Multi-level structure combined with tio 2 Preparation and Application of Composite Graphene Anode Materials

A technology of composite graphene and negative electrode materials, which is applied in the field of electrochemical energy storage, can solve the problems of low conductivity and cycle performance that cannot meet the requirements, achieve high conductivity, improve electrochemical kinetics, and high-current discharge capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Three-dimensional Hierarchical Structured TiO 2 The preparation method of composite graphene negative electrode material, the method comprises the following steps:

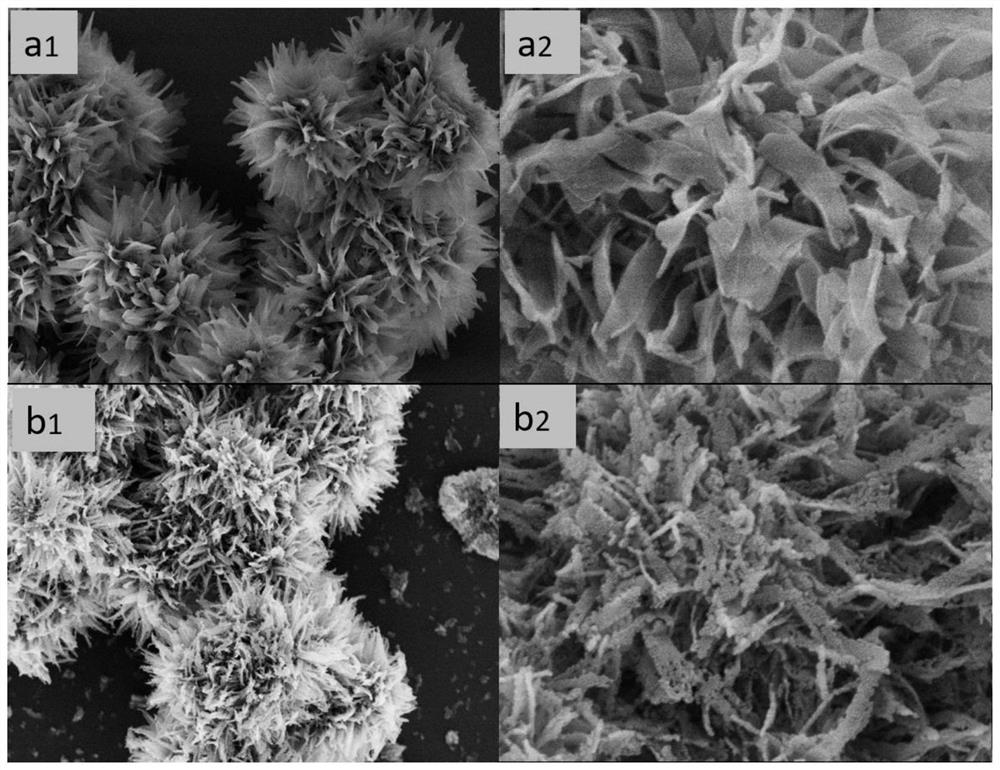

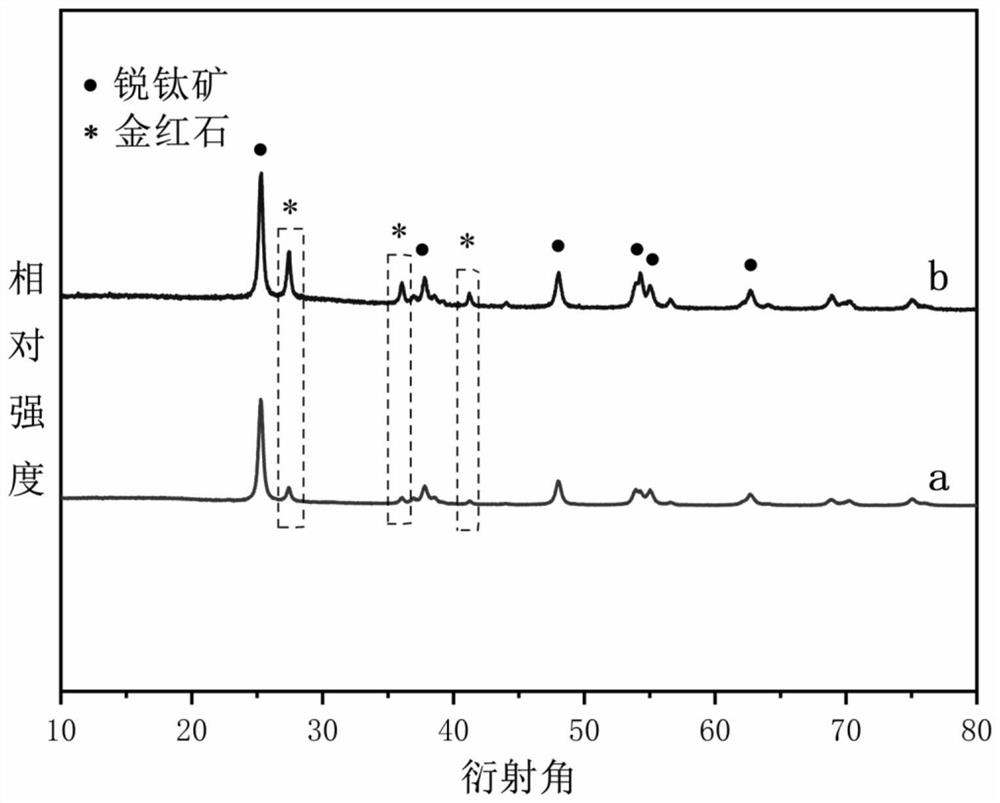

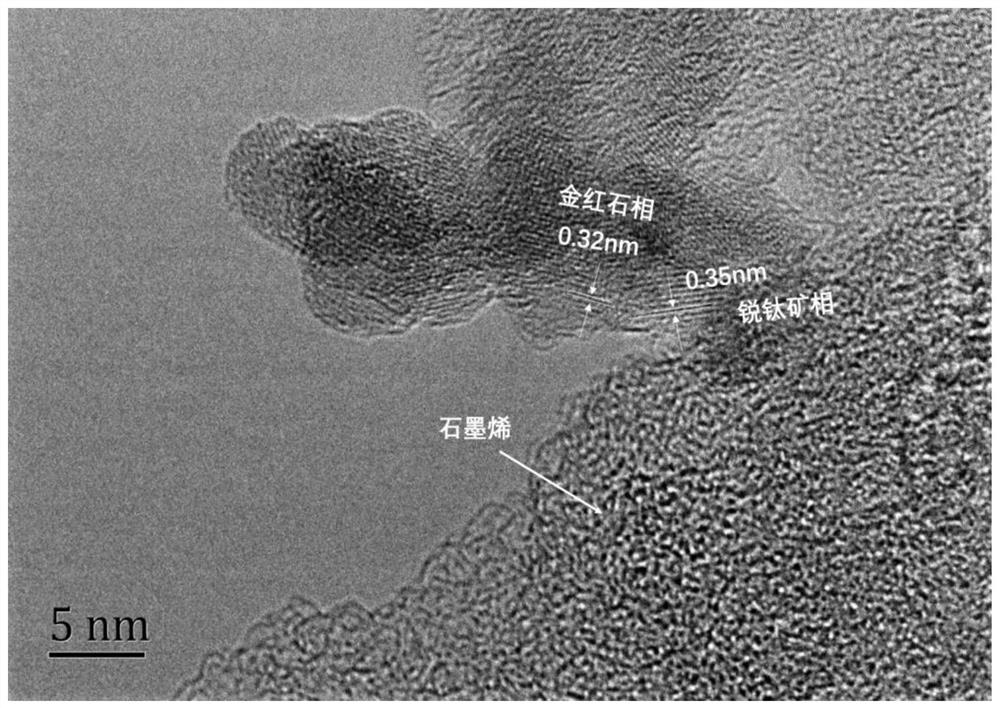

[0026] 1. Mix glycerol and ethanol uniformly at a volume ratio of 1:4 to obtain a primary solvent. According to the volume ratio of tetrabutyl titanate (TBOT) to the primary solvent is 10%, add titanic acid to the primary solvent tetrabutyl ester. After stirring evenly, put it into the reactor, and conduct a solvothermal reaction at 180°C for 50 hours to obtain a three-dimensional multi-level structure TiO 2 Precursor. Depend on figure 1 The a1 and a2 SEM images in the figure can clearly see that the three-dimensional multi-level structure TiO 2 The precursor is a three-dimensional multi-level flower structure assembled by a similar "ribbon" structure.

[0027] Ⅱ. The three-dimensional hierarchical structure TiO obtained in step Ⅰ 2 The precursor is placed in the furnace with an air flow rate of 25ml / ...

Embodiment 2

[0031] Three-dimensional Hierarchical Structured TiO 2 The preparation method of composite graphene negative electrode material, the method comprises the following steps:

[0032] 1. Mix glycerin and ethanol uniformly at a volume ratio of 1:1 to obtain a primary solvent. According to the volume ratio of tetrabutyl titanate (TBOT) to the primary solvent is 2%, add titanic acid to the primary solvent tetrabutyl ester. After stirring evenly, put it into the reactor, and conduct a solvothermal reaction at 180°C for 12 hours to obtain a three-dimensional multi-level structure TiO 2 Precursor.

[0033] Ⅱ. The three-dimensional hierarchical structure TiO obtained in step Ⅰ 2The precursor was placed in the furnace with an air flow rate of 1ml / min. First, the temperature was raised to 400°C at a heating rate of 5°C / min, and the temperature was maintained for 1 hour. After the first calcination was completed, the sample was cooled to room temperature and then the second secondary ca...

Embodiment 3

[0036] Three-dimensional Hierarchical Structured TiO 2 The preparation method of composite graphene negative electrode material, the method comprises the following steps:

[0037] 1. Mix glycerin and ethanol uniformly at a volume ratio of 1:2 to obtain a primary solvent. According to the volume ratio of tetrabutyl titanate (TBOT) to the primary solvent is 5%, add titanic acid to the primary solvent tetrabutyl ester. After stirring evenly, put it into the reactor, and conduct a solvothermal reaction at 180°C for 20 hours to obtain a three-dimensional multi-level structure TiO 2 Precursor.

[0038] Ⅱ. The three-dimensional hierarchical structure TiO obtained in step Ⅰ 2 The precursor is placed in the furnace with an air flow rate of 20ml / min. First, the temperature is raised to 300°C at a rate of 2°C / min, and the temperature is maintained for 3 hours. After the first calcination is completed, the sample is cooled to room temperature and then the second secondary calcination....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com