Lithium ion battery anode material and preparation method thereof

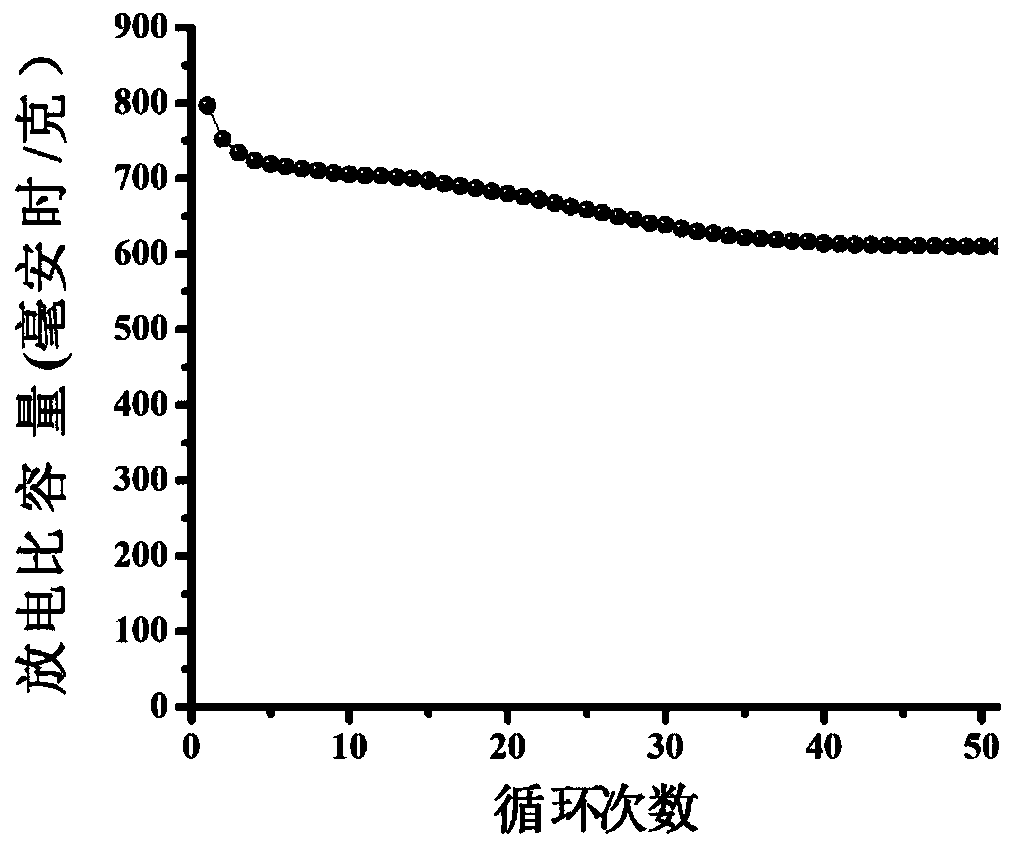

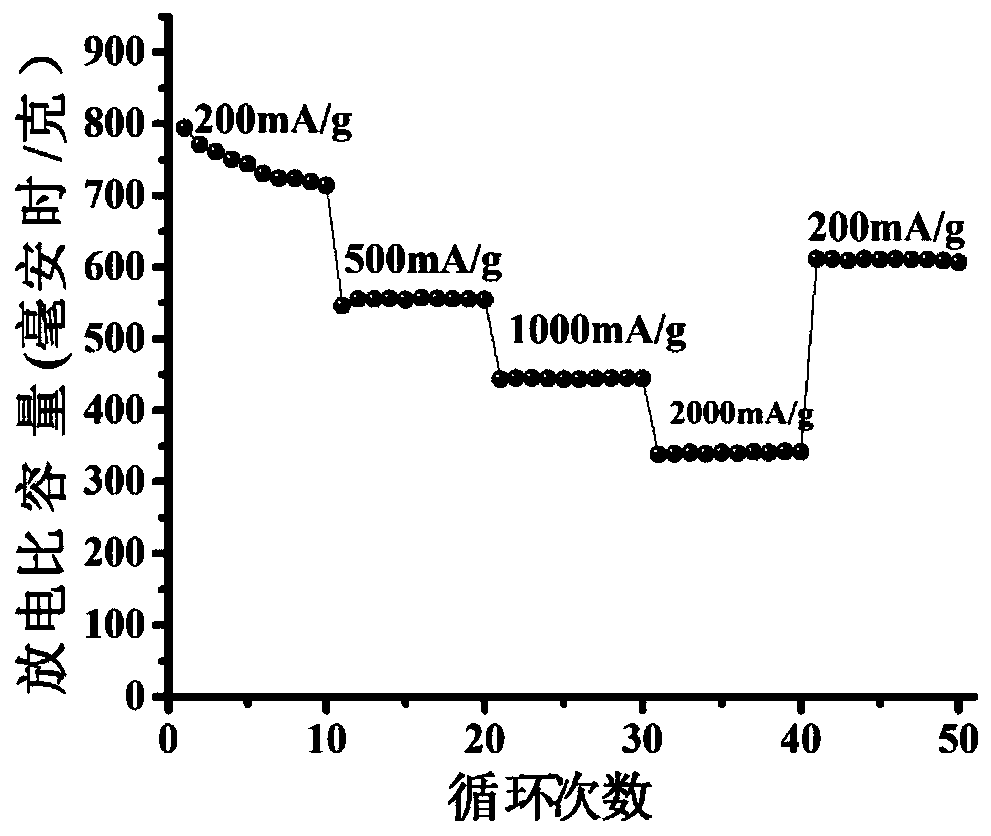

A lithium-ion battery and negative electrode material technology, applied in the field of material chemistry, can solve the problems of small reversible capacity and poor cycle performance, and achieve the effect of improving electrochemical performance, good cycle life, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of ZnS hollow nanospheres:

[0025] Dissolve 0.8g of zinc chloride and 1.5g of thiourea in 80mL of distilled water (solution A), weigh another 0.8g of gelatin into 80mL of distilled water, heat and stir in a water bath until the gelatin dissolves (solution B). The two solutions were mixed, stirred for 20 min, and transferred to a Teflon-lined autoclave. The reactor was heated to 100-150°C and kept for 12 hours. After naturally cooling to room temperature, the product was collected by centrifugation, washed three times with distilled water and absolute ethanol, and dried in an oven at 60°C.

[0026] (2) Preparation of zinc selenide-zinc sulfide composite materials:

[0027] The zinc sulfide hollow nanospheres and selenium powder prepared in step (1) were mixed and ground evenly at a mass ratio of 15:1, placed in a tube furnace, heated to 500°C under an argon atmosphere, kept for 4 hours, and then heated in the furnace Cool to room temperature.

[0028...

Embodiment 2

[0031] (1) Preparation of ZnS hollow nanospheres:

[0032] Dissolve 0.5g of zinc chloride and 1g of thiourea in 50mL of distilled water (solution A), weigh another 0.5g of gelatin into 50mL of distilled water, heat and stir in a water bath at 60°C until the gelatin dissolves (solution B). The two solutions were mixed, stirred for 10 min, and transferred to a Teflon-lined autoclave. The autoclave was heated to 100°C and held for 12 hours. After naturally cooling to room temperature, the product was collected by centrifugation, washed three times with distilled water and absolute ethanol, and dried in an oven at 60°C.

[0033] (2) Preparation of zinc selenide-zinc sulfide composite materials:

[0034] The zinc sulfide hollow nanospheres and selenium powder prepared in step (1) were mixed and ground evenly according to the mass ratio of 20:1, placed in a tube furnace, heated to 400°C under an argon atmosphere, kept for 3 hours, and then heated in the furnace Cool to room tempe...

Embodiment 3

[0036] (1) Preparation of zinc sulfide hollow nanospheres:

[0037] Dissolve 1g of zinc chloride and 2g of thiourea in 100mL of distilled water (solution A), add 1g of gelatin into 100mL of distilled water, heat and stir in a water bath at 80°C until the gelatin dissolves (solution B). The two solutions were mixed, stirred for 30 min, and transferred to a Teflon-lined autoclave. The autoclave was heated to 150°C and held for 24 hours. After naturally cooling to room temperature, the product was collected by centrifugation, washed three times with distilled water and absolute ethanol, and dried in an oven at 60°C.

[0038] (2) Preparation of zinc selenide-zinc sulfide composite materials:

[0039] The zinc sulfide hollow nanospheres and selenium powder prepared in step (1) were mixed and ground evenly at a mass ratio of 10:1, placed in a tube furnace, heated to 600°C under an argon atmosphere, kept for 6 hours, and then heated in the furnace Cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com