Patents

Literature

164results about How to "High lithium storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Core-shell structured carbon for cathode material of lithium ion battery and preparation method thereof

InactiveCN101969122AImprove energy density and power densityGood coulombic efficiencyCell electrodesSecondary cellsLithium electrodeLarge capacity

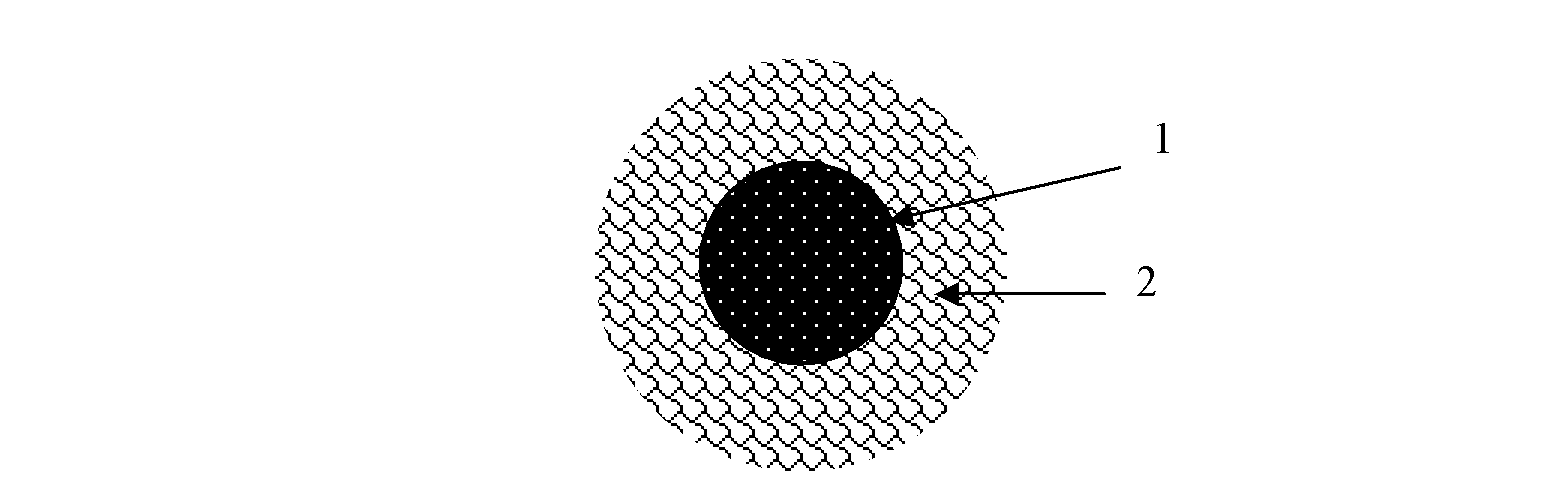

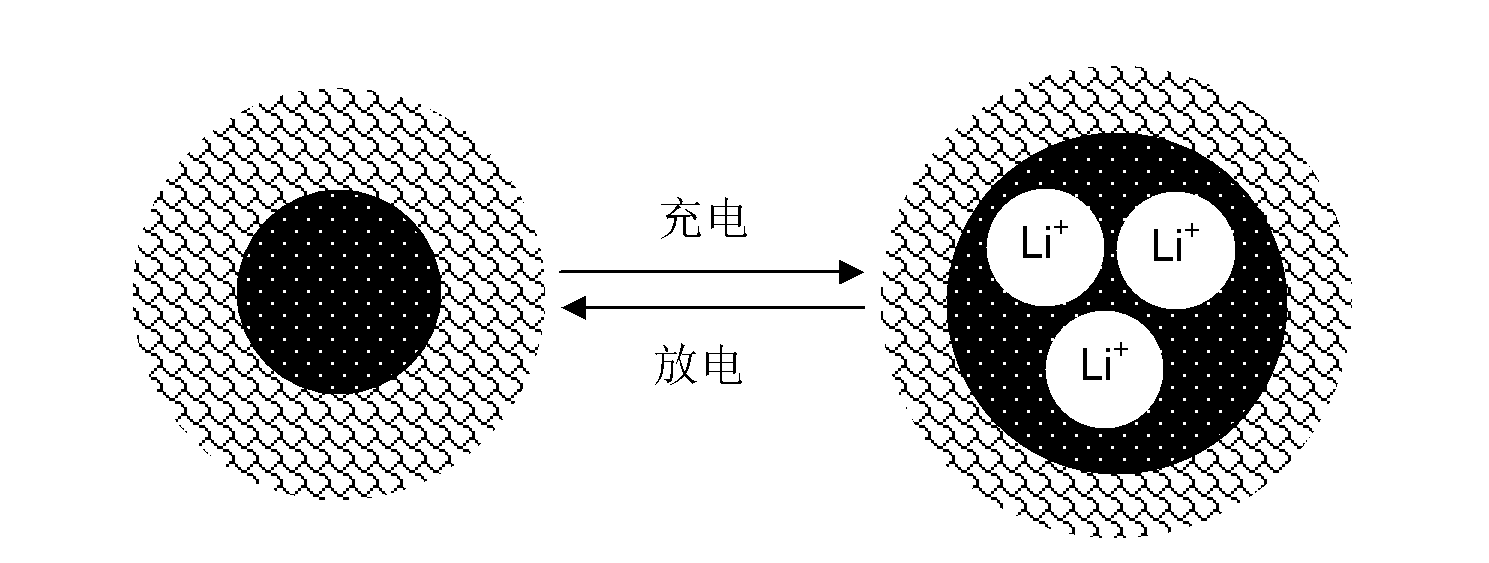

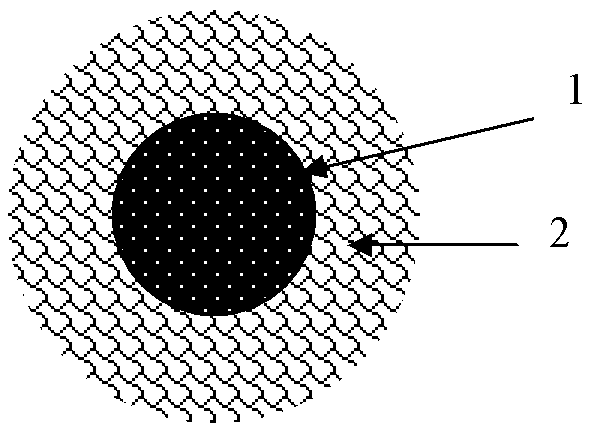

The invention relates to the technical field of lithium ion batteries, in particular to core-shell structured carbon for a cathode material of a lithium ion battery and a preparation method thereof, and the lithium ion battery taking the core-shell structured carbon as the cathode material and a preparation method thereof. The core-shell structured carbon comprises a hard carbon material serving as a 'core' and soft carbon 'shell' which is coated on the surface of the 'core'. On the one hand, the hard carbon material serving as the 'core' provides a large number of spaces for storing lithium and channels for lithium ions to move, and the energy density and power density of the material are improved, and on the other hand, the soft carbon 'shell' with a graphite structure ensures that the material has high coulombic efficiency and cycle performance, so that the lithium ion battery made of the core-shell structured carbon serving as the cathode material has high capacity, high power characteristic, high cycle performance and high first charge and discharge coulombic efficiency, the preparation method is simple, and the cost is low.

Owner:DONGGUAN MCNAIR NEW POWER

Negative electrode material used for lithium battery and preparation method and application thereof

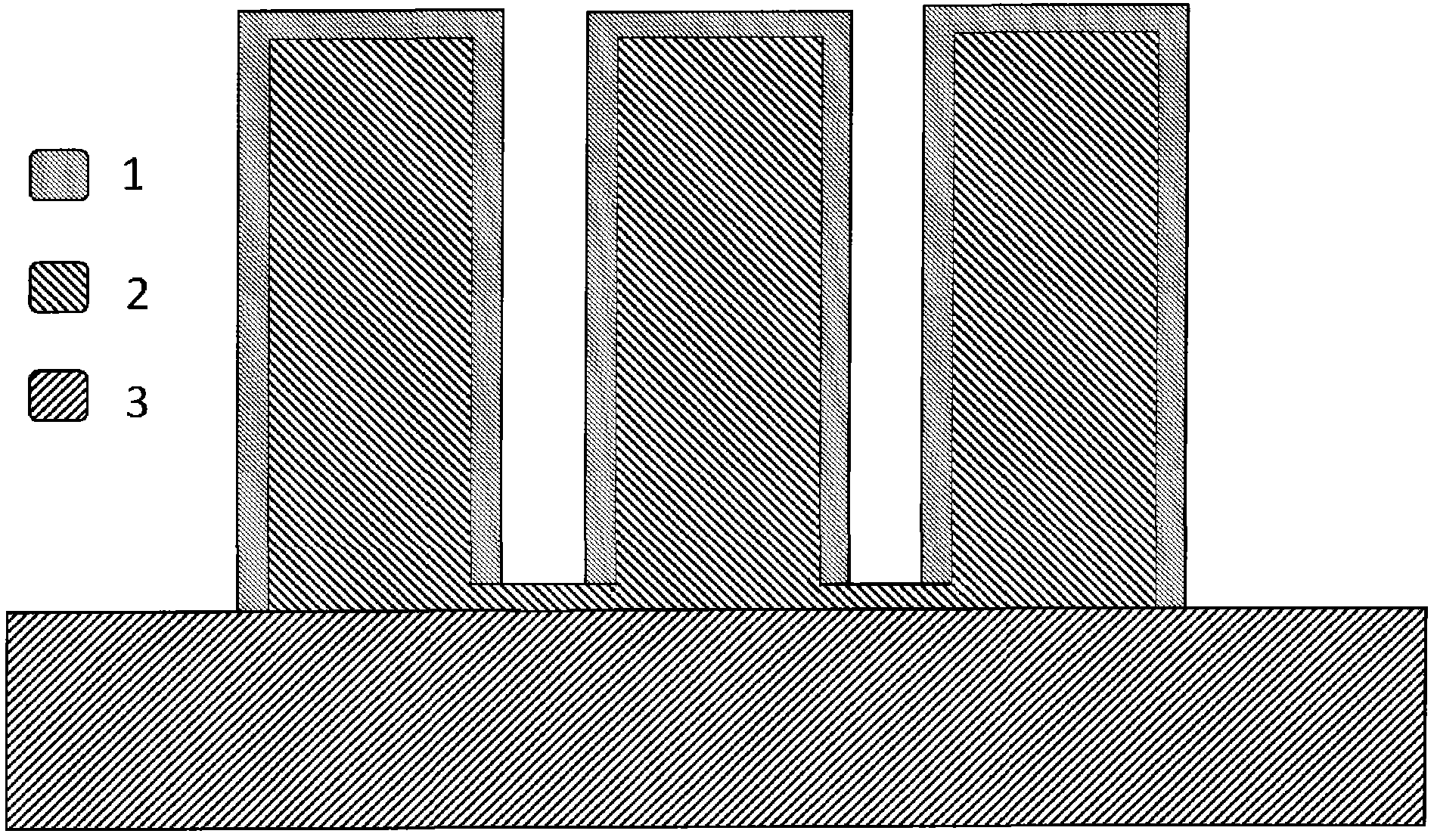

ActiveCN103474632AStable structureImprove performanceMaterial nanotechnologyCell electrodesPorosityMicro nano

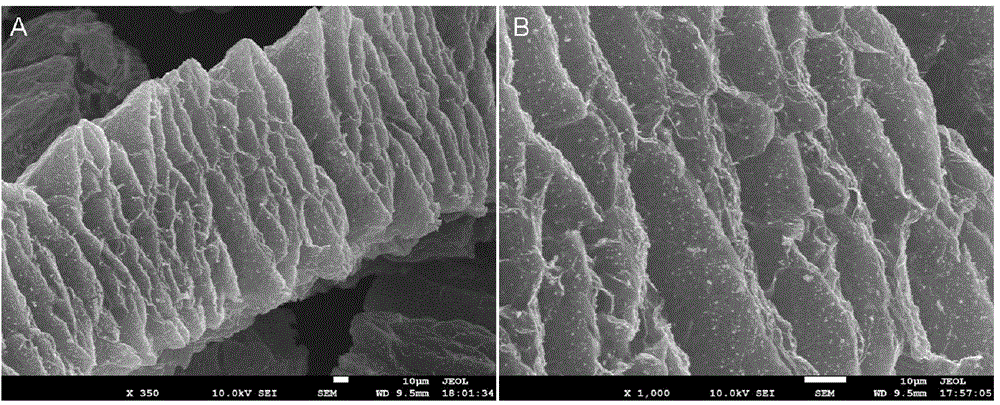

The invention relates to a negative electrode material used for a lithium battery and a preparation method and application thereof, the negative electrode material includes a conductive substrate material layer and a silicon based thin film material layer, the silicon based thin film material layer contains one or more components selected from the group consisting of silicon element, SiOX and silicon alloy, wherein, 0 < X =< 2; in the silicon based thin film material layer, silicon accounts for 10-100% of the weight of the silicon based thin film material layer; the silicon based thin film material layer is a thin film formed by regular and / or irregular columnar and / or fibrous micro nano naps, wherein the micro nano naps are connected with each other by root parts, and the root parts of the micro nano naps are connected with the conductive substrate material layer; gaps are existed among the micro nano naps, and the porosity among the micro nano naps is 2%-98%; the diameter size of the micro nano naps is 1 nm to 10 mum, and the thickness of the silicon based thin film material layer is 50 nm-10 mum.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

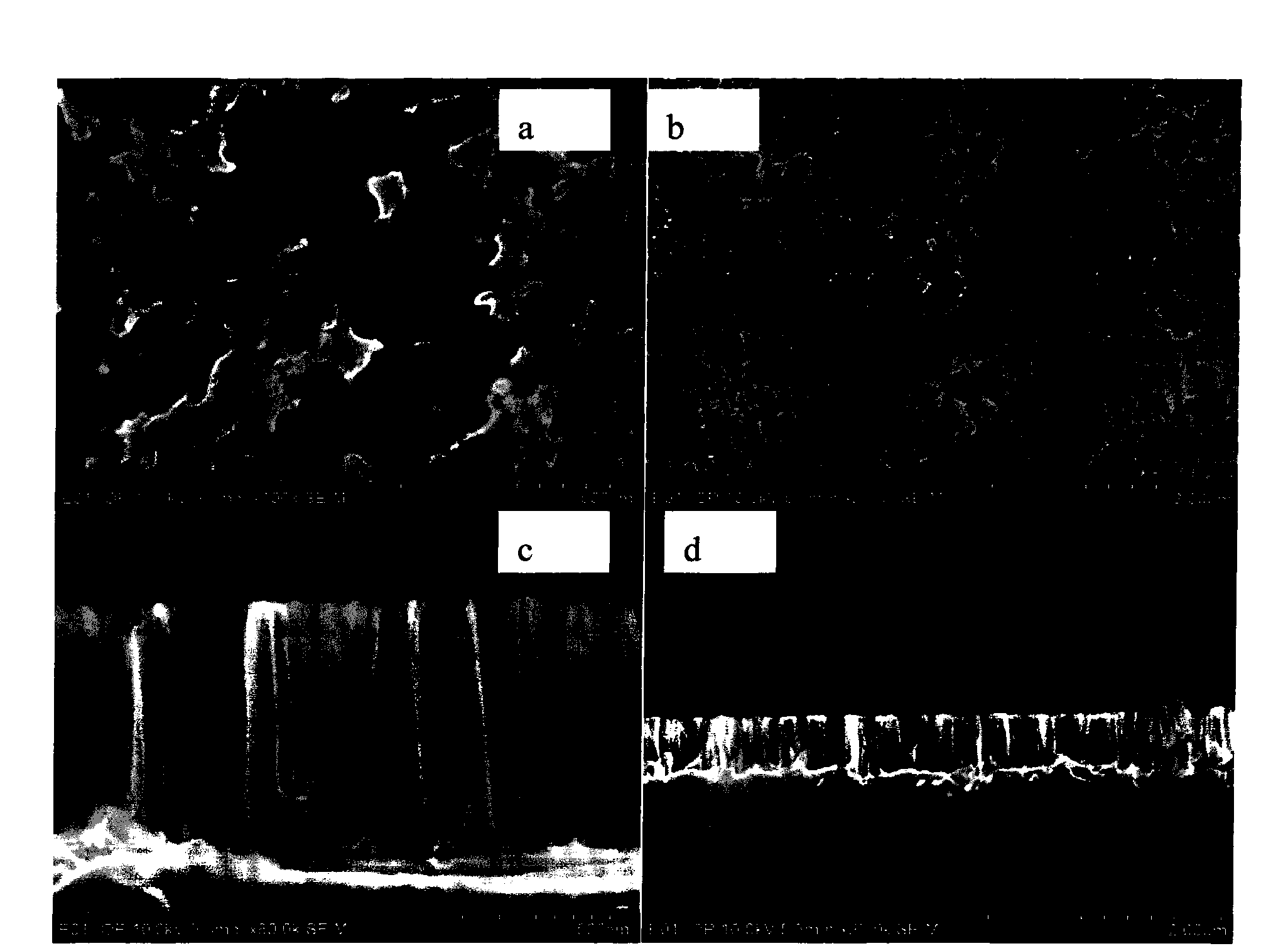

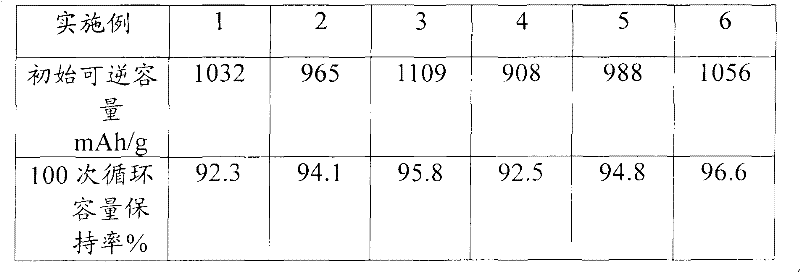

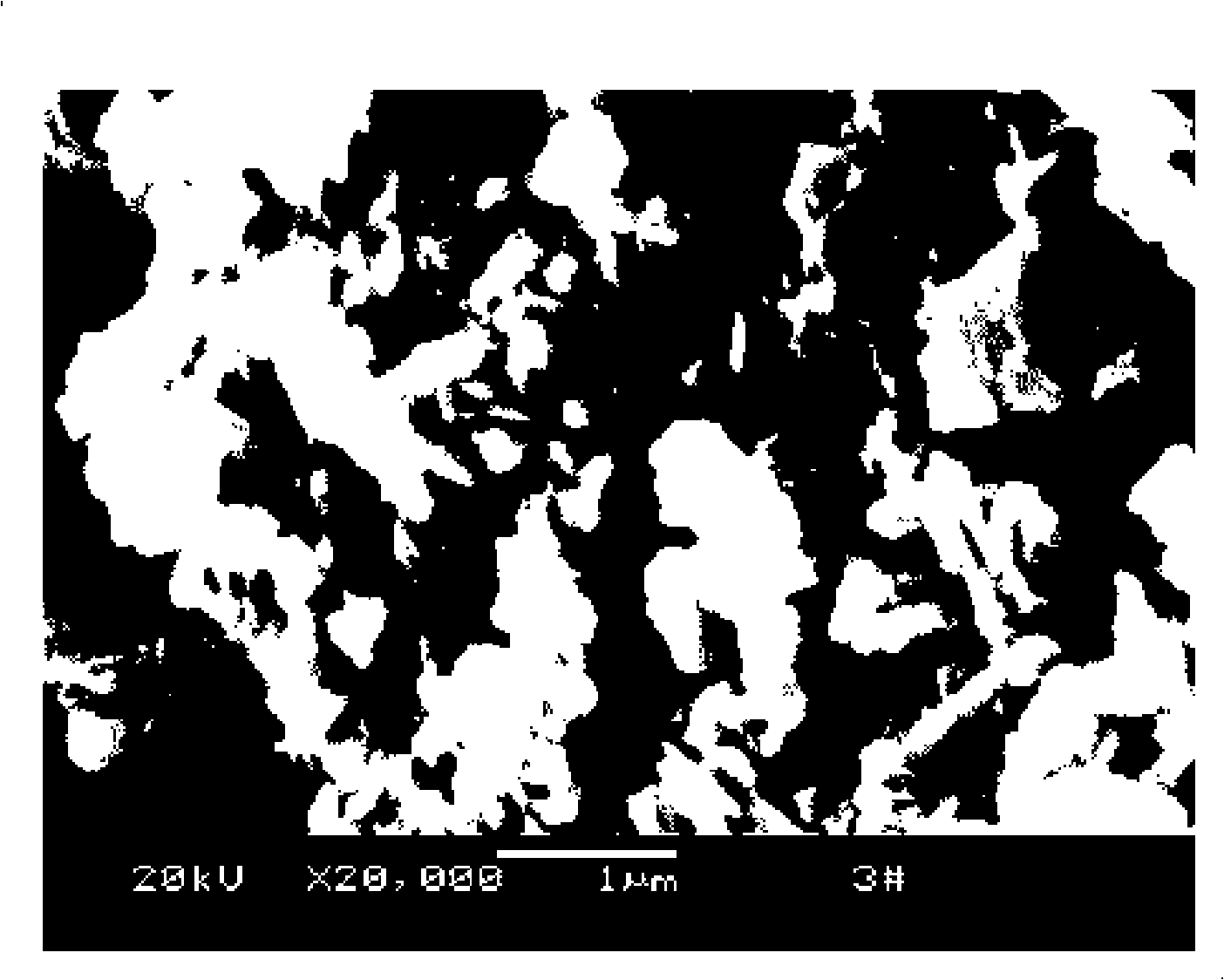

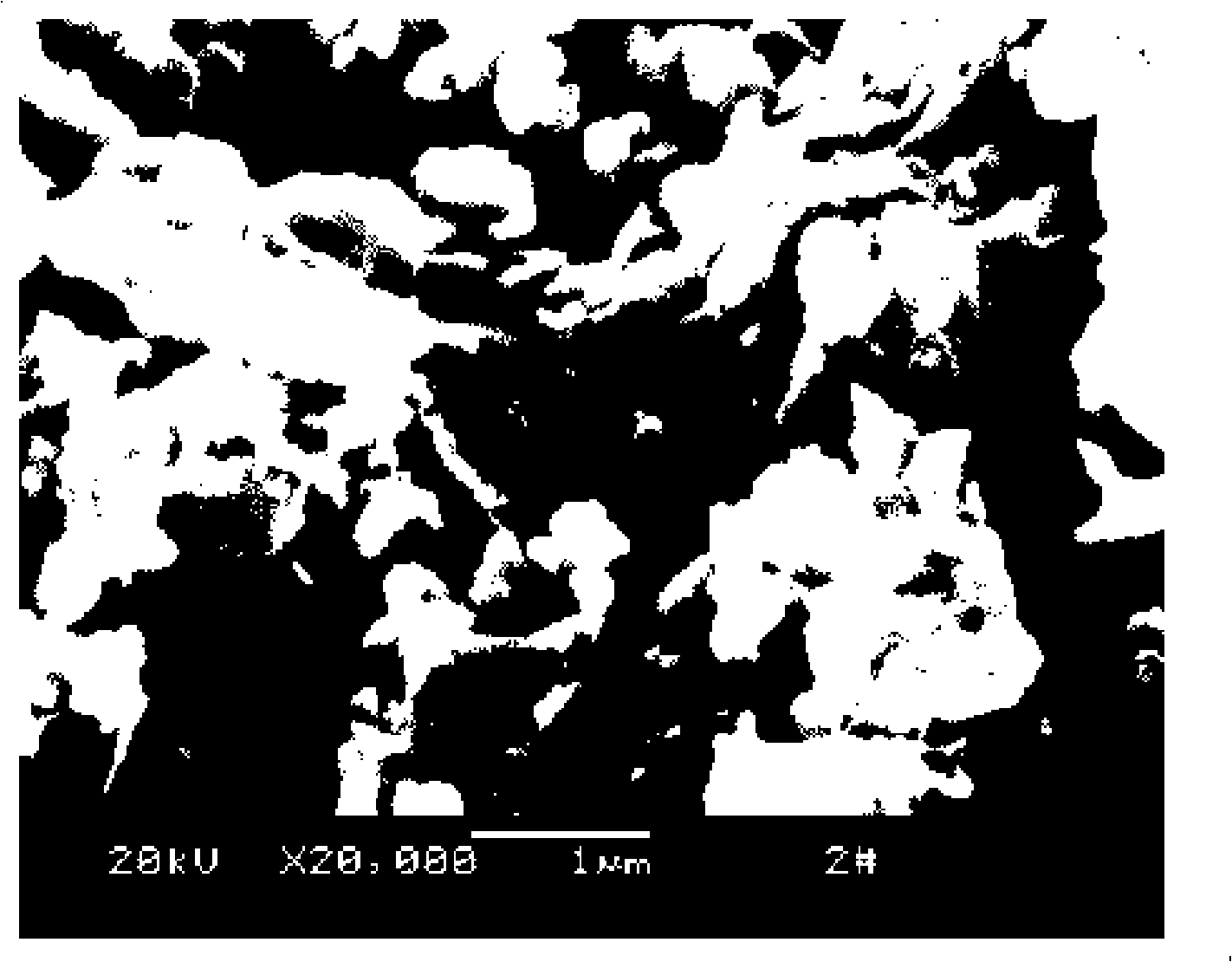

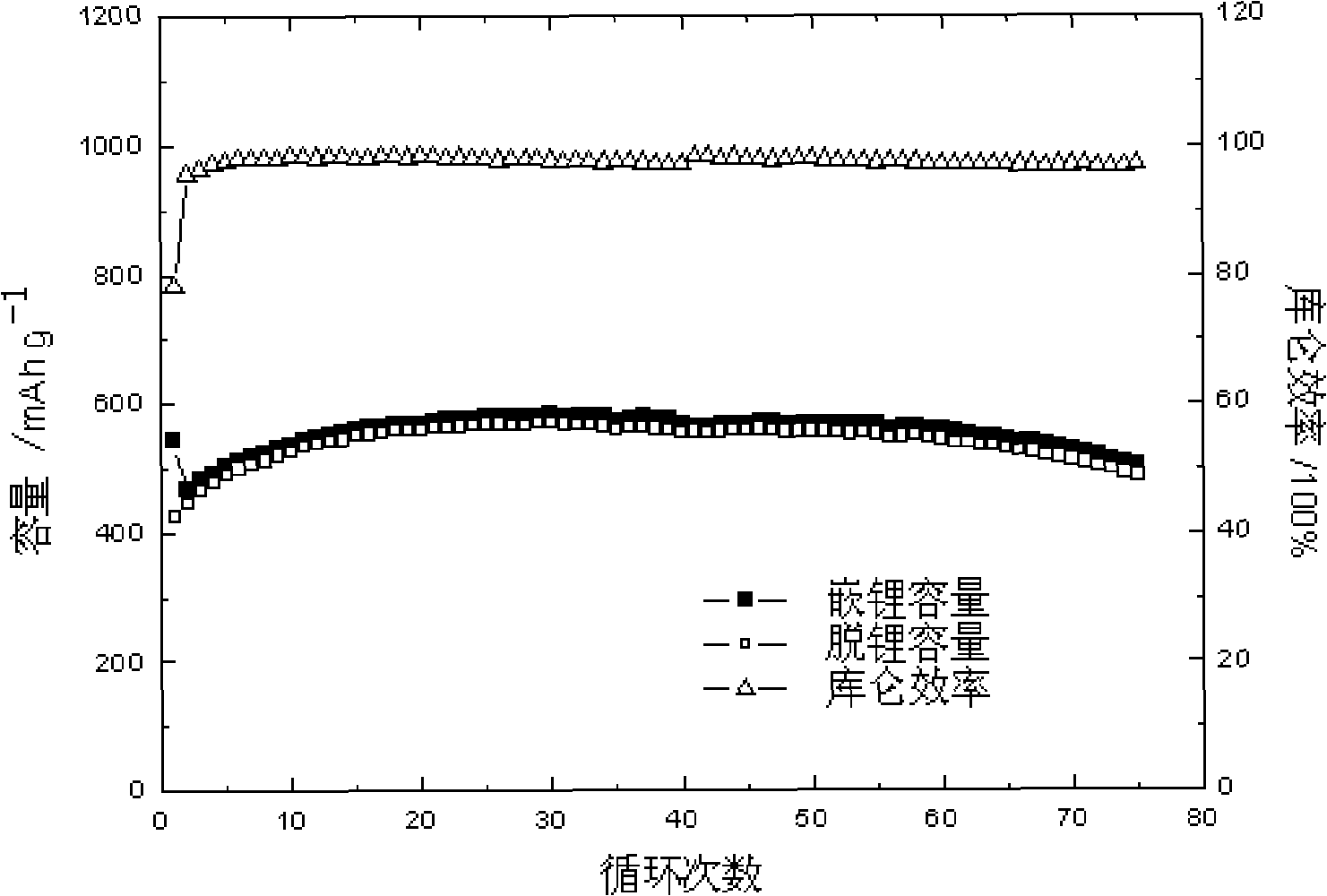

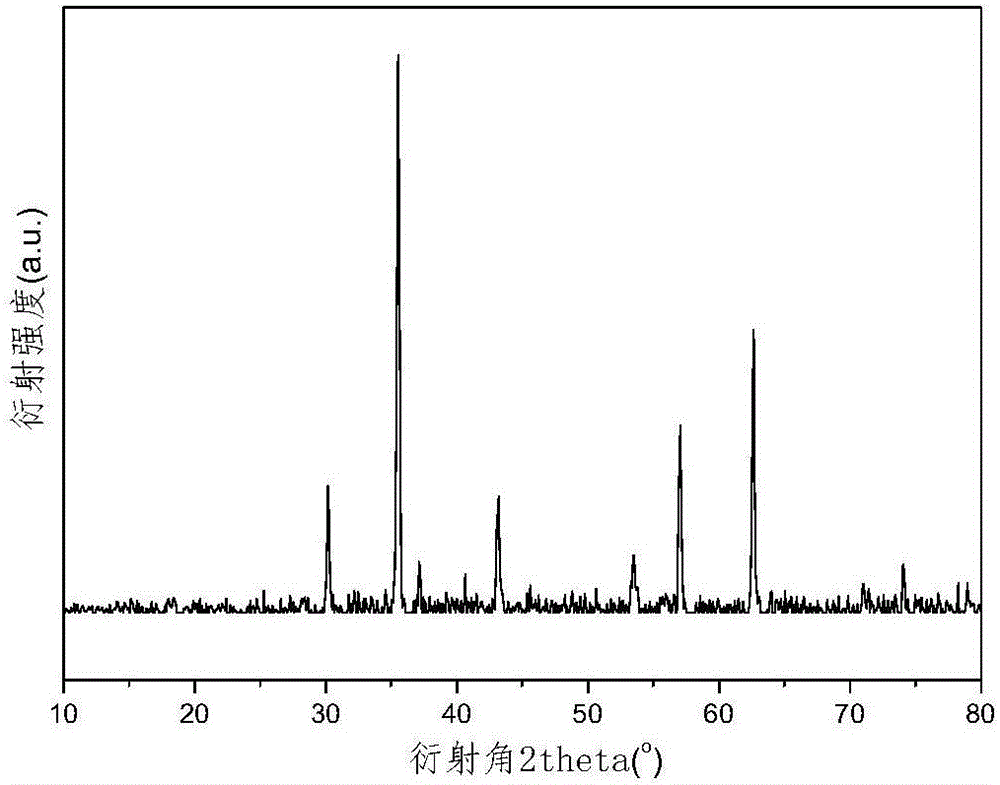

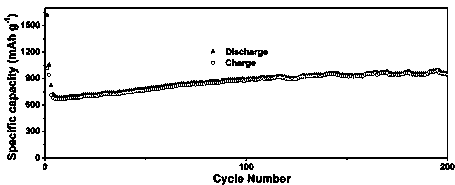

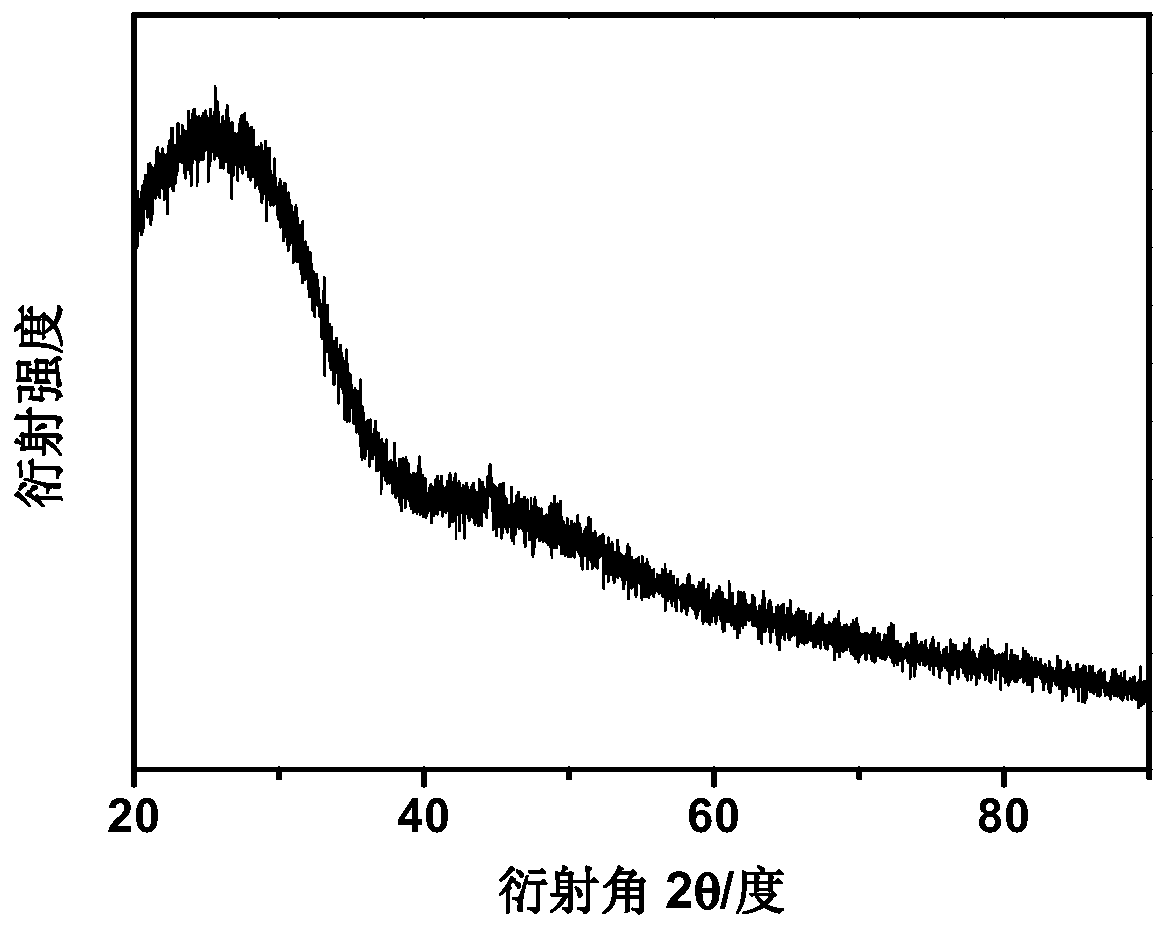

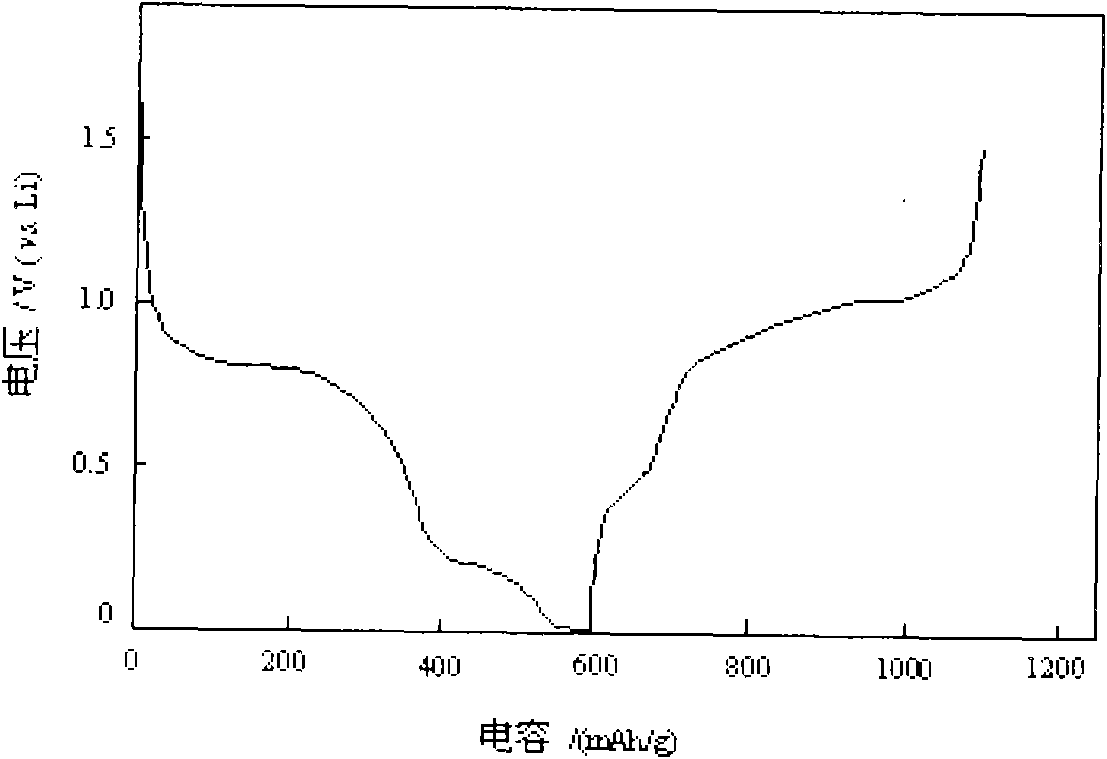

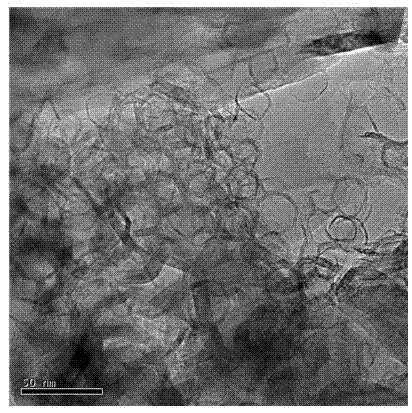

Lithium-ion battery graphitized mesoporous carbon/silicon composite anode materials and preparation method thereof

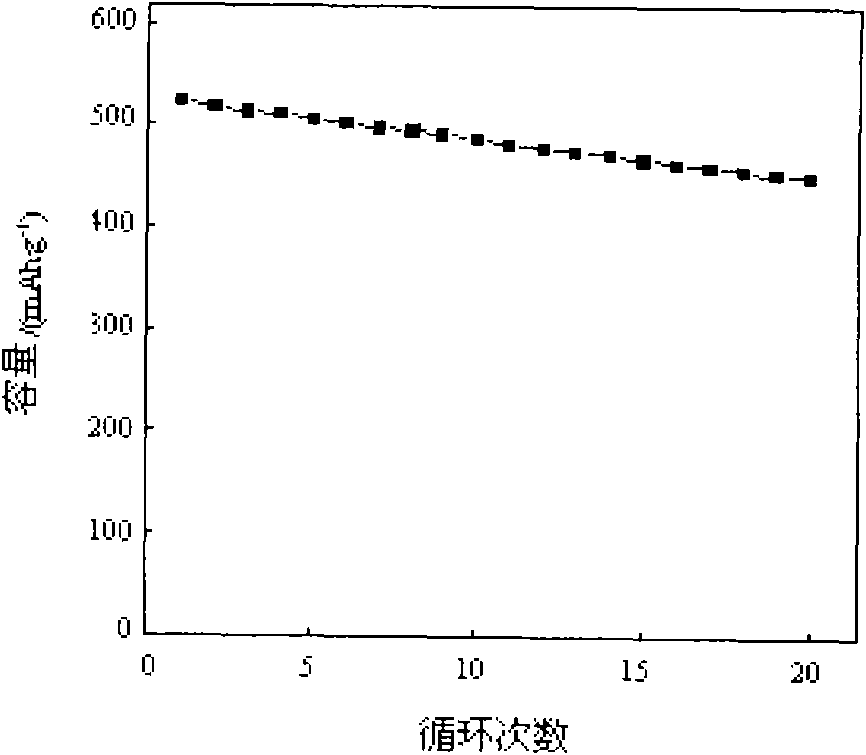

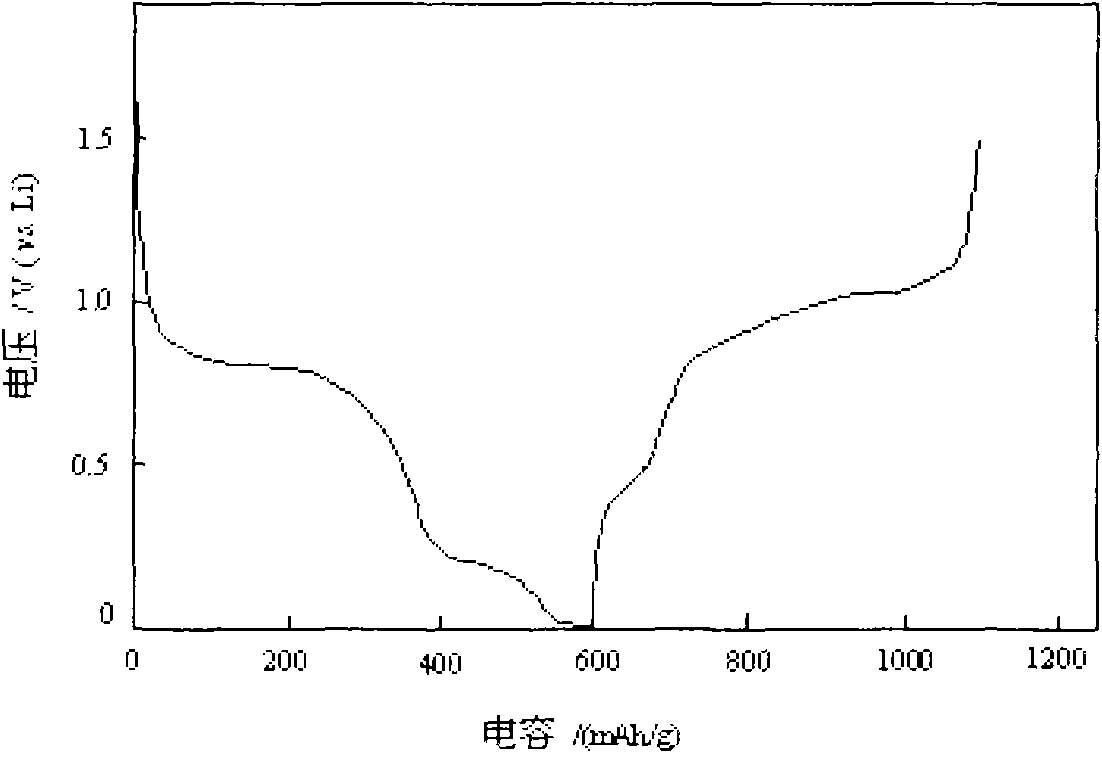

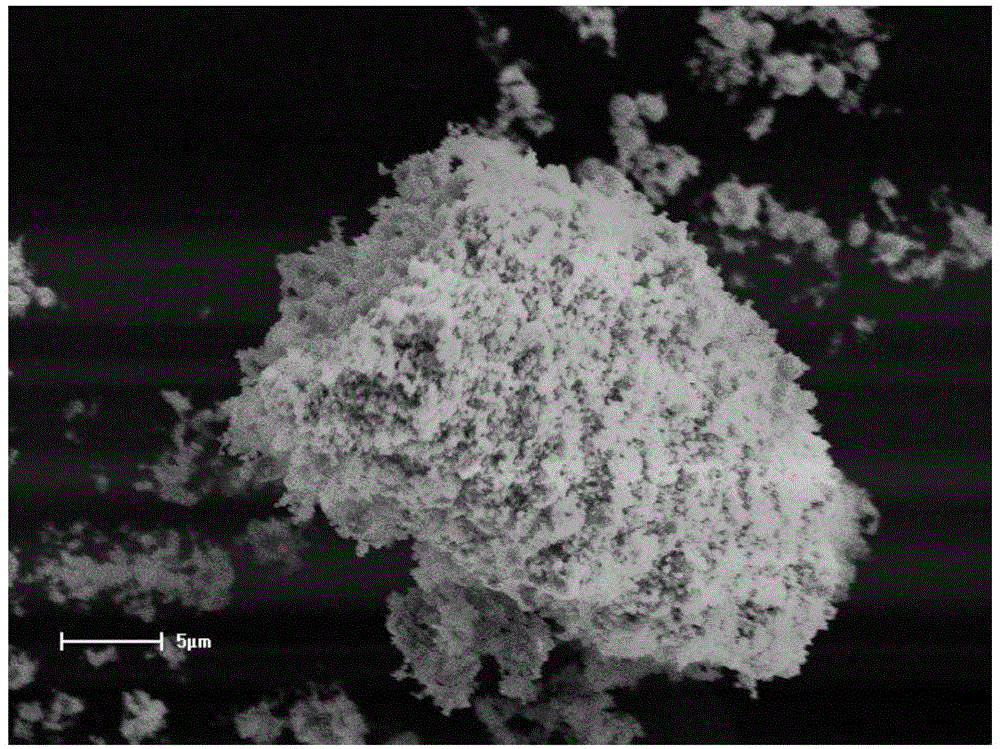

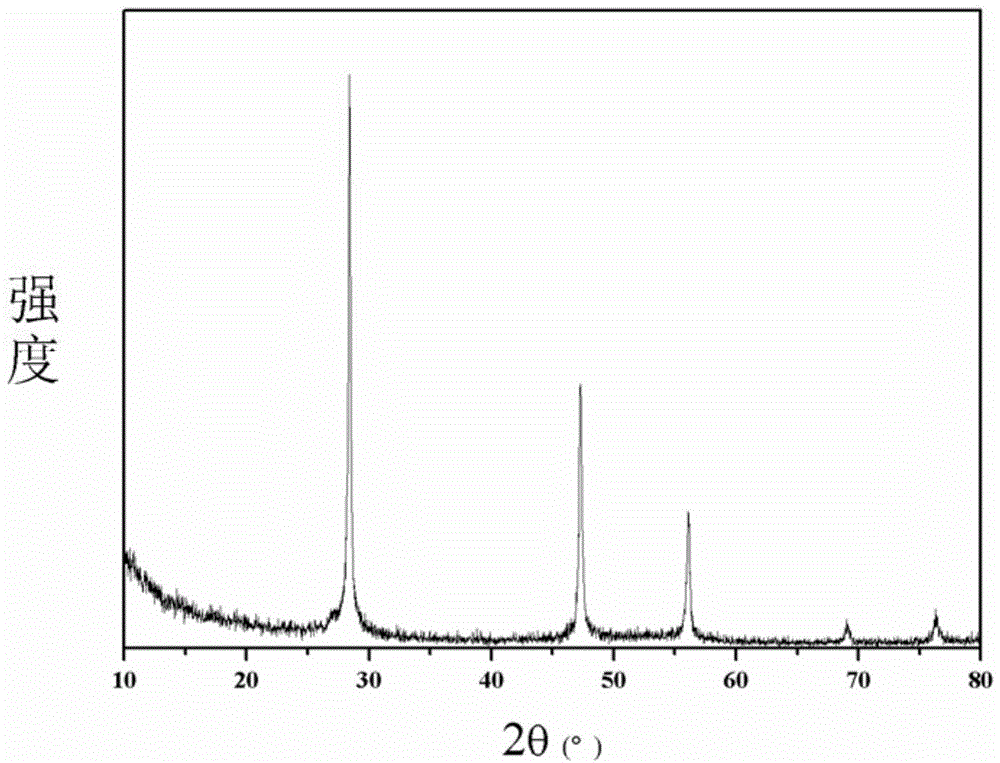

InactiveCN102456876AHigh lithium storage capacityImprove cycle lifeCell electrodesAmorphous siliconSilicon oxide

The invention discloses lithium-ion battery graphitized mesoporous carbon / silicon composite anode materials and a preparation method thereof. Mesoporous carbon materials with different degrees of graphitization are synthesized by using mesoporous silicon oxide as a hard template and combining transition metal (Fe, Ni, Co, etc) catalysis, and the mesoporous carbon materials are used as the carrier to deposit amorphous silicon on the mesoporous carbon pore walls through the chemical vapor deposition (CVD) technology to obtain the graphitized mesoporous carbon / silicon composite anode materials. The composite materials have stable performance; and when used as the anode materials of the lithium-ion battery, the composite materials have the advantages of large lithium storage capacity, long life, high safety and the like.

Owner:李溪

Composite cathode material for lithium ion cell and preparing method thereof

ActiveCN101286560AEvenly dispersedWell mixedElectrode manufacturing processesChemical/physical/physico-chemical processesComposite cathodeGraphite

The invention relates to a lithium ion battery composite cathode material and a preparation method thereof, which belongs to the technical field of lithium ion battery. The invention aims at improving the cycle performance of silicon cathode material at the same time when keeping the high ratio volume of lithium ion battery silicon cathode material. The proposal of the invention is that silica-based material coated by disordered carbon is treated with surface modification processing by utilizing lithium salt, namely, the lithium salt is coated on the surface of Si / G / DC (silicon / graphite / disordered carbon) to be prepared into the composite cathode material, therefore, the lithium-embedding and removing depth of the silicon can be effectively controlled, and the material is the lithium ion battery composite cathode material which has high specific capacity and good cyclical stability; furthermore, the material is safe and pollution-free, and presents higher thermal stability in various lithium salt electrolytes and solvents.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

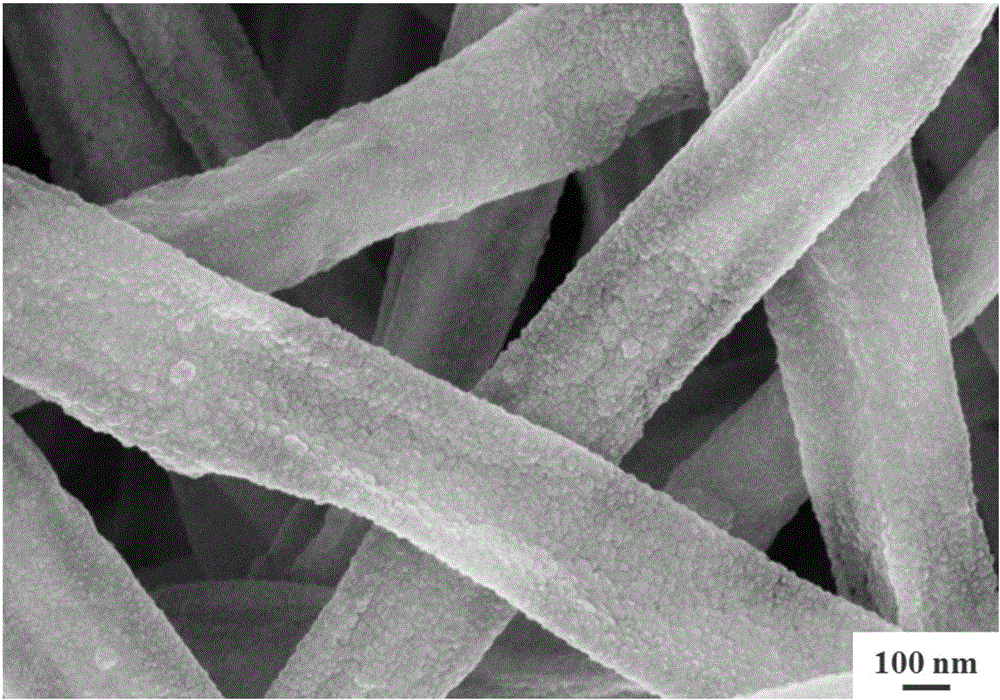

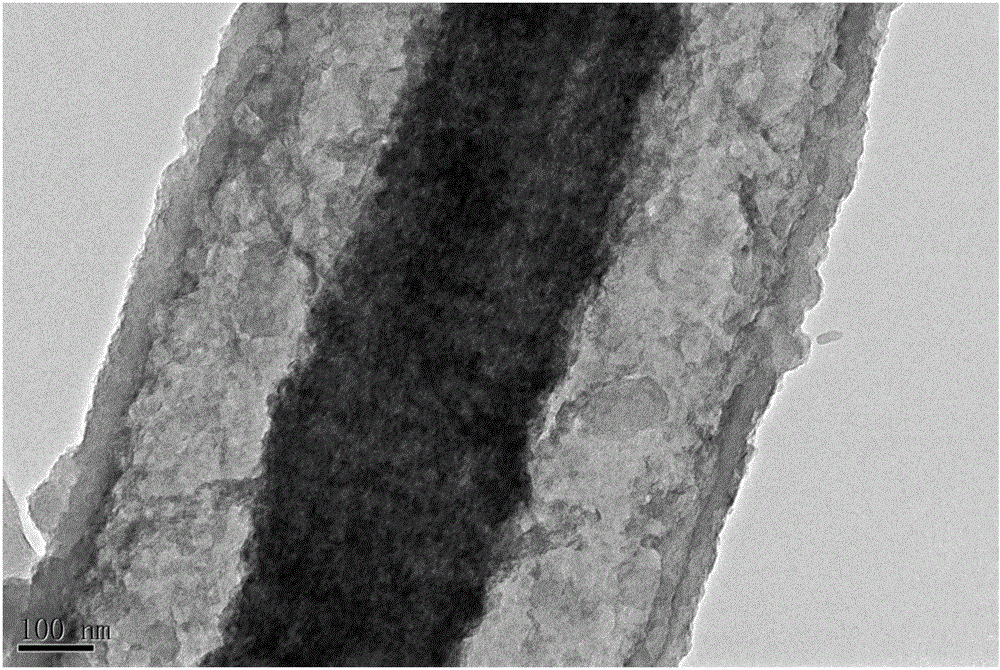

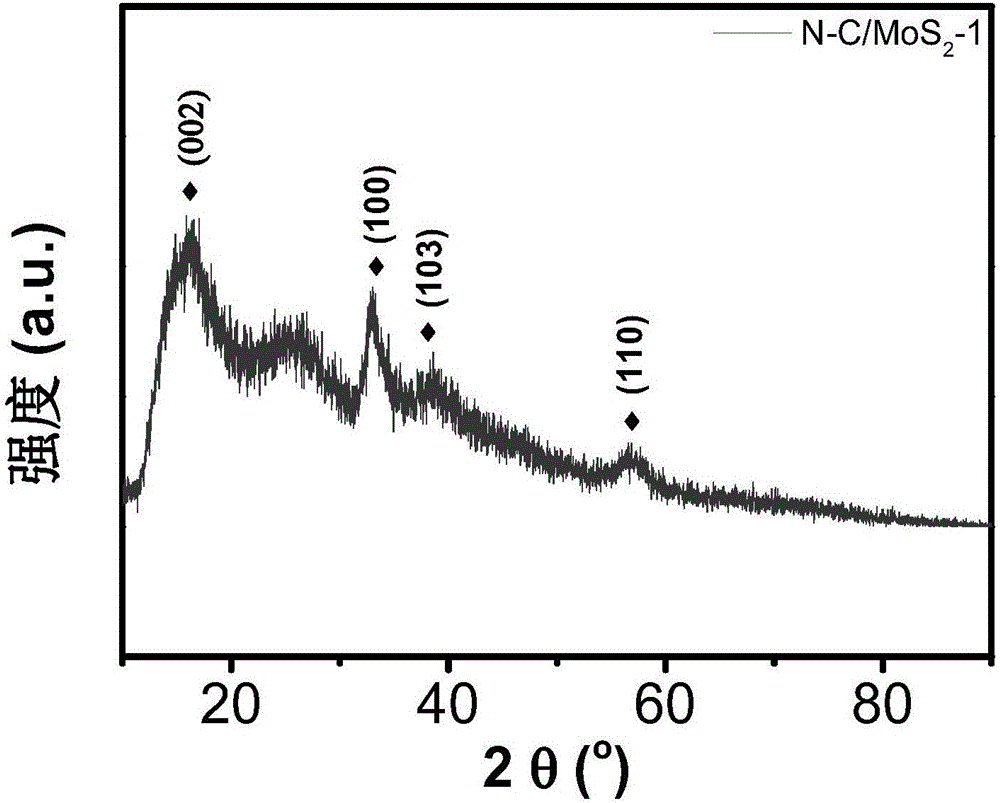

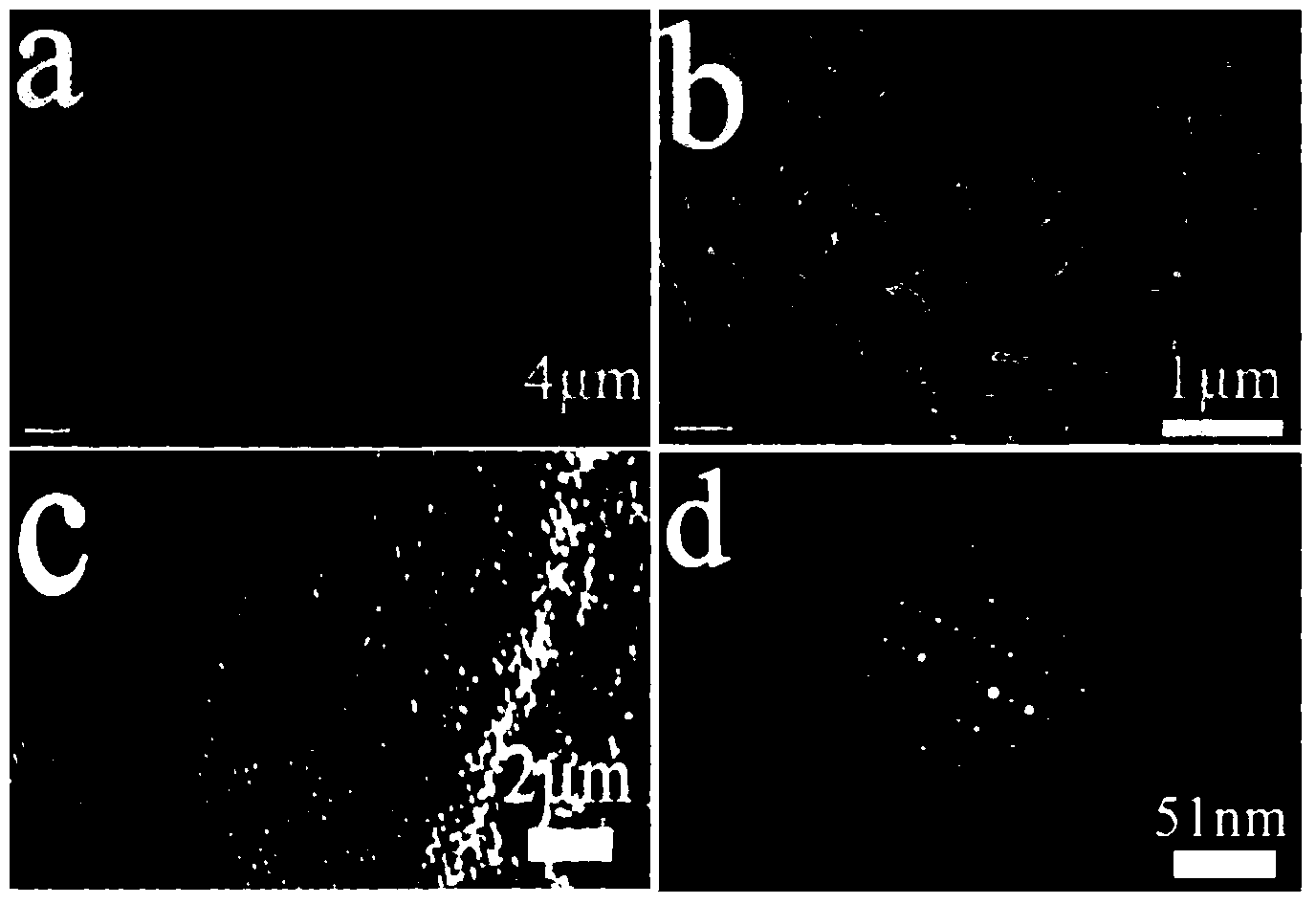

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

ActiveCN106450181AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsFiberIn situ polymerization

The invention relates to a molybdenum disulfide / nitrogen-doped carbon nanofiber composite material and a preparation method and an application thereof. The composite material is of a pipe sleeving structure, a molybdenum disulfide fiber core is arranged in the composite material and a nitrogen-doped carbon nanofiber shell is arranged outside the composite material; and a gap is arranged between the molybdenum disulfide fiber core and the nitrogen-doped carbon nanofiber shell. The preparation method comprises the steps of dissolving ammonium thiomolybdate and polymethyl methacrylate into a solvent and carrying out electrostatic spinning to obtain a polymethyl methacrylate / ammonium thiomolybdate nanofiber; carrying out drying and surface treatment, immersing the nanofiber into a pyrrole / hydrochloric acid solution, dropwise adding a ferric chloride / hydrochloric acid solution and carrying out in-situ polymerization to obtain the fiber coated with polypyrrole on the surface; and washing and drying the fiber, carrying out high-temperature reduction under the condition of taking an argon / hydrogen mixed gas as a protective atmosphere and then carrying out high-temperature carbonization under an argon condition. The composite material has high specific capacity and good cycle stability, and can be used as an efficient and safe novel negative electrode material of a lithium-ion battery.

Owner:DONGHUA UNIV

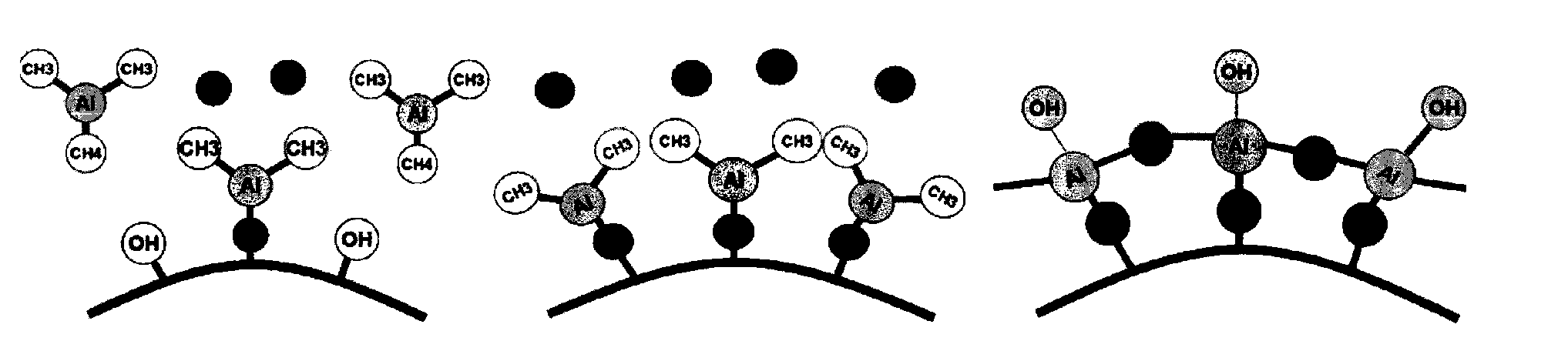

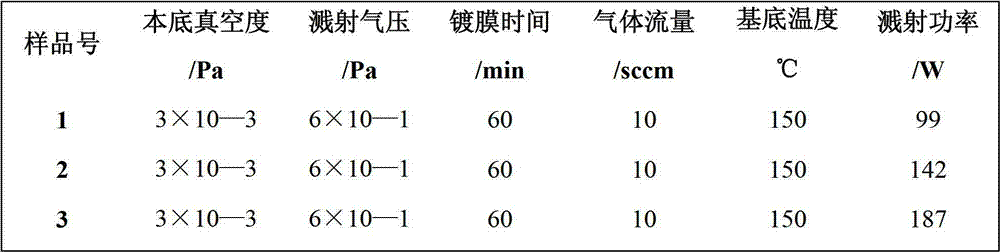

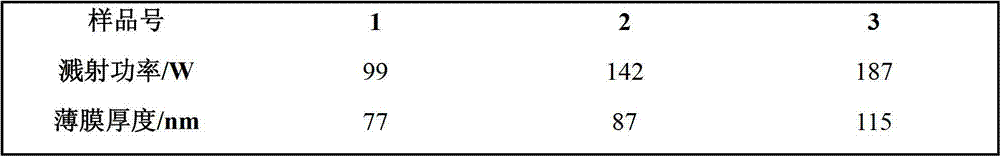

Composite negative electrode material coating modification method of lithium ion battery

ActiveCN102779988AImprove uniformityHigh purityCell electrodesVacuum evaporation coatingFilm-coated tabletFilm coating

The invention relates to a preparation method of composite negative electrode material of a lithium ion battery. The material comprises a negative electrode material, and a metal film and a metal oxide film coating the surface of the negative electrode material, wherein the metal film or metal oxide film is prepared by magnetron sputtering method. The negative electrode material prepared by the modification method provided by the invention has the advantages of remarkably improved lithium storage capacity, cycling performance, dynamic performance, and so on, and can remarkably improve the first coulombic efficiency, the cycling performance and so on of the lithium ion battery.

Owner:CHANGZHOU UNIV

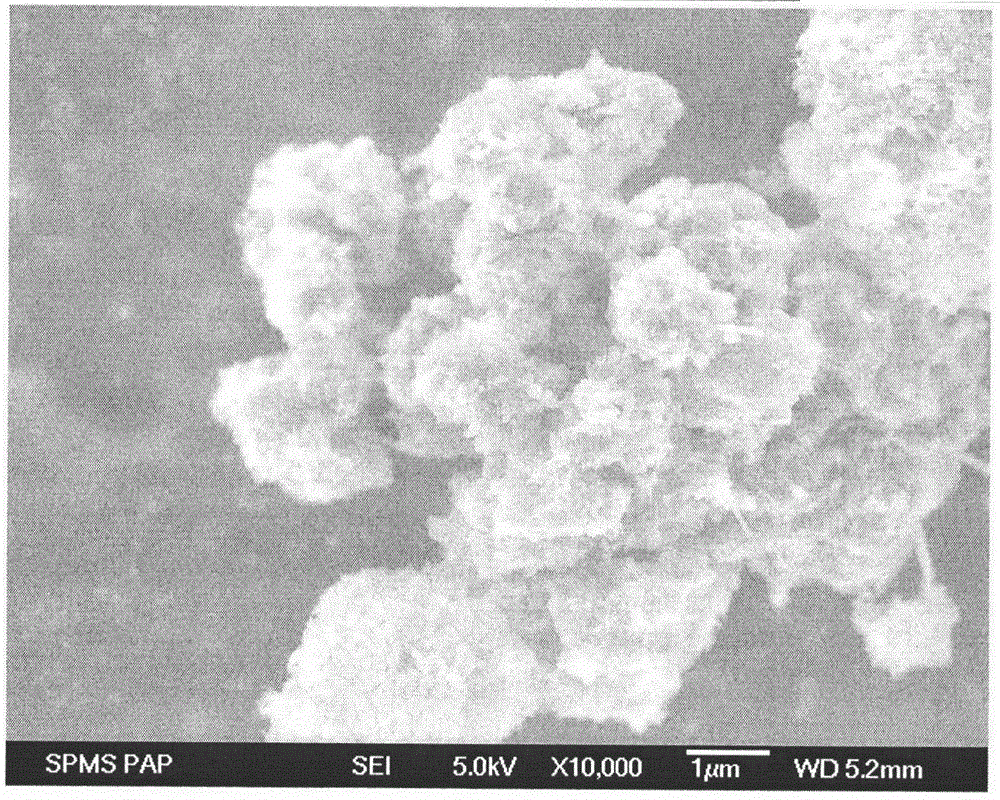

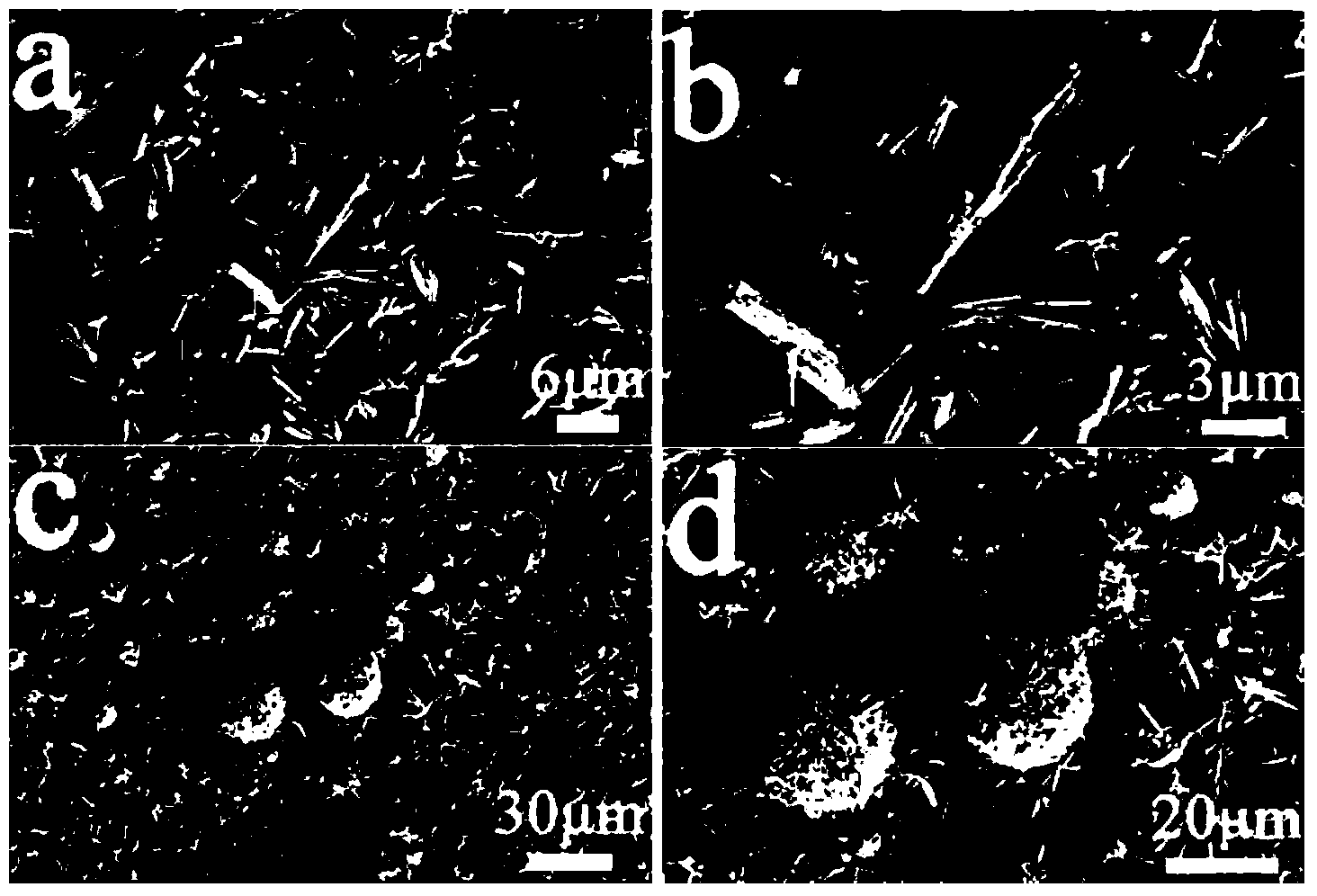

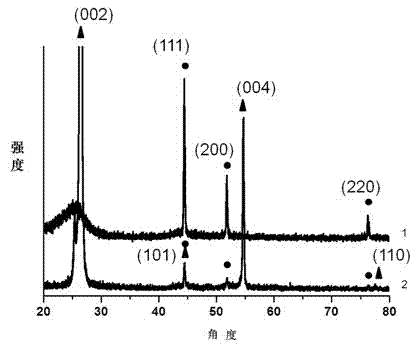

Method for preparation of ferric oxide/graphene/carbon fiber composite material

InactiveCN104037405AHigh lithium storage capacityHigh electron mobilityCell electrodesSecondary cellsFiberComposite cathode

The invention aims to develop a preparation method for a ferric oxide / graphene / carbon fiber composite material that is characterized by high lithium storage capacity, high conductivity and fast charging rate and can be used as a lithium ion secondary battery's cathode material. The method includes: firstly preparing nano-ferric oxide, then compounding the nano-ferric oxide with graphene to form a Fe2O3 / graphene composite material, and then on the basis, adding carbon fiber to further strengthen various properties of the composite cathode material so as to strengthen the lithium storage capacity and reduce the internal resistance of the cathode material. Finally, the ferric oxide / graphene / carbon fiber composite material can be obtained.

Owner:佛山市顺德宇红纳米科技有限公司

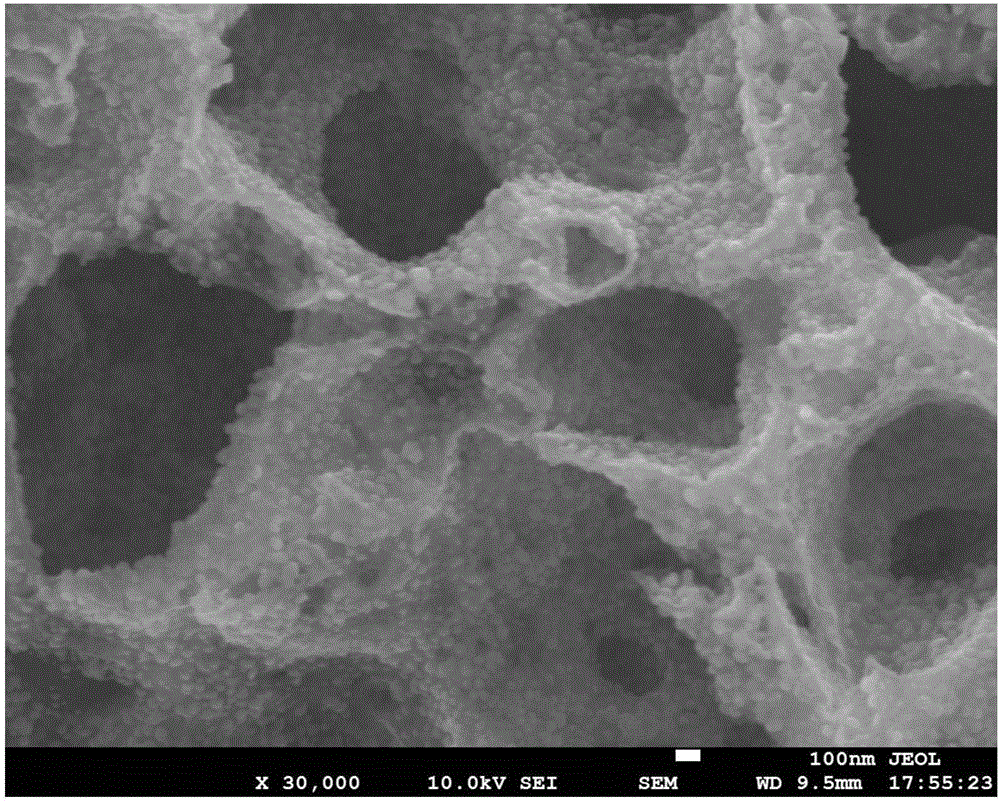

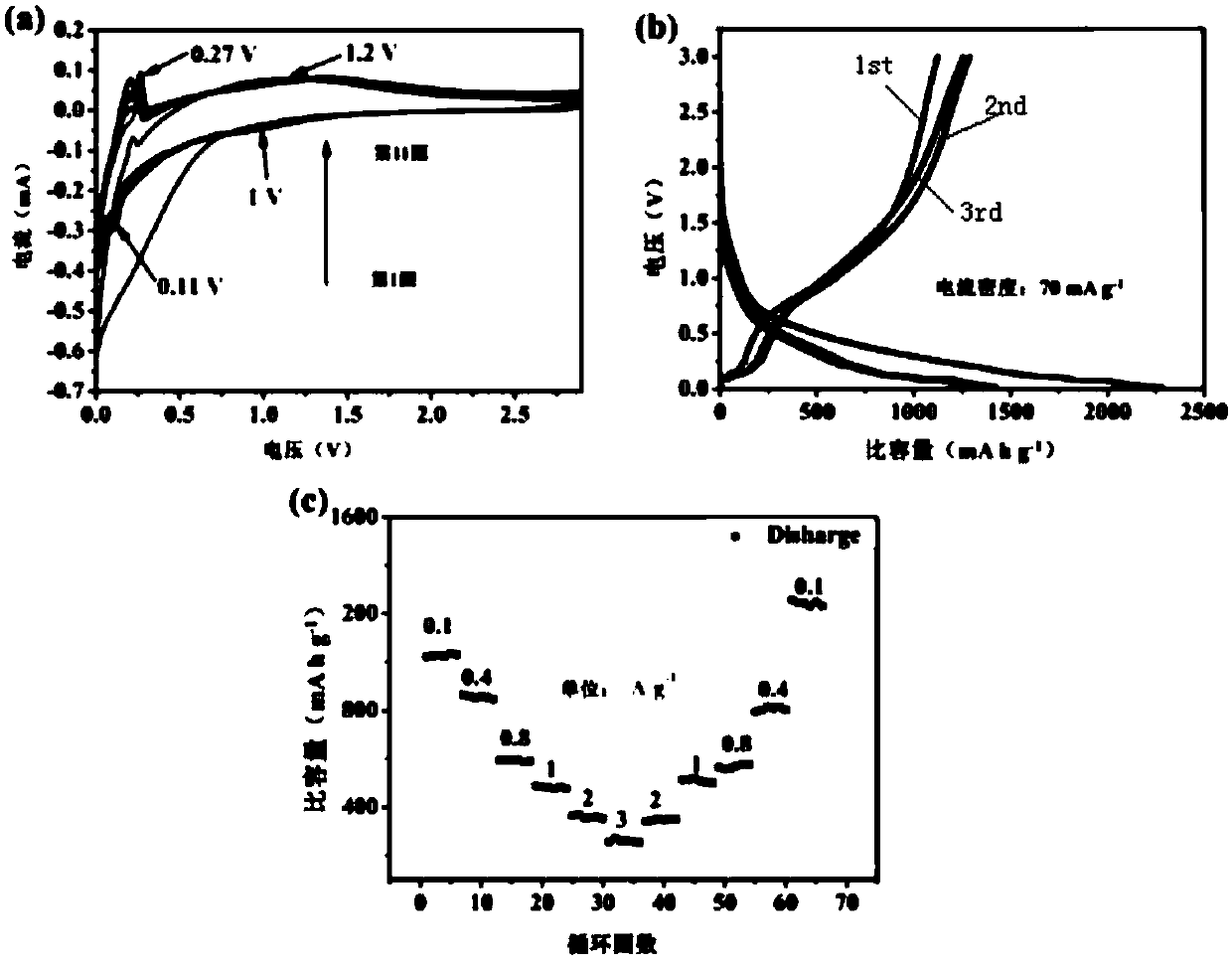

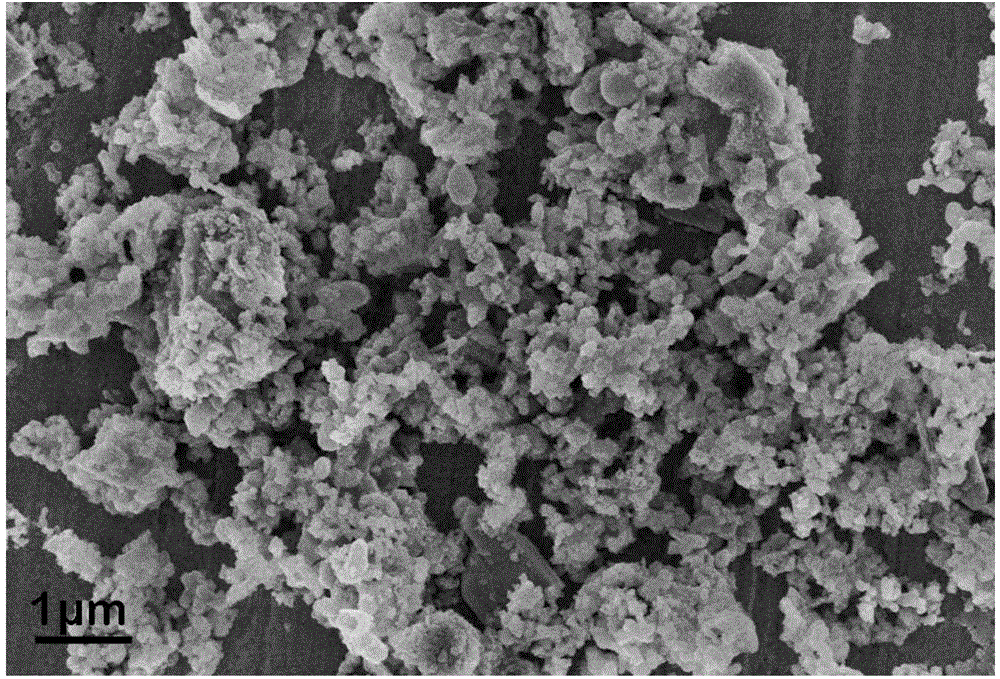

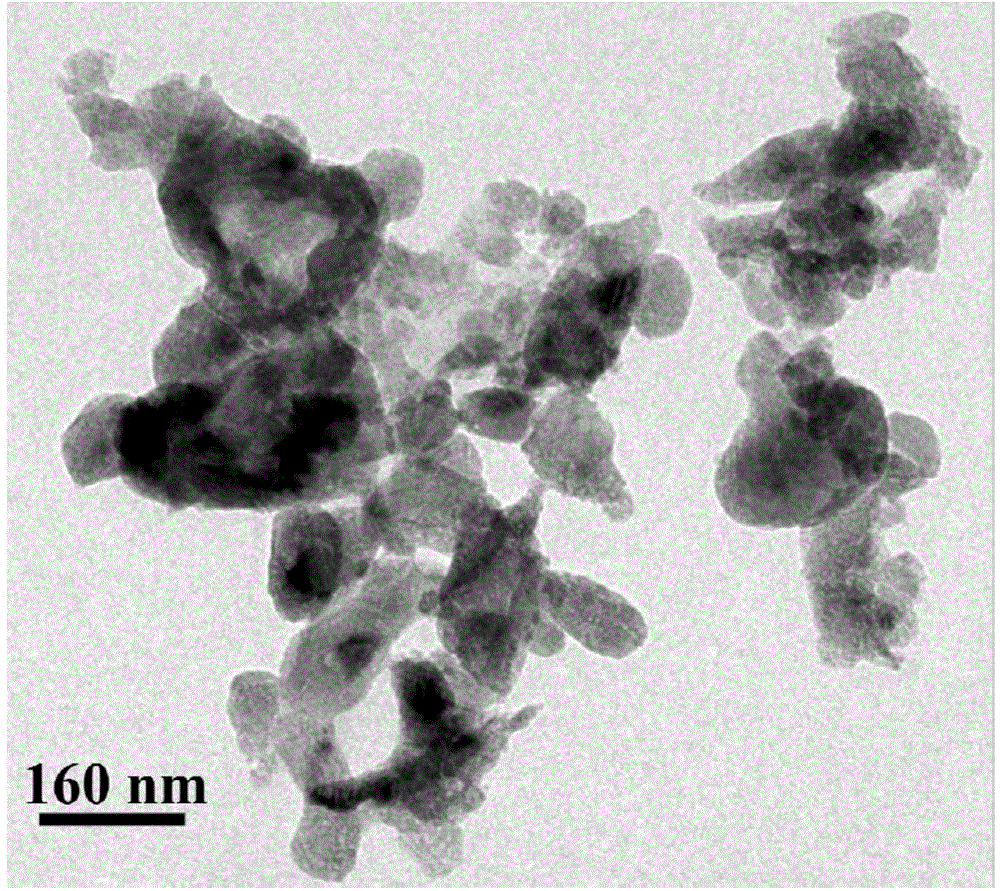

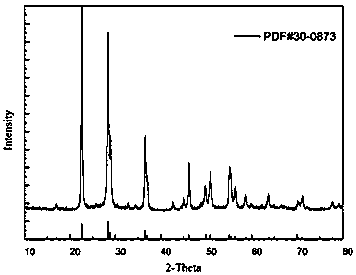

Porous graphene supported carbon coated iron oxide nanoparticle composite material and preparation method thereof

ActiveCN106207121AAlleviate volume changesHigh lithium storage capacityCell electrodesWater bathsPorous graphene

The invention belongs to the technical field of lithium ion battery materials, and specifically relates to a porous graphene supported carbon coated iron oxide nanoparticle composite material and a preparation method thereof. The porous graphene supported carbon coated iron oxide nanoparticle composite material is prepared from the following steps: (1) directly preparing graphene oxide with graphite ore as a raw material by using a closed oxidation method; (2) preparing a ferric salt aqueous solution, wherein the specific steps are as follows: weighing and dissolving cetyl trimethyl ammonium bromide in water to obtain a clear cetyl trimethyl ammonium bromide solution, adding a ferric salt, stirring until the ferric salt is completely dissolved, and adding an ammonia solution to prepare the ferric salt aqueous solution; and (3) stirring and ultrasonic mixing the graphene oxide solution with the ferric salt aqueous solution, placing the mixture in a water bath kettle, reacting at 80-100 DEG C for 0.5-5h, stewing at a room temperature, removing clear liquid, freeze drying a head product, and carrying out heat treatment on the head product in an inert atmosphere to obtain the porous graphene supported carbon coated iron oxide nanoparticle composite material.

Owner:SHANXI UNIV

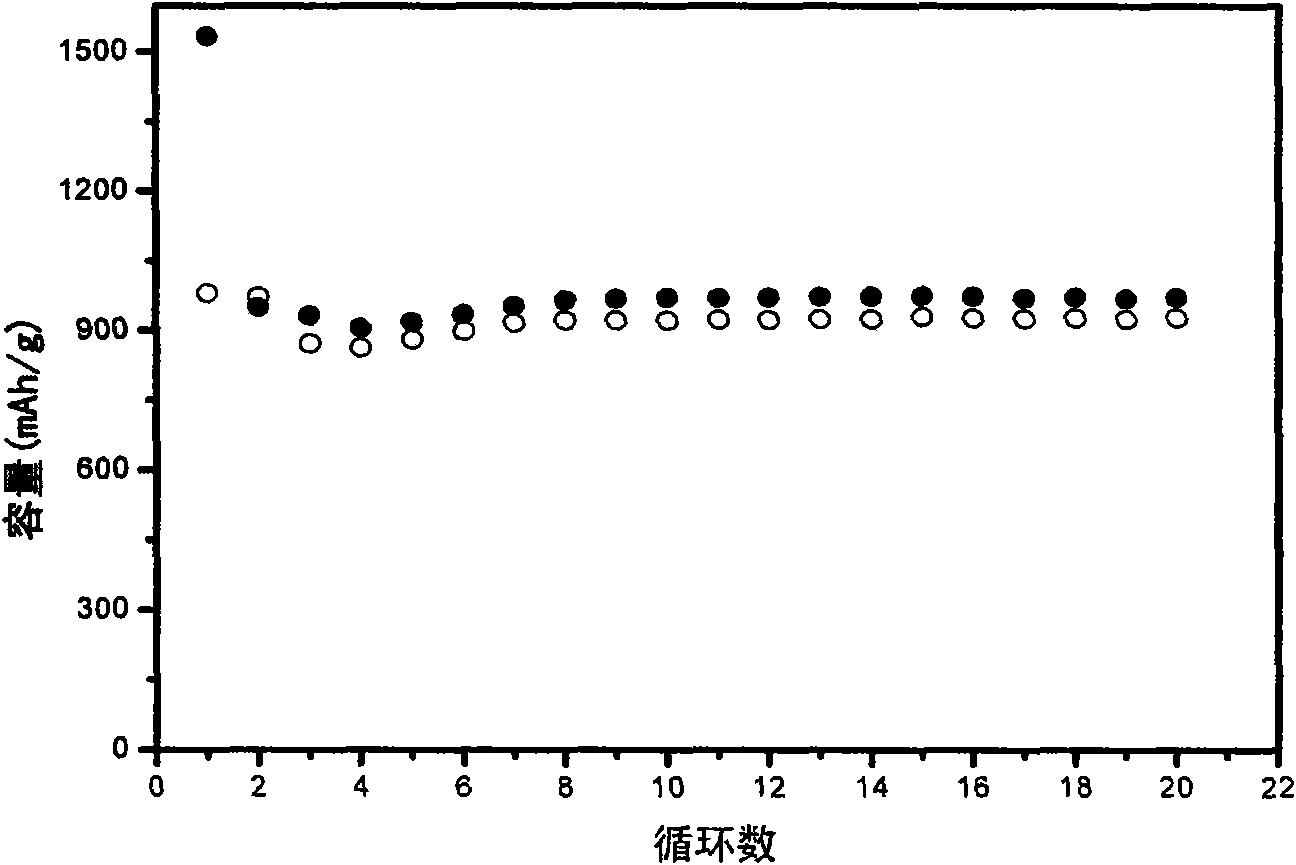

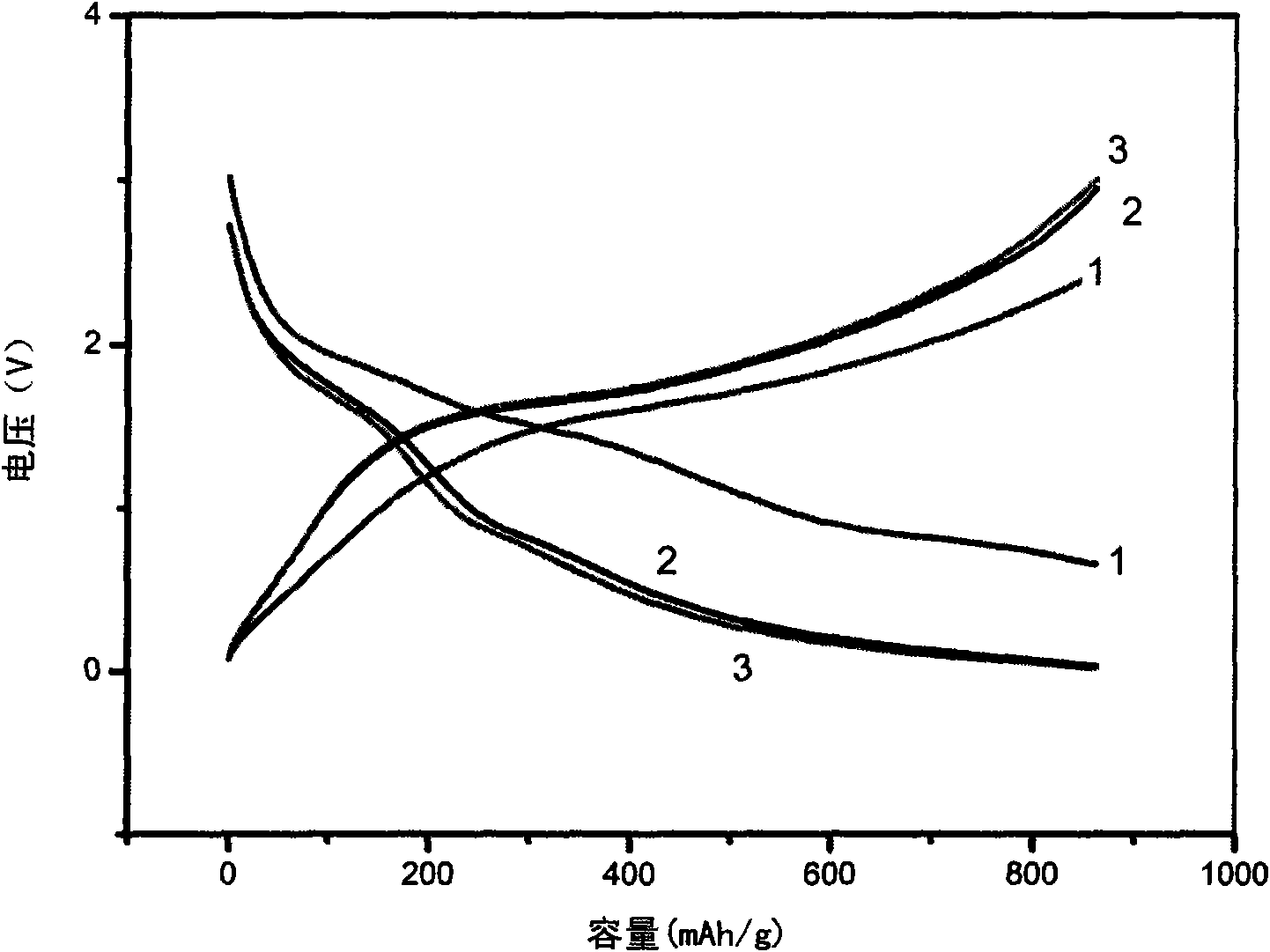

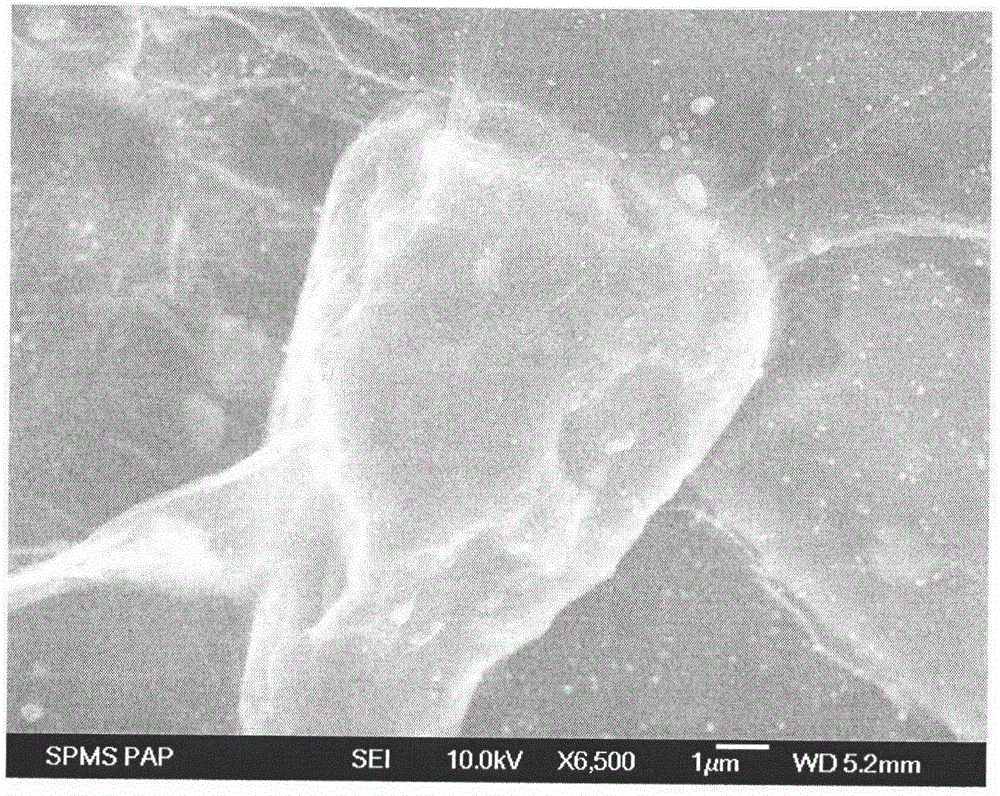

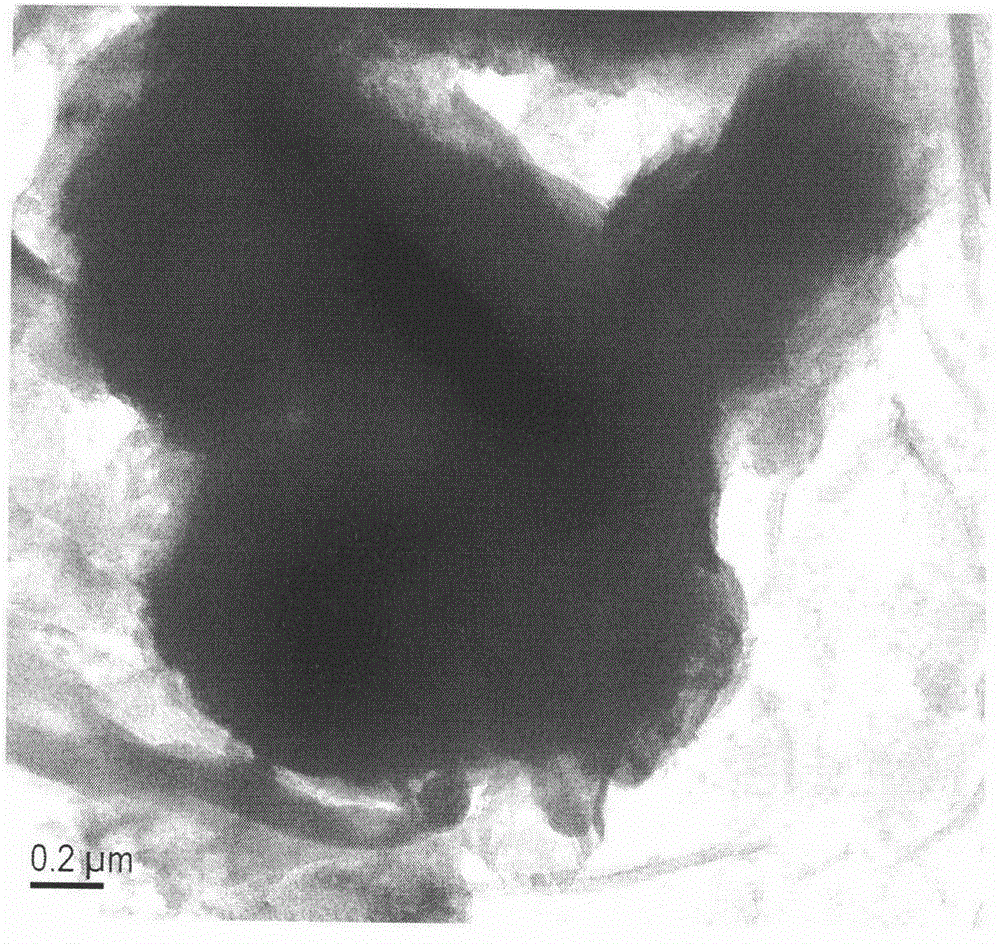

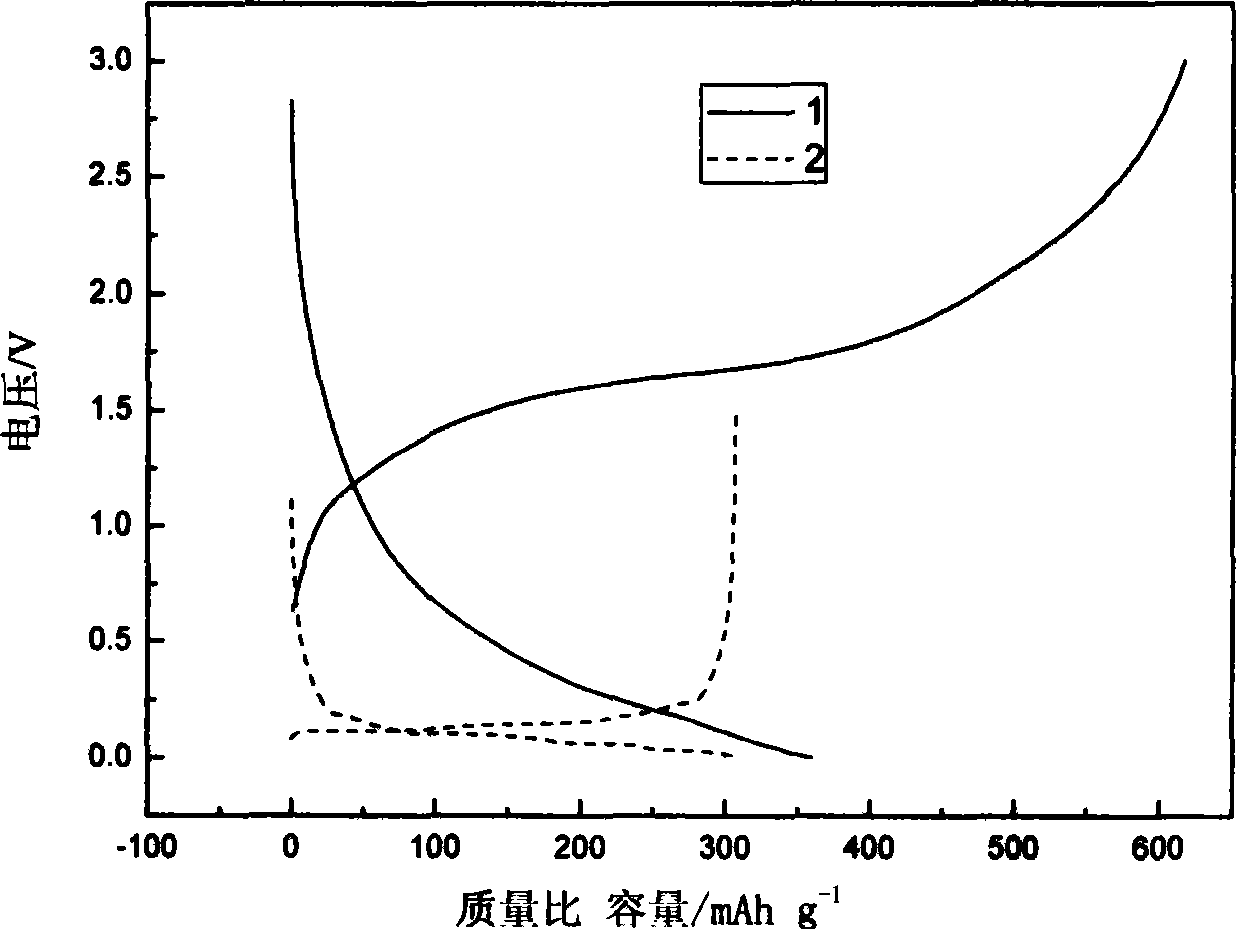

Anode material for lithium ion battery and preparation method thereof

ActiveCN102044674AImprove electrochemical performanceAlleviate volume changesCell electrodesCopper organic compoundsAluminium-ion batterySodium-ion battery

The invention relates to an anode material for a lithium ion battery, which is a complex formed by an organic compound and a metal or metalloid material. The invention also provides a preparation method of the anode material, comprising the steps of: uniformly mixing the metal or metalloid material and the organic compound under an atmospheric pressure within a temperature range of 0-25 DEG C andadding an oxidizing agent to obtain the required complex of the organic compound and the metal or metalloid material. According to the invention, the complex compound can be directly used as the anode material of a lithium ion battery and can be also mixed with other lithium storing materials in a proportion of 1-99 wt%; the anode material has very high lithium storing capacity and good circulating performance without being subjected to a plurality of circulations, can improve the electrical contact and adhering performances among electrode material particles as well as between an electrode material and a current collector, can effectively restrain the volume change of the electrode material in a charge-discharge process, can slow down the capacity attenuation of the electrode material, and can prolong the circulating life of the constituted battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

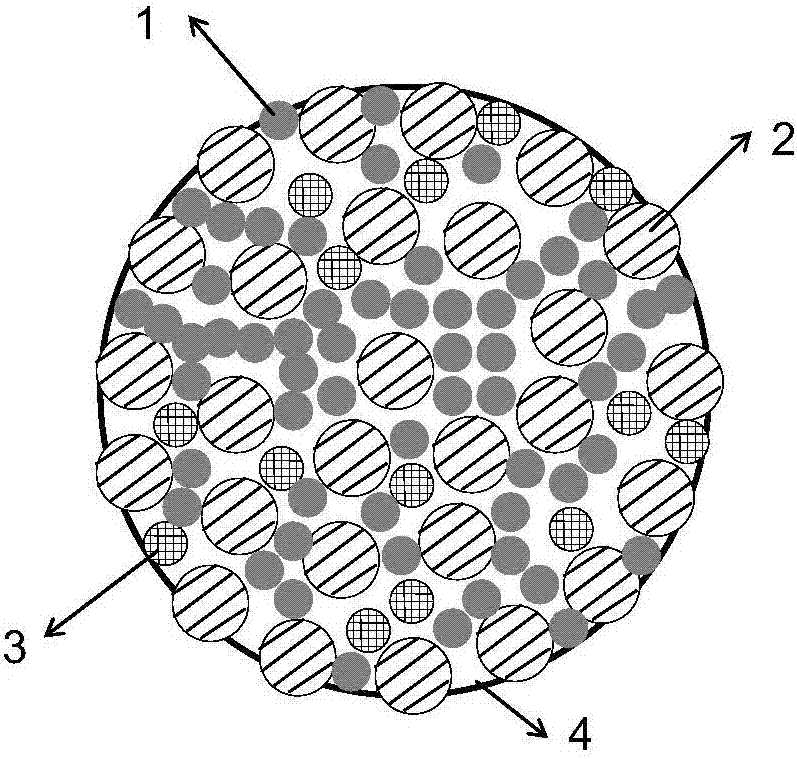

Preparation method of N-doped coated graphene micron silicon composite material

The invention relates to a preparation method of an N-doped graphene coated micron silicon composite material, in particular relates to a preparation method of a lithium ion battery cathode material, and provides the preparation method of an N-doped graphene and micron silicon composite material. The preparation method comprises the following steps: preparing oxidized graphene; preparing an oxidized graphene coated micron silicon composite material, that is, adding water to the oxidized graphene to prepare solution, adding micron silicon particles to the solution, carrying out ultrasound and mechanical agitation on the solution to obtain micron silicon and graphene mixed solution, carrying out freeze drying or spray drying on the micron silicon and graphene mixed solution to obtain oxidized graphene / micron silicon composite material; preparing N-doped graphene and micron silicon composite material, that is, placing the oxidized graphene / micron silicon composite material in a high-pressure reaction kettle, adding hydrazine hydrate, sealing to react, and drying to obtain the N-doped graphene and micron silicon composite material. The preparation method is used for preparing the lithium ion battery cathode material.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lithium ion battery negative electrode MOF material and application thereof

ActiveCN107732248AHigh lithium storage capacityWith lithium storage performanceNon-aqueous electrolyte accumulator electrodesLithiumHigh energy

The invention discloses a lithium ion battery negative electrode MOF material. The MOF material disclosed by the invention is prepared by reacting porphyrin or porphyrin derivative of the porphyrin with transition metal or a transition metal cluster through a solvent thermal or wet chemistry method. When the MOF material is utilized as a lithium ion battery negative electrode material, the MOF material has a series of advantages of high specific capacity, long cycle life, outstanding rate capability and the like. Theoretical calculation proves that an active site of the action between the MOFmaterial disclosed by the invention and metal lithium has excellent performance, and the MOF material can be applied to developing high energy density lithium ion batteries.

Owner:南京铁鸣能源科技有限公司

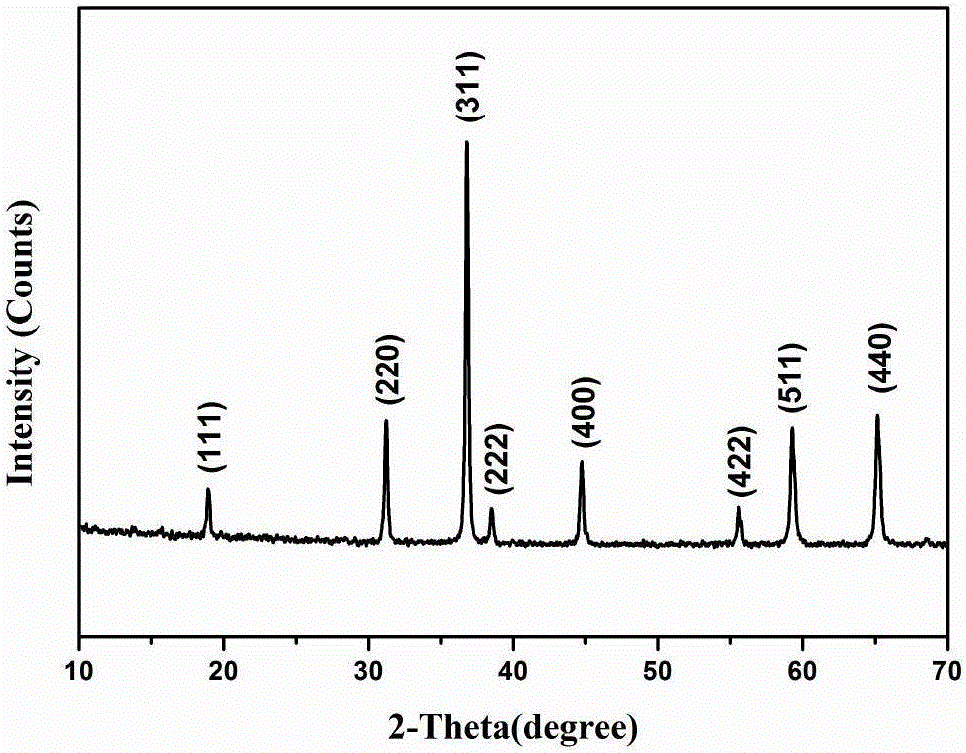

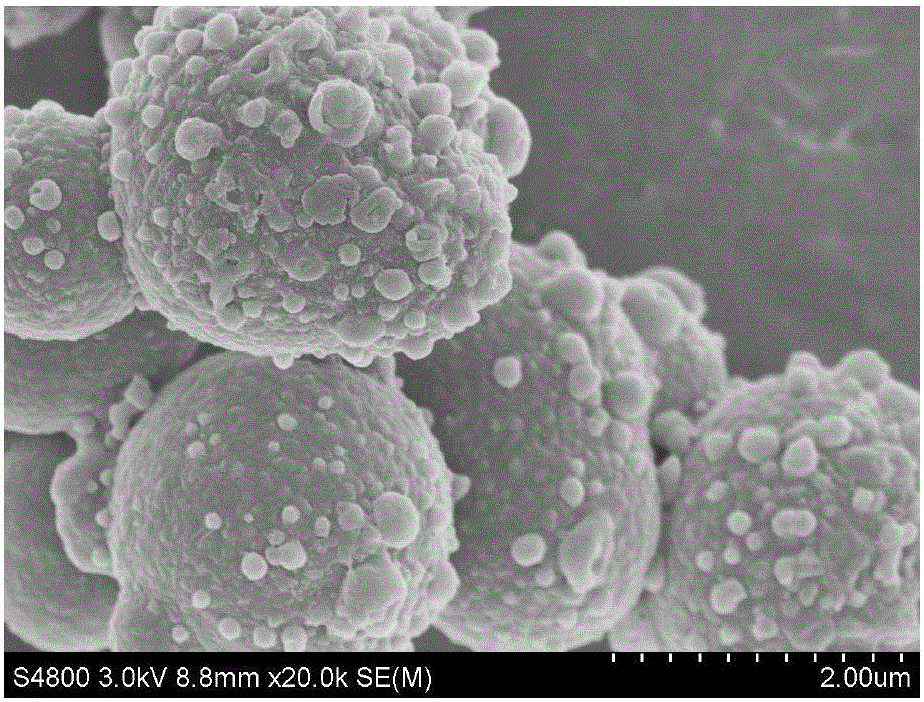

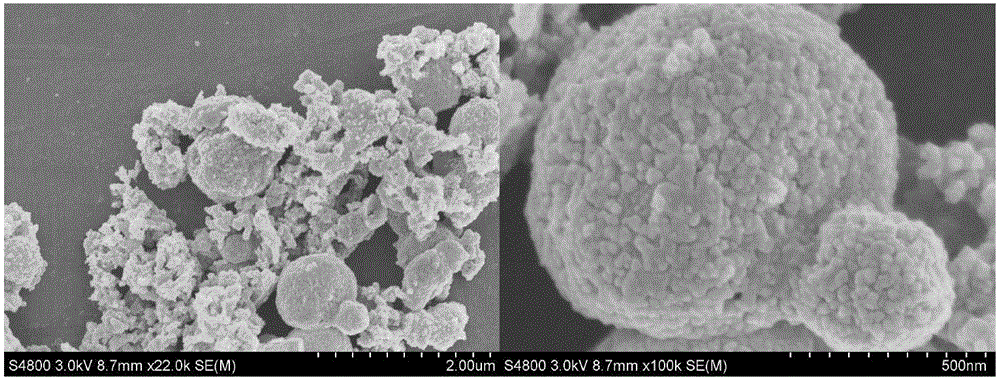

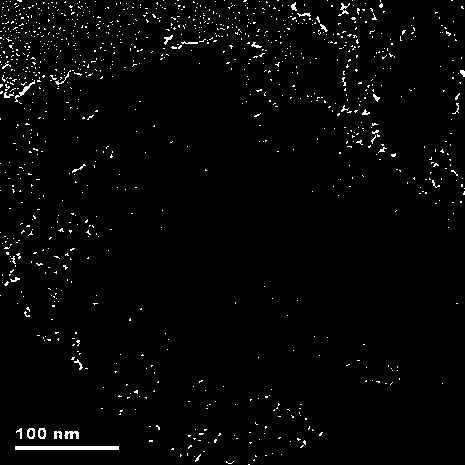

Preparation method of lithium ion battery anode material using biomass as carbon source and with C@Co3O4 core-shell structure

ActiveCN105826538AImprove cycle stabilityImproved magnification performanceCell electrodesSecondary cellsElectrochemistryHeat treated

Provided is a preparation method of a lithium ion battery anode material using biomass as a carbon source and with a C@Co3O4 core-shell structure .Edible fungus is utilized as biomass carbon, a carbon sphere precursor having surface activity is obtained through hydrothermal carbonization of concentrated sulfuric acid and then is heated and stirred in a solution containing cobalt salt to make the cobalt salt adsorbed on the surface, and then the lithium ion battery anode material with the C@Co3O4 core-shell structure is obtained through heat treatment .The electrical conductivity of the material is not only improved, the volume expansion effect of Co3O4 in the charging and discharging process is also relieved, and a Co3O4 structure is stabilized, so that the cycling stability and rate performance of a lithium ion battery are improved somewhat, and the lithium ion battery anode material having excellent electrochemical properties is obtained .

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of graphene-supported stannic oxide quantum dot negative electrode material for lithium ion battery

InactiveCN103441254ATight and evenly attachedHigh lithium storage capacityCell electrodesLithium-ion batteryReducing agent

The invention discloses a preparation method of a graphene / stannic oxide quantum dot composite electrode material for a lithium ion battery. In the sample preparation process, that graphene-supported stannic oxide quantum dots are synthesized under relatively mild experiment conditions by utilizing a wet chemical method, and urea is adopted as a reducing agent to reduce graphite oxide, so that the preparation method has the advantages of simple and controllable reaction conditions and low production cost; by introducing graphene, not only can the conductivity of the composite material be improved but also volume change in the stannic oxide charge-discharge process can be effectively buffered; therefore the composite material shows good cycling stability.

Owner:QINGDAO UNIV OF SCI & TECH

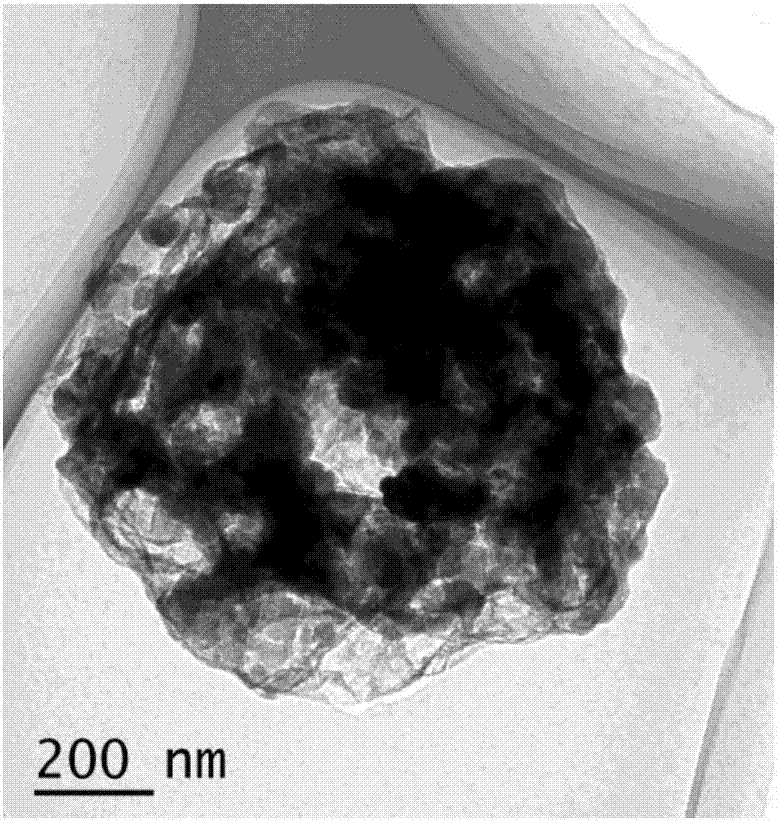

Porous silicon based composite anode material, preparation method and lithium ion battery

ActiveCN107123790APromote circulationHigh lithium storage capacityCell electrodesSecondary cellsNano siliconSodium-ion battery

The invention provides a porous silicon based composite anode material, a preparation method and a lithium ion battery. The porous material includes: a porous amorphous carbon matrix; silicon-containing nano particles and metal particles loaded on the porous amorphous carbon matrix, wherein the metal particles include one or more of Sn, Cu and Mn. The porous structure in the porous material is conducive to rapid exchange of lithium ions on a contact surface, and has good cycling stability; the metal particles and porous amorphous carbon serve as a support skeleton of the composite porous anode material, enable the formation of a stable SEI film on the anode composite material surface, can give full play to the advantage of high lithium storage capacity of silicon materials and make the electrode stably release reversible capacity. Therefore, the nano silicon based composite porous material has high reversible capacity and excellent cycling performance.

Owner:宁波富理电池材料科技有限公司

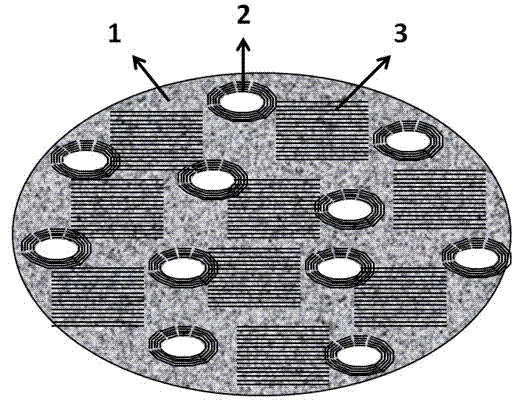

Anode material used for lithium ion battery and preparation methods thereof

InactiveCN102637875AImprove cycle stabilityHigh lithium storage capacityCell electrodesFilament/thread formingFiberCarbon fibers

The invention provides an anode material used for a lithium ion battery and preparation methods thereof. The anode material comprises two layers, namely a core layer and a cage layer, wherein the core layer has higher lithium storage capacity; the cage layer is a structural layer which is formed by mutual entanglement of carbon fibers, has a loose structure, is internally provided with uniform three-dimensional holes and is integrally cage-shaped; and the surface of the core layer is uniformly coated by the cage layer, so that the volume change of the core layer in the Li<+> intercalation / de-intercalation process can be effectively relieved and the cycling stability of the lithium ion battery can be maintained. The anode material provided by the invention can be prepared by two methods, namely an electrostatic spinning method and a biological culture method.

Owner:DONGHUA UNIV

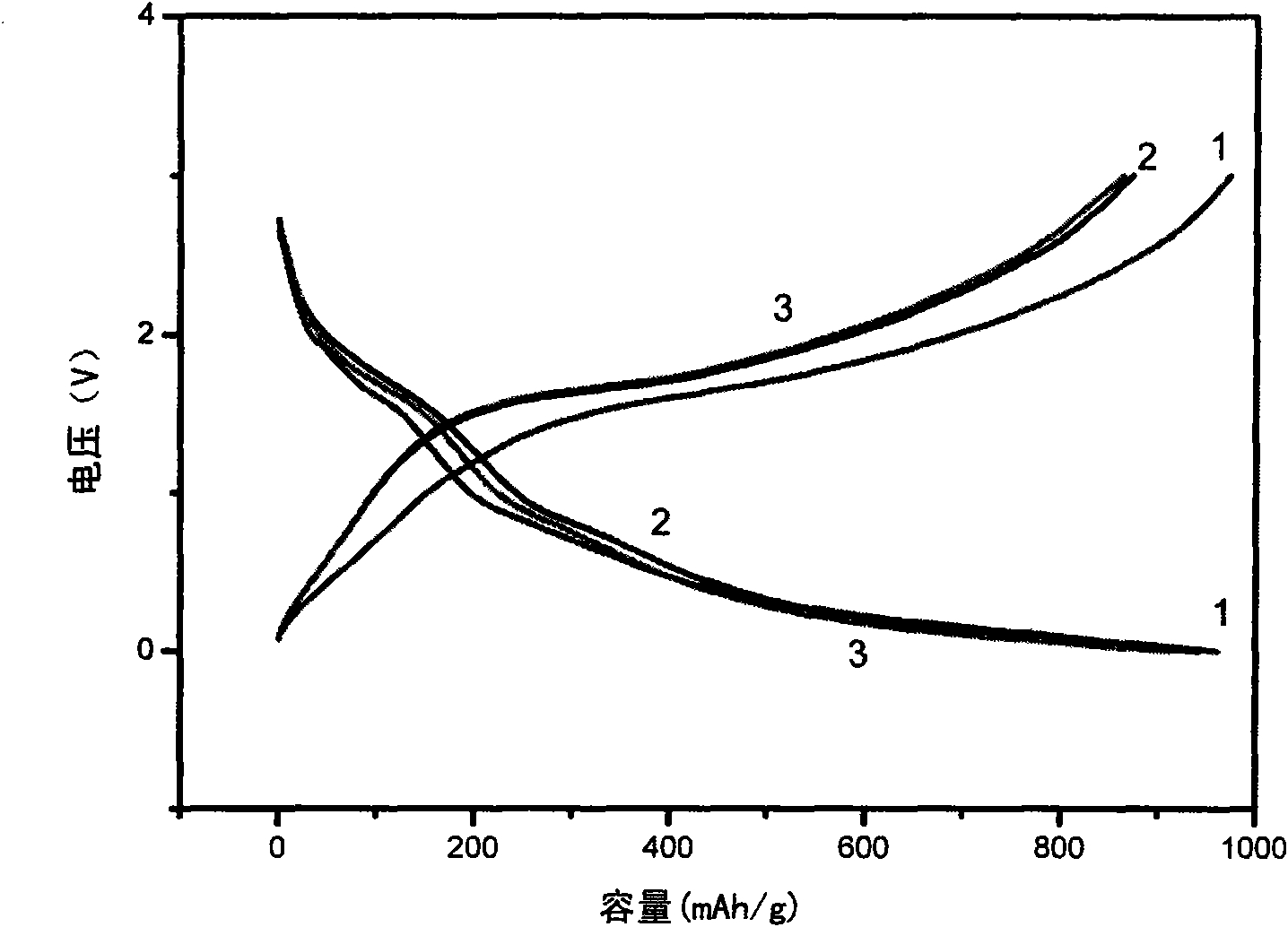

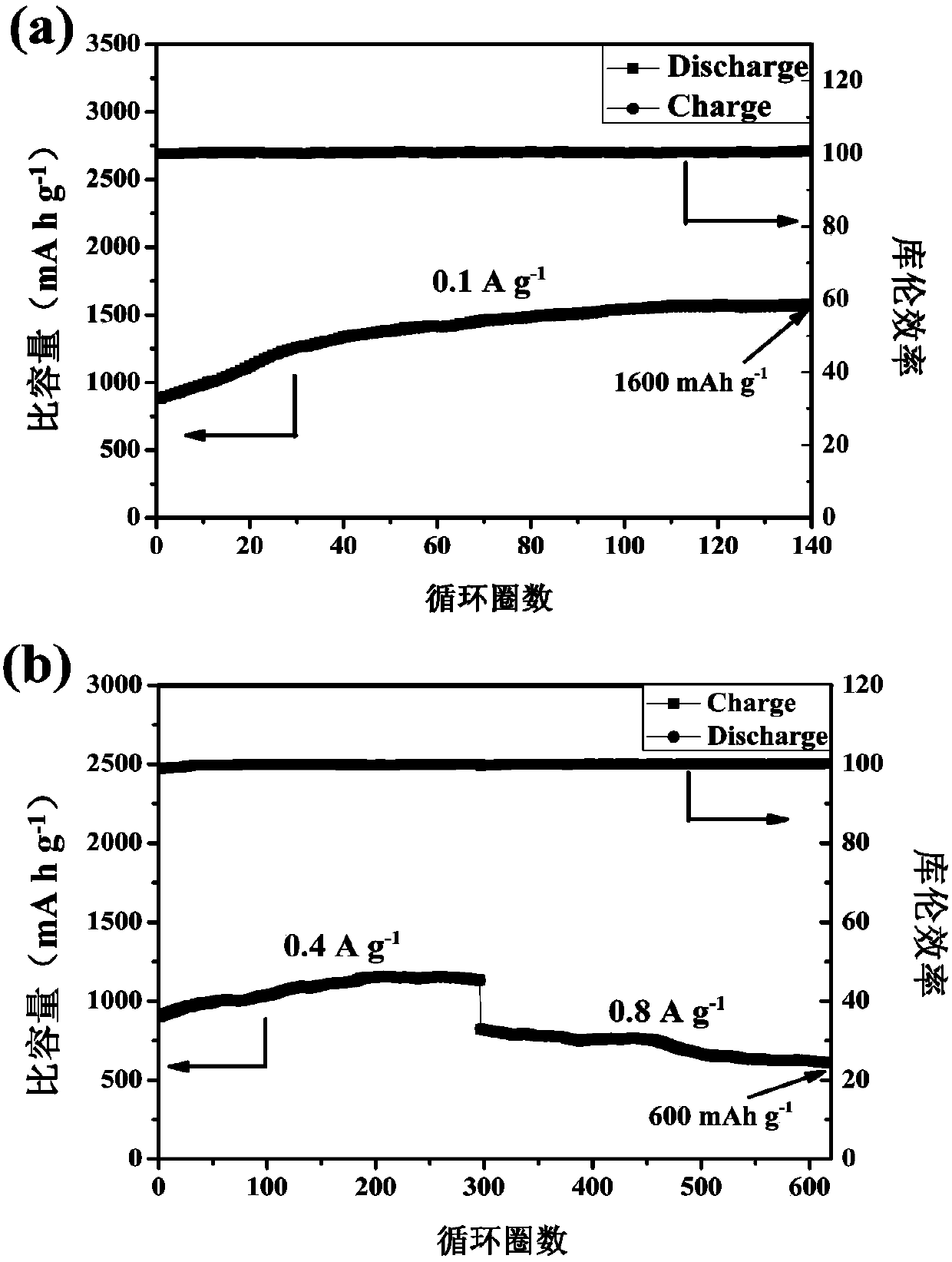

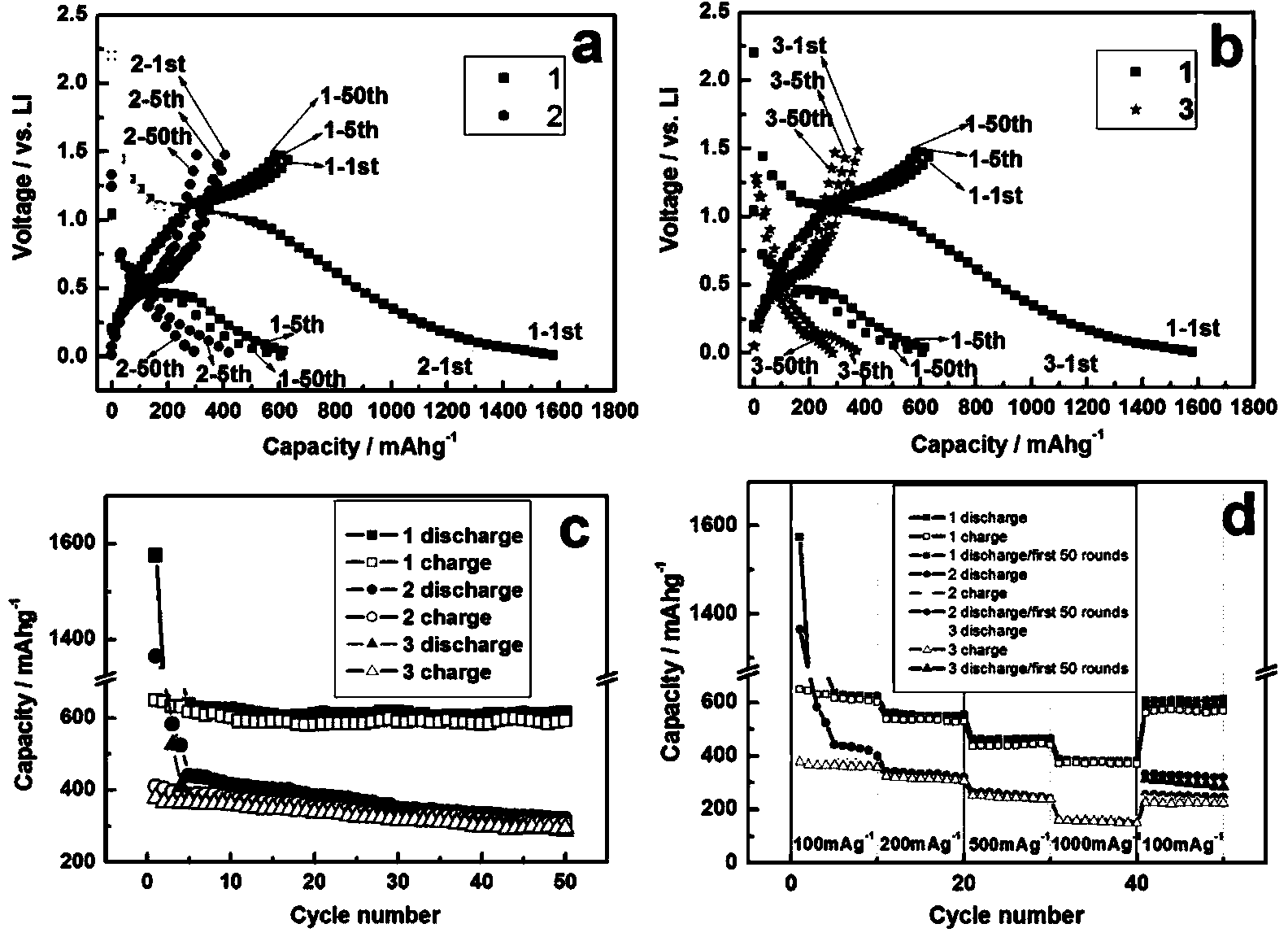

Method for preparing Fe2O3 and expanded graphite composite material of lithium ion battery

InactiveCN104953103AAvoid destructionBreak down evenlyCell electrodesSecondary cellsMicrowaveThermal decomposition method

The invention provides a method for preparing a Fe2O3 and expanded graphite composite material of a lithium ion battery. The method particularly comprises the steps that expanded graphite is used as a carrier material, the ferrocene is used as the precursor of Fe2O3, the expanded graphite and the Fe2O3 are mixed based on the mass ratio being 1:2-12, and the Fe2O3 and expanded graphite composite material is prepared by adopting the high pressure decomposition method or the microwave reaction method or the high temperature thermal decomposition method. The method is wide in raw material source, low in cost, simple in preparation technology, low in investment, high in operability and suitable for large-scale production. The Fe2O3 and expanded graphite composite material can be used as a negative electrode material of a common or flexible lithium ion battery, and has the advantages of being high in capacity, good in circulation and rate capability and the like.

Owner:SHANXI UNIV

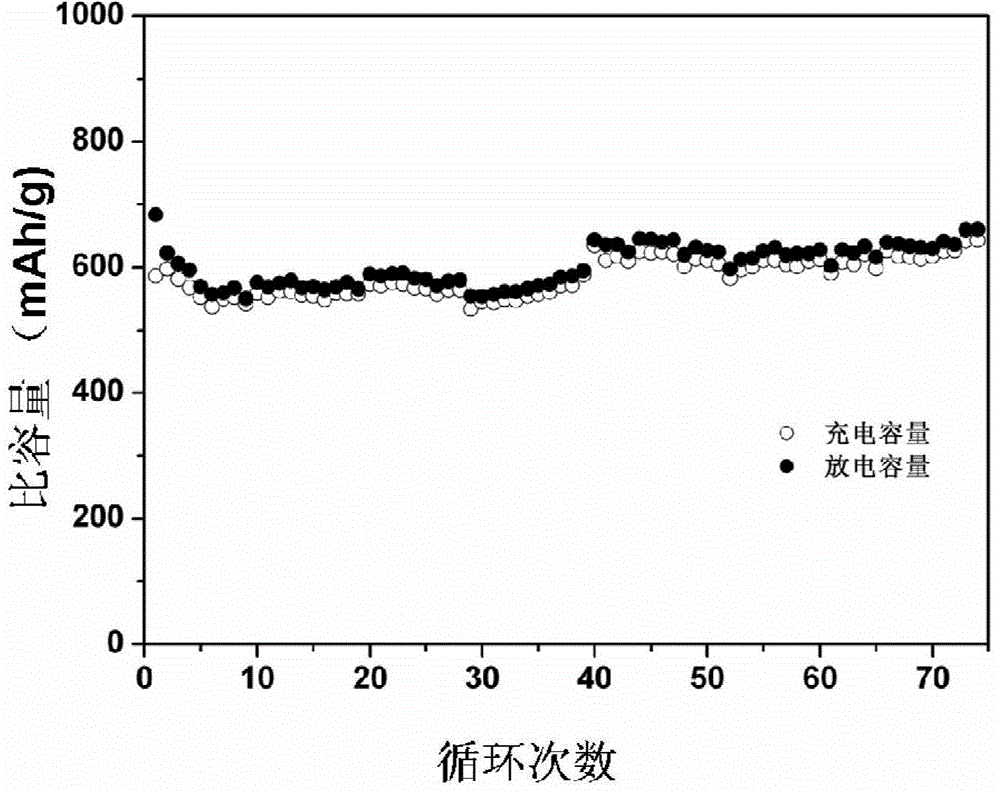

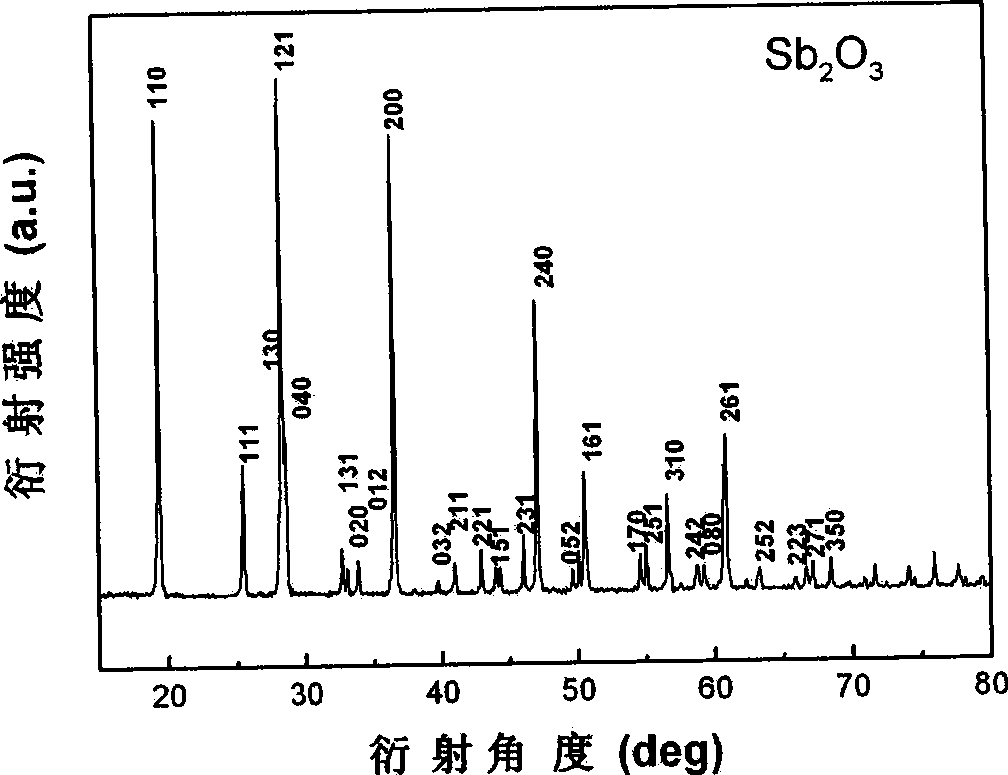

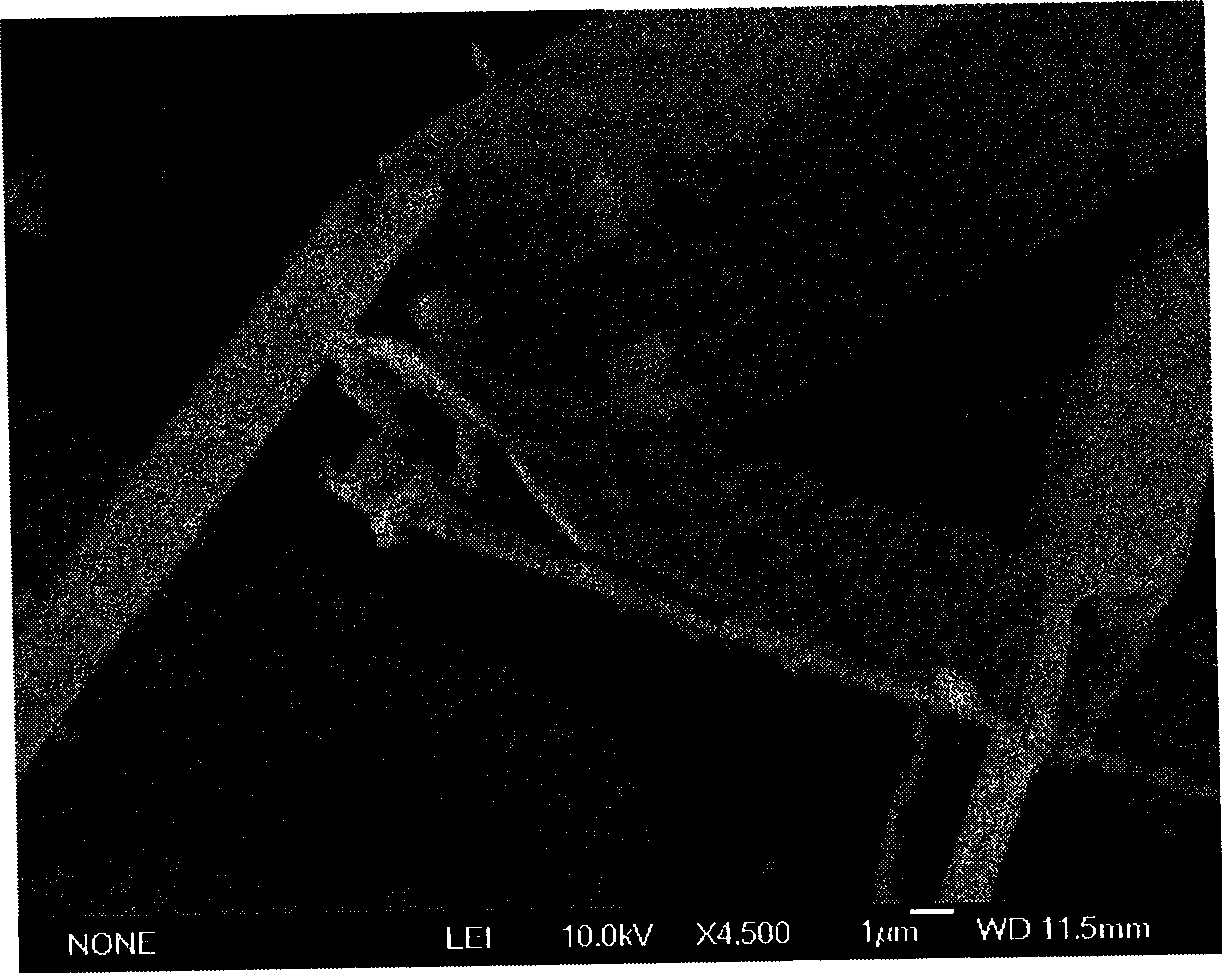

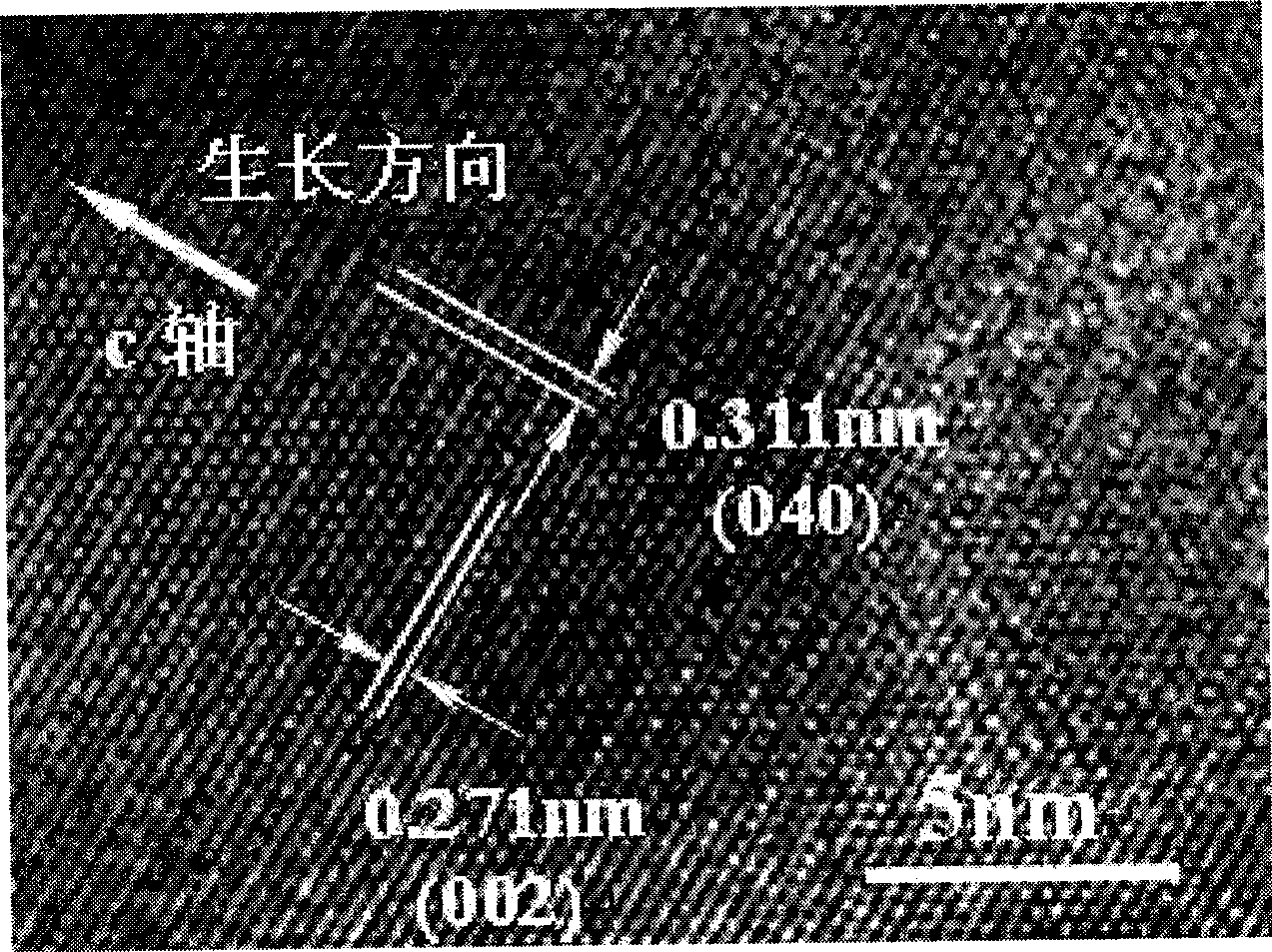

Method for preparing diantimony trioxide lithium battery anode material with hollow prism structure

InactiveCN101519224AHigh lithium storage capacityCell electrodesAntimony compoundsSynthesis methodsPrism

The invention discloses a hydro-thermal synthesis method for a diantimony trioxide material with a hollow prism structure with a unique microscopic structure, which mainly comprises the following steps of slowly releasing hydroxyl ions by using urea as a source of the hydroxyl ions to ensure that diantimony trioxide slowly reacts in a mild alkaline environment to form the diantimony trioxide material with the unique hollow prism consisting of laminated structures through nucleation, slow crystallization and self-assembling oriented growth. The diantimony trioxide with the hollow prism structure taken as an anode material of a lithium ion battery has excellent lithium storage performance.

Owner:SHANGHAI UNIV

Amorphous tetratin triphosphate/phosphorus/few-layer graphene negative material for lithium ion batteries and preparation method and application thereof

InactiveCN109841820AImprove efficiencyAlleviate volume changesCell electrodesSecondary cellsLithium iron phosphatePhosphate

The invention discloses an amorphous tetratin triphosphate / phosphorus / few-layer graphene negative material for lithium ion batteries and a preparation method and an application thereof. The negative material is formed by coating amorphous tetratin triphosphate and phosphorus with a few layers of graphene carbon. The preparation method includes the following steps: mixing and ball-milling tin powder and phosphorus powder to obtain tin triphosphate; and mixing the obtained tin triphosphate with expanded graphite and carrying out ball-milling to obtain the amorphous tetratin triphosphate / phosphorus / few-layer graphene negative material. The negative material prepared in the invention is matched with a lithium iron phosphate positive material, and a lithium ion battery assembled by using the negative material and the lithium ferrous phosphate positive material has the advantages of high capacity and stable cycle and has application potential. The preparation method of the invention has theadvantages of simple process, good repeatability, less time consumption and environment friendliness, and is conducive to actual industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Carbon-coated antimony-zinc alloy material of cathode for lithium-ion battery and method for preparing same

InactiveCN101847721AHigh lithium storage capacityImprove cycle lifeCell electrodesZinc alloysLithium-ion battery

The invention relates to carbon-coated antimony-zinc alloy material of the cathode for a lithium-ion battery and a method for preparing the same. The method for preparing the carbon-coated antimony-zinc alloy material of the cathode for the lithium-ion battery comprising the following steps: mixing antimony oxide, zinc oxide and organic carbon source material, fully grinding the mixture into the ball shape, mixing the ground material evenly, putting the mixture into a tube furnace, heating the mixture to 650-1100 DEG C under the protection of the inert gas, preserving the temperature of the mixture for 1-6h, and gradually cooling down the mixture to the room temperature to obtain the carbon-coated antimony-zinc alloy material of the cathode for the lithium-ion battery. The molar ratio of the antimony to the zinc in the carbon-coated antimony-zinc alloy is 1:2 to 2:1, and the content of the carbon is 1-8 percent (by weight) of the antimony-zinc alloy. The carbon-coated antimony-zinc alloy cathode material for the lithium-ion battery has high lithium storage capacity, good recycling performance, simple preparation method and low cost, thereby being suitable for industrial production.

Owner:NINGBO POLYTECHNIC

Preparation method of carbon coated Sn-Co/graphene microsphere negative electrode material of lithium ion battery

ActiveCN104409708AHigh filling densityIncrease volume capacityMaterial nanotechnologyNegative electrodesMicrosphereSodium-ion battery

In the prior art, there is no a lithium ion cell negative electrode material, which is based on a Sn-Co alloy and can have the advantages of large lithium storage capacity, high coulomb efficiency, long cycle life, and large filling density at the same time. In order to solve the problem mentioned above, the invention provides a preparation method of a carbon coated Sn-Co alloy / graphene microsphere negative electrode material of a lithium ion battery, and belongs to the technical field of lithium ion battery negative electrode materials. The preparation method comprises the following steps: depositing nano Sn-Co alloy onto the graphene surface through a wet process, then granulating nano intermediates through a spray drying method, coating the composite microsphere intermediates by asphalt, and finally heating to carbonize the intermediates so as to obtain the carbon coated Sn-Co alloy / graphene microsphere negative electrode material. The technology of the preparation method is simple, and thus the preparation method is suitable for massive industrial production. The prepared carbon coated Sn-Co alloy / graphene microsphere negative electrode material has the advantages of large lithium storage capacity, high coulomb efficiency, long cycle life, and large filling density.

Owner:江苏嘉明碳素新材料有限公司

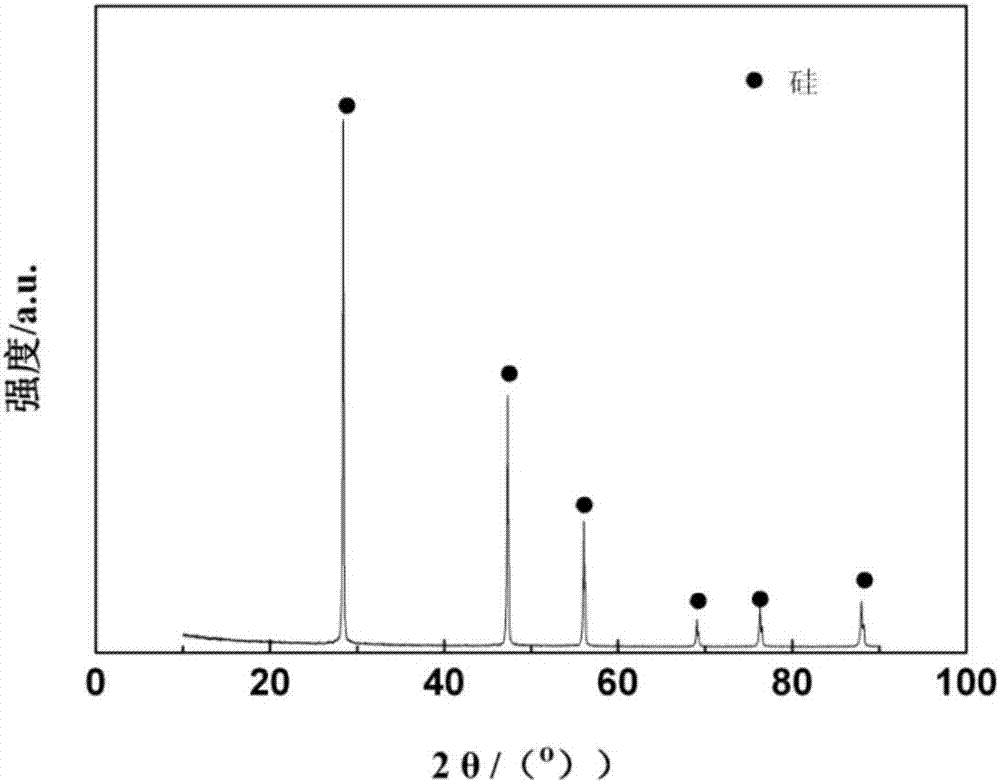

Method for synthesizing nano-silicon powder by using silicon tetrachloride as raw material and application of nano-silicon powder

InactiveCN104528728AReduce the temperatureHigh yieldMaterial nanotechnologyCell electrodesNano siliconMolten salt

The invention relates to a method for synthesizing nano-silicon powder by using silicon tetrachloride as a raw material and an application of the nano-silicon powder. The invention belongs to the field of nano-silicon powder preparation and application and specifically relates to a technology for preparing high-performance nano-silicon powder in a molten salt system at low temperature by using silicon tetrachloride as a raw material. The prepared nano-silicon powder is used as a lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH OF CHINA

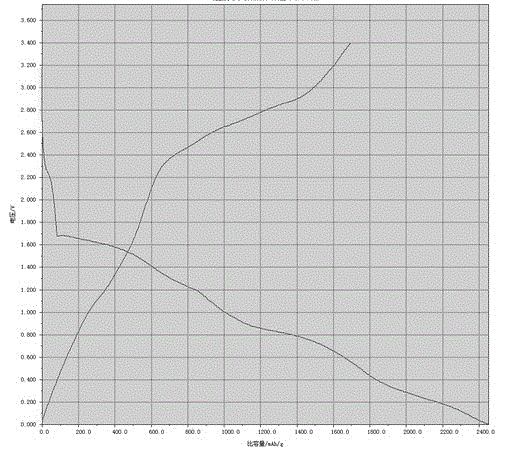

Lithium nitride/ceramic base composite material with high activity lithiation/delithiation performance

The invention belongs to the field of lithium ion batteries and super-capacitors, and in particular relates to a lithium nitride / ceramic-based composite anode material and a preparation method thereof, wherein the lithium nitride / ceramic-based composite anode material is prepared by a mechanochemical method and has high specific capacity, electrochemical lithium intercalation-detercalation reversibility and steady cycle performance. The composite material is a composite material which takes lithium nitride as an activity reinforced body and ceramic powder containing silicon element as a matrix; in the composite material, the chemical bonding is taken as a main interfacial bonding mode between the reinforced body and the matrix, the reinforced body and the matrix have good structural stability, and the mol ratio of the reinforcement body to the matrix is 1: 1-9: 1. The material has better electrochemical cycle performance and rate performance; and the material has a wider voltage window, has good ionic conductivity and cyclicity, and has potential application value in novel super-capacitor electrode materials. The preparation method is simple and easy to control, and the needed raw materials do not contain heavy metal elements and have the advantages of environmental protection and low cost.

Owner:DALIAN MARITIME UNIVERSITY

Method for preparing multilevel structure copper nitrate anode material

ActiveCN104993147AUniform particle sizeAct as a skeleton supportCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a method for preparing a multilevel structure copper nitrate anode material. The method comprises the steps of dissolving 100-200 g copper nitrate powder in 500 ml distilled water, adding 1-5 g carbon fiber after complete dissolution, stirring for 30 min at a high speed, then heating to 60-80 DEG C, adding 50-100 ml ethyl alcohol and 5 ml 1 mol / L glacial acetic acid, stirring for 3 min, then adding 1-2 g carbon black, and continuing to stir till complete volatilization; then, placing the obtained head product in an oven to be baked for 24 h at 60 DEG C, taking out the product, and grinding the product into powder, so that the multilevel structure copper nitrate anode material is obtained. The method has the advantage that the obtained copper nitrate anode material is of a stable multilevel composite structure, and the multilevel composite structure enables the copper nitrate anode material to have high capacity and long service life.

Owner:NINGBO UNIV

Preparation method and application of spherical tin sulfide consisting of nanorods

InactiveCN103915625ABuffer volume effectWill not cause mutual extrusion pulverizationTin compoundsCell electrodesCyclic processLithium-ion battery

The invention discloses a preparation method and application of spherical tin sulfide consisting of nanorods, belonging to the technical field of lithium ion battery materials. The invention further provides a preparation method of a negative electrode material. The method comprises the following steps: uniformly mixing a sulfur source, a tin source and a surfactant; heating a mixed solution by using a hydro-thermal method; filtering and drying the product to obtain a lithium battery negative electrode material of the spherical tin sulfide consisting of nanorods. Compared with spherical tin sulfide consisting of nanosheets, the spherical tin sulfide consisting of nanorods has the advantages that the cycle performance is improved, the stability of nanorods is higher than that of nanosheets in a circulating process, the volume change of an electrode material is suppressed effectively, the capacity fading of the electrode material is slowed down, and the cycle life of a battery is prolonged effectively.

Owner:JINAN UNIVERSITY

Preparation method of graphite negative electrode material containing hollow carbon nanostructure for lithium ion battery

ActiveCN102867945AGood compatibilityImprove cycle stabilityCell electrodesSodium-ion batteryMetal particle

The invention relates to a preparation method of a graphite negative electrode material containing a hollow carbon nanostructure for a lithium ion battery. The preparation method comprises the following steps of: firstly adopting an explosion method to prepare asphalt doped with nano-metal particles, crushing the asphalt doped with the nano-metal particles to obtain powdered asphalt with the particle size of 60-300 meshes, adopting the powdered asphalt as a binding agent, taking natural graphite as aggregate, uniformly mixing the two by adopting a ball milling way or a mechanical stirring method, and adopting a hot-pressing sintering method to obtain the graphite negative electrode material containing the hollow carbon nanostructure for the lithium ion battery. A catalyst disclosed by the invention has the advantages of high lithium storage capacity, high coulombic efficiency, good cycle performance, excellent rate capability and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of niobium pentoxide/reduced graphene oxide composite negative electrode material

PendingCN110323429AHigh electrical conductivityGood electrical conductivityMaterial nanotechnologyCell electrodesArgon atmosphereOxide composite

The invention discloses a preparation method of a niobium pentoxide / reduced graphene oxide composite negative electrode material. The preparation method comprises the following steps of (1) mixing graphene oxide nanosheets with water and carrying out stirring and ultrasonic dispersing to obtain graphene oxide nano-dispersion; (2) dissolving niobium pentachloride into water and stirring to obtain niobium pentachloride suspension, sequentially adding an organic cosolvent and hexamethyleneteramine into the niobium pentachloride suspension and stirring to obtain a white solution; (3) mixing the graphene oxide nano-dispersion with the white solution, stirring until uniform dispersion to obtain a mixed solution, putting the obtained mixed solution into a high pressure reactor to carry out hydrothermal reaction; (4) after hydrothermal reaction is completed, washing and drying the obtained sediments to obtain solid powder; and (5) carrying out thermal treatment on the solid powder in argon atmosphere. The preparation method is convenient to operate and controllable in reaction conditions; and a lithium battery provided with a negative electrode prepared from the obtained composite negativeelectrode material has excellent cycle performance and rate capability.

Owner:CENT SOUTH UNIV

Application by using carbon nanotube/urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of lithium ion battery

InactiveCN107959028AImprove processing efficiencyImprove crushing precisionCell electrodesArgon atmosphereCarbon nanotube

The invention relates to application by using carbon nanotube / urea formaldehyde resin carbon-coated spherical microcrystalline graphite as negative electrode material of a lithium ion battery. Spherical microcrystalline graphite material is adopted as the lithium ion negative-electrode material to prepare the lithium ion battery, wherein the weight ratio of the negative electrode material, SBR (50% of solid content), CMC to Super-p is 97.5: 1.5: 2: 1, then moderate deionized water is added to mix to be syrup-like liquid, copper foil is coated with the liquid and dried in a vacuum drying oven for 12 h to prepare a negative electrode plate, an electrolyte of the lithium ion battery adopts 1MLiPF6 / EC+DEC+DMC=1: 1: 1, a separator is microporous polypropylene membrane, a counter electrode is alithium tablet, and the battery is assembled in a glove box with an airtight argon atmosphere. When the lithium ion battery is charged and discharged at the ratio of 0.1 C, a first charging and discharging cycle charging capacity is 390 mAh / g, and when the lithium ion battery is charged and discharged at the ratio of 5 C, after 500 times of cycles, the capacity retention ratio is 97.2%.

Owner:林荣铨

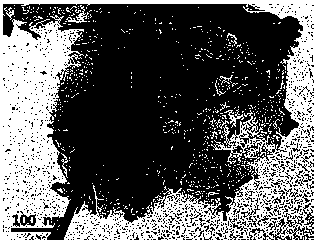

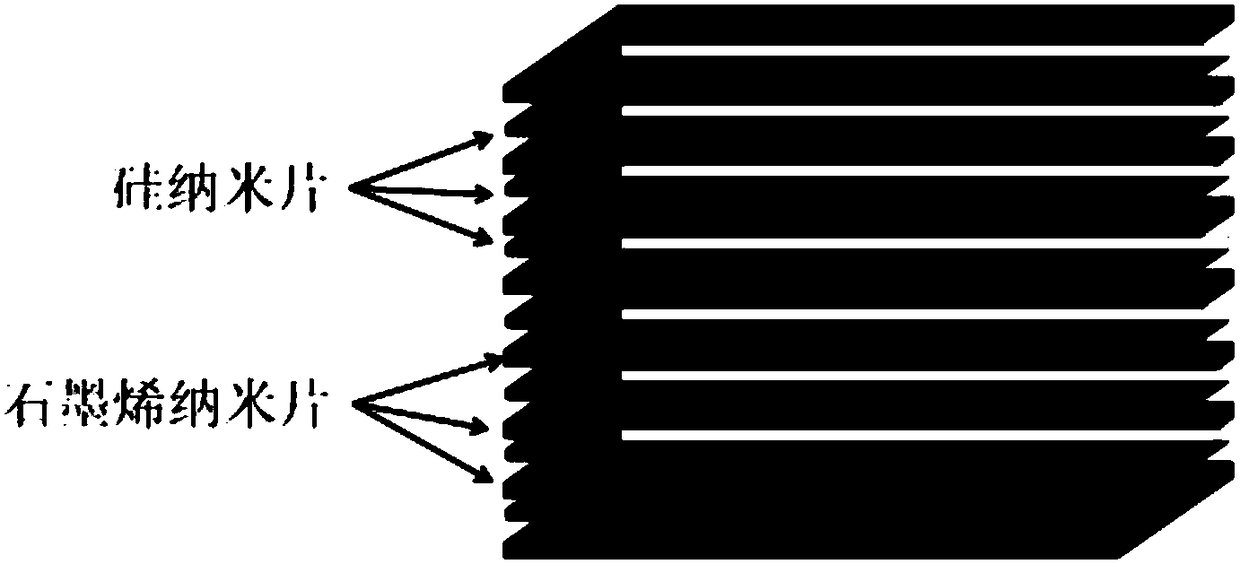

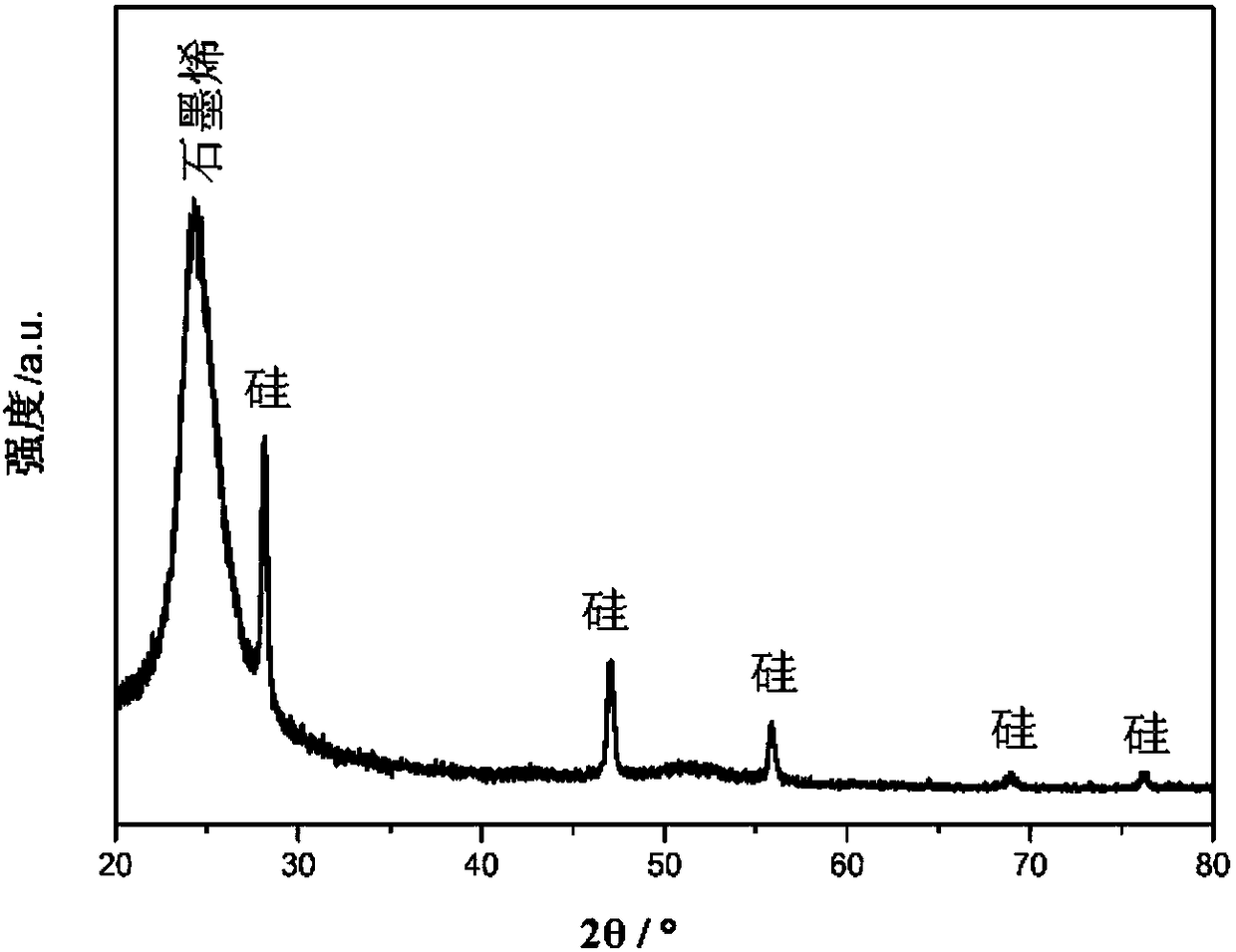

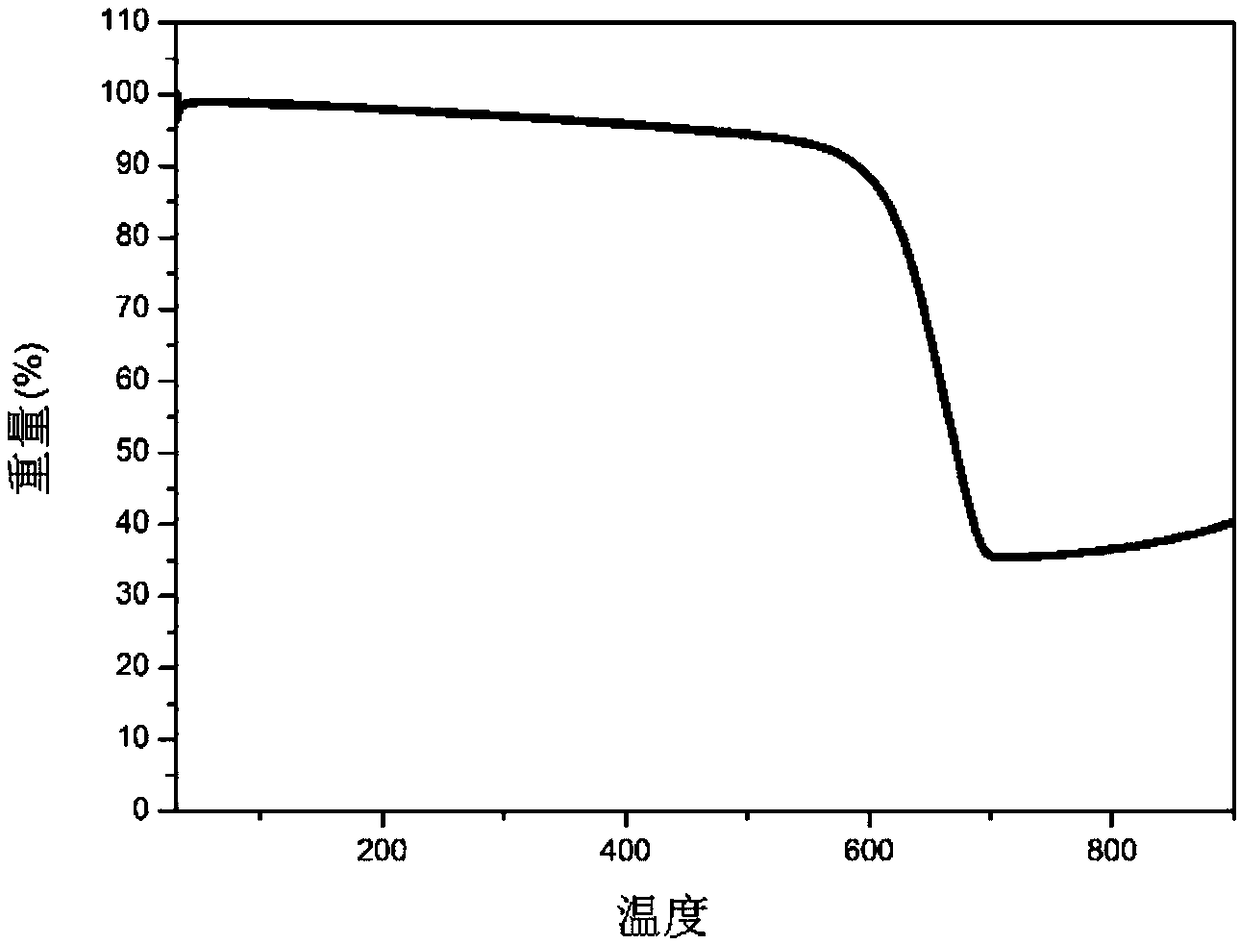

Silicon nanosheet-graphene nanosheet composite, preparation and application

InactiveCN108183204AHigh lithium storage capacityImprove cycle performanceMaterial nanotechnologyCell electrodesFast chargingRoom temperature

The invention belongs to the field of materials for lithium-ion batteries and discloses a silicon nanosheet-graphene nanosheet composite, preparation and application. Graphite oxide is prepared with ahummer method and subjected to ultrasonic exfoliation in deionized water, and graphene oxide nanosheet suspension is formed; Li13Si4 granules are added to ethanol, the mixture is stirred at room temperature for a reaction, filtering is performed, silicon granules are obtained and redispersed in ethanol, ultrasonic processing is performed, and silicon nanosheet suspension is obtained; the grapheneoxide nanosheet suspension and the silicon nanosheet suspension are stirred and mixed uniformly, evaporated to be dry and subjected to annealing treatment at 600-1000 DEG C under vacuum condition, and the silicon nanosheet-graphene nanosheet composite is obtained. The obtained silicon nanosheet-graphene nanosheet composite has the advantages that lithium storage capacity is high, cycle performance is good, charge-discharge is fast, and compared with normal charge-discharge rate, capacity of the composite fades little under fast charge-discharge.

Owner:SOUTH CHINA AGRI UNIV

Graphene-coated titanium niobium oxide composite electrode material, lithium primary battery and preparation method thereof

InactiveCN109167049AEasy to prepareLow costNon-aqueous electrolyte cellsPositive electrodesHigh energyLithium-ion battery

A lithium primary battery comprise TiNbxO2 (2 +2. 5x) core and graphene coating layer, lithium primary battery and preparation method thereof, wherein that mass fraction of the graphene coating layeris 0.01%-5% wt%, where x is 1.8-2.3. A manufacture method comprises mix a titanium source and a niobium source, and sintering to obtain a TiNbxO2 (2 +2.5 x) material; TiNbxO (2 + 2.5 x) was mixed withgraphene or graphene precursor and sintered to obtain graphene-coated titanium niobium oxide composite electrode material. The primary lithium battery uses the graphene-coated titanium niobium oxidecomposite electrode material as the positive electrode active material and the lithium as the negative electrode active material. The TiNbxO_(2 +2.5 x) composite electrode material utilizes the high lithium storage capacity of TiNbxO (2 +2.5 x) and the good conductivity of graphene, and adopts the graphene-coated TiNbxO (2 +2.5 x) material, which greatly improves the gram capacity exertion and magnification performance of the material. The preparation method is simple and the cost is low. The lithium primary battery has high energy density, high safety and reliability, and has the characteristics of large current pulse.

Owner:天津普兰能源科技有限公司

Preparation method of 3D porous graphite/carbon nanotube-nanometer silicon aerogel lithium ion battery cathode material

ActiveCN108258210AHigh specific capacityImproved magnification performanceCell electrodesSecondary cellsPorous grapheneHigh rate

The invention relates to a preparation method of a 3D porous graphite / carbon nanotube-nanometer silicon aerogel lithium ion battery cathode material, and belongs to the technical field of lithium ionbattery cathode materials, and solves the problem of poor cycling stability of the existing lithium ion battery cathode material. A carbon nanotube is taken as an internal conductive network and a carrier framework of nanometer silicon, and further combines with porous graphite in a sheet to construct the 3D porous graphite / carbon nanotube-nanometer silicon aerogel lithium ion battery cathode material. The high specific capacity of the nanometer silicon is fully used, and meanwhile, the high rate performance and the high cycle performance are realized with the help of the graphite and the carbon nanotube.

Owner:SHANXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com