Composite negative electrode material coating modification method of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, ion implantation plating, metal material coating processes, etc., can solve the problems of large irreversible capacity, complicated preparation methods of negative electrode materials, and low cycle stability of negative electrode materials, etc. To achieve the effect of high density, good uniformity and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

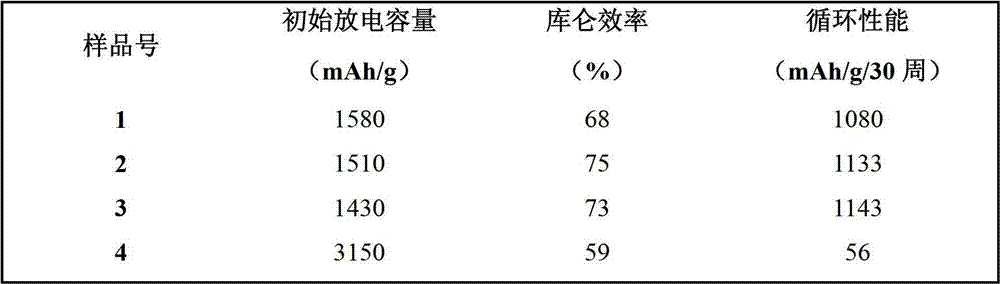

Examples

Embodiment 1

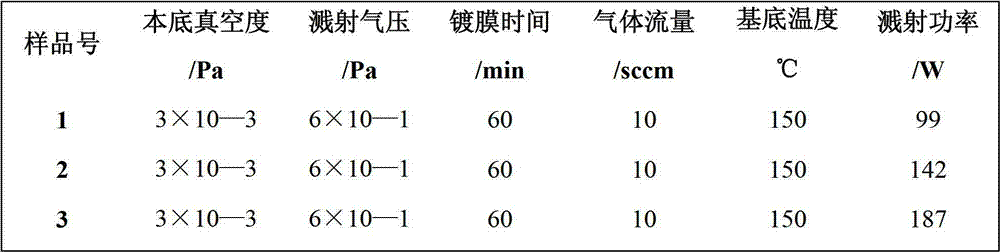

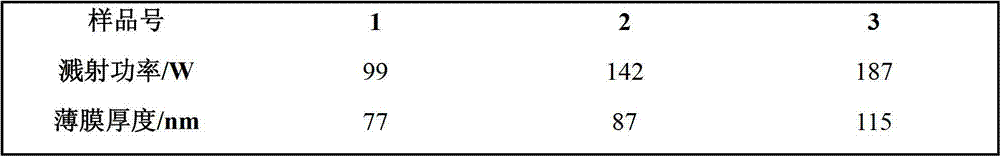

[0021] Embodiment 1 magnetron sputtering coating method. Take the magnetron sputtering metal-coated copper film on the surface of silicon powder particles as an example.

[0022] 1. Open the vacuum chamber and install the sample container filled with silicon powder particles on the resonator

[0023] (The threaded post on the resonator fits into the threaded hole in the bottom of the sample container);

[0024] 2. Close the vacuum chamber and turn on the mechanical pump in the vacuum pumping device to evacuate to 0.8Pa;

[0025] 3. Turn on the molecular pump in the vacuum pumping device to vacuum to 2.5×10 -3 Pa;

[0026] 4. Turn on the flowmeter and fill the vacuum chamber with hydrogen to 0.4Pa;

[0027] 5. Turn on the ultrasonic generator, adjust the ultrasonic frequency to 20kHz and power to 1000W;

[0028] 6. Turn on the power of the target, adjust the power to 1000W, and start sputtering the copper film; the target is a circular copper target with a purity of 99.99%...

Embodiment 2

[0031] Embodiment 2 Chemical vapor deposition plating non-metallic film. Chemical vapor deposition of carbon nanotubes after magnetron sputtering metal copper film on the surface of silicon powder particles as an example

[0032] 1. The preparation method of using nickel nitrate and nickel acetate as the catalyst precursor salt loaded on the particles of silicon copper plating film: Weigh nickel nitrate or nickel acetate, add it to the solvent under the condition of magnetic stirring, and stir vigorously for 1 hour Add the silicon copper-coated film powder, continue to stir for 30 minutes, evaporate the solvent after stirring, take it out and dry it under vacuum for 12 hours to obtain the silicon copper-coated film powder evenly loaded with catalyst precursor salt.

[0033] 2. Weigh a certain amount of silicon-coated copper film powder loaded with catalyst precursor salt and put it into a quartz boat, and then place it in the middle constant temperature zone of the tube furnac...

Embodiment 3

[0034] In Example 3, the liquid-phase precursor is first coated and then treated at high temperature. Take the carbon film coated on the surface of silicon powder particles after magnetron sputtering metal copper film as an example.

[0035] Mix the powder of silicon copper plating film with asphalt and resin evenly, and treat it for 1-10 hours in an inert atmosphere at 800-1200°C.

[0036] Since the solid-phase mixing is the mixture between pitch and silicon oxide / graphite / carbon nanotube composite material, it is difficult to achieve the purpose of uniform mixing, which will inevitably cause the pitch to not be evenly coated on the copper-coated silicon film during the carbonization process. The surface of the powder particles, and it will also cause certain damage to the powder composite material of the silicon copper-coated film, so the asphalt is selected to be dissolved in the organic solvent trichlorethylene, and then the powder of the silicon copper-coated film is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com