Preparation method of N-doped coated graphene micron silicon composite material

A technology of nitrogen-doped graphene and silicon composite materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problem that the tap density of nano-silicon and graphene has not reached industrial production, and the lack of systematic research on the performance of composite materials, For the first time, the Coulombic efficiency did not meet the problems of industrial production, and achieved good cycle stability, strong scalability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

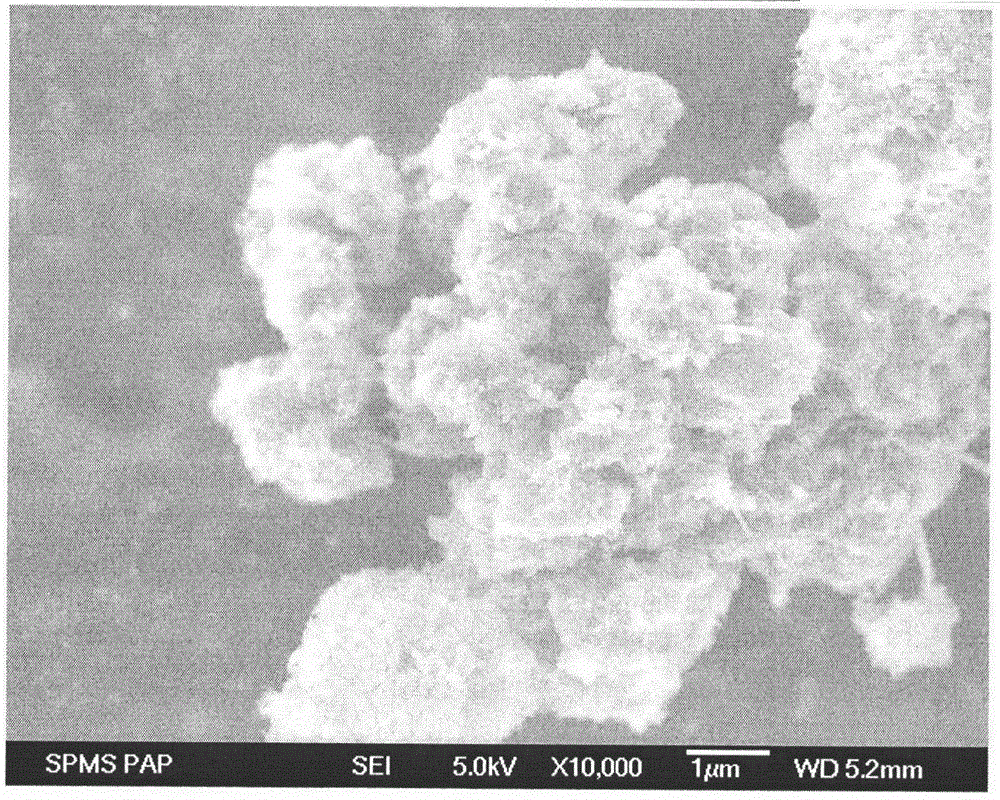

[0020] Specific Embodiment 1: The preparation method of nitrogen-doped graphene-wrapped micro-silicon composite material in this embodiment is carried out according to the following steps:

[0021] 1. Preparation of Graphene Oxide

[0022] Using natural graphite with a size of 10-300 microns as raw material, concentrated sulfuric acid as intercalation agent, potassium permanganate as oxidant, the graphene oxide aqueous solution was prepared by the Hummers method, and the graphene oxide aqueous solution was centrifuged at 3000 rpm to take the supernatant liquid, and then the supernatant was centrifuged at 8000 rpm to obtain the precipitate to obtain graphene oxide;

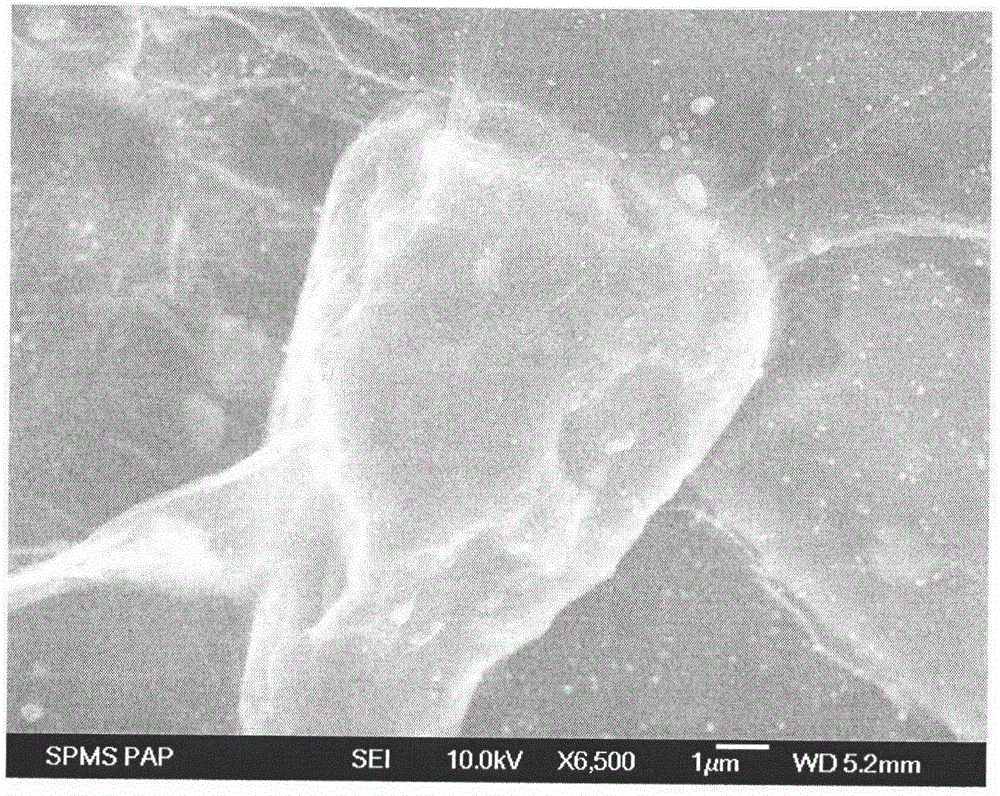

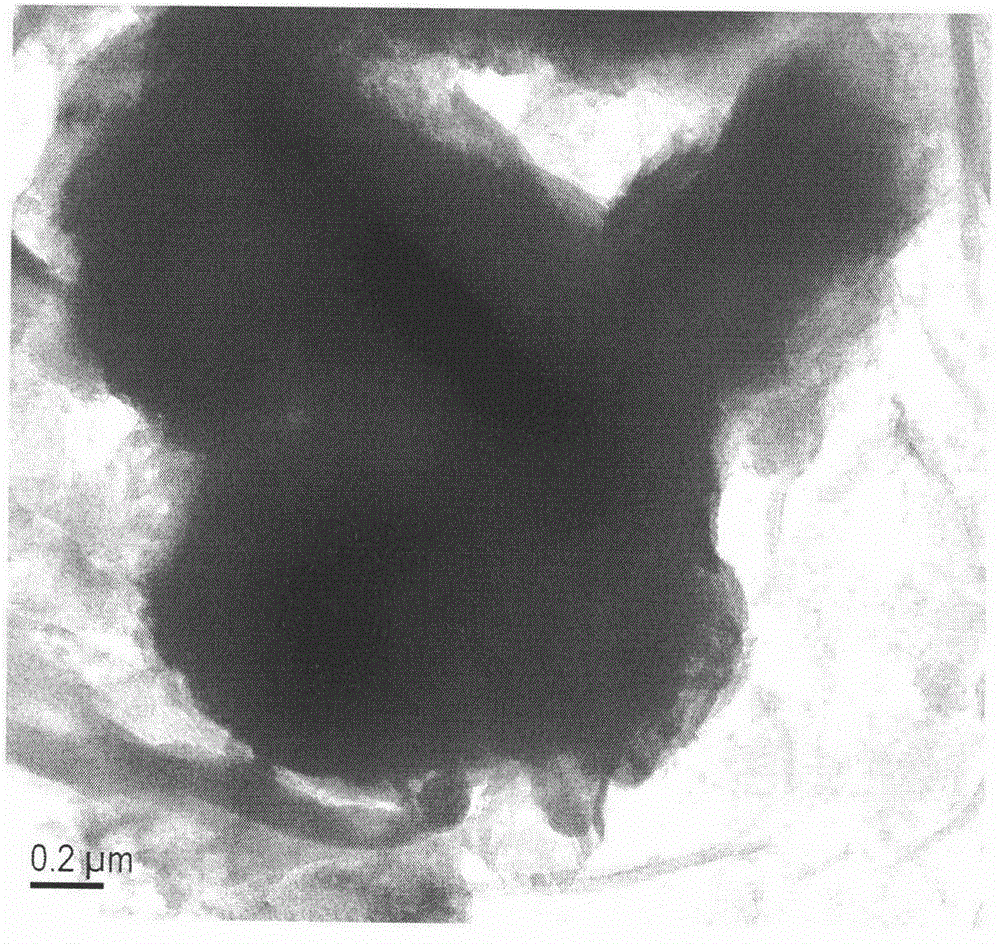

[0023] 2. Preparation of graphene oxide-wrapped micron silicon particle composites

[0024] The graphene oxide obtained in step 1 was added to deionized water to form a 2 mg / mL solution, and micron silicon particles were added to the solution, the solution was ultrasonically treated for 2 hours, and then mechanica...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 2, the mass ratio of graphene oxide to micron silicon particles is 1:1-3. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 in that the mass ratio of graphene oxide to micron silicon particles in step 2 is 1:2. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com