Preparation method and application of spherical tin sulfide consisting of nanorods

A nanorod-shaped, tin sulfide technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problem of high irreversible capacity, achieve the effect of increasing lithium storage capacity, simple equipment, and reducing irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of a spherical tin sulfide negative electrode material composed of nanorods: after uniformly mixing a sulfur source, a tin source and a surfactant, heating the mixed solution by a hydrothermal method, filtering and drying the obtained product, and obtaining a nano Rod-shaped spherical tin sulfide lithium battery negative electrode material. Among them, polyvinylpyrrolidone (PVP) is used as the surfactant, thiourea is used as the sulfur source, and tin tetrachloride crystalline powder is used as the tin source.

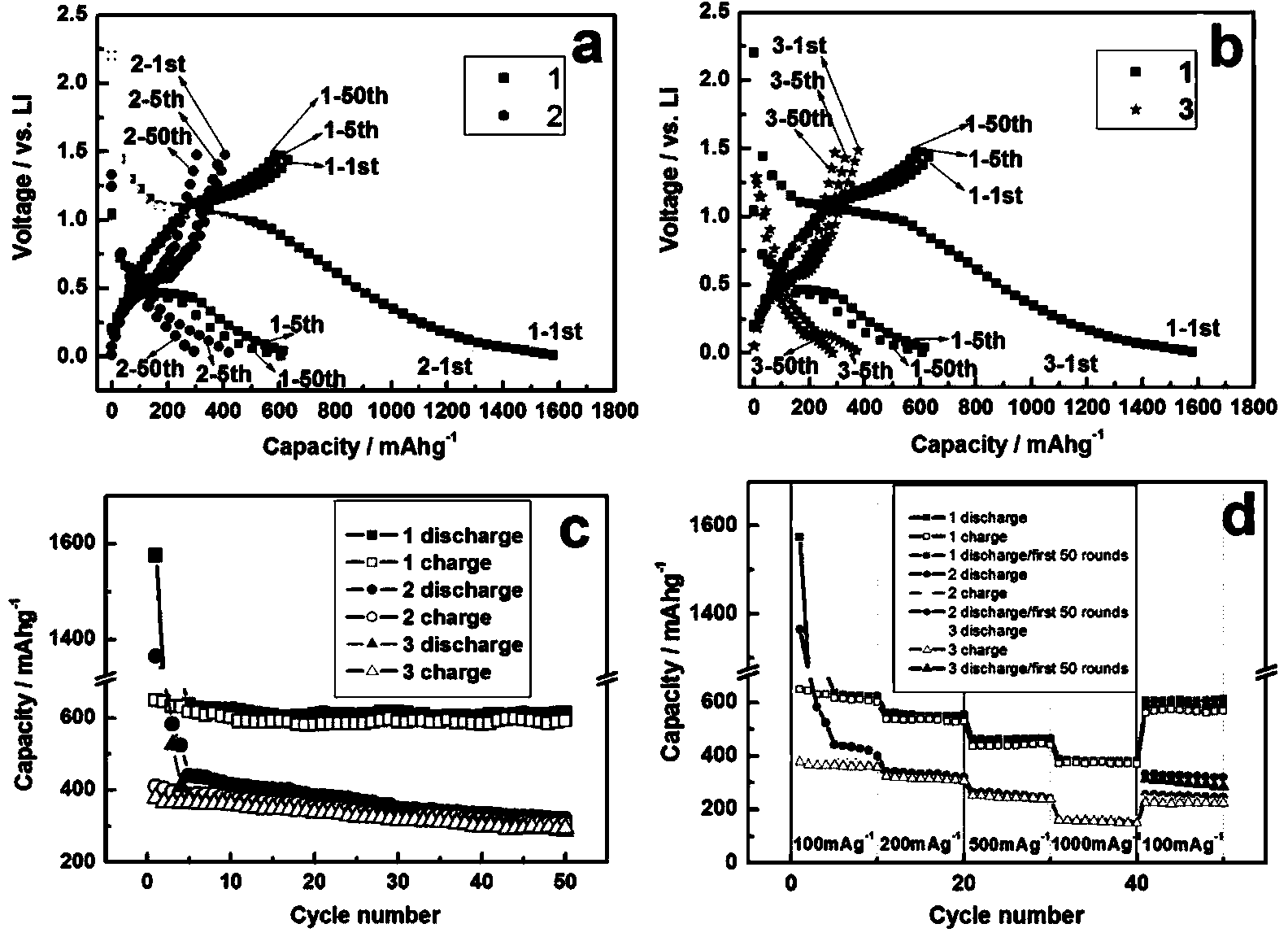

[0026] In order to reduce the huge volume effect of tin sulfide, as well as the electrode pulverization or even peeling off from the current collector during the lithium-ion battery cycle, a method of reducing the size of tin sulfide can be adopted. Nanoization is an effective method to reduce the volume change. The 3D hierarchical structure formed by the self-assembly of nanostructures exhibits a large surface area, ...

Embodiment 1

[0031] The preparation method of spherical tin sulfide composed of nanorod-shaped lithium ion battery negative electrode material in this embodiment is specifically prepared according to the following steps:

[0032] 1) Weigh tin tetrachloride crystalline powder and thiourea according to the mass ratio of 1:4, and then weigh polyvinylpyrrolidone, whose mass ratio to tin tetrachloride crystalline powder is 1:1;

[0033] 2) Put the powder weighed in step 1) into deionized water, and stir until the powder is completely dissolved to obtain a uniform mixed solution;

[0034] 3) Transfer the homogeneous mixed solution obtained in step 2) into a stainless steel reaction kettle, and react at 160°C for 6 hours;

[0035] 4) After the product obtained in step 3) is filtered and cleaned, it is dried in a vacuum drying oven at 60° C. to obtain a spherical tin sulfide material composed of nanorods.

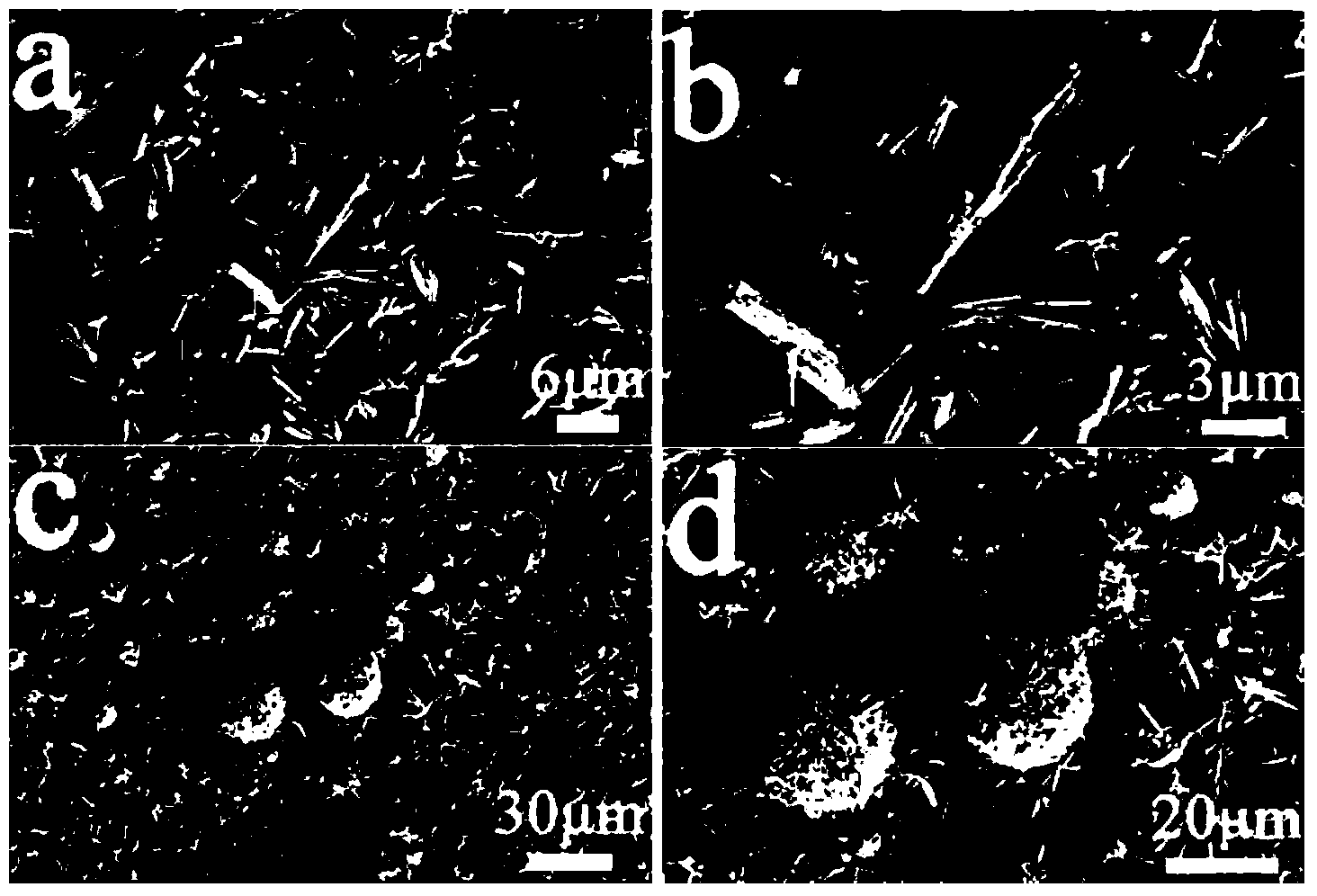

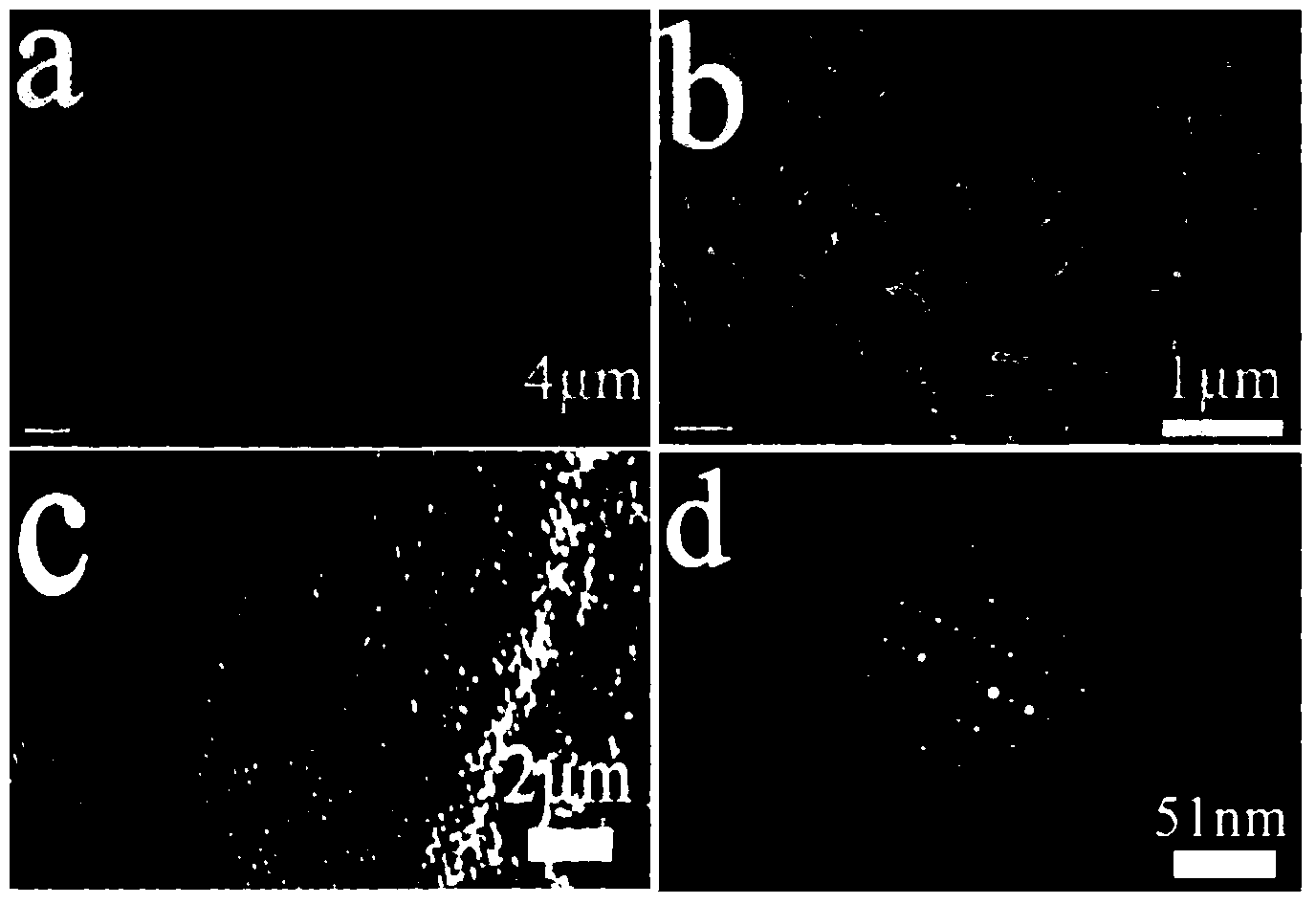

[0036] like figure 1 As shown in the scanning electron microscope (SEM) image of the tin ...

Embodiment 2

[0040] The preparation method of spherical tin sulfide composed of nanorod-shaped lithium-ion battery negative electrode material in this embodiment is specifically prepared according to the following steps:

[0041] 1) Weigh tin tetrachloride crystalline powder and thiourea according to the mass ratio of 1:2, and then weigh polyvinylpyrrolidone, whose mass ratio to tin tetrachloride crystalline powder is 1:2;

[0042] 2) Put the powder weighed in step 1) into deionized water, and stir until the powder is completely dissolved by magnetic stirring method to obtain a uniform mixed solution;

[0043] 3) Transfer the homogeneous mixed solution obtained in step 2) into a stainless steel reaction kettle, and react at 120°C for 6 hours;

[0044] 4) After the product obtained in step 3) is filtered and cleaned, it is dried in a vacuum drying oven at 60° C. to obtain a spherical tin sulfide material composed of nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com