Mo2C and carbon-coated molybdenum-based heterostructure material as well as preparation method and application thereof

A heterogeneous structure and carbon encapsulation technology, which is applied in the preparation/purification of carbon, nanotechnology for materials and surface science, structural parts, etc., can solve difficult problems such as material volume expansion and particle breakage, and promote Effects of electrochemical kinetics, improving cycle stability, and improving lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] a Mo 2 The preparation method of the molybdenum-based heterostructure material sandwiched by C and carbon comprises the following steps:

[0031] S1. Dissolve the molybdenum source and complexing agent in 20-100mL of Mo of a certain concentration 2 CT X In the dispersion, the obtained solution is hydrothermally treated at 100-200°C for 2-40h. After filtering with deionized water until the filtrate was neutral, the obtained solid was dried at 40-100 °C for 10-40 h. The concentration of molybdenum ions in the solution is 1-15 mg / mL.

[0032] S2. Dissolve 0.1-2 g of the above solid in 30-600 mL of an initiator solution with a concentration of 5 mmol / L-1 mol / L, stir for 0.1-12 h, and add 0.1-2 g of polymer monomers. Under stirring conditions, after polymerization for 2-48 h, the suspension was filtered with deionized water until the filtrate was neutral, and the obtained solid was dried at 40-150° C. for 2-48 h. Finally, the solid is placed in a tube furnace, and is he...

Embodiment 1

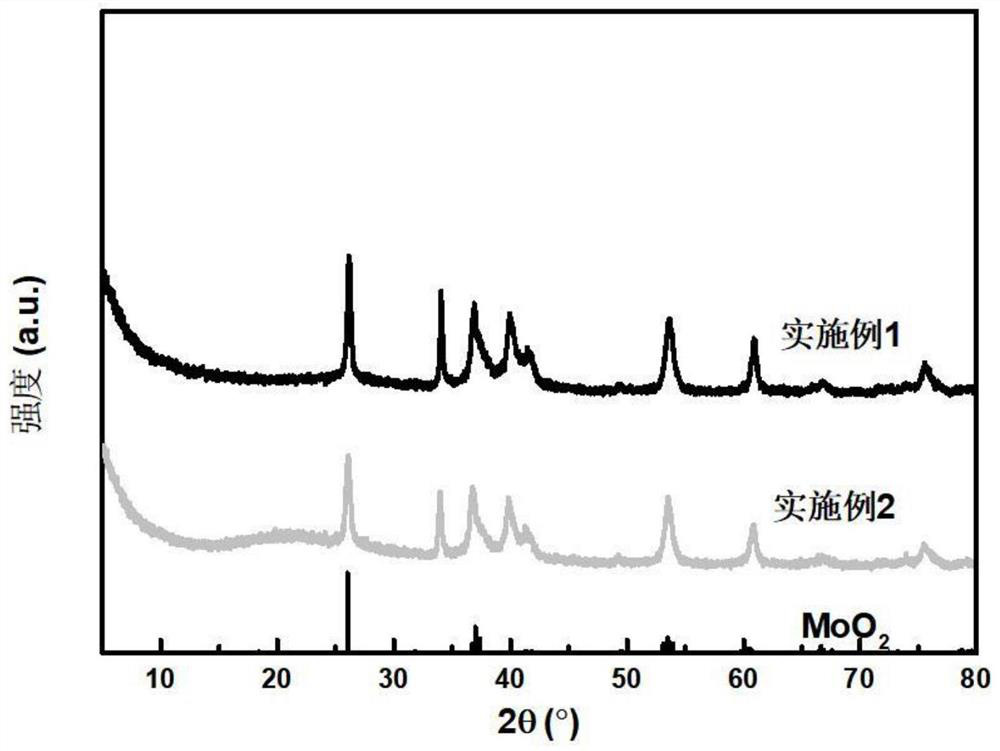

[0037] Dissolve 200 mg of ammonium molybdate and 100 mg of melamine in 30 mL of Mo with a concentration of 2.5 mg / mL 2 CT X In the dispersion, the obtained solution was hydrothermally treated at 120°C for 12h. After filtering with deionized water until the filtrate was neutral, the obtained solid was dried at 60°C for 24h. 0.2 g of the above solid was dissolved in 60 mL of a tris solution with a concentration of 10 mmol / L and stirred for 0.2 h, and 0.2 g of dopamine hydrochloride was added. Under stirring conditions, after polymerization for 12 h, the suspension was filtered with deionized water until the filtrate was neutral, and the obtained solid was dried at 80° C. for 12 h. Finally, the solid was placed in a tube furnace, and under the protection of argon atmosphere, the temperature was raised to 600 °C for 3 h at a heating rate of 2 °C / min to obtain Mo 2 Molybdenum-based heterostructure material sandwiched by C and carbon.

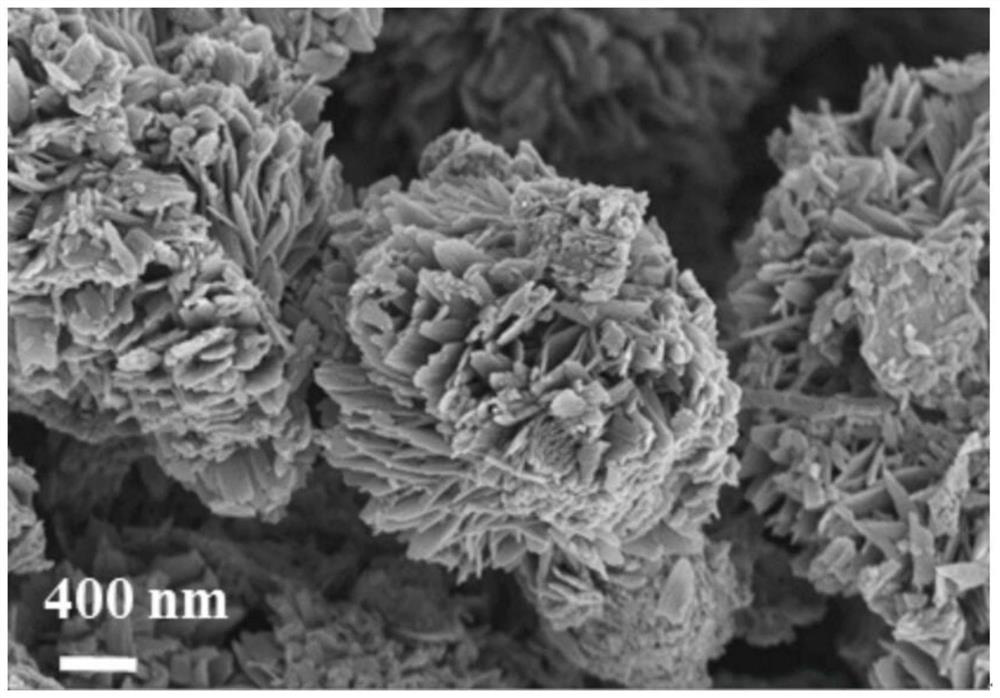

[0038] figure 1 In order to obtain the sc...

Embodiment 2

[0041] Dissolve 400 mg of ammonium molybdate and 200 mg of melamine in 60 mL of Mo with a concentration of 2 mg / mL 2 CT X In the dispersion, the obtained solution was hydrothermally treated at 120°C for 12h. After filtering with deionized water until the filtrate was neutral, the obtained solid was dried at 60°C for 24h. 0.2 g of the above solid was dissolved in 60 mL of a tris solution with a concentration of 10 mmol / L and stirred for 0.2 h, and 0.2 g of dopamine hydrochloride was added. Under stirring conditions, after polymerization for 12 h, the suspension was filtered with deionized water until the filtrate was neutral, and the obtained solid was dried at 100° C. for 12 h. Finally, the solid was placed in a tube furnace, and under the protection of argon atmosphere, the temperature was raised to 600 °C for 3 h at a heating rate of 2 °C / min to obtain Mo. 2 Molybdenum-based heterostructure material sandwiched by C and carbon.

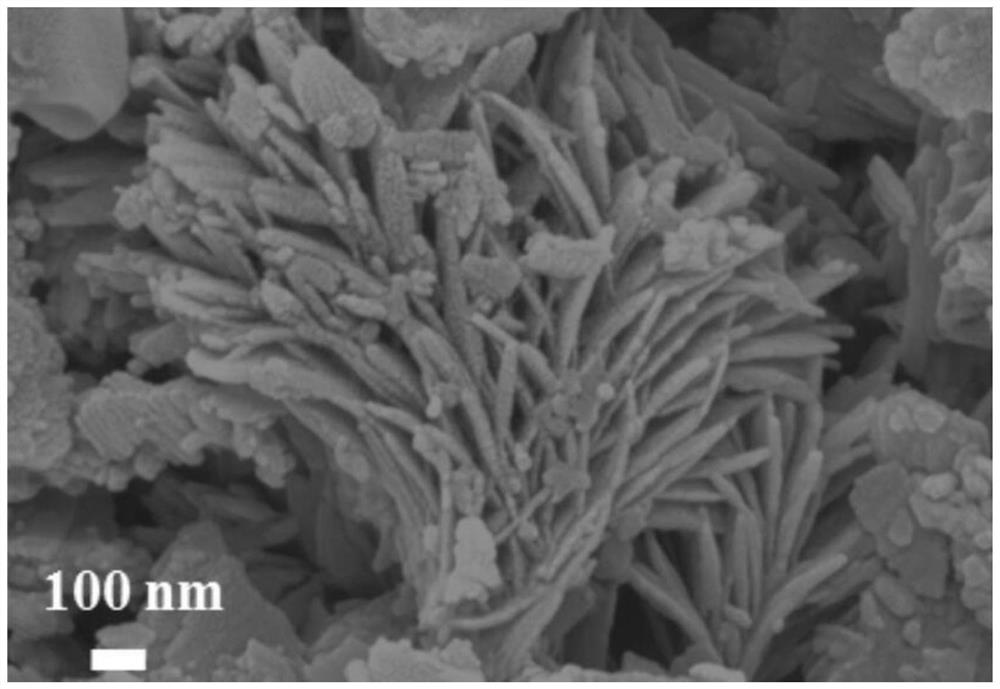

[0042] figure 2 In order to obtain a sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com