A vapor chamber with composite capillary structure of metal foam and copper powder

A technology of metal foam and vapor chamber, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problems of low capillary core performance and small penetration resistance, and achieve small effective capillary radius , Small penetration resistance, ensuring the effect of working medium backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the embodiments of the present invention are not limited thereto.

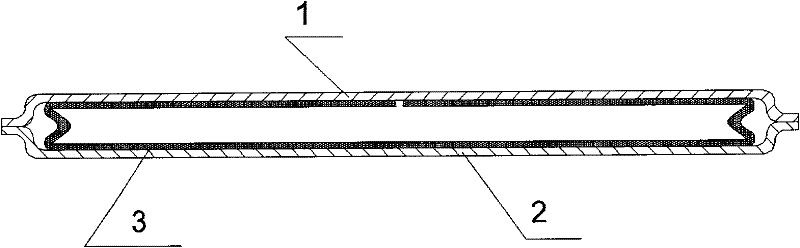

[0028] Such as figure 1 As shown, a vapor chamber with a metal foam and copper powder composite capillary core structure includes an upper cover plate 1, a lower cover plate 2, and a capillary core 3 located in a cavity formed by the upper cover plate 1 and the lower cover plate 2 . The upper cover plate 1 and the lower cover plate 2 use TP-2 deoxidized copper plate as the blank (other types of deoxidized red copper materials can also be used), and are formed (or machined) by stamping into such as figure 2 and image 3 The cavity-shaped structure shown in the figure is surrounded by welding sealing tape, and the low-temperature boiling heat-transfer working medium is poured into the cavity-shaped cavity.

[0029] Such as Figure 5b Shown, metal foam (generally in plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com