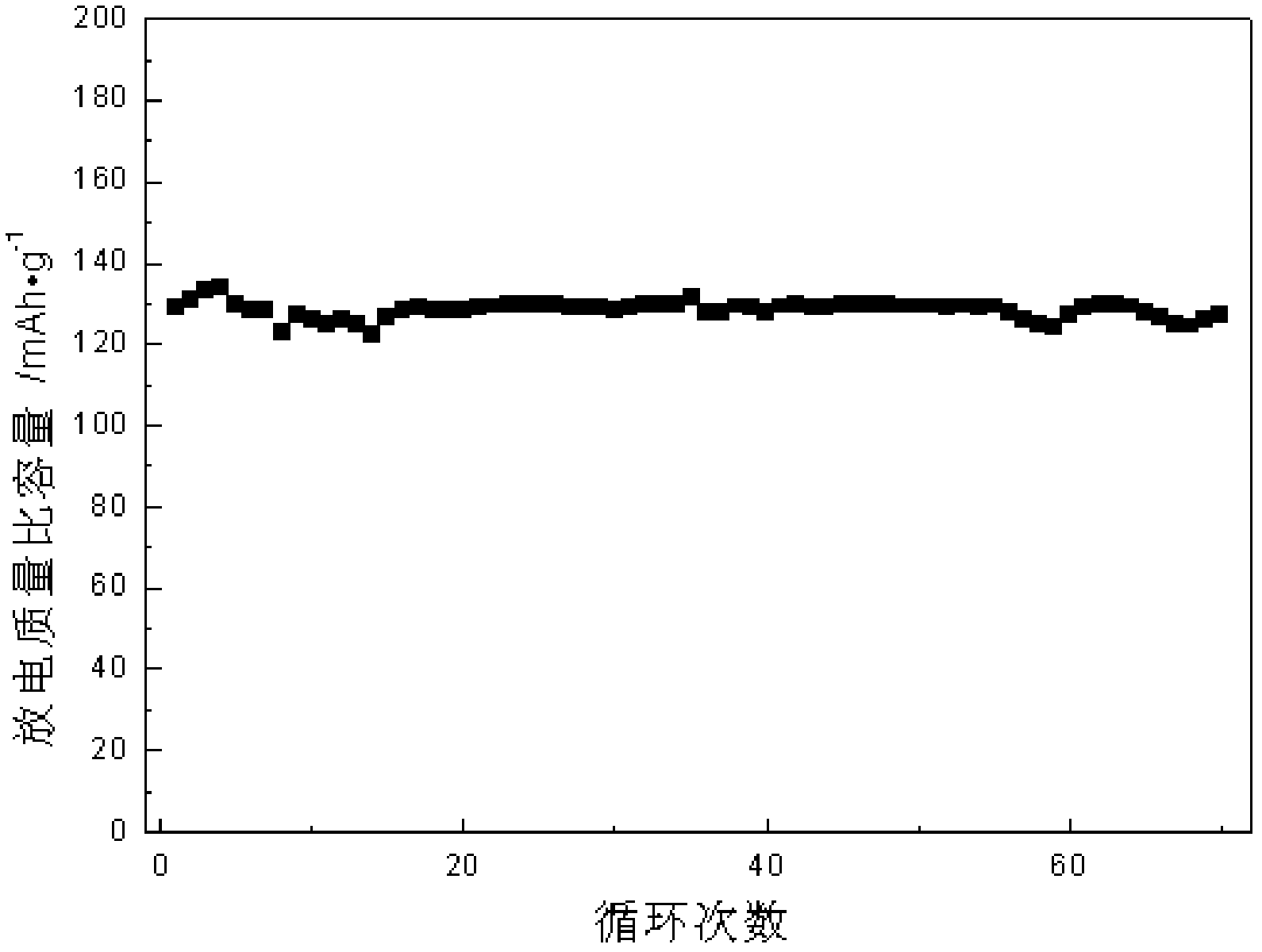

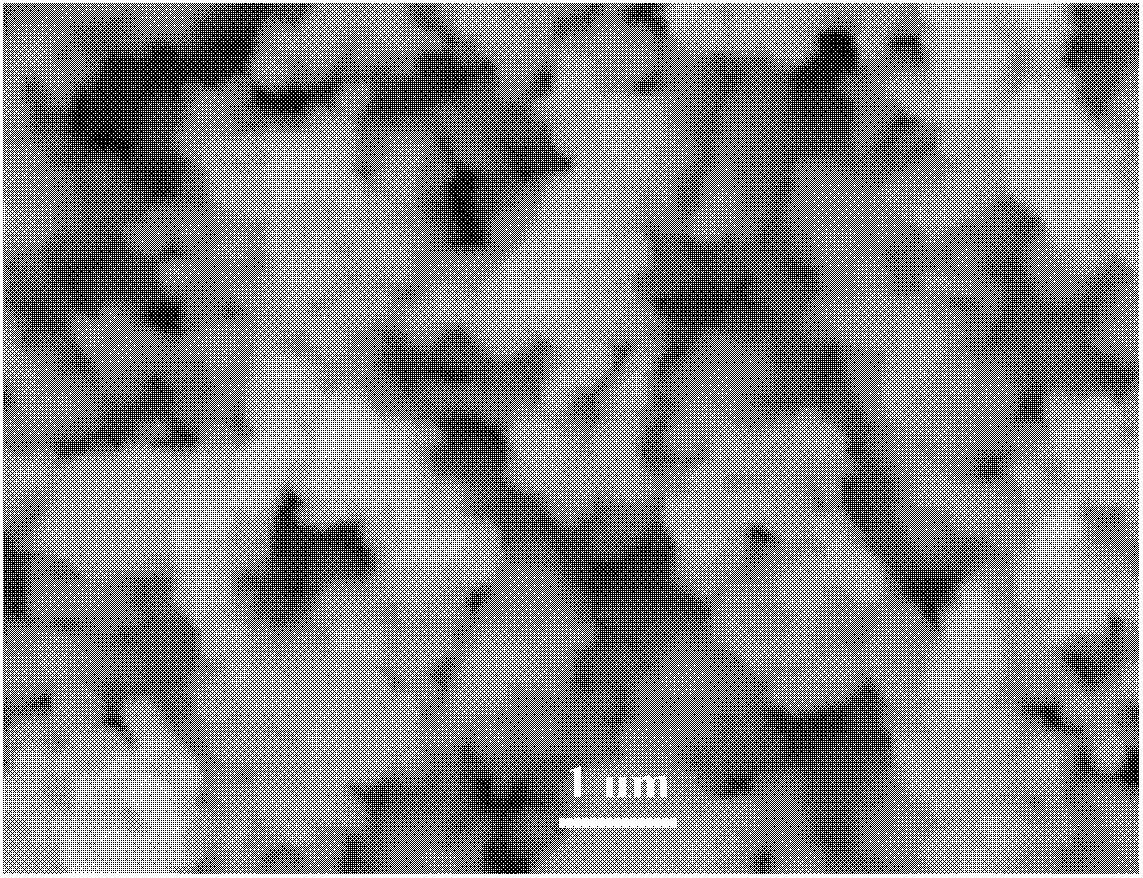

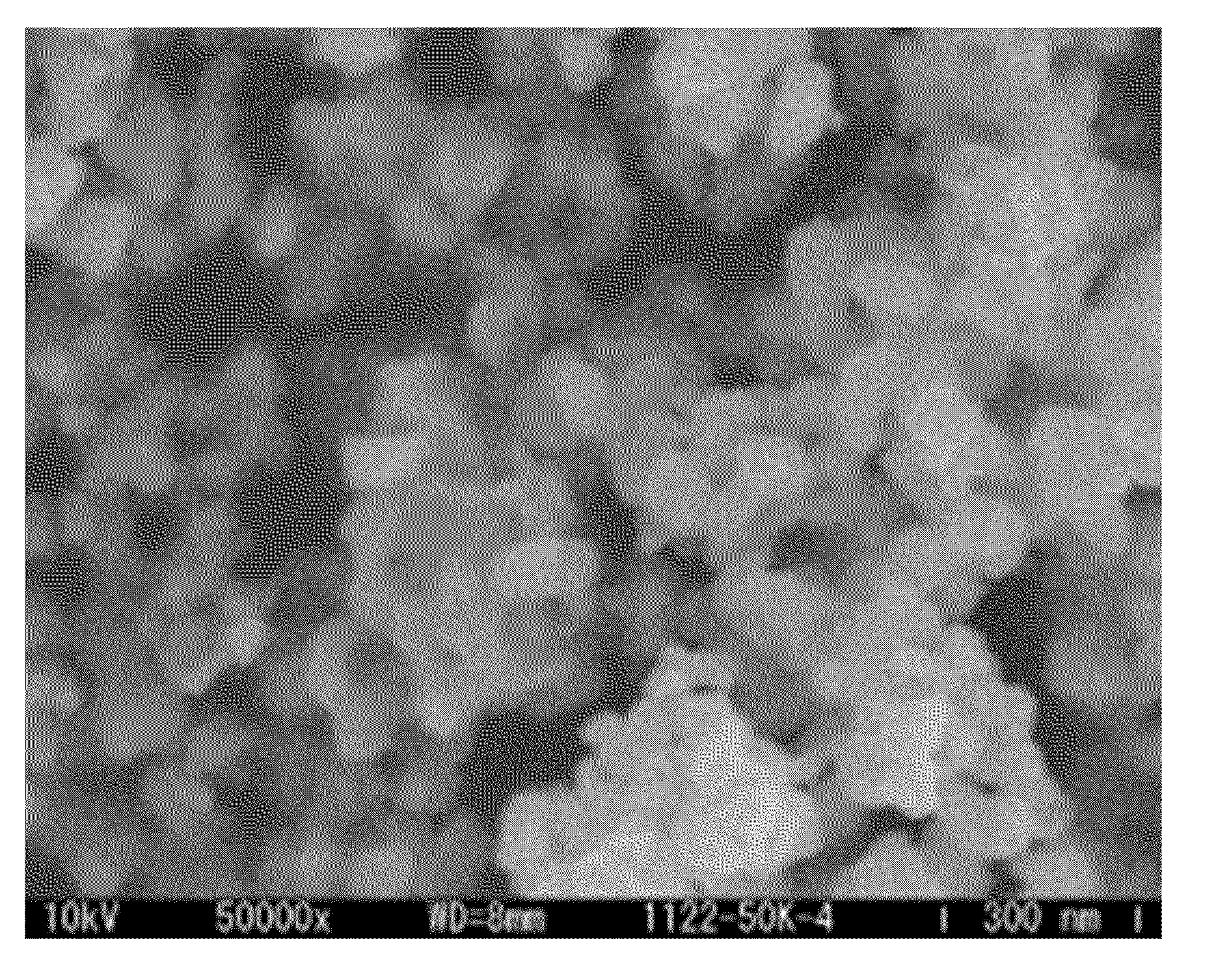

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

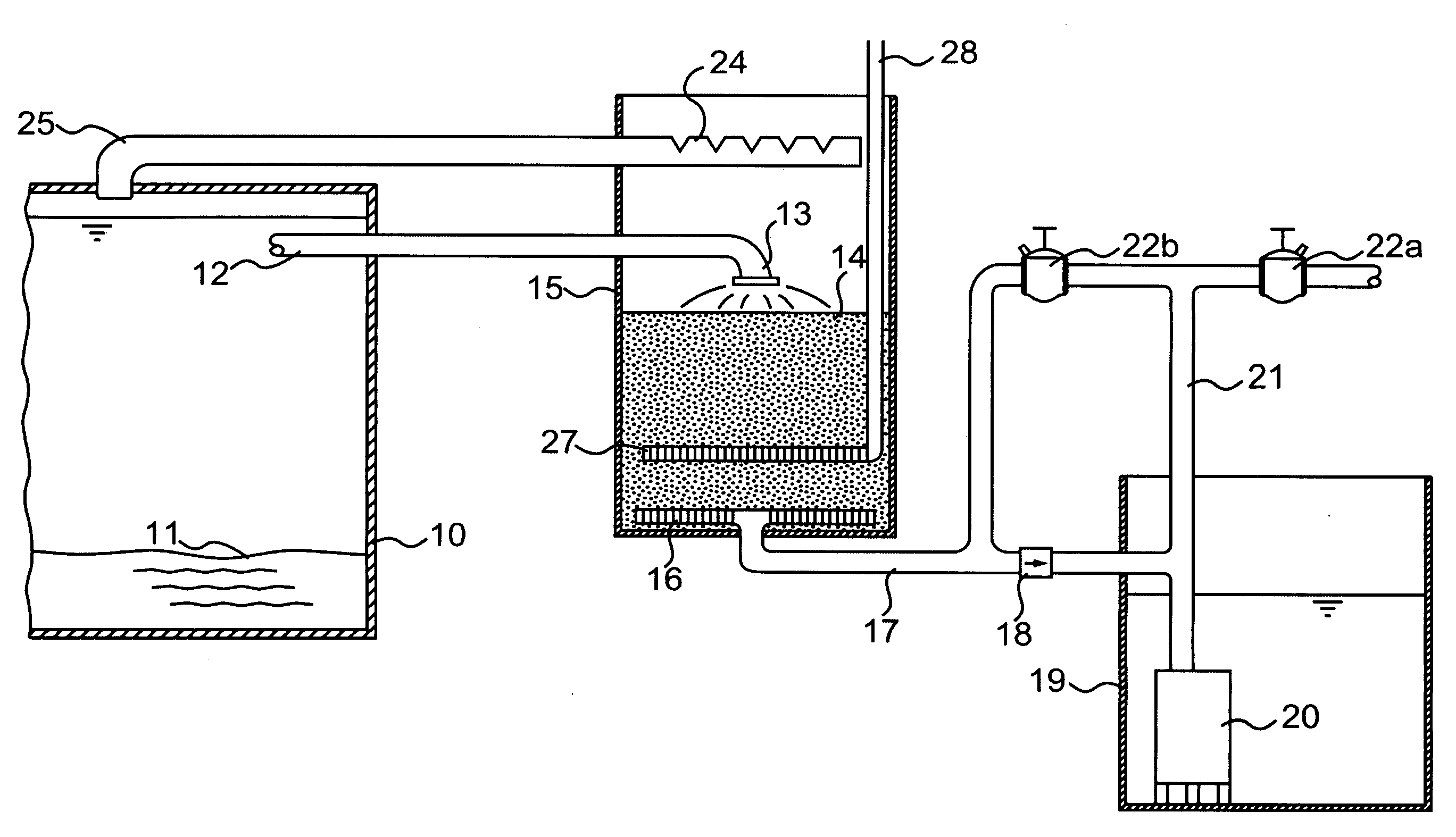

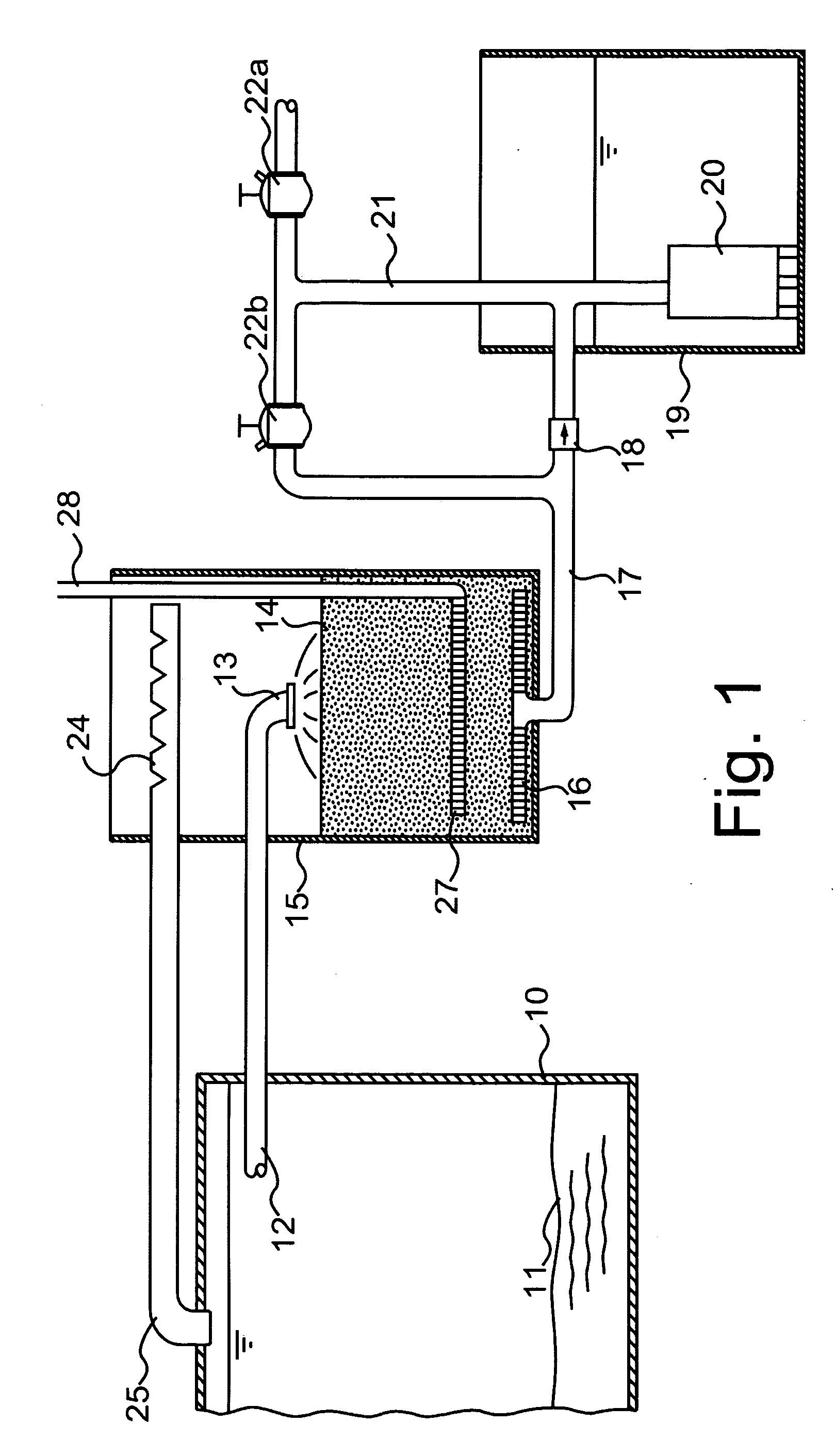

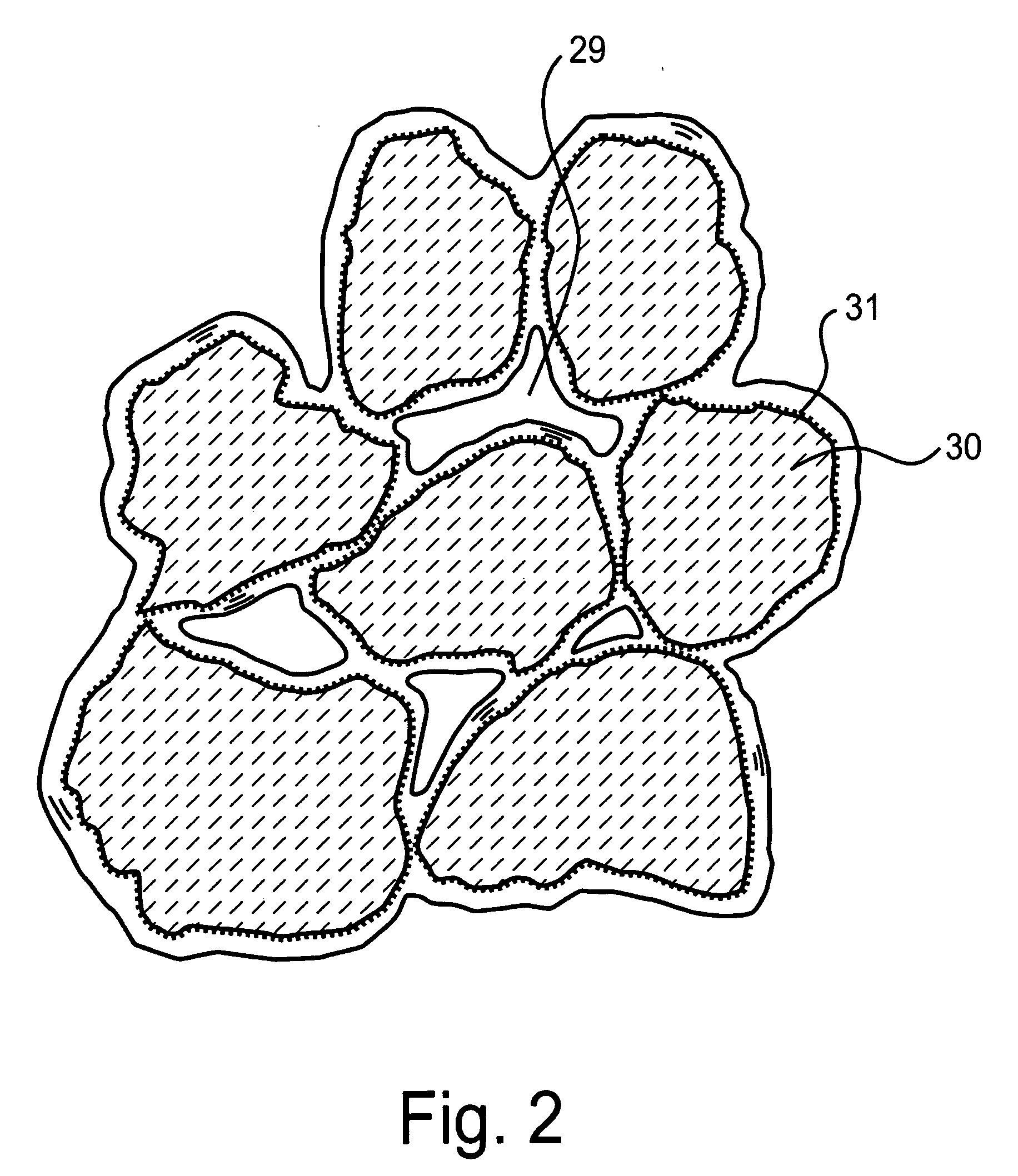

Backwashing unsaturated wastewater filter

ActiveUS20090294356A1Improve uniformityImprove efficiencyTreatment using aerobic processesSpecific water treatment objectivesWater sourceBiofilm growth

A compact high efficiency combined biological and physical unsaturated wastewater treatment filter configured for periodic backwashing is disclosed. The filter utilizes packed media and removes pollutants and pathogens from wastewater and other dirty water sources. The filter comprises a periodic backwashing means to less the chance that biofilm growth will clog the media pores. However, such backwashing still leaves sufficient biofilm attached to the media to maintain a very high level of treatment. In the preferred embodiment, the filter utilizes high frequency dosing to cause pore saturation at or near the surface during dosing and shortly thereafter in order to maximize distribution uniformity and to induce downward airflow into the media. The system provides a number of unexpected benefits; including allowing a very low distribution pressure and providing high oxygen transfer at low energy utilization into the filter media for aerobic biodegradation of pollutants.

Owner:BZAM LLC

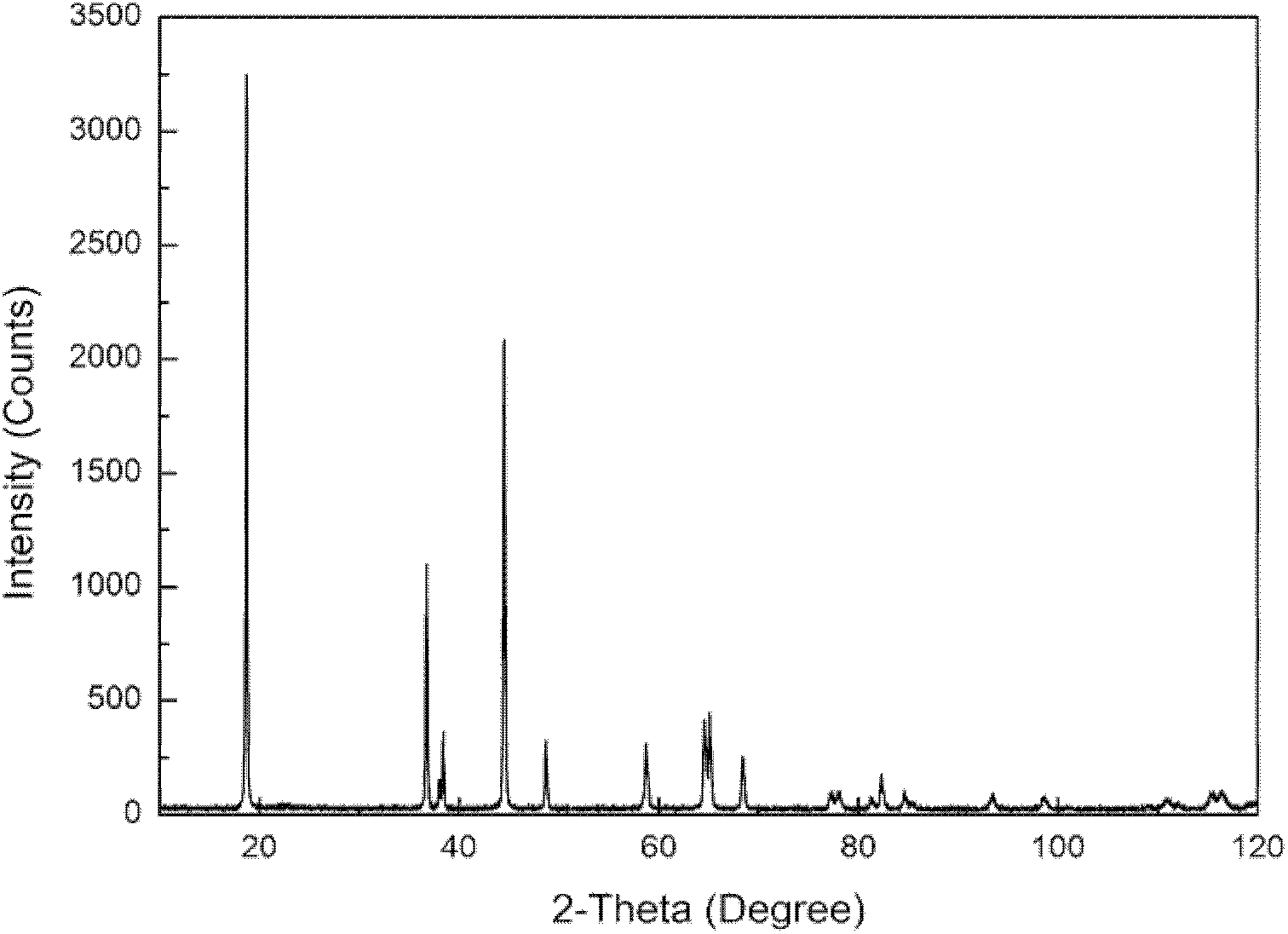

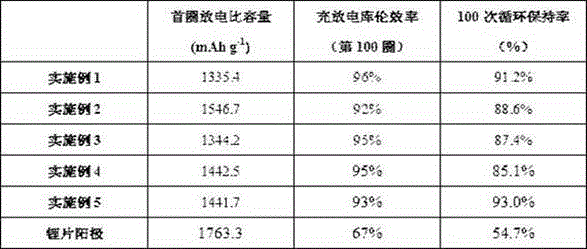

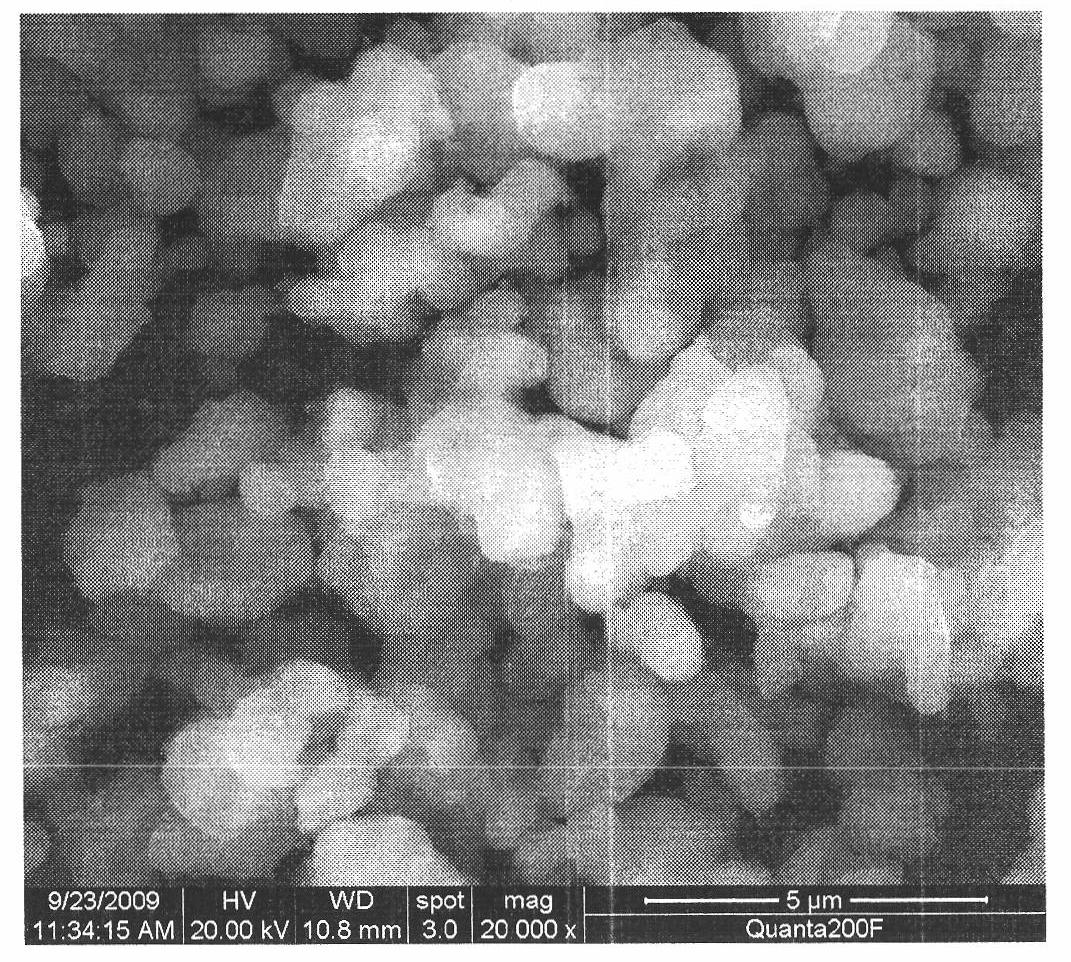

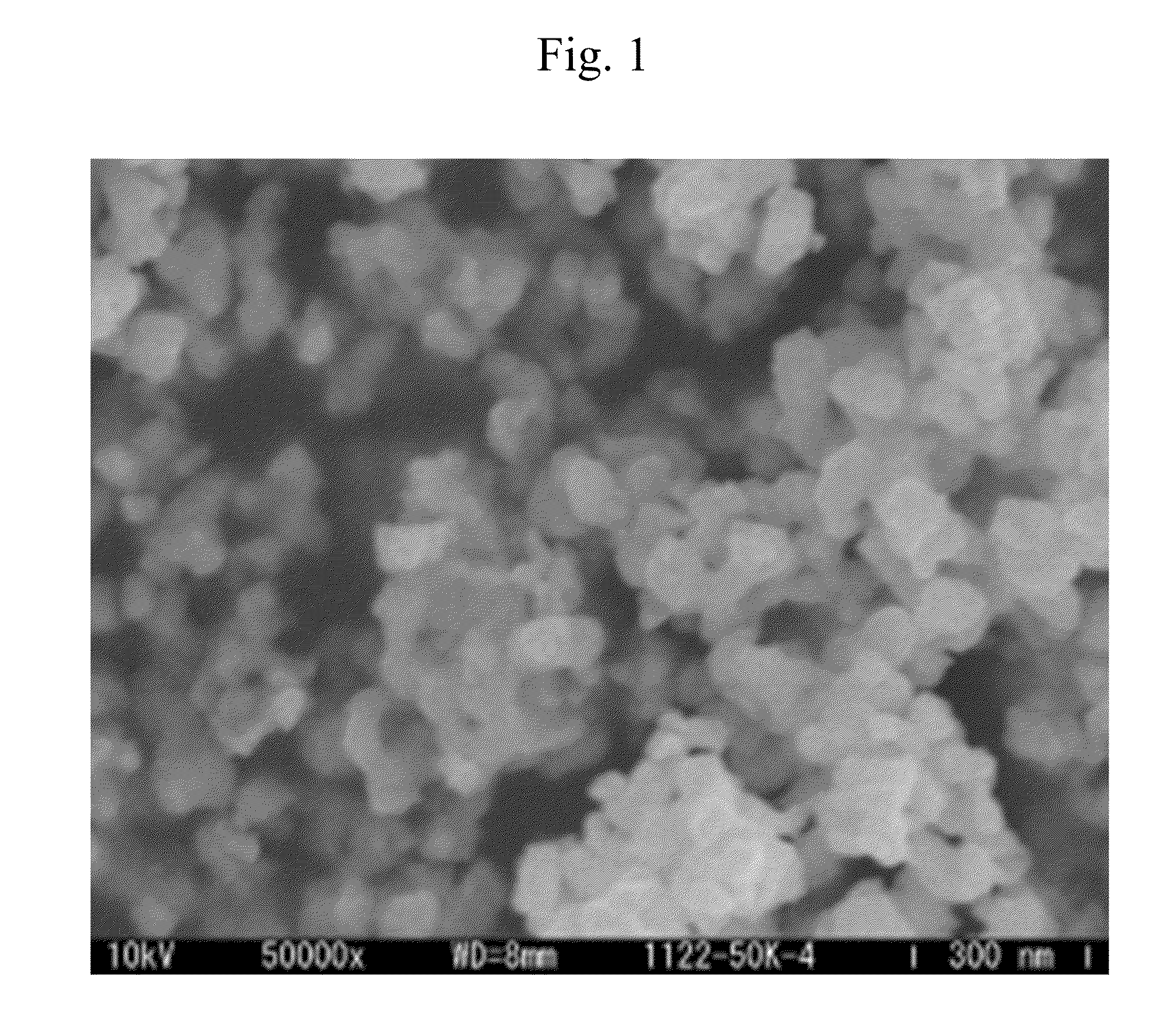

Method for preparing ternary complex anode material (LiNixCoyMn1-x-yO2)

The invention discloses a method for preparing a ternary complex anode material (LiNixCoyMn1-x-yO2), which is characterized in that the lithium ion battery anode material (LiNixCoyMn1-x-yO2) is prepared by adopting a coprecipitation-silicon cladding-high temperature sintering-desilicication integrated method, and specifically comprises the following steps: mixing a nickel source and a cobalt source with a manganese source according to molar ratio of nickel-cobalt-manganese: x:y:(1-x-y), adding with water, stirring to form a solution, adding with a certain amount of ammonia water and a sodium hydroxide solution to generate a uniform NixCoyMn1-x-y(OH)2 ocyhydrate precursor, washing and filtering the precursor, adding with a certain amount of polyvinylpyrrolidone, stirring for a certain period, adding with a certain quantity of organosilicon reagents, stirring continuously to obtain an ocyhydrate precursor wrapped by organosilicon reagent-polyvinylpyrrolidone, washing, filtering, drying and then mixing the ocyhydrate precursor with a lithium source, calcining the mixture under air or an oxygen atmosphere under the temperature of 450-950 DEG C for 2-48 hours, and removing a silicon wrapping layer on a product by the utilizing a sodium hydroxide solution, thus obtaining the nanoscale or standard nanoscale lithium ion battery ternary complex anode material (LiNixCoyMn1-x-yO2). The particle size of the anode material prepared by the invention ranges from 80nm-180nm, the initial charging / discharging performance achieves 194.4-210.3mAh / g, and the electrochemical performance is excellent.

Owner:CENT SOUTH UNIV

Method for planting tree plant

InactiveCN101461307APlay the effect of controlling insects with insectsMoisture conservationHorticultureSoil-working methodsFlavorHibiscus

The invention discloses a planting method of tea plant, comprising: a) levelling off the mountains and making farmland in November; b) planting hibiscus for 2-3 years in and around the ten garden; c) digging delves of 0.5-1 meter long, 0.5-1 meter wide and 0.5-0.7 meter deep around and among the tea garden, then using weeds as base fertilizer, for one layer of fertilizer and one layer of earth to plant fructus chaenomelis, wherein plant spacing is 2.5-3 meters; d) planting sweet-scented osmanthus around the tea garden; e) planting ashitaba, pyrethrum and clover on the two sides of tea plant. Compared with the prior art, the invention adopts tea planting method in multidimension development high performance, for protecting zoology and produced tea having the characteristics of tight cord, full-bodied flavor, bright color, total weight of amino acid in chemical components is 4.39-4.5%, weight concentration of water extraction is more than 44.51%.

Owner:黄山市多唯生物(集团)有限公司

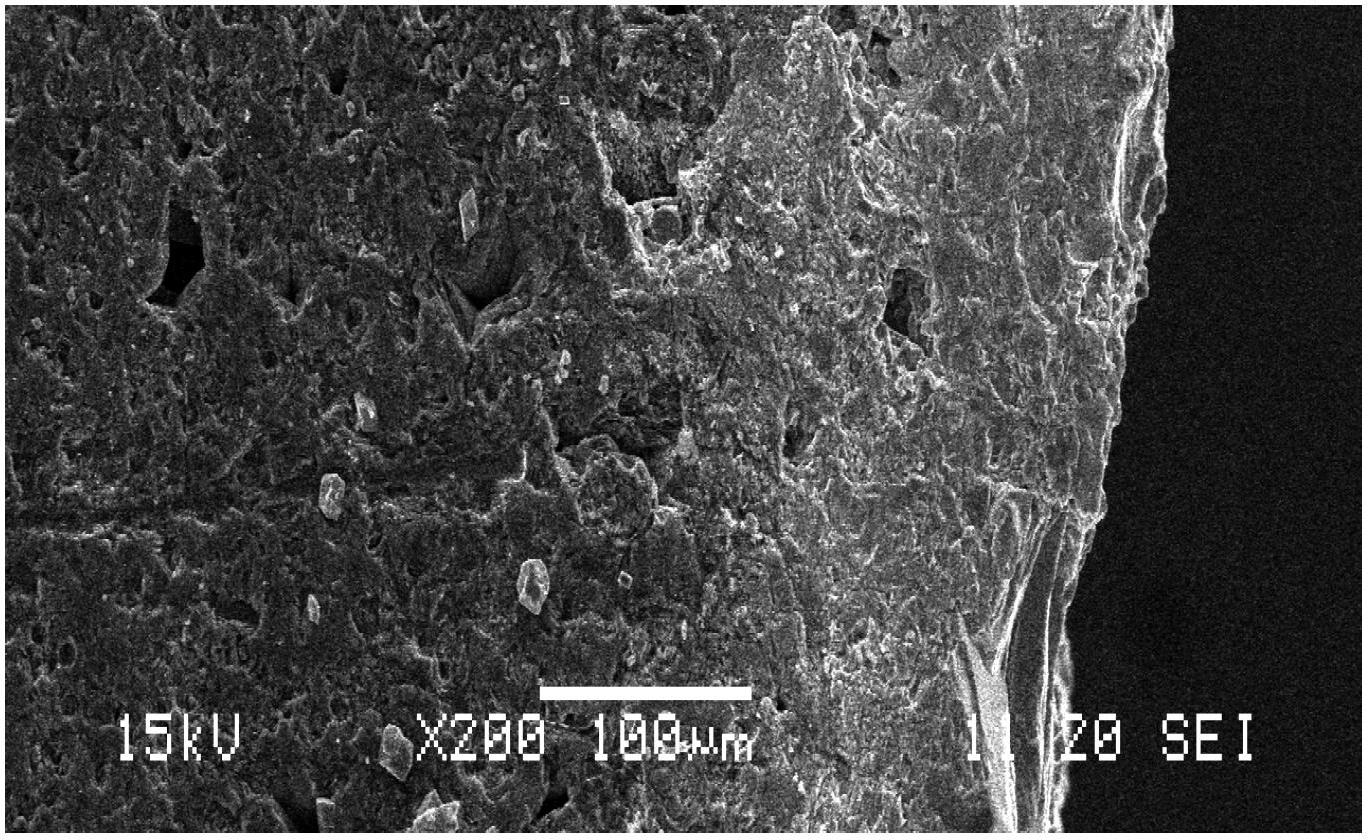

Cell or tissue-culturing carrier, and culturing method

InactiveUS6897064B2Inhibiting and suppressing excessive growthPromote regenerationBacteriaVertebrate cellsGel basedCulture cell

A cell or tissue-culturing carrier which can effectively regenerate an intended a cell or tissue, while suppressing an excessive growth of fibroblasts, and a method of culturing a cell or tissue by using the above carrier, the cell or tissue-culturing carrier wherein fibroblasts showing substantially no growing property in a gel based on the hydrogel-forming polymer, is constituted by using a hydrogel-forming polymer; an aqueous solution of which shows a thermo-reversible sol-gel transition such that it assumes a sol state at a lower temperature and assumes a gel state at a higher temperature.

Owner:MEBIOL

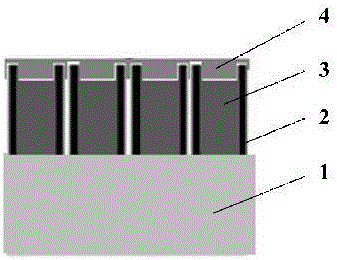

Lithium anode for high-specific-energy secondary battery

InactiveCN106025230AGuaranteed stabilityOvercoming breakageFuel and primary cellsMaterial nanotechnologyPhysicsMetallic lithium

The invention discloses a lithium anode for a high-specific-energy secondary battery. The lithium anode for the high-specific-energy secondary battery consists of a conductive substrate, a nanotube array, lithium metal and a barrier layer, wherein the nanotube array grows on the conductive substrate in an oriented manner; the lithium metal exists in the nanotube array; the barrier layer covers the nanotube structure. The lithium anode for the high-specific-energy secondary battery has the advantages that the lithium metal exists in a pipeline structure in a sealed manner, lithium dendrites can be prevented effectively, and a metal organic frame (MOF) which is rich in electrolyte or another lithium conducting material is used as the barrier layer, so that overgrowth of the lithium dendrites in local nanotubes can be prevented effectively, and the safety of the battery is ensured.

Owner:SHENZHEN RES INST CENT SOUTH UNIV

Method of improving skills with a composition comprising non-digestible saccharide

InactiveUS20100063002A1Composition is easyEasy to manageBiocideOrganic active ingredientsGut floraGerontology

The present invention concerns a therapy aimed at language and / or social skills in infants through administration of components stimulating the development of a healthy intestinal flora.

Owner:NUTRICIA

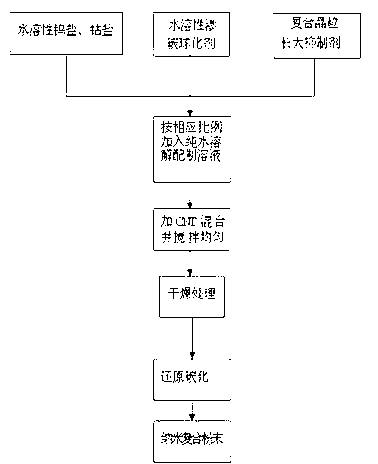

Method for manufacturing nanometer tungsten/cobalt carbide composite powder

The invention discloses a method for manufacturing nanometer tungsten / cobalt carbide composite powder. The method is characterized by comprising technological steps of firstly, dissolving, by mass, 55-92% of water-soluble tungsten salt, 3-40% of water-soluble cobalt salt, 3-6% of water-soluble carburizing and nodulizing agents and 0.1-2% of water-soluble composite grain growth inhibitors into water with the mass 3-5 times that of a mixture of the water-soluble tungsten salt, the water-soluble cobalt salt, the water-soluble carburizing and nodulizing agents and the water-soluble composite grain growth inhibitors to prepare mixed aqueous solution; secondly, adding carbon nano-tubes (CNT) accounting for 1-10% of the total mass of the aqueous solution into the mixed aqueous solution obtained in the first step and enabling the carbon nano-tubes to be uniformly mixed in the mixed aqueous solution; thirdly, performing quick low-temperature spray drying for mixed aqueous solution obtained in the second step to obtain precursor powder of ultrafine tungsten and cobalt composite salt; and fourthly, performing reduction synthesis and carbon conditioning at the temperature ranging from 900 DEG C to 1000 DEG C for the precursor powder obtained in the third step to prepare tungsten / cobalt carbide composite powder materials with nanostructures.

Owner:ADVANCED FOR MATERIALS & EQUIP

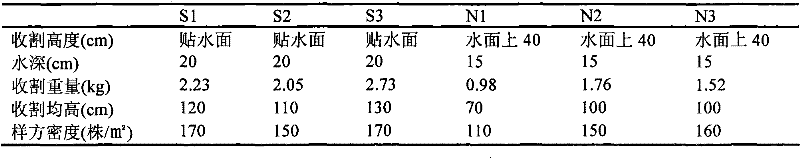

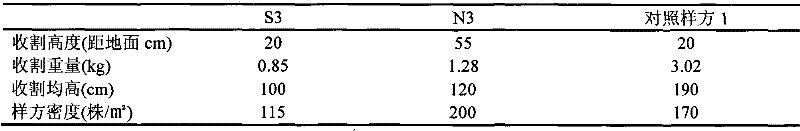

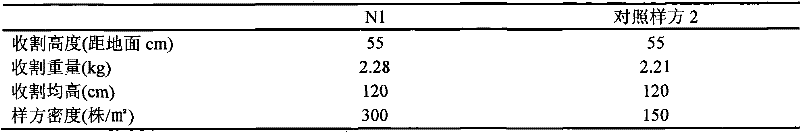

Water eco-environment protection method based on water plant harvesting

InactiveCN102491522AAvoid overgrowthPrevent algal bloomsSustainable biological treatmentBiological water/sewage treatmentPropaguleEutrophication

A water eco-environment protection method based on water plant harvesting. The invention relates to a water eco-environment protection method, which is characterized in that water plants are cultivated in a water body or naturally recovered water plants are utilized; nitrogen and phosphorous nutrients are absorbed by water plant growth; the water plants are harvested in growth period by manual work or waterweed harvesting equipment so as to promote the regrowth of the water plants; harvesting is carried out for multiple times, ends in the growth period and is carried out for the last time after the water plants grow seeds or vegetative propagule so as to extract the nitrogen and phosphorus nutrients from water in the form of water plant residues. The invention aims to maximize the accumulated biomass of the water plants during the whole growth period or optimize the water quality purifying effect and simultaneously remove nutrients in the water body and deposits, alleviate the eutrophication process of the water body and prevent the water plants from decaying and polluting the water body once again. The method provided by the invention is suitable for daily ecological maintenance of shallow lakes, urban landscape water, slow flow rivers, small reservoirs, wetlands and ponds.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

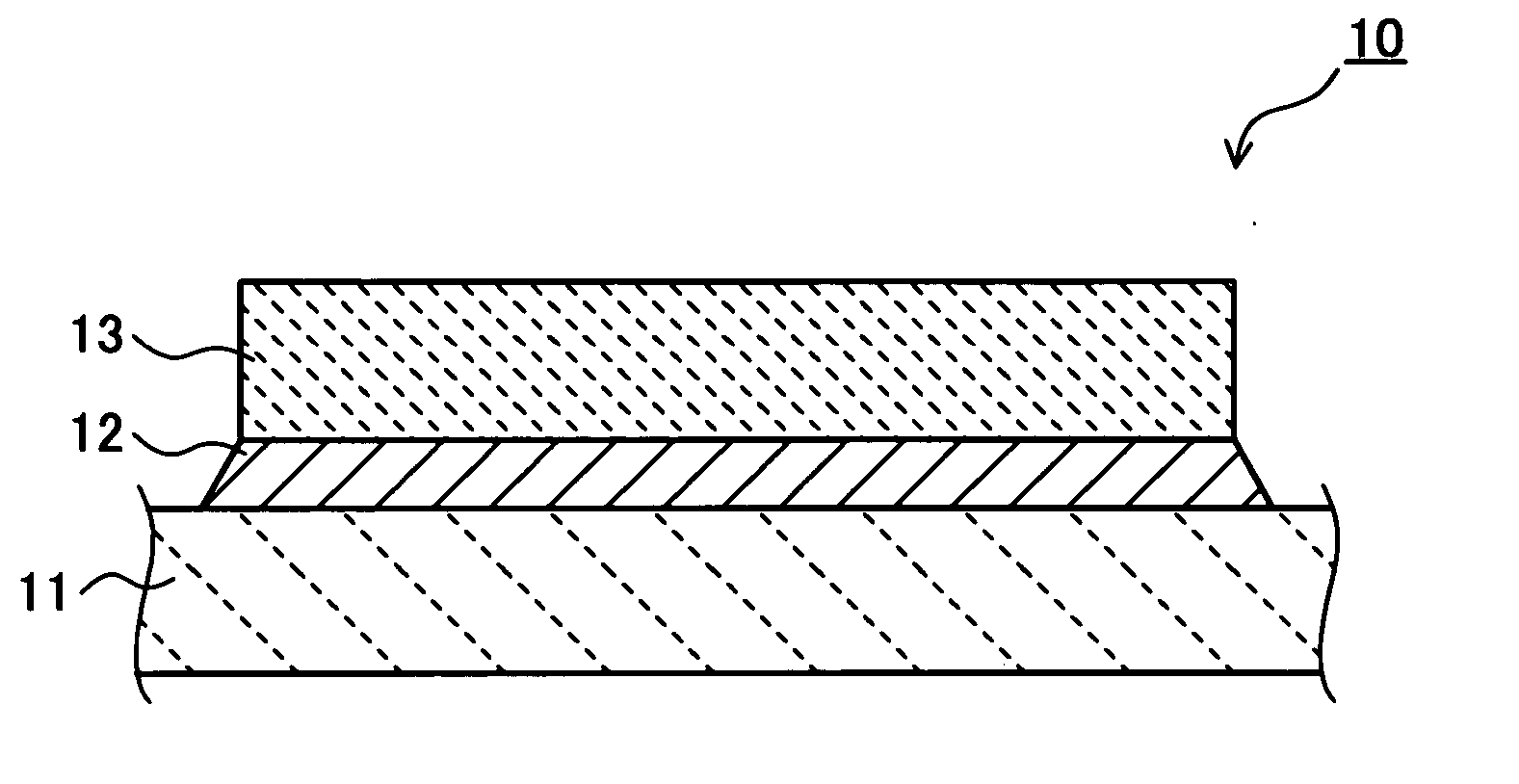

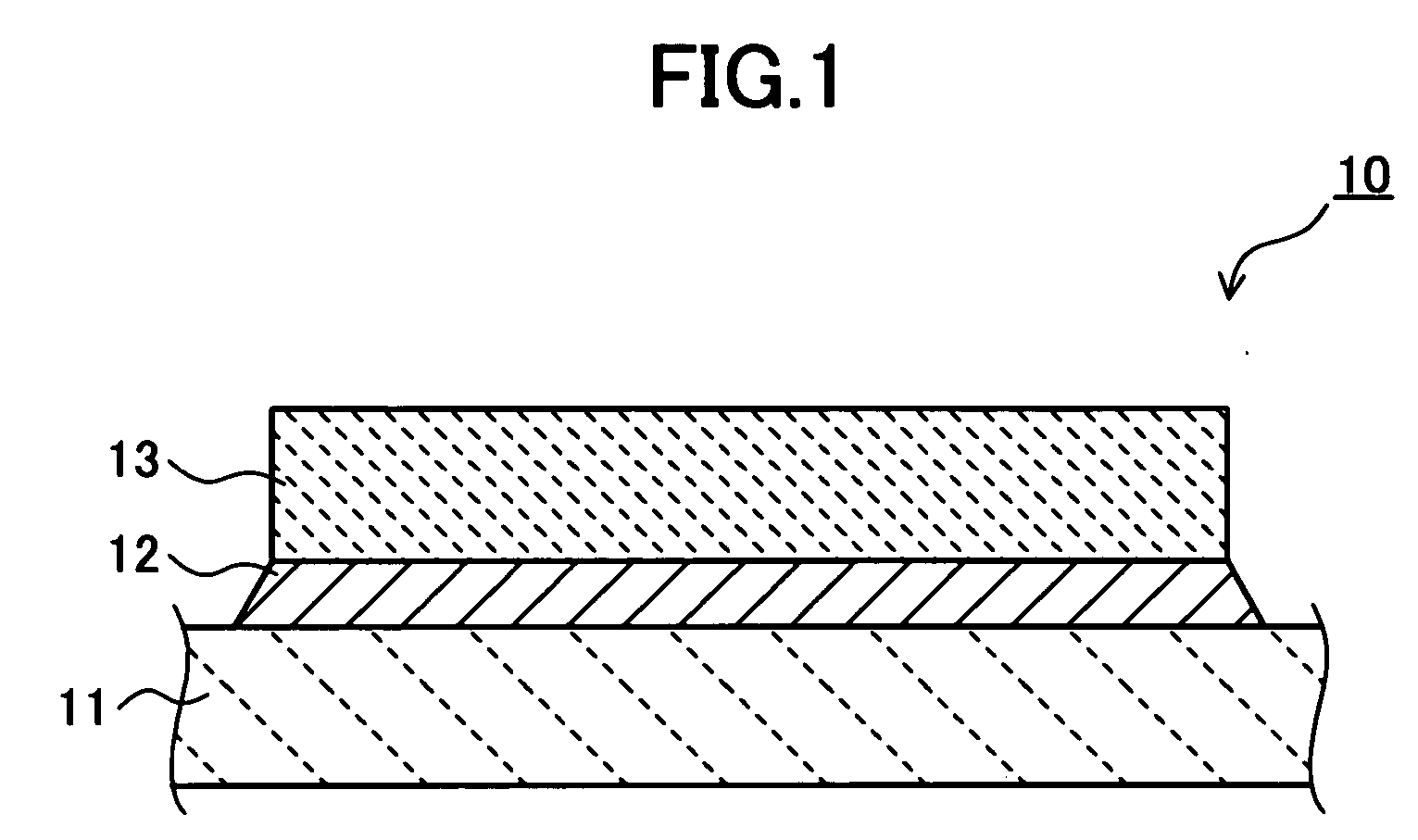

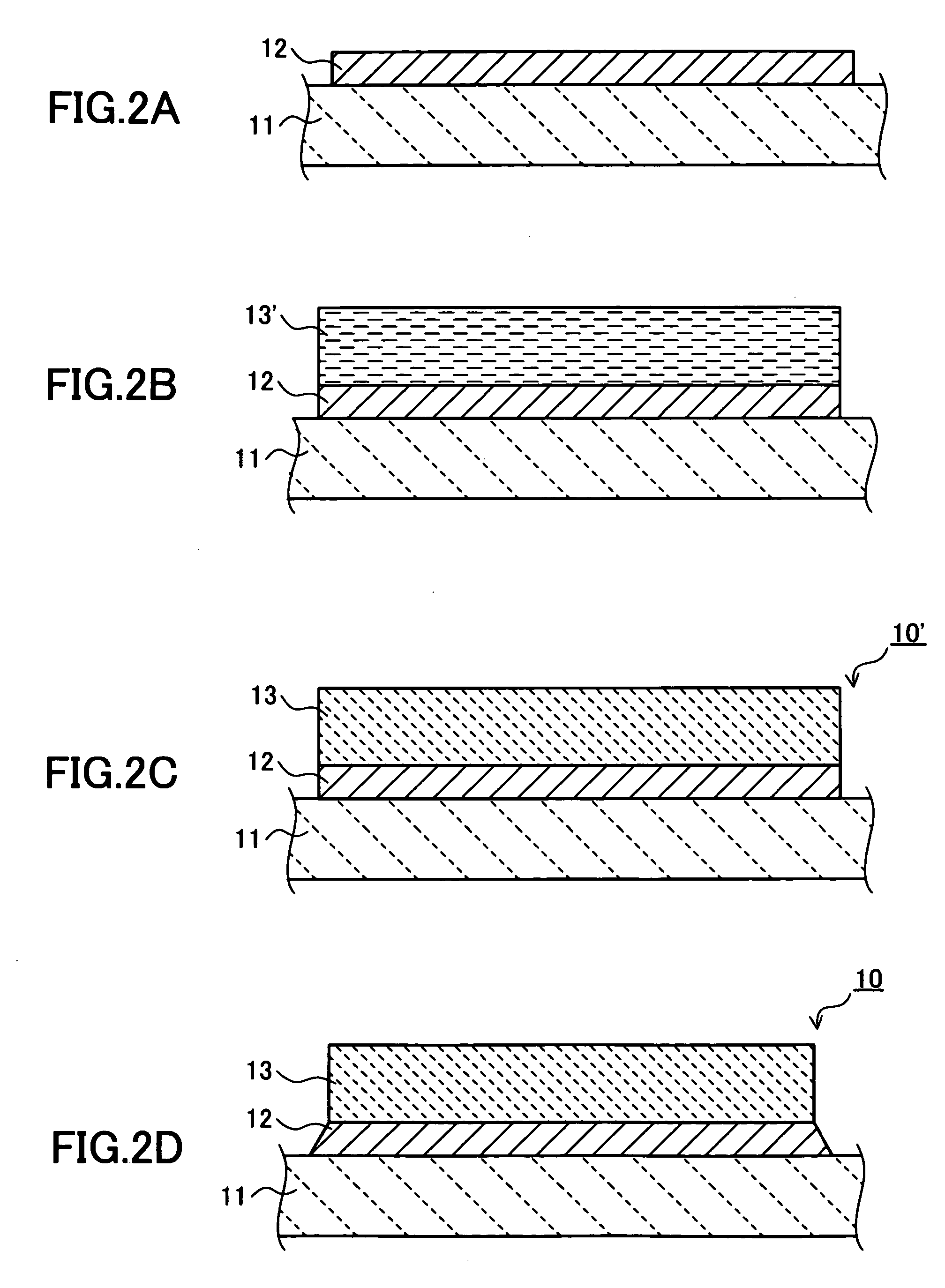

Piezoelectric/electrostrictive device and method for manufacturing the same

InactiveUS20060119229A1Grow moreReduce residual stressPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesFree coolingOptoelectronics

A piezoelectric / electrostrictive device includes a substrate, an electrode layer adhering to the surface of the substrate, and a piezoelectric / electrostrictive layer adhering to the electrode layer. The electrode layer is deformed by high-temperature creep. A method for manufacturing the piezoelectric / electrostrictive device includes the cooling step of cooling the piezoelectric / electrostrictive device after firing at a temperature decreasing rate of at least the rate of natural cooling. The cooling step includes the sub-step of holding the piezoelectric / electrostrictive device at a constant temperature lower than the firing temperature. The holding temperature is set within the range of temperatures at which high-temperature creep occurs in the metal of the electrode layer. Thus, residual stress in the piezoelectric / electrostrictive layer can be reduced.

Owner:NGK INSULATORS LTD

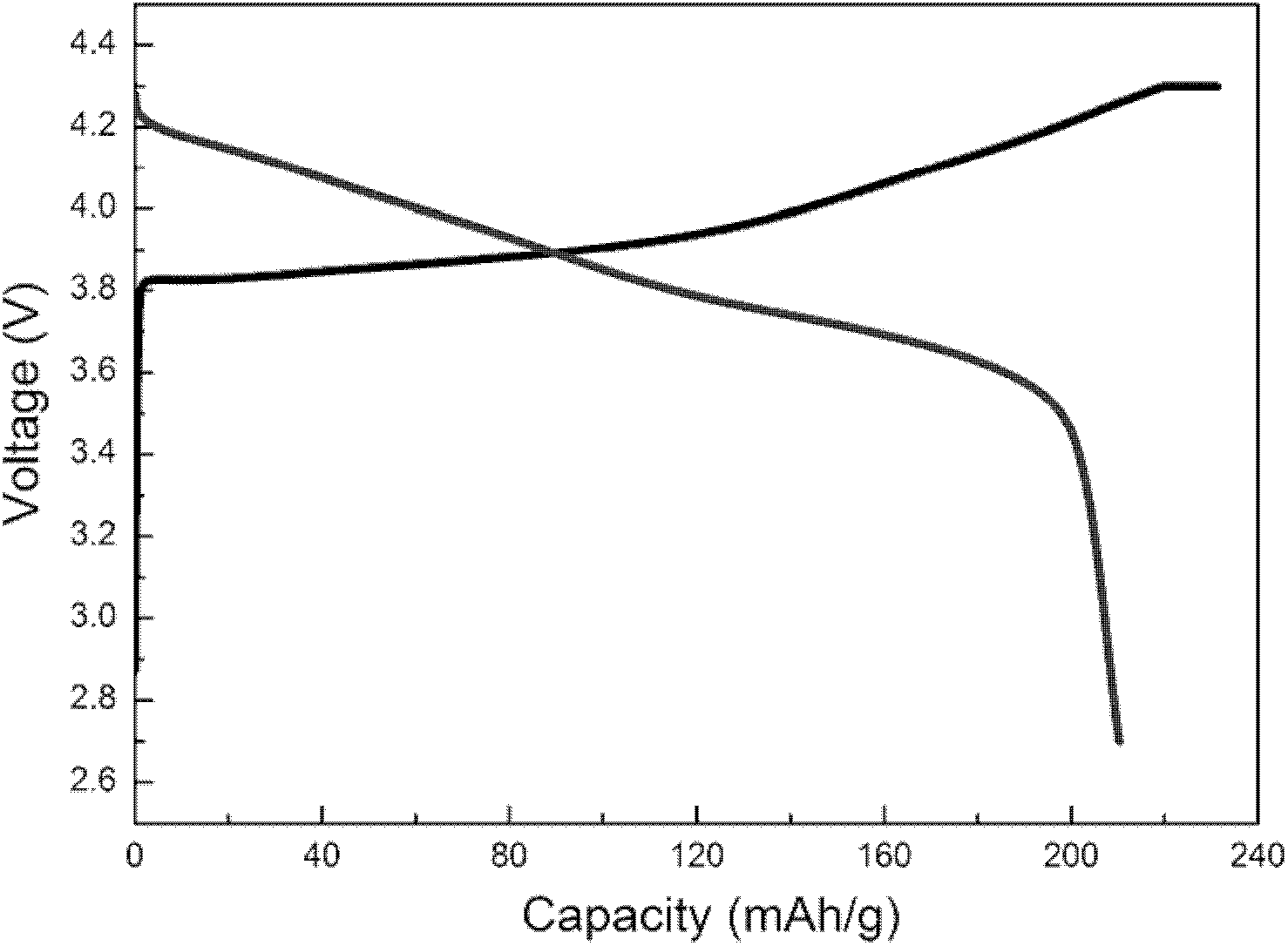

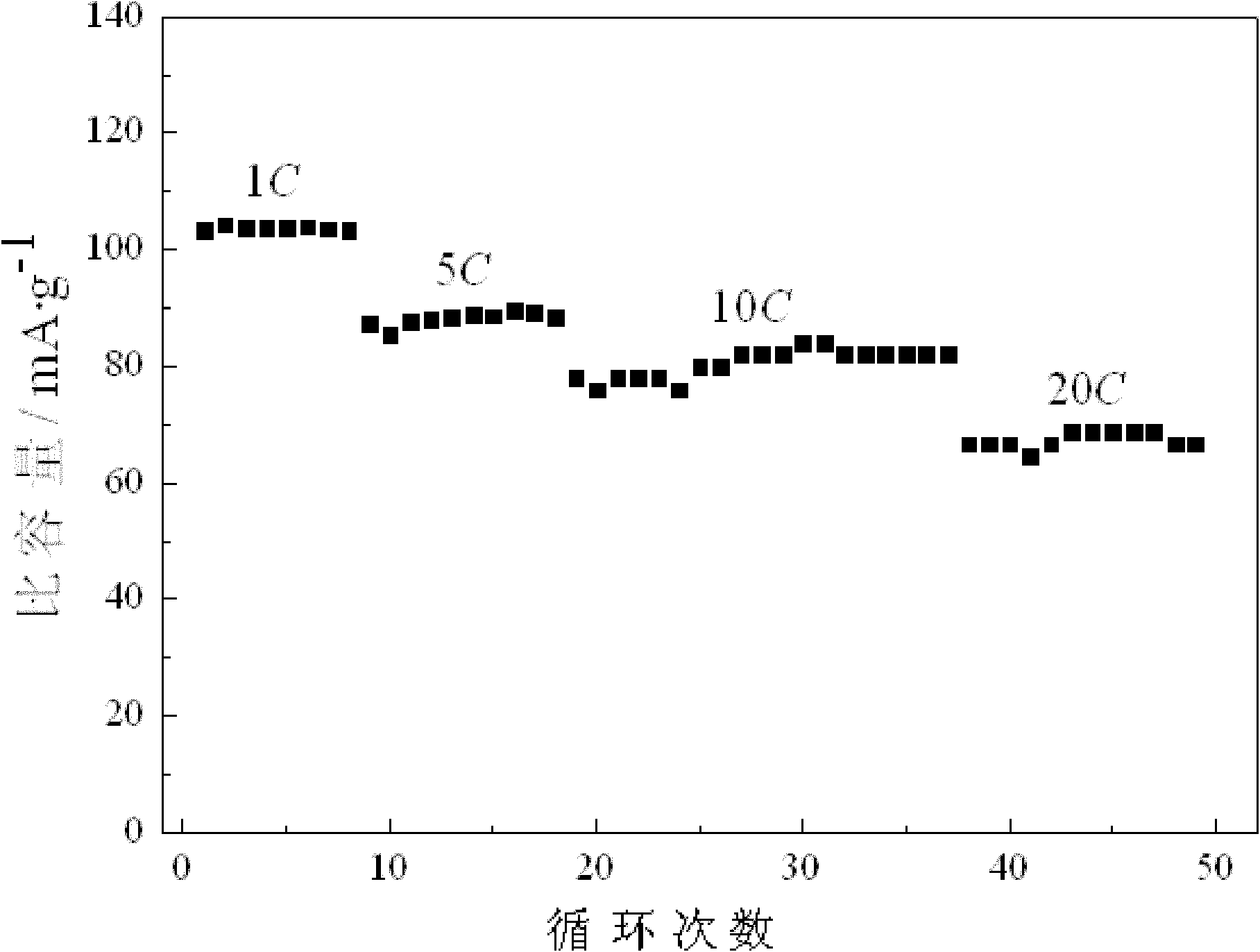

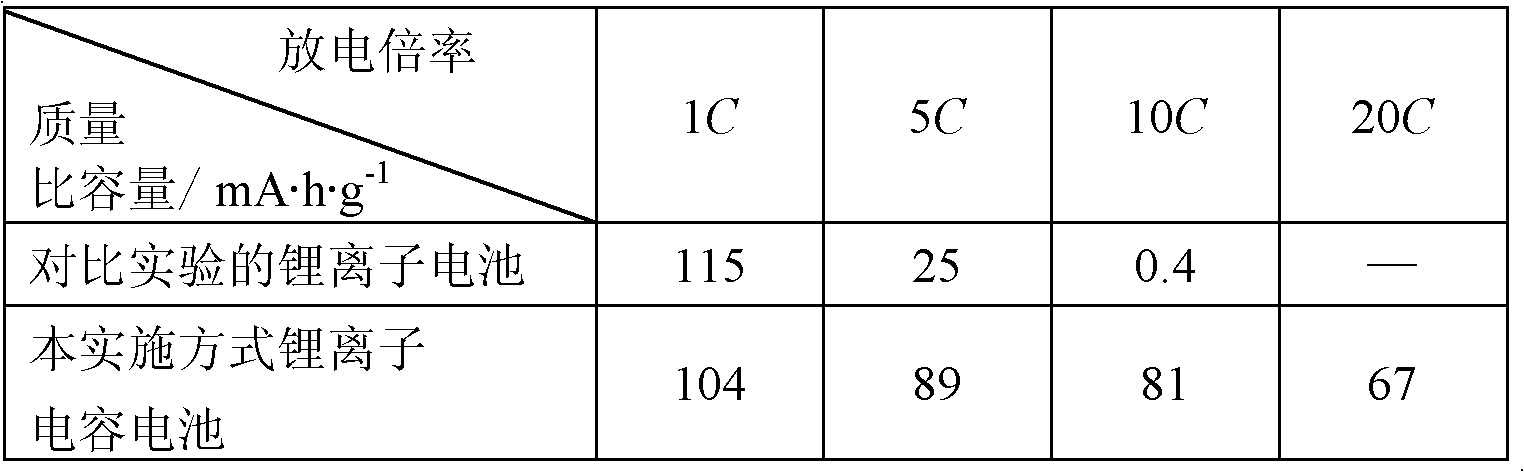

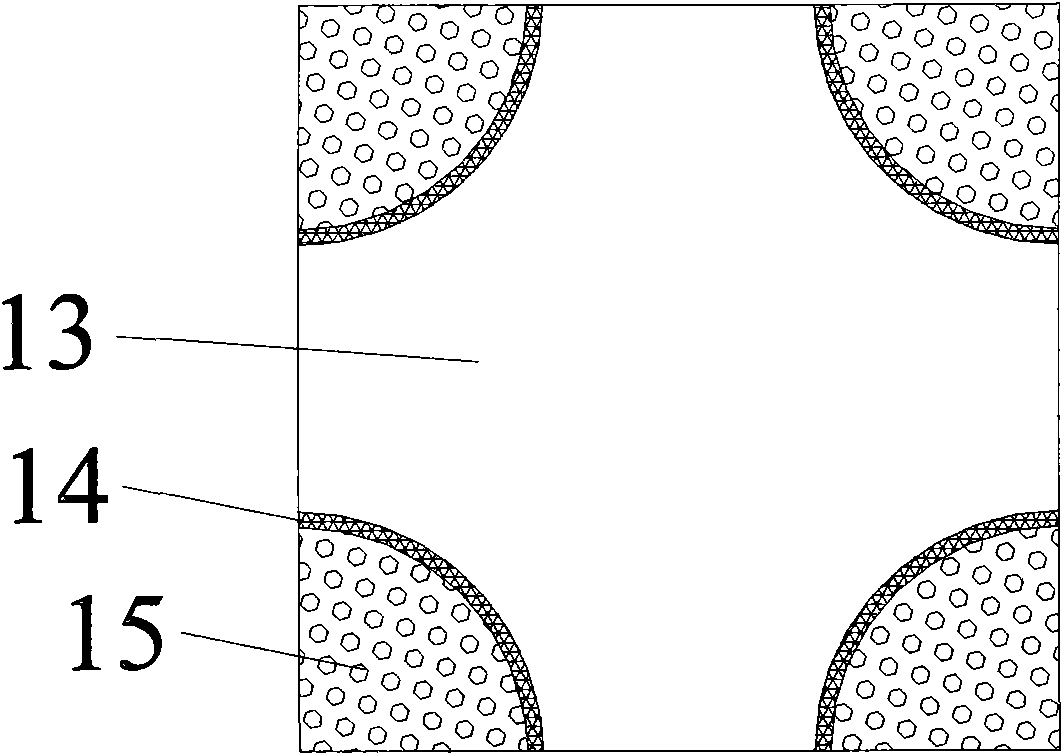

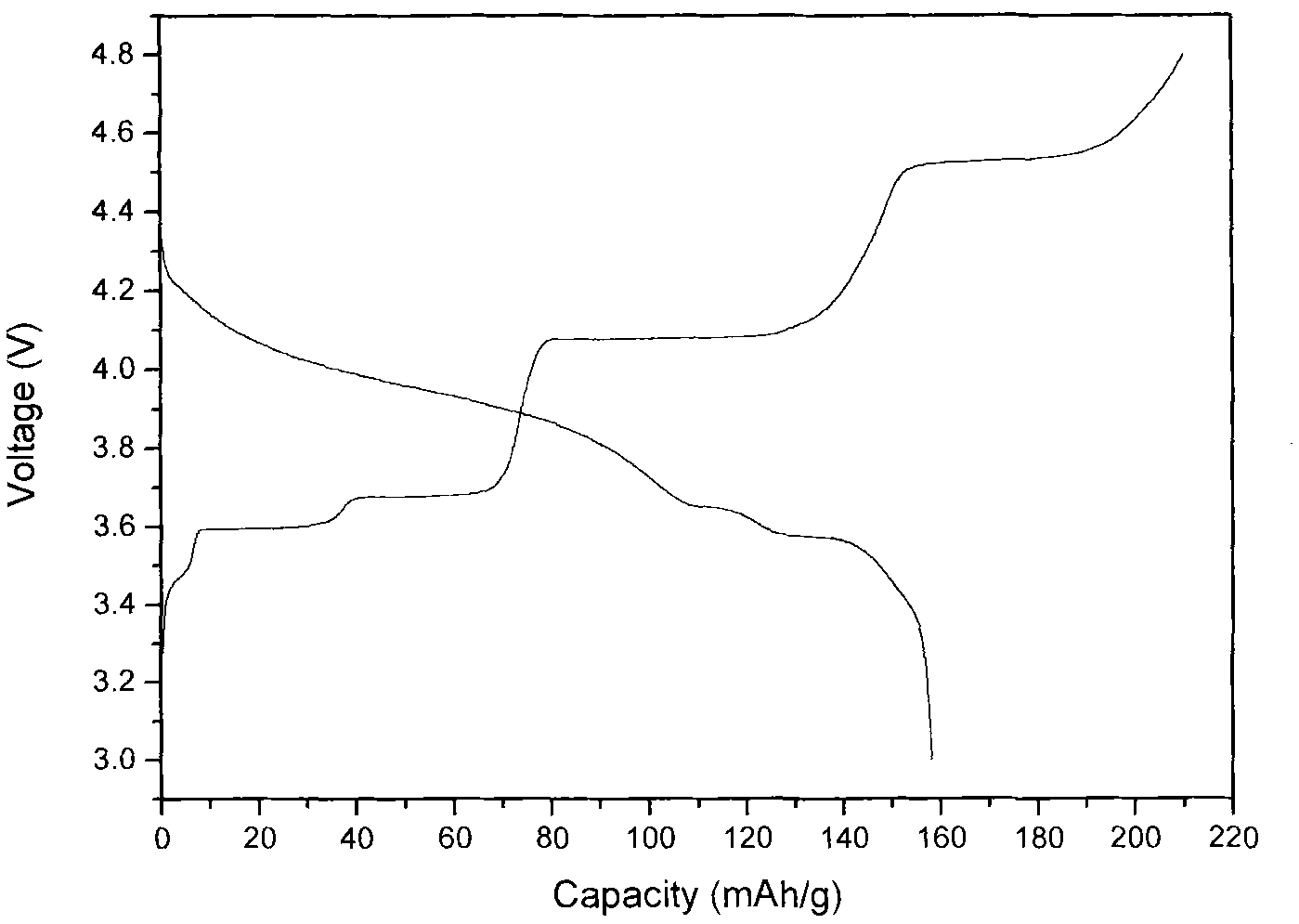

Capacitor carbon/lithium iron phosphate composite material, preparation method thereof and lithium-ion capacitor battery using same as cathode material

InactiveCN101944588AImprove high rate charge and discharge performanceIncrease surface areaElectrolytic capacitorsNon-aqueous electrolyte accumulator electrodesCapacitanceElectrical battery

The invention discloses a capacitor carbon / lithium iron phosphate composite material, a preparation method thereof and a lithium-ion capacitor battery using the same as a cathode material and relates to a lithium iron phosphate material, a preparation method and a lithium-ion capacitor battery using the lithium iron phosphate material as a cathode material, solving the problems of higher preparation cost of the traditional lithium iron phosphate and poor high-magnification charge / discharge properties of the lithium-ion batteries prepared from the traditional lithium iron phosphate. The composite material is formed by loading the lithium iron phosphate on activated carbon. The preparation method comprises the following steps of: preparing a lithium iron phosphate precursor by using a trivalent ferric salt, a phosphorus compound, a lithium source compound and an organic micromolecule carbon source as raw materials; and then mixing the precursor with the activated carbon and sintering. In the invention, the cathode sizing agent of the lithium-ion capacitor battery comprises the capacitor carbon / lithium iron phosphate composite material, a conductive agent and a bonding agent; the particle size distribution of the composite material is uniform; the trivalent ferric salt is used as a raw material, and the cost on the preparation is low; and the capacitor battery has good charge / discharge cycle performances and the mass specific capacity larger than 60mA.h.g<-1> under 20C magnification.

Owner:HARBIN INST OF TECH

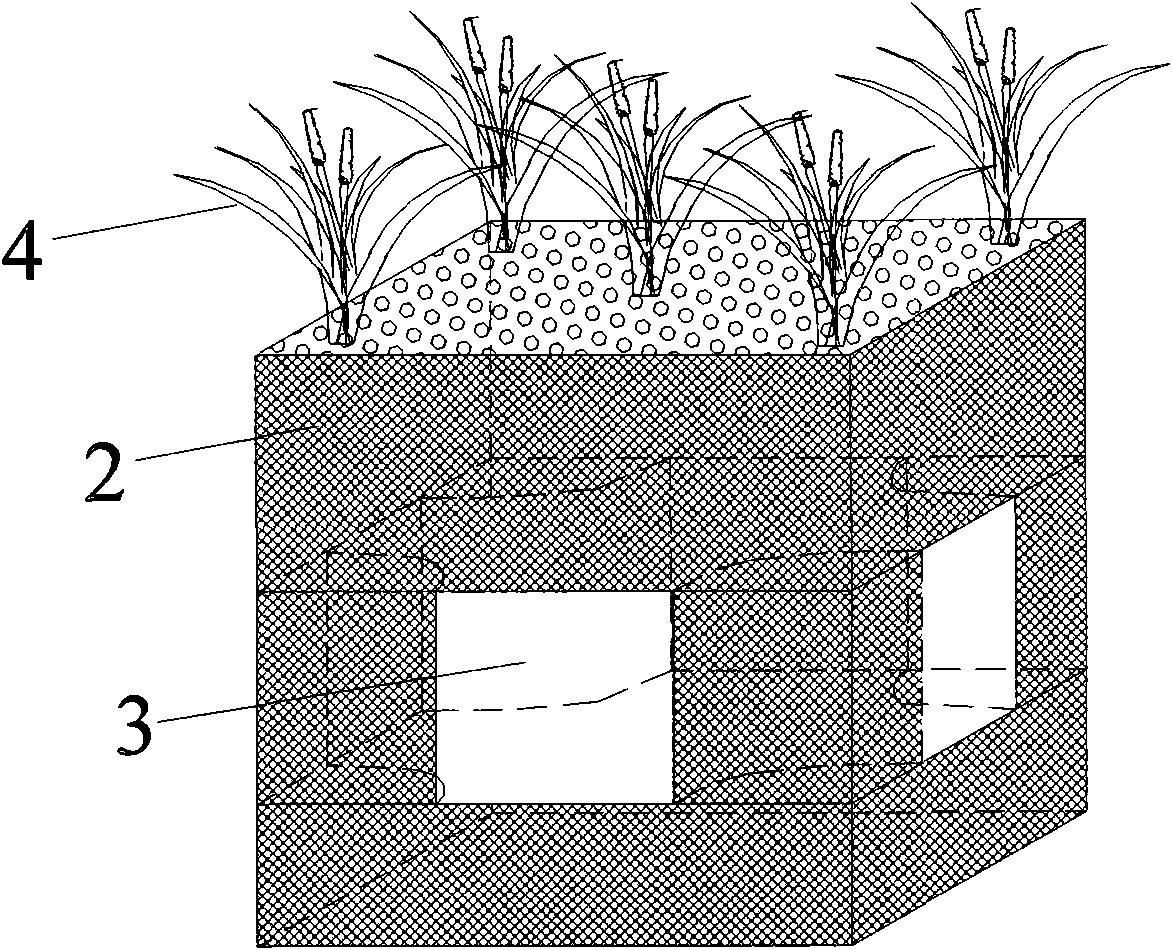

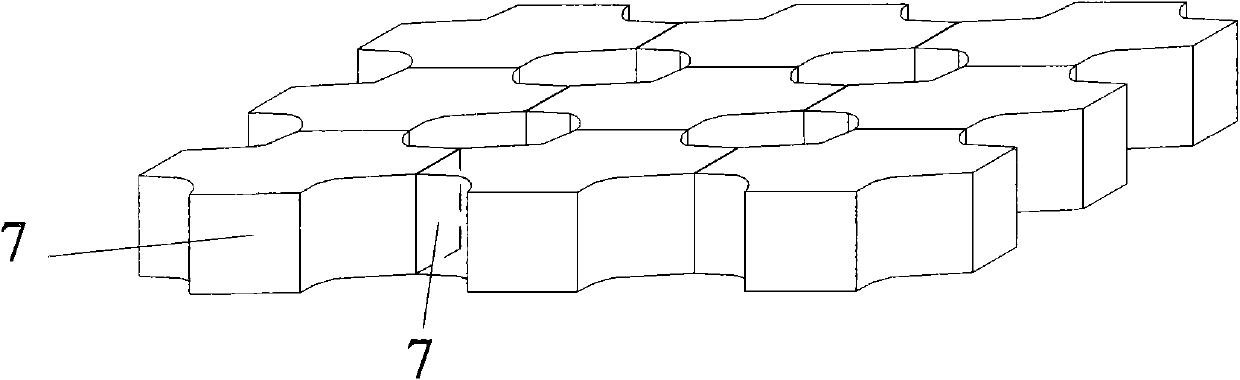

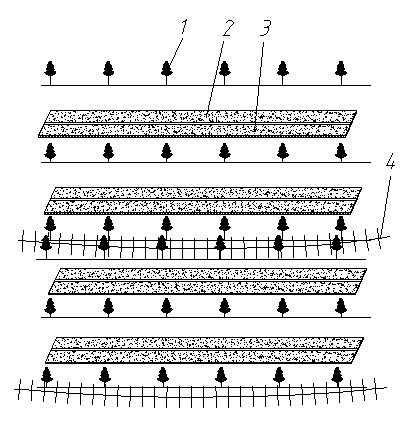

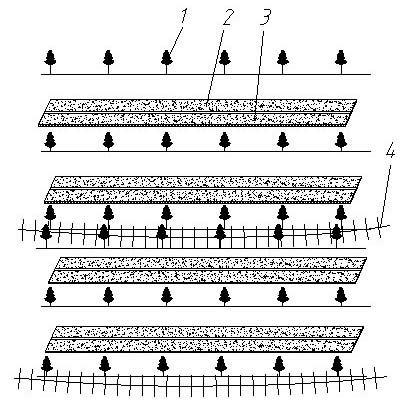

Ecologically adjustable fish reef ecological floating bed device

InactiveCN101905926AFully play the role of metabolismAvoid overgrowthBiological water/sewage treatmentFood chainPlankton

The invention provides an ecologically adjustable fish reef ecological floating bed device. The device comprises a floating bed frame, a plurality of fish reef module units and aquatic plants, wherein each fish reef module unit is connected with one another and fixed by the floating bed frame and comprises a grid and an organism ceramsite layer, a fish reef channel layer and a packing layer which are arranged from top to bottom sequentially and are separated from one another by interlayers; the grids surround around the organism ceramsite layers, the fish reef channel layers and the packing layers and the bottoms of the packing layers respectively; fish reef passages are respectively opened around the fish reef channel layers; holes are opened at the position, corresponding to openings of the fish reef passages, of the grids to make the fish reef channel layers communicate with outside; and the aquatic plants are arranged on the organism ceramsite layers. The device can ensure the normal growth and prevent the overgrowth of the aquatic plants at the same time; and meanwhile, a simple food chain of 'organisms-planktons-fishes' is formed inside the device to improve the purifying capacity of water of the device.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Sweet orange planting method

The invention provides a sweet orange planting method. At a germination stage, 1-1.5kg of a germination fertilizer which is topdressed twice is applied per hole; the germination fertilizer comprises the following raw materials in parts by weight: 15-18 parts of urea, 8-12 parts of ammonium nitrate, 18-20 parts of potassium chloride, 35-45 parts of calcium superphosphate, 20-25 parts of diatomite, 1-2 parts of JT composite bacteria and 20-30 parts of biogas slurry; and at a fruit swelling stage, 3-5kg of a fruit swelling fertilizer, which is topdressed once in ring-shaped ditches with depth of 10-20 cm, is applied per hole; and the fruit swelling fertilizer comprises the following raw materials in parts by weight: 30-35 parts of urea, 40-45 parts of potassium chloride, 25-35 parts of calcium superphosphate, 2-5 parts of magnesium sulfate, 0.1-0.2 part of borax and 20-30 parts of biogas slurry. According to the sweet orange planting method disclosed by the invention, tree growth and fruit swelling needs of sweet orange are met by a proper nitrogen phosphorus potassium ratio; tree seedlings are strong in freezing resistance and resistance to plant diseases and insect pests; and the fruit yield is increased by 15%-20%.

Owner:阮积恩

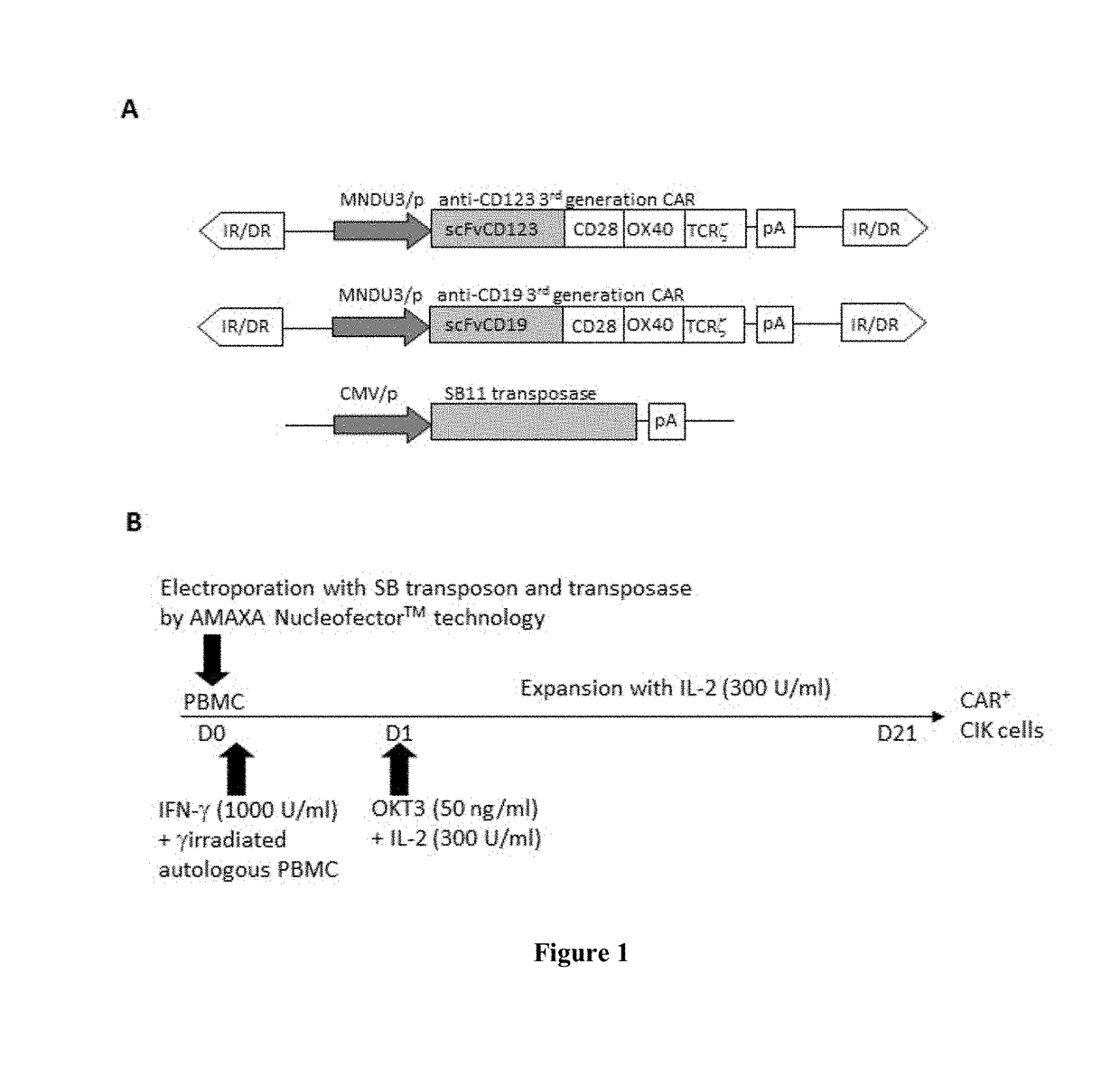

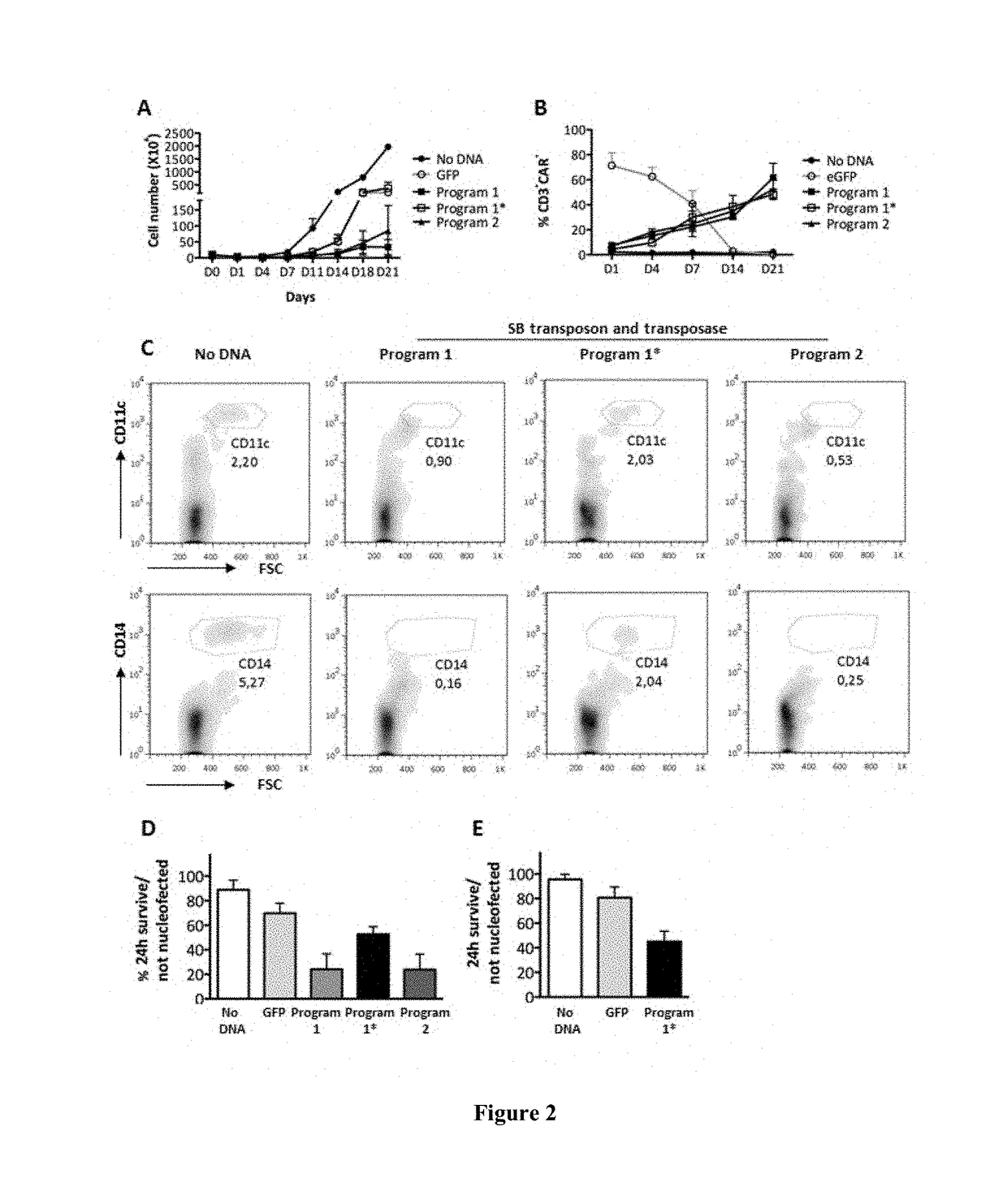

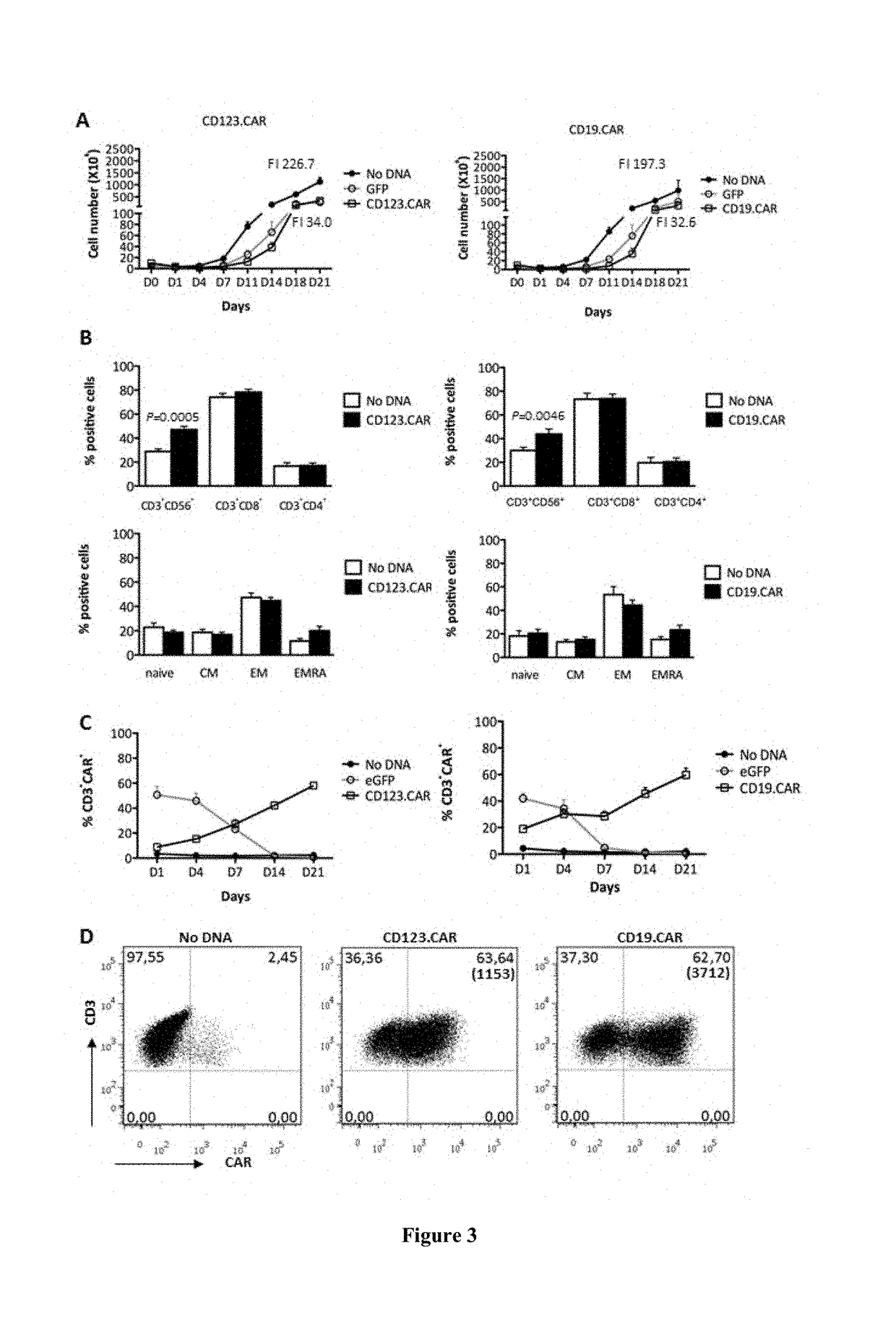

Improved method for the generation of genetically modified cells

ActiveUS20170355957A1Avoid overgrowthLow toxicityPolypeptide with localisation/targeting motifImmunoglobulin superfamilyEffector cellPopulation

The invention provides a method for the improved generation of genetically modified cells in vitro, in order to obtain a population of effector cells with immunotherapeutic activity and methods of using such cells in protocols for adoptive cell therapy. The invention further provides non-viral genetically modified cells, cell populations and cell cultures and the use thereof in the treatment or prevention of diseases and disorders.

Owner:FOND MATILDE TETTAMANTI E MENOTTI DE MARCHI ONLUS

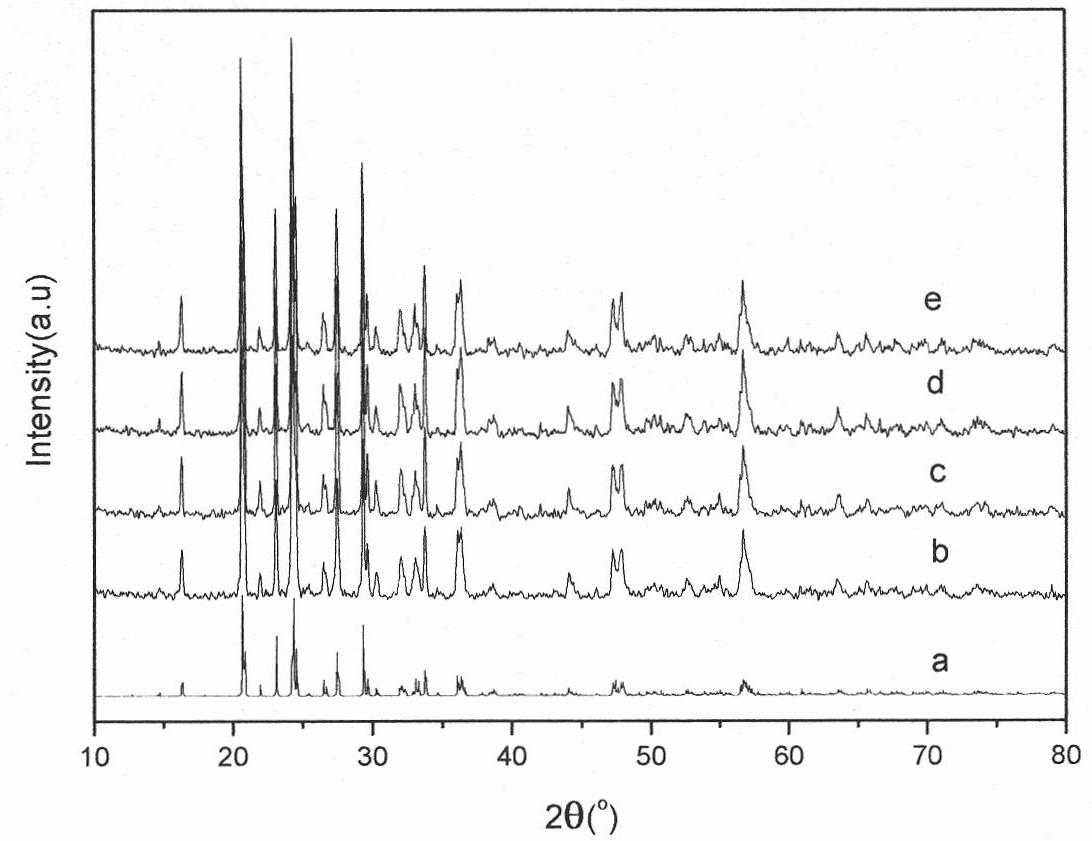

Method for preparing cathode material lithium vanadium phosphate of lithium ion battery by using fast sol-gel method

InactiveCN101841024AAvoid overgrowthGrowth inhibitionCell electrodesCooking & bakingSodium-ion battery

The invention discloses a method for preparing a cathode material lithium vanadium phosphate of a lithium ion battery by using a fast sol-gel method, which specifically comprises the following steps of: (1) adding vanadic oxide into the solution of a reducing acid, heating the mixed solution to 60 to 80 DEG C and stirring the mixed solution for 10 to 50 minutes at a constant temperature to obtain blue solution; (2) adding lithium salts into the blue solution, wherein a stoichiometric ratio of the lithium salts to the vanadic oxide is 3-3.2: 2.9-3.05: 0.95-1.05; (3) treating an obtained powder material in an inert atmosphere at 200 to 400 DEG C for 2 to 4 hours to obtain a precursor; and (4) mixing and grinding uniformly the obtained precursor and another carbon source and cooling the mixture to obtain the cathode material lithium vanadium phosphate of the lithium ion battery. The method has the advantages that: (1) a synthesis process is simplified, the cost is reduced and the method is applied to industrial production; (2) the baking time is greatly shortened, the granularity of the product is reduced and the synthesized material has a nano-size; and (3) the carbon source is mixed before baking, carbon granules also can prohibit the growth of material granules and the synthesized material granules are uniform and fine.

Owner:NANCHANG UNIV

Flue-cured tobacco cultivation method resisting spring drought

The invention relates to a flue-cured tobacco cultivation method resisting spring drought. The method comprises the steps that variety distribution is reasonably planned; ditching and ridging are carried out, and a two-row concave ridge which is 200-240cm in width and 20-25cm in height is implemented; for transplantation, seedlings are transplanted early in good time, transplantation is generally finished during the period from the end of March to the middle ten days of April, the method of a well cellar with the diameter of 8-9cm and the depth of 16-20cm is adopted, and a shovel is utilized for marking out a concave furrow which is 8-10cm in width and 2-3cm in depth on the ridge, so that the well cellar is dug easily, and water is prevented from being wasted; fertilizer is applied according to the equal nitrogen principle, and 30-50% of organic nitrogenous fertilizer is additionally applied to soil for the second time; film mulching is carried out, a film is uniformly compacted through soil in a line-shaped mode, and a gap between the surface of the soil and the film is 0.5-1cm. The method simple and easy to implement is adopted for carrying out flue-cured tobacco cultivation, harm to growth and development of flue-cured tobaccos due to the drought can be reduced, an effective yield increase way is provided for tobacco-growing areas suffering from the drought, the output value is increased, and the economic benefit is increased.

Owner:WEINING COUNTY BRANCH OF BIJIE CITY TOBACCO +1

Sn-Ag-Cu lead-free solder containing Nd, Li, As and In

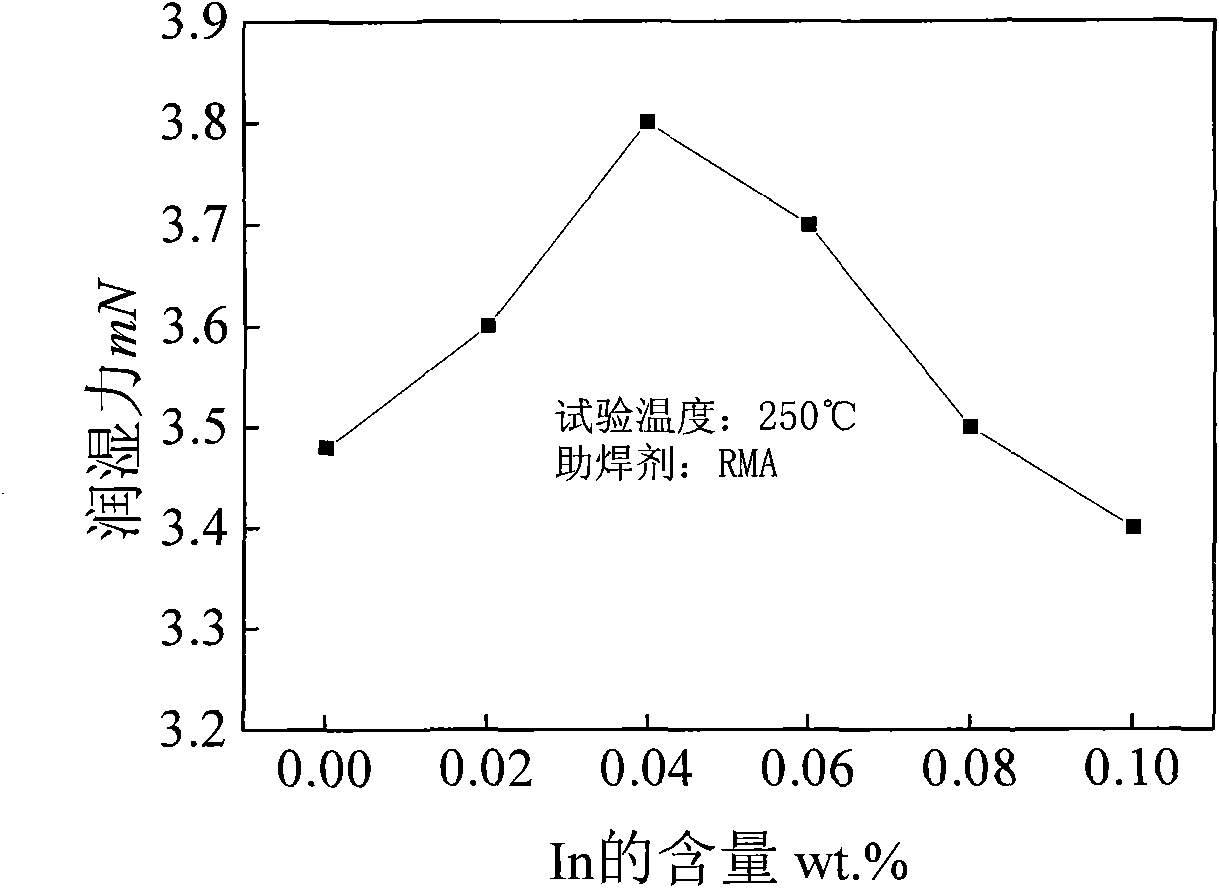

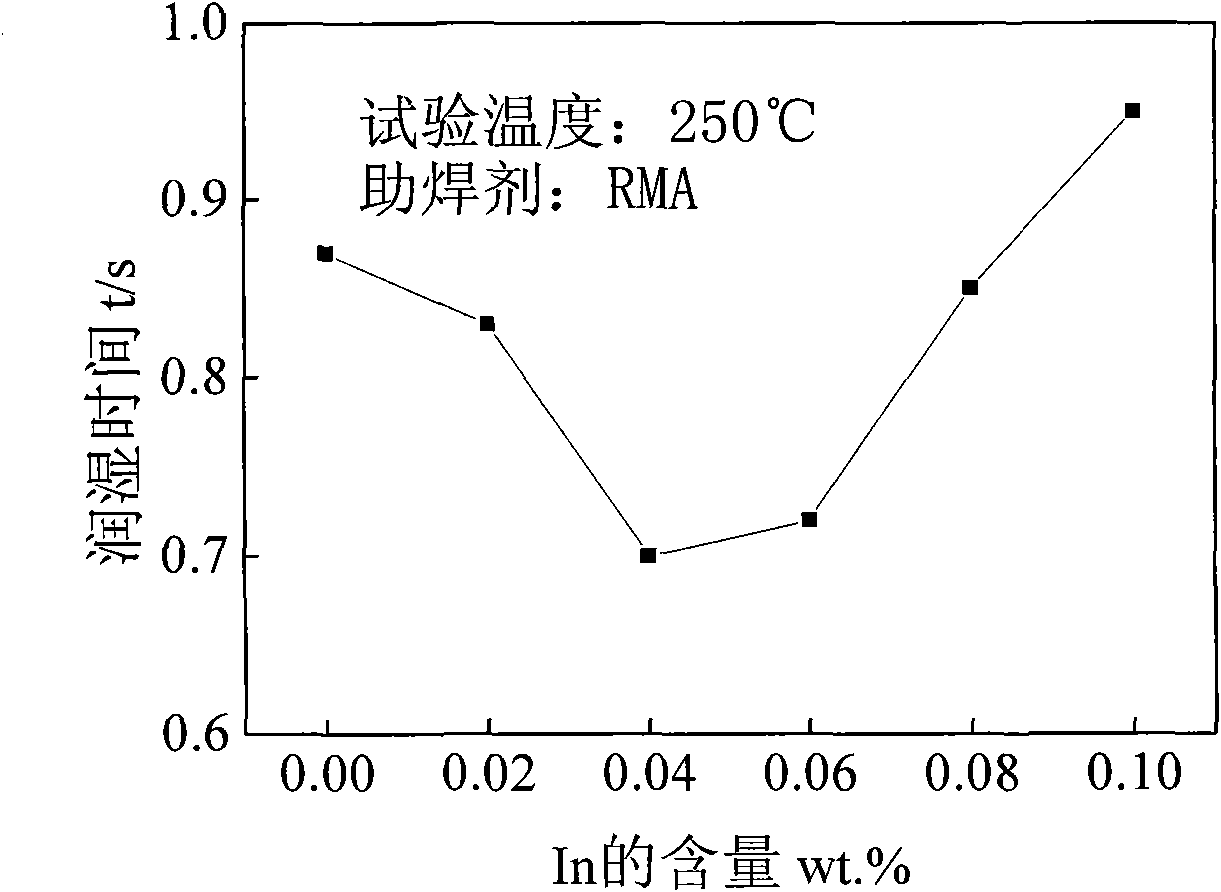

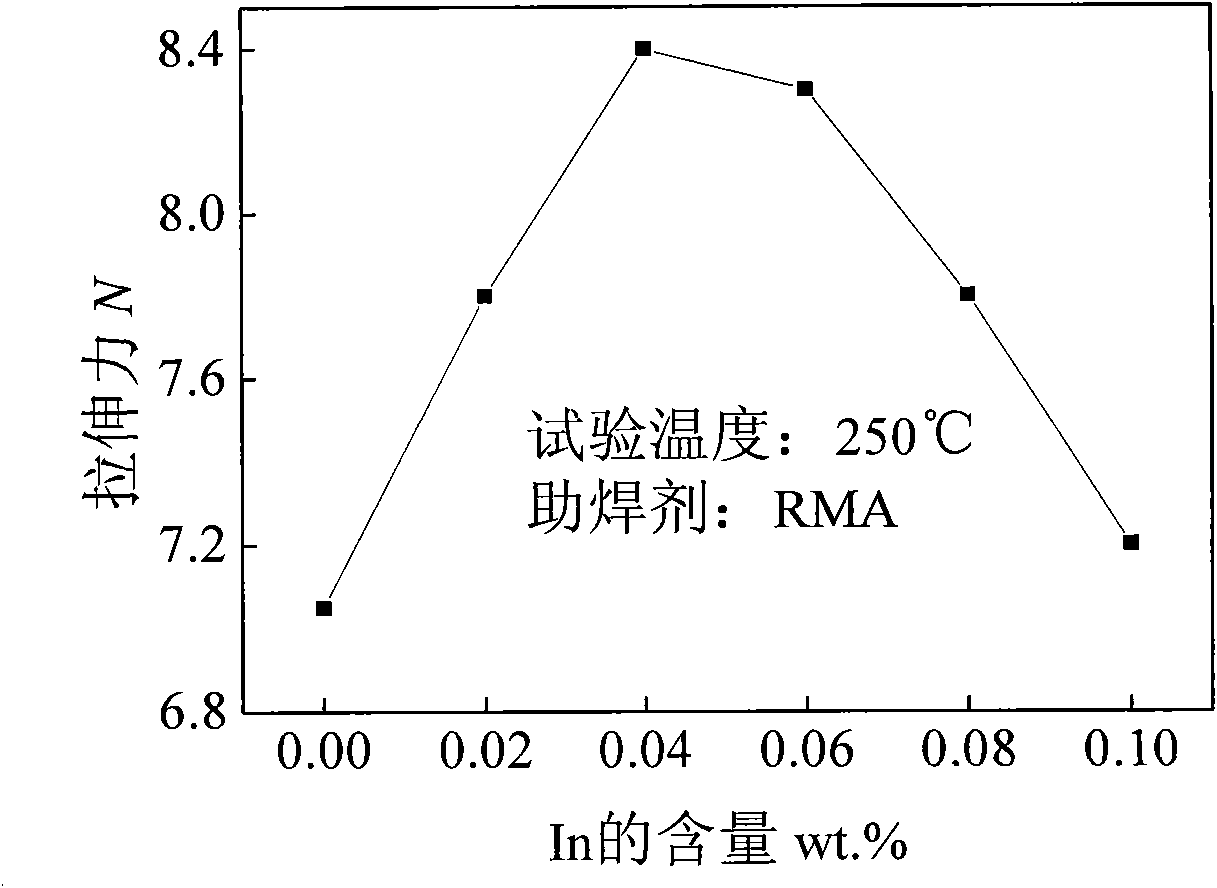

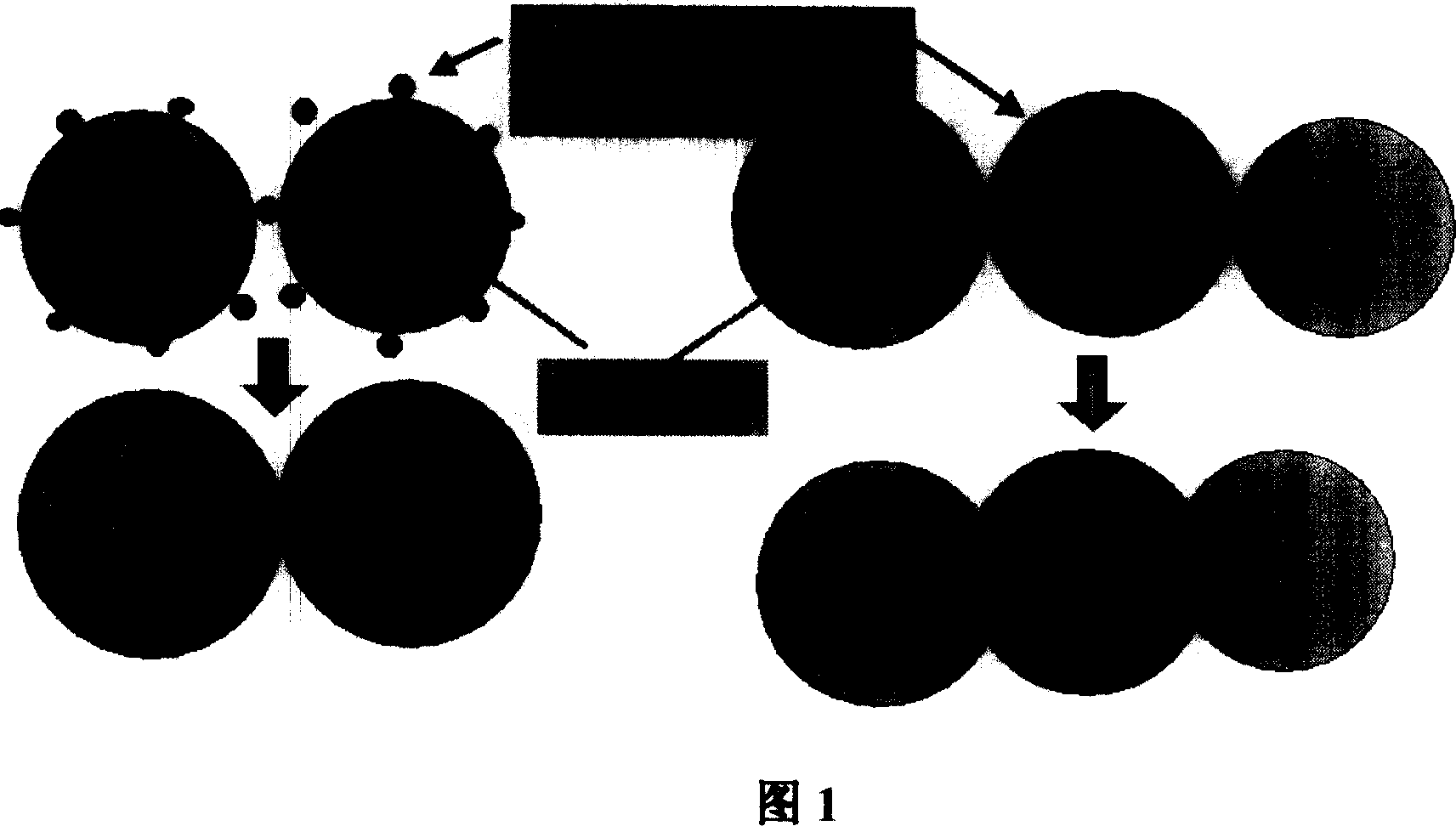

ActiveCN101579790AImprove wettabilityImprove creep resistanceWelding/cutting media/materialsSoldering mediaChemical compositionMetallic materials

The invention relates to a Sn-Ag-Cu lead-free solder containing Nd, Li, As and In, and belongs to soldering materials of metal materials. The solder comprises the following chemical compositions by mass percentage: 0.5 to 4.5 percent of Ag, 0.2 to 1.5 percent of Cu, 0.001 to 0.5 percent of Nd, 0.001 to 0.1 percent of Li, 0.001 to 0.1 percent of As, 0.001 to 0.1 percent of In, 0.001 to 0.1 percent of Pb, and the balance of Sn. The solder has excellent soldering performance (mainly including the wettability), and excellent mechanical property and creep resistant property, and is applicable to wave soldering, reflow soldering and other welding methods in the electronic industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

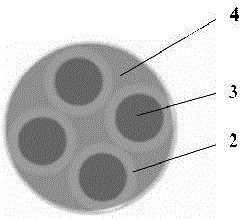

Preparation method of dispersion fuel pellet with high uranium loading capacity

ActiveCN108335760AHigh thermal conductivityHigh retention performanceNuclear energy generationReactor fuel susbtancesCore shellMaterials science

The invention discloses a preparation method of a dispersion fuel pellet with high uranium loading capacity, which comprises the steps of firstly adopting means such as pelleting, self-grinding balling and rolling coating to realize the balling of a uranium-based fuel and the coating with a reinforcing phase, then performing high temperature plasma sintering on a coated ball to obtain the uranium-based fuel pellet; forming a large amount of pores in a core pellet of the fuel by utilizing the volatilization of a pore-forming agent under high temperature, then promoting the low-temperature rapiddensification sintering of the reinforcing phase by combining the high temperature plasma sintering technology and a sintering aid, thus obtaining the dispersion fuel pellet with high uranium loadingcapacity, wherein the dispersion fuel pellet has a special core-shell structure in which the compact reinforcing phase coats the porous fuel core pellet, and the special core-shell structure is loosein the interior and compact in the exterior. The method has the advantages that the preparation is simple and the preparation cost is low, can be used for the scale production of the uranium-based fuel pellet; the uranium-based fuel pellet prepared by the method has the advantages of high thermal conductivity, high safety, high uranium loading capacity and high economy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

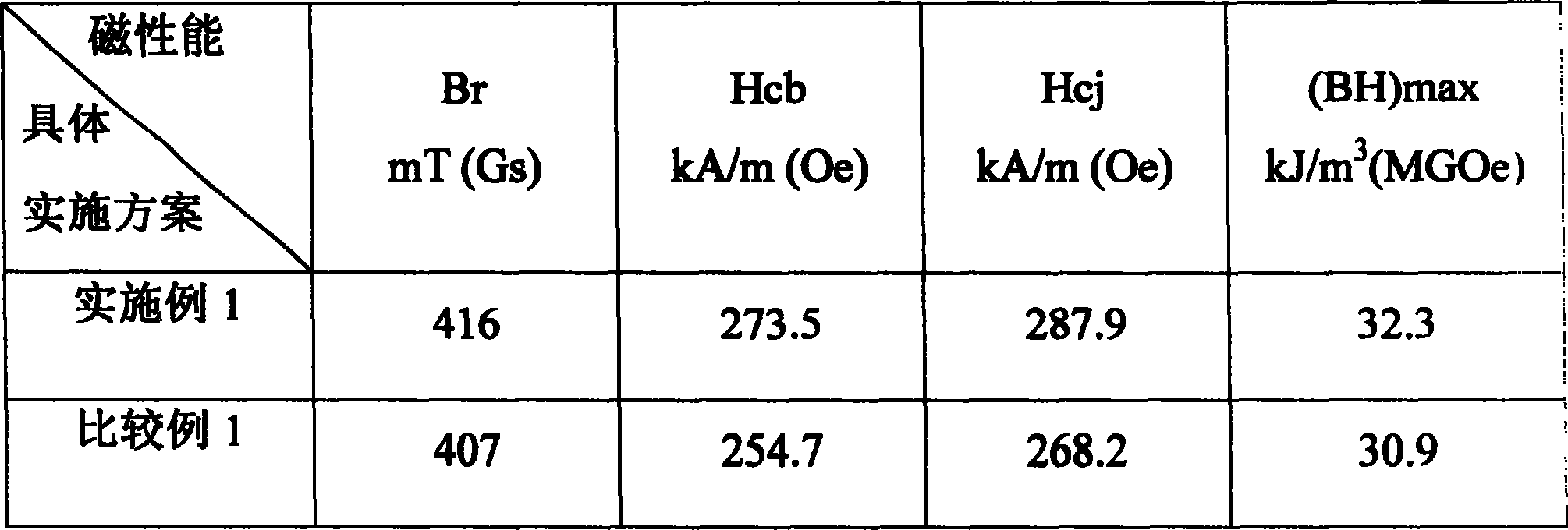

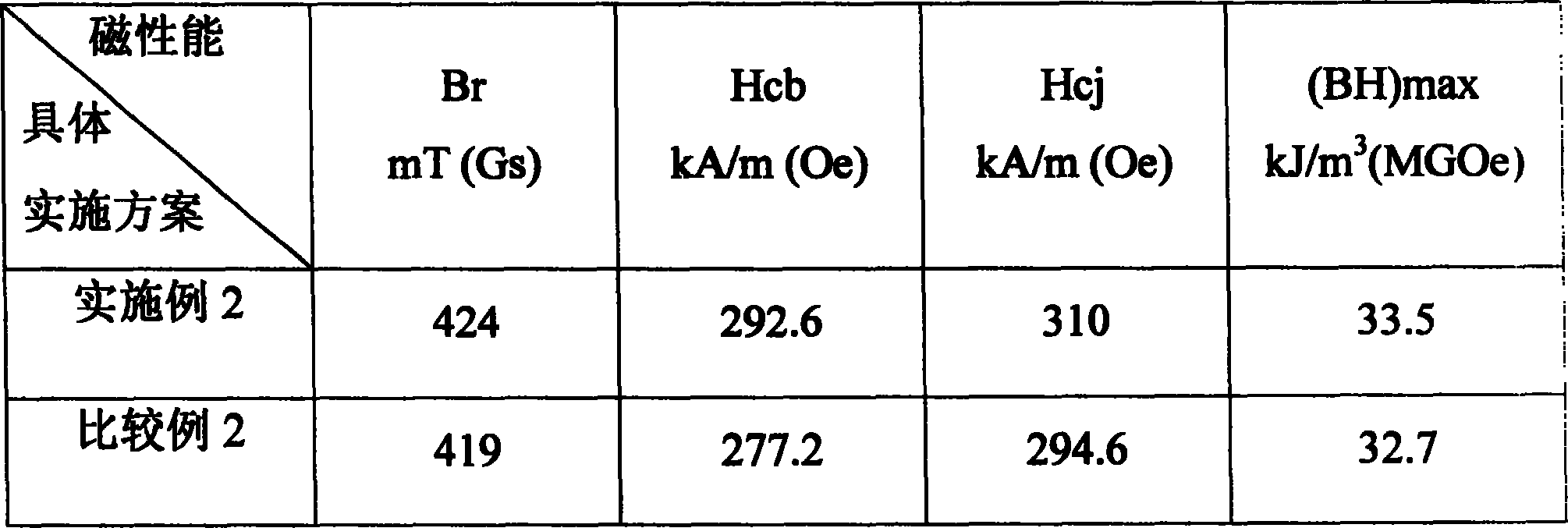

Application of nano material in ferrite

The present invention relates to the application of nano-material in ferrite. The nano-material is an ideal crystal micro-structure 'control agent', and can be partly dissolved on a grain boundary in a solid way; thus the nano-material can effectively reduce the sintering temperature, prevent the excessive growth of ferrite, maintain the ferrite of single domain, and improve the function of density of sintered ferrite at the same time so as to improve the magnetic properties. Besides, the nano-material is a good ''replacement agent of ion''.In the solid-phase reaction, some elements enter the crystallite structure to perfect the crystal structure, so as to further improve saturated magnetic field strength of ferrite and improve the anisotropic constant and other functions of magnetic crystal.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for interplanting cultivation of annulate in orange garden in Three Gorges Reservoir Area

InactiveCN101919337APromote growthReduce pests and diseasesOrganic fertilisersHorticultureDiseaseOrange Tree

The invention discloses a method for the interplanting cultivation of annulate in an orange garden in Three Gorges Reservoir Area, which comprises: (1) spreading a first layer of material in a one-bed two-ridge mode; (2) performing hole sowing; (3) spreading material again in a thickness of 2 to 3 centimeters in places where hole sowing on the first layer of culture material is performed and a thickness of 7 to 8 centimeters in other places; (4) sowing on surface layer again and in holes in the place where the second layer of culture material is 7 to 8 centimeters thick, wherein the stains on the upper and lower corresponding rows are staggered; and (5) covering earth and sealing holes. In the invention, the raw materials of the culture material are cheap or free local crop waste and nutritive soil, so a large amount of agricultural waste can be consumed. The annulate and the orange trees grow complementarily by taking mutual advantages, so both oranges and annulate can be harvested. The annulate can inhibit the weeds from overgrowing, reduce the diseases and insect pests in the orange garden and well promote the growth of the orange trees. And a typical model of sound ecological circulation is built.

Owner:倪九派

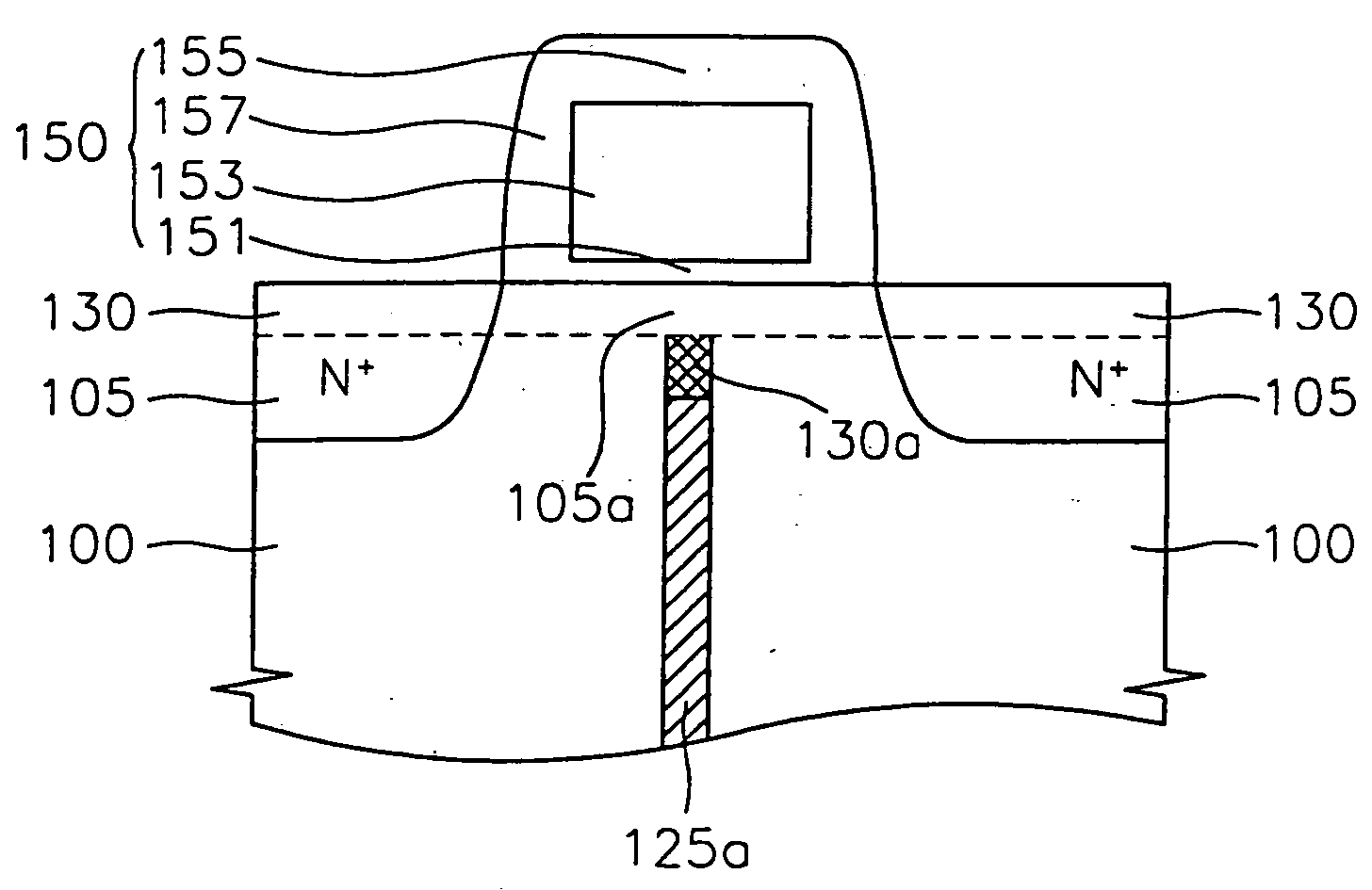

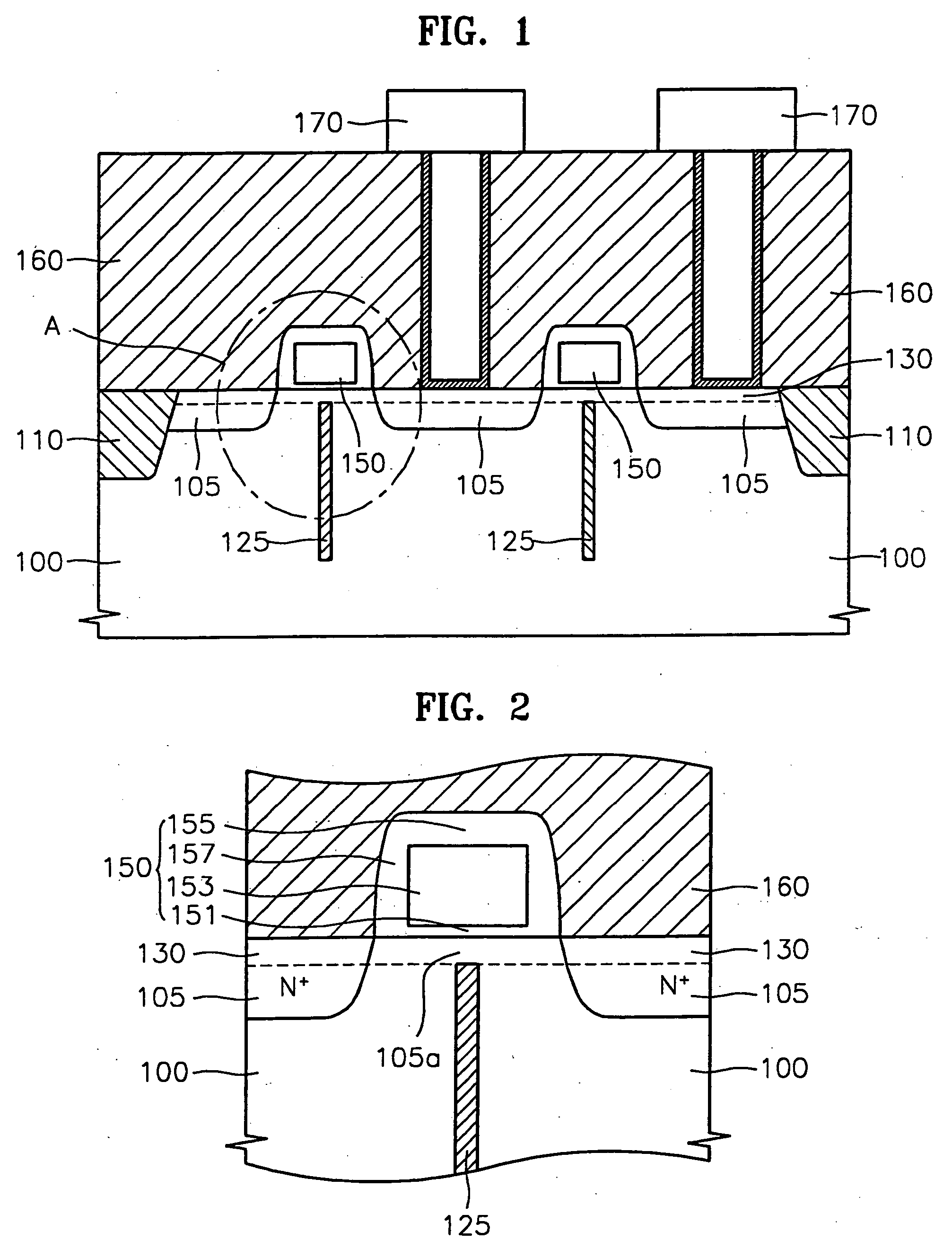

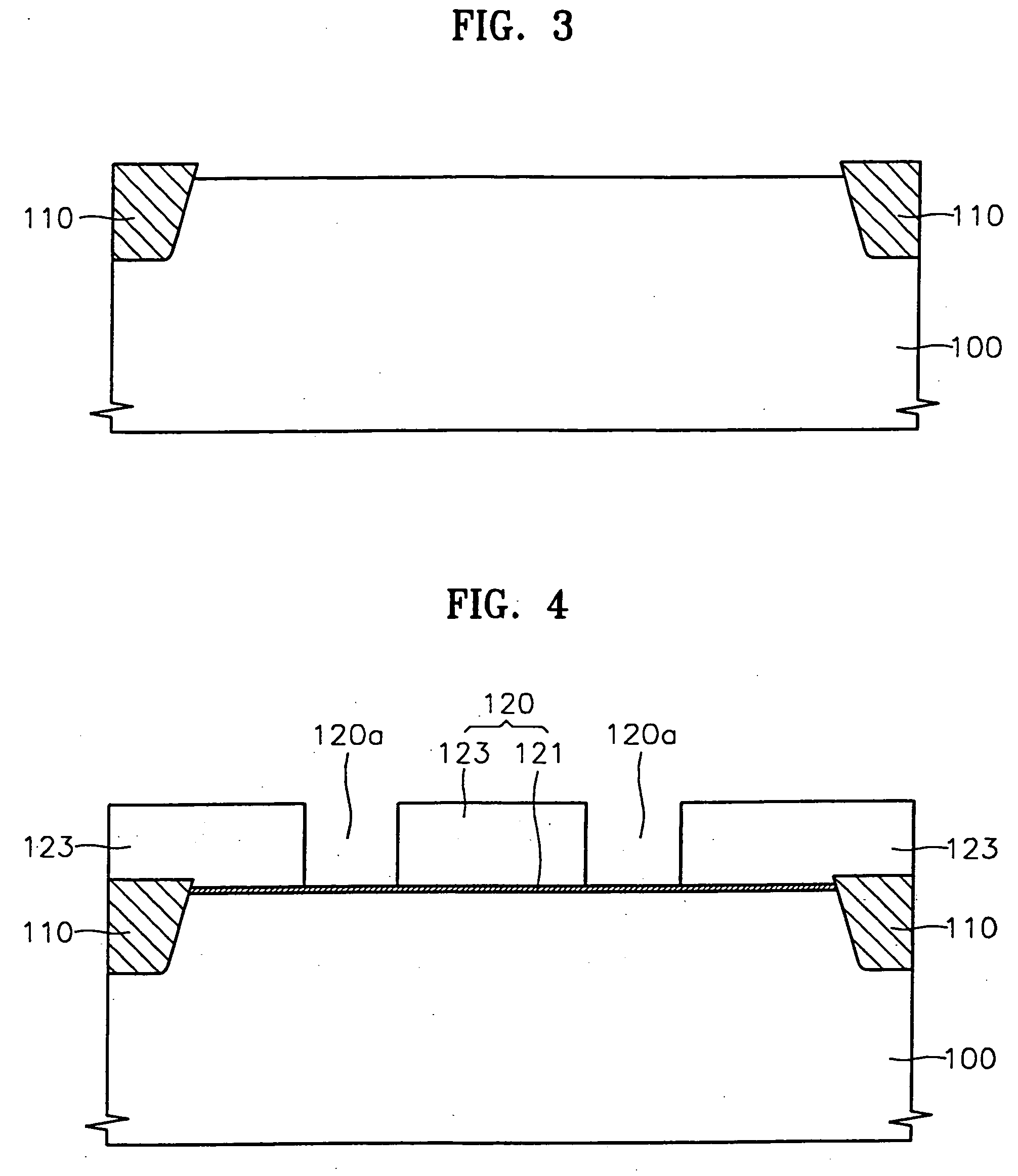

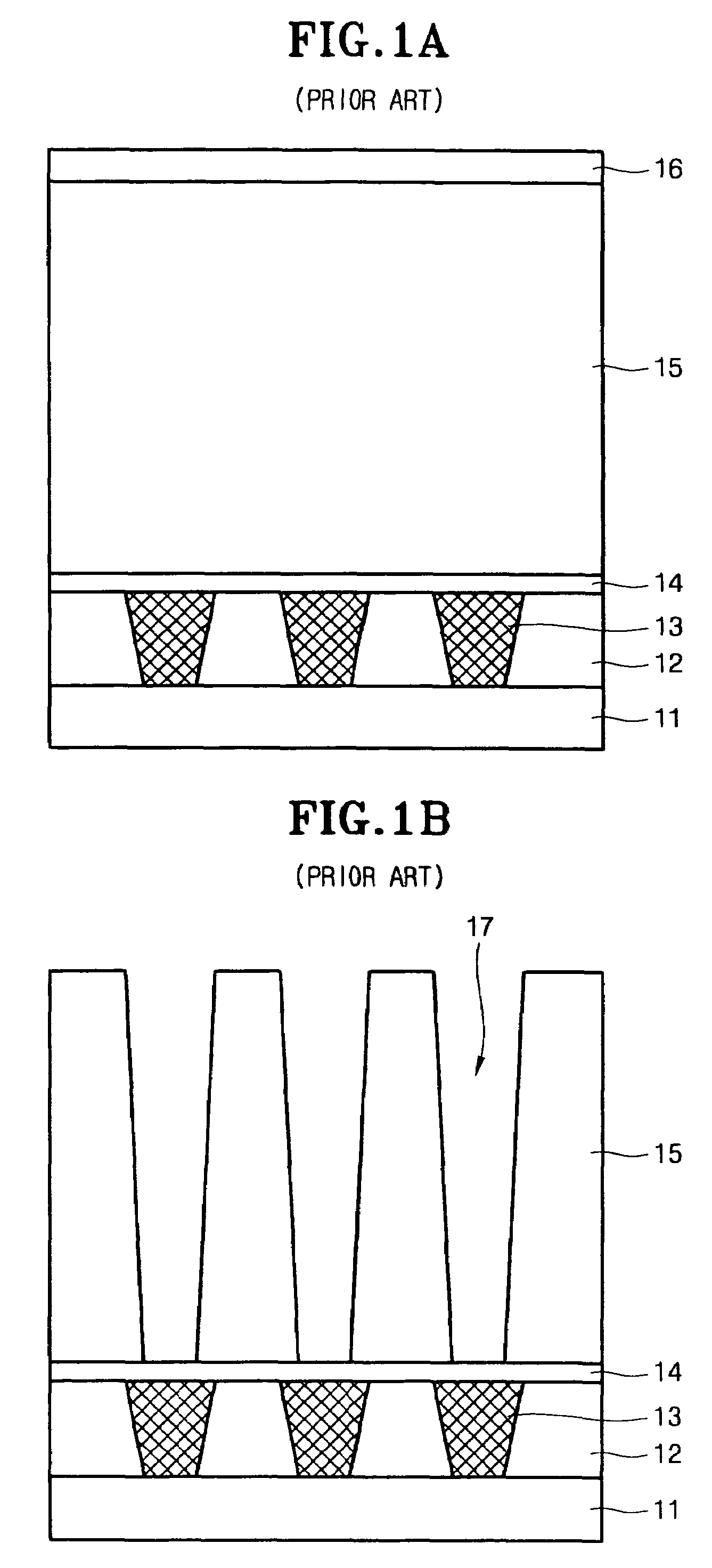

Semiconductor device and method for fabricating the same

InactiveUS20060160295A1Excellent electrical propertiesEffective preventionTransistorSemiconductor/solid-state device detailsDevice materialSemiconductor

A semiconductor device and a method for fabricating the same are provided. The provided semiconductor device includes a field oxide layer formed in a semiconductor substrate to define an active region; gate structures formed on the active region; source / drain junctions formed on either side of the gate structures on the semiconductor substrate; a channel silicon layer arranged under the gate insulating layer to operate as a channel for connecting sources and drains; and buried junction isolation insulating layers under the channel silicon layer. The buried junction isolation insulating layers isolate source / drain junction regions of a MOS transistor, so that a short circuit in a bulk region under the channel of a transistor due to the high-integration of the device can be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

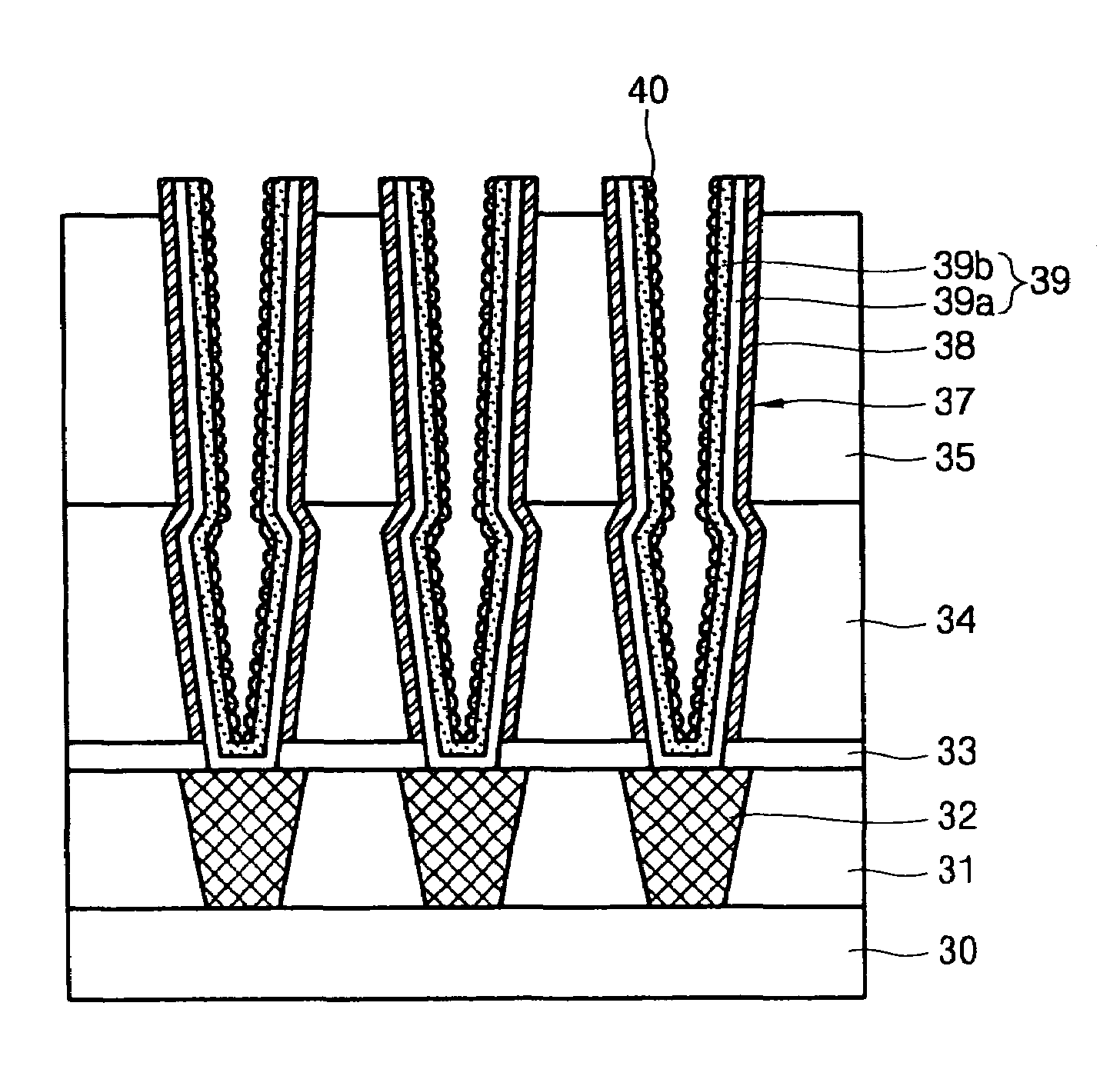

Method for forming capacitor of semiconductor device

InactiveUS7112506B2Increase the effective surface areaAvoid overgrowthTransistorSolid-state devicesNitrideDouble polysilicon

Disclosed is a method for forming a capacitor of a semiconductor device. An etch stop layer, first oxide layer and second oxide layer are sequentially deposited on an insulating interlayer of a substrate. Contact holes through which portions of the etch stop layer are exposed above plugs of the insulating interlayer are formed. The contact holes are cleaned by a cleaning solution having an etching selectivity which is higher for the first oxide layer than for the second oxide layer, thereby enlarging lower portions of the contact holes. A spacer nitride layer is formed on surfaces of the contact holes and the second oxide layer. Portions of the spacer nitride layers located on the second oxide layer and above the plugs together with portions of the etch stop layer located on the plugs are removed. A double polysilicon layer is formed on the spacer nitride layer segments.

Owner:SK HYNIX INC

Planting method for interplanting rhizoma polygonate under pear trees

InactiveCN108040724AAvoid sun exposureImprove survival rateCultivating equipmentsRoot crop cultivationPlant nodulePear tree

The invention discloses a planting method for interplanting rhizoma polygonate under pear trees and relates to the technical filed of planting. The method comprises the steps of land selection, soil loosening, pear tree transplantation, rhizoma polygonate treatment and planting, weeding, fertilization and the like. By adopting the planting method, rhizoma polygonate can be prevented from being insolated, the survival rate of rhizoma polygonate is increased, and accordingly the yield of rhizoma polygonate is increased; the root systems of the pear trees are developed and have root nodule or mycorrhiza, the soil fertility is improved, and the appropriate growth environment can be provided for rhizoma polygonate for a long time; overground parts of pear leaves and rhizoma polygonate plants are treated and can be applied to organic fertilizer for improving the soil quality, waste is sufficiently used, and the yield of the pear trees and rhizoma polygonate is increased; through interplanting of the pear trees and rhizoma polygonate, weed infestation is avoided, the use amount of the weed killer is effectively reduced, and the labor cost is saved.

Owner:渠县新市贡和中草药农民专业合作社

Carbon/carbon composite ultrahigh temperature anti-oxidation coating and preparation process thereof

The invention provides a carbon / carbon composite ultrahigh temperature anti-oxidation coating which is composed of ZrB2, HfC, SiC, TiB2 and Sc2O3 in a certain volume percentage. In addition, the invention also provides a preparation process of the carbon / carbon composite ultrahigh temperature anti-oxidation coating. The process comprises the steps of 1, conducting grinding, polishing, washing and drying on a carbon / carbon composite; 2, conducting ball milling on the ZrB2, the HfC, the SiC, the TiB2, the Sc2O3 and an organic solvent to obtain slurry; 3, coating the slurry on the surface of the carbon / carbon composite to obtain a slurry coating; and 4, sintering the carbon / carbon composite with the slurry coating on the surface by an electron beam, and obtaining the carbon / carbon composite ZrB2-HfC-SiC-TiB2-Sc2O3 coating. The coating prepared according to the process is compact, uniform, good in mechanical property, high in binding strength with a carbon / carbon composite substrate and capable of effectively improving the ultrahigh temperature anti-oxidation performance of the carbon / carbon composite.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

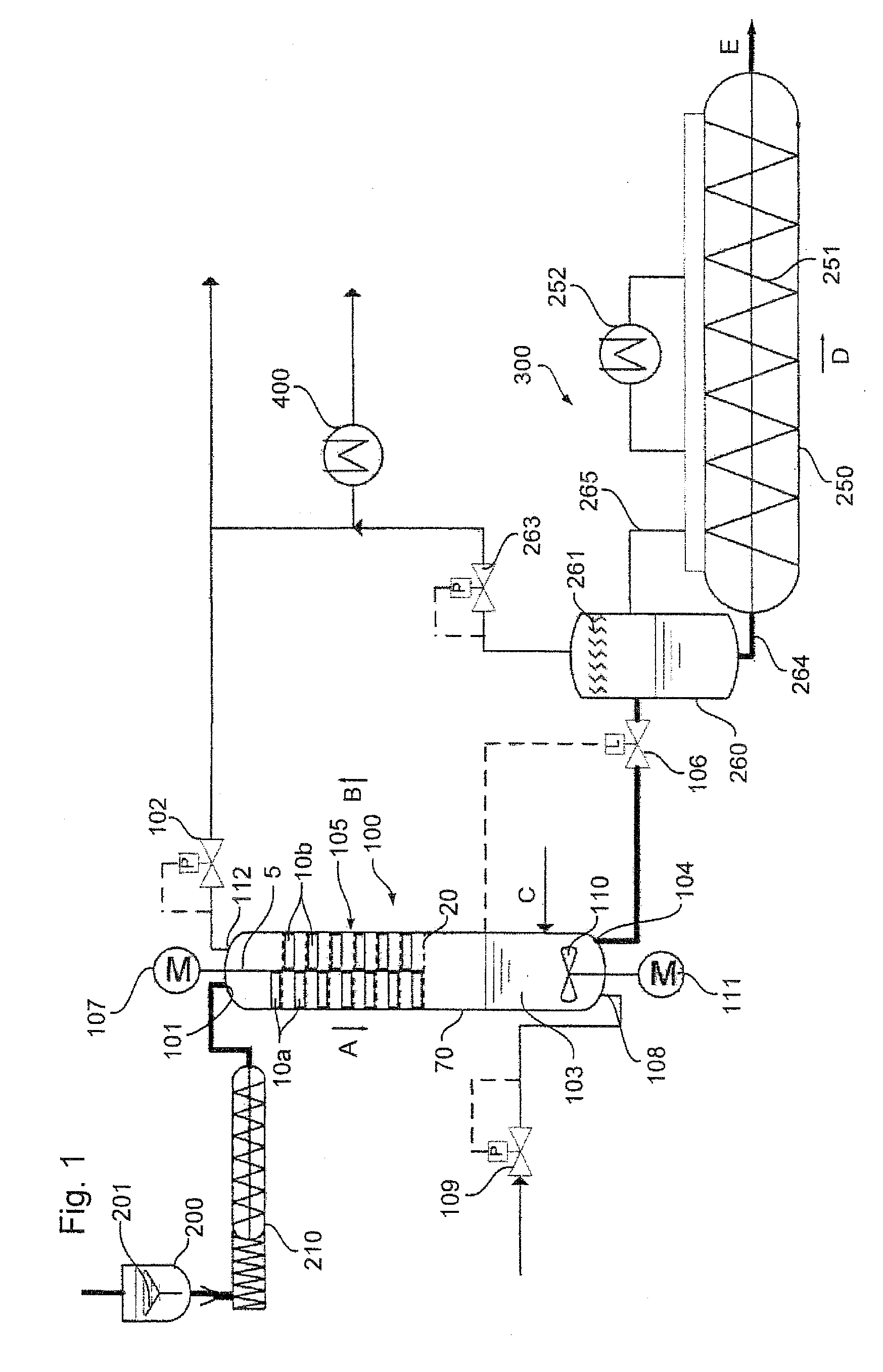

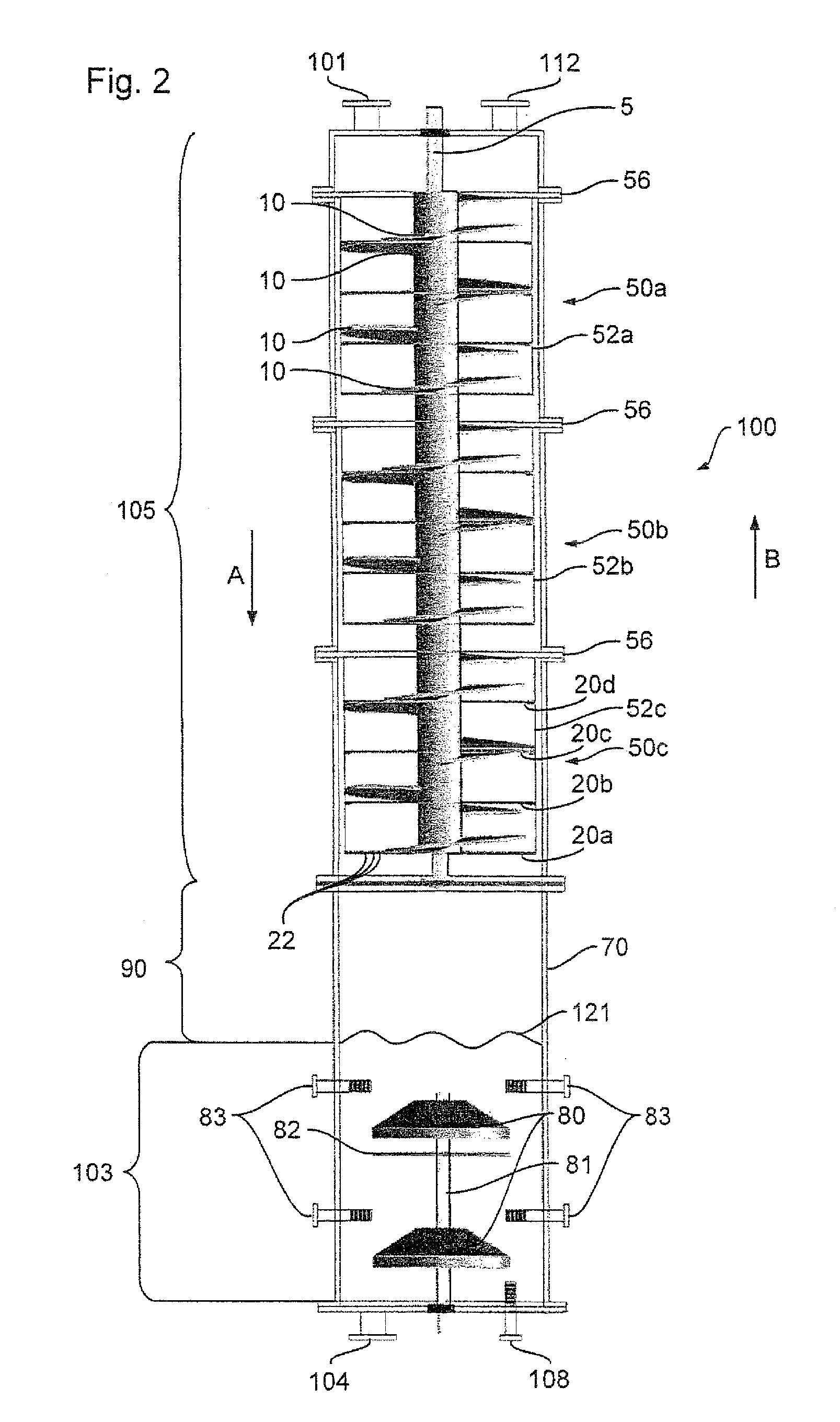

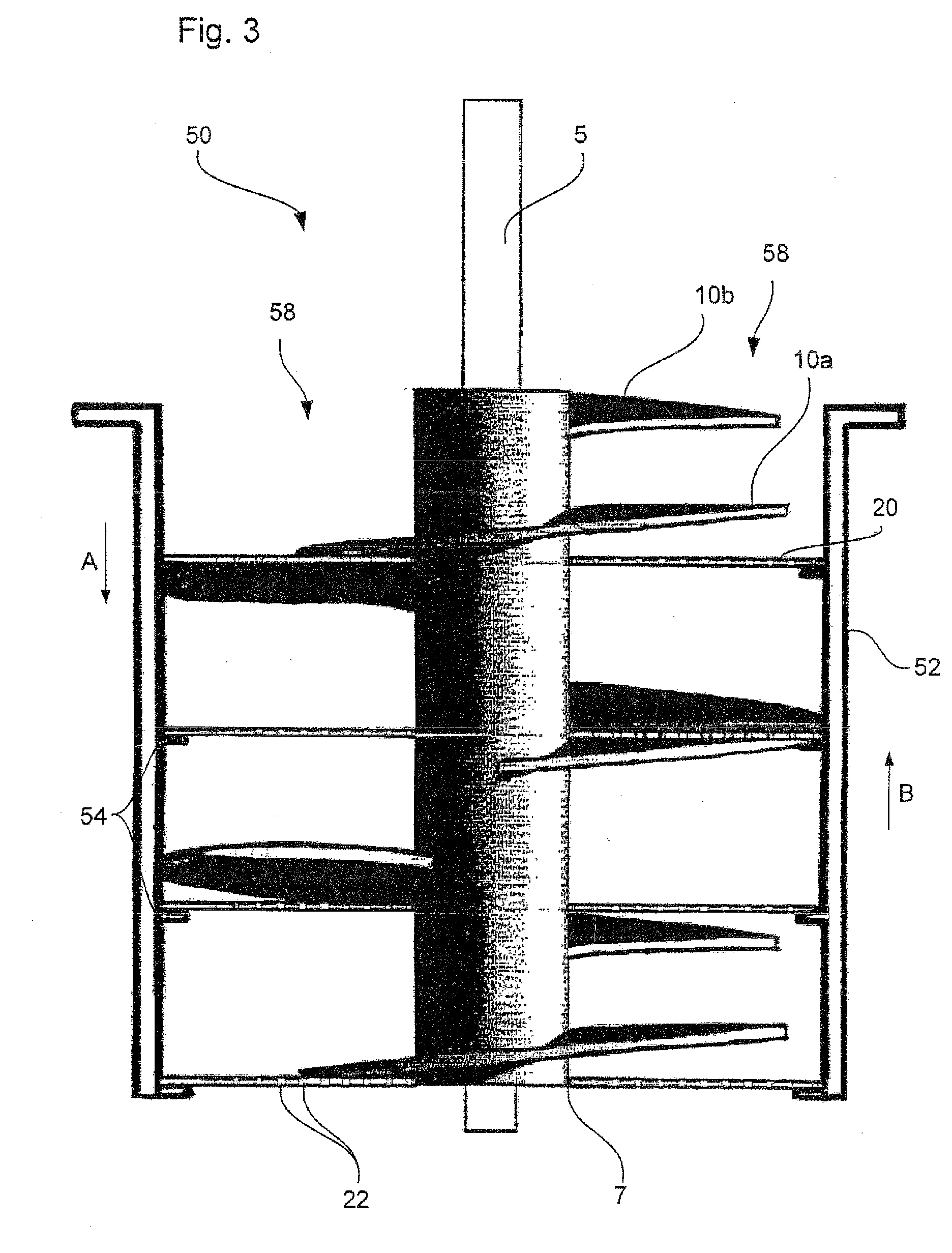

Hydrothermal process for the preparation of coal-like material from biomass and evaporation column

InactiveUS20120000120A1Overgrowth of the column in radial direction can be preventedAvoid overgrowthBiofuelsSolid fuelsEvaporationCoal

The present Invention relates to a hydrothermal process for the preparation of coal-like material from biomass, in which a reaction mixture comprising biomass is heated by contacting with steam, the steam moving counter-currently relative to the reaction mixture, to obtain a reaction mixture comprising activated biomass, and the activated biomass is subsequently polymerized to give a reaction mixture comprising coal-like material. According to another aspect, the present invention relates to a column, preferably a vertically oriented evaporation column, comprising horizontally oriented mass transfer trays, rotor elements mounted on a rotor shaft that is vertically oriented and passes through a rotor shaft opening in the mass transfer trays, and a housing provided with suitable upper and lower inlets and outlets. The column can be used with benefit in the hydrothermal process of the invention. The process is advantageous in that it allows the quick, energy-efficient and stable production of high-quality coal-like material.

Owner:CARBON SOLUTIONS

Multicomponent composite fertilizer special for peanuts

InactiveCN101709012AImprove immunityPrevent regenerationFertilizer mixturesDiseaseContinuous cropping

The invention discloses a multicomponent composite fertilizer special for peanuts, which belongs to a crop fertilizer. The multicomponent composite fertilizer special for peanuts comprises the following components: 35 percent of total nutrients including 16 percent of nitrogen, 10 percent of phosphorus and 9 percent potassium, more than or equal to 10 percent of medium and trace elements, 7-9 percent of organic matter and 2-5 percent of amino acid. The medium and trace elements comprise trace elements including molybdenum, zinc, manganese, boron and iron. The multicomponent composite fertilizer special for peanuts has the advantages of nutrient content assurance and reasonable proportioning balance. The multicomponent composite fertilizer special for peanuts can effectively improve the immunological competence of the peanuts, regulate endogenous hormone, inhibit the regeneration of insect eggs, activate the activity of root azotobacter, promote root development, quicken nutrient absorption, achieve the functions of strengthening seedlings, promoting growth and promoting flowering, prevent bacterial wilt, continuous cropping symptoms and leaf spots, also prevent excessive growth and take special effect on symptoms including mosaic disease, chlorotic disorder, flocculi, defoliation and the like. After applied, the multicomponent composite fertilizer special for peanuts can effectively improve the percentage of fertile fruits and the thousand grain weight, promote the mellow and full degrees of fruits and achieve remarkable effect of production increase.

Owner:江苏心实肥业集团有限公司

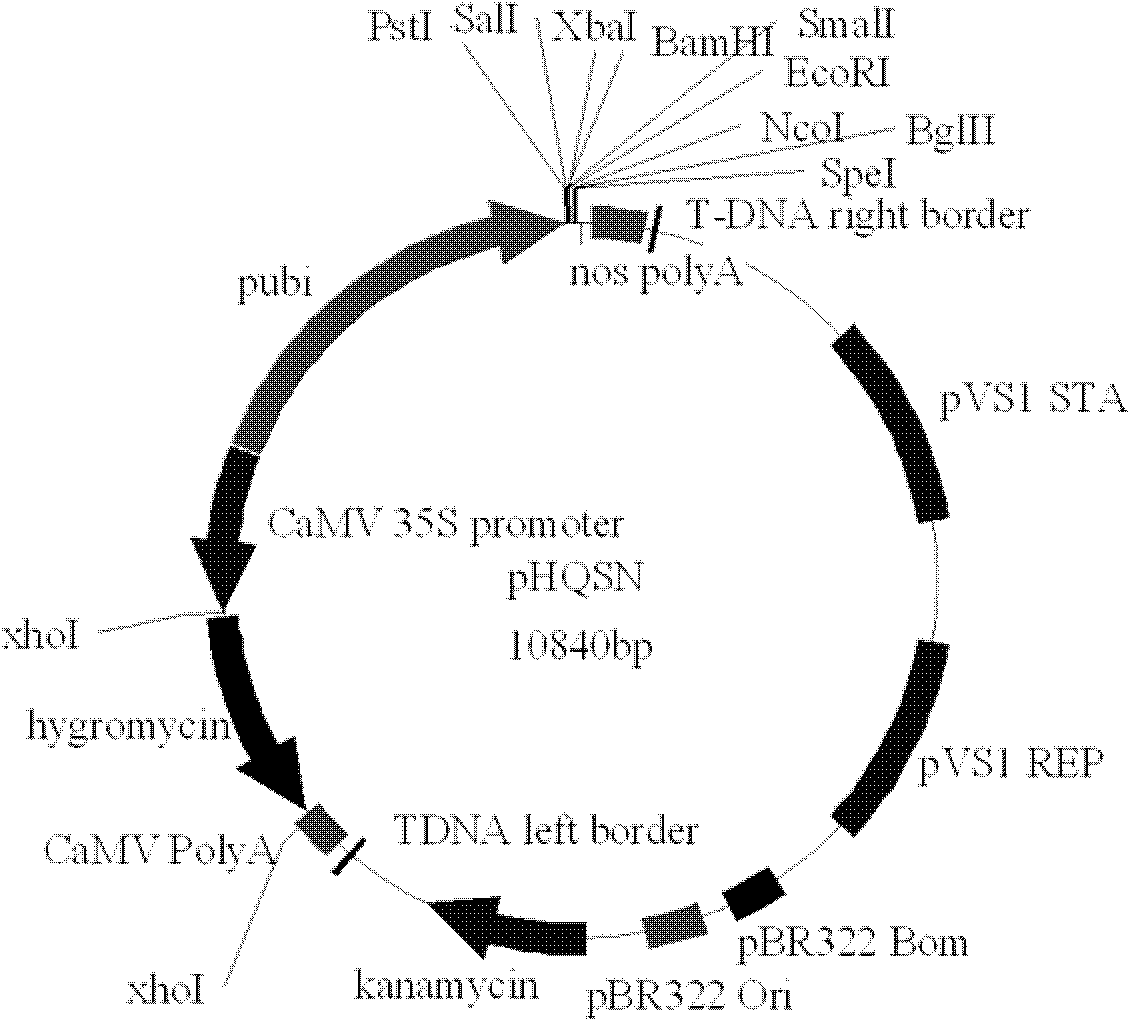

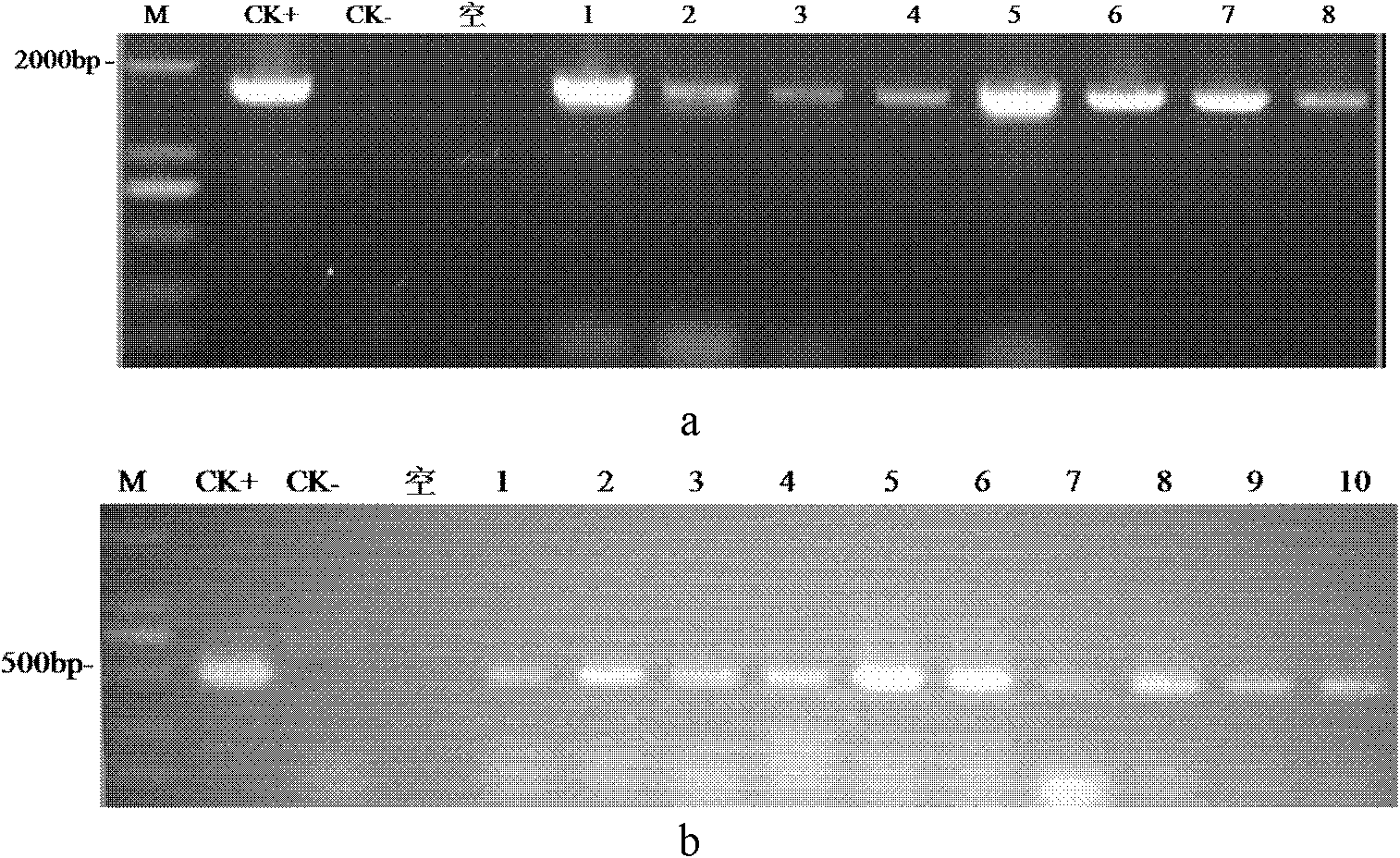

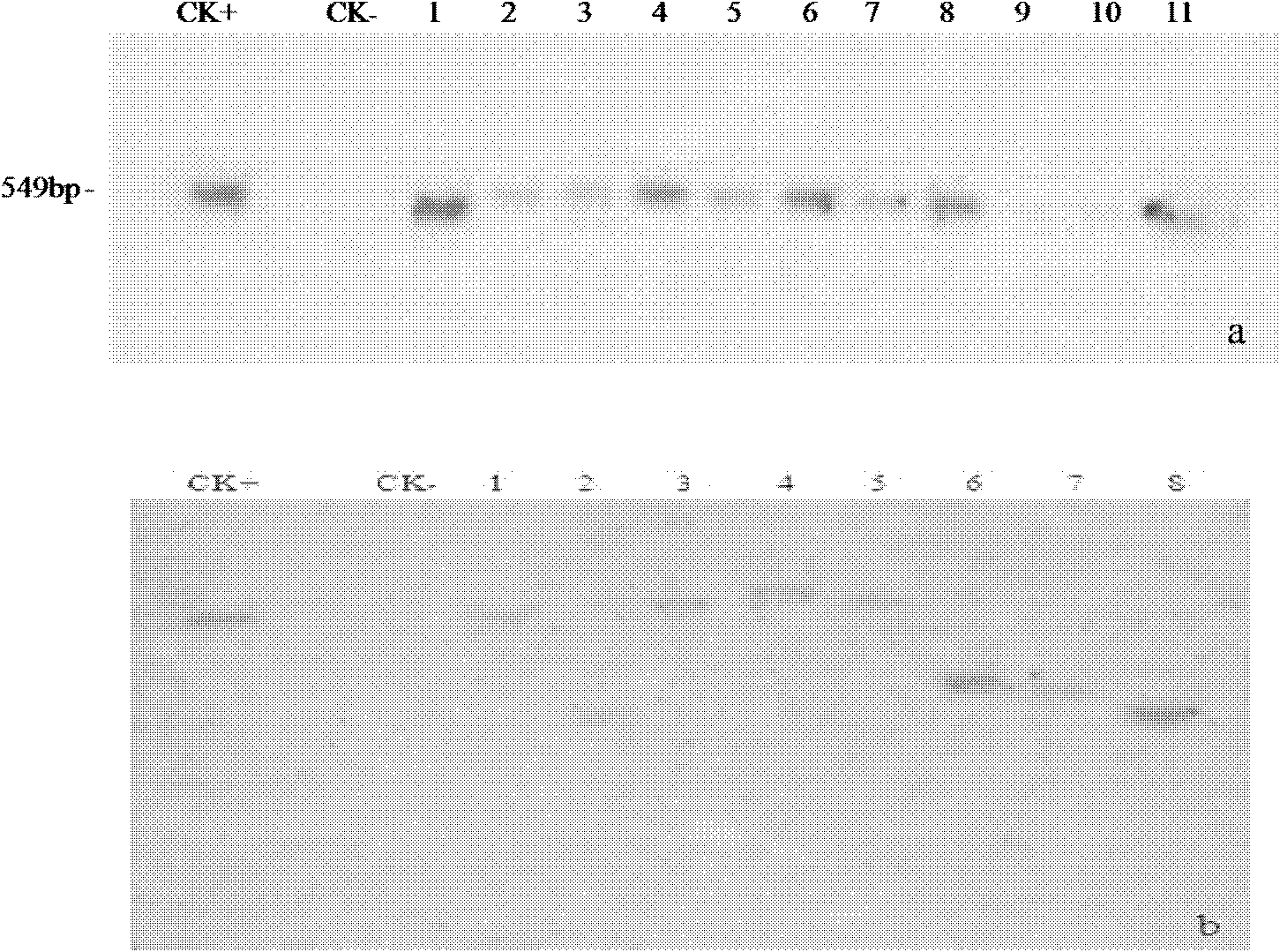

Method for building high-efficiency regenerating and transforming system of Oryza sativaL. subsp. japonica 11

InactiveCN102220277AHigh induction rateEnough to transform the materialFermentationGenetic engineeringGenetically modified riceRice plants

The invention belongs to the field of genetic engineering of plants and discloses a method for building a high-efficiency regenerating and transforming system of Oryza sativaL. subsp. japonica 11 through cultivation of induction of embryogenic callus, subculture multiplication of embryogenic callus, transformation mediated by agrobacterium tumefaciens, cocultivation of embryogenic callus and agrobacterium tumefaciens, screening and cultivation of resistant callus and seedlings differentiation of resistant callus. The method has the advantages of simple technological processes, low production cost, and capabilities of obviously increasing the inductivity of the embryogenic callus, the subculture multiplication rate and the differentiation and regeneration rate of the embryogenic callus of the Oryza sativaL. subsp. japonica 11 and simultaneously shortening the period of obtaining regenerative rice plants; and on the basis, an improved agrobacterium tumefaciens-mediated method can be used for remarkably increasing the efficiency of obtaining the transgenosis rice plants and shortening the period of obtaining regenerative rice plants.

Owner:SOUTH CHINA UNIV OF TECH

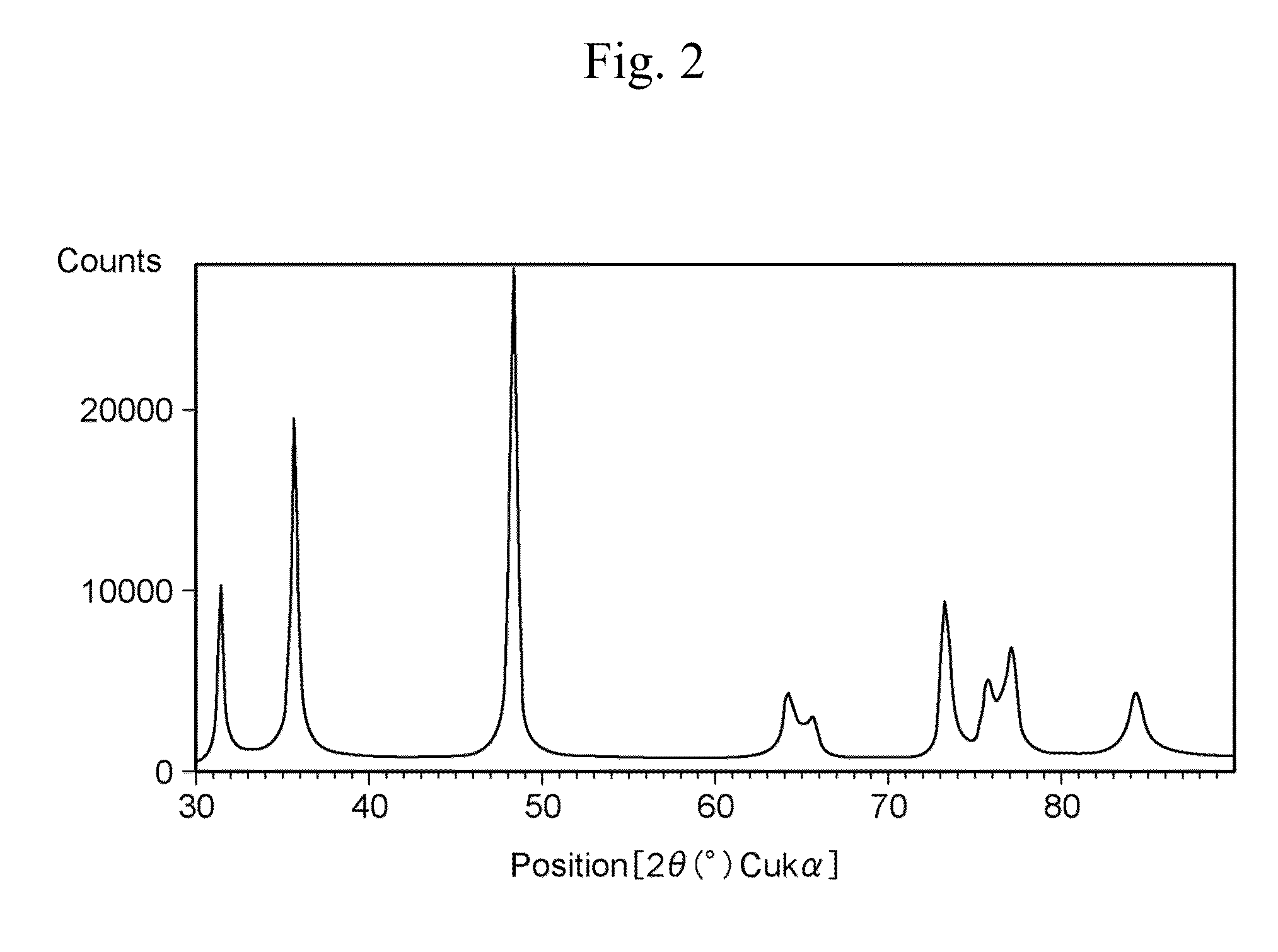

Fine metal carbide particles and methods of manufacturing the same

InactiveUS20110268969A1Small particle sizeLow costMaterial nanotechnologyLiquid surface applicatorsCarbonizationReaction intermediate

There is provided fine metal carbide particles which do not require pulverization of an initial material, a reaction intermediate and a product that causes the contamination with metallic impurities, which can promote a carbonization reaction uniformly at a lower temperature than in the past, and which can be manufactured at a low cost; and a method of manufacturing the same. The fine metal carbide particles are prepared by heat-treating, in a nonoxidizing atmosphere or a vacuum atmosphere, a solid obtained by drying an aqueous metal complex solution containing a water-soluble metal compound, and a low-molecular-weight water-soluble organic compound having one or more functional group(s) selected from the group consisting of amino group, hydroxyl group and carboxyl group, and having at least one of oxygen and nitrogen as heteroatom(s). In the fine metal carbide particles, the average particle diameter is 100 nm or less, the content of iron as impurities is 100 ppm or less, and the ratio of the total carbon amount is within ±0.3 wt % around a theoretical ratio of the total carbon amount calculated from the composition of the metal carbide.

Owner:FUKUOKA PREFECTURAL GOVERNMENT +1

Drying method of Chinese medicinal material

ActiveCN103006715AAvoid overgrowthImprove product qualityPlant ingredientsElectric heatingEngineering

The invention discloses a drying method of a Chinese medicinal material. The method comprises the following steps of: (1) uniformly spreading a Chinese medicinal material in an environment control room with thickness of between 2.0 and 6.0cm; setting an ultraviolet lamp, an ozone generator, a refrigeration air conditioner and an industrial dehumidifier, controlling the environment temperature to be between 10 and 22 DEG C by the refrigeration air conditioner, controlling the environment humidity to be between 10 and 50 percent by the industrial dehumidifier, and dehumidifying and drying the Chinese medicinal material for 2 to 24 hours; and (2) transferring the Chinese medicinal material into an electrothermal draught circulating drying oven for drying at a temperature of between 50 and 70 DEG C for 2 to 12 hours. The drying method improves the product quality, is applicable to drying treatment of massive Chinese medicinal materials, as well as foods, medicaments, pollen and the like.

Owner:湖州新驰医药科技有限公司

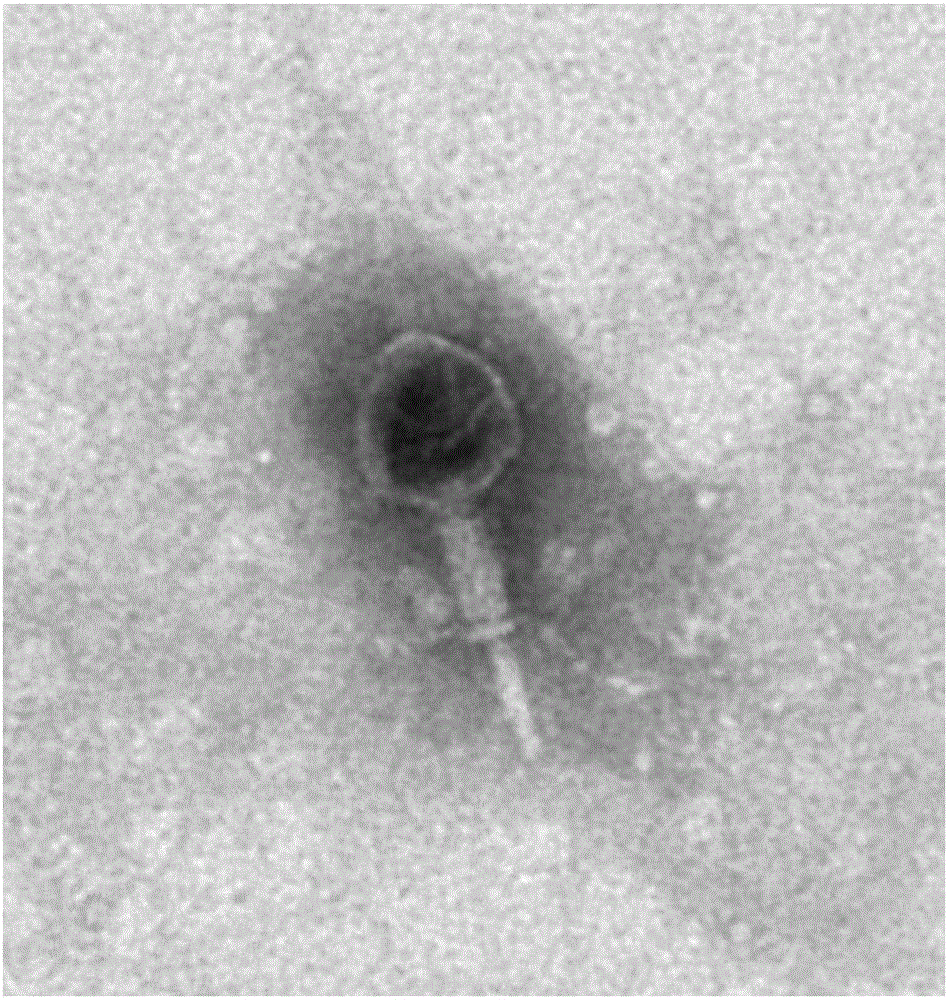

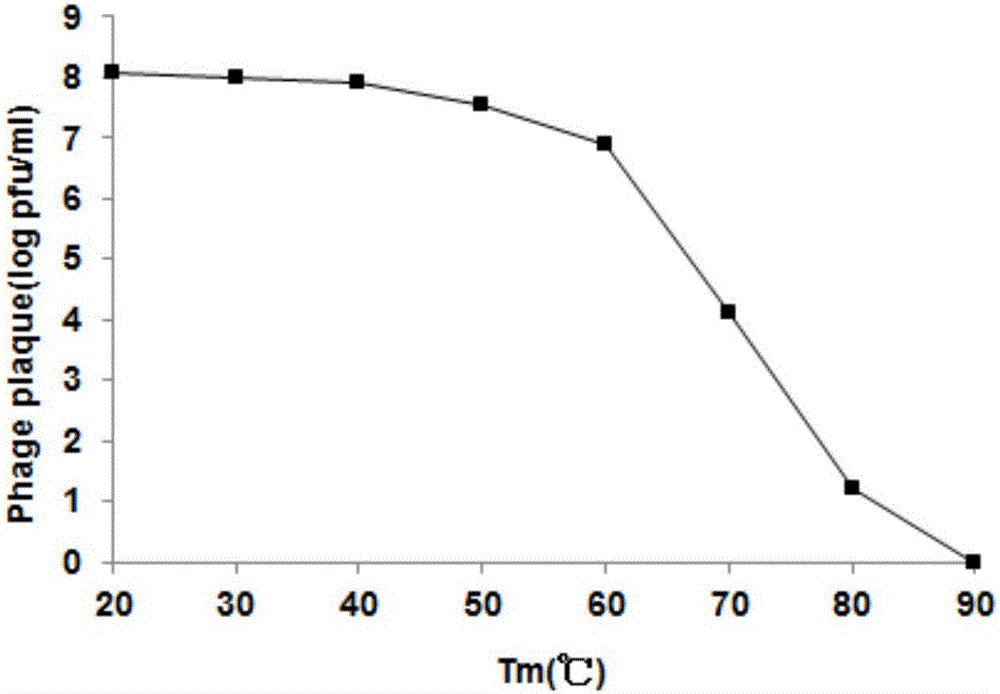

Enterohaemorrhagic escherichia coli phage and application thereof

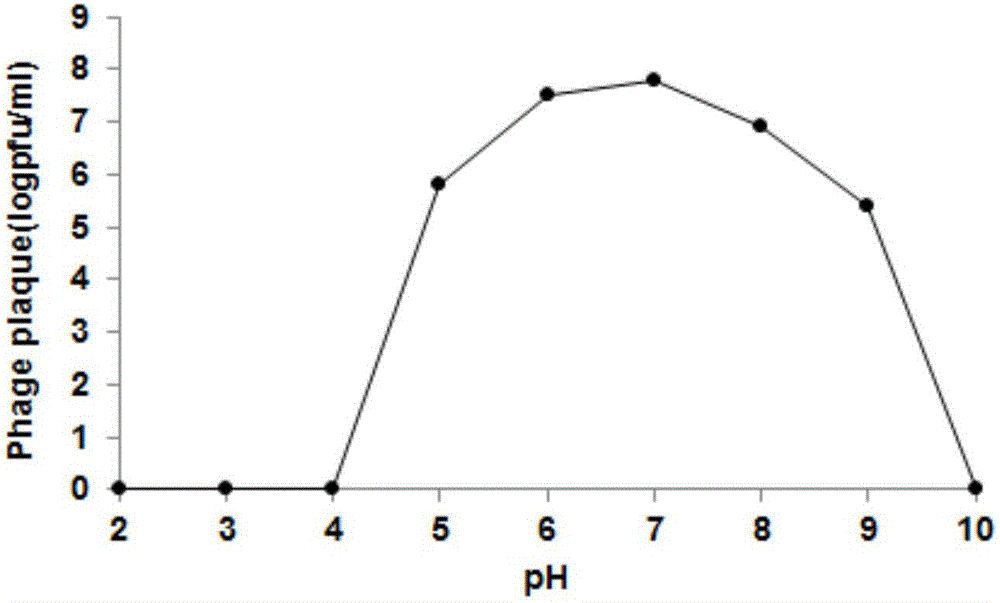

ActiveCN106754751AWide host rangeAvoid survivalAntibacterial agentsDigestive systemAnaplasma phagocytophilumMolecular biology

The invention relates to enterohaemorrhagic escherichia coli phage and an application thereof. The enterohaemorrhagic escherichia coli phage is characterized in that the preservation number of a phage strain is CCTCC NO:M 2016539, and the phage strain is preserved at the China Center for Type Culture Collection at Wuhan university in China on September 29, 2016, and is classified and named asenterohaemorrhagic coliphage vB-ECM-MIE, entero-haemorrhagic-Escherichia-coli-O157:H7 phage vB-ECM-MIE. The enterohaemorrhagic escherichia coli phage has efficient sterilization capacity on EHEC.

Owner:韩鸣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com