a kind of s-ni 3 Preparation method of c/nio composite lithium-sulfur battery cathode material

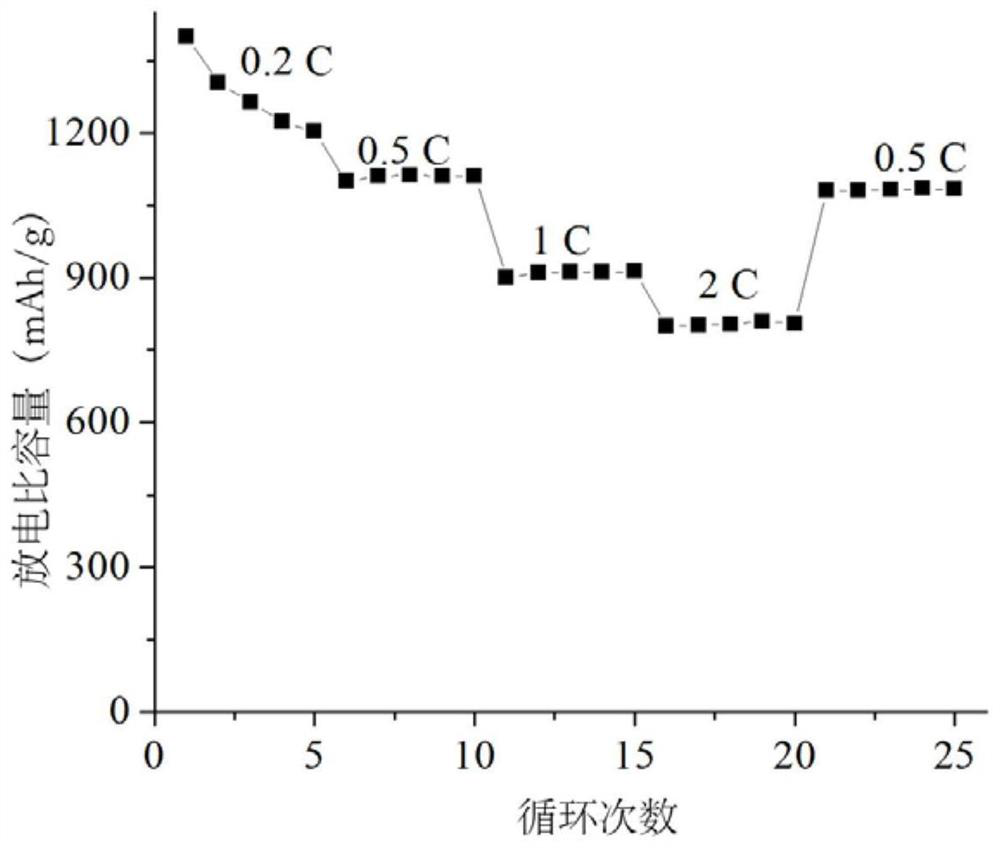

A positive electrode material, lithium-sulfur battery technology, applied in the field of material chemistry, can solve the problems of obvious shuttle effect, low sulfur loading, poor cycle stability, etc., and achieve the effect of shortening the transmission path, high specific capacity, and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to prepare the Ni-BTC material:

[0028] Mix 20mL of deionized water, 20mL of absolute ethanol, and 20mL of N,N dimethylformamide according to the volume ratio of 1:1:1, add 0.6g of nickel nitrate, 0.4g of trimesic acid, 2.5g of polyvinylpyrrolidone, and stir. 1h, ultrasonic for 1h. After completion, it was transferred to a stainless steel reaction kettle lined with PTFE, kept at 180 °C for 12 h, and the product was collected after completion, washed three times with methanol, and dried to obtain Ni-BTC material.

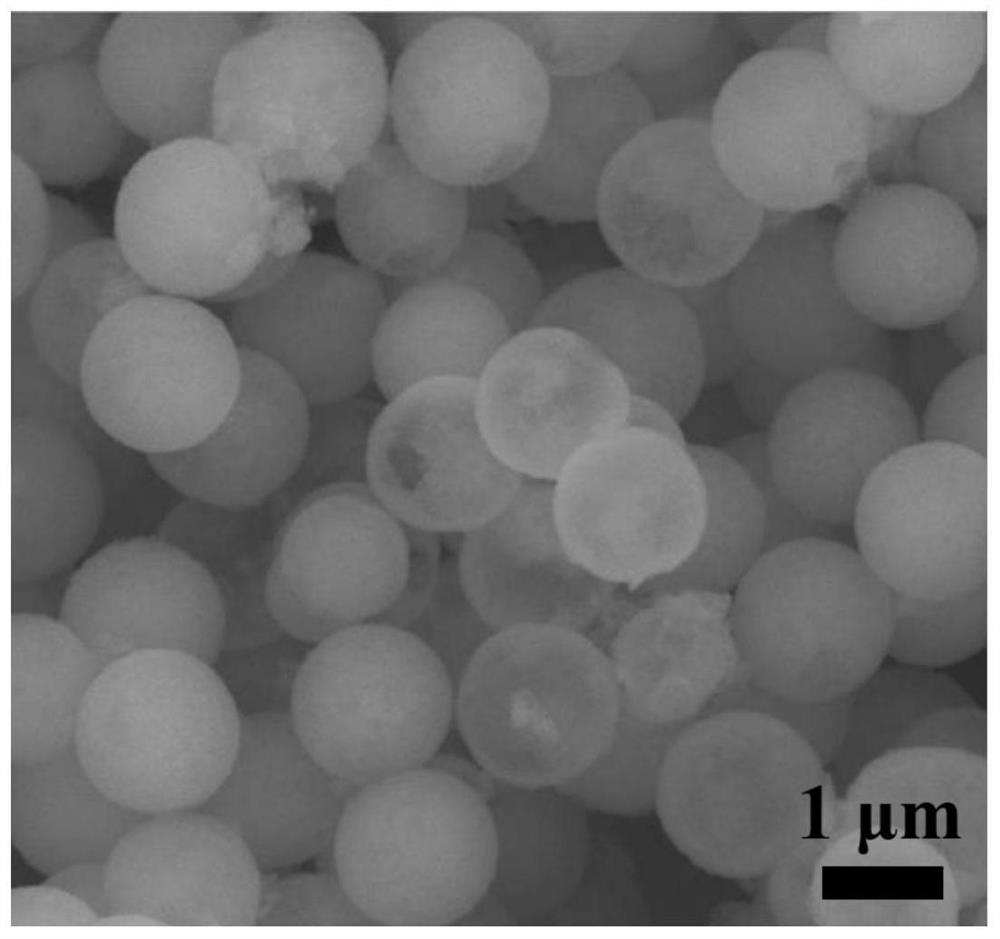

[0029] The second step is to prepare Ni 3 C / NiO material:

[0030] 0.8 g of the Ni-BTC prepared in step 1 was placed in a ceramic boat, heated to 350 °C at a heating rate of 1 °C / min in an argon atmosphere, kept for 2 h, and heated at a temperature of 30 mL / min during the heat preservation process. Pass hydrogen into the tube furnace at a rate of 15min, then continue to heat up to 450 ° C, and pass acetylene gas into the tube furnace at a...

Embodiment 2

[0034] The first step is to prepare the Ni-BTC material:

[0035] Mix 15mL deionized water, 15mL absolute ethanol, and 15mL N,N dimethylformamide according to the volume ratio of 1:1:1, add 0.5g nickel nitrate, 0.3g trimesic acid, 2g polyvinylpyrrolidone, stir for 0.5 h, ultrasound for 0.5h. After completion, it was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and kept at 160 degrees Celsius for 12 hours. After the reaction was completed, the product was collected, washed three times with methanol, and dried.

[0036] The second step is to prepare Ni 3 C / NiO material:

[0037] 0.5 g of the Ni-BTC material prepared in step 1 was placed in a porcelain boat, heated to 300 °C at a heating rate of 0.5 °C / min in an argon atmosphere, kept for 1 h, and heated at a rate of 20 mL / min during the heat preservation process. Pour hydrogen into the tube furnace at the rate of 10 min, then continue to heat up to 400 °C, and pass acetylene gas into th...

Embodiment 3

[0041] The first step is to prepare the Ni-BTC material:

[0042]Mix 30mL deionized water, 30mL absolute ethanol, and 30mL N,N dimethylformamide according to the volume ratio of 1:1:3, add 1g nickel nitrate, 0.6g trimesic acid, 3g polyvinylpyrrolidone, stir for 1h, Ultrasound for 1h. After completion, it was transferred to a stainless steel reaction kettle lined with PTFE, and kept at 200 degrees Celsius for 24 hours. After the reaction was completed, the product was collected, washed three times with methanol, and dried to obtain the Ni-BTC material.

[0043] The second step is to prepare Ni 3 C / NiO material:

[0044] 1 g of the Ni-BTC prepared in the first step was spread on a ceramic boat, heated to 400 °C at a heating rate of 1 °C / min in an argon atmosphere, kept for 2 h, and heated at a temperature of 50 mL / min during the heat preservation process. Pass hydrogen into the tube furnace at a rate of 20min, then continue to heat up to 500 ° C, and pass acetylene gas into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com