Patents

Literature

39results about How to "Shorten the pathway of diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

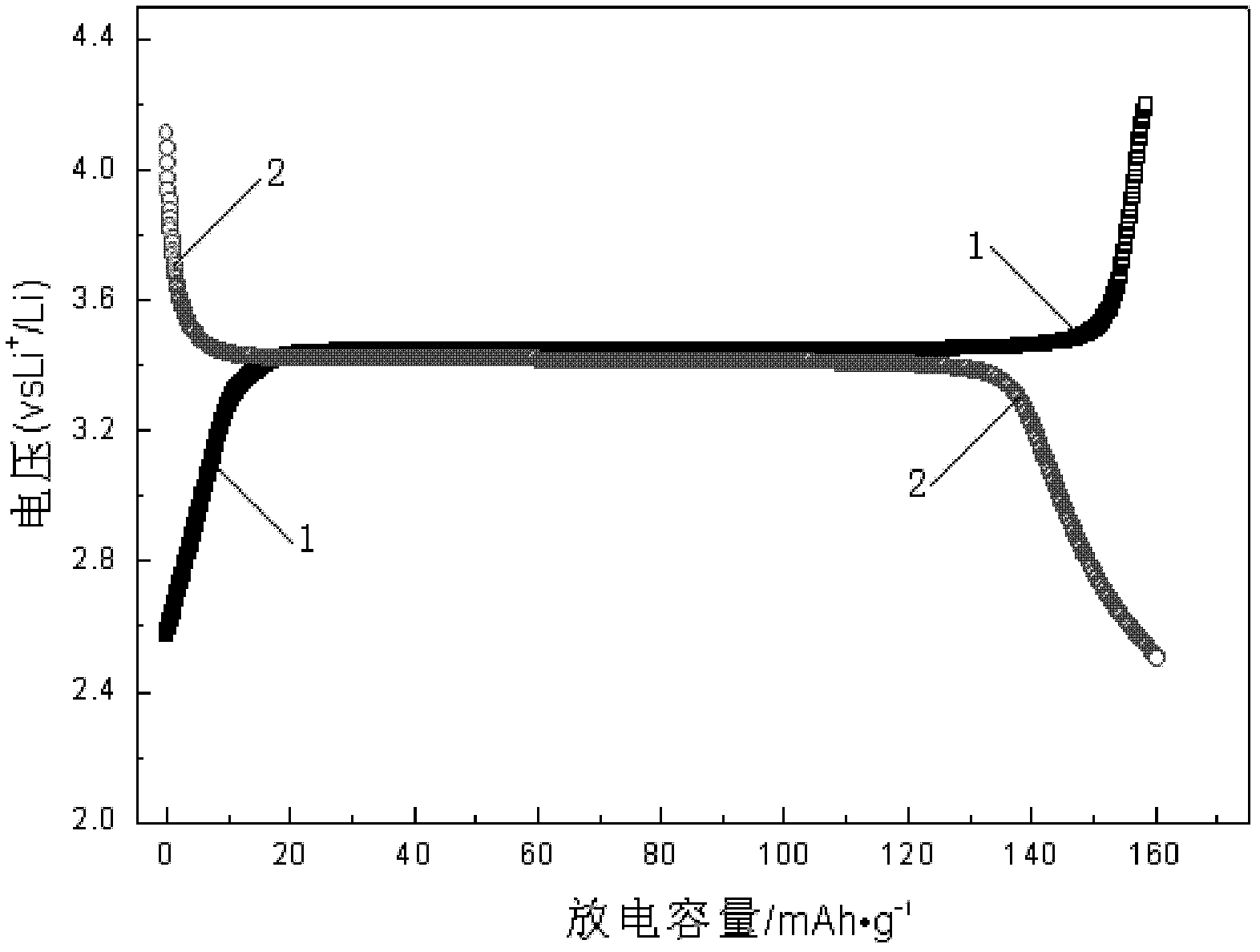

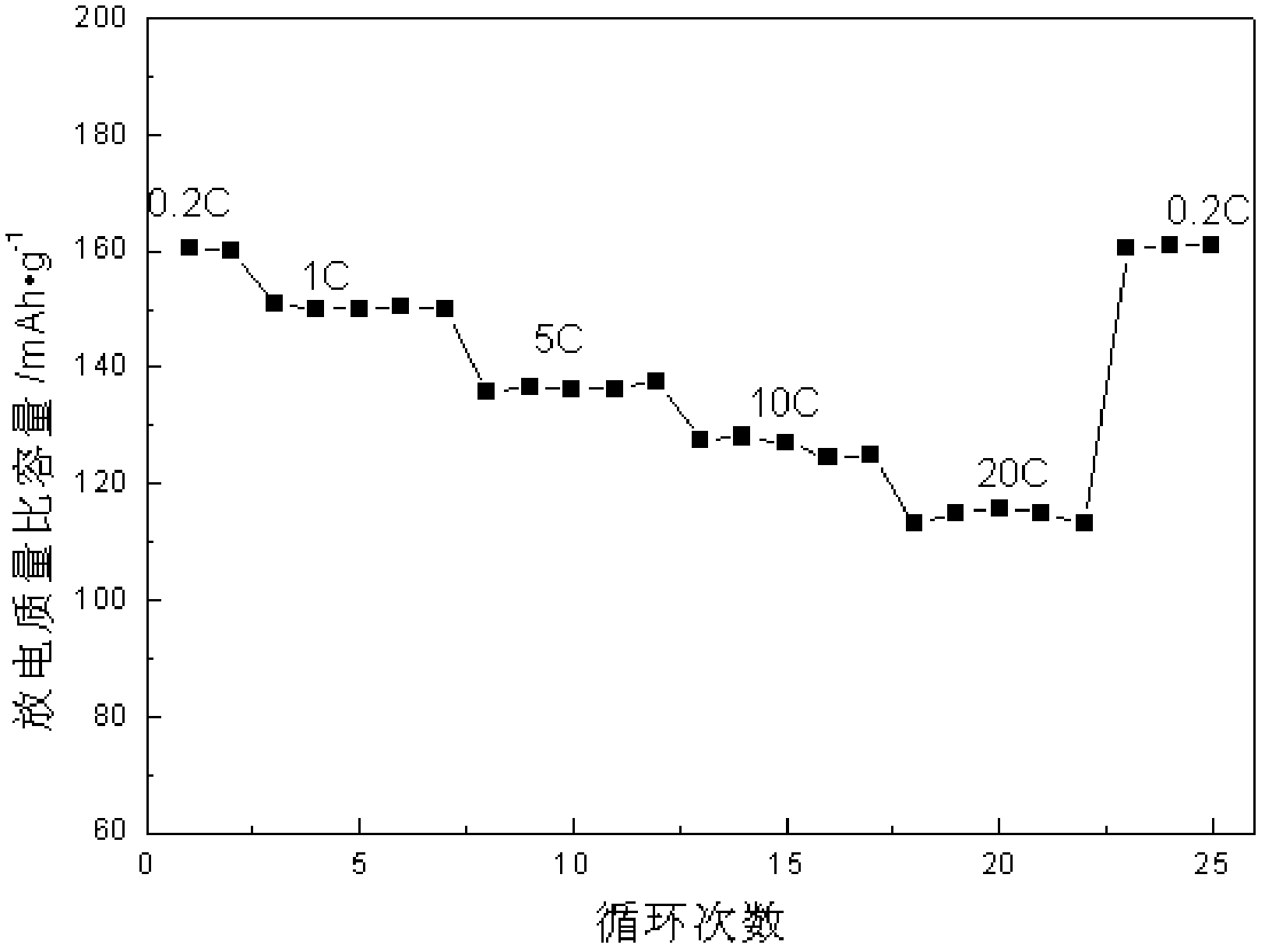

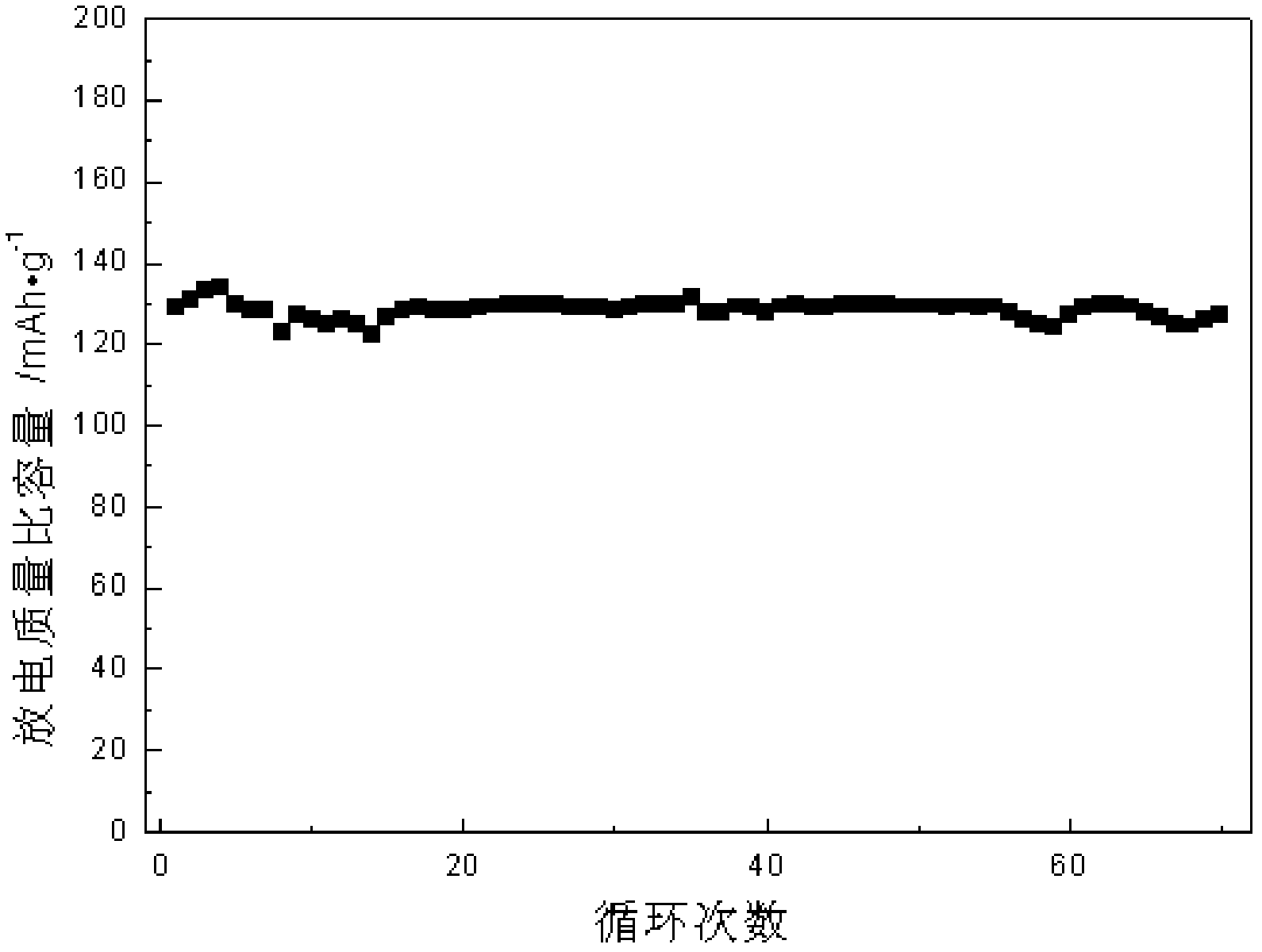

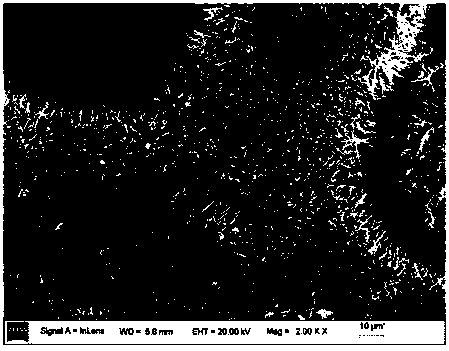

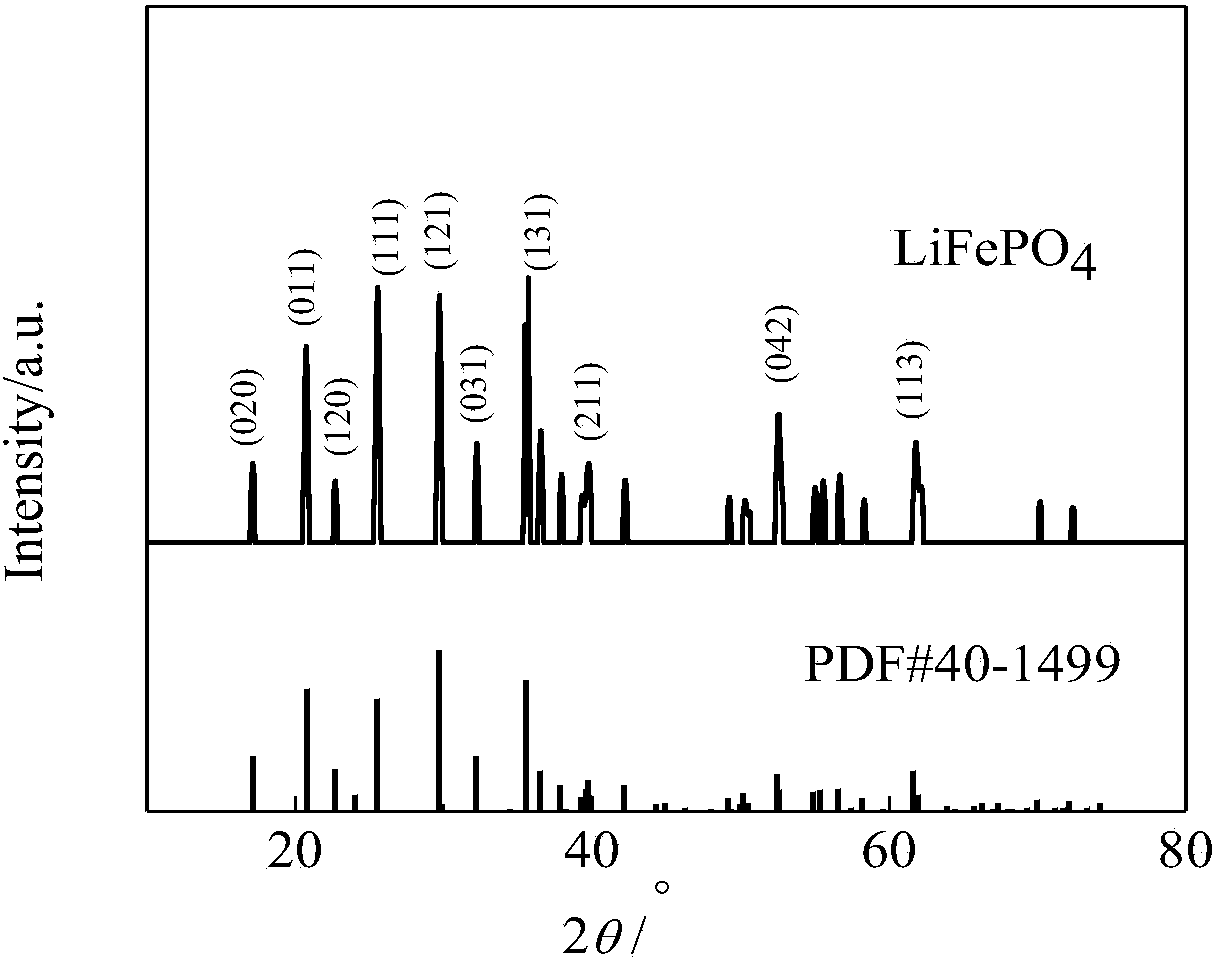

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

Electrode material in hollow tubular structure, and preparation method for electrode material

InactiveCN105513831AExcellent supercapacitor performanceIncrease loadHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrochemical corrosion

The invention provides an electrode material in a hollow tubular structure, and the electrode material is in the hollow tubular structure which consists of a composite hydroxide / copper hydroxide / copper-contained metal substrate. The chemical formulation of the composite hydroxide is MxM'y(OH)2, wherein M is Ni2+ or Co2+, M' is Co2+, Al3+, or Fe3+. According to the invention, a method of solution dipping and constant potential deposition, and a copper hydroxide nanowire array grows on the copper-contained metal substrate in an in-situ manner. The composite hydroxide is deposited on a copper hydroxide nanorod in electrolyte containing mixed metal salt solution in a manner of electro-deposition through employing the method of constant potential deposition. Meanwhile, electrochemical corrosion enables the copper hydroxide nanorod to be dissolved in a process of electro-deposition, thereby obtaining the hollow tubular structure of the composite hydroxide / copper hydroxide / copper-contained metal substrate. The electrode material is good in super-capacitance performance, and can be used for a super-capacitor.

Owner:BEIJING UNIV OF CHEM TECH +1

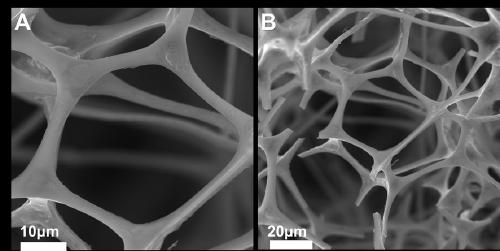

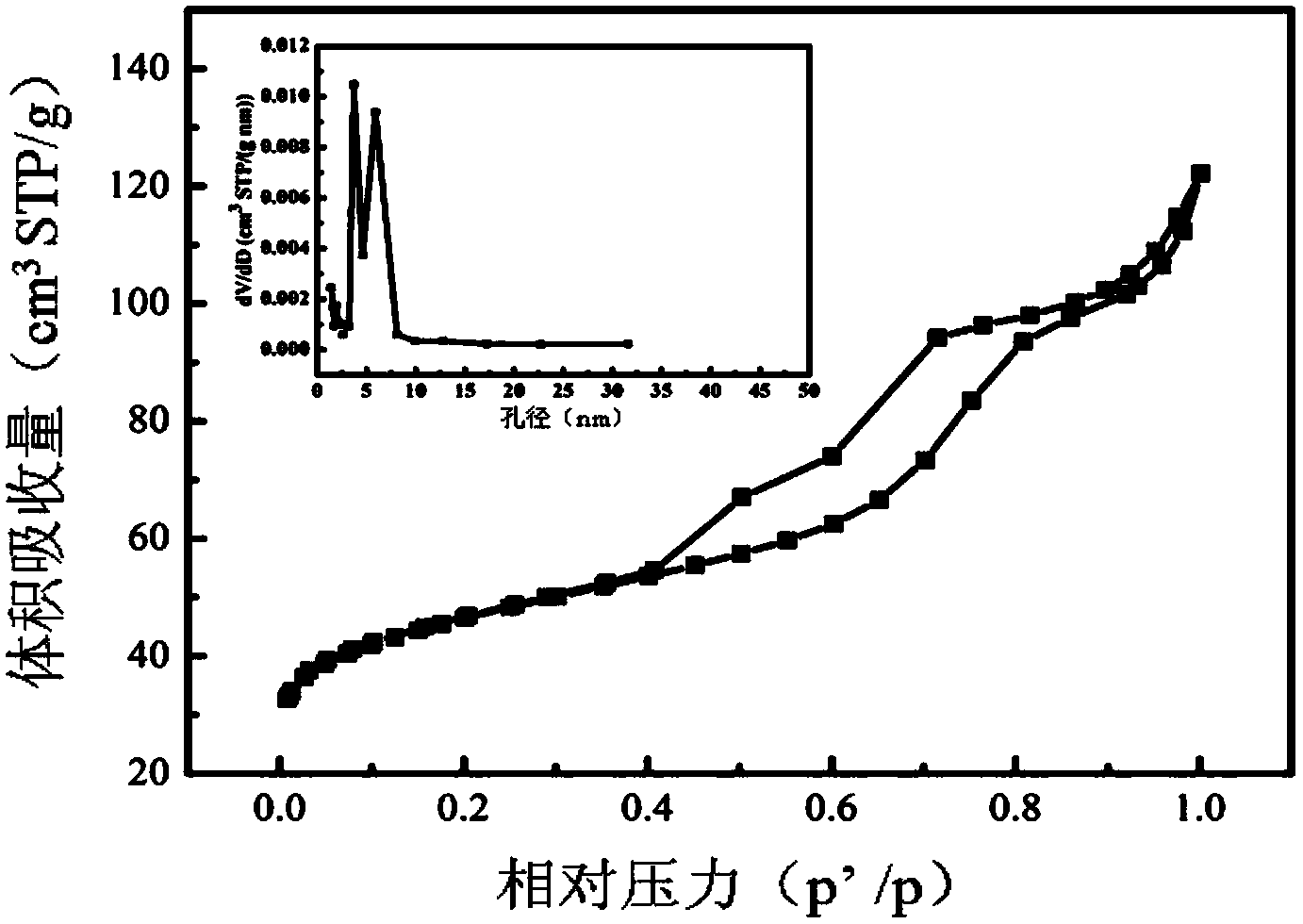

Preparation method of hierarchical pore carbon foam used for supercapacitor electrode

InactiveCN103449396AExcellent electrochemical performanceImprove high current charge and discharge performanceCarbon preparation/purificationParaffin waxCapacitance

The invention relates to a preparation method of a hierarchical pore carbon foam used for a supercapacitor electrode. The method comprises: firstly taking formaldehyde, resorcinol, silicon dioxide nanoparticles and water according to a mass ratio of 1:1-2:0.1-1:0.5-10, mixing them uniformly and taking the mixture as a water phase; adopting liquid paraffin as an oil phase, using Span 80 and Tween 80 as emulsifiers, weighing Span 80, Tween 80, the oil phase and the water phase according to a mass ratio of 2:3:8-20:15-30, mixing the water phase, the oil phase and the emulsifiers under stirring to obtain an oil-in-water type emulsion, adding a catalyst to solidify make the emulsion, conducting drying, then performing high temperature carbonization, removing the silicon dioxide nanoparticles from the carbonized material by dissolution in an HF solution with a mass percent of 40%, thus obtaining carbon foam, mixing the carbon foam with KOH in a mass ratio of 3-7:1, then conducting activation at 800-1000DEG C, thus obtaining the hierarchical pore carbon foam. When the hierarchical pore carbon foam provided in the invention is used as a supercapacitor electrode, high specific capacitance can be effectively maintained, and simultaneously the large current charge-discharge performance of the electrode can be improved.

Owner:TONGJI UNIV

Method for preparing porous carbon/binary transition metal oxide microsphere material

InactiveCN106992078AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesPorous carbonMicrosphere

The invention relates to a method for preparing a porous carbon / binary transition metal oxide nanosphere material. The method includes the steps of mixing glycerol and isopropyl alcohol according to a volume ratio of glycerol: isopropyl alcohol = 1: 3 to 5, adding Ni(NO3)2<separateion dot>6H2O and Co(NO3)2<separateion dot>6H2O according to a mass ratio of Ni(NO3)2<separateion dot>6H2O: Co(NO3)2<separateion dot>6H2O: glycerol = 1: 2: 250, stirring into a pink transparent solution, adding F127 according to a mass ratio of F127: Ni(NO3)2<separateion dot>6H2O = 1 to 20: 9, stirring until the white powder is completely dissolved in the transparent solution, conducting hydrothermal treatment at 180 DEC C for 6h, and obtaining NiCo glyceride nanospheres; after washing and drying, heating the NiCo glyceride nanospheres in a tube furnace injected with air from the room temperature to 350 DEG C at a heating rate of 0.5 to 5 DEG C / min, maintaining the constant temperature for 2-4h, and obtaining binary transition metal oxide NiCo2O4 nanospheres; and dispersing in a 0.05 M glucose solution, conducting hydrothermal treatment at 170 DEC C for 4h, after washing and drying, conducting carbonization in a nitrogen atmosphere for 4 to 6 hours, and obtaining porous carbon / binary transition metal oxide nanospheres via natural cooling. The method of the invention has the advantage of simple process, and the obtained porous carbon / binary metal oxide nanospheres exhibit a high specific capacity value and a long stable cycle life as a supercapacitor electrode material.

Owner:TONGJI UNIV

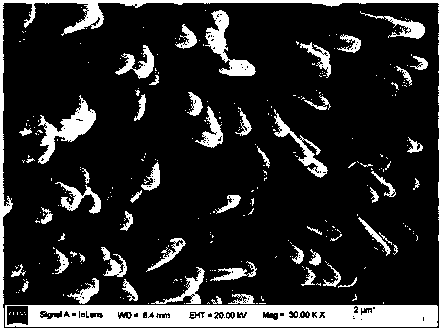

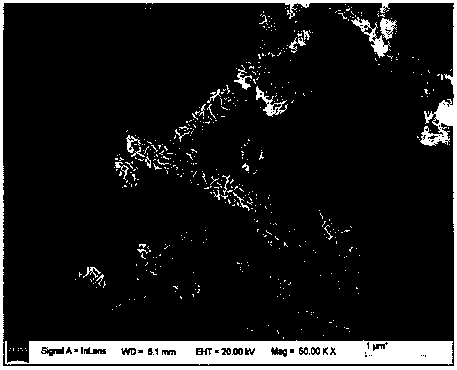

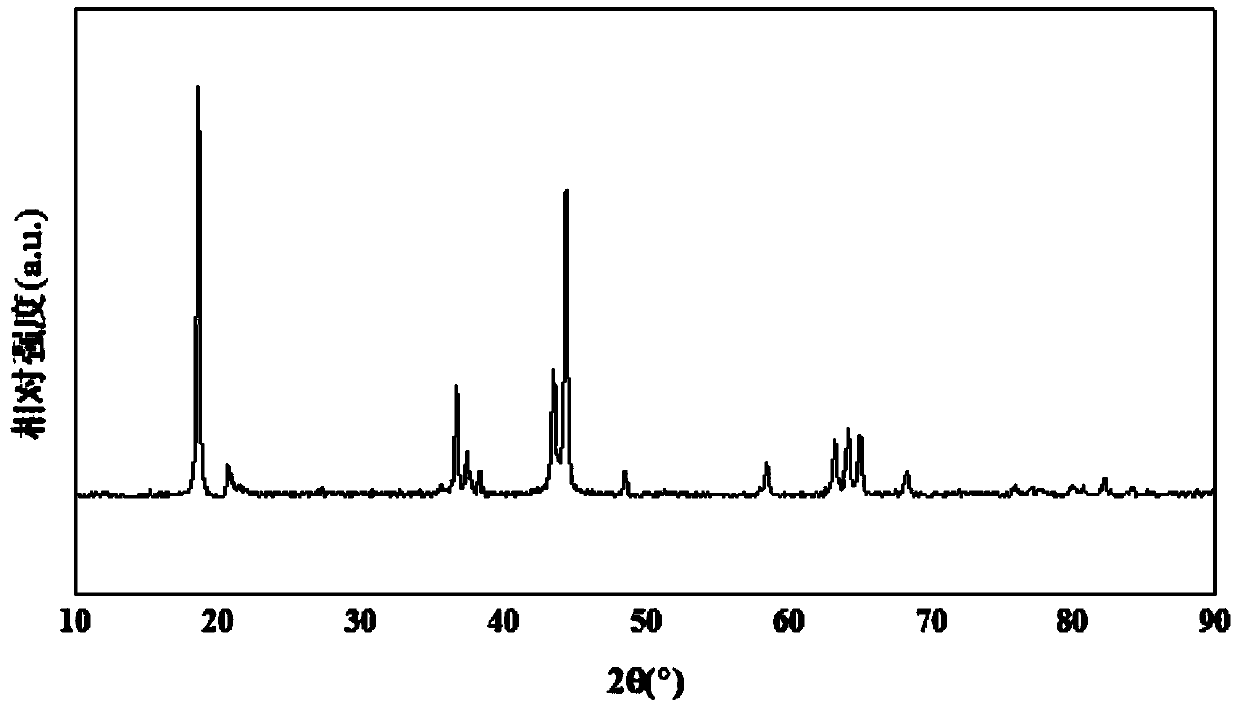

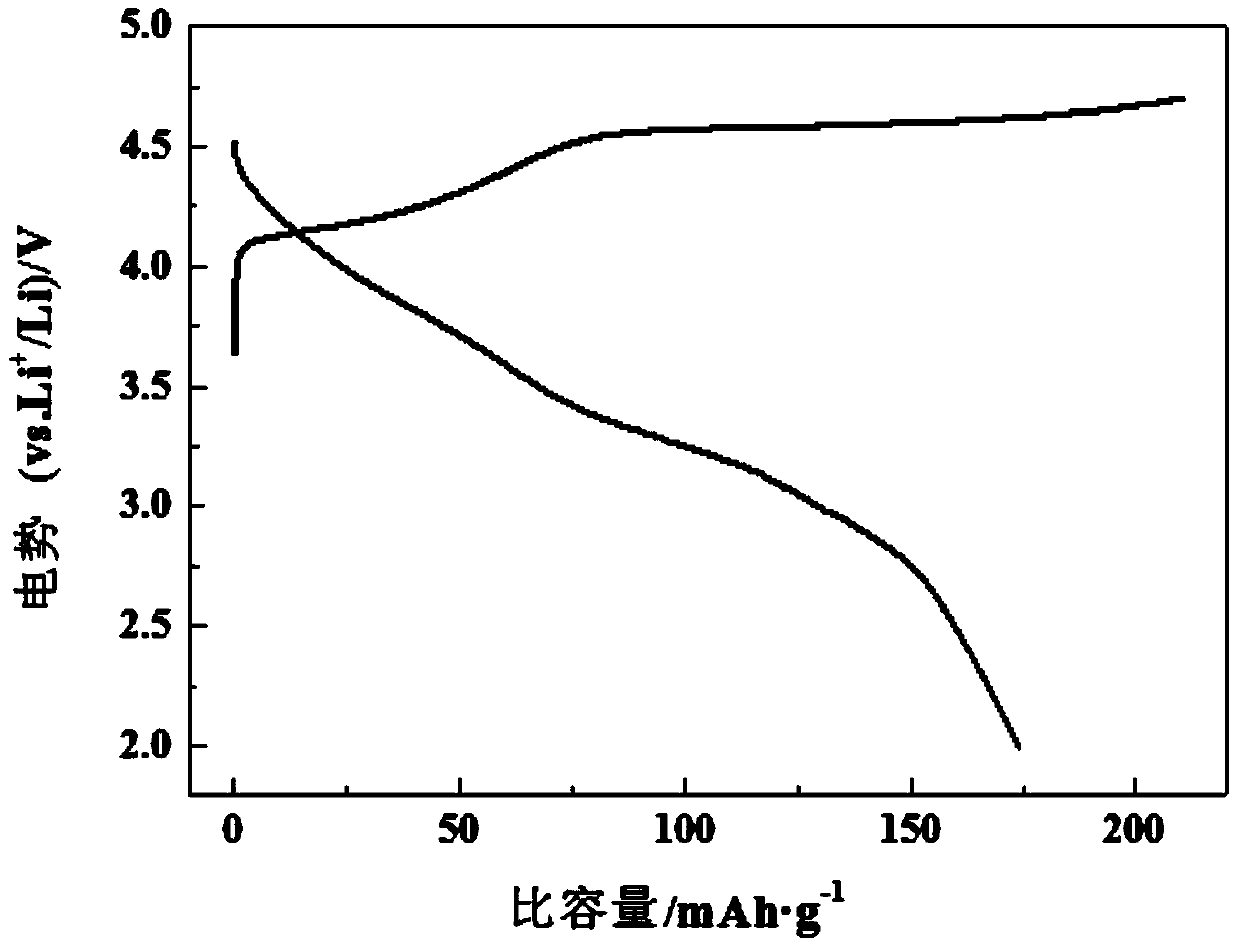

Preparing method for submicron particles of nickel-manganese-base lithium ion battery anode material

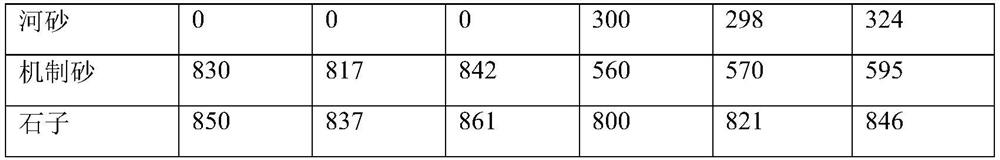

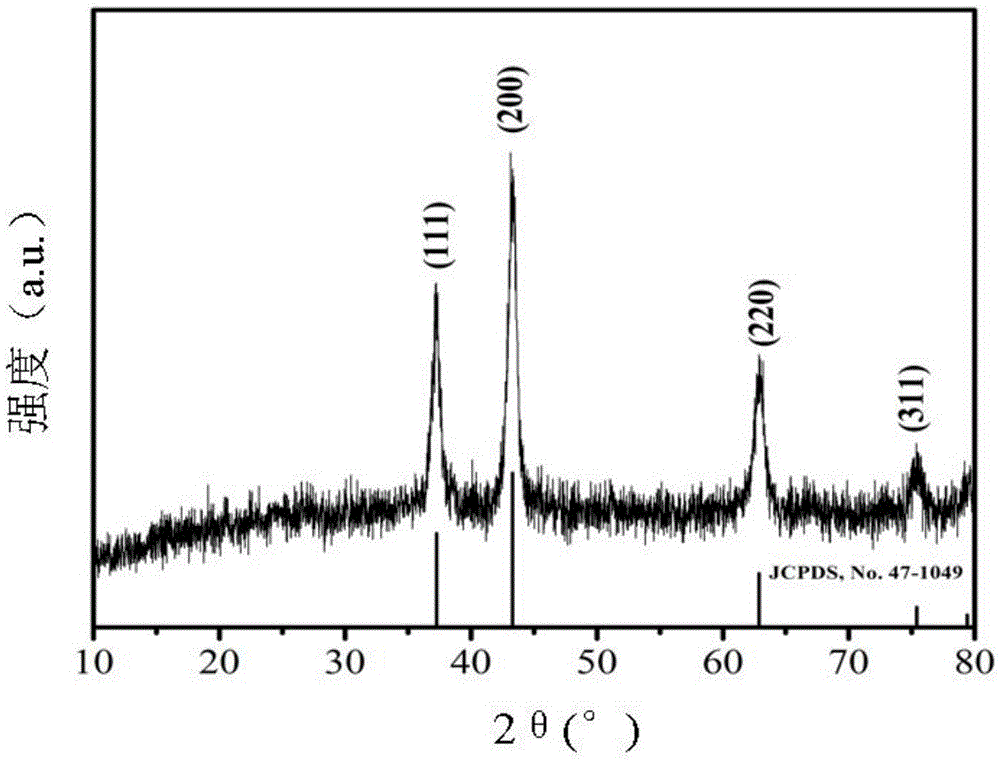

InactiveCN104009217AShorten the pathway of diffusionIncreased lattice stabilityMaterial nanotechnologyCell electrodesFiberManganese

The invention relates to a preparing method of a nickel-manganese-base lithium ion battery anode material, in particular to a preparing method for submicron particles for the nickel-manganese-base lithium ion battery anode material. The technical problems that a material obtained through an existing preparing method for the nickel-manganese-base lithium ion battery anode material is large in particle size and poor in electrical property are solved. The preparing method includes the steps that according to the chemical formula Li (MxNiyMn1-x-y) O2, a electrostatic spinning precursor solution is prepared through metal nitrates, N, N-dimethyl formamide and polyvinylpyrrolidone; the electrostatic spinning precursor solution is spun into nano-fibers through an electrostatic spinning machine, and the nano-fibers are calcinated to obtain the submicron particles for the nickel-manganese-base lithium ion battery anode material. The particle diameter of the submicron particles is 50 nm-200 nm, the specific discharge capacity under the condition of 1000 mA / g large current reaches 110 mAh / g, and only differs from that under the condition of 20 mA / g current by 39.3 mAh / g. The submicron particles for the nickel-manganese-base lithium ion battery anode material can be used in a high-power lithium ion battery.

Owner:HARBIN INST OF TECH

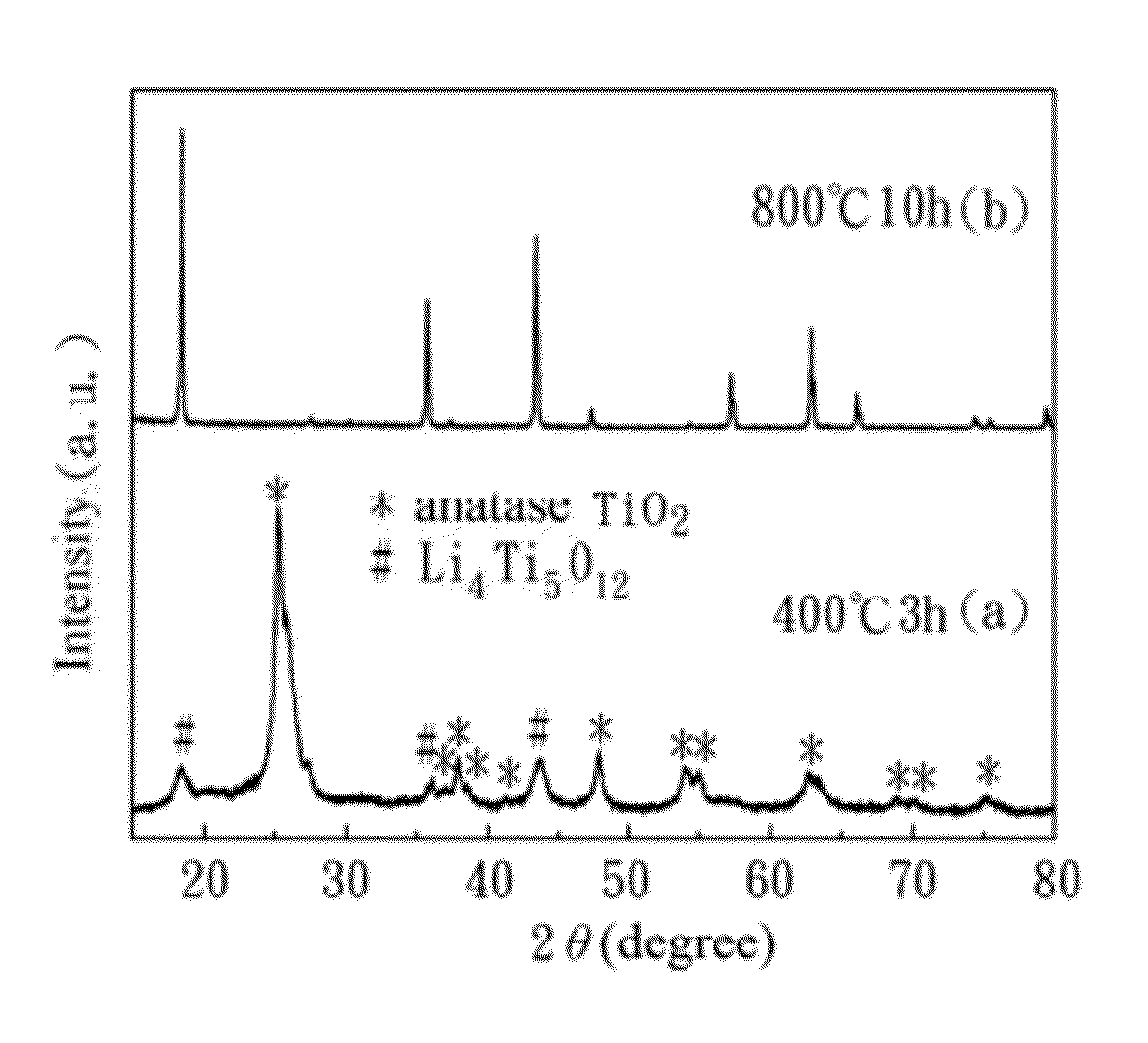

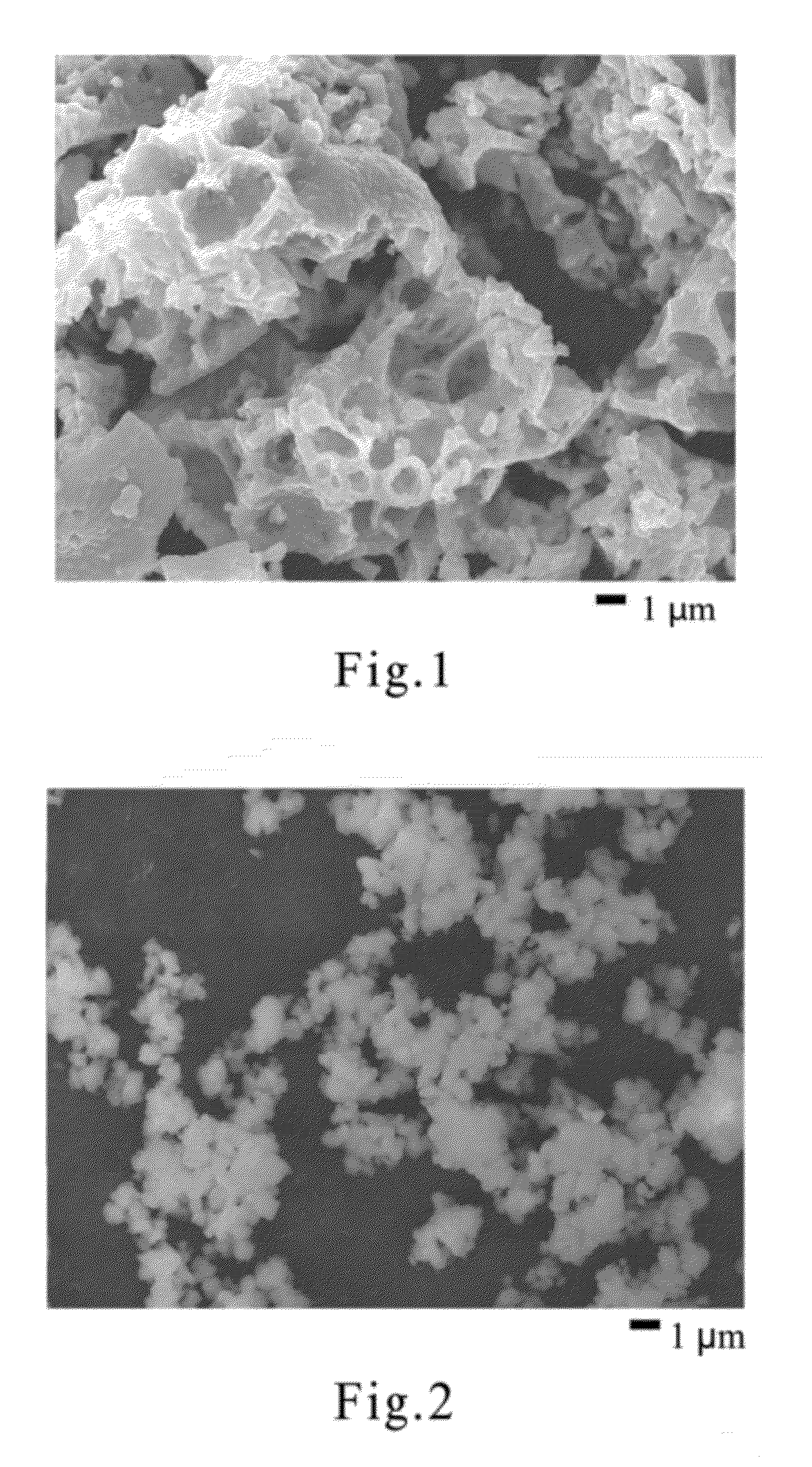

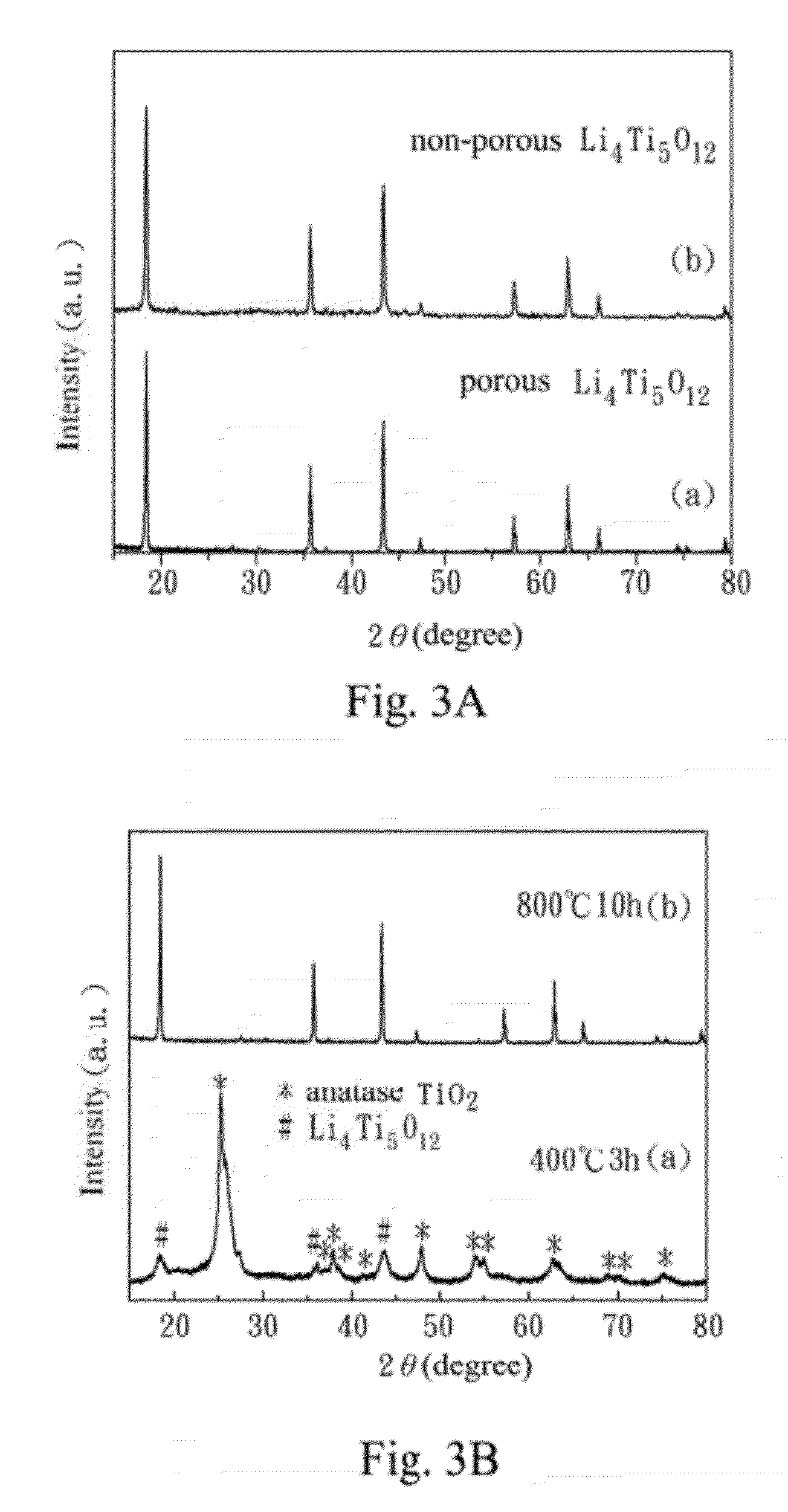

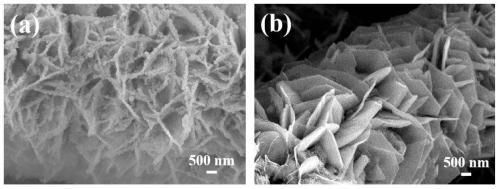

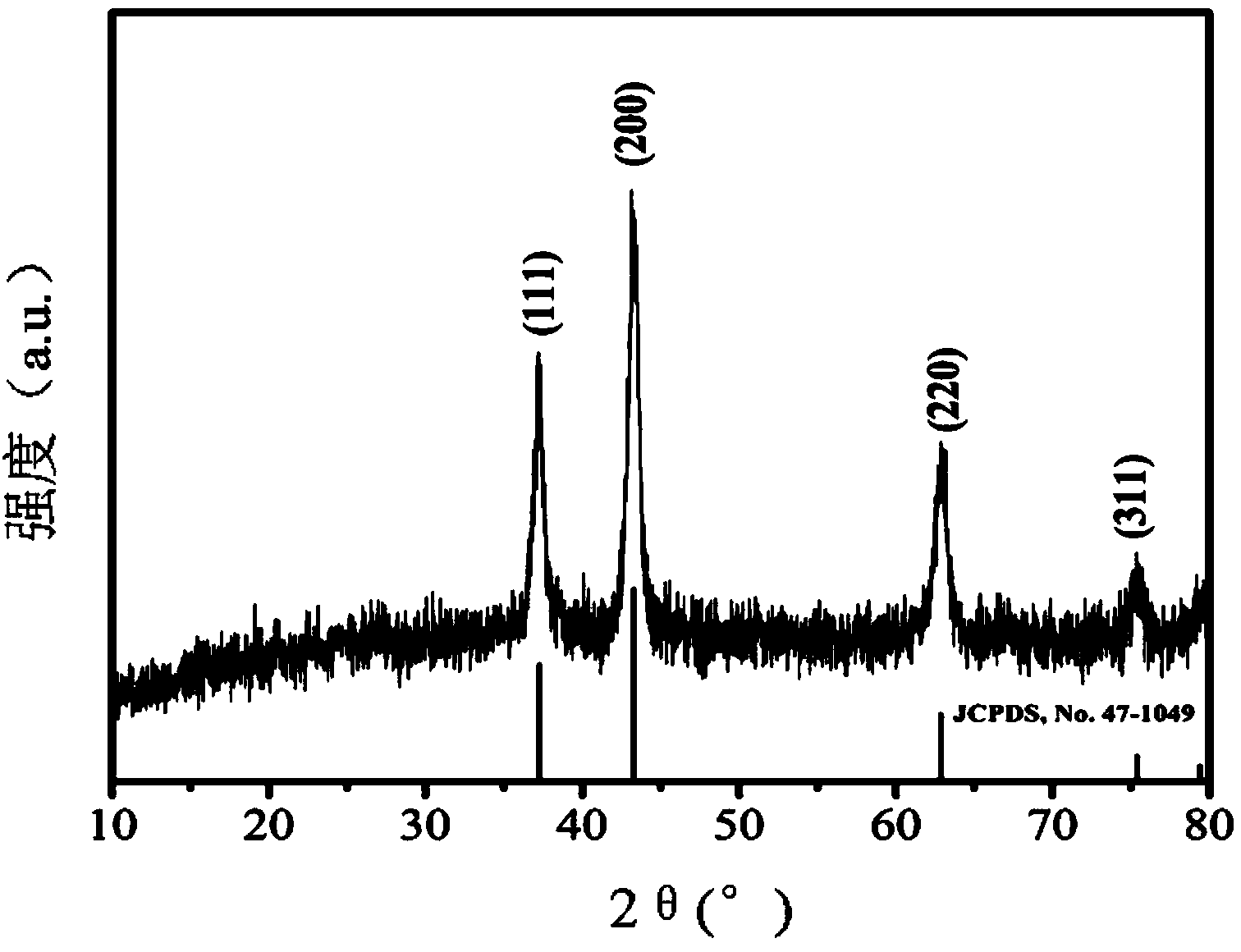

Porous li4ti5o12 anode material, method of manufacturing the same and battery comprising the same

InactiveUS20120308880A1Improve securityGood electrochemical propertiesCell electrodesSecondary cellsOrganic acidElectrochemistry

The present invention relates to a porous lithium titanium oxide anode material, a method of manufacturing the same, and a battery comprising the same. The method of manufacturing a porous lithium titanium oxide anode material of the present invention includes the following steps: (A) mixing a lithium salt and an organic acid, and adding a titanium salt immediately; (B) performing a first heat treatment at 300-800° C. for three hours; and (C) performing a second heat treatment at 600-800° C. for ten hours to obtain a porous lithium titanium oxide anode material. The cost of manufacturing the porous lithium titanium oxide anode material can be reduced through the aforementioned method, and a lithium battery having excellent electrochemical properties and cycling stabilities can be produced by the present invention.

Owner:NATIONAL TSING HUA UNIVERSITY

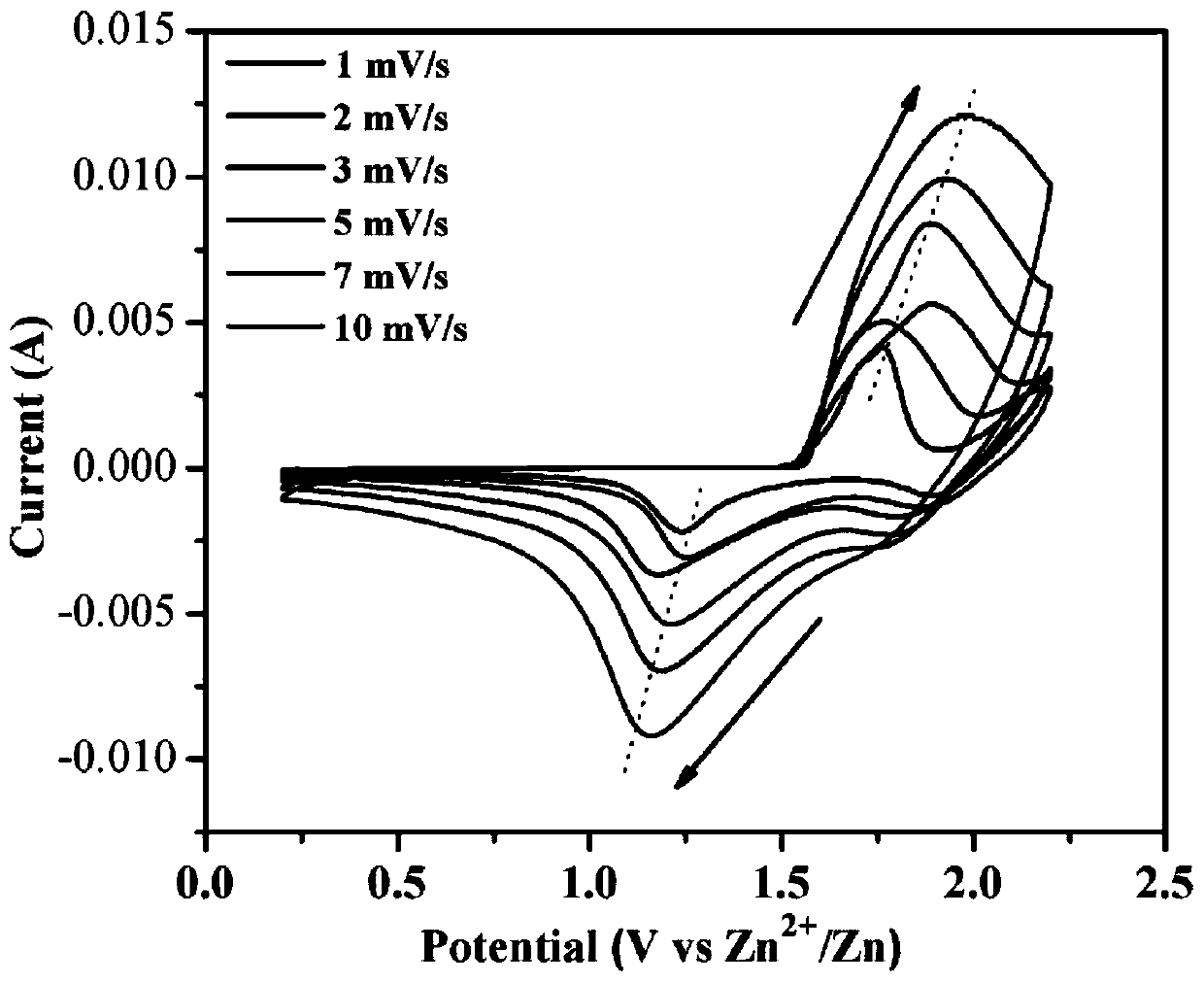

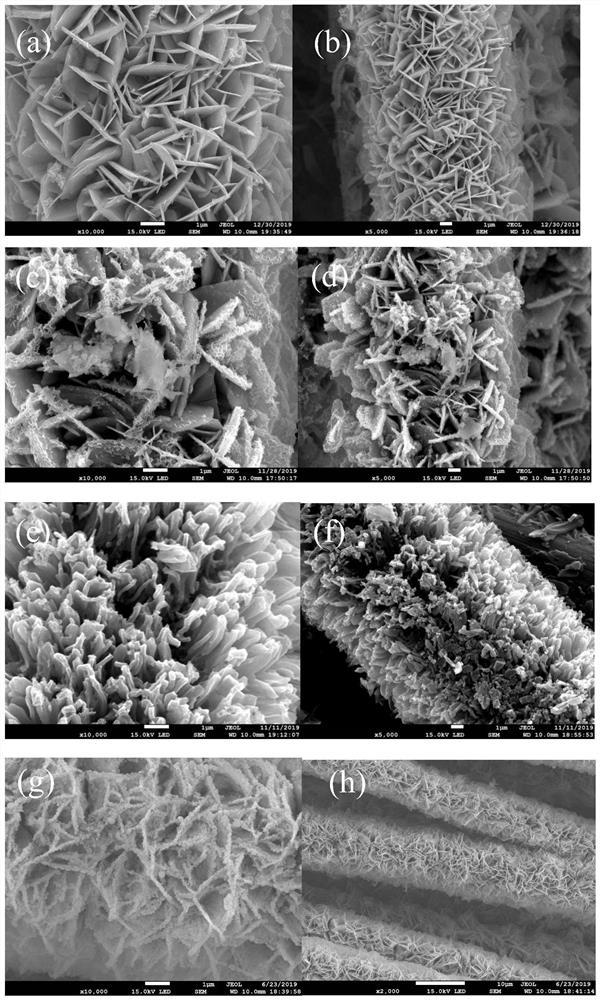

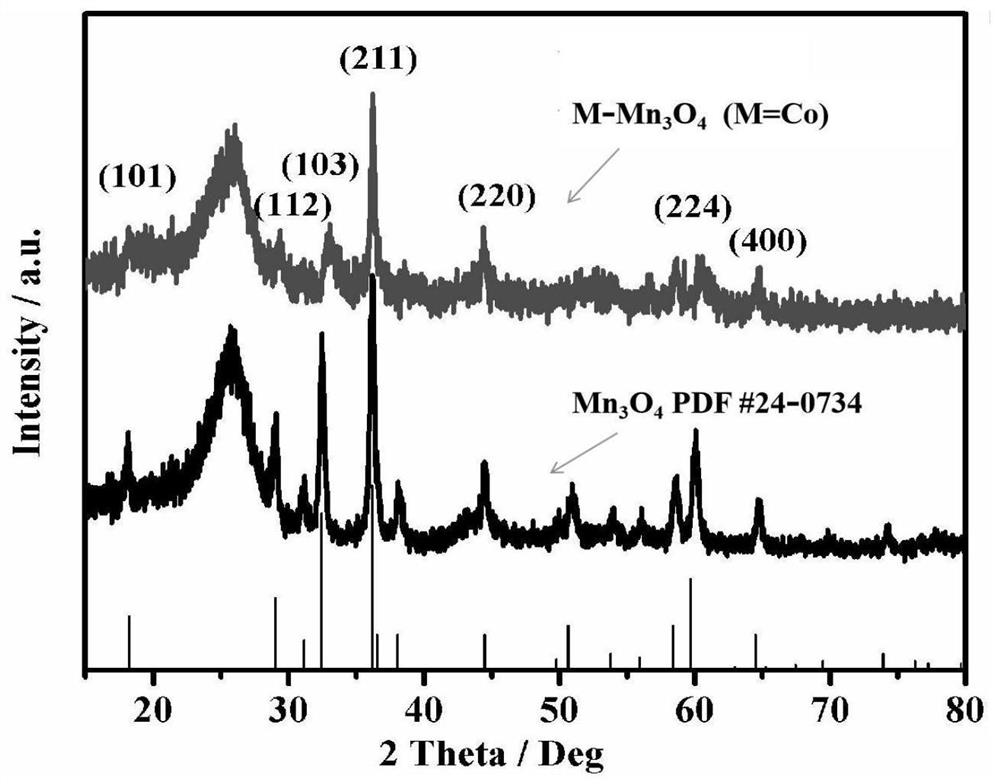

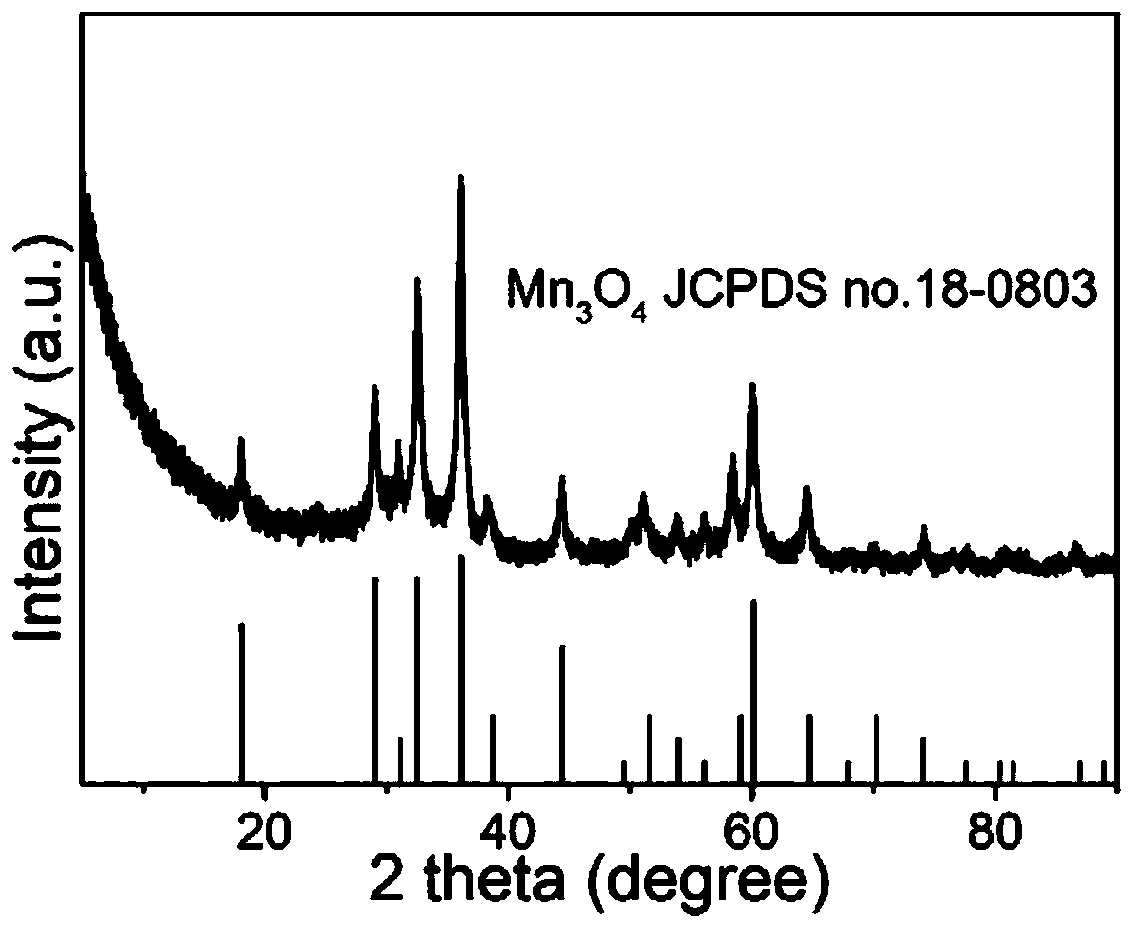

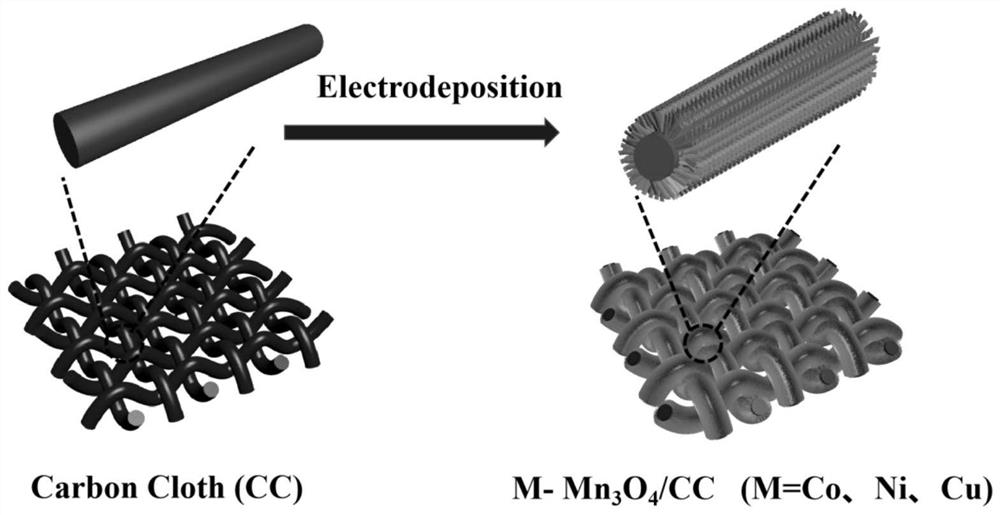

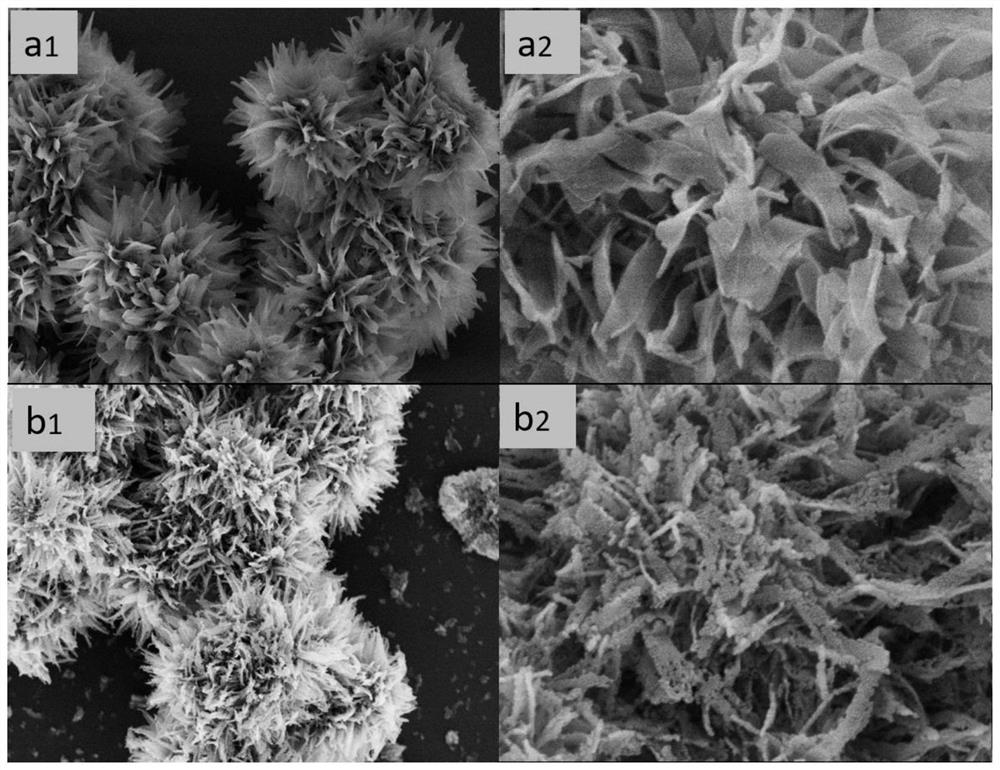

Long-life manganese-based water system mixed zinc ion capacitor and preparation method thereof

ActiveCN111508728AShorten the pathway of diffusionFast transferHybrid capacitor electrolytesHybrid capacitor electrodesElectrolytic agentManganese

The invention discloses a long-life manganese-based water system mixed zinc ion capacitor and a preparation method thereof, and belongs to the technical field of electrochemical energy storage devices. The capacitor comprises a manganese-based positive electrode, an electrolyte, a zinc sheet negative electrode, a diaphragm arranged between the positive electrode and the negative electrode and a shell, and the manganese-based positive electrode is of a Mn3O4 / C nanosheet array composite structure; the electrolyte is composed of soluble zinc salt, soluble sodium salt and deionized water; the Mn3O4 / C nanosheet array composite structure is obtained by taking carbon cloth as a matrix and uniformly depositing a Mn3O4 nanosheet array on the carbon cloth by utilizing an electro-deposition method. The capacitor prepared by the invention can provide specific capacity of 200mAh / g when working in a voltage range of 0-1.8 V, and the manganese-based water system mixed zinc ion capacitor disclosed bythe invention shows excellent cycling stability, has a capacity retention ratio of 81% in 1500 cycles, and is low in cost and simple in preparation process.

Owner:绍兴容辛能源技术股份有限公司

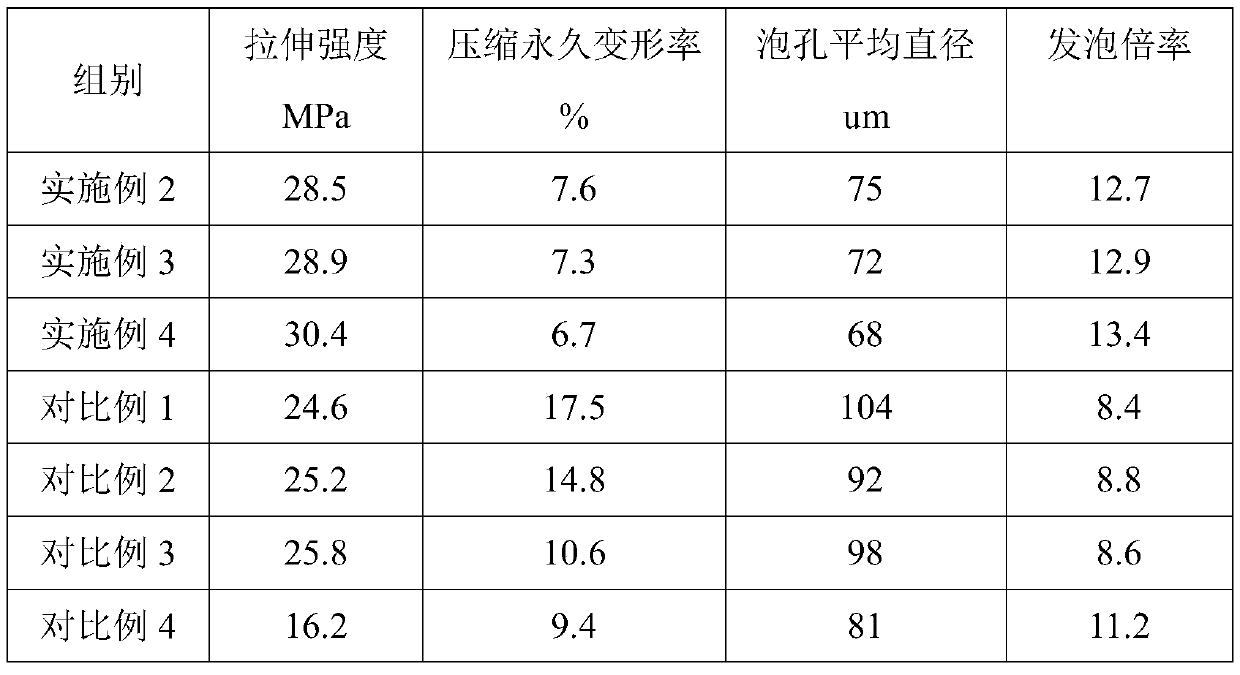

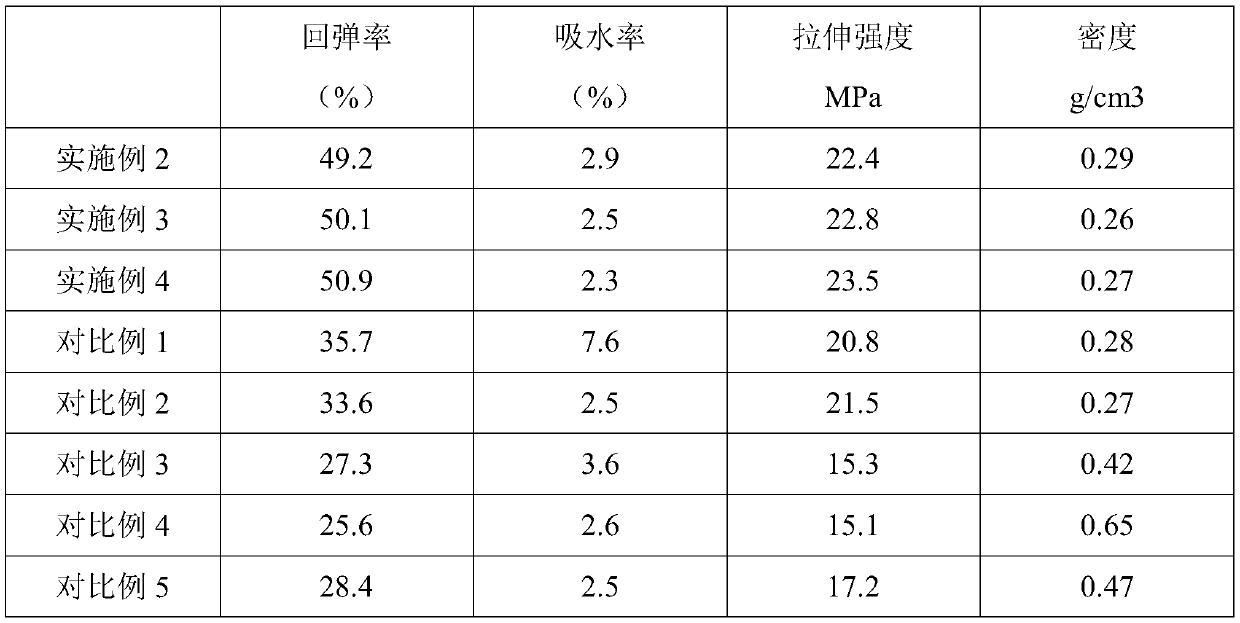

PP/POE supercritical foaming composite material and preparation method thereof

The invention discloses a PP / POE supercritical foaming composite material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 140 to 165 parts of polypropylene, 35 to 42 parts of polyolefin elastomer, 10 to 14 parts of maleic anhydride grafted polypropylene, 10 to 14 parts of a maleic anhydride grafted polypropylene modifier, 2 to 3 partsof a nucleating agent, 8 to 12 parts of mesoporous silica, 1.5 to 2 parts of a dispersing agent and 0.8 to 1.2 parts of a cross-linking agent. According to the PP / POE supercritical foaming compositematerial disclosed by the invention, the raw material composition is carefully selected, and the content of each raw material is optimized, so that the respective advantages are brought into full play, mutual complementation and mutual promotion are realized, the product quality is improved, and the prepared PP / POE supercritical foaming composite material is high in tensile strength and good in mechanical property; the compression set rate is low, and good elasticity is achieved; the foaming ratio is high, foam holes are uniform, the size is moderate and compact, the foam hole structure is complete, the sealing performance is good, and the foaming effect is good.

Owner:福建安达福新材料科技有限公司

Preparation method of spherical lithium ion battery anode composite material

InactiveCN107910541AHigh specific surface areaImprove electrochemical performanceMaterial nanotechnologySecondary cellsPhysical chemistrySolvent

The invention provides a preparation method of a spherical lithium ion battery anode composite material. The preparation method comprises the following steps that 1, 0.1-2 mmol of a saccharide compound is weighed and added into 20-80 mL of a water and ethylene glycol mixed solution to be dissolved by heating, and a solution A is obtained; 2, 0.1-10 mmol of a vanadium source is weighed and added into the solution A to be dissolved by heating, and a solution B is obtained; 3, the solution B is subjected to a solvothermal reaction for 1-28 h on the condition that the temperature is 160 DEG C to 220 DEG C, and a precursor is obtained; and 4, the obtained precursor is washed, centrifuged, dried and subjected to thermal treatment in an inert atmosphere, and the V2O3-C material is obtained. According to the preparation method, the specific surface area of the whole material can be increased to enable the contact area between an electrolyte solution and V2O3 to be increased, the diffusion pathof ions can be shortened, and the electrochemical performances of the V2O3-C material are improved; and the stability of the material in the long-term charging and discharging process is kept.

Owner:CENT SOUTH UNIV

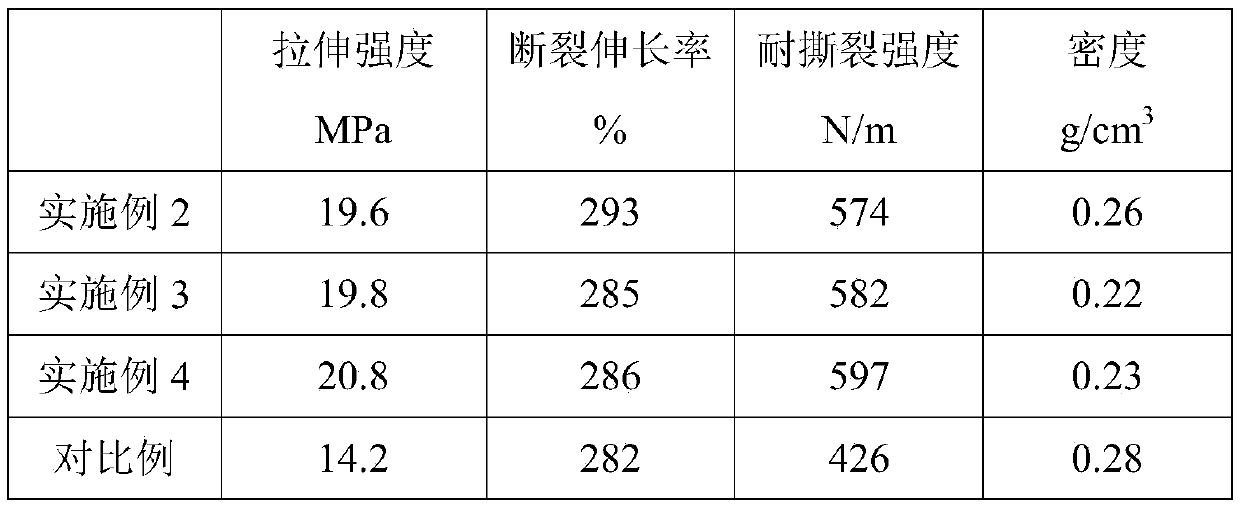

TPU/EVA supercritical foam composite material and preparation method thereof

InactiveCN110724375AGood foaming effectGood foaming efficiencyPolymer scienceThermoplastic polyurethane

The invention discloses a TPU / EVA supercritical foam composite material and a preparation method thereof. The TPU / EVA supercritical foam composite material is prepared from, by weight, 300-360 parts of a thermoplastic polyurethane elastomer, 66-73 parts of an ethylene-vinyl acetate copolymer, 25-33 parts of a maleic anhydride grafting modifier, 9-14 parts of peroxide and 1.2-1.6 parts of a nucleating agent. The TPU / EVA supercritical foam composite material has the advantages of good foaming effect, high foaming efficiency, uniform, small and dense cells, excellent mechanical properties and useproperties such as light weight and high strength, high tensile strength, large elongation at break, good mechanical properties, high tear strength, good tear resistance and low density.

Owner:福建安达福新材料科技有限公司

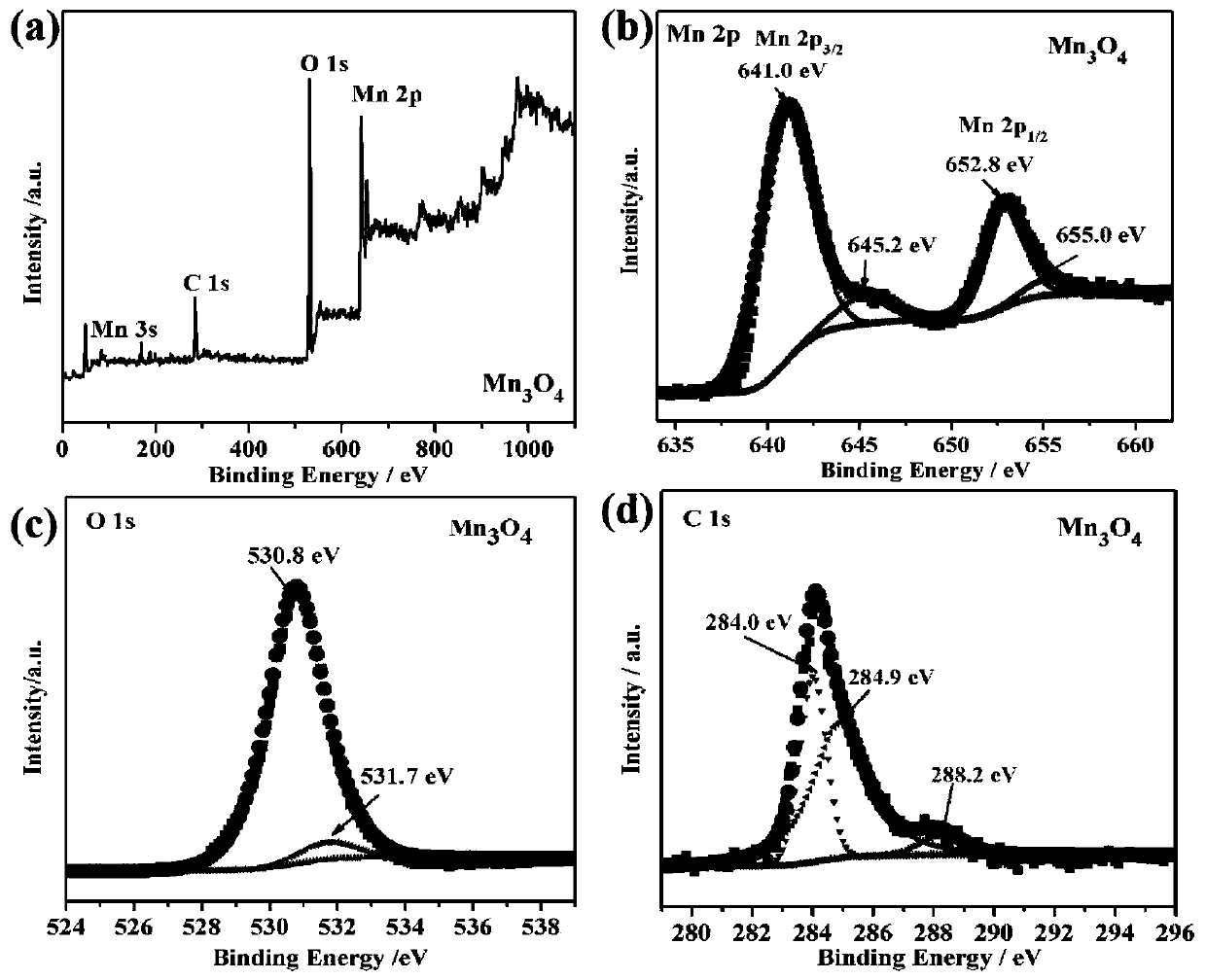

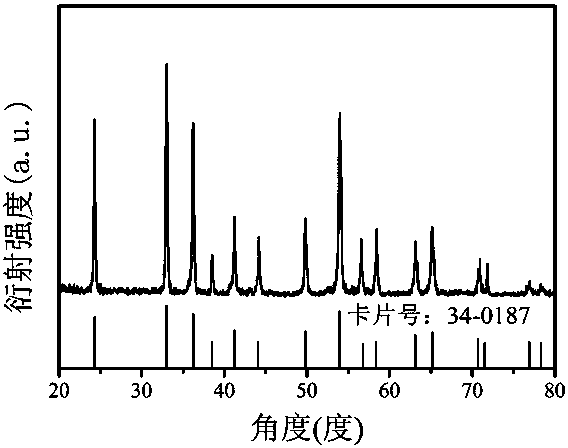

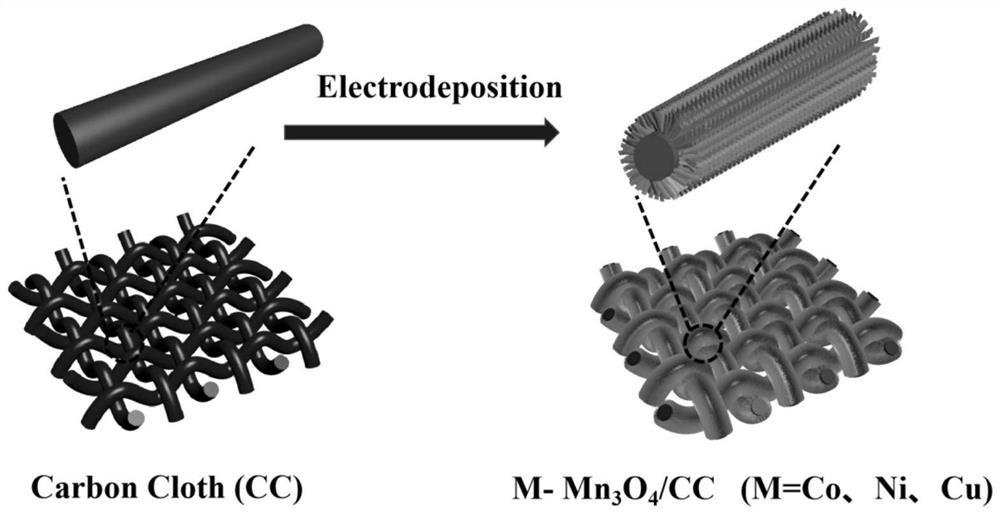

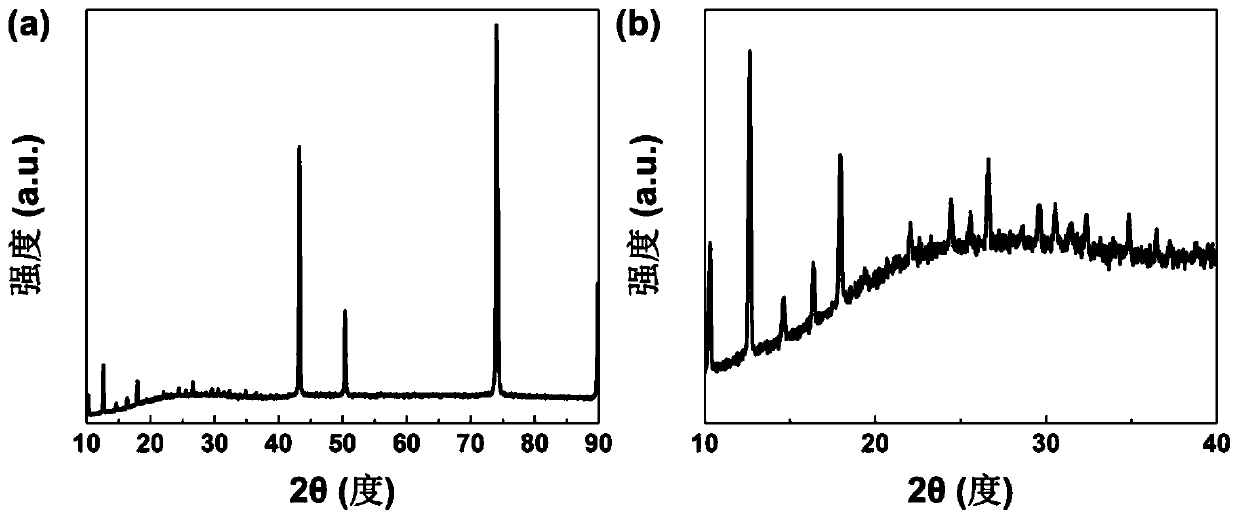

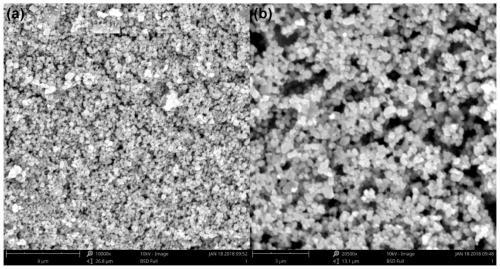

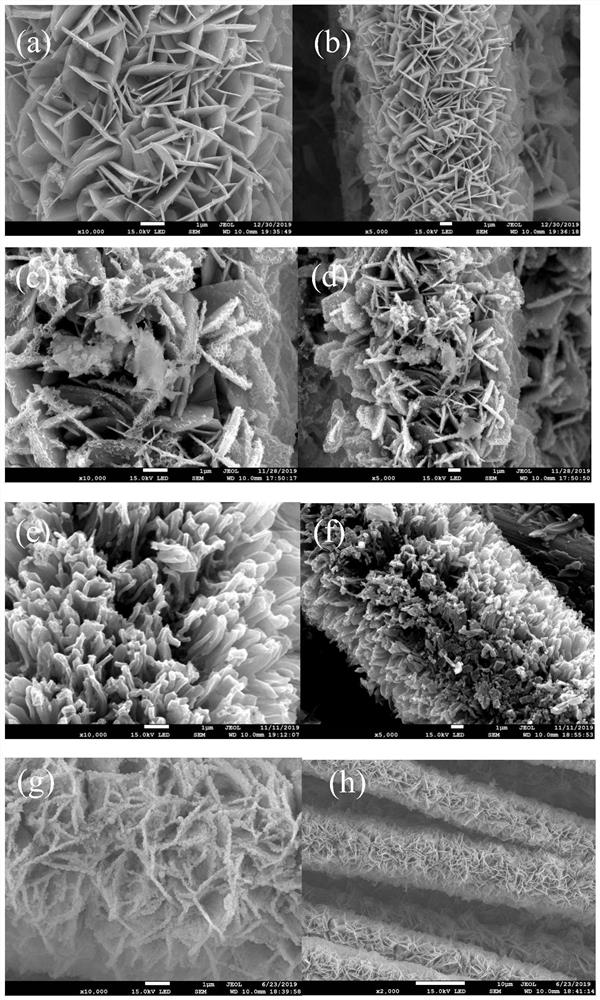

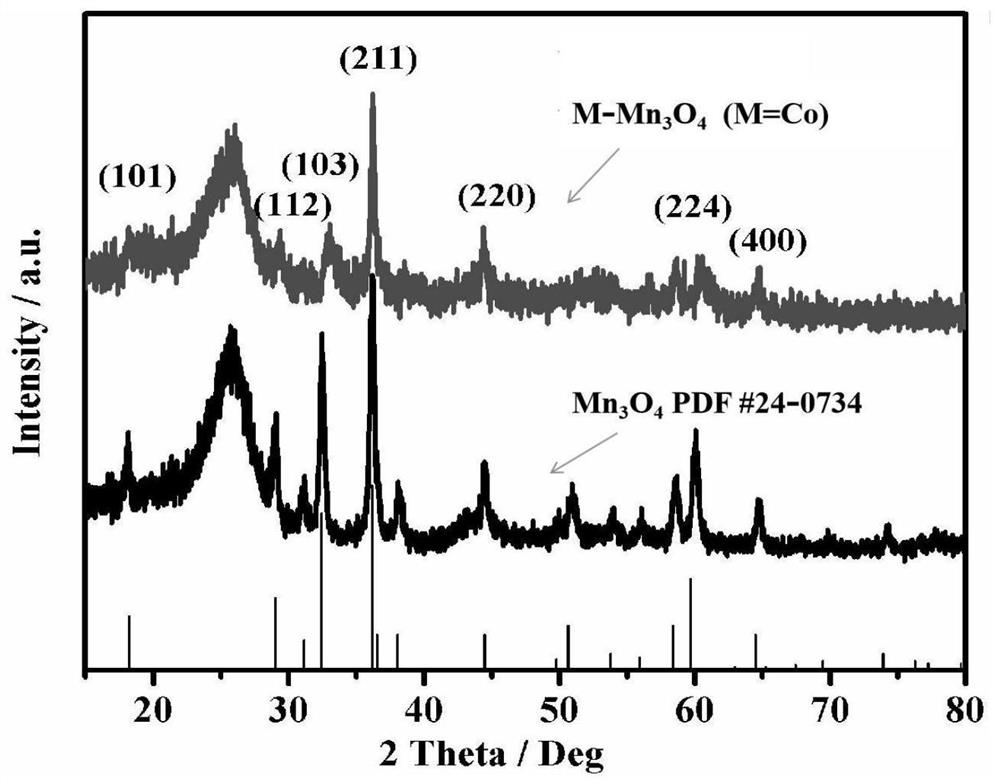

Transition metal ion doped manganous-manganic oxide nanosheet array based on carbon cloth growth as well as preparation method and application thereof

ActiveCN112374545AUniform depositionImprove electrochemical performanceMaterial nanotechnologyElectrolytic inorganic material coatingElectrical batteryManganous-manganic oxide

The invention relates to a transition metal ion doped manganous-manganic oxide nanosheet array based on carbon cloth growth as well as a preparation method and an application thereof. According to theinvention, a high-potential window of the manganese-based material is used as an advantage, and the manganese-based material is modified by doping transition metal ions on the basis, so that the electrochemical performance of the zinc ion battery is integrally improved. The method comprises the following basic steps: firstly, pre-treating the empty carbon cloth; then growing a transition metal ion doped manganous-manganic oxide nanosheet array on the hollow carbon cloth by adopting an electro-deposition method; and finally cleaning and drying. A one-step method is adopted, convenience and simplicity are achieved, raw materials are convenient to obtain, cost is low, toxicity is avoided, and the problems that in a traditional process, materials contain too many impurities, and operation istedious are solved. For the cathode material of the zinc ion battery, the structure is optimized by doping the manganese-based oxide into the transition metal ions, so that the electrochemical performance of the battery is improved. Therefore, a very good thought is provided for material selection or improvement of the cathode material of the zinc ion battery in the future.

Owner:HUBEI UNIV

Composite cathode sheet for lithium-sulfur battery and preparation method thereof, and application thereof

ActiveCN109671907AAvoid churnReduce churnMaterial nanotechnologySecondary cellsComposite cathodeLithium–sulfur battery

The present invention provides a composite cathode sheet for a lithium-sulfur battery and a preparation method thereof, and application thereof. The composite cathode sheet comprises a nano microporous carbon-sulfur composite material, conductive agent and polyvinylidene fluoride. The aperture of the nanoporous carbon in the composite material is smaller than 0.8nm. The common existence form S8 ofsublimed sulfur is converted to short-chain sulfur molecules S2-4 to prevent the lithium-sulfur battery from generating diffluent high-order polysulfide in the discharge process, avoid generation ofa shuttle effect and improve the cycle stability of the lithium-sulfur battery.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

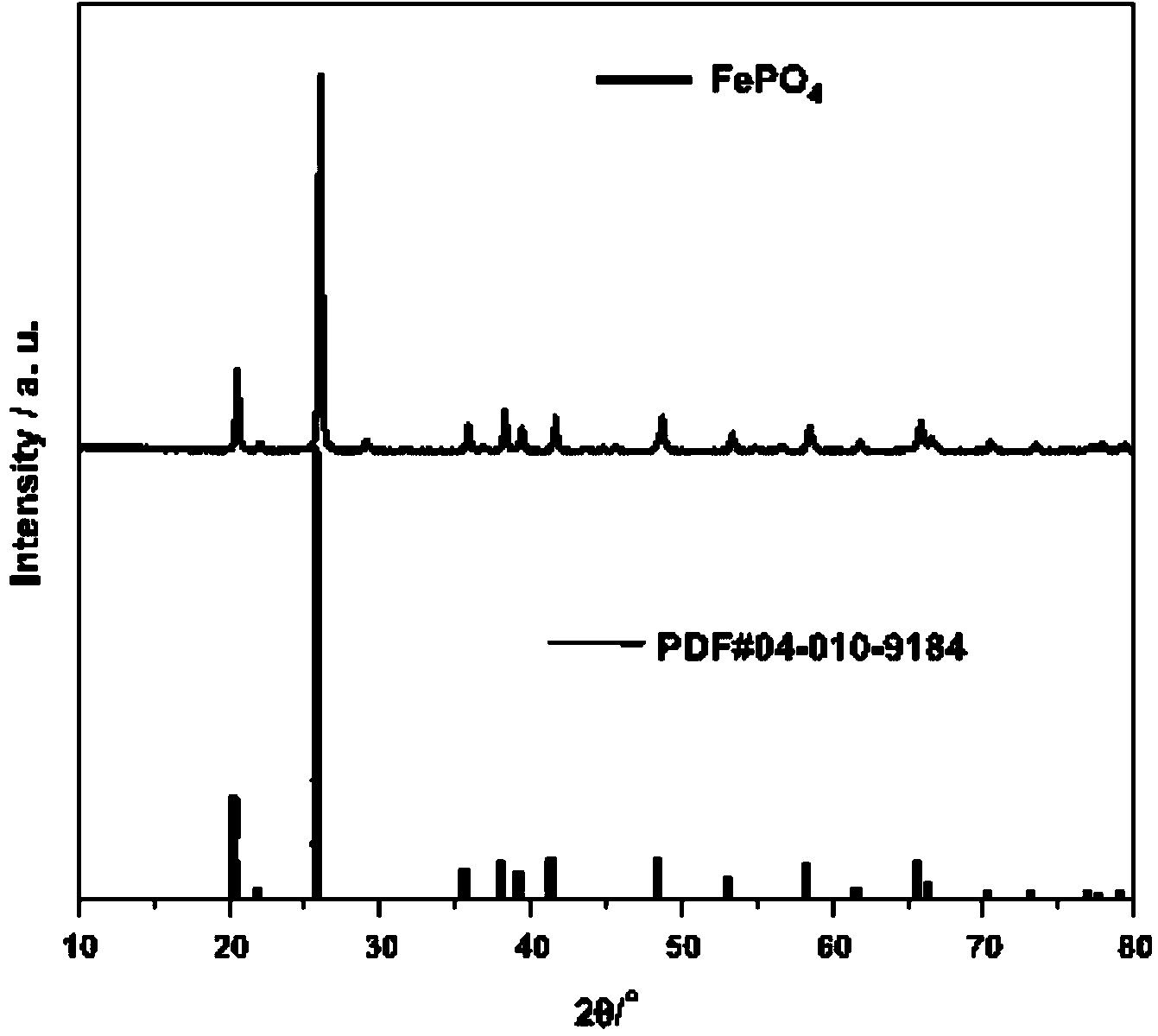

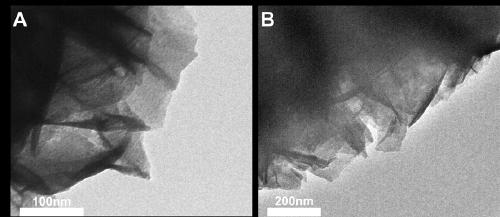

Nano solid-core iron phosphate-carbon source-graphene composite material and preparation method thereof

ActiveCN104167550AImprove the synthesis processShort synthesis processMaterial nanotechnologyCell electrodesSulfate radicalsPhosphoric acid

The invention discloses a nano solid-core iron phosphate-carbon source-graphene composite material; the surfaces of nano solid-core iron phosphate particles are coated with a carbon source, the particles are connected through graphene, and the nano solid-core iron phosphate-carbon source-graphene composite material is formed. The invention also discloses a preparation method of the material. The process flow is simple, the cost is low, at the same time, nitrate radicals are adopted, and the disadvantages in a traditional process that sulfate radicals in an FeSO4 raw material are difficult to wash cleanly and chloride ions in an FeCl3 raw material have a corrosion effect on equipment are overcome. The prepared lithium iron phosphate positive electrode material has the tap density reaching up to 1.68 g / cm<3>, has large volume specific capacity, is beneficial for preparation of a positive electrode material slurry and coating of an electrode slice, and improves the quality of the electrode slice.

Owner:吴位跃

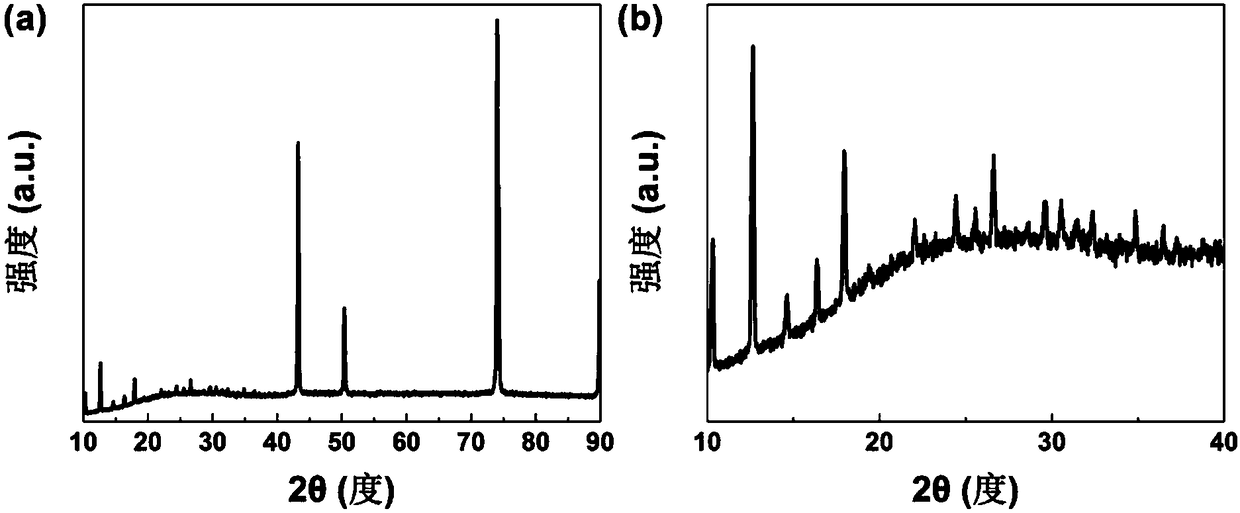

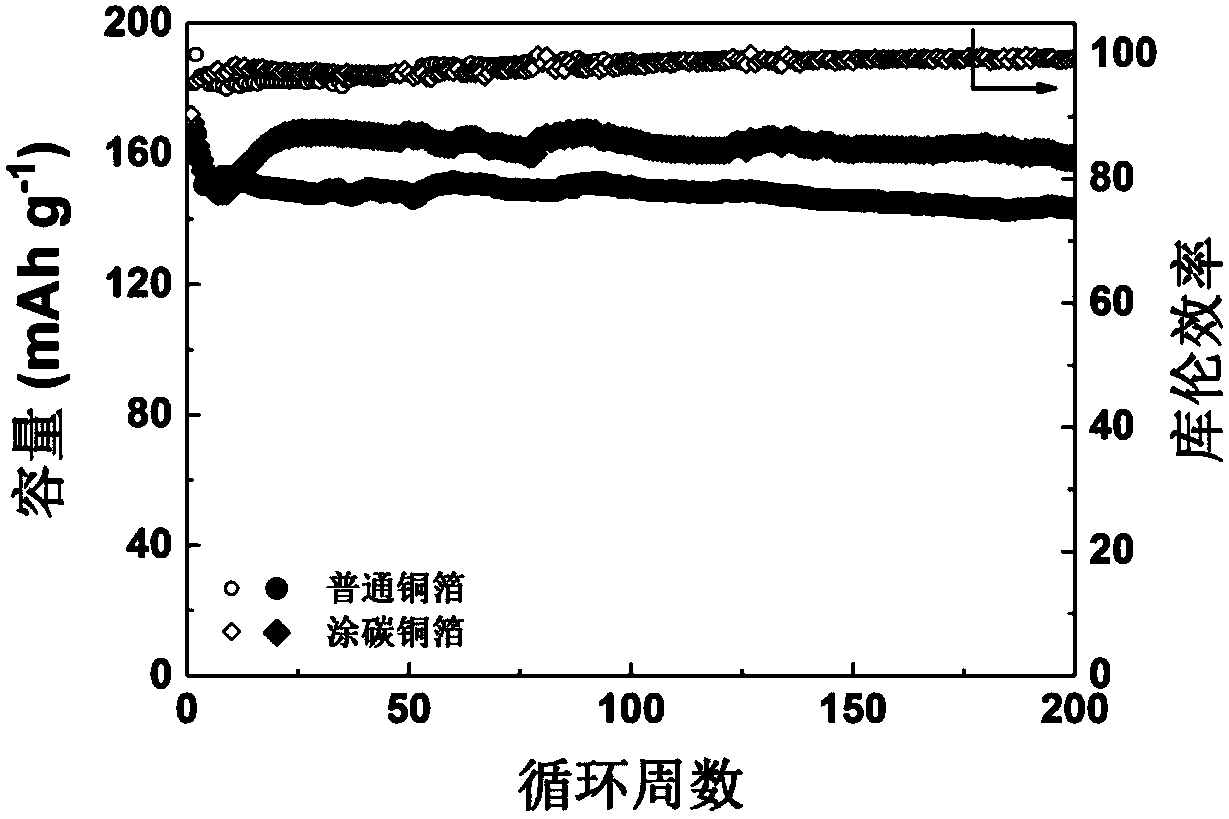

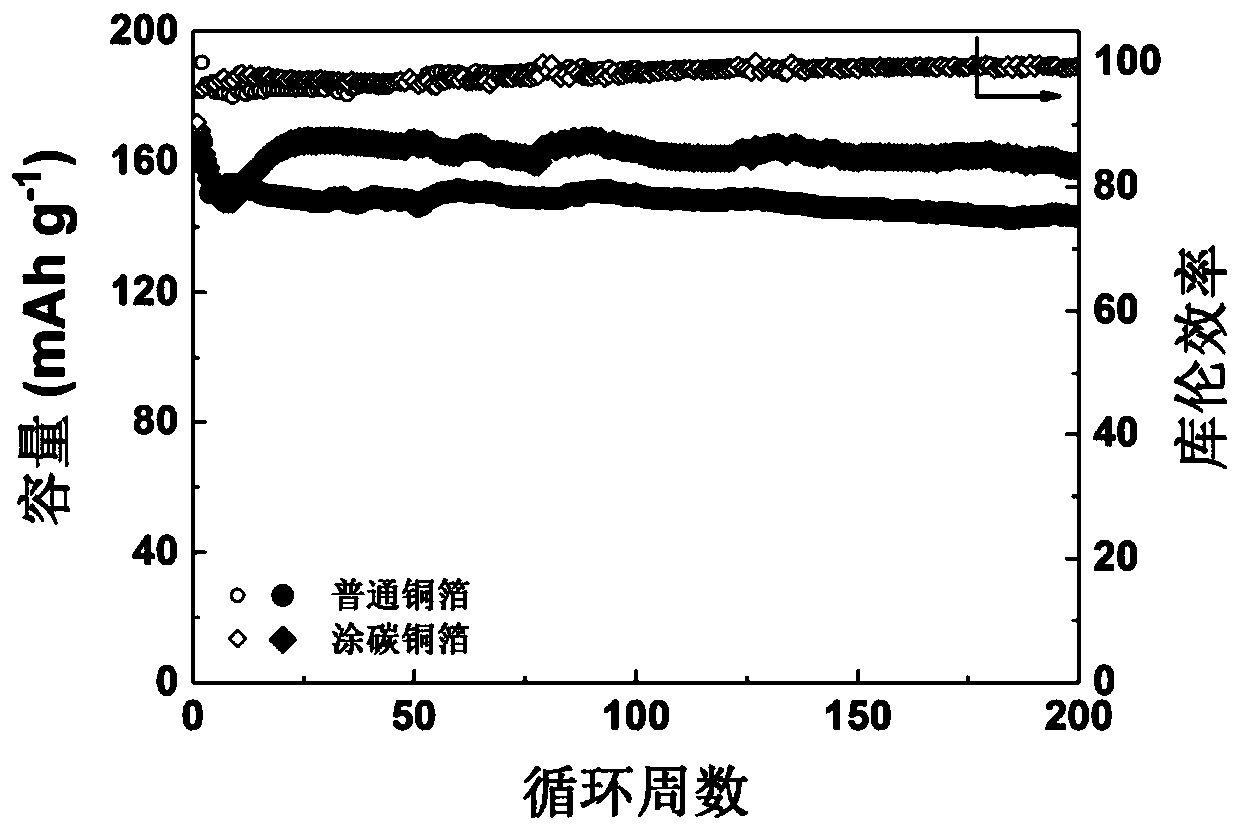

Composite current collector and preparation method thereof

ActiveCN108539280AImprove bindingNot easy to fall offFinal product manufactureElectrode carriers/collectorsCarbon coatingEngineering

The invention relates to a preparation method of a composite current collector, and belongs to the field of batteries. The preparation method comprises the following steps: 1) pretreating a current collector, to be more specific, first removing oil in the current collector respectively with ethanol, acetone and deionized water in an ultrasonic cleaning device, and drying the current collector forlater use; 2) coating carbon slurry, to be more specific, first configuring a MOF solution, then placing the current collector in the step 1) in a solution, and drying after the reaction for standby use; 3) drying and carbonizing, to be more specific, placing the dried current collector in the step 2) in a protective atmosphere and carbonizing at a high temperature to obtain the current collectorwith a coating layer on the surface; 4) pickling, to be more specific, pickling the current collector in the step 3) to remove a non-carbon material on the surface of the current collector to obtain the current collector containing a carbon coating layer; and 5) drying and grinding, to be more specific, drying and grinding the obtained current collector to obtain the composite current collector. Ametal frame compound is carbonized, the carbonized metal frame compound is used as the coating layer of the current collector, adhesion between the coating layer and a substrate body is strong, the coating layer is not easy to fall off, and an obtained battery has good cycle performance.

Owner:SHANDONG UNIV

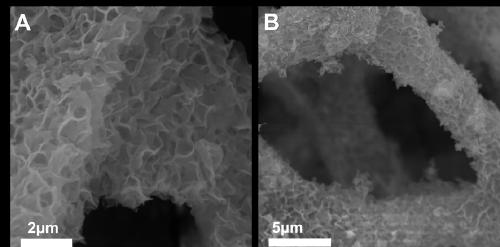

Preparation method of supercapacitor electrode material based on carbonized melamine foam-coated Bi2O3 nanosheets

ActiveCN109950050AHigh abundance of structuresLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesCapacitanceSupercapacitor

The invention discloses a preparation method of a supercapacitor electrode material based on carbonized melamine foam-coated Bi2O3 nanosheets. The preparation method comprises the following steps: (1)carrying out hydrothermal reaction on water-soluble bismuth salt and the carbonized melamine foam; (2) removing residual solvents, Bi <3+> and NO3 <-> by using a cleaning agent to obtain an intermediate product; (3) reacting in an inert atmosphere, annealing the intermediate product and filtering to obtain the supercapacitor electrode material based on melamine carbide foam-coated Bi2O3 nanosheets. The invention provides a simple solvothermal method. According to the method, Bi2O3 nanosheets are grown on carbonized melamine foam in situ to form a three-dimensional nuclear sheath structure. The electrode material has good electrical conductivity and high specific surface area. The storage of electrolyte is facilitated and the diffusion path of electrolyte ions is shortened. The contact area of the electrolyte and the material is increased, so that the capacitance is improved. Moreover, when the capacitor is constructed, the use of a binder and a conductive additive is avoided. The prepared material can be made into a flexible electrode. The preparation method is simple, harmless to the environment and low in cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

PA/TPU supercritical foamed composite material and preparation method thereof

The invention discloses a PA / TPU supercritical foamed composite material and a preparation method thereof. The PA / TPU supercritical foamed composite material is prepared from the following raw materials in parts by weight: 200-240 parts of polyamide, 160-180 parts of organic silicon modified polyurethane, 70-77 parts of a maleic anhydride grafted modifier, 45-52 parts of maleic anhydride grafted high-density polyethylene, 22-26 parts of glass fiber, 15-18 parts of a cross-linking agent and 5-7 parts of a nucleating agent. The PA / TPU supercritical foamed composite material is good in foaming effect and moderate and uniform in pore size, and good appearance performance, mechanical performance and the like are guaranteed; the tensile strength is high, the tearing strength is high, and the tearing resistance is good; the material has the advantages of low density, light weight, high strength and the like, and has excellent mechanical properties and usability.

Owner:福建安达福新材料科技有限公司

Nylon/polyurethane supercritical foamed composite material and preparation method thereof

The invention discloses a nylon / polyurethane supercritical foamed composite material and a preparation method thereof. The nylon / polyurethane supercritical foamed composite material is prepared from the following raw materials in parts by weight: 300-350 parts of polyamide, 60-72 parts of polyurethane, 40-48 parts of a polyamide-polysiloxane segmented copolymer, 6-8 parts of graphene fiber, 5-7 parts of a cross-linking agent and 3-4 parts of a nucleating agent. The nylon / polyurethane supercritical foamed composite material disclosed by the invention is good in foaming effect and high in foaming efficiency; the foam holes are uniform, small and compact; the advantages of high resilience rate, low water absorption rate, good dimensional stability, small irreversible deformation after being pressed, high tensile strength, good mechanical properties, light weight, high strength and the like excellent mechanical properties and use properties are achieved.

Owner:福建安达福新材料科技有限公司

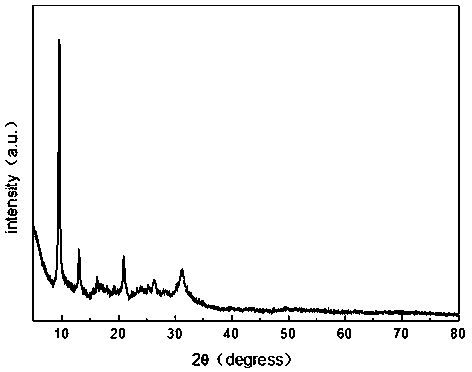

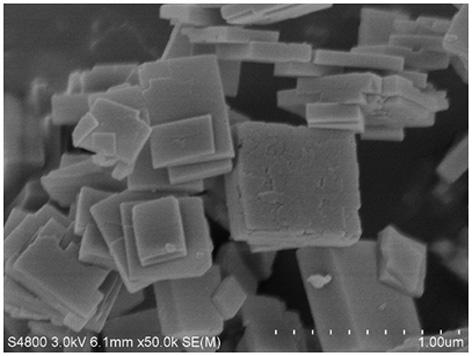

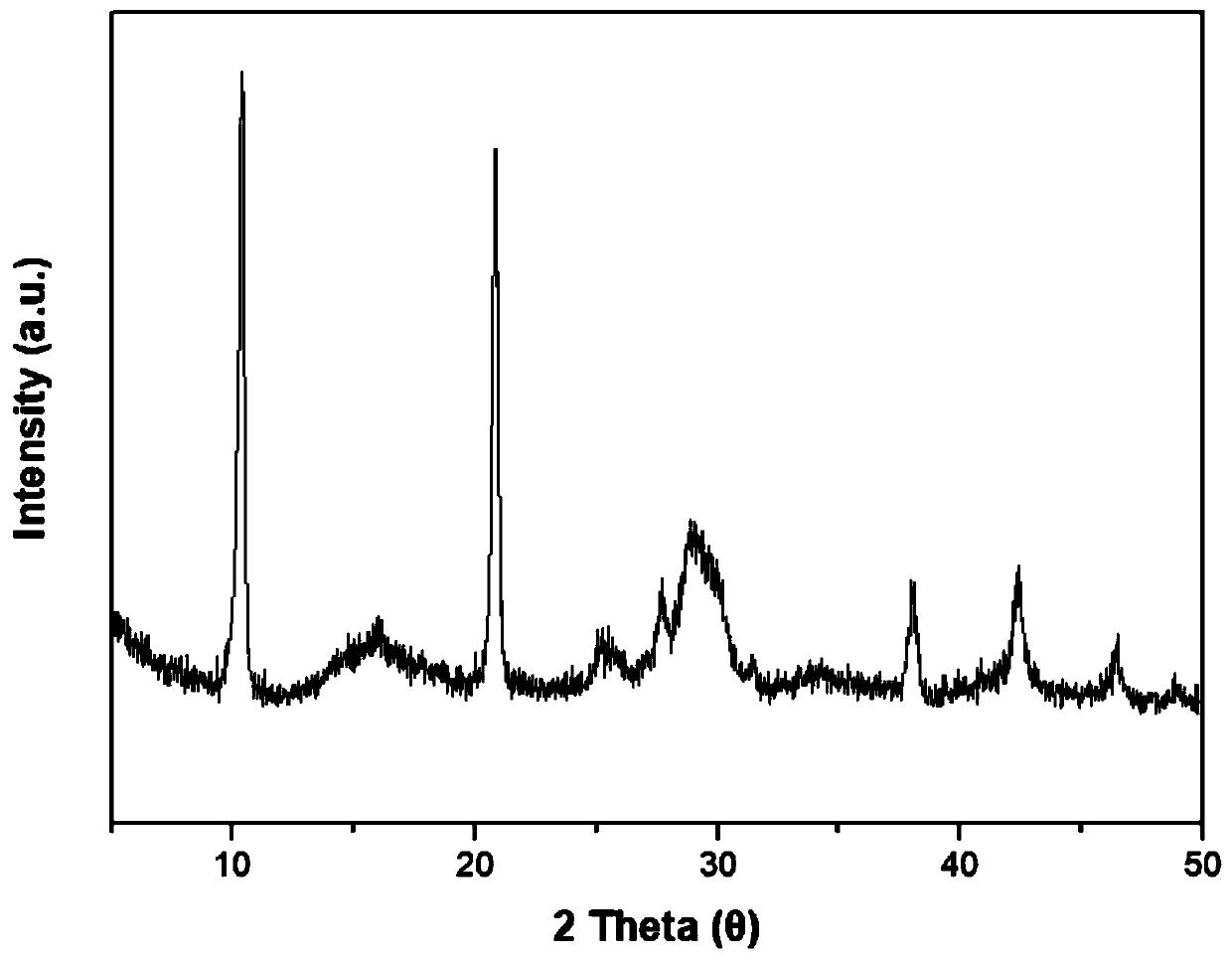

Rapid preparing method of large-specific-surface-area SAPO-34 molecular sieve

ActiveCN110407220AIncrease supersaturationIncrease growth rateMolecular sieve catalystsEthylene productionGlycerolStructural unit

The invention discloses a rapid preparing method of a large-specific-surface-area SAPO-34 molecular sieve. The molecular sieve is obtained with an aluminum source, a phosphorus source, a silicon source, a template TEAOH, deionized water and glycerol as the raw materials through crystallization for 4-16 hours at 160-200 DEG C. The introduced glycerol and water in synthesis liquid can form hydrogenbonds, and therefore the content of water in the synthesis liquid is reduced, the saturability of a solution is increased, the rapid nucleation of crystal nucleuses is promoted, the growth of the crystal nucleuses in the later period is facilitated, and the size of particles of the molecular sieve is reduced. Meanwhile, a hydroxyl group in the glycerol and a primary structural unit in the synthesis liquid can have a covalent bonding reaction, the adsorption of the primary structural unit to the surface of the glycerol is promoted, the growth rate of the crystal nucleuses is increased, the required crystallization time is shortened, and thus the preparing cycle of the SAPO-34 molecular sieve can be obviously shortened.

Owner:SINOCHEM QUANZHOU ENERGY TECH CO LTD

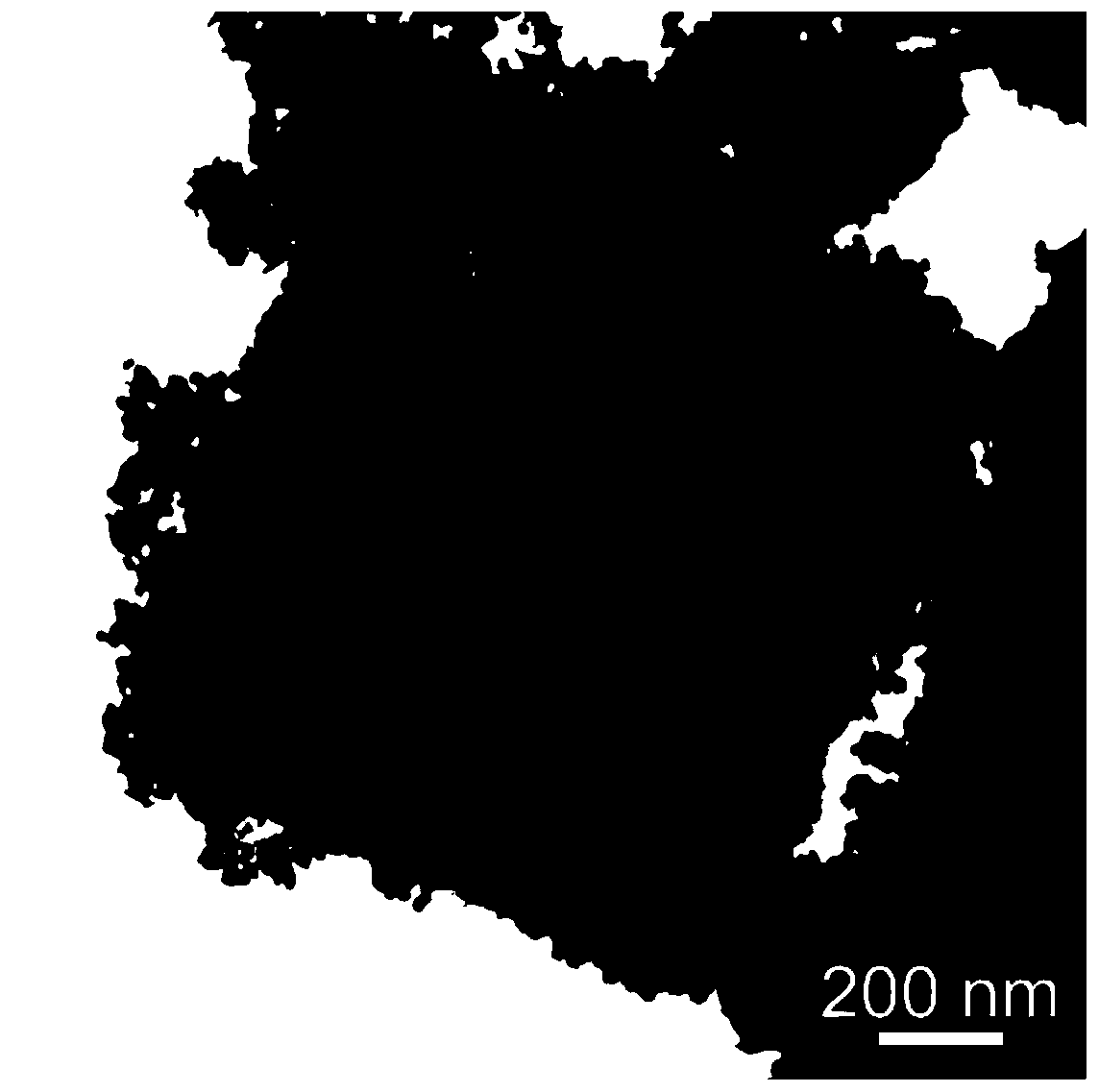

Method for preparing Fe-doped Mn3O4 carbon-nitrogen material with hollow nano-frame structure and application thereof

ActiveCN110148763AIncreased oxygen reduction activityRegular shapeCell electrodesPrussian blueZinc–air battery

The invention discloses a method for preparing a Fe-doped Mn3O4 carbon-nitrogen material with a hollow nano-frame structure and the application of the material in an oxygen reduction reaction and a zinc-air battery. The method comprises the steps of (1) separately preparing a Fe(CN)6<3-> / PVP solution and a Mn<2+> solution, (2) uniformly mixing the Fe(CN)6<3-> / PVP solution and the Mn<2+> solution and standing to obtain KMnFe(CN)6 khaki Prussian blue similar precipitation, and (3) performing alkali washing on KMnFe(CN)6 solid powder in a NaOH solution and raising the temperature to perform thermal processing at 250 DEG C to 350 DEG C in an inert atmosphere to obtain the Fe-doped Mn3O4 carbon-nitrogen material with the hollow nano-frame structure. The preparation method of the invention has the advantages of low cost and simple and universal use, the obtained material has the open hollow nano-frame structure, the material can be used as an electrocatalytic material of oxygen reduction reaction, and the material has high activity and excellent stability energy and can be applied as a positive electrode material of the zinc-air battery.

Owner:NANJING NORMAL UNIVERSITY

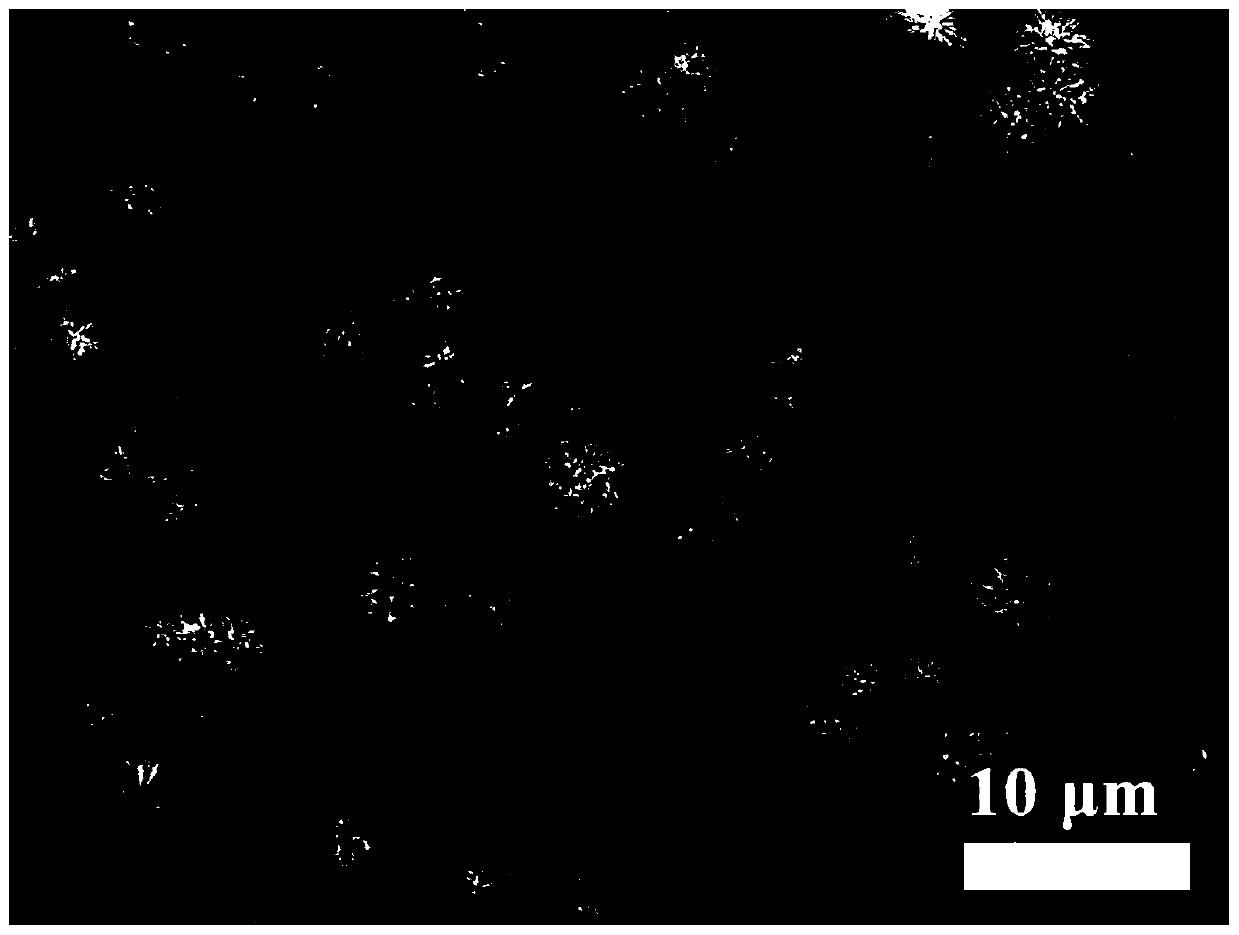

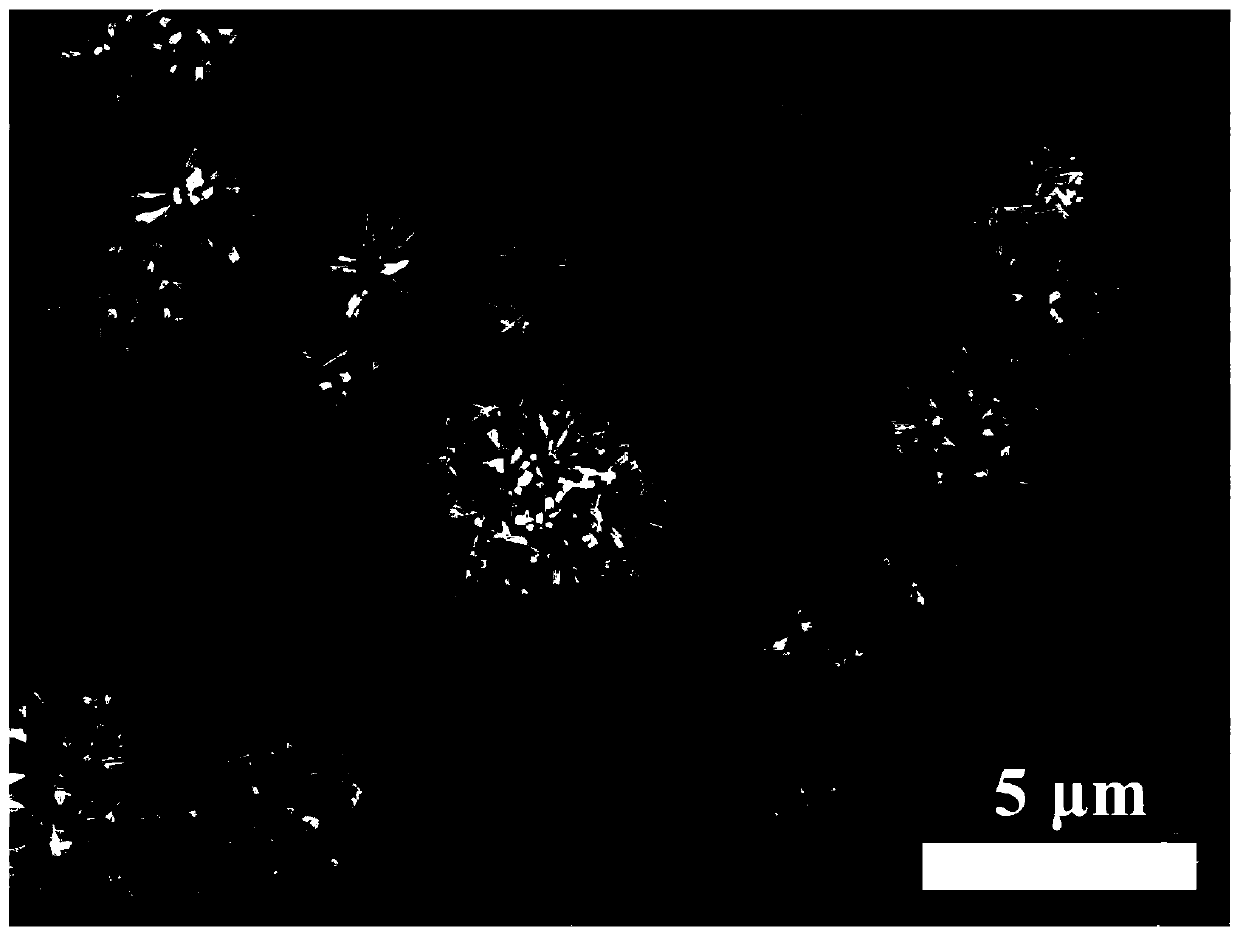

Application of chestnut-shaped graded manganese selenide/carbon composite material as lithium ion battery anode material

InactiveCN110364702AImprove conductivityShorten the pathway of diffusionCell electrodesSecondary cellsCarbon compositesCapacitance

The invention discloses application of a chestnut-shaped graded manganese selenide / carbon composite material as a lithium ion battery anode material. The diameter of the chestnut-shaped graded manganese selenide / carbon composite material is about 1-5 [mu]m. The chestnut-shaped graded manganese selenide / carbon composite material has the multiple characteristics of the high conductivity, the high specific surface area, the high volume change inhibition effect, the relatively higher working voltage platform and the pseudo-capacitance enhancement, so that the safety of the lithium ion battery is improved, the cycling stability and the rate capability of the lithium ion battery are improved, and the assembled lithium ion battery has the better electrochemical performance.

Owner:HANGZHOU DIANZI UNIV

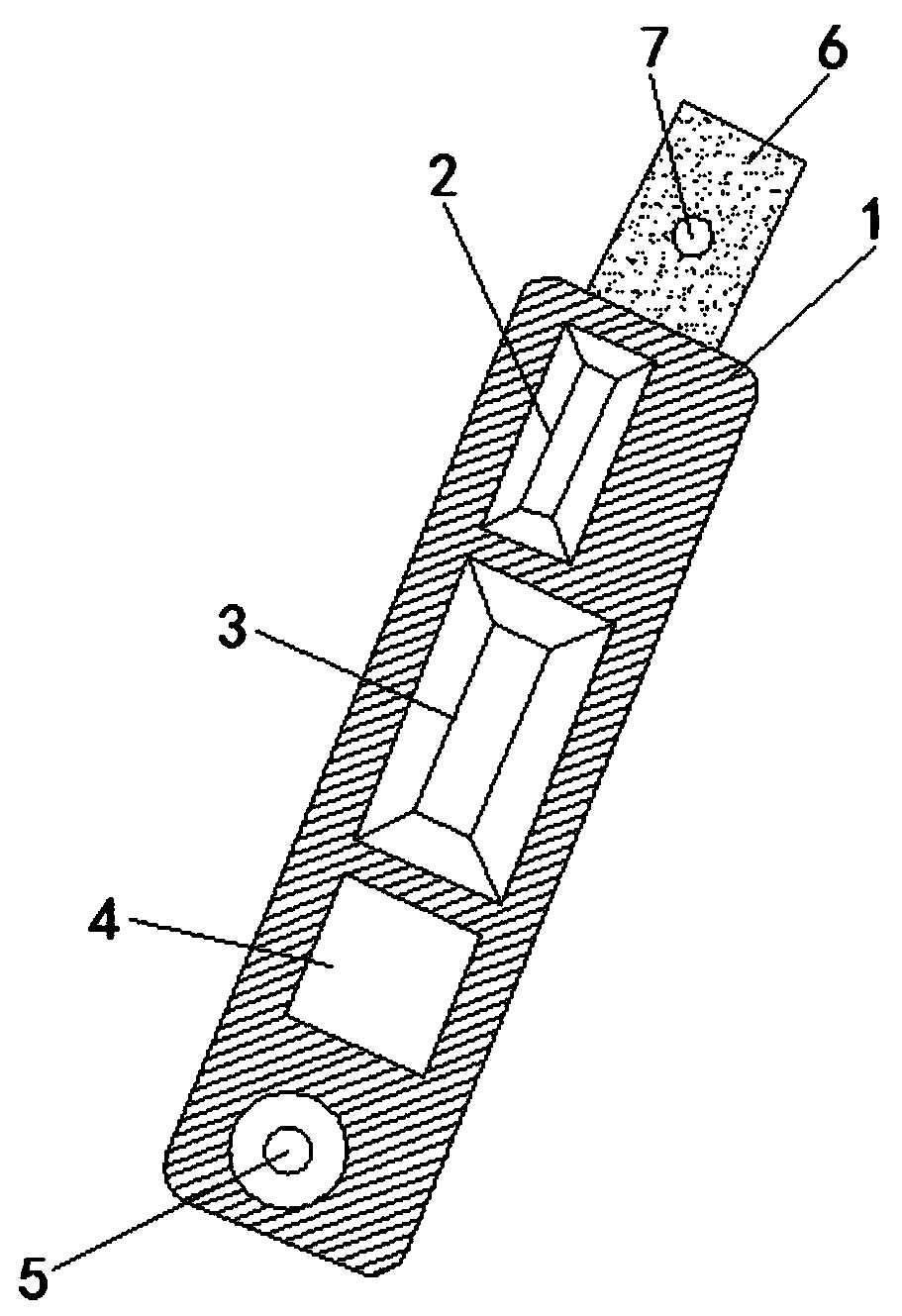

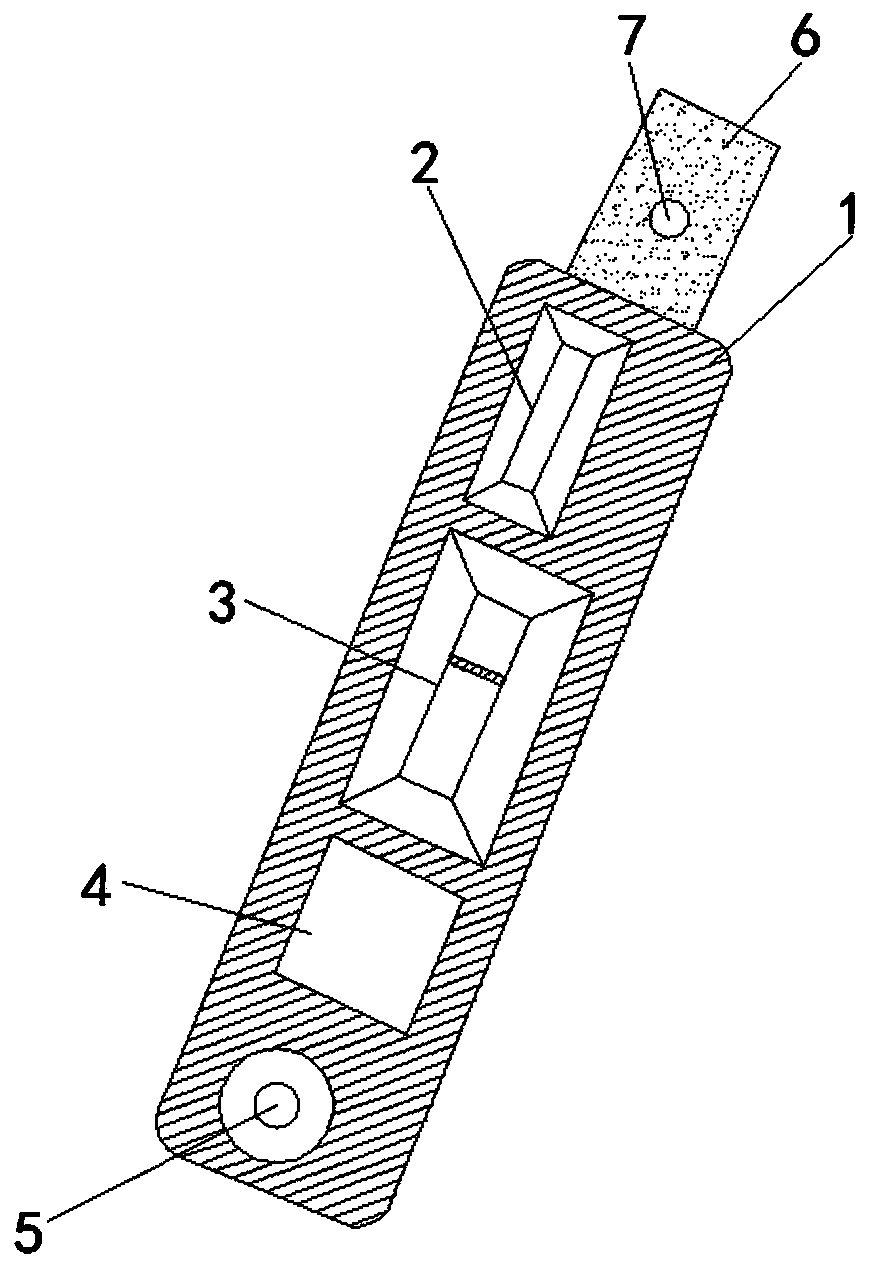

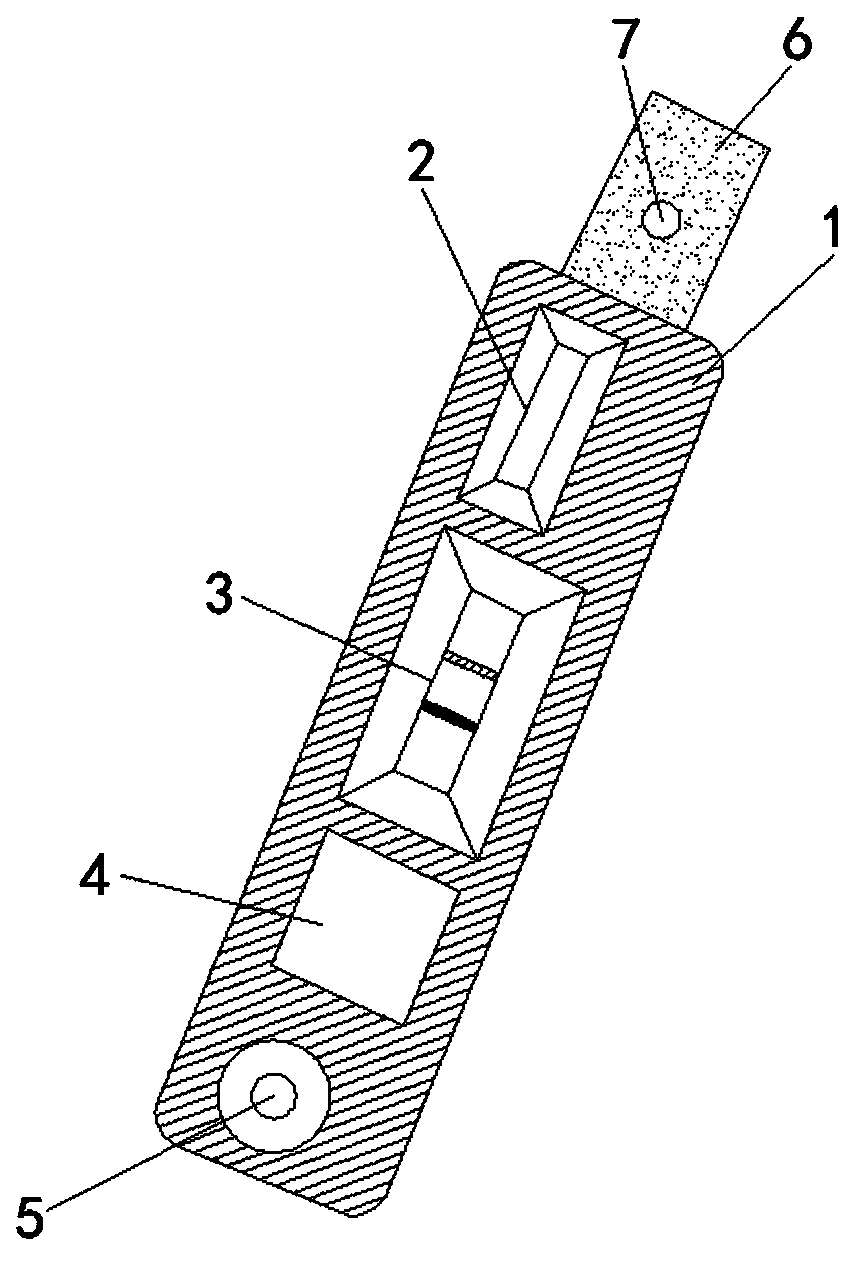

Rapid detection card for African swine fever virus

The invention relates to the technical field of African swine fever virus detection and discloses an rapid detection card for African swine fever virus, which comprises a cover plate, a sample pad, acellulose nitrate film, a water absorption pad, a sample adding hole, an expanding plate, a clamping column, a PVC supporting plate, a handle, a pressing block and a clamping plate, wherein the PVC supporting plate is fixedly connected to the back surface of the cover plate; the sample pad contacted with the cover plate is adhered to the front surface of the PVC supporting plate; the cellulose nitrate film contacted with the cover plate is adhered to the front surface of the PVC supporting plate; the sample adding hole is form in the front surface of the cover plate, the sample adding hole ismovably connected with the water absorption pad; the top of the cover plate is fixedly connected with the expanding plate, the expanding plate is fixedly connected with the clamping column, the innerpart of the handle is connected with the pressing block, the pressing block is connected with the clamping plate, the clamping plate is in contact with the expanding plate, the rapid detection card for the African swine fever virus achieves the purpose of safer use and reduces the transmission and diffusion paths of the African swine fever.

Owner:丁建红

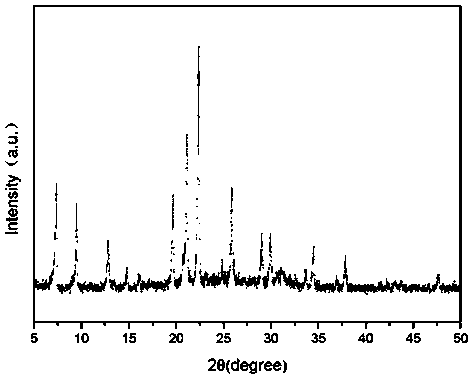

Preparation method of ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material

InactiveCN104140128AEasy accessShorten the pathway of diffusionNickel oxides/hydroxidesCapacitanceSulfate

The invention relates to a preparation method of a ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material. The preparation method comprises the steps that nickel sulfate, guanidine hydrochloride and sodium chloride are used as raw materials, mesoporous carbon is used as a template, and then the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is prepared through a template method. Compared with the prior art, the preparation method has the advantages that the mesoporous carbon is used as the template, the guanidine hydrochloride is used as precipitating agents firstly without adding any surface active agents, and deionized water is adopted as a reaction solvent; the raw materials are cheap, and the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is nontoxic, harmless, simple in technological process, controllable in particle morphology, free from complex postprocessing processes and low in cost, and has good application prospect.

Owner:TONGJI UNIV

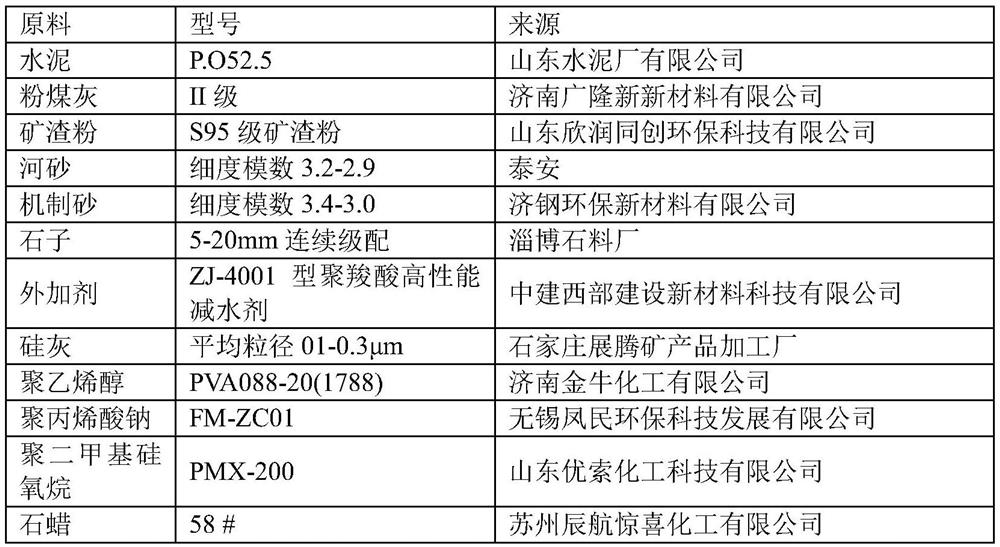

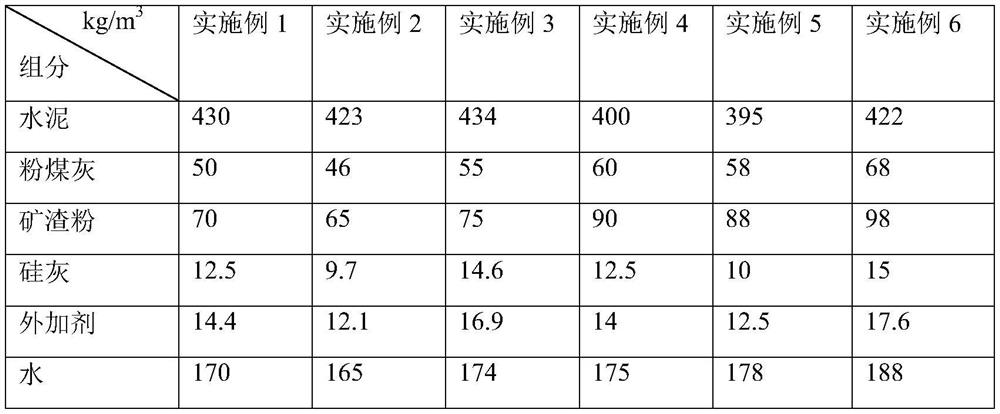

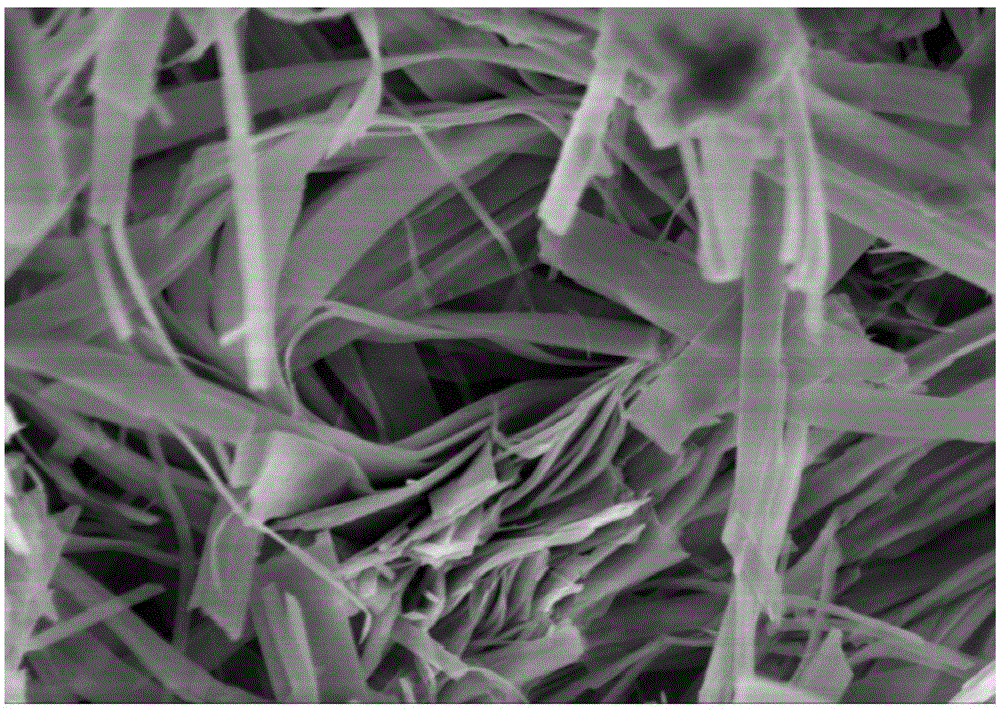

A kind of super high-rise jacking self-compacting concrete and its construction technology

ActiveCN113929401BIncrease rationalityImprove homogeneityBuilding material handlingCrack resistanceSlag

The present application relates to the field of building materials, and specifically discloses a super high-rise self-compacting concrete and a construction process thereof. The super high-rise jacking self-compacting concrete includes the following components in parts by weight: 395-434 parts of cement, 46-68 parts of fly ash, 65-98 parts of slag powder, 9.7-15 parts of silica fume, 12.1-17.6 parts of admixture, 165-188 parts of water, 0-324 parts of river sand, 570-842 parts of machine-made sand, and 821-861 parts of stones; the content of stone powder in the machine-made sand is ≤12%; the construction process is: S1, preparing concrete, S2, Concrete transportation and pumping, S3, curing. The super high-rise jacking self-compacting concrete of the present application has the advantages of good workability, good homogeneity, little loss over 3 hours, high crack resistance, high impermeability and strong carbonization resistance.

Owner:SHANDONG JIANZE CONCRETE

A preparation method of a ribbon-shaped hierarchical mesoporous nickel oxide high specific capacitance electrode material

InactiveCN104140128BEasy accessShorten the pathway of diffusionNickel oxides/hydroxidesCapacitanceSulfate

The invention relates to a preparation method of a ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material. The preparation method comprises the steps that nickel sulfate, guanidine hydrochloride and sodium chloride are used as raw materials, mesoporous carbon is used as a template, and then the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is prepared through a template method. Compared with the prior art, the preparation method has the advantages that the mesoporous carbon is used as the template, the guanidine hydrochloride is used as precipitating agents firstly without adding any surface active agents, and deionized water is adopted as a reaction solvent; the raw materials are cheap, and the ribbon type graded mesoporous nickel oxide high-specific-capacitance electrode material is nontoxic, harmless, simple in technological process, controllable in particle morphology, free from complex postprocessing processes and low in cost, and has good application prospect.

Owner:TONGJI UNIV

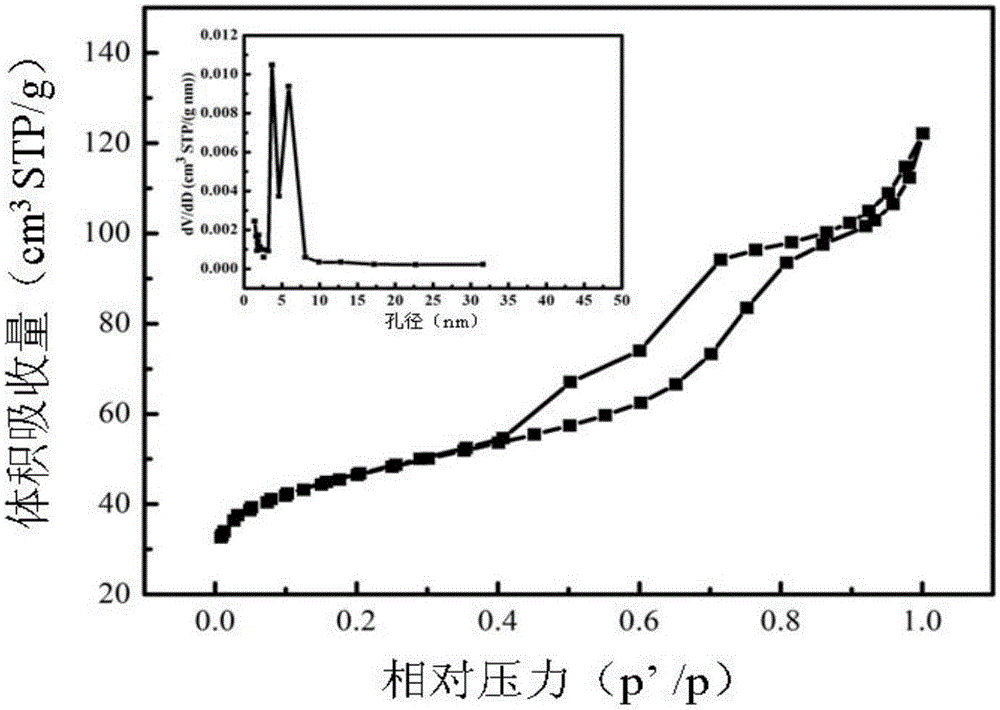

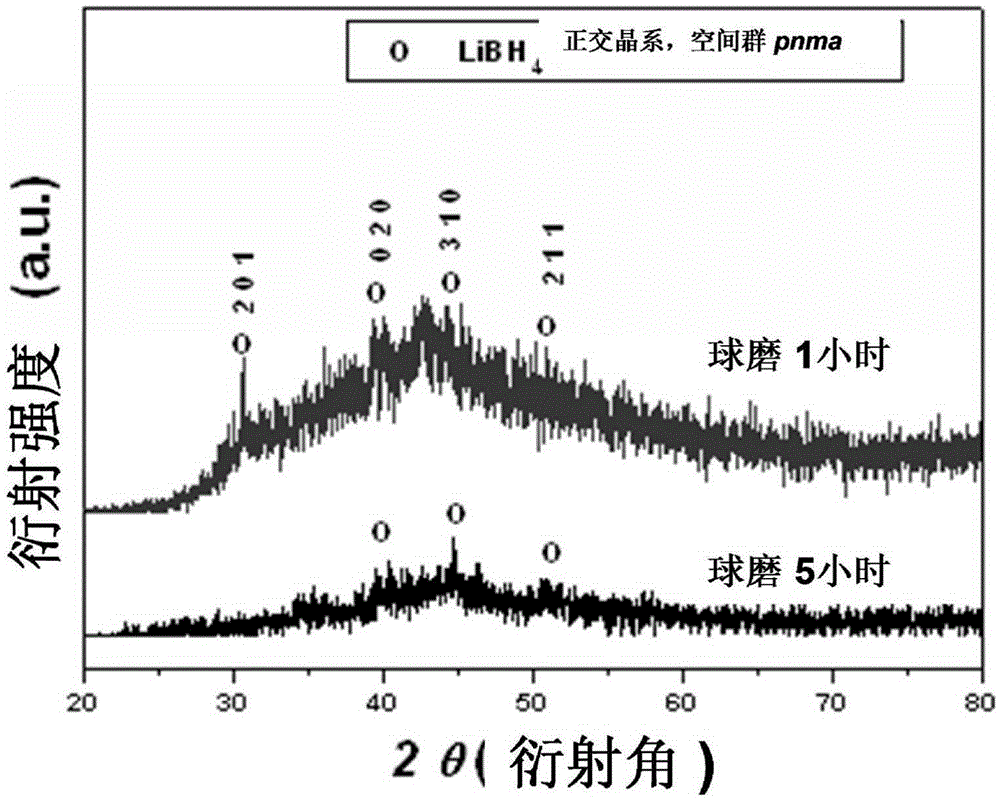

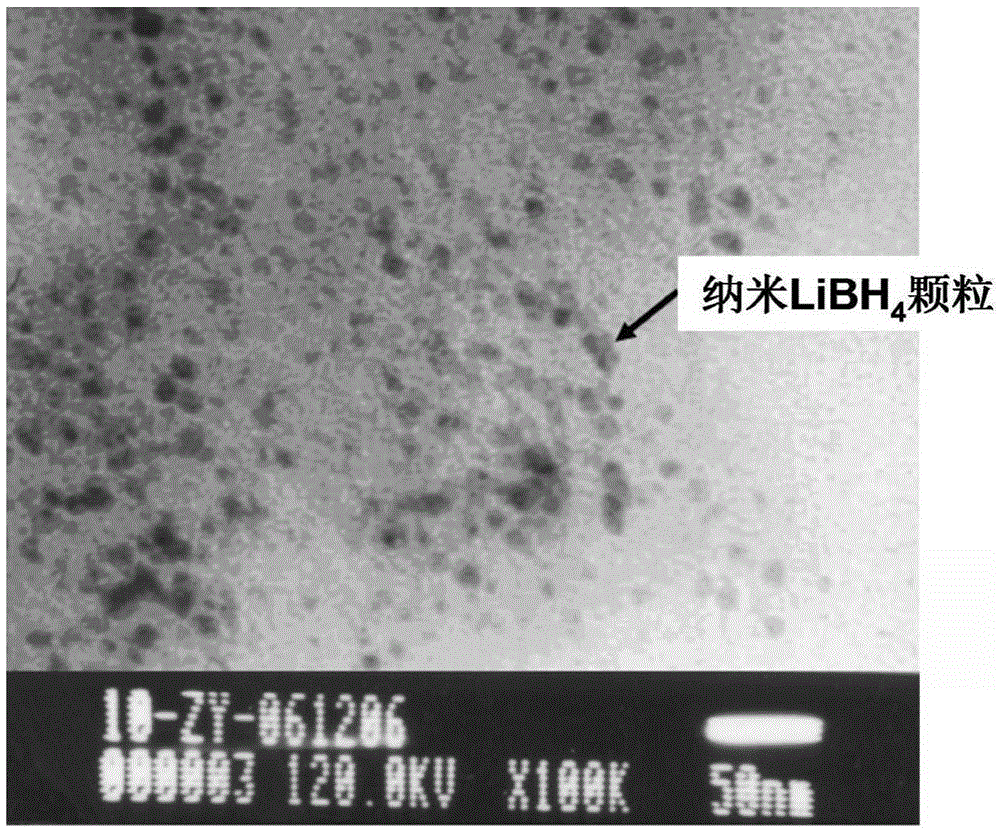

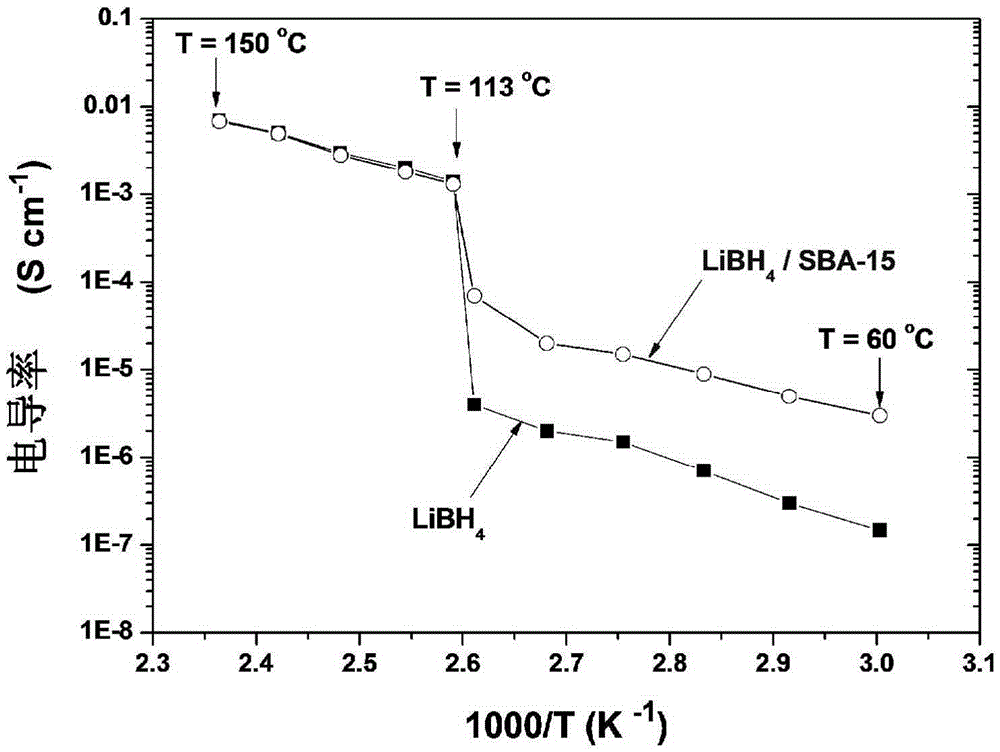

A nanoscale lithium ion conductor and its preparation method

ActiveCN103762346BEasy to prepareLow costMaterial nanotechnologySolid electrolytesElectrical conductorDiffusion network

The invention provides a lithium ion conductor with a nanoscale. The lithium ion conductor comprises a mesoporous silicon material and solid solution phase particles dispersed in the mesoporous silicon material, wherein the solid solution phase particles are selected from one or more of LiBH4 solid solution phase particles, 4LiBH4-LiF solid solution phase particles, 4LiBH4-LiCl solid solution phase particles, 4LiBH4-LiBr solid solution phase particles and 4LiBH4-LiI solid solution phase particles; the mesoporous silicon material is SBA-15. The lithium ion conductor has the beneficial effects that a preparation method of the lithium ion conductor is simple and is relatively low in cost; by dispersing lithium borohydride and lithium halide in the mesoporous silicon material, the diffusion path of the ions is greatly shortened, the diffusion network channel of the ions is widened, and the phase inversion temperature of the lithium ion conductor is reduced, thus greatly improving the electrical conductivity of the lithium ion conductor.

Owner:SOUTHEAST UNIV

A kind of composite current collector and preparation method thereof

ActiveCN108539280BImprove bindingNot easy to fall offFinal product manufactureElectrode carriers/collectorsElectrical batteryCarbonization

The invention relates to a preparation method of a composite current collector, which belongs to the field of batteries. The preparation method includes: 1) Current collector pretreatment: first use ethanol, acetone and deionized water to remove the oil stains on the current collector in an ultrasonic cleaner, and dry it for later use; 2) Coating carbon slurry: first Configure the MOF solution, then place the current collector in step 1) in the solution, dry it after reaction, and wait for use; 3) Dry carbonization: place the dried current collector in step 2) in a protective atmosphere and heat it under high temperature Carbonization to obtain a current collector with a coating layer on the surface; 4) Pickling: pickling step 3) the current collector to remove non-carbon substances on the surface of the current collector to obtain a current collector with a carbon coating; 5) Drying and milling Pressing: drying and rolling the obtained current collector. In the present invention, the carbonized metal frame is used as the current collector coating after the carbonization, the coating and the substrate have strong bonding force, the coating is not easy to fall off, and the obtained battery has good cycle performance.

Owner:SHANDONG UNIV

Preparation method of ferrous lithium hydrogen phosphate

ActiveCN102683699BShorten the pathway of diffusionIncrease contact areaCell electrodesLithium oxideO-Phosphoric Acid

The invention discloses a preparation method of ferrous lithium hydrogen phosphate. The preparation method sequentially comprises the following steps of: preparing ferrite phosphoric acid mixed solution by using soluble ferrite and phosphoric acid; preparing lithium hydroxide solution by using lithium hydroxide; adding pure water into a three-opening flask, and stirring and synchronously dropwise adding the ferrite phosphoric acid mixed solution and the lithium hydroxide solution in case of normal pressure backflow in a heating way; synchronously dropwise adding the ferrite phosphoric acid mixed solution and the lithium hydroxide solution, continuously stirring, and reflowing for 2-8 hours in a heating way, and carrying out solid-liquid separating and washing; and drying the washed solid to obtain the ferrous lithium hydrogen phosphate. The preparation method has the advantages that according to the preparation method, the commercially available lithium source, phosphorus source and iron source have a heating reflow reaction in case of liquid phase under normal pressure, so that the ferrous lithium hydrogen phosphate can be obtained. The raw materials are easy to obtain, and the preparation method is easy to operate, and low in energy consumption. The ferrous lithium phosphate can be easily prepared from the ferrous lithium hydrogen phosphate, compared with the existing preparation method of the ferrous lithium hydrogen phosphate, the preparation method greatly shortens the process route, and greatly simplifies the operation steps.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

A transition metal ion-doped trimanganese tetraoxide nanosheet array based on carbon cloth growth and its preparation method and application

ActiveCN112374545BUniform depositionImprove electrochemical performanceMaterial nanotechnologyElectrolytic inorganic material coatingElectrical batteryManganous-manganic oxide

The invention relates to a carbon cloth-based transition metal ion-doped trimanganese tetraoxide nanosheet array, a preparation method and application thereof. The present invention utilizes the high potential window of the manganese-based material itself as an advantage, and on this basis doped transition metal ions to modify the manganese-based material, thereby improving the electrochemical performance of the zinc-ion battery as a whole. Basic steps: first pretreat the empty carbon cloth; then grow transition metal ion-doped trimanganese tetraoxide nanosheet arrays on the empty carbon cloth by electrodeposition; finally wash and dry. The invention adopts a one-step method, which is convenient and simple, and the raw materials are conveniently obtained, with low cost and non-toxicity, which solves the problems of too many impurities in the material and cumbersome operation in the traditional technology. For the zinc-ion battery cathode material, the present invention optimizes the structure by doping the manganese-based oxide with transition metal ions, thereby improving the electrochemical performance of the battery. This provides a good idea for the selection or improvement of cathode materials for zinc-ion batteries in the future.

Owner:HUBEI UNIV

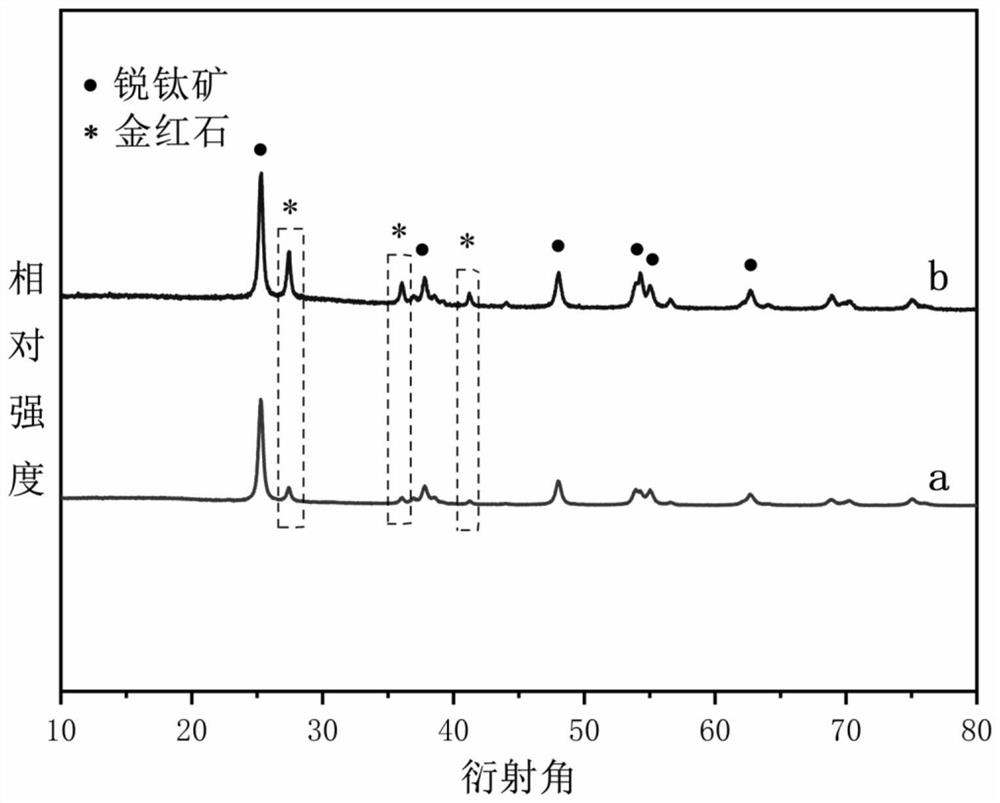

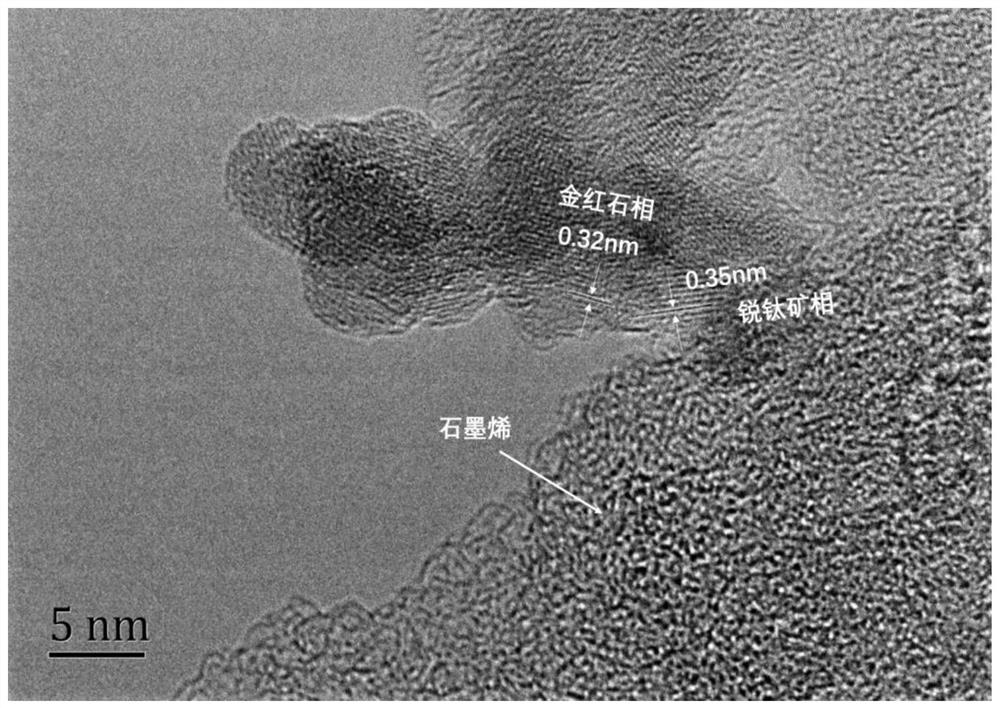

Multi-level structure combined with tio 2 Preparation and Application of Composite Graphene Anode Materials

ActiveCN111446416BImprove electrochemical kineticsImprove conductivitySecondary cellsNegative electrodesGraphiteGraphene

The invention discloses a multi-level structure combined with TiO 2 A method for preparing a composite graphene negative electrode material, comprising the following steps: using tetrabutyl titanate as a titanium source, alcohol compounds as a primary solvent, and preparing a precursor by a solvothermal method; the precursor is lower than the phase transition temperature, Transformation into phase-bound TiO with anatase and rutile phases via a two-step calcination method 2 ; Combined with TiO 2 Mix evenly with graphene and place in a secondary solvent, constant temperature, and ultrasonic treatment to obtain a three-dimensional multi-level structure of TiO 2 Composite graphene materials. A Hierarchical Structured TiO 2 The composite graphene negative electrode material is prepared by the above preparation method. A battery electrode is composed of multi-level structure combined with TiO 2 Composite graphene negative electrode material is prepared. The final material of the present invention has both nano-TiO 2 The high cycle life endowed to the battery, and the high conductivity and large current discharge ability endowed by graphene to the electrode material.

Owner:JIANGSU DONGYUAN ELECTRIC APPLIANCEGROUP

Composite positive electrode sheet for lithium-sulfur battery, preparation method and application thereof

ActiveCN109671907BAvoid churnReduce churnMaterial nanotechnologySecondary cellsElectrical batteryLithium–sulfur battery

Owner:XIAN JIAOTONG LIVERPOOL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com